Page 1

EX3300 Switch Hardware Guide

Published

2020-12-15

Page 2

Juniper Networks, Inc.

1133 Innovation Way

Sunnyvale, California 94089

USA

408-745-2000

www.juniper.net

Juniper Networks, the Juniper Networks logo, Juniper, and Junos are registered trademarks of Juniper Networks, Inc. in

the United States and other countries. All other trademarks, service marks, registered marks, or registered service marks

are the property of their respective owners.

Juniper Networks assumes no responsibility for any inaccuracies in this document. Juniper Networks reserves the right

to change, modify, transfer, or otherwise revise this publication without notice.

EX3300 Switch Hardware Guide

Copyright © 2020 Juniper Networks, Inc. All rights reserved.

The information in this document is current as of the date on the title page.

ii

YEAR 2000 NOTICE

Juniper Networks hardware and software products are Year 2000 compliant. Junos OS has no known time-related

limitations through the year 2038. However, the NTP application is known to have some difficulty in the year 2036.

END USER LICENSE AGREEMENT

The Juniper Networks product that is the subject of this technical documentation consists of (or is intended for use with)

Juniper Networks software. Use of such software is subject to the terms and conditions of the End User License Agreement

(“EULA”) posted at https://support.juniper.net/support/eula/. By downloading, installing or using such software, you

agree to the terms and conditions of that EULA.

Page 3

Table of Contents

1

About the Documentation | x

Documentation and Release Notes | x

Using the Examples in This Manual | x

Merging a Full Example | xi

Merging a Snippet | xii

Documentation Conventions | xii

Documentation Feedback | xv

Requesting Technical Support | xv

Self-Help Online Tools and Resources | xvi

Creating a Service Request with JTAC | xvi

iii

Overview

EX3300 System Overview | 18

EX3300 Switches Hardware Overview | 18

Benefits of the EX3300 Switch | 18

EX3300 Switches First View | 19

Uplink Ports | 19

Power over Ethernet Plus Ports | 19

EX3300 Switch Models | 20

EX3300 Switch Hardware and CLI Terminology Mapping | 21

Chassis Physical Specifications for EX3300 Switches | 24

EX3300 Chassis | 24

Front Panel of an EX3300 Switch | 25

Rear Panel of an EX3300 Switch | 26

LCD Panel in EX3300 Switches | 27

LCD Panel Modes | 28

LCD Panel Menus | 29

Chassis Status LEDs in EX3300 Switches | 33

Management Port LEDs in EX3300 Switches | 35

Page 4

Network Port and Uplink Port LEDs in EX3300 Switches | 36

2

EX3300 Cooling System | 39

Airflow Direction in EX3300 Switch Models | 40

Front-to-Back Airflow | 40

Back-to-Front Airflow | 41

EX3300 Power System | 42

Power Supply in EX3300 Switches | 43

Power Specifications for EX3300 Switches | 44

AC Power Cord Specifications for EX3300 Switches | 45

Site Planning, Preparation, and Specifications

Site Preparation Checklist for EX3300 Switches | 48

EX3300 Site Guidelines and Requirements | 49

iv

Environmental Requirements and Specifications for EX Series Switches | 50

General Site Guidelines | 55

Site Electrical Wiring Guidelines | 55

Rack Requirements | 56

Cabinet Requirements | 57

Requirements for Mounting an EX3300 Switch on a Desktop or Wall | 58

Clearance Requirements for Airflow and Hardware Maintenance for EX3300 Switches | 59

EX3300 Network Cable and Transceiver Planning | 61

Pluggable Transceivers Supported on EX3300 Switches | 61

SFP+ Direct Attach Copper Cables for EX Series Switches | 62

Cable Specifications | 63

List of DAC Cables Supported on EX Series Switches | 63

Standards Supported by These Cables | 64

Understanding EX Series Switches Fiber-Optic Cable Signal Loss, Attenuation, and

Dispersion | 64

Signal Loss in Multimode and Single-Mode Fiber-Optic Cable | 64

Attenuation and Dispersion in Fiber-Optic Cable | 65

Calculating the Fiber-Optic Cable Power Budget for EX Series Devices | 66

Calculating the Fiber-Optic Cable Power Margin for EX Series Devices | 66

Page 5

EX3300 Management Cable Specifications and Pinouts | 68

3

Management Cable Specifications | 68

Console Port Connector Pinout Information | 69

USB Port Specifications for an EX Series Switch | 70

RJ-45 Management Port Connector Pinout Information | 70

RJ-45 Port, SFP Port, SFP+ Port, QSFP+ Port, and QSFP28 Port Connector Pinout

Information | 71

RJ-45 to DB-9 Serial Port Adapter Pinout Information | 76

EX3300 Virtual Chassis | 77

Planning EX3300 Virtual Chassis | 77

Understanding EX3300 Virtual Chassis Hardware Configuration | 78

Virtual Chassis Cabling Configuration Examples for EX3300 Switches | 78

Initial Installation and Configuration

v

Unpacking and Mounting the EX3300 Switch | 82

Unpacking an EX3300 Switch | 82

Parts Inventory (Packing List) for an EX3300 Switch | 83

Register Products—Mandatory to Validate SLAs | 84

Installing and Connecting an EX3300 Switch | 85

Mounting an EX3300 Switch | 86

Mounting an EX3300 Switch on a Desk or Other Level Surface | 86

Mounting an EX3300 Switch on Two Posts in a Rack or Cabinet | 87

Mounting an EX3300 Switch on Four Posts in a Rack or Cabinet | 90

Mounting an EX3300 Switch in a Recessed Position in a Rack or Cabinet | 93

Mounting an EX3300 Switch on a Wall | 94

Connecting the EX3300 to Power | 97

Connect Earth Ground to an EX Series Switch | 97

Parts and Tools Required for Connecting an EX Series Switch to Earth Ground | 98

Special Instructions to Follow Before Connecting Earth Ground to an EX Series Switch | 102

Connecting Earth Ground to an EX Series Switch | 103

Connecting AC Power to an EX3300 Switch | 104

Connecting DC Power to an EX3300 Switch | 106

Page 6

Connecting the EX3300 to External Devices | 109

4

Connect a Device to a Network for Out-of-Band Management | 110

Connect a Device to a Management Console Using an RJ-45 Connector | 110

Connecting the EX3300 to the Network | 112

Install a Transceiver | 112

Connect a Fiber-Optic Cable | 115

Configuring Junos OS on the EX3300 | 116

EX3300 Switch Default Configuration | 116

Connecting and Configuring an EX Series Switch (CLI Procedure) | 121

Connecting and Configuring an EX Series Switch (J-Web Procedure) | 125

Configuring the LCD Panel on EX Series Switches (CLI Procedure) | 129

Disabling or Enabling Menus and Menu Options on the LCD Panel | 130

Configuring a Custom Display Message | 131

vi

Dashboard for EX Series Switches | 132

Graphical Chassis Viewer | 133

System Information Panel | 135

Health Status Panel | 138

Capacity Utilization Panel | 142

Alarms Panel | 143

File System Usage | 143

Chassis Viewer | 143

Maintaining Components

Maintain Transceivers | 162

Remove a Transceiver | 162

Remove a QSFP28 Transceiver | 165

Install a Transceiver | 167

Install a QSFP28 Transceiver | 169

Maintain Fiber-Optic Cables | 171

Connect a Fiber-Optic Cable | 171

Disconnect a Fiber-Optic Cable | 172

How to Handle Fiber-Optic Cables | 173

Page 7

Troubleshooting Hardware

5

6

7

Troubleshooting EX3300 Components | 176

Understand Alarm Types and Severity Levels on EX Series Switches | 176

Chassis Component Alarm Conditions on EX3300 Switches | 178

Check Active Alarms with the J-Web Interface | 183

Monitor System Log Messages | 185

Troubleshoot Temperature Alarms in EX Series Switches | 189

Contacting Customer Support and Returning the Chassis or Components

Returning an EX3300 Switch or Component for Repair or Replacement | 196

Returning an EX3300 Switch or Component for Repair or Replacement | 196

Locating the Serial Number on an EX3300 Switch or Component | 197

Listing the Switch and Components Details with the CLI | 197

vii

Locating the Chassis Serial Number ID Label on an EX3300 Switch | 198

Contact Customer Support to Obtain Return Material Authorization | 198

Packing an EX3300 Switch or Component for Shipping | 199

Packing a Switch for Shipping | 200

Packing Switch Components for Shipping | 201

Safety and Compliance Information

General Safety Guidelines and Warnings | 204

Definitions of Safety Warning Levels | 205

Qualified Personnel Warning | 208

Warning Statement for Norway and Sweden | 209

Fire Safety Requirements | 209

Fire Suppression | 209

Fire Suppression Equipment | 209

Installation Instructions Warning | 211

Chassis and Component Lifting Guidelines | 211

Restricted Access Warning | 213

Ramp Warning | 215

Page 8

Rack-Mounting and Cabinet-Mounting Warnings | 216

Grounded Equipment Warning | 222

Laser and LED Safety Guidelines and Warnings | 223

General Laser Safety Guidelines | 223

Class 1 Laser Product Warning | 224

Class 1 LED Product Warning | 225

Laser Beam Warning | 226

Radiation from Open Port Apertures Warning | 227

Maintenance and Operational Safety Guidelines and Warnings | 228

Battery Handling Warning | 229

Jewelry Removal Warning | 230

Lightning Activity Warning | 232

viii

Operating Temperature Warning | 233

Product Disposal Warning | 235

General Electrical Safety Guidelines and Warnings | 236

Action to Take After an Electrical Accident | 237

Prevention of Electrostatic Discharge Damage | 238

AC Power Electrical Safety Guidelines | 239

AC Power Disconnection Warning | 241

DC Power Electrical Safety Guidelines | 242

DC Power Disconnection Warning | 243

DC Power Grounding Requirements and Warning | 245

DC Power Wiring Sequence Warning | 247

DC Power Wiring Terminations Warning | 250

Multiple Power Supplies Disconnection Warning | 253

TN Power Warning | 254

Agency Approvals for EX Series Switches | 254

Page 9

Compliance Statements for EMC Requirements for EX Series Switches | 255

Canada | 256

Taiwan | 257

European Community | 257

Israel | 257

Japan | 257

Korea | 258

United States | 258

FCC Part 15 Statement | 258

Nonregulatory Environmental Standards | 259

Compliance Statements for Acoustic Noise for EX Series Switches | 260

Statements of Volatility for Juniper Network Devices | 260

ix

Page 10

About the Documentation

IN THIS SECTION

Documentation and Release Notes | x

Using the Examples in This Manual | x

Documentation Conventions | xii

Documentation Feedback | xv

Requesting Technical Support | xv

Use this guide to install hardware and perform initial software configuration, routine maintenance, and

troubleshooting for the EX3300 switch. After completing the installation and basic configuration procedures

covered in this guide, refer to the Junos OS documentation for information about further software

configuration.

x

Documentation and Release Notes

To obtain the most current version of all Juniper Networks®technical documentation, see the product

documentation page on the Juniper Networks website at https://www.juniper.net/documentation/.

If the information in the latest release notes differs from the information in the documentation, follow the

product Release Notes.

Juniper Networks Books publishes books by Juniper Networks engineers and subject matter experts.

These books go beyond the technical documentation to explore the nuances of network architecture,

deployment, and administration. The current list can be viewed at https://www.juniper.net/books.

Using the Examples in This Manual

If you want to use the examples in this manual, you can use the load merge or the load merge relative

command. These commands cause the software to merge the incoming configuration into the current

candidate configuration. The example does not become active until you commit the candidate configuration.

Page 11

If the example configuration contains the top level of the hierarchy (or multiple hierarchies), the example

is a full example. In this case, use the load merge command.

If the example configuration does not start at the top level of the hierarchy, the example is a snippet. In

this case, use the load merge relative command. These procedures are described in the following sections.

Merging a Full Example

To merge a full example, follow these steps:

1. From the HTML or PDF version of the manual, copy a configuration example into a text file, save the

file with a name, and copy the file to a directory on your routing platform.

For example, copy the following configuration to a file and name the file ex-script.conf. Copy the

ex-script.conf file to the /var/tmp directory on your routing platform.

system {

scripts {

commit {

file ex-script.xsl;

}

}

}

interfaces {

fxp0 {

disable;

unit 0 {

family inet {

address 10.0.0.1/24;

}

}

}

}

xi

2. Merge the contents of the file into your routing platform configuration by issuing the load merge

configuration mode command:

[edit]

user@host# load merge /var/tmp/ex-script.conf

load complete

Page 12

Merging a Snippet

To merge a snippet, follow these steps:

1. From the HTML or PDF version of the manual, copy a configuration snippet into a text file, save the

file with a name, and copy the file to a directory on your routing platform.

For example, copy the following snippet to a file and name the file ex-script-snippet.conf. Copy the

ex-script-snippet.conf file to the /var/tmp directory on your routing platform.

commit {

file ex-script-snippet.xsl; }

2. Move to the hierarchy level that is relevant for this snippet by issuing the following configuration mode

command:

[edit]

user@host# edit system scripts

[edit system scripts]

xii

3. Merge the contents of the file into your routing platform configuration by issuing the load merge

relative configuration mode command:

[edit system scripts]

user@host# load merge relative /var/tmp/ex-script-snippet.conf

load complete

For more information about the load command, see CLI Explorer.

Documentation Conventions

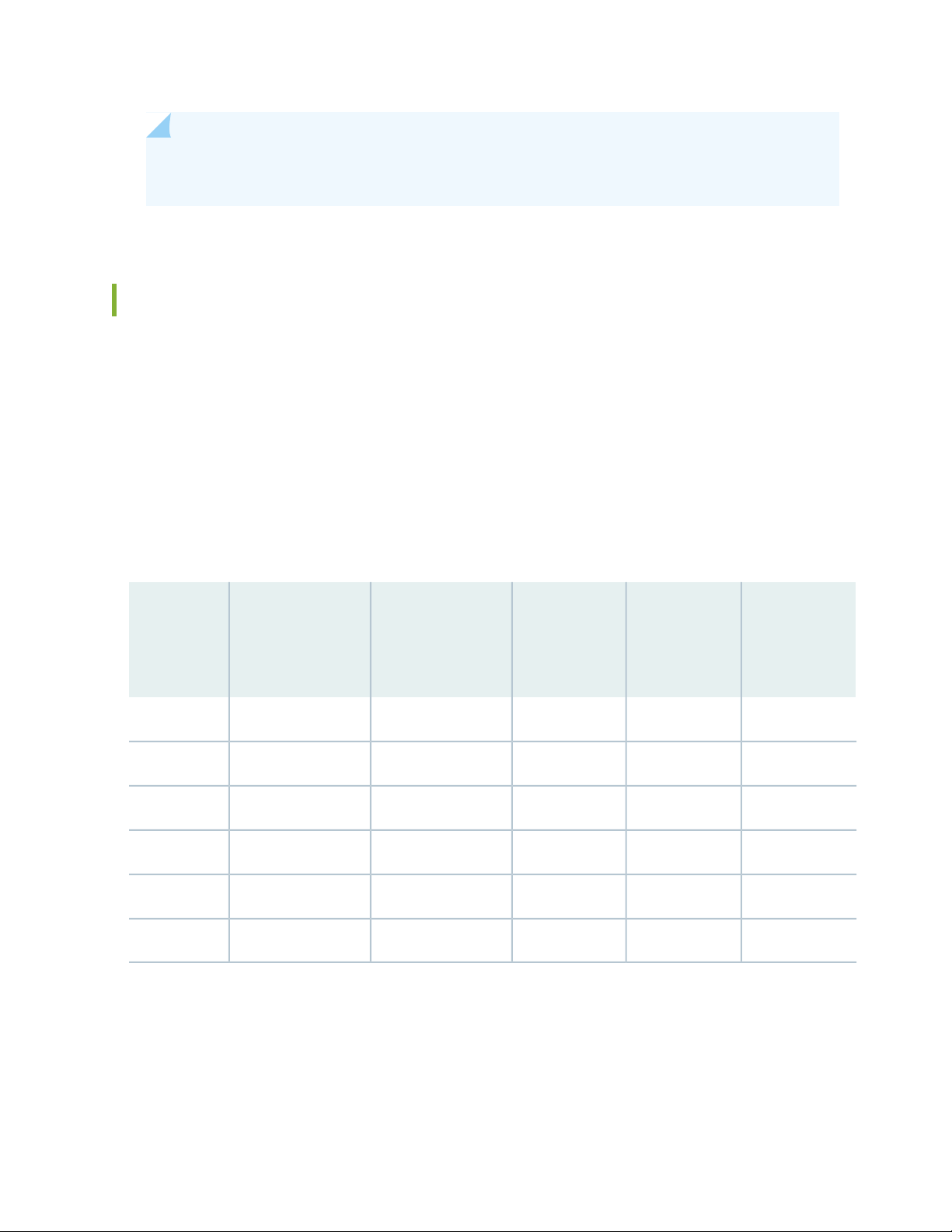

Table 1 on page xiii defines notice icons used in this guide.

Page 13

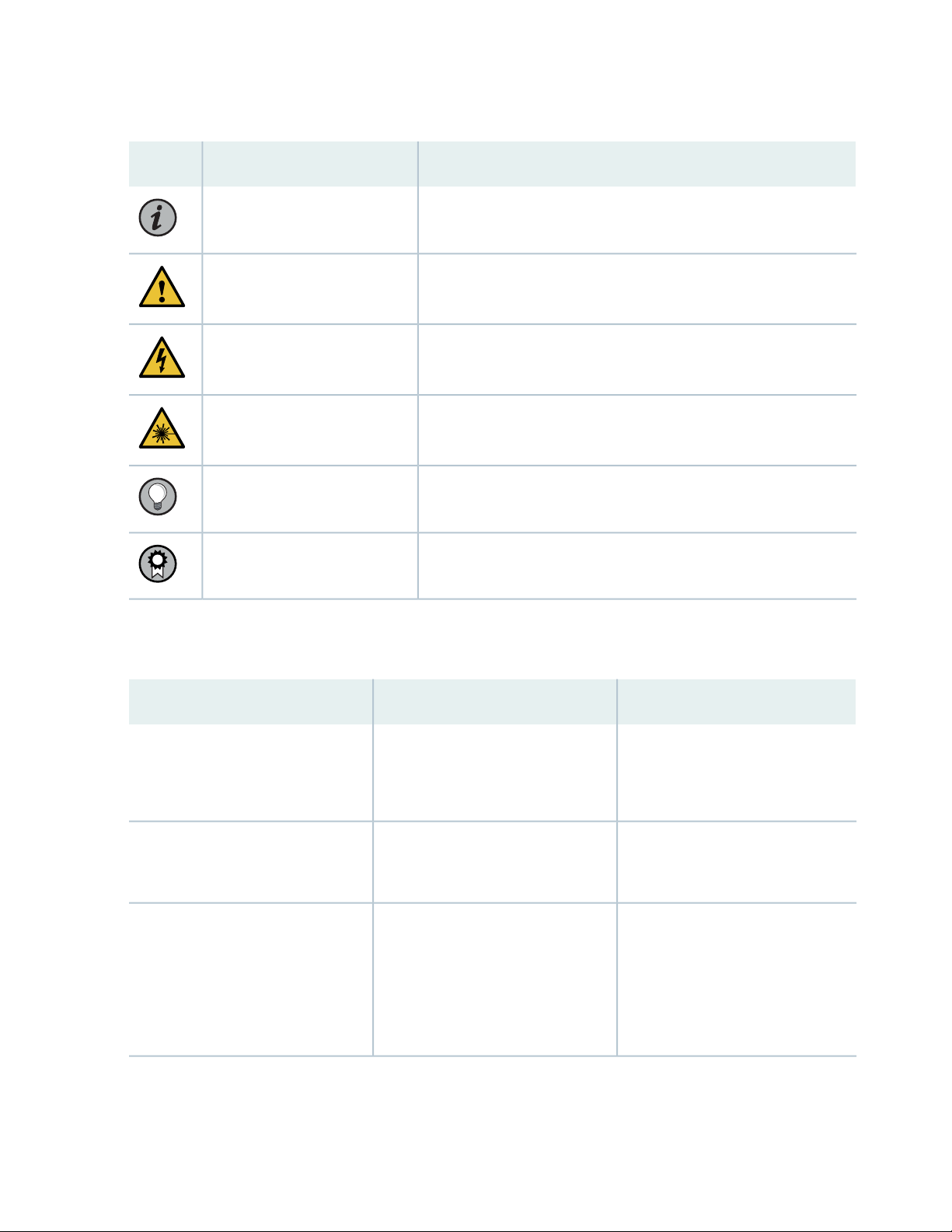

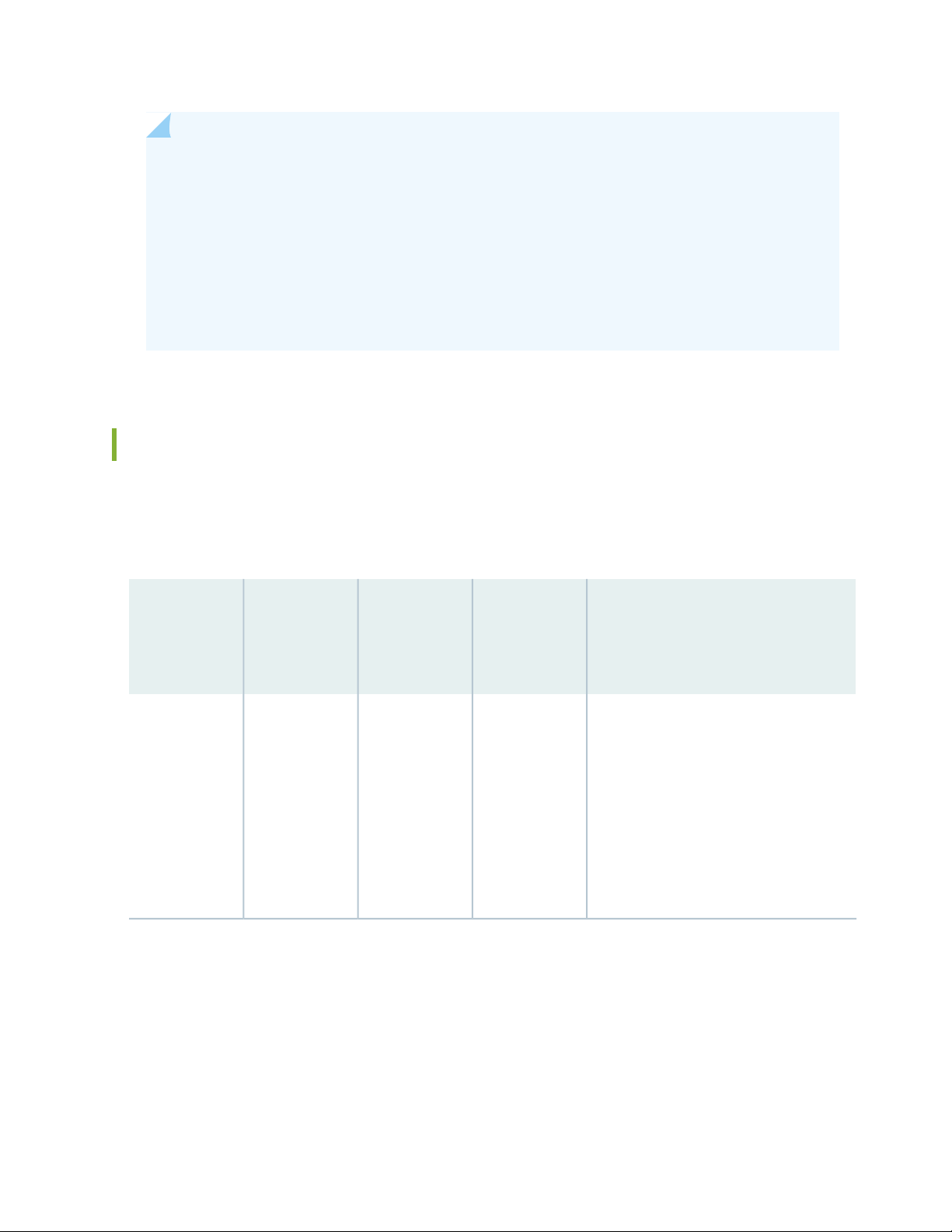

Table 1: Notice Icons

xiii

DescriptionMeaningIcon

Indicates important features or instructions.Informational note

Caution

Indicates a situation that might result in loss of data or hardware

damage.

Alerts you to the risk of personal injury or death.Warning

Alerts you to the risk of personal injury from a laser.Laser warning

Indicates helpful information.Tip

Alerts you to a recommended use or implementation.Best practice

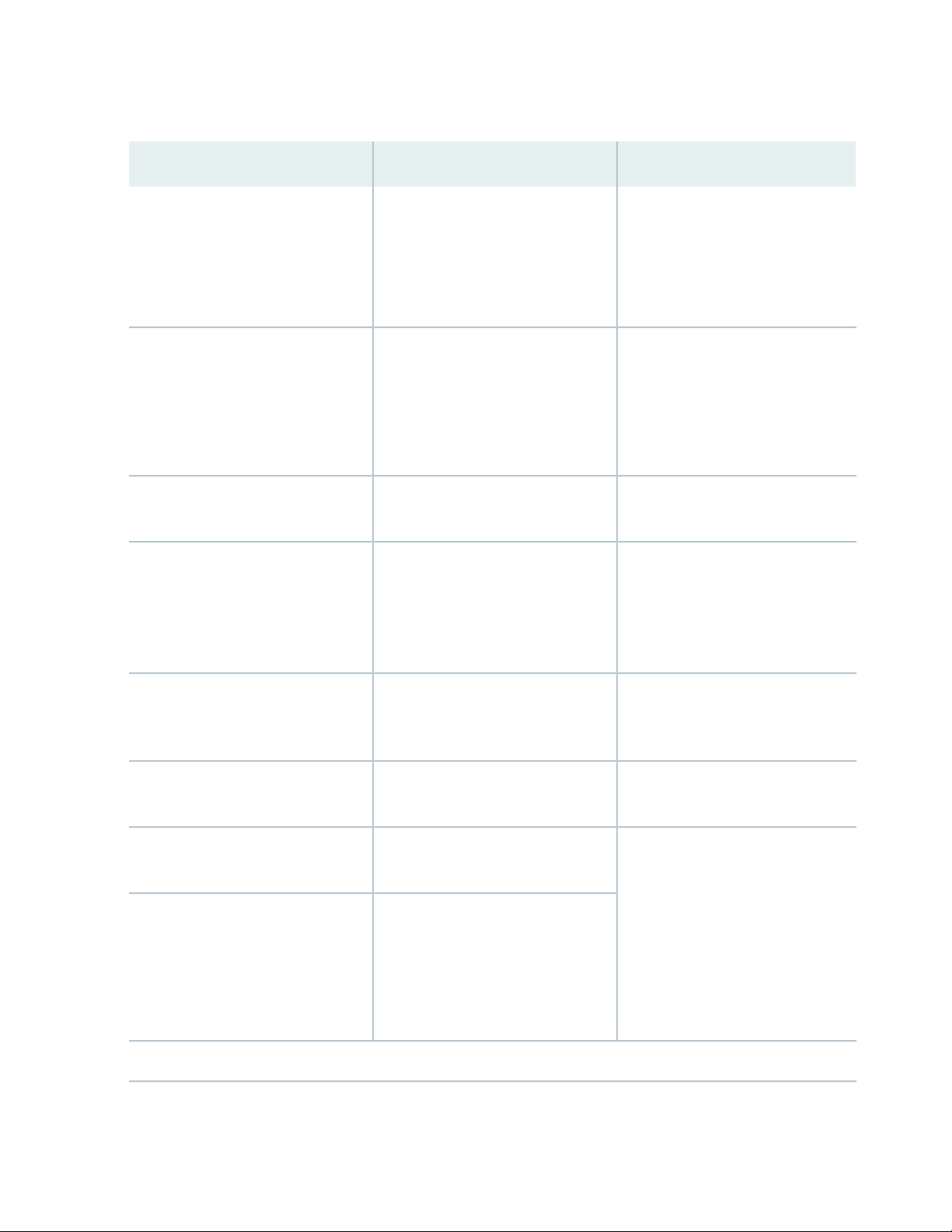

Table 2 on page xiii defines the text and syntax conventions used in this guide.

Table 2: Text and Syntax Conventions

ExamplesDescriptionConvention

Fixed-width text like this

Italic text like this

Represents text that you type.Bold text like this

Represents output that appears on

the terminal screen.

Introduces or emphasizes important

•

new terms.

Identifies guide names.

•

Identifies RFC and Internet draft

•

titles.

To enter configuration mode, type

the configure command:

user@host> configure

user@host> show chassis alarms

No alarms currently active

A policy term is a named structure

•

that defines match conditions and

actions.

Junos OS CLI User Guide

•

RFC 1997, BGP Communities

•

Attribute

Page 14

Table 2: Text and Syntax Conventions (continued)

xiv

ExamplesDescriptionConvention

Italic text like this

Text like this

< > (angle brackets)

| (pipe symbol)

Represents variables (options for

which you substitute a value) in

commands or configuration

statements.

Represents names of configuration

statements, commands, files, and

directories; configuration hierarchy

levels; or labels on routing platform

components.

variables.

Indicates a choice between the

mutually exclusive keywords or

variables on either side of the symbol.

The set of choices is often enclosed

in parentheses for clarity.

Configure the machine’s domain

name:

[edit]

root@# set system domain-name

domain-name

To configure a stub area, include

•

the stub statement at the [edit

protocols ospf area area-id]

hierarchy level.

The console port is labeled

•

CONSOLE.

stub <default-metric metric>;Encloses optional keywords or

broadcast | multicast

(string1 | string2 | string3)

# (pound sign)

[ ] (square brackets)

Indention and braces ( { } )

; (semicolon)

GUI Conventions

Indicates a comment specified on the

same line as the configuration

statement to which it applies.

Encloses a variable for which you can

substitute one or more values.

Identifies a level in the configuration

hierarchy.

Identifies a leaf statement at a

configuration hierarchy level.

rsvp { # Required for dynamic MPLS

only

community name members [

community-ids ]

[edit]

routing-options {

static {

route default {

nexthop address;

retain;

}

}

}

Page 15

Table 2: Text and Syntax Conventions (continued)

xv

ExamplesDescriptionConvention

Bold text like this

> (bold right angle bracket)

Represents graphical user interface

(GUI) items you click or select.

Separates levels in a hierarchy of

menu selections.

In the Logical Interfaces box, select

•

All Interfaces.

To cancel the configuration, click

•

Cancel.

In the configuration editor hierarchy,

select Protocols>Ospf.

Documentation Feedback

We encourage you to provide feedback so that we can improve our documentation. You can use either

of the following methods:

Online feedback system—Click TechLibrary Feedback, on the lower right of any page on the Juniper

•

Networks TechLibrary site, and do one of the following:

Click the thumbs-up icon if the information on the page was helpful to you.

•

Click the thumbs-down icon if the information on the page was not helpful to you or if you have

•

suggestions for improvement, and use the pop-up form to provide feedback.

E-mail—Send your comments to techpubs-comments@juniper.net. Include the document or topic name,

•

URL or page number, and software version (if applicable).

Requesting Technical Support

Technical product support is available through the Juniper Networks Technical Assistance Center (JTAC).

If you are a customer with an active Juniper Care or Partner Support Services support contract, or are

Page 16

covered under warranty, and need post-sales technical support, you can access our tools and resources

online or open a case with JTAC.

JTAC policies—For a complete understanding of our JTAC procedures and policies, review the JTAC User

•

Guide located at https://www.juniper.net/us/en/local/pdf/resource-guides/7100059-en.pdf.

Product warranties—For product warranty information, visit https://www.juniper.net/support/warranty/.

•

JTAC hours of operation—The JTAC centers have resources available 24 hours a day, 7 days a week,

•

365 days a year.

Self-Help Online Tools and Resources

For quick and easy problem resolution, Juniper Networks has designed an online self-service portal called

the Customer Support Center (CSC) that provides you with the following features:

Find CSC offerings: https://www.juniper.net/customers/support/

•

Search for known bugs: https://prsearch.juniper.net/

•

xvi

Find product documentation: https://www.juniper.net/documentation/

•

Find solutions and answer questions using our Knowledge Base: https://kb.juniper.net/

•

Download the latest versions of software and review release notes:

•

https://www.juniper.net/customers/csc/software/

Search technical bulletins for relevant hardware and software notifications:

•

https://kb.juniper.net/InfoCenter/

Join and participate in the Juniper Networks Community Forum:

•

https://www.juniper.net/company/communities/

Create a service request online: https://myjuniper.juniper.net

•

To verify service entitlement by product serial number, use our Serial Number Entitlement (SNE) Tool:

https://entitlementsearch.juniper.net/entitlementsearch/

Creating a Service Request with JTAC

You can create a service request with JTAC on the Web or by telephone.

Visit https://myjuniper.juniper.net.

•

Call 1-888-314-JTAC (1-888-314-5822 toll-free in the USA, Canada, and Mexico).

•

For international or direct-dial options in countries without toll-free numbers, see

https://support.juniper.net/support/requesting-support/.

Page 17

1

CHAPTER

Overview

EX3300 System Overview | 18

EX3300 Chassis | 24

EX3300 Cooling System | 39

EX3300 Power System | 42

Page 18

EX3300 System Overview

IN THIS SECTION

EX3300 Switches Hardware Overview | 18

EX3300 Switch Models | 20

EX3300 Switch Hardware and CLI Terminology Mapping | 21

Chassis Physical Specifications for EX3300 Switches | 24

EX3300 Switches Hardware Overview

18

IN THIS SECTION

Benefits of the EX3300 Switch | 18

EX3300 Switches First View | 19

Uplink Ports | 19

Power over Ethernet Plus Ports | 19

Juniper Networks EX Series Ethernet Switches provide scalable connectivity for the enterprise market,

including branch offices, campus locations, and data centers. The switches run the Juniper Networks Junos

operating system (Junos OS), which provides Layer 2 and Layer 3 switching, routing, and security services.

The same Junos OS code base that runs on EX Series switches also runs on all Juniper Networks M Series,

MX Series, and T Series routers and SRX Series services gateways.

Juniper Networks EX3300 Ethernet Switches provide connectivity for low-density environments.

Benefits of the EX3300 Switch

Support for Virtual Chassis—EX3300 switches support Virtual Chassis technology. You can interconnect

a maximum of 10 EX3300 switches to form a Virtual Chassis.

High flexibility—EX3300 switches provide a flexible solution that supports converged data, voice, and

video environments.

Page 19

Support for Power over Ethernet (PoE)—EX3300-24P and EX3300-48P models support the IEEE 802.3at

PoE standard, also known as PoE+, delivering up to 30 watts of power per port to support networked

devices such as telephones, video cameras, IEEE 802.11n wireless LAN (WLAN) access points, and video

phones.

EX3300 Switches First View

EX3300 switches provide:

Either 24 or 48 built-in network ports with 10/100/1000BASE-T Gigabit Ethernet connectors (ports

•

labeled 0 through 23 or 0 through 47)

Four uplink ports (ports labeled 0 through 3)

•

Virtual Chassis capability—You can connect up to ten EX3300 switches together to form one unit that

•

you manage as a single chassis, called a Virtual Chassis.

Power over Ethernet Plus (PoE+) on all network ports (in PoE+-capable models only)

•

19

Uplink Ports

Each EX3300 switch has four autosensing uplink ports. You can use the uplink ports on the switch to:

Connect an access switch to a distribution switch

•

Interconnect member switches of a Virtual Chassis

•

The uplink ports labeled 0 and 1 (interfaces ge-0/1/0 and ge-0/1/1 or xe-0/1/0 and xe-0/1/1) are

configured by default as network ports. To use uplink ports 0 and 1 to interconnect Virtual Chassis members,

you must configure them as Virtual Chassis ports (VCPs).

The uplink ports labeled 2 and 3 (interfaces ge-0/1/2 and ge-0/1/3 or xe-0/1/2 and xe-0/1/3) are

configured by default as VCPs. You can use these uplink ports to interconnect Virtual Chassis members.

To use uplink ports 2 and 3 as network ports, you must configure them as network ports.

The uplink ports support SFP and SFP+ transceivers. For a list of supported transceivers, see “Pluggable

Transceivers Supported on EX3300 Switches” on page 61.

Power over Ethernet Plus Ports

EX3300 switches are available in models with or without PoE+ capability. Models that support PoE+

provide that support on all network ports.

PoE+ ports provide electrical current to devices—such as IP phones, wireless access points, and security

cameras—through network cables, thus eliminating the need for separate power cords for those devices.

Page 20

NOTE: IEEE 802.3af and IEEE 802.3at powered devices require category 5 or higher Ethernet

cables.

EX3300 Switch Models

The EX3300 switch models are available:

With 24 or 48 network ports

•

With or without PoE+ capability

•

With front-to-back or back-to-front airflow

•

With AC or DC power supplies

•

20

Table 3 on page 20 lists the EX3300 switch models.

Table 3: EX3300 Switch Models

Ports in Which

PoE+ Is AvailableAccess PortsModel

Maximum

System Power

Available for

PoE

Direction of

Airflow

First Junos OS

Release

11.3R1Front-to-back––24 Gigabit EthernetEX3300-24T

11.3R1Front-to-back405 WAll 24 ports24 Gigabit EthernetEX3300-24P

11.3R1Front-to-back––24 Gigabit EthernetEX3300-24T-DC

11.3R1Front-to-back––48 Gigabit EthernetEX3300-48T

11.3R1Back-to-front––48 Gigabit EthernetEX3300-48T-BF

11.3R1Front-to-back740 WAll 48 ports48 Gigabit EthernetEX3300-48P

Page 21

NOTE: In rare cases, EX3300 switches running a Junos OS release prior to Release 11.3R4 or

Release 11.4R2 might experience some traffic loss or a link failure as a result of

non-user-configurable settings that are not optimized. To resolve this issue, upgrade to one of

the following Junos OS releases:

Junos OS Release 11.3—R4 and later

•

Junos OS Release 11.4—R2 and later

•

Junos OS Release 12.1—R1 and later

•

EX3300 Switch Hardware and CLI Terminology Mapping

This topic describes the hardware terms used in EX3300 switch documentation and the corresponding

terms used in the Junos OS command line interface (CLI). See Table 4 on page 21.

21

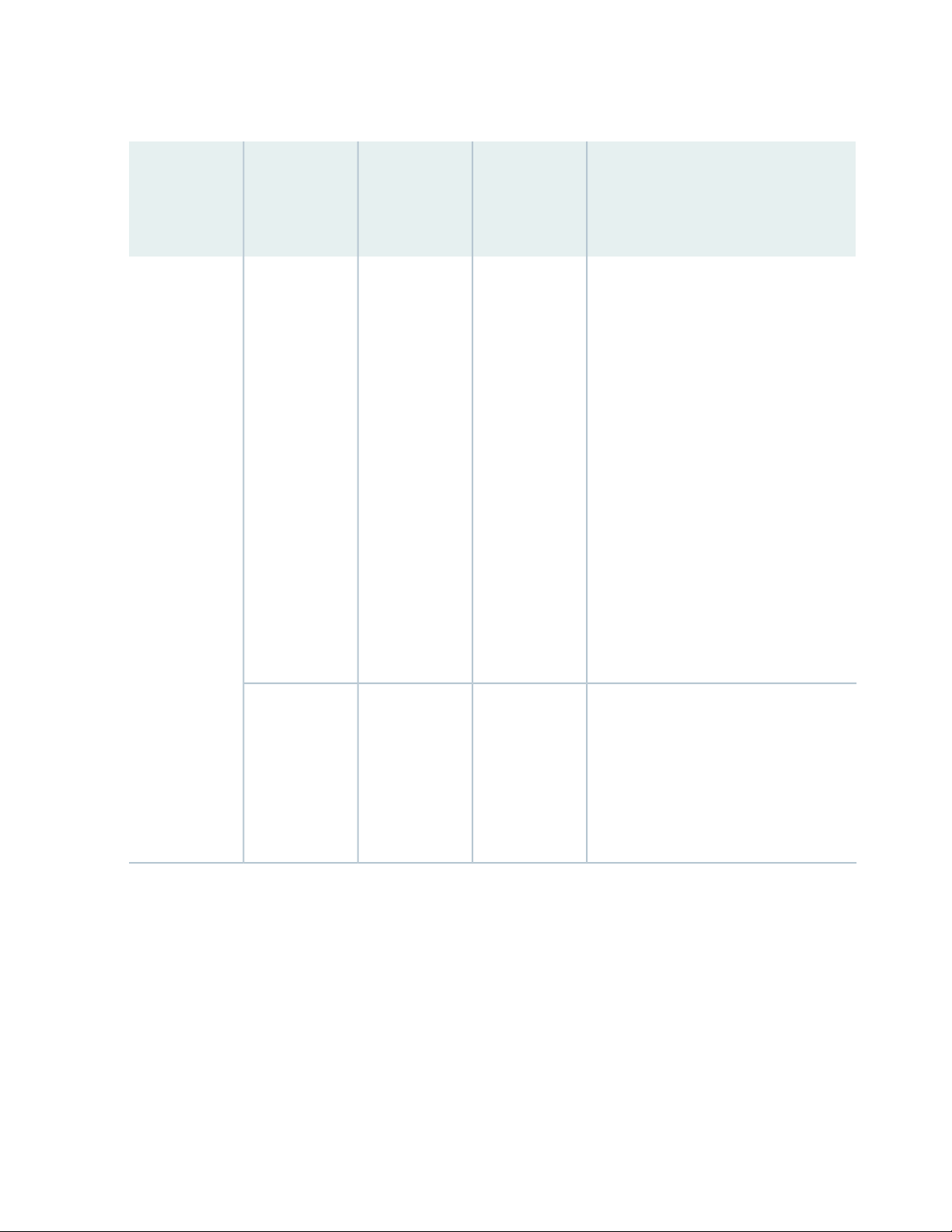

Table 4: CLI Equivalents of Terms Used in Documentation for EX3300 Switches

Hardware

Item (Field as

Displayed in

CLI)

Chassis

Description

(Field as

Displayed in

CLI)

following:

EX3300-24T

•

EX3300-24P

•

EX3300-24T-DC

•

EX3300-48T

•

EX3300-48T-BF

•

EX3300-48P

•

Value (Field as

Displayed in

CLI)

Item in

Documentation

Switch chassis–One of the

Additional Information

“Chassis Physical Specifications for

EX3300 Switches” on page 24

Page 22

Table 4: CLI Equivalents of Terms Used in Documentation for EX3300 Switches (continued)

22

Hardware

Item (Field as

Displayed in

CLI)

FPC (n)

Description

(Field as

Displayed in

CLI)

On EX3300

standalone

switches:

Abbreviated

name of the

Flexible PIC

Concentrator

(FPC)

One of the

following:

EX3300-24T

•

EX3300-24P

•

EX3300-24T-DC

•

EX3300-48T

•

EX3300-48T-BF

•

EX3300-48P

•

Value (Field as

Displayed in

CLI)

Value of n is

always 0.

Item in

Documentation

The switch does

not have actual

FPCs. In this

case, FPC refers

to the switch

itself.

Additional Information

Understanding Interface Naming

Conventions

On EX3300

Virtual Chassis:

Member ID of

•

the switch

within the

Virtual

Chassis

n is a value in

the range of

0-9.

Understanding Virtual Chassis ComponentsIn this case, the

FPC number

refers to the

member ID

assigned to the

switch.

Page 23

Table 4: CLI Equivalents of Terms Used in Documentation for EX3300 Switches (continued)

23

Hardware

Item (Field as

Displayed in

CLI)

PIC (n)

Description

(Field as

Displayed in

CLI)

Abbreviated

name of the

Physical

Interface Card

(PIC)

following:

24x

•

10/100/1000

BASE-T

48x

•

10/100/1000

BASE-T

Value (Field as

Displayed in

CLI)

n is a value in

the range of

0–1.

PIC 0One of the

Item in

Documentation

The switch does

not have actual

PIC devices; see

entries for PIC 0

through PIC 1

for the

equivalent item

on the switch.

Built-in network

ports on the

front panel of

the switch

Additional Information

Understanding Interface Naming

Conventions

“Front Panel of an EX3300 Switch” on

page 25

Xcvr (n)

Power Supply

(n)

Abbreviated

name of the

transceiver

Built-in power

supply

PIC 14x GE/XE SFP+

n is a value

equivalent to

the number of

the port in

which the

transceiver is

installed.

always 0.

Built-in uplink

ports on the

front panel of

the switch

Optical

transceivers

Power supplyValue of n is

“Front Panel of an EX3300 Switch” on

page 25

“Pluggable Transceivers Supported on

EX3300 Switches” on page 61

“Power Supply in EX3300 Switches” on

page 43

“EX3300 Cooling System” on page 39Fan tray–Built-in fan trayFan Tray

Page 24

Chassis Physical Specifications for EX3300 Switches

The EX3300 switch chassis is a rigid sheet-metal structure that houses the hardware components.

Table 5 on page 24 summarizes the physical specifications of the EX3300 switch chassis.

Table 5: Physical Specifications of the EX3300 Switch Chassis

ValueDescription

1.75 in. (4.45 cm)Chassis height

24

Chassis width

Weight

EX3300 Chassis

IN THIS SECTION

17.5 in. (44.5 cm)

•

19 in. (48.2 cm) with mounting brackets attached

•

12 in. (30.5 cm)Chassis depth

EX3300-24T: 10 lb (4.6 kg)

•

EX3300-24P: 11.6 lb (5.3 kg)

•

EX3300-24T-DC: 9.8 lb (4.5 kg)

•

EX3300-48T: 10.8 lb (4.9 kg)

•

EX3300-48T-BF: 10.8 lb (4.9 kg)

•

EX3300-48P: 12.8 lb (5.8 kg)

•

Front Panel of an EX3300 Switch | 25

Rear Panel of an EX3300 Switch | 26

LCD Panel in EX3300 Switches | 27

Chassis Status LEDs in EX3300 Switches | 33

Management Port LEDs in EX3300 Switches | 35

Network Port and Uplink Port LEDs in EX3300 Switches | 36

Page 25

Front Panel of an EX3300 Switch

g021216

0 1 2 3

ALM

EX3300 PoE+

SYS

MST

LCD panel

Network ports

Chassis

status

LEDs

Enter buttonSFP+ uplink ports

Menu button

The front panel of an EX3300 switch consists of the following components:

Network ports:

•

Depending on the switch model, 24 or 48 10/100/1000BASE-T Gigabit Ethernet ports (ports labeled

•

0 through 23 or 0 through 47)

Power over Ethernet Plus (PoE+) available in all network ports in EX3300-24P and EX3300-48P models

•

Power over Ethernet Plus (PoE+) not available in any network port in EX3300-24T, EX3300-24T-DC,

•

EX3300-48T, and EX3300-48T-BF models

Four built-in uplink ports:

•

The uplink ports support 1-gigabit small form-factor pluggable (SFP) transceivers, 10-gigabit small

•

form-factor pluggable (SFP+) transceivers, or a combination of these transceivers.

Ports labeled 0 and 1 are, by default, configured as network ports. You can configure these ports as

•

Virtual Chassis ports (VCPs).

25

Ports labeled 2 and 3 are, by default, configured as VCPs. You can configure these ports as network

•

ports.

Network port and uplink port LEDs

•

Three chassis status LEDs

•

LCD panel and the LCD navigation buttons

•

Air intake or air exhaust, depending on the switch model—The intake or exhaust is located immediately

•

below the top edge of the front panel.

Figure 1 on page 25 shows the front panel of an EX3300 switch with 48 Gigabit Ethernet ports.

Figure 2 on page 26 shows the front panel of an EX3300 switch with 24 Gigabit Ethernet ports.

Figure 1: Front Panel of an EX3300 Switch with 48 Gigabit Ethernet Ports

Page 26

Figure 2: Front Panel of an EX3300 Switch with 24 Gigabit Ethernet Ports

g021217

0 1 2 3

ALM

EX3300

SYS

MST

LCD panel

Network ports

Chassis

status

LEDs

Enter buttonSFP+ uplink ports

Menu button

AC power

cord inlet

Air exhaust

with fan

Serial number

ID label

USB

port

Management

Ethernet por t

Console RPS

port

port

Protective

earthing terminal

ESD

point

g021202

Rear Panel of an EX3300 Switch

The rear panel of the EX3300 switch consists of the following components:

Management Ethernet port

•

USB port

•

26

Console port

•

Protective earthing terminal

•

Redundant power system (RPS) port

•

ESD point

•

Air intake or air exhaust, depending on the switch model

•

Serial number ID label

•

AC power cord inlet or DC power terminal block

•

Figure 3 on page 26 shows the rear panel of an EX3300 switch with AC power supply.

The power cord retainer extends out of the chassis by 3 in. (7.62 cm).

Figure 3: Rear Panel of an EX3300 Switch with an AC Power Supply

Figure 4 on page 27 shows the rear panel of an EX3300 switch with DC power supply.

Page 27

Figure 4: Rear Panel of an EX3300 Switch with a DC Power Supply

g021203

DC power

terminals

Air exhaust

with fan

Serial number

ID label

USB

port

Management

Ethernet por t

Console RPS

port

port

Protective

earthing terminal

ESD

point

LCD Panel in EX3300 Switches

IN THIS SECTION

LCD Panel Modes | 28

27

LCD Panel Menus | 29

The LCD panel on the front panel of the switch shows two lines of text, each of which can contain a

maximum of 16 characters. The LCD panel displays a variety of information about the switch and also

provides a menu to perform basic operations such as initial setup and reboot.

There are two navigation buttons—Menu and Enter—to the right of the LCD panel.

See Figure 5 on page 27.

Figure 5: LCD Panel

You can configure the second line of the LCD panel to display a custom message. If the LCD panel is

configured to display a custom message, the Menu button and the Enter button are disabled. See

“Configuring the LCD Panel on EX Series Switches (CLI Procedure)” on page 129.

The LCD panel has a backlight. If the LCD panel is idle for 60 seconds, the backlight turns off. You can

turn on the backlight by pressing the Menu or Enter button once. After turning on the backlight, you can

Page 28

toggle between the LCD panel menus by pressing the Menu button and navigate through the menu options

by pressing the Enter button.

LCD Panel Modes

The LCD panel operates in four modes: boot, idle, status, and maintenance.

The LCD panel operates in boot mode during switch reboot. The boot mode displays the key milestones

in the switch boot process. The boot mode does not have any menu options. After the boot process is

complete, the LCD panel automatically reverts to the Idle menu.

In an EX3300 switch that is not a member of a Virtual Chassis, the first line of the LCD panel displays:

The slot number—For a standalone EX3300 switch, the slot number is always 00.

•

The role of the switch—For a standalone EX3300 switch, the role is always RE (for primary).

•

Hostname

•

In an EX3300 switch that is a member of a Virtual Chassis, the first line of the LCD panel displays:

28

The slot number (the member ID for the Virtual Chassis member)

•

Role of the switch in a Virtual Chassis (RE for primary, BK for backup, and LC for linecard member)

•

Hostname

•

In the idle mode, the second line displays the mode of the network ports’ Status LED and the number of

chassis alarms. The number of alarms is updated every second.

In the status mode, the second line displays:

Virtual Chassis port (VCP) status (for an EX3300 switch that is a member of a Virtual Chassis)

•

Status of the power supply

•

Status of the fan and temperature

•

Version of Junos OS for EX Series switches loaded on the switch

•

In the maintenance mode, the second line displays one of the following options that you can use to configure

and troubleshoot the switch:

System halt

•

System reboot

•

Load rescue

•

Request VC port (for an EX3300 switch that is a member of a Virtual Chassis)

•

Factory default

•

System EZSetup

•

Page 29

LCD Panel Menus

The LCD panel has three menus: Idle, Status, and Maintenance. Toggle between the LCD panel menus by

pressing the Menu button. Navigate through the menu options by pressing the Enter button.

Table 6 on page 29 describes the LCD panel menu options.

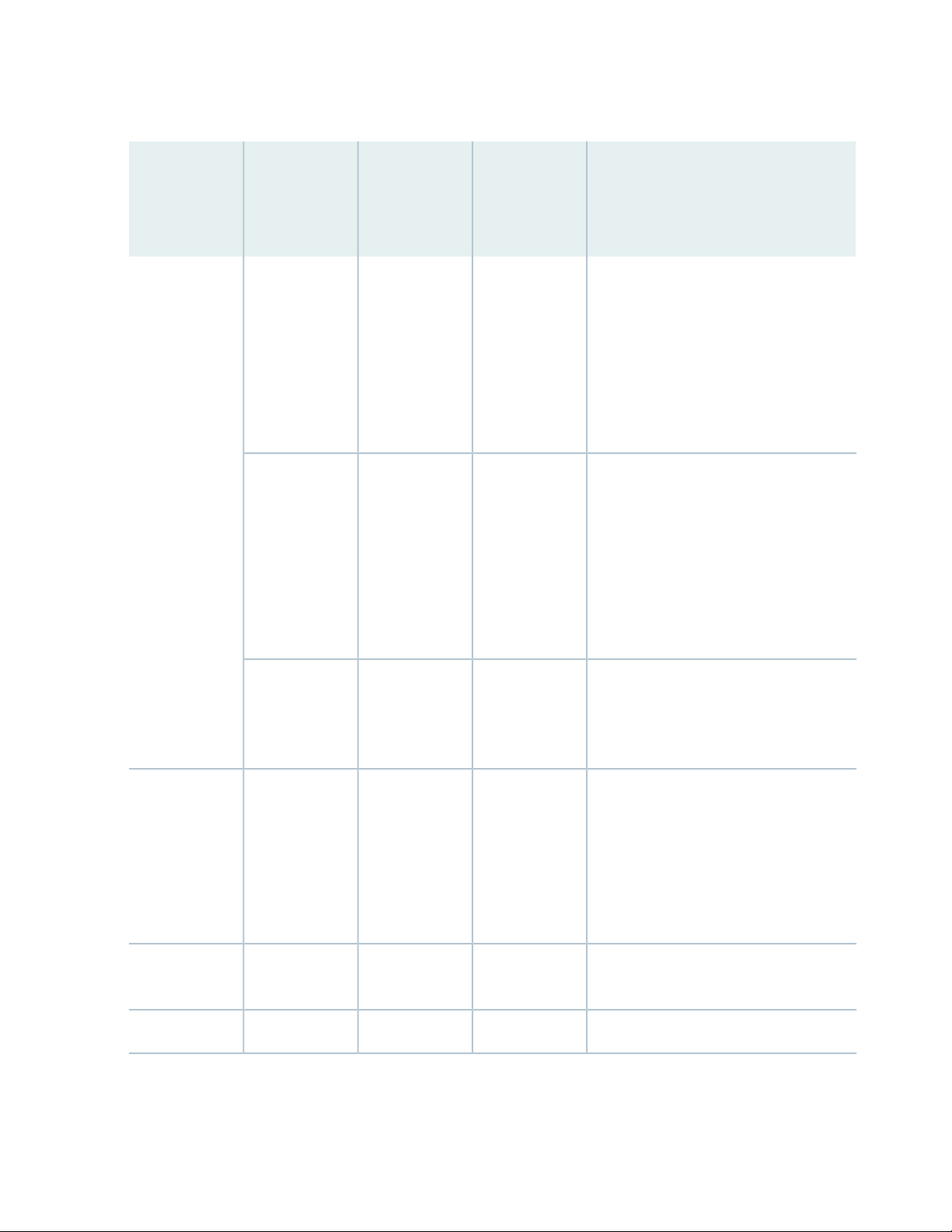

Table 6: LCD Panel Menu Options

DescriptionMenu

29

IDLE

In the Idle menu:

Press Enter to cycle through the Status LED modes:

•

SPD (speed)

•

ADM (administrative status)

•

DPX (duplex)

•

POE (Power over Ethernet)

•

See “Network Port and Uplink Port LEDs in EX3300 Switches” on page 36 for information on the

Status LED modes.

Press Menu to exit the Idle menu and go to the Status menu.

•

Page 30

Table 6: LCD Panel Menu Options (continued)

DescriptionMenu

30

STATUS

The Status menu has the following options:

Show VCP status—Choose one of the following:

•

Press the Enter button to display the Virtual Chassis port (VCP) status: Up, Down, Disabled.

•

NOTE: This option is available only for an EX3300 switch that is a member of a Virtual Chassis

configuration.

Press the Menu button to go to the next option in the Status menu.

•

Show PSU status—Choose one of the following:

•

Press the Enter button to display the status of the power supply: OK, Failed, Absent.

•

Press the Menu button to go to the next option in the Status menu.

•

Show Environment status—Choose one of the following:

•

Press the Enter button to display the status of the fan and temperature:

•

Fan status: OK, Failed, Absent

•

Temp status: OK, High, Shutdown

•

Press the Menu button to go to the next option in the Status menu.

•

Show Junos version—Choose one of the following:

•

Press the Enter button to display the version of Junos OS for EX Series switches loaded on the

•

switch.

Press the Menu button to go to the next option in the Status menu.

•

EXIT STAT MENU?—Choose one of the following:

•

Press the Enter button to exit the Status menu. Then press the Menu button to go to the

•

Maintenance menu.

On an EX3300 switch that is a member of a Virtual Chassis configuration, press the Menu button

•

to return to the Show VCP status option.

NOTE: This option is available only for an EX3300 switch that is a member of a Virtual Chassis

configuration.

If you do not want users to use Status menu options, disable the entire menu or individual menu

options. See “Configuring the LCD Panel on EX Series Switches (CLI Procedure)” on page 129.

Page 31

Table 6: LCD Panel Menu Options (continued)

DescriptionMenu

MAINT

(Maintenance

Menu)

31

Page 32

Table 6: LCD Panel Menu Options (continued)

DescriptionMenu

The Maintenance menu has the following options to configure and troubleshoot the switch:

SYSTEM HALT?—Choose one of the following:

•

Press the Enter button to halt the switch. Press the Enter button again to confirm the halt.

•

Press the Menu button to go to the next option in the Maintenance menu.

•

SYSTEM REBOOT?—Choose one of the following:

•

Press the Enter button to reboot the switch. Press the Enter button again to confirm the reboot.

•

Press the Menu button to go to the next option in the Maintenance menu.

•

LOAD RESCUE?—Choose one of the following:

•

Press the Enter button to roll back the switch to the rescue configuration. Press the Enter button

•

again to confirm the rollback.

Press the Menu button to go to the next option in the Maintenance menu.

•

32

REQUEST VC PORT?—Choose one of the following:

•

Press the Enter button to configure an uplink port in an EX3300 switch or to delete a VCP from

•

the switch configuration.

NOTE: This option is available only for an EX3300 switch that is a member of a Virtual Chassis

configuration.

Press the Menu button to go to the next option in the Maintenance menu.

•

FACTORY DEFAULT?—Choose one of the following:

•

Press the Enter button to restore the switch to the factory default configuration. Press the Enter

•

button again to confirm the restoration.

Press the Menu button to go to the next option in the Maintenance menu.

•

ENTER EZSETUP?—Choose one of the following:

•

Press the Enter button to launch EZSetup. Press the Enter button again to confirm the launch.

•

NOTE: You can use the ENTER EZSETUP option only if the switch is in the factory default

configuration. For information about EZSetup, see “Connecting and Configuring an EX Series

Switch (J-Web Procedure)” on page 125.

Press the Menu button to go to the next option in the Maintenance menu.

•

EXIT MAINT MENU?—Choose one of the following:

•

Press the Enter button to exit the Maintenance menu. Then press the Menu button to go to the

•

Idle menu.

Press the Menu button to go to the System Halt option.

•

Page 33

Table 6: LCD Panel Menu Options (continued)

DescriptionMenu

If you do not want users to use Maintenance menu options, disable the entire menu or individual

menu options. See “Configuring the LCD Panel on EX Series Switches (CLI Procedure)” on page 129.

SEE ALSO

Connecting and Configuring an EX Series Switch (CLI Procedure) | 121

Chassis Status LEDs in EX3300 Switches

The front panel of an EX3300 switch has three chassis status LEDs labeled ALM, SYS, and MST on the far

right side of the panel, above the uplink ports (see Figure 6 on page 33).

33

You can view the colors of the LEDs remotely through the CLI by issuing the operational mode command

show chassis lcd.

Figure 6: Chassis Status LEDs in an EX3300 Switch

Table 7 on page 34 describes the chassis status LEDs in an EX3300 switch, their colors and states, and

the status they indicate.

Page 34

Table 7: Chassis Status LEDs in an EX3300 Switch

34

State and DescriptionColorLED Label

There is no alarm or the switch is halted.UnlitALM (Alarm)

Red

Amber

There is a major alarm.

NOTE: When you connect power to the switch, the Alarm

(ALM) LED lights red. This behavior is normal. Plugging

an active Ethernet cable into the management (MGMT)

port on the switch completes the network link and turns

off the ALM LED. (See “Connect a Device to a Network

for Out-of-Band Management” on page 110.)

Connecting the switch to a dedicated management

console instead of a network does not affect the ALM

LED. The LED remains red until the switch is connected

to a network.

There is a minor alarm.

NOTE: The Alarm (ALM) LED lights amber if you commit

a configuration to make it active on the switch and do not

also create a rescue configuration to back it up. To save

the most recently committed configuration as the rescue

configuration, enter the operational mode command

request system configuration rescue save.

GreenSYS (System)

GreenMST (Primary)

On steadily—Junos OS for EX Series switches has been

•

loaded on the switch.

Blinking—The switch is booting.

•

Off—The switch is powered off or is halted.

•

In a standalone EX3300 switch:

On steadily—The switch is functioning normally.

•

Off—The switch is powered off or is halted.

•

In a Virtual chassis configuration:

On steadily—The switch is the primary in the Virtual

•

Chassis configuration.

Blinking—The switch is the backup in the Virtual Chassis

•

configuration.

Off—The switch is a linecard member in the Virtual

•

Chassis configuration or is halted.

Page 35

A major alarm (red) indicates a critical error condition that requires immediate action.

g027006

Link/Activity

LED

Status

LED

A minor alarm (amber) indicates a noncritical condition that requires monitoring or maintenance. A minor

alarm that is left unchecked might cause interruption in service or performance degradation.

All three LEDs can be lit simultaneously.

SEE ALSO

Check Active Alarms with the J-Web Interface | 183

Understand Alarm Types and Severity Levels on EX Series Switches | 176

Management Port LEDs in EX3300 Switches

The management port on the rear panel of an EX3300 switch has two LEDs that indicate link/activity and

port status (see Figure 7 on page 35).

35

Figure 7: LEDs on the Management Port on an EX3300 Switch

Table 8 on page 35 describes the Link/Activity LED.

Table 8: Link/Activity LED on the Management Port on an EX3300 Switch

State and DescriptionColorLED

GreenLink/Activity

Blinking—The port and the link are active, and there is

•

link activity.

On steadily—The port and the link are active, but there

•

is no link activity.

Off—The port is not active.

•

Table 9 on page 36 describes the Status LED.

Page 36

Table 9: Status LED on the Management Port on an EX3300 Switch

012345678910111213141516171819202122

23

g027005

0

1

Link/Activity LED Status LED

g021204

Link/Activity

LED

Status

LED

Port 0

Port 2

Port 3

Port 1

0 1 2 3

ALM

EX3300 PoE+

SYS

MST

State and DescriptionLCD IndicatorLED

36

SPDStatus

Indicates the speed. The speed indicators are:

One blink per second—10 Mbps

•

Two blinks per second—100 Mbps

•

Three blinks per second—1000 Mbps

•

SEE ALSO

Connect a Device to a Network for Out-of-Band Management | 110

Network Port and Uplink Port LEDs in EX3300 Switches

Each network port and uplink port on the front panel of an EX3300 switch has two LEDs that indicate

link/activity and port status. See Figure 8 on page 36 and Figure 9 on page 36.

Figure 8: LEDs on the Network Ports on the Front Panel

Figure 9: LEDs on the Uplink Ports

Table 10 on page 37 describes the Link/Activity LED.

Page 37

Table 10: Link/Activity LED on the Network Ports and Uplink Ports in EX3300 Switches

State and DescriptionColorLED

37

GreenLink/Activity

Blinking—The port and the link are active, and there is link activity.

•

On steadily—The port and the link are active, but there is no link

•

activity.

Off—The port is not active.

•

The LEDs labeled Status LED in Figure 8 on page 36 and Figure 9 on page 36 indicate the status of one

of the four port parameters—speed, administrative status, duplex mode, and Power over Ethernet Plus

(PoE+) status. From the Idle menu of the LCD, use the Enter button on the LCD panel to toggle between

the SPD, ADM, DPX, and POE, indicators.

Table 12 on page 39 describes the Status LED on the network ports and table describes the Status LED

on the uplink ports.

Page 38

Table 11: Status LED on the Network Ports in EX3300 Switches

State and DescriptionLCD IndicatorLED

38

LED: SPDStatus

LED: ADM

LED: DPX

LED: POE

Indicates the speed.

The status indicators are:

Unlit—10 Mbps

•

Blinking—100 Mbps

•

On steadily—1000 Mbps

•

Indicates the administrative status. The status indicators

are:

On steadily—Port is administratively enabled.

•

Off—Port is administratively disabled.

•

Indicates the duplex mode.

The status indicators are:

Green—Port is set to full-duplex mode.

•

Unlit—Port is set to half-duplex mode.

•

Indicates the PoE status.

The status indicators are:

On steadily—PoE is available on the port.

•

Blinking—PoE is available on the port, but no power is

•

drawn from the port because of one of the following:

No device that draws power from the port is

•

connected to the port.

A device that draws power from the port is connected

•

to the port, but the device is not drawing any power

from the port.

Unlit—PoE is not enabled on the port.

•

Page 39

Table 12: Status LED on the Uplink Ports in EX3300 Switches

State and DescriptionLCD IndicatorLED

39

LED: SPDStatus

LED: ADM

LED: DPX

LED: POE

Indicates the speed.

The status indicators are:

Unlit—10/100 Mbps

•

Blinking—1000 Mbps

•

On steadily—10 Gbps

•

Indicates the administrative status. The status indicators

are:

On steadily—Port is administratively enabled.

•

Off—Port is administratively disabled.

•

Indicates the duplex mode.

The uplink ports are always set to full-duplex; therefore,

the LED for uplink ports is always green.

Indicates the PoE status.

PoE is not enabled on uplink ports; therefore, the LED for

uplink ports is always unlit.

EX3300 Cooling System

IN THIS SECTION

Airflow Direction in EX3300 Switch Models | 40

Front-to-Back Airflow | 40

Back-to-Front Airflow | 41

The cooling system in an EX3300 switch consists of two fans: one along the rear of the chassis and another

along the left side of the chassis. The fans provide front-to-back or back-to-front chassis cooling depending

on the switch model.

Page 40

Airflow Direction in EX3300 Switch Models

Table 13 on page 40 shows the different EX3300 switch models and their direction of airflow.

Table 13: Airflow Direction in EX3300 Switch Models

Direction of AirflowModel

Front-to-backEX3300-24T

Front-to-backEX3300-24P

Front-to-backEX3300-24T-DC

Front-to-backEX3300-48T

Back-to-frontEX3300-48T-BF

40

Front-to-backEX3300-48P

Front-to-Back Airflow

In front-to-back airflow models, the air intake is located on the front of the chassis. Cool air is pulled into

the chassis and pushed toward the rear of the chassis. Hot air exhausts from the rear of the chassis. See

Figure 10 on page 41.

Page 41

Figure 10: Front-to-Back Airflow Through the EX3300 Switch Chassis

g021205

Chassis rear

Chassis front

Fan

Fan

Air intake

Fan air

exhaust

Air intake

Air exhaust

41

Back-to-Front Airflow

In back-to-front airflow models, the air intake is located on the rear of the chassis. Cool air is pulled into

the chassis and pushed toward the front of the chassis. Hot air exhausts from the front of the chassis. See

Figure 11 on page 42.

Page 42

Figure 11: Back-to-Front Airflow Through the EX3300 Switch Chassis

g021247

Chassis rear

Chassis front

Fan

Fan

Air exhaust

Fan air

intake

Air exhaust

Air intake

42

Under normal operating conditions, the fans operate at moderate speeds for minimal noise. Temperature

sensors in the chassis monitor the temperature within the chassis. If any fan fails or if the temperature

inside the chassis rises above the threshold, the switch raises an alarm and all functioning fans operate at

a higher speed than normal. If the temperature inside the chassis rises above the threshold, the switch

shuts down automatically.

RELATED DOCUMENTATION

Clearance Requirements for Airflow and Hardware Maintenance for EX3300 Switches | 59

EX3300 Power System

IN THIS SECTION

Power Supply in EX3300 Switches | 43

Power Specifications for EX3300 Switches | 44

AC Power Cord Specifications for EX3300 Switches | 45

Page 43

Power Supply in EX3300 Switches

The power supply in EX3300 switches is built in along the rear panel of the chassis, with an AC power

cord inlet or DC power terminal block on the rear panel to connect power to the switch.

NOTE: After powering on the switch, wait for at least 60 seconds before powering it off. After

powering off the switch, wait for at least 60 seconds before powering it back on.

After the switch has been powered on, it can take up to 60 seconds for status indicators—such

as show chassis command output and messages on the LCD panel—to indicate that the power

supply is functioning normally. Ignore error indicators that appear during the first 60 seconds.

Table 14 on page 43 lists the power consumed by each EX3300 switch model. The maximum power

available on a PoE+ port is 30 W. The guranteed power is 25.5 W.

Table 14: Power Consumed by EX3300 Switches

43

SEE ALSO

Number of PoE-Enabled

PortsModel Number

24EX3300-24P

48EX3300-48P

Maximum Power

Consumed by the Switch

is drawn)

is drawn)

Maximum System Power

Available for PoE

–50 W–EX3300-24T

405 W60 W (when no PoE power

–50 W–EX3300-24T-DC

–76 W–EX3300-48T

–76 W–EX3300-48T-BF

740 W91 W (when no PoE power

Connecting AC Power to an EX3300 Switch | 104

Connecting DC Power to an EX3300 Switch | 106

Page 44

Power Specifications for EX3300 Switches

This topic describes the power supply electrical specifications for EX3300 switches.

Table 15 on page 44 provides the AC power supply electrical specifications for EX3300 switches.

Table 16 on page 44 provides the DC power supply electrical specifications for EX3300 switches.

Table 15: AC Power Supply Electrical Specifications for EX3300 Switches

SpecificationItem

100 through 240 VACAC input voltage

50 Hz/60 Hz nominalAC input line frequency

44

AC system current rating

7 A at 100 VAC and 2.9 A at 230 VAC (for switches with ports enabled

•

for PoE)

1.8 A at 100 VAC and 0.5 A at 230 VAC (for switches with no ports

•

enabled for PoE)

Table 16: DC Power Supply Electrical Specifications for EX3300 Switches

SpecificationItem

-43 through -75 VDCDC input voltage

2 A maximumDC input current

100 WPower supply output

1 ms minimumOutput holdup time

NOTE: For DC power supplies, we recommend that you provide at least 2.5 A at 48 VDC and

use a facility circuit breaker rated for 10 A minimum. Doing so enables you to operate the switch

in any configuration without upgrading the power infrastructure, and allows the switch to function

at full capacity using multiple power supplies.

Page 45

AC Power Cord Specifications for EX3300 Switches

A detachable AC power cord is supplied with the AC power supplies. The coupler is type C13 as described

by International Electrotechnical Commission (IEC) standard 60320. The plug at the male end of the power

cord fits into the power source outlet that is standard for your geographical location.

CAUTION: The AC power cord provided with each power supply is intended for use

with that power supply only and not for any other use.

NOTE: In North America, AC power cords must not exceed 4.5 meters in length, to comply with

National Electrical Code (NEC) Sections 400-8 (NFPA 75, 5-2.2) and 210-52 and Canadian

Electrical Code (CEC) Section 4-010(3). The cords supplied with the switch are in compliance.

45

Table 17 on page 45 gives the AC power cord specifications for the countries and regions listed in the

table.

Table 17: AC Power Cord Specifications

Juniper Model NumberPlug StandardsElectrical SpecificationsCountry/Region

CBL-EX-PWR-C13-ARIRAM 2073 Type RA/3250 VAC, 10 A, 50 HzArgentina

250 VAC, 10 A, 50 HzAustralia

SAA/3

Switzerland, and United

Kingdom)

CBL-EX-PWR-C13-AUAS/NZZS 3112 Type

CBL-EX-PWR-C13-BRNBR 14136 Type BR/3250 VAC, 10 A, 50 HzBrazil

CBL-EX-PWR-C13-CHGB 1002-1996 Type PRC/3250 VAC, 10 A, 50 HzChina

CBL-EX-PWR-C13-EUCEE (7) VII Type VIIG250 VAC, 10 A, 50 HzEurope (except Italy,

CBL-EX-PWR-C13-INIS 1293 Type IND/3250 VAC, 10 A, 50 HzIndia

Japan

CBL-EX-PWR-C13-ILSI 32/1971 Type IL/3G250 VAC, 10 A, 50 HzIsrael

CBL-EX-PWR-C13-ITCEI 23-16 Type I/3G250 VAC, 10 A, 50 HzItaly

CBL-EX-PWR-C13-JPSS-00259 Type VCTF125 VAC, 12 A, 50 Hz or 60

Hz

Page 46

Table 17: AC Power Cord Specifications (continued)

46

Juniper Model NumberPlug StandardsElectrical SpecificationsCountry/Region

Korea

Hz

250 VAC, 10 A, 50 HzSouth Africa

ZA/13

Taiwan

50 Hz

CBL-EX-PWR-C13-KRCEE (7) VII Type VIIGK250 VAC, 10 A, 50 Hz or 60

CBL-EX-PWR-C13-USNEMA 5-15 Type N5-15125 VAC, 13 A, 60 HzNorth America

CBL-EX-PWR-C13-SASABS 164/1:1992 Type

CBL-EX-PWR-C13-SZSEV 6534-2 Type 12G250 VAC, 10 A, 50 HzSwitzerland

CBL-EX-PWR-C13-TWNEMA 5-15P Type N5-15P125 VAC, 11 A and 15 A,

CBL-EX-PWR-C13-UKBS 1363/A Type BS89/13250 VAC, 10 A, 50 HzUnited Kingdom

Figure 12 on page 46 illustrates the plug on the power cord for some of the countries or regions listed in

Table 17 on page 45.

Figure 12: AC Plug Types

Page 47

2

CHAPTER

Site Planning, Preparation, and

Specifications

Site Preparation Checklist for EX3300 Switches | 48

EX3300 Site Guidelines and Requirements | 49

EX3300 Network Cable and Transceiver Planning | 61

EX3300 Management Cable Specifications and Pinouts | 68

EX3300 Virtual Chassis | 77

Page 48

Site Preparation Checklist for EX3300 Switches

The checklist in Table 18 on page 48 summarizes the tasks you need to perform when preparing a site for

EX3300 switch installation.

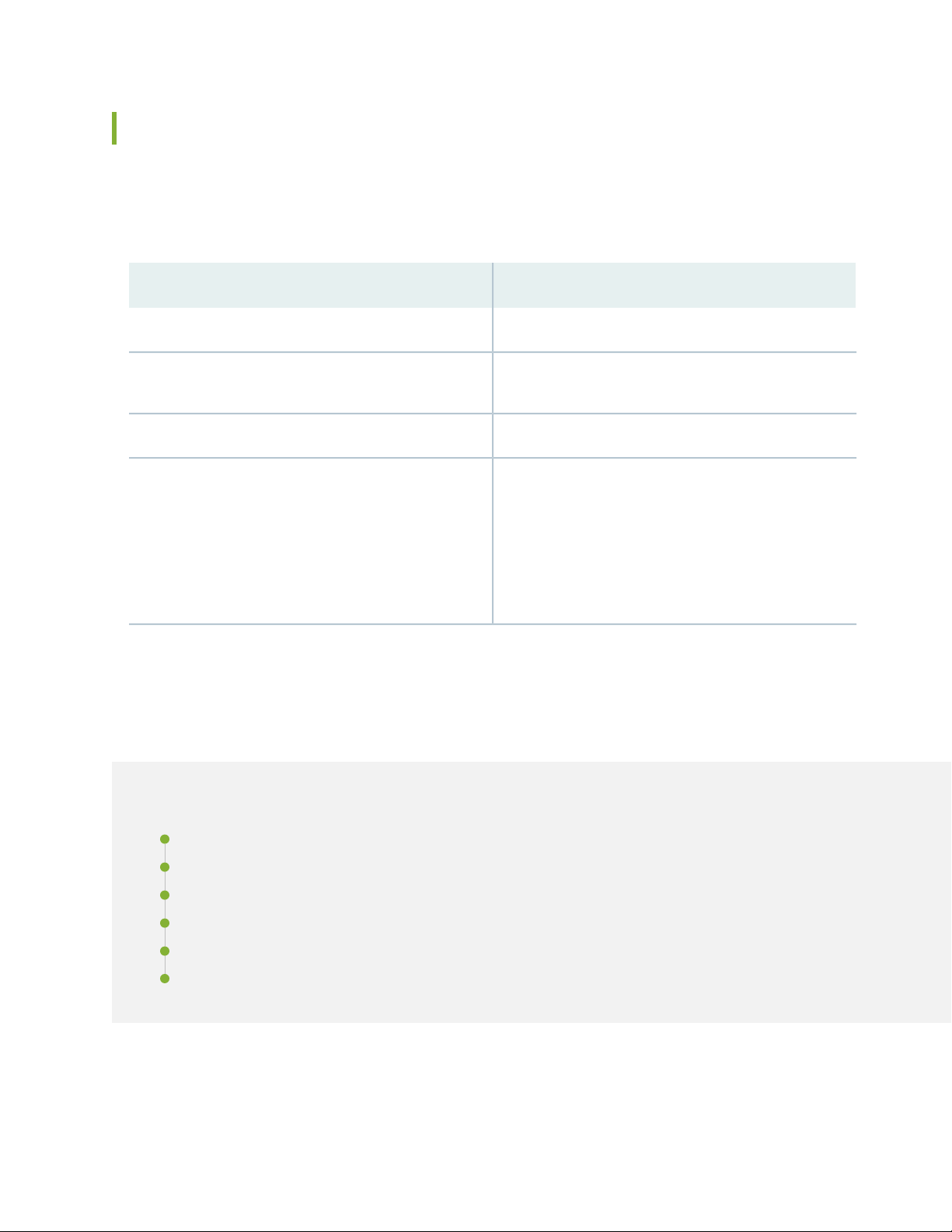

Table 18: Site Preparation Checklist

DatePerformed byFor More InformationItem or Task

Environment

48

Verify that environmental factors such as

temperature and humidity do not exceed

switch tolerances.

Power

Measure distance between external power

sources and switch installation site.

Locate sites for connection of system

grounding.

Calculate the power consumption and

requirements.

Hardware Configuration

Choose the number and types of switches

you want to install.

Rack or Cabinet

“Environmental Requirements and

Specifications for EX Series

Switches” on page 50

“Power Specifications for EX3300

Switches” on page 44

“EX3300 Switches Hardware

Overview” on page 18

Verify that your rack or cabinet meets the

minimum requirements for the installation

of the switch.

Plan rack or cabinet location, including

required space clearances.

Secure the rack or cabinet to the floor and

building structure.

“Rack Requirements” on page 56

“Cabinet Requirements” on

page 57

“Clearance Requirements for

Airflow and Hardware

Maintenance for EX3300

Switches” on page 59

Page 49

Table 18: Site Preparation Checklist (continued)

Wall

49

DatePerformed byFor More InformationItem or Task

Verify that the wall meets the minimum

requirements for the installation of the

switch.

Verify that there is appropriate clearance in

your selected location.

Cables

Acquire cables and connectors:

Determine the number of cables needed

•

based on your planned configuration.

Review the maximum distance allowed

•

for each cable. Choose the length of cable

based on the distance between the

hardware components being connected.

Plan the cable routing and management.

“Requirements for Mounting an

EX3300 Switch on a Desktop or

Wall” on page 58

“Clearance Requirements for

Airflow and Hardware

Maintenance for EX3300

Switches” on page 59

RELATED DOCUMENTATION

Installing and Connecting an EX3300 Switch | 85

EX3300 Site Guidelines and Requirements

IN THIS SECTION

Environmental Requirements and Specifications for EX Series Switches | 50

General Site Guidelines | 55

Site Electrical Wiring Guidelines | 55

Page 50

Rack Requirements | 56

Cabinet Requirements | 57

Requirements for Mounting an EX3300 Switch on a Desktop or Wall | 58

Clearance Requirements for Airflow and Hardware Maintenance for EX3300 Switches | 59

Environmental Requirements and Specifications for EX Series Switches

The switch must be installed in a rack or cabinet housed in a dry, clean, well-ventilated, and

temperature-controlled environment.

Ensure that these environmental guidelines are followed:

The site must be as dust-free as possible, because dust can clog air intake vents and filters, reducing the

•

efficiency of the switch cooling system.

50

Maintain ambient airflow for normal switch operation. If the airflow is blocked or restricted, or if the

•

intake air is too warm, the switch might overheat, leading to the switch temperature monitor shutting

down the switch to protect the hardware components.

Table 19 on page 50 provides the required environmental conditions for normal switch operation.

Table 19: EX Series Switch Environmental Tolerances

Environment Tolerance

Switch or

device SeismicTemperatureRelative HumidityAltitude

EX2200-C

No performance

degradation up to

5,000 feet (1524

meters)

Normal operation ensured

in the relative humidity

range 10% through 85%

(noncondensing)

Normal operation ensured

in the temperature range

32° F (0° C) through 104°

F (40° C) at altitudes up to

5,000 ft (1,524 m).

For information about

extended temperature SFP

transceivers supported on

EX2200 switches, see

Pluggable Transceivers

Supported on EX2200

Switches.

Complies with Zone

4 earthquake

requirements as per

GR-63, Issue 4.

Page 51

Table 19: EX Series Switch Environmental Tolerances (continued)

Environment Tolerance

Switch or

device SeismicTemperatureRelative HumidityAltitude

51

EX2200

(except

EX2200-C

switches)

EX2300-C

EX2300

(except

EX2300-C

switches)

EX3200

No performance

degradation up to

10,000 feet

(3048 meters)

No performance

degradation up to

5,000 feet

(1524 meters)

No performance

degradation up to

13,000 feet

(3962 meters) at

104° F (40° C) as

per GR-63

No performance

degradation up to

10,000 feet

(3048 meters)

Normal operation ensured

in the relative humidity

range 10% through 85%

(noncondensing)

Normal operation ensured

in the relative humidity

range 10% through 85%

(noncondensing)

Normal operation ensured

in the relative humidity

range 10% through 85%

(noncondensing)

Normal operation ensured

in the relative humidity

range 10% through 85%

(noncondensing)

Normal operation ensured

in the temperature range

32° F (0° C) through 113°

F (45° C)

Normal operation ensured

in the temperature range

32° F (0° C) through 104°

F (40° C)

Normal operation ensured

in the temperature range

32° F (0° C) through 113°

F (45° C)

Normal operation ensured

in the temperature range

32° F (0° C) through 113°

F (45° C)

Complies with Zone

4 earthquake

requirements as per

GR-63, Issue 4.

Complies with Zone

4 earthquake

requirements as per

GR-63, Issue 4.

Complies with Zone

4 earthquake

requirements as per

GR-63, Issue 4.

Complies with Zone

4 earthquake

requirements as per

GR-63, Issue 4.

EX3300

EX3400

EX4200

No performance

degradation up to

10,000 feet

(3048 meters)

No performance

degradation up to

10,000 feet

(3048 meters)

No performance

degradation up to

10,000 feet

(3048 meters)

Normal operation ensured

in the relative humidity

range 10% through 85%

(noncondensing)

Normal operation ensured

in the relative humidity

range 10% through 85%

(noncondensing)

Normal operation ensured

in the relative humidity

range 10% through 85%

(noncondensing)

Normal operation ensured

in the temperature range

32° F (0° C) through 113°

F (45° C)

Normal operation ensured

in the temperature range

32° F (0° C) through 113°

F (45° C)

Normal operation ensured

in the temperature range

32° F (0° C) through 113°

F (45° C)

Complies with Zone

4 earthquake

requirements as per

GR-63, Issue 4.

Complies with Zone

4 earthquake

requirements as per

GR-63, Issue 4.

Complies with Zone

4 earthquake

requirements as per

GR-63, Issue 4.

Page 52

Table 19: EX Series Switch Environmental Tolerances (continued)

Environment Tolerance

Switch or

device SeismicTemperatureRelative HumidityAltitude

52

EX4300

The

maximum

thermal

output for

EX4300-48T

is 423

BTU/hour

and for

EX4300-48P

is 5844

BTU/hour.

EX4500

EX4300 switches

except the

EX4300-48MP

model— No

performance

degradation up to

10,000 feet

(3048 meters)

EX4300-48MP

model— No

performance

degradation up to

6,000 feet

(1829 meters)

No performance

degradation up to

10,000 feet

(3048 meters)

EX4300 switches except

the EX4300-48MP

model— Normal operation

ensured in the relative

humidity range 10%

through 85%

(noncondensing)

EX4300-48MP model—

Normal operation ensured

in the relative humidity

range 5% through 90%

(noncondensing)

Normal operation ensured

in the relative humidity

range 10% through 85%

(noncondensing)

Normal operation ensured

in the temperature range

32° F (0° C) through 113°

F (45° C)

Normal operation ensured

in the temperature range

32° F (0° C) through 113°

F (45° C)

Complies with Zone

4 earthquake

requirements as per

GR-63, Issue 4.

Complies with Zone

4 earthquake

requirements as per

GR-63, Issue 4.

EX4550

No performance

degradation up to

10,000 feet

(3048 meters)

Normal operation ensured

in the relative humidity

range 10% through 85%

(noncondensing)

EX4550-32F switches—

•

Normal operation

ensured in the

temperature range 32°

F (0° C) through 113° F

(45° C)

EX4550-32T switches—

•

Normal operation is

ensured in the

temperature range 32°

F through 104° F (40° C)

Complies with Zone

4 earthquake

requirements as per

GR-63, Issue 4.

Page 53

Table 19: EX Series Switch Environmental Tolerances (continued)

Environment Tolerance

Switch or

device SeismicTemperatureRelative HumidityAltitude

53

EX4600

EX4650

No performance

degradation to

6,562 feet

(2000 meters)

No performance

degradation to

6,000 feet

(1829 meters)

Normal operation ensured

in the relative humidity

range 5% through 90%,

noncondensing

Short-term operation

•

ensured in the relative

humidity range 5%

through 93%,

noncondensing

NOTE: As defined in

NEBS GR-63-CORE,

Issue 4, short-term

events can be up to 96

hours in duration but

not more than 15 days

per year.

Normal operation ensured

in the relative humidity

range 10% through 85%

(condensing)

Normal operation

•

ensured in the

temperature range 32°

F (0° C) through 113° F

(45° C)

Nonoperating storage

•

temperature in shipping

container: – 40° F

(–40° C) through 158° F

(70° C)

Normal operation is ensured

in the temperature range

32° F (0° C) through 104°

F (40° C)

Complies with Zone

4 earthquake

requirements per

NEBS GR-63-CORE,

Issue 4.

Complies with Zone

4 earthquake

requirements as per

GR-63, Issue 4.

EX6210

EX8208

EX8216

No performance

degradation up to

10,000 feet

(3048 meters)

No performance

degradation up to

10,000 feet

(3048 meters)

No performance

degradation up to

10,000 feet

(3048 meters)

Normal operation ensured

in the relative humidity

range 10% through 85%

(noncondensing)

Normal operation ensured

in the relative humidity

range 10% through 85%

(noncondensing)

Normal operation ensured

in the relative humidity

range 10% through 85%

(noncondensing)

Normal operation is ensured

in the temperature range

32° F (0° C) through 104°

F (40° C)

Normal operation is ensured

in the temperature range

32° F (0° C) through 104°

F (40° C)

Normal operation is ensured

in the temperature range

32° F (0° C) through 104°

F (40° C)

Complies with Zone

4 earthquake

requirements as per

GR-63, Issue 4.

Complies with Zone

4 earthquake

requirements as per

GR-63, Issue 4.

Complies with Zone

4 earthquake

requirements as per

GR-63, Issue 4.

Page 54

Table 19: EX Series Switch Environmental Tolerances (continued)

Environment Tolerance

Switch or

device SeismicTemperatureRelative HumidityAltitude

54

EX9204

EX9208

EX9214

No performance

degradation up to

10,000 feet

(3048 meters)

No performance

degradation up to

10,000 feet

(3048 meters)

No performance

degradation up to

10,000 feet

(3048 meters)

Normal operation ensured

in the relative humidity

range 5% through 90%

(noncondensing)

Normal operation ensured

in the relative humidity

range 5% through 90%

(noncondensing)

Normal operation ensured

in the relative humidity

range 5% through 90%

(noncondensing)

Normal operation is ensured

in the temperature range

32° F (0° C) through 104°

F (40° C)

Nonoperating storage

temperature in shipping

container: – 40° F (–40° C)

to 158° F (70° C)

Normal operation is ensured

in the temperature range

32° F (0° C) through 104°

F (40° C)

Nonoperating storage

temperature in shipping

container: – 40° F (–40° C)

to 158° F (70° C)

Normal operation is ensured

in the temperature range

32° F (0° C) through 104°

F (40° C)

Complies with Zone

4 earthquake

requirements as per

GR-63.

Complies with Zone

4 earthquake

requirements as per

GR-63.

Complies with Zone

4 earthquake

requirements as per

GR-63.

EX9251

The

maximum

thermal

output is

1705

BTU/hour

(500 W).

No performance

degradation up to

10,000 ft (3048 m)

Normal operation ensured

in relative humidity range

of 5% to 90%,

noncondensing

Nonoperating storage

temperature in shipping

container: – 40° F (–40° C)

through 158° F (70° C)

Normal operation ensured

in temperature range of 32°

F (0° C) to 104° F (40° C)

Nonoperating storage

temperature in shipping

container: – 40° F (–40° C)

to 158° F (70° C)

Complies with

Telcordia

Technologies Zone

4 earthquake

requirements

Page 55

Table 19: EX Series Switch Environmental Tolerances (continued)

Environment Tolerance

Switch or

device SeismicTemperatureRelative HumidityAltitude

55

XRE200

No performance

degradation up to

10,000 feet

(3048 meters)

Normal operation ensured

in the relative humidity

range 10% through 85%

(noncondensing)

Normal operation ensured

in the temperature range

41° F (5° C) through 104°

F (40° C)

Complies with Zone

4 earthquake

requirements as per

GR-63, Issue 4.

NOTE: Install EX Series switches only in restricted areas, such as dedicated equipment rooms

and equipment closets, in accordance with Articles 110– 16, 110– 17, and 110– 18 of the

National Electrical Code, ANSI/NFPA 70.

General Site Guidelines

Efficient device operation requires proper site planning and maintenance and proper layout of the equipment,

rack or cabinet (if used), and wiring closet.

To plan and create an acceptable operating environment for your device and prevent environmentally

caused equipment failures:

Keep the area around the chassis free from dust and conductive material, such as metal flakes.

•

Follow prescribed airflow guidelines to ensure that the cooling system functions properly and that

•

exhaust from other equipment does not blow into the intake vents of the device.

Follow the prescribed electrostatic discharge (ESD) prevention procedures to prevent damaging the

•

equipment. Static discharge can cause components to fail completely or intermittently over time.