Page 1

2ch digital audio leveller

d06

LEVEL MAGIC™

Page 2

Page 3

–

pag

FOREWORD

Thank you for buying and using the 2-channel Digital Audio Level Processor

d06.

You have acquired the latest generation of digital dynamic range processing

and also a piece of equipment which is unique in its design and

specification.

Please read this manual carefully to ensure you have all the information you

need to use the 2 - channel Digital Audio Level Processor d06.

The unit was manufactured to the highest industrial standards and went

through extensive quality control checks before it was supplied.

1

If you have any comments or questions about installing, setting-up or using

the d06, please do not hesitate to contact us.

Operation manual do6, chapter 1 – Content

e 1 of 4

Page 4

CONTENT

2. Function description

2.1 Basic description

2.2 Block diagram

2.3 Audio signal processing

2.3.1 Gain

2.3.2 Audio Leveler Level Magic™

2.3.3 Limiter

2.4 The Jünger Audio Dynamics Principle

2.4.1 Program

2.4.2 Influence of signal delay time

3. Installation

3.1 Unpack the unit

3.2 Power supply

3.3 Connections

3.4 Rack mounting

3.5 Operation safety

3.6 Synchronization the digital output

3.7 Rear panel connectors

3.7.1 Audio connections

3.7.2 GPI

3.7.3 GPO (tally)

3.7.4 Serial RS422 or RS232 or CAN

3.7.5 LAN ( Ethernet)

3.8 Switches and jumpers for configuration

3.8.1 Selection of the serial remote interface

3.8.2 Calibration of the analog inputs and outputs

Operation manual do6, chapter 1 – Content – page 2 of 4

Page 5

–

pag

4. Network integration

5. Operation

5.1 GUI operation

5.1.1 Setting the d06 parameters

5.1.2 Setup the device

5.1.3 General settings

5.1.4 Preset operation

5.1.5 GPI/O set up

5.1.6 LAN Controller set up

5.1.6.1 System Configuration

5.1.6.2 Backup 6 restore

5.1.6.3 Software update

5.1.6.4 Reboot the LAN Controller

5.2. Front Panel Operation (optional)

5.2.1 Setting the reference levels

5.2.2. Menu selection

5.2.3. Preset menu

5.2.4. Configuration menu

5.3.5. Parameter menu

6. Technical specifications

7. Warranty and service information

8. CE Declaration of Conformity

Operation manual do6, chapter 1 – Content

e 3 of 4

Page 6

Operation manual do6, chapter 1 – Content – page 4 of 4

Page 7

2. FUNCTIONAL DESCRIPION

FUNCTIONAL DESCRIPTION

The digital dynamics processor d06 is a professional studio device that is

performing automated levelling of digital audio signals.

The dynamic range processor principles developed by Jünger Audio enable

level managing devices like compressors, AGC and limiters to be produced

with exceptionally high audio quality, without coloration, pumping, breathing,

distortion or modulation effects sometimes associated with this type of

processor.

In short, almost inaudible processing - with ease of use. The outstanding

quality of the processing is based on the Multi-Loop dynamic range control

principle in combination with adaptive controlled processing algorithms

developed by Jünger Audio.

The unit is easy to operate and requires only a limited number of settings to

be made by the user to achieve optimum results. All other parameters

necessary for inaudible processing are continuously automatically controlled

in response to changes in the programme signal.

features

• 2-channel digital audio levelling processor

• various link modes: stereo 1/2 or ch1 and ch2 independent

• adjustable input gain (channel independent) -20...+20 dB

• adaptive controlled audio levelling processing

- Leveler, Transient Processor, Limiter

• user friendly preset and recall function (10 presets)

• extern sync mode, AES/EBU, WCLK or VIDEO

• RS-232/422 interface for serial remote

• GPI interface for parallel remote control, tally output

• operation via web interface (LAN)

• optional operation via front panel

2

2.1

BASIC

DESCRIPTION

operation manual d06, chapter 2 - Functional Description - page 1 of 8

Page 8

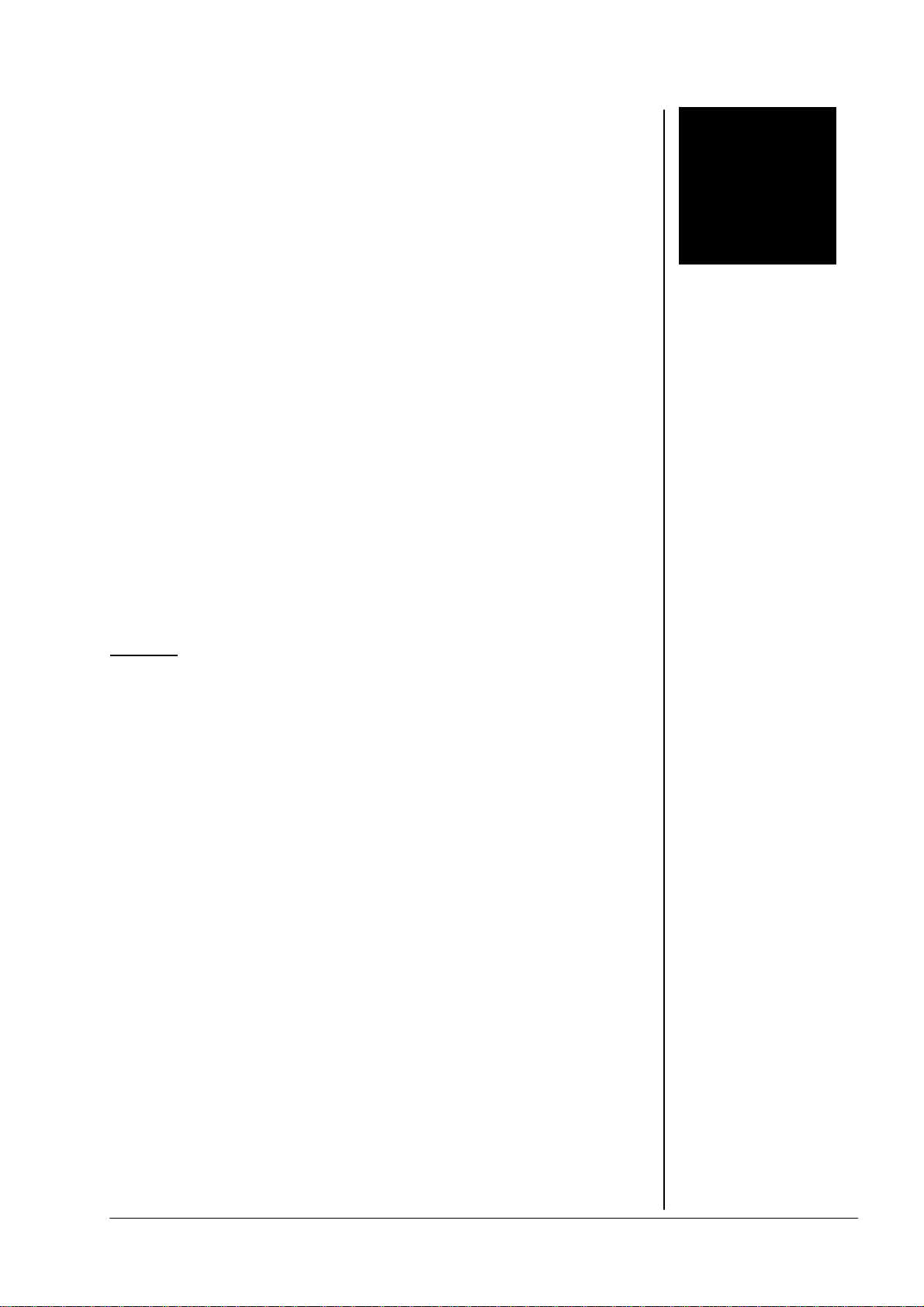

2. FUNCTIONAL DESCRIPTION

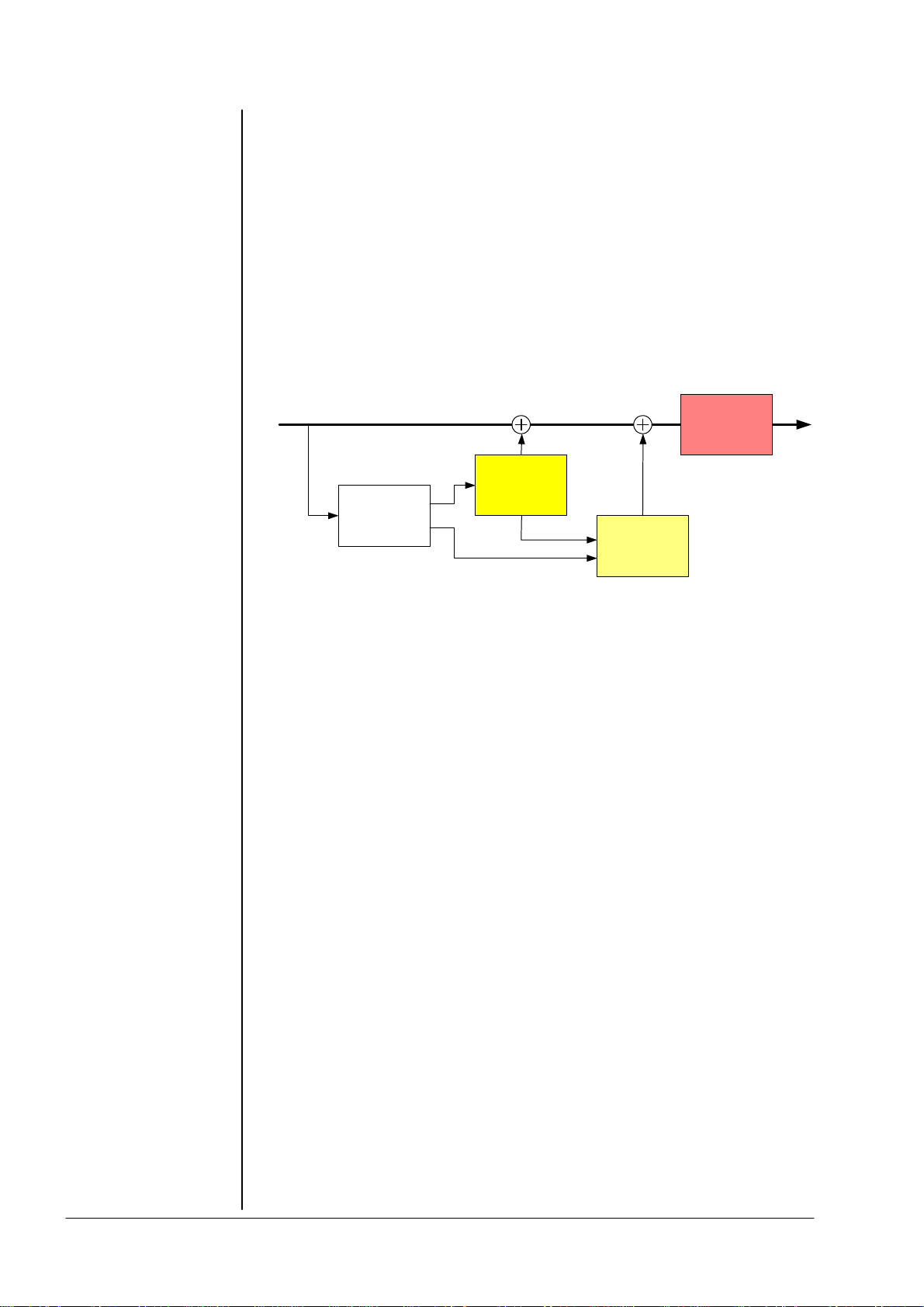

2.2

BLOCK

DIAGRAM

operation manual d06, chapter 2 - Functional Description - page 2 of 8

Page 9

2. FUNCTIONAL DESCRIPION

All signal processing is done in the digital domain by Texas Instruments

floating point signal processors. The use of 32 bit word length for calculation

ensures that there is no deterioration in signal quality, even if an audio signal

with a maximum word length of 24 bit is input into the processing of the unit.

GAIN means linear amplification of input signals. The input gain can be

changed in steps of 0.1 dB , within a range from -20...+20 dB for both

channels.

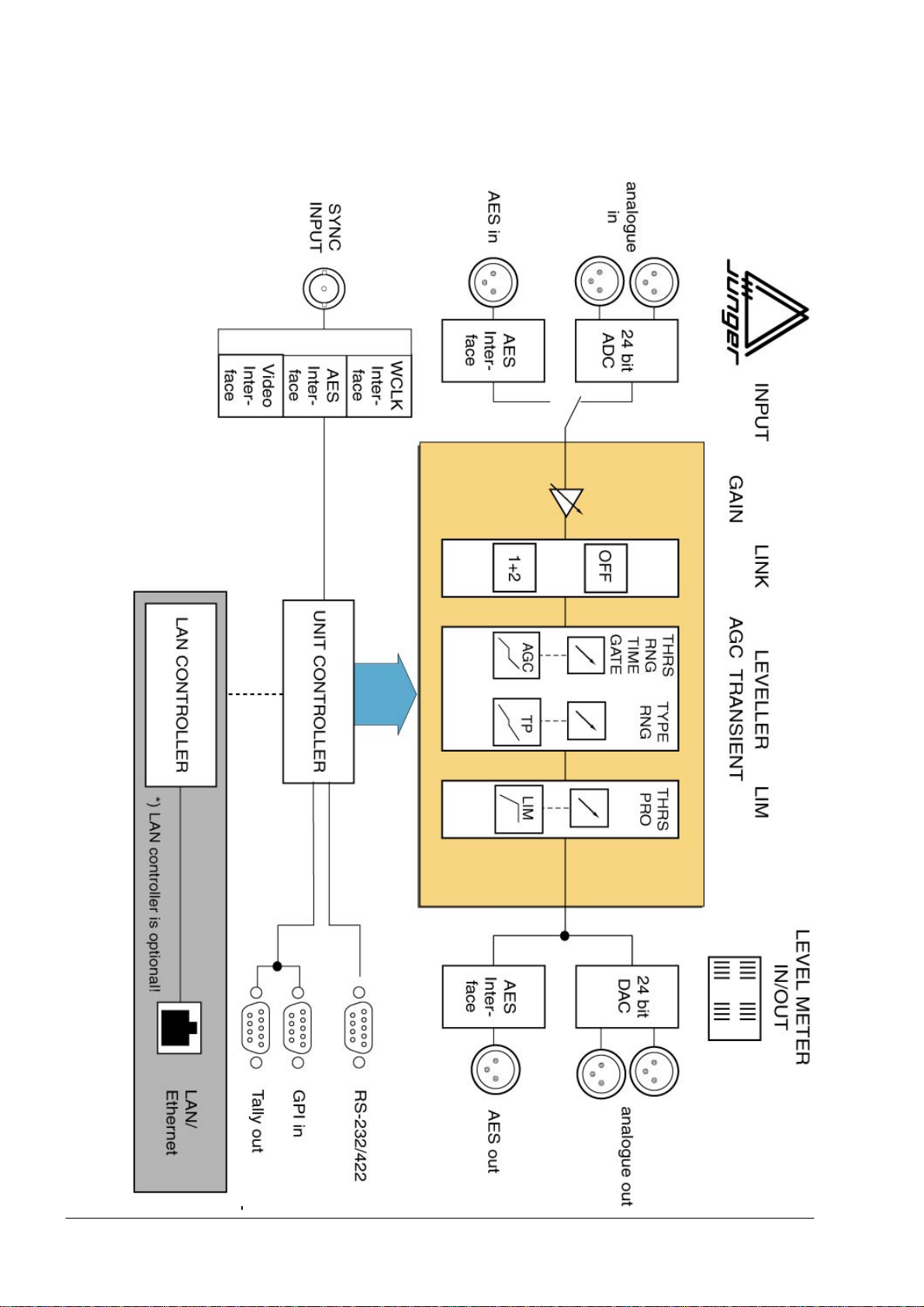

Level Magic ™ is a unique algorithm to make automated audio levelling

possible.

Input level change

Pic. 2 is showing a

theoretical level change of

+5dB and –5dB around

program level.

Working with AGC

In pic.3 a conventional

AGC is used to adjust the

level. As we can see the

AGC needs a certain time

to react, that is necessary

for mostly inaudible gain

correction. But that’s too

long to get a proper

correction of the input level

change.

Level Magic ™

Level Magic ™ is a unique

combination of a transient

processor and an adaptive

AGC process. The

transient processor can fill

the lack of level control

against the slow acting

AGC. The total gain of

Level Magic ™ is the

addition of the gain by the

transient processor and the

gain of the AGC.

Transient

Processor

AGC

adaptive

AGC

2.3

AUDIO SIGNAL

PROCESSING

2.3.1

GAIN

2.3.2

AUDIO LEVELLER

LEVEL MAGIC™

operation manual d06, chapter 2 - Functional Description - page 3 of 8

Page 10

Adjustment

procedure

Process

description

2. FUNCTIONAL DESCRIPTION

The Level Magic ™ process needs to be setup in three steps

- select one of the default presets for your apllication

(see preset description in chapter 5)

- adjust the operation level and peak level referring to standards that

are used for your application

- if the default preset is not giving satisfying results change the

parameters indivdually

Level Magic ™ is using a unique combination of QP and RMS level detectors

to analyze the incoming audio signal. By comparing QP and RMS

measurement results we can find out how much transients are coming in.

Dependent on that the necessary resulting gain is controlled in relation

between transient processor and AGC.

Limiter

Transient

Processor

Level

Detection

AGC

Parameter

description

Transient processor is doing fast gain change and the AGC is doing slow gain

change (depending on settings). The way how Level Magic is acting on the

audio is mostly determined by balancing between slow and fast gain changing

process. The AGC should be set in a way that the gain change is mostly

inaudible (1dB per 5 seconds or slower). The Transient Processor should be

set that incoming level jumps are reduced but originally dynamic range is not

changed too much. As more possible gain by the Transient processor

(RANGE), as more reduction of the dynamic range will be.

SOFT level control: AGC range …15dB, time >=2min

Transient range …4dB, soft process

MID level control: AGC range …12dB, time >=1min

Transient range …6-8dB, mid process

HARD level control: AGC range …10dB, time >=40sec

Transient range …10dB, hard process

Parameter description:

AGC

OP-level operation level, target level for the AGC and for

the Transient Processor

Range max. gain by the AGC

Time time to reach the max. gain change

Gate threshold level where the AGC stops gain

change and moves gain slowly to the long

term average gain

Transient Processor

Process a combination of level ratio and release

characteristic for the fast gain change (soft, mid,

hard)

Range max. level change by the Transient Processor

operation manual d06, chapter 2 - Functional Description - page 4 of 8

Page 11

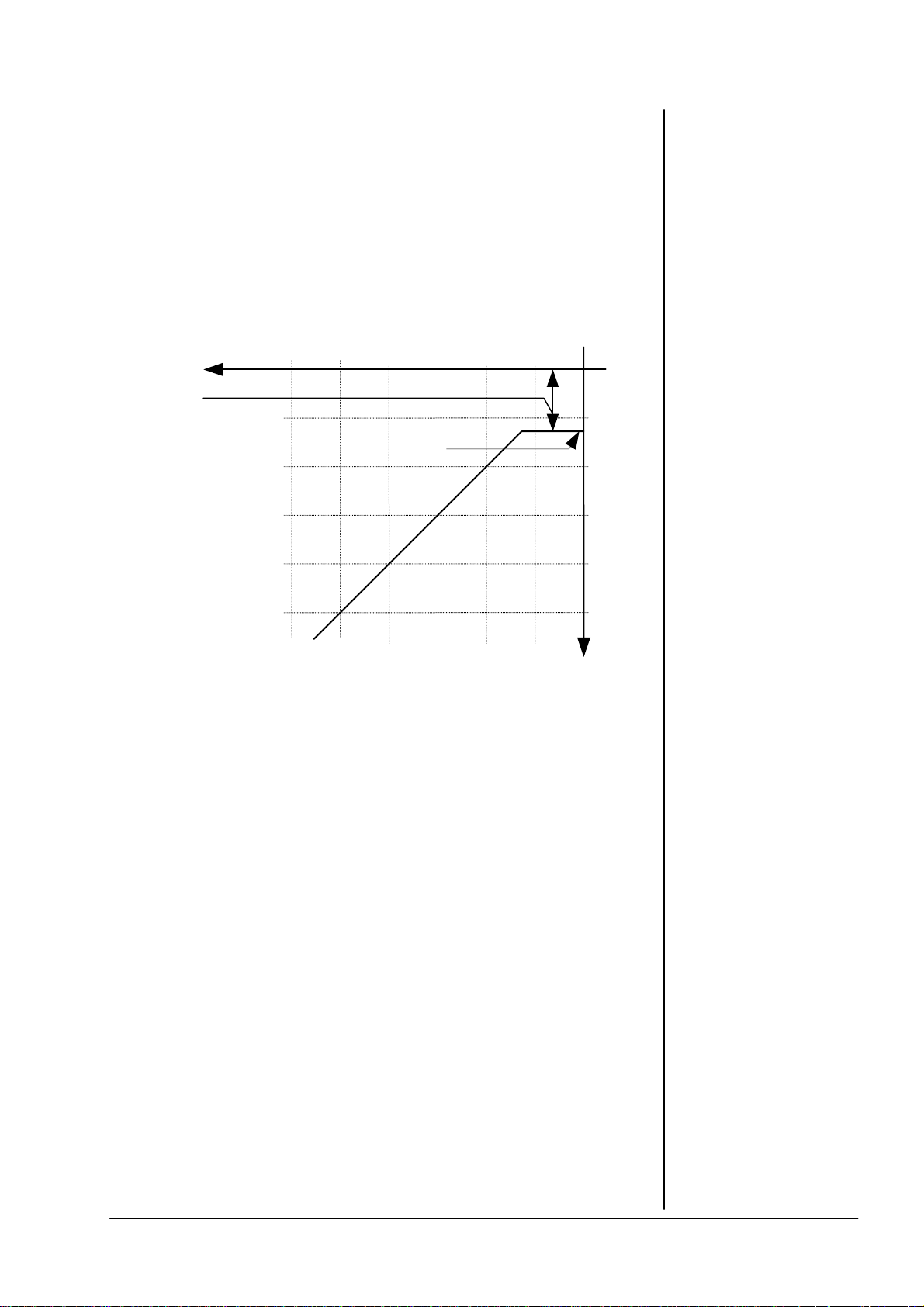

2. FUNCTIONAL DESCRIPION

The static characteristics of the d06 limiter usually refers to a digital output

level of 0 dBFS (dB Full Scale). This is useful for most applications of the

dynamics processor as the on-following digital recording system is supposed

to be balanced down to the final bit.

For applications using headroom the output level can be adjusted within 0 ... -

20 dBFS in steps of 0.1 dB. The limiter threshold determines the maximum

output level.

The static characteristic for the limiter at a limiter threshold of -12dBFS is

illustrated in fig. 6.

limiter

threshold

0...-20dBFS

input

-40

-60

-50

max. output

level

-30

-20

-10

[dBFS]

-10

-20

-30

2.3.3

LIMITER

fig. 6:

basic function:

limiter

-40

-50

output

For the dynamics functions a signal delay of approx. 2 ms is built in. This

delay makes it possible to arrange the algorithm of the limiter in such a way

that the control mechanism is activated before maximum level is reached (look

ahead limiter). Within the rise time of the signal the peak level is recognised

and the maximum is calculated in such a way that limiter threshold level is

reached precisely without causing clipping.

A change in the dynamic range of an audio signal is a non-linear process. The

gain of a dynamic range processor is not constant as it is with the gain of a

linear amplifier. The gain varies in time depending on the input signal and

depending on the specific control algorithm of the dynamics processor. These

variations in the gain, which represent the real control process, should take

place without any bothersome side effects.

The dynamic range processor principle developed by Jünger Audio makes it

possible to realize dynamics processors (compressor, limiter, expander) with

very high audio quality, without signal discoloration, pumping or breathing,

without distortion and modulation products - in short, with almost inaudible

processing - and they are very easy to use.

2.4

THE JUNGER

AUDIO DYNAMICS

PROCESSOR

PRINCIPLE

operation manual d06, chapter 2 - Functional Description - page 5 of 8

Page 12

2. FUNCTIONAL DESCRIPTION

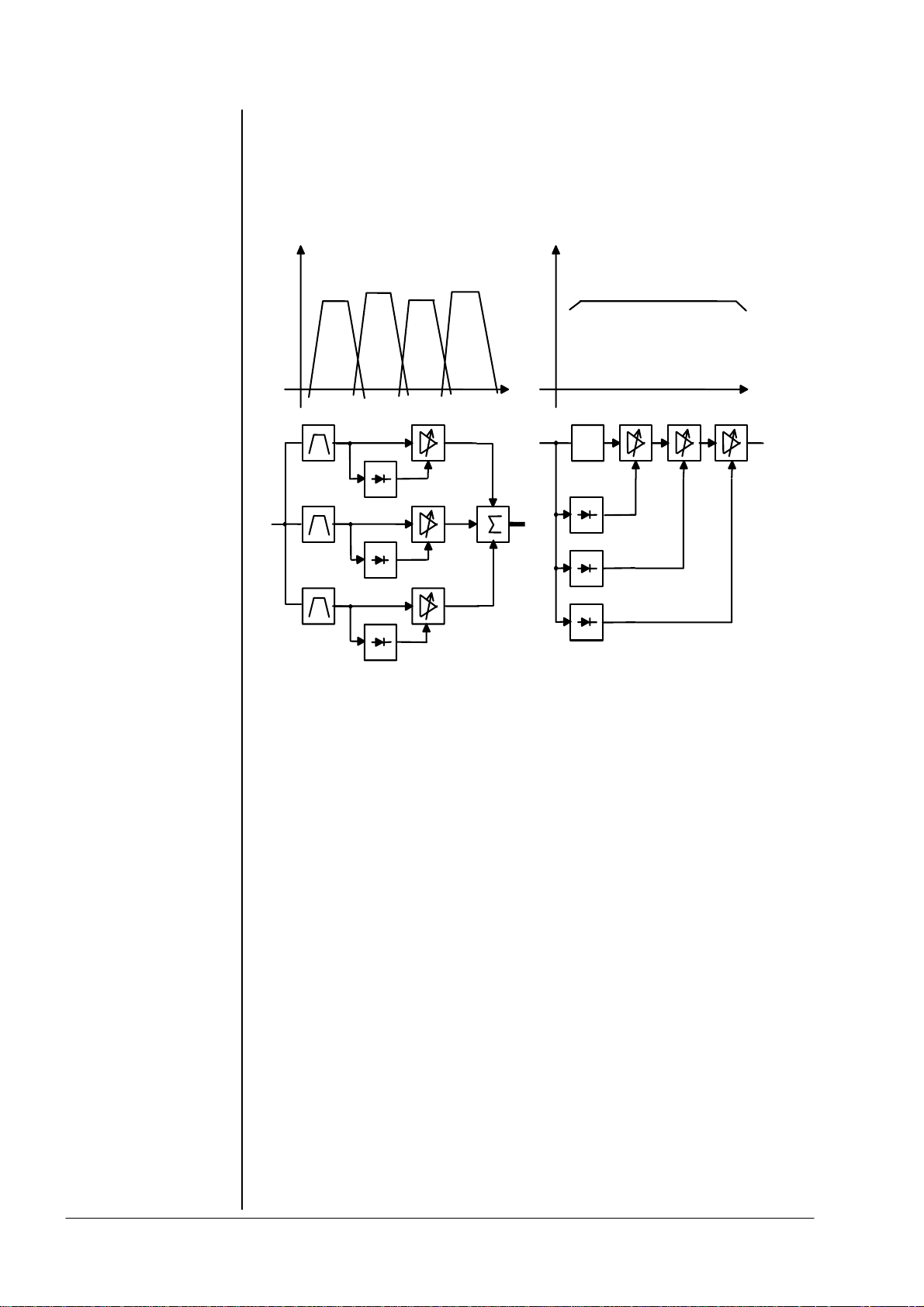

The Junger Audio dynamics processors work according to a Multi-loop

principle, operating with an interaction between several frequency linear

control circuits. This is quite different to the popular multiband structure which

changes the sound.

A A

Multi - Band

f

delay

1

Multi - Loop

1

2

2

n

m

f

2.4.1

PROGRAM

The resulting attack and release times of the Multi-loop system are variable

and adapted to the evolution of the input signal. This allows relatively long

attack times during steady-state signal conditions but also very short attack

times when there are impulsive input transients.

The Multi-loop structure also permits a short time delay between the control

circuit and the gain changing element. The gain control circuit has time to

preview the signal and become active before it reaches the output. This is

particularly important for the limiter, which provides a precisely leveled output

signal absolutely free of overshoots (clipping).

For some of the control parameter it is possible to define a limited range of

time constant values which are allowed for the adaptive dynamic range

algorithms. Inside this range the time constants can be varied by the adaptive

processing. Setting the range of time constant values may be sometimes

useful, to get the best signal processing performance regarding specific

programme material.

Parameter related to the transient response of the control circuit are important

for distortionfree processing. These time constants are allways adaptive

controlled without remarkable limitation of parameter range. This is caused by

the presence of transient pulses in allmost each kind of programme material.

The algorithm has to guarantee best reaction for fast increasing level of

transient signals anytime even if classical music with slow dying out

characteristic is processed. In all cases the attack time of the limiter for very

short transients is zero.

operation manual d06, chapter 2 - Functional Description - page 6 of 8

Page 13

2. FUNCTIONAL DESCRIPION

Especially the release time of the control circuit has more influence to the

increase of loudness as any other parameter. The ranging of time constants in

processing time groups reflects this fact. The range for processing time shows

influence on release time parameter mostly.

The selection of the parameter limiter PROCESS changes the range of time

constant values as follows:

PRO processing time

-------------------------------------------------------- 0 2 ms to 0.2 sec

1 5 ms to 0.5 sec

2 10 ms to 0.8 sec

3 15 ms to 1.2 sec

4 30 ms to 2.5 sec

5 50 ms to 3.5 sec

6 70 ms to 5.0 sec

7 100 ms to 6.0 sec

8 150 ms to 8.0 sec

9 250 ms to 10.0 sec

The audio signal delay through the dynamics processor is approx. 2ms due

to delaying of the audio signal using internal memory. A small delay is

deliberately introduced to the audio signal in order to allow limiter and

compressor algorithms which can 'preview' the audio signal before

changing it. That is the signal curve can be changed before maximum level is

reached. This delay must be considered before attempting to mix signals

processed by the dynamics processor with other undelayed signals.

When mixing together a delayed signal and a direct signal there may be

cancellation of the signal waveform at some frequencies and re-inforcement

of the waveform at other frequencies (comb filter effect). Corresponding

2ms delay of direct signals should therefore be carried out before mixing

them with delayed processed signals.

2.4.2

INFLUENCE OF

SIGNAL DELAY

TIME

operation manual d06, chapter 2 - Functional Description - page 7 of 8

Page 14

2. FUNCTIONAL DESCRIPTION

operation manual d06, chapter 2 - Functional Description - page 8 of 8

Page 15

3. INSTALLATION

INSTALLATION

The digital audio level processor d06 was packed carefully in the factory and

the packaging is designed to protect the equipment from rough handling.

Please examine carefully the packaging and its contents for any signs of

physical damage, which may have occured in transit.

The digital audio level processor d06 is a device under the safety category

Schutzklasse 1 in keeping with the VDE 0804 standards and may only used

with power supply installations built according to regulations.

Check the voltage details printed at the rear panel are the same as your local

mains electricity supply.

The digital audio level processor d06 is equipped with standard connectors

(see also chapter 3).

Before connecting the digital audio level processor d06 switch the power off at

all connected units.

The digital audio level processor d06 is made as standard 19“ unit (EIA

format). It occupies 1 RU (44 mm height) space in a rack. Please allow at

least additional 3inch of space for the connectors on the rear panel.

When installing the unit in a 19“ rack the rear side of the unit needs some

support, especially for mounting in flight cases.

The digital audio level processor d06 should not be installed near units which

produce strong magnetic fields or extreme heat. Do not install the audio

processor directly above or below power amplifiers.

If, during operation, the sound is interrupted or displays no longer illuminate,

or if abnormal odor or smoke is detected immediately disconnect the power

cord plug and contact your dealer or Junger Audio.

3

3.1

UNPACK THE

UNIT

3.2

POWER SUPPLY

3.3

CONNECTIONS

3.4

RACK MOUNTING

3.5

OPERATION

SAFETY

operation manual d06, chapter 3 - Installation - page 1 of 10

Page 16

3.6

SYNCHRONIZING

THE DIGITAL

OUTPUT

3.7

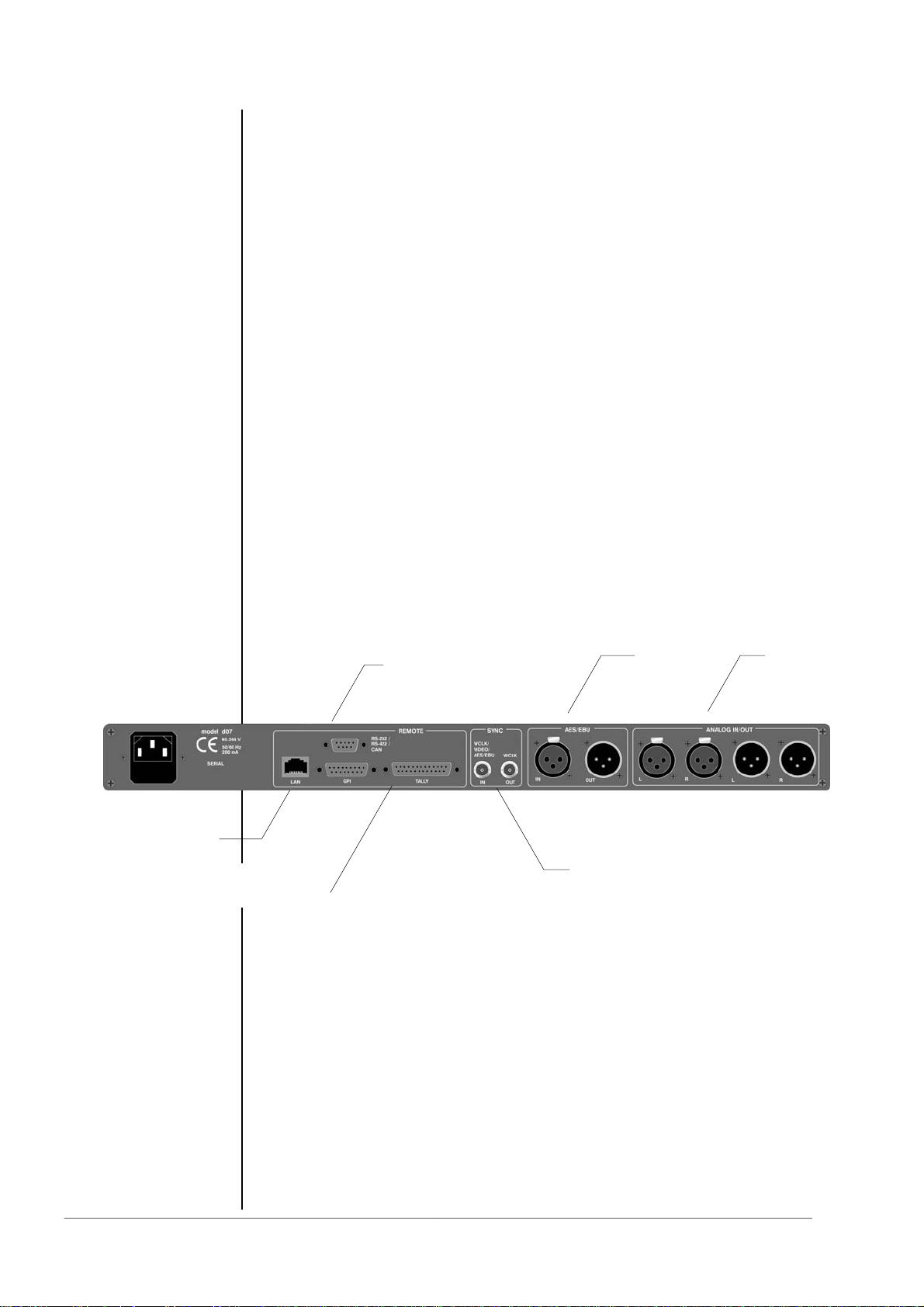

REAR PANEL

CONNECTORS

LAN-controller

web interface

3. INSTALLATION

The digital audio level processor d06 has a digital signal output. For the

problem-free combination of following digital devices, the digital signal

processing can be locked to an external clock reference. The selection of the

corresponding sync source is made in the SYNC MODE menu during setup. If

the chosen sync input is connected with the sync signal, this signal is used for

synchronization automatically. All sync sources can be used for locking A/Dconverters at the analogue inputs as well. The digital output signal can be

clocked with the following clock frequencies:

INTERNAL locks both the A/D-converters and the digital output with

the internal reference 44,1 or 48 kHz. Digital inputs are

connected via sample rate converter

AES INPUT locks with the clock frequency of the input signal at

EXT AES locks with the AES signal at the sync input

EXT WCLK locks with the word clock signal at the sync input

EXT VIDEO locks with black burst at sync input (internal 48 kHz) Digital

Important Note! Video Sync is an option for the d06. For the very rare case

that you can not synchronize the d06 to AES, you may buy such option from

Junger Audio. Pls contact your local dealer for details.

GPI REMOTE

IN/OUT

POWER INPUT

IEC mains input connector 85-264V, 50/60 Hz with integrated fuse

REMOTE

serial remote interface RS-422 (232)

connector: 9pin SUB-D, female

GPI

parallel remote interface

TALLY-out open relay contact

connector: 25pin SUB-D, female

GPI-in optical coupler +3,5…+30V

connector: 15pin SUB-D, female

digital input CH 1/2 (AES/EBU, 44,1...48 kHz)

(AES, 44,1...48 kHz) Digital inputs are connected via sample

rate converter

(WCLK, 44,1...48 kHz) Digital inputs are connected via sample

rate converter

inputs are connected via sample rate converter

SERIAL

REMOTE

DIGITAL

I/O

SYNC IN

WCLK OUT

ANALOGUE

I/O

operation manual d06, chapter 3 - Installation - page 2 of 10

Page 17

3. INSTALLATION

SYNC

SYNC IN input for ext. sync signals :

AES 3 format, 75 Ohm, unbalanced

video sync (black burst), 75Ohm, unbalanced

word clock (TTL level), 75Ohm, unbalanced

Connector : BNC socket

WCLK OUT output for word clock (system clock of d06)

(TTL level), 75Ohm

Connector : BNC socket

DIGITAL IN

AES/EBU standard format

Connector : XLR female

DIGITAL OUT

AES/EBU standard format

Connector : XLR male

ANALOG IN/OUT

Analog input 24bit A/D-converter

floating, balanced

Connector : XLR female

Analog output : 24 bit D/A-converter

Floating, balanced

Connector : XLR male

The analogue audio inputs are RFI filtered. Analog I/Os are balanced and

floating like transformer coupled devices. All the audio connectors are via rear

panel mounted connectors. Standard XLR connectors are used. These are

always wired to the AES standard:

pin 1 X Shield

pin 2 L Live audio 0°

pin 3 R Return audio 180°.

Balanced connections are preferred whenever the other equipment provides

balanced inputs/outputs. All line level connections should be wired with twin

shielded cable for low noise and reliability. The shields of the cable should be

connected at one end only. Input cable shielding therefore needs to be

derived from the signal source end as pin 1 is ground lifted for low frequencies

at the inputs.

If the equipment that drives the digital audio level processor d06 has

unbalanced outputs you must add a wire jumper to connect Pin 1 of the XLR

to Pin 3.

If the equipment connected to the d06 has unbalanced inputs only, we

recommend to use a balanced (i.e. 2 core shielded) cable where Pin 1 and

Pin 3 are connected in the XLR plug end away from the digital audio level

processor d06.

3.7.1

AUDIO

CONNECTIONS

operation manual d06, chapter 3 - Installation - page 3 of 10

Page 18

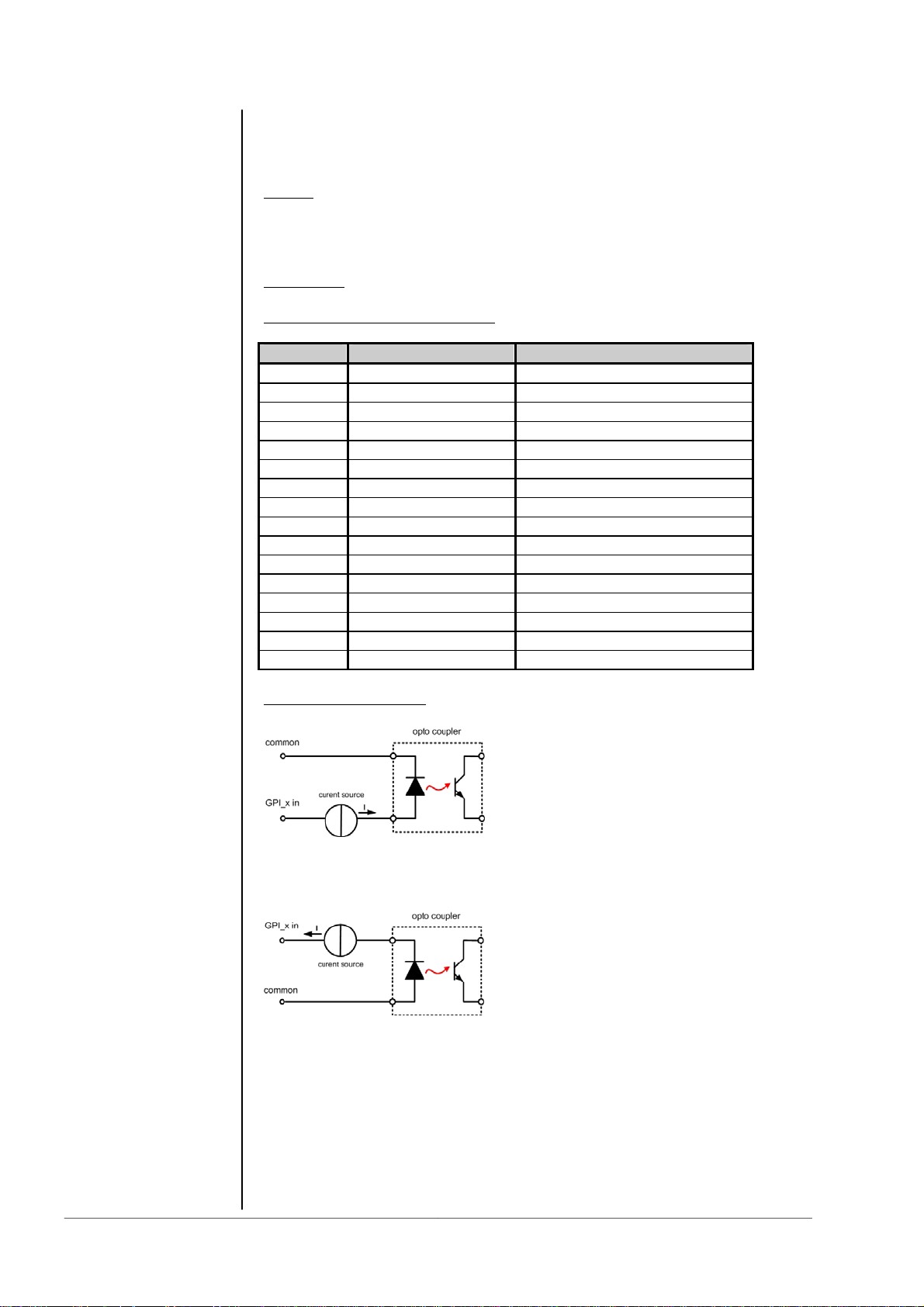

3.7.2

GPI

3. INSTALLATION

The digital audio level processor d06 can be remote-controlled by means of

parallel GPI inputs.

Use to

* switch between STEREO / 2CH link mode

* selection of INPUT 2 / 1

* switching the device to BYPASS

Connector :

Pin assignment of the connector :

Electrical specification :

GPI input potential free by opto-coupler in line with

a current source

For serial numbers S/N 59 and higher (HW Revision 2a and higher) the

polarity of the GPI inputs has been changed. to make use of the internal

ground based auxiliary 5 V for "low active" switching.

Signal duration must be at least 50msec.

Note : An internal auxiliary voltage feed of +5V is available on pin 9

via a 110 Ω resistor. Ground is available from the shield of the connector

only! When using the auxiliary voltage feed, there is no electrical isolation

given anymore and the risk to inject unwanted noise is high!

Important Note : You must take care about the polarity of the external voltage

applied to the GPIs. Wrong polarity may destroy electronic components

and may cause fire inside the d06!

: * recall of PRESETs 1-4

D-SUB 15pin, female

Pin Signal name Functions

1 GPI1 in Defined by d06 config

2 GPI2 in Defined by d06 config

3 GPI3 in Defined by d06 config

4 GPI4 in Defined by d06 config

5 GPI5 in Defined by d06 config

6 GPI6 in Defined by d06 config

7 GPI7 in Defined by d06 config

8 GPI8 in Defined by d06 config

9 + 5V 110 Ω

10 GPI1/GPI2 common

11 GPI3 common

12 GPI4 common

13 GPI5 common

14 GPI6 common

15 GPI7/GPI8 common

Shield -5V GND of d06 Chassis

ON: +3.5…+30V between GPIx input

and GPx common

OFF: less then 1.5V between GPIx input

and GPIx common

ON: -3.5…-30V between GPIx input

and GPx common

OFF : less then 1.5V betwee GPIx input

and GPIx common

operation manual d06, chapter 3 - Installation - page 4 of 10

Page 19

3. INSTALLATION

The digital audio level processor d06 can aknowledge specific device statuses

via parallel GPO (Tally) lines.

Use to

Connector

female panel jack

Pin assignment of the connector :

Electrical specifications :

Tally output relay : common / normally closed / normally opened

24V - 1A

125V - 0,5A

P

: monitor the d06 status

: D-SUB 25pin

Pin Signal name Functions

1 Tally 1 normally closed

2 Tally 1 normally opened Defined by d06 config

3 TALLY 2 common

4 Tally 3 normally closed

5 Tally 3 normally opened Defined by d06 config

6 TALLY 4 common

7 Tally 5 normally closed

8 Tally 5 normally opened Defined by d06 config

9 Tally 6 common

10 Tally 7 normally closed

11 Tally 7 normally opened Defined by d06 config

12 TALLY 8 common

13 + 5V 110 Ohm

14 TALLY 1 common

15 Tally 2 normally closed

16 Tally 2 normally opened Defined by d06 config

17 TALLY 3 common

18 Tally 4 normally closed

19 Tally 4 normally opened Defined by d06 config

20 TALLY 5 common

21 Tally 6 normally closed

22 Tally 6 normally opened Defined by d06 config

23 TALLY 7 common

24 Tally 8 normally closed

25 Tally 8 normally opened Defined by d06 config

Screen -5V GND of do6 chassis

= 62,5VA

max

3.7.3

GPO (TALLY)

operation manual d06, chapter 3 - Installation - page 5 of 10

Page 20

3.7.4 Serial

RS422

or

RS 232

or

CAN

3. INSTALLATION

The digital audio level processor d06 can be remote-controlled by means of

serial remote RS-232/422.

Use

: * network configuration

* administrative setup (consol interface)

Protocol :

Connector

female panel jack

Pin assignment of the connector in serial interface mode :

Pin assignment in CAN-bus mode :

This connector has multiple functions which may be internally changed by

connectors and jumpers (see 3.8). The factory default format setting is RS232

and it is connected with the serial interface of the LAN Controller.

By using a terminal program (115kB/sec. 8,N,1 no flow control) you may

communicate with the consol of the LAN Controller, e.g. to change the IP

configuration of the device.

available on request

: D-SUB 9pin

Pin Signal name Functions

1 Rx + RS422

2 TxD RS232

3 RxD RS232

4 NC not used

5 GND Ground

6 Rx - RS422

7 NC not used

8 Tx - RS422

9 Tx + RS422

Pin Signal name Functions

1 NC Not used

2 CAN-l CAN-bus low signal

3 NC Not used

4 NC Not used

5 GND Ground

6 GND Ground

7 CAN-H CAN-bus high signal

8 NC Not used

9 NC Not used

operation manual d06, chapter 3 - Installation - page 6 of 10

Page 21

3. INSTALLATION

Connector : RJ 45 with status LEDs

8 pin panel jack

Pin assignment of the connector :

Pin Signal name Functions

1 TX + Ethernet send

2 TX - Ethernet send

3 RX + Ethernet receive

4

5

6 RX - Ethernet receive

7

8

9

Electrical specifications : 100Mbit/s auto negotiation port

Application remarks :

This port allows remote control of the d06 by TCP/IP over Ethernet (web

interface). Setting up the network interface is described in chapter 4.

The LAN Controller of the d06 has a web server which offers a graphical user

interface (GUI). For proper operation you need IE7 or FireFox 2.0.

You simply must use the IP address of the do6 as an URL. (see chapter 5.1

for details).

d06 control block diagram :

3.7.5

LAN

(Ethernet)

operation manual d06, chapter 3 - Installation - page 7 of 10

Page 22

3.8

A

Switches and

jumpers for

configuration

3.8.1

Selection of the

serial remote

interface

3. INSTALLATION

Some basic settings can be done by switches and jumpers on the PCB.

These settings are general changes for operation and should be performed by

qualified engineering staff only.

To set any internal jumper or switches it is necessary to open the unit.

Important Note! DO NOT CHAGE ANY SETTINGS WHILE POWER IS

CONNECTED TO THE UNIT!

Loosen the screws on the top cover and remove. Then you can see all jumper

and switches as shown in the schematic below. After setting of jumper or

switches reassemble the unit in opposite order.

D06/07

J2

232/422

J3

/B

3.8.2

Calibration of the

analog inputs and

outputs

DSP card

J2 : RS-232 / RS-422 (format selection)

J3 : A / B serial Interface of the DSP controller (A)

The factory default calibration of the d06 is done in reference to the German

radio broadcast standard, i.e. +15dBu = 0dBFS. If you want to use a different

reference standard (e.g. +24dBu = 0dBFS) you can change the setting via dip

switches on the main board of the d06 :

The DIP switches are located close to the analog input and output hardware

on the PCB.

Main board

or the LAN controller (B)

operation manual d06, chapter 3 - Installation - page 8 of 10

Page 23

3. INSTALLATION

For the factory setting of +15dBu=0bBFS the DIP switch

“+15dBu” is turned ON.

To change the setting for another standard the respective DIP switch must be

set to ON while all others must be OFF.

Important Note! Make sure that there is only one DIP switch turned ON!

CUSTOM Refernce Level (using Switch 6 ADJ)

If none of these stansard reference settings correspond to your needs, you

may set the reference to a CUSTOM level by adjusting the input sensitivity via

the two potentiometers (L and R) next to the analog input and output

connectors at the rear of the box.

Important Note! This should only be done with measuring instruments!

Set up the reference level manually :

1. Set all dip switches to OFF except #6 (ADJ) = ON.

2. Adjust the potentiometers to the desried CUSTOM reference level.

You must feed the analog input with a known refernce level and

measure the digital output.

Important Note! Make sure that the DSP processing is bypassed,

because it may add gain, that gives wrong level reading at the output!

3. When the adjustments are complete, ‘freeze’ the custom settings by

setting DIP switch #6 to OFF. If not, your reference level set up may

be changed by accident.

operation manual d06, chapter 3 - Installation - page 9 of 10

Page 24

3. INSTALLATION

operation manual d06, chapter 3 - Installation - page 10 of 10

Page 25

4. NETWORK INTERGRATION

NETWORK INTEGRATION

To control the Junger audio devices via web browser you must set up an

TCP/IP over Ethernet connection. If you are not familiar with the network

setup, please consult a network administrator for assistance and read ALL

the manual carefully!

There are two ways to communicate with the device via Ethernet:

1. You can connect the device to the LAN your PC is integrated

(if there is one existing already)

2. You can connect the device directly to your PC using an

Ethernet crossover cable.

In both cases network settings of the device or your PC or even both have to be

changed and matched.

The default network configuration of the Jünger devices is:

IP Address : on a label at the LAN connector socket at the rear of the device

Netmask : 255.255.0.0.

Gateway : 10.110.0.1.

1. Integration into an existi ng LAN

When you want to integrate the device into an existing LAN you have to

change its IP-address, the (sub) network mask and the gateway. You will get

valid settings from your network administrator.

You can do that two ways :

A Connecting the device over a serial cable to your PC and change the

network configuration with a terminal program (e.g. HyperTerminal

included in Windows installation)

B Disconnect your PC from your LAN (physically), match your PC’s

IP setup to the setup of the device for getting access to the device via

Ethernet crossover cable, change the device’s network configuration via

Ethernet crossover cable. Then change again your PC’s configuration

and connect both your PC and the device to the LAN.

4

operation manual d06, chapter 4 - Network Integration - page 1 of 6

Page 26

4. NETWORK INTEGRATION

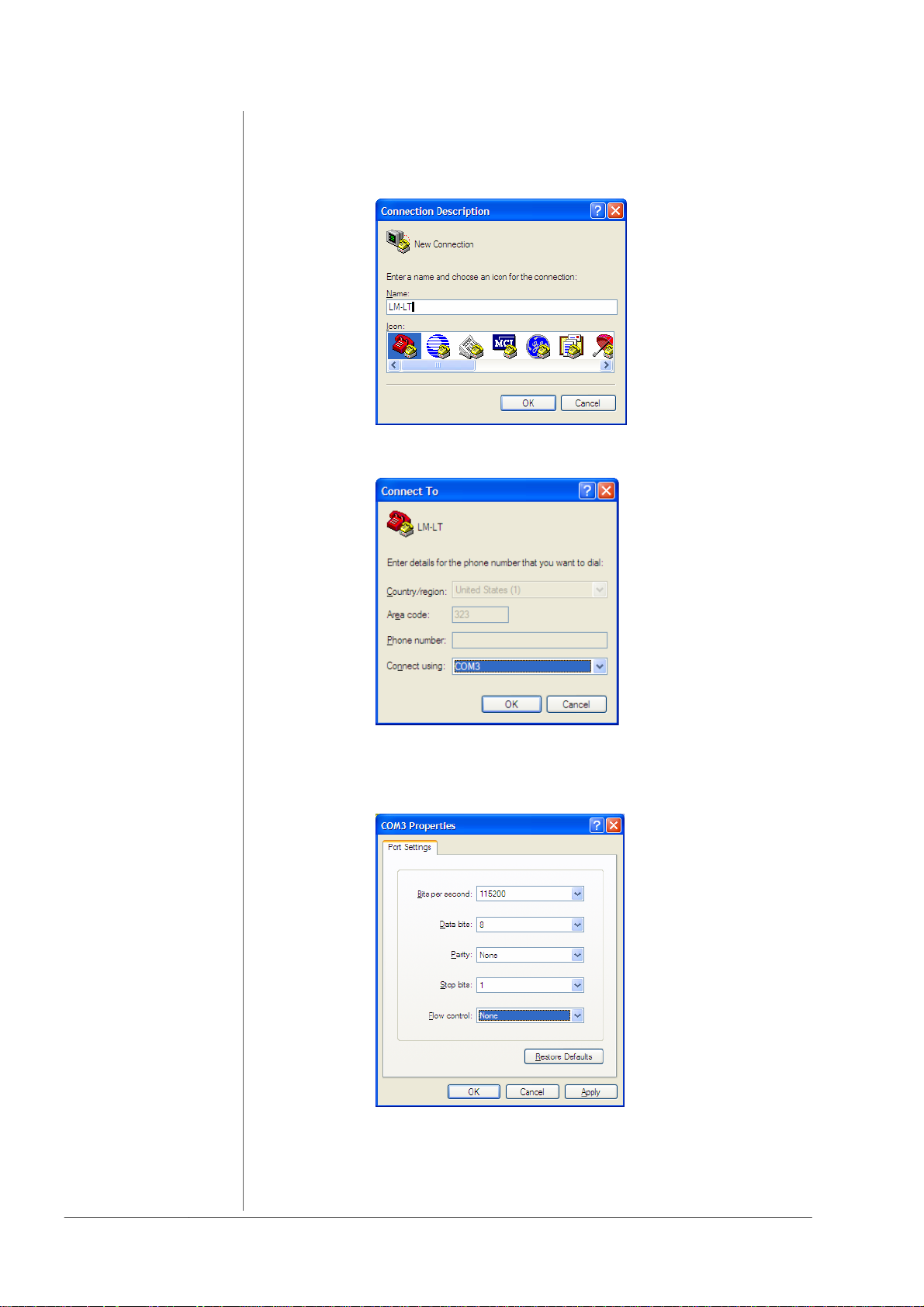

A)

Connect the device via a 9 pin serial cable (connected 1 to 1) to your

PC. Start your terminal program (e.g. Start -> All Programs -> Accessories ->

Communications -> HyperTerminal).

Enter a name of your choice and press OK

Choose the communication port (physical or virtual if you are

using an USB > serial converter) you are working with

and press OK

Set the port settings as they are shown in the window above

and press OK.

operation manual d06, chapter 4 - Network Integration - page 2 of 6

Page 27

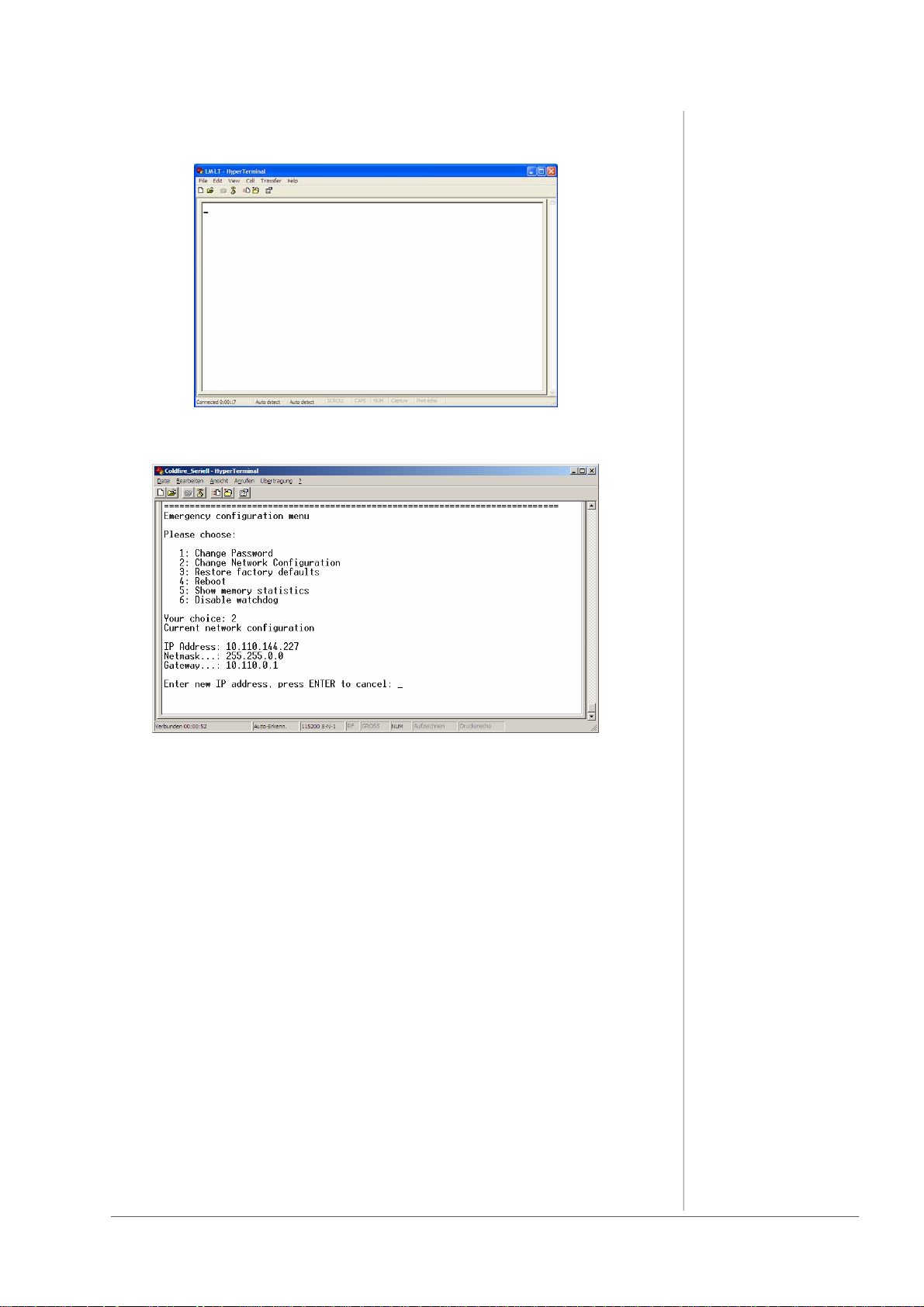

You will get to the Hyper terminal window:

Press ENTER and you will get a similar window :

4. NETWORK INTERGRATION

Now you can change the network configuration so that it fits into your LAN.

You might have changed the IP-address of the device, so please renew the

label at the rear of the device, otherwise it will cause confusion.

When you ever “Restore factory defaults” (i.e. initializing the device) the

default IP-address and network configuration will be active again. In case of

need you can read the default IP-address always on the controller in the

device!

B)

You can also change the IP address of the device over Ethernet connection.

Disconnect your PC from the LAN, connect it to the device directly via

Ethernet crossover cable (not connected 1 to 1, but 1 to 8 etc…).

Change the network configuration of your PC (write down the current settings,

you need them later to reconnect to your LAN!) via the

“Local Area Connection Properties” menu (Windows: Start -> Control Panel ->

Network connections -> Local Area Connection -> Local Area Connection

Status -> Properties -> Internet Protocol (TCP/IP).

operation manual d06, chapter 4 - Network Integration - page 3 of 6

Page 28

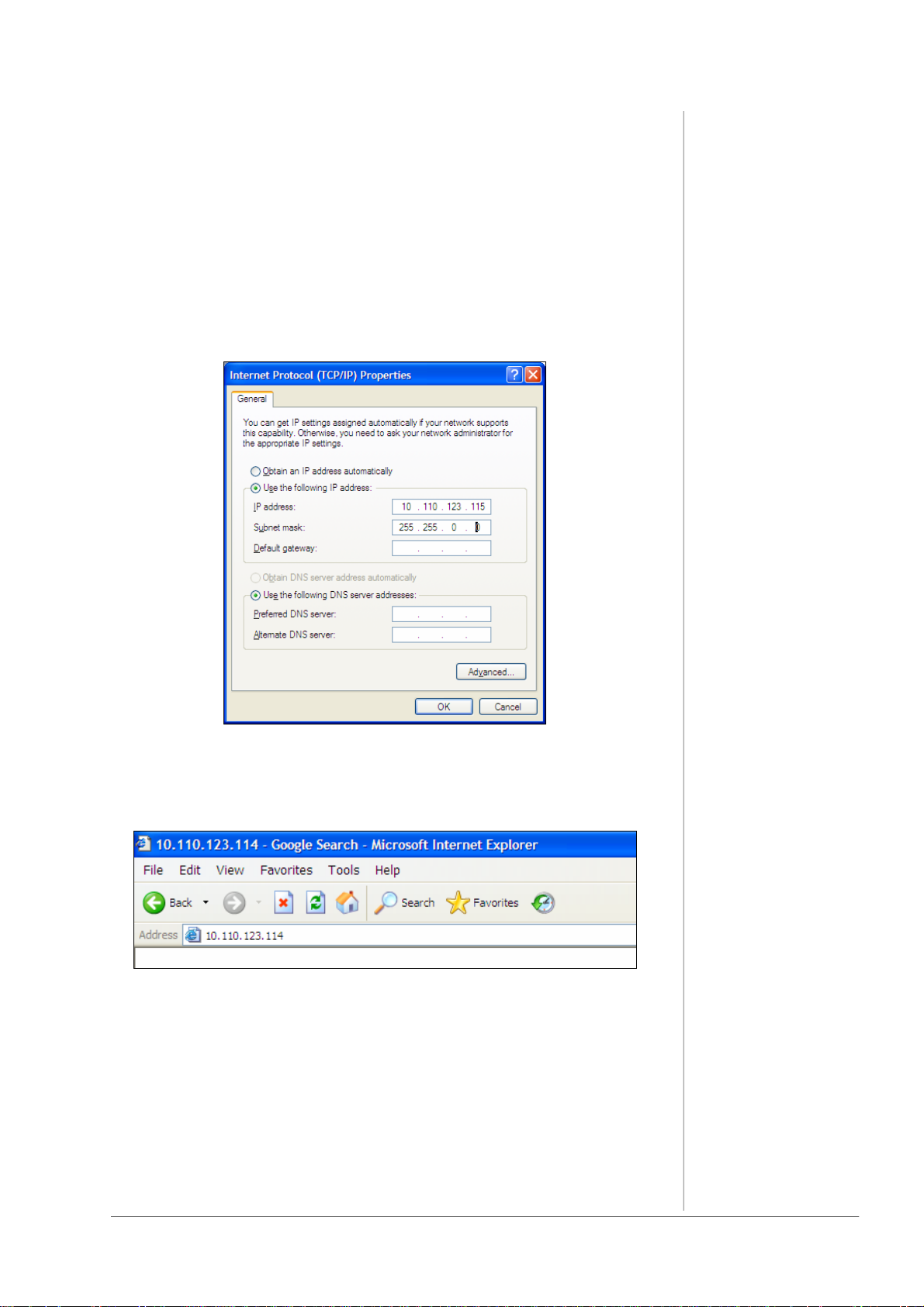

4. NETWORK INTEGRATION

Scroll in the list and choose Internet Protocol (TCP/IP).

Make sure that the ‘check box’ for this item is checked, and then click on

Properties.

In this example, the Ethernet TCP/IP is set to ‘Obtain an IP address

automatically.’

If, in your case, it is set to

‘Use the following IP address,’

jot down the current settings on a piece of paper

(IP address, Subnet Mask, and Default gateway, if used).

You will need them later to restore the IP address of the PC to what it is

required to work on your LAN.

operation manual d06, chapter 4 - Network Integration - page 4 of 6

Page 29

4. NETWORK INTERGRATION

Then change the settings in order to be able to communicate with the device.

You have to choose an IP-address “near” to that of the device.

So if the settings of the device are e.g.

IP Address: 10.110.123.114

Netmask: 255.255.0.0.

Gateway: 10.110.0.1.

You have to take 10.110.123.115 as IP-address (or something near to the

device’s address, only 10.110.123. have to be the same!) and the same

netmask. The gateway is not important when you are using an Ethernet

crossover cable.

When you have changed the settings, press OK. Now you will be able to

communicate from PC to device via web browser (e.g. internet explorer) with an

Ethernet crossover cable. Just type in the device’s IP-address into your

browser:

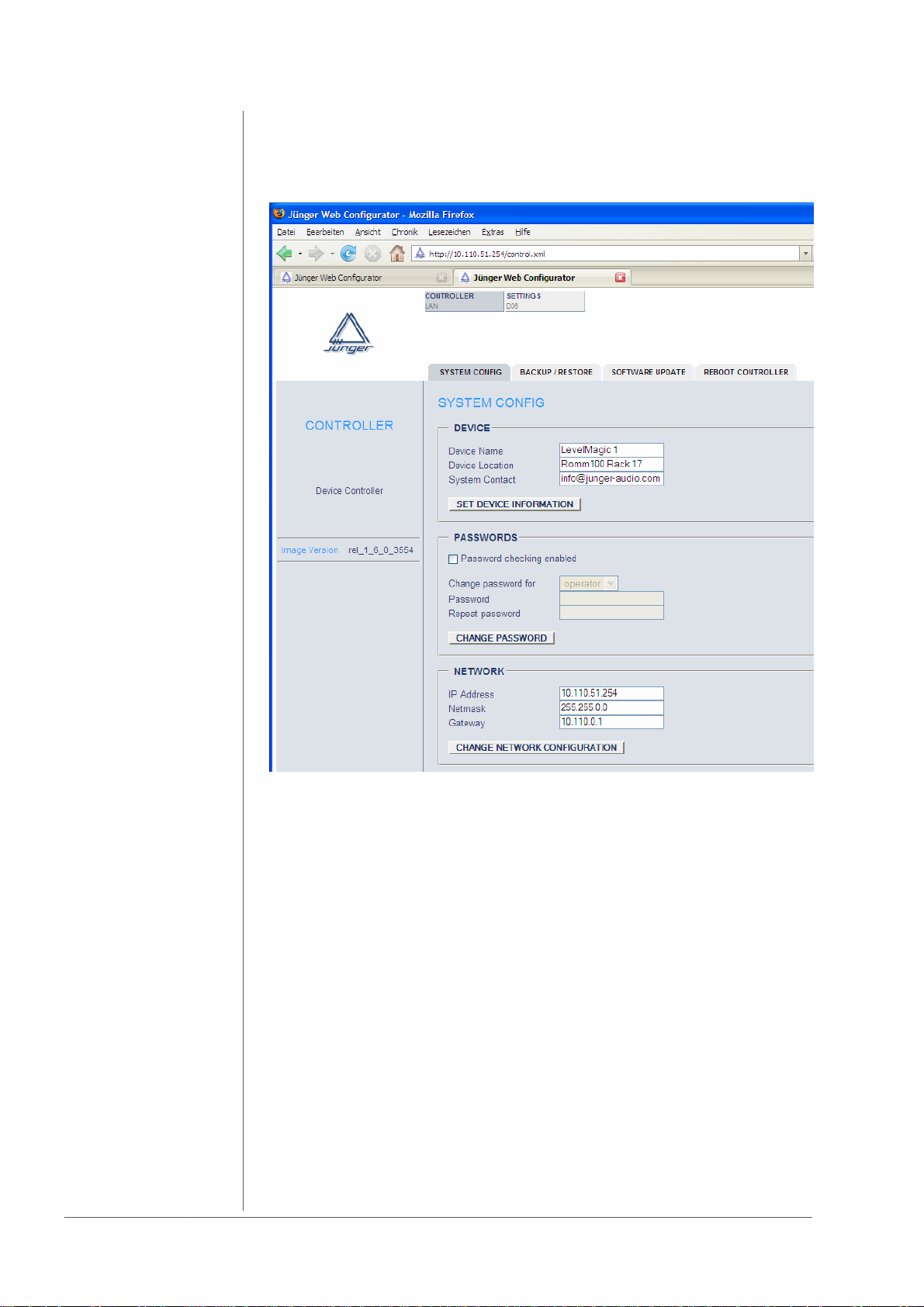

Then you will come to the modules web page:

operation manual d06, chapter 4 - Network Integration - page 5 of 6

Page 30

4. NETWORK INTEGRATION

Under CONTROLLER -> SYSTEM CONFIGURATION you will be able to

change the device’s network configuration according to the settings of the LAN

you want to use.

After having changed the settings click CHANGE NETWORK

CONFIGURATION and after that REBOOT THE CONTROLLER and afterwards

reboot the LAN Controller : CONTROLLER -> REBOOT CONTROLLER.

Rebooting the device activates the changes you have made to the network

configuration. If you changed the IP address of the device to a different

network as your PC, you may not be able to reach the web interface after

the reboot.

Now you have to change the settings of your PC network configuration again

and connect both the PC and the device to the LAN you want to use by 1:1

Ethernet cable to a router or hub. Then you will be able to communicate with the

device over web browser via the chosen IP-address.

operation manual d06, chapter 4 - Network Integration - page 6 of 6

Page 31

OPERATION

GUI

5. OPERATION

5.1

GUI operation

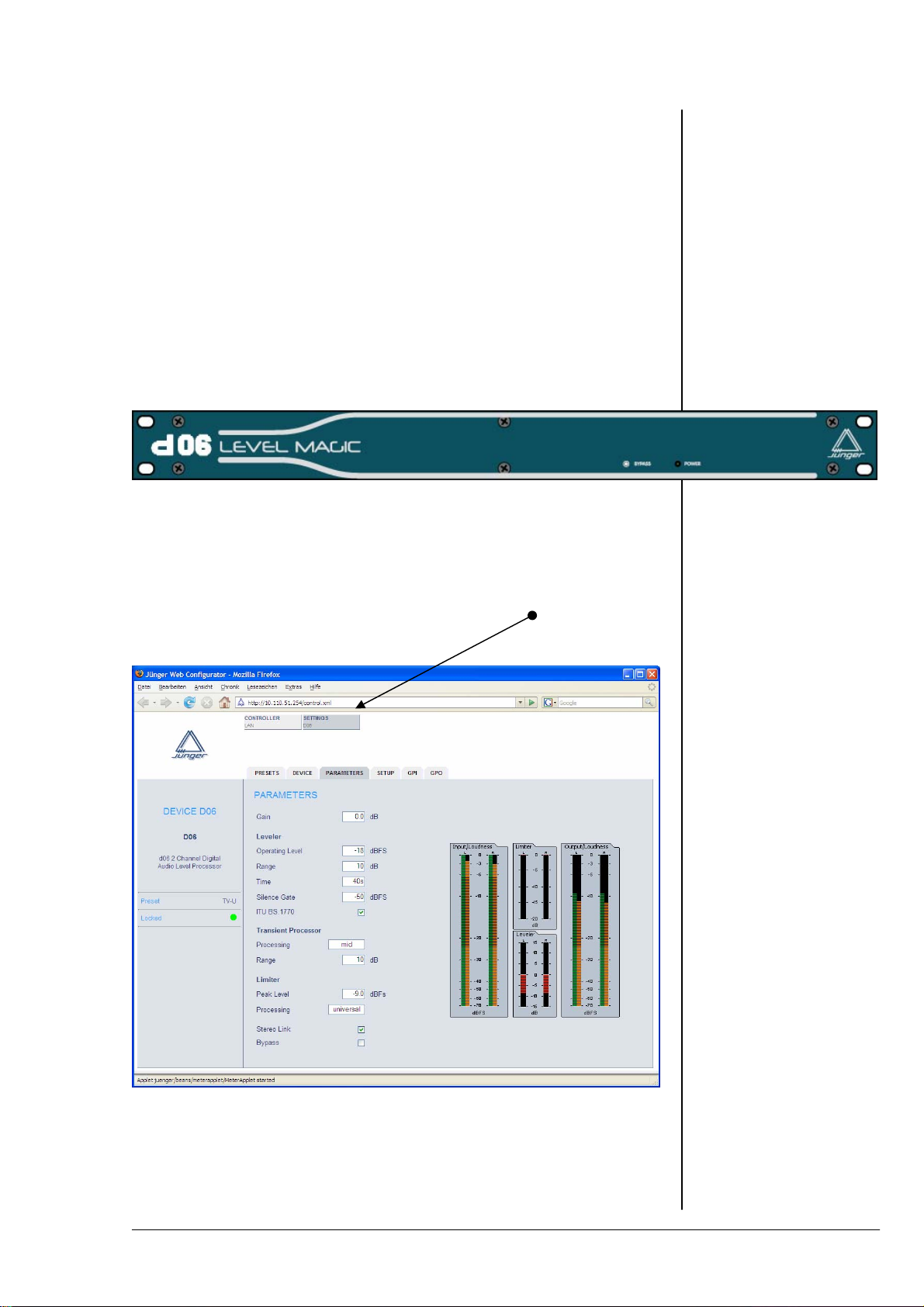

The GUI of the d06 can be reached by connecting the d06 to a PC via

LAN (either by a switch or cross over cable) and using its IP address as

an URL for a web browser. Junger Audio supports both the IE7 and

FireFox 2.0 and higher versions. The application assumes that there is a

JAVA VM (1.6. or higher) installed on that PC in order to display level bar

graphs: You must use the device IP address as an URL to connect

with the d06.

PARAMETERS

This will open the PARAMETERS page of the GUI.

Here you must setup the dynamic operation of the d06.

operation manual d06, chapter 5 - Operation - page 1 of 12

Page 32

5.1.1

Setting the d06

parameters

5. OPERATION

Gain : static gain to align the d06 to the level diagram of the

system / installation

Leveler

Operating Level : the target level of the leveler process

Range : the range for the leveler to move gain up and down in

Time : the time for the leveler process to reach the maximum

Silence Gate : a value for the leveler process to stop gain change. This

ITU BS.1770 : the leveler process may be ITU BS.1770 weighted (see

Transient Processor

Processing : the Transient Processor is a compressor like, fast

Range : the range of the Transient Processor limits the amount

Limiter

Peak Level : the Junger brick wall limiter is well known in the audio

Processing : the algorithms are self adapting to the program. For very

order to match with the Operating Level

Range value (if needed).

The recommendation is, not to be faster than 3dB /

10sec. because this is an area where the human ear may

not recognize a level change

will prevent from unwanted noise if the input level drops

for a longer time below it. If the signal disappears for

longer time, the processing gain will move back to 0dB

ITU documentations for details). This setting applies with

the ITU loudness standard. In the case ITU is enabled,

the Operating Level equals to the Dolby

acting circuit, which deals with fast level changes. Those

level changes are quite different for program genres. For

a maximum fit of the process with different program

types, you may change the behavior. Our

recommendation is to use the “mid” setting for most

programs, while “fast” is recommended for sports style

(Soccer, Tennis, Golf etc.), program

of gain change. A higher value of Range will limit the

dynamic of the input program

industry for its outstanding performance. Due to the fact

that the algorithm will be applied on sample basis and the

look ahead function, there will be newer ever an overload

at the output. On top of that, this value defines the

maximum output level of the d06

critical material it may be advisable to give it a good

starting point, to make the limiter inaudible as possible.

The recommendation is to work with the setting UNI

which works for most of the material

®

Dialnorm Level

operation manuad d06, chapter 5 - Operation - page 2 of 12

Page 33

5. OPERATION

As mentioned before, the d06 has a DSP controller, which also operates the

front panel. You can imagine this controller as the DSP co-processor for all

relevant real time communication.

DEVICE

5.1.2

Setup the device

On this page you may set up a name for the device. This name may be used

in other applications.

Restart DSP : in case of a processing problem you may restart the

DSP and its co-processor by pressing the

<RESTART> soft button

Initialize and Restore Factory Defaults :

this function instructs the DSP controller to set all

PARAMETERS, the PRESETS, the SETUP and the

GPI/Os to values defined by the factory defaults

Controller Version : the firmware version of the DSP controller

DSP Version : the firmware version of the DSP program

Backup Settings and Presets to File :

all relevant variables used by the DSP controller may

be saved to a file for later backup or you may use it to

copy such settings to an other d06

Restore Settings and Presets from File :

you may search for a file to restore the settings of the

DSP controller and start the restore process here

operation manual d06, chapter 5 - Operation - page 3 of 12

Page 34

5.1.3

General settings

5. OPERATION

The d06 has analog as well as digital inputs and it features the external

synchronization of the digital output to an external reference. On this page

you may change such settings.

SETUP

Input : the radio buttons will switch between analog and

digital (AES/EBU) input

Sync : the d06 may be synchronized to :

internal reference 48kHz

internal reference 44.1kHz

AES XLR input

external AES BNC rear connector

External Wordclock BNC rear connector

Video Sync BNC rear connector

Important Note! Video Sync is an option for the d06. For the very rare case

that you can not synchronize the d06 to AES, you may buy such option from

Junger Audio. Pls contact your local dealer for details.

operation manuad d06, chapter 5 - Operation - page 4 of 12

Page 35

5. OPERATION

The d06 has 10 Presets. Those Preset may be recalled by the user at any

time. Preset #5 - #10 are factory Presets while Preset #1 - #4 are user

presets which may be overwritten by the user.

PRESETS

5.1.4

Preset operation

Load Preset : the drop down list offers the selection of one of the 10

Presets of the d06. Pressing the <LOAD NOW> soft

button will load the pre selected Preset

Save as Preset # : the number displayed by the drop down list represents

the memory number of the Preset (#1 - #4), where

you will store

Name : You may give your Presets a digit name here

Backup : You can backup all Presets to a file

Restore Presets from File:

Here you may select a file from the PC file system to

restore all Presets or to copy them to an other d06

operation manual d06, chapter 5 - Operation - page 5 of 12

Page 36

5.1.5

GPI/O set up

5. OPERATION

GPI

5.1.6

LAN Controller

set up

GPI 1 to GPI 8 : you can assign each physical GPI input one function

by moving the slider across the input field.

The options are:

PRESET-1 to PRESTE-4 (loads assigned preset)

STEREO (turns the link mode = On)

DIGITAL (selects the digital input)

BYPASS (activates the bypass relay)

GPO

GPO 1 to GPO 8 : you can assign each physical GPO (Tally) one status

by moving the slider across the input field.

The options are :

PRESET-1 to PRESET-4 (is selected)

STEREO (link mode is selected)

LIMITER (activity of the limiter)

CLIP (input signal is clipping)

DIGITAL (input is active)

BYPASS (relay is active)

The LAN Controller of the d06 provides its own menu. You must press the

<CONTROLLER> soft button:

operation manuad d06, chapter 5 - Operation - page 6 of 12

Page 37

5. OPERATION

5.1.6.1

System

configuration

DEVICE : you may assign the device a name string and a

location string as well as a contact address. This

information may be used by an external monitoring

system like a SNMP manager

PASSWORDS : the do6 may be setup for password operation. If this

function is turned on, one must use the passwords

you may set up here. The password protected mode

knows three different user levels:

The Viewer can only view the

embedded level display

The Operator can change presets in

addition to it

The Administrator can do everything

NETWORK : you may change the IP configuration of the device

METERING : in order to receive data for the level display,

if a local fire wall is active, you must reserve UDP

ports (for which the fire wall will held open).

To set up those UDP ports for local PCs, you must

open the firewall settings (right click on the network

symbol in the task bar of windows and select :

”Change Windows Firewall settings”. This will

open the “General” tab. Click on the “Exceptions”

tab in order to open the Exception page

operation manual d06, chapter 5 - Operation - page 7 of 12

Page 38

5. OPERATION

On the Exceptions page open the “Add Port” menu:

Here you must give this rule a unique name (e.g. “d06 #1.1”) and assign it a

UDP port number from the number of UDP Ports, set up by:

UDP Port Range Start / UDP Port Range End (see METERING).

If you want to connect from different PCs with the same device, it is sufficient

enough to assign one port, because different PCs will open different IP

sockets because they have different IP address (but use the same UDP port

number).

If you want to connect from the same PC with different devices, a unique

UDP port number for every remote device is necessary!

Important Note! To connect multiple browser sessions from the same PC

with the same device is not implemented! In such case the next browser

session will not get UDP data from that device. This will cause a red colored

meter display :

operation manuad d06, chapter 5 - Operation - page 8 of 12

Page 39

5. OPERATION

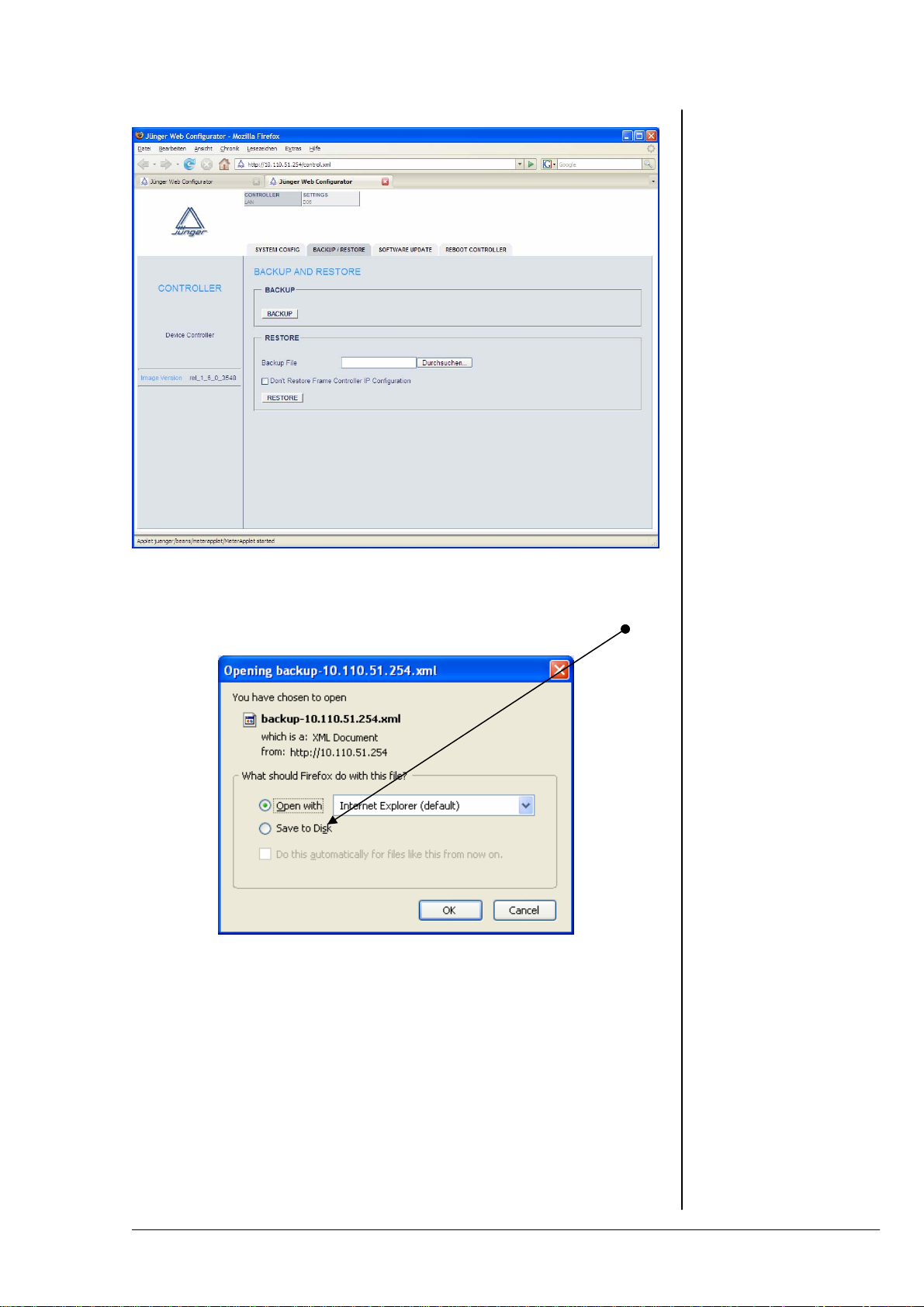

5.1.6.2

Backup & restore

BACKUP : if you press the <BACKUP> soft button, the

LAN Controller will generate an XML file that

represents all settings of the device.

If done, you may download the file to your PC :

RESTORE : here you can select a backup file from the file system.

The process will start when you press the

<RESTORE> soft button.

operation manual d06, chapter 5 - Operation - page 9 of 12

Page 40

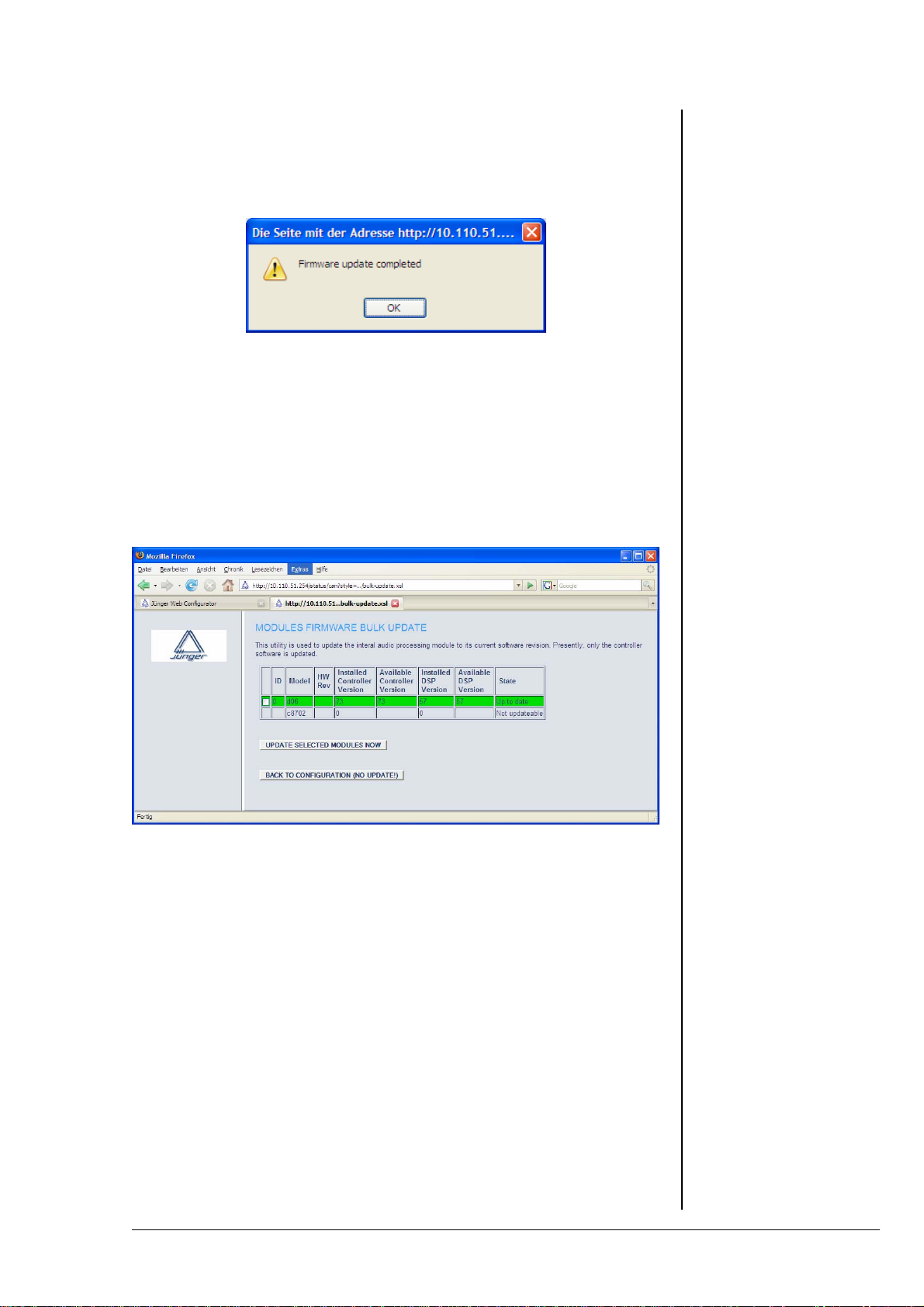

5.1.6.3

Software update

5. OPERATION

In chapter 3 we have explained that the d06 has 3 major components :

The DSP, the DSP Controller and the LAN Controller. To update the

LAN Controller, you must select the firmware file (also called the image)

from the local file system of your PC (you may get such file via HTTP

download from Junger Audio). If you press the <START UPDATE NOW>

soft button, the PC will upload the image file to the LAN Controller and will

initiate the “burning” process of its FLASH memory. This will take about

5min. When the process of “burning” the flash memory starts,

you will see a progress bar.

operation manuad d06, chapter 5 - Operation - page 10 of 12

Page 41

5. OPERATION

From this moment on, there is no communication with the LAN Controller

possible. If the progress bar comes to its end, the browser will restart

communication with the LAN Controller and you will get a message that the

process has finished :

MODULE FIRMWARE BULK UPDATE

The image file also carries the actual firmware files for

the DSP and the DSP Controller. This function offers

you an update of both components. When you press

the soft button, the LAN Controller reads the installed

versions and compares it with the release version it

has “on board”. You will get a display to make a

choice if you want to update :

For the above example there is no update needed.

(C8702 is the internal label for the LAN controller).

MODULE FIRMWARE SINGLE UPDATE

If there is the need to update one of the components

by a firmware that is not “on board” of the LAN

Controller, you may use this function. It offers you

either to update the (DSP) Controller and/or the DSP.

The firmware file must be provided from the file

system of the PC.

REBOOT CONTROLLER

This function allows you to reboot the LAN Controller.

operation manual d06, chapter 5 - Operation - page 11 of 12

5.1.6.4

Reboot the

LAN Controller

Page 42

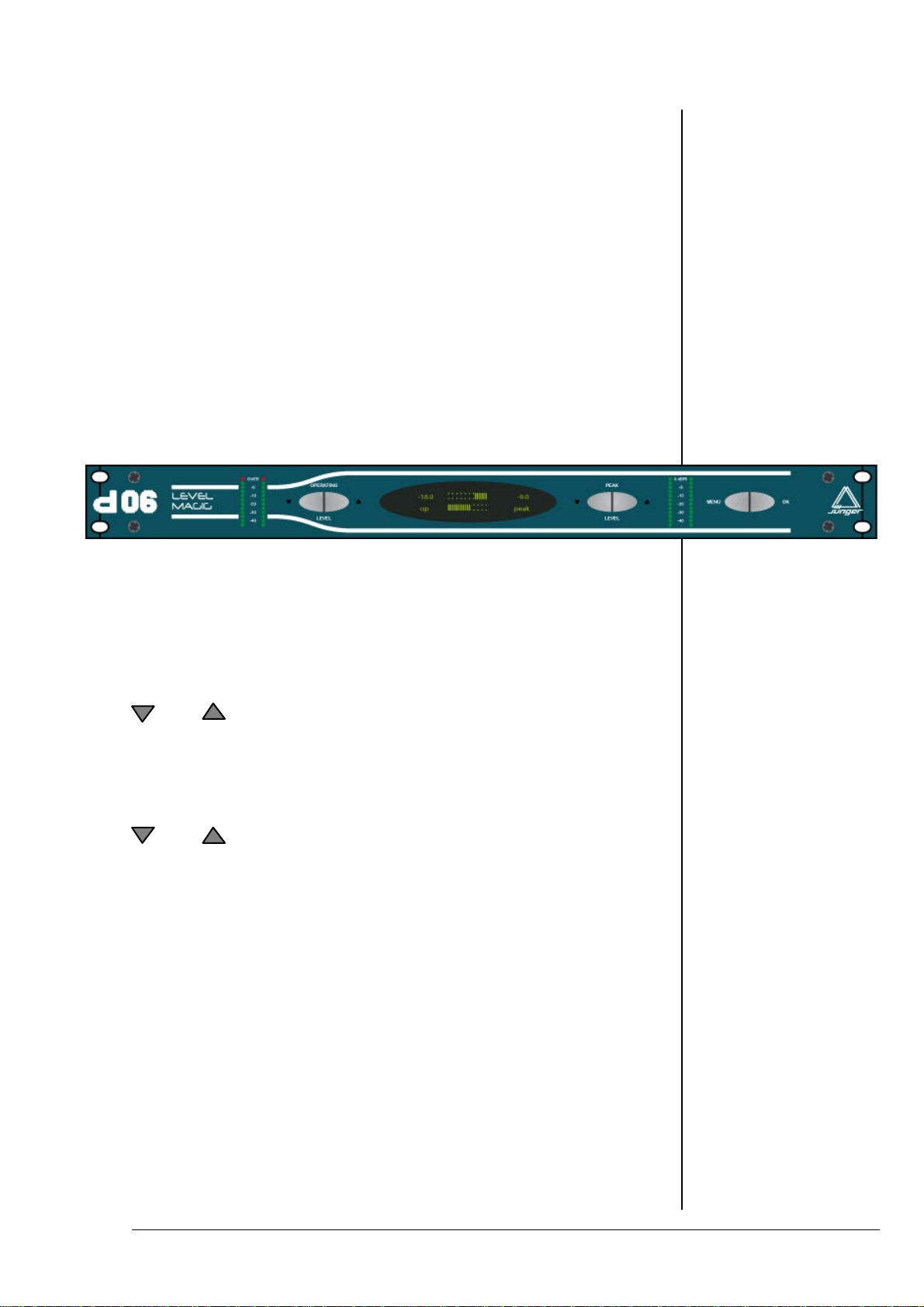

5. OPERATION

operation manuad d06, chapter 5 - Operation - page 12 of 12

Page 43

OPERATION

front panel

5. OPERATION

5.2

Front panel

operation

Functions of the buttons :

OPERATING

setup of operating level - OL

setup of parameter values

LEVEL

PEAK

setup of limiter threshold - PEAK

selection of menu items

LEVEL

<MENU> enter a menu / escape a menu

<OK> next menu level

prompt a selection or a value

load / save a preset

operation manual d06, chapter 5 - Operation - page 1 of 8

Page 44

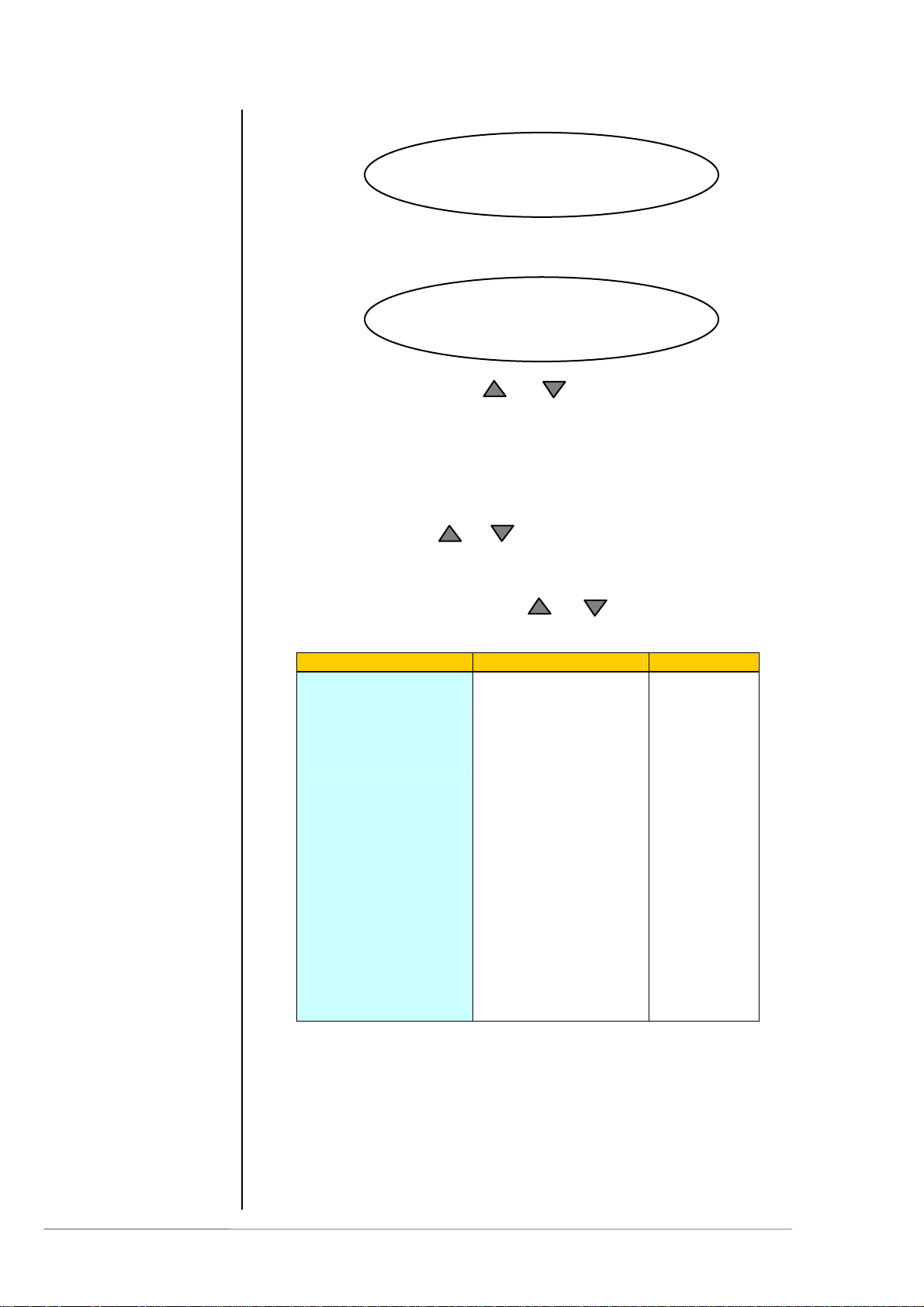

5.2.1

Setting the

reference levels

5. OPERATION

The picture below shows an example main display after power on:

OP ……..…

IIIII

PEAK

5.2.2

Menu selection

5.2.3

Preset menu

-18.0 …

The top display shows the current limiter gain reduction

[0dB at right hand], while the bottom display shows momentary gain

change introduced by the leveler process [0dB at center].

There are two reference levels :

OP = Operating Level (target level of the leveler process)

PEAK = Peak Level (Threshold of the brick wall limiter)

These are top level settings. They can be adjusted without calling the

menu :

Simply press the respective up and down arrow buttons to

change values. The range of the settings are :

OP = -40 … 0dBFS in steps of 1dBFS

PEAK = -20 … 0dBFS in steps of 0,1dBFS

Î If you press the arrow button for more than 2,5 sec. the values will

change automatically

Î Push the OK button to display the actual input level in

numeric values

Press <MENU> to enter menu selection.

Push the PEAK LEVEL or buttons to navigate in either direction:

PRESET CONFIG PARAMETER PRESET

Press <OK> to open one of the selected menus.

……. -9.0

IIIIII

PRESET

Press <OK> to enter the PRESET menu :

LOAD

PRESET 1: PR 1

operation manuad d06, chapter 5 - Operation - page 2 of 8

Page 45

5. OPERATION

Push the PEAK LEVEL or buttons to select LOAD or SAVE :

SAVE

PRESET 1: PR 1

Push the OPERATING LEVEL or buttons to select a preset by

number (example preset # 5) :

LOAD

PRESET 5: TV-U

Important Note: The d06 has 10 presets to load, while presets #1 - #4

may be overwritten by the user, Presets #5 - #10 are factory presets

which can not be overwritten!

Press <OK> to load or save the selected preset and jump back to the

main display or press <MENU> to jump back (escape) to main display

without changes :

OP ……..…

-18.0 …

The table at the end of this chapter shows the values of the factory

PRESETS.

IIIIII

PEAK

IIIII

……. -9.0

operation manual d06, chapter 5 - Operation - page 3 of 8

Page 46

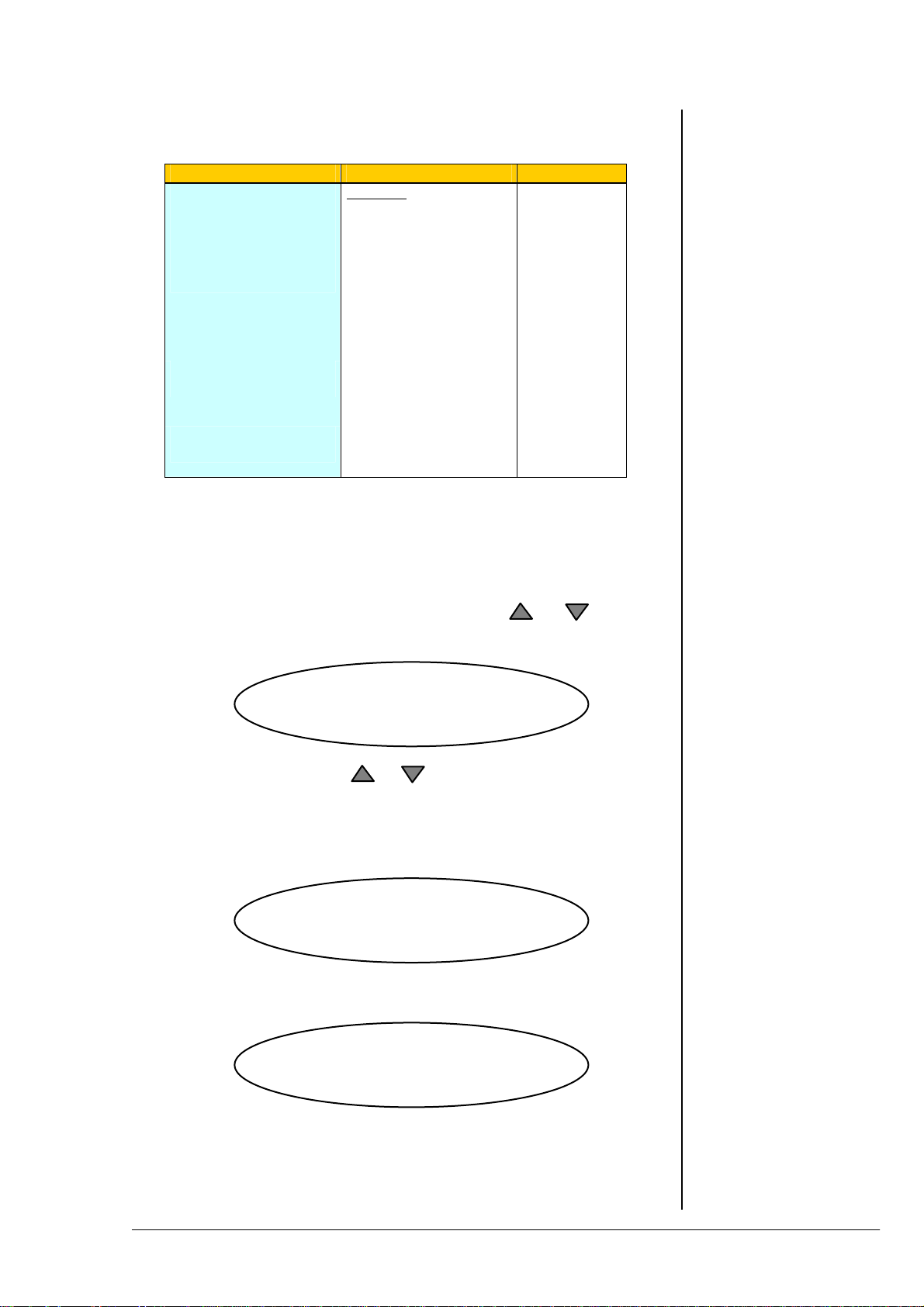

5.2.4

Configuration

menu

5. OPERATION

CONFIG

Press <OK> to enter the CONFIG menu :

INPUT

digital

Push the OPERATING LEVEL or buttons to select between :

digital and analog.

Press <OK> to make selection and jump back to the CONFIG menu or

press <MENU> to jump back (escape) to the CONFIG menu without

changes.

The table below shows the details of the CONFIG menu if you

push the PEAK LEVEL or buttons to select one of the

CONFIG parameters.

For each CONFIG parameter there are several values.

If you push the OPERATING LEVEL or buttons you will select

one of these values :

Parameter Value Class

INPUT

SYNC

MODE

LOCK

PASSWORD

There are 4 digits

GPI

(There are 6

physical GPIs)

analogue

digital

intern 48 kHz

intern 44,1 KHz

Input

extern AES

2-channel

stereo

unlocked

locked

0 1 2 3 4 5 6 7 8 9

OFF

PRESET1

PRESET2

PRESET3

PRESET4

STEREO

INPUT2

BYPASS

SETUP

SETUP

PRESET

SETUP

SETUP

SETUP

operation manuad d06, chapter 5 - Operation - page 4 of 8

Page 47

5. OPERATION

Table continues from previous page

Parameter Value Class

TALLY

(GPO)

(There are 8

physical GPOs)

SOFTWARE

VERSION

CONTRAST

BRIGHTNESS 1

8 Tallies :

OFF

PRESET1

PRESET2

PRESET3

PRESET4

STEREO

LIMIT

CLIP

INPUT2

BYPASS

C: controller firmware #

D: DSP firmware #

0 … 7 SETUP

0 … 7 SETUP

SETUP

Display only

The Class column shows where such parameter belongs to,

if it will be stored in a preset or not.

The PASSWORD, GPI and TALLY menus have a 3

rd

level so you must

press <OK> again if you want to make changes there.

E.g. to change the password, push the PAEK LEVEL or

buttons to move the flashing arrowheads between the four digits :

PASSWORD

> 1 < 2 3 4

Push the OPERATING LEVEL or buttons to change the

respective number.

If the d06 front panel is locked to prevent from unauthorized operation,

one will be notified in the main display if you push a cursor button :

locked

You may press the <MENU> button now, to open the password menu :

ENTER PASSWORD

> 1 < 2 3 4

See above how to enter the correct password. If done press <OK> to

open the front panel operation again. It will stay open until you reach the

upper menu level (main display). This will lock the front panel again.

operation manual d06, chapter 5 - Operation - page 5 of 8

Page 48

5.2.4

Parameter menu

5. OPERATION

PARAMETER

Press <OK> to enter the PARAMETER menu :

GAIN

0.0 dB

For each PARAMETER there are several values. You must

push the OPERATING LEVEL or buttons to select between

those values:

Parameter name : Value Steps Class

GAIN

OPERATING

LEVEL

LEVELLER

Range :

LEVELLER

Time :

LEVELLER

Silence Gate:

LEVELLER

ITU BS.1770:

TRANSIENT PROC

Processing:

TRANSIENT PROC

Range:

PEAK LEVEL

PEAK LIMITER

Processing:

The Class column shows where such parameter belongs to

(if it will be stored in a preset or not).

-20dB ... +20dB 0.1dB PRESET

0.0dBFS ….-40.0dBFS 1dBFS PRESET

0dB ... +40dB 1dB PRESET

20, 40sec.

1, 2, 5, 10, 20, 40min.

1, 2h

-60dBFS ... -20dBFS 1dB PRESET

ON

OFF

soft

mid

hard

0dB … 15dB 1dB PRESET

0.0dBFS … -20.0dBFS 0.1dBF

LIVE

SPEECH

POP

UNI

CLASSIC

PRESET

PRESET

PRESET

PRESET

S

PRESET

operation manuad d06, chapter 5 - Operation - page 6 of 8

Page 49

Table of preset parameters and their values :

Preset name : TV-U R -U R-SP TV-L

Parameter name :

GAIN

OL

Operating Level

LEVELLER AGC

Range :

LEVELLER AGC

Time :

LEVELLER AGC

Silence Gate:

LEVELLER AGC

ITU BS.1770:

TRANSIENT PROC

Processing:

TRANSIENT PROC

Range:

PEAK

Limiter Threshold

PEAK LIMITER

Processing:

MODE

0.0dB 0.0dB 0.0dB

-18dBFS -9dBFS -9dBFS -18dBFS

10dB 10dB 10dB 10dB

40sec. 40sec. 20sec. 20sec.

-50dBFS -50dBFS -40dBFS -50dBFS

ON ON ON ON

mid mid hard hard

10dB 10dB 15dB 10dB

-9.0dBFS 0.0dBFS 0.0dBFS -9.0dBFS

UNI UNI SPEECH LIVE

stereo stereo stereo stereo

5. OPERATION

operation manual d06, chapter 5 - Operation - page 7 of 8

Page 50

5. OPERATION

operation manuad d06, chapter 5 - Operation - page 8 of 8

Page 51

6. TECHNICAL SPECIFICATIONS

TECHNICAL

SPECIFICATIONS

sample rate 44.1/48 kHz

audio data format 24 bit

DIGITAL IN/OUT

AES/EBU

connector XLR, 110 balanced

input format AES professional, AES consumer

output format same as input format

channel status bits :

from digital input to digital output transparent

from analog input to digital output fixed channel status bits

* professional

* sample rate 48kHz

* 2ch mode

* 24 bit audio

ANALOG IN/OUT

ANALOG IN

Resolution 24bit

sample rate 44.1 … 48kHz

dynamic range 110dB (RMS)

114dB (A-weighted)

THD+N <0.002% @ max. input level

frequency response 20Hz...20kHz (+/-0.5dB @ SR=48kHz)

CMRR –100dB @ 50Hz

max. input level +28dBu @ 0dBFS

input impedance 10 kOhm, balanced, floating

connector XLR, 1-shield, 2-live, 3-return

ANALOG OUT

Resolution 24bit

sample rate 44.1 … 48kHz

dynamic range 108dB (RMS)

110dB (A-weighted)

THD+N <0.002% @ max output level

frequency response 20Hz...20kHz (+/-0.5dB @ SR=48kHz)

max. output level +28dBu @ 0dBFS

output impedance 30 Ohm, balanced, floating

connector XLR, 1-shiled, 2-live, 3-return

6

digital signal

processing

digital

in- / outputs

analog

in- / outputs

operation manual d06 chapter 6 - Technical Specifications - page 1 of 2

Page 52

sync

in- / outputs

remote control

general

5. TECHNICAL SPECIFICATIONS

SYNC IN

WCLK connector BNC, 75Ohm, coaxial

level TTL-level

input format Wordclock

AES/EBU connector BNC, 75 Ohm, coaxial

level 0,5 ... 5 Vpp

input format AES professional, AES consumer

VIDEO connector BNC, 75 Ohm, coaxial

level 0...1 Vpp

input format Blackburst or PAL/NTSC composite video

WCLK OUT

WCLK connector BNC, 10kOhm, coaxial

level TTL-level

output format Wordclock

REMOTE

serial remote interface RS-232

connector 9 pin SUB-D female

serial remote interface RS-422

connector 9 pin SUB-D female

serial remote interface CAN (1.0)

GPI parallel remote

level opto coupler, 3 … 24V control voltage

connector 15 pin SUB-D female

Tally Out

level relais contact

connector 25 pin SUB-D female

power consumption appr. 15 VA

dimensions 19“, 1 RU, 250 mm depth

weight appr. 5 kg

operation manual d06, chapter 6 - Technical Specifications - page 2 of 2

Page 53

7. WARRANTY AND SERVICE INFORMATION

WARRANTY AND SERVICE

INFORMATION

JÜNGER AUDIO grants a two-year warranty on the

2-channel digital audio level processor d06

If the unit has to be serviced, please send it, ideally in the

original box, to:

JÜNGER AUDIO - Studiotechnik GmbH

Justus-von-Liebig-Str. 7

D - 12489 Berlin

GERMANY

Tel.: +49 - 30 – 677721 - 0

Fax.: +49 - 30 – 677721 - 46

7

operation manual d06, chapter 7 - Warranty and service information - page 1 of 2

Page 54

7. WARRANTY AND SERVICE INFORMATION

operation manual d06, chapter 7 - Warranty and service information - page 1 of 2

Page 55

KONFORMITÄTSERKLÄRUNG

DECLARATION OF CONFORMITY

Geräteart : Digitaler Dynamikprozessor

Type of equipment : Digital dynamics processor

Produkt / Product : d06

Das bezeichnete Produkt stimmt mit den Vorschriften folgender EU-Richtlinie(n) überein:

The aforementioned product complies with the following Europaen Council Directive(s):

89/336/EWG (geändert durch 91/263/EWG und 92/31/EWG)

(changed by 91/263/EEC and 92/31/EEC)

Richtlinie der Rates zur Angleichung der Rechtsvorschriften der

Mitgliedsstaaten über die elektromagnetische Verträglichkeit

Council Directive on the approximation of the laws of the

Member States relating to electromagnetic compatibility

73/23/EWG (geändert durch 93/68/EWG)

(changed by 93/68/EEC)

Richtlinie des Rates vom 19. Februar 1973 betreffend elektrische

Betriebsmittel zur Verwendung innerhalb bestimmter

Spannungsgrenzen

Council Directive of February 19th 1973 concerning electircal

equipment for operation within certain voltage limits

Zur vollständigen Einhaltung dieser Richtlinie(n) wurden folgende Normen heran gezogen:

To fully comply with this(these) Directive(s), the following standards have been used:

EN 55022 : 1987

EN 50082-1 : 1993

EN 60065 : 2002

Dieser Erklärung liegen zugrunde : Prüfbericht(e) des EMV-Prüflabors

Interne Vorschriften zur Sicherheits-Prüfung

This certification is based on : Test report(s) generated by EMC-test laboratory

Internal regulations for safety check

MEB Messelektronik Berlin : Kalibrier- und Prüflabor

accredited EMC laboratory

Aussteller / Holder of certificate : Jünger Audio Studiotechnik GmbH

Justus-von-Liebig-Strasse 7

D - 12489 Berlin

Berlin, 18.03.2003 .....................................................................................

(Ort/Place) (Datum/Date) (Herbert Jünger, Geschäftsführer/Managing Director)

Page 56

Loading...

Loading...