Page 1

Product documentation

KNX Room controller display compact module

Art.-No.: 4093 KRM TS D

ALBRECHT JUNG GMBH & CO. KG

Volmestraße 1

D-58579 Schalksmühle

Telefon: +49.23 55.8 06-0

Telefax: +49.23 55.8 06-1 89

E-mail: mail.info@jung.de

Internet: www.jung.de

www.jung-katalog.de

Issue: 20.10.2009

13557800

Page 2

Product documentation

Content

1 Product definition 4 ................................................................................................................

1.1 Product catalogue 4 ...........................................................................................................

1.2 Function 4 ..........................................................................................................................

1.3 Accessories 6 ....................................................................................................................

2 Installation, electrical connection and operation 7 .............................................................

2.1 Safety instructions 7 ..........................................................................................................

2.2 Device components 8 ........................................................................................................

2.3 Fitting and electrical connection 9 .....................................................................................

2.4 Commissioning 13 .............................................................................................................

2.5 Operation 15 ......................................................................................................................

2.5.1 Basic display 16 .........................................................................................................

2.5.2 Second operating level 17 ..........................................................................................

3 Technical data 26 ....................................................................................................................

4 Software description 27 .........................................................................................................

4.1 Software specification 27 ...................................................................................................

4.2 Software "Continuous controller module 3gang 146A11" 28 .............................................

4.2.1 Scope of functions 28 .................................................................................................

4.2.2 Notes on software 31 .................................................................................................

4.2.3 Object table 32 ...........................................................................................................

4.2.3.1 Object table, pushbutton sensor function section 32 ..........................................

4.2.3.2 Object table, controller function section 45 .........................................................

4.2.3.3 Display object table 62 ........................................................................................

4.2.4 Functional description 66 ...........................................................................................

4.2.4.1 Pushbutton sensor 66 .........................................................................................

4.2.4.1.1 Operation concept and button evaluation 66 ..............................................

4.2.4.1.2 "Switching" function 73 ................................................................................

4.2.4.1.3 "Dimming" function 74 .................................................................................

4.2.4.1.4 "Venetian blind" function 76 ........................................................................

4.2.4.1.5 Value transmitter function 80 ......................................................................

4.2.4.1.6 "Scene extension" function 83 .....................................................................

4.2.4.1.7 Function "2-channel operation" 84 ..............................................................

4.2.4.1.8 "Controller extension" function 86 ...............................................................

4.2.4.1.9 "Fan control" function 87 .............................................................................

4.2.4.1.10 "Controller operating mode" function 88 ......................................................

4.2.4.1.11 "Setpoint shift" function 89 ..........................................................................

4.2.4.1.12 "Change in the display reading" function 90 ................................................

4.2.4.1.13 Status LED 91 .............................................................................................

4.2.4.1.14 Disabling function 93 ...................................................................................

4.2.4.1.15 Transmission delay 96 ................................................................................

4.2.4.1.16 Alarm message 97 ......................................................................................

4.2.4.2 Room temperature controller 98 .........................................................................

4.2.4.2.1 Operating modes and operating mode change-over 98 ..............................

4.2.4.2.2 Control algorithms and calculation of command values 101 .......................

4.2.4.2.3 Adapting the control algorithms 108 ............................................................

4.2.4.2.4 Operating mode change-over 111 ..............................................................

4.2.4.2.5 Temperature setpoints 120 .........................................................................

4.2.4.2.6 Room temperature measurement 134 ........................................................

4.2.4.2.7 Command value and status output 137 ......................................................

4.2.4.2.8 Fan controller 141 .......................................................................................

4.2.4.2.9 Disable functions of the room temperature controller 148 ...........................

4.2.4.2.10 Valve protection 149 ...................................................................................

4.2.4.3 Room temperature controller extension 150 .......................................................

4.2.4.3.1 Connection to room temperature controller 150 ..........................................

Art.-No.: 4093 KRM TS D

Page 2 of 241

Page 3

Product documentation

4.2.4.3.2 Operating functions 153 ..............................................................................

4.2.4.3.3 Display functions 155 ..................................................................................

4.2.4.3.4 Room temperature measurement 157 ........................................................

4.2.4.3.5 Behaviour after a device restart 158 ...........................................................

4.2.4.4 Light scene function 159 .....................................................................................

4.2.4.5 Display 162 .........................................................................................................

4.2.4.5.1 Displayed information 162 ...........................................................................

4.2.4.5.2 Display control 165 ......................................................................................

4.2.4.6 Delivery state 168 ...............................................................................................

4.2.5 Parameters 169 ..........................................................................................................

4.2.5.1 General parameters 169 .....................................................................................

4.2.5.2 Parameter for room temperature measurement 174 ..........................................

4.2.5.3 Parameters on the pushbutton sensor function section 176 ...............................

4.2.5.4 Parameter for the controller function section 211 ...............................................

4.2.5.5 Parameters for the display 233 ...........................................................................

4.2.5.6 Parameter on scene function 236 .......................................................................

5 Appendix 239 ...........................................................................................................................

5.1 Index 239 ...........................................................................................................................

Art.-No.: 4093 KRM TS D

Page 3 of 241

Page 4

Product definition

1 Product definition

1.1 Product catalogue

Product name: Room controller display compact module

Use: Sensor

Design: UP (concealed)

Art.-No.: 4093 KRM TS D

1.2 Function

This device combines the functions of a KNX/EIB bus coupling unit, a single-room temperature

controller with setpoint specification, and a push-button sensor, in just one bus subscriber. The

combination of these functions makes it possible, for example, to control the light, the blinds,

and the room temperature centrally from the entry area of a room. The room temperature

controller and pushbutton sensor functions are each independent function sections of the device

with their own parameter blocks in the ETS.

The device has 3 control surfaces that can be used to operate the integrated room temperature

controller and the pushbutton sensor. The functions can be configured in the ETS. Optionally,

the number of control surfaces can be expanded to include up to 4 additional ones by

connecting an expansion module to the basic unit. Configuration and commissioning of the

expansion module is clearly structured and easy to perform using the application program of the

basic unit.

Pushbutton sensor functionality:

When a rocker or button is pressed, the device transmits telegrams to the KNX/EIB, depending

on the ETS parameter settings. These can be, for instance, telegrams for switching or

pushbutton control, for dimming or for controlling blinds. It is also possible to program value

transmitter functions, such as dimming value transmitters, light scene extensions, temperature

value transmitters or brightness value transmitters.

In connection with a room temperature controller equipped with a 1-byte object for change-over

of operating modes, the device can be used as a full-featured controller extension. The device

can also be used for presence detection or for setpoint shifting purposes and to indicate

different controller states.

The operation concept of a control surface can be configured in the ETS either as a rocker

function or alternatively as a push-button function. With the rocker function, one control surface

is divided into two actuation pressure points with the same basic function. In the push-button

function either a control surface is divided into 2 functionally separate actuation pressure points

(2 buttons), or a control surface is evaluated as single-surface operation (only one button).

With the rocker function and the double-surface push-button function, the button arrangement

can be set either as "vertical" (top-bottom operation) or as "horizontal" (left-right operation) for

each control surface. With the rocker function it is also possible to trigger special functions using

full-surface operation.

The device has two status LEDs for each of the lower control surfaces and for the control

surfaces of the expansion module, which, according to the function of the rocker or button can

be internally connected to the operating function. Each status LEDs can then also signal

completely independent display information, operating states of room temperature controllers or

indicate the results of logic value comparisons, flash or be permanently switched on or off. The

control surface next to the display does not have status LEDs.

Room temperature controller functionality

The device can be used for single-room temperature control. Depending on the operating mode,

the current temperature setpoint and on the room temperature, a command value for heating or

cooling control can be sent to the KNX/EIB for the control circuit. In addition to the heating or

cooling basic level, activating an additional heater and/or cooling unit means that an additional

heating or cooling unit can be used. In this connection, you can set the temperature setpoint

difference between the basic and the additional level by a parameter in the ETS. For major

deviations between the temperature setpoint and the actual temperature, you can activate this

additional level to heat up or cool down the room faster. You can assign different control

Art.-No.: 4093 KRM TS D

Page 4 of 241

Page 5

Product definition

algorithms to the basic and additional levels.

For heating and cooling functions, you can select continuous or switching PI or switching 2-point

feedback control algorithms.

The room temperature can be recorded either by the internal or by an external temperature

sensor. Combined temperature recording by both sensors can also be configured.

The controller distinguishes between different operating modes (comfort, standby, night, frost/

heat protection) each with their own temperature setpoints for heating or cooling.

General:

A bus coupling unit is already permanently integrated in the device, allowing the device to be

connected directly to the bus cable during commissioning.

When used, an operation LED can either serve as an orientation light (also flashing), or can be

activated via a separate communication object. When the device is in the programming mode,

the operation LED flashes with a frequency of about 8 Hz. The same flashing rate is also used

for indicating that a rocker has been actuated by a press on the full surface. In this case the

LED returns to the programmed behaviour after the operation. If no or a wrong application has

been loaded into the pushbutton sensor, the operation LED flashes with a frequency of about

0.75 Hz to indicate an error. The device does not then work.

Art.-No.: 4093 KRM TS D

Page 5 of 241

Page 6

Product definition

1.3 Accessories

Cover kit for Room controller module Art.-No.: ..4093 TSA..

Push-button extension module Art.-No.: 4094 TSEM

Cover kit, 4-gang, for Extension modul Art.-No.: ..404 TSA..

Extension flex Art.-No.: TSEMV70

Art.-No.: 4093 KRM TS D

Page 6 of 241

Page 7

Installation, electrical connection and operation

2 Installation, electrical connection and operation

2.1 Safety instructions

Electrical devices may only be fitted and installed by electrically skilled persons. The

applicable accident prevention regulations must be observed.

Failure to observe the instructions may cause damage to the device and result in fire and

other hazards.

Make sure during the installation that there is always sufficient insulation between the

mains voltage and the bus. A minimum distance of at least 4 mm must be maintained

between bus conductors and mains voltage cores.

The device may not be opened or operated outside the technical specifications.

Art.-No.: 4093 KRM TS D

Page 7 of 241

Page 8

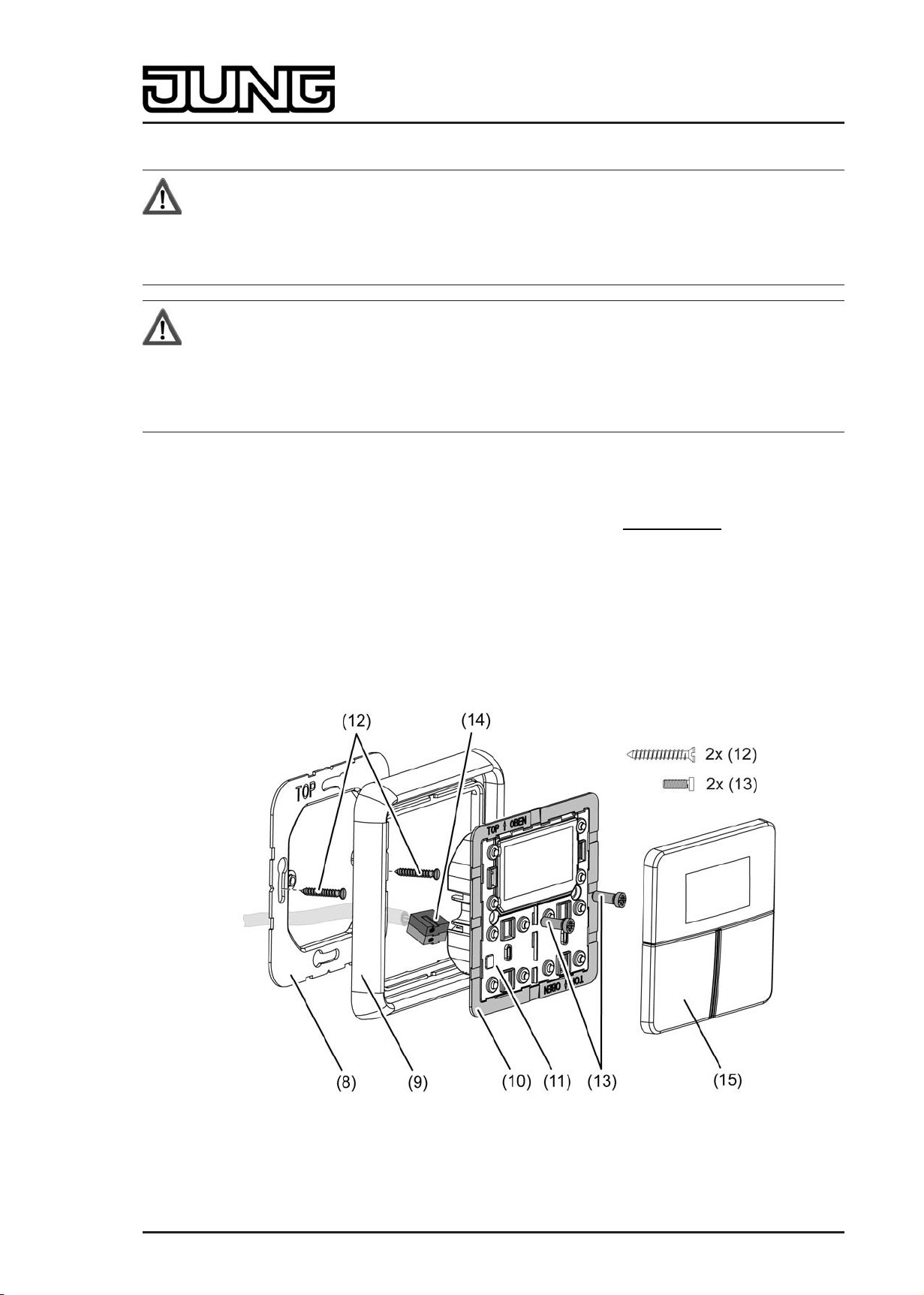

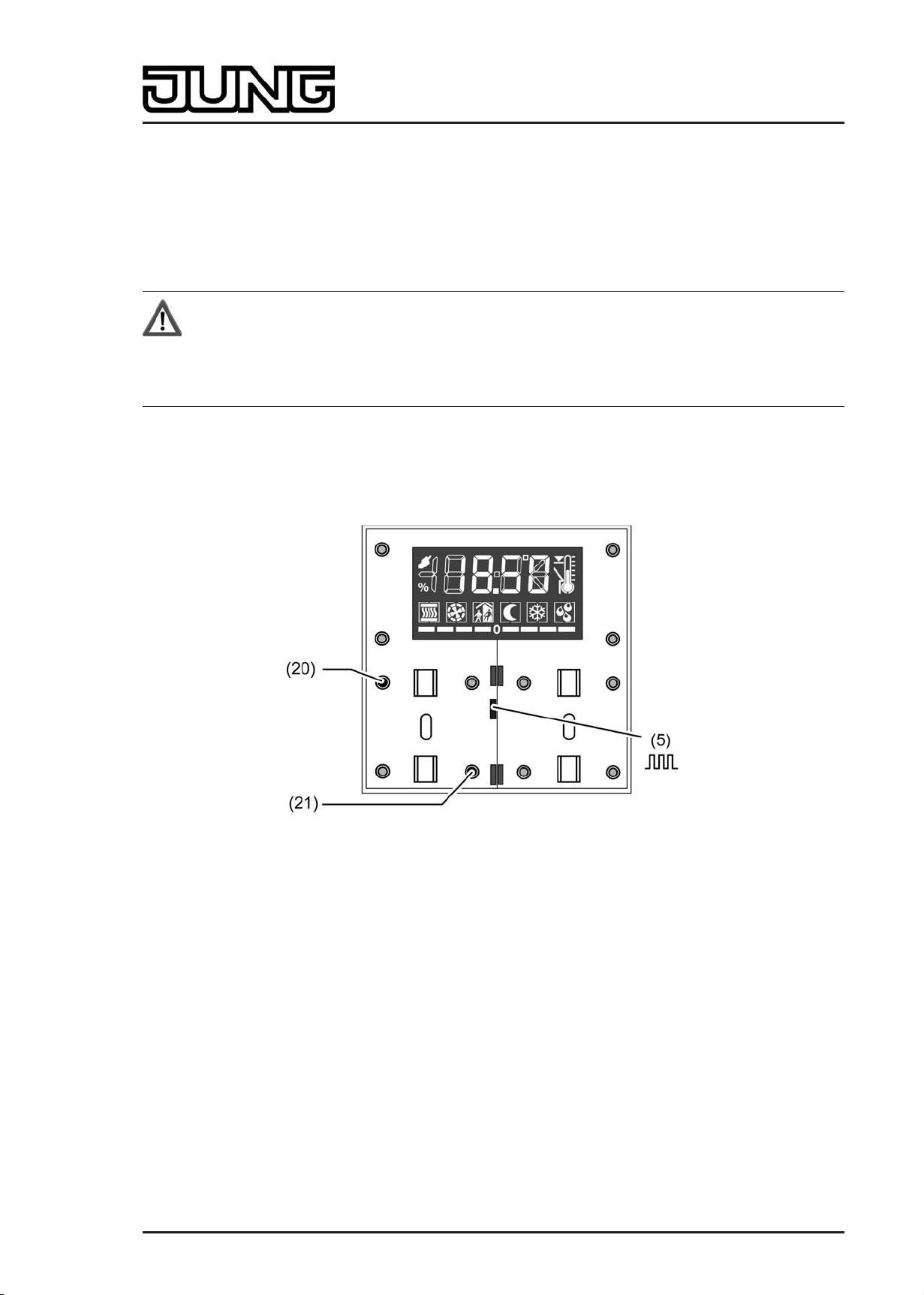

2.2 Device components

Installation, electrical connection and operation

picture 1: Device components, front side

(1) LCD with backlighting

(2) Control surfaces (rockers 1...2)

(3) Display control surface (rocker 3)

(4) Status LEDs (2 x per control surface for rockers 1...2)

(5) Operation LED

picture 2: Device components, rear side

(6) Connection for KNX/EIB bus cable

(7) Connection for pushbutton sensor expansion module

Art.-No.: 4093 KRM TS D

Page 8 of 241

Page 9

Installation, electrical connection and operation

2.3 Fitting and electrical connection

DANGER!

Electrical shock on contact with live parts in the installation environment.

Electrical shocks can be fatal.

Before working on the device, disconnect the power supply and cover up live

parts in the working environment.

DANGER!

When mounting with 230 V devices under a common cover, e.g. socket outlets,

there is a danger of electrical shocks in the event of a fault!

Electrical shocks can be fatal.

Do not install any 230 V devices in combination with a pushbutton expansion

module under a common cover!

Snapping on the adapter frame

An adapter frame is required for the CD design. The adapter frame must be snapped onto the

continuous controller module before the device is connected and fastened to the wall.

o With the adapter frame (10) in the correct orientation, snap it from the front onto the

continuous controller module (11) (picture 3). Note marking TOP = top/front.

i If the pushbutton sensor expansion is used, the adapter frame also has to be mounted on

the pushbutton sensor expansion module.

Fitting and connecting the continuous controller module

picture 3: Fitting the continuous controller module

(8) Supporting frame

Art.-No.: 4093 KRM TS D

Page 9 of 241

Page 10

Installation, electrical connection and operation

(9) Design frame

(10) Adapter frame

(11) Continuous controller module

(12) Box screws

(13) Fastening screws

(14) KNX connection terminal

(15) Design control surfaces

i Recommended installation height: 1.50 m.

i The installation of the supporting frame depends on the design used.

Supporting frame side "A" to the front for switch design ranges A, CD and FD.

Supporting frame side "B" to the front for switch design range LS.

o Mount supporting frame (8) in the right orientation on an appliance box. Note marking TOP;

marking "A" or "B" in front. Use the enclosed box screws (12).

o Position the design frame (9) on the supporting frame.

o Connect the continuous controller module (11) with KNX connection terminal (14), which is

connected to the KNX bus cable, on the rear side of the module. Run the connecting cable

downwards from the continuous controller module and then into the appliance box from the

rear.

o Push continuous controller module onto the supporting frame.

o Fasten the continuous controller module to supporting frame using the enclosed plastic

screws (13). Tighten the plastic screws only lightly.

o Before mounting the control surfaces (15), load the physical address into the device (see

chapter 2.4. Commissioning).

Art.-No.: 4093 KRM TS D

Page 10 of 241

Page 11

Installation, electrical connection and operation

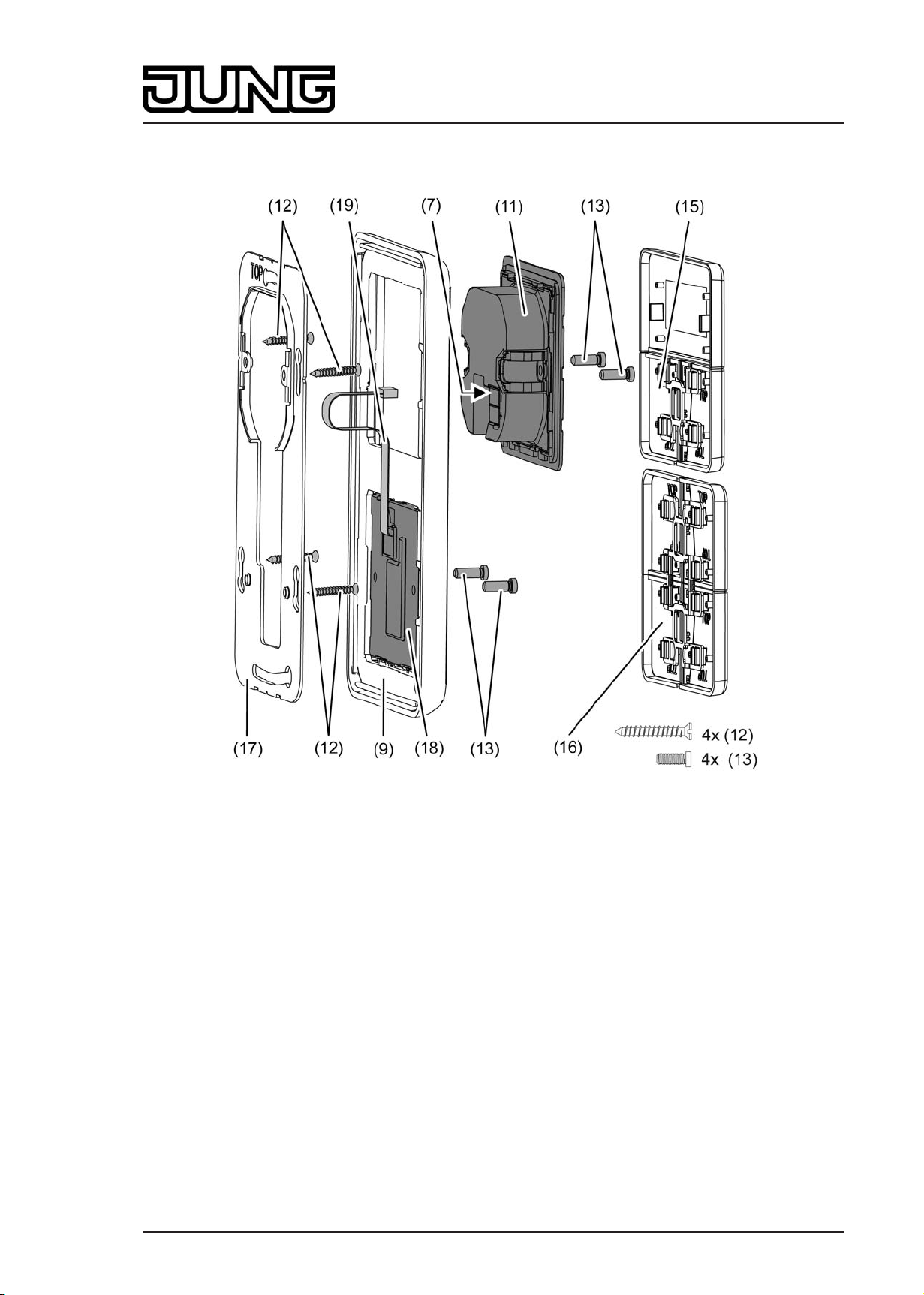

Fitting and connecting continuous controller module with pushbutton sensor expansion

module

picture 4: Fitting the pushbutton sensor expansion module (example of combined fitting)

(7) Connection point in continuous controller module for connecting cable of the expansion

module

(9) Design frame

(11) Continuous controller module

(12) Box screws

(13) Fastening screws

(15) Design control surfaces for the continuous controller module

(16) Design control surfaces for the expansion module

(17) Large supporting frame for combined fitting of continuous controller module and expansion

module

(18) Pushbutton sensor expansion module

(19) Connecting cable for pushbutton sensor expansion module with plug

Art.-No.: 4093 KRM TS D

Page 11 of 241

Page 12

Installation, electrical connection and operation

i The installation of the supporting frame depends on the design used.

Supporting frame side "A" to the front for switch design ranges A, CD and FD.

Supporting frame side "B" to the front for switch design range LS.

One pushbutton sensor expansion module can be connected to each continuous controller

module. For combined fitting of an expansion module directly underneath the continuous

controller module, the large supporting frame (17) must be fitted (picture 4). The large

supporting frame is contained in the scope of supply of the pushbutton sensor expansion

module.

For combined fitting on just a single appliance box, fit the continuous controller module with the

KNX bus connection in the appliance box and countersink the fixing screws of the expansion

module in the wall, for example using Ø 6 x 10 mm boreholes. The large supporting frame can

be used as a template for this.

i Recommended installation height for the continuous controller module: 1.50 m.

The expansion module can be installed in a separate box with the extension (see

accessories) at a height of 1.10 m. The extension must be routed through a pipe. In this

installation a separate small supporting frame is used for the expansion module (included

in the scope of supply for the extension).

o For combined fitting underneath the continuous controller module: Fit large supporting

frame (17) in the right orientation on an appliance box. Note marking TOP; marking "A" or

"B" in front. Use the enclosed box screws (12).

For individual fitting of the expansion module at 1.10 m: Fit small supporting frames for the

continuous controller module and for the expansion module in the right orientation on two

appliance boxes. Note marking TOP; marking "A" or "B" in front. Use the enclosed box

screws (12).

o Position the design frame (9) on the supporting frame(s).

o For combined fitting underneath the continuous controller module: Fit pushbutton sensor

expansion module (18) in the large supporting frame. Route connecting cable (19) between

supporting frame and intermediate web.

For individual fitting of the expansion module at 1.10 m: Fit pushbutton sensor expansion

module (18) in separate small supporting frame. Guide connecting cable (19) through a

pipe into the box of the continuous controller module.

o With the plug of the connecting cable in the right orientation, insert it into the connection

point in the continuous controller module (7). When doing so, ensure that the connecting

cable is not pinched.

o Connect the continuous controller module (11) with KNX connection terminal, which is

connected to the KNX bus cable, on the rear side of the module. Run the connecting cable

downwards from the continuous controller module and then into the appliance box from the

rear.

o Push continuous controller module onto the supporting frame.

o Fasten module to supporting frame using the enclosed plastic screws (13). Tighten the

plastic screws only lightly.

o Mount the control surfaces on the pushbutton sensor expansion module (16). Before

mounting the control surfaces on the continuous controller module (15), load the physical

address into the device (see chapter 2.4. Commissioning).

Art.-No.: 4093 KRM TS D

Page 12 of 241

Page 13

Installation, electrical connection and operation

2.4 Commissioning

After the device has been connected to the bus and mounted on the wall, it can be put into

operation. Commissioning is basically confined to programming with the ETS and attaching the

decorative control surfaces.

Assignment of the physical address

DANGER!

Electrical shock when live parts are touched.

Electrical shocks can be fatal.

Before working on the device, disconnect the power supply and cover up live

parts in the working environment.

The device has an integrated bus coupling unit. It has no separate programming button or LED.

Programming mode is activated by a defined and time-delayed press on the first rocker and

signalled by the operation LED. To program the physical address, the decorative control

surfaces must not be in place on the device.

The physical address is programmed as described below...

picture 5: Buttons for activating Programming mode

o Activate Programming mode. Press button at the top left of rocker 1 (20) and keep it

depressed (picture 5). Then press the second button at the bottom right of rocker 1 (21).

Programming mode is activated. The operation LED (5) flashes quickly (approx. 8 Hz).

"Prog" is shown on the display of the device.

i Use suitable objects to push the buttons (e.g. thin screwdriver, tip of a ballpoint pen, etc.)

i To exclude any inadvertent activation of Programming mode during a 'normal' use of the

control surface in later operation, the time between the first and the second button

actuation must be at least 200 ms. Pressing both buttons simultaneously (time between

first and second actuation < 200 ms) will not result in an activation of Programming mode.

i It should be noted that the operation LED also flashes quickly in the case of a full-surface

operation of rocker 1 (see functional description). The difference from quick flashing in

programming mode is that with a full-surface operation the rocker of the LED returns to the

parameterized basic state when the buttons are released. In programming mode, flashing

continues until the operating mode is ended. The state of the LED defined by Programming

mode will always prevail.

o Program the physical address with the help of the ETS.

Art.-No.: 4093 KRM TS D

Page 13 of 241

Page 14

Installation, electrical connection and operation

The operation LED switches back to the previous status (off, on or flashing slowly).

i If Programming mode is to be activated or deactivated in a device which is already

programmed with a valid application, there is the possibility that telegrams will be

transmitted to the bus at the time the button is pressed. The telegram transmitted depends

on the push-button function programmed.

i The expansion module does not receive any physical address of its own. It is activated by

the application program loaded in the continuous controller module.

Programming the application

The application must then be programmed into the device with the help of the ETS. The ETS3.0

from version "d" onwards detects automatically whether a valid application has already been

programmed into the device before. To reduce the programming time, the ETS3 downloads the

whole application only if the device was programmed beforehand with another application or

with no application at all. In all other cases, the ETS makes a time-optimised partial download in

which only the modified data is loaded into the device. For commissioning. it is recommended to

use the ETS3.0 from Version d Patch A onwards.

i The expansion module does not receive any physical address of its own. It is activated by

the application program loaded in the continuous controller module.

Installing the decorative control surfaces

The decorative control surfaces are available as a complete set of buttons. Individual buttons or

the complete set of buttons can be replaced using buttons with symbols.

The design control surfaces are not included in the scope of supply of the continuous controller

module or the pushbutton sensor expansion module. These must be ordered specially

according to the required design.

The physical address of the continuous controller module must be programmed in the device in

advance.

o Place control surfaces on the continuous controller module in the right orientation and also

on the pushbutton sensor expansion module (if used), and snap in with a short push. Note

marking TOP.

i To simplify installation, a complete set of buttons is fitted with a mounting spider at the

factory. This mounting spider is not essential for installing the decorative control surfaces,

meaning that it is not required when adding symbol buttons to the button panel.

Art.-No.: 4093 KRM TS D

Page 14 of 241

Page 15

Installation, electrical connection and operation

2.5 Operation

The device consists of three mechanically separate control surfaces. The control surfaces are

the design covers attached to the device with push-button elements underneath. A distinction is

made between the display control surface (23) and the control surfaces of the pushbutton

sensor function (22) (picture 6).

picture 6: Arrangement of the control surfaces on the front of the device

(22) Pushbutton sensor control surfaces (rocker 1 left / rocker 2 right) incl. 4 status LEDs

Function: Any desired pushbutton sensor function or controller operation, operation of the

second display operating level

(23) Display control surface (rocker 3)

Function: Any desired pushbutton sensor function or controller operation

The lower control surfaces (rockers 1 & 2) are allocated to the pushbutton sensor function. The

function of these rockers can also be configured in the ETS to any desired pushbutton sensor

function. Alternatively it is possible to set operation of the integrated room temperature

controller. It is also possible to activate and operate the second display operating level via

button evaluation of these surfaces (see chapter 2.5.2. Second operating level).

The display is surrounded by the upper display control surface (rocker 3). The function of this

surface can also be configured in the ETS to any desired pushbutton sensor function.

Alternatively the room temperature controller can be operated.

The pushbutton sensor function is an independent function section of the device with its own

parameter blocks in the ETS. Insofar as the control surfaces are to operate the integrated room

temperature controller, the following functions can be parameterised in the pushbutton

configuration: setpoint shift, presence button, operating mode change-over, fan control. For a

more detailed description of the operating functions, please see Chapter 4. of this

documentation.

The operation concept of a control surface can be configured in the ETS either as a rocker

function or alternatively as a push-button function. With the rocker function, one control surface

is divided into two actuation pressure points with the same basic function. In the push-button

function either a control surface is divided into 2 functionally separate actuation pressure points

(2 buttons), or a control surface is evaluated as single-surface operation (only one large button).

If a control surface is used as a single rocker function, then it is also possible to trigger special

functions using full-surface operation.

With the rocker function and the double-surface push-button function, the button arrangement

can be set either as "vertical" or as "horizontal" for each control surface. The variable

specification of the button arrangement does not, however, apply to operation of the second

display operating level via rockers 1 & 2. There the button arrangement is fixed (see chapter

2.5.2. Second operating level).

Art.-No.: 4093 KRM TS D

Page 15 of 241

Page 16

Installation, electrical connection and operation

Optionally, the number of control surfaces can be expanded to include up to 4 additional ones

by connecting an expansion module to the continuous controller module. Configuration and

commissioning of the expansion module is clearly structured and easy to perform using the

application program of the continuous controller module. The control surfaces of the expansion

module can be set in the ETS to any desired pushbutton sensor function, or also to controller

operation.

Between the lower control surfaces of the continuous controller module (rockers 1 & 2) there

are 4 red status LEDs, 2 for each rocker. These status LEDs can be internally connected to the

operating function according to the function of the rocker or pushbuttons, thus indicating the

operating status directly. They may, however, also be used for signalling completely

independent functions or be permanently on or off.

The operation LED can also signal the switching state of its own object, flash or be permanently

on or off. Besides functions that can be set using the ETS, the operation LED also indicates that

the device is in the programming mode for commissioning or diagnosis purposes.

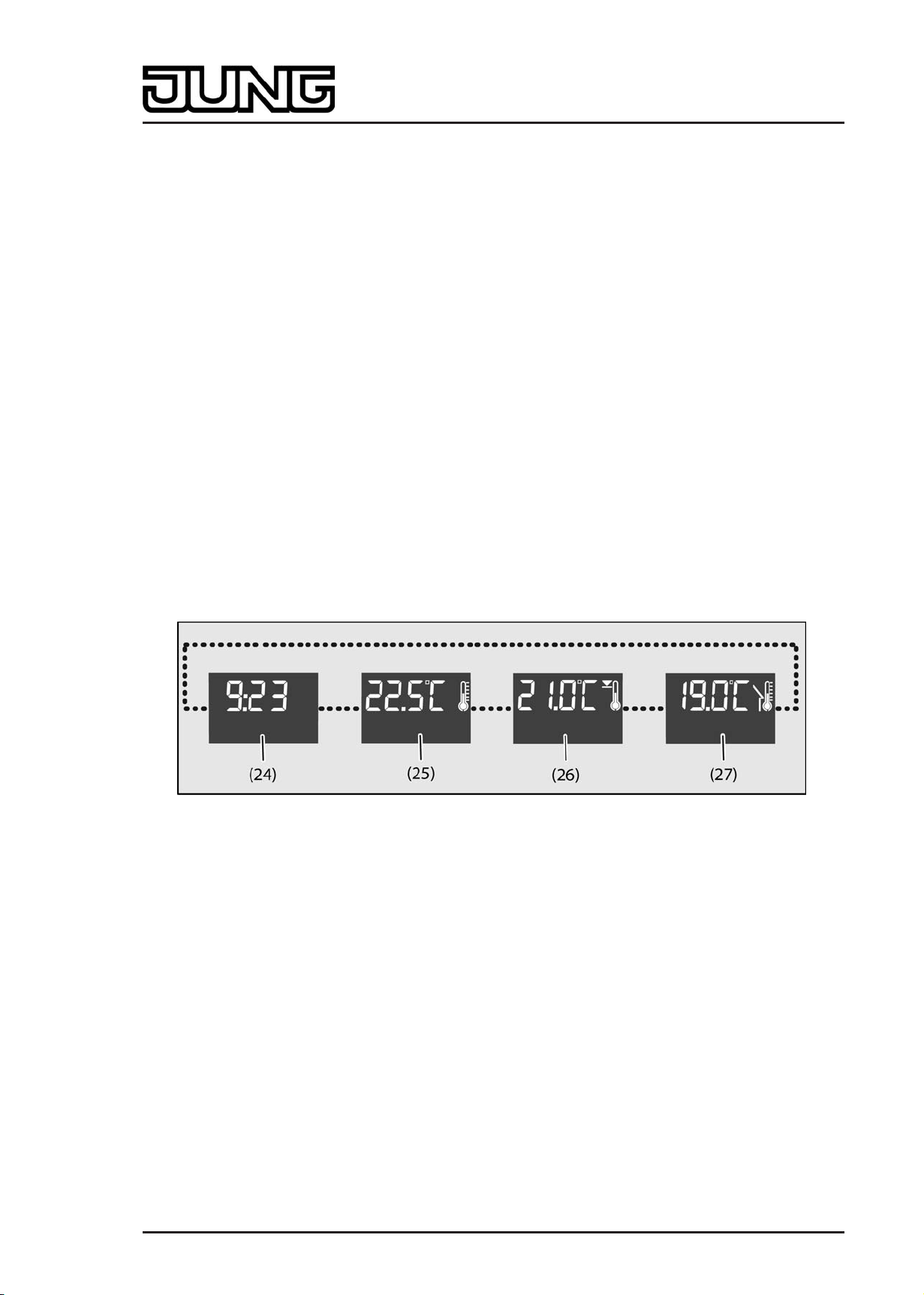

2.5.1 Basic display

During device operation, the basic display of the display can show up to four different display

functions. This means that is possible to display the time, the setpoint temperature, the actual

temperature (room temperature) or the outdoor temperature (picture 7). The information is

shown separately on the display. It is possible to change over between the information

automatically after set times or in a controlled manner by pressing a button on the device.

These properties, and the actually visible display information, are configured in the ETS before

the device is commissioned (see chapter 4.2.4.5. Display).

picture 7: Possible display information of the basic display

(24) Time display (with flashing seconds mark ":")

(25) Actual temperature display (room temperature)

(26) Setpoint temperature display

(27) Outdoor temperature display

i The temperatures can be displayed in °C or alternately in °F. The display format can be

configured in common for all temperature values in the ETS.

Art.-No.: 4093 KRM TS D

Page 16 of 241

Page 17

Installation, electrical connection and operation

2.5.2 Second operating level

The second operating level makes it possible to make various basic settings on the unit locally

without using the ETS. In order to avoid the unintentional disruption of essential functions,

access to individual settings or to the entire second operating level can be prevented via the

parameterisation in the ETS. An active button disable also disables access to the second

operating level.

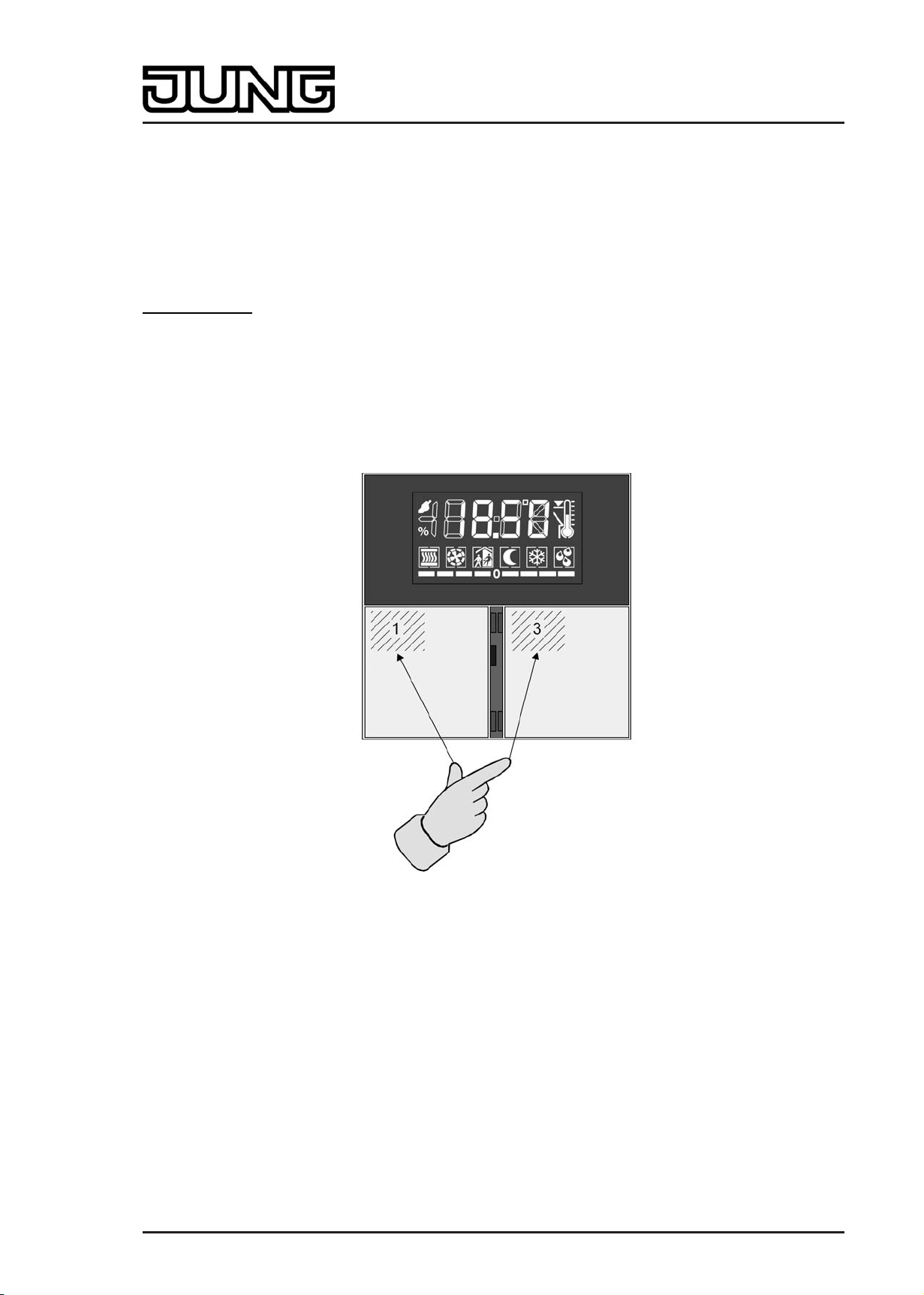

Calling up the second operating level

The second operating level is called up by pressing buttons 1 and 3 on the device

simultaneously(picture 8). It must be ensured here that the control surfaces are pressed at the

upper left corner in order to be independent of the configured button arrangement.

The device leaves the second operating level again when buttons 1 and 3 are pressed again

simultaneously. Depending on the setting of the ETS parameter "Save changes after manual

exit?" all settings that have been made are saved or discarded in this case. The parameters

"Automatic exit of the second operating level", "Time until automatic exit" and "Save changes?"

define whether the device terminates the second operating level automatically if no entries are

made, and whether in this case all of the changed settings are saved or discarded (see "Exiting

the second operating level").

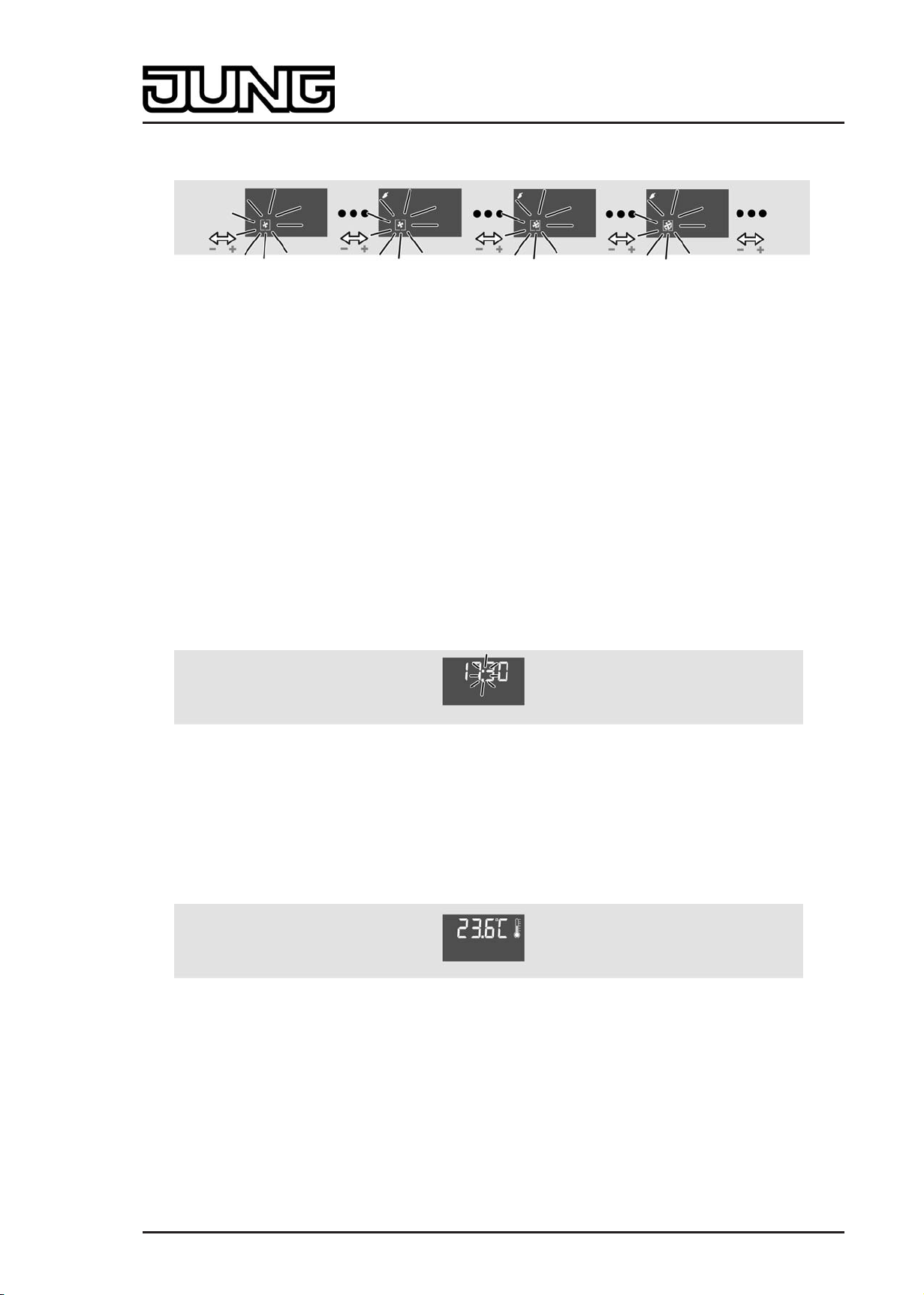

picture 8: Button combination to call up the second operating level

Operation in the second operating level

The settings in the second operating level are organised in a ring-shaped menu. This is shown

in the display. Selection and settings are performed using the 1...4 buttons of the device

(picture 9). Within the second operating level the button arrangement of the control surfaces is

preset to "top / bottom" independently of the ETS configuration, and cannot be changed.

Moreover, buttons 1...4 are always available for operation of the second operating level,

independently of any single-surface operation configured in the ETS.

The four buttons have the following functions...

Button 1: + change-over or value change in positive direction

Button 2: - change-over or value change in negative direction

Button 3: n Jump to the previous menu entry

Button 4: o Jump to the next menu entry

Art.-No.: 4093 KRM TS D

Page 17 of 241

Page 18

Installation, electrical connection and operation

i Continuous adjustment of the value settings is possible if buttons 1 or 2 are held in the

depressed position.

picture 9: Button assignment for operation in the second operating level

Configuration in the ETS offers various options for influencing the entries that are visible and

changeable in the menu...

1. If entries are configured via parameterisation as "hidden", they do not appear in the menu.

This setting is performed in the ETS separately for various menu entries in the parameter node

"General -> Second operating level" Some entries are always visible and can thus not be

configured as invisible in the ETS. When the device functions as a controller extension,

controller settings (setpoint temperatures, setpoint shifting, operating mode, fan control) are

fundamentally not accessible in the second operating level.

2. The setpoint temperatures of the continuous controller can either be changeable, or can

alternatively only show the current value and thus not be editable. This setting is performed in

the ETS in the parameter node "Room temperature control -> Controller general -> Second

operating level".

The menu entry that is shown as the first entry when the second operating level is called up can

be selected in the ETS using the parameter "First menu item in second operating level". The

sequence of the subsequent entries is then fixed as shown below.

The following menu functions can be called up in the second operating level, if not explicitly

disabled in the ETS. The symbols shown in the display indicated which function or which

temperature value is displayed or set.

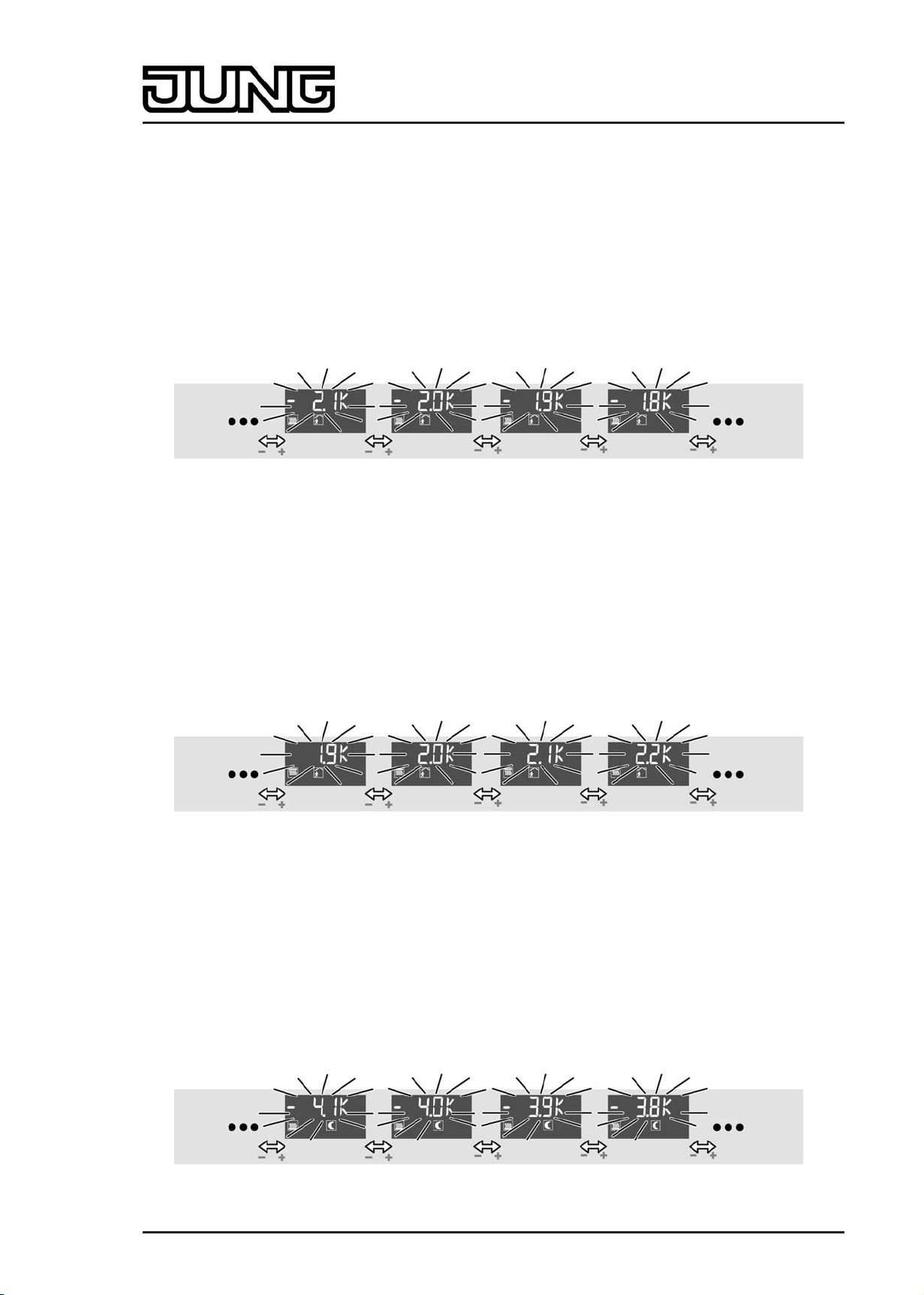

Setting the basic temperature ("Continuous controller" menu):

picture 10: Setting the basic temperature

The + and - buttons can be used to adjust the basic temperature in increments of +/- 1 K. The

symbols ó and ÿ light up in the display. The basic temperature is displayed flashing as an

absolute value in °C or °F (parameter-dependent).

The basic temperature designates the comfort setpoint temperatures for heating and cooling,

depending on the configured operating mode. With "Heating only" it sets the setpoint

Art.-No.: 4093 KRM TS D

Page 18 of 241

Page 19

Installation, electrical connection and operation

temperature for comfort heating directly. With "Cooling only", on the other hand, it sets the

setpoint temperature for comfort cooling. With "Heating and cooling" the basic setpoint sets the

setpoint temperature for heating directly or indirectly depending on the deadband position. The

setpoint temperature for cooling is then derived from this, taking the deadband into account.

(see chapter 4.2.4.2.5. Temperature setpoints)

The menu entry "Basic temperature" is visible as an option as a component of the "Continuous

controller" menu. The editing function can be disabled separately. This menu is not accessible

in controller extensions.

Setting the setpoint temperature "Lowering for standby mode, heating" ("Continuous controller"

menu):

picture 11: Setting the setpoint temperature "Lowering for standby mode, heating"

The + and - buttons can be used to adjust the temperature decrease for standby mode for

heating with an increment of +/- 0.1 K. The symbols ô and â light up in the display. The

temperature decrease is displayed flashing as a relative value in K.

The menu entry "Setpoint temperature lowering standby" is visible as an option as a component

of the "Continuous controller" menu. The editing function can be disabled separately. This menu

is not accessible in controller extensions.

Setting the setpoint temperature "Raising for standby mode, cooling" ("Continuous controller"

menu):

picture 12: Setting the setpoint temperature "Raising for standby mode, cooling"

The + and - buttons can be used to adjust the temperature increase for standby mode for

cooling with an increment of +/- 0.1 K. The symbols ô and è light up in the display. The

temperature increase is displayed flashing as a relative value in K.

The menu entry "Setpoint temperature raising standby" is visible as an option as a component

of the "Continuous controller" menu. The editing function can be disabled separately. This menu

is not accessible in controller extensions.

Setting the setpoint temperature "Lowering for night mode, heating" ("Continuous controller"

menu):

picture 13: Setting the setpoint temperature "Lowering for night mode, heating"

Art.-No.: 4093 KRM TS D

Page 19 of 241

Page 20

Installation, electrical connection and operation

The + and - buttons can be used to adjust the temperature decrease for night mode for heating

with an increment of +/- 0.1 K. The symbols õ and â light up in the display. The temperature

decrease is displayed flashing as a relative value in K.

The menu entry "Setpoint temperature lowering night" is visible as an option as a component of

the "Continuous controller" menu. The editing function can be disabled separately. This menu is

not accessible in controller extensions.

Setting the setpoint temperature "Raising for night mode, cooling" ("Continuous controller"

menu):

picture 14: Setting the setpoint temperature "Raising for night mode, cooling"

The + and - buttons can be used to adjust the temperature increase for night mode for cooling

with an increment of +/- 0.1 K. The symbols õ and è are illuminated in the display. The

temperature increase is displayed flashing as a relative value in K.

The menu entry "Setpoint temperature raising night" is visible as an option as a component of

the "Continuous controller" menu. The editing function can be disabled separately. This menu is

not accessible in controller extensions.

Setting presence mode ("Presence" menu):

picture 15: Setting presence mode

A "P" is shown in the display to indicate that the presence mode can be edited. The symbols

additionally shown in the display identify the active operating mode of the internal room

temperature controller. Depending on this, presence mode can be adjusted as follows using the

+ and - buttons...

"Comfort" operating mode active:

No setting of presence mode is possible. The ó symbol lights up statically.

"Standby" operating mode active:

The buttons + or - can be used to change over the operating mode between Comfort ó and

Standby ô. In each case, the symbols activated by the Presence operating mode flash.

"Night" operating mode active:

The buttons + or - can be used to change over the operating mode between Night õ and

Comfort extension óõ. In each case, the symbols activated by the Presence operating mode

flash.

"Frost/heat protection" operating mode active:

The buttons + or - can be used to change over the operating mode between Frost/heat

protection ö and Comfort extension óö. In each case, the symbols activated by the Presence

operating mode flash.

i The comfort extension cannot be activated using the presence function in the second

operating level if the frost/heat protection has been activated via the window status!

Art.-No.: 4093 KRM TS D

Page 20 of 241

Page 21

Installation, electrical connection and operation

i In the second operating level, presence mode and operating mode (see "Setting the

operating mode" below) may never be changed at the same time before a "save"

command. Otherwise the presence status is always reset, and thus the manual setting may

not be applied. If the controller operating mode and the presence mode have to be

changed, first the operating mode has to be changed and the setting has to be saved. Only

after that is it possible to change the presence mode and save this setting by calling up the

second operating level again.

The menu entry "Presence" is visible as an option. This menu is not accessible in controller

extensions.

Setting the setpoint shift ("Setpoint shift" menu):

picture 16: Setting the setpoint shift

The menu entry for setpoint shifting is indicated in the display by the bar scale "- - - - 0 - - - -".

The buttons + and - can be used to adjust the basic setpoint shift by up to 4 levels. Here the

shift is shown in the display as a relative numeric value in kelvin (K)

The increment of the shift depends on the ETS parameter "Increment of the 4-level setpoint

shift" in the parameter branch "Room temperature controller -> Controller general -> Setpoints".

i A setpoint shift cannot be saved when the second operating level is exited if the frost/heat

protection is activated in the controller! In this case the settings of the setpoint shift in the

second operating level are lost.

The menu entry "Setpoint shift" is visible as an option. This menu is not accessible in controller

extensions.

Setting the operating mode ("Operating mode" menu):

picture 17: Setting the operating mode

The buttons + and - can be used to adjust the controller operating mode. The symbol for the

active operating mode flashes in the display. The modes that can be set are "Comfort" ó,

"Standby" ô, "Night" õ and "Frost/heat protection" ö.

It should be noted that a set operating mode with a low priority cannot be activated immediately

when the second operating level is exited if an operating mode with a higher priority (e.g. frost

protection via window status) has been specified by the controller (see chapter 4.2.4.2.4.

Operating mode change-over). The operating mode set in the second operating level is only

accepted by the controller when the operating mode with a higher priority has been terminated

and in the meantime no other operating mode specification with a higher priority has been

performed (e.g. via operation of a pushbutton sensor or via communication objects).

The menu entry "Operating mode" is visible as an option. This menu is not accessible in

controller extensions.

Art.-No.: 4093 KRM TS D

Page 21 of 241

Page 22

Installation, electrical connection and operation

Fan control ("Fan levels" menu):

picture 18: Fan controller

The + and - buttons can be used to influence the fan operating mode (automatic / manual

mode). In manual mode it is possible to change over the fan level independently of the

controller command values (see chapter 4.2.4.2.8. Fan controller).

When the menu entry "Fan levels" is called up, the fan symbol in the display flashes, and

indicates the current fan level by means of the illuminated arc segments ( ì, í, î etc.). If no

arc segment is illuminated, the fan is switched off. The display also shows whether the fan

controller is in automatic or manual operation. In manual operation the Ü symbol is also

illuminated. The number of illuminated arc segments depends on the number of fan levels

configured.

i In fan control in the second operating level the fan level and automatic mode can be set

directly without taking into account the specific settings of the fan controller (Parameter

"Fan level on change-over to manual", the switch-on level or fan run-on times).

The menu item "Fan levels" is visible as an option, but only if the fan control is also enabled in

the controller for the ETS. This menu is not accessible in controller extensions.

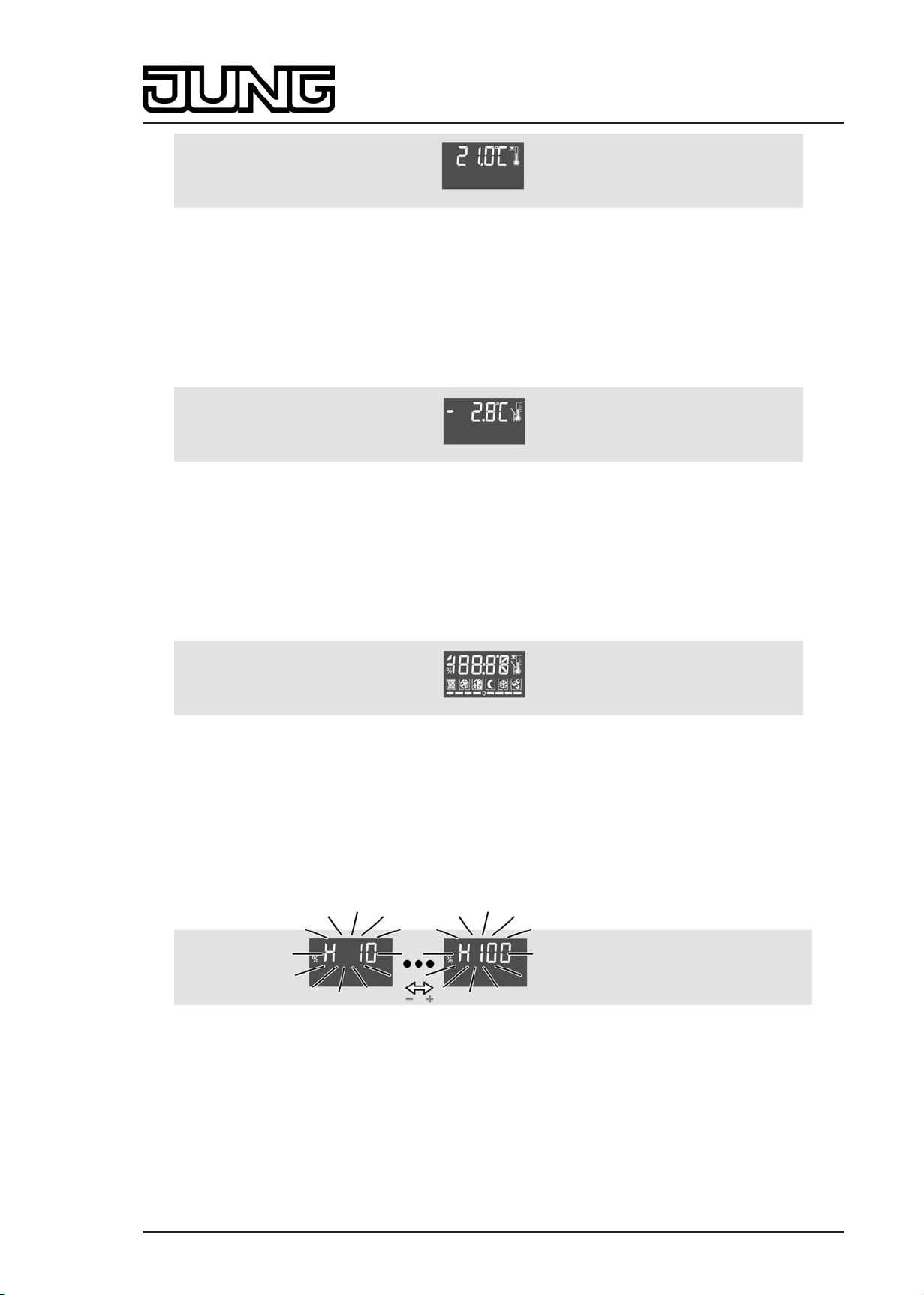

Indicating the time:

picture 19: Indicating the time

Only indication of the current time. No adjustment possibility.

The menu entry "Time" is visible as an option.

Indication of actual temperature:

picture 20: Indication of actual temperature

Only Indication of the current room temperature No adjustment possibility.

The menu entry "Actual temperature" is visible as an option.

Indication of setpoint temperature:

Art.-No.: 4093 KRM TS D

Page 22 of 241

Page 23

Installation, electrical connection and operation

picture 21: Indication of setpoint temperature

Only indication of the current setpoint temperature. No adjustment possibility.

The menu entry "Setpoint temperature" is visible as an option.

Indicating the outdoor temperature:

picture 22: Indicating the outdoor temperature

Only indication of the current outdoor temperature No adjustment possibility.

The menu entry "Outdoor temperature" is visible as an option.

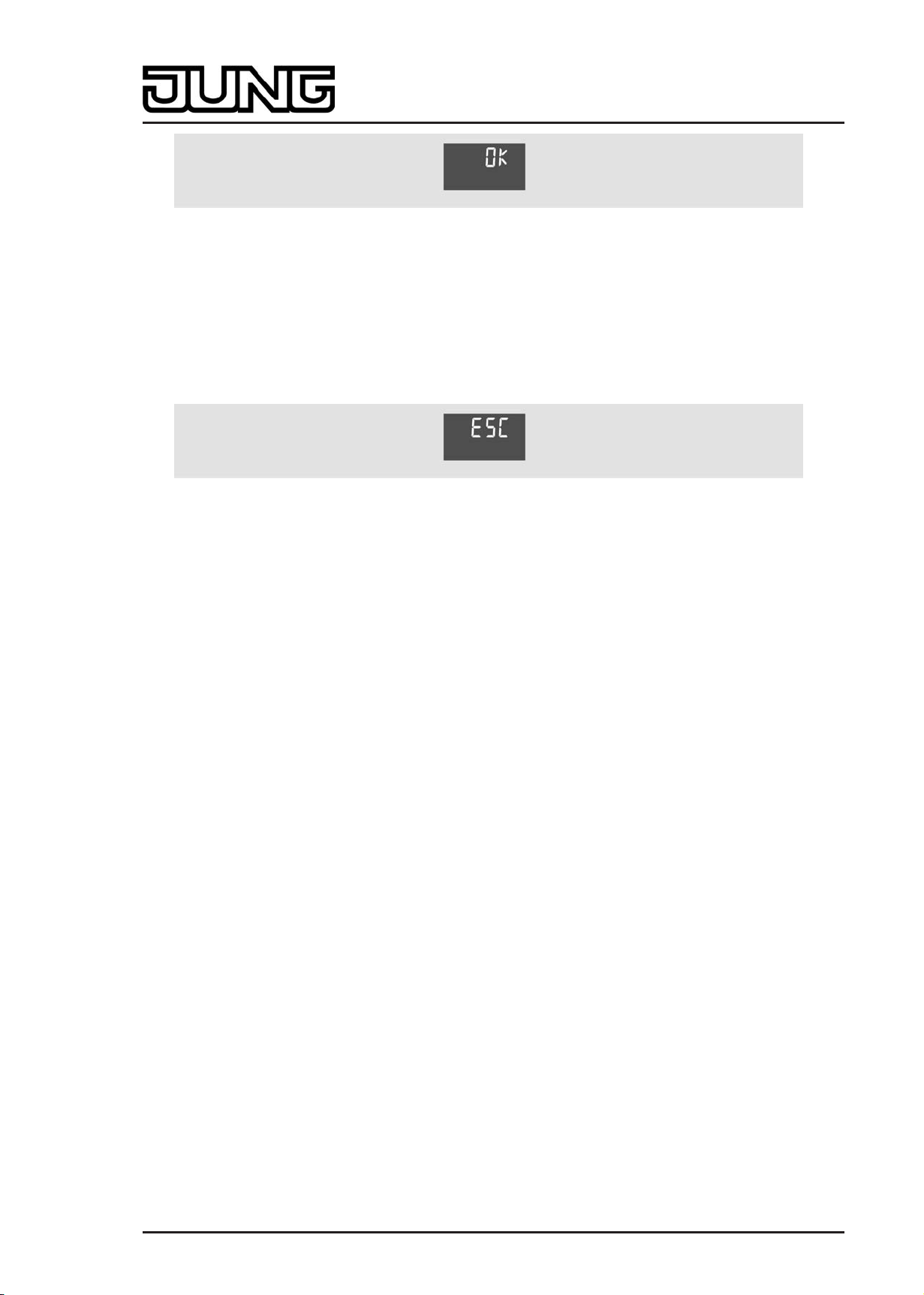

Setting the display contrast:

picture 23: Setting the display contrast

Illuminate all elements of the display. The buttons + and - can be used to adjust the display

contrast.

The menu item "Display contrast" is always visible.

Setting the display brightness:

picture 24: Setting the display brightness

"H" and the brightness value of the backlighting are displayed in the backlighting. The buttons +

and - can be used to adjust the brightness of the display in the range from 10 to 100%. For

additional notes about control of the backlighting, via the second operating level, please see the

chapter "Display control" (see page 165-166).

The menu item "Display brightness" is always visible.

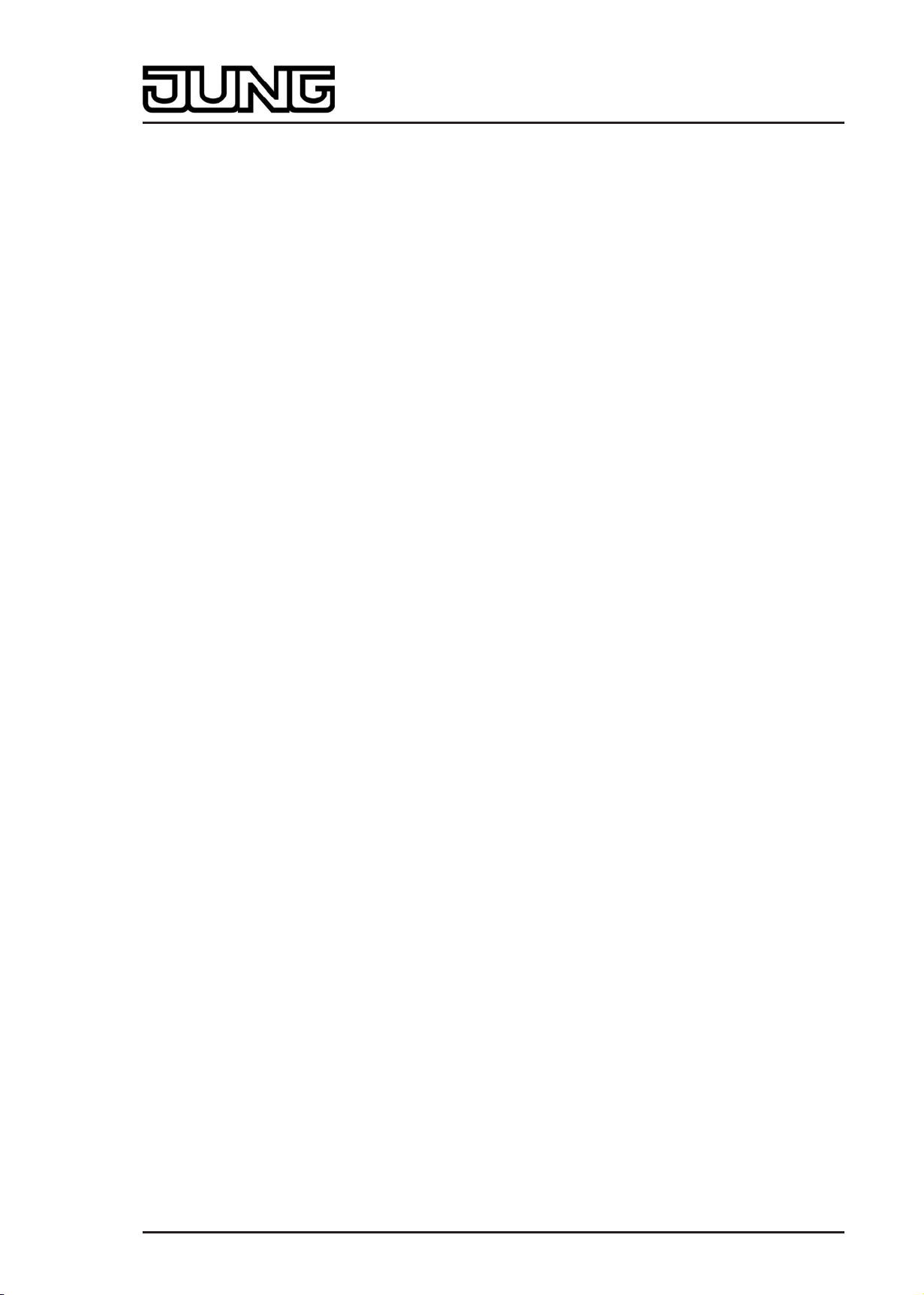

Exiting the second operating level by pressing Save:

Art.-No.: 4093 KRM TS D

Page 23 of 241

Page 24

Installation, electrical connection and operation

picture 25: Exiting the second operating level by pressing Save:

"OK" is displayed. The buttons + or - can be used to exit the second operating level with a

"save" command (see "Exiting the second operating level").

This option is always visible.

Exiting the second operating level without saving:

picture 26: Exiting the second operating level without saving

"ESC" is shown on the display. The buttons + or - can be used to exit the second operating level

without saving the settings (see "Exiting the second operating level").

This option is always visible.

i All menu entries are displayed or not depending on the configuration of the ETS. If, for

example, the controller is parameterised only for heating, no setpoints for cooling can be

displayed or set in the menu. When the device functions as a controller extension,

controller settings (setpoint temperatures, setpoint shifting, operating mode, fan control) are

fundamentally not accessible in the second operating level.

If an entry has been parameterised as the first menu item in the ETS that is not accessible

at all due to the other settings, the first possible entry is displayed according to the defined

menu sequence (see above).

i When a menu entry is shown on the display, the setting currently valid in the controller is

identified using the symbols or the display value, if the setting has not already been

changed previously in the second operating level. If the setting has already been changed

and not yet accepted validly (see "Exiting the second operating level"), the last manual

setting will be shown on the display, and not the real state of the controller.

Exiting the second operating level

Settings that have been made in the second operating level are only accepted validly in the

device when the operating level is exited with a "Save" command. It is possible to discard

settings by exiting the second operating level without a "Save" process. When exiting the

second operating level, a distinction is made among the following cases...

- Exiting by means of button combination: The second operating level is exited by pressing

buttons 1 and 3 on the device simultaneously (picture 8). Here the parameter "Save

changes after exiting with button combination?" defines whether the settings are saved or

not when the second operating level is exited using the button combination.

Art.-No.: 4093 KRM TS D

Page 24 of 241

Page 25

Installation, electrical connection and operation

- Automatic exiting: Automatic exiting of the second operating level can optionally be

configured in the ETS using the parameter of the same name in the parameter branch

"General -> Second operating level". In this case the device leaves the second operating

level when no additional operation takes place after the last push-button operation within

the "Time until automatic exit" configured in the ETS. With automatic exiting it is also

possible to define with the parameter "Save changes after automatic exiting?" whether the

settings are saved or not.

- Exiting with "OK": In the second operating level the menu item "OK" can be selected with

the n or o buttons. The buttons + or - can then be used to exit the second operating level.

All settings are always saved in this case!

- Exiting with "ESC": In the second operating level the menu item "ESC" can be selected

with the n or o buttons. The buttons + or - can then be used to exit the second operating

level. In this case the settings are not saved and are discarded!

Art.-No.: 4093 KRM TS D

Page 25 of 241

Page 26

Technical data

3 Technical data

General

Safety class III

Mark of approval KNX

Ambient temperature -5 ... +45 °C

Storage/transport temperature -25 ... +70 °C

KNX/EIB supply

KNX medium TP 1

Commissioning mode S mode

Rated voltage KNX DC 21 V ... 32 V SELV

Power consumption KNX typical 150 mW

Connection mode KNX Connection terminal

Art.-No.: 4093 KRM TS D

Page 26 of 241

Page 27

Software specification

4 Software description

4.1 Software specification

ETS search paths: - Heating, A/C, Ventilation / Valve / Room controller display

compact module

- Push-button / Push-button, general / Room controller display

compact module

BAU used: FZE 1066 + µC

KNX/EIB type class: 3b device with cert. Physical layer + stack

Configuration: S mode standard

PEI type: "00"

PEI connector: No connector

Application program:

No. Short description Name Version from mask

Hex

/ "0"

Dec

version

1 Multifunctional room temperature

controller / pushbutton sensor

application:

Up to 3 control surfaces on the

continuous controller module for the

pushbutton sensor function and for

operation of the integrated room

temperature controller. Can be

expanded to include 4 additional

control surfaces using an expansion

module.

Continuous

controller module

3gang 146A11

1.1

for ETS3.0d

onwards

705

Art.-No.: 4093 KRM TS D

Page 27 of 241

Page 28

Software "Continuous controller module 3gang 146A11"

Scope of functions

4.2 Software "Continuous controller module 3gang 146A11"

4.2.1 Scope of functions

General functions

- The operation LED can be permanently on or off or alternatively be switched via a

communication object.

- Internal clock to indicate the time on the device display. The time information is made

available to the device using a communication object (e.g. by a KNX/EIB timer switch).

Automatic time request possible after a device restart.

- LC display with switchable backlighting. On the display, icons signal various operating

states of the integrated room temperature controller or the controller extension. In addition,

up to four display functions (time, actual temperature, setpoint temperature, outdoor

temperature) can be shown on the display either alternating over time or controlled by

pressing a button.

- Integrated scene control. Internal storage of up to eight scenes with eight output channels,

recall of internal scenes by means of a presettable scene number, selection of object types

for the output channels; for each scene, the storage of the individual output values and the

transmission of the output values can be permitted or inhibited; the individual channels can

be delayed during scene recall; as scene extension, 64 scenes can be recalled and stored.

- The number of control surfaces can be expanded using a pushbutton sensor expansion

module.

Functions of the integrated pushbutton sensor

- Each control surface can either be used as a single rocker or as two independent buttons.

- For push-button function either double-surface or single-surface principle.

- Each rocker can be used for the functions 'switching', 'dimming', 'Venetian blind', '1 byte

value transmitter', '2-byte value transmitter', 'scene extension' and '2-channel operation'.

- Each button can be used for the functions 'switching', 'dimming', 'Venetian blind', '1 byte

value transmitter', '2-byte value transmitter', 'scene extension' and '2-channel operation',

'controller extension', 'fan controller', 'controller operating mode', 'setpoint shift', and

'change in the display reading'. The 'fan controller', 'controller operating mode' and 'setpoint

shift' functions are used to operate the integrated room temperature controller.

- 2-channel operating function: each rocker or each button can be set for controlling two

independent channels. This means that only one button-press is enough to transmit up to

two telegrams to the bus. The channels can be configured independently of one another for

the functions Switching, Value transmitter (1 byte) or Temperature value transmitter (2

bytes).

- For the rocker functions Dimming, Venetian blind (operation concept "Long – Short or

Short")' and 2-channel operation, full-surface rocker actuation can also be evaluated. With

full-surface rocker operation, switching telegrams and scene recall requests can be

triggered on the bus in addition to and independently of the configured rocker function.

- The switching function permits the following settings: reaction after pressing and/or

releasing, switch on, switch off, and toggle.

- The dimming function permits the following settings: times for short and long actuation,

dimming in different levels, telegram repetition on long press, transmission of stop telegram

after end of press.

- The shutter control permits the following settings: four different operation concepts with

times for short and long press and slat adjustment.

- The 1-byte and 2-byte value transmitter function permits the following settings: selection of

the value range (0 … 100 %, 0 … 255, 0 … 65535, 0 … 1500 lux, 0 … 40 °C), value on

button-press, value change on sustained button-press with different level sizes, optional

overflow on reaching the end of a value range.

- The controller extension function permits the following settings to operate an external room

temperature controller: operating mode change-over with normal and high priority, defined

selection of an operating mode, change between different operating modes, change of

presence status, setpoint shift.

Art.-No.: 4093 KRM TS D

Page 28 of 241

Page 29

Software "Continuous controller module 3gang 146A11"

Scope of functions

- Each control surface has two status LEDs (exception: display control surface). When a

status LED is internally connected with the rocker or the button, it can signal a button-press

or the current status of a communication object. The status indication can also be in

inverted form. When a status LED is not dependent on the rocker or button, it can be

permanently on or off, indicate the status of an independent communication object, the

operating state of a room temperature controller or the result of a comparison between

signed or unsigned 1 byte values.

- The rockers or buttons can be disabled via a 1-bit object. The following settings are

possible: polarity of the disabling object, behaviour at the beginning and at the end of

disabling. During an active disable, all or some of the rockers / buttons can have no

function, can perform the function of a selected button or execute one of two presettable

disabling functions.

- A delay to the automatically transmitted communication objects of the controller external

after a device reset can be configured. The delay time is automatically produced by the

subscriber address (physical address).

- All LEDs of the pushbutton sensor can flash simultaneously in the event of an alarm

message. The following settings are possible: Value of alarm message object for the states

alarm / no alarm, alarm acknowledge by pressing a button, transmission of the

acknowledge signal to other devices.

Functions of the integrated room temperature controller

- Various operating modes can be activated: Comfort, Standby, Night and Frost/heat

protection

- Each operating mode can be assigned its own temperature setpoints (for heating and/or

cooling).

- Comfort extension possible using presence button in Night or Frost/heat protection mode.

Configurable duration of the comfort extension.

- Operating mode change-over via 1-byte object according to KONNEX or using up to four

individual 1-bit objects.

- Frost/heat protection change-over via window status.

- Indication of room temperature controller information via the device display

- Function buttons to operate the controller (setpoint shift and second operating level, for

example to change the setpoint temperatures).

- Operating modes "Heating", "Cooling", "Heating and cooling" each with or without

additional level.

- Various control types can be configured for each heating or cooling level: PI feedback

control (permanent or switching PWM) or 2-point feedback control (switching).

- Control parameter for PI controller (if desired: proportional range, reset time) and 2-point

controller (hysteresis) adjustable.

- The temperature setpoints for the additional level are derived via a configurable level offset

from the values of the basic level.

- Automatic or object oriented change-over between "Heating" and "Cooling".

- Temporary setpoint shifting or permanent setpoint shifting through operation of the function

buttons on the device or via communication objects possible (e.g. using a controller

extension). Indication of the setpoint shift on the device display by means of a line graphic.

- Complete (1-byte) or partial (1-bit) status information configurable and transmissible on the

bus via objects.

- Deactivating the feedback control or the additional level possible using separate 1-bit

objects.

- Internal and external temperature sensor for room temperature measurement possible.

- Configurable internal to external determination of measured value and enabled external

sensor for room temperature measurement. Settable polling time of the external

temperature sensor.

- The room temperature measurement (actual value) can be adjusted separately for the

internal and external sensor using parameters.

- The actual and setpoint temperatures can be output on the bus if a configurable deviation

is detected (also periodically).

- Separate or shared command value output in heating and cooling mode. This produces

one or two command value objects for each level.

- Normal or inverted command value output configurable

- Automatic transmission and cycle time for command value output configurable

Art.-No.: 4093 KRM TS D

Page 29 of 241

Page 30

Software "Continuous controller module 3gang 146A11"

Scope of functions

- Floor temperature limit possible in heating mode. Thus temperature-controlled switch-off of

a floor heater as protective function.

- Setpoint temperature limit possible in cooling mode. If necessary, the controller limits the

setpoint temperature to specific values and prevents an adjustment beyond statutory limits.

Functions of the integrated controller extension

- Alternatively to the function of the room temperature controller, the extension mode can be

activated. This allows control of an external room temperature controller.

- Full control of the controller (operating modes, presence functions and setpoint shift).

- Full-featured indication of the controller status on the display of the extension (heating /

cooling reporting, setpoint shift, room temperature, setpoint temperature and current

operating mode).

- Room temperature measurement also possible on the extension.

Art.-No.: 4093 KRM TS D

Page 30 of 241

Page 31

Software "Continuous controller module 3gang 146A11"

Notes on software

4.2.2 Notes on software

ETS configuration and commissioning

For configuration and commissioning of the device, at least ETS3.0 from Version d Patch A

onwards is required. Advantages with regard to downloading (significantly shorter loading times)

and parameter programming using the integrated database plug-in can be expected only if this

ETS version or later versions are used.

The necessary product database is offered in the *.VD4 format. No product database is

available for ETS2 and older versions of ETS3.

Art.-No.: 4093 KRM TS D

Page 31 of 241

Page 32

Software "Continuous controller module 3gang 146A11"

4.2.3 Object table

Number of communication objects: 112

Number of addresses (max): 254

Number of assignments (max): 255

Dynamic table management Yes

Maximum table length 509

4.2.3.1 Object table, pushbutton sensor function section

Objects for rocker or push-button function (basic or module control surfaces)

Function: Switching

Object table

Object

0

h

Function

Switching

Name

T.rocker/T.button 1

1,2

Type

1-bit

DPT

1.xxx

Flag

C, W, T,

(R)

Description 1-bit object for the transmission of switching telegrams (ON, OFF).

Function: Dimming

Object

0

h

Function

Switching

Name

T.rocker/T.button 1

1,2

Type

1-bit

DPT

1.xxx

Flag

C, W, T,

(R)

Description 1-bit object for the transmission of switching telegrams (ON, OFF).

Function: Dimming

Object

18

h

Function

Dimming

Name

T.rocker/T.button 1

1,2

Type

4-bit

DPT

3.007

Flag

C, W, T,

(R)

Description 4-bit object for the transmission of relative dimming telegrams.

3

3

3

1: The number of rockers or buttons depends on the planned pushbutton sensor variant and the

pushbutton sensor expansion module. Mixed operation of rocker or push-button functions in a

pushbutton sensor is possible on the basic module and the expansion module.

2: The objects have been described for rocker 1 or button 1 as an example. The objects for the

rockers/buttons of the basic device and the module rockers/buttons are defined in the same way

by shifting the object number and changing the object name.

3: For reading, the R-flag must be set. The last value written to the object via the bus or by the

device will be read.

Art.-No.: 4093 KRM TS D

Page 32 of 241

Page 33

Function: Venetian blind

Software "Continuous controller module 3gang 146A11"

Object table

Object

0

h

Function

Short-time operation

Name

T.rocker/T.button 1

1,2

Type

1-bit

DPT

1.007

Flag

C, -, T, (R)

3

Description 1-bit object for the transmission of telegrams with which a Venetian blind or

shutter drive motor can be stopped or with which the blind slats can be

adjusted by short-time operation.

Function: Venetian blind

Object

18

h

Function

Long-time operation

Name

T.rocker/T.button 1

1,2

Type

1-bit

DPT

1.008

Flag

C, W, T,

3

(R)

Description 1-bit object for the transmission of telegrams with which a Venetian blind or

shutter drive motor can be can be moved upwards or downwards.

Function: 1-byte value transmitter

Object

0

h

Function

Value

Name

T.rocker/T.button 1

1,2

Type

1-byte

DPT

5.xxx

Flag

C, W, T,

3

(R)

Description 1-byte object for the transmission of values from 0 to 255 (corresponding to

values from 0 % to 100 %). If the adjustment of the value is enabled, the

object can transmit telegrams cyclically after a long press with which the value

can be reduced or increased by a presettable amount.

Function: 2-byte value transmitter

Object

0

h

Function

Value

Name

T.rocker/T.button 1

1,2

Type

2-byte

DPT

7.xxx

Flag

C, W, T,

3

(R)

Description 2-byte object for the transmission of values from 0 to 65535. If the adjustment

of the value is enabled, the object can transmit cyclical telegrams after a long

press with which the value can be reduced or increased by an adjustable

amount.

1: The number of rockers or buttons depends on the planned pushbutton sensor variant and the

pushbutton sensor expansion module. Mixed operation of rocker or push-button functions in a

pushbutton sensor is possible on the basic module and the expansion module.

2: The objects have been described for rocker 1 or button 1 as an example. The objects for the

rockers/buttons of the basic device and the module rockers/buttons are defined in the same way

by shifting the object number and changing the object name.

3: For reading, the R-flag must be set. The last value written to the object via the bus or by the

device will be read.

Art.-No.: 4093 KRM TS D

Page 33 of 241

Page 34

Software "Continuous controller module 3gang 146A11"

Function: 2-byte value transmitter

Object table

Object

0

h

Function

Temperature value

Name

T.rocker/T.button 1

1,2

Type

2-byte

DPT

9.001

Flag

C, W, T,

3

(R)

Description 2 -byte object for the transmission of a temperature value from 0 °C to 40 °C.

If the adjustment of the value is enabled, the object can transmit telegrams

cyclically after a long press with which the value can be reduced or increased

by 1 K.

Function: 2-byte value transmitter

Object

0

h

Function

Brightness value

Name

T.rocker/T.button 1

1,2

Type

2-byte

DPT

9.004

Flag

C, W, T,

3

(R)

Description 2-byte object for the transmission of a brightness level value from 0 to 1500

lux. If the adjustment of the value is enabled, the object can transmit cyclical

telegrams after a long press with which the value can be reduced or increased

by 50 lux.

Function: Scene extension

Object

0

h

Function

Scene extension

Name

T.rocker/T.button 1

1,2

Type

1-byte

DPT

18.001

Flag

C, -, T, (R)

3

Description 1-byte object for recalling or for storing one of 64 scenes max. from a scene

pushbutton sensor.

Function: 2-channel operation

Object

0

h

Function

Channel 1 switching

Name

T.rocker/T.button 1

1,2

Type

1-bit

DPT

1.xxx

Flag

C, W, T,

3

(R)

Description 1-bit object for the transmission of switching telegrams, if 2-channel operation

is activated.

Function: 2-channel operation

Object

0

h

Function

Channel 1 value

Name

T.rocker/T.button 1

1,2

Type

1-byte

DPT

5.xxx

Flag

C, -, T, (R)

3

Description 1-byte object for the transmission of value telegrams, if 2-channel operation is

activated.

1: The number of rockers or buttons depends on the planned pushbutton sensor variant and the

pushbutton sensor expansion module. Mixed operation of rocker or push-button functions in a

pushbutton sensor is possible on the basic module and the expansion module.

2: The objects have been described for rocker 1 or button 1 as an example. The objects for the

rockers/buttons of the basic device and the module rockers/buttons are defined in the same way

by shifting the object number and changing the object name.

3: For reading, the R-flag must be set. The last value written to the object via the bus or by the

device will be read.

Art.-No.: 4093 KRM TS D

Page 34 of 241

Page 35

Function: 2-channel operation

Software "Continuous controller module 3gang 146A11"

Object table

Object

0

h

Function

Channel 1 value

Name

T.rocker/T.button 1

1,2

Type

2-byte

DPT

9.001

Flag

C, -, T, (R)

3

Description 2-byte object for the transmission of value telegrams, if 2-channel operation is

activated.

Function: 2-channel operation

Object

18

h

Function

Channel 2 switching

Name

T.rocker/T.button 1

1,2

Type

1-bit

DPT

1.xxx

Flag

C, W, T,

3

(R)

Description 1-bit object for the transmission of switching telegrams, if 2-channel operation

is activated.

Function: 2-channel operation

Object

18

h

Function

Channel 2 value

Name

T.rocker/T.button 1

1,2

Type

1-byte

DPT

5.xxx

Flag

C, -, T, (R)

3

Description 1-byte object for the transmission of value telegrams, if 2-channel operation is

activated.

Function: 2-channel operation

Object

18

h

Function

Channel 2 value

Name

T.rocker/T.button 1

1,2

Type

2-byte

DPT

9.001

Flag

C, -, T, (R)

3

Description 2-byte object for the transmission of value telegrams, if 2-channel operation is

activated.

1: The number of rockers or buttons depends on the planned pushbutton sensor variant and the

pushbutton sensor expansion module. Mixed operation of rocker or push-button functions in a

pushbutton sensor is possible on the basic module and the expansion module.

2: The objects have been described for rocker 1 or button 1 as an example. The objects for the

rockers/buttons of the basic device and the module rockers/buttons are defined in the same way

by shifting the object number and changing the object name.

3: For reading, the R-flag must be set. The last value written to the object via the bus or by the

device will be read.

Art.-No.: 4093 KRM TS D

Page 35 of 241

Page 36

Software "Continuous controller module 3gang 146A11"

Object table

Objects for full-surface operation with rocker function (for dimming, Venetian blind and

2-channel operation)

Function: Full-surface operation

Object

1

h

Function

Switching

Name

T.rocker 1

full-surface

actuation

1,2

Type

1-bit

DPT

1.xxx

Flag

C, W, T,

3

(R)

Description 1-bit object for the transmission of switching telegrams (ON, OFF) for full-

surface operation of a sensor area.

Function: Full-surface operation

Object

1

h

Function

Scene extension

Name

T.rocker 1

full-surface

actuation

1,2

Type

1-byte

DPT

18.001

Flag

C, -, T, (R)

3

Description 1-byte object for recalling or for storing one of 64 scenes max. from a scene

pushbutton sensor for full-surface operation of a sensor area.

Objects for status LED

Function: Status LED in case of rocker function

Object

36

h

Function

Status LED top

Name

T.rocker 1

4,2

Type

1-bit

DPT

1.xxx

Flag

C, W, -, (R)

5

Description 1-bit object for activation of the status LED.

Function: Status LED in case of rocker function

Object

36

h

Function

Status LED top

Name

T.rocker 1

4,2

Type

1-byte

DPT

5.xxx,

6.xxx,

Flag