Page 1

ALBRECHT JUNG GMBH & CO. KG

Volmestraße 1

D-58579 Schalksmühle

www.jung.de

325 569 03 12.05

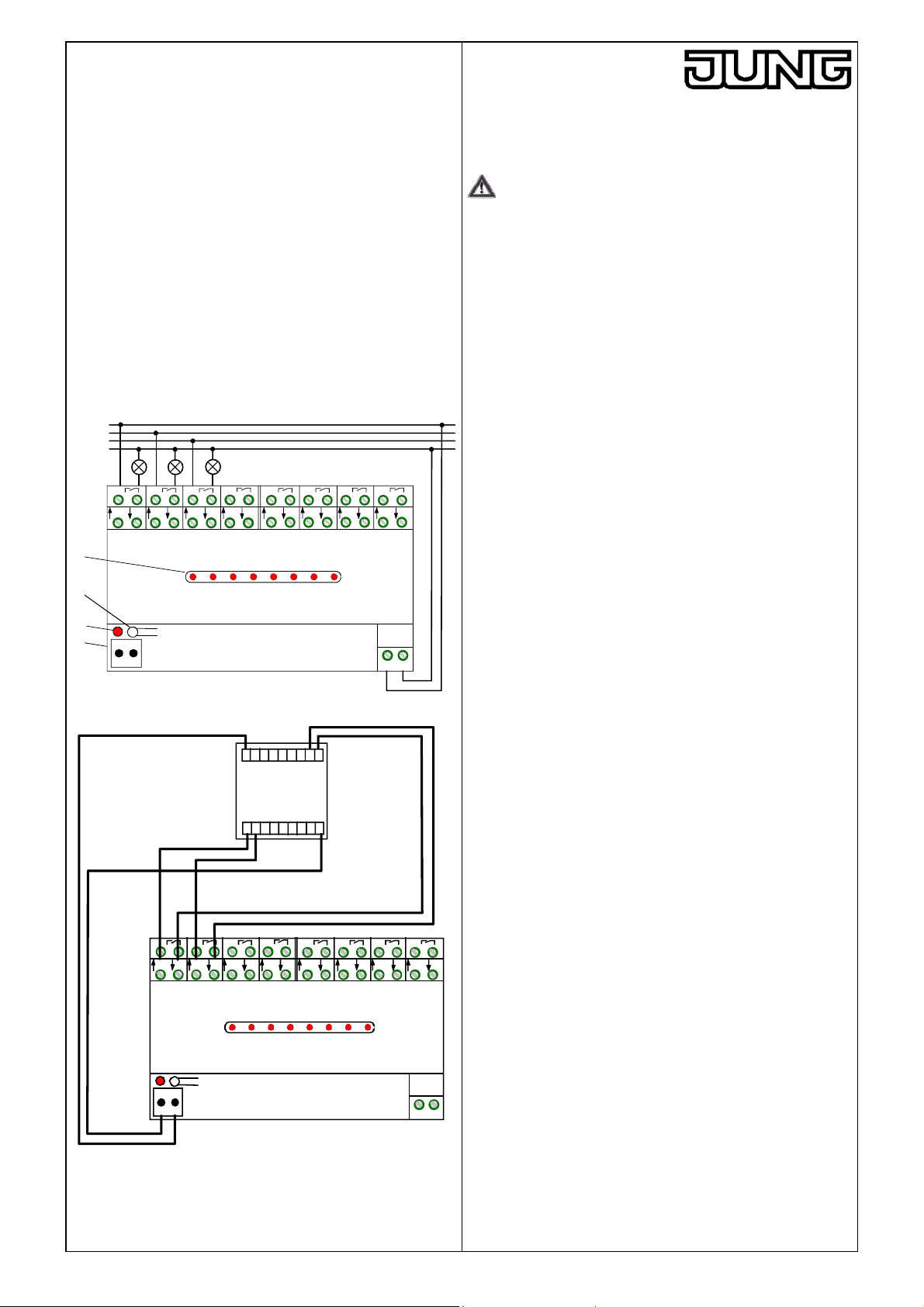

fig. A

L1

L2

L3

N

A1

A2

A3 A4

A2' A3' A4'

A1'

(1)

(2)

(3)

(4)

- +

24 V DC

80 mA

E2 E3 E4

E1

A1 A2 A3 A4 A5 A6 A7 A8

A5

A5'

E5

A6

A6' A7' A8'

E6

A8

A7

E7

E8

LN

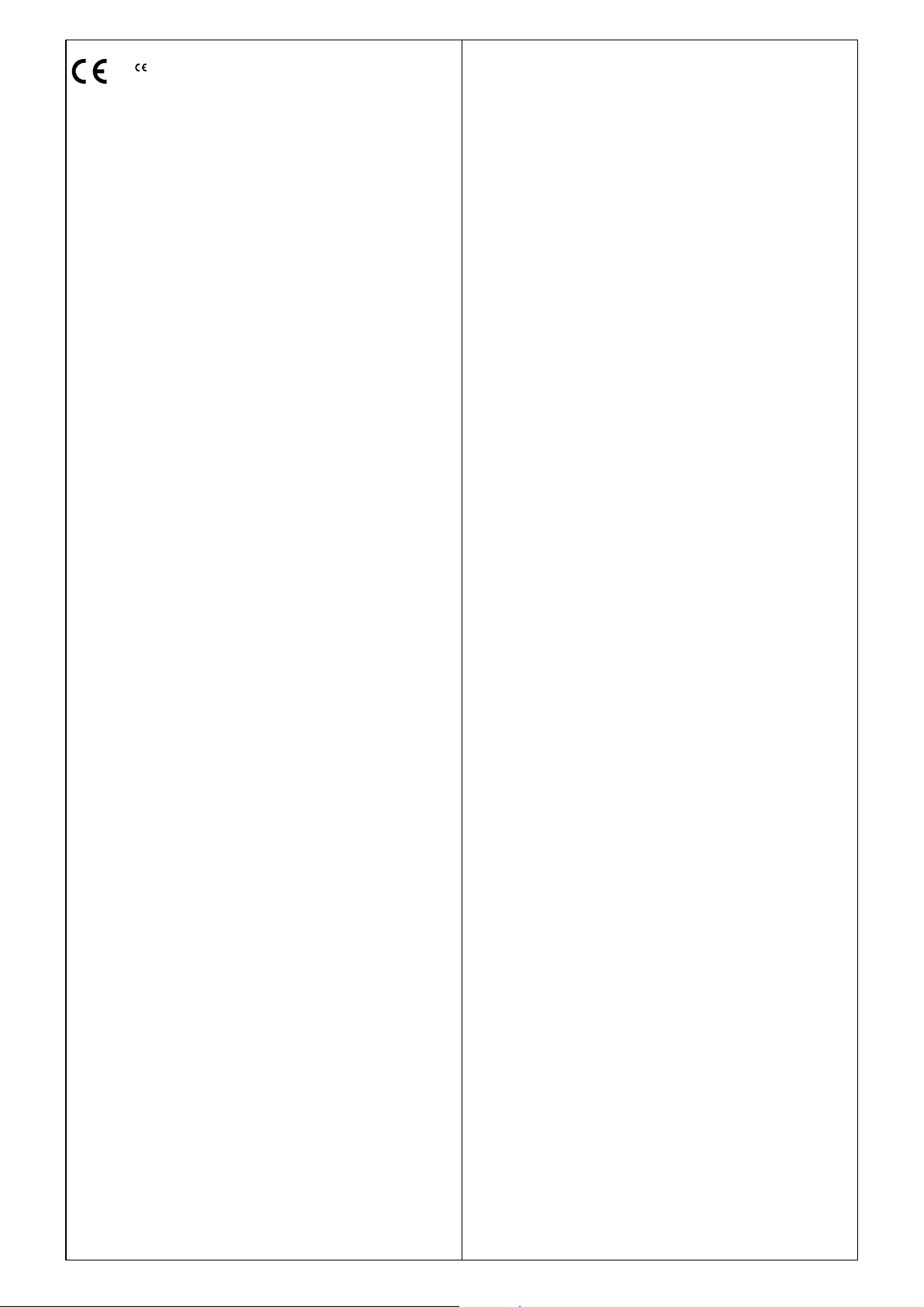

fig. B

43215678+

Output ter minals

Touch Sensor

..2248..

LED inputs

321 5678-

4

A2 A3 A4 A5 A6 A7 A8

A1' E1

- +

24 V DC

80 mA

A2'

E2 E3

A3' A4' E5

A1 A2 A3 A4 A5 A6 A7 A8

E4

A6'

E6

A7'

E7

A8'

LN

AC 230 V ~

8-channel relay station

Operating instructions

Art. Nr. RS8REG

Safety warnings

Attention: Electrical equipment must be installed and fitted only

by qualified electricians.

To prevent electric shocks, disconnect the mains supply (by

cutting out the circuit breaker) before working on the device.

or on the load. Failure to observe any of the installation

instructions may result in fire and in other hazards.

Function

Important:

The relay station is not a KNX / EIB device.

The relay station is equipped with 8 potential-free load contacts (n.o.

contacts) for a maximum current of 10 A each for the switching of

different loads, e.g. lighting.

The relay station can be operated as a momentary-contact (toggle

mode) or as a maintained-contact (doorbell mode) actuator.

The station is controlled with an AC/DC 24V 20 mA touch sensor (e.g.

Art. no. ..2248..) or with mechanical pushbuttons.

The output terminals A1‘ – A8‘ can be used for the connection of

checkback LEDs.

The relay station supplies the control voltage (positive pole) for the

switching inputs (E1-E8) and the common ground line for the

checkback LEDs at its DC output

Operation

The relay station is operated by means of the connected touch

sensor.

The red LEDs (1) of the relay station indicate the switching state of

the relay contacts.

relay contact closed LED on

relay contact closed open LED off

Fitting

Fit the relay station by snapping it onto a mounting rail as per DIN EN

50022.

Installation:

Connect the supply voltage AC 230 V ~ for the relay station to

terminals "L" and "N", see fig. A.

Connect the loads to be switched to the output terminals A1 – A8 of

the relay station, see fig. A. The illustration shows 3 lamps connected

to different phase conductors. The remaining terminals are connected

in the same way.

The schematic in fig. B shows the relay station used in combination

with the AC/DC 24V 20 mA touch sensor.

Mechanical pushbuttons, e.g. 534U, can be used as an alternative.

Connect the switching inputs of the relay station E1 – E8 with outputs

1 - 8 of the touch sensor (e.g. Art. no. ..2248..).

The schematic in fig. B is a wiring example. The remaining terminals

E8A5'

are connected in the same way.

Connect the LED inputs 1 - 8 of the touch sensor with the output

terminals A1‘ – A8‘ (DC 24 V, 10 mA) of the relay station.

The schematic in fig. B is a wiring example. The remaining terminals

are connected in the same way.

In this case, the switching state of the relay contacts is indicated by

the LEDs of the touch sensor

relay contact closed LED on

relay contact closed open LED off

Connect the 24 V DC output (4) of the relay station with the correct

polarity to the touch sensor, see fig. B.

Important:

In the event of a short-circuit at the DC output,

the station will no longer accept commands from the

pushbutton.

the relays will switch off briefly (ca. 1 s).

Page 2

The -sign is a free trade sign addressed

exclusively to the author iti es an d does not

include any warranty of any properties.

Commissioning

Pushbutton (2) and LED (3) are accessible only during the fitting and

installation activities, see fig. A.

For switching over between the two modes of operation press the

pushbutton (2) for at least 7 s.

The selected opmode is stored in a non-volatile memory.

The device is delivered preset to the toggle mode.

doorbell mode LED (3) lit up red;

the relay contact is closed as long as the

control pushbutton is kept depressed.

toggle mode LED (3) lit up green

the relay contact is closed or opened after

each press of the control pushbutton.

Response to mains failures

After a mains failure, all relay contacts are open and must be

activated again.

Troubleshooting

If an undefined fault occurs during operation of the device, the

LED (3) lights up yellow.

Acknowledge the fault by pressing the pushbutton (2) for ca. 1.5 s.

The relay station is then in the toggle mode. If necessary, switch over

to the other opmode, see commissioning.

Technical Data

Rated voltage: AC 230 / 240 V ~, 50 / 60 Hz

Operating temperature: - 5 °C ... + 45 °C

Storage temperature: - 25 °C ... + 70 °C

Fitting width: 144 mm (8 modules)

Outputs A1 – A8

Contact type: potential-free n.o. contact (µ contact)

Switching capacity: AC 250 V ~ / 10 A

Contact rating:

incandescent lamps: 1400 W

HV halogen lamps: 1225 W

conventional transformers: 1200 VA

Tronic transformers: 1200 VA

motors: 600 W

fluorescent lamps: not approved

minimum load: 12 V, 100 mA

Outputs A1‘ – A8‘: R

DC 24 V / 10 mA max.

= 330 Ω

out

Switching inputs E1 – E8: Rin = 200 kΩ

24 V max.

Screw terminals

0.5 – 4 mm² single wire

2 x 0.5 – 2.5 mm² single wire

0.34 – 4 mm² stranded without ferrule

0.14 – 2.5 mm² stranded with ferrule

DC output: 24 V DC, 80 mA

pushlock terminals

Power consumption

Typically (all relays on): 7.7 W

Maximum (all outputs at full load) 12.5 W

Standby: 0.5 W

Length of control line: 100 m max.

Technical specifications subject to change

Please leave these instructions with your customer after installation.

Guarantee

Our products are under guarantee within the scope of the statutory

provisions.

Please return the unit postage paid to our central service

department giving a brief description of the fault:

ALBRECHT JUNG GMBH & CO. KG

Service-Center

Kupferstr. 17-19

D-44532 Lünen

Service-Line: +49 (0) 23 55 . 80 65 53

Telefax: +49 (0) 23 55 . 80 61 65

E-Mail: mail.vka@jung.de

Technical matters (general)

Service-Line: +49 (0) 23 55 . 80 65 55

Telefax: +49 (0) 23 55 . 80 62 55

E-Mail: mail.vkm@jung.de

Technical matters (KNX / EIB)

Service-Line: +49 (0) 23 55 . 80 65 56

Telefax: +49 (0) 23 55 . 80 62 55

E-Mail: mail.vkm@jung.de

Loading...

Loading...