Page 1

Inductive

conductivity transmitter

in stainless steel housing

JUMO CTI-750

Type 202756

B 20.2756.0.1

Operating manual

11.07/00488788

Page 2

Page 3

Contents

1 Typographical conventions ...................................................... 8

1.1 Warning signs ..............................................................................................8

1.2 Attention-drawing signs ...............................................................................8

2 General ....................................................................................... 9

2.1 Foreword ......................................................................................................9

2.2 Structure of the JUMO CTI-750..................................................................10

3 Inductive conductivity measurement .................................... 11

3.1 Field of application .....................................................................................11

3.2 Function .....................................................................................................12

4 Identifying the device ............................................................. 13

4.1 Type nameplate .........................................................................................13

4.2 Type declaration ........................................................................................14

4.3 JUMO CTI-750 as "Head transmitter" ........................................................14

4.4 JUMO CTI-750 as "Transmitter with separate sensor" .............................15

5 Device description .................................................................. 17

5.1 Technical data, transmitter ......................................................................17

6 Assembly .................................................................................. 21

6.1 General ...................................................................................................... 21

6.2 Dimensions / Process connections, head transmitter ...............................22

6.3 JUMO CTI-750 with separate sensor ........................................................24

6.4 Assembly examples ...................................................................................28

7 Installation ............................................................................... 30

7.1 General ......................................................................................................31

8 Setup program ........................................................................ 34

8.1 Function .....................................................................................................34

9 Commissioning ....................................................................... 35

9.1 Head transmitter or transmitter with separate sensor ...............................35

9.2 Replacement sensor ..................................................................................35

Page 4

Contents

10 Operation ................................................................................. 36

10.1 Operating elements ....................................................................................36

10.2 Principle of operation .................................................................................38

10.3 Principle .....................................................................................................40

10.4 Measurement mode ...................................................................................41

10.5 Operator level .............................................................................................41

10.6 Administrator level .....................................................................................49

10.7 Calibration level ..........................................................................................51

10.8 The desalination function ...........................................................................52

11 Calibrating ............................................................................... 56

11.1 General ...................................................................................................... 56

11.2 Calibration of the relative cell constant ......................................................56

11.3 Calibration of the temperature coefficient of the measurement solution ...57

12 Maintenance ............................................................................ 65

12.1 Cleaning the conductivity sensor ...............................................................65

13 Rectifying errors and faults ................................................... 66

13.1 Device inspection .......................................................................................66

14 Annex ....................................................................................... 72

14.1 Before configuring .................................................................................. 72

Page 5

5

A

A/D-converter 17

Sediments 11, 65

Desalination reduction 53

DESALINATION FUNCTION 48

Desalination function 48, 52, 74

Desalination function: Start 48

Desalination function: Stop 48

Desalination 11

Desalination valve 52

REDUCTION 48

Reduction 74

DISTANCE 47

Distance 74

Alarm window 47

Analog output in case of "Alarm" 18–19

Connection 34

Connection layout of the transmitter 33

Weld-on threaded connector28

Display 17

OUTPUT BINARY 46

Output binary 74

OUTPUT CONDUCTIVITY 44

Output conductivity 72

OUTPUT TEMPERATURE 45

Output temperature 73

Outputs 33

Output signal 18

Output signal, temperature 19

SWITCHOFF DELAY 48

Switchoff delay 74

B

Operating in levels 40

Operation principle 38

IN CASE OF ALARM 44–45

In case of alarm 73

IN CASE OF ALARM / CALIB. 47

in case of alarm / at the time of calibration 74

IN CASE OF HOLD 47

in case of Hold 74

IN CASE OF CALIBRATION 44, 46

In case of calibration 73, 74

LIGHTING 49

Lighting 75

Calculation of a temperature coefficient 60

REFERENCE TEMPERATURE 42

Reference temperature 72

Binary inputs 33

Biocide 52

Burden 18–19

C

CIP 11

CIP-Process 11

D

DOSING TIME 48

Dosing time 74

Pressure 20

E

Levels of the Administrator level 50

MOUNTING FACTOR 43

Mounting factor 21, 72

Installation position 21

Installation variants 22

INPUT BINARY 48

input binary 74

INPUT CONDUCTIVITY 42

Input conductivity 72

INPUT TEMPERATURE 45

Input temperature 73

UNIT 45

Unit 73

SWITCH-OFF DELAY48

Switch-off delay 74

Setting parameters 48

Electrical connection 17, 30

Electromagnetic compatibility 30

Removing the pigmenting 32

Determining the TC-curve 60

explosion-endangered areas 30

F

Error possibilities 66

FILTERING TIME 43, 45

Filtering time 72, 73

FUNCTION 46, 48

Function 20, 74

G

galvanic separation 34

Housing 17

Accuracy 19–20

DEVICE DATA 49

Device data 75

Weight 17

LIMITING VALUE 47

Limiting value 74

H

MANUAL OPERATION 44, 46–47

Page 6

6

Manual operation 73–74

MANUAL VALUE 44, 46

Manual value 73–74

Date of manufacture 13

Attention-drawing signs 8

Hold function 48

HYSTERESIS 47

K

CALIBR.-INTERVAL 43

Calibration interval 72

Calibration timer 18

Characteristic 19

Compensation range 19

Configurable parameters 34

Configuring 72

CONTRAST 49

Contrast 75

CONCENTR. RANGE43

CONCENTR. MEASUREMENT 43

Concentration measurement 18, 72

L

LCD INVERSE 49

LCD inverse 75

Limit comparator 46

Solvent 65

M

MANUAL SPECIFICATION 45

Manual specification 73

Material 20

MEASUREMENT RANGE 42

Measurement range 72

MEASUREMENT RANGE 1 42

Measurement range, sensor 20

Measurement range / Temperature coefficient

switching

48

Transmitter head 24

Measurement process 11

MEASUREMENT VALUE ACQUISITION 45

Measurement value acquisition 73

Installation location 21

N

natural 20

natural water 20

non-linear temperature coefficient 60

O

OFFSET 43, 45

Offset 72–73

P

Parameters, configurable 34

Password 49

Polarization 11

PULSE DURATION 48

Pulse duration 74

R

Reference fluid 70

Reference measuring instrument 71

Reference temperature 19

REL. CELL CONSTANT 42

Relative cell constant 72

S

Breaking capacity of the semiconductor relay

17

System of protection 17

Sensor part 25

Service-Hotline 9

Setup interface 34

SAFETY VALUE 44, 46

Safety value 73, 74

SIGNAL TYPE 44–45

Signal type 72–73

SCALING START 44–45

Scaling start 73

SCALING END 44–45

Scaling end 73

Sunlight radiation 21

Voltage supply 17, 33

LANGUAGE 49

Language 75

T

Keyboard lock 48

TEMP. COEFFICIENT 42

TEMP. COMPENSATION 42

Temperature of the measurement medium 20

Temperature acquisition 19

Temperature coefficient 19, 72

Temperature compensation 72

Temperature compensation with the TC-curve

61

Temperature measurement range 19

TC-curve 61

U

Influence of ambient temperature 18–19

reconfigure 72

Page 7

7

V

LOCKING TIME 48

Locking time 74

Pre-calculated values 69

W

Warning signs 8

Resistant loop 67

Wiping contact 47

Z

CELL CONSTANT 42

Cell constant 72

permissible storage temperature 17

permissible ambient temperature 17

Page 8

8

1 Typographical conventions

1.1 Warning signs

1.2 Indicative signs

Caution

This sign is used if, by carefully following or not following instructions, harm to

persons can occur

Caution

This sign is used if, by carefully following or not following instructions, dam-

age to devices or data can occur

Note

This sign is used when your attention is to be drawn to something special.

abc

1

Footnote

Footnotes are remarks that refer. to specific places in the text. Footnotes

consist of two parts:

Flag in the text and footnote text.

The flagging in the text is done by superscript serial numbers.

✱ Action indication

This sign indicates that an activity to be carried out is being described.

The individual work steps are marked by this star.

Example:

✱ Loosen the crosshead screws..

Page 9

9

2 General

2.1 Foreword

Please read the operating manual before you commission the device. Store

the operating manual at a place that is accessible for all users at all times.

Please help us to improve this operating manual.

We would be grateful for your suggestions.

Telephone(06 61) 60 03-7 14

Telefax (06 61) 60 03-6 05

All the required settings are described in this manual. Should there

be any difficulties nonetheless at the time of commissioning, we

request you not to carry out any impermissible manipulations. You

could render your warranty entitlement null and void.

Please get in touch with the nearest branch or with the head office.

In case of technical queries

Service-Hotline:

Telephone:(06 61) 60 03-3 00 or (06 61) 60 03-6 53

Telefax: (06 61) 60 03-88 13 00 or (06 61) 60 03-88 16 53

E-mail: Service@jumo.net

Page 10

2 General

10

2.2 Structure of the JUMO CTI-750

Examples

(1) Transmitter (4) Inductive conductivity measuring

probe

(2) Process connection (5) with or without graphics LC-display

(3) Temperature sensor

Model:

Transmitter and

conductivity measuring

probe combined,

type 202756/xx...

Model:

Transmitter w ith

separate sensor,

type 202756/xx...

(2)

(1)

(3)

(1)

(2)

(4)

(5)

(4)

(3)

Page 11

11

3 Inductive conductivity measurement

3.1 Range of Applications

General The inductive measurement process allows a mostly maintenance-free acqui-

sition of the specific conductivity even in difficult medium conditions. In contrast to the conductive measurement process, problems like electrode

replacement and polarization do not occur.

Brief description

The device is used for the measurement / control of the conductivity / concentrations of liquid media. Using it is particularly recommended in media in which

significant deposits from carried dirt, oil grease or of lime and gypsum are

expected. The integrated temperature measurement makes exact and fast

temperature compensation possible, which is particularly important for the

measurement of the conductivity. Additional functions such as the combined

switching of the measurement range and temperature coefficient make possible the optimum use in case of CIP-processes.

Two integrated switching outputs can be freely programmed for limit value

monitoring or conductivity / concentration and /or temperature. In addition,

alarm and control tasks (desalination) can be assigned.

Operation is either via a membrane keyboard and a plain text graphical display

(user language can be changed) or via a comfortable PC-Setup program. By

simply turning the housing cover, reading the display is possible both in case

of installation in vertical or horizontal pipes. By means of the Setup program,

the device configuration data can also be saved and printed for plant documentation purposes. To prevent manipulation, the device can also be supplied

without a keyboard / display. In this case, the Setup program is required for

programming.

The JUMO CTI-750 can be supplied as a combine device (transmitter and

measuring cell in one device) or as a shouldered version (transmitter and measuring cell connected by cables). The separate version is particularly suitable

for plants with intense vibrations and/or intense temperature radiation at the

measurement location or for installation at not easily accessible places.

Typical usage

fields

- CIP-cleaning (CIP = Clean In Place / Process)

- Concentration monitoring or chemical dosing

- Foodstuffs beverages and pharmaceutical industries

-Product monitoring (phase separation, Product / Product mixture /

Water) in the beverage industry, breweries, dairies

- Control (e.g. phase separation of cleaners / rinsing water of

cleaning processes e.g.. bottle cleaning plants and in case of container

cleaning)

Page 12

3 Inductive conductivity measurement

12

3.2 Function

of the transmitter

The JUMO CTI-750 transmitter is conceived for use at the location. A robust

housing protects the electronics and the electrical connections from aggressive ambient influences (system of protection IP 67). In the standard version,

the device has one analog signal input for the conductivity / concentration and

the temperature. The further processing of the standard signals can take place

in suitable display / control devices or, e.g. directly in a PLC.

The output signals are galvanically separated from one another and from the

measurement medium.

of the measuring cell

The measurement of the conductivity takes place with an inductive probe. A

sinusoidal AC is supplied to the transmitting coil. Depending on the conductivity of the liquid to be measured, a current is induced in the receiver coil. The

current is proportional to the conductivity of the medium. The cell constant of

the inductive probe is geometry-dependent. In addition, the cell constant can

be influenced by parts in its immediate vicinity.

(1) Plastic body (4) Measurement medium

(2) T-shaped flow channel (5) Temperature sensor Pt100

(3) Fluid loop

(2)

(1)

(3)

(4)

(5)

Page 13

13

4 Identifying the device

4.1 Type nameplate

on the

transmitter

on the connecting

cable

(only in case of

separate sensor)

JUMO GmbH & Co. KG

Fulda, Germany

www.jumo.net

JUMO CTI-750

Typ: 202756/16-607-0000-82/000

VARTN: 20/00445843

F-Nr.: 00909467 01 0 0745 0001

DC 19...31 V 3W

ⱕ

F-Nr.: 00909467 01 0 0517 0001

In the case of devices with a separate sensor (base type supplementation (2)

66), for every instrument, the transmitter and the separate sensor are matched

to one another at the factory.

When connecting the components, ensure that the production number of the

external sensor (on the flag tag on the connecting cable) is identical to the production number of the transmitter (on the nameplate).

The date of manufacture is encrypted in the "F-No." :

0517 means year of manufacture 2005 / calendar week 17

Page 14

4 Identifying the device

14

4.2 Type explanation

4.3 JUMO CTI-750 as "Head-mounted transmitter"

1

Only in conjunction with additional code 767 (measuring cell material

PEEK).

2

If required, M12-plug / -sockets, additional code 580 should be ordered.

3

Specify additional codes in succession separated by a comma.

4

Assembly material (mounting brackets) not part of the scope of supply.

(1) Basic type

202756 JUMO CTI-750

Inductive transmitter / switching device

for conductivity / concentration and temperature

(2) Basic type supplementation

16 Head-mounted transmitter in stainless steel housing

with display / keyboard

(3) Process connection

o 107 Stud thread G1 1/4A

o 108 Stud thread G1 1/2A

o 110 Stud thread G2A

o 606 Screwed pipe connection DN40, DIN 11 851

(MK DN50, milk cone)

o 607 Screwed pipe connection DN50, DIN 11 851

(MK DN40, milk cone)

o 608 Screwed pipe connection DN65, DIN 11 851

(MK DN65, milk cone)

o 609 Screwed pipe connection DN80, DIN 11 851

(MK DN80, milk cone)

o 617 Clamp 2 1/2"

4

o 686 VARIVENT® DN40/50

1

o 690 SMS 2"

(4) Immersion length

o 000 see "Dimensions / Process connections (head-

mounted transmitter"

(5) Electrical connection

o82Cable glands

o 83 M12-plug / -sockets

(instead of the cable glands)

2

o 84 Two cable glands M16 and a dummy plug

(6) Extra codes

3

000 None

o 268 Temperature sensor inside

X 767 Measuring cell material PEEK

X 768 Measuring cell material PVDF

o 844 Voltage supply AC 24 V

(1) (2) (3) (4) (5) (6)

Ordering key / - - - / , ...

Ordering example 202756 / 16 - 607 - 000 - 82 / 000

Page 15

15

4 Identifying the device

4.4 JUMO CTI-750 as "Transmitter with separate sensor"

(1) Basic type

202756 JUMO CTI-750

Inductive transmitter / switching device

for conductivity / concentration and temperature

(2) Basic type supplementation

26 Transmitter in stainless steel housing, with display / keyboard

(without sensor)

5

66 Transmitter in stainless steel housing, with display / keyboard includ-

ing sensor (cable length 10 m)

85 Replacement sensor with 10 m cable

1, 5

for transmitter in stainless steel housing

(3) Process connection

X 000 not available

o o o 107 Stud thread G1 1/4A

o o o 108 Stud thread G1 1/2A

o o o 110 Stud thread G2A

o o o 606 Screwed pipe connection DN40, DIN 11 851 (MK DN40, milk cone)

o o o 607 Screwed pipe connection DN50, DIN 11 851 (MK DN50, milk cone)

o o o 607 Screwed pipe connection DN65, DIN 11 851 (MK DN65, milk cone)

o o o 607 Screwed pipe connection DN80, DIN 11 851 (MK DN80, milk cone)

o o o 617 Clamp 2 1/2"

1

ooo 686 VARIVENT® DN40/50

2

o o o 690 SMS 2"

5

o o 706 Submerged version

6

(4) Immersion length

X 0000 see "Dimensions / Process connections (separate sensor)"

X o o 0500 0500 mm

X o o 0000 1000 mm

X o o 0000 1500 mm

X o o 0000 2000 mm

X o o xxxx Special length (in grid of 250 mm; e.g. 0250; 0750; 1250; 1750)

(5) Electrical connection

X 21 Fixed cable with M12-socket at separate sensor

o o 82 Cable glands on operating part

o o 83 M12-plug / sockets on operating part

3

o o 84 Two cable glands M16 and a dummy plug

(6) Extra codes

4

X X X 000 no extra code

o o 268 Temperature sensor inside

o o 580 1 set M12-plug / sockets

X X X 767 Measuring cell material PEEK

X X X 768 Measuring cell material PVDF

o o 844 Voltage supply AC 24 V

Page 16

4 Identifying the device

16

1

Assembly material (Union / grooved nut, mounting bracket) not part of

scope of supply. If required, please order as well, see accessories.

2

Only in conjunction with additional code 767 (measuring cell material

PEEK).

3

If required, M12-plug / -sockets, additional code 580 should be ordered.

4

Specify additional codes in succession separated by a comma.

5

An equalizing set is indispensable for commissioning. If not available,

please order as well, see Accessories.

6

Only in conjunction with additional code 768 (measuring cell material

PVDF).

(1) (2) (3) (4) (5) (6)

Ordering key / - - - / , ...

Ordering example 202756 / 66 - 607 - 1000 - 82 / 767

Page 17

17

5 Device description

5.1 Technical data, transmitter

5.1.1 General

A/D-converter Resolution: 15-bit

sampling time:500 ms = 2 measurements/s

Voltage supply For operation on SELF- or PELV-circuits

Standard production feature:

DC 19…31 V (nominal DC 24 V), the device has reverse polarity protection

Ripple: < 5%

Power drawn with display: ≤ 3 W

Power drawn without display: ≤ 2.6 W

In case of extra code 844:

AC 24 V ±10%

Breaking capacity of the semiconductor relay

U< 50 V AC/DC

I ≤ 200 mA

electrical connection

Threaded plug terminals 2.5 mm

2

or M12-plug/ sockets

Display (option) Graphic-LCD with background lighting; Contrast adjustable

dimensions: 62 x 23 mm

permissible

ambient temperature

(transmitter)

-5…+50°C

max. 93% rel. atmospheric humidity, without thawing

permissible

storage temperature

(transmitter)

-10…+65°C

max. 93% rel. atmospheric humidity, without thawing

System of protection

(transmitter)

IP 67

Housing Stainless steel, material no. 1.4305

Weight depending on the model and process connection

about 2.4 kg

Page 18

5 Device description

18

5.1.2 Conductivity-/ Concentration transmitter

Concentration

measurement

(implemented in

the device software)

- NaOH (sodium hydroxide solution)

0...15 % by weight or 25...50 % by weight

- HNO

3

(nitric acid); pay attention to the chemical resistance of the sensor!

0...25 % by weight or 36...82 .% by weight

- Customer-specific concentration curve

freely programable via the setup program (see "Special functions")

Calibration

timer

adjustable: 0...999 days (0 = off)

Output signal

conductivity /

concentration

0...10 V / 10...0 V

2...10 V / 10...2 V

0...20 mA / 20...0 mA

4...20 mA / 20...4 mA

The output signal is freely scalable.

Load ≤ 500 Ω for current output

≥ 2kΩ for voltage output

Influence of

ambient temperature

≤ 0.1%/K

Analog output

in case of

"Alarm"

Low (0 mA / 0 V / 3.4 mA / 1,4 V) or

High (22.0 mA / 10,7 V) or

a fixed value that can be set (safety value)

Measurement

ranges

Four measurement ranges can be selected.

One of these measurement ranges can be activated via an external switch or a

PLC .

Measurement ranges, transmitter

Accuracy

(in % of the start -

of measurement range)

0...500 µS/cm

≤0.5%

0...1000 µS/cm

0...2000 µS/cm

0...5000 µS/cm

0...10 mS/cm

0...20 mS/cm

0...50 mS/cm

0...100 mS/cm

0...200 mS/cm

0...500 mS/cm

0...1000 mS/cm

0...2000 mS/cm

1

Page 19

19

5 Device description

1

not temperature-compensated

Note:

The overall accuracy is formed from the accuracy of the transmitter + the

accuracy of the sensor.

5.1.3 Temperature transmitter

Temperature

acquisition

manual -20.0...25.0...150°C / °F

or

automatic

Temperature

measurement

range

-20...150°C / °F

Characteristic linear

Accuracy ≤ 0.5% of the measurement range

Influence of

ambient temperature

≤ 0.1%/K

Output -signal

temperature

0...10 V / 10...0 V

2...10 V / 10...2 V

0...20 mA / 20...0 mA

4...20 mA / 20...4 mA

The output signal is freely scalable.

Load ≤ 500 Ω for current output

≥ 2 kΩ for voltage output

Analog output

in case of

"Alarm"

Low (0 mA / 0 V / 3.4 mA / 1,4 V) or

High (22.0 mA / 10,7 V) or

a fixed value that can be set (safety value)

5.1.4 Temperature compensation

Reference temperature

15...30°C adjustable

Temperature

coefficient

0.0...5.5 %/K adjustable

Page 20

5 Device description

20

Compensation

range

-20...150°C

Function - Linear compensation (constant temperature coefficient).

This type of compensation can be applied with acceptable for many normal

types of water. The temperature coefficient used is then about 2.2 %/K.

- Natural water (DIN EN27888 or ISO 7888).

In this case, a so-called non-linear temperature compensation is applied.

According to the above standard, the corresponding type of compensation

can be applied in the case of natural ground waters, spring waters and

above-ground waters.

The conductivity of the water is compensated in the range from 0°C to

36°C.

- Not linear (for learning function, see special functions)

Here, the actual flow of the temperature coefficient during a heating-up or

cooling process is determined with the transmitter.

5.1.5 Sensor

Material PEEK (Polyetheretherketone) or

PVDF (Polyvenylidenfluoride)

Note!:

Temperature, pressure and measurement medium influence the life of the

measuring cell

Temperature of

the measurement medium

-10 ... +120°C

short-term 140°C (sterilization)

Pressure max. 10 bar

1

not temperature-compensated

Measurement range

Sensor

Accuracy

(in % of the start -

of measurement range)

0...500 µS/cm

≤1%

0...1000 µS/cm

0...2000 µS/cm

≤0.5%

0...5000 µS/cm

0...10 mS/cm

0...20 mS/cm

0...50 mS/cm

0...100 mS/cm

0...200 mS/cm

0...500 mS/cm

0...1000 mS/cm

≤1%

0...2000 mS/cm

1

Page 21

21

6 Installation

6.1 General

Installation

location

The compatibility of the material with the measurement medium must be

checked by the customer.

Ensure easy accessibility for subsequent calibration.

The fastening must be secure and low-vibration.

Avoid direct sunlight.

It is necessary to pay attention to a good flow through and around the sensor

(1).

When installing in a pipe, a minimum distance of 20 mm must be maintained

from the sensor to the pipe wall.

If these minimum distances cannot be maintained, the parameter "Mounting

factor" can be used to achieve limited equalization.

In immersion operation in a basin, an installation location that is representative

for the typical conductivity or concentration must be provided.

Mounting location

The JUMO CTI-750 can be mounted in any position.

Screwing in and

unscrewing the

separate sensor

No cable twisting should occur.

Avoid tensile forces on the cable, especially jerky pulling.

Sensor details

(1)

Stainless steel sleeve: Material

1.4571

Sealing: FPM

Page 22

6 Installation

22

6.2 Dimensions / Process connections, head transmitter

Installation variants

Process

connection

(1.4301)

71

130

207

40

84

177

130

71

56

37

Process

connection

(1.4301)

71

130

224

20

60

104

G

Model with

process connection 607

MK DN50

Model with

process connection 617

Clamp 21/2"

(mounting bracket not part

of scope of supply)

Process

connection

Slotted union nut

F50

(1.4301)

71

84

40

212

130

Model with process connection

107 = Stud thread G1 1/4A

108 = Stud thread G1 1/2A

110 = Stud thread G2A

Version with

process connection 686

VARIVENT® DN50

(mounting bracket not

in scope of supply)

Page 23

23

6 Installation

Process

connection

(1.4301)

Ring nut

SMS 2"

(1.4301)

130

71

215

84

40

Model with

process connection 690

SMS 2"

Page 24

6 Installation

24

6.3 JUMO CTI-750 with separate sensor

Tran sm it te rhead

Wall fastening

ø110

84

71

176

100

91

120

ø5.5

120

100

Page 25

25

6 Installation

Sensor part

Process

connection

(1.4301)

M12 socket

(PBT / PA)

Cable gland

M16 (PA)

M12 socket

(PBT / PA)

Cable gland

M16 (PA)

M12 socket

(PBT / PA)

Cable gland

M16 (PA)

Process connection 686

VARIVENT DN50

(1.4301)

®

M12 socket

(PBT / PA)

Cable gland

M16 (PA)

Shouldered version with

process connection 607

MK DN50

(union nut not part

of scope of supply)

Shouldered version with

process connection 686

VARIVENT

®

DN50

(mounting bracket not

in scope of supply)

Shouldered version with

process connection 617

Clamp 21/2"

(mounting bracket not part

of scope of supply)

Shouldered version with

process connection

107 = Stud thread G1 1/4A

108 = Stud thread G1 1/2A

110 = Stud thread G2A

Page 26

6 Installation

26

M12 socket

(PBT / PA)

Cable gland

M16 (PA)

Process

connection

(1.4301)

Shouldered version with

process connection 690

SMS 2"

(union nut not part

of scope of supply)

Page 27

27

6 Installation

6.3.1 Separate sensor as submerged version

M12 socket

(PBT/PA)

Cable gland

System of protection

IP68 up to 0,2 bar)

according to EN 60529

(PA)

110

Submerged

pipe

(PVDF)

ø40

EL = Submerged length

44

Shouldered version with

process connection 706

Immersion version

(pipe clamps not part of the scope of supply)

57

18

3

100

+5

0

Fixing screw

Flange mov

a

ø

100

ø

165

ø

18

Fixing screw

Flange

movable

60

18

3

100

+5

0

ø

18

ø

125

ø

165

Optional accessories:

Flange DN 32, Sales no.: 20/00083375

Optional accessories:

Flange DN 50, Sales no.: 20/00083376

Page 28

6 Installation

28

6.4 Installation examples

Process connection 607

Screwed pipe fitting DN50,

DIN 11 851

(MK DN50, Milk cone)

(1.4301)

Ring nut DN50

(1.4301)

Threded pipe adapter

DIN. S, DN50

(Edelstahl)

Reducing Tee DIN, short SSS DN65/50

(e.g. 1.4301)

(to be provided by the plant operator supplied bynot JUMO)

Tee DIN 11 852, SSS

DN50

Dim. A shortened to 30 mm

Process sonnection 607

Screwed pipe fitting DN50

DIN11 851

(MK DN50, Milk cone)

(1.4301)

Flow direction

Process connection 617

Clamp 21/2"

(1.4301)

Clamping ring

(e.g. 1.4301)

Threaded pipe adapter, S

DN2,5"

(stainless steel)

Reducing Tee DIN, short SSS DN65/50

(e.g. 1.4301)

(to be provided by the plant operator supplied bynot JUMO)

Weld-on threaded connector

DN50, DIN 11 851

(counter-piece to process connection

-607)

Sales no.: 20/00085020

Page 29

29

6 Installation

Tee DIN, short SSS DN65/50

(e.g. 1.4301)

(to be provided by the plant operator supplied bynot JUMO)

Page 30

30

7 Installation

❏ When selecting the conductor material for the installation and for the elec-

trical connections of the device, compliance is required with the specifications of VDE 0100 "Regulations governing the installation of heavy-current

systems with rated voltages below 1000 V" or the relevant country specifications.

❏ The electrical connections may only be set up by technically qualified per-

sonnel.

❏ Completely isolate the device from the main supply, if live parts can be

touched while working.

❏ The electromagnetic compatibility corresponds to EN 61326.

❏ The input, output and supply cables must be laid spatially separated from

one another and not parallel to one another.

❏ The device is not suitable for installation in explosion-endangered areas.

❏ Apart from faulty installation, wrongly set values on the device can also

have an adverse impact on the following process in its proper functioning,

or result in damage.

❏ The device must be grounded:

Head-mounted transmitters:

e.g. indirectly above a metallic pipe.

Transmitter with separate sensor:

e.g. indirectly above a metallic pipe or above the wall fastening.

The electrical connections may only be set up by technically

qualified personnel.

Page 31

31

7 Installation

7.1 General

Open the operating unit

✱ Unscrew the cover (1)

Connect the

cables

(1)

For connecting the individual cores, pull out the threaded plug

terminals (1) in the operating unit.

Lead the connecting cables through the cable glands (2).

(1)

(2)

SETUP

Page 32

7 Installation

32

Wiring

Wiring suggestion, headmounted transmitter

Wiring suggestion

Tran sm it te r

with separate

sensor

Caution:

In the case of devices with a separate sensor and M12-plugs/ -sockets, the

threaded terminals in the device are pigmented.

Removing the pigmenting will result in the warranty being rendered null and

void.

In the case of devices with a separate sensor (base type supplementation (2) /65

or /60), for every instrument, the transmitter and the separate sensor are matched

to one another at the factory.

When connecting the components, ensure that the production number of the

external sensor (on the flag tag on the connecting cable) is identical to the production number of the transmitter (on the nameplate).

Cable gland

M16 (PA)

Cable gland

M12 (PA)

Supply and signal output

(conductivity and temperature)

Cable gland

M12 (PA)

Binary input

Switching outputs

Connector I

Supply and signal output

(conductivity and concentration)

M12 built-in plug conn.

5-pole

Connector II

Signal output temperature

and binary input

Switching outputs

M12 built-in socket conn.

8-pole

Connector III

Inductive sensor

M12

8-pole

built-in socket conn.

Page 33

33

7 Installation

Connection layout of the transmitter

Connection Threaded

terminals

Plug / Pin

Voltage supply

Standard production feature:

Voltage supply

DC 19…31 V

(with polarity reversal protection)

In case of extra code 844:

AC 24 V

1 L+

2 L-

I / 1

I / 2

Outputs

analog signal output

conductivity/ concentration

0...20 mA or 20...0 mA or

4...20 mA or 20...4 mA

or

0...10 V or 10...0 V or

2...10 V or 10...2 V

(galvanically separated)

3 +

4 -

I / 3

I / 4

analog signal output

temperature

0...20 mA or 20...0 mA or

4...20 mA or 20...4 mA

or

0...10 V or 10...0 V or

2...10 V or 10...2 V

(galvanically separated)

5+

6-

II / 1

II / 2

Switching output K1

(potential-free)

Switch position indication

LED K1

7

8

II / 3

II / 4

Switching output K2

Switch position indication

LED K2

9

10

II / 5

II / 6

Binary inputs

Binary input E1 11

12

II / 7

I / 5

Binary input E2 13

14

II / 8

I / 5

8

7

10

9

11

12

13

14

Page 34

34

8 Setup-Program

8.1 Function

Configurable

parameters

With the optional Setup program that is available, the transmitter can be comfortably matched to the requirements.

- Setting the measurement range and the measurement range limits.

- Setting the behavior of the outputs in case of overshooting of the measurement range.

- Setting the functions of the switching outputs K1 and K2.

- Setting the functions of the binary inputs E1 and E2.

- Setting special functions (e.g. desalination function).

- Setting a customer-specific characteristic

-etc.

Connection

Data transmission from and to the transmitter can only take place if

the voltage supply is connected to it see chapter 7 "Installation",

page 30ff.

The Setup interface does not have any galvanic isolation. Therefore, when connecting the PC interface cable, it is imperative to

ensure that either the voltage supply of the transmitter or of the PC

are not electrolytically coupled to the ground (e.g. notebook

should be used in battery mode).

SETUP

PC interface cable

TN 70/00350260 or 70/00456352

Inserted adapter

(present in the Setup set)

Voltage supply

Page 35

35

9 Commissioning

9.1 Head transmitter or transmitter with separate sensor

✱ Install the device, see "Installation", page 21.

✱ Connect the device, see "Installation", page 30.

9.2 Replacement sensor

✱ Connect the sensor, see the operating manual of the replacement sensor.

✱ Calibrate the sensor, see the operating manual of the replacement sensor.

The measuring transmitters are checked in the factory for flawless

operability and shipped ready for operation.

In the case of devices with a separate sensor (base type supplementation (2)

66), for every instrument, the transmitter and the separate sensor are matched

to one another at the factory.

When connecting the components, ensure that the production number of the

external sensor (on the flag tag on the connecting cable) is identical to the production number of the transmitter (on the nameplate).

Page 36

36

10 Operation

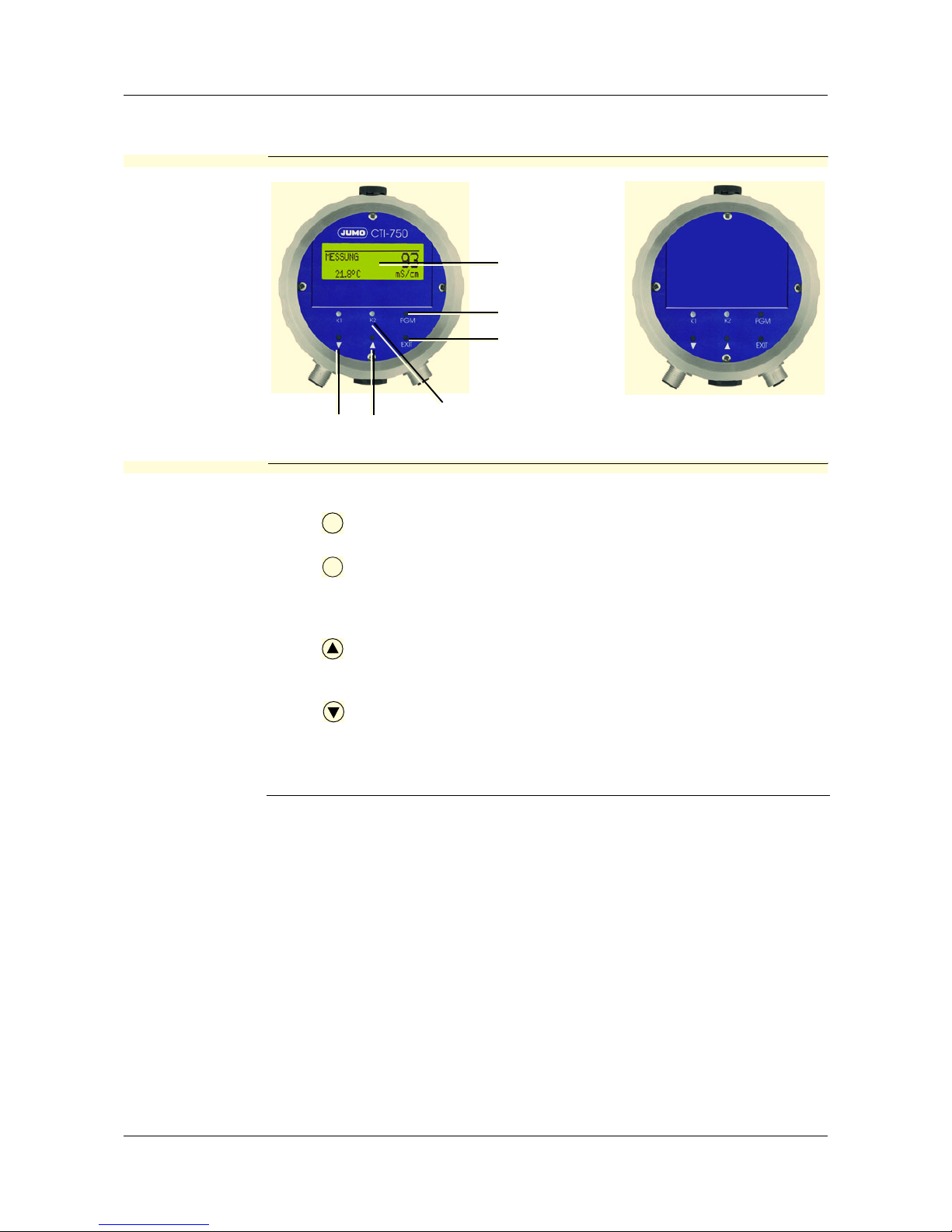

10.1 Operating elements

JUMO CTI-750

with and without

LC-Display

(1) Graphical LC-display,

background lit up.

(2) Key

confirm inputs, select menu.

(3) Key

interrupt inputs without saving /

interrupt calibration.

One menu-level back.

(4) Key

increase numerical value /

forward the selection.

(5) Key

decrease numerical value /

forward the selection.

(1)

(2)

(3)

(4)

(5)

(5)

PGM

EXIT

(6) LEDs "K1" / "K2" indicate the

status of the switching outputs.

In normal operation, the LED

flows when the corresponding

switching output is active.

If the wiper function is activated, the LED only indicates

the status.

The LED "K1" flashes during the

calibration.

In case of an error, LEDs "K1" and

LED "K2".flash.

Page 37

37

10 Operation

LC-Display

(1)

(2)

(3)

(4)

(5)

(6)

Output K1 is active

Output K2 is active

Binary input 1 is

triggered

Binary input 2 is

triggered

Keyboard is locked

Device status (hints)

- Alarm (e.g. overrange)

- Calib. flashing (calibration

timer

run out)

- Calib (customer calibration

enabled)

(7)

(8)

(9)

(10)

(11)

Output mode

- manual (manual operation)

- hold (hold operation)

Conductivity /concentration-

measured value

Unit of the conductivity- /con-

centrations measured value

Medium temperature

Device status e.g.

- Measurement (normal)

- Desalination (desalination

function)

- Dosing (desalination function)

- Locked (desalination function)

- Status of the calibration

(1) (2) (3) (4) (6)(5) (7)

(8)

(9)(10)

(11)

Page 38

10 Operation

38

10.2 Operation principle

10.2.1 Operating in levels

Measurement mode, see chapter 10.4 "Measurement mode", page 41

OPERATOR LEVEL, see chapter 10.5 "Operating level", page 41

INPUT CONDUCTIVITY MEASUREMENT RANGE 1...4

TEMP.COMPENSATION

TEMP.COEFFICIENT 1...4

REFERENCE TEMPERATURE

REL.CELL CONSTANT

MOUNTING FACTOR

CONCENTR.MEASUREMENT

CONCENTR.RANGE

OFFSET

FILTER TIME

CALIBR.INTERVAL

OUTPUT CONDUCTIVITY SIGNAL TYPE

SCALING START 1...4

SCALING END 1...4

IN CASE OF ALARM

IN CASE OF CALIBRATION

SAFETY VALUE

MANUAL OPERATION

MANUAL VALUE

INFLOW TEMPERATURE UNIT

MEASURED VALUE ACQUISITION

MANUAL SPEC.

OFFSET

FILTERING TIME

OUTFLOW TEMPERATURE SIGNAL TYPE

SCALING START

SCALING END

IN CASE OF ALARM

AT TIME O F C A L I B R AT I O N

SAFETY VALUE

MANUAL OPERATION

MANUAL VALUE

OUTPUT BINARY 1 FUNCTION

LIMIT VALUE

HYSTERESIS

DISTANCE

MANUAL OPERATION

IN CASE OF HOLD

IN CASE OF ALARM / CALIB.

SWITCH-ON DELAY

SWITCH-OFF DELAY

PULSE DURATION

OUTPUT BINARY 2 FUNCTION

LIMIT VALUE

HYSTERESIS

DISTANCE

MANUAL OPERATION

IN CASE OF HOLD

IN CASE OF ALARM / CALIB.

SWITCH-ON DELAY

SWITCH-OFF DELAY

PULSE DURATION

INPUT BINARY 1 FUNCTION

INPUT BINARY 2 FUNCTION

DESALINATION FUNCTION REDUCTION

DOSING TIME

LOCKING TIME

Page 39

10 Operation

39

DEVICE DATA LANGUAGE

CONTRAST

LIGHTING

LCD INVERSE

ADMINISTR.-LEVEL, see chapter 10.6 "Administrator level", page 49

Password

PAR AMET ER-L EVEL

, see chapter 10.6.1 "Parameter level", page 50

INPUT CONDUCTIVITY.

OUTPUT CONDUCTIVITY

INPUT TEMPERATURE

OUTPUT TEMPERATURE

OUTPUT BINARY 1

OUTPUT BINARY 2

INPUT BINARY 1

INPUT BINARY 2

DESALINATION FUNCTION

DEVICE DATA

ENABLE LEVEL

, see chapter 10.6.2 "Release level", page 50

INPUT CONDUCTIVITY.

OUTPUT CONDUCTIVITY

INPUT TEMPERATURE

OUTPUT TEMPERATURE

OUTPUT BINARY 1

OUTPUT BINARY 2

INPUT BINARY 1

INPUT BINARY 2

DESALINATION FUNCTION

DEVICE DATA

CALIB ENABLE

, see chapter 10.6.3 "Calibration release (CALIB.RELEASE)", page 50

REL. CELL CONST.

TEMP. COEFF.. LINEAR

TEMP. COEFF. N-LINEAR

CALIBR.-LEVEL

, see chapter 10.7 "Calibration level", page 51

REL. CELL CONST.

TEMP. COEFF.. LINEAR

TEMP. COEFF. N-LINEAR

DESALINATION FUNCTION

, see chapter 10.8 "The desalination function", page 52

REDUCTION

DOSING TIME

LOCKING TIME

Page 40

10 Operation

40

10.3 Principle

Level

Page 41

41

10 Operation

10.4 Measurement mode

Depiction In the measurement mode, the conductivity compensated to the reference

temperature, or the concentration, and the temperature of the measurement

medium are displayed.

10.5 Operating level

In this level, all the parameters that have been released by the Administrator

(Administrator level) can be edited. All the other parameters (marked by a key

) can only be read.

✱ Press the key for longer than 3 seconds.

✱ Select "OPERATOR LEVEL".

(1) MEASUREMENT -> Measurement mode

(2) 20.5°C -> Temperature of the measurement medium

(3) 203 mS/cm -> compensated conductivity of the measurement medium

(referred to the reference temperature, generally 25°C).

PGM

(1)

(2)

(3)

Page 42

10 Operation

42

10.5.1 INPUT CONDUCTIVITY (Input conductivity)

MEASUREMENT RANGE 1...4

1

0...500 µS/cm

0...1000 µS/cm

0...2000 µS/cm

0...5000 µS/cm

0...10 mS/cm

0...20 mS/cm

0...50 mS/cm

0...100 mS/cm

0...200 mS/cm

0...500 mS/cm

0...1000 mS/cm

0...2000 mS/cm UNK

2

1

The measurement ranges 2, 3 and 4 are only used if

"INPUT BINARY" is configured on "MEASUREMENT RANGE./TEMP C.".

2

This measurement range is not temperature-compensated.

TEMP. COMPENSATION

LINEAR

NON-LINEAR (see "Non-linear temperature coefficient (ALPHA)", page 60)

NAT WATERS (permissible temperature range 0...36°C according to EN 27

888)

TEMP. COEFFICIENT 1...4

1

0...2.20...5.5%

1

The ranges 2, 3 and 4 are only used if

"INPUT BINARY" is configured on "MEASUREMENT RANGE./TEMP C.".

REFERENCE TEMPERATURE

15.0...25.0...30°C

CELL CONSTANT

2.00...6.80...10.0 1/cm

Checking or changing is only necessary if there is a substitute sensor (base

type supplementation 85) connected to the transmitter with a separate sensor.

The cell constant is printed on the substitute sensor (K=x,xx).

REL. CELL CONSTANT

80.0...100.0...120%

Page 43

43

10 Operation

MOUNTING FACTOR

80.0...100.0...120%

If the minimum distances (20 mm) of the sensor to the outer wall cannot be

maintained, a limited compensation can be achieved with this parameter.

CONCENTR. MEASUREMENT

NO FUNCT.

NaOH

HNO3

CUST. SPEC. (The input of the values is only possible with the optional

Setup program)

CONCENTR.

RANGE

In case of HNO

3

0...25 % by WEIGHT

36...82 % by WEIGHT

In case of NaOH

0...15 % by WEIGHT

25...50 % by WEIGHT

OFFSET

-100...0...+100 mS/cm (+/- 10% of the measurement range)

FILTERING TIME

00:00:00...00:00:01...00:00:25 H:M:S

CALIBR.-INTERVAL

0...999 DAYS (0 = switched off)

Page 44

10 Operation

44

10.5.2 OUTPUT CONDUCTIVITY. (Output conductivity)

SIGNAL TYPE

0...20 mA

4...20 mA

20...0 mA

20...4 mA

0...10 V

2...10 V

10...0 V

10...2 V

SCALING START 1...4

1

0 µS/cm = 4 mA

Can be set in the current measurement range, depending on the signal type

1

The ranges 2, 3 and 4 are only used if

"INPUT BINARY" is configured on "MEASUREMENT RANGE./TEMP C.".

SCALING END 1...4

1

1000 µS/cm = 20 mA

Can be set in the current measurement range, depending on the signal type

1

The ranges 2, 3 and 4 are only used if

"INPUT BINARY" is configured on "MEASUREMENT RANGE./TEMP C.".

IN CASE OF

ALARM

LOW (0 mA / 0 V / 3,4 mA / 1,4 V)

HIGH (22 mA / 10.7 V)

SAFETY VALUE (depending on the signal type)

AT THE TIME OF CALIBRATION

ACCOMPANYING

FROZEN

SAFETY VALUE

SAFETY VALUE

0,0...4,0...22,0 mA (depending on the signal type)

0...10,7 V

MANUAL OPERATION

off

on

MANUAL VALUE

0,0...4,0...22,0 mA (depending on the signal type)

0...10,7 V

Page 45

45

10 Operation

10.5.3 INFLOW TEMPERATURE

UNIT

°C

°F

MEASUREMENT VALUE ACQUISITION

Sensor

manual

MANUAL SPECIFICATION

-20.0...25.0...150.0°C

OFFSET

-15.0...0.0...+15.0°C

FILTERING TIME

00:00:00...00:00:01...00:00:25 H:M:S

10.5.4 OUTFLOW TEMPERATURE

SIGNAL TYPE

0...20 mA

4...20 mA

20...0 mA

20...4 mA

0...10 V

2...10 V

10...0 V

10...2 V

SCALING START

-20 ... 0.0°C = 4 mA (depending on the signal type)

SCALING END

+200 ... 150.0°C = 20 mA (depending on the signal type)

IN CASE OF ALARM

LOW (0 mA / 0 V / 3,4 mA / 1,4 V)

HIGH (22 mA / 10.7 V)

SAFETY VALUE (depending on the signal type)

Page 46

10 Operation

46

AT THE TIME OF CALIBRATION

ACCOMPANYING

FROZEN

SAFETY VALUE

SAFETY VALUE

0,0...4,0...22,0 mA (depending on the signal type)

0...10,7 V

MANUAL OPERATION

off

on

MANUAL VALUE

0,0...4,0...22,0 mA (depending on the signal type)

0...10,7 V

10.5.5 OUTPUT BINARY 1 and OUTPUT BINARY 2

FUNCTION

NO FUNCTION

COND. MIN.

COND. MAX.

COND. LK1

COND. LK2

TEMP. MIN.

TEMP. MAX.

TEMP. LK1

TEMP. LK2

CALIBR. TIMER

ALARM

Max limit comparator Min limit comparator

Hysteresis

Cond.

On

Off

Limit value

Setpoint

Hysteresis

Limit value

Setpoint

Cond.

On

Off

Page 47

47

10 Operation

LIMIT VALUE

-20.0... 999.0 (depending on the function, see above)

HYSTERESIS

0.0...1.0...999.0 (depending on the function, see above)

DISTANCE

0.0... 999.0 (depending on the function, see above)

MANUAL OPERATION

OFF

ON

IN CASE OF HOLD

INACTIVE

ACTIVE

FROZEN

IN CASE OF ALARM / CALIB.

INACTIVE

ACTIVE

FROZEN

Alarm window LK1 Alarm window LK2

Wiper contact

Triggering condition longer than

pulse duration

Wiper contact

Triggering condition shorter than

pulse duration

Hysteresis

Cond.

On

Off

Limit value

Setpoint

Distance

Hysterese

Sollwert

Lf

Ein

Aus

Grenzwert

Abstand

Page 48

10 Operation

48

SWITCH-ON DELAY

00:00:00...01:00:00 H:M:S

SWITCH-OFF DELAY

00:00:00...01:00:00 H:M:S

PULSE DURATION

00:00:00...01:00:00 H:M:S (see above: "Function, wiping contact)

10.5.6 INPUT BINARY 1 and INPUT BINARY 2

FUNCTION

NO FUNCTION

KEYBOARD LOCK/HOLD

MEASUREMENT RANGE./TEMP C.

DESALINATION FUNCTION.

10.5.7 DESALINATION FUNCTION (Description see "The desalination function", page

52)

REDUCTION

0...10...50%

DOSING TIME

0:00:00...00:01:00...18:00:00 H:M:S

LOCKING TIME

0:00:00...00:01:00...18:00:00 H:M:S

Setting parameters binary input 1 binary input 2

Measurement range- /

Temperaturecoefficient

switching

MB1 / Tk1 open open

MB2 / Tk2 closed open

MB3 / Tk3 open closed

MB4 / Tk4 closed closed

Keyboard lock closed X

Hold-function X closed

Desalination function: Start close (flank 0 - 1) open

Desalination function Stop open close (flank 0 - 1)

Page 49

49

10 Operation

10.5.8 DEVICE DATA

LANGUAGE

GERMAN

ENGLISH

FRENCH

SPANISH

POLISH

SWEDISH

ITALIAN

PORTUGUESE

DUTCH

RUSSIAN

CONTRAST

0...6...11

LIGHTING

OFF

ON

FOR OPERATION (about 50 s after the last keystroke,

the lighting gets switched off)

INVERSE LCD

OFF

ON

10.6 Administrator level

- All the parameters can be edited in this level.

- In this level, it is also possible to determine which parameters a "normal"

user may edit or which calibrations may be carried out.

Editable parameters can be edited in the operator level.

Non-editable parameters are marked in the operator level with a key symbol .

You can get to the Administrator level as follows:

✱ Press the key for longer than 3 seconds.

✱ With the keys or , select "ADMINISTRATOR-LEVEL".

✱ Keys or input the password 300.

✱ Press the key .

By inputting the password 7485 in the Administrator level, the

operating language is reset to English.

PGM

PGM

Page 50

10 Operation

50

Levels of the

Administrator

level

10.6.1 Parameter level

In this level, the Administrator can edit any parameter of the operator level.

The structure of the parameter level in the Administrator level is identical to the

operator level

see "Operating level", page 41 and onwards.

10.6.2 Release level

In this level, the Administrator can determine which parameters the operator is

permitted to modify in the operator level..

The options "READ ONLY" and "EDIT" are available for the purpose.

The structure of the parameter level in the Administrator level is identical to the

operator level

see "Operating level", page 41 and onwards.

10.6.3 Calibration release (CALIB.-RELEASE)

In this level, the Administrator can specify whether the operator may calibrate

- the relative cell constant

- the linear temperature coefficient

- the non-linear temperature coefficient

Page 51

51

10 Operation

i.e. change them

10.7 Calibration level

In this level, the calibrations released by the Administrator (Administrator level)

can be carried out.

✱ Press the key for longer than 3 seconds.

✱ With the keys or , select "CALIBRATION-LEVEL".

10.7.1 REL. CELL CONSTANT. (relative cell constant)

If this function has been released by the Administrator, the operator can calibrate the relative cell constant of the JUMO CTI-750 here;

see "Calibration of the relative cell constant", page 56.

10.7.2 TEMP. COEF. LINEAR (Temperature coefficient linear)

If this function has been released by the Administrator, the operator can calibrate the JUMO CTI-750 on fluids with linear temperature coefficients;

see "Linear temperature coefficient (ALPHA)", page 57.

10.7.3 TEMP. CO. N-LINEAR (Temperature coefficient, non-linear)

If this function has been released by the Administrator, the operator can calibrate the JUMO CTI-750 on fluids with non-linear temperature coefficients;

see "Non-linear temperature coefficient (ALPHA)", page 60.

PGM

Page 52

10 Operation

52

10.8 The desalination function

Brief description

In the case of cooling water, using the conductivity, the total salt content is

assessed. Upon reaching a limiting conductivity (at maximum permissible salt

concentration / densification), dilution of the cooling water is necessary. For

this purpose, a desalination valve is opened, densified water flows out and is

supplemented with fresh water. After the conductivity of the cooling water has

dropped below the limit value, the desalination valve is closed again.

Addition of biocide

In order to prevent biological growth in cooling systems, biocides are added to

the cooling water. There is no ideal control variable for the added quantity and

time of a biocide dosing. In most cases, the dosing time is used as the control

variable. Here, the dosing quantity is obtained from the pump capacity and

pump operating time (plant-specific). The success of the biocide treatment

must be checked at regular intervals.

Desalination

before the addition of biocide

If a conductivity-enhancing biocide is added to the cooling water, the conductivity can cross the limit value as a result. Thereupon, the desalination valve

would open and a part of the added biocide would be discharged into the

effluent canal (note and comply with the legal conditions!).

To prevent this, before adding the biocide, the conductivity in the cooling system is reduced by desalination by about 10% below the limit value. Thereafter,

the desalination valve is temporarily blocked.

Desalination

locking

After the addition of the biocide, the desalination should be blocked till the

biocide that has been added has mostly decomposed in the cooling system

(not and comply with the legal requirements.).

Realization in

the case of the

JUMO CTI-750

- The desalination function is only possible in the mode "Conductivity measurement". Not in the case of concentration measurement..

- If the desalination function is activated, all the parameters that are not relevant for this function are turned off.

- The desalination function can be started via the binary input 1 and stopped

using the binary input 2, see "INPUT BINARY 1 and INPUT BINARY 2",

page 48.

The desalination function can also be stopped with the key.

- The current status of the desalination function is shown in the display.

- The desalination valve is controlled through output K1.

- The addition of biocide is controlled via output K2.

- After the desalination, K1 goes into the configured Hold state (desalination

locking).

EXIT

Page 53

53

10 Operation

- The desalination reduction can be set in the range from 1...50% below the

actual limit value of binary input 1. The default setting is 10% below the

limit value.

10.8.1 Setting the desalination function

All the parameters are plant-dependent and must be matched to the prevalent

conditions.

✱ Press the key for longer than 3 seconds.

✱ With the keys or , select the "OPERATOR LEVEL"; with key , con-

firm the selection.

✱ With the keys or , select "INPUT BINARY"; with key , confirm the

selection.

PGM

PGM

PGM

Page 54

10 Operation

54

✱ With the keys or , select "DESALINATION FUNCT.". with key ,

confirm the selection.

✱ Use the key to switch to the operator level.

✱ With the key select "DESALINATION FUNCTION".

✱ With key , confirm the selection.

✱ Set the desalination reduction with the keys or in the range from

1...10...50% below the actual limit value.

✱ with key , confirm the setting.

✱ With the keys or , select "DOSING TIME"; with key , confirm the

selection.

✱ Set the dosing time with the keys or in the range from

0:00:00...00:01:00...18:00:00 H:M:S.

✱ with key , confirm the setting.

PGM

EXIT

PGM

PGM

PGM

PGM

Page 55

55

10 Operation

✱ With the keys or , select "LOCKING TIME"; with key , confirm the

selection.

✱ Set the locking time with the keys or in the range from

0:00:00...00:01:00...18:00:00 H:M:S.

✱ with key , confirm the setting.

If there is a failure of the supply voltage during the running of the

desalination function, the function is canceled.

In order that the desalination function can run again, it must be

started again.

PGM

PGM

Page 56

56

11 Calibration

11.1 General

For increasing the accuracy, the device has various calibration options.

11.2 Calibration of the relative cell constant

In case of increased demands on the accuracy, the cell constant must first be

calibrated.

Precondition - the JUMO CTI-750 must be supplied with power.

see chapter 7 "Installation", page 30ff.

- The sensor must be connected to the transmitter (in case of "shouldered"

construction).

- The transmitter is in "Measurement mode".

✱ Submerge the conductivity sensor in a reference solution of known conduc-

tivity.

✱ Press the key for longer than 3 seconds.

✱ With the keys or , select "CALIBRATION-LEVEL". With key , con-

firm the selection.

At regular intervals (depending on the measurement medium), the

conductivity sensor must be cleaned and calibrated.

The LED "K1" flashes during the calibration.

During the calibration, the temperature of the measurement solution must remain constant.

PGM

PGM

Page 57

57

11 Calibration

✱ With the keys or , select "REL. CELL CONSTANT.". with key ,

confirm the selection.

✱ When the measured value is stable, press the key.

✱ With the keys or , correct the displayed uncompensated conductiv-

ity value to the conductivity value of the reference solution.

✱ Press the key.

The relative cell constant calculated by the JUMO CTI-750 is displayed.

✱ Accept the relative cell constant determined -> press the key for longer

than 3 seconds, or

discard the value -> press the key .

The transmitter is in the "Calibration menu".

✱ Press key ;

The transmitter is in "Measurement mode" and displays the compensated

conductivity of the reference solution.

11.3 Calibration of the temperature coefficient of the measurement solution

11.3.1 Linear temperature coefficient (ALPHA)

The conductivity of any measurement solution changes according it its specific temperature coefficient.

We therefore recommend carrying out the calibration of the temperature coefficient

PGM

PGM

PGM

PGM

EXIT

EXIT

Page 58

11 Calibration

58

Precondition - the JUMO CTI-750 must be supplied with power.

see chapter 7 "Installation", page 30ff.

- The sensor must be connected to the transmitter (in case of "shouldered"

construction).

- The transmitter is in "Measurement mode".

✱ Submerge the conductivity sensor in a sample of the measurement solu-

tion.

✱ Press the key for longer than 3 seconds.

✱ With the keys or , select "CALIBRATION-LEVEL". with key , con-

firm the selection.

✱ With the keys or , select "TEMP. COEFF LINEAR". with key , con-

firm the selection.

✱ With the keys or , input the operating temperature and confirm with

the key .

The operating temperature must be at least 5°C above or below

the reference temperature (25.0°C).

PGM

PGM

PGM

PGM

Page 59

59

11 Calibration

The LC-Display now shows

- at the top (1) the selected operating temperature (flashing)

- below that (2) the reference temperature (flashing)

- below that (3) the current sensor temperature (static)

✱ Heat the measurement medium till both the reference temperature as well

as the operating temperature are reached (the corresponding value does

not flash any more).

The LC-display now shows the determined temperature coefficient in %/K.

Accept the temperature coefficient determined -> press the key for longer

than 3 seconds, or

discard the value -> press the key .

The transmitter is in the "Calibration menu".

✱ Press key ;

The transmitter is in "Measurement mode" and displays the compensated

conductivity of the reference solution.

During the calibration, the temperature changing speed of the

measurement solution of

10 K/min in the case of JUMO CTI-750 with a free-standing temperature sensor or

1 K/min in the case of JUMO CTI-750 with an integrated temperature sensor

must not be exceeded.

As soon as one of the target temperatures is reached, its display

becomes static (not flashing).

Calibration is also possible in the cooling process (under dropping

temperature). The start is made above the operating temperature,

the end below the reference temperature.

PGM

EXIT

EXIT

(1)

(2)

(3)

Page 60

11 Calibration

60

11.3.2 Non-linear temperature coefficient (ALPHA)

General Since the temperature coefficient of some media is not constant over a larger

temperature range, the JUMO CTI-750 has the facility to divide a temperature

range (T

start

to T

end

) into 5 sub-ranges. In each of these ranges, compensation

can be carried out with different TC values. This so-called TC curve can

- be edited with the Setup program and transmitted to the device

- or calibrated automatically at the device.

Determining the

TC-curve

Calculation of a

temperature

coefficient

α = Temperature coefficient (TC)

γ = uncompensated conductivity

γ

Ref

T=T

Start 1

Temperature

Uncompensated

conductivity

γ

2

T

2

T

Ref

T=T

End 6

T

5

T

3

T

4

1

2

3

4

5

Page 61

61

11 Calibration

TC-curve

Temperature

compensation

with the TCcurve

With the help of the current medium temperature, the corresponding temperature coefficient is determined from the TC curve,’

see "TC-curve", page 61.

Intermediate values, e.g. (α

x

in the case of Tx) between two determined values

(α

3

in the case of T3) and (α4 in the case of T4) are approximated linearly.

With the TC determined, the compensated electric conductance is calculated

as in the case of the linear temperature compensation.

Sequence of the

automatic

calibration on

the JUMO CTI750

The TC curve is plotted automatically in a temperature range determined by

the user. Here, the temperature range from the starting to the final temperature

is divided into 5 equal sections.

The temperature range must be greater than 20 Kelvin and overlap the reference temperature.

Example: Reference temperature 25°C, starting temperature 18°C and final

temperature 50°C.

If the measured temperature is less than the starting temperature,

compensation is done with the first TC.

If the measured temperature is greater than the final temperature,

compensation is done with the last TC.

Page 62

11 Calibration

62

Precondition - the JUMO CTI-750 must be supplied with power.

see chapter 7 "Installation", page 30ff.

- The sensor must be connected to the transmitter (in case of "shouldered"

construction).

- The transmitter is in "Measurement mode".

✱ Submerge the conductivity sensor in a sample of the measurement solu-

tion.

✱ Press the key for longer than 3 seconds.

✱ With the keys or , select "CALIBRATION-LEVEL". with key , con-

firm the selection.

✱ With the keys or , select "TEMPCO. N-LINEAR". with key , con-

firm the selection.

The temperature changing speed may not exceed

- 10 K/min in case of a free-standing temperature sensor and

- 01 K/min in case of an integrated temperature sensor

!

PGM

PGM

PGM

Page 63

63

11 Calibration

✱ With the keys or , input the starting temperature and confirm with

the key .

✱ With the keys or , input the final temperature and confirm with the

key .

The transmitter automatically determines the temperature data points. The LC

display now shows

- at the top (1) the next temperature to be reached (flashing)

- below that (2), the current sensor temperature (static)

✱ Heat the measurement medium till the flashing temperature is exceeded or

undershot.

The starting temperature must be below the reference temperature

(25.0°C).

The final temperature must be at least 20°C above the starting

temperature.

PGM

PGM

(1)

(2)

Page 64

11 Calibration

64

The next temperature to be reached is displayed flashing.

✱ Heat the measurement medium till the flashing temperature is exceeded.

✱ Repeat the procedure till all 6 temperature coefficients are determined by

the JUMO CTI-750.

The LC-display now shows the determined temperature coefficients in %/K.

✱ Accept the temperature coefficients determined -> press the key for

longer than 3 seconds, or

discard the values -> press the key .

The transmitter is in the "Calibration menu".

✱ Press key ;

The transmitter is in "Measurement mode" and displays the compensated

conductivity of the reference solution.

During the calibration, the temperature changing speed of the

measurement solution of

10 K/min in the case of JUMO CTI-750 with a free-standing temperature sensor or

1 K/min in the case of JUMO CTI-750 with an integrated temperature sensor

must not be exceeded.

As soon as one of the target temperatures is reached, its display

becomes static (not flashing).

PGM

EXIT

EXIT

Page 65

65

12 Maintenance

12.1 Conductivity-clean sensor

Deposits Deposits on the sensor part can be removed with a soft brush (e.g. bottle

brush).

Do not use any solvents.

Stubborn sediments or deposits can be dissolved with dilute

hydrochloric acid and removed.

Comply with the safety specifications.

Page 66

66

13 Rectifying errors and faults

Error

possibilities

t

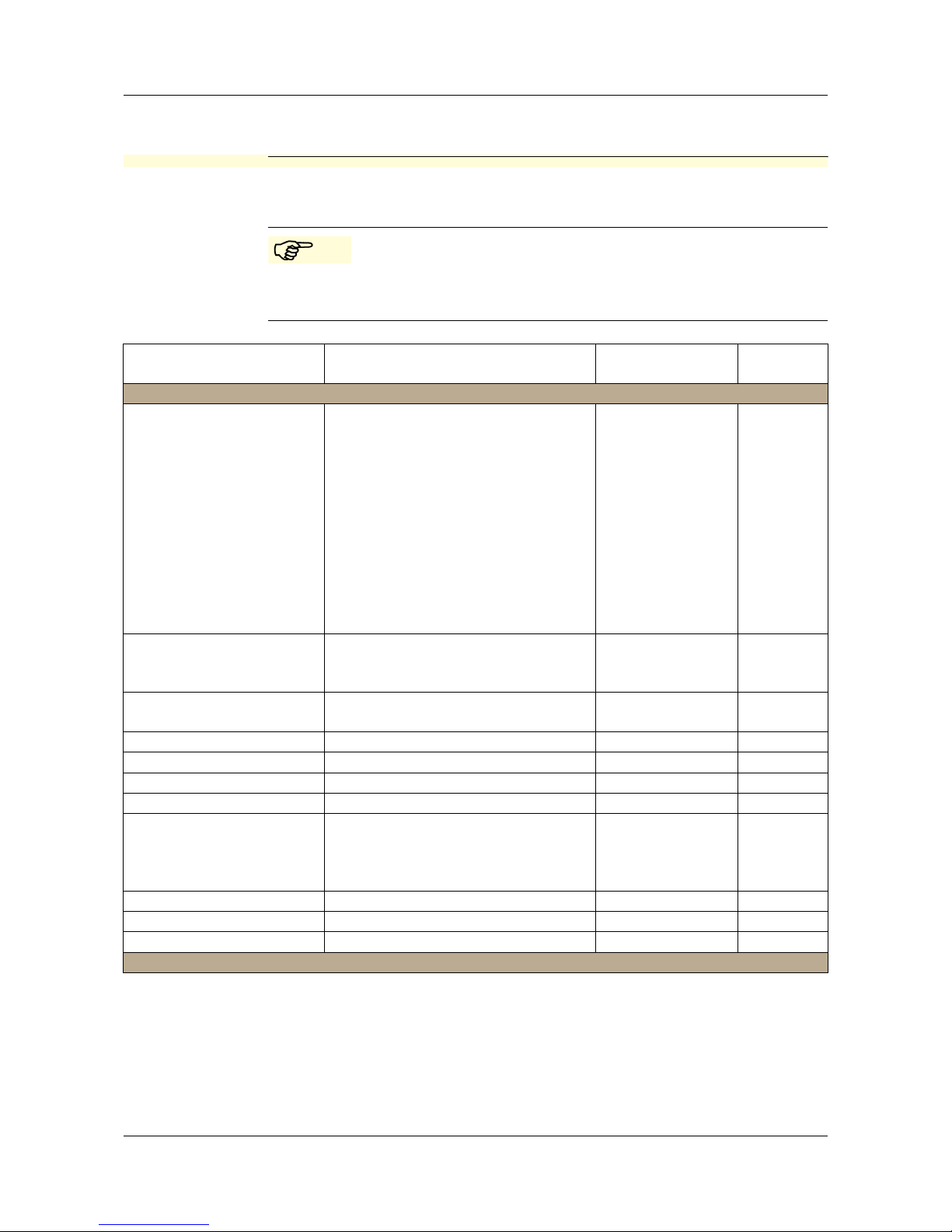

13.1 Device checking

General The device is calibrated at the factory and is maintenance-free. If measure-

ment value variations from unknown causes should occur nonetheless, the

transmitter can be checked as follows.

Problem Possible cause Measure

No display of measured

value

or

signal output

Voltage supply absent Check voltage supply,

check terminals

Measured value display

000 or

signal output 0%

(e.g. 4 mA)

Sensor not submerged in

medium;

Tank level too low

Fill up tank

Flow meter

blocked

Clean the flow meter

Sensor faulty see "Device checking",

page 66

Measured value display

8888 flashing +

device status ALARM

flashing.

The temperature display

is OK

or

LED 1 + LED 2

flashing

Out of range => the measurement/ display range

was exceeded or undershot

select suitable measurement range or check the

concentration table

Measured value display

8888 flashing +

device status ALARM

flashing.

The temperature display

is 8888 flashing

or

LED 1 + LED 2

flashing

The temperature sensor

is faulty

The transmitter or the

conductivity sensor must

be replaced.

or

set measured value ac-

quisition "Inflow temperature" briefly to manual,

see "INFLOW TEMPERATURE" , page 45.

wrong or varying

measured value display

Sensor not submerged

deep enough

Fill the tank

no blending taking place ensure good blending

near the sensor, ensure

clearance of

about 5 mm for

circulation

Air bubbles Check installation loca-

tion,

see "General", page 21.

Page 67

67

13 Rectifying errors and faults

13.1.1 Checking with resistance loop

Position of the

resistance loop

✱ Lead a wire through the measurement cell (see Figure)

✱ Connect the resistance R to the wire

Calculation of

the

resistance

Formula for calculation of the resistance of the resistance loop:

Remark: 1 mS/cm = 1·10

-3

S/cm

1 µS/cm = 1·10

-6

S/cm

In case of display values up to 20 mS, the resistance loop must have 1 turn.

In case of display values from 50 mS onwards, the resistance loop must have

3 turns.

When calibrating the sensitive part of the measurement cell, do not

place on or touch any surface, else the measured value will get falsified.

R =

N

2

· K

R = Resistance of the resistance loop

Lf N = Number of turns in the loop

K = Cell constant

Lf = desired display in S/cm

The cell constant of the JUMO CTI-750 depends on the structural

shape.!

The Tee measuring cell has a cell constant of 6.80 1/cm.

The VARIVENT

®

-measuring celll has a cell constant of 6.50 1/cm.

Page 68

13 Rectifying errors and faults

68

Example 1 The JUMO CTI-750 with Tee-shaped measuring cell should display 20 mS:

To get a display of 20 mS/cm, the resistance loop (with 1 turn) must have a resistance of 340 Ohm.

Example 2 The JUMO CTI-750 with Tee-shaped measuring cell should display 500 mS:

To get a display of 500 mS/cm, the resistance loop (with 3 turns) must have a

resistance of 122.4 Ohm.

R =

1

2

·6.80 1/cm

= 340

Ω

20·10-3 S/cm

R =

3

2

·6.80 1/cm

= 122.4

Ω

500·10-3 S/cm

Page 69

69

13 Rectifying errors and faults

Pre-calculated

values

The display value 0 is obtained when the sensor is dry and without conducting

coats, as well as when there is no resistance loop.

Structural shape/ Cell constant

Material: PEEK

K = 6.80 1/cm

Material: PEEK

K = 6.50 1/cm

Display in case of

measurement

range end

Number of

turns

Cell constant

[1/cm]

Required resis-

tance

[Ω]

500 µS/cm 1 6,80 13600,00

1 6,50 13000,00

1000 µS/cm 1 6,80 6800,00

1 6,50 6500,00

2000 µS/cm 1 6,80 3400,00

1 6,50 3250,00

5000 µS/cm 1 6,80 1360,00

1 6,50 1300,00

10 mS/cm 1 6,80 680,00

1 6,50 650,00

20 mS/cm 1 6,80 340,00

1 6,50 325,00

50 mS/cm 3 6,80 1224,00

3 6,50 1170,00

100 mS/cm 3 6,80 612,00

3 6,50 585,00

200 mS/cm 3 6,80 306,00

3 6,50 292,50

500 mS/cm 3 6,80 122,40

3 6,50 117,00

1000 mS/cm 3 6,80 61,20

3 6,50 58,50

2000 mS/cm 3 6,80 30,60

3 6,50 29,25

Material: PVDF

K = 5.45 1/cm

Page 70

13 Rectifying errors and faults

70

Carry out test ✱ Determine test resistance.

✱ Connect the JUMO CTI-750 electrically, see chapter 7 "Installation", page

30.

✱ Select the corresponding measurement range, see chapter 10.5.1 "INPUT

CONDUCTIVITY (Input conductivity)", page 42 -> MEASUREMENT RANGE

1...4

✱ Set TC to 0%/K, see chapter 10.5.1 "INPUT CONDUCTIVITY (Input con-

ductivity)", page 42 -> TEMP.COEFFICIENT.

✱ Put the resistance loop in place in accordance with the figure.

13.1.2 Testing with reference fluid

Put in test solution

Carry out test ✱ Prepare the conductivity test solution in a sufficiently large container

✱ Connect the device electrically, see chapter 7 "Installation", page 30.

✱ Select the measurement range according to the conductivity test solution,

see chapter 10.5.1 "INPUT CONDUCTIVITY (Input conductivity)", page 42 > MEASUREMENT RANGE 1...4

✱ Set TC to 0%/K, see chapter 10.5.1 "INPUT CONDUCTIVITY (Input con-

ductivity)", page 42 -> TEMP.COEFFICIENT.

✱ Submerge the measurement cell in the container and do not move any

more during the measurement.