Page 1

Signal panel

Signal panel

Art.-No.: MBT 2424

Operating instructions

1 Safety instructions

Electrical equipment may only be installed and fitted by electrically skilled persons.

Failure to observe the instructions may cause damage to the device and result in fire and

other hazards.

Do not use any sharp objects, acids or organic solvents for cleaning. Device can be

damaged.

Do not operate the device with sharp or pointed objects. The surface could be damaged.

These instructions are an integral part of the product, and must remain with the end

customer.

2 Device components

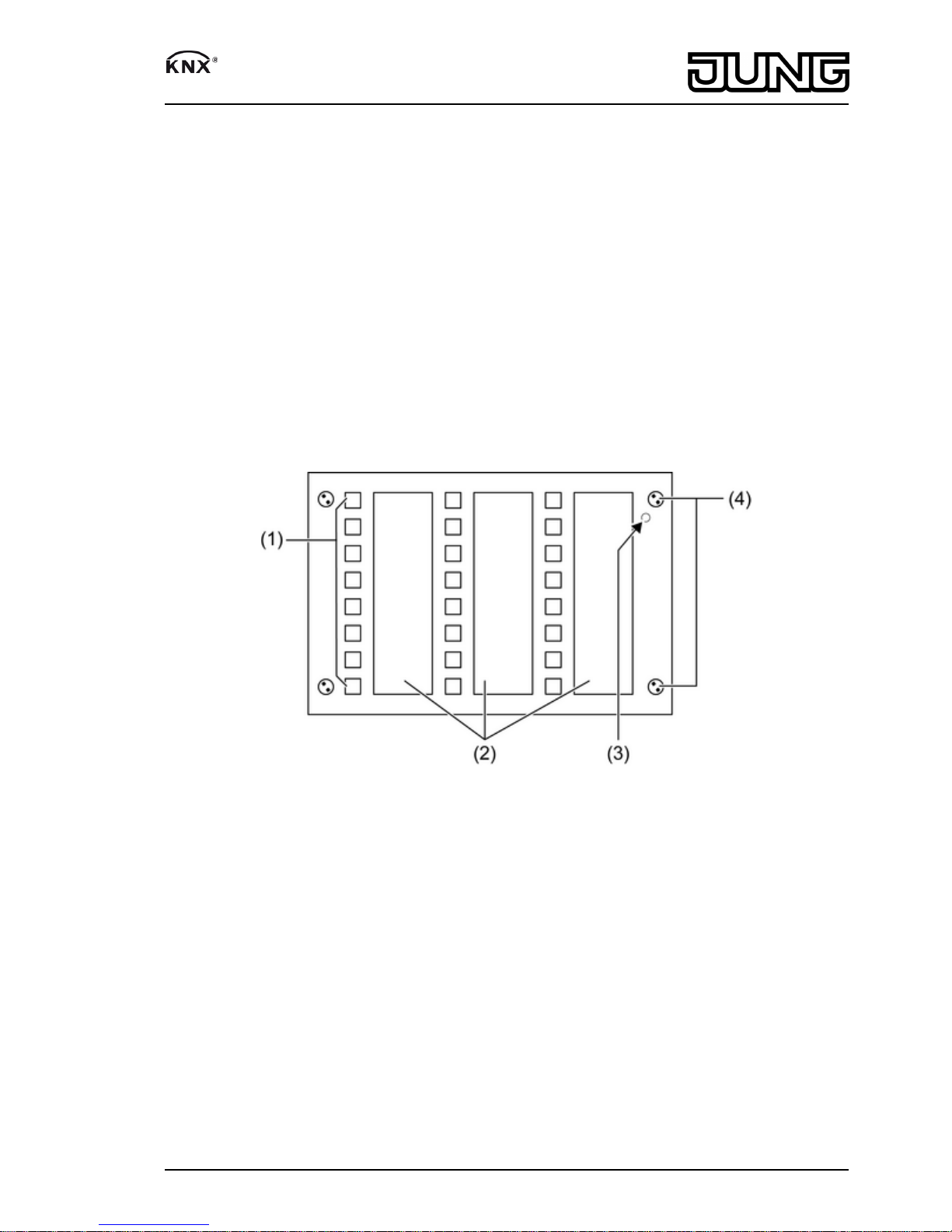

Figure 1: Front view

(1) Sensor areas with status LED

(2) Labelling with push-in labels

(3) Position of the programming LED

(4) Fastening screws, front plate

A suitable bit for the safety screw is included.

3 Function

System information

This device is a product of the KNX system and complies with the KNX directives. Detailed

technical knowledge obtained in KNX training courses is a prerequisite to proper

understanding.

The function of this device depends upon the software. Detailed information on loadable

software and attainable functionality as well as the software itself can be obtained from the

manufacturer´s product database. Planning, installation and commissioning of the device are

carried out with the aid of KNX-certified software. The latest versions of product database and

the technical descriptions are available on our website.

1/7

82575503

J:0082575503

07.12.2010

Page 2

Intended use

- Operating loads, e.g. light switching and dimming, controlling blinds/shutters, etc.

- Visualising switching states

- Concealed mounting in double appliance box - without centre bar - to DIN 49073

Product characteristics

- Push-button functions: switching, scanning, dimming, Venetian blind, value transmitter,

calling up modes, etc.

- High-quality glass surface with 24 buttons

- Operation through touching the sensor buttons

- Labelling with push-in labels

- Status indication with 24 LEDs; the colours red, green and blue can be configured

- Acoustic signal display, e.g. for button press

- Fault message on dismantling

- Logic and time functions

- Integrated bus coupling unit

- Supply via separate power supply (accessory) or the auxiliary voltage output of the KNX

power supply

4 Operation

Operating a function or load

Each sensor area has a function assigned to it. Operation is carried out by pressing the sensor

areas and depends on the specific function.

o Switch: Short press on sensor area.

o Dim: Long press on the sensor area. The dimming process ends when the sensor area is

released.

o Move Venetian blind: Long press on sensor area.

o Stop or adjust Venetian blind: Short press on sensor area.

o Call up light scene: Short press on sensor area.

o Save light scene: Long press on sensor area.

o Set value, e.g. brightness or temperature setpoint: Short press on sensor area.

Cleaning the surface

o Clean the glass surface with a soft cloth. If needed, moisten the cleaning cloth.

i Do not use sharp objects for cleaning.

i Do not use sharp cleaning agents, acids or organic solvents.

i Keep moisture from penetrating into the device.

5 Information for electrically skilled persons

5.1 Fitting and electrical connection

DANGER!

Electrical shock on contact with live parts in the installation environment.

Electrical shocks can be fatal.

Before working on the device, disconnect the power supply and cover up live

parts in the working environment.

2/7

82575503

J:0082575503

07.12.2010

Signal panel

Page 3

Mounting and connecting the device

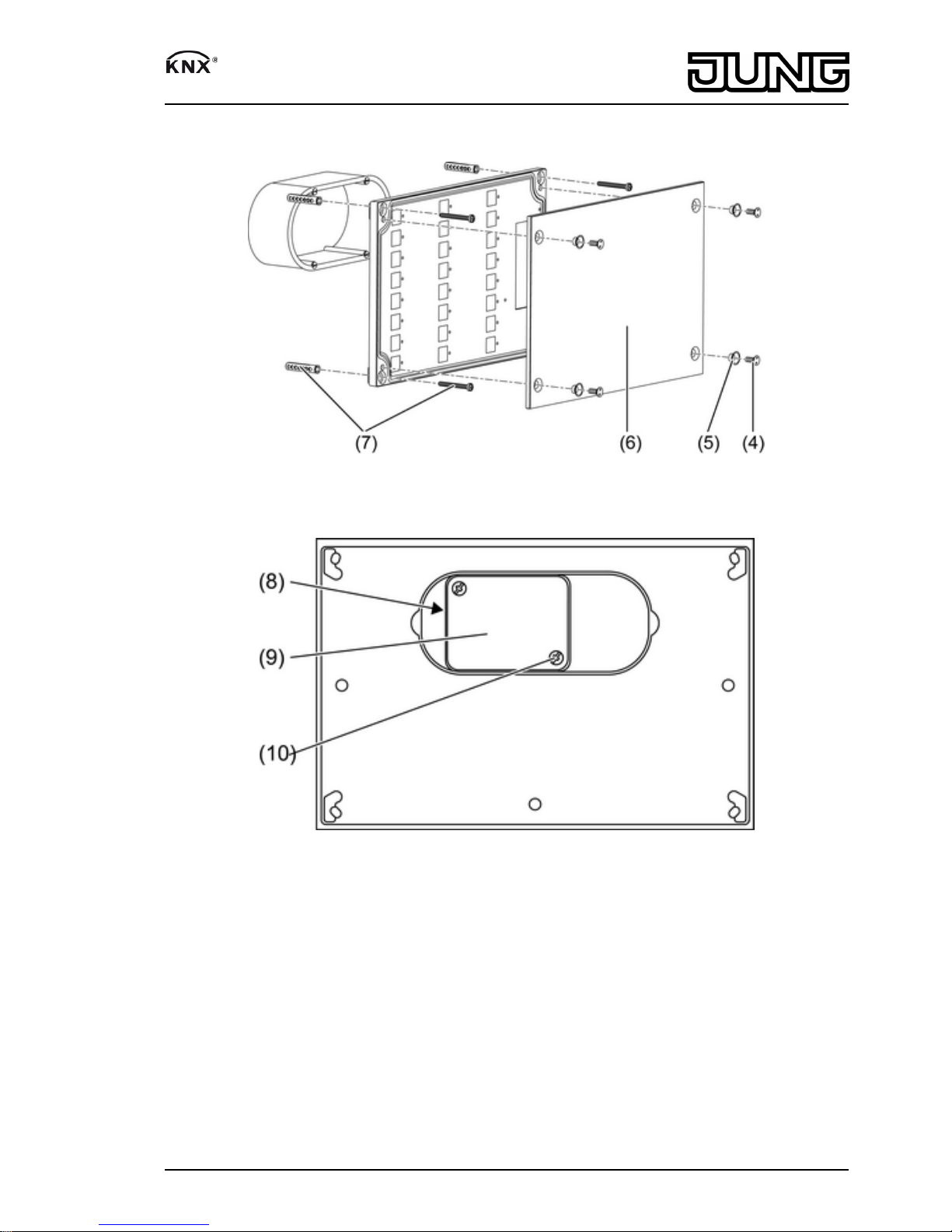

Figure 2: Installation – Overview

Figure 3: Rear view

3/7

82575503

J:0082575503

07.12.2010

Signal panel

Page 4

Figure 4: Connection box opened

(5) Screw sleeve

(6) Front plate

(7) Screws/anchor set

(8) Connection box

(9) Lid of the connection box

(10) Lid screw

(11) Cable penetration

(12) Power supply connection, yellow/white connector

(13) Bus connection, red/black connector

Recommended installation height: 1.50 m.

Installation only using deep concealed appliance box, double.

Only for horizontal installation.

Only install on flat walls.

i Soiling in the slots on the front plate, e.g. due to unsuitable pins or paper strips, cannot be

removed. The labelling of the sensor areas must be able to resist wipes and moisture and

must be made on suitable media, e.g. transparent film.

Recommendation: Use two layers of transparent film and label the inner side (figure 5).

Figure 5: Labelling with two layers of transparent film

4/7

82575503

J:0082575503

07.12.2010

Signal panel

Page 5

o Mark the installation location using the enclosed template. Install the concealed appliance

box, anchor holes for screw fastening Ø = 6 mm.

o Slacken the fastening screws (4) with the enclosed tool – two-hole spanner bit SP-4 – and

remove the front plate (6).

o Slacken the lid screws (10) on the connection box (8) and remove the lid (9).

o Run the connecting cables through the openings (11) of the connection box.

o Connect the bus wires with the red and black bus terminal to the bus connection (13).

o Connect the power supply with the yellow and white terminal to the connection (12).

i The second wire pair of the bus cable can be used to provide the power supply.

o Close the lid (9).

i The physical address must be noted on the device. If possible load the physical address

into the device before final mounting (see chapter 5.2. Commissioning).

o Place the device in the concealed box and screw it to the substrate. Use the enclosed

screw/anchor set (7).

o Push the written push-in labels into the top of the intended slots on the rear side of the front

plate.

o Attach the front plate. Insert the screw sleeves (5) and fasten them to the housing using the

fastening screws (4). Max. torque: 0.5 Nm.

5.2 Commissioning

Loading the physical address and application software

The device is connected and ready for operation.

The power supply and bus voltage are switched on.

o Press the top left and right sensor areas simultaneously.

The programming LED on the right edge of the panel (3) lights up.

o Assign physical address.

The programming LED goes out.

o Load the application software into the device.

o Note the physical address on the labels on the rear side of the device and behind the front

plate.

Checking the LED function

The device is connected and ready for operation.

o Press the top left and bottom right sensor areas simultaneously.

All the LEDS light up in sequence for 2 seconds each in red, green and blue.

6 Appendix

6.1 Technical data

External supply

Rated voltage AC/DC 24 V SELV

Rated frequency 50 / 60 Hz

Power consumption max. 2.2 W

Connection of power supply Connection terminal

Single stranded 0.6 ... 0.8 mm²

Front plate

Dimensions W×H×D approx. 236x156x14 mm

Installation depth approx. 39 mm

Push-in labels

Dimensions L×W approx. 132×39.5 mm

Ambient conditions

Ambient temperature -20 ... +70 °C

Storage/transport temperature -20 ... +75 °C

5/7

82575503

J:0082575503

07.12.2010

Signal panel

Page 6

Relative humidity 15 ... 95 % rel. humidity (No moisture

condensation)

Protection rating IP 54

Safety class III

KNX

KNX medium TP 1

Commissioning mode S-mode

Rated voltage KNX DC 21 ... 32 V SELV

Connection, Bus Connection terminal

Current consumption KNX max. 5 mA

6.2 Troubleshooting

The programming LED flashes green, the device has no function.

The device has not been programmed.

Load the application software into the device.

When operated, functions are only triggered after a delay or not trigged at all.

The device adjusts the detection characteristics regularly. Long actuation of one or more sensor

areas – e.g. for cleaning or during installation – may cause the detection system to become less

sensitive.

The detection characteristics will automatically readjust to normal conditions after a short

time without operation.

Only ever press one sensor area.

6.3 Accessories

Power supply AC 24 V ~ Art.-No.: WSSV10

Power supply 320 mA Art.-No.: 2005 REG

Power supply 640 mA Art.-No.: 2002 REG

Two-gang appliance box, e.g. Kaiser, Art. no. 9062-02

JUNG Labelling tool – www.jung-label.de

6.4 Warranty

We reserve the right to make technical and formal changes to the product in the interest of

technical progress.

We provide a warranty as provided for by law.

Please send the unit postage-free with a description of the defect to our central customer

service office:

ALBRECHT JUNG GMBH & CO. KG

Service Center

Kupferstr. 17-19

D-44532 Lünen

Service-Line: +49 (0) 23 55 . 80 65 51

Telefax: +49 (0) 23 55 . 80 61 89

mail.vka@jung.de

General equipment

Service-Line: +49 (0) 23 55 . 80 65 55

Telefax: +49 (0) 23 55 . 80 62 55

mail.vkm@jung.de

KNX equipment

Service-Line: +49 (0) 23 55 . 80 65 56

Telefax: +49 (0) 23 55 . 80 62 55

mail.vkm@jung.de

The Πsymbol is a free trade symbol, which is solely intended for the authorities and does not

guarantee any properties.

6/7

82575503

J:0082575503

07.12.2010

Signal panel

Page 7

ALBRECHT JUNG GMBH & CO. KG

Volmestraße 1

D-58579 Schalksmühle

Telefon: +49.23 55.8 06-0

Telefax: +49.23 55.8 06-1 89

E-mail: mail.info@jung.de

Internet: www.jung.de

www.jung-katalog.de

7/7

82575503

J:0082575503

07.12.2010

Signal panel

Loading...

Loading...