Page 1

es

Paperless Recorder

for secure acquisition

of FDA-compliant

measurement data

B 95.5011.4

Installation Instructions

11.04/00415650

Page 2

Menu structure of the paperless recorder

Page 3

Contents

1 Introduction 5

1.1 Preface .......................................................................................................... 5

1.2 Arrangement of the documentation ........................................................... 6

1.3 Typographical conventions ......................................................................... 8

2 Identifying the instrument version 9

2.1 Nameplate ..................................................................................................... 9

2.2 Type designation ........................................................................................ 10

2.3 Standard accessories ................................................................................ 11

2.4 Accessories ................................................................................................ 11

3 Installation 13

3.1 Location and climatic conditions .............................................................. 13

3.2 Mounting in position .................................................................................. 13

4 Electrical connection 15

4.1 Installation notes ........................................................................................ 15

4.2 Procedure .................................................................................................... 16

4.3 Connection diagram .................................................................................. 17

5 Function check 21

6 Device replacement / software update 23

7 Technical data 25

8Index 29

Page 4

Contents

Page 5

1.1 Preface

B

1 Introduction

Please read these Installation Instructions before commissioning the instrument. Keep the instructions in a place that is accessible to all users at all

times.

Please assist us to improve these installation instructions, where necessary.

Your suggestions will be appreciated.

If any problems should occur during commissioning, please do not

H

carry out any manipulations on the unit, as this could endanger

your rights under the instrument warranty!

Please contact the nearest subsidiary or the head office in such a

case.

E

When returning modules, assemblies and components, the regulations of EN 61340-5-1 and EN 61340-5-2 “Protection of electronic

devices from electrostatic phenomena” must be observed. Use

only the appropriate ESD packaging for transport.

Please note that we cannot accept any liability for damage caused

by ESD (electrostatic discharge).

5

Page 6

1 Introduction

1.2 Arrangement of the documentation

The documentation for this instrument is addressed to the equipment manufacturer (OEM) and users with appropriate technical expertise. It consists of

the following parts:

Sales documentation in PDF file format

White Paper The White Paper presents the company’s position with regard to the legislation

“21 CFR Part 11” of the American health authority FDA (Food and Drug Administration). With each section of the regulatory text, the user is given information on the fulfillment of the requirements.

Product

description

The product description illustrates the safety and operating concepts behind

the system, and the results that can be achieved by JUMO in the course of the

validation of an installation. It is intended to serve as an introduction to the

system, and not as a formal technical documentation.

Instrument documentation in printed form

B 95.5011.1 Operating Instructions

The operating instructions are an extract from the operating manual. They cover the basic operation of the paperless recorder.

B 95.5011.4 Installation Instructions

The installation instructions describe the installation of the paperless recorder

and the connection of the supply and signal cables. The instructions also contain a list of the technical data.

Instrument documentation in PDF file format

The “Instrument documentation in PDF file format” is on the CD that is included in the delivery.

B 95.5011.0 Operating Manual

It contains information about commissioning, operation and parameter setting

on the instrument as well as through the PC setup program (option).

B 95.5011.1 Operating Instructions

The operating instructions are an extract from the operating manual. They cover the basic operation of the paperless recorder.

6

Page 7

B 95.5011.2.0 Interface description (serial interfaces)

This provides information on the communication (RS232; RS422/RS485) with

supervisory systems.

Interface description (Ethernet interface)

This provides information on the connection of a paperless recorder to a company-internal network. The description is incorporated in the B 95.5011.2.0

B 95.5011.2.1 Interface description (LON interface)

This provides information on the connection and use of modules of the “JUMO

mTRON automation system”.

B 95.5011.2.3 Interface description (PROFIBUS-DP interface)

This provides information on the connection of a paperless recorder to a

PROFIBUS-DP system.

B 95.5011.4 Installation instructions

The installation instructions describe the installation of the paperless recorder

and the connection of the supply and signal cables. They also contain a list of

the technical data.

1 Introduction

T 95.5011 Data sheet

The data sheet contains general information, the order details and the technical data.

H

All documents are available on the Internet for downloading at

www.jumo.net

7

Page 8

1 Introduction

1.3 Typographical conventions

Warning signs

The signs for Danger and Caution are used in this manual under the following

conditions:

Danger

This symbol is used where there may be danger to personnel if the instruc-

V

A

E

tions are disregarded or not followed accurately!

Caution

This symbol is used where there may be damage to equipment or data if the

instructions are disregarded or not followed accurately!

Caution

This symbol is used where special precautions must be taken when handling

electrostatically sensitive components.

Note signs

H

v

1

abc

h

Note

This symbol is used to draw your special attention to a remark.

Reference

This sign refers to further information in other manuals, chapters or sections.

Footnote

Footnotes are comments that refer to specific parts of the text. Footnotes

consist of two parts: a marking in the text and the footnote text.

The marking in the text is arranged as continuous superscript numbers.

Action

This sign marks the description of a required action.

The individual steps are indicated by this asterisk, e. g.

h Press the

h Confirm with

h key

E

8

Page 9

2 Identifying the instrument version

2.1 Nameplate

Identification

Position The nameplate is affixed to the paperless recorder.

Contents It contains important information such as:

Description Designation on

nameplate

Instrument type Typ 955011/10-888,000-51-

Sales number VARTN 95/00342163

Production number F-Nr 0022969000003130006

Supply voltage AC 110 … 240V

Typ Please compare the type that was supplied with your order details. You can

identify the type by referring to Chapter 2.2 “Type designation”.

VARTN The sales number unambiguously designates the article in the catalog. It is

used for communication between the customer and the sales department.

F-Nr The production number indicates the production date (year/week). The figures

concerned are in position 12, 13, 14, 15.

Example:

F-Nr 0022969000003130006

This shows that the paperless recorder was manufactured in 2003, week 13.

Example

0032-0032-23,020

+10/-15%, 48…63Hz

Repeat order for a recorder in the identical version

When placing a repeat order for a paperless recorder of the same type, it is necessary to state “Typ”, “VARTN” and “F-Nr.” This is the only way an instrument

of the same type can be produced.

9

Page 10

2 Identifying the instrument version

2.2 Type designation

Paperless recorder for secure acquisition of FDA-compliant meas. data

(1) Basic version

955011/00 paperless recorder, no analog inputs

955011/01

paperless recorder, no analog inputs, incl. PC

software package and interface cable/adapter

955011/10 paperless recorder with 6 analog inputs

955011/20

paperless recorder with 6 analog inputs, incl. PC

software package and interface cable/adapter

955011/11 paperless recorder with 12 analog inputs

955011/21

x x 000 not assigned

x x x x 888 factory-set

x x x x 000 not assigned

x x 888 factory-set

x x x x x x 51 RS232C (standard)

x x x x x x 54 RS422/485

x x x x x x 66 RS232C and LON

x x x x x x 67 RS422/485 and LON

x x x x x x 68 RS232C and PROFIBUS-DP

x x x x x x 69 RS422/485 and PROFIBUS-DP

x x x x x x 0032 32MB backup memory

x x x x x x 0064 64MB backup memory

x x x x x x 0128 128MB backup memory

x x x x x x 0000 no external memory

x x x x x x 0032 32MB CompactFlash memory card

x x x x x x 0064 64MB CompactFlash memory card

x x x x x x 0128 128MB CompactFlash memory card

x x x x x x 23 110 — 240V AC +10/-15%, 48 — 63Hz

xxxxxx 25 20—30VAC/DC, 48—63Hz

x x x x x x 008 Ethernet connection

x x x x x x 020 lithium battery for memory buffering (ex-factory)

xxxxxx 021

x x x x x x 061 UL approval

x x x x x x 258 7 logic inputs, 1 open-collector output,

xxxxxx 350

x x x x x x 444 stainless steel front with membrane keys

Order code - , - - - - / ,...

Order example 955011/10 - 888 , 000 - 51 - 0032 - 0032 - 23 / 020

1. List extra codes in sequence, separated by commas.

2. The UL approval (061) only applies to the panel-mounting unit.

paperless recorder with 12 analog inputs incl. PC

software package and interface cable/adapter

(2) Inputs 1 — 6 (configurable)

(3) Inputs 7 — 12 (configurable)

(4) Interface

(5) Internal memory

(6) External memory

(7) Supply

(8) Extra codes

storage capacitor (instead of extra code 020)

4 relay outputs, voltage output 24V DC 50mA

universal carrying case TG-35

(1) (2) (3) (4) (5) (6) (7) (8)

2

1

10

Page 11

2 Identifying the instrument version

2.3 Standard accessories

- 1 Installation Instructions B 95.5011.4

- 1 Operating Instructions B 95.5011.1

- 2 mounting brackets

- 4 cable-tie with foot (can be released)

for strain relief of the sensor connection cables

- 1 CD with additional documentation

(see Chapter 1.2 “Arrangement of the documentation”)

2.4 Accessories

- PC software package consisting of:

setup program,

PC evaluation software (PCA3000),

PCA communications software (PCC),

PC Security Manager software (PCS) and

PC Audit Trail Manager software (PCAT).

- PC interface cable with TTL/RS232 converter and adapter,

for setup program, Sales No. 95/00350260

11

Page 12

2 Identifying the instrument version

12

Page 13

3.1 Location and climatic conditions

The location should be as free as possible from shock and vibration. Stray

electromagnetic fields from motors, transformers etc. should be avoided.

The ambient temperature at the location can be 0 to +45°C, at a relative humidity of ≤75%, no condensation.

v Chapter 4.1 “Installation notes”

3.2 Mounting in position

Outline

drawings

3 Installation

13

Page 14

3 Installation

Fitting into

the panel

Fitting in

position

min. 200

Panel

h Insert the paperless recorder from the front into the panel cut-out.

h From the back of the panel, hook the two mounting brackets into the

recesses on the sides of the housing. The flat sides of the brackets must be

against the housing.

h Place the mounting brackets against the rear of the panel and tighten

them evenly.

14

Page 15

4.1 Installation notes

k The choice of the cable, the installation and the electrical connection

must conform to the requirements of VDE 0100 “Regulations on the Installation of Power Circuits with nominal voltages below 1000V”, or the

appropriate local regulations.

k Work inside the instrument must only be carried out to the extent de-

scribed and, like the electrical connection, only by qualified personnel.

k If contact with live parts is possible while working on the instrument, it

must be isolated from the supply on both poles.

k The electromagnetic compatibility (EMC) conforms to the standards and

regulations listed under Technical Data.

v Chapter 7 “Technical data”

k Run the input, output and supply cables separately, and not parallel to

one another.

k All input and output cables without connection to the supply network

must be arranged as twisted and screened cables. Earth the screen on

the instrument side to the earth potential.

4 Electrical connection

k Earth the instrument at the PE terminal to the protective conductor. This

cable should have the same cross-section as the supply cable. Earthing

cables should be run in a star layout to a common earthing point which is

connected to the protective conductor of the supply. Do not loop the

earthing cable, i.e. do not run it from one instrument to another.

k Do not connect any additional loads to the supply terminals of the instru-

ment.

k The instrument is not suitable for use in hazardous areas.

k Inductive loads close to the instrument, such as contactors or solenoid

valves, should have RC modules fitted for interference suppression.

k The supply to the instrument must be provided with additional fusing.

Depending on the supply voltage, the following fuse values apply:

20 — 30V AC/DC, 48 — 63Hz : fuse 2A slow

110 — 240V AC +10/-15%, 48 — 63Hz : fuse 1A slow

A type-G miniature cartridge fuse marked F1 is built into the instrument

itself:

20 — 30V AC/DC, 48 — 63Hz : fuse 1.6A slow

110 — 240V AC +10/-15%, 48 — 63Hz : fuse 0.63A slow

15

Page 16

4 Electrical connection

4.2 Procedure

h Carry out electrical connection as per Chapter 4.3 “Connection diagram”.

h Screw back panel cover on (spacer bolt first)

h If necessary, use cable-ties for strain relief of connecting cables.

16

Page 17

4 Electrical connection

4.3 Connection diagram

The electrical connection must only be carried out

by qualified personnel.

V

Back panel Rear view with pluggable screw terminals

(L-)

(L+)

Cover for

back panel

Hole for lead sealing

Holes provided for the

cable-ties supplied,

for strain relief of the

connection cables

17

Page 18

4 Electrical connection

Terminal assignment

Supply Supply voltage

as per data sheet

Analog

Thermocouple 1 to 12

inputs

Resistance thermometer

in 2-wire circuit

Resistance thermometer

in 3-wire circuit

Resistance thermometer

in 4-wire circuit

Resistance transmitter 1 to 12

Connector

L1(L+)

N (L-)

PE

1 to 12

1 to 12

1 to 12

Connection diagram

21 345

R

R

A

21 345

21 345

L

R=R

AL

Potentiometer in 2-wire circuit 1 to 12

Potentiometer in 3-wire circuit 1 to 12

Potentiometer in 4-wire circuit 1 to 12

Voltage input ≤ 200mV 1 to 12

Voltage input > 200mV 1 to 12

Current input 1 to 12

Interfaces RS232C 9-pole SUB-D socket

2 RxD receive data

3 TxD transmit data

5 GND ground

20

21 345

R

A

21 345

21 345

1

2

3

4

5

R

R=R

6

7

8

9

L

AL

18

Page 19

4 Electrical connection

Terminal assignment

Interfaces RS422 9-pole SUB-D socket

(extra code)

3 TxD+ transmit data +

4 RxD+receive data +

5 GND ground

8 TxD- transmit data 9 RxD- receive data -

RS485 9-pole SUB-D socket

(extra code)

3 TxD+/RxD+ transmit/receive data +

5 GND ground

8 TxD-/RxD- transmit/receive data -

LON 9-pole SUB-D socket

(extra code)

3Net_A

9Net_B

PROFIBUS-DP 9-pole SUB-D socket

(extra code)

3 RxD/TxD-P B-cable

receive/transmit data-Plus

5 DGND data transmission potential

6 VP supply voltage-Plus

8 RxD/TxD-N A-cable

receive/transmit data-N

Connector

20

20

21

21

Connection diagram

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

1

2

3

4

5

6

7

8

9

6

7

8

9

6

7

8

9

6

7

8

9

Relay

outputs

Ethernet RJ45 socket

22

(extra code)

1 TX+ transmit data +

2 TX- transmit data 3 RX+ receive data +

6 RX- receive data -

Setup interface

23

The recorder also has a setup interface

on the front panel (wired in parallel).

Do not use both at the same time.

Relay K1

(changeover, 3A, 230V AC)

1

Relay K2 to K5

(make/break contact, 3A, 230V AC)

1

30

31

(extra code)

1. with resistive load.

SELV circuits and supply circuits must not be combined.

K2

8

1

21

3

K4

65

87

K5

21

43

K3

19

Page 20

4 Electrical connection

Terminal assignment

Digital I/O Open-collector output

(25V max., 100mA max.)

(extra code)

3 ground

4 collector

Logic inputs, voltage-operated

(extra code)

LOW = -3 to +5V DC

HIGH = 12 to 30V DC

1 +24V/50mA

auxiliary supply not stabilized

2GND

5 Logic input 7

6 Logic input 6

7 Logic input 5

8 Logic input 4

9 Logic input 3

10 Logic input 2

11 Logic input 1

Connector

32

32

Connection diagram

2345678910111

+

–

Example:

input 4 (terminal 8)

contact-operated

Input Terminal

111

210

39

48

57

66

75

20

Page 21

Start screen

5 Function check

When the paperless recorder is installed and connected, it can be started up.

After the supply voltage has been connected or switched on, the start screen

will appear briefly.

Visualization

level

Further steps

After the end of the initialization phase, the visualization level is automatically

started.

The recorder is now in recording mode.

The instrument can be configured by an authorized person, either

A

from the instrument keys or by using the setup program. Additional

information about the configuration can be found in the Operating

Manual B 95.5011.0.

Afterwards, please check again that connection, configuration and

operational mode are correct.

21

Page 22

5 Function check

22

Page 23

6 Device replacement / software update

If you need to replace the device or update the software, this chapter will help

you back up and restore all necessary settings and parameters.

h Fill in this page before replacing the device.

Proof of

service

Activity

1. Save measurement data to CF card or through the PCC software.

2. Save configuration data (setup) to CF card or through the setup software.

3. If used, save reports to CF card.

Please note: reports cannot be terminated through the PC software.

4. If used, read out counter values with the setup software and write them down.

Counter 1 : ________________________________________________

Counter 2 : ________________________________________________

Ext. counter 1 : ________________________________________________

Ext. counter 2 : ________________________________________________

Order number : _______________________________________________

Date : _______________________________________________

Device designation : _______________________________________________

Production number : _______________________________________________

done

yes no

5. Read off IP address, Subnet-Mask and Gateway on the device or through

the setup software and write them down.

IP address : _________ . ________ . _______ .__________

Subnet-Mask : _________ . ________ . _______ .__________

Gateway : _________ . ________ . _______ .__________

6. Read off values for fine calibration for all analog inputs on the device

and write them down.

Start act. / Start targ./ End act. / End targ.

Analog input 1 : _________ / ________ / _______ /__________

Analog input 2 : _________ / ________ / _______ /__________

Analog input 3 : _________ / ________ / _______ /__________

Analog input 4 : _________ / ________ / _______ /__________

Analog input 5 : _________ / ________ / _______ /__________

Analog input 6 : _________ / ________ / _______ /__________

Analog input 7 : _________ / ________ / _______ /__________

Analog input 8 : _________ / ________ / _______ /__________

Analog input 9 : _________ / ________ / _______ /__________

Analog input 10 : _________ / ________ / _______ /__________

Analog input 11 : _________ / ________ / _______ /__________

Analog input 12 : _________ / ________ / _______ /__________

23

Page 24

6 Device replacement / software update

Info After uploading the user list, the users must log in with the password that was

initially assigned by the administrator.

If a user no longer knows the password, then the user status has to be set to

“New” and a new password assigned through the PCS software.

After altering the device software (update), the process data are stored in a

new PCA3000 archive.

Notes

24

Page 25

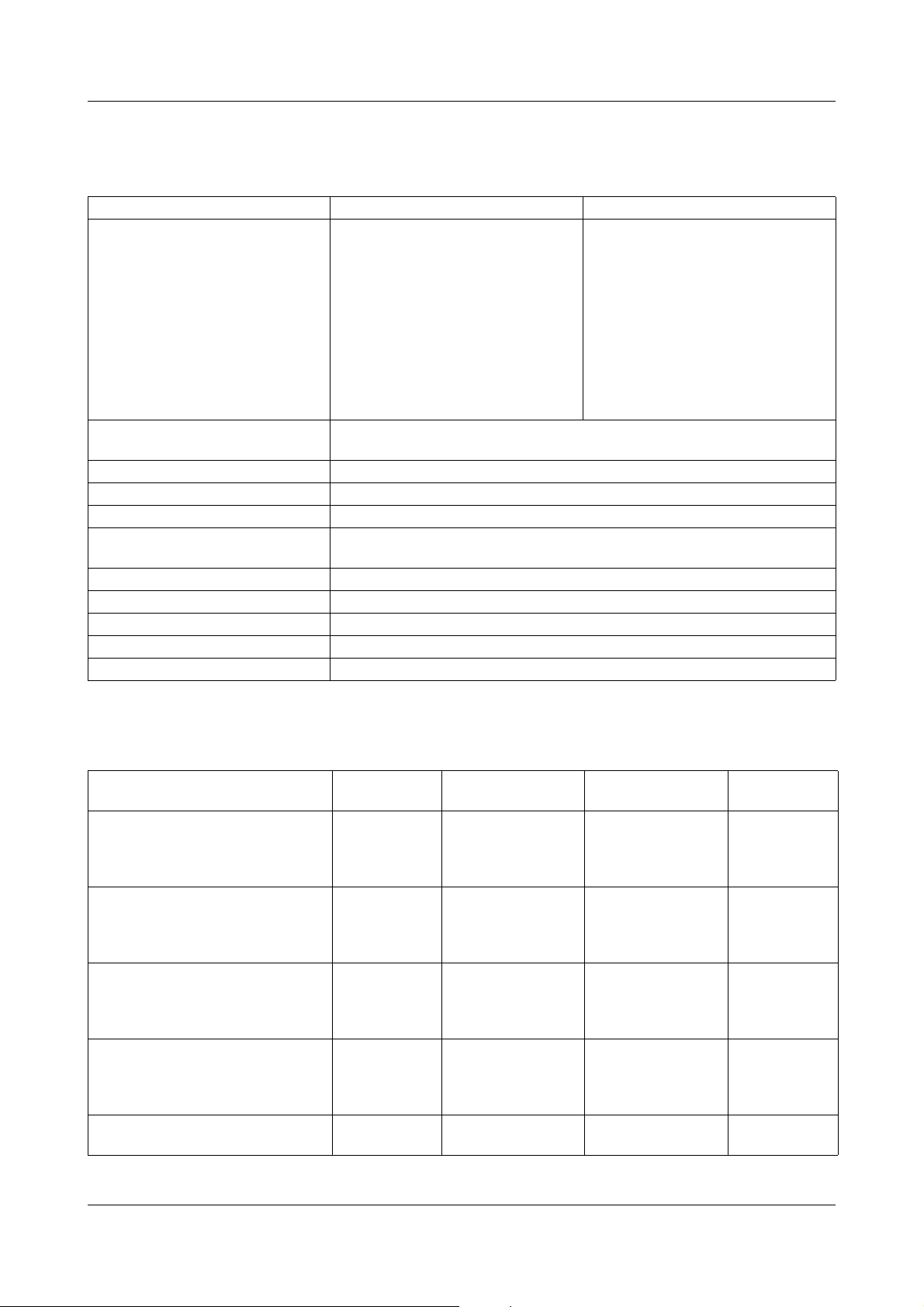

7 Technical data

Analog inputs (channels 1 — 12)

Thermocouple

Designation Type Standard Range Linearization accuracy

Fe-Con L DIN 43 710

Fe-Con J EN 60 584

Cu-Con U DIN 43 710

Cu-Con T EN 60 584

NiCr-Ni K EN 60 584

NiCr-Con E EN 60 584

NiCrSi-NiSi N EN 60 584

Pt10Rh-Pt S EN 60 584

Pt13Rh-Pt R EN 60 584

Pt30Rh-Pt6Rh B EN 60 584

Chromel-Copel

Shortest span L, J, U, T, K, E, N, Chromel-Copel:

Range start/end freely programmable within the limits in 0.1°C steps

Cold junction Pt100 internal or thermostat external constant

Cold junction accuracy (internal) ± 1°C

Cold junction temperature

(external)

Sampling cycle 6 or 12 channels 125msec

Input filter 2nd order digital filter; filter constant adjustable from 0 to 10.0sec

Test voltage 500V (across optocoupler)

Resolution >14 bit

Features also programmable in °F

1.The linearization accuracy refers to the maximum span.

The linearization accuracy is reduced for shorter spans.

-200 to +900°C

-210 to +1200°C

-200 to +600°C

-270 to +400°C

-270 to +1372°C

-270 to +1000°C

-270 to +1300°C

-50 to +1768°C

-50 to +1768°C

0 to 1820°C

-200 to +800°C

S, R, B:

-50 to +100°C adjustable through setup software

±0.1%

±0.1% above -100°C

±0.1% above -150°C

±0.15% above -150°C

±0.1% above -80°C

±0.1% above -80°C

±0.1% above -80°C

±0.15% above 0°C

±0.15% above 0°C

±0.15% above 400°C

±0.15%

100°C

500°C

1

Resistance thermometer

Designation Standard Connection Range Linearization

accuracy

Pt 100 EN 60 751 2/3-wire

2/3-wire

4-wire

4-wire

Pt 100 JIS 2/3-wire

2/3-wire

4-wire

4-wire

Pt 500 EN 60 751 2/3-wire

2/3-wire

4-wire

4-wire

Pt 1000 EN 60 751 2/3-wire

2/3-wire

4-wire

4-wire

Ni 100 EN 60 751 2/3-wire

4-wire

-200 to +500°C

-200 to +850°C

-200 to +500°C

-200 to +850°C

-200 to +500°C

-200 to +650°C

-200 to +500°C

-200 to +650°C

-200 to +500°C

-200 to +850°C

-200 to +500°C

-200 to +850°C

-200 to +500°C

-200 to +850°C

-200 to +500°C

-200 to +850°C

-60 to +180°C

-60 to +180°C

±0.4°C

±0.8°C

±0.4°C

±0.5°C

±0.4°C

±0.8°C

±0.4°C

±0.5°C

±0.4°C

±0.8°C

±0.4°C

±0.5°C

±0.4°C

±0.8°C

±0.4°C

±0.5°C

±0.4°C

±0.4°C

Measuring

current

500µA

250µA

500µA

250µA

500µA

250µA

500µA

250µA

250µA

250µA

250µA

250µA

500µA

250µA

500µA

250µA

500µA

500µA

25

Page 26

7 Technical data

Designation Standard Connection Range Linearization

accuracy

Cu 50 2/3-wire

2/3-wire

4-wire

4-wire

Connection type 2-, 3- or 4-wire circuit

Shortest span 15°C

Sensor lead resistance max. 30Ω per core for 3-/4-wire circuit

Range start/end freely programmable within the limits in 0.1°C steps

Sampling cycle 6 or 12 channels 125msec

Input filter 2nd order digital filter; filter constant adjustable from 0 to 10sec

Test voltage 500V (across optocoupler)

Resolution > 14bit

Features also programmable in °F

-50 to +100°C

-50 to +200°C

-50 to +100°C

-50 to +200°C

max. 10Ω per core for 2-wire circuit

±0.5°C

±0.9°C

±0.5°C

±0.6°C

Measuring

current

500µA

250µA

500µA

250µA

Resistance transmitter and potentiometer

Range Accuracy Measuring current

up to 180Ω

up to 390Ω

up to 2000Ω

up to 4000Ω

Connection type resistance transmitter: 3-wire circuit

Shortest span 6Ω

Sensor lead resistance max. 30Ω per core for 4-wire circuit

Resistance values freely programmable within the limits in 0.1 Ω steps

Sampling cycle 6 or 12 channels 125msec

Input filter 2nd order digital filter;

±150mΩ

±300mΩ

±2Ω

±4Ω

500µA

250µA

500µA

250µA

potentiometer: 2-/3-wire circuit

max. 20Ω per core for 2- and 3-wire circuit

up to 200 Ω range: max. 10 Ω per core for 2- and

3-wire circuit

filter constant adjustable from 0 to 10.0sec

Input for DC voltage, DC current

Basic range Accuracy Input resistance

-20 to +70mV

-5 to +105mV

-10 to +210mV

-0.5 to +12V

-0.05 to +1.2V

-1.2 to +1.2V

-12 to +12V

Shortest span 5mV

Range start/end freely programmable within the limits

-2 to +22mA

-22 to +22mA

Shortest span 0.5mA

±80µV

±100µV

±240µV

±6mV

±1mV

±2mV

±12mV

(up to 999mV in 0.01 mV steps, above 1V in 1 mV steps)

±20µA

±44µA

≥ 1 MΩ

R

IN

≥ 1 MΩ

R

IN

≥ 1 MΩ

R

IN

≥ 470 kΩ

R

IN

≥ 470 kΩ

R

IN

≥ 470 kΩ

R

IN

≥ 470 kΩ

R

IN

burden voltage ≤ 1V

burden voltage ≤ 1V

26

Page 27

7 Technical data

Range start/end freely programmable within the limits in 0.1 mA steps

Sampling cycle 6 or 12 channels 125msec

Input filter 2nd order digital filter; filter constant adjustable from 0 to 10.0sec

Feature adjustable linearizations for thermocouples and resistance thermometers

(for connection of transmitters without linearization)

Transducer short-circuit/break

Short-circuit

Thermocouple not detected detected

Resistance thermometer detected detected

Resistance transmitter detected detected

Potentiometer not detected detected

Voltage up to ± 1V not detected detected

Voltage > ± 1V not detected not detected

Current not detected not detected

1. programmable reaction of instrument, e.g. triggering alarm

1

Logic inputs (extra code)

Break

1

Number 7 to DIN VDE 0411, Part 500;

max. 25Hz, max. 32V

Level logic “0“: -3 to +5V,

logic “1”: 12 to 30V

Sampling cycle minimum 1sec

Outputs

1 relay (ex-factory) changeover, 3A, 230V AC

4 relays (extra code) make/break, 3A, 230V AC

1 open-collector output

(extra code)

1 voltage output

(extra code)

1. with resistive load. SELV circuits and supply circuits must not be combined.

max. 25V, max. 100mA

24V DC, 50mA

1

1

External analog inputs / logic inputs / logic outputs

Type JUMO mTRON automation system

Sampling cycle 1sec

Technical data see Data Sheet:

70.4015 Relay module

70.4020 Analog input module

70.4030 Logic module

Configuration Project design software iTOOL (70.4090)

27

Page 28

7 Technical data

Screen

Resolution 320 x 240 pixels

Size 5.7"

Number of colors 27 colors

Electrical data

Supply

(switch-mode power supply)

Electrical safety

Test voltages (type test)

- mains supply circuit to

measuring circuit

- mains supply circuit to housing

(protective conductor)

- measuring circuits to

measuring circuit and housing

- electrical isolation between

the analog inputs

Supply voltage error < 0.1% of range span

Power consumption approx. 25VA

Electrical connection at rear by plug-in screw terminals,

max. conductor cross-section 2.5mm

110 — 240V AC +10/-15%, 48 — 63Hz or

20 — 30 V AC/DC, 48 — 63Hz

to EN 61 010, Part 1 of August 2002

overvoltage category II, pollution degree 2

with AC supply: 3.7kV/50Hz, 1min,

with AC/DC supply: 510V/50Hz, 1min

with AC supply: 2.3kV/50Hz, 1min,

with AC/DC supply: 510V/50Hz, 1min

510V/50Hz, 1min

up to 30V AC and 50V DC

2

or 2x 1.5mm2 with ferrules

Environmental influences

Ambient temperature range 0 to +45°C

Ambient temperature error 0.03% per °C

Storage temperature range -20 to +60°C

Climatic conditions ≤ 75% rel. humidity, no condensation

EMC

- interference emission

- immunity to interference

to industrial requirements

EN 61 326

Class A

Housing

Housing front zinc die-casting or stainless steel

Housing type panel-mounting housing to DIN 43 700,

galvanized steel sheet

Bezel size 200mm x 144mm

Depth behind panel 233mm

Panel cut-out 138

Housing fixing in panel to DIN 43 834

Operating position unrestricted, taking into account the viewing angle of the screen,

Protection to EN 60 529 Category 2,

front IP54 (IP65 with extra code stainless steel front),

Weight approx. 3.5kg

28

+1.0

mm x 138

horizontal ±50°,

vertical ±30°

rear IP20

+1.0

mm

Page 29

A

Accessories 11

Analog inputs 18

B

Back panel 17

C

Climatic conditions 13

Commissioning 5

Connection diagram 17

Cover for back panel 17

D

Digital I/O 20

Documentation, arrangement of 6

8 Index

E

Electrical connection 15

Electrostatic discharge (ESD) 5

F

Fitting into the panel 14

Function check 21

I

Identification of namplate 9

Installation 13

Installation notes 15

Instrument documentation in PDF file format 6

Instrument documentation in printed form 6

Instrument version, identification of 9

Interfaces 18–19

Introduction 5

L

Location 13

M

Mounting in position 13

29

Page 30

8 Index

N

Nameplate 9

Note signs 8

O

Outline drawings 13

P

PROFIBUS-DP 10, 19

R

Rear view 17

Relay outputs 19

Repeat order for recorder in the identical version 9

Returning 5

S

Sales documentation in printed form 6

Standard accessories 11

Start screen 21

Supply 18

T

Technical data 25

Type designation 10

Typographical conventions 8

V

Visualization level 21

W

Warning signs 8

Warranty 5

30

Page 31

Page 32

JUMO GmbH & Co. KG

Street address:

Moltkestraße 13 - 31

36039 Fulda, Germany

Delivery address:

Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

e-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2TT, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

e-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO PROCESS CONTROL INC.

885 Fox Chase, Suite 103

Coatesville, PA 19320, USA

Phone: 610-380-8002

1-800-554-JUMO

Fax: 610-380-8009

e-mail:

Internet: www.JumoUSA.com

info@JumoUSA.com

Loading...

Loading...