Page 1

BX7000 Multi-Access

Gateway

Hardware Guide

This product includes the Envoy SNMP Engine, developed by Epilogue Technology, an Integrated Systems Company. Copyright ©

1986-1997, Epilogue Technology Corporation. All rights reserved. This program and its documentation were developed at private expense,

and no part of them is in the public domain.

This product includes memory allocation software developed by Mark Moraes, copyright © 1988, 1989, 1993, University of Toronto.

This product includes FreeBSD software developed by the University of California, Berkeley, and its contributors. All of the documentation

and software included in the 4.4BSD and 4.4BSD-Lite Releases is copyrighted by the Regents of the University of California. Copyright ©

1979, 1980, 1983, 1986, 1988, 1989, 1991, 1992, 1993, 1994. The Regents of the University of California. All rights reserved.

GateD software copyright © 1995, the Regents of the University. All rights reserved. Gate Daemon was originated and developed through

release 3.0 by Cornell University and its collaborators. Gated is based on Kirton’s EGP, UC Berkeley’s routing daemon (routed), and DCN’s

HELLO routing protocol. Development of Gated has been supported in part by the National Science Foundation. Portions of the GateD

software copyright © 1988, Regents of the University of California. All rights reserved. Portions of the GateD software copyright © 1991, D. L.

S. Associates.

This product includes software developed by Maker Communications, Inc., copyright © 1996, 1997, Maker Communications, Inc. Juniper

Networks, the Juniper Networks logo, JUNOS, NetScreen, ScreenOS, and Steel-Belted Radius are registered trademarks of Juniper

Networks, Inc. in the United States and other countries. JUNOSe is a trademark of Juniper Networks, Inc. All other trademarks, service

marks, registered trademarks, or registered service marks are the property of their respective owners.

Juniper Networks assumes no responsibility for any inaccuracies in this document. Juniper Networks reserves the right to change, modify,

transfer, or otherwise revise this publication without notice.

Releas e

4.3

August 2011

530-027514-01, Revision 1.0

Copyright © 2011, Juniper Networks, Inc.

Page 2

Products made or sold by Juniper Networks or components thereof might be covered by one or more of the following patents that are

owned by or licensed to Juniper Networks: U.S. Patent Nos. 5,473,599, 5,905,725, 5,909,440, 6,192,051, 6,333,650, 6,359,479, 6,406,312,

6,429,706, 6,459,579, 6,493,347, 6,538,518, 6,538,899, 6,552,918, 6,567,902, 6,578,186, and 6,590,785.

BX7000 Multi-Access Gateway Hardware Guide

Copyright © 2010, Juniper Networks, Inc.

All rights reserved. Printed in USA.

Revision History

JAugust 2011—530-027514-01, Revision 1.0.

The information in this document is current as of the date listed in the revision history.

Year 2000 Notice

Juniper Networks hardware and software products are Year 2000 compliant. The JUNOS software has no known time-related limitations

through the year 2038. However, the NTP application is known to have some difficulty in the year 2036.

ii Copyright © 2010, Juniper Networks, Inc.

Page 3

END USER LICENSE AGREEMENT

READ THIS END USER LICENSE AGREEMENT ("AGREEMENT") BEFORE DOWNLOADING, INSTALLING, OR USING THE SOFTWARE. BY

DOWNLOADING, INSTALLING, OR USING THE SOFTWARE OR OTHERWISE EXPRESSING YOUR AGREEMENT TO THE TERMS

CONTAINED HEREIN, YOU (AS CUSTOMER OR IF YOU ARE NOT THE CUSTOMER, AS A REPRESENTATIVE/AGENT AUTHORIZED TO BIND

THE CUSTOMER) CONSENT TO BE BOUND BY THIS AGREEMENT. IF YOU DO NOT OR CANNOT AGREE TO THE TERMS CONTAINED

HEREIN, THEN (A) DO NOT DOWNLOAD, INSTALL, OR USE THE SOFTWARE, AND (B) YOU MAY CONTACT JUNIPER NETWORKS

REGARDING LICENSE TERMS.

1.The Parties. The parties to this Agreement are (i) Juniper Networks, Inc. (if the Customer's principal office is located in the Americas) or

Juniper Networks (Cayman) Limited (if the Customer's principal office is located outside the Americas) (such applicable entity being

referred to herein as "Juniper"), and (ii) the person or organization that originally purchased from Juniper or an authorized Juniper reseller

the applicable license(s) for use of the Software ("Customer") (collectively, the "Parties").

2.The Software. In this Agreement, "Software" means the program modules and features of the Juniper or Juniper-supplied software, for

which Customer has paid the applicable license or support fees to Juniper or an authorized Juniper reseller, or which was embedded by

Juniper in equipment which Customer purchased from Juniper or an authorized Juniper reseller. "Software" also includes updates, upgrades

and new releases of such software. "Embedded Software" means Software which Juniper has embedded in or loaded onto the Juniper

equipment and any updates, upgrades, additions or replacements which are subsequently embedded in or loaded onto the equipment.

3. License Grant. Subject to payment of the applicable fees and the limitations and restrictions set forth herein, Juniper grants to Customer

a non-exclusive and non-transferable license, without right to sublicense, to use the Software, in executable form only, subject to the

following use restrictions:

a. Customer shall use Embedded Software solely as embedded in, and for execution on, Juniper equipment originally purchased by

Customer from Juniper or an authorized Juniper reseller.

b. Customer shall use the Software on a single hardware chassis having a single processing unit, or as many chassis or processing

units for which Customer has paid the applicable license fees; provided, however, with respect to the Steel-Belted Radius or Odyssey

Access Client software only, Customer shall use such Software on a single computer containing a single physical random access

memory space and containing any number of processors. Use of the Steel-Belted Radius or IMS AAA software on multiple computers

or virtual machines (e.g., Solaris zones) requires multiple licenses, regardless of whether such computers or virtualizations are

physically contained on a single chassis.

c. Product purchase documents, paper or electronic user documentation, and/or the particular licenses purchased by Customer may

specify limits to Customer's use of the Software. Such limits may restrict use to a maximum number of seats, registered endpoints,

concurrent users, sessions, calls, connections, subscribers, clusters, nodes, realms, devices, links, ports or transactions, or require the

purchase of separate licenses to use particular features, functionalities, services, applications, operations, or capabilities, or provide

throughput, performance, configuration, bandwidth, interface, processing, temporal, or geographical limits. In addition, such limits

may restrict the use of the Software to managing certain kinds of networks or require the Software to be used only in conjunction with

other specific Software. Customer's use of the Software shall be subject to all such limitations and purchase of all applicable

licenses.

d. For any trial copy of the Software, Customer's right to use the Software expires 30 days after download, installation or use of the

Software. Customer may operate the Software after the 30-day trial period only if Customer pays for a license to do so. Customer

may not extend or create an additional trial period by re-installing the Software after the 30-day trial period.

e. The Global Enterprise Edition of the Steel-Belted Radius software may be used by Customer only to manage access to Customer's

enterprise network. Specifically, service provider customers are expressly prohibited from using the Global Enterprise Edition of the

Steel-Belted Radius software to support any commercial network access services.

The foregoing license is not transferable or assignable by Customer. No license is granted herein to any user who did not originally purchase

the applicable license(s) for the Software from Juniper or an authorized Juniper reseller.

4. Use Prohibitions. Notwithstanding the foregoing, the license provided herein does not permit the Customer to, and Customer agrees not

to and shall not: (a) modify, unbundle, reverse engineer, or create derivative works based on the Software; (b) make unauthorized copies of

the Software (except as necessary for backup purposes); (c) rent, sell, transfer, or grant any rights in and to any copy of the Software, in any

form, to any third party; (d) remove any proprietary notices, labels, or marks on or in any copy of the Software or any product in which the

Software is embedded; (e) distribute any copy of the Software to any third party, including as may be embedded in Juniper equipment sold

in the secondhand market; (f) use any 'locked' or key-restricted feature, function, service, application, operation, or capability without first

purchasing the applicable license(s) and obtaining a valid key from Juniper, even if such feature, function, service, application, operation, or

capability is enabled without a key; (g) distribute any key for the Software provided by Juniper to any third party; (h) use the Software in any

manner that extends or is broader than the uses purchased by Customer from Juniper or an authorized Juniper reseller; (i) use Embedded

Software on non-Juniper equipment; (j) use Embedded Software (or make it available for use) on Juniper equipment that the Customer

did not originally purchase from Juniper or an authorized Juniper reseller; (k) disclose the results of testing or benchmarking

to any third party without the prior written consent of Juniper; or (l) use the Software in any manner other than as expressly provided

herein.

5. Audit. Customer shall maintain accurate records as necessary to verify compliance with this Agreement. Upon request by Juniper,

Customer shall furnish such records to Juniper and certify its compliance with this Agreement.

6. Confidentiality. The Parties agree that aspects of the Software and associated documentation are the confidential property of Juniper.

As such, Customer shall exercise all reasonable commercial efforts to maintain the Software and associated documentation in confidence,

which at a minimum includes restricting access to the Software to Customer employees and contractors having a need to use the Software

for Customer's internal business purposes.

7. Ownership. Juniper and Juniper's licensors, respectively, retain ownership of all right, title, and interest (including copyright) in and to the

Software, associated documentation, and all copies of the Software. Nothing in this Agreement constitutes a transfer or conveyance of

any right, title, or interest in the Software or associated documentation, or a sale of the Software, associated documentation, or copies of

the Software.

8. Warranty, Limitation of Liability, Disclaimer of Warranty. The warranty applicable to the Software shall be as set forth in the warranty

statement that accompanies the Software (the "Warranty Statement"). Nothing in this Agreement shall give rise to any obligation to

support the Software. Support services may be purchased separately. Any such support shall be governed by a separate, written support

services agreement. TO THE MAXIMUM EXTENT PERMITTED BY LAW, JUNIPER SHALL NOT BE LIABLE FOR ANY LOST PROFITS, LOSS

OF DATA, OR COSTS OR PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES, OR FOR ANY SPECIAL, INDIRECT, OR

of the Software

Copyright © 2011, Juniper Networks, Inc. iii

Page 4

CONSEQUENTIAL DAMAGES ARISING OUT OF THIS AGREEMENT, THE SOFTWARE, OR ANY JUNIPER OR JUNIPER-SUPPLIED

SOFTWARE. IN NO EVENT SHALL JUNIPER BE LIABLE FOR DAMAGES ARISING FROM UNAUTHORIZED OR IMPROPER USE OF ANY

JUNIPER OR JUNIPER-SUPPLIED SOFTWARE. EXCEPT AS EXPRESSLY PROVIDED IN THE WARRANTY STATEMENT TO THE EXTENT

PERMITTED BY LAW, JUNIPER DISCLAIMS ANY AND ALL WARRANTIES IN AND TO THE SOFTWARE (WHETHER EXPRESS, IMPLIED,

STATUTORY, OR OTHERWISE), INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE,

OR NONINFRINGEMENT. IN NO EVENT DOES JUNIPER WARRANT THAT THE SOFTWARE, OR ANY EQUIPMENT OR NETWORK

RUNNING THE SOFTWARE, WILL OPERATE WITHOUT ERROR OR INTERRUPTION, OR WILL BE FREE OF VULNERABILITY TO

INTRUSION OR ATTACK. In no event shall Juniper's or its suppliers' or licensors' liability to Customer, whether in contract, tort (including

negligence), breach of warranty, or otherwise, exceed the price paid by Customer for the Software that gave rise to the claim, or if the

Software is embedded in another Juniper product, the price paid by Customer for such other product. Customer acknowledges and agrees

that Juniper has set its prices and entered into this Agreement in reliance upon the disclaimers of warranty and the limitations of liability set

forth herein, that the same reflect an allocation of risk between the Parties (including the risk that a contract remedy may fail of its

essential purpose and cause consequential loss), and that the same form an essential basis of the bargain between the Parties.

9. Termination. Any breach of this Agreement or failure by Customer to pay any applicable fees due shall result in automatic termination of

the license granted herein. Upon such termination, Customer shall destroy or return to Juniper all copies of the Software and related

documentation in Customer's possession or control.

10. Taxes. All license fees payable under this agreement are exclusive of tax. Customer shall be responsible for paying Taxes arising from

the purchase of the license, or importation or use of the Software. If applicable, valid exemption documentation for each taxing jurisdiction

shall be provided to Juniper prior to invoicing, and Customer shall promptly notify Juniper if their exemption is revoked or modified. All

payments made by Customer shall be net of any applicable withholding tax. Customer will provide reasonable assistance to Juniper in

connection with such withholding taxes by promptly: providing Juniper with valid tax receipts and other required documentation showing

Customer's payment of any withholding taxes; completing appropriate applications that would reduce the amount of withholding tax to be

paid; and notifying and assisting Juniper in any audit or tax proceeding related to transactions hereunder. Customer shall comply with all

applicable tax laws and regulations, and Customer will promptly pay or reimburse Juniper for all costs and damages related to any liability

incurred by Juniper as a result of Customer's non-compliance or delay with its responsibilities herein. Customer's obligations under this

Section shall survive termination or expiration of this Agreement.

11. Export. Customer agrees to comply with all applicable export laws and restrictions and regulations of any United States and any

applicable foreign agency or authority, and not to export or re-export the Software or any direct product thereof in violation of any such

restrictions, laws or regulations, or without all necessary approvals. Customer shall be liable for any such violations. The version of the

Software supplied to Customer may contain encryption or other capabilities restricting Customer's ability to export the Software without

an export license.

12. Commercial Computer Software. The Software is "commercial computer software" and is provided with restricted rights. Use,

duplication, or disclosure by the United States government is subject to restrictions set forth in this Agreement and as provided in DFARS

227.7201 through 227.7202-4, FAR 12.212, FAR 27.405(b)(2), FAR 52.227-19, or FAR 52.227-14(ALT III) as applicable.

13. Interface Information. To the extent required by applicable law, and at Customer's written request, Juniper shall provide Customer with

the interface information needed to achieve interoperability between the Software and another independently created program, on

payment of applicable fee, if any. Customer shall observe strict obligations of confidentiality with respect to such information and shall use

such information in compliance with any applicable terms and conditions upon which Juniper makes such information available.

14. Third Party Software. Any licensor of Juniper whose software is embedded in the Software and any supplier of Juniper whose products

or technology are embedded in (or services are accessed by) the Software shall be a third party beneficiary with respect to this Agreement,

and such licensor or vendor shall have the right to enforce this Agreement in its own name as if it were Juniper. In addition, certain third

party software may be provided with the Software and is subject to the accompanying license(s), if any, of its respective owner(s). To the

extent portions of the Software are distributed under and subject to open source licenses obligating Juniper to make the source code for

such portions publicly available (such as the GNU General Public License ("GPL") or the GNU Library General Public License ("LGPL")),

Juniper will make such source code portions (including Juniper modifications, as appropriate) available upon request for a period of up to

three years from the date of distribution. Such request can be made in writing to Juniper Networks, Inc., 1194 N. Mathilda Ave., Sunnyvale,

CA 94089, ATTN: General Counsel. You may obtain a copy of the GPL at http://www.gnu.org/licenses/gpl.html, and a copy of the LGP L at

http://www.gnu.org/licenses/lgpl.html.

15. Miscellaneous. This Agreement shall be governed by the laws of the State of California without reference to its conflicts of laws

principles. The provisions of the U.N. Convention for the International Sale of Goods shall not apply to this Agreement. For any disputes

arising under this Agreement, the Parties hereby consent to the personal and exclusive jurisdiction of, and venue in, the state and federal

courts within Santa Clara County, California. This Agreement constitutes the entire and sole agreement between Juniper and the Customer

with respect to the Software, and supersedes all prior and contemporaneous agreements relating to the Software, whether oral or written

(including any inconsistent terms contained in a purchase order), except that the terms of a separate written agreement executed by an

authorized Juniper representative and Customer shall govern to the extent such terms are inconsistent or conflict with terms contained

herein. No modification to this Agreement nor any waiver of any rights hereunder shall be effective unless expressly assented to in writing

by the party to be charged. If any portion of this Agreement is held invalid, the Parties agree that such invalidity shall not affect the validity

of the remainder of this Agreement. This Agreement and associated documentation has been written in the English language, and the

Parties agree that the English version will govern. (For Canada: Les parties aux présentés confirment leur volonté que cette convention de

même que tous les documents y compris tout avis qui s'y rattaché, soient redigés en langue anglaise. (Translation: The parties confirm that

this Agreement and all related documentation is and will be in the English language)).

iv Copyright © 2010, Juniper Networks, Inc.

Page 5

Table of Contents

About This Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Documentation Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiv

List of Technical Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Obtaining Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xv

Documentation Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Requesting Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

PART 1 Setting Up the Gateway

CHAPTER 1 BX7000 Multi-Access Gateway Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

BX7000 Multi-Access Gateway Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Gateway System Architecture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Packet Processor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Host Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Hardware Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Gateway Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Front Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

T1/E1 Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Ethernet Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Console Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

USB Host Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

External Alarm Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Power Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

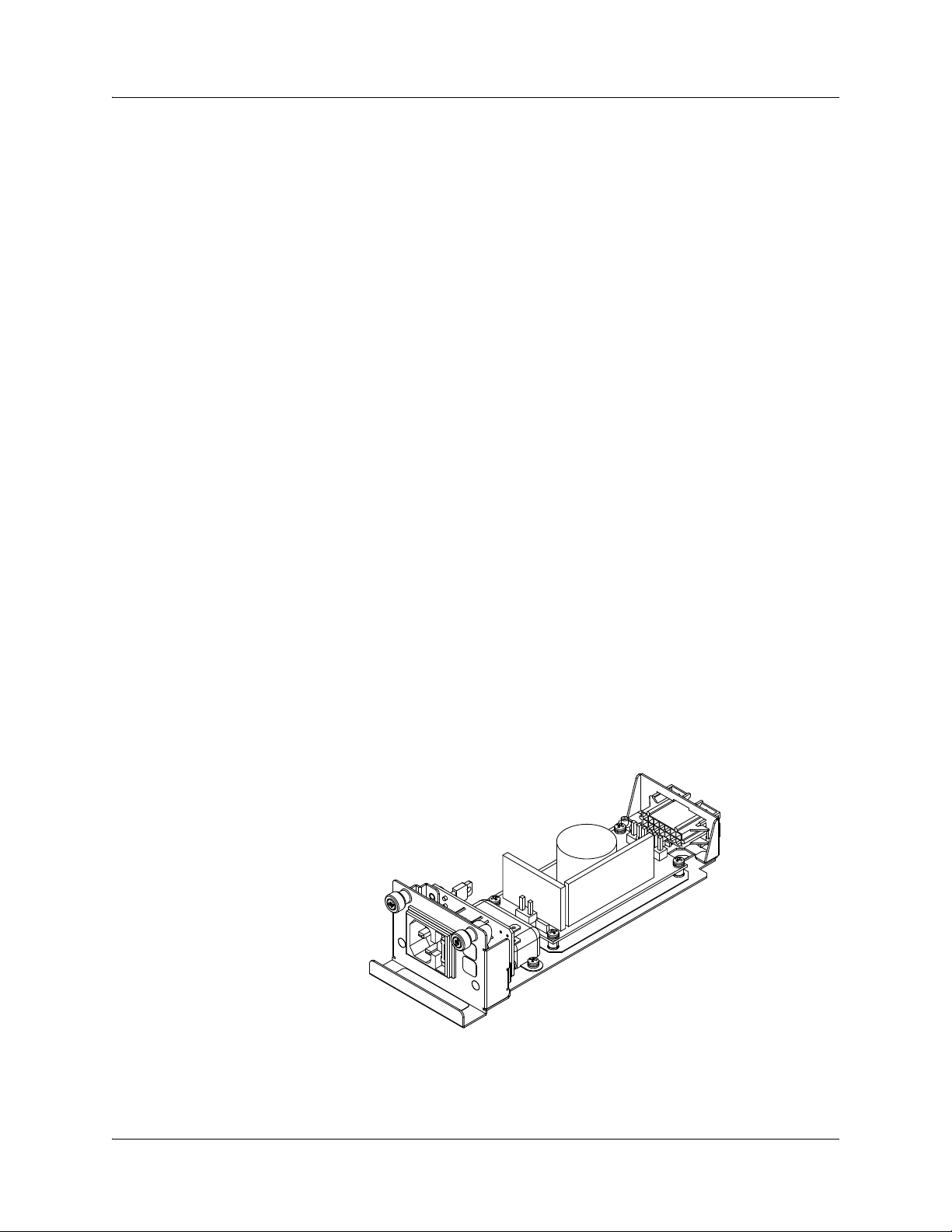

Advanced Clocking Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Location of Advanced Clocking Module in the Chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

CHAPTER 2 Preparing the Site for Gateway Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Site Preparation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Wall Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Rack Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Rack Size and Strength. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Proper Rack Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Cabinet Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Cabinet Size and Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cabinet Airflow Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Clearance Requirements for Airflow and Hardware Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

CHAPTER 3 Unpacking and Inspecting the Gateway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Unpacking the Gateway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Inspecting the Gateway Components and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Wall-Mounting Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

23-inch Rack-Mounting Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

:

Copyright © 2011, Juniper Networks, Inc. v

Page 6

:

If You Detect or Suspect Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

CHAPTER 4 Installing the Gateway. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Safety Requirements, Warnings, and Guidelines for Installing the Gateway. . . . . . . . . . . . . . . . . .27

Before you Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Installing the Cable Management brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Wall-Mounted Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Tools and Parts Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Installing the Gateway on a Wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Rack-Mounted Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Installation Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Tools and Parts Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Installing the Gateway in a Rack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

CHAPTER 5 Connecting the Gateway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Before you Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Cabling the Gateway to Management and Alarm Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Connecting to a Console Terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Connecting to an Ethernet Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Connecting to an External Alarm Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Connecting to T1/E1 Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Connecting to the Advanced Clocking Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

CHAPTER 6 Grounding and Powering the Gateway. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Tools and Parts Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Connecting the Grounding Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Providing Power to the Gateway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Connecting Power to an AC-Powered Gateway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Connecting Power to a DC-Powered Gateway. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Powering On the Gateway. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Powering Off the Gateway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

CHAPTER 7 Accessing and Configuring the Gateway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Console Port Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Assigning an IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

SSH Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

PART 2 Hardware Maintenance, Troubleshooting, and Replacement Procedures

CHAPTER 8 Maintaining the Gateway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Routine Maintenance Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Maintaining Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Maintaining Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Maintaining the Advanced Clocking Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

CHAPTER 9 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Diagnosing Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Understanding the Status LEDs to Troubleshoot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

LED Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Chassis and Interface Alarm Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Troubleshooting Power Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Troubleshooting High-Temperature Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Troubleshooting the Advanced Clocking Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

CHAPTER 10 Replacing Hardware Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Field-Replaceable Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

vi Copyright © 2010, Juniper Networks, Inc.

Page 7

Tools and Parts Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Replacing an AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Removing an AC Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Installing an AC Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Replacing a DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Removing a DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Installing a DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Replacing an AC Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Disconnecting an AC Power Cord. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Connecting an AC Power Cord. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Replacing a DC Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Removing a DC Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Installing a DC Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Replacing the Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Replacing SFP Transceivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Removing an SFP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Installing an SFP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Replacing Alarm Relay Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Replacing the Advanced Clocking Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Removing the Advanced Clocking Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Installing the Advanced Clocking Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

:

PART 3 Appendices

Appendix A System Specifications

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Gateway Environmental Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Advanced Clocking Module Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Power Guidelines, Requirements, and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Site Electrical Wiring Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Chassis Grounding Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

AC Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

AC Power Cord Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

DC Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

DC Power Cable Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Appendix B

Safety and Regulatory Compliance Information

Definition of Safety Warning Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Safety Guidelines and Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

General Safety Guidelines and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Fire Safety Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Installation Safety Guidelines and Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Laser and LED Safety Guidelines and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Maintenance and Operational Safety Guidelines and Warnings . . . . . . . . . . . . . . . . . . . . . . . 88

Electrical Safety Guidelines and Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Agency Approvals and Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Agency Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Compliance Statements for NEBS Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Compliance Statements for EMC Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Compliance Statements for Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Compliance Statement for Acoustic Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Cabling Recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

vii

Page 8

:

Hardware Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Federal Communications Commission (FCC) Statement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

FCC Requirements for Consumer Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Food and Drug Administration, Center for Devices, and Radiological Health . . . . . . . . . . . 101

Canadian Department of Communications Radio Interference Regulations . . . . . . . . . . .101

Réglement sur le brouillage radioélectrique du ministère des communications . . . . . . . 102

Industry Canada Notice CS-03 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Avis CS-03 d'Industrie Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

D.O.C. Explanatory Notes: Equipment Attachment Limitations . . . . . . . . . . . . . . . . . . . . . . . 103

Voluntary Control Council for Interference (VCCI) Statement for Japan . . . . . . . . . . . . . . 103

Appendix C Cabling Details

RJ-45 Connector Pinouts for RJ-45 Console Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

RJ-45 Connector Pinouts for Copper Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

SFP Connector Pinouts for Fiber-Optic Ethernet Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

RJ-45 Connector Pinouts for T1/E1 Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Type B Connector Pinouts for USB Console Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

Type A Connector Pinouts for USB FLASH Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

RJ-45 Connector Pinouts for the BITS Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

BNC Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Appendix D Contacting Customer Support and Returning Hardware

Locating Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Chassis Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Contacting Customer Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Information You Might Need to Supply to JTAC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Return Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Tools and Parts Required. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Returning Products for Repair or Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Packing Instructions for Returning a Chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Appendix E Declaration of Conformity

PART 4 Index

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

viii Copyright © 2010, Juniper Networks, Inc.

Page 9

List of Tables

Table 1: Notice Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Table 2: Text and Syntax Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Table 3: BX7000 Multi-Access Gateway Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvii

Table 1: Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 2: System LED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Table 3: T1/E1 Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Table 4: Ethernet Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Table 5: Optical Interface Support for Gigabit Ethernet SFPs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 6: Advanced Clocking Module Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 10: Site Preparation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 11: Gateway Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 12: Installation Kit Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 13: Parts of a Wall-Mounting Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 14: Parts of a 23-inch Rack-Mounting Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 15: Wall-Mounting Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 16: Chassis Alarm Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 17: Interface Alarm Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 18: Causes of Power Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 19: Field-Replaceable Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Table 20: Tools and Parts Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Table 21: General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Table 22: Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Table 23: Gateway Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Table 24: Advanced Clocking Module Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Table 25: AC Power Supply Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Table 26: AC Power Cord Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Table 27: DC Power Supply Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Table 28: DC Power Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Table 29: RJ-45–RS-232 Pinouts for RJ-45 Console. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Table 30: RJ-45 Connector Pinouts for Ethernet Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Table 31: SFP Connector Pinouts for Fiber-Optic Ethernet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Table 32: RJ-45 Connector Pinouts for T1/E1 Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Table 33: USB Type B Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

Table 34: USB Type A Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Table 35: RJ-45 Connector Pinouts for BITS Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Table 36: BNC Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

:

Copyright © 2011, Juniper Networks, Inc. ix

Page 10

:

x Copyright © 2010, Juniper Networks, Inc.

Page 11

List of Figures

Figure 1: System Architecture of the BX7000 Multi-Access Gateway . . . . . . . . . . . . . . . . . . . . . . . . . .4

Figure 2: Front View of the BX7000 Multi-Access Gateway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Figure 3: Front Panel of the BX7000 Multi-Access Gateway. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Figure 4: LED in the Advanced Clocking Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Figure 5: T1/E1 Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Figure 6: Ethernet Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Figure 7: Console Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 8: AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 9: DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 10: Advanced Clocking Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 11: Position of Advanced Clocking Module on the Gateway. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Figure 12: Front View of Advanced Clocking Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 13: Chassis Dimensions and Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 14 Installing the Cable Management Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 15: Installing the Wall-Mounting Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 16: Wall-Mounting the Gateway. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 17: Rack-Mounting Brackets for the Gateway. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 18: Rack-Mounting the Gateway. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Figure 19: Management and Console Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 20: Connector for Ethernet Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 21: Grounding Points on the Gateway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Figure 22: Attaching Grounding Wire to the Grounding Lug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 23: Removing an AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 24: Installing an AC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 25: Removing a DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure 26: Installing a DC Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 27: Replacing the Fuse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 28: SFP Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Figure 29: Installing an SFP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 30: Alarm Relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Figure 31: Removing the Advanced Clocking Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 32: Installing the Advanced Clocking Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Figure 33: AC Plug Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Figure 34: Serial Number ID Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

Figure 35: Chassis Serial Number Label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

:

Copyright © 2011, Juniper Networks, Inc. xi

Page 12

:

xii Copyright © 2010, Juniper Networks, Inc.

Page 13

About This Guide

This preface provides the following guidelines for using the BX7000 Multi-Access Gateway

Hardware Guide:

z Objectives on page xiii

z Audience on page xiii

z Documentation Conventions on page xiv

z List of Technical Publications on page xv

z Obtaining Documentation on page xv

z Documentation Feedback on pagexvi

z Requesting Support on page xvi

Objectives

About This Guide

Audience

This guide describes the hardware components, installation procedures, basic configuration

procedures, and basic troubleshooting procedures for the BX7000 Multi-Access Gateway. It also

explains how to prepare your site for the gateway installation, unpack and install the hardware,

power on the gateway, and perform routine maintenance. After completing the installation

procedures covered in this guide, see the BXOS Configuration Guide for information about further

BX operating system (BXOS) configuration.

This guide is designed for network administrators who install, set up, monitor, and maintain the

gateway or prepare a site for gateway installation. It is intended for the following audience:

z Customers with technical knowledge and experience with networks and network security, the

Internet, and Internet routing protocols

z Network administrators who install and manage the gateway

Copyright © 2011, Juniper Networks, Inc. Objectives x iii

Page 14

About This Guide

Personnel operating the equipment must be trained and competent; must not conduct themselves

in a careless, willfully negligent, or hostile manner; and must abide by the instructions provided in

the documentation.

Documentation Conventions

Table 1 on page xiv defines the notice icons used in this guide.

Table 1 : N ot ice I cons

Icon Meaning Description

Information Note Indicates important features or

instructions.

Caution Indicates a situation that might

result in loss of data or hardware

damage.

Warning Alerts you to the risk of personal

injury or death.

Laser Warning Alerts you to the risk of laser

hazard.

Table 2 on page xiv defines the text and syntax conventions used in this guide.

Table 2: Text and Syntax Conventions

Convention Description Examples

Bold sans serif typeface Represents text that you type. To enter configuration mode, type the

configure command:

cli@BX7000> configure

Fixed-width typeface

Represents output on the terminal screen. cli@BX7000> show chassis alarms

No alarms currently active

Italic typeface z Introduces important new terms.

z Identifies book names.

z Identifies RFC and Internet draft titles.

Italic sans serif typeface

Represents variables (options for which you

substitute a value) in commands or configuration

statements.

Sans serif typeface Represents names of configuration statements,

commands, files, and directories; IP addresses;

configuration hierarchy levels; or labels on

gateway components.

( ) (parentheses) Enclose optional keywords or variables. set cell-scrambling (enable | disable);

| (pipe symbol) Indicates a choice between the mutually

exclusive keywords or variables on either side of

the symbol. The set of choices is often enclosed in

parentheses for clarity.

z A policy term is a named structure that

defines match conditions and actions.

z BXOS Configuration Guide

z RFC 1997, BGP Communities Attribute

Configure the gateway as a DHCP relay

agent:

[edit system]

cli@BX7000# set dhcp-relay

ip-address

z To configure the buildout value of the T1

;

interface, include the buildout statement

at the [edit interface

interface-name

hierarchy level.

z The console port is labeled CONSOLE.

[edit interface

interface-name

]

set loopback (local | remote | none);

]

xiv Documentation Conventions Copyright © 2010, Juniper Networks, Inc.

Page 15

Convention Description Examples

# (pound sign) Indicates a comment specified on the same line

as the configuration statement to which it applies.

[ ] (square brackets) Identify a level in the configuration hierarchy. [edit]

Indention and braces ( { } ) Enclose a keyword and variable at specific

hierarchy levels. You can substitute one or more

values for the variable.

; (semicolon) Identifies a leaf statement at a configuration

hierarchy level.

rsvp {# Required for dynamic MPLS only}

protocols {

ospf {

area 1.1.1.1 {

interface ge-1/0/1 {

admin-state enable;

}

}

}

}

gateway Refers to BX7000 Multi-Access Gateway

List of Technical Publications

Table 3 on page xv lists the BX7000 Multi-Access Gateway documentation.

To configure and operate the BXOS software, use the configuration statements and operational

mode commands documented in the BXOS Configuration Guide and BXOS CLI Users Guide and

Command Reference.

About This Guide

Table 3: BX7000 Multi-Access Gateway Documentation

Document Description

BX7000 Multi-Access Gateway Hardware

Guide

BXOS Configuration Guide Provides a detailed software description of the BXOS software. This guide:

BXOS CLI Users Guide and Command

Refer ence

BX7000 Multi-Access Gateway Getting

Started Guide

Provides a detailed hardware description of the gateway. This guide:

z Explains how to unpack, install, mount, access, and maintain the gateway.

z Explains the various hardware components such as power supply, chassis, and ports.

z Provides troubleshooting of the hardware-related issues.

z Explains the configuration statements used to configure various properties of the

gateway.

z Describes how to configure the basic system properties, protocols, interfaces,

pseudowires, and tunnels.

z Explains statement hierarchies and parameters used in configuration.

Provides a detailed description of all the configuration mode and operational mode

commands. This guide:

z Explains how to start the CLI and the components of the CLI.

z Contains information about the commands used to set the gateway properties (set

commands) and the commands used to view the outputs (show commands).

Provides an overview on installing the gateway. This guide:

z Explains how to quickly set up the gateway.

z Contains the basic steps to install the gateway and establish the basic gateway

connectivity.

Obtaining Documentation

To obtain the most current version of all Juniper Networks technical documentation, see the

products documentation page on the Juniper Networks web site at: http://www.juniper.net/

To order a documentation CD, which contains this guide and other Juniper Networks technical

documents, contact your sales representative.

List of Technical Publications xv

Page 16

About This Guide

Copies of the Management Information Bases (MIBs) available in a software release are included

on the documentation CDs and at http://www.juniper.net/

Documentation Feedback

We encourage you to provide feedback, comments, and suggestions so that we can improve the

documentation. You can send your comments to techpubs-comments@juniper.net, or fill out the

documentation feedback form at https://www.juniper.net/cgi-bin/docbugreport/. If you are

using e-mail, be sure to include the following information with your comments:

z Document name

z Document part number

z Page number

z Software release version (not required for Network Operations Guides [NOGs])

Requesting Support

Technical product support is available through the Juniper Networks Technical Assistance Center

(JTAC). If you are a customer with an active J-Care or JNASC support contract, or are covered under

warranty, and need post sales technical support, you can access our tools and resources online or

open a case with JTAC.

z JTAC policies—For a complete understanding of our JTAC procedures and policies, review the

JTAC User Guide located at

http://www.juniper.net/customers/support/downloads/710059.pdf.

z Product warranties—For product warranty information, visit

http://www.juniper.net/support/warranty/

z JTAC Hours of Operation —The JTAC centers have resources available 24 hours a day, 7 days a

week, 365 days a year.

Self-Help Online Tools and Resources

For quick and easy problem resolution, Juniper Networks has designed an online self-service portal

called the Customer Support Center (CSC) that provides you with the following features:

z Find CSC offerings: http://www.juniper.net/customers/support/

z Search for known bugs: http://www2.juniper.net/kb/

z Find product documentation: http://www.juniper.net/techpubs/

z Find solutions and answer questions using our Knowledge Base: http://kb.juniper.net/

z Download the latest versions of software and review release notes:

http://www.juniper.net/customers/csc/software/

z Search technical bulletins for relevant hardware and software notifications:

https://www.juniper.net/alerts/

z Join and participate in the Juniper Networks Community Forum:

http://www.juniper.net/company/communities/

z Open a case online in the CSC Case Management tool: http://www.juniper.net/cm/

To verify service entitlement by product serial number, use our Serial Number Entitlement (SNE)

Tool located at https://tools.juniper.net/SerialNumberEntitlementSearch/

Opening a Case with JTAC

You can open a case with JTAC on the Web or by telephone.

xvi Documentation Feedback Copyright © 2010, Juniper Networks, Inc.

Page 17

z Use the Case Management tool in the CSC at http://www.juniper.net/cm/

z Call 1-888-314-JTAC (1-888-314-5822 toll-free in the USA, Canada, and Mexico).

For international or direct-dial options in countries without toll-free numbers, visit us at

http://www.juniper.net/support/requesting-support.html

About This Guide

Requesting Support xvii

Page 18

About This Guide

xviii Requesting Support Copyright © 2010, Juniper Networks, Inc.

Page 19

PA RT 1

Setting Up the Gateway

z BX7000 Multi-Access Gateway Overview on page 3

z Preparing the Site for Gateway Installation on page 19

z Unpacking and Inspecting the Gateway on page 23

z Installing the Gateway on page 27

z Connecting the Gateway on page 33

z Grounding and Powering the Gateway on page 37

z Accessing and Configuring the Gateway on page 43

:

Copyright © 2011, Juniper Networks, Inc. 1

Page 20

:

2 Copyright © 2010, Juniper Networks, Inc.

Page 21

CHAPTER 1: BX7000 Multi-Access Gateway Overview

CHAPTER 1

BX7000 Multi-Access Gateway Overview

This chapter gives an overview of BX7000 Multi-Access Gateway. It contains the following

sections:

z BX7000 Multi-Access Gateway Overview on page 3

z Gateway System Architecture on page 3

z Hardware Components on page 4

z Advanced Clocking Module on page 13

BX7000 Multi-Access Gateway Overview

The gateway is a mobile backhaul aggregation system that supports both Ethernet and

time-division multiplexing (TDM) interfaces. It aggregates 2G TDM and 3G Asynchronous Transfer

Mode (ATM) cellular traffic streams (voice, audio, and video) from multiple cell sites and carries

the streams towards the base station controller (BSC) or radio network controller (RNC) over

emulated circuits. It allows simultaneous delivery of real-time and delay-tolerant traffic, enhancing

bandwidth utilization. In addition, it performs IPv4 forwarding.

Gateway System Architecture

The gateway can be deployed at the cell sites (base transceiver station (BTS)) and access or

aggregation hub for the cell sites. The gateway architecture separates the control operations from

the packet forwarding operations, which helps to eliminate processing and traffic bottlenecks.

The gateway architecture consists of two parts:

z Packet processor—Performs route lookups, packet forwarding, and interworking functions for

pseudowire aggregations

z Host processor—Provides Layer 3 routing services and network management

Though there are two logical parts, physically they are packaged in a single integrated chip, using

an internal fabric to communicate with each other. The packet processor and the host processor

are realized using an off-the-shelf network processor. See Figure 1 on page 4 for an overview of the

gateway architecture.

Copyright © 2011, Juniper Networks, Inc. BX7000 Multi-Access Gateway Overview 3

Page 22

CHAPTER 1: BX7000 Multi-Access Gateway Overview

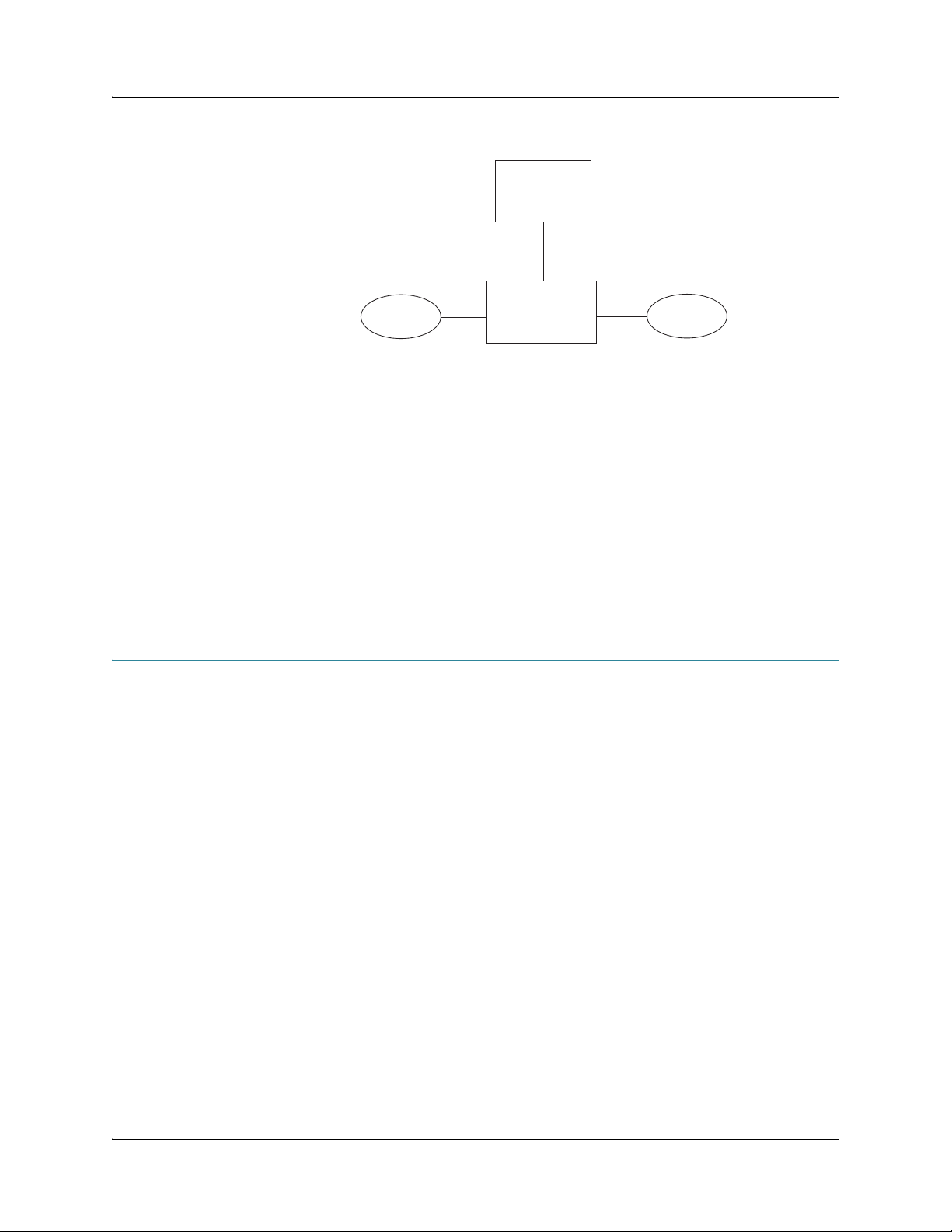

Figure 1: System Architecture of the BX7000 Multi-Access Gateway

Host Processor

Fabric

Packet Processor

The packet processor consists of four packet processing engines that perform Layer 2 and Layer 3

packet switching. It can process packets at an aggregate rate of 120 megabits per second. The

network processor promotes quick movement of packets through the gateway.

Host Processor

The host processor handles all routing protocol processes as well as the software processes that

control the gateway interfaces, the chassis components, the system management, and user

access to the gateway. These routing and software processes run on top of a kernel that interacts

with the packet processor. The host processor handles all packets that concern routing protocols,

freeing the packet processor to handle only packets that transit through the system. It also

provides different levels of system configuration and management functions, including

command-line interface (CLI), SNMP, and a NETCONF interface.

Hardware Components

This section provides the overview of the gateway’s hardware components:

z Gateway Chassis on page 4

z Front Panel on page 5

z LEDs on page 5

z T1/E1 Ports on page 6

z Ethernet Ports on page8

z Console Ports on page 11

z USB Host Port on page 12

z External Alarm Contacts on page 12

z Power Supplies on page 12

Packets in

Packet Processor

Packets out

g002900

Gateway Chassis

The chassis of the gateway is a rigid sheet metal structure that houses all the other gateway

components (see Figure 2 on page 5). The chassis measures 2.6 in. (6.7 cm) high, 17.51 in.

(44.47 cm) wide, and 9.44 in. (23.97 cm) deep (from front to the rear of the chassis) and installs in

a standard 19-in. equipment rack or in a standard enclosed cabinet.

4 Hardware Components Copyright © 2010, Juniper Networks, Inc.

Page 23

CHAPTER 1: BX7000 Multi-Access Gateway Overview

Air

Ground

Power supply

0 2 4 6 8 10 12 14

1 3 5 7 9 11 13 15

Table 1 on page 5 summarizes the physical specifications for the gateway chassis.

Table 1: Physical Specifications

Description Val ue

Chassis dimensions 2.6 in. (6.7 cm) high

17.51 in. (44.47 cm) wide

9.44 in. (23.97 cm) deep (from front to rear chassis)

Gateway weight DC model: 14.1 lb (6.4 Kg)

AC model: 13.22 lb (6.0 kg)

The gateway chassis can be mounted horizontally in a rack or vertically on a wall. All the power

receptacles, input/output ports, and expansion slots are located on the front panel of the gateway.

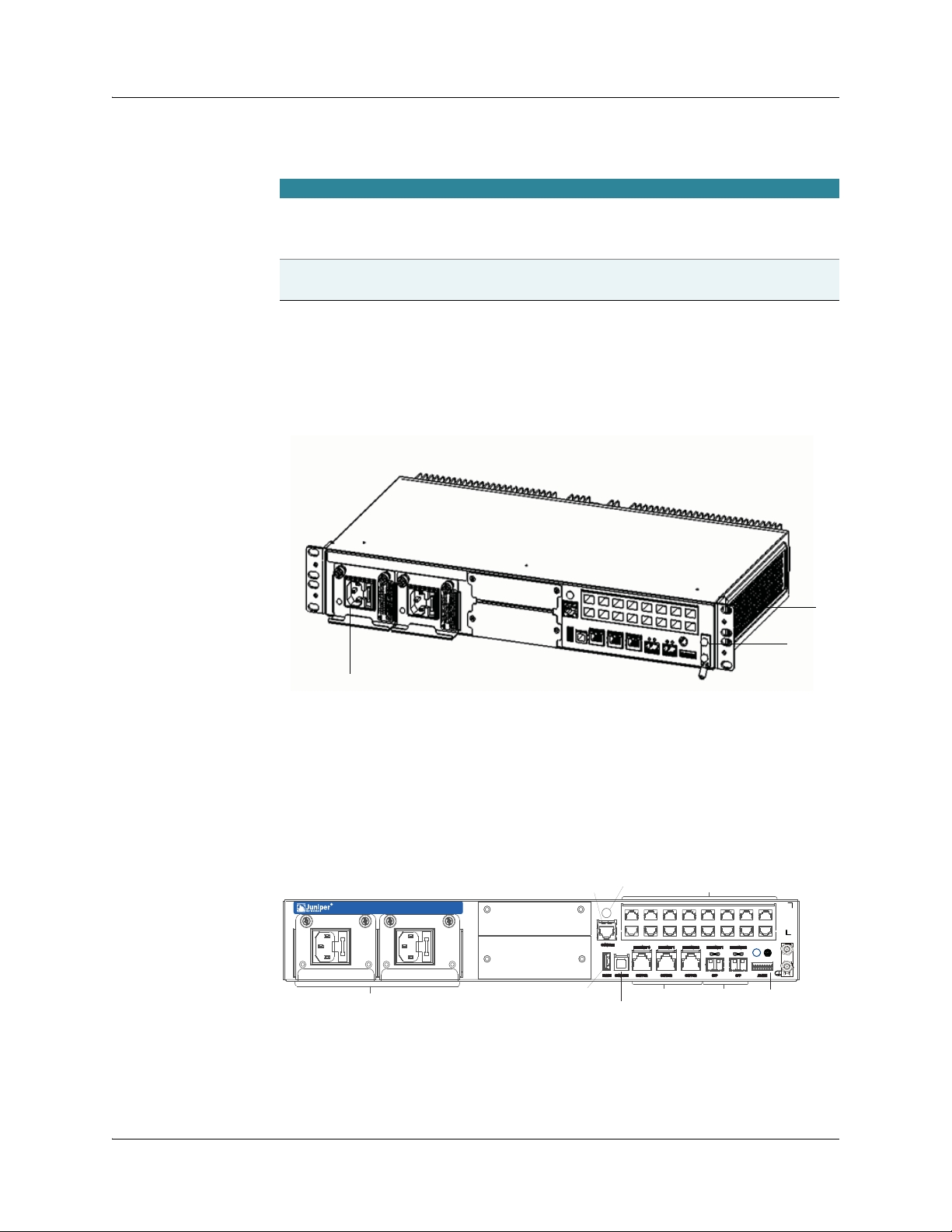

Figure 2: Front View of the BX7000 Multi-Access Gateway

Front Panel

LEDs

The front panel of the gateway has two power supplies, 16 T1/E1 ports, two console ports, one

universal serial bus (USB) host port, five Ethernet ports, one external alarm contact, LEDs that

allow you to view the status of the gateway and the ports, and two slots for expansion (see

Figure 3 on page 5).

Figure 3: Front Panel of the BX7000 Multi-Access Gateway

Power supplies

BX 7000

CLOCK CARD

EXPANSION BAY

INTERFACE CARD

EXPANSION BAY

RJ-45 console port

USB host port

System LED

1 3 5 7 9 11 13 15

0 2 4 6 8 10 12 14

Copper ethernet ports

USB console port

T1/E1 Ports

Optical ports

External alarm

Grounding studs

Port LEDs

For more information on port LEDs, see “T1/E1 Ports” on page 6 and “Ethernet Ports” on page 8.

Hardware Components 5

g002902

Page 24

CHAPTER 1: BX7000 Multi-Access Gateway Overview

System LED

A tricolor system LED indicates the status of the power supplies, temperature, and conditions

based on chassis configuration such as LOS (loss of signal), Ethernet link down. A condition that

causes a change in the system LED indication also activates the corresponding alarm relay contact

on the front panel. Table 2 on page 6 describes the status of the system LED.

Table 2 : Syste m LE D

Shape Color State Description

Green

On steadily The gateway is functioning normally,

temperature and outputs are within

range, and no alarms are present

Ye l lo w

On steadily A non-critical or minor condition

requires monitoring—Possible causes

include one of the power supplies

removed from the gateway or high

temperature

Red

On steadily A critical condition that can cause the

gateway to stop functioning and

requires immediate attention—

Possible causes include component

removal or failure

Off

Gateway powered down or initializing

Synchronization Status LED on the Advanced Clocking Module

The advanced clocking module has a bicolor LED to indicate the synchronization status of the

clocks. Figure 4 on page 6 shows the LED of the advanced clocking module. If the LED is green, the

advanced clocking module is locked with an input source. If the LED is amber, the advanced

clocking module is currently not locked and is either in holdover mode or free-running mode.

Figure 4: LED in the Advanced Clocking Module

LED

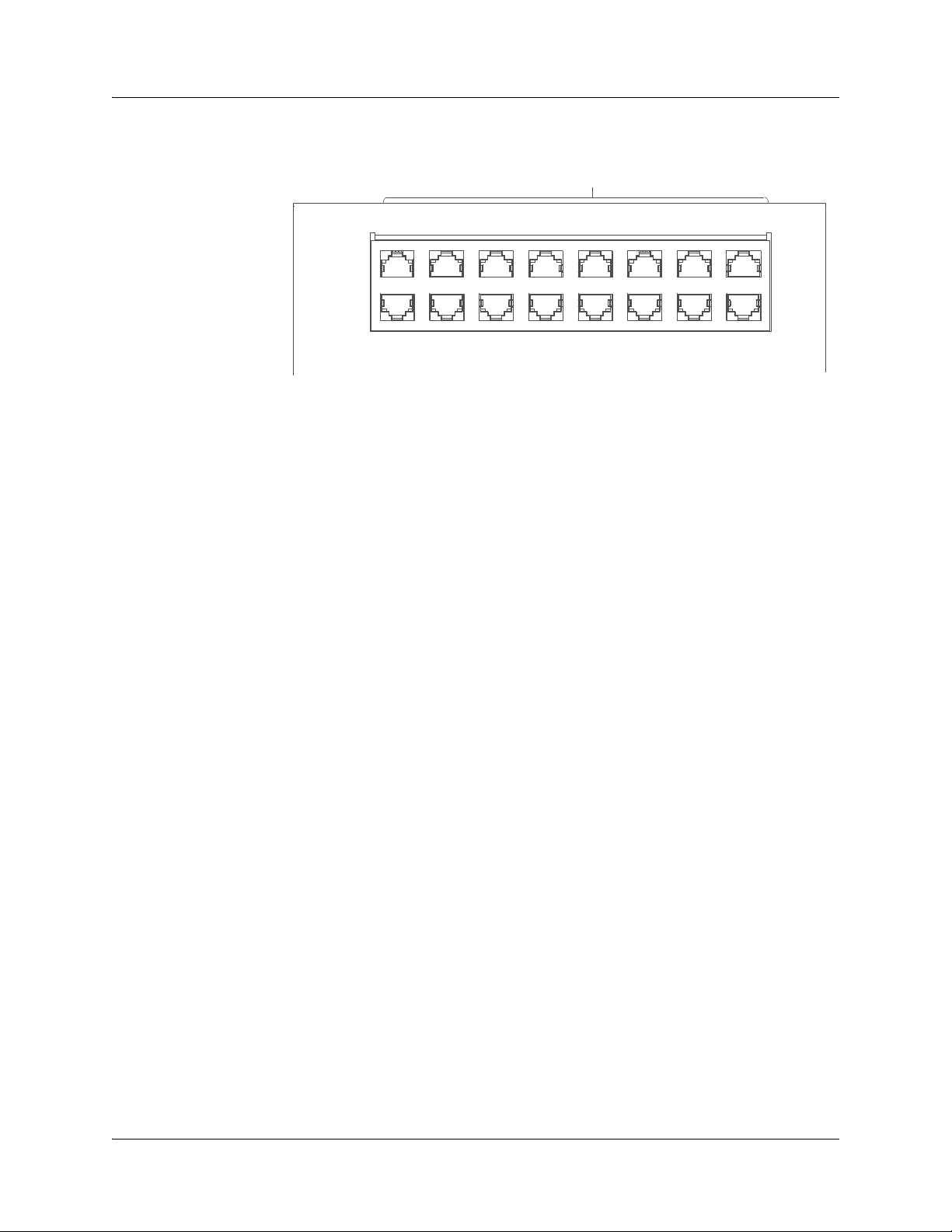

T1/E1 Ports

The T1/E1 ports provide connection to T1 or E1 network media types such as switches. They receive

incoming packets from the network and transmit outgoing packets to the network. Figure 5 on

page 6 shows the T1/E1 ports.

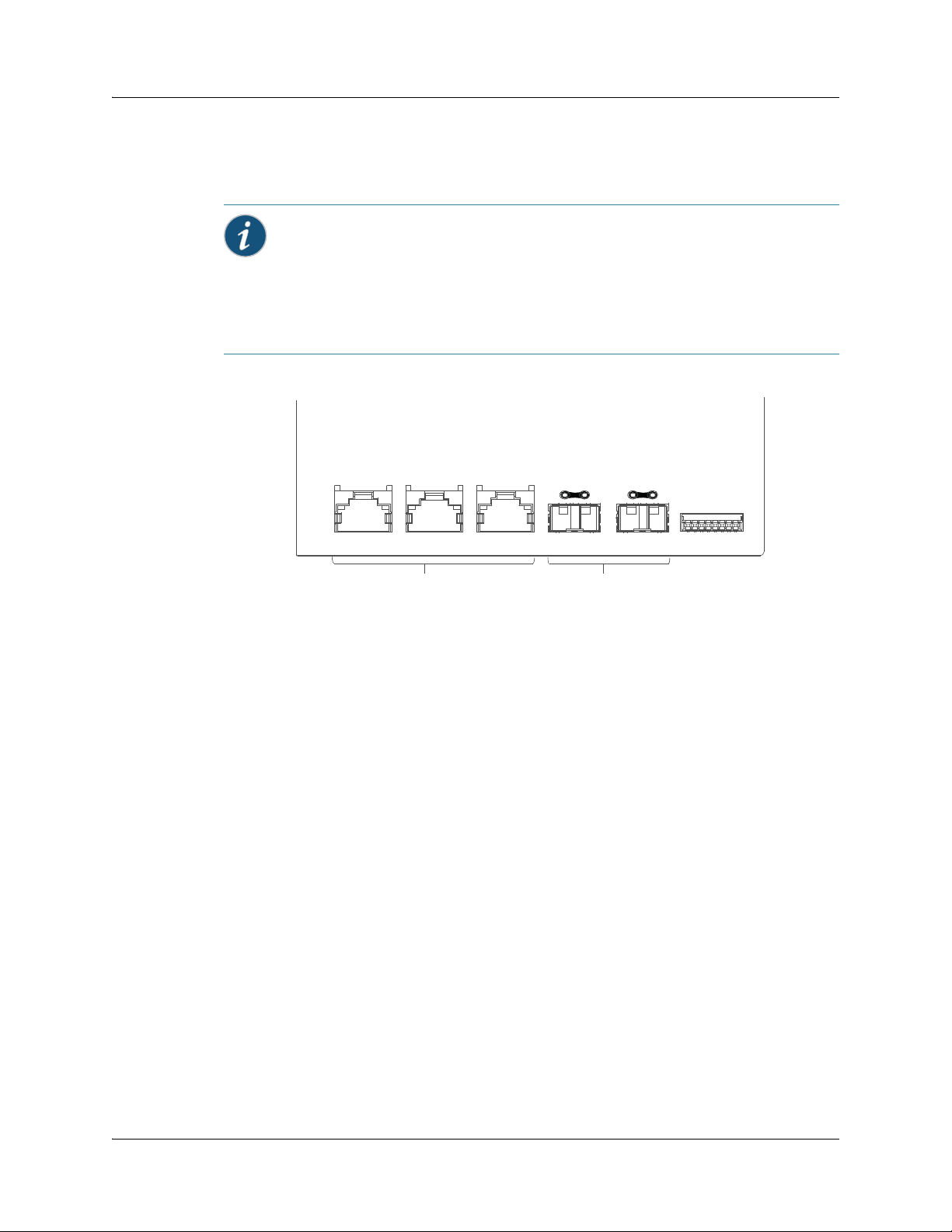

Figure 5: T1/E1 Ports

6 Hardware Components Copyright © 2010, Juniper Networks, Inc.

Page 25

CHAPTER 1: BX7000 Multi-Access Gateway Overview

T1/E1 ports

1 3 5 7 9 11 13 15

0 2 4 6 8 10 12 14

For information about the ports and connectors in the gateway, see Table 3 on page 8.

g002940

Hardware Components 7

Page 26

CHAPTER 1: BX7000 Multi-Access Gateway Overview

Table 3 : T 1/ E1 Po rt s

Description z 16 RJ-45 ports which can be configured either as T1 or E1

Hardware features z 16 T1/E1 ports supporting ATM, IMA, High-Level Data

Software features

Cables and connectors 16 RJ-45 connectors (one per port)—RJ-45 to RJ-45

LEDs Two rectangular single color LEDs for each T1/E1 port

Alarms, errors, and events z Alarm Indication Signal (AIS, YLW)

Link Control (HDLC)

z LEDs for status indication; for more information, see

LEDs

on page 8

z T1 framing: super frame (SF) and extended super frame

(ESF)

z E1 framing: G.703

z G.704—Channel Associated Signaling Multiframe

Format

z G.704-no-crc—Basic E1 framer format without CRC

z Per-port loop timing

z Integrated support for G.703 unframed mode and G.704

Channel Associated Signaling Multiframe Format; and

G.704-no-crc

z Encapsulations:

− High-Level Data Link Control (HDLC)

− Asynchronous Transfer Mode (ATM)

− Inverse Multiplexing over ATM (ATM-IMA)

− Point-to-Point Protocol (PPP)

− Transparent (Trans)

interface cable, Category 3

Link LED

z Green is lit in the following conditions:

− Admin-state is up and there is traffic through the port

− Admin-state is up and link is up

z Green is off in one of the following conditions:

− Error in traffic

− Link is down

− Admin-state down

Error LED

z Yellow is lit in the following error conditions:

− Admin-state is up and error in traffic

− Admin-state is up and link is down

z Yellow is off during admin-state down

z Excessive zeros (EXZ)

z Loss of frame (LOF), Loss of signal (LOS)

z Controlled Slip (CS)

Ethernet Ports

Five Ethernet ports are located in the lower right of the gateway (see Figure 6 on page 9). The

Ethernet ports can be used as either data ports or management ports.

z Three (10/100/1000Base-TX) copper Ethernet ports labeled ETHERNET 0, ETHERNET 1, and

ETHERNET 2.

z Two (1000 Base-X-SFP) fiber-optic Gigabit Ethernet ports with small form-factor pluggable

transceivers (SFPs) labeled ETHERNET 1 and ETHERNET 2.

8 Hardware Components Copyright © 2010, Juniper Networks, Inc.

Page 27

CHAPTER 1: BX7000 Multi-Access Gateway Overview

SFPs contain optical transceivers that support fiber-optic cable. Two rectangular LEDs on each

side of the copper Ethernet ports and two circular LEDs above each SFP show the link and the

status of ports. Table 4 on page 10 describes the functions of the Ethernet ports.

Note: For ETHERNET 1 and ETHERNET 2, you can connect both the copper Ethernet port and

the fiber-optic Ethernet port. However, only the copper port or the fiber-optic port can be active

at a time. If both ports are connected, the fiber-optic port will be active.

You can also use combination of these ports as follows:

z ETHERNET 1 of copper Ethernet port and ETHERNET 2 of fiber-optic Ethernet port