Page 1

EX9208 Switch Hardware Guide

Published

2020-12-15

Page 2

Juniper Networks, Inc.

1133 Innovation Way

Sunnyvale, California 94089

USA

408-745-2000

www.juniper.net

Juniper Networks, the Juniper Networks logo, Juniper, and Junos are registered trademarks of Juniper Networks, Inc. in

the United States and other countries. All other trademarks, service marks, registered marks, or registered service marks

are the property of their respective owners.

Juniper Networks assumes no responsibility for any inaccuracies in this document. Juniper Networks reserves the right

to change, modify, transfer, or otherwise revise this publication without notice.

EX9208 Switch Hardware Guide

Copyright © 2020 Juniper Networks, Inc. All rights reserved.

The information in this document is current as of the date on the title page.

ii

YEAR 2000 NOTICE

Juniper Networks hardware and software products are Year 2000 compliant. Junos OS has no known time-related

limitations through the year 2038. However, the NTP application is known to have some difficulty in the year 2036.

END USER LICENSE AGREEMENT

The Juniper Networks product that is the subject of this technical documentation consists of (or is intended for use with)

Juniper Networks software. Use of such software is subject to the terms and conditions of the End User License Agreement

(“EULA”) posted at https://support.juniper.net/support/eula/. By downloading, installing or using such software, you

agree to the terms and conditions of that EULA.

Page 3

Table of Contents

1

About the Documentation | xiv

Documentation and Release Notes | xiv

Using the Examples in This Manual | xiv

Merging a Full Example | xv

Merging a Snippet | xvi

Documentation Conventions | xvi

Documentation Feedback | xix

Requesting Technical Support | xix

Self-Help Online Tools and Resources | xx

Creating a Service Request with JTAC | xx

iii

Overview

EX9208 System Overview | 22

EX9208 Switch Hardware Overview | 22

Benefits | 23

Software | 23

Chassis Physical Specifications | 23

Host Subsystem | 24

Line Cards | 25

Cooling System | 26

Power Supplies | 26

EX9208 Switch Configurations | 27

EX9208 Switch Hardware and CLI Terminology Mapping | 30

Chassis Physical Specifications of an EX9208 Switch | 35

Field-Replaceable Units in an EX9200 Switch | 38

EX9208 Chassis | 40

Understanding EX9208 Switch Component and Functionality Redundancy | 40

Craft Interface in an EX9200 Switch | 42

Host Subsystem LEDs | 44

Fan LEDs | 44

Page 4

Power Supply (PEM) LEDs | 45

Switch Fabric LEDs and Control Buttons | 45

Line Card LEDs and Control Buttons | 46

Alarm LEDs and Alarm Cutoff Button | 46

Alarm Relay Contacts | 47

Midplane in an EX9200 Switch | 48

Cable Management Brackets in an EX9208 Switch | 50

EX9208 Cooling System | 51

Fan Tray | 51

Airflow Direction in the EX9208 Switch Chassis | 52

EX9208 Power System | 53

AC Power Supply in an EX9208 Switch | 53

AC Power Supply Description | 54

iv

AC Power Supply Configurations | 55

AC Power Supply Specifications for EX9208 Switches | 56

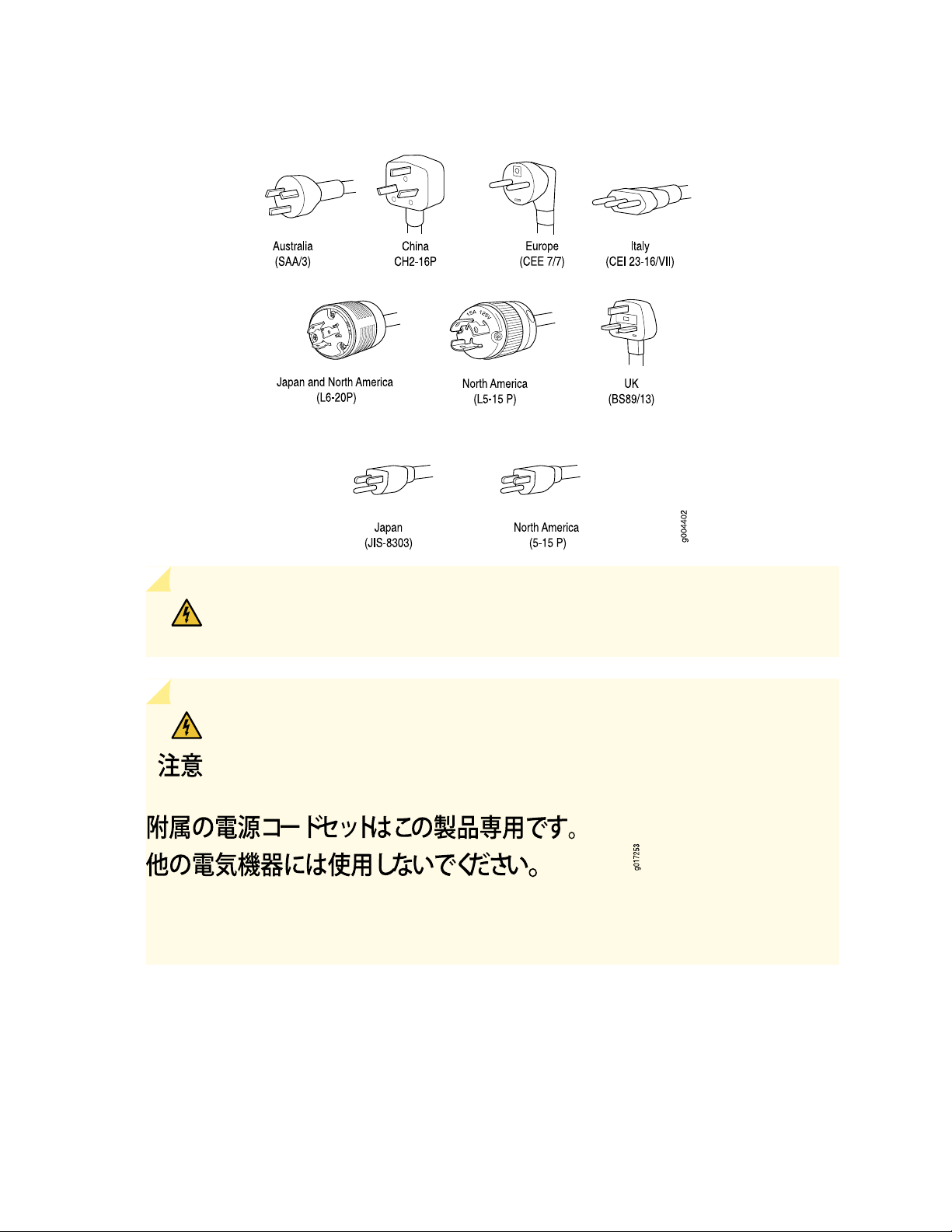

AC Power Cord Specifications for an EX9208 Switch | 57

AC Power Supply LEDs in an EX9208 Switch | 59

DC Power Supply in an EX9208 Switch | 60

DC Power Supply Description | 61

DC Power Supply Configurations | 61

DC Power Supply Specifications for EX9208 Switches | 62

DC Power Supply LEDs in an EX9208 Switch | 63

Power Requirements for EX9200 Switch Components | 64

EX9200 Host Subsystem | 65

Host Subsystem in an EX9200 Switch | 66

Routing Engine Module in an EX9200 Switch | 67

Routing Engine Module LEDs in an EX9200 Switch | 70

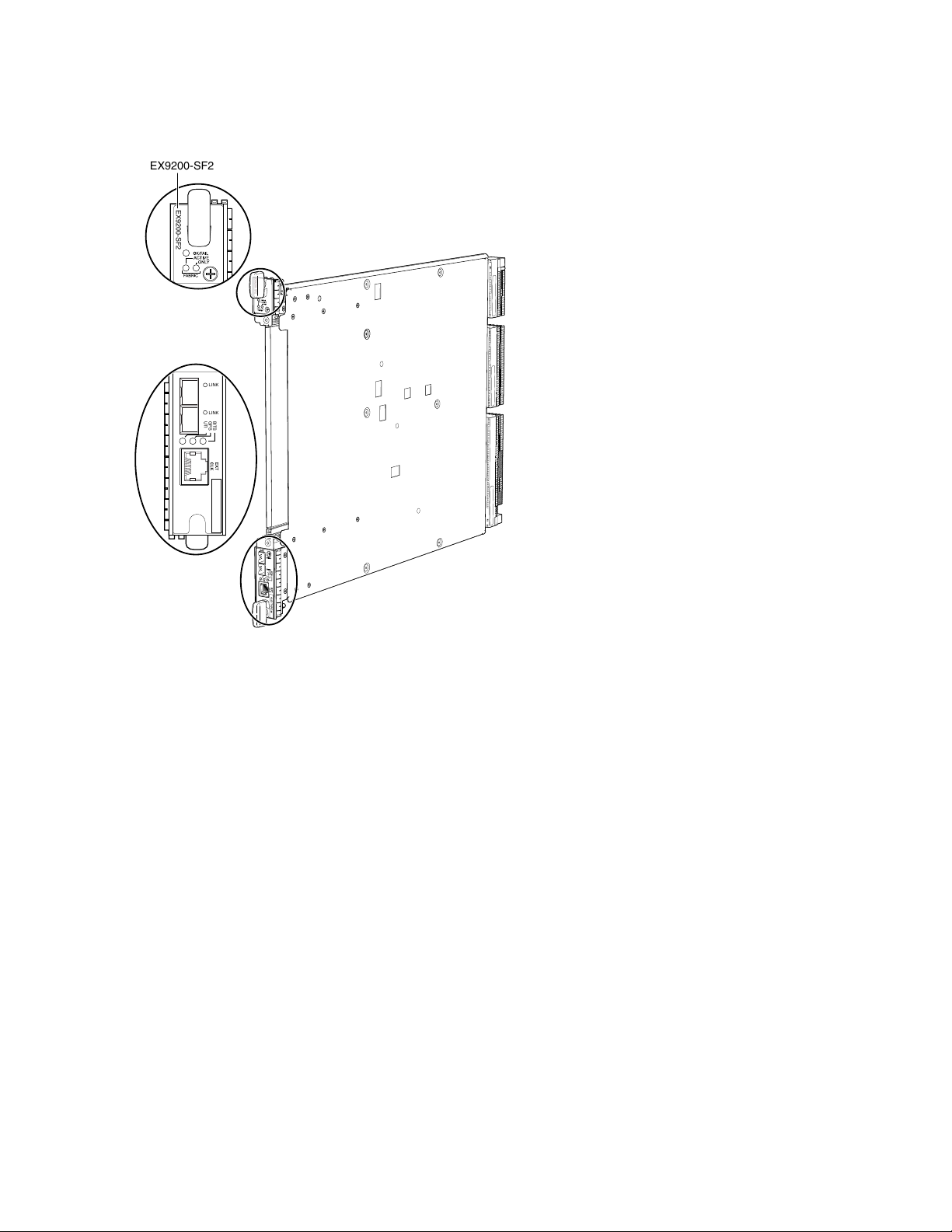

Switch Fabric Module in an EX9200 Switch | 73

Switch Fabric Module LEDs in an EX9200 Switch | 76

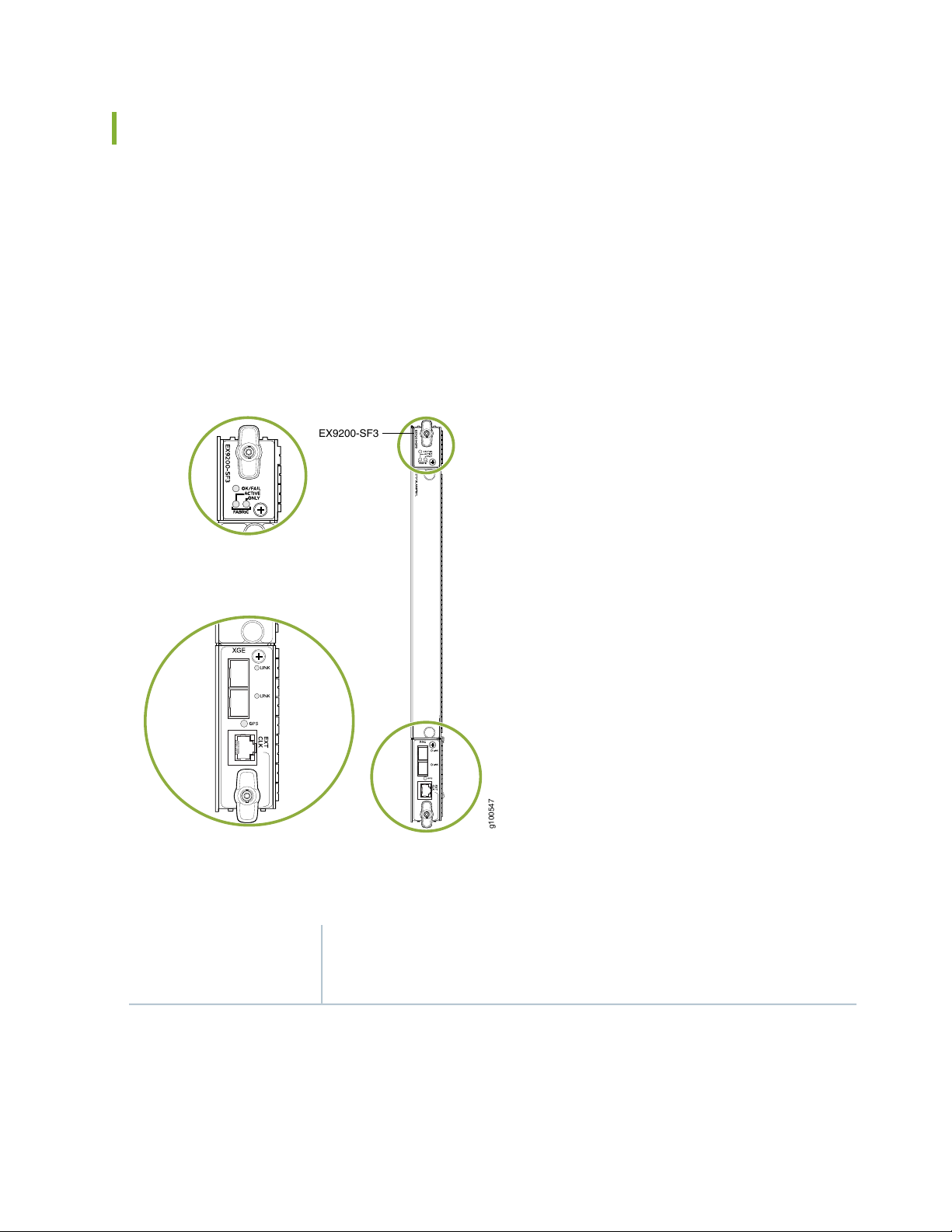

EX9200-SF3 Module in an EX9200 Switch | 77

EX9200-SF3 Components and Features | 78

EX9200-SF3 LEDs | 79

EX9200-SF3 Fabric Bandwidth Performance and Redundancy | 79

Page 5

EX9200-SF3 Maximum Power Consumption per Ambient Temperature and CB Slot | 81

Interoperability with Existing Hardware | 82

EX9200-SF3 Unsupported Functions and Capabilities from Legacy Swith Fabric

Modules | 83

EX9200 Line Cards | 83

Line Card Model and Version Compatibility in an EX9200 Switch | 84

EX9200-2C-8XS Line Card | 87

Line Card Models | 87

Line Card Components | 88

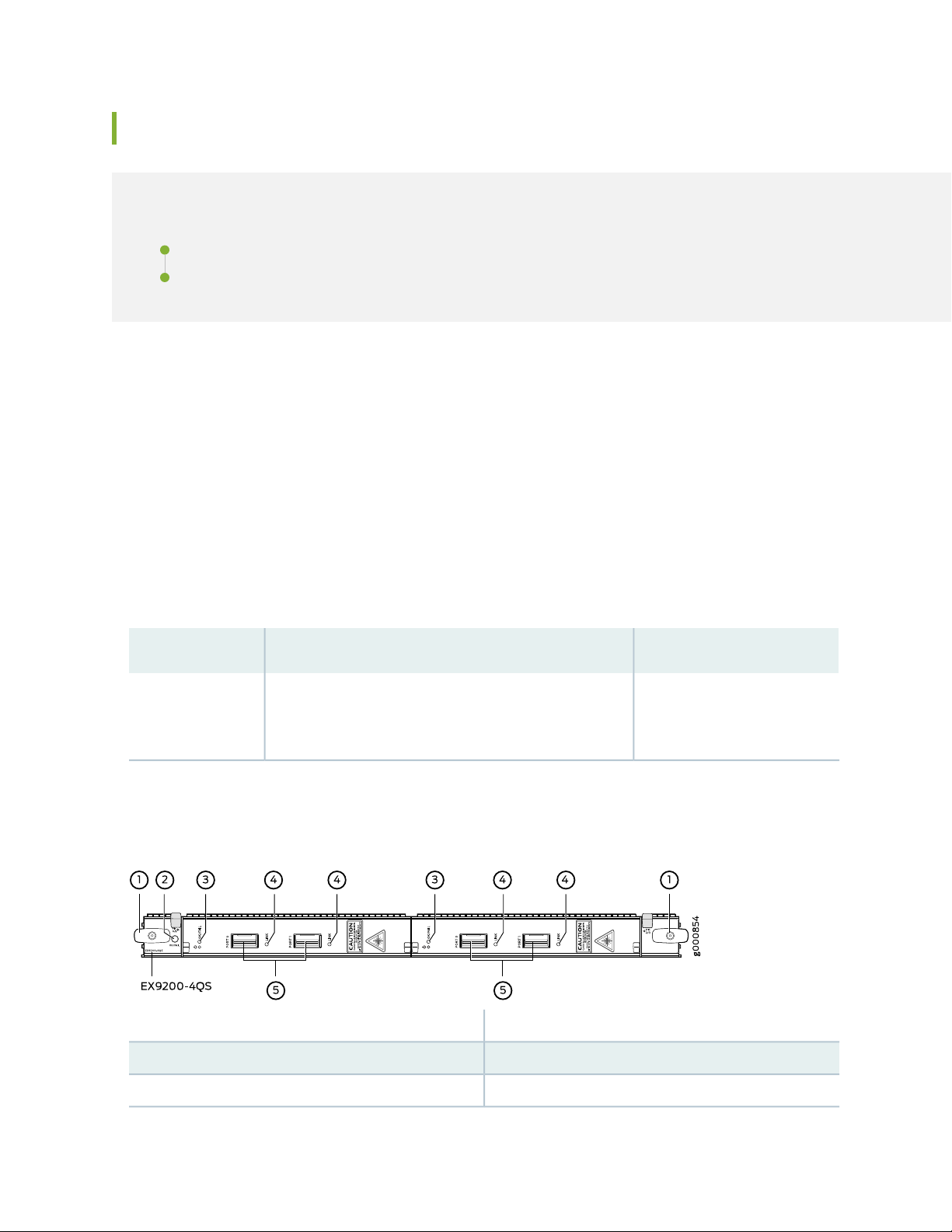

EX9200-4QS Line Card | 89

Line Card Models | 89

Line Card Components | 90

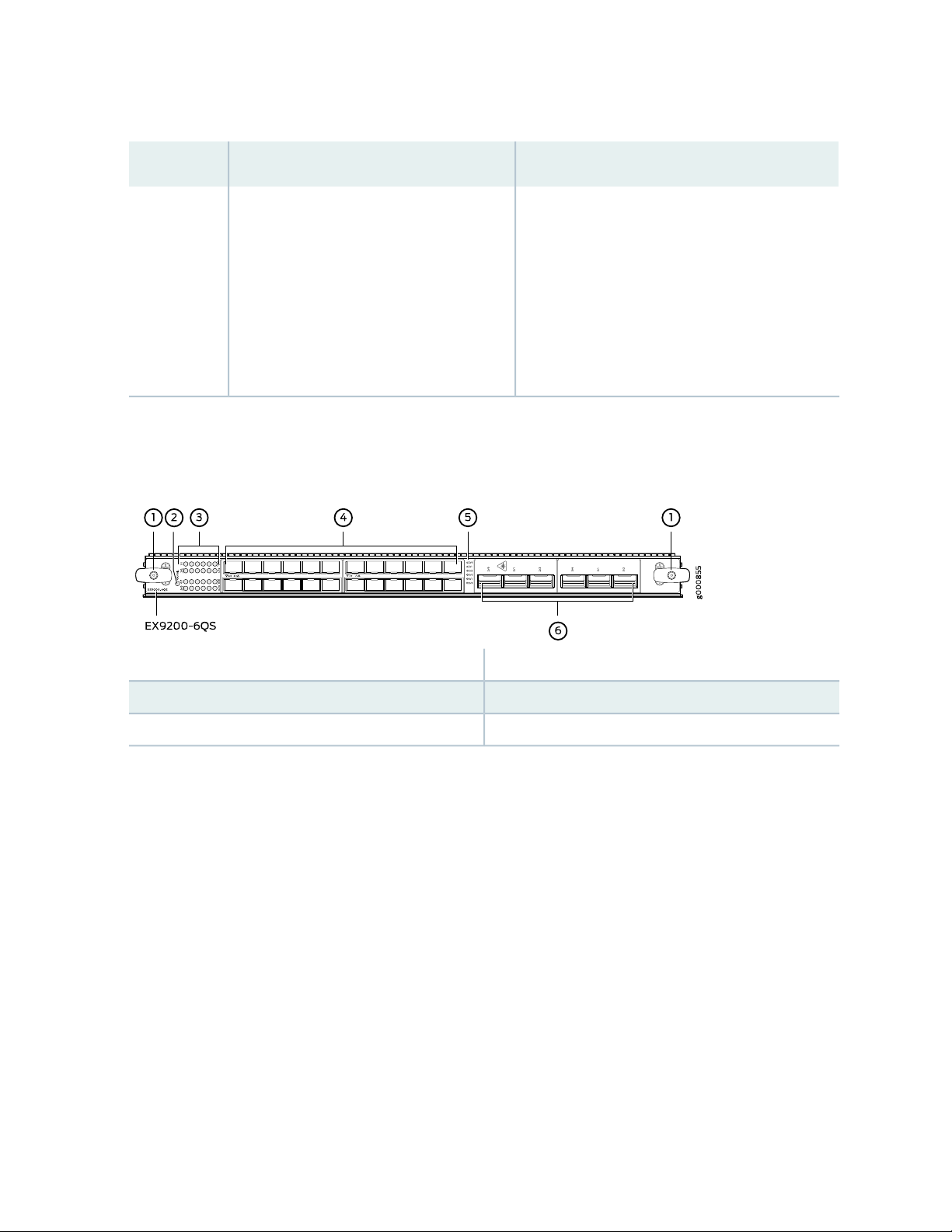

EX9200-6QS Line Card | 90

Line Card Models | 90

v

Line Card Components | 91

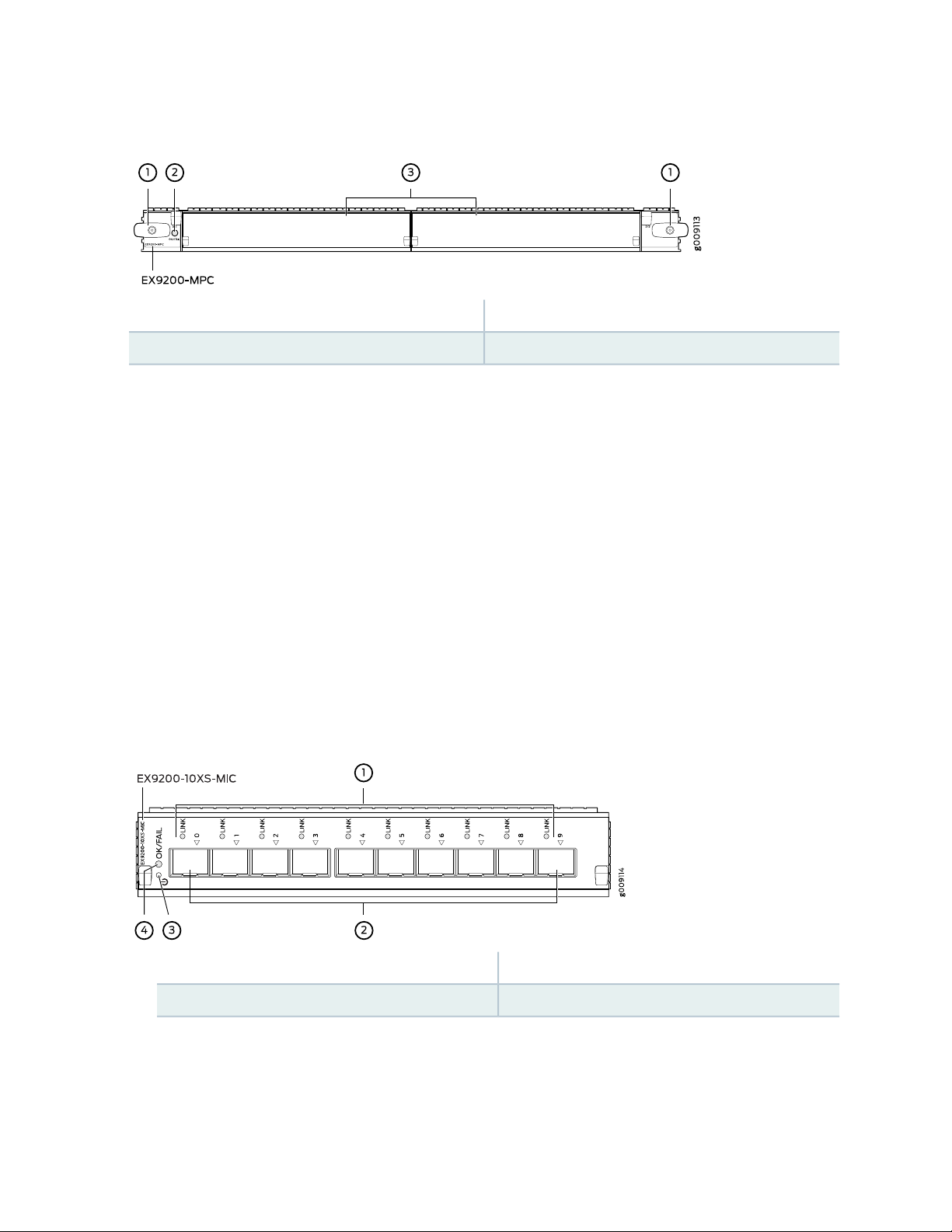

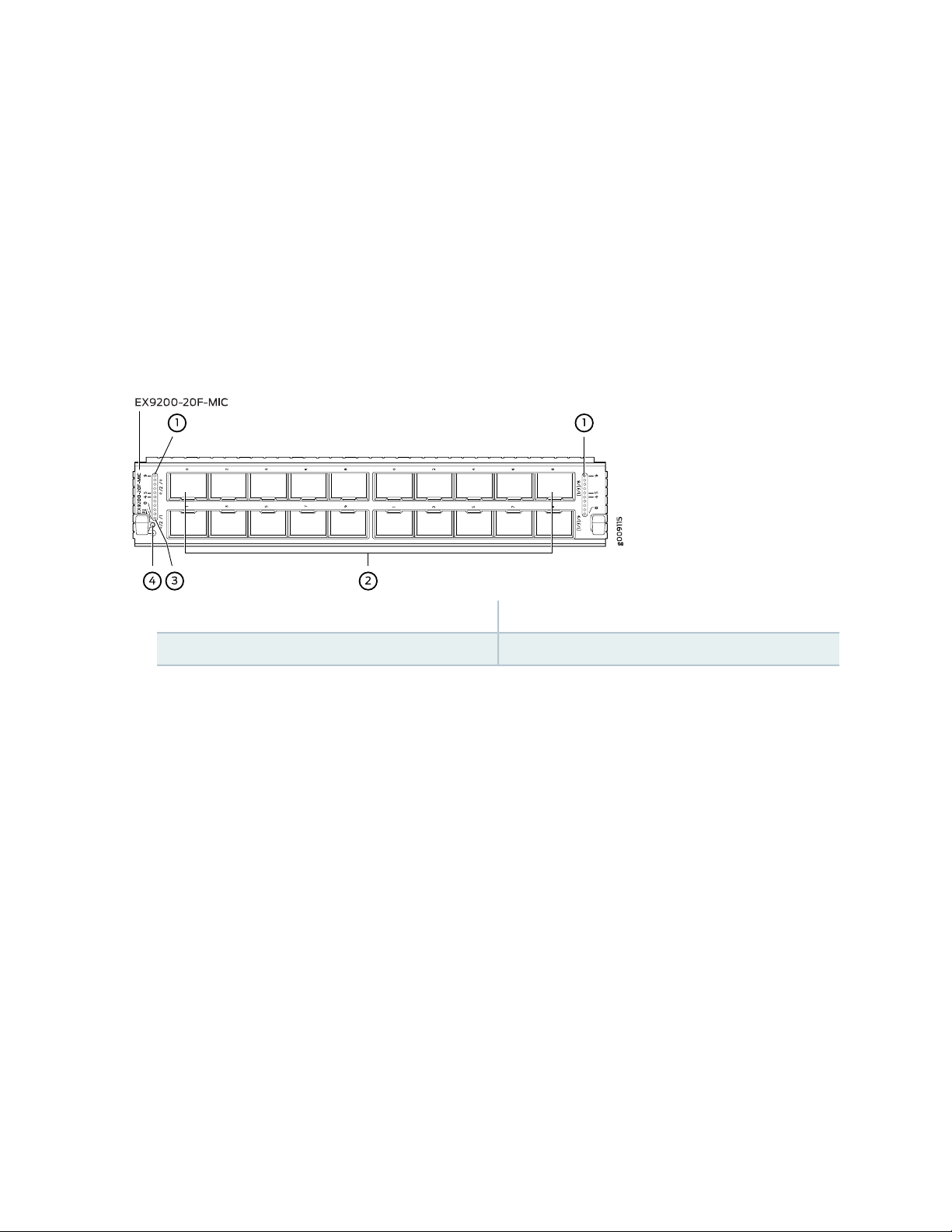

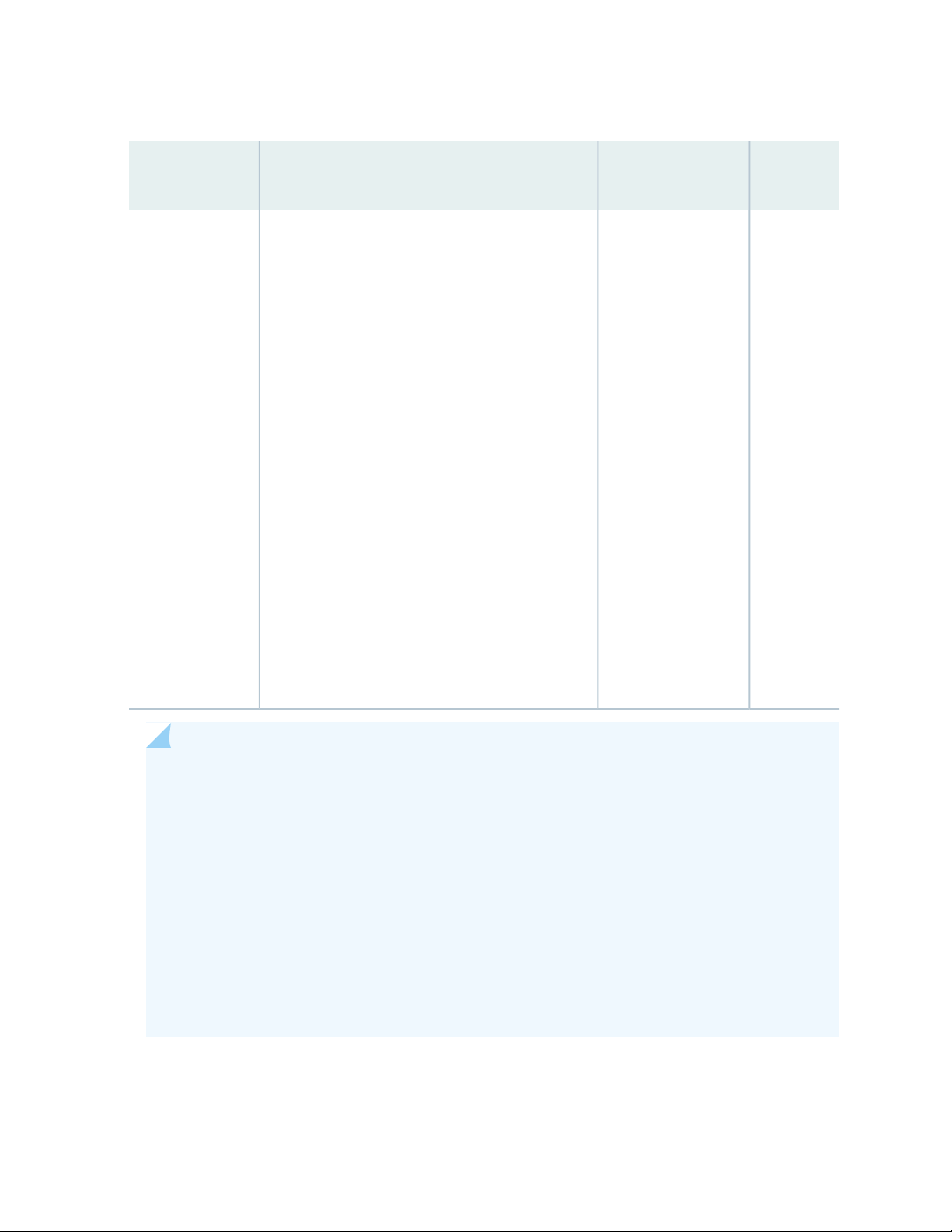

EX9200-MPC Line Card | 93

Line Card Models | 93

Line Card Components | 94

EX9200-12QS Line Card | 96

Line Card Models | 97

Line Card Components | 98

EX9200-15C Line Card | 99

Line Card Models | 99

Line Card Components | 101

EX9200-15C Power Requirements | 101

EX9200-15C LEDs | 102

Cables and Connectors | 102

EX9200-32XS Line Card | 103

Line Card Models | 103

Line Card Components | 104

EX9200-40T Line Card | 104

Line Card Models | 104

Line Card Components | 105

Page 6

EX9200-40F Line Card | 106

2

Line Card Models | 106

Line Card Components | 107

EX9200-40F-M Line Card | 107

Line Card Models | 107

Line Card Components | 108

EX9200-40XS Line Card | 109

Line Card Models | 109

Line Card Components | 110

Line Card LED in an EX9200 Switch | 111

Network Port LEDs on Line Cards in an EX9200 Switch | 111

Modular Interface Card LED in an EX9200 Switch | 112

Configuring Rate Selectability on an EX9200-12QS Line Card to Enable Different Port

Speeds | 113

vi

Configuring Rate Selectability at the PIC Level | 113

Configuring Rate Selectability at the Port Level | 115

Site Planning, Preparation, and Specifications

Site Preparation Checklist for an EX9208 Switch | 119

EX9208 Site Guidelines and Requirements | 120

Environmental Requirements and Specifications for EX Series Switches | 121

General Site Guidelines | 126

Site Electrical Wiring Guidelines | 126

Clearance Requirements for Airflow and Hardware Maintenance for an EX9208 Switch | 127

Rack Requirements | 129

Cabinet Requirements | 130

Power Requirements for EX9200 Switch Components | 131

Grounding Cable and Lug Specifications for EX9200 Switches | 133

Grounding Points Specifications for an EX9200 Switch | 133

Grounding Cable Lug Specifications for an EX9200 Switch | 134

Page 7

Grounding Cable Specifications for an EX9200 Switch | 134

3

EX9200 Network Cable and Transceiver Planning | 135

Pluggable Transceivers Supported on EX9200 Switches | 135

Understanding EX Series Switches Fiber-Optic Cable Signal Loss, Attenuation, and

Dispersion | 136

Signal Loss in Multimode and Single-Mode Fiber-Optic Cable | 136

Attenuation and Dispersion in Fiber-Optic Cable | 137

Calculating the Fiber-Optic Cable Power Budget for EX Series Devices | 138

Calculating the Fiber-Optic Cable Power Margin for EX Series Devices | 138

EX9200 Management Cable Specifications and Pinouts | 140

Management Cable Specifications | 140

Console Port Connector Pinout Information | 141

USB Port Specifications for an EX Series Switch | 142

vii

RJ-45 Management Port Connector Pinout Information | 142

RJ-45 to DB-9 Serial Port Adapter Pinout Information | 143

Initial Installation and Configuration

Unpacking and Mounting the EX9208 Switch | 145

Unpacking the EX9200 Switch | 145

Unpacking a Line Card Used in an EX9200 Switch | 147

Parts Inventory (Packing List) for an EX9208 Switch | 148

Register Products—Mandatory to Validate SLAs | 150

Installing and Connecting an EX9208 Switch | 151

Installing a Mounting Shelf in a Rack or Cabinet for an EX9208 Switch | 151

Moving the Mounting Brackets for Center-Mounting an EX9200 Switch | 154

Mounting an EX9200 Switch on a Rack or Cabinet Using a Mechanical Lift | 156

Mounting an EX9208 Switch on a Rack or Cabinet Without Using a Mechanical Lift | 160

Connecting the EX9208 to Power | 162

Connect Earth Ground to an EX Series Switch | 162

Parts and Tools Required for Connecting an EX Series Switch to Earth Ground | 163

Special Instructions to Follow Before Connecting Earth Ground to an EX Series Switch | 167

Page 8

Connecting Earth Ground to an EX Series Switch | 168

4

Connecting AC Power to an EX9208 Switch | 169

Powering On an AC-Powered EX9200 Switch | 171

Connecting DC Power to an EX9208 Switch | 173

Powering On a DC-Powered EX9200 Switch | 178

Connecting the EX9200 to External Devices | 180

Connecting an EX9200 Switch to a Network for Out-of-Band Management | 180

Connecting an EX9200 Switch to a Management Console or an Auxiliary Device | 181

Connecting the EX9200 Switch to an External Alarm-Reporting Device | 183

Connecting the EX9200 to the Network | 184

Install a Transceiver | 184

Connect a Fiber-Optic Cable | 187

Configuring Junos OS on the EX9200 | 188

viii

EX9200 Switch Default Configuration | 188

Connecting and Configuring an EX9200 Switch (CLI Procedure) | 189

Maintaining Components

Routine Maintenance Procedures for EX9200 Switches | 195

Maintaining the EX9200 Cooling System | 195

Removing a Fan Tray from an EX9200 Switch | 195

Installing a Fan Tray in an EX9200 Switch | 197

Maintaining the Fan Tray in EX9200 Switches | 199

Maintaining the Air Filter in EX9200 Switches | 202

Maintaining the EX9208 Power System | 202

Removing an AC Power Supply from an EX9208 Switch | 203

Installing an AC Power Supply in an EX9208 Switch | 205

Removing a DC Power Supply from an EX9208 Switch | 206

Installing a DC Power Supply in an EX9208 Switch | 209

Maintaining Power Supplies in EX9200 Switches | 210

Maintaining the EX9200 Host Subsystem | 211

Taking the Host Subsystem Offline in an EX9200 Switch | 212

Removing an RE Module from an EX9200 Switch | 213

Page 9

Installing an RE Module in an EX9200 Switch | 215

Upgrading an EX9200-SF to an EX9200-SF2 | 217

Preparing the EX9200 Switch for an EX9200-SF2 Upgrade | 217

Powering Off the Switch | 218

Removing a Routing Engine from an EX9200-SF Module | 218

Replacing the EX9200-SF with the EX9200-SF2 | 218

Installing a Routing Engine into an EX9200-SF2 | 219

Powering On the Switch | 219

Completing the EX9200-SF2 Upgrade | 220

Upgrading to an EX9200-SF3 | 221

Preparing the EX9200 Switch for an EX9200-SF3 Upgrade | 222

Powering Off the Switch | 222

Removing a Routing Engine from an SF Module | 222

Replacing the EX9200-SF or EX9200-SF2 with the EX9200-SF3 | 223

ix

Installing a Routing Engine into an EX9200-SF3 | 223

Powering On the Switch | 223

Completing the EX9200-SF3 Upgrade | 224

Removing an SF Module from an EX9200 Switch | 225

Installing an SF Module in an EX9200 Switch | 227

Maintaining the Host Subsystem in EX9200 Switches | 230

Maintaining the EX9200 Line Cards | 234

Handling and Storing Line Cards | 235

Holding a Line Card | 235

Storing a Line Card | 239

Maintaining Line Card Cables | 240

Unpacking a Line Card Used in an EX9200 Switch | 240

Removing a Line Card from an EX9200 Switch | 241

Installing a Line Card in an EX9200 Switch | 244

Removing a MIC from an EX9200-MPC Line Card | 246

Installing a MIC in an EX9200-MPC Line Card | 249

Maintain Transceivers | 254

Remove a Transceiver | 255

Remove a QSFP28 Transceiver | 258

Page 10

Install a Transceiver | 260

5

Install a QSFP28 Transceiver | 262

Maintaining Alarm Relay Wire | 264

Disconnecting the Alarm Relay Wires from the Craft Interface in an EX9200 Switch | 264

Connecting the Alarm Relay Wires to the Craft Interface in an EX9200 Switch | 265

Maintain Fiber-Optic Cables | 266

Connect a Fiber-Optic Cable | 267

Disconnect a Fiber-Optic Cable | 268

How to Handle Fiber-Optic Cables | 268

Maintaining the EX9208 Cable Management Brackets | 269

Installing Cable Management Brackets on an EX9208 Switch | 269

Removing Cable Management Brackets from an EX9208 Switch | 271

x

Removing an EX9208 from a Rack or Cabinet | 271

Powering Off an EX9200 Switch | 271

Removing an EX9200 Switch from a Rack or Cabinet Using a Mechanical Lift | 272

Removing an EX9208 Switch from a Rack or Cabinet Without Using a Mechanical Lift | 273

Troubleshooting Hardware

Troubleshooting EX9200 Components | 277

Troubleshooting the Cooling System in an EX9200 Switch | 277

Troubleshooting Power Supplies in an EX9200 Switch | 278

Troubleshooting Line Cards in EX9200 Switches | 279

Troubleshooting Traffic Drops on EX9200-6QS Line Cards | 282

Understand Alarm Types and Severity Levels on EX Series Switches | 282

Chassis Component Alarm Conditions on EX9200 Switches | 284

Backup Routing Engine Alarms | 289

Monitor System Log Messages | 291

Troubleshoot Temperature Alarms in EX Series Switches | 296

Page 11

Contacting Customer Support and Returning the Chassis or Components

6

7

Returning an EX9208 Chassis or Components | 302

Returning an EX9200 Switch or Component for Repair or Replacement | 302

Locating the Serial Number on an EX9208 Switch or Component | 303

Listing the Switch and Components Details with the CLI | 303

Locating the Serial Number ID Label on an EX9200 Switch Chassis | 306

Locating Serial Number ID Labels on FRU Components | 307

Contact Customer Support to Obtain Return Material Authorization | 310

Packing an EX9200 Switch or Component | 310

Packing an EX9200 Switch | 311

Packing EX9200 Switch Components for Shipping | 312

Safety and Compliance Information

xi

General Safety Guidelines and Warnings | 316

Definitions of Safety Warning Levels | 317

Qualified Personnel Warning | 320

Warning Statement for Norway and Sweden | 321

Fire Safety Requirements | 321

Fire Suppression | 321

Fire Suppression Equipment | 321

Installation Instructions Warning | 323

Chassis and Component Lifting Guidelines | 323

Restricted Access Warning | 325

Ramp Warning | 327

Rack-Mounting and Cabinet-Mounting Warnings | 328

Grounded Equipment Warning | 334

Page 12

Radiation from Open Port Apertures Warning | 335

Laser and LED Safety Guidelines and Warnings | 336

General Laser Safety Guidelines | 336

Class 1 Laser Product Warning | 337

Class 1 LED Product Warning | 338

Laser Beam Warning | 339

Maintenance and Operational Safety Guidelines and Warnings | 339

Battery Handling Warning | 341

Jewelry Removal Warning | 342

Lightning Activity Warning | 344

Operating Temperature Warning | 345

Product Disposal Warning | 347

xii

General Electrical Safety Guidelines and Warnings | 348

Action to Take After an Electrical Accident | 349

Prevention of Electrostatic Discharge Damage | 350

AC Power Electrical Safety Guidelines | 351

AC Power Disconnection Warning | 353

DC Power Electrical Safety Guidelines | 354

DC Power Disconnection Warning | 355

DC Power Grounding Requirements and Warning | 357

DC Power Wiring Sequence Warning | 359

DC Power Wiring Terminations Warning | 362

Multiple Power Supplies Disconnection Warning | 365

TN Power Warning | 366

Agency Approvals for EX Series Switches | 366

Battery Compliance Statement for Environmental Requirements for EX Series

Switches | 367

Page 13

Compliance Statements for EMC Requirements for EX Series Switches | 368

Canada | 368

Taiwan | 369

European Community | 369

Israel | 370

Japan | 370

Korea | 370

United States | 371

FCC Part 15 Statement | 371

Nonregulatory Environmental Standards | 371

Compliance Statements for Acoustic Noise for EX Series Switches | 372

xiii

Page 14

About the Documentation

IN THIS SECTION

Documentation and Release Notes | xiv

Using the Examples in This Manual | xiv

Documentation Conventions | xvi

Documentation Feedback | xix

Requesting Technical Support | xix

Use this guide to install hardware and perform initial software configuration, routine maintenance, and

troubleshooting for the EX9208 switch. After completing the installation and basic configuration procedures

covered in this guide, refer to the Junos OS documentation for information about further software

configuration.

xiv

Documentation and Release Notes

To obtain the most current version of all Juniper Networks®technical documentation, see the product

documentation page on the Juniper Networks website at https://www.juniper.net/documentation/.

If the information in the latest release notes differs from the information in the documentation, follow the

product Release Notes.

Juniper Networks Books publishes books by Juniper Networks engineers and subject matter experts.

These books go beyond the technical documentation to explore the nuances of network architecture,

deployment, and administration. The current list can be viewed at https://www.juniper.net/books.

Using the Examples in This Manual

If you want to use the examples in this manual, you can use the load merge or the load merge relative

command. These commands cause the software to merge the incoming configuration into the current

candidate configuration. The example does not become active until you commit the candidate configuration.

Page 15

If the example configuration contains the top level of the hierarchy (or multiple hierarchies), the example

is a full example. In this case, use the load merge command.

If the example configuration does not start at the top level of the hierarchy, the example is a snippet. In

this case, use the load merge relative command. These procedures are described in the following sections.

Merging a Full Example

To merge a full example, follow these steps:

1. From the HTML or PDF version of the manual, copy a configuration example into a text file, save the

file with a name, and copy the file to a directory on your routing platform.

For example, copy the following configuration to a file and name the file ex-script.conf. Copy the

ex-script.conf file to the /var/tmp directory on your routing platform.

system {

scripts {

commit {

file ex-script.xsl;

}

}

}

interfaces {

fxp0 {

disable;

unit 0 {

family inet {

address 10.0.0.1/24;

}

}

}

}

xv

2. Merge the contents of the file into your routing platform configuration by issuing the load merge

configuration mode command:

[edit]

user@host# load merge /var/tmp/ex-script.conf

load complete

Page 16

Merging a Snippet

To merge a snippet, follow these steps:

1. From the HTML or PDF version of the manual, copy a configuration snippet into a text file, save the

file with a name, and copy the file to a directory on your routing platform.

For example, copy the following snippet to a file and name the file ex-script-snippet.conf. Copy the

ex-script-snippet.conf file to the /var/tmp directory on your routing platform.

commit {

file ex-script-snippet.xsl; }

2. Move to the hierarchy level that is relevant for this snippet by issuing the following configuration mode

command:

[edit]

user@host# edit system scripts

[edit system scripts]

xvi

3. Merge the contents of the file into your routing platform configuration by issuing the load merge

relative configuration mode command:

[edit system scripts]

user@host# load merge relative /var/tmp/ex-script-snippet.conf

load complete

For more information about the load command, see CLI Explorer.

Documentation Conventions

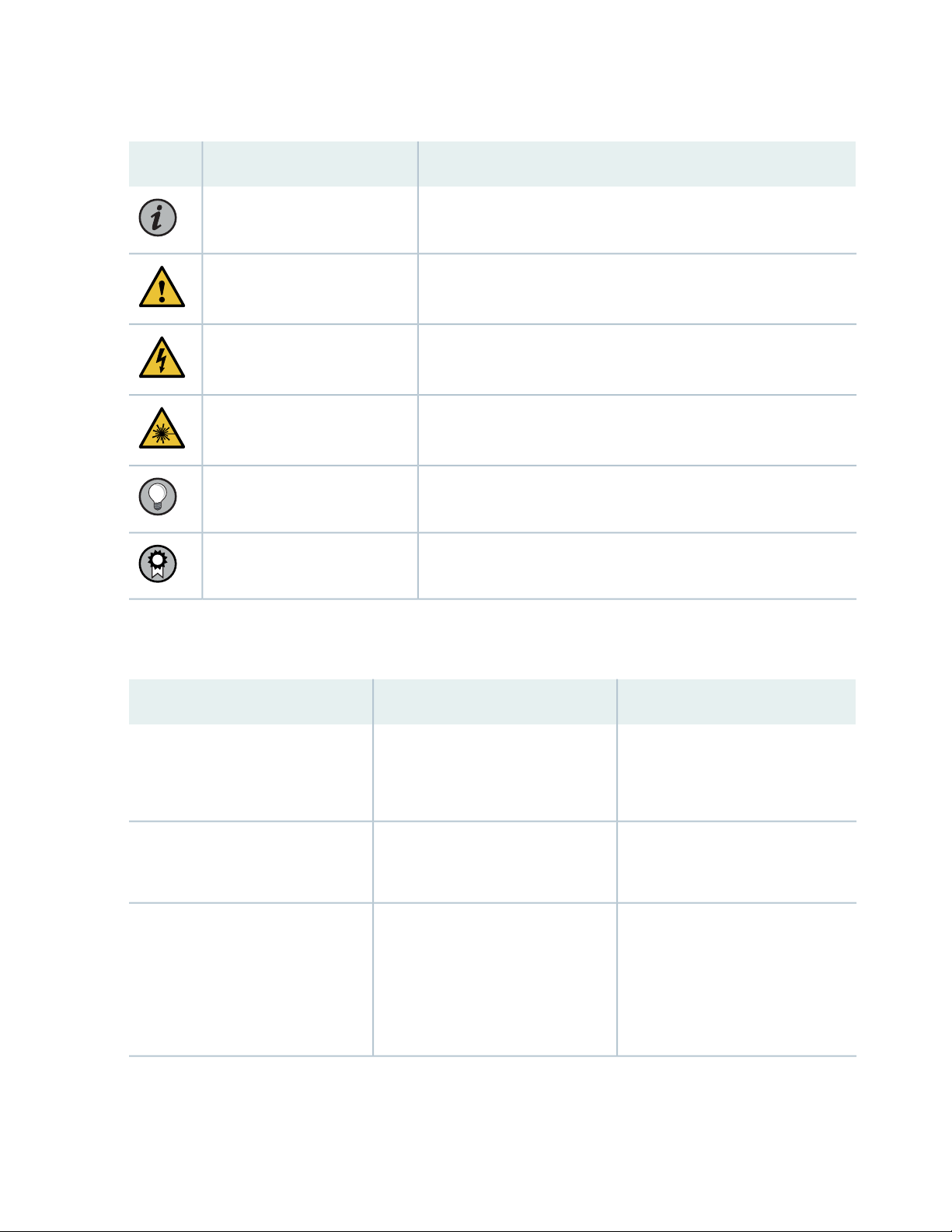

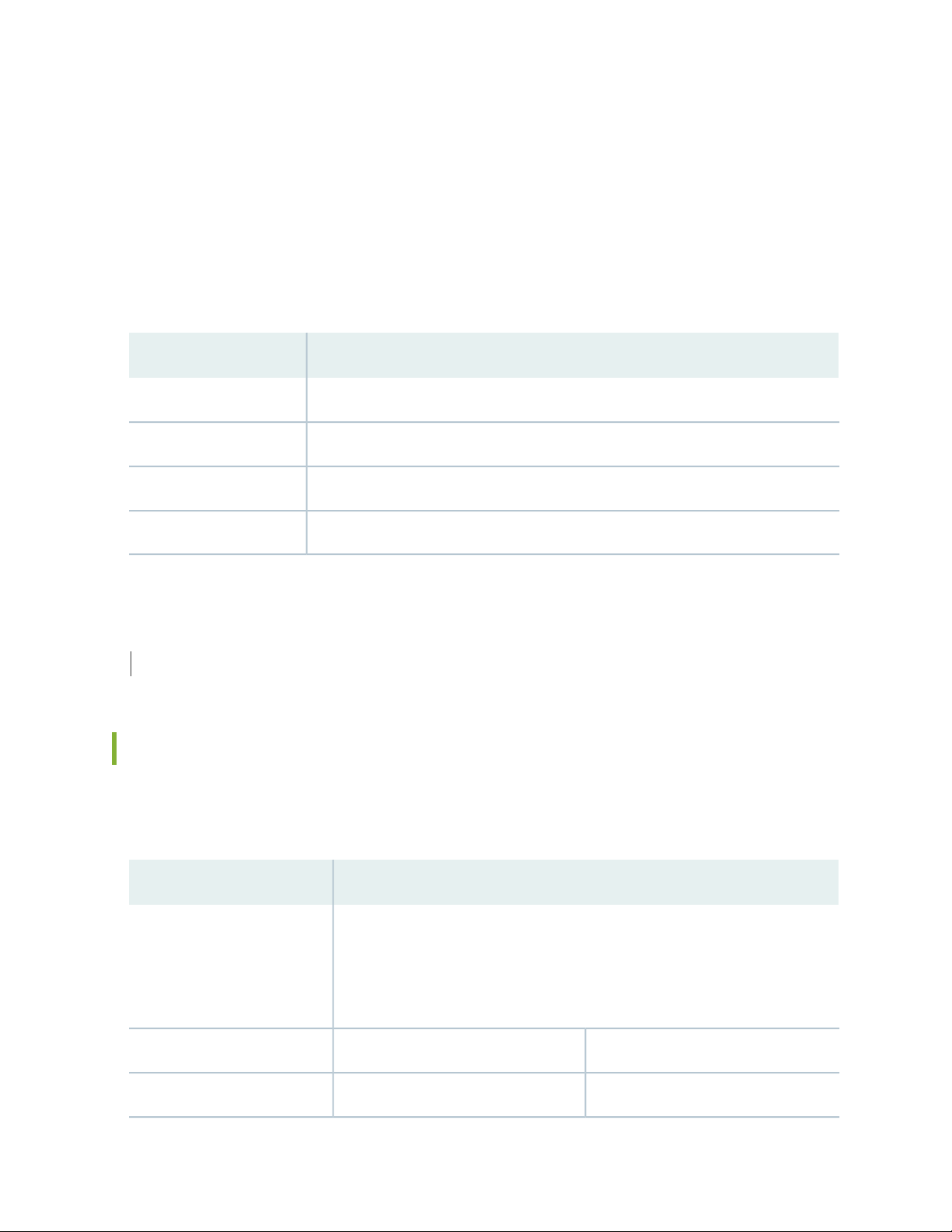

Table 1 on page xvii defines notice icons used in this guide.

Page 17

Table 1: Notice Icons

xvii

DescriptionMeaningIcon

Indicates important features or instructions.Informational note

Caution

Indicates a situation that might result in loss of data or hardware

damage.

Alerts you to the risk of personal injury or death.Warning

Alerts you to the risk of personal injury from a laser.Laser warning

Indicates helpful information.Tip

Alerts you to a recommended use or implementation.Best practice

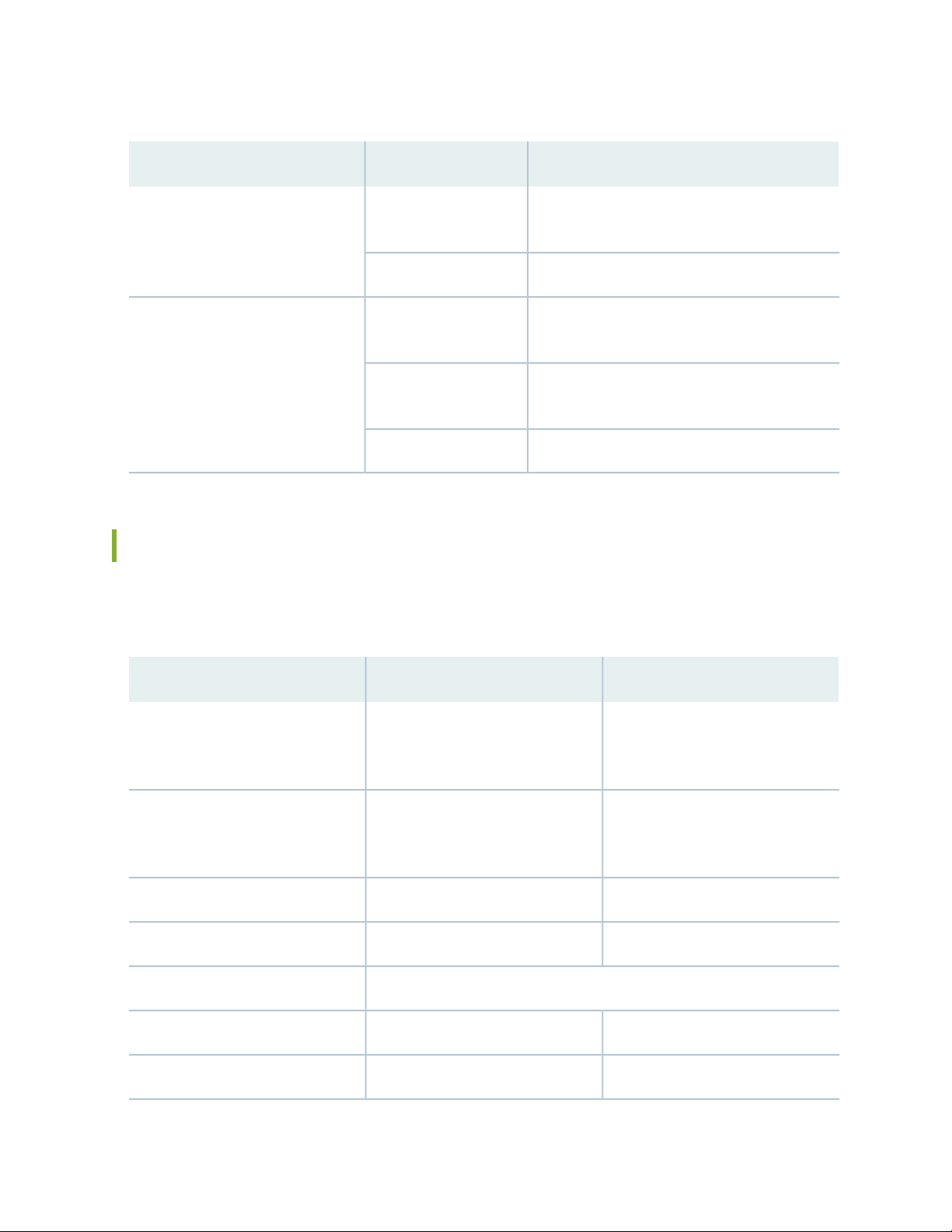

Table 2 on page xvii defines the text and syntax conventions used in this guide.

Table 2: Text and Syntax Conventions

ExamplesDescriptionConvention

Fixed-width text like this

Italic text like this

Represents text that you type.Bold text like this

Represents output that appears on

the terminal screen.

Introduces or emphasizes important

•

new terms.

Identifies guide names.

•

Identifies RFC and Internet draft

•

titles.

To enter configuration mode, type

the configure command:

user@host> configure

user@host> show chassis alarms

No alarms currently active

A policy term is a named structure

•

that defines match conditions and

actions.

Junos OS CLI User Guide

•

RFC 1997, BGP Communities

•

Attribute

Page 18

Table 2: Text and Syntax Conventions (continued)

xviii

ExamplesDescriptionConvention

Italic text like this

Text like this

< > (angle brackets)

| (pipe symbol)

Represents variables (options for

which you substitute a value) in

commands or configuration

statements.

Represents names of configuration

statements, commands, files, and

directories; configuration hierarchy

levels; or labels on routing platform

components.

variables.

Indicates a choice between the

mutually exclusive keywords or

variables on either side of the symbol.

The set of choices is often enclosed

in parentheses for clarity.

Configure the machine’s domain

name:

[edit]

root@# set system domain-name

domain-name

To configure a stub area, include

•

the stub statement at the [edit

protocols ospf area area-id]

hierarchy level.

The console port is labeled

•

CONSOLE.

stub <default-metric metric>;Encloses optional keywords or

broadcast | multicast

(string1 | string2 | string3)

# (pound sign)

[ ] (square brackets)

Indention and braces ( { } )

; (semicolon)

GUI Conventions

Indicates a comment specified on the

same line as the configuration

statement to which it applies.

Encloses a variable for which you can

substitute one or more values.

Identifies a level in the configuration

hierarchy.

Identifies a leaf statement at a

configuration hierarchy level.

rsvp { # Required for dynamic MPLS

only

community name members [

community-ids ]

[edit]

routing-options {

static {

route default {

nexthop address;

retain;

}

}

}

Page 19

Table 2: Text and Syntax Conventions (continued)

xix

ExamplesDescriptionConvention

Bold text like this

> (bold right angle bracket)

Represents graphical user interface

(GUI) items you click or select.

Separates levels in a hierarchy of

menu selections.

In the Logical Interfaces box, select

•

All Interfaces.

To cancel the configuration, click

•

Cancel.

In the configuration editor hierarchy,

select Protocols>Ospf.

Documentation Feedback

We encourage you to provide feedback so that we can improve our documentation. You can use either

of the following methods:

Online feedback system—Click TechLibrary Feedback, on the lower right of any page on the Juniper

•

Networks TechLibrary site, and do one of the following:

Click the thumbs-up icon if the information on the page was helpful to you.

•

Click the thumbs-down icon if the information on the page was not helpful to you or if you have

•

suggestions for improvement, and use the pop-up form to provide feedback.

E-mail—Send your comments to techpubs-comments@juniper.net. Include the document or topic name,

•

URL or page number, and software version (if applicable).

Requesting Technical Support

Technical product support is available through the Juniper Networks Technical Assistance Center (JTAC).

If you are a customer with an active Juniper Care or Partner Support Services support contract, or are

Page 20

covered under warranty, and need post-sales technical support, you can access our tools and resources

online or open a case with JTAC.

JTAC policies—For a complete understanding of our JTAC procedures and policies, review the JTAC User

•

Guide located at https://www.juniper.net/us/en/local/pdf/resource-guides/7100059-en.pdf.

Product warranties—For product warranty information, visit https://www.juniper.net/support/warranty/.

•

JTAC hours of operation—The JTAC centers have resources available 24 hours a day, 7 days a week,

•

365 days a year.

Self-Help Online Tools and Resources

For quick and easy problem resolution, Juniper Networks has designed an online self-service portal called

the Customer Support Center (CSC) that provides you with the following features:

Find CSC offerings: https://www.juniper.net/customers/support/

•

Search for known bugs: https://prsearch.juniper.net/

•

xx

Find product documentation: https://www.juniper.net/documentation/

•

Find solutions and answer questions using our Knowledge Base: https://kb.juniper.net/

•

Download the latest versions of software and review release notes:

•

https://www.juniper.net/customers/csc/software/

Search technical bulletins for relevant hardware and software notifications:

•

https://kb.juniper.net/InfoCenter/

Join and participate in the Juniper Networks Community Forum:

•

https://www.juniper.net/company/communities/

Create a service request online: https://myjuniper.juniper.net

•

To verify service entitlement by product serial number, use our Serial Number Entitlement (SNE) Tool:

https://entitlementsearch.juniper.net/entitlementsearch/

Creating a Service Request with JTAC

You can create a service request with JTAC on the Web or by telephone.

Visit https://myjuniper.juniper.net.

•

Call 1-888-314-JTAC (1-888-314-5822 toll-free in the USA, Canada, and Mexico).

•

For international or direct-dial options in countries without toll-free numbers, see

https://support.juniper.net/support/requesting-support/.

Page 21

1

CHAPTER

Overview

EX9208 System Overview | 22

EX9208 Chassis | 40

EX9208 Cooling System | 51

EX9208 Power System | 53

EX9200 Host Subsystem | 65

EX9200 Line Cards | 83

Page 22

EX9208 System Overview

IN THIS SECTION

EX9208 Switch Hardware Overview | 22

EX9208 Switch Configurations | 27

EX9208 Switch Hardware and CLI Terminology Mapping | 30

Chassis Physical Specifications of an EX9208 Switch | 35

Field-Replaceable Units in an EX9200 Switch | 38

EX9208 Switch Hardware Overview

22

IN THIS SECTION

Benefits | 23

Software | 23

Chassis Physical Specifications | 23

Host Subsystem | 24

Line Cards | 25

Cooling System | 26

Power Supplies | 26

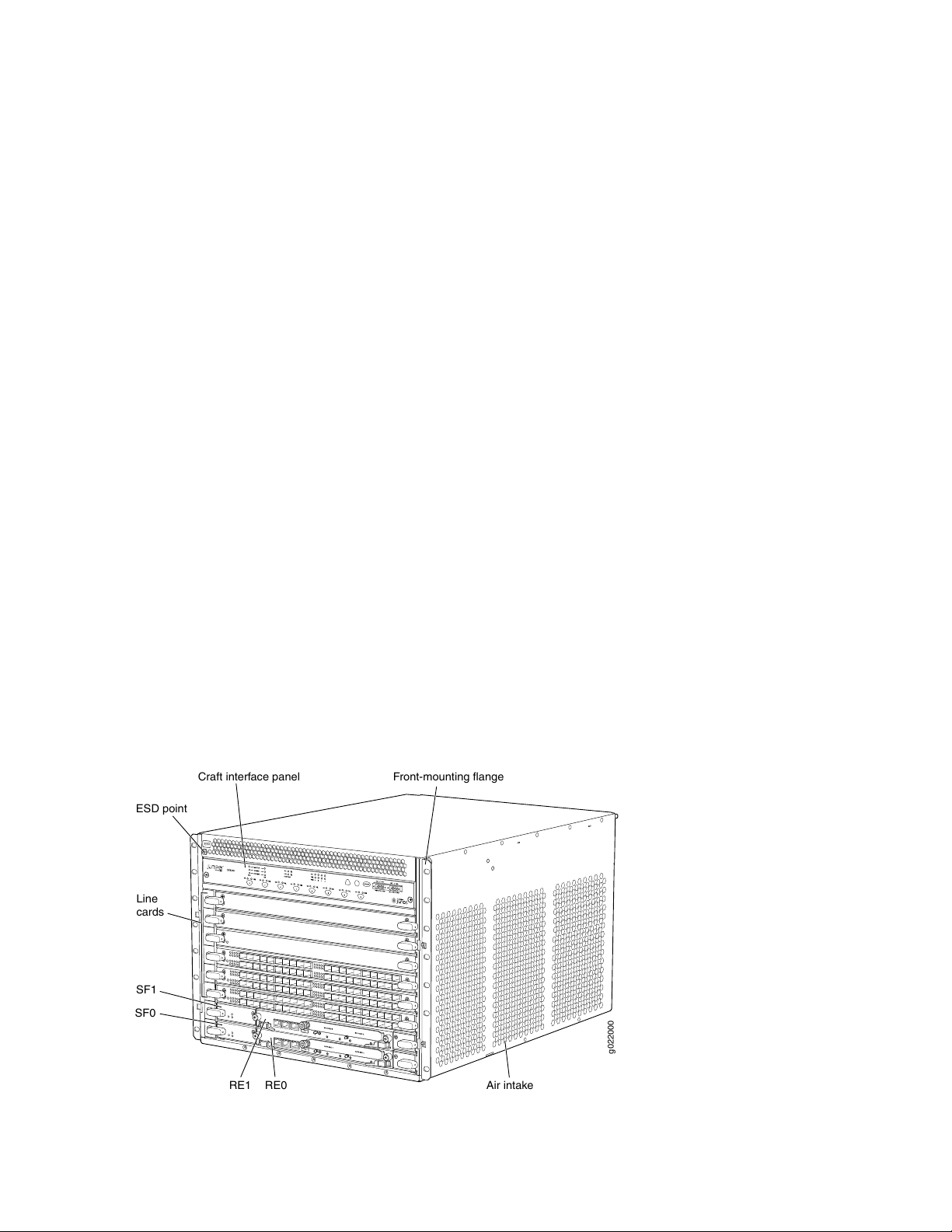

Juniper Networks EX9208 Ethernet Switches provide high performance, scalable connectivity, and

carrier-class reliability for high-density environments such as campus-aggregation and data-center networks.

The EX9208 switch has a throughput of up to 4.8 terabits per second (Tbps) or up to 240 gigabits per

second (Gbps) per slot full duplex. The EX9208 switch is a modular system that provides high availability

and redundancy for all major hardware components, including Routing Engine modules (RE modules),

Switch Fabric modules (SF modules), fan tray (redundant fans), and power supplies.

You can manage EX9208 switches by using the same interfaces that you use for managing other devices

running the Juniper Networks Junos operating system (Junos OS)—the CLI, the Network and Security

Manager (NSM), and Junos Space.

Page 23

Benefits

ESD

g022000

Front-mounting flange

SF1

RE1 RE0

Line

cards

SF0

ESD point

Craft interface panel

Air intake

Simplified network architecture—EX9208 switches deliver a simple, secure, virtualized network environment

that increases business agility. They are ideal for simplifying campus, data center, and combined campus

and data center network environments by collapsing network layers. In a multichassis link aggregation

(MC-LAG) configuration in the campus, you can use EX9208 switches to eliminate Spanning Tree Protocol

(STP); they collapse the core and aggregation layers, thereby simplifying the network architecture and

network operations. In a data center, you can use EX9208 switches to collapse core and aggregation layers.

In combined campus and data center environments, EX9208 switches consolidate network layers to simplify

the network architecture and operations.

MACsec support—EX9200-40F-M and EX9200-40XS line cards and EX9200-20F-MIC for EX9200-MPC

line card supports IEEE 802.1AE MACsec with AES-256 bit encryption, ensuring link-layer data

confidentiality, data integrity, and data origin authentication.

Software

23

Juniper Networks EX Series Ethernet Switches run Junos OS, which provides Layer 2 and Layer 3 switching,

routing, and security services.

Chassis Physical Specifications

The EX9208 switch is eight rack units (8 U) in size. Five EX9208 switches can fit in a standard 48 U rack.

Each EX9208 switch is designed to optimize rack space and cabling. See Figure 1 on page 23,

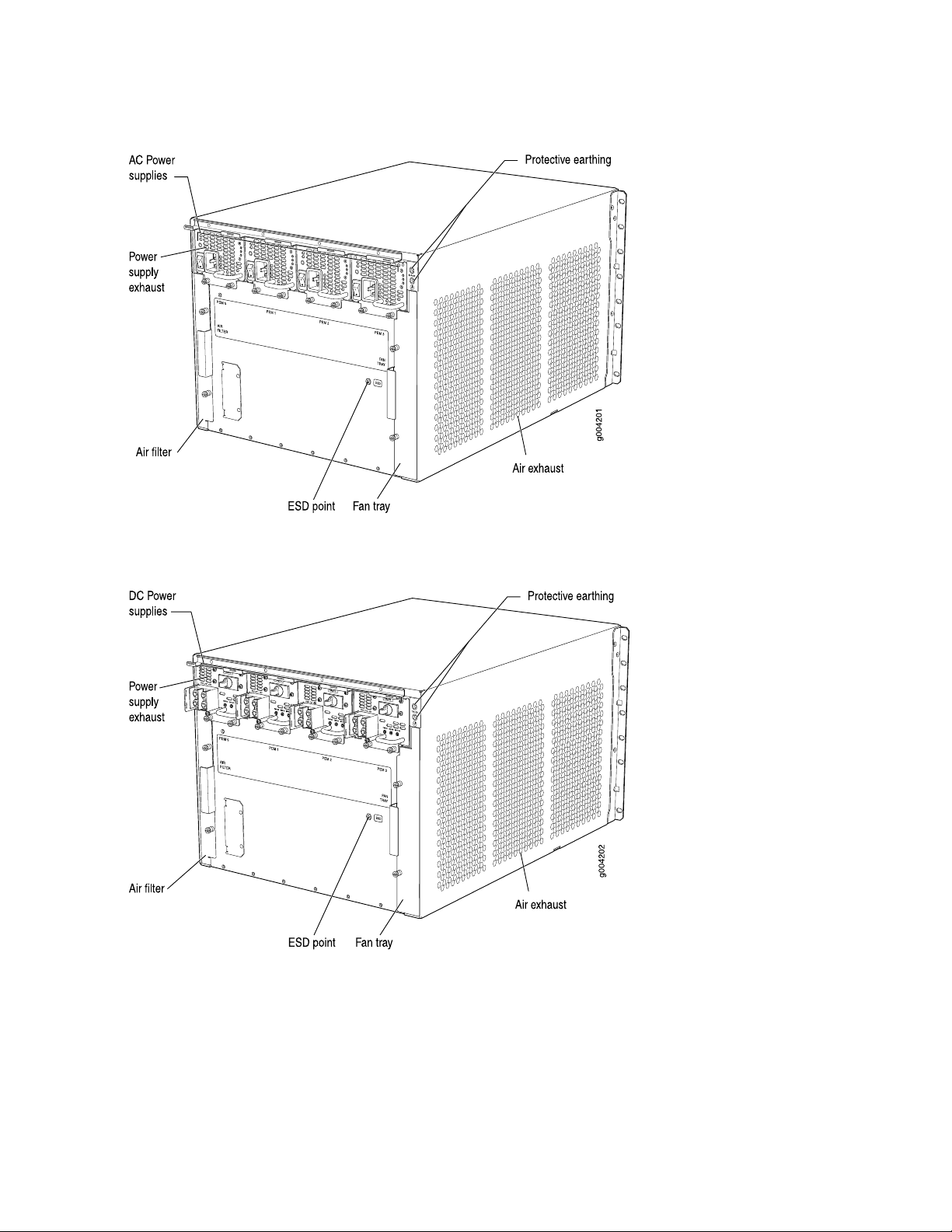

Figure 2 on page 24, and Figure 3 on page 24.

Figure 1: Front View of an EX9208 Switch

Page 24

Figure 2: Rear View of an EX9208 Switch with AC Power Supplies

24

Figure 3: Rear View of an EX9208 Switch with DC Power Supplies

Host Subsystem

Switching and routing functionality, system management, and system control functions of an EX9208

switch are performed by the host subsystem. The host subsystem consists of a Routing Engine functioning

together with a Switch Fabric.

Page 25

You can install either one or two host subsystems in the slots labeled 0 and 1 in the front panel of the

chassis. A base-configuration EX9208 switch has one host subsystem. A redundant-configuration EX9208

switch has a second host subsystem. For more information, see “EX9208 Switch Configurations” on page 27.

Line Cards

The EX9208 switch has six horizontal line card slots and supports line rate for each line card. The line cards

in EX9208 switches combine a Packet Forwarding Engine and Ethernet interfaces in a single assembly.

Line cards are field-replaceable units (FRUs) that you can install in the line card slots—labeled 0 through

5—on the front of the switch chassis. All line cards are hot-removable and hot-insertable. Table 3 on page 25

lists the line cards available for EX9208 switches.

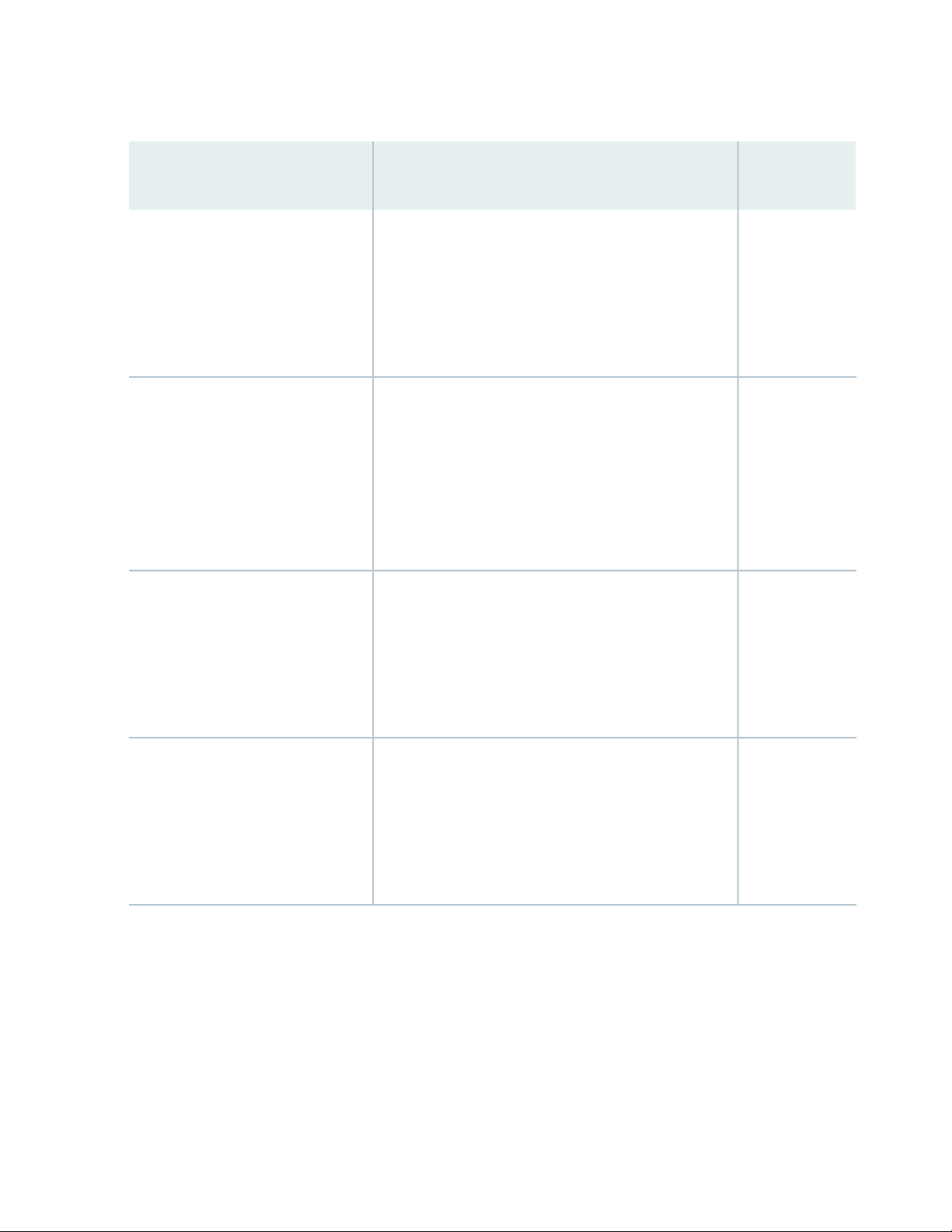

Table 3: Line Cards Available for EX9208 Switches

Additional InformationDescriptionModel

25

EX9200-2C-8XS

EX9200-4QS

EX9200-6QS

EX9200-MPC

EX9200-12QS

Ethernet ports and eight 10-Gigabit

Ethernet ports

Ethernet ports

Ethernet ports and 24 10-Gigabit

Ethernet ports

of the following MICs:

EX9200-10XS-MIC

•

EX9200-20F-MIC

•

EX9200-40T-MIC

•

Ethernet rate-selectable ports, each

of which can house transceivers

“EX9200-2C-8XS Line Card” on page 87A line card with two 100-Gigabit

“EX9200-4QS Line Card” on page 89A line card with four 40-Gigabit

“EX9200-6QS Line Card” on page 90A line card with six 40-Gigabit

“EX9200-MPC Line Card” on page 93A modular line card that accepts any

“EX9200-12QS Line Card” on page 96A line card with six 40-Gigabit

EX9200-15C

EX9200-32XS

“EX9200-15C Line Card” on page 99line card with 15 rate-selectable

ports. All ports can operate at

10-Gbps, 25-Gbps, 40-Gbps, or

100-Gbps speeds

“EX9200-32XS Line Card” on page 103A line card with 32 10-Gigabit

Ethernet ports

Page 26

Table 3: Line Cards Available for EX9208 Switches (continued)

26

Additional InformationDescriptionModel

EX9200-40T

EX9200-40F

EX9200-40F-M

EX9200-40XS

Cooling System

“EX9200-40T Line Card” on page 104A line card with 40

10/100/1000BASE-T ports that

support RJ-45 connectors

“EX9200-40F Line Card” on page 106A line card with 40 1-Gigabit

Ethernet ports

“EX9200-40F-M Line Card” on page 107A line card with 40 1-Gigabit

Ethernet ports with Media Access

Control Security (MACsec) capability

“EX9200-40XS Line Card” on page 109A line card with 40 10-Gigabit

Ethernet ports with Media Access

Control Security (MACsec) capability,

each of which can house 10-gigabit

small form-factor pluggable plus

(SFP+) transceivers

The cooling system in an EX9208 switch is a field-replaceable unit (FRU). It consists of a hot-removable

and hot-insertable fan tray. The fan tray contains six fans. The fan tray installs vertically on the right back

of the chassis and provides side-to-side chassis cooling. See “EX9208 Cooling System” on page 51.

Power Supplies

Power supplies for the EX9208 switch are fully redundant, load-sharing, and hot-removable and

hot-insertable FRUs. Each EX9208 switch chassis can hold up to four AC or DC power supplies.

Table 4 on page 26 shows the details of the power supplies available for EX9208 switches.

Table 4: Power Supplies Supported on EX9208 Switches

Output PowerInput VoltagePower Supply

1167 WLow-voltage line (100–120 VAC)2520 W AC

2050 WHigh-voltage line (200–240 VAC)

2400 W to 2600 W–40 VDC through –70 VDC2400 W DC

Page 27

A base-configuration EX9208 switch ships with three low-line (100–120 VAC) or two high-line

(200–240 VAC) AC power supplies. An AC-powered, redundant-configuration EX9208 switch ships with

four low-line (100–120 VAC) or four high-line (200–240 VAC) AC power supplies. See “AC Power Supply

in an EX9208 Switch” on page 53.

A DC-powered, redundant-configuration EX9208 switch ships with four DC power supplies. See “DC

Power Supply in an EX9208 Switch” on page 60.

CAUTION: Do not mix AC and DC power supplies in the same chassis.

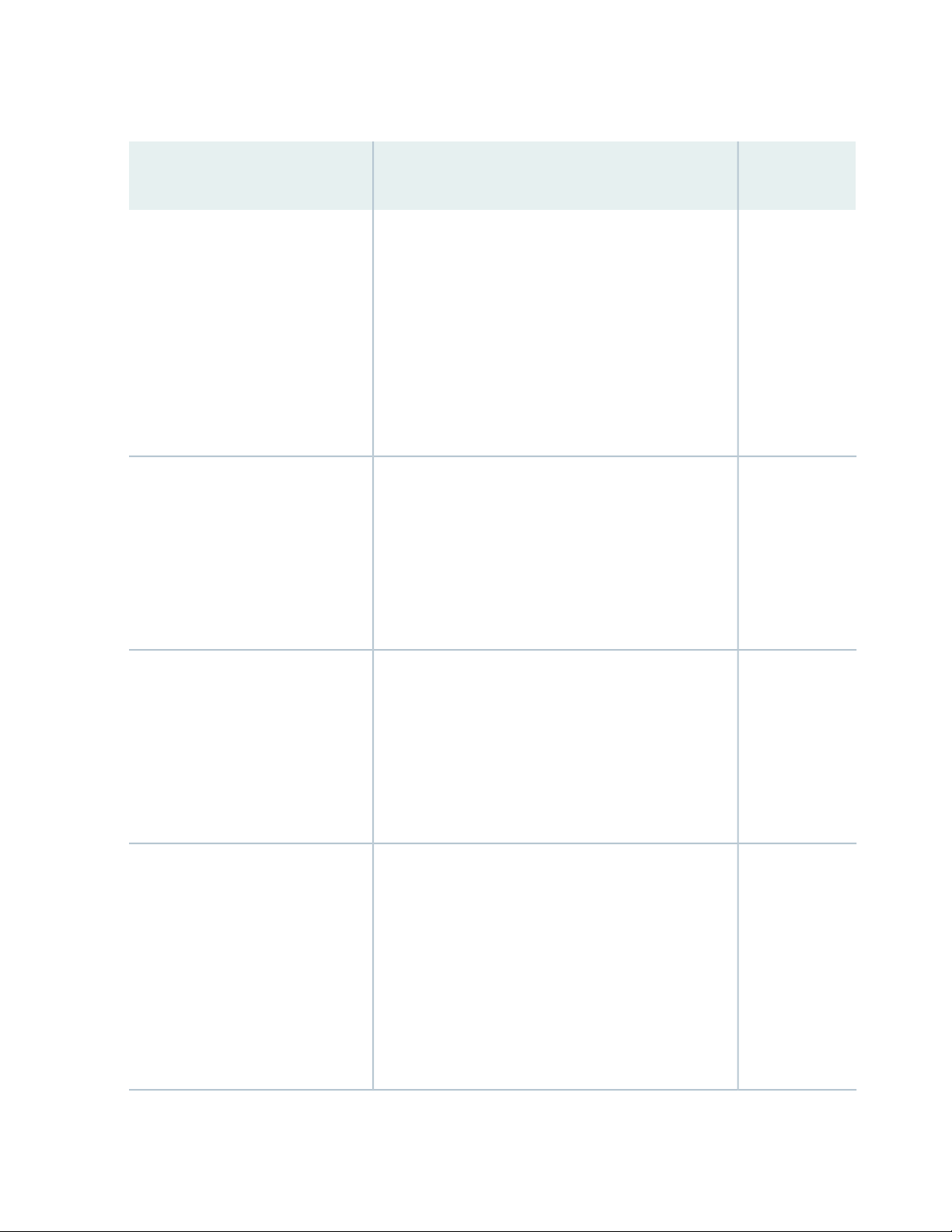

EX9208 Switch Configurations

Table 5 on page 27 lists the hardware configurations for an EX9208 switch—base (AC) and redundant (AC

and DC versions)—and the components included in each configuration.

27

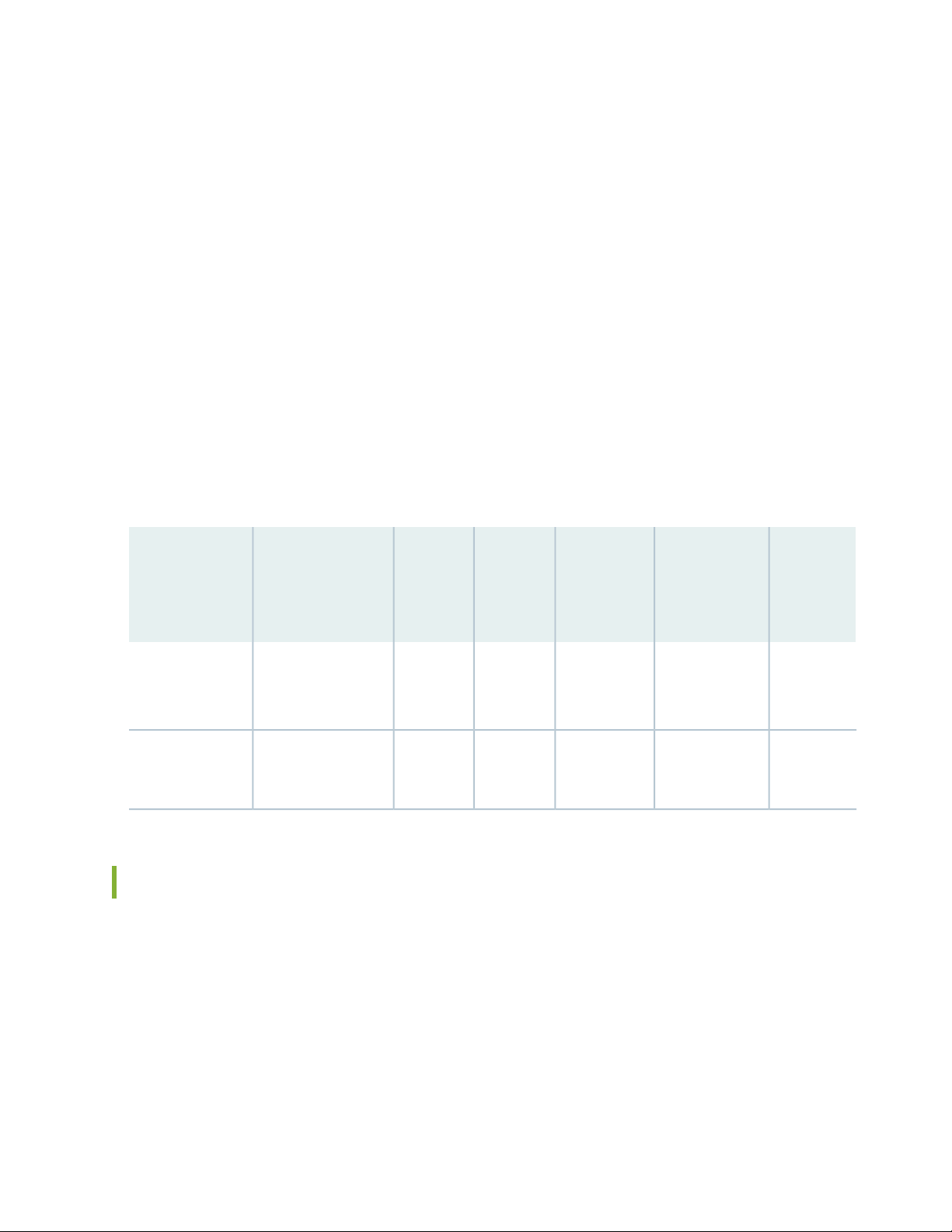

Table 5: EX9208 Switch Hardware Configurations

EX9208-BASE3C-AC

(base configurationwith 2520 W AC

power supplies)

EX9208-RED3C-DC

(redundant configuration with

2520 W AC power supplies)

Chassis with craft interface and midplane

•

One EX9200-SF3 module

•

One EX9200-RE2 module

•

One fan tray

•

Three 2520 W AC power supplies

•

Blank panels for the line card slots

•

Blank panel for the empty power supply slot

•

Chassis with craft interface and midplane

•

Two EX9200-SF3 modules

•

Two EX9200-RE2 modules

•

One fan tray

•

Four 2520 W DC power supplies

•

Blank panels for line card slots

•

First Junos OS

ReleaseConfiguration ComponentsSwitch Configuration

20.3R1

20.3R1

Page 28

Table 5: EX9208 Switch Hardware Configurations (continued)

28

First Junos OS

ReleaseConfiguration ComponentsSwitch Configuration

EX9208-RED3C-AC

(redundant configuration with

2520 W AC power supplies)

EX9208-BASE3B-AC

(base configuration with 2520 W AC

power supplies)

EX9208-RED3B-DC

(redundant configuration with

2520 W AC power supplies)

Chassis with craft interface and midplane

•

Two EX9200-SF3 modules

•

Two EX9200-RE2 modules

•

One fan tray

•

Four 2520 W AC power supplies

•

Blank panels for line card slots

•

Chassis with craft interface and midplane

•

One EX9200-SF2 module

•

One EX9200-RE2 module

•

One fan tray

•

Three 2520 W AC power supplies

•

Blank panels for the line card slots

•

Blank panel for the empty power supply slot

•

Chassis with craft interface and midplane

•

Two EX9200-SF2 modules

•

Two EX9200-RE2 modules

•

One fan tray

•

Four 2520 W DC power supplies

•

Blank panels for line card slots

•

20.3R1

17.1R1

17.1R1

EX9208-RED3B-AC

(redundant configuration with

2520 W AC power supplies)

Chassis with craft interface and midplane

•

Two EX9200-SF2 modules

•

Two EX9200-RE2 modules

•

One fan tray

•

Four 2520 W AC power supplies

•

Blank panels for line card slots

•

17.1R1

Page 29

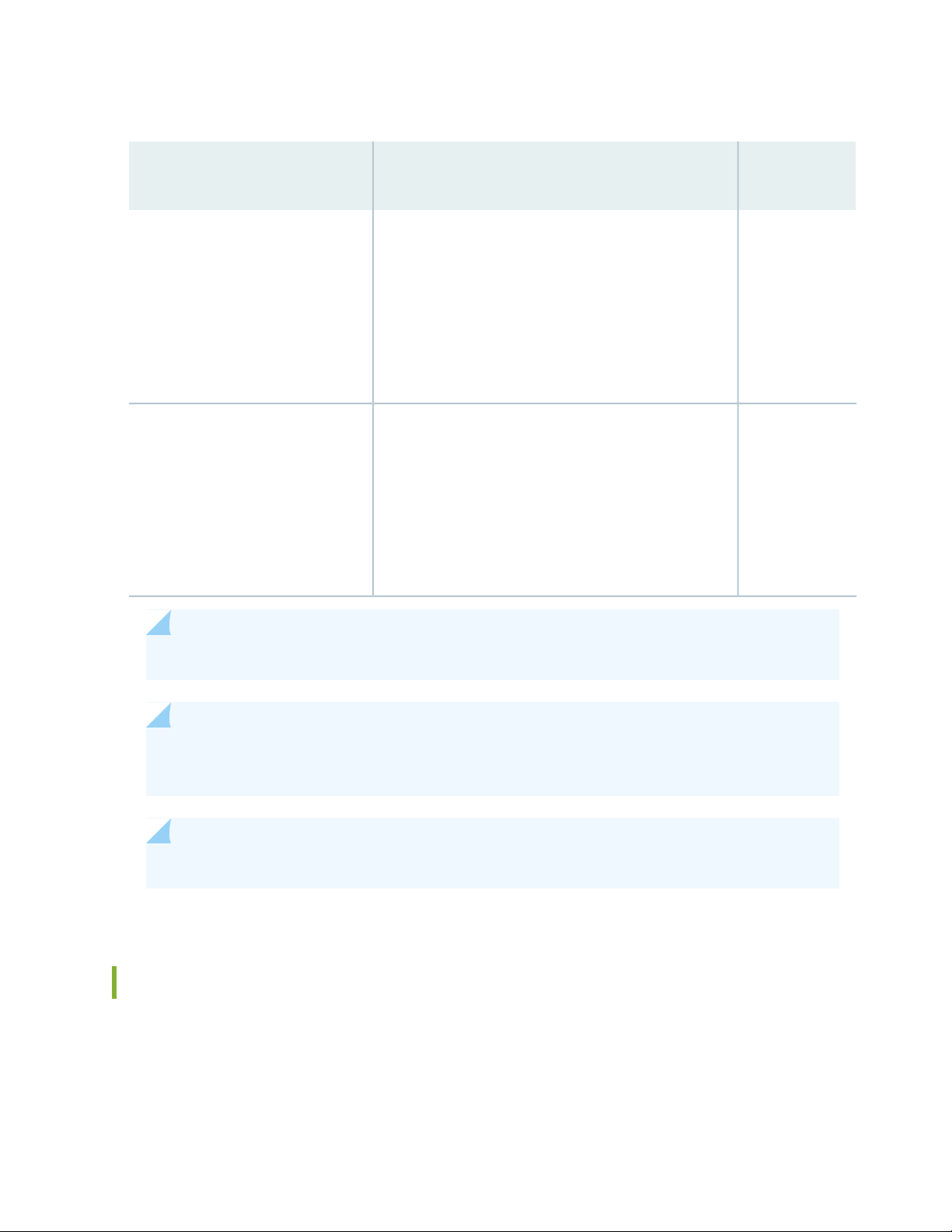

Table 5: EX9208 Switch Hardware Configurations (continued)

29

First Junos OS

ReleaseConfiguration ComponentsSwitch Configuration

EX9208-BASE3A-AC

(base configuration with 2520 W AC

power supplies)

EX9208-REDUND3A-AC

(redundant configuration with

2520 W AC power supplies)

EX9208-REDUND3A-DC

(redundant configuration with

2400 W DC power supplies)

Chassis with craft interface and midplane

•

One EX9200-SF2 module

•

One EX9200-RE module

•

One fan tray

•

One air filter kit

•

Three 2520 W AC power supplies

•

One EX9200-SF module cover panel

•

Six line card cover panels

•

Blank panels for empty power supply slots

•

Chassis with craft interface and midplane

•

Two EX9200-SF2 modules

•

Two EX9200-RE modules

•

One fan tray

•

One air filter kit

•

Four 2520 W AC power supplies

•

Six line card cover panels

•

Chassis with craft interface and midplane

•

Two EX9200-SF2 modules

•

Two EX9200-RE modules

•

One fan tray

•

One air filter kit

•

Four 2400 W DC power supplies

•

Six line card cover panels

•

14.1

14.1

14.1

EX9208-BASE-AC

(base configuration with 2520 W AC

power supplies)

Chassis with craft interface and midplane

•

One EX9200-SF module

•

One EX9200-RE module

•

One fan tray

•

One air filter kit

•

Three 2520 W AC power supplies

•

One EX9200-SF module cover panel

•

Six line card cover panels

•

Blank panels for empty power supply slots

•

12.3R2

Page 30

Table 5: EX9208 Switch Hardware Configurations (continued)

30

First Junos OS

ReleaseConfiguration ComponentsSwitch Configuration

EX9208-REDUND-AC

(redundant configuration with

2520 W AC power supplies)

EX9208-REDUND-DC

(redundant configuration with

2400 W DC power supplies)

Chassis with craft interface and midplane

•

Two EX9200-SF modules

•

Two EX9200-RE modules

•

One fan tray

•

One air filter kit

•

Four 2520 W AC power supplies

•

Six line card cover panels

•

Chassis with craft interface and midplane

•

Two EX9200-SF modules

•

Two EX9200-RE modules

•

One fan tray

•

One air filter kit

•

Four 2400 W DC power supplies

•

Six line card cover panels

•

NOTE: You can install up to six line cards (in any combination) in the switch.

12.3R2

12.3R2

NOTE: Line cards are not part of the base or redundant configuration. You must order them

separately.

NOTE: Power cords and additional power supplies (AC or DC) must be purchased separately.

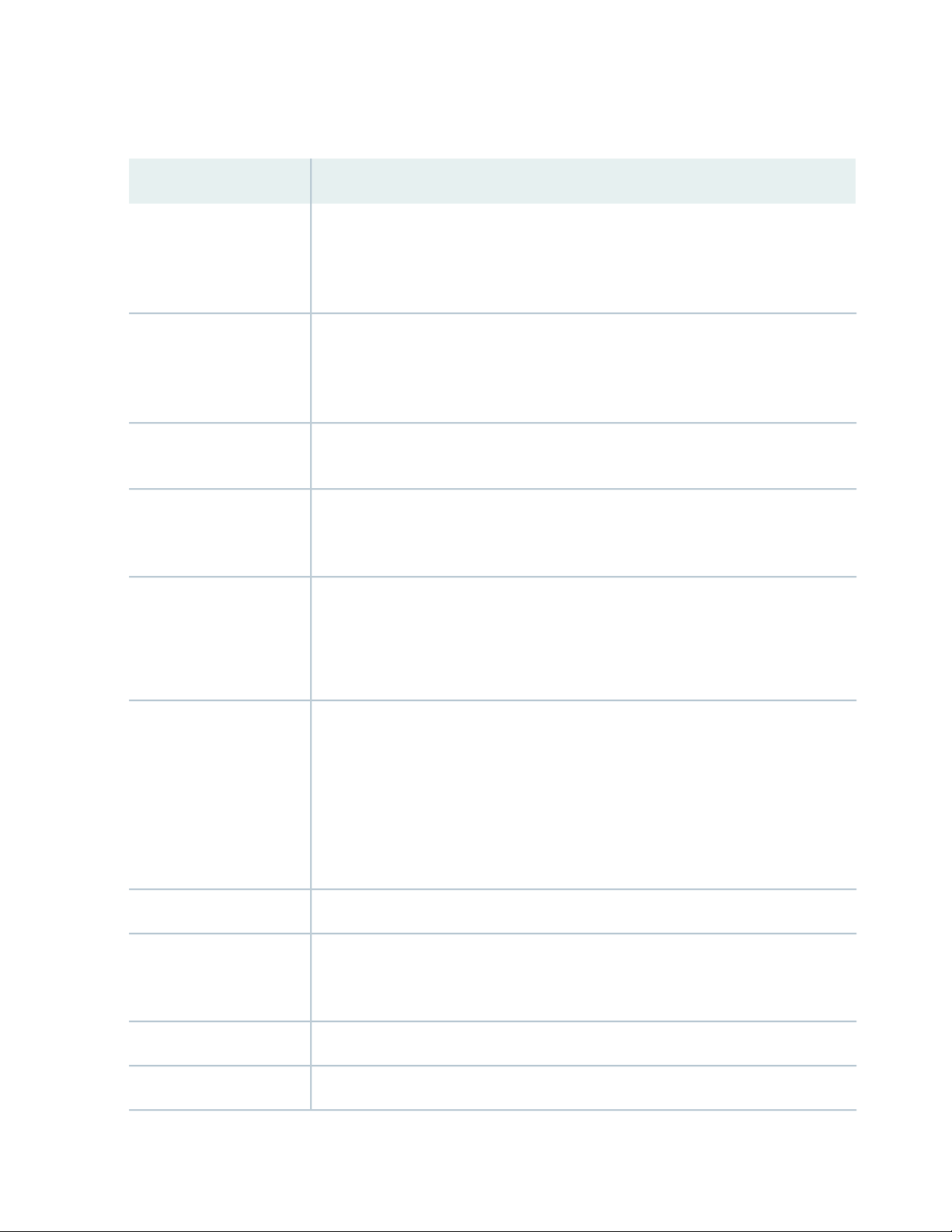

EX9208 Switch Hardware and CLI Terminology Mapping

This topic describes the hardware terms used in EX9208 switch documentation and the corresponding

terms used in the Junos OS CLI. See Table 6 on page 31.

Page 31

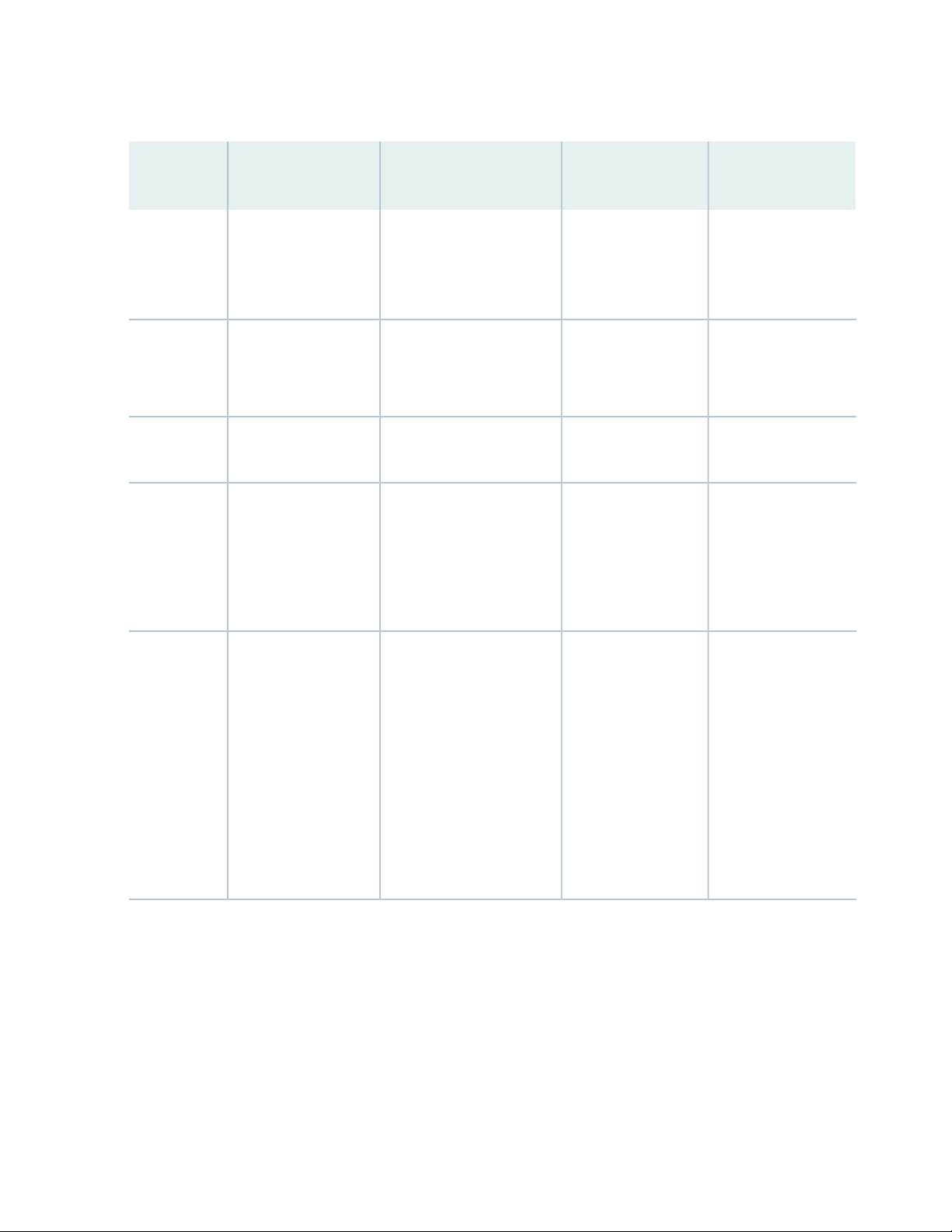

Table 6: CLI Equivalents of Terms Used in Documentation for EX9208 Switches

31

Hardware

Item (CLI)

Midplane

PEM (n)

EX9208-BP

•

EX9208-BP3

•

One of the following:

PS 1.4-2.52 kW;

•

90-264 V AC in

DC 2.4 kW Power

•

Entry Module

n is a value in the range

0-3. The value corresponds

to the power supply slot

number.

Item in

DocumentationValue (CLI)Description (CLI)

Switch chassis–EX9208Chassis

Switch midplane–One of the following:

Craft Interface–Front Panel DisplayFPM Board

AC or DC power

supply

Additional

Information

“Chassis Physical

Specifications of an

EX9208 Switch” on

page 35

Midplane in an

EX9200 Switch

Craft Interface in an

EX9200 Switch

AC Power Supply in

•

an EX9208 Switch

on page 53

DC Power Supply

•

in an EX9208

Switch on page 60

Routing

Engine (n)

One of the following:

RE–S–EX9200

•

–1800X4

RE–S–EX9200

•

–2X00x6

0-1.

In a base configuration,

only one entry appears.

In a redundant

configuration, two entries

appear–one for each

Routing Engine module (RE

module) installed in the

chassis.

RE modulen is a value in the range

“Routing Engine

Module in an EX9200

Switch” on page 67

Page 32

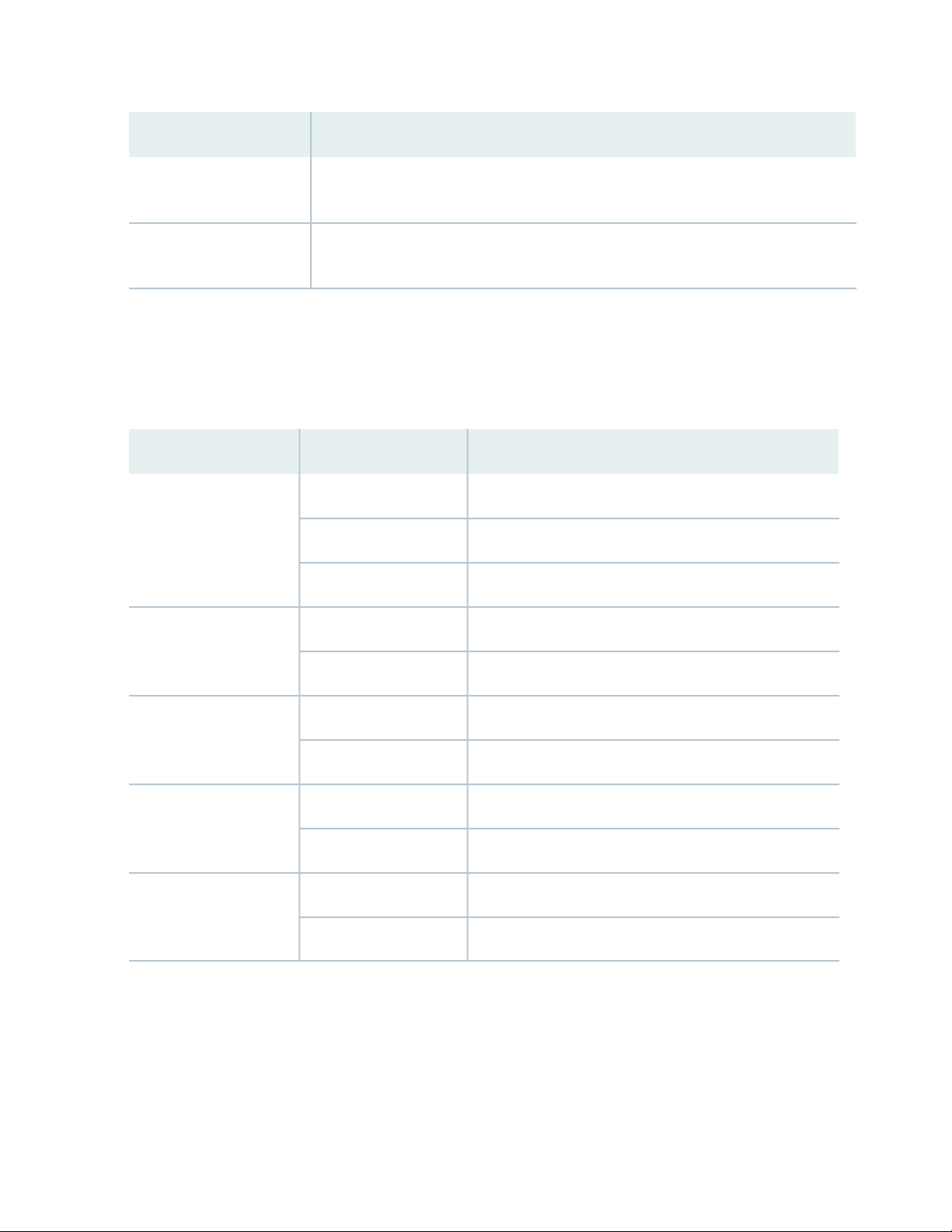

Table 6: CLI Equivalents of Terms Used in Documentation for EX9208 Switches (continued)

32

Hardware

Item (CLI)

CB (n)

FPC (n)

One of the following:

EX9200–SCBE

•

EX9200–SF2

•

EX9200-SF3

•

Abbreviated name of

the line card.

One of the following:

EX9200-2C-8XS

•

EX9200 4x40G

•

QSFP

EX9200

•

24x10GE+6x40GE

EX9200-MPC

•

EX9200-12QS

•

EX9200-15C

•

EX9200 32x10G

•

SFP

EX9200 40x1G

•

Copper

EX9200-40x1G-SFP

•

EX9200-40FE

•

EX9200-40XS

•

0-1.

Multiple line items appear

in the CLI if more than one

Switch Fabric modules (SF

modules) is installed in the

chassis.

CB0 and CB1 stand for SF

modules.

n is a value in the range

0-5. The value corresponds

to the line card slot number

in which the line card is

installed.

Item in

DocumentationValue (CLI)Description (CLI)

SF modulen is a value in the range

Line card (The switch

does not have actual

FPCs—the line cards

are the FPC

equivalents on the

switch.)

Additional

Information

“Switch Fabric

Module in an EX9200

Switch” on page 73

EX9200-2C-8XS

•

Line Card on

page 87

EX9200-4QS Line

•

Card on page 89

EX9200-6QS Line

•

Card on page 90

EX9200-MPC Line

•

Card on page 93

EX9200-12QS Line

•

Card on page 96

EX9200-15C Line

•

Card on page 99

EX9200-32XS Line

•

Card on page 103

EX9200-40T Line

•

Card on page 104

EX9200-40F Line

•

Card on page 106

EX9200-40F-M

•

Line Card on

page 107

EX9200-40XS Line

•

Card on page 109

Page 33

Table 6: CLI Equivalents of Terms Used in Documentation for EX9208 Switches (continued)

33

Hardware

Item (CLI)

MIC (n)

Abbreviated name of

the Modular Interface

Card (MIC).

One of the following

if EX9200-MPC line

card is installed:

10X10GE SFPP

•

20X1GE SFP

•

MACSEC

40x1GE RJ45

•

n is a value in the range

0-1.

Item in

DocumentationValue (CLI)Description (CLI)

Line card

NOTE:

The switch does not

have actual MICs

except in the

EX9200-MPC line

card—the line cards

are the MIC

equivalents on the

switch. EX9200-MPC

is a modular line card

that accepts any of

the following MICs:

EX9200-10XS-MIC

•

EX9200-20F-MIC

•

EX9200-40T-MIC

•

Additional

Information

EX9200-2C-8XS

•

Line Card on

page 87

EX9200-4QS Line

•

Card on page 89

EX9200-6QS Line

•

Card on page 90

EX9200-MPC Line

•

Card on page 93

EX9200-12QS Line

•

Card on page 96

EX9200-15C Line

•

Card on page 99

EX9200-32XS Line

•

Card on page 103

EX9200-40T Line

•

Card on page 104

EX9200-40F Line

•

Card on page 106

EX9200-40F-M

•

Line Card on

page 107

EX9200-40XS Line

•

Card on page 109

Page 34

Table 6: CLI Equivalents of Terms Used in Documentation for EX9208 Switches (continued)

34

Hardware

Item (CLI)

PIC (n)

Abbreviated name of

the Physical Interface

Card (PIC).

n is a value in the range

0-3.

Item in

DocumentationValue (CLI)Description (CLI)

Line card (The switch

does not have actual

PICs.)

Additional

Information

EX9200-2C-8XS

•

Line Card on

page 87

EX9200-4QS Line

•

Card on page 89

EX9200-6QS Line

•

Card on page 90

EX9200-MPC Line

•

Card on page 93

EX9200-12QS Line

•

Card on page 96

EX9200-15C Line

•

Card on page 99

EX9200-32XS Line

•

Card on page 103

EX9200-40T Line

•

Card on page 104

EX9200-40F Line

•

Card on page 106

EX9200-40F-M

•

Line Card on

page 107

EX9200-40XS Line

•

Card on page 109

Xcvr (n)

Fan tray

Abbreviated name of

the transceiver.

Tray

the number of the port in

which the transceiver is

installed.

Optical transceiversn is a value equivalent to

Fan tray–Enhanced Left Fan

“Pluggable

Transceivers

Supported on EX9200

Switches” on page 135

“EX9208 Cooling

System” on page 51

Page 35

Chassis Physical Specifications of an EX9208 Switch

The EX9208 switch chassis is a rigid sheet-metal structure that houses the other switch components.

Table 7 on page 35 summarizes the physical specifications of the EX9208 switch chassis. See

Figure 4 on page 37, Figure 5 on page 37, and Figure 6 on page 38.

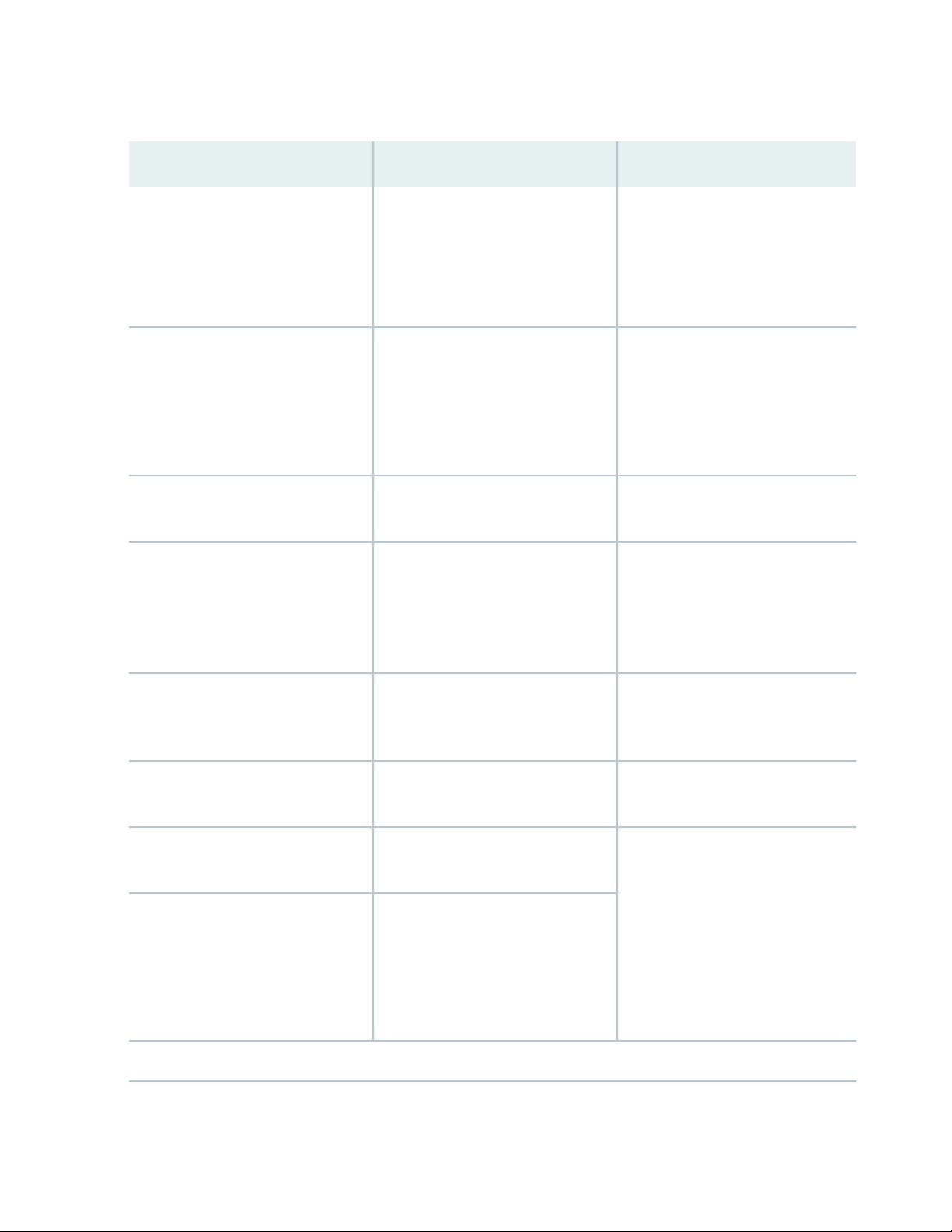

Table 7: Physical Specifications of the EX9208 Switch Chassis

DepthWidthHeightWeightDescription

35

Chassis

module (RE

module)

Switch Fabric

module (SF

module)

midplane, craft

interface (front-panel

display), fan tray,

aChassis Physical

Specifications of an

EX9208 Switchir

filter, and cable

management

brackets: 65.5 lb

(29.7 kg)

Maximum

configuration:

163.6 lb (74.2 kg)

Routing Engine

installed)

17.5 in. (44.5 cm)14.0 in. (35.6 cm)Chassis with

24.5 in. (62.2 cm)

(from front to chassis

rear) Total depth

(including cable

management brackets)

27.75 in. (70.5 cm)

7.75 in. (19.7 cm)11 in. (27.9 cm)1.25 in. (3.2 cm)2.4 lb (1.9 kg)Routing Engine

22 in. (55.9 cm)17 in. (43.2 cm)1.25 in. (3.2 cm)9.6 lb (4.4 kg) (with

Switch Fabric

module

Management

Brackets

21.2 in. (53.85 cm)15.7 in. (39.87 cm)1.2 in. (3.05 cm)13.6 lb (6.2 kg)EX9200-SF3

23.3 in. (59.2 cm)1.76 in. (4.5 cm)11.58 in. (29.4 cm)6.8 lb (3.84 kg)Fan Tray

22.23 in. (56.5 cm)0.31 in. (0.8 cm)10.1 in. (25.7 cm)1.0 lb (0.5 kg)Air filter

4.5 in. (11.4 cm)0.25 in. (0.6 cm)9.9 in. (25.1 cm)0.3 lb (0.8 kg)Cable

Page 36

Table 7: Physical Specifications of the EX9208 Switch Chassis (continued)

line card

card

card

card

36

DepthWidthHeightWeightDescription

4 in. (10.2 cm)14.5 in. (36.8 cm)1.75 in. (4.4 cm)6.6 lb (2.99 kg)AC power supply

4 in. (10.2 cm)14.5 in. (36.8 cm)1.75 in. (4.4 cm)6.2 lb (2.81 kg)DC power supply

22 in. (55.9 cm)17 in. (43.2 cm)1.25 in. (3.2 cm)19.4 lb (8.8 kg)EX9200-2C-8XS

22 in. (55.9 cm)17 in. (43.2 cm)1.25 in. (3.2 cm)16.8 lb (7.6 kg)EX9200-4QS line

22 in. (55.9 cm)17 in. (43.2 cm)1.25 in. (3.2 cm)21 lb (9.25 kg)EX9200-6QS line

22 in. (55.9 cm)17 in. (43.2 cm)1.25 in. (3.2 cm)15.96 lb (7.3 kg)EX9200-MPC line

card

card

card

card

card

7.86 in. (20 cm)6.67 in. (16.9 cm)1.25 in. (3.2 cm)1.54 lb (0.7 kg)EX9200-10XS-MIC

7.86 in. (20 cm)6.67 in. (16.9 cm)1.25 in. (3.2 cm)1.2 lb (0.54 kg)EX9200-20F-MIC

22 in. (55.9 cm)13.36 in. (33.9 cm)1.25 in. (3.2 cm)1.9 lb (0.9 kg)EX9200-40T-MIC

22 in. (55.9 cm)17 in. (43.2 cm)1.25 in. (3.2 cm15.7 lb (7.12 kg)EX9200-12QS line

21.2 in. (53.85 cm)15.7 in. (39.87 cm)1.2 in. (3.05 cm)20.4 lb (9.25 kg)EX9200-15C line

22 in. (55.9 cm)17 in. (43.2 cm)1.25 in. (3.2 cm)19.2 lb (8.7 kg)EX9200-32XS line

22 in. (55.9 cm)17 in. (43.2 cm)1.25 in. (3.2 cm)14.0 lb (6.6 kg)EX9200-40T line

22 in. (55.9 cm)17 in. (43.2 cm)1.25 in. (3.2 cm)14.8 lb (6.7 kg)EX9200-40F line

line card

22 in. (55.9 cm)17 in. (43.2 cm)1.25 in. (3.2 cm)14.8 lb (6.7 kg)EX9200-40F-M

Page 37

Table 7: Physical Specifications of the EX9208 Switch Chassis (continued)

ESD

g022000

Front-mounting flange

SF1

RE1 RE0

Line

cards

SF0

ESD point

Craft interface panel

Air intake

card

Figure 4: EX9208 Switch

37

DepthWidthHeightWeightDescription

22 in. (55.9 cm)17 in. (43.2 cm)1.25 in. (3.2 cm)17 lb (7.7 kg)EX9200-40XS line

Figure 5: EX9208 Switch with AC Power Supplies

Page 38

Figure 6: EX9208 Switch with DC Power Supplies

38

You can mount an EX9208 switch on a standard 19-in. four-post rack or a standard 800-mm enclosed

cabinet. You can mount up to six EX9208 switches in a standard (48 rack unit (U)) rack.

SEE ALSO

Installing and Removing EX9208 Switch Hardware Components

Field-Replaceable Units in an EX9200 Switch

Field-replaceable units (FRUs) are switch components that you can replace at your site. The EX9200 switch

uses the following types of FRUs:

Hot-insertable and hot-removable—You can remove and replace these components without powering

•

off the switch or disrupting the switching function.

Hot-pluggable—You can remove and replace these components without powering off the switch, but

•

the switching function is interrupted until you replace the component.

Table 8 on page 39 lists the FRUs for the EX9200 switch and their types.

Page 39

Table 8: FRUs in an EX9200 Switch

39

TypeFRU

Hot-insertable and hot-removable.Power supplies

Hot-insertable and hot-removable.Fan tray and air filter

Routing Engine module (RE module)

Switch Fabric module (SF module)

Redundant configuration:

Primary RE module is hot-pluggable.

•

Backup RE module is hot-insertable and hot-removable.

•

Base configuration:

You must disable the switch before removing any RE module.

•

See “Taking the Host Subsystem Offline in an EX9200 Switch”

on page 212.

See EX9204 Switch Configurations, “EX9208 Switch

Configurations” on page 27, and EX9214 Switch Configurations.

Redundant configuration:

Primary SF module is hot-pluggable.

•

Backup SF module is hot-insertable and hot-removable.

•

Base configuration:

You must disable the switch before removing any SF module.

•

See “Taking the Host Subsystem Offline in an EX9200 Switch”

on page 212.

Line cards

See “Pluggable Transceivers Supported on

EX9200 Switches” on page 135 for the Junos OS

release in which the transceivers were

introduced.

See EX9204 Switch Configurations, “EX9208 Switch

Configurations” on page 27, and EX9214 Switch Configurations.

Hot-insertable and hot-removable. We recommend that you take

the line cards offline before removing them. See “Removing a

Line Card from an EX9200 Switch” on page 241.

Hot-insertable and hot-removable.SFP, SFP+, QSFP+, and CFP transceivers

Page 40

NOTE: Line cards are not part of the base or redundant configuration. You must order them

separately.

NOTE: If you have a Juniper J-Care service contract, register any addition, change, or upgrade

of hardware components at

https://www.juniper.net/customers/support/tools/updateinstallbase/ . Failure to do so can

result in significant delays if you need replacement parts. This note does not apply if you replace

existing components with the same type of component.

EX9208 Chassis

40

IN THIS SECTION

Understanding EX9208 Switch Component and Functionality Redundancy | 40

Craft Interface in an EX9200 Switch | 42

Midplane in an EX9200 Switch | 48

Cable Management Brackets in an EX9208 Switch | 50

Understanding EX9208 Switch Component and Functionality Redundancy

The Juniper Networks EX9208 Ethernet Switches are available as fully redundant system. A redundant

EX9208 switch configuration is designed so that no single point of failure can cause the entire switch to

fail. See “EX9208 Switch Configurations” on page 27.

The following hardware components provide redundancy to an EX9208 switch:

Host Subsystem—The host subsystem consists of a Routing Engine functioning together with a Switch

•

Fabric. The host subsystem performs switching and routing functionality, system management, and

system control functions of the switch. The switch can have one or two host subsystems. If two host

subsystems are installed, one functions as the primary and the other functions as the backup. If the

primary host subsystem (or either of its components) fails, the backup can take over as the primary. To

Page 41

operate, each host subsystem requires a Routing Engine module (RE module) installed directly into in a

Switch Fabric module (SF module).

If the Routing Engines are configured for graceful switchover, the backup Routing Engine automatically

synchronizes its configuration and state with the primary Routing Engine. Any update to the primary

Routing Engine state is replicated on the backup Routing Engine. If the backup Routing Engine assumes

primary role, packet forwarding continues through the switch without interruption. See “Host Subsystem

in an EX9200 Switch” on page 66.

Power supplies—In the low-line (100 V) AC power configuration, the switch contains three or four AC

•

power supplies, located horizontally at the rear of the chassis in slots PEM0 through PEM3 (left to right).

Each AC power supply provides power to all components in the switch. When three power supplies are

present, they share power almost equally within a fully populated system. Four AC power supplies

provide full power redundancy. If one power supply fails or is removed, the remaining power supplies

instantly assume the entire electrical load without interruption. Three power supplies provide the

maximum configuration with full power for as long as the switch is operational.

In the high-line (200 V) AC power configuration, the switch contains two or four AC power supplies

located horizontally at the rear of the chassis in slots PEM0 through PEM3 (left to right). Each AC power

supply provides power to all components in the switch. When two or more power supplies are present,

they share power almost equally within a fully populated system. Four AC power supplies provide full

power redundancy. If one power supply fails or is removed, the remaining power supplies instantly

assume the entire electrical load without interruption. Two power supplies provide the maximum

configuration with full power for as long as the switch is operational.

41

In the DC configuration, two power supplies are required to supply power to a fully configured switch.

One power supply supports approximately half of the components in the switch, and the other power

supply supports the remaining components. The addition of two power supplies provides full power

redundancy. If one power supply fails or is removed, the remaining power supplies instantly assume the

entire electrical load without interruption. Two power supplies provide the maximum configuration with

full power for as long as the switch is operational.

See “AC Power Supply in an EX9208 Switch” on page 53 and “DC Power Supply in an EX9208 Switch”

on page 60.

Cooling system—The cooling system in EX9208 switches consists of fan tray and air filter. The fan tray

•

contains six fans. Under normal operating conditions, the fans in the fan tray run at less than full speed.

If one of the fans fails, the host subsystem increases the speed of the remaining fans to provide sufficient

cooling for the switch indefinitely. See “EX9208 Cooling System” on page 51.

Page 42

Craft Interface in an EX9200 Switch

g022028

3

1

5

4

8

7

6

2

IN THIS SECTION

Host Subsystem LEDs | 44

Fan LEDs | 44

Power Supply (PEM) LEDs | 45

Switch Fabric LEDs and Control Buttons | 45

Line Card LEDs and Control Buttons | 46

Alarm LEDs and Alarm Cutoff Button | 46

Alarm Relay Contacts | 47

42

The craft interface enables you to view status and troubleshooting information at a glance and to perform

many system control functions. The craft interface is located on the front panel of the switch. It contains

LEDs and on and off buttons for switch components, the alarm relay contacts, and an alarm cutoff button.

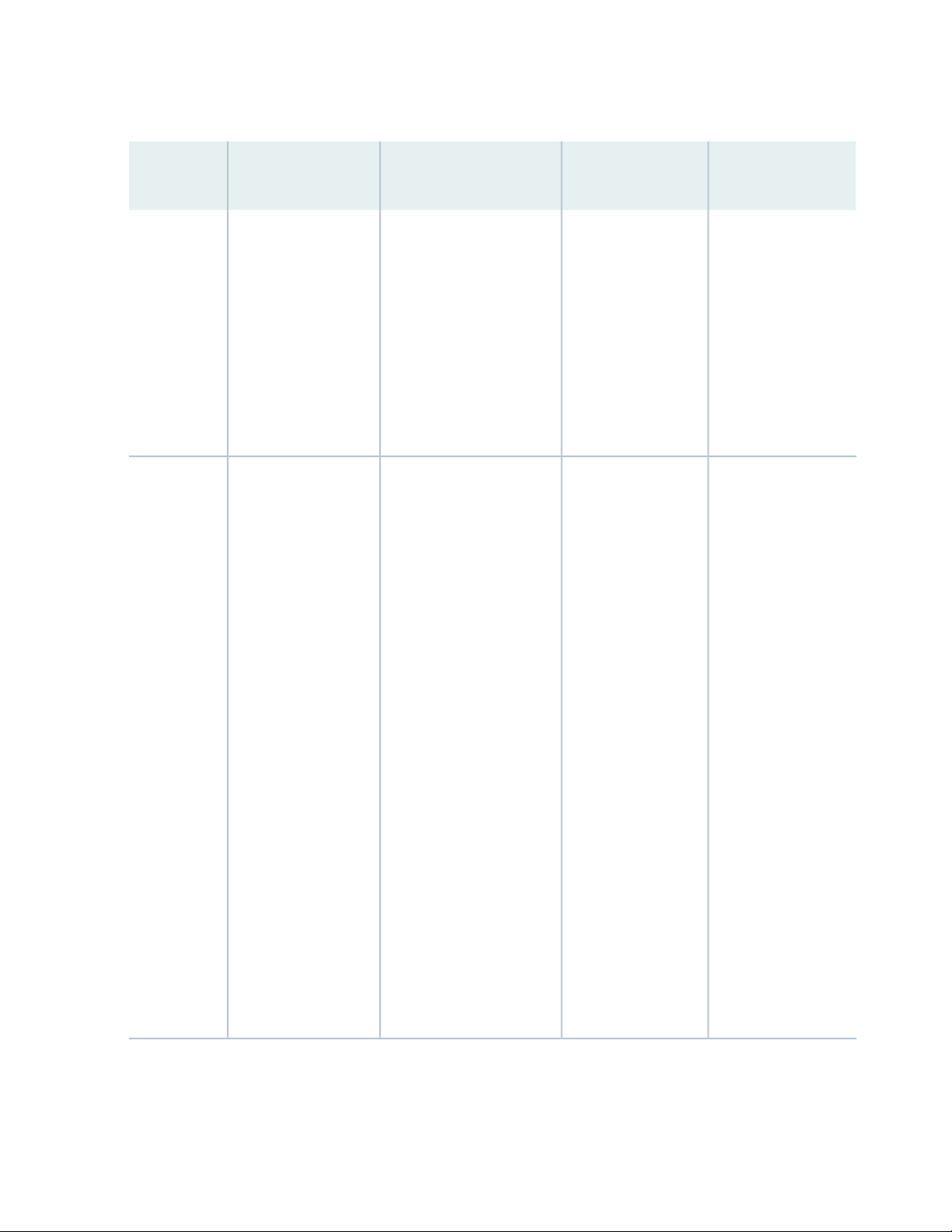

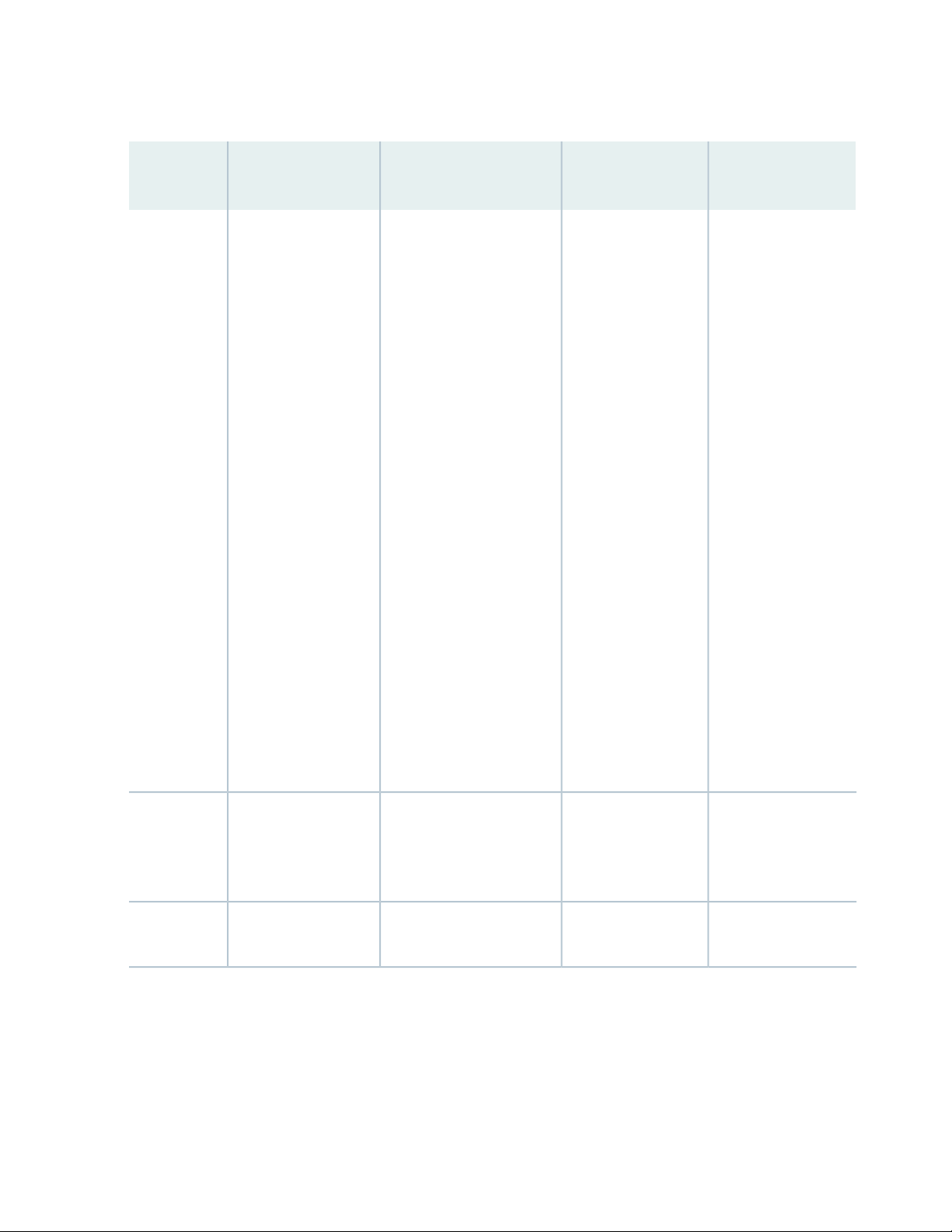

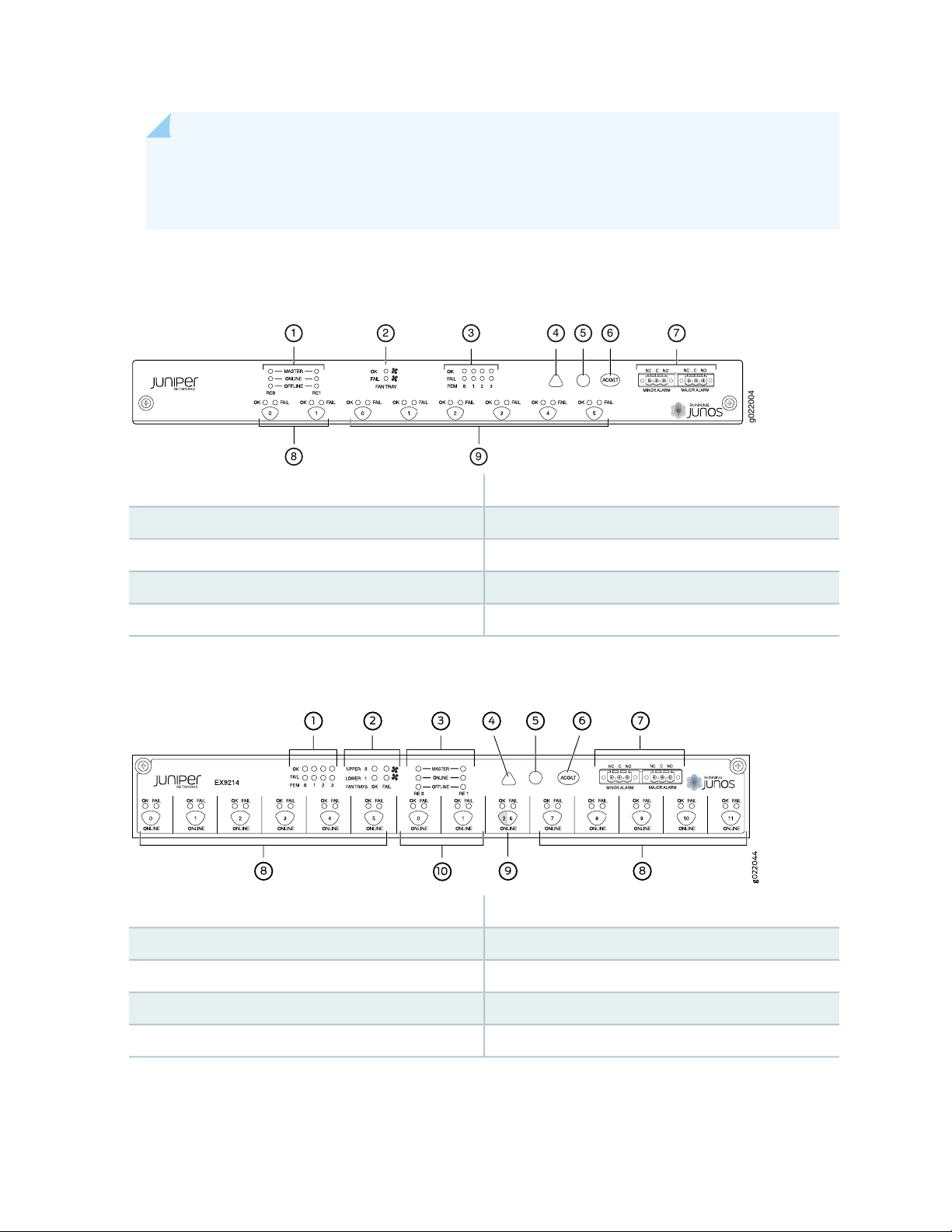

Figure 7 on page 42 shows the craft interface in an EX9204 switch. Figure 8 on page 43 shows the craft

interface in an EX9208 switch. Figure 9 on page 43 shows the craft interface in an EX9214 switch.

Figure 7: Craft Interface in an EX9204 Switch

5—1— Major alarm LEDHost subsystem LEDs

6—2— Alarm cutoff/lamp test buttonFan LEDs

7—3— Alarm relay contactsPower supply LEDs

Minor alarm LED

8—4— LEDs and control buttons for Switch Fabric and Line

cards

Page 43

NOTE: You can install a line card or an SF module in the multifunctional slot labeled 1|0 in

g022004

1 2 3 4 5 6 7

8 9

EX9204 switches. The corresponding LED displays information depending on the hardware

installed in that slot.

Figure 8: Craft Interface in an EX9208 Switch

6—1— Alarm cutoff/lamp test buttonHost subsystem LEDs

43

5—Major alarm LED

Figure 9: Craft Interface in an EX9214 Switch

7—2— Alarm relay contactsFan LEDs

8—3— Switch Fabric LEDs and control buttonsPower supply LEDs

9—4— Line card LEDs and control buttonsMinor alarm LED

6—1— Alarm cutoff/lamp test buttonPower supply LEDs

7—2— Alarm relay contactsFan LEDs

8—3— Line card LEDs and control buttonsHost subsystem LEDs

9—4— Switch Fabric/line card LED and control buttonMinor alarm LED

10—5— Switch Fabric LEDs and control buttonsMajor alarm LED

Page 44

NOTE: You can install a line card or a Switch Fabric module (SF module) in slot nine—labeled 2

| 6. The corresponding LED displays information depending on the hardware installed in that

slot.

NOTE: At least one Switch Fabric module (SF module) with a Routing Engine module (RE module)

must be installed in the switch for the craft interface to obtain power.

The craft interface has the following components:

Host Subsystem LEDs

Each host subsystem (RE module with SF module) has three LEDs, located on the upper left of the craft

interface, to indicate its status. The LEDs grouped with labels RE0 and RE1 show the status of the host

subsystems installed in the switch. Table 9 on page 44 describes the functions of these LEDs.

44

Table 9: Host Subsystem LEDs on the Craft Interface

DescriptionStatusLabel

Host subsystem is functioning as the primary.GreenMASTER

Unlit

Host subsystem is either functioning as the backup or

not installed.

Host subsystem is online and is functioning normally.GreenONLINE

Host subsystem is either offline or not installed.Unlit

Host subsystem is installed but Routing Engine is offline.RedOFFLINE

Host subsystem is not installed.Unlit

Fan LEDs

The fan LEDs are located on the top left of the craft interface. Table 10 on page 45 describes the functions

of the fan LEDs.

Page 45

Table 10: Fan LEDs on the Craft Interface

DescriptionStatusLabel

Fan is functioning normally.GreenOK

Fan is not installed.Unlit

Fan has failed.RedFAIL

Fan is not installed or functioning normally.Unlit

Power Supply (PEM) LEDs

Each power supply has two LEDs on the craft interface that indicate its status. The LEDs—labeled 0 through

3—are located on the craft interface next to the PEM label. Table 11 on page 45 describes the functions

of the power supply LEDs on the craft interface.

45

Table 11: Power Supply LEDs on the Craft Interface

DescriptionStatusLabel

Power supply is functioning normally.GreenOK

Power supply in not installed.Off

Power supply has failed.RedFAIL

Power supply is not installed or functioning normally.Off

Switch Fabric LEDs and Control Buttons

Each Switch Fabric module has two LEDs on the craft interface that indicates its status. The LEDs—OK

and FAIL—are associated with control buttons and are located along the bottom of the craft interface.

You can turn the SF modules on or off by pressing these buttons on the craft interface.

Table 12 on page 46 describes the status of the SF module LEDs.

Page 46

Table 12: Switch Fabric Module LEDs on the Craft Interface

46

DescriptionStatusLabel

GreenOK

Unlit

On steadily—The SF module is functioning

normally.

Blinking—The SF module is coming online or

going offline.

The SF module is not online.Unlit

The SF module has failed.RedFAIL

The SF module is not installed or is not functioning

normally.

Line Card LEDs and Control Buttons

Each line card has two LEDs—OK and FAIL—on the craft interface that indicates its status. The line card

LEDs are associated with control buttons and are located along the bottom of the craft interface. You can

turn a line card online or offline by using its control button on the craft interface. Table 13 on page 46

describes the function of the line card LEDs.

Table 13: Line Card LEDs on the Craft Interface

DescriptionStatusLabel

On steadily—Line card is functioning normally.GreenOK

Blinking—Line card is coming online or going offline.

Line card is not online.Unlit

Line card has failed.RedFAIL

Line card is not installed or functioning normally.Unlit

Alarm LEDs and Alarm Cutoff Button

Two large alarm LEDs are located at the upper right of the craft interface. The circular LED called major

alarm LED glows to indicate a critical condition that can result in a system shutdown. The triangular LED

called minor alarm LED glows to indicate a less severe condition (warning) that requires monitoring or

maintenance. Both LEDs can be lit simultaneously.

Page 47

A condition that causes an LED to be lit also activates the corresponding alarm relay contact on the craft

g022029

Craft Interface panel

Alarm

relay

contacts

interface.

The alarm cutoff/lamp test (ACO/LT) button, located next to the alarm LEDs, is a control button for alarms.

You can press the ACO/LT button to deactivate major and minor alarms. Deactivating an alarm turns off

both LEDs and deactivates the device attached to the corresponding alarm relay contact on the craft

interface.

Table 14 on page 47 describes the alarm LEDs and the alarm cutoff/lamp test button.

Table 14: Alarm LEDs and Alarm Cutoff/Lamp Test Button

DescriptionStatusAlarm LEDs and Button

47

Red

Major alarm LED

Yellow

Minor alarm LED

–

Alarm cutoff/lamp test button

Indicates a critical condition that can cause the switch to stop

functioning. Possible causes include component removal, failure,

or overheating.

Indicates a serious but nonfatal error condition, such as warning

for a maintenance or a significant increase in component

temperature.

Deactivates major and minor alarms. Causes all LEDs on the

craft interface to light (for testing) when pressed and held.

Alarm Relay Contacts

The craft interface has two alarm relay contacts for connecting the switch to external alarm devices.

Whenever a system condition triggers either the critical (major alarm) or warning (minor alarm) alarm on

the craft interface, the alarm relay contacts are also activated. The alarm relay contacts are located on the

upper right of the craft interface.

Figure 10 on page 47 shows the alarm relay contacts in EX9200 switches.

Figure 10: Alarm Relay Contacts in EX9200 Switches

Page 48

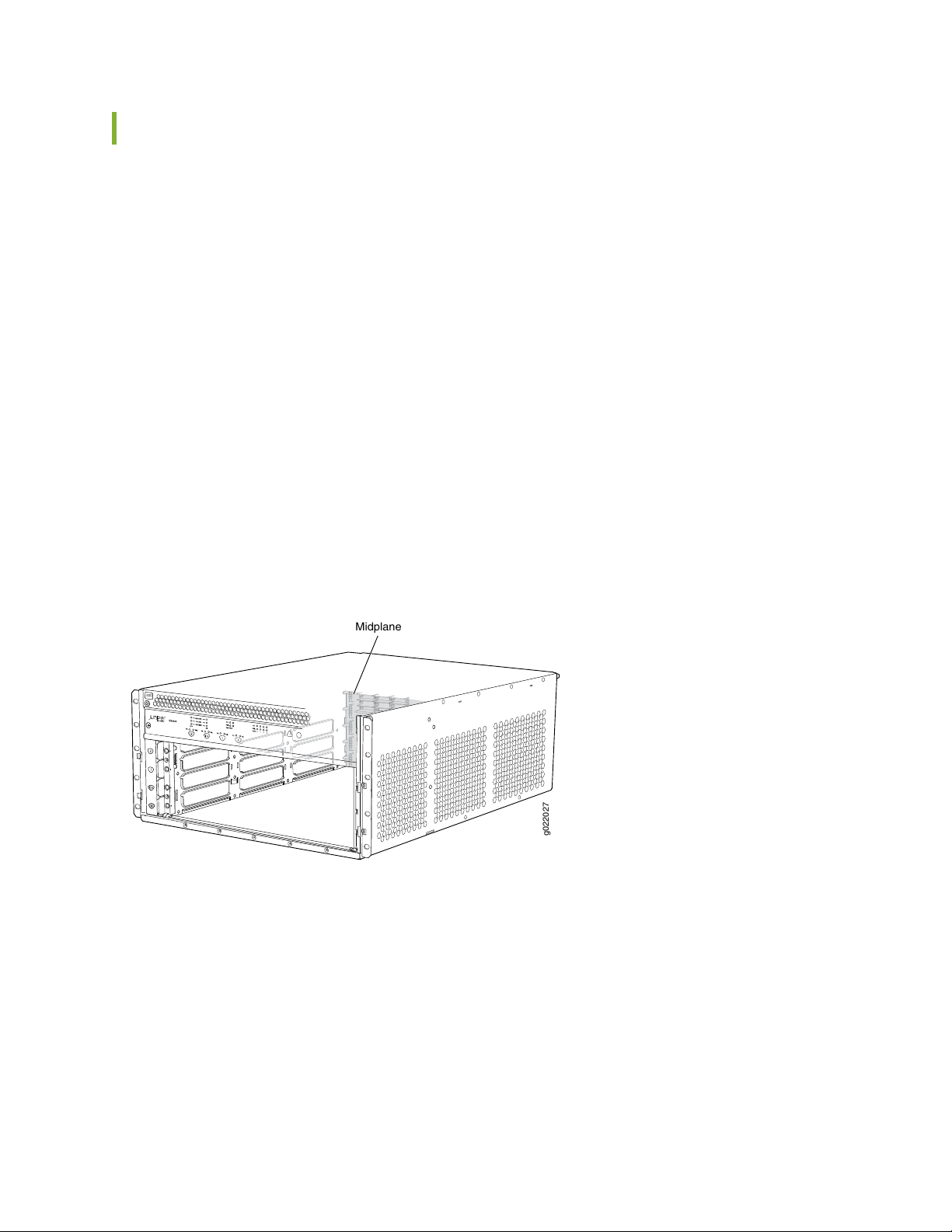

Midplane in an EX9200 Switch

ESD

g022027

Midplane

The midplane is located on the rear of the chassis and forms the rear of the card cage. The Switch Fabric

modules (SF modules) and line cards are installed into the midplane from the front of the chassis, and the

power supplies install into the midplane from the rear of the chassis. The cooling system components also

connect to the midplane.

The midplane performs the following major functions:

Provides a data path—Data packets are transferred across the midplane between the line cards through

•

the Switch Fabric on the host subsystem.

Distributes power—The power supplies connect to the midplane, which distributes power to all the

•

switch components.

Provides a signal path—The midplane provides the signal path to the line cards, Switch Fabric, and other

•

system components for monitoring and control of the system.

Figure 11 on page 48 shows the midplane in an EX9204 switch. Figure 12 on page 49 shows the midplane

in an EX9208 switch. Figure 13 on page 49 shows the midplane in an EX9214 switch.

48

Figure 11: Midplane in an EX9204 Switch

Page 49

Figure 12: Midplane in an EX9208 Switch

g022001

Midplane

g022043

Midplane

49

Figure 13: Midplane in an EX9214 Switch

Page 50

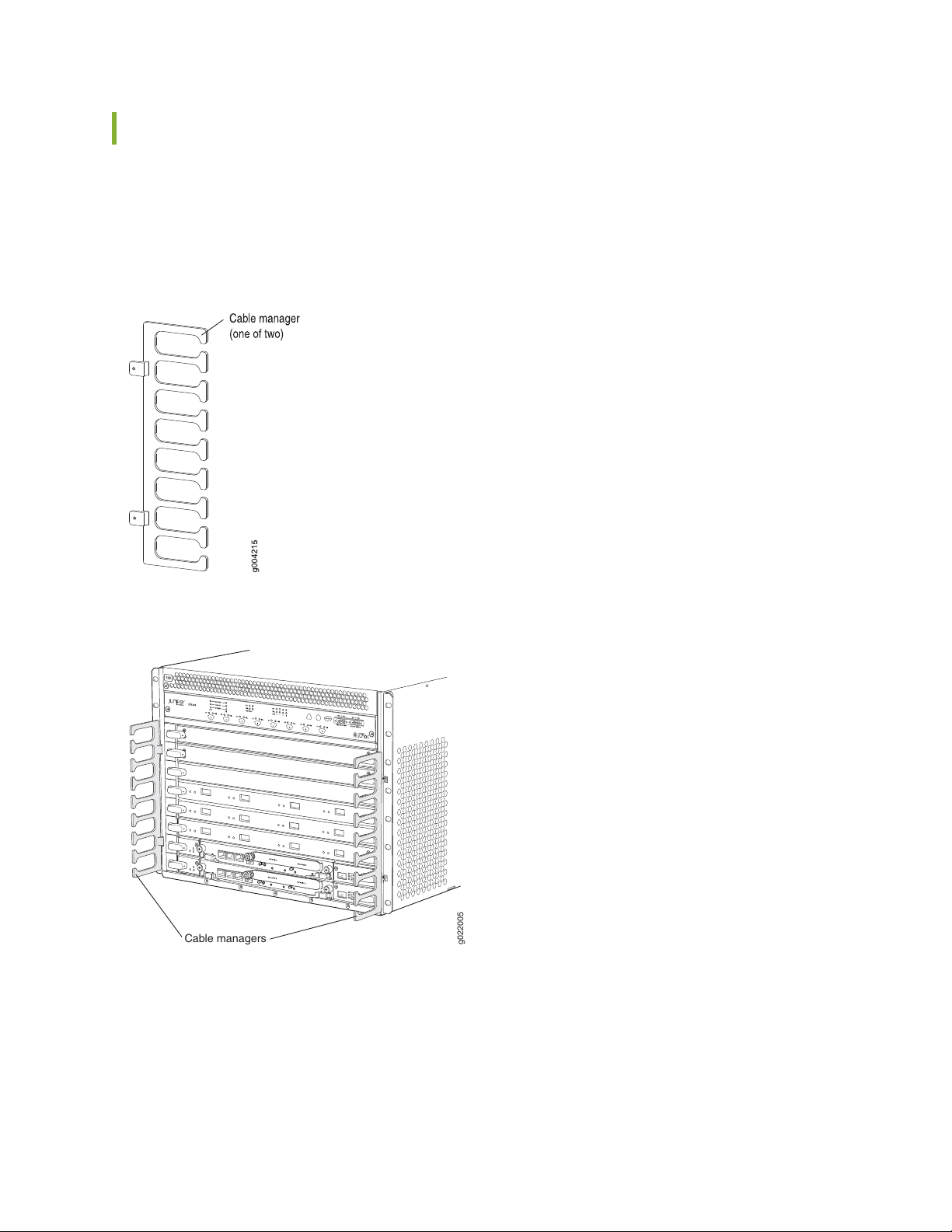

Cable Management Brackets in an EX9208 Switch

g022005

Cable managers

The cable management brackets (see Figure 14 on page 50) consist of plastic dividers located on the left

and right sides of each line card slot and Switch Fabric module (SF module) slot. The cable management

brackets allow you to route the cables outside the switch and away from the line cards and SF modules.

Figure 14: Cable Management Brackets

50

Figure 15: Cable Management Brackets Installed on the Switch

Page 51

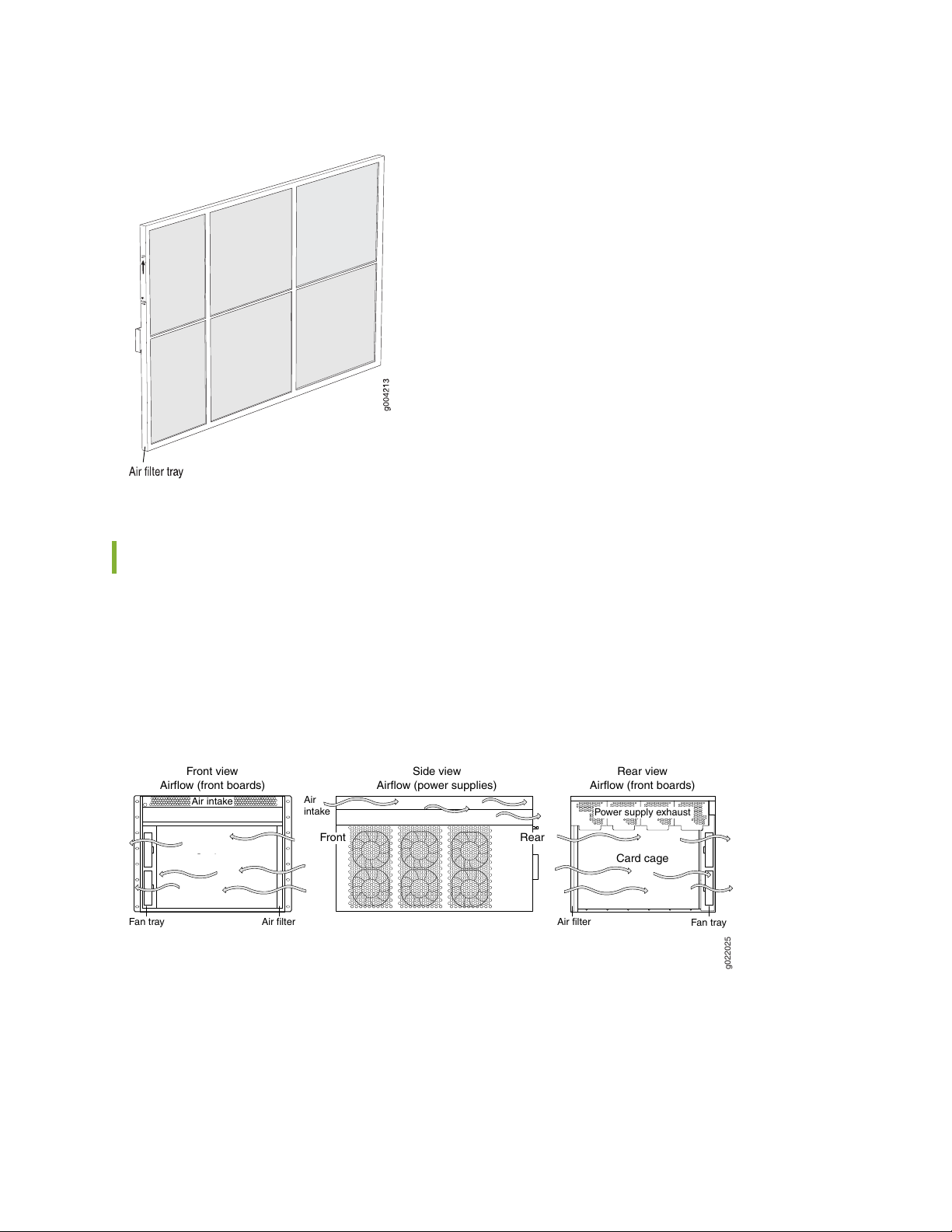

EX9208 Cooling System

IN THIS SECTION

Fan Tray | 51

Airflow Direction in the EX9208 Switch Chassis | 52

The cooling system in an EX9208 switch consists of a fan tray and an air filter. The cooling system

components work together to keep all switch components within the acceptable temperature range.

51

Fan Tray

Fan tray is a hot-insertable and hot-removable field-replaceable unit (FRU) and contains six fans. The fan

tray and air filter install vertically in the rear of the switch. See Figure 16 on page 51 and

Figure 17 on page 52.

Figure 16: Fan Tray for an EX9208 Switch

Page 52

Figure 17: Air Filter for an EX9208 Switch

Fan tray

Card cage

g022025

Front view

Airflow (front boards)

Side view

Airflow (power supplies)

Front

Air filter Air filter

Air

intake

Air intake

Power supply exhaust

Fan tray

Rear

Card cage

Rear view

Airflow (front boards)

52

Airflow Direction in the EX9208 Switch Chassis

The air intake to cool the chassis is located on the side of the chassis next to the air filter. Air is pulled

through the chassis toward the fan tray, where it is exhausted out through the side of the chassis. The air

intake to cool the power supplies is located in the front of the chassis above the craft interface. See

Figure 18 on page 52.

Figure 18: Airflow Through the EX9208 Switch Chassis

The host subsystem monitors the temperature of switch components. Under normal operating conditions,

the fans in the fan tray run at less than full speed. If a fan fails or the ambient temperature rises above a

threshold, the speed of the remaining fans is automatically adjusted to keep the temperature within the

acceptable range. If the ambient maximum temperature specification is exceeded and the system cannot

Page 53

be adequately cooled, the Routing Engine shuts down the system by disabling output power from each

power supply.

You cannot replace a single fan. If one or more fans fail, you must replace the entire fan tray.

RELATED DOCUMENTATION

Clearance Requirements for Airflow and Hardware Maintenance for an EX9208 Switch | 127

EX9208 Power System

IN THIS SECTION

53

AC Power Supply in an EX9208 Switch | 53

AC Power Supply Specifications for EX9208 Switches | 56

AC Power Cord Specifications for an EX9208 Switch | 57

AC Power Supply LEDs in an EX9208 Switch | 59

DC Power Supply in an EX9208 Switch | 60

DC Power Supply Specifications for EX9208 Switches | 62

DC Power Supply LEDs in an EX9208 Switch | 63

Power Requirements for EX9200 Switch Components | 64

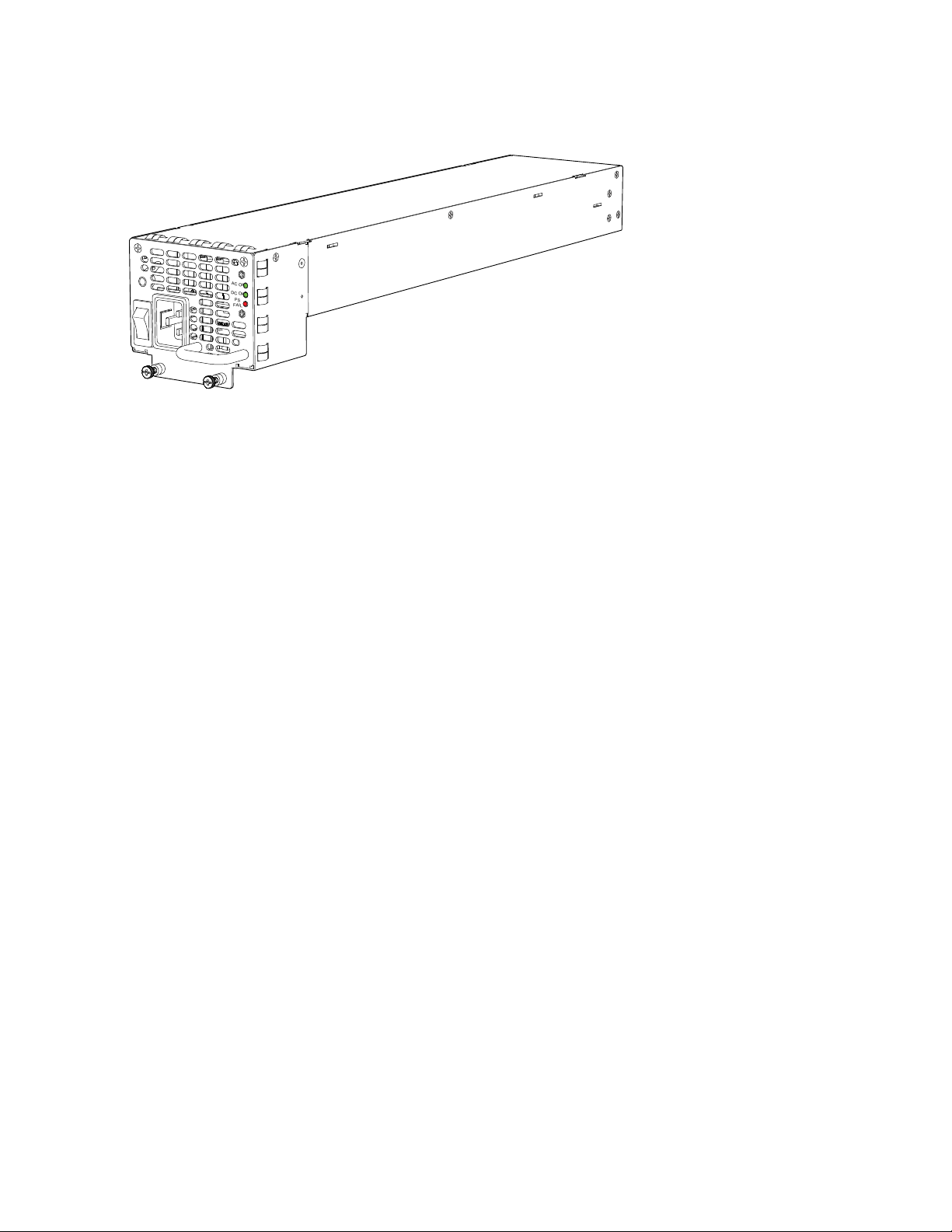

AC Power Supply in an EX9208 Switch

IN THIS SECTION

AC Power Supply Description | 54

AC Power Supply Configurations | 55

Page 54

An EX9208 switch is configurable with two, three, or four AC power supplies. The power supplies connect

to the midplane, which distributes the different output voltages produced by the power supplies to the

switch components, depending on their voltage requirements. Each power supply is cooled by its own

internal cooling system.

CAUTION: EX9208 switches use either AC or DC power supplies. Do not mix AC and

DC power supplies in a switch. The first type of power supply detected by the switch

when initially powered on determines the type of power supply allowed by the switch.

All installed power supplies of the other type are disabled by the switch. If you install

a power supply of the other type while the switch is operating, the switch disables the

power supply and generates an alarm.

This topic describes the AC power supplies in EX9208 switches.

AC Power Supply Description

54

The AC power supplies in EX9208 switches are hot-insertable and hot-removable field-replaceable units

(FRUs).

You can install up to four AC power supplies in an EX9208 switch. Power supplies are installed in the rear

of the chassis in slots PEM0 through PEM3 (left to right).

WARNING: The switch is installed in a restricted-access location. It has a separate

protective earthing terminal (sized for UNC 1/4-20 ground lugs) provided on the chassis

in addition to the grounding pin of the power supply cord. This separate protective

earthing terminal must be permanently connected to earth.

CAUTION: Before switch installation begins, ensure that a licensed electrician has

attached an appropriate grounding lug to the grounding cable that you supply. Using

a grounding cable with an incorrectly attached lug can damage the switch.

Each AC power supply weighs approximately 6.6 lb (2.99 kg) and consists of one AC appliance inlet, an

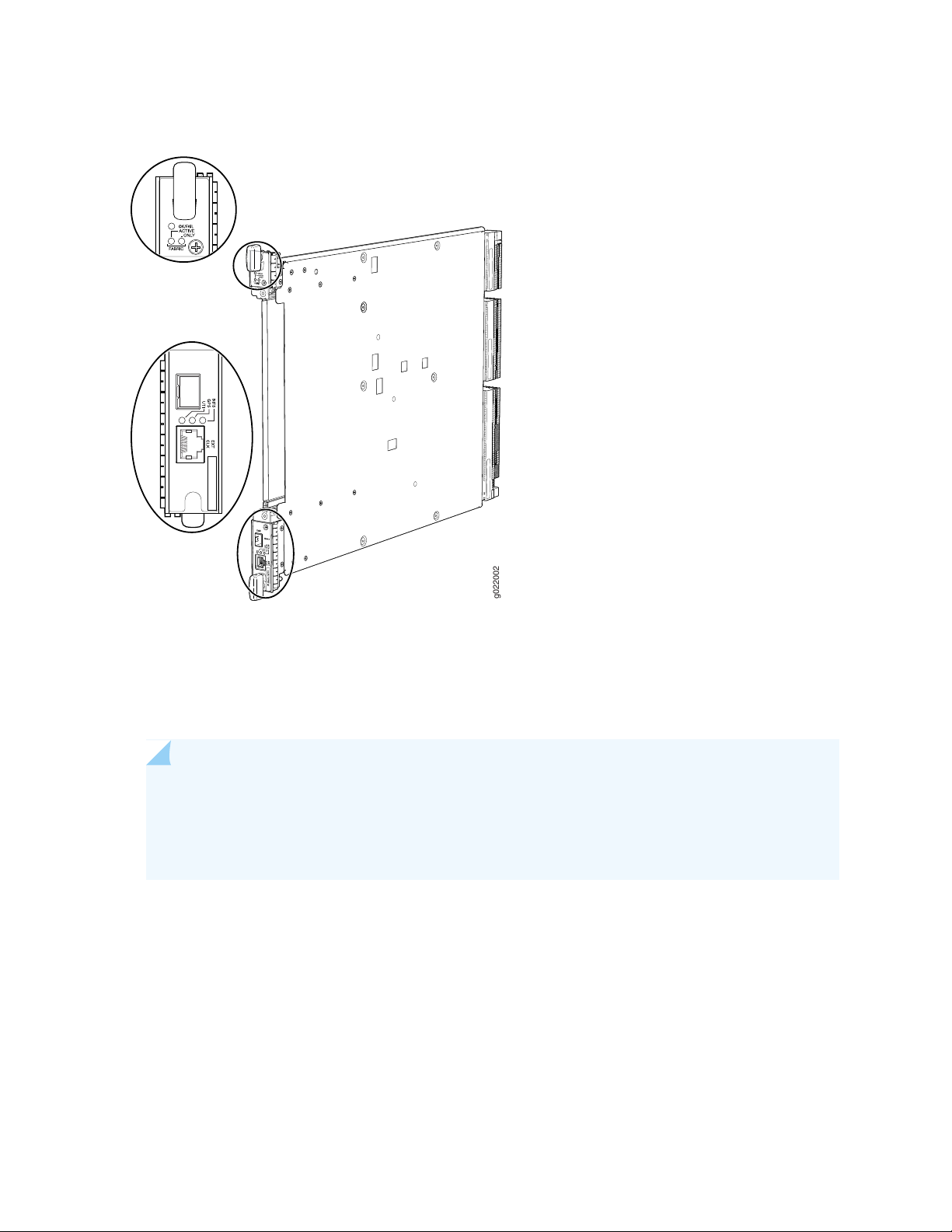

AC input switch, a fan, and LEDs to monitor the status of the power supply. See Figure 19 on page 55.

Page 55

Figure 19: AC Power Supply for an EX9208 Switch

AC OK

DC OK

PS

FAIL

Each power supply has its own fan and is cooled by its own internal cooling system.

EX9208 switches support 2520 W AC power supply. The AC power supply supports both the low-voltage

line (100–120 VAC) and the high-voltage line (200–240 VAC) AC power configurations.

55

Each AC power supply has a single AC appliance inlet located on the power supply that requires a dedicated

AC power feed. We recommend that you use a customer site circuit breaker rated for 16.0 A @ 100 VAC

or 16.0 A @ 200 VAC circuit breaker minimum for each AC power supply, or as required by local code.

Doing so enables you to operate the switch in any configuration without upgrading the power infrastructure.

AC Power Supply Configurations

The EX9208 switch supports either the low-line (100–120 V) AC power configuration or the high-line

(200–240 V) AC power configuration.

In the low-line (100–120 V) AC power configuration, the EX9208 switch contains three or four AC power

•

supplies, located horizontally at the rear of the chassis in slots PEM0 through PEM3 (left to right). Each

AC power supply provides power to all components in the switch. When three power supplies are

present, they share power almost equally within a fully populated system. Four AC power supplies

provide full power redundancy. If one power supply fails or is removed, the remaining power supplies

assume the entire electrical load without interruption. Three power supplies provide the maximum

configuration with full power for as long as the switch is operational. The low-line configuration requires

three power supplies and the fourth power supply provides redundancy.

In the high-line (200–240 V) AC power configuration, the EX9208 switch contains two or four AC power

•

supplies, located horizontally at the rear of the chassis in slots PEM0 through PEM3 (left to right). In a

high-line AC power configuration, each AC power supply provides power to all components in the switch.

When two or more power supplies are present, they share power almost equally within a fully populated

system. Four AC power supplies provide full power redundancy. If one power supply fails or is removed,

the remaining power supplies assume the entire electrical load without interruption. Two power supplies

provide the maximum configuration with full power for as long as the switch is operational. In the

Page 56

two-PEM high-line configuration, slots PEM0 and PEM1 or PEM2 and PEM3 are used. The high-line

configuration requires two power supplies, with the third and fourth providing redundancy.

SEE ALSO

Installing an AC Power Supply in an EX9208 Switch | 205

AC Power Supply Specifications for EX9208 Switches