Page 1

E-series™ Routing Platforms

ERX™ Hardwa

Release 7.0.x

re Guide

Juniper Networks, Inc.

1194 North Mathilda Avenue

Sunnyvale, California 94089

USA

408-745-2000

www.juniper.net

Part Number: 162–xxxxx-00, Revision A00

Page 2

This product includes the Envoy SNMP Engine, developed by Epilogue Technology, an Integrated Systems Company. C opyright

© 1986-1997, Epilogue Technology Corporation. All rights reserved. This program and its documentation were developed

at private expense, and no part of them is in the public domain.

This product in

This product includes FreeBSD software developed by the University of California, Berkeley, and its contributors. All of the documentation and

software included in the 4.4BSD and 4.4BSD-Lite Releases is copyrighted by the Regents of the University of California. Copyright © 1979, 1980,

1983, 1986, 1988, 1989, 1991, 1992, 1993, 1994. The Regents of the University of California. All rights reserved.

GateD software copyright © 1995, the Regents of the University. All rights reserved. Gate Daemon was originated and developed through release

3.0 by Cornell University and its collaborators. Gated is based on Kirton’s EGP, UC Berkeley’s routing daemon (routed), and DCN’s HELLO routing

protocol. Development of Gated has been supported in part by the National Science Foundation. Portions of the GateD software copyright © 1988,

Regents of the University of California. All rights reserved. Portions of the GateD software copyright © 1991, D. L. S. Associates.

This product i

Juniper Networks, the Juniper Networks logo, NetScreen, NetScreen Technologies, the NetScreen logo, NetScreen-Global Pro, ScreenOS, and

GigaScreen are registered trademarks of Juniper Networks, Inc. in the United States and other countries.

The following are trademarks of Juniper Networks, Inc.: ERX, ESP, E-series, Instant Virtual Extranet, Internet Processor, J2300, J4300, J6300, J-Protect,

J-series, J-Web, JUNOS, JUNOScope, JUNOScript, JUNOSe, M5, M7i, M10, M10i, M20, M40, M40e, M160, M320, M-series, MMD, NetScreen-5GT,

NetScreen-5XP, NetScreen-5XT, NetScreen-25, NetScreen-50, NetScreen-204, NetScreen-208, NetScreen-500, NetScreen-5200, NetScreen-5400,

NetScreen-IDP 10, NetScreen-IDP 100, NetScreen-IDP 500, NetScreen-Remote Security Client, NetScreen-Remote VPN Client, NetScreen-SA 1000 Series,

NetScreen-SA 3000 Series, NetScreen-SA 5000 Series, NetScreen-SA Central Manager, NetScreen Secure Access, NetScreen-SM 3000, NetScreen-Security

Manager, NMC-RX, SDX, Stateful Signature, T320, T640, T-series, and TX Matrix. All other trademarks, service marks, registered trademarks, or

registered service marks are the property of their respective owners. All specifications are subject to change without notice.

Juniper Netw

change, mod

Copyright © 2005, Juniper Networks, Inc. All rights reserved.

E-series™ Routing Platforms ERX™ Hardware Guide, Release 7.0.x

Copyright © 2005, Juniper Networks, Inc.

All rights reserved. Printed in USA.

cludes memory allocation software developed by Mark Moraes, copyright © 1988, 1989, 1993, University of Toronto.

ncludes software developed by Maker Communications, Inc., Copyright © 1996, 1997, Maker Communications, Inc.

orks assumes no responsibility for any inaccuracies in this document. Juniper Networks reserves the right to

ify, transfer, or otherwise revise this publication without notice.

Writing: Jo

Editing: Be

Illustrati

Cover Design

Revision History

7 September 2004—Removed software installation chapter, 7.0.x

1 August 2004—Protocol and module combinations appendices moved to new book; minor updates, 6.0.0b1

17 September 2004—Minor updates, 6.0.0b2

1 November 2004—Minor updates, 6.0.x

15 December 2004—Minor updates, 6.1.0b1

7 February 2005—Beta draft, added HA blurb to SRP section, 6.1.0b2

7 March 2005—Updated rack illustrations, moved hw compliances and install guidelines to new Appendix, minor updates, 6.1.x

The information in this document is current as of the date listed in the revision history.

Juniper Netw

otherwise r

Products made or sold by Juniper Networks (including the ERX-310, ERX-705, ERX-710, ERX-1410, ERX-1440, M5, M7i, M10, M10i, M20, M40, M40e,

M160, M320, and T320 routers, T640 routing node, and the JUNOS and SDX-300 software) or components thereof might be covered by one or more of the

following patents that are owned by or licensed to Juniper Networks: U.S. Patent Nos. 5,473,599, 5,905,725, 5,909,440, 6,192,051, 6,333,650, 6,359,479,

6,406,312, 6,429,706, 6,459,579, 6,493,347, 6,538,518, 6,538,899, 6,552,918, 6,567,902, 6,578,186, and 6,590,785.

SOFTWARE LICENSE

The terms a

extent app

indicate t

Generally speaking, the software license restricts the manner in which you are permitted to use the software and may contain prohibitions against certain

uses. The software license may state conditions under which the license is automatically terminated. You should consult the license for further details.

hn Borelli, Helen Shaw

n Mann, Fran Mues

on: John Borelli

: Edmonds Design

orks assumes no responsibility for any inaccuracies in this document. Juniper Networks reserves the right to change, modify, transfer or

evise this publication without notice.

nd conditions for using this software are described in the software license contained in the acknowledgment to your purchase order or, to the

licable, to any reseller agreement or end-user purchase agreement executed between you and Juniper Networks. By using this software, you

hat you understand and agree to be bound by those terms and conditions.

Page 3

For complete product documentation, please see the Juniper Networks Web site at www.juniper.net/techpubs.

End User License Agreement

READ THIS END USER LICENSE AGREEMENT (“AGREEMENT”) BEFORE DOWNLOADING, INSTALLING, OR USING THE SOFTWARE. BY DOWNLOADING,

INSTALLING, OR USING THE SOFTWARE OR OTHERWISE EXPRESSING YOUR AGREEMENT TO THE TERMS CONTAINED HEREIN, YOU (AS CUSTOMER

OR IF YOU ARE NOT THE CUSTOMER, AS A REPRESENTATIVE/AGENT AUTHORIZED TO B IND THE CUSTOMER) CONSENT TO BE BOUND BY THIS

AGREEMENT. IF YOU DO NOT OR CANNOT AGREE TO THE TERMS CONTAINED HEREIN, THEN (A) DO NOT DOWNLOAD, INSTALL, OR USE THE

SOFTWARE, AND (B) YOU MAY CONTACT JUNIPER NETWORKS REGARDING LICENSE TERMS.

1. The Parties. The parties to this Agreement are Juniper Networks, Inc. and its subsidiaries (collectively “Juniper”), and the person or organization that

originally purchased from Juniper or an authorized Juniper reseller the applicable license(s) for use of the Software (“Customer”) (collectively, the “Parties”).

2. The Software. In this Agreement, “Software” means the program modules and features of the Juniper or Juniper-supplied software, and updates and

releases of such software, for which Customer has pai d the applicable license or support fees to Juniper or an authorized Juniper reseller.

3. License Grant. Subject to payment of the applicable fees and the limitations and restrictions set forth herein, Juniper grants to Customer a

non-exclusive and non-transferable license, without right to sublicense, to use the Software, in executable form only, s ubject to the following use restrictions:

a. Customer shall use the Software solely as embedded in, and for execution on, Juniper equipment originally purchased by Customer from Juniper or an

authorized Juniper reseller, unless the applicable Juniper documentation expressly permits installation on non-Juniper equipment.

b. Customer shall use the Software on a single hardware chassis having a single processing unit, or as many chassis or processing units for which

Customer has paid the applicable license fees.

c. Product purchase documents, paper or electronic user documentation, and/or the particular licenses purchased by Customer may specify limits to

Customer’s use of the Software. Such limits may restrict use to a maximum number of seats, registered endpoints, concurrent users, sessions, calls,

connections, subscribers, clusters, nodes, or transactions, or require the purchase of separate licenses to use particular features, functionalities, services,

applications, operations, or capabilities, or provide throughput, performance, configuration, bandwidth, interface, processing, temporal, or geographical

limits. Customer’s use of the Software shall be subject to a ll such limitations and purchase of all applicable licenses.

oing license is not transferable or assignable by Customer. No license is granted herein to any user who did not originally purchase the applicable

The foreg

(s) for the Software from Juniper or an authorized Juniper reseller.

license

4. Use Pr

not: (a)

necessa

propri

Softwa

featur

if suc

to any

Junip

equip

auth

5. Au

furn

6. Co

sha

res

7. O

ass

the

8.

th

se

PE

O

O

A

LAW, JUNIPER DISCLAIMS ANY AND ALL WARRANTIES IN AND TO THE SOFTWARE (WHETHER EXPRESS, IMPLIED, STATUTORY, OR OTHERWISE),

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR NONINFRINGEMENT. IN NO EVENT DOES

JUNIPER WARRANT THAT THE SOFTWARE, OR ANY EQUIPMENT OR NETWORK RUNNING THE SOFTWARE, WILL OPERATE WITHOUT ERROR OR

INTERRUPTION, OR WILL BE FREE OF VULNERABILITY TO INTRUSION OR ATTACK. In no event shall Juniper’s or its suppliers’ or licensors’ liability to

Customer, whether in contract, tort (including negligence), breach of warranty, o r otherwise, exceed the price paid by Customer for the Software that gave

rise to the claim, or if the Software is embedded in another Juniper product, the price paid by Customer for such other product. Customer acknowledges

and agrees that Juniper has set its prices and entered into this Agreement in reliance upon the disclaimers of warranty and the limitations of liabilityset

ohibitions. Notwithstanding the foregoing, the license provided herein does not permit the Customer to, and Customer agrees not to and shall

modify, unbundle, reverse engineer, or create derivative works based on the Software; (b) make unauthorized copies of the Software (except as

ry for backup purposes); (c) rent, sell, transfer, or grant any rights in and to any copy of the Software, in any form, to any third party; (d) remove any

etary notices, labels, or marks on or in any copy of the Software or any product in which the Software is embedded; (e) distribute any copy of the

re to any third party, including as may be embedded in Juniper equipment sold in the secondhand market; (f) use any ‘locked’ or key-restricted

e, function, service, application, operation, or capability without first purchasing the applicable license(s) and obtaining a valid key from Juniper, even

h feature, function, service, application, operation, or capability is enabled without a key; (g) distribute any key for the Software provided by Juniper

third party; (h) use the Software in any manner that extends or is broader than the uses purchased by Customer from Juniper or an authorized

er reseller; (i) use the Software on non-Juniper equipment where the Juniper documentation does not expressly pe rmit installation on non-Juniper

ment; (j) use the Software (or make it available for use) on Juniper equipment that the Customer did not originally purchase from Juniper or an

orized Juniper reseller; or (k) use the Software in any manner other than as expressly provided herein.

dit. Customer shall maintain accurate records as necessary to verify compliance with this Agreement. Upon request by Juniper, Customer shall

ish such records to Juniper and certify its compliance with this Agreement.

nfidentiality. The Parties agree that aspects of the Software and associated documentation are the confidential property of Juniper. As such, Customer

ll exercise all reasonable commercial efforts to maintain the Software and associated documentation in confidence, which at a minimum includes

tricting access to the Software to Customer employees and contractors having a need to use the Software for Customer’s internal business purposes.

wnership. Juniper and Juniper’s licensors, respectively, retain ownership of all right, title, and interest (including copyright) in and to the Software,

ociated documentation, and all copies of the Software. Nothing in this Agreement constitutes a transfer or conveyance of any right, title, or interestin

Software or associated documentation, or a sale of the Software, associated documentation, or copies of the Software.

Warranty, Limitation of Liability, Disclaimer of Warranty. The warranty applicable to the Software shall be as set forth in the warranty statement

at accompanies the Software (the “Warranty Statement”). Nothing in this Agreement shall give rise to any obligation to support the Software. Support

rvices may be purchased separately. Any such support shall be governed by a separate, written support services agreement. TO THE MAXIMUM EXTENT

RMITTED BY LAW, JUNIPER SHALL NOT BE LIABLE FOR ANY LOST PROFITS, LOSS OF DATA, OR COSTS OR PROCUREMENT OF SUBSTITUTE GOODS

R SERVICES, OR FOR ANY SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES ARISING OUT OF THIS AGREEMENT, THE SOFTWARE, OR ANY JUNIPER

R JUNIPER-SUPPLIED SOFTWARE. IN NO EVENT SHALL JUNIPER BE LIABLE FOR DAMAGES ARISING FROM UNAUTHORIZED OR IMPROPER USE OF

NY JUNIPER O R JUNIPER-SUPPLIED SOFTWARE. EXCEPT AS EXPRESSLY PROVIDED IN THE WARRANTY STATEMENT TO THE EXTENT PERMITTED BY

Page 4

forth herein, that the same reflect an allocation of risk between the Parties (including the risk that a contract remedy may fail of its essential purpose and

cause consequential loss), and that the same form an essential basis of the bargain between the Parties.

9. Term i na tio n. Any breach of this Agreement or failure by Customer to pay any applicable fees due shall result in automatic termination of the

license granted herein. Upon such termination, Customer shall destroy or return to Juniper all copies of the Software and related documentation in

Customer’s possession or control.

10. Taxes. All license fees for the Software are exclusive of taxes, withholdings, duties, or levies (collectively “Taxes”). Customer shall be responsible

for paying Taxes arising from the purchase of the license, or importation or use of the Software.

11 . Export. Customer agrees to comply with all applicable export laws and restrictions and regulations of any United States and any applicable foreign

agency or authority, and not to export or re-export the Software or any direct product thereof in violation of any such restrictions, laws or regulations, or

without all necessary approvals. Customer shall be liable for any such violations. The version of the Software supplied to Customer may contain encryption

or other capabilities restricting Customer’s ability to export the Software without an export license.

12. Commercial Computer Software. The Software is “commercial computer software” and is provided with restricted rights. Use, duplication, or

disclosure by the United States government is subject to restrictions set forth in this Agreement and as provided in DFARS 227.7201 through 227.7202-4,

FAR 12.212, FAR 27.405(b)(2), FAR 52.227-19, or FAR 52.227-14(ALT III) as applicable.

13. Interface Information.To the extent required by applicable law, and at Customer’s written request, Juniper shall provide Customer with the

interface information needed to achieve interoperability between the Software and another independently created program, on payment of applicable

fee, if any. Customer shall observe strict obligations of confidentiality with respect to such information and shall use such information in compliance

with any applicable terms and conditions upon which Juniper makes such information available.

14. Third Party Software.Any licensor of Juniper whose software is embedded in the Software and any supplier of Juniper whose products or technology

are embedded in (or services are accessed by) the Software sha ll be a third party beneficiary with respect to this Agreement, and such licensor or vendor

shall have the right to enforce this Agreement in its own name as if it were Juniper. In addition, certain third party software may be provided with the

Software and is subject to the accompanying license(s), if any, of its respective owner(s). To the extent portions of the Software are distributed under and

subject to open source licenses obligating Juniper to make the source code for such portions publicly available (such as the GNU General Public License

(“GPL”) or the GNU Library General Public License (“LGPL”)), Juniper will make such source code portions (including Juniper modifications, as appropriate)

available upon request for a period of up to three years from the date of distribution. Such request can be made in writing to Juniper Networks, Inc.,

1194 N. Mathilda Ave., Sunnyvale, CA 94089, ATTN: General Counsel. You may obtain a copy of the GPL at http://www.gnu.org/licenses/gpl.html, and a

copy of the LGPL at http://www.gnu.org/licenses/lgpl.html.

15. Miscellaneous. This Agreement shall be governed by the laws of the State of California without reference to its conflicts of laws principles. The

provisions of the U.N. Convention for the International Sale of Goods shall not apply to this Agreement. For any disputes arising under this Agreement,the

Parties hereby consent to the personal and exclusive jurisdiction of, and venue in, the state and federal courts within Santa Clara County, California.

This Agreement constitutes the entire and sole agreement between Juniper and the Customer with respect to the Software, and supersedes all prior and

contemporaneous agreements relating to the Software, whether oral or written (including any inconsistent terms contained in a purchase order), except

that the terms of a separate written agreement executed by an authorized Juniper representative and Customer shall govern to the extent such terms are

inconsistent or conflict with terms contained herein. No modification to this Agreement nor any waiver of any rights hereunder shall be effective unless

expressly assented to in writing by the party to be charged. If any portion of this Agreement is held invalid, the Parties agree that such invalidity shall not

affect the validity of the remainder of this Agreement. This Agreement and associated documentation has been written in the English language, and

the Parties agree that the English version will govern. (For Canada: Les parties aux présentés confirment leur volonté que cette convention de même

que tous les documents y compris tout avis qui s’y rattaché, soient redigés en langue anglaise. (Translation: The parties confirm that this Agreement

and all related documentation is and will be in the English language)).

Page 5

Table of Cont

ents

About This G

Objectives ............................................................................ xi

Audience..............................................................................xi

E-series Routers..................................................................... xii

Documentation Conventions ...................................................... xii

List of Technical Publications ......................................................xiv

Obtaining Documentation ......................................................... xv

Documentation Feedback.......................................................... xv

Requesting Support.................................................................xvi

Part 1

Chapter 1 E-series Ove

Installing and Using E-series Routers

Overview ..............................................................................3

Where E-series Routers Fit In ........................................................3

E-series Routers.......................................................................5

ERX-14xx Models................................................................5

ERX-7xx Models .................................................................7

ERX-310 Router ..................................................................9

E-series Modules.................................................................... 10

SRP Module......................................................................11

Module Details............................................................. 13

SRP Module Redundancy................................................. 14

Nonvolatile Storage ....................................................... 14

SRP I/O Module ................................................................ 14

Module Details............................................................. 15

Line Modules ................................................................... 15

Packet Classification ...................................................... 16

I/O Modules .................................................................... 16

Network Management Tools ....................................................... 17

CLI Management............................................................... 17

SNMP MIB Management ...................................................... 17

NMC-RX Device Management System ....................................... 17

Redundancy Features............................................................... 17

SRP Modules ................................................................... 17

NVS Cards.................................................................. 18

Line Modules ................................................................... 18

Power ........................................................................... 20

Fans ............................................................................. 21

uide

rview

xi

3

Table of Contents v

Page 6

ERX 7.0.x Hardware Guide

Chapter 2 Unpacking and Inspecting E-series Routers

Before You Begin.................................................................... 23

Unpacking ERX-14xx Models ...................................................... 23

Unpacking ERX-7xx Models and ERX-310 Routers .............................. 24

Inspecting E-series Router Components and Accessories ....................... 25

If You Detect or Suspect Damage ................................................. 25

Contacting Juniper Networks ...................................................... 25

The Next Step ....................................................................... 26

Chapter 3 Installing E-series Routers

Before You Begin.................................................................... 27

Freestanding Installation ........................................................... 27

Rack-Mounted Installation ......................................................... 28

Installation Guidelines ......................................................... 28

Safety Guidelines............................................................... 30

Preparing the Equipment Racks .............................................. 32

Installing the Router ........................................................... 32

The Next Step ....................................................................... 33

Chapter 4 Installing Modules

23

27

35

Overview ............................................................................ 35

Slot Groups ..................................................................... 36

Slot Groups for the ERX-1410 Router .................................... 36

Slot Groups for the ERX-7xx Models..................................... 37

Combinations of Line Modules In Slot Groups............................... 38

OC48 Line Modules............................................................ 38

GE-2 Line Modules............................................................. 38

Managing Modules Using the Software....................................... 38

Hot-Swapping Modules........................................................ 38

Protecting Modules and Slots ................................................. 38

Order of Installation ........................................................... 40

Required Tools and Safety Items ............................................. 40

Safety Guidelines ................................................................... 40

Installing SRP I/O and SRP Modules............................................... 41

Installing an SRP I/O Module.................................................. 42

Installing an SRP Module...................................................... 42

Installing Line and I/O Modules.................................................... 44

Installing a Line Module or an I/O Module ................................... 44

Removing a Line Module, SRP Module, or SRP I/O Module ..................... 45

Installing Components for Line Module Redundancy............................ 47

Installing the Line Modules....................................................47

Installing the Redundancy Midplane ......................................... 48

Installing the I/O Modules ..................................................... 49

Verifying the Installation ...................................................... 50

Configuring Line Module Redundancy ............................................ 50

The Next Step ....................................................................... 50

vi Table of Contents

Page 7

Table of Contents

Chapter 5 Cabling E-series Routers

Cabling Overview................................................................... 51

Required Tools, Wires, and Cables ................................................ 53

Cabling the SRP I/O Module ....................................................... 54

External Timing Ports ......................................................... 54

Management Ports ............................................................ 57

Connecting to the Network............................................... 58

Connecting to a Console Terminal ....................................... 58

Cabling the E-series Router for Power............................................. 58

Task 1: Turn Off All E-series Router Power................................... 61

Task 2: Connect the Grounding Cables....................................... 61

Task 3: Connect the Power Cables............................................ 61

ERX-7xx models, ERX-14xx models, ERX-310 router (DC model) .... 61

ERX-310 router (AC model)............................................... 63

Cabling I/O Modules ................................................................ 64

BNC Connectors................................................................ 64

HSSI Connectors ............................................................... 64

RJ-45 Connectors...............................................................65

RJ-48C Connectors ............................................................. 65

LC Duplex Connectors ......................................................... 66

SC Duplex Connectors......................................................... 66

SMB Connectors................................................................ 68

X.21/V.35 Connectors.......................................................... 69

Redundant Ports ............................................................... 70

The Next Step ....................................................................... 70

51

Chapter 6 Powering Up E-series Routers

Before You Power Up the System.................................................. 71

Powering Up......................................................................... 71

Initialization Sequence ........................................................ 72

Status LEDs.......................................................................... 73

Powering Down ..................................................................... 73

The Next Step ....................................................................... 73

Chapter 7 Accessing E-series Routers

Setting Up Management Access ................................................... 75

Console Port Setup ................................................................. 76

Using HyperTerminal ......................................................... 76

Connecting Directly to the E-series Router .................................. 76

Assigning an IP Address ....................................................... 78

Telnet Setup ......................................................................... 78

SNMP ................................................................................ 80

The Next Step ....................................................................... 80

Chapter 8 Maintaining E-series Routers

Required Tools and Items .......................................................... 81

Storing Modules and Components ................................................ 82

71

75

81

Table of Contents vii

Page 8

ERX 7.0.x Hardware Guide

Cleaning the System................................................................ 82

Upgrading NVS Cards on SRP Modules ........................................... 83

Upgrading a System That Contains One SRP Module....................... 83

Upgrading a System That Contains Two SRP Modules ...................... 84

Replacing an NVS Card ........................................................ 85

Upgrading Memory on SRP Modules.............................................. 86

Checking the Memory Installed............................................... 87

Removing SODIMMs........................................................... 87

Adding New SODIMMs ........................................................ 87

Verifying the Upgrade ......................................................... 89

Replacing SFPs on GE I/O Modules................................................ 89

Removing SFPs................................................................. 89

Installing SFPs.................................................................. 90

Verifying the Installation ...................................................... 93

Replacing Fan Trays ................................................................ 93

Removing the Fan Tray ........................................................ 95

Installing the Fan Tray ........................................................95

Installing a Cable-Management Bracket on ERX-7xx Models ................... 96

Chapter 9 Troubleshooting

Diagnosing Problems............................................................... 99

Initialization Sequence ........................................................ 99

Troubleshooting Power Failures...................................................100

Understanding Status LEDs to Troubleshoot.....................................100

LED Identification............................................................. 101

LED Activity ...................................................................106

Redundancy Status ...........................................................109

Monitoring Temperatures of Modules............................................109

Resetting Line Modules and SRP Modules ....................................... 110

Double-Bit Errors on SRP Modules ............................................... 110

Detecting Double-Bit Errors .................................................. 110

Fixing Double-Bit Errors...................................................... 111

Chapter 10 System Specifications

ERX-14xx Models Specifications ................................................. 113

ERX-7xx Models Specifications...................................................116

ERX-310 Router Specifications ................................................... 119

Part 2

Appendixes

99

113

Appendix A Installation Guidelines and Requirements

Your Preinstallation Responsibilities .............................................125

Environmental Requirements.....................................................126

Regulatory Compliances ..........................................................126

Safety Guidelines ..................................................................126

viii Table of Contents

125

Page 9

Table of Contents

ERX-310 Power Cord Warnings (AC Model) .................................128

Equipment Rack Requirements...................................................128

Mechanical Requirements....................................................130

Space Requirements..........................................................130

Proper Rack Installation ......................................................130

Cabling Recommendations .......................................................131

Hardware Compliance.............................................................132

Federal Communications Commission (FCC) Statement ..................132

FCC Requirements For Consumer Products ................................133

Food and Drug Administration, Center for Devices and Radiological

Health..........................................................................133

Canadian Department Of Communications Radio Interference

Regulations ....................................................................133

Réglement sur le brouillage radioélectrique du ministère des

communications ..............................................................133

Industry Canada Notice CS-03...............................................133

Avis CS-03 d’Industrie Canada...............................................134

D.O.C. Explanatory Notes: Equipment Attachment Limitations ..........135

Notes explicatives du ministère des Communications: limites visant les

accessoires ....................................................................135

EC Declaration of Conformity................................................136

Voluntary Control Council for Interference (VCCI) Statement for Japan ..136

Appendix B Cable Pinouts

SRP I/O Module ....................................................................13

CT1andCE1I/OMod

Appendix C Customer Support

Contacting Customer Support ....................................................145

Return Procedure ..................................................................145

Locating Component Serial Numbers ...........................................146

Information You Might Need to Supply to JTAC .................................147

Tools and Parts Required..........................................................148

Returning Products for Repair or Replacement .................................148

Packing Instructions for Returning a Chassis ...............................148

Appendix D Declaration of Conformity

Declaration of Conformity ........................................................151

Part 3

Index

Index................................................................................155

ules.........................................................140

137

7

145

151

Table of Contents ix

Page 10

ERX 7.0.x Hardware Guide

x Table of Contents

Page 11

About This Gu

This preface p rovides the following guidelines for using this m anual and related

Juniper Networks, Inc., technical documents:

Objectives on p age xi

ide

Objective

Audience on

E-series Routers on page xii

Documentation Conventions on page xii

List of Tech

Obtaining Doc um entation on page xv

Documentation Feedback on page xv

Requesting

page xi

nical Publications on page xiv

Support on page xvi

s

This E-seri

to install and start the E -series router.

NOTE: An E-s

install a fu tu re release or reinstall the system software, see Appendix B, Installing

JUNOSe Software.

If the information in the latest Release Notes differs from the information in

this guide

es™ Routing Platforms Hardware Guide provides the information you need

eries router is shipped with the latest system software installed. To

, follow the Release Notes.

Audience

This guide

E-series routers in an Internet access environment.

is intended for experienced system and network specialists working with

Audience xi

Page 12

ERX 7.0.x Hardware Guide

To use this guide, you need a broad understanding of networks in general, the

Internet in pa

also be familiar with one or more of the following Internet routing protocols:

Border Gateway Protocol (BGP)

Routing Information Protocol (RIP)

Intermediate System-to-Intermediate System (IS-IS)

Open Shortest Path First (OSPF)

Internet Control Message Protocol (ICMP) router discovery

Internet Group Management Protocol (IGMP)

Distance Vector Multicast Routing Protocol (DVMRP)

Protocol-Independent Multicast (PIM)

rticular, networking principles, and network configuration. You m ust

E-series Routers

Multiprotocol Label Switching (MPLS)

Resource Reservation Protocol (RSVP)

Simple Network Management Protocol (SNMP)

Five models of E-series routers are available:

ERX-1440 router

ERX-1410 router

ERX-710 router

ERX-705 router

ERX-310 router

All models use the same software. For information about the differences between

themodels,seetheE-seriesHardwareGuide.

In the E-series documentation, the term ERX-14xx models refers to both th e

ERX-1440 ro

refers to both the ERX-710 router and the ERX-705 router. Other E-series router

designations refer to specific models.

uter and the ERX-1410 router. Similarly, the term ERX-7xx models

Documentation Conventions

Table 1 defines the notice icons used in this guide.

xii Documentation Conventions

Page 13

Table 1: Notice Icons

Icon Meaning Description

Informational note Indicates important features or

instructions.

Caution

Indicates a situation that might result in

loss of data or hardware damage.

About This Guide

Table 2 defin

Warning

es text conventions used in this guide and the command syntax

Alertsyoutotheriskofpersonalinjury

or death.

conventions used primarily in the JUNOSe Command Reference Guide.Formore

information about command syntax, see the JUNOSe System Basics Configuration

Guide, Chap

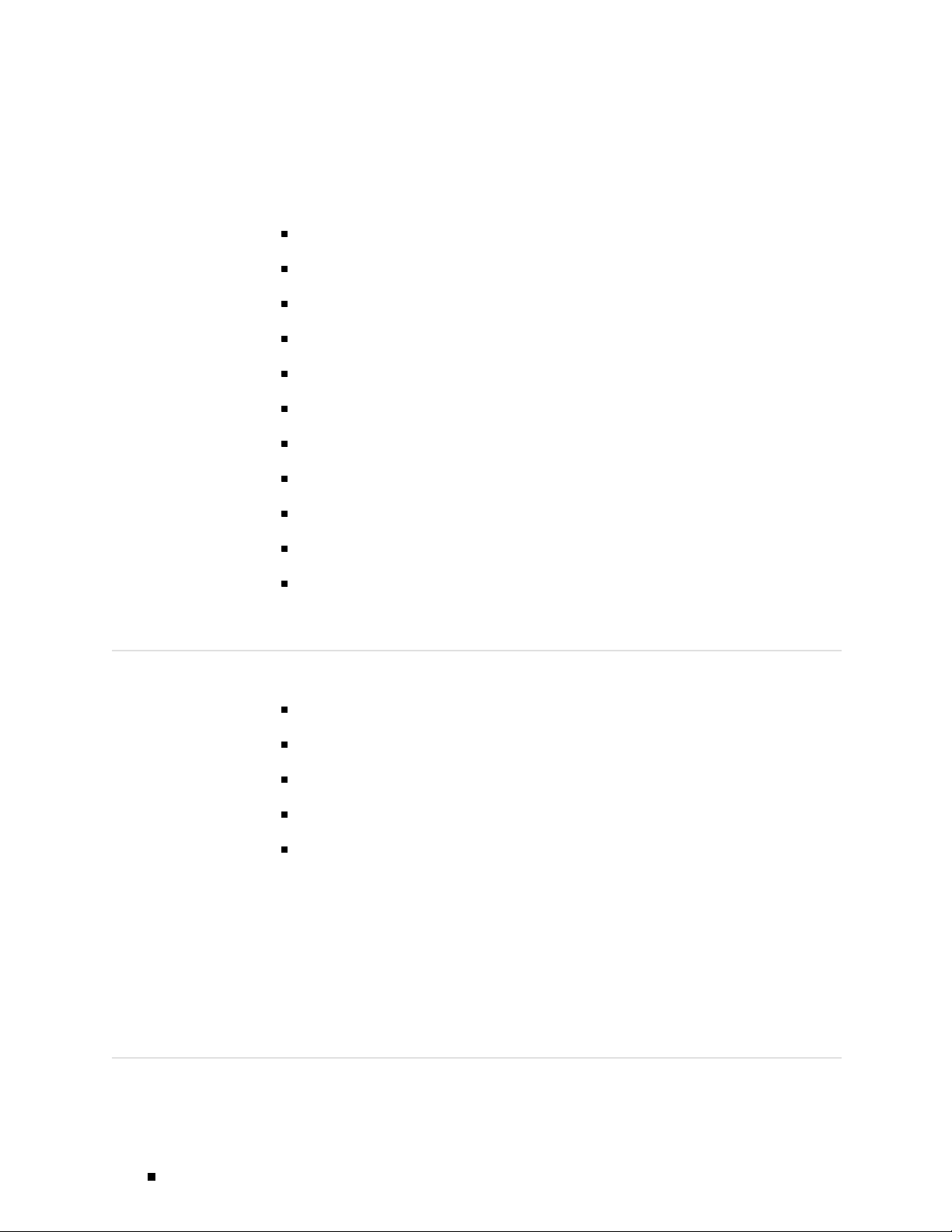

Table 2: Tex

Convention Description Examples

Text Conventions

Bold typeface Represents names of commands and

Bold sans serif typeface

Fixed-width typeface

Italic ty

+ (plus sign) linking key names Indicates that you must press two or

Syntax Conventions in the Command Reference Guide

Plain typeface Represents keywords. terminal length

Italic typeface

|(pipesymbol)

[ ] (square brackets) Enclose an optional choice of a single

t and Syntax Conventions

peface

ter 2, Command Line Interface.

keywords in text.

Represents text that you must type.

Represents output on the term i nal

screen.

Emphasizes words.

Identifies variables.

Identifies chapter, appendix,

and book names.

more keys simultaneously.

Represents variables.

Indicates a choice between the

keywords or variables on either side of

the symbol. (Specifying a choice can be

either optional or required.)

keyword or variable.

Issue the clock source

command.

Specify the keyword exp-msg.

host1(config)#traffic class low-loss1

host1#show ip community list

Community standard list 1

permit 0:100 0:200 0:300

There are two levels of access,

user and privileged .

clusterId , ipAddress.

Appendix A, System

Specifications.

Press Ctrl+b.

mask , accessListName

diagnostic | line

[ internal | external ]

Documentation Conventions xiii

Page 14

ERX 7.0.x Hardware Guide

Convention Description Examples

[ ]* (square brackets and the asterisk) Enclose an optional choice of one or

more keywords or variables.

{}(braces)

Enclosearequ

keyword or variable.

ired choice of a single

[level1|level2|l1]*

{ permit | deny } { in | out }

{ clusterId | ipAddress }

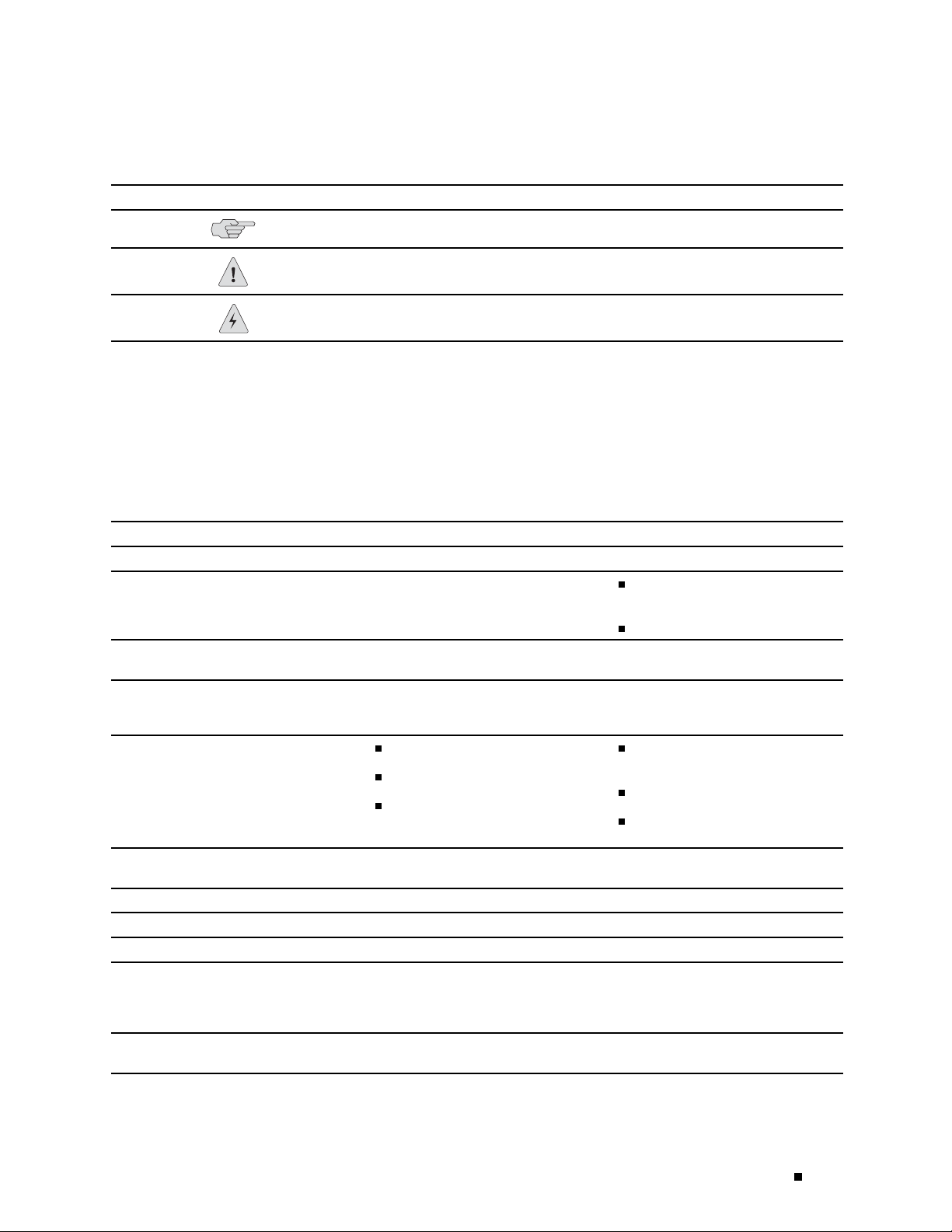

List of Technical Publications

Table 3 lists and describes the E-series document set. A complete list of

abbreviations used in this document set, along with their spelled-out terms, is

provided in the JUNOSe System Basics Configuration Guide, Appendix A, Abbreviations

and Acronyms .

Table 3: Juniper Networks E-series Technical Publications

Document Description

E-series Hardware Guide

E-series Module Guide

JUNOSe System Basics Configuration Guide

JUNOSe Physical Layer Configuration Guide

JUNOSe Link Layer Configuration Guide

JUNOSe Routing Protocols Configuration Guide, Vol. 1

JUNOSe Routing Protocols Configuration Guide, Vol. 2

JUNOSe Policy and QoS Configuration Guide

JUNOSe Broadband Access Configuration Guide

Provides the necessary procedures for getting the router

operational, including information on installing, cabling,

powering up, configuring the router for management access,

and general troubleshooting. Describes SRP modules, line

modules, and I/O modules available for the E-series routers.

Provides detailed specifications for line modules and I/O

modules, and information about the compatibility of these

modules with JUNOSe software releases. Lists the layer

2 protocols, layer 3 protocols, and applications that line

modules and their corresponding I/O modules support.

Provides module LED information.

Describes planning and configuring your network, installing

JUNOSe software, managing the router, configuring

passwords and security, configuring the router clock, and

configuring virtual routers. Includes a list of references that

provide information on the protocols and features supported

by the router.

Describes configuring physical layer interfaces.

Describes configuring link layer interfaces.

Provides information about configuring routing policy and

configuring IP, IP routing, and IP security.

Describes BGP routing, MPLS, BGP-MPLS VPNs, and

encapsulation of layer 2 services.

Provides information about configuring policy management

and qua

Provides information about configuring remote access.

lity of service (QoS).

xiv List of Technical Publications

Page 15

Document Description

JUNOSe Command Reference Guide

AtoM

JUNOSe Command Reference Guide N to Z

JUNOSe Comprehensive Index

Release Note

JUNOSe Release Notes

s

Together comprise the JUNOSe Command Reference

Guide. Contain important information about commands

implemented in the system software. Use to look up

command descriptions, command syntax, a command’s

related mode, or a description of a command’s parameters.

Use with the JUNOSe configuration guides.

ProvidesacompleteindexoftheJUNOSesoftware

documentation set.

In the Release Notes, you will find the latest information about

features, changes, known problems, resolved problems,

and system maximum values. If the information in the

Release Notes differs from the information found in the

documentation set, follow the Release Notes.

Release notes are included on the corresponding software CD

and are available on the Web.

About This Guide

Obtaining Documentation

To obtain the most current version of all Juniper Networks technical documentation,

see the products documentation page on the Juniper Networks Web site at

http://www.juniper.net/.

To order printed copies of this guide and other Juniper Networks technical

documents, or to order a documentation CD, which contains this guide, contact

your sales representative.

Copies of the Management Information Bases (MIBs) available in a software release

are included on the documentation CDs and at

Documentation Feedback

We encourage you to provide feedback, comments, and suggestions so

that we can improve the documentation. You can send your comments to

techpubs-comments@juniper.net, or fill out the documentation feedback form at

http://www.juniper.net/techpubs/docbug/docbugreport.html. If you are using e-mail, be

sure to include the following information with your comments:

Document nam e

Document part number

http://www.juniper.net/.

Page number

Software release version

Documentation Feedback xv

Page 16

ERX 7.0.x Hardware Guide

Requesting Suppor t

For technical support, open a support case with the Case Manager link at

http://www.j

uniper.net/support/

or call 1-888-314-JTAC (from the United States,

Canada, or Mexico) or 1-408-745-9500 (from elsewhere).

xvi Requesting Support

Page 17

Part 1

Installing and Using E-series Routers

E-series O verview on page 3

Unpacking an

Installing E-series Routers on page 27

Installing Modules on page 35

Cabling E-se

Powering Up E-series Routers on page 71

Accessing E-series Routers on page 75

Maintainin

Troubleshooting on page 99

System Specific ati ons on page 11 3

d Inspecting E-series Routers on page 23

ries Routers on p age 51

g E-series Routers on page 81

Installing and Using E-series Routers 1

Page 18

2 Installing and Using E-series Routers

Page 19

Chapter 1

E-series Ove

This chapter provides introductory information about the E-series routers. It

contains the following sections:

Overview on page 3

Where E-ser

E-series Routers on page 5

E-series Modules on page 10

Network Man

Redundancy Features on page 17

Overview

E-series routers are modular, carrier-class networking devices that deliver

performance, reliability, and service differentiation to both business and

consumer I

low power consumption, and fully redundant Internet access routing and

edge aggregation. The ERX-310 router supports the same services, but

with small

complete edge solution for IP-optimized carriers.

rview

ies Routers Fit In on page 3

agement Tools on page 17

nternet users. The ERX-7xx/14xx models offer high port density,

er capacity and scaling capabilities. E-series routers offer the

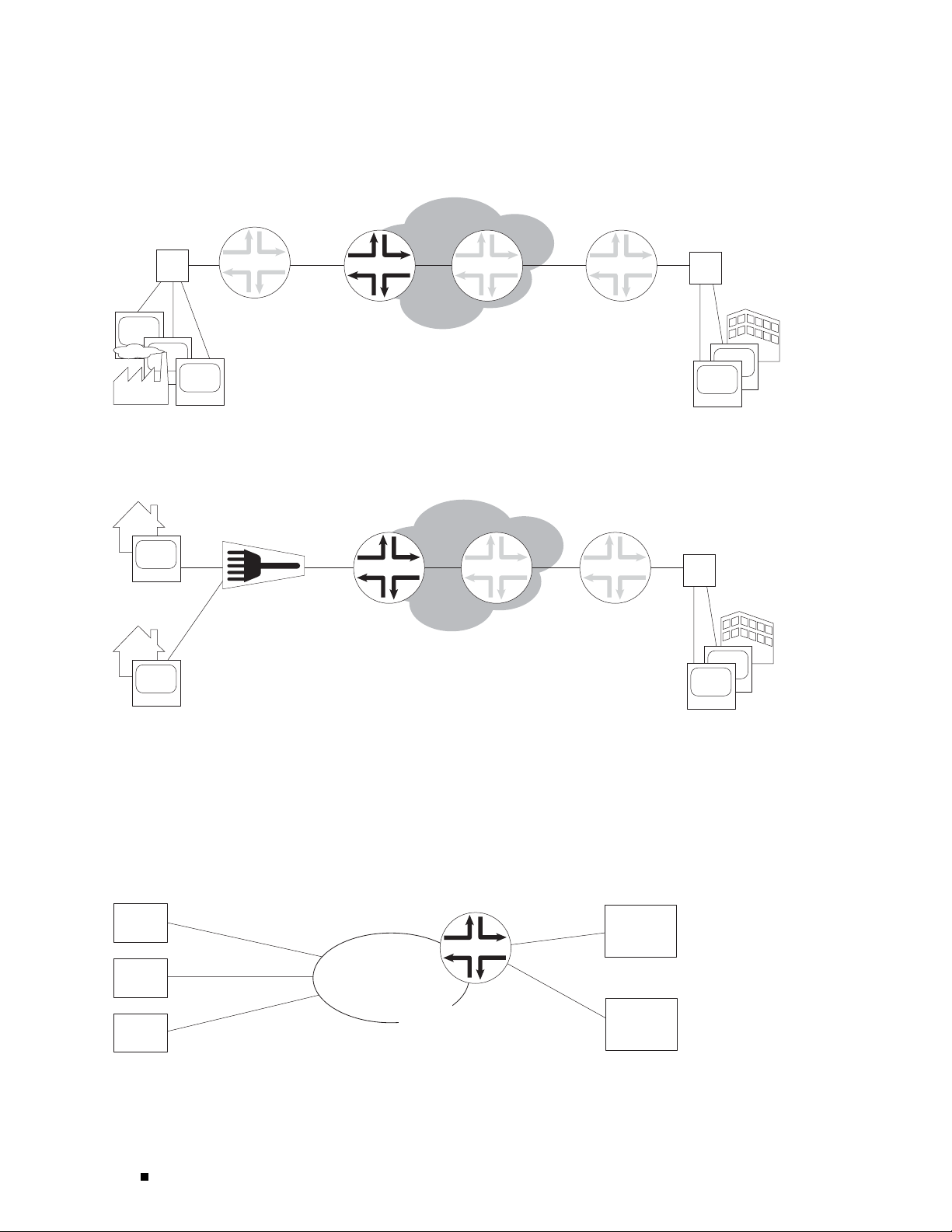

Where E-s

eries Routers Fit In

Communic

and Figure 2 illustrate the location of E-series routers as an edge router in

an end-to-end Internet network. In Figure 1, the customers are businesses

using T1/

subscriber lines (DSLs) with a DSL access multiplexer (DS LAM ).

ations with the router can take place over a variety of media. Figure 1

T3 communication lines. In Figure 2, the customers are using digital

Where E-series Routers Fit In 3

Page 20

ERX 7.0.x Hardware Guide

Figure 1: E-series Router Communicating over T1/T3 Lines

Internet

Hub

Remote

access

router

PC

Desktop

T1/T3

ERX

OC3

Core

router

Figure 2: E-series Router Communicating over DSL Lines

Internet

PC

Home office

PC

DSLAM

DS3

ERX

OC3

Core

router

Remote

access

router

Remote

access

router

Hub

PC

Desktop

Hub

PC

g013033

Home office

Figure

CPE

CPE

CPE

In Figure 3, the ERX-310 router is being used as an access router in a

small POP location. The router is deployed by the service provider at the

custom

3: ERX-310 Router Deployed in a Small POP

xDSL

T1/E1

T3/E3

GE

er site as a CPE (customer premises equipment).

SONET or ATM

infrastructure

GE

OC3/12

cOC3

cOC12

ERX

GE

OC3

VPN

ISP

Desktop

g013726

g013034

4 Where E-series Routers Fit In

Page 21

E-series Routers

E-series Overview

Five models of E-series routers are available:

ERX-1440 router

ERX-1410 router

ERX-710 router

ERX-705 router

ERX-310 router

All models use the same software. However, the specific model determines the:

Combination of line modules supported

Conditions for line rate performance of line modules

ERX-14xx Models

Type, capacity, and number of SRP modules used

NOTE: In the Ethe ERX-1440 router and the ERX-1410 router. The terms ERX-1440 router and

ERX-1410 router refer to the specific models. See Figure 4 and Figure 5.

The ERX-1440 router manages an extremely high volume of network traffic,

and uses a 40-Gbps switch route p rocessor (SRP) mo du le, either the SRP-40G or

SRP-40G+ mod

however, the software continues to support both modules.) In this model, all

line modules operate at full wire speed simultaneously.

The ERX-1410 router manages high levels of network traffic, and uses the 10-Gbps

SRP module (S

line m odule s either to operate a t full line rate performance or to allow line

modules to operate at a rate dependent on the resources available. The former

option rest

configuring performance of line modules, see JUNOSe System Basics Configuration

Guide, Chapter 5, Managing Lin e Modules and SRP M odules.

NOTE: Th e 10

10-Gbps SRP module used in the ERX-1410 router. See section “SRP Module” on

page 11 for more in formation.

series documentation, the term ERX-14xx models refers to both

ule. (The SRP-40G+ module obsoletes the SRP-40G module;

RP-10G). You can configure the ERX-1410 router to enable the

ricts the allowed combination s of line modules. For information on

-Gbps SRP module used in the ERX-310 router is different from the

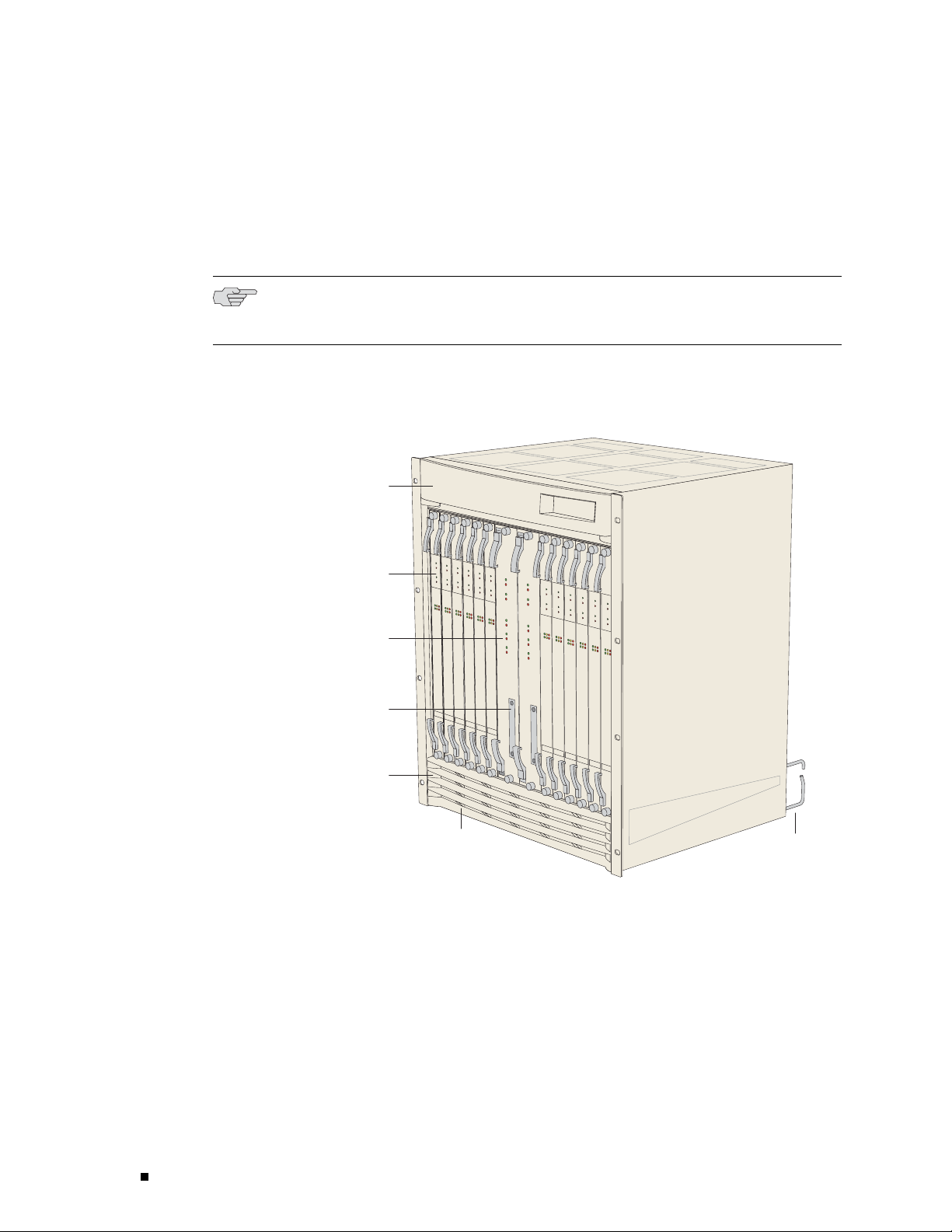

Externally, the ERX-1440 chassis is the same as the ERX-1410 chassis (see Figure 4

and Figure 5). Both routers contain 14 vertical slots to accommodate modules.

E-series Routers 5

Page 22

ERX 7.0.x Hardware Guide

Internally, the ERX-1440 chassis differs from the ERX-1410 chassis, and

includes a spe

cial midplane for the 40-Gbps SRP module.

Installation

systems. All ERX-7xx/14xx models use the same SRP I/O module, but

different power input modules are used.

NOTE: The rout

chapter, depending on the line modules in the slots.

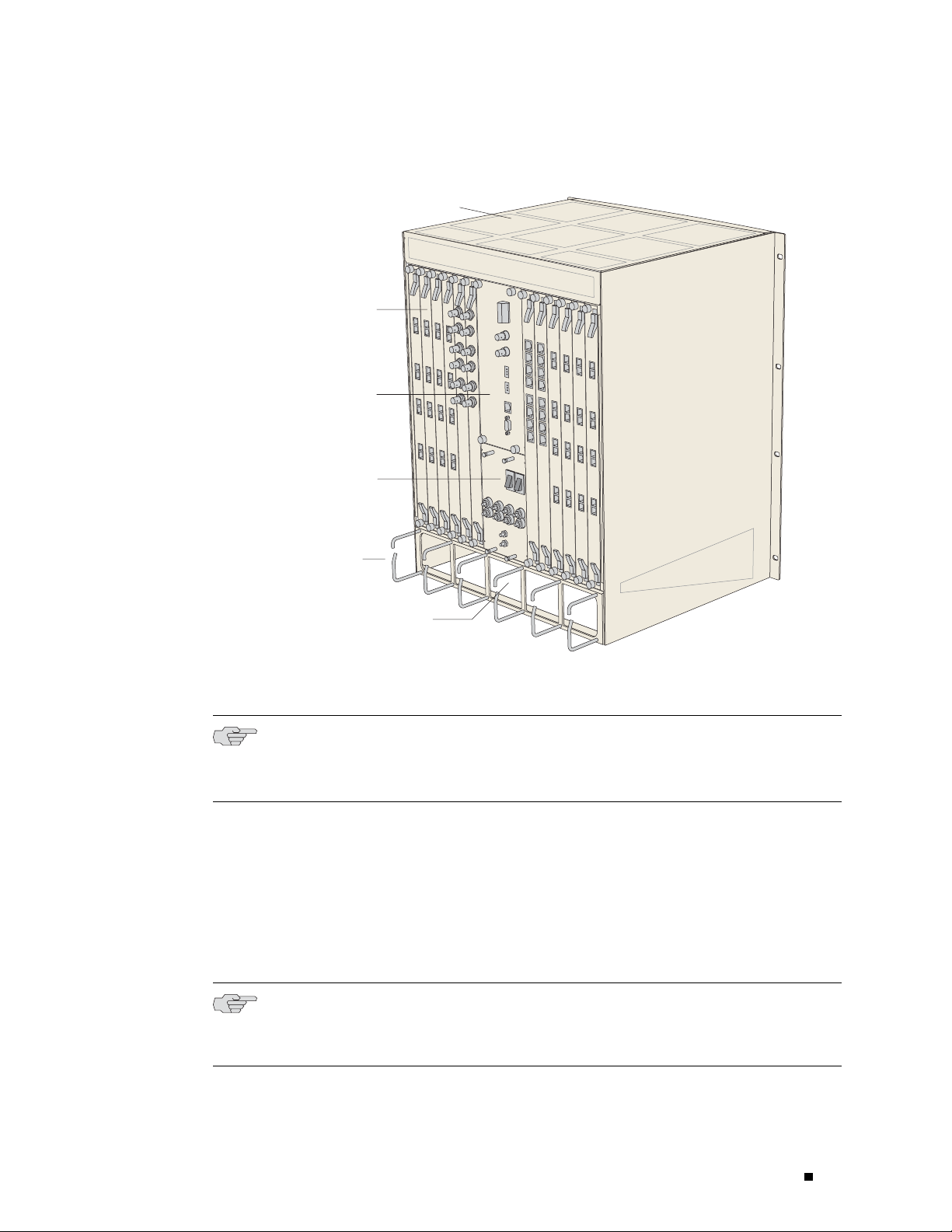

Figure 4: ERX-14xx Model, Front View

Fan tray

behind bezel

Line module

SRP module

procedures and operating procedures are identical for both

er may look different from the routers shown in the figures in this

PCMCIA slot

Air filter (optional)

behind bezel

Bezel

g013727

Cable

management

bracket

6 E-series Routers

Page 23

Figure 5: ERX-14xx Model, Rear View

I/O

module

SRP I/O

module

Power input

module

E-series Overview

Fan tray

ERX-7xx

Models

Cable

management

bracket

Plenum

g013728

NOTE: In the E-series documentation, the term ERX-7xx models refers to both the

ERX-705

router and the ERX-710 router. The terms ERX-705 router and ERX-710

router refer to t he specific models. See Figure 6 and Figure 7.

The ERX-

7xx models are robust, high-density routers with less capacity

than the ERX-14xx models. The ERX-7xx models use either the

SRP-10G module or the SRP-5G module.

You can configure the ERX-7xx models to enable the line modules to operate either

line rate performance or at a rate dependent on the resources available. For

at full

information about configuring performance of line modules, see JUNOSe System

Basics Configuration Guide, Chapter 5, Managing Lin e Modules and SRP Mo dules .

NOTE: Th

e 10-Gbps SRP module used in the ERX-310 router is different from the

10-Gbps SRP module used in the ERX-710 router. See “SRP Module” on page 11

for more information.

E-series Routers 7

Page 24

ERX 7.0.x Hardware Guide

The ERX-705 chassis is the same as the ERX-710 chassis (see Figure 6 and Figure 7).

The chassis co

ntains seven slots to accommodate m o dule s. Installation procedures

and operating procedures are identical for both systems. All ERX-7xx/14xx models

use the same SRP I/O module, but different power input modules are used.

NOTE: The rout

chapter, depending on the line modules in the slots.

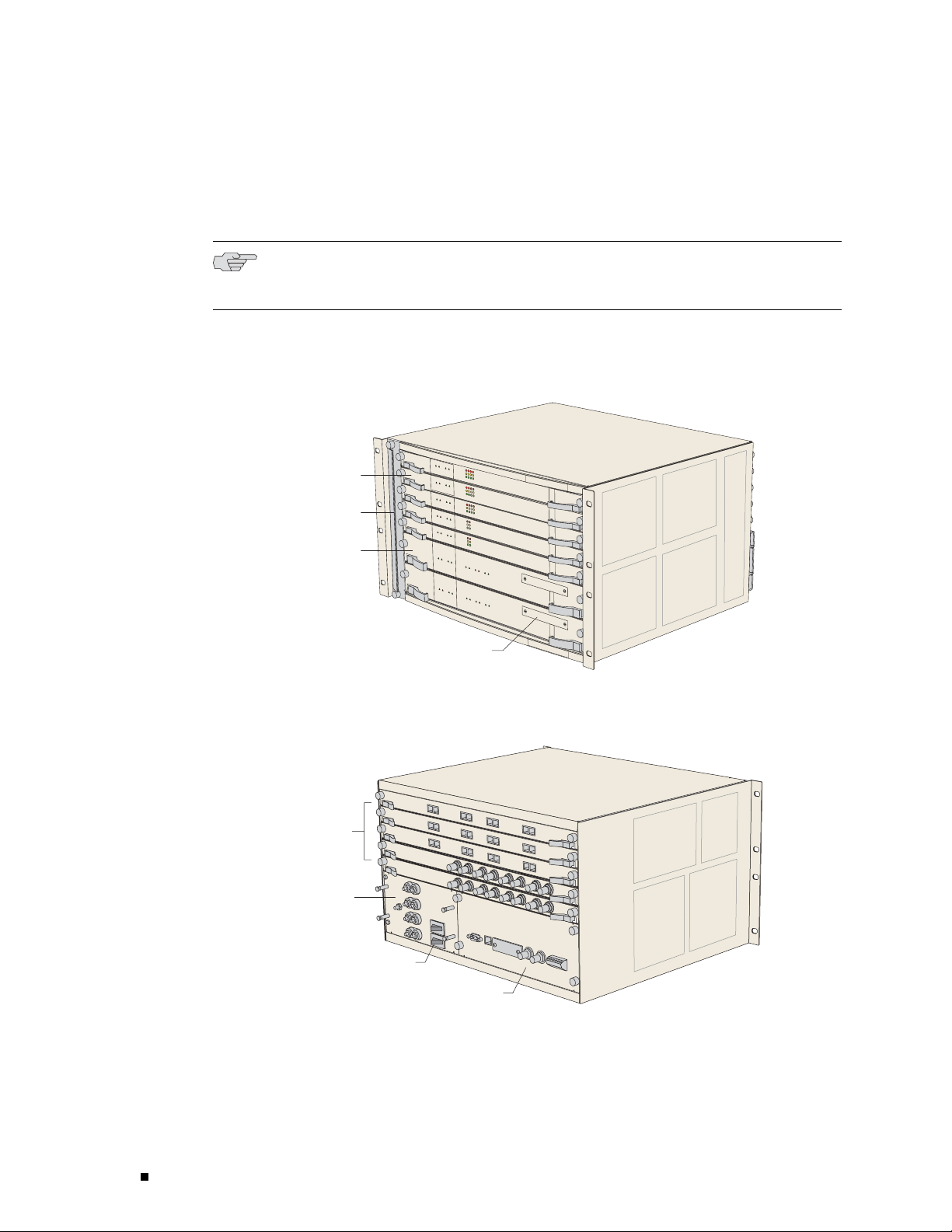

Figure 6: ERX-7xx Model, Front View

Line module

Fan tray

SRP module

Figure 7: E

RX-7xx Model, Rear View

er may look different from the routers shown in the figures in this

PCMCIA slot

g013729

8 E-series Routers

I/O

modules

Power input

module

Power switches

SRP I/O module

g013730

Page 25

ERX-310 Router

E-series Overview

The ERX-310 router is a low-end platform that supports all of the same

services as th

e ERX-7xx/14xx models, but with smaller capacity and scaling

capabilities. Like the ERX-7xx/14xx models, the ERX-310 router uses the

same software architecture, providing a single IP entry point into the network

with the same

IP-based protocols and services that are available on other

E-series routers. The ERX-310 router is designed to be used as a small

distributed POP router as well as a high-end CPE router.

The ERX-310 router is a three-slot chassis with a midplane architecture. One slot

supports one

nonredundant 10-Gbps SRP module, while the other two slots support

line modules. The router supports existing E-series ASIC-based line m odules (except

the OC48/STM16 line module), as well a s a select number of combination cards.

The combina

tion cards provide a fixed combination of interfaces on the I/O module

so that a single slot can support multiple interfaces (ATM OC3 and GE, for example).

NOTE: The 10-Gbps SRP module used in the ERX-310 router is d ifferent from the

10-Gbps SRP

module used in the ERX-7xx/14xx models. See section “SRP Module”

on page 11for more information.

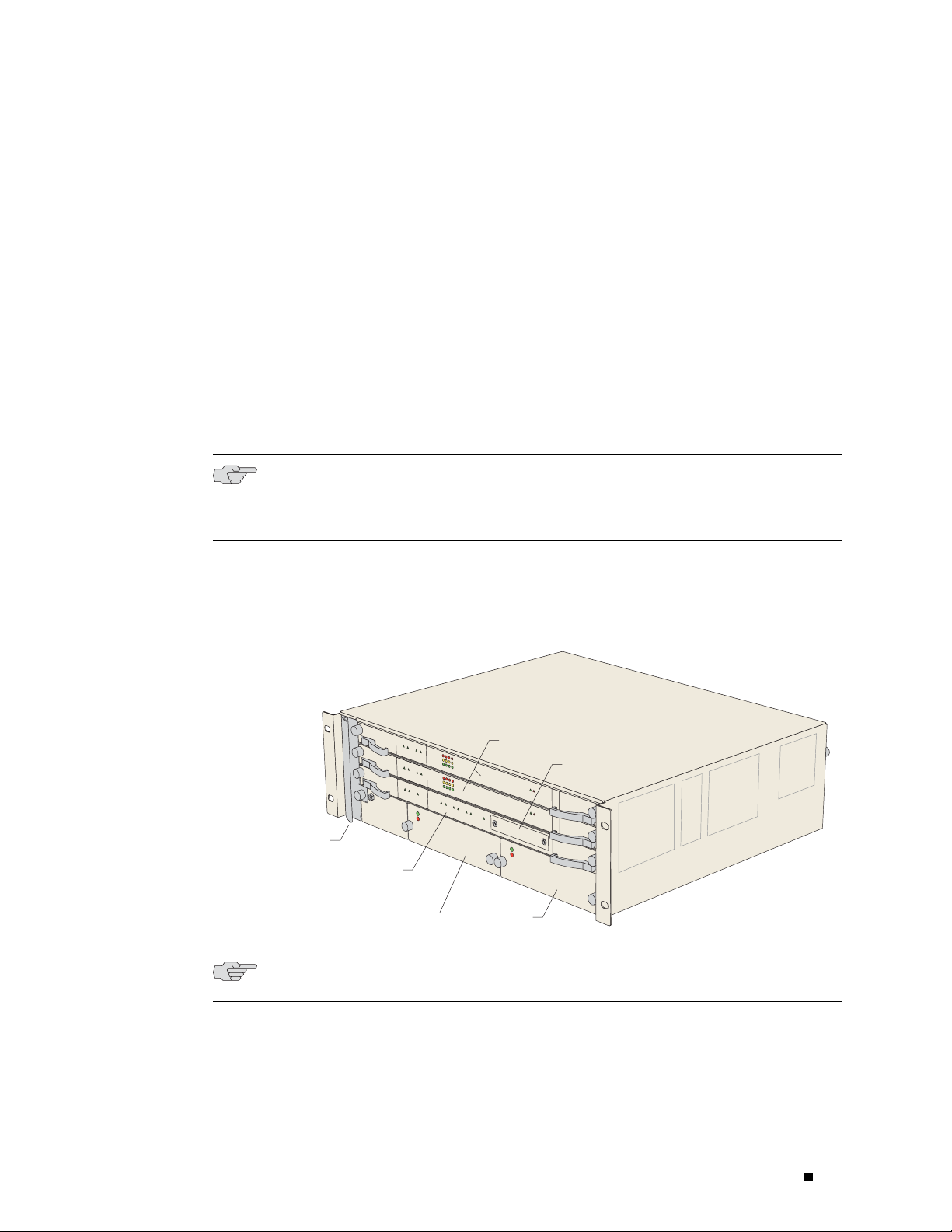

Figure 8: ER

The ERX-310

X-310 Router, Front View (AC M odel)

Fan tray

NOTE: DC

router is available in either redundant AC- or DC-powered models.

SRP module

AC power

supply A

model has blank filler panels in power supply slots.

Line modules

AC power

supply B

PCMCIA slot

g013731

E-series Routers 9

Page 26

ERX 7.0.x Hardware Guide

Figure 9: ERX-310 Router, Rear View (AC Model)

g013732

I/O module

SRP I/O

module

ESD grounding jack

AC power inputs and

switches A and B

Grounding posts

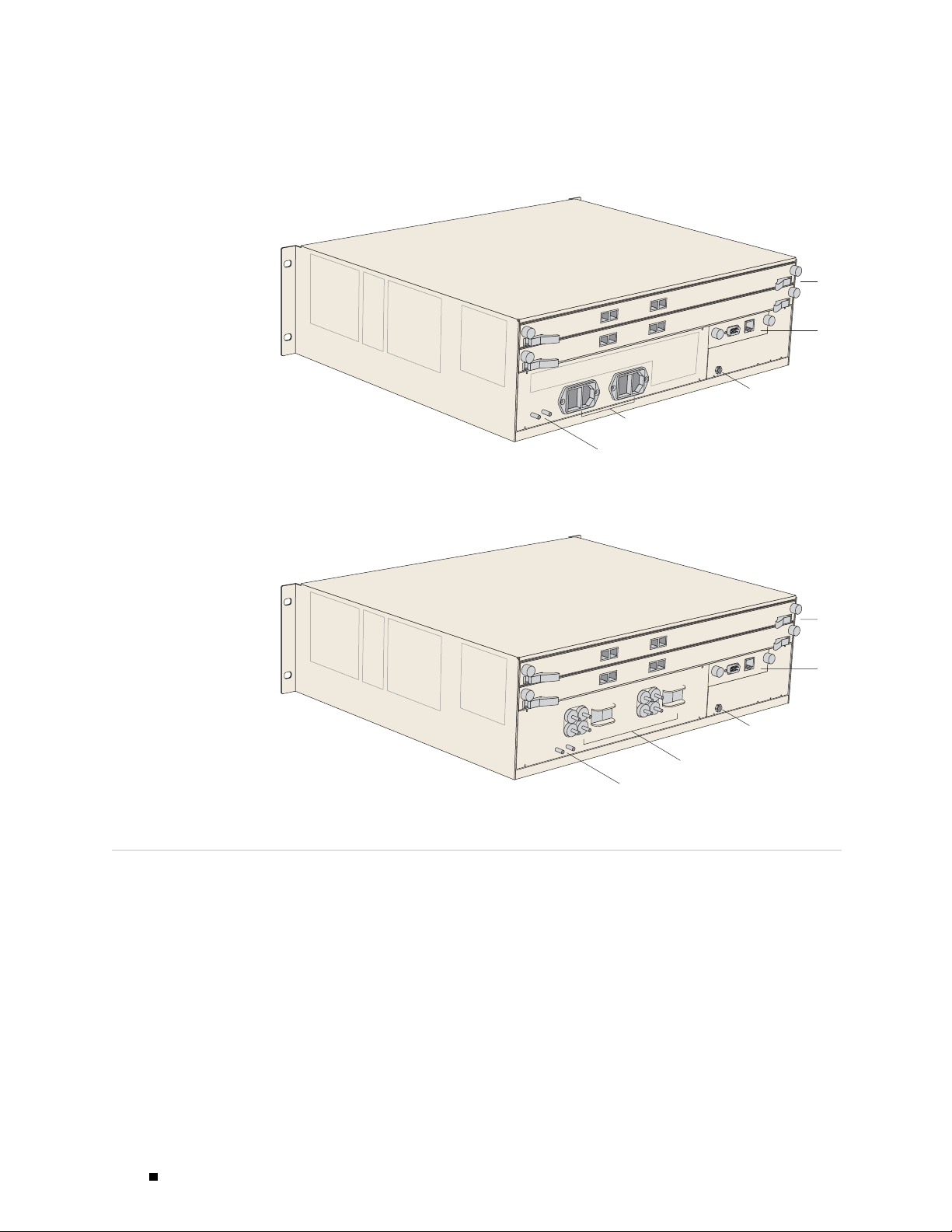

Figure 10:

E-seri

es Modules

ERX-310 Router, Rear View (DC Model)

g013733

The sys

tem supports an SRP module and a selection of line modules. You can

use any line module for access or uplink . Access line modules receive traffic

from low-speed circuits, and th e system routes the traffic onto higher-speed

k line modules and then to the core of the network.

uplin

I/O

module

SRP I/O

module

ESD grounding jack

DC power inputs

and switches A and B

Grounding posts

10 E-series Modules

Each m

oduleconnectstoacorrespondingI/Omoduleviaapassive

midplane. See Figure 11.

The front panel of each module contains a collection of status LEDs

(light-emitting diodes). For information about how to interpret the

see “Troubleshooting” on page 99.

LEDs,

Page 27

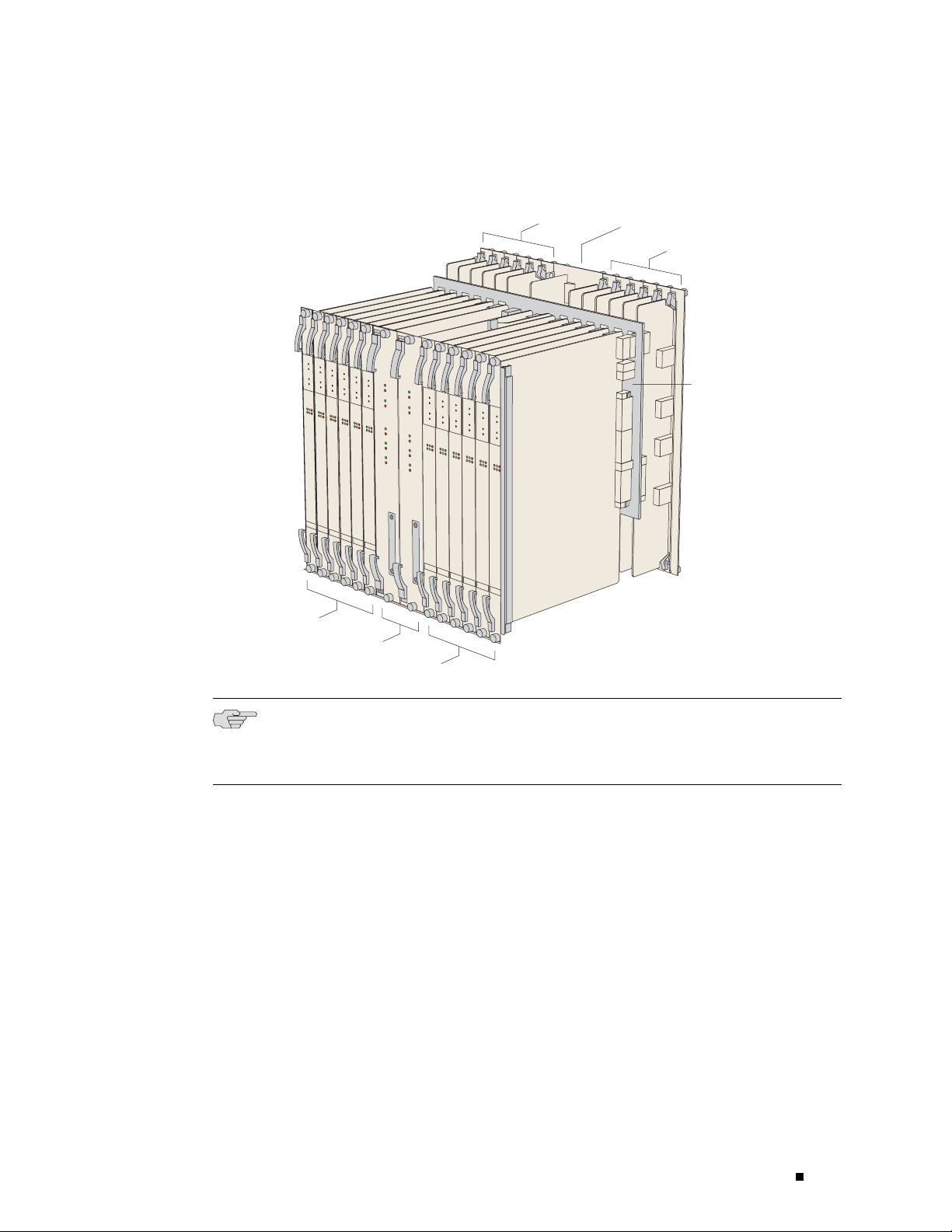

Figure 11: Modules in ERX-14xx Model

E-series Overview

Line modules

SRP modules

Line modules

I/O modules

SRP I/O

module

I/O modules

Connection via

passive midplane

g013734

SRP Module

NOTE: So

me line modules require a minimu m amount of memory to be used with

JUNOSe Release 5.3.0 or a higher-numbered release. Refer to the E-series Module

Guide for line module specifications.

Switch route processor (SRP) modules perform system management, routing

alculations and maintenance, forwarding table computations, statistics

table c

processing, configuration storage, and other control plane functions. Each SRP

module is a PowerPC-based system with its own memory, nonvolatile disk

e, and power supply (see Figure 12 and Figure 13).

storag

E-series Modules 11

Page 28

ERX 7.0.x Hardware Guide

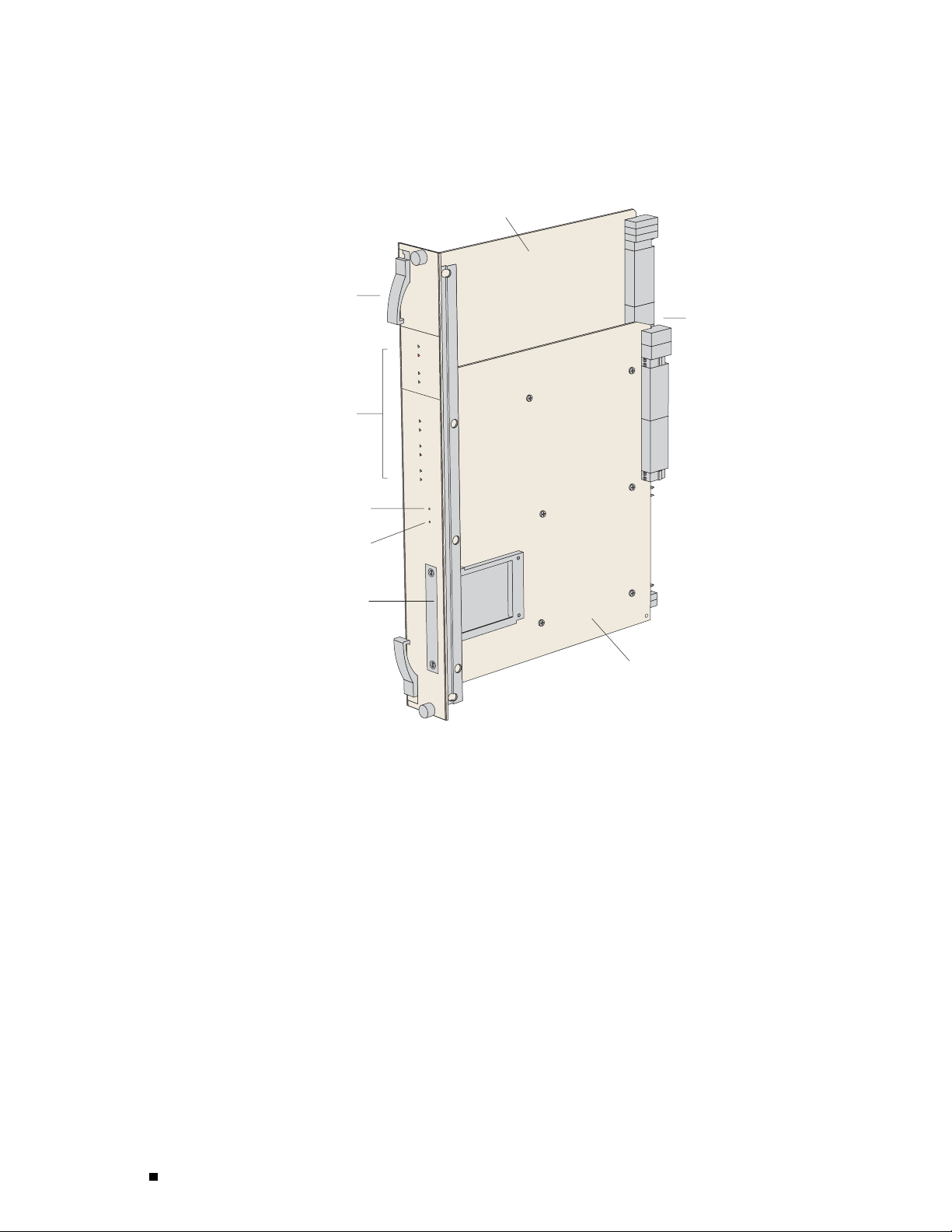

Figure 12: ERX-7xx/14xx SRP Module

Ejector

Status LEDs

Fabric board

Midplane

connectors

Board reset

button

NMI button

PCMCIA

NVS card

System

processor board

g013735

12 E-series Modules

Page 29

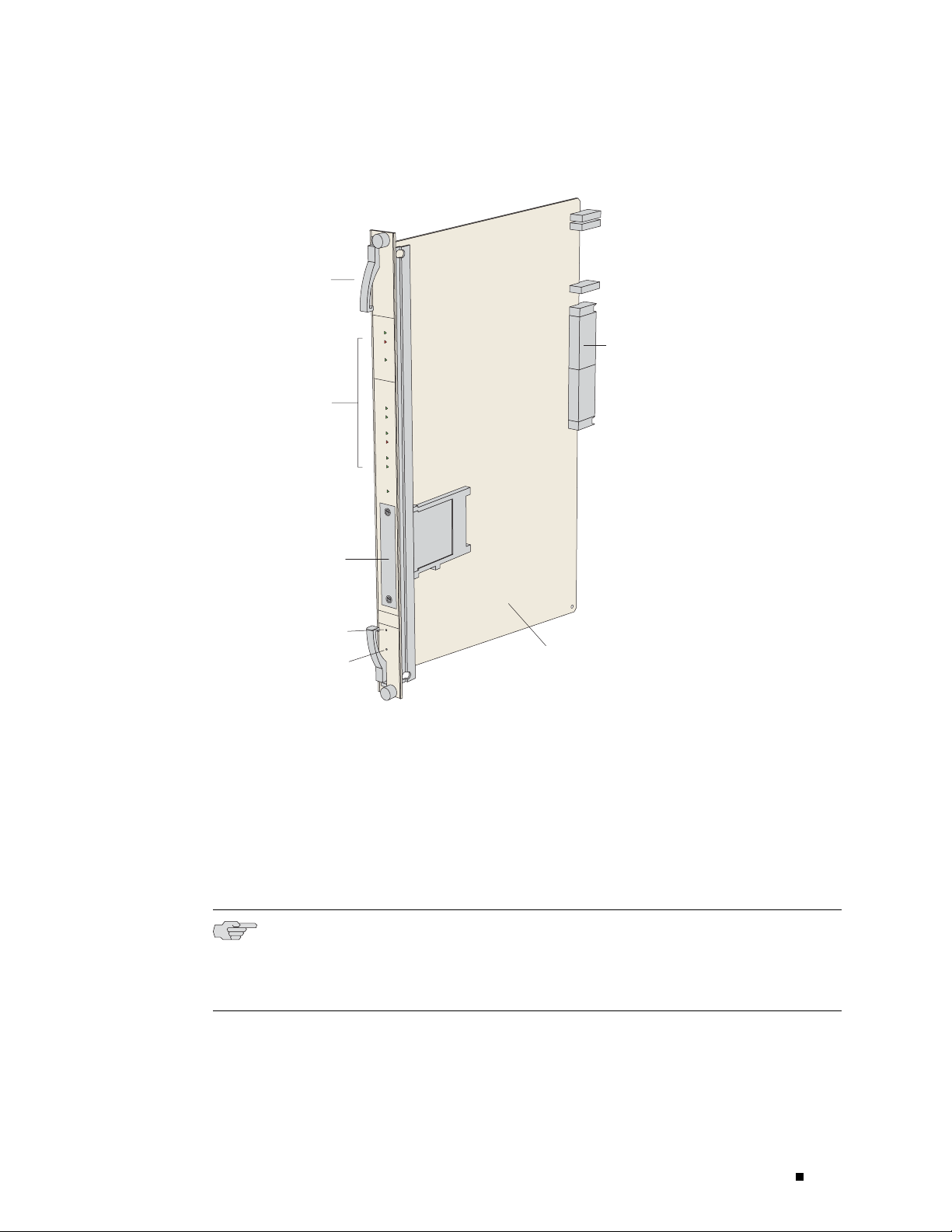

Figure 13: ERX-310 SRP Module

Ejector

Status

LEDs

E-series Overview

g013736

Midplane

connectors

PCMCIA

NVS card

Board reset

button

NMI button

Integrated fabric system

processor board

Module Details

ERX-7xx/14xx models use up to two redundant SRP modules operating in an

/standby configuration. ERX-310 routers use only one SRP module. An

active

SRP module must be present for any system to boot.

SRP modules ranging from 5 Gbps to 40 Gbps can be used in ERX-7xx/14xx

models. Onlya10-GbpsSRPmodule(SRP-SE10G)canbeusedinERX-310

rs. See E-series Module Guide for complete information.

route

NOTE: Because of different physical dimensions and switch fabric capabilities, SRP

modules are not interchangeable between systems. For example, the 10-Gbps SRP

module

and vice versa.

used in ERX-7xx/14xx models cannot be used in the ERX-310 router,

E-series Modules 13

Page 30

ERX 7.0.x Hardware Guide

CAUTION: Do not remove the SRP module while the system is running.

NOTE: Some SRP mod ules require a minimum amount of memory to be used with

JUNOSe Release

Guide for module specifications.

5.3.0 or a higher-numbered release. Refer to E-series Module

SRP I/O Module

For details abo

ut installing SRP modules, see “Installing Modules” on page 35.

SRP Module Redundancy

SRP module redundancy is available only for ERX-7x x/14xx models. See

“Redundancy F

eatures” on page 17 later in this chapter, for more information.

Nonvolatile Storage

ThePCMCIAslotonthefrontoftheSRPmoduleholdsaTypeIIPCMCIAnonvolatile

storage (NVS)

system’s software and configuration files. The PCMCIA c ard is factory installed.

CAUTION: Alth

router, we recommend that you do not do so. If you remove the card while data

is being written to or copied from the NVS card, data may be lost or corrupted.

Therefore, Ju

before removing a PCMCIA NVS card.

card (see Figure 12 and Figure 13). Th is card is loa ded with the

ough you can remove PCMCIA NVS (Flash) cards from a running

niper Networks strongly recommends that you shut down the router

14 E-series Modules

The SRP I/O module is a single corresponding input/output module that interfaces

with the SRP module(s) through the system’s midplane. The same SRP I/O

module work

used in ERX-7xx/14xx models cannot be used in the ERX-310 router, and

vice versa. See Figure 5, Figure 7, and Figure 9 for locations.

s w ith all SRP modules, but is router specific. The I/O module

Page 31

E-series Overview

Module Details

The SRP module provides standard craft management interfaces, including:

10/100Base-T—Enables access to the E-series router for Ethernet management

functions via

CLIorSNMP,forexample.

Line Modules

RS-232—Provi

configuration through a PC (running terminal emulation software) or ASCII

terminal. Allows direct CLI access.

Alarm contacts—Provide for remote indication o f critical, ma jor, and minor

E-series rou

External tim

used by the E-series router remains synchronized with the network’s system

clock. BNC connectors and wire wraps are available for ERX-7xx/14xx models

only.

For details

Line m odules process data from different types of network connections. For

informatio

specific line modules, see the E-series Module Guide.

Figure 14 sh ows a representative line module. For details a bout in stalling

line modules, see “Installing Modules” on page 35.

about installing the SRP I/O module, see “Installing Modules” on page 35.

n about available line modules and which SRP modules support

des a serial connecti on for monitoring the system’s hardware

ter alarms (ERX-7xx/14xx models only; currently not implemented)

ing inputs—Provide a method of ensuring that the clock timing

E-series Modules 15

Page 32

ERX 7.0.x Hardware Guide

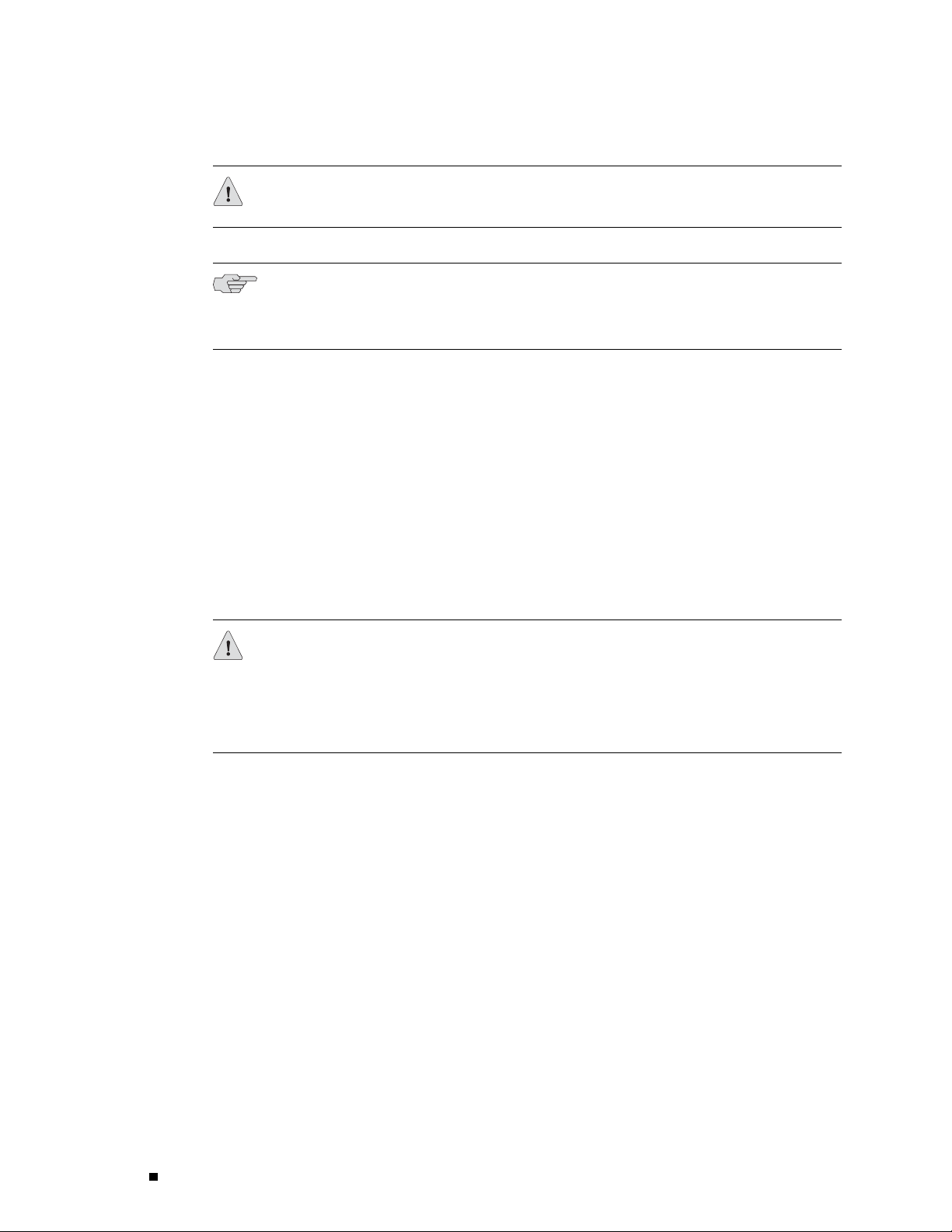

Figure 14: Representative Line Module

Ejector

Status LEDs

Board reset

button

NMI button

Midplane

connectors

g013737

Packet Classification

Most line modules support packet classification on ingress (some non-ASIC line

module

fields (such as source and destination IP address, source a nd destinatio n port,

and protocol), the ingress IP interface, layer 2 fields, or some combination

of the

s do not). A classification engine on the line module matches specific

se against user-configured filters at wire speed.

I/O Modules

16 E-series Modules

Most line modules have a corresponding input/output (I/O) module that provides

ysical interconnection to the network. Insert e ach I/O module into the

the ph

back of the system, directly be hin d its corresponding line module.

For information about which line modules pair with which I/O modules, see the

E-series Module Guide. See Figure 5, Figure 17, and Figure 9 for locations. For

ls about installing I/O modules, se e “Installing Modules” on page 35.

detai

Page 33

Network Management Tools

You can use different management tools to configure the system to

meet the speci

CLI Management

The CLI provides fully developed and automated configuration and status

functionalit

network. For a full discussion of the CLI, see the JUNOSe System Basics

Configuration Guide, Chapter 2, Command Line Interface.

SNMP MIB M anagement

The system offers a complete SNMP interface for configuration, status,

and alarm reporting. The system supports both Standard and Enterprise

MIBs (Manage

Enterprise MIB is ASN.1 notated for easy importing into third-party SNMP

management applications. For more information, see JUNOSe System Basics

Configurat

ion Guide, Chapter 3, Configuring SNMP.

E-series Overview

fic networking requirements.

y through a local RS-232 port, Telnet, or SSH via any reachable

ment Information Bases). The Juniper Networks E-series

NMC-RX Device Management System

The NMX-RX application provides a global method of managing all routers,

line modul

es, and ports through a graphical user interface.

Redundancy Features

The system has the following redundancy features.

SRP Modules

NOTE: This s

one SRP module and therefore do not offer SRP module redundancy.

ERX-7xx/14

When two SRP modules of the same type are installed in the chassis, one

acts as a primary and the second as a standby. Both SRP modules share a

single SRP

If the stan

(and h igh-availability mode is not enabled), it reboots the system and takes

control. If high-availability mode has been enabled, automatic switchover

occurs wi

the software to the redundant SRP and reboot it. For information about

configuring and managing SRP module redundancy, see JUNOSe System

Basics Co

ection applies to ERX-7xx/14xx models only. ERX-310 routers contain

xx models use a 1:1 redundancy scheme for the SRP module.

I/O module located in the rear of the chassis.

dby SRP module detects that the primary SRP module is not active

th near hitless failover. If you upgrade software, you must copy

nfiguration Guide, Chapter 5, Managing Modules.

Redundancy Features 17

Page 34

ERX 7.0.x Hardware Guide

After you install two SRP modules, the modules negotiate for the prima ry role.

Anumberoffac

preference is given to the module in the lower-numbered slot. The SRP modules

record their latest roles and retain them the next time you switch on the system.

For informati

tors determine which module becomes the primary; however,

on about installing SRP modules, see “Installing Modules” on page 35.

NVS Cards

If you have two SRP modules installed in a system, you can use NVS cards

of different

higher-capacity NVS card will equal tha t of the lower-capacity NVS card. For

information about installing NVS cards, see “Installing Modules” on page 35.

When you install new NVS cards or SRP modules, you must issue the synchronize

command to m

module with the file system of the NVS card on the primary SRP module.

(The NVS card on the redundant SRP module will hereafter be referred to

as the redun

hereafter be referred to as the primary NVS card.)

capacities on the SRP modules. The effective capacity of the

atchthefilesystemoftheNVScardontheredundantSRP

dant NVS card; the NVS card on the primary SRP module will

Line Modules

If the capacity of the primary NVS card is equa l to or smaller than that of the

redundant NVS card, the system copies all the files from the primary NVS card to the

redundant

of the redundant NVS card, the system creates an invisible synchronization reserve

file on the prim ary NVS card, provided that there is enough space for the file.

The purpose of the synchronization file is to prevent the creation of data that

will not f

is not visible when you view the files in NVS. The size of the file is equal

to the difference in capacities of the two NVS cards. For example, if the

primary N

a capacity of 220 MB, the size of the synchronization file is 4 MB, and only

220 MB of space is available on the primary NVS card.

If there is not enough space on the primary NVS card to create the synchronization

reserve

on the console. To resolve this issue, either delete unwanted files from the primary

NVS card or replace the redundant NVS card with a higher-capacity NVS card.

NOTE: Th

offer line module redundancy.

NVS card. However, if the capacity o f the primary N VS card exceeds that

it on the redundant NVS card. The file contains no useful data, and

VS card has a capacity of 224 MB and the redundant NVS card has

file, the synchronize command fails, and a warning message is disp layed

is section applies to ERX-7xx/14xx models only. ERX-310 routers do not

ERX-7xx

For details about which line modules support redundancy, see E-series Module

18 Redundancy Features

/14xx models support line module redundancy for several line modules.

Page 35

E-series Overview

Guide. In this scheme, an extra line module in a group of identical line modules

provides redu

ndancy in case of line module failure. To use this feature, you need a:

Spare line mod

Redundancy mi

Redundancy I/

Aredundancym

ule

dplane

O module

idplane may cover 3–6 slots. It provides additional connectivity

that enables the spare line module to assume control of the I/O module associated

with any failed line module in the redundancy group. The spare I/O module

provides con

The process b

nectivity from the spare line module to the redundancy m idplan e.

y which the system switches to the spare line m odule is called

switchover. When switchover occurs, the system:

1. BreakstheconnectionbetweentheprimaryI/Omoduleandtheprimary

line module.

2. Connects the primary I/O module to the spare line module via the redundancy

midplane and redundancy I/O module.

Protocol processing then takes place on the spare line module.

Figure 15 shows the data flow when a spare line module becomes active.

Redundancy Features 19

Page 36

ERX 7.0.x Hardware Guide

Figure 15: Data Flow When a Spare Line Module Is Active

Redundancy

I/O module

Primary

I/O module

Midplane

g013738

Power

Redundancy

midplane

Spare line module

Primary line module

For information about installing modules for line module redundancy, see

lling Modules” on page 35. For information about configuring and

“Insta

managing SRP module redundancy, see JUNOSe System Basics Configuration

Guide, Chapter 5, Managing Lin e Modules and SRP M odules.

All E-series routers provide a power architecture that distributes redundant –48 VDC

feeds through the router to each line module, SRP module, and fan module where

-DC converters provide local conversion to the required secondary voltages.

DC-to

1. A packet arrives at the primary I/O module.

2. The packet passes along the redundancy

midplane from the primary I/O module to

the redundancy I/O module.

3. The packet passes from the redundancy

I/O module to the spare line module.

4. The spare line module processes the packet.

The ER

version can be configured with one or two hot-swappable power supplies for optional

redundancy (see Figure 8 and Figure 9). The power supplies convert AC power to

inte

20 Redundancy Features

X-310 router is available with either DC or AC power inputs. The AC-powered

rnal –48 V redundant DC feeds that are then distributed through the router.

Page 37

Fans

E-series Overview

Forced air-cooling keeps the temperature of the E-series modules and components

within normal

operating limits. In ERX-14xx models, six cooling fans are located in

atrayatthetopoftherouter(seeFigure4). InERX-7xxmodels,fourcoolingfans

arelocatedinatrayononesideoftherouter(seeFigure6). IntheERX-310router,

two cooling f

ans are located in a tray on one side of the router (see Figure 8).

The system mo

nitors the temperature of each module. If the temperature of a

module exceeds the maximum limit, the system immediately goes into thermal

protection mode and the modules are powered off. The ERX system controller

enters a low p

ower mode, keeps the modules in a power-off condition, and does

not respond to any management interface commands. For information about

troubleshooting high operating temperatures, see “Troubleshooting” on p age 99.

In ERX-7xx/14xx models, the fan tray has two redundant converters that power

the fans (fo

r the ERX-14xx models, a –24 V, 50 W converter; for the ERX-7xx

models, a –12 V, 15 W converter). If one converter fails, the other takes over.

The ERX-310 router does not have redundant converters.

For all E-series routers, the system software reports an alarm if any

of the fans

or con verters fail.

Redundancy Features 21

Page 38

ERX 7.0.x Hardware Guide

22 Redundancy Features

Page 39

Chapter 2

Unpacking an

Routers

This chap te

routers. It contains the following sections:

Before You B

Unpacking ERX-14xx Models on page 23

Unpacking ERX-7xx Models and ERX-310 Routers on pag e 24

Inspecting

If You Detect or Suspect Damage on page 25

Contacting Juniper Networks on page 25

The Next Ste

Before You Begin

d Inspecting E-series

r reviews shipping contents and unpacking procedures for E-series

egin on pa ge 23

E-series Router Components and Accessories on pa ge 25

p on page 26

Before you begin unpacking the router, be sure you have the following tools:

A N o. 2 Phillips screwdriver

A utility knife

A mechanical lift, or at least two people to assist in lifting

Unpacking ERX-14xx Models

ERX-14xx models come boxed, bolted, and strapped to a skid. For your

convenience, Juniper Networks recommends that you unpack the E-series

router in t

he location where you want to install it.

Unpacking ERX-14xx Models 23

Page 40

ERX 7.0.x Hardware Guide

WARNING: Three people are required to install the E-series router in a rack: two to

lift the system

into position and one to screw it to th e rack.

To unpack ERX-14xx models:

1. Cut the two straps that secure the carton to the skid, open the carton from the

top, and remov

2. Unlock the four plastic clips that hold the box to the sk id by squeezing them in

their center a

3. Remove the three screws that attach each of the two L-brackets to the router.

4. To avoid scratching the router when removing it from the skid, detach one of

e the box of accessories that sits on top of the router.

nd pulling out, and then lift the carton off the router.

the L-brackets from the skid by removing the three screws. See Figure 16.

Figure 16: Re

moving an L-Bracket

L-bracket

g013739

Unpacking ERX-7xx Models and ERX-310 Routers

ERX-7xx models and ERX-310 routers are shipped boxed, but not attached to a

skid. Fo

the E-series router in the location whe re you want to install it.

24 Unpacking ERX-7xx Models and ERX-310 Routers

r your convenience, Juniper Networks recommends that you unpack

Page 41

Unpacking and Inspecting E-series Routers

To unpack an ERX-7xx model or an ERX-310 router:

1. Open the carton from the top.

2. Remove the box of accessories that sits on top of the system.

3. Remove the rou

WARNING: Three people are required to install the E-series router in a rack: two to

liftthesystemintopositionandonetoscrewittotherack.

ter from the box.

Inspecting E-series Router Components and Accessories

After you remove the equipment from the shipping containers:

Confirm the contents of each container.

Inspect all external s urfaces and external connectors for visible signs of

damage.

Inspect all a

Document any d

Confirm that t

your ordered configuration.

ccessories shipped with each unit.

amage noted during your inspection.

he router has the correct number and type of modules for

If You Detect

or Suspect Damage

If you detect

Contact the s

Contact your

Contacting Juniper Networks

Please contact Juniper Networks at 1-888-314-JTAC (within the United

States) or 4

sales representative if you have any questio ns or concerns. See “Customer

Support” on page 145, for complete contact information.

08-745-9500 (from outside the United States), or contact your

or suspect damage to any equipment:

hipper responsible for delivery, and formally report the damage.

Juniper Networks sales representative or reseller.

Contacting Juniper Networks 25

Page 42

ERX 7.0.x Hardware Guide

The Next Step

To familiarize yourself with the electrical, environmental, and other guidelines

and requireme

nts for installing E-series routers, turn to .

If you are fami