Page 1

CTP2000 Series Circuit to Packet Platforms

Published

2020-08-31

Hardware Guide

Page 2

Juniper Networks, In.

1133 Innovation Way

Sunnyvale, California 94089

USA

408-745-2000

www.juniper.net

Copyright © 2020 Juniper Networks, Inc. All rights reserved.

Juniper Networks, the Juniper Networks logo, Juniper, and Junos are registered trademarks of Juniper Networks, Inc.

and/or its affiliates in the United States and other countries. All other trademarks may be property of their respective

owners.

Juniper Networks assumes no responsibility for any inaccuracies in this document. Juniper Networks reserves the right

to change, modify, transfer, or otherwise revise this publication without notice.

CTP2000 Series Circuit to Packet Platforms Hardware Guide

Copyright © 2019 Juniper Networks, Inc. All rights reserved.

ii

Revision History

February 2017—Revision 2

January 2019—Revision 3

The information in this document is current as of the date on the title page.

END USER LICENSE AGREEMENT

The Juniper Networks product that is the subject of this technical documentation consists of (or is intended for use with)

Juniper Networks software. Use of such software is subject to the terms and conditions of the End User License Agreement

(“EULA”) posted at https://support.juniper.net/support/eula/. By downloading, installing or using such software, you

agree to the terms and conditions of that EULA.

Page 3

Table of Contents

1

Overview

CTP2000 Series Platform Overview | 2

Introducing CTP Series Platforms | 2

CTP2000 Series Processor | 2

CTP2008 Platform | 3

CTP2024 Platform | 5

CTP2056 Platform | 7

CTP2000 Series Interface Modules | 11

CTP2000 Serial Interface Modules | 11

iii

CTP2000 Multiservice Interface Module | 12

CTP2000 T1/E1 Interface Module | 13

CTP2000 Compression Module | 13

CTP2000 4WE&M Interface Module | 14

Supervisory Signaling | 18

CTP2000 2W-FXS and 2W-FXO Interface Modules | 20

Required Cables and Pinouts | 22

Analog FXS/FXO Loop-Start Signaling | 22

Answer Supervision | 22

Disconnect Supervision | 22

Analog FXS/FXO Ground-Start Signaling | 23

Digital Signaling | 23

Digital FXS/FXO Loop-Start Signaling | 23

Digital FXS/FXO Ground-Start Signaling | 24

CTP2000 8P-IRIG Interface Module | 26

CTP2000 Clock Interface Modules | 27

External Reference Clock | 29

Installation Notes for Clock Interface Modules | 30

CTP2000 PMC Module | 30

Page 4

Planning

2

System Specifications | 33

CTP2008 Platform Specifications and Certification | 33

CTP2024 Platform Specifications and Certification | 35

CTP2056 Platform Specifications and Certification | 38

Planning and Preparing the Site | 40

Before You Install a CTP Platform | 40

CTP2000 Environmental Requirements | 40

Equipment Rack Requirements | 42

CTP2000 Rack Requirements | 42

CTP2000 Mechanical Requirements | 42

iv

CTP2000 Space Requirements | 43

CTP2000 Rack Installation | 43

CTP Cabling Recommendations | 44

Cable and Pinout Specifications | 45

CTP2000 4WE&M Interface Connector Pinouts | 45

CTP2000 4WE&M RTM Connector A Pinouts | 45

CTP2000 4WE&M Connector B Pinouts | 46

CTP2000 FXS and FXO Interface Module Cables and Pinouts | 48

Required Cables | 48

RTM Pinout Locations | 48

FXS Connector Pinouts | 49

FXO Connector Pinouts | 50

T1/E1 Interface Module Pinouts | 51

CTP2000 Serial Interface Module Pinouts | 52

CTP2000 Series Console Cable Pinouts | 63

CTP Fast Ethernet and Power Cables | 68

Fast Ethernet Cables | 69

DC Power Cables | 69

Terminal Block and Circuit Breaker Specifications | 69

Page 5

Safety

3

4

General Safety Guidelines and Warnings | 72

CTP Safety Guidelines and Warnings | 72

Module Installation Safety Guidelines and Warnings | 74

Safety Guidelines and Warnings for Installing CTP Modules | 74

Hardware Compliance | 76

Declaration of Conformity for CTP2000 Platforms | 76

Federal Communications Commission (FCC) Statement | 78

FCC Requirements for Consumer Products | 78

Food and Drug Administration, Center for Devices and Radiological Health | 79

Compliance with Canadian Regulations | 79

v

Industry Canada Notice | 79

Industry Canada Notice CS-03 | 80

Avis CS-03 d'Industrie Canada | 80

Canadian Department of Communications Explanatory Notes | 81

DOC Explanatory Notes: Equipment Attachment Limitations | 81

Notes explicatives du ministère des Communications: limites visant les accessoires | 81

Statements of Volatility for Juniper Network Devices | 82

Installation

Unpacking and Inspecting the CTP Platform | 87

Before You Unpack the CTP Platform | 87

Unpacking the CTP Device | 87

Inspecting Platform Components and Accessories | 88

If You Detect or Suspect Damage | 89

Contacting Juniper Networks | 89

Installing the Chassis | 90

Before You Install the CTP2000 Platform | 90

Installing the CTP2000 Platform in Freestanding Mode | 91

Special Guidelines for Installing CTP2056 Chassis in a Rack | 91

Installing the CTP2000 Platform in a Rack | 92

Page 6

Installing Modules | 93

CTP2000 Modules Installation Overview | 93

Protecting CTP2000 Modules and Slots | 94

Required Tools and Safety Items for Installing CTP Modules | 95

Installing a CTP Interface Module, Processor Module, or Clock Module | 95

Removing a CTP Interface Module, Processor Module, or Clock Module | 96

Installing or Removing a CTP2000 Series CompactFlash Card | 98

Installing a PMC on CTP2000 Platforms | 99

Installing and Removing SFPs in a CTP Module | 102

Installing SFPs in a CTP2000 Module | 102

Removing SFPs in a CTP2000 Module | 104

Upgrading Components for Memory Upgrades | 106

vi

Upgrading CTP2000 Series Components for Memory Upgrades | 106

Cabling | 108

Cabling the CTP2000 Platform Overview | 108

Required Tools, Wires, and Cables for the CTP2000 Platform | 109

CTP2000 Management Ports | 110

Cabling a CTP2000 T1/E1 Interface Module | 111

Cabling the CTP Platform for DC Power | 111

Task 1: Turning Off All CTP Platform Power | 112

Task 2: Connecting the Grounding Cable to the CTP Platform (CTP2056 Platform Only) | 112

Task 3: Connecting the Power Cables to the CTP2000 Platform | 113

Powering On | 115

Before You Power On the CTP2000 Platform | 115

Powering On the CTP2000 Platform | 116

Powering Off the CTP Platform | 119

Page 7

Configuration

5

6

7

Accessing the CTP2000 Platform | 121

Setting Up Management Access on the CTP2000 Platform | 121

CTP2000 Console Port Setup | 122

Using HyperTerminal with the CTP2000 Platform | 123

Connecting Directly to the CTP2000 Platform | 124

CTP2000 Platform SSH Setup | 125

Maintenance

Maintaining Components | 127

Required Tools for Maintaining the CTP Platform | 127

Storing CTP Modules and Other Components | 127

Cleaning the CTP Platform | 128

vii

Replacing an AC Power Supply | 129

Product Reclamation and Recycling | 131

Product Reclamation and Recycling Program | 131

Replacing Fan Trays | 133

Removing a CTP2000 Fan Tray | 133

Installing a CTP2000 Fan Tray | 133

Packing and Returning Hardware | 135

Return Procedure | 135

Returning CTP Products for Repair or Replacement | 136

Troubleshooting

Troubleshooting Power Failures | 138

CTP Platform Does Not Power On | 138

CTP Platform Shuts Down | 139

Contacting Customer Support | 140

Contacting Customer Support | 140

Locating CTP Component Serial Numbers | 141

Information You Might Need to Supply to JTAC | 141

Page 8

1

PART

Overview

CTP2000 Series Platform Overview | 2

CTP2000 Series Interface Modules | 11

Page 9

CHAPTER 1

CTP2000 Series Platform Overview

IN THIS CHAPTER

Introducing CTP Series Platforms | 2

CTP2000 Series Processor | 2

CTP2008 Platform | 3

CTP2024 Platform | 5

CTP2056 Platform | 7

2

Introducing CTP Series Platforms

Juniper Networks CTP Series Circuit to Packet platforms provide advanced technology and features

required to reliably transport legacy time-division multiplexing (TDM) and other circuit-based applications

across next-generation IP networks. CTP Series platforms create an IP packet flow from a serial data or

analog voice connection at one end and provide the necessary processing to re-create the serial bit stream

or analog signal from the received packet flow at the other end.

CTP Series platforms provide compact and lightweight chassis, high port density, and multiple Ethernet

interfaces. Each CTP Series platform runs the CTP operating system (CTPOS) and can be managed by the

Juniper Networks CTPView Network Management System. The CTPView Network Management System

is a secure, Web-based management tool for provisioning, managing, running diagnostics, monitoring, and

reporting on all CTP Series devices and circuits in the network.

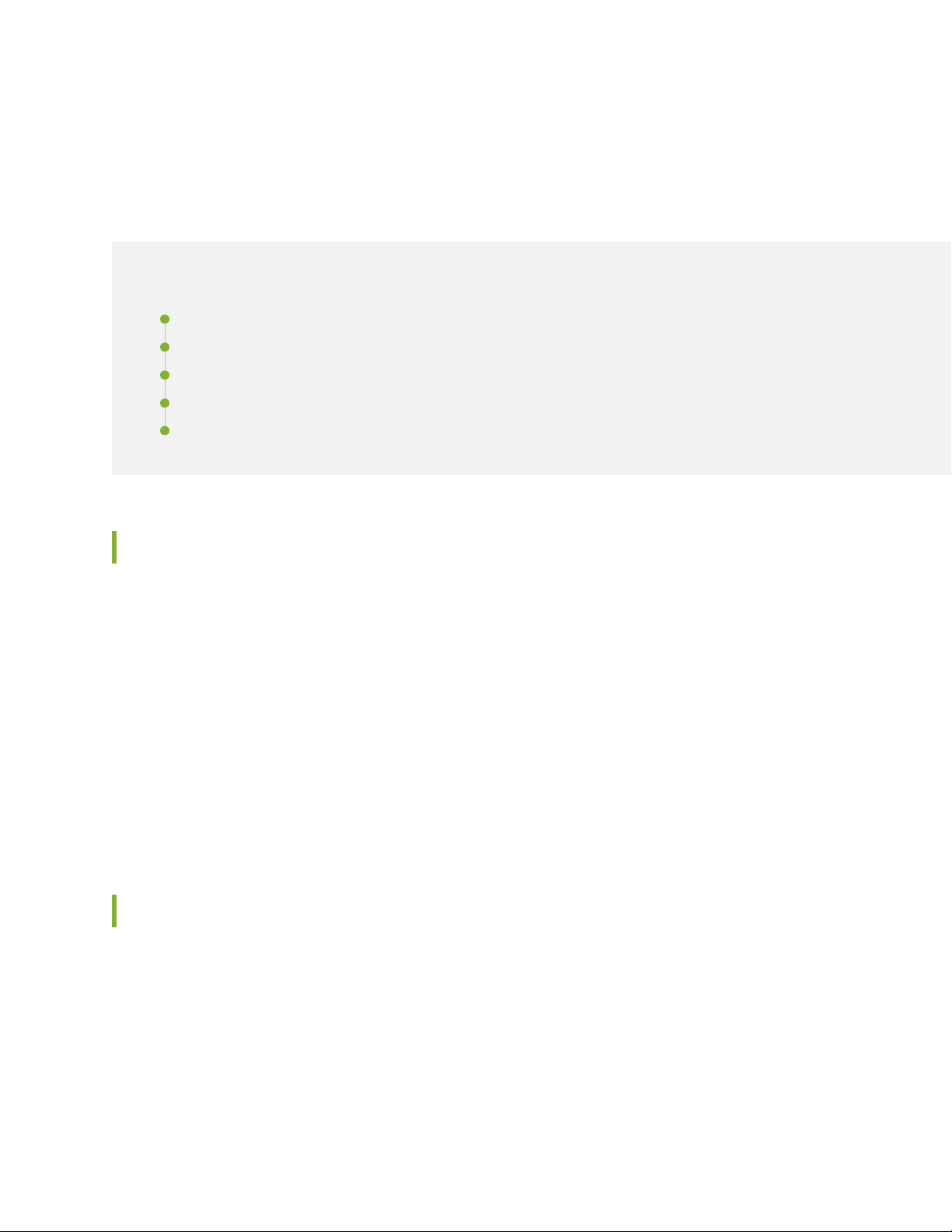

CTP2000 Series Processor

Starting with CTPOS Release 6.6, Juniper Networks CTP2000 Series Circuit to Packet platforms support

the PP833 processors (see Figure 1 on page 3) in addition to the older PP310 and PP332 family of

processors.

The front panel of the PP833 processor comprises the following components (see Figure 1 on page 3):

Page 10

PMC—Both PMC slots are available to support compatible fiber PMC modules. For more information

g0 09 077

PMC/XMC1 PMC/XMC2

2 USB 1 ETH1 ETH2S R U P RS232H

PMC/XMC1 PMC/XMC2

USB1

USB2 ETH1

ETH2

Console

USBOptional fiber PMC

Interface module, slot 0

Card extractor

Power supply screw Power supply extractor

g015387

•

about the PMC module, see “CTP2000 PMC Module” on page 30 and “Installing a PMC on CTP2000

Platforms” on page 99.

Ethernet connection—Provides the 1-Gbps Ethernet connection to the IP network by means of a local

•

Ethernet switch or router.

Console connection—Provides an asynchronous tty connection for locally configuring the CTP Series

•

device. Because of front panel space limitations, the PP833 processor provides an RS232 serial console

via a supplied USB-to-DB9 cable (p/n 720-071594), in which the DB-9 connector has the same pinout

as a standard RS-232 DTE port.

Figure 1: PP833 Processor (AC and DC Version, Front View)

3

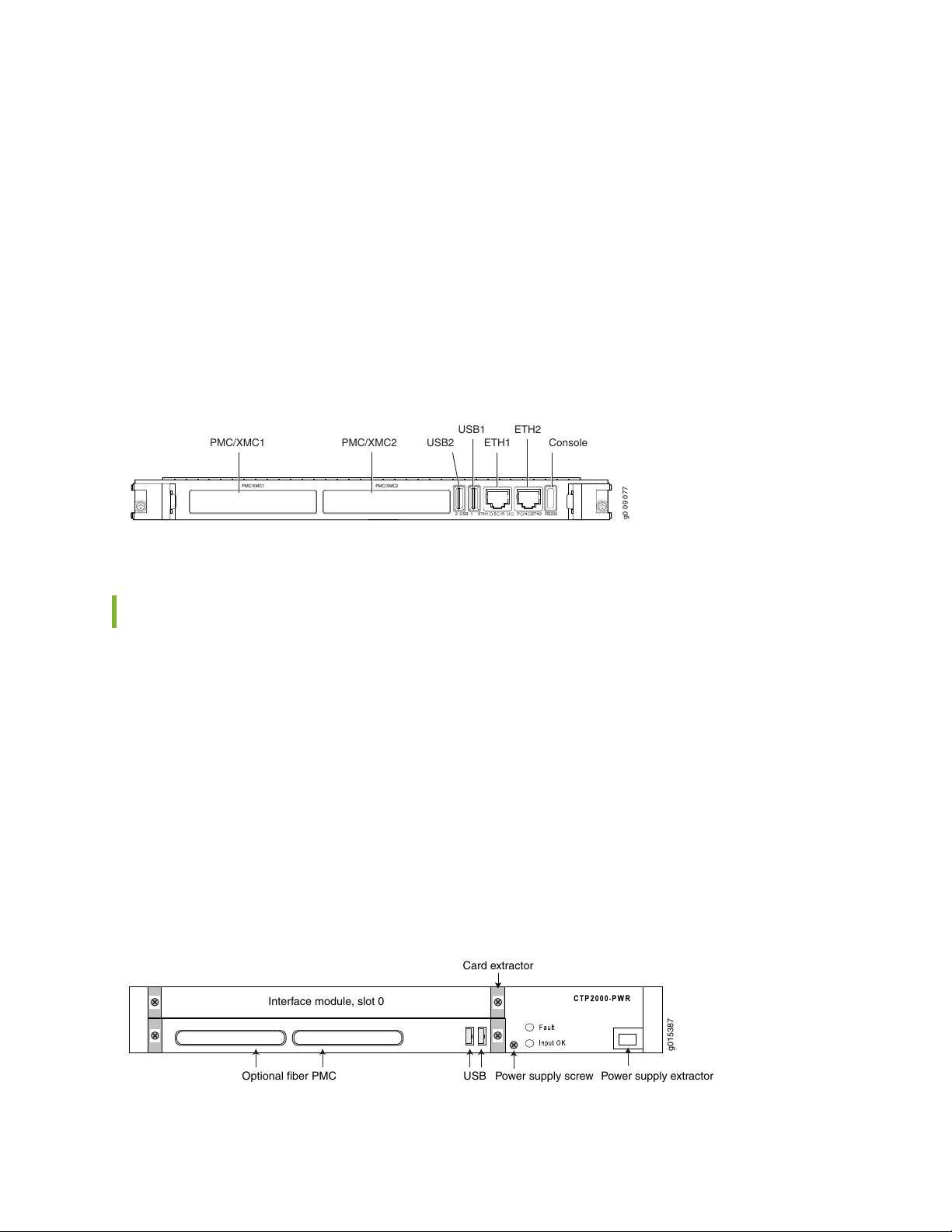

CTP2008 Platform

The Juniper Networks CTP2008 Circuit to Packet platform is a 3-U high, full-rack wide chassis designed

for tabletop or shelf installation. It can also be installed in a rack with the supplied rack-mounting kit. The

CTP2008 platform has one removable interface module and one removable processor module, and is

available in both AC-powered and DC-powered versions. It has a removable fan tray, and airflow is

side-to-side. Figure 2 on page 3, Figure 3 on page 4, and Figure 4 on page 5 show the CTP2008 chassis

containing the PP332 processor (which requires an RTM card for Ethernet and console port accesses).

The new PP833 processor module does not require an RTM card. All PP833 module access is located on

the front panel with all CTP serial and T1/E1 ports. If you are upgrading from the old PP310 or PP332

processor to the PP833 processor, the RTM card may be left in the node. But, none of the interfaces

(Ethernet or serial ports) on the RTM panel are functional.

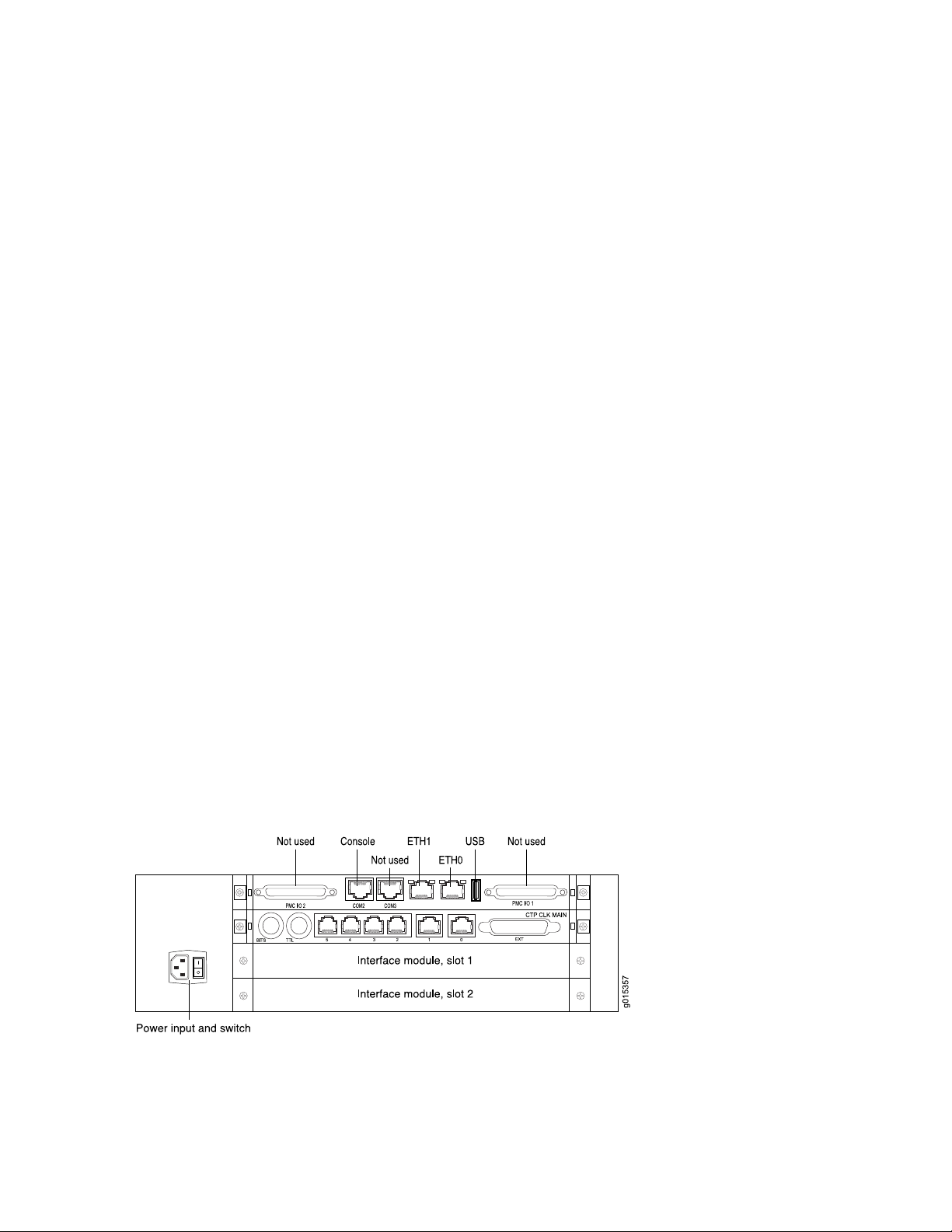

Figure 2: CTP2008 Chassis Containing the PP332 Processor (AC and DC Version, Front View)

Page 11

The front panel comprises the following components (see Figure 2 on page 3):

ETH1 USBConsole

Power input and switch

COM2 COM3

PMC I/O 1

PMC I/O 2

Not used Not used

Not used ETH0

g015353

Interface module—Frame processing and forwarding engines.

•

Processor module—Two slots are available on this module for an optional fiber Gigabit Ethernet or Fast

•

Ethernet PMC module. The primary SC connector is on the left side. For more information about the

PMC module, see “CTP2000 PMC Module” on page 30 and “Installing a PMC on CTP2000 Platforms”

on page 99.

Power supply extractor—Push the button to eject the power supply module.

•

The rear panel (RTM) comprises the following components (see Figure 3 on page 4 and

Figure 4 on page 5):

Clock module—Provides clock distribution between modules when the backplane is in use by voice

•

applications.

Power supply—Use a standard IEC power cord for the AC version. Use a 22-AWG fork terminal connector

•

for the DC version. There is no power redundancy for the AC version and the DC version.

There are no power switches on CTP2000 Series DC models, so a readily accessible disconnect device

must be provided as part of the electrical installation of the unit. We recommend the 22-AWG wire for

DC power terminals.

4

Ethernet connection—Provides the 1-Gbps Ethernet connection to the IP network by means of a local

•

Ethernet switch or router.

Console connection—Provides an asynchronous tty connection for locally configuring the CTP Series

•

device. On the PP310 and PP332 processors, you can connect a console directly to the COM2 port

(which is an RJ-45 type connector) found on the RTM panel.

Figure 3: CTP2008 Platform Containing the PP332 Processor (AC Version, Rear View)

Page 12

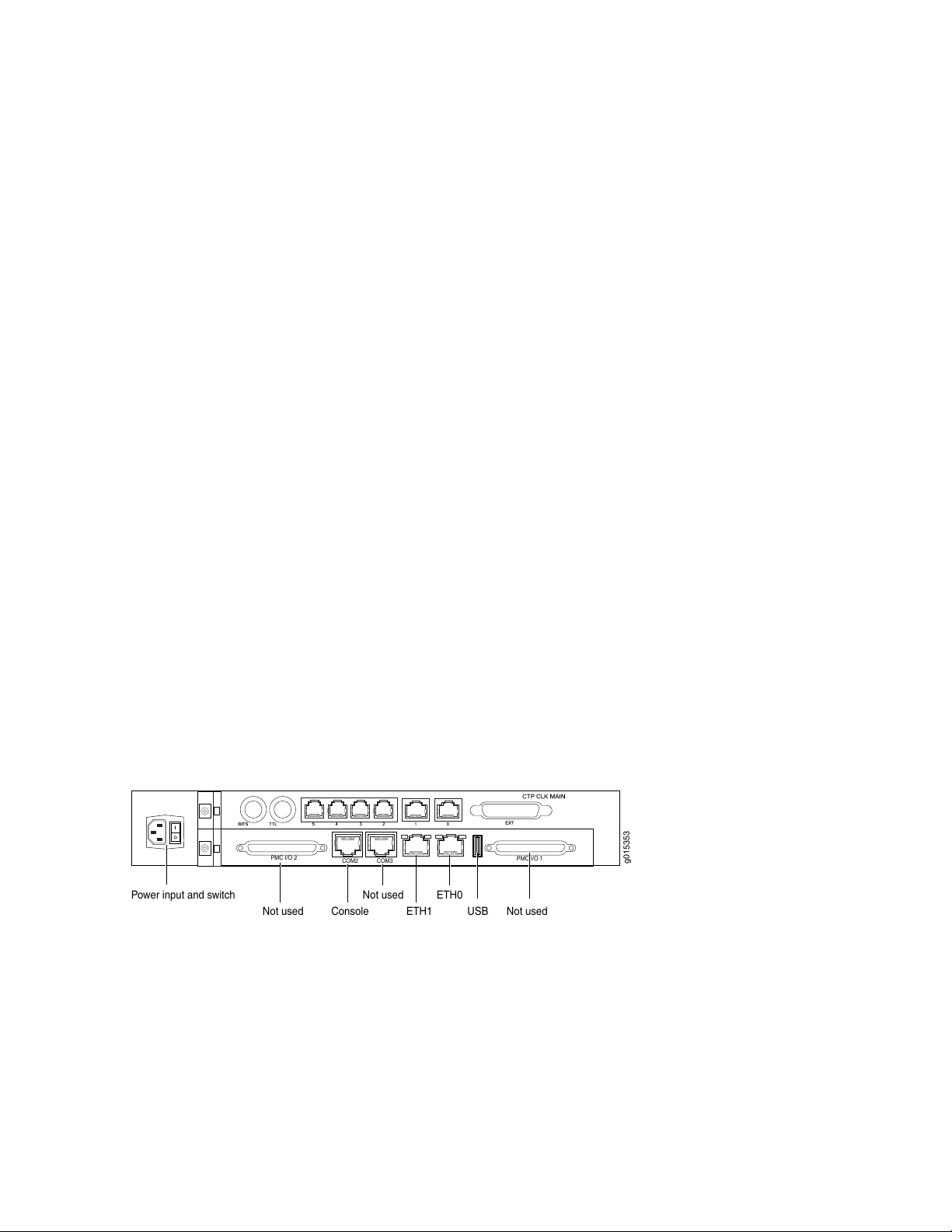

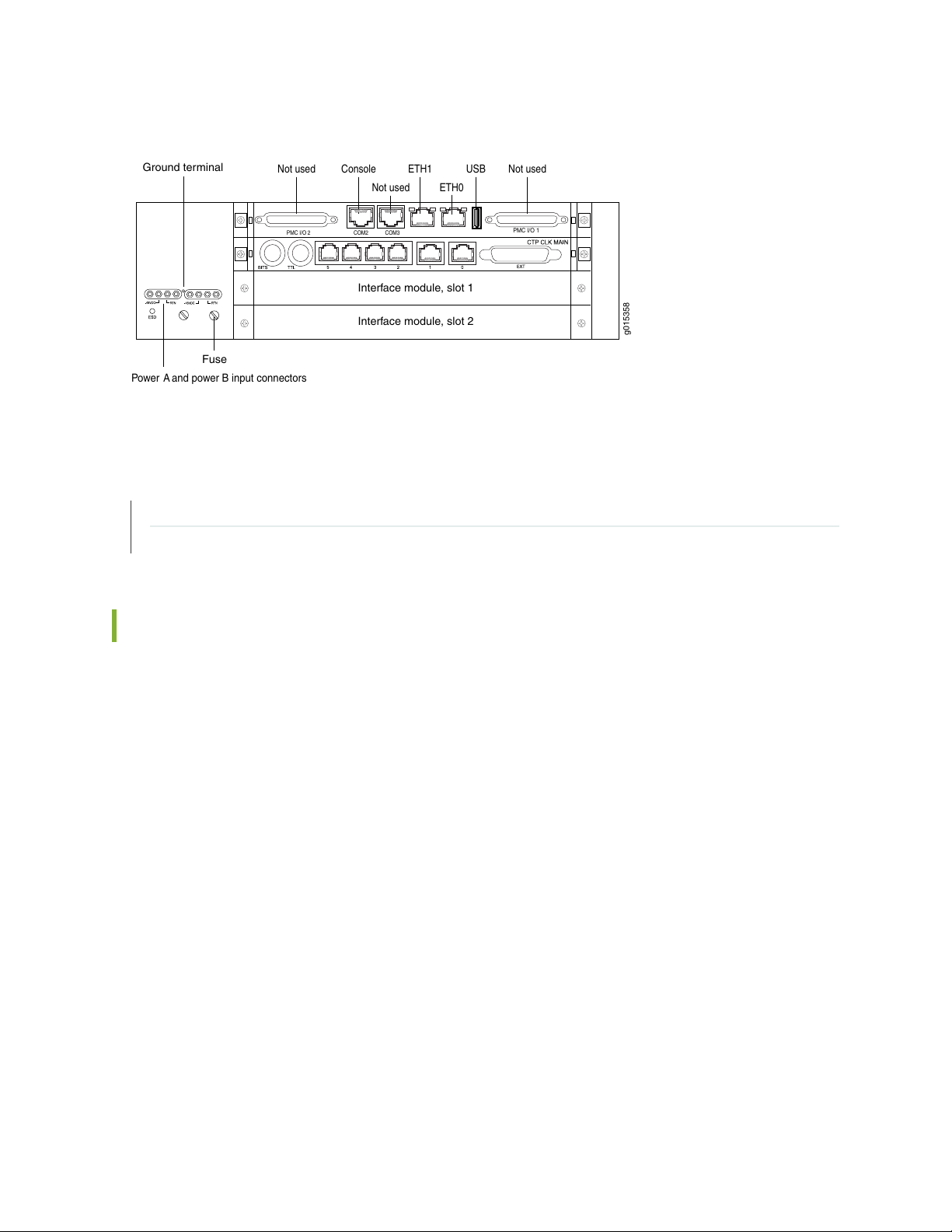

Figure 4: CTP2008 Platform Containing the PP332 Processor (DC Version, Rear View)

g015354

ETH1 USBConsolePower A input connector

COM2 COM3

PMC I/O 1PMC I/O 2

Not used Not used

Not used

ETH0

ESD

-48VDC

RTN

Fuse

USB

Optional fiber PMC

Power supply screw Power supply extractor

Interface module, slot 0

Fan tray with fan alarm

Removable air filter

Interface module, slot 1

Interface module, slot 2

g015388

RELATED DOCUMENTATION

CTP2024 Platform | 5

CTP2056 Platform | 7

5

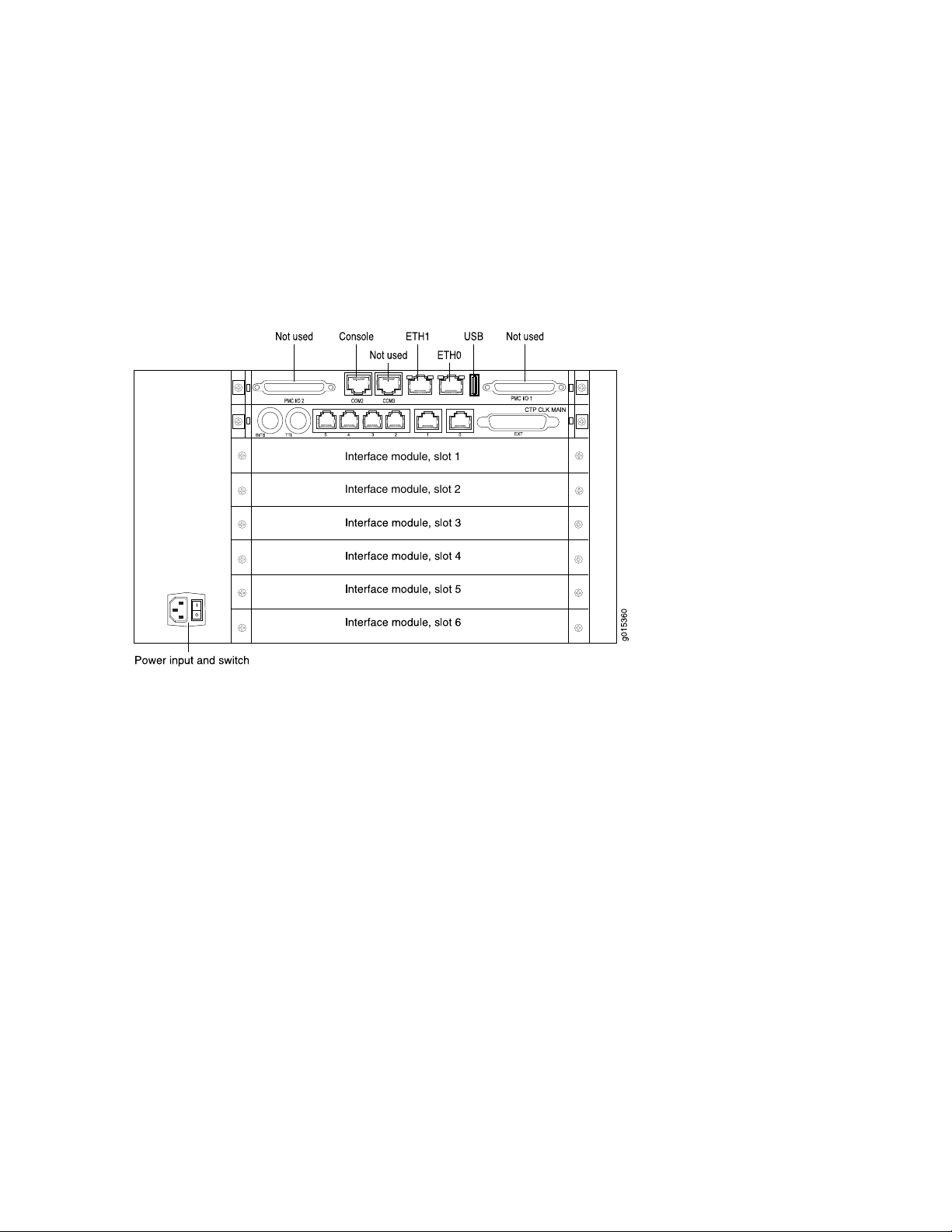

CTP2024 Platform

The Juniper Networks CTP2024 Circuit to Packet platform can have up to three removable interface

modules and one removable processor module, and is available in both AC-powered and DC-powered

versions. It has a removable fan tray, and airflow is side-to-side. Figure 5 on page 5, Figure 6 on page 6,

and Figure 7 on page 7 show the CTP2024 chassis containing the PP332 processor (which requires an

RTM card for Ethernet and console port accesses). The new PP833 processor module does not require an

RTM card. All PP833 module access is located on the front panel with all CTP serial and T1/E1 ports. If

you are upgrading from the old PP310 or PP332 processor to the PP833 processor, the RTM card may

be left in the node. But, none of the interfaces (Ethernet or serial ports) on the RTM panel are functional.

Figure 5: CTP2024 Chassis Containing the PP332 Processor (AC and DC Version, Front View)

The front panel comprises the following components (see Figure 5 on page 5):

Page 13

Interface modules—Frame processing and forwarding engines.

•

Processor module—Two slots are available on this module for an optional fiber Gigabit Ethernet or Fast

•

Ethernet PMC module. The primary SC connector is on the left side. For more information about the

PMC module, see “CTP2000 PMC Module” on page 30 and “Installing a PMC on CTP2000 Platforms”

on page 99.

Power supply extractor—Push the button to eject the power supply module.

•

Fan tray and air filter.

•

The rear panel (RTM) comprises the following components (see Figure 6 on page 6 and

Figure 7 on page 7):

Clock module—Provides clock distribution between modules when the backplane is in use by voice

•

applications.

Power supply—Use a standard IEC power cord for the AC version. Use a 22-AWG fork terminal connector

•

for the DC version. Power redundancy is supported for the AC version and the DC version. A single IEC

power cord is used to connect the redundant AC power supply modules, which keeps the chassis turned

on in the event of failure of one of the power supplies.

6

There are no power switches on CTP2000 Series DC models, so a readily accessible disconnect device

must be provided as part of the electrical installation of the unit. We recommend the 22-AWG wire for

DC power terminals.

Ethernet connection—Provides the 1-Gbps Ethernet connection to the IP network by means of a local

•

Ethernet switch or router.

Console connection—Provides an asynchronous tty connection for locally configuring the CTP Series

•

device. On the PP310 and PP332 processors, you can connect a console directly to the COM2 port

(which is an RJ-45 type connector) found on the RTM panel.

Figure 6: CTP2024 Platform Containing the PP332 Processor (AC Version, Rear View)

Page 14

Figure 7: CTP2024 Platform Containing the PP332 Processor (DC Version, Rear View)

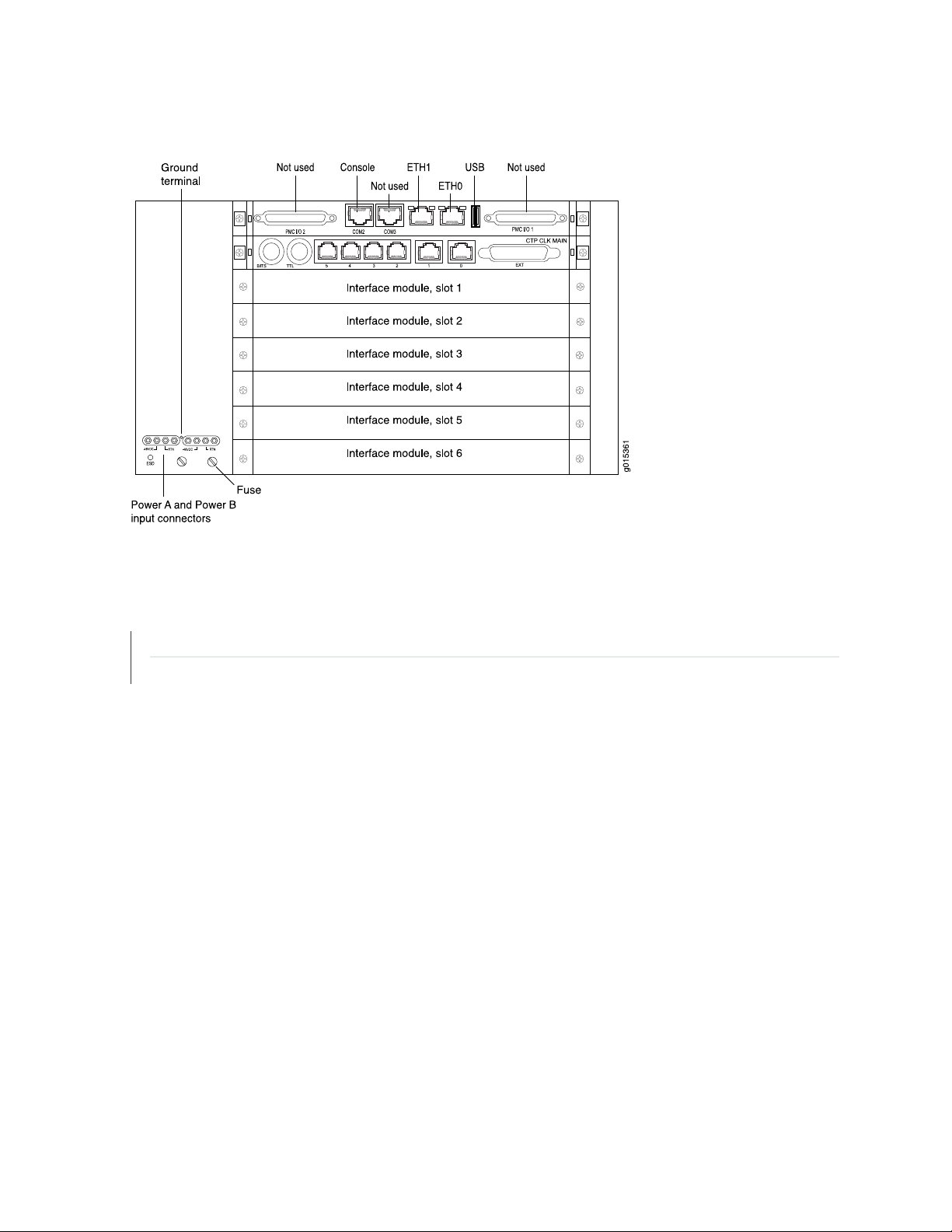

Power A and power B input connectors

Ground terminal

Fuse

ETH1 USBConsole

COM2 COM3PMC I/O 2

Not used

Not used

Interface module, slot 1

Interface module, slot 2

g015358

Not used

ETH0

PMC I/O 1

RELATED DOCUMENTATION

7

CTP2008 Platform | 3

CTP2056 Platform | 7

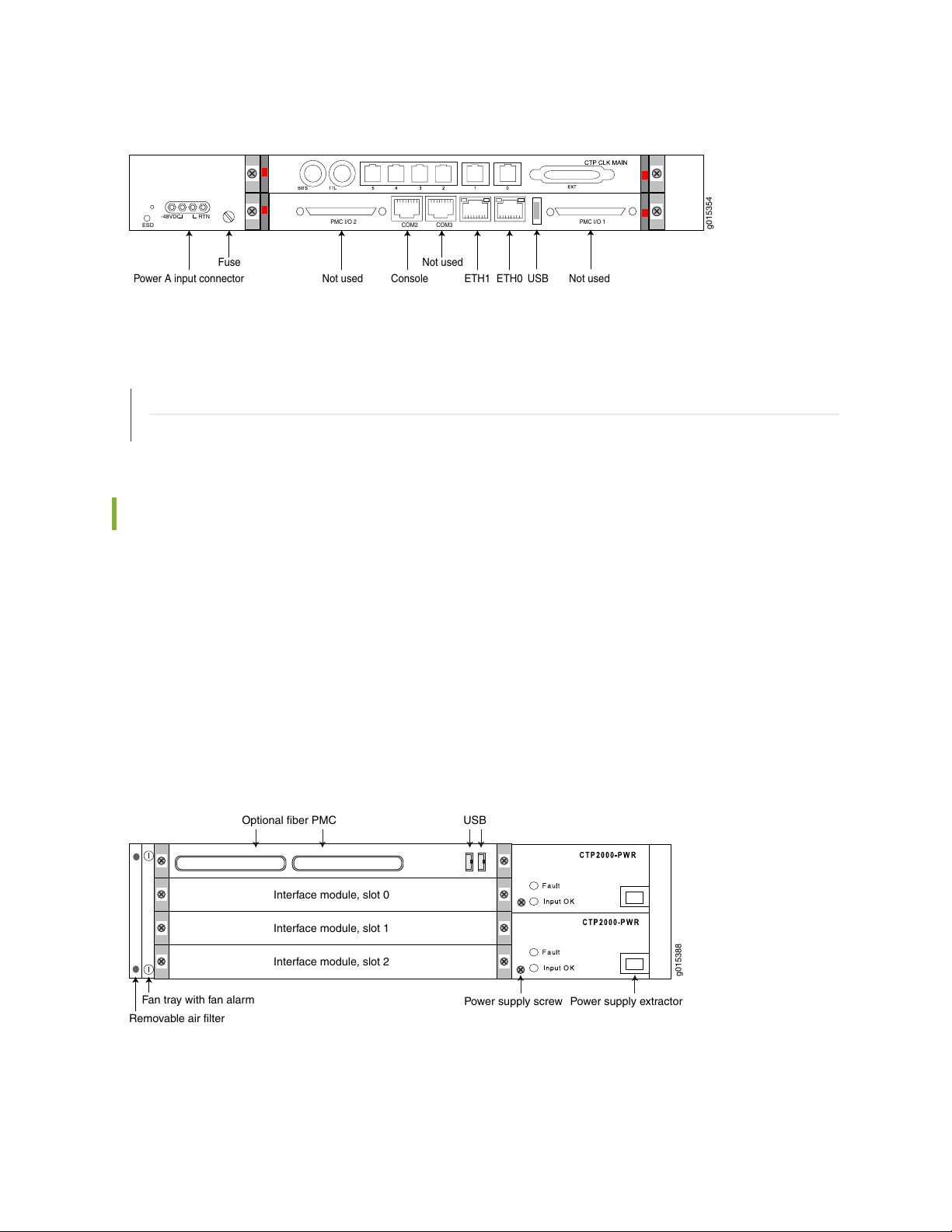

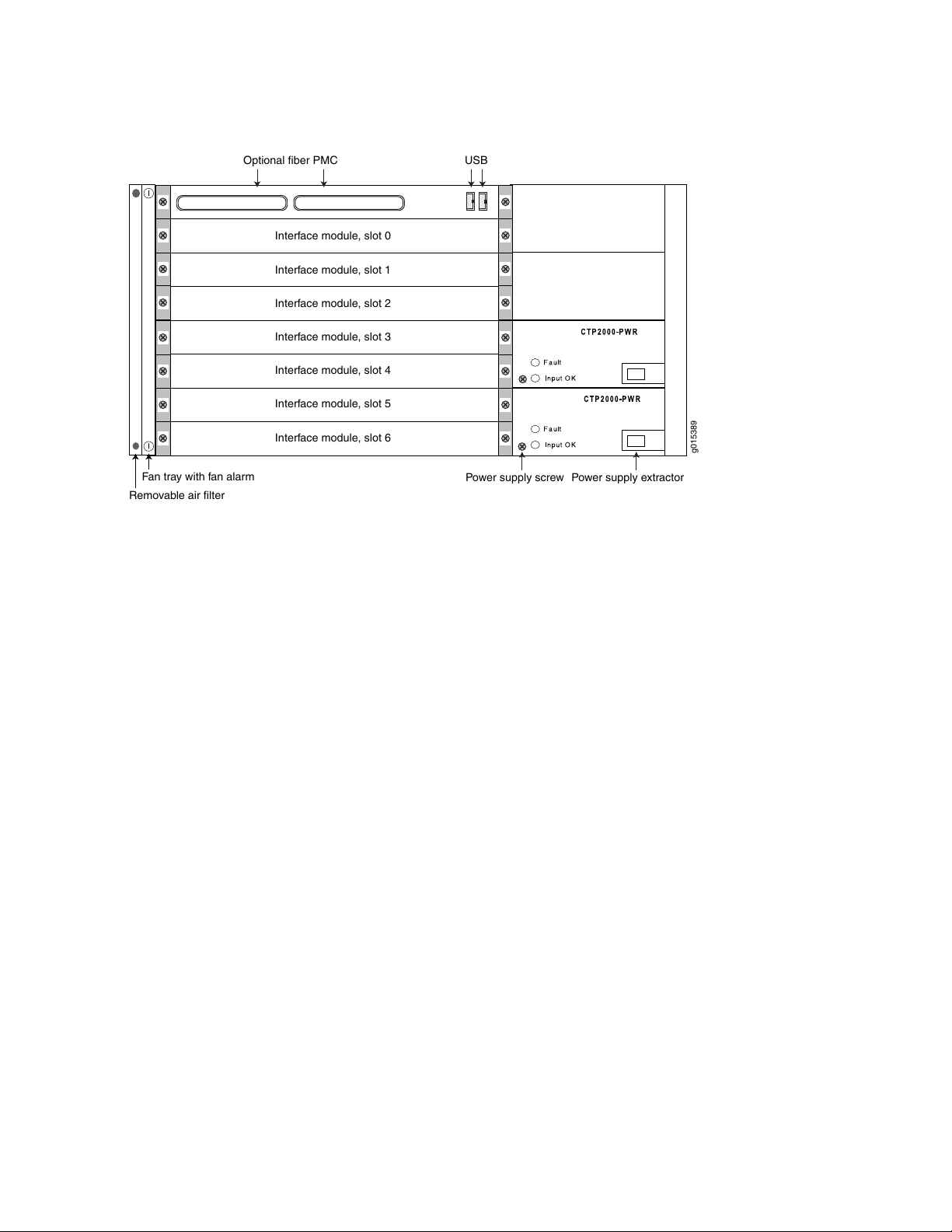

CTP2056 Platform

The Juniper Networks CTP2056 Circuit to Packet platform can have up to seven removable interface

modules and one removable processor module, and is available in both AC-powered and DC-powered

versions. It has a removable fan tray, and airflow is side-to-side. Figure 8 on page 8, Figure 9 on page 9,

and Figure 10 on page 10 show the CTP2056 chassis containing the PP332 processor (which requires an

RTM card for Ethernet and console port accesses). The new PP833 processor module does not require an

RTM card. All PP833 module access is located on the front panel with all CTP serial and T1/E1 ports. If

you are upgrading from the old PP310 or PP332 processor to the PP833 processor, the RTM card may

be left in the node. But, none of the interfaces (Ethernet or serial ports) on the RTM panel are functional.

Page 15

Figure 8: CTP2056 Chassis Containing the PP332 Processor (AC and DC Version, Front View)

USB

Optional fiber PMC

Power supply screw Power supply extractor

Interface module, slot 0

Interface module, slot 1

Interface module, slot 2

Interface module, slot 3

Interface module, slot 4

Interface module, slot 5

Interface module, slot 6

Fan tray with fan alarm

Removable air filter

g015389

8

The front panel comprises the following components (see Figure 8 on page 8):

Interface modules—Frame processing and forwarding engines.

•

Processor module—Two slots are available on this module for an optional fiber Gigabit Ethernet or Fast

•

Ethernet PMC module. The primary SC connector is on the left side. For more information about the

PMC module, see “CTP2000 PMC Module” on page 30 and “Installing a PMC on CTP2000 Platforms”

on page 99.

Power supply extractor—Push the button to eject the power supply module.

•

Fan tray and air filter.

•

The rear panel (RTM) comprises the following components (see Figure 9 on page 9 and

Figure 10 on page 10):

Clock module—Provides clock distribution between modules when the backplane is in use by voice

•

applications.

Power supply—Use a standard IEC power cord for the AC version. Use a 22-AWG fork terminal connector

•

for the DC version. Power redundancy is supported for the AC version and the DC version. A single IEC

power cord is sufficient to connect the redundant AC power supply modules, which keeps the chassis

turned on in the event of failure of one of the power supplies.

There are no power switches on CTP2000 Series DC models, so a readily accessible disconnect device

must be provided as part of the electrical installation of the unit. We recommend the 22-AWG wire for

DC power terminals.

Page 16

Ethernet connection—Provides the 1-Gbps Ethernet connection to the IP network by means of a local

Interface module, slot 1

Interface module, slot 2

•

Ethernet switch or router.

Console connection—Provides an asynchronous tty connection for locally configuring the CTP Series

•

device. On the PP310 and PP332 processors, you can connect a console directly to the COM2 port

(which is an RJ-45 type connector) found on the RTM panel.

Figure 9: CTP2056 Platform Containing the PP332 Processor (AC Version, Rear View)

9

Page 17

Figure 10: CTP2056 Platform Containing the PP332 Processor (DC Version, Rear View)

10

RELATED DOCUMENTATION

CTP2008 Platform | 3

CTP2024 Platform | 5

Page 18

CHAPTER 2

CTP2000 Series Interface Modules

IN THIS CHAPTER

CTP2000 Serial Interface Modules | 11

CTP2000 Multiservice Interface Module | 12

CTP2000 T1/E1 Interface Module | 13

CTP2000 Compression Module | 13

CTP2000 4WE&M Interface Module | 14

CTP2000 2W-FXS and 2W-FXO Interface Modules | 20

CTP2000 8P-IRIG Interface Module | 26

11

CTP2000 Clock Interface Modules | 27

CTP2000 PMC Module | 30

CTP2000 Serial Interface Modules

The Juniper Networks CTP2008, CTP2024, and CTP2056 Circuit to Packet platforms have up to one,

three, and seven serial interface modules, respectively. The interface modules are interchangeable between

the platforms.

The following interface modules have two 100-pin connectors similar to the connectors provided on the

CTP1004 and CTP1012 platforms. Each connector provides four ports by means of the quad cable. (See

“Cabling the CTP2000 Platform Overview” on page 108.) The lowest-numbered ports start at the top right.

CTP2000 IM-8P—Provides the standard software-configurable data interfaces, including EIA530,

•

EIA530A, RS-232, and V.35; 8 port.

CTP2000 IM-8P-T1—Provides the standard software-configurable data interfaces, plus a configurable

•

T1/E1 interface; 8 port.

CTP2000 IM-8P-V—Provides the standard software-configurable data interfaces, plus a configurable

•

4WTO interface; 8 port.

Page 19

Figure 11: Sample Serial Interface Module

g015452

CTP2000 IM 8PIRIG

CTP2000 IM 8P MS

RELATED DOCUMENTATION

Cabling the CTP2000 Platform Overview | 108

CTP2000 Serial Interface Module Pinouts | 52

CTP2000 T1/E1 Interface Module | 13

CTP2000 Compression Module | 13

CTP2000 4WE&M Interface Module | 14

CTP2000 2W-FXS and 2W-FXO Interface Modules | 20

CTP2000 8P-IRIG Interface Module | 26

12

CTP2000 Multiservice Interface Module

The Juniper Networks CTP2000 Circuit to Packet platform optionally includes an 8-port Serial Multiservice

Interface module (CTP2000-IM-8p-MS) as shown in Figure 12 on page 12.

Figure 12: CTP2000 Serial Multiservice Interface Module

The cable used with the Serial Multiservice Interface module is CTP-CBL-4Q.

The module can operate in the following modes:

Audio—Provides single and dual channel audio support for varying quality audio from 8-bit, 8-KHz quality

•

to 8-bit up to 16-bit, 48-KHz quality (CD quality).

4WTO—Provides single and dual channel audio support for 8-bit, 8-KHz quality with squelch support

•

for radio backhaul. In 4WTO mode, the Multiservice interface module is interoperable with 4WTO

daughter cards.

IRIG—Enables an interrange instrumentation group time code (IRIG-B) signal to be transported through

•

an IP network.

TDC—Provides combined time-correlated support for IRIG/NRZ data for telemetry applications.

•

Page 20

The interface module is supported on CTP bundles; You use the bundles to configure the modes of

0 1 32

7654

CTP2000 IM-T1/E1

g015363

operation.

RELATED DOCUMENTATION

Serial Multiservice Interface Module Overview

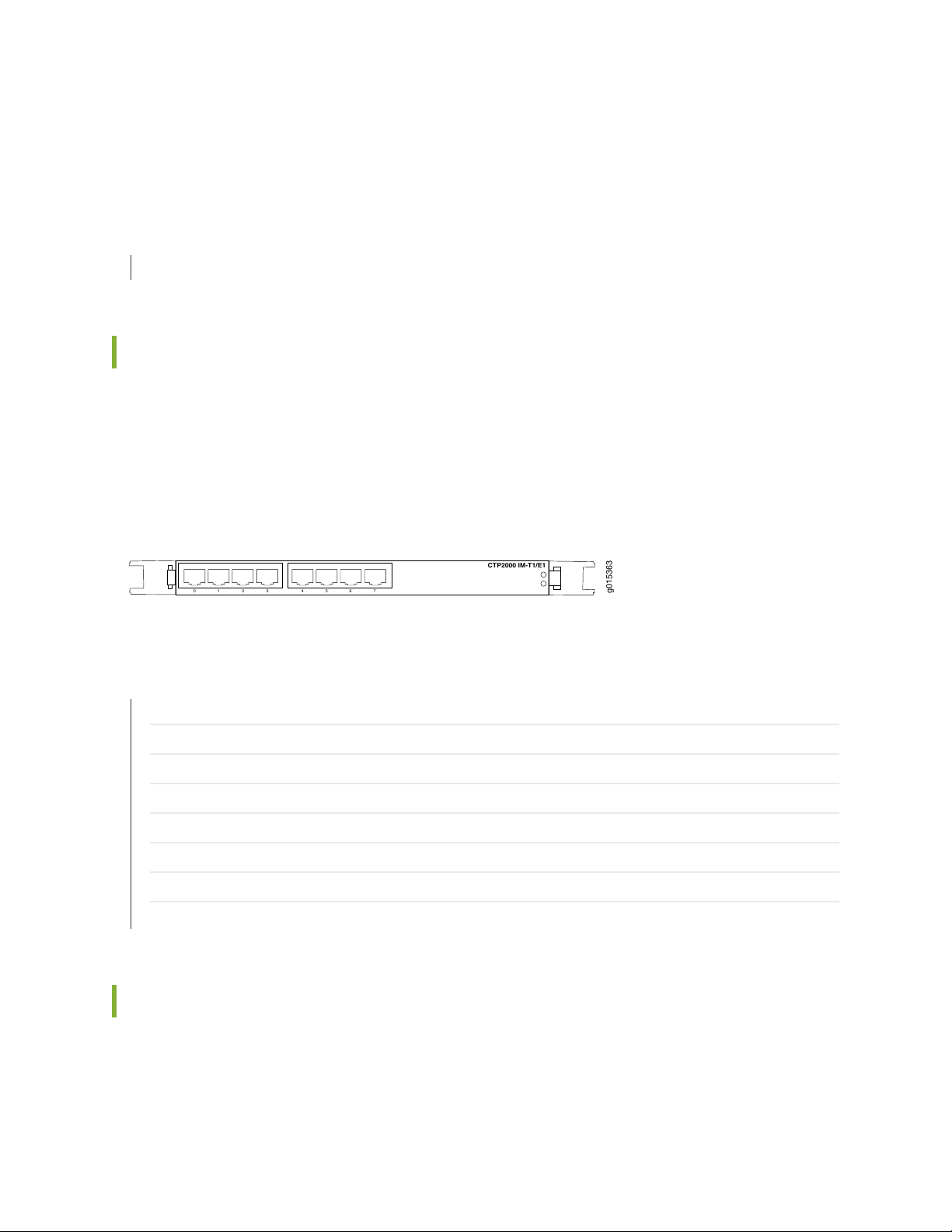

CTP2000 T1/E1 Interface Module

The CTP2000 Series T1/E1 interface module has RJ-48 ports numbered 0–7 left to right. It provides a

configurable eight-port E1 (2.048 MHz) or T1 (1.544 MHz) interface with AMI or B8ZS encoding. (See

Figure 13 on page 13.) You can use the eight port T1/E1 interface module to interconnect digital voice

applications with CESoPSN bundles.

13

Figure 13: CTP2000 IM-8P-T1/E1 Interface Module

RELATED DOCUMENTATION

CTP2000 Serial Interface Modules | 11

CTP2000 Compression Module | 13

CTP2000 4WE&M Interface Module | 14

CTP2000 2W-FXS and 2W-FXO Interface Modules | 20

CTP2000 8P-IRIG Interface Module | 26

T1/E1 Interface Module Pinouts | 51

Cabling a CTP2000 T1/E1 Interface Module | 111

CESoPSN Bundle Overview

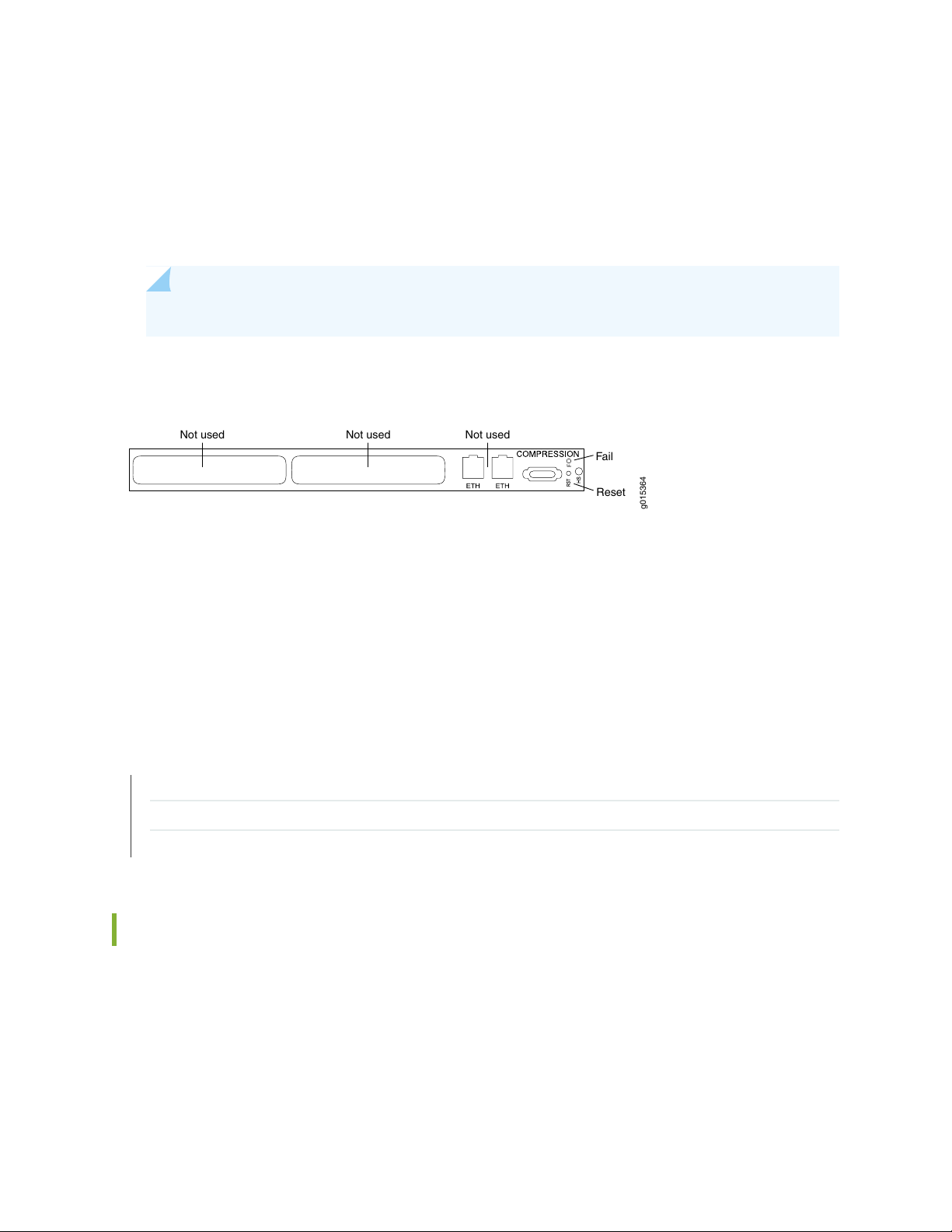

CTP2000 Compression Module

The CTP2000 Series Compression Module enables serial data and voice bundles to be compressed and

passed through a CTP2000 platform. It provides twice the digital signal processor (DSP) density of the

original compression module. (See Figure 14 on page 14.)

Page 21

Voice bundles originating from the CTP2000 IM-8P-T1/E1, analog CTP2000 IM-4WE&M,

Not used Not used Not used

Fail

Reset

g015364

CTP2000-IM-2W-FXS, and CTP2000-IM-2W-FXO modules can use the CTP2000 Compression 2 High

Density Interface Module to compress voice bundles. Voice bundles ranging from 1–24 channels on a T1

module, 1–30 channels on an E1 module, and 1–8 channels on a 4WE&M module can be bundled and

connected through the Compression 2 High Density Module to compress the voice bundle and build the

IP packet.

NOTE: CTP2000 Compression Module can no longer be purchased.

Figure 14: Compression Module

14

The Compression Module supports these compression algorithms:

G.711 (64k)

•

G.729AB (8k)

•

This module supports Mu-Law and A-Law companding, echo cancellation, silence suppression, fax/modem

detection, and tone relay. You can configure the compression options when you configure the voice bundle.

RELATED DOCUMENTATION

CTP2000 T1/E1 Interface Module | 13

CTP2000 4WE&M Interface Module | 14

CTP2000 2W-FXS and 2W-FXO Interface Modules | 20

CTP2000 4WE&M Interface Module

The CTP2000 Series 4WE&M interface module has eight 4-wire E&M ports. It is used with voice

compression (VCOMP) bundles in CTP2000 models and can be used only with a CTP2000 compression

module. You can use the 4WE&M interface module to interconnect analog 4WE&M voice applications

with CESoPSN bundles.

Page 22

NOTE: You can use the eight port T1/E1 interface module to interconnect digital voice

Port signaling LEDs

Not used

RJ-21 25-pair connectors

4WEM RTM

g015366

applications with CESoPSN bundles.

Four-wire audio interfaces with E and M signaling interfaces (4WE&M) are commonly used as trunks

between a central office (CO) and a private branch exchange (PBX). E and M is a type of supervisory line

signaling that uses separate leads, called the "E" (ear) lead and "M" (mouth) lead and are traditionally used

in the telecommunications industry. In 4WE&M signaling, two wires are used to receive and two wires are

used to transmit, incorporating simplex control and differential payload in each channel. Type I, II, and V

signaling is supported.

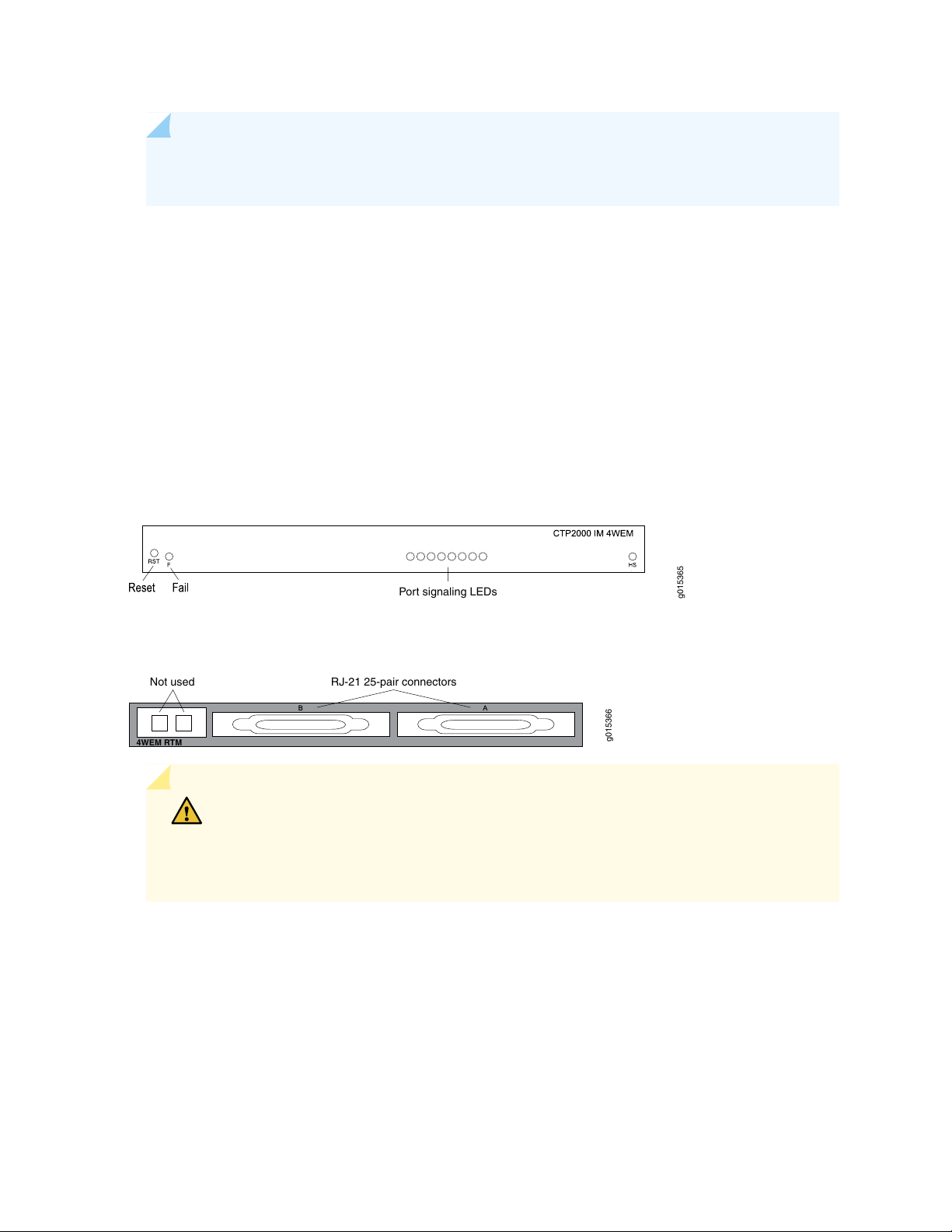

The 4WE&M interface module consists of a front card and a rear transition module (RTM). Port interfaces

are located on connectors A and B of the RTM. (See Figure 15 on page 15 and Figure 16 on page 15.) The

RJ-45 connectors are not used.

Figure 15: CTP2000 4WE&M Module

15

Figure 16: 4WE&M RTM

CAUTION: Power to the RTM is supplied from the interface module. Using an RTM

other than those matched to the interface module may result in damage to both the

interface module and the RTM. For example, never install a clock module RTM directly

behind a 4WE&M interface module.

Voice ports can be used only by voice compression bundles (VCOMP) and cannot be used for CTP, SAToP,

or CESoPSN bundles. There is no software configuration of 4WE&M ports. Signaling type is configured

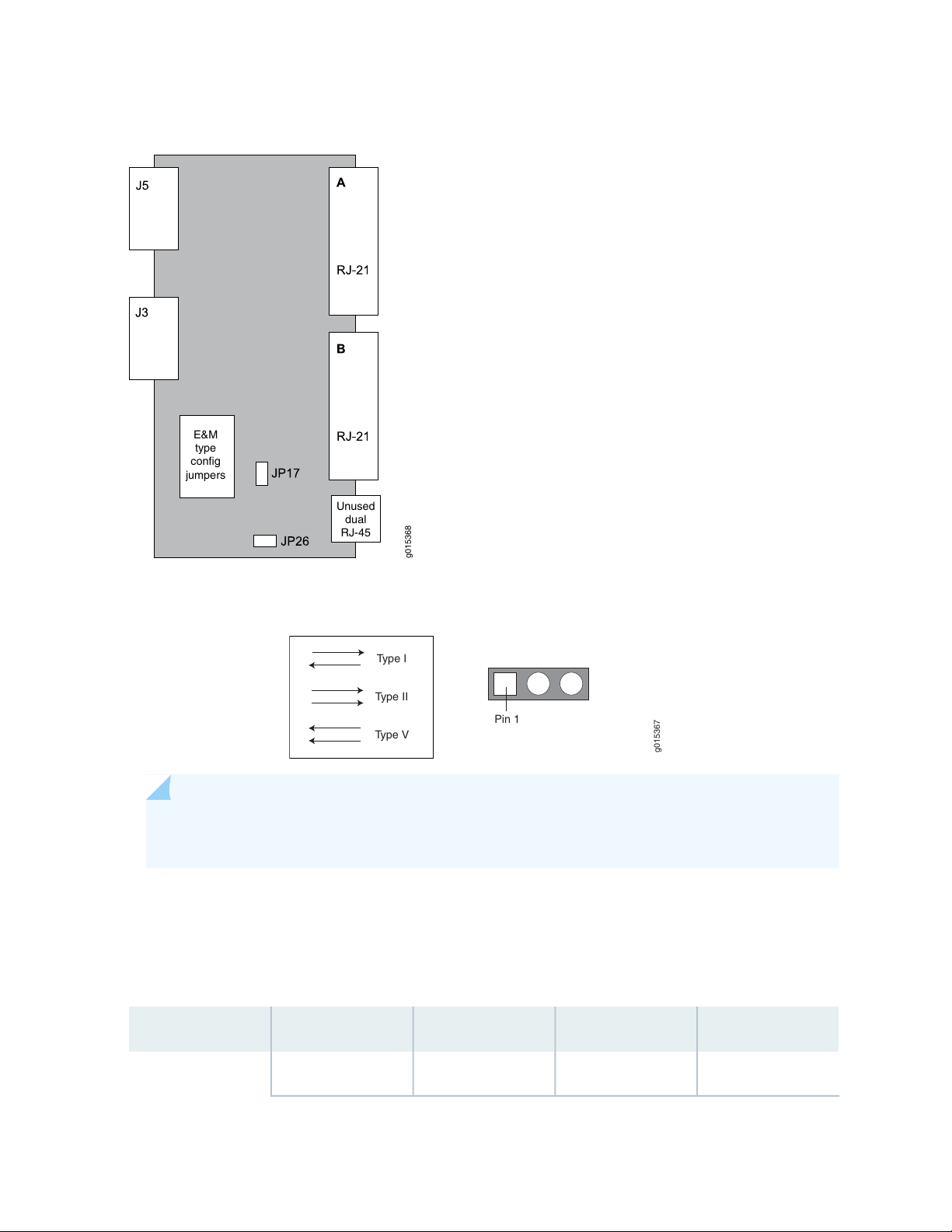

by means of jumpers (see Figure 18 on page 16 and Table 1 on page 16). One or more 4WE&M ports can

be mapped to a VCOMP bundle. The bundle configuration specifies the remote destination, the local port

or ports transported by the bundle, voice compression options, as well as other configuration options.

Page 23

Figure 17: Jumper Locations on the RTM

g015368

E&M

type

config

jumpers

Unused

dual

RJ-45

Pin 1

Type I

Type II

Type V

g015367

16

Figure 18: Jumper Positions for Signaling Types

NOTE: Jumper JP17 must be in Position 1-2 (see Table 1 on page 16) if any ports are set for

Type II signaling. This jumper ties all signal battery (SB) signals to battery voltage (–48V).

Jumper JP26 is used to connect all signal grounds (SG) to the chassis ground. When jumper JP26 is in

Position 1-2, the signal ground is connected to the chassis ground. In Position 2-3, it is isolated from the

chassis ground.

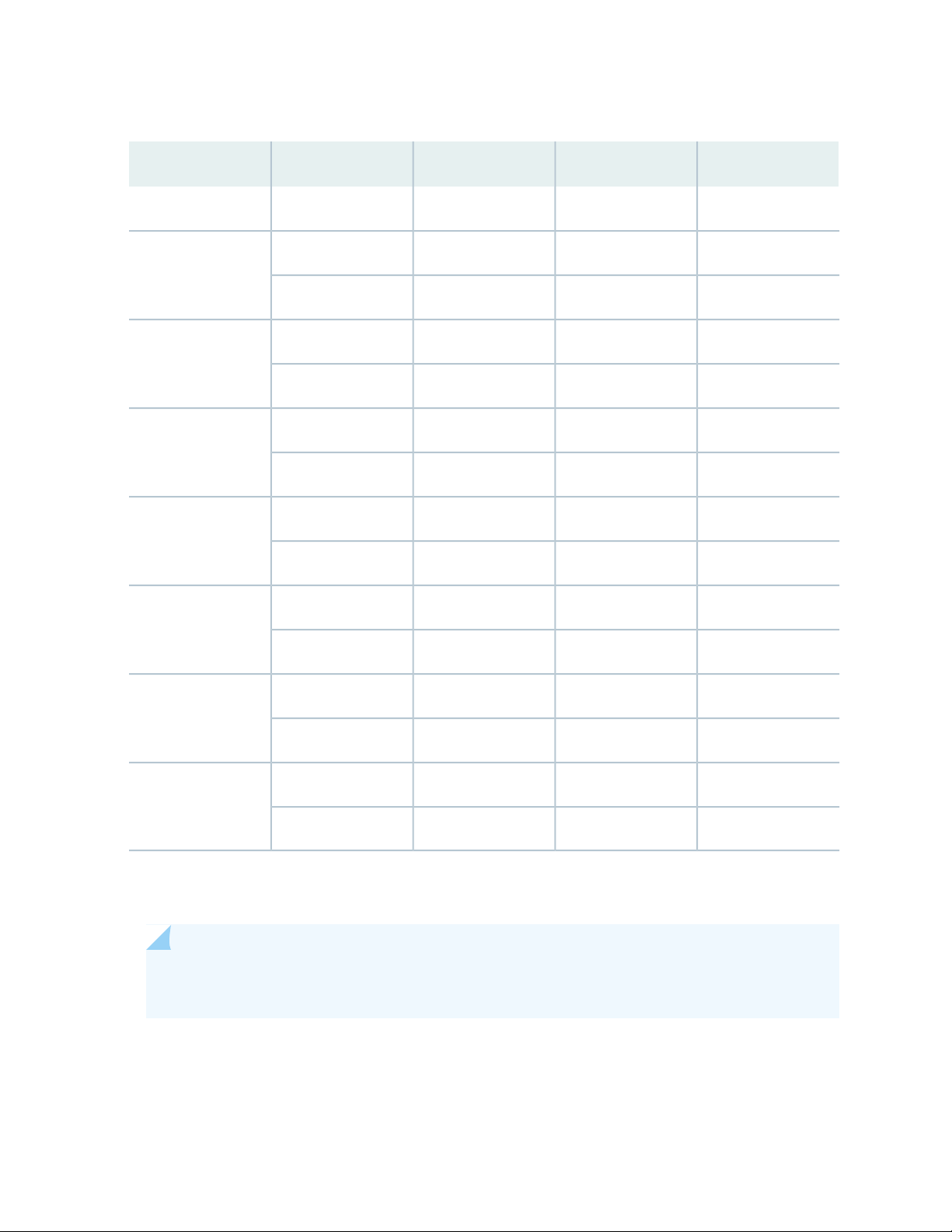

Table 1: Jumper Positions for Configuring Port Signaling Type

Signaling Type VSignaling Type IISignaling Type IJumper

Position 1-2Position 2-3Position 1-2JP1Port 0

Page 24

Table 1: Jumper Positions for Configuring Port Signaling Type (continued)

17

Signaling Type VSignaling Type IISignaling Type IJumper

Position 1-2Position 2-3Position 2-3JP9

Position 1-2Position 2-3Position 1-2JP2Port 1

Position 1-2Position 2-3Position 2-3JP10

Position 1-2Position 2-3Position 1-2JP3Port 2

Position 1-2Position 2-3Position 2-3JP11

Position 1-2Position 2-3Position 1-2JP4Port 3

Position 1-2Position 2-3Position 2-3JP12

Position 1-2Position 2-3Position 1-2JP5Port 4

Position 1-2Position 2-3Position 2-3JP13

Position 1-2Position 2-3Position 1-2JP6Port 5

Position 1-2Position 2-3Position 2-3JP14

Position 1-2Position 2-3Position 1-2JP7Port 6

Position 1-2Position 2-3Position 2-3JP15

Position 1-2Position 2-3Position 1-2JP8Port 7

Position 1-2Position 2-3Position 2-3JP16

The rear transition board uses two RJ-21 25-pair Telco connectors labeled A and B to interface the audio

and control connections for eight E&M channels.

NOTE: Because of space limitations, a 180º RJ-21 connector is required. The CTP 4WE&M RTM

supports clips to secure the RJ-21 cable connections to the RTM.

The R1/T1 pair and the R/T pair are the audio inputs and outputs of each port, respectively. For example,

the audio input pair for port 0 is R1 and T1 on pins 2 and 27 of connector A. The audio output pair for

port 0 is R and T on pins 1 and 26.

Page 25

See Table 2 on page 18 for signal definitions. See “CTP2000 4WE&M Interface Connector Pinouts” on

page 45 for the connector A and B pinouts.

Table 2: Signal Definitions

Signal DefinitionSignal Name

Audio transmit pair, 600 OhmPort x T, R

Audio receive pair, 600 OhmPort x T1, R1

E lead–outputPort x E

M lead–inputPort x M

Input for signal ground for signaling type IIPort x SG

18

Port x SB

GND

Output signal battery (–48V) for signaling type II. Note that JP17 must be in

position 1-2.

Signal ground. E and M leads are referenced to this ground for signaling types

I and V. Use JP26 to connect this ground to chassis ground.

Supervisory Signaling

Supervisory signaling is the means by which a telephone user requests a service or initiates a call. The

signaling unit (CTP platform) interacts with the trunk unit (PBX) by means of either two or four leads,

depending on the signaling type. (See Figure 19 on page 19.) The signaling unit controls the E lead, whereas

the trunk side controls the M lead. The two signaling states are on-hook and off-hook. During inactivity

both units are on-hook. See Table 3 on page 20 for a summary of signaling types supported by the CTP2000

4WE&M module.

NOTE: 4WE&M and 4WTO audio paths are always up independent of the signaling state.

Page 26

Figure 19: Analog 4WE&M Signaling Types

19

Type I uses two leads—the E and M leads—for signaling. During inactivity, the E lead is open and the M-lead

is connected to ground. The CTP device connects the E lead to a grounding point to signal off-hook, and

the PBX connects the M lead to the battery (–48 V) to signal off-hook. Note that two signaling units cannot

be connected back-to-back. With type I signaling, the signaling and trunk units must be connected by

means of a common ground. Because the two sides are not isolated, they are susceptible to noise in the

audio channels.

Type II uses four leads—E, SG, M, and SB—for signaling. During inactivity, both the E and M leads are open.

To signal off-hook, the PBX connects the M lead to SB and the CTP device connects the E lead to SG.

Note that two signaling units can be connected back-to-back if the appropriate signaling leads are swapped.

With Type II signaling, the signaling unit and the trunk do not share a common ground.

Page 27

Type V uses two leads, the E and M leads, for signaling. During inactivity, both the E and M leads are open.

The CTP device signals off-hook by connecting the E lead to ground. The trunk circuit signals off-hook by

connecting the M lead to ground. As with type I, with type V signaling, the two units share a common

ground. Type V signaling allows for signaling units to be connected back-to-back.

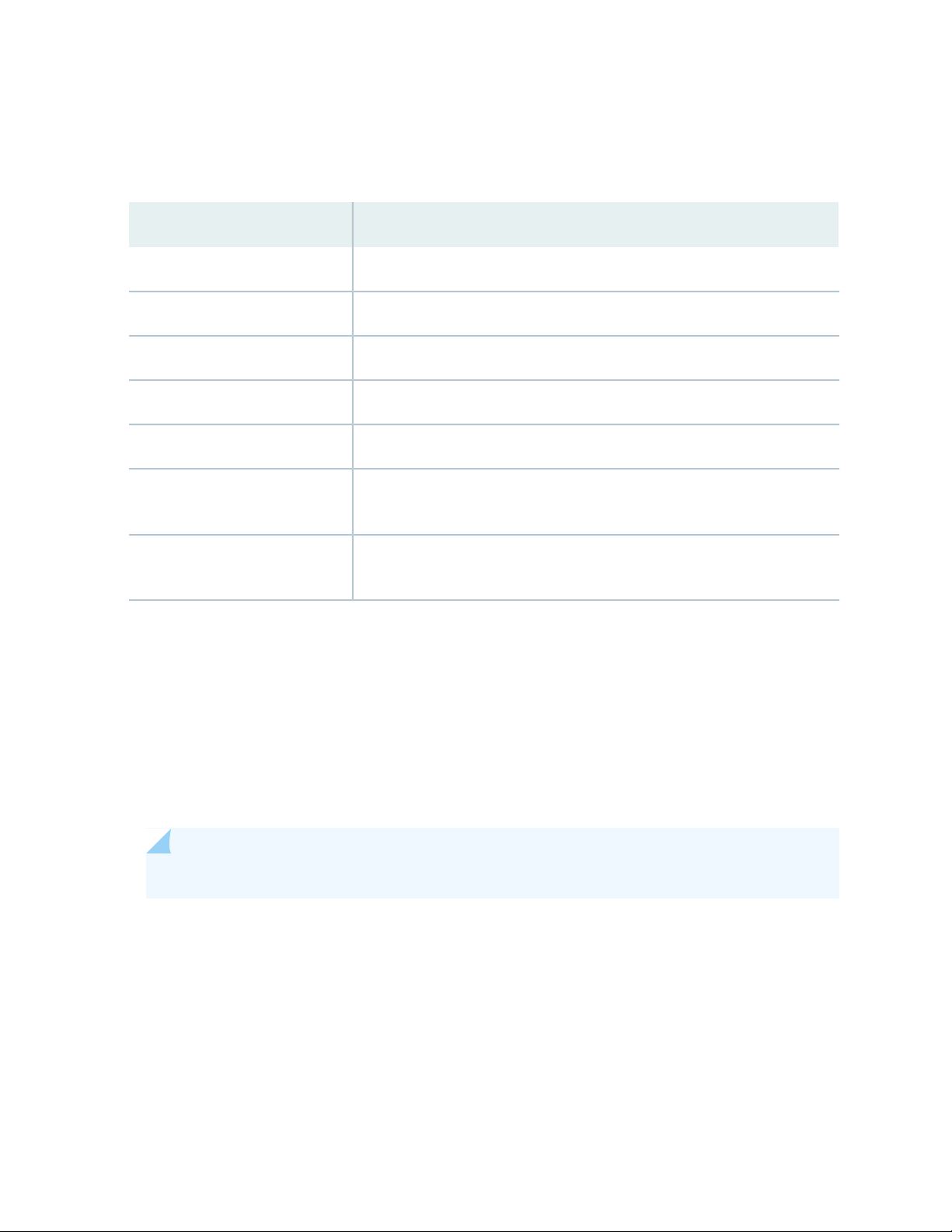

Table 3: Supported Signaling Types for the CTP2000 4WE&M Module

CTP (E Lead)PBX (M Lead)Signaling LeadsSignaling Type

Off-hookOn-hookOff-hookOn-hook

GroundOpenBatteryGroundE, MI

SGOpenSBOpenE, M, SG, SBII

GroundOpenGroundOpenE, MV

20

RELATED DOCUMENTATION

CTP2000 4WE&M Interface Connector Pinouts | 45

CTP2000 Serial Interface Modules | 11

CTP2000 T1/E1 Interface Module | 13

CTP2000 Compression Module | 13

CTP2000 2W-FXS and 2W-FXO Interface Modules | 20

CTP2000 8P-IRIG Interface Module | 26

CESoPSN Bundle Overview

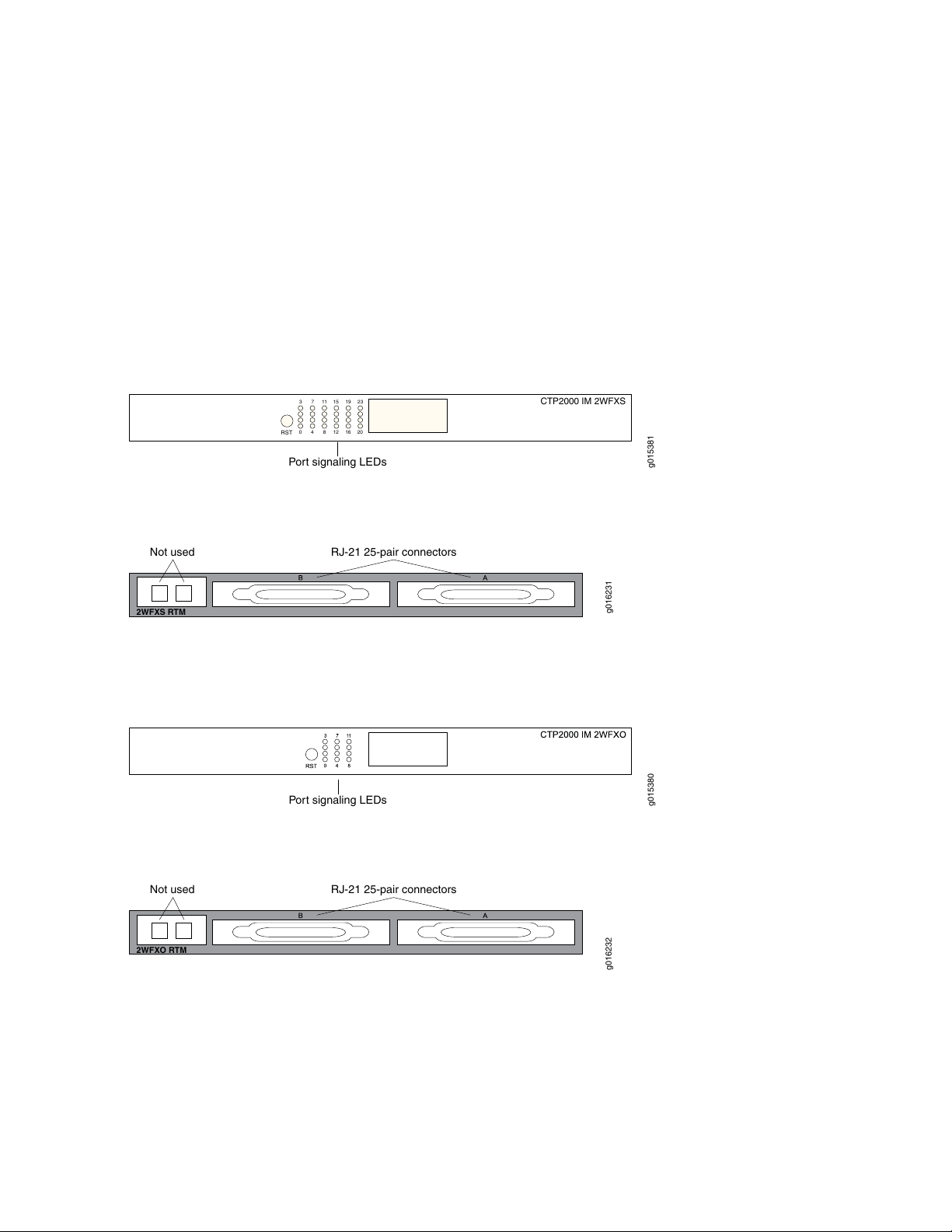

CTP2000 2W-FXS and 2W-FXO Interface Modules

The CTP2000 2W-FXS and CTP2000 2W-FXO interface modules provide analog support for voice

applications. The 2W-FXS module has 24 two-wire FXS ports and the 2W-FXO interface module has 12

two-wire FXS ports. Both are paired with an RTM.

FXS interfaces point to the subscriber and supply battery and ring voltage. Some FXS devices also provide

•

dial tone, but CTP FXS interfaces do not. FXS interfaces detect when the attached FXO interface goes

off-hook and on-hook. An FXS interface is a two-wire interface; the leads are called the tip (T) and the

ring (R).

FXO interfaces point to the central office. An analog phone is an example of an FXO device. The FXO

•

interface must detect ring voltage (the analog phone rings) and provide on- and off-hook indication to

Page 28

the FXS interface. An FXO interface is a two-wire interface; the leads are called the tip (T) and the ring

RST

2016

128

40

2319151173

CTP2000 IM 2WFXS

Port signaling LEDs

g015381

Not used

RJ-21 25-pair connectors

2WFXS RTM

g016231

Port signaling LEDs

g015380

Not used

RJ-21 25-pair connectors

2WFXO RTM

g016232

(R).

You can interconnect the following voice applications with CESoPSN bundles:

Analog 4WE&M voice applications using the 4WE&M interface module

•

Digital voice applications using the T1/E1 interface module

•

Both interface modules consist of a front module and an RTM. See Figure 20 on page 21 and

Figure 21 on page 21 for the CTP2000 2W-FXS interface module.

Figure 20: Front Panel of CTP2000 2W-FXS Interface Module

21

Figure 21: Rear Panel of CTP2000 2W-FXS RTM

See Figure 22 on page 21 and Figure 23 on page 21 for the CTP2000 2W-FXO interface module.

Figure 22: Front Panel of CTP2000 2W-FXO Interface Module

Figure 23: Rear Panel of CTP2000 2W-FXO RTM

Both modules use connector A on the RTM. For both modules, connector B and the RJ-45 connectors are

not used. See “CTP2000 FXS and FXO Interface Module Cables and Pinouts” on page 48 for connector

pinout information.

You set the signaling by using the software on both modules. You cannot reconfigure the jumper parameters.

Page 29

Required Cables and Pinouts

The CTP2000 2W-FXS and 2W-FXO interface modules require the use of double-shielded cables (copper

braid plus aluminum mylar foil) to ensure EMI compliance. See “CTP2000 FXS and FXO Interface Module

Cables and Pinouts” on page 48 for particulars about cable pinouts.

Analog FXS/FXO Loop-Start Signaling

There are two basic signaling protocols for FXS/FXO interfaces: loop-start and ground-start. Residential

telephones use loop-start. Ground-start is typically used between a CO and a PBX to prevent “glare.” Glare

occurs when a call is established by the FXS device and the FXO device tries to make a call before the ring

has been detected.

When a call is initiated from the CO (or FXS) side, the FXS interface puts an AC ring voltage on the R lead

(typically 70-90 Vrms). This ring voltage generates the ringing that you hear on an analog phone. When

the FXO device answers the call (someone picks up the handset), the switch is closed between the T and

R leads to complete a loop between the battery and ground in the FXS device. The FXS device detects

the current, which flows from the battery (–48 V) through the R leads and back through the T leads to

ground and stops the ring voltage.

22

When a call is initiated by the CPE (or FXO) device, the device goes off-hook, closing the connection

between the T and R leads. The FXS device senses the current flow in the loop. Either the attached FXS

device, or an upstream FXS device, provides dial tone to the FXO device after it is ready to accept the

digits for the call destination. Providing dial tone is a form of start-dial supervision.

On the FXO device, when the device is on-hook, there is an open lead between the T and R leads. When

the device is off-hook, the T and R leads are shorted with a typical load of ~300 Ohms. With loop-start,

the T and R leads on the FXO interface can be switched without adversely affecting the signaling.

Glare occurs when a call is established by the FXS device and the FXO tries to make a call before the ring

has been detected. Because it takes time for the FXO device (or person about to place a call) to detect

ringing, it is possible for the FXS and FXO devices to both seize the line without knowledge that the other

end has done so. Ground-start circuits were established the minimize the possibility of glare. See “Analog

FXS/FXO Ground-Start Signaling” on page 23.

Answer Supervision

Answer supervision is a signal used by the phone companies to determine when to start billing the originator

of the call. Without answer supervision, you could get billed for the time the phone was ringing, even if

the call was never picked up. When the FXS device has detected that the FXO device has gone off-hook,

it reverses the polarity between the T and R leads for the duration of the call.

Disconnect Supervision

Disconnect supervision is a signal sent by the FXS device to the FXO device to indicate that the call has

ended. The disconnect supervision signal can be either a battery reversal, battery denial (more than 350

ms), or a tone.

Page 30

Note that loop-start circuits are not sensitive to tip/ring reversal. For example, the tip on the FXO device

may be connected to either the tip or ring on the FXS.

Analog FXS/FXO Ground-Start Signaling

Ground-start signaling is used to minimize the potential for glare. Unlike loop-start circuits, ground-start

circuits operate correctly only when the FXO tip is connected to the FXS tip and the FXO ring is connected

to the FXS ring. Also, unlike loop-start circuits, the FXS and FXO grounds must be at the same potential.

When on-hook, the FXO ring is not connected to either the tip or ground. Likewise, when idle, the FXS

tip is not connected to ground. When a call is initiated from the CO (FXS side), the FXS grounds its tip and

applies an AC ring voltage to the R lead. The FXO device senses the grounded tip and AC ring voltage, and

then goes off-hook by closing the loop (connecting R to T). The FXO has 100 ms to respond to the grounded

tip/ring voltage. This time constraint is used to minimize glare. Once the FXO has closed the loop, the call

proceeds as in the loop-start case.

When a call is initiated by the customer (FXO) side, the FXO starts by grounding the R lead. The FXS side

responds by grounding its T lead. After the FXO has detected the grounded T lead, it closes the loop by

removing the R lead from ground and closing the loop. With ground-start circuits, a far-end disconnect

(FXS side) is indicated by the FXS disconnecting the tip from ground. The FXO senses the tip disconnect

and goes on-hook by opening the loop.

23

Digital Signaling

Channel banks are often used to multiplex and demultiplex FXS or FXO interfaces onto T1 or E1 digital

circuits. In the process, the analog signal is converted into pulse code modulation (PCM) and carried by

one of the channels in the time-division multiplexing (TDM) circuit. For the interface to function properly,

it must be able to signal the remote end of the T1/E1 connection as well as respond to signals from the

remote end. Signaling is carried over the TDM circuit using either channel-associated signaling (CAS) or

common-channel signaling (CCS). Generally, four signaling bits (A, B, C, and D) may be used; however, two

signaling bits are most common (A and B).

For CTP analog voice products to work with digital devices, A and B bits are generated and transported

across the network.

Digital FXS/FXO Loop-Start Signaling

For loop-start signaling of FXS and FXO interfaces, the A bit is used to indicate the state of the current

loop, whereas the B bit is used for ringing. In the idle state (no ringing, FXO on-hook), A=0 and B=1. A=1

when the FXO is off-hook. Ringing is signaled by the B bit toggling between 0 and 1. Typically the toggling

is 2 seconds off and 4 seconds on. For digital loop-state, the signaling is bidirectional.

Because hook indication is detected by the analog FXS interface, this device is responsible for generating

the A bit. Likewise, because the analog FXS interface generates the ring voltage, this device must respond

Page 31

to the B bit. Because the signaling is bidirectional, the FXS side must echo the B bit when sending out the

A bit.

The same logic applies to the FXO interface. The FXO device goes on/off-hook. It must respond to the A

bit, going off-hook when A transitions from 0 to 1, and going on-hook when A goes from 1 to 0. The analog

FXO interface detects ringing; therefore, it is responsible for generating the B bit value. The FXO device

must echo the A value when sending out the digital signaling over the network.

Two situations for this call sequence must be considered: when the CTP is the FXO device and when the

CTP platform is the FXS device. In both cases, before the call starts, the FXO is on-hook (A=1) and there

is no ringing (B=1).

For an analog CTP FXS interface, before the call starts, the CTP interface must generate A=0 and send

•

both A=0 and B=1. When the call initiates from the CO, the B bit is toggled. In response to this toggling,

the CTP device generates a ring voltage on the analog FXS interface. When the attached FXO device

goes off-hook, the CTP FXS interface detects the off-hook, sets the A bit to 1, and stops the ring voltage.

During the call, the CTP device sends A = B = 1 signaling bits. At the end of the call, the FXO device

goes back to on-hook, the CTP detects the on-hook, sends out A=0 and B=1 signaling bits, and the circuit

returns to the idle state.

24

For an analog CTP FXO interface, before the call starts the FXO is on-hook and no ringing is generated

•

by the attached FXS device. In this, the idle state, the CTP interface generates B=1 and sends both A=0

and B=1. When the call comes in from the CO, the CTP FXO interface detects ring voltage and starts

toggling the B bit. When the other end of the VCOMP bundle goes off-hook, it sends A=1 to the CTP.

In response, the CTP FXO interface closes the loop, going off-hook. With ringing stopped, the CTP

interface sends A = B = 1 during the call. At the end of the call the interface is again idle, and the CTP

interface sends A=0 and B=1 signaling bits.

Digital FXS/FXO Ground-Start Signaling

Unlike loop-start interfaces, in which the FXO and FXS each separately control a single signaling bit, with

ground-start signaling each side controls both the A and B bits. We must consider each interface when

the call is initiated by either interface. (See Table 4 on page 24, Table 5 on page 25, Table 6 on page 25,

and Table 7 on page 25). In all cases, when the FXO/FXS interface is idle, the FXO interface generates A

= B = 1 signaling bits and the FXS A = 0, B = 1. When a call is in progress, either side initiates a call

termination if it receives these signaling bits. For example, an FXS goes on-hook if it receives A=B=1

signaling bits.

Table 4: Ground-Start Signaling at FXO Interface for Call Initiated by the FXO Interface

Signaling Bits from FXOSignaling Bits to FXO

11 (A=1, B=1)01 (A=0, B=1)Idle (before call starts)

1100FXO grounds ring

0100FXS goes off-hook (grounds tip)

Page 32

Table 4: Ground-Start Signaling at FXO Interface for Call Initiated by the FXO Interface (continued)

Signaling Bits from FXOSignaling Bits to FXO

0111FXO goes off-hook (closes loop)

0111Duration of call

Table 5: Ground-Start Signaling at FXO Interface for Call Initiated by the FXS Interface

Signaling Bits from FXOSignaling Bits to FXO

11 (A=1, B=1)01 (A=0, B=1)Idle (before call starts)

00/01 (B-bit toggles)01FXS goes off-hook (grounds tip and

sends AC ring signal)

0111FXO goes off-hook (closes loop)

25

0111Duration of call

Table 6: Ground-Start Signaling at FXS Interface for Call Initiated by the FXS Interface

Signaling Bits from FXSSignaling Bits to FXS

01 (A=0, B=1)11 (A=1, B=1)Idle (before call starts)

0100/01 (B-bit toggles)FXS goes off-hook (grounds tip and

sends AC ring signal)

1101FXO goes off-hook (closes loop)

1101Duration of call

Table 7: Ground-Start Signaling at FXS Interface for Call Initiated by the FXO Interface

Signaling Bits from FXSSignaling Bits to FXS

01 (A=0, B=1)11 (A=1, B=1)Idle (before call starts)

sends AC ring signal)

0011FXO grounds ring

0001FXS goes off-hook (grounds tip and

Page 33

Table 7: Ground-Start Signaling at FXS Interface for Call Initiated by the FXO Interface (continued)

Signaling Bits from FXSSignaling Bits to FXS

1101FXO goes off-hook (closes loop)

1101Duration of call

RELATED DOCUMENTATION

CTP2000 Serial Interface Modules | 11

CTP2000 T1/E1 Interface Module | 13

CTP2000 Compression Module | 13

CTP2000 4WE&M Interface Module | 14

CTP2000 8P-IRIG Interface Module | 26

26

CTP2000 FXS and FXO Interface Module Cables and Pinouts | 48

CESoPSN Bundle Overview

CTP2000 8P-IRIG Interface Module

The CTP2000 8P-IRIG interface module enables an interrange instrumentation group time code (IRIG-B)

signal to be transported through an IP network. IRIG-B is a special time code transmission format that uses

a hybrid analog/digital physical interface. The IRIG-B standard consists of a family of rate-scaled serial

time codes with formats containing up to three coded expressions or words. The IRIG-B pulse code contains

one frame of 100 elements per second for the time of the year and GPS receiver status. IRIG-B encodes

day of year, hour, minute, and second data on a 1-KHz carrier frequency, with an update rate of once per

second.

The CTP2000 8P-IRIG module has eight ports. You can configure direction, high and low level output, and

data range for this module. (See Figure 24 on page 27.)

NOTE: CTP2000 8P-IRIG Interface Module can no longer be purchased.

Page 34

Figure 24: CTP2000 8P-IRIG Interface Module

g015378

CTP2000 IM 8PIRIG

CTP2000 IM 8P IRIG

RELATED DOCUMENTATION

CTP2000 Serial Interface Modules | 11

CTP2000 T1/E1 Interface Module | 13

CTP2000 Compression Module | 13

CTP2000 4WE&M Interface Module | 14

CTP2000 2W-FXS and 2W-FXO Interface Modules | 20

27

CTP2000 Clock Interface Modules

Clock interface modules provide clock distribution between modules when the backplane is in use by voice

applications.

The clock rear transition module (RTM) is used to input a reference clock into the CTP2000 platform. The

clock RTM is installed in the rear of the chassis behind the first interface module as follows:

On CTP2008 devices, the first slot above the processor RTM.

•

On the CTP2024 and CTP2056 devices, the first slot below the processor RTM.

•

Clock distribution is accomplished through a “hub-and-spoke” configuration composed of a main module

and a spoke module. Clock main modules (Figure 25 on page 27) and clock spoke modules

(Figure 26 on page 28) allow more clock input types in the CTP2000 chassis and provide the capability

for clock distribution when both serial or T1/E1 interface modules and voice modules are installed in the

same CTP2000 chassis.

Figure 25: Clock Main Module

Page 35

Figure 26: Clock Spoke Module

g015377

Hub module

Spoke module

g015375

The clock main module accepts an external clock reference and distributes it to the spoke module using

a twisted pair cable. Each nonvoice card receives the clock on the first RJ-45 and sends it to the front

module.

Figure 27: Hub-and-Spoke Setup

28

The main clock module has two BNC inputs (BITS and TTL), six RJ-45 ports, and one DB-25 port. Each

RJ-45 port can be connected to one spoke module. The spoke module has one ingress RJ-45 port and one

DB-25 interface. (See Figure 25 on page 27, Figure 26 on page 28, and Figure 27 on page 28.)

NOTE: The latest version of the clock main module does not have the BITS connector and no

longer supports a BITS BNC input. If you need a BITS timing reference to or from a CTP2000

node, you can use any of ports te-0/0 through te-0/3 if you have a T1/E1 interface module in

the first slot.

Page 36

NOTE: BITS input is a T1/E1 line interface unit (LIU), with AMI (alternate mark inversion) encoding

enabled and B8ZS/HDB3 (Zero Suppression) disabled. The equalization is set for a 0-133 feet

cable. An internal 100 ohm termination is present, although it might need to be externally

augmented based on the type of cabling used. Any valid AMI signal works properly and it is not

restricted to only the "all 1" BITS signal but the ones density must be sufficient to prevent LOS

(according to the ITU G.775 recommendation). The TTL input has a slice point of 3.3V/2 = 1.65V

relative to chassis ground (GND). Therefore, any signal on the coaxial center conductor that

transitions through that voltage registers a transition. There are many signals, besides TTL, that

satisfy this criteria. An external termination must be provided that matches the impedance of

the cable that goes to the BNC connector.

If you can configure the rate in CTP menu, then the TTL supports a frequency of 2048 KHz for

the TTL clock input, provided the signal is good and noise-free (terminated properly). TTL is

rate-agile, while BITS is restricted to T1/E1 frequencies.

The TTL input is high-impedance (no on-board termination provided) because a variety of cable

types might exist that you can use to drive signal to this connector, such as RG-58 coax (50 ohm),

RG-59 coax (75 ohm), or twisted pair (100-120 ohm). Instead of applying a particular impedance

termination on the board and have it incorrectly done, we recommend that you configure the

impedance termination based on your network environment. For example, a 50 ohm termination

is needed if you are using RG-58/U coax cable, which has 50 ohm impedance.

29

External Reference Clock

The CTP2000 device can receive the external reference clock from any of the following inputs on the

clock main module:

The DB-25 connector. The clock input is provided on pins 24 and 11.

•

The T1/E1 BITS inputs

•

NOTE: The latest version of the clock main module does not have the BITS connector and no

longer supports a BITS input. If you need a BITS timing reference to or from a CTP2000 node,

you can use any of ports te-0/0 through te-0/3 if you have a T1/E1 interface module in the

first slot.

The T1/E1 TTL input

•

Page 37

Installation Notes for Clock Interface Modules

Main modules and spoke modules are not hot-swappable.

•

Nonvoice modules and voice modules can be installed in any slot.

•

Main clock RTMs must be installed in slot 0 behind either a serial module or a T1/E1 module.

•

Spoke RTMs must be installed behind serial modules and the lowest-numbered T1/E1 slot.

•

If a T1/E1 module is installed in the slot that is closest to the processor, a spoke RTM is not needed

•

behind any T1/E1 modules. They will synchronize to the H.100 clock.

For platforms with only nonvoice boards (serial or T1/E1 module), only a main RTM is needed for external

•

clock reference input.

NOTE: The clock RTM is installed in the rear of slot 0 next to the CPU slot. When you upgrade

from an older processor to a PP833 processor, you can leave the CPU RTM in the chassis. Leaving

the CPU RTM in the chassis will not adversely affect the functioning of the PP833 processor.

Leaving the RTM installed will provide proper airflow within the CTP node.

30

RELATED DOCUMENTATION

Installing a CTP Interface Module, Processor Module, or Clock Module | 95

Removing a CTP Interface Module, Processor Module, or Clock Module | 96

CTP2000 PMC Module

The PCI mezzanine card (PMC) is mounted on the processor module and can be installed or replaced in

the field. Two PMC slots are available in the processor’s front panel to support two compatible PMC

modules. Figure 28 on page 31 displays the location of the PMC module on the CPU card. The following

PMC modules are available:

CTP-FX2000GE-UPG—Dual SC multimode fiber Gigabit Ethernet PMC module offers dual 1000 Mbit

•

Ethernet connectivity with SX signaling on an SC fiber connector.

CTP-FX2000FE-UPG—Dual SC multimode fiber Fast Ethernet PMC module offers dual 100FX Fast

•

Ethernet connectivity on an SC fiber connector.

CTP-Fiber-PMC—Fiber PMC card supports up to two SFP modules. Supported SFP modules are:

•

CTP-SFP-1GE-T: Small form-factor pluggable 1000BASE-T Gigabit Ethernet module (uses Cat 5 cable)

•

Page 38

CTP-SFP-1GE-SX: Small form -factor pluggable 1000BASE- SX Gigabit Ethernet optic module

•

CTP-SFP-1GE-LX: Small form-factor pluggable 1000BASE-LX Gigabit Ethernet optic module

•

For information about how to install a PMC on CTP2000 Platforms, see “Installing a PMC on CTP2000

Platforms” on page 99.

Figure 28: CTP2000 PMC Module Location

31

RELATED DOCUMENTATION

CTP2000 Serial Interface Modules | 11

CTP2000 T1/E1 Interface Module | 13

CTP2000 Compression Module | 13

CTP2000 4WE&M Interface Module | 14

CTP2000 2W-FXS and 2W-FXO Interface Modules | 20

CTP2000 8P-IRIG Interface Module | 26

Installing a PMC on CTP2000 Platforms | 99

Page 39

2

PART

Planning

System Specifications | 33

Planning and Preparing the Site | 40

Equipment Rack Requirements | 42

Cable and Pinout Specifications | 45

Page 40

CHAPTER 3

System Specifications

IN THIS CHAPTER

CTP2008 Platform Specifications and Certification | 33

CTP2024 Platform Specifications and Certification | 35

CTP2056 Platform Specifications and Certification | 38

CTP2008 Platform Specifications and Certification

33

Table 8: CTP2008 Platform Specifications

SpecificationCategory

Weight

16 lb (7.25 kg)Chassis only

Dimensions

Chassis only

Environmental Requirements

1.75 in. (4.44 cm) high

17.25 in. (43.81 cm) wide

11.25 in. (28.57 cm) deep

32° to 104° F (0° to 40° C)Ambient operating temperature

5% to 90% (noncondensing)Ambient operating humidity

DC Input

–40 to –72 VDCVoltage

3A @ –48 VDCCurrent

Page 41

Table 8: CTP2008 Platform Specifications (continued)

SpecificationCategory

144 WPower

2 independent line feedsRedundancy (input power)

AC Input

100–240 VACPower required

50–60 HzAC line frequency

2.0Nominal current (115V amps)

200 WPower

34

Space Requirements

Airflow

Safety Agency Certification

3 ft. (90 cm) behind device or rack.

Do not block air vents on the front or back of the device.

Air intake occurs from the front of the device.

Air is exhausted out the back of the device.

AS/NZS 60950:2000 Safety of Information Technology Equipment

•

CAN/CSA-C22.2, No. 60950-1–03, First Edition, Information Technology

•

Equipment - Safety - Part 1: General Requirements

EN60825-1, Safety of Laser Products - Part 1: Equipment Class,

•

Requirements, and User's Guide (2001)

IEC 60950-1(2001-10) Ed. 1.0 Information Technology Equipment - Safety

•

- Part 1: General Requirements

Low Voltage Directive (2006/95/EC)

•

UL 60950-1, First Edition, Information Technology Equipment - Safety -

•

Part 1: General Requirements

Page 42

Table 8: CTP2008 Platform Specifications (continued)

SpecificationCategory

35

Electromagnetic Emissions Agency

Certification

AS/NZS CISPR 22:2004

•

EMC Directive (89/336/EEC)

•

EN 300 132–2 (Narrowband and Wideband)

•

EN55022 Class A (CISPR-22 Class A)

•

EN55024, Annex C for WAN Equipment Performance Criteria A, B, and

•

C

EN 61000-4-2, EN 61000-4-3, EN 61000-4-4, EN 61000-4-6

•

ETSI 300-386, Telecommunication Network Equipment; ElectroMagnetic

•

Compatibility (EMC) requirements

IECS-03 Issue 3 Class A

•

FCC Part 15 Class A

•

VCCI (Voluntary Control Council for Interference by Information

•

Technology Equipment)

RELATED DOCUMENTATION

CTP2024 Platform Specifications and Certification | 35

CTP2056 Platform Specifications and Certification | 38

CTP2024 Platform Specifications and Certification

Table 9: CTP2024 Platform Specifications

SpecificationCategory

Weight

20 lb (9.07 kg)Chassis only

Dimensions

Chassis only

3.5 in. (8.89 cm) high

17.25 in. (43.81 cm) wide

11.25 in. (28.57 cm) deep

Page 43

Table 9: CTP2024 Platform Specifications (continued)

SpecificationCategory

Environmental Requirements

32° to 104° F (0° to 40° C)Ambient operating temperature

5% to 90% (noncondensing)Ambient operating humidity

DC Input

–40 to –72 VDCVoltage

3A @ –48 VDCCurrent

144 WPower

2 independent line feedsRedundancy (input power)

36

AC Input

Space Requirements

Airflow

100–240 VACPower required

50–60 HzAC line frequency

2.0Nominal current (115V amps)

200 WPower

3 ft. (90 cm) behind device or rack.

Do not block air vents on the front or back of the device.

Air intake occurs from the front of the device.

Air is exhausted out the back of the device.

Page 44

Table 9: CTP2024 Platform Specifications (continued)

SpecificationCategory

37

Safety Agency Certification

Electromagnetic Emissions Agency

Certification

AS/NZS 60950:2000 Safety of Information Technology Equipment

•

CAN/CSA-C22.2, No. 60950-1–03, First Edition, Information Technology

•

Equipment - Safety - Part 1: General Requirements

EN60825-1, Safety of Laser Products - Part 1: Equipment Class,

•

Requirements, and User's Guide (2001)

EN 60950-1:2001, First Edition, Information Technology Equipment - Safety

•

- Part 1: General Requirements

IEC 60950-1(2001-10) Ed. 1.0 Information Technology Equipment - Safety

•

- Part 1: General Requirements

Low Voltage Directive (2006/95/EC)

•

UL 60950-1, First Edition, Information Technology Equipment - Safety -

•

Part 1: General Requirements

AS/NZS CISPR 22:2004

•

EMC Directive (89/336/EEC)

•

EN 300 132–2 (Narrowband and Wideband)

•

EN55022 Class A (CISPR-22 Class A)

•

EN55024, Annex C for WAN Equipment Performance Criteria A, B, and C

•

EN 61000-4-2, EN 61000-4-3, EN 61000-4-4, EN 61000-4-6

•

ETSI 300-386, Telecommunication Network Equipment; ElectroMagnetic

•

Compatibility (EMC) requirements

IECS-03 Issue 3 Class A

•

FCC Part 15 Class A

•

VCCI (Voluntary Control Council for Interference by Information Technology

•

Equipment)

RELATED DOCUMENTATION

CTP2008 Platform Specifications and Certification | 33

CTP2056 Platform Specifications and Certification | 38

Page 45

CTP2056 Platform Specifications and Certification

Table 10: CTP2056 Platform Specifications

SpecificationCategory

Weight

27 lb (12.25 kg)Chassis only

Dimensions

38

Chassis only

Environmental Requirements

DC Input

7.0 in. (17.8 cm) high

17.25 in. (43.81 cm) wide

11.25 in. (28.57 cm) deep

32° to 104° F (0° to 40° C)Ambient operating temperature

5% to 90% (noncondensing)Ambient operating humidity

–40 to –72 VDCVoltage

4A @ –48 VDCCurrent

192 WPower

2 independent line feedsRedundancy (input power)

AC Input

Space Requirements

100–240 VACPower required

50–60 HzAC line frequency

2.5Nominal current (115V amps)

250 WPower

3 ft. (90 cm) behind device or rack.

Do not block air vents on the front or back of the device.

Page 46

Table 10: CTP2056 Platform Specifications (continued)

SpecificationCategory

39

Airflow

Safety Agency Certification

Electromagnetic Emissions Agency

Certification

Air intake occurs from the front of the device.

Air is exhausted out the back of the device.

AS/NZS 60950:2000 Safety of Information Technology Equipment

•

CAN/CSA-C22.2, No. 60950-1–03, First Edition, Information Technology

•

Equipment - Safety - Part 1: General Requirements

EN60825-1, Safety of Laser Products - Part 1: Equipment Class,

•

Requirements, and User's Guide (2001)

EN 60950-1:2001, First Edition, Information Technology Equipment - Safety

•

- Part 1: General Requirements

IEC 60950-1(2001-10) Ed. 1.0 Information Technology Equipment - Safety

•

- Part 1: General Requirements

Low Voltage Directive (2006/95/EC)

•

UL 60950-1, First Edition, Information Technology Equipment - Safety -

•

Part 1: General Requirements

AS/NZS CISPR 22:2004

•

EMC Directive (89/336/EEC)

•

EN 300 132–2 (Narrowband and Wideband)

•

EN55022 Class A (CISPR-22 Class A)

•

EN55024, Annex C for WAN Equipment Performance Criteria A, B, and C

•

EN 61000-4-2, EN 61000-4-3, EN 61000-4-4, EN 61000-4-6

•

ETSI 300-386, Telecommunication Network Equipment; ElectroMagnetic

•

Compatibility (EMC) requirements

IECS-03 Issue 3 Class A

•

FCC Part 15 Class A

•

VCCI (Voluntary Control Council for Interference by Information Technology

•

Equipment)

RELATED DOCUMENTATION

CTP2008 Platform Specifications and Certification | 33

CTP2024 Platform Specifications and Certification | 35

Page 47

CHAPTER 4

Planning and Preparing the Site

IN THIS CHAPTER

Before You Install a CTP Platform | 40

CTP2000 Environmental Requirements | 40

Before You Install a CTP Platform

40

Before you install a Juniper Networks CTP Circuit to Packet platform:

Verify that the electrical supply meets all power requirements. See the system specifications for the

•

applicable CTP model.

Verify that the site meets all environment specifications. Refer to the environmental requirements and

•

the system specifications for the applicable CTP model.

Verify that the cables you plan to use meet the specifications, and review the cabling recommendations.

•

Verify the operation of all telephone circuits, digital services, and T1 facilities required for installation.

•

Ensure that all IP requirements are met, such as IP addresses, subnet masks, and any specific routing

•

protocol information.

CTP2000 Environmental Requirements

See one of the following topics for complete environmental specifications:

CTP2008 Platform Specifications and Certification on page 33

•

CTP2024 Platform Specifications and Certification on page 35

•

CTP2056 Platform Specifications and Certification on page 38

•

Choose a location for the device that is dry, relatively dust free, well ventilated, and air conditioned. If you

install equipment in a rack, be sure that the floor is capable of supporting the combined weight of the rack

Page 48

and the installed equipment. Place the device in a location with sufficient access to power and network

cables.

Like other network devices, the device generates a significant amount of heat. You must provide a balanced

environment so that the device performs properly and safely. See the individual system specifications for

acceptable ranges of temperature and humidity.

Be sure to allow enough space around the device for adequate ventilation. Inadequate ventilation can

cause the device to overheat.

CAUTION: Do not block the air vents on the device. Otherwise, the device might

overheat.

RELATED DOCUMENTATION

41

Before You Install a CTP Platform | 40

Page 49

CHAPTER 5

Equipment Rack Requirements

IN THIS CHAPTER

CTP2000 Rack Requirements | 42

CTP2000 Mechanical Requirements | 42

CTP2000 Space Requirements | 43

CTP2000 Rack Installation | 43

CTP Cabling Recommendations | 44

42

CTP2000 Rack Requirements

When allocating equipment rack space, consider the following:

Type of equipment racks recommended for the system

•

Number of equipment racks required to hold your current system configuration

•

Future expansion

•

Make sure that your distribution rack meets basic mechanical and space requirements and complies with

conventional standards. In the United States, use EIA-310-D Cabinets, Racks, Panels, and Associated Equipment,

September 1992.

RELATED DOCUMENTATION

CTP2000 Mechanical Requirements | 42

CTP2000 Space Requirements | 43

CTP2000 Rack Installation | 43

CTP2000 Mechanical Requirements

Follow these mechanical requirements for your rack:

Page 50

Select from the following rack options:

•

Two-post rack—a freestanding enclosed cabinet with two mounting posts in the front

•

Telco-type rack—two adjacent mounting posts that you must secure to the floor or an overhead

•

structure

Four-post rack—a freestanding open rack, either open or closed

•

The rack must have at least two mounting posts.

•

The distance between the mounting holes in the two posts must be 18.31 in. +/-.063 in., as specified in

•

the EIA-310-D document.

A fully loaded rack with three CTP2056 systems must structurally support at least 100 lb (46 kg).

•

An optional mounting kit is available for midchassis mounting. Contact your Juniper Networks sales

•

representative for more information.

43

RELATED DOCUMENTATION

CTP2000 Rack Requirements | 42

CTP2000 Space Requirements | 43

CTP2000 Rack Installation | 43

CTP2000 Space Requirements

If you use an enclosed rack for the device, ensure that there is a minimum of 3 in. of clearance between

the inner side wall and the system. This clearance space ensures adequate air flow.

RELATED DOCUMENTATION

CTP2000 Rack Requirements | 42

CTP2000 Mechanical Requirements | 42

CTP2000 Rack Installation | 43

CTP2000 Rack Installation

To confirm proper equipment rack installation, verify the following:

Page 51

Racks are installed and electrically grounded according to manufacturer instructions.

•

Equipment racks are anchored to the floor and, when possible, anchored to the ceiling as well.

•

Equipment rack installations comply with applicable local, state, and national codes.

•

RELATED DOCUMENTATION

CTP2000 Mechanical Requirements | 42

CTP2000 Rack Requirements | 42

CTP2000 Space Requirements | 43

Special Guidelines for Installing CTP2056 Chassis in a Rack | 91

CTP Cabling Recommendations

44

We suggest that you comply with the following recommendations:

Ensure that cable distance and rate limits meet IEEE-recommended maximum speeds and distances for

•

signaling purposes. For information about attenuation and power loss in optical fiber cables see:

ANSI T1.646a-1997 Telecommunications – Broadband ISDN - Physical Layer Specification for

•

User-Network Interfaces Including DS1/ATM (1997)

ANSI T1.646-1995 Telecommunications – Broadband ISDN - Physical Layer Specification for

•

User-Network Interfaces Including DS1/ATM (1995)

Ensure that power cables deliver sufficient power to the device.

•

Attach laser fiber connectors only to Class 1 laser devices in accordance with IEC 60825-1, Safety of

•

Laser Products - Part 1.

Route cables so that they do not restrict ventilation or airflow.

•

Route cables so that modules and field-replaceable units are easily accessible.

•

Route cables in a logical direction to prevent loss of connectivity to other equipment in the rack, associated

•

equipment in adjacent racks, or to the backbone network.

Consider using cable-management brackets to keep network cables untangled and orderly and to prevent

•

cables from hindering access to other slots.

For additional cable recommendations, consult the document GR-63–CORE: Network Equipment Building

System (NEBS) Requirements: Physical Protection, Issue 2, April 2002.

Page 52

CHAPTER 6

Cable and Pinout Specifications

IN THIS CHAPTER

CTP2000 4WE&M Interface Connector Pinouts | 45

CTP2000 FXS and FXO Interface Module Cables and Pinouts | 48

T1/E1 Interface Module Pinouts | 51

CTP2000 Serial Interface Module Pinouts | 52

CTP2000 Series Console Cable Pinouts | 63

CTP Fast Ethernet and Power Cables | 68

Terminal Block and Circuit Breaker Specifications | 69

45

CTP2000 4WE&M Interface Connector Pinouts

IN THIS SECTION

CTP2000 4WE&M RTM Connector A Pinouts | 45

CTP2000 4WE&M Connector B Pinouts | 46

CTP2000 4WE&M RTM Connector A Pinouts

See Table 11 on page 45 for connector A pinout information. See “CTP2000 4WE&M Interface Module”

on page 14 for signal definitions.

Table 11: CTP2000 4WE&M RTM Pinouts–Connector A

Connector A

PinSignalSignalPin

26Port 0 TPort 0 R1

Page 53

Table 11: CTP2000 4WE&M RTM Pinouts–Connector A (continued)

Connector A

46

PinSignalSignalPin

27Port 0 T1Port 0 R12

28Port 0 EPort 0 SG3

29Port 0 MPort 0 SB4

30Port 1 TPort 1 R5

31Port 1 T1Port 2 R16

32Port 1 EPort 2 SG7

33Port 1 MPort 2 SB8

34Port 2 TPort 2 R9

35Port 2 T1Port 2 R110

36Port 2 EPort 2 SG11

37Port 2MPort 2 SB12

38Port 3 TPort 3 R13

39Port 3 T1Port 3 R114

40Port 3 EPort 3 SG15

41Port 3 MPort 3 SB16

50GNDGND25

CTP2000 4WE&M Connector B Pinouts

See Table 12 on page 47 for connector B pinout information. See“CTP2000 4WE&M Interface Module”

on page 14 for signal definitions.

Page 54

Table 12: CTP2000 4WE&M RTM Pinouts–Connector B

Connector B

47

PINSignalSignalPIN

26Port 4 TPort 4 R1

27Port 4 T1Port 4 R12

28Port 4 EPort 4 SG3

29Port 4 MPort 4 SB4

30Port 5 TPort 5 R5

31Port 5 T1Port 5 R16

32Port 5 EPort 5 SG7

33Port 5 MPort 5 SB8

34Port 6 TPort 6 R9

35Port 6 T1Port 6 R110

36Port 6 EPort 6 SG11

37Port 6MPort 6 SB12

38Port 7 TPort 7 R13

39Port 7 T1Port 7 R114

40Port 7 EPort 7 SG15

41Port 7 MPort 7 SB16

50GNDGND25

RELATED DOCUMENTATION

CTP2000 4WE&M Interface Module | 14

Page 55

CTP2000 FXS and FXO Interface Module Cables and Pinouts | 48

CTP2000 Series Console Cable Pinouts | 63

CTP2000 FXS and FXO Interface Module Cables and Pinouts

IN THIS SECTION

Required Cables | 48

RTM Pinout Locations | 48

FXS Connector Pinouts | 49

FXO Connector Pinouts | 50

48

Required Cables

The CTP2000 2W-FXS and 2W-FX0 interface modules require the use of double-shielded cables (copper

braid plus aluminum mylar foil) to ensure EMI Compliance.

RTM Pinout Locations

Figure 29 on page 49 shows the pinout locations for both the CTP2000 2W-FXS and 2W-FXO interface

modules.

Page 56

Figure 29: RTM Pinouts for CTP2000 2W-FXS and 2W-FXO Interface Modules

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

RJ21x

g016233

49

FXS Connector Pinouts

The RTM for the CTP2000 2W-FXS interface module uses a RJ-21 25-pair Telco connector labeled A. The

A connector has 24 FXS ports.

FXS R is connected to FXO T; FXS T is connected to FXO T.

Table 13 on page 49 lists the RTM pinouts for the FXS module.

Table 13: CTP2000 FXS Connector Pinouts on the RTM

PinSignalSignalPin

26Port 0 TPort 0 R1

27Port 1 TPort 1 R2

28Port 2 TPort 2 R3

29Port 3 TPort 3 R4

30Port 4 TPort 4 R5

31Port 5 TPort 5 R6

32Port 6 TPort 6 R7

33Port 7 TPort 7 R8

Page 57

Table 13: CTP2000 FXS Connector Pinouts on the RTM (continued)

50

PinSignalSignalPin

34Port 8 TPort 8 R9

35Port 9 TPort 9 R10

36Port 10 TPort 10 R11

37Port 11 TPort 11 R12

38Port 12 TPort 12 R13

39Port 13 TPort 13 R14

40Port 14 TPort 14 R15

FXO Connector Pinouts

41Port 15 TPort 15 R16

42Port 16 TPort 16 R17