Page 1

JUMO AQUIS touch P

Modular Multichannel Measuring Device for

Liquid Analysis with Integrated Controller and

Paperless Recorder

Type 202580

Operating Manual

b20.2580.0en

V2.00/EN/00607974

Page 2

Caution!

If the device or a sensor connected to it fails abruptly, it is likely that a

dangerous overdosage has occurred!

For this case, appropriate precautionary measures must be taken.

NOTE!

Read this operating manual before putting the device into service.

Keep the operating manual at a location that is readily accessible to

all users.

Page 3

Content

1 Safety information ...........................................................13

1.1 Warning symbols .............................................................................13

1.2 Indicative symbols ...........................................................................13

1.3 Intended use .................................................................................... 14

1.4 Qualification of personnel ................................................................ 14

2 Acceptance of goods, storage, and transport ..............15

2.1 Checking the delivery ......................................................................15

2.2 Important information about storage and transport .......................... 15

2.3 Returning goods ..............................................................................15

2.3.1 Accompanying letter for repair ......................................................... 15

2.3.2 Protection against electrostatic discharge (ESD) ............................ 16

2.4 Disposal ...........................................................................................16

3 Device Description ..........................................................17

3.1 Brief description ............................................................................... 17

3.2 Block diagram .................................................................................. 19

3.3 Device setup .................................................................................... 20

4 Identifying the device version ........................................21

4.1 Nameplate .......................................................................................21

4.2 Order details ....................................................................................22

5 Mounting ..........................................................................27

5.1 Notes ...............................................................................................27

5.2 Dimensions ......................................................................................28

5.3 Panel insertion ................................................................................. 30

6 Electrical connection ......................................................33

6.1 Installation notes .............................................................................. 33

6.2 Connecting cables ...........................................................................35

6.2.1 Preparing coaxial cables for pH/redox electrodes ........................... 35

6.2.2 Conductor cross-sections for base unit and power supply unit .......37

6.2.3 Conductor cross-sections for optional boards ................................. 38

6.3 Galvanic isolation ............................................................................. 39

Page 4

Content

6.4 Connection diagram ......................................................................... 40

6.4.1 Overview of connections .................................................................. 40

6.4.2 Analog inputs base unit ...................................................................42

6.4.3 Analog inputs optional boards ......................................................... 44

6.4.4 Analog outputs ................................................................................. 52

6.4.5 Binary inputs ....................................................................................53

6.4.6 Binary outputs, power supply unit board .......................................... 55

6.4.7 Binary outputs, optional boards ....................................................... 56

6.4.8 Mains power connection ..................................................................57

6.4.9 Voltage supply outputs .................................................................... 58

6.4.10 Interfaces .........................................................................................59

7 Startup ..............................................................................61

7.1 Initial startup ....................................................................................61

7.2 Function test ....................................................................................62

7.2.1 Checking the optional boards ..........................................................62

7.2.2 Checking sensors and inputs/outputs .............................................. 62

8 Operation .........................................................................65

8.1 Operating concept ...........................................................................65

8.1.1 Passwords and user rights .............................................................. 65

8.1.2 Display and control elements ...........................................................67

8.1.3 Menu structure ................................................................................. 68

8.1.4 Entry of text and numbers ................................................................ 73

8.2 Device menu .................................................................................... 75

8.2.1 Log-on/Log-out ................................................................................ 78

8.2.2 User level ......................................................................................... 79

8.2.3 Functional level ................................................................................ 80

8.2.4 Device information ........................................................................... 82

8.2.5 Service .............................................................................................83

8.2.6 Calibrating the touchscreen ............................................................. 84

8.3 Alarm/Event list ................................................................................ 85

8.3.1 Alarm list .......................................................................................... 86

Page 5

Content

8.3.2 Event list ..........................................................................................88

8.4 Memory Manager (USB flash drive) ................................................90

8.5 Operating the controllers .................................................................93

8.5.1 Automatic control mode ................................................................... 94

8.5.2 Controller in the manual mode ......................................................... 96

8.5.3 Hold mode .......................................................................................97

8.5.4 Optimizing controllers ......................................................................98

8.6 Operation of the data monitor/recording function ............................ 99

8.6.1 Data monitor/recording function control elements .........................100

8.6.2 History function .............................................................................. 103

8.7 Online visualization ........................................................................ 104

9 Parameterization ...........................................................109

9.1 Date and time ................................................................................109

9.2 Parameter Sets (Controller parameter) ......................................... 110

9.3 Setpoint values ..............................................................................113

9.4 Manual values ................................................................................ 113

10 Configuration .................................................................115

10.1 Important information ..................................................................... 115

10.2 Basic settings ................................................................................. 116

10.3 Display ...........................................................................................117

10.3.1 General Information ....................................................................... 117

10.3.2 Screen ...........................................................................................118

10.3.3 Colors ............................................................................................118

10.4 Operating loop ...............................................................................119

10.4.1 General screens ............................................................................119

10.4.2 Detailed screens ............................................................................ 120

10.5 Analog inputs ................................................................................. 121

10.5.1 Base unit temperature inputs ......................................................... 121

10.5.2 Universal inputs of base unit and optional boards ......................... 123

10.5.3 pH/Redox/NH

10.5.4 CR/Ci analysis inputs (conductive/inductive conductivity) ............. 128

analysis inputs ....................................................... 126

3

Page 6

Content

10.5.5 CR/Ci measuring ranges ...............................................................129

10.6 Analog outputs of base unit and optional boards ........................... 132

10.7 Digital inputs of base unit and optional boards .............................. 133

10.8 Digital outputs of base unit and optional boards ............................ 134

10.9 Limit monitoring and alarms ........................................................... 135

10.9.1 Limit monitoring .............................................................................135

10.9.2 Alarms for analog signals .............................................................. 135

10.9.3 Digital signal alarms ....................................................................... 138

10.10 Calibration timers ........................................................................... 139

10.10.1 Configuration of the calibration timers ........................................... 139

10.11 Controller .......................................................................................140

10.11.1 Configuration of the controllers ...................................................... 140

10.11.2 Controller inputs .............................................................................144

10.11.3 Disturbance feedforward control .................................................... 145

10.11.4 Self-optimization ............................................................................146

10.12 Setpoint value configuration ..........................................................147

10.13 Timers ............................................................................................148

10.13.1 Control timer .................................................................................. 150

10.14 Washtimer ......................................................................................151

10.15 Counters ........................................................................................152

10.16 Ethernet .........................................................................................153

10.17 Serial interfaces ............................................................................. 154

10.18 Formula ..........................................................................................154

10.19 Logic formula .................................................................................155

10.20 Manual values (configuration) ........................................................155

10.21 External analog inputs ...................................................................156

10.22 External digital inputs ..................................................................... 157

10.23 Flow ...............................................................................................157

11 Retrofitting optional boards .........................................161

11.1 Inserting optional boards ...............................................................161

11.2 Ci base calibration .........................................................................164

Page 7

Content

12 Calibration in general ...................................................169

12.1 Notes .............................................................................................169

12.2 General information .......................................................................169

12.2.1 General procedure for calibration .................................................. 169

12.3 Calibration logbook ........................................................................ 171

13 Calibrating a pH measuring chain ...............................175

13.1 Notes .............................................................................................175

13.2 General information .......................................................................175

13.2.1 Calibration methods for pH sensors ..............................................175

13.2.2 Calibration default settings for pH sensors ................................... 176

13.3 pH Calibration routines ..................................................................178

13.3.1 Zero-point calibration ..................................................................... 178

13.3.2 Two-point and Three-point calibration ........................................... 180

14 Calibrating Redox sensors ...........................................183

14.1 Notes .............................................................................................183

14.2 General information .......................................................................183

14.2.1 Calibration methods for Redox sensors ......................................... 183

14.2.2 Calibration default settings for Redox sensors .............................. 184

14.3 Redox calibration routines ............................................................. 185

14.3.1 Zero-point calibration ..................................................................... 185

14.3.2 Two-point Calibration ..................................................................... 186

15 Calibrating ammonia sensors ......................................187

15.1 Notes .............................................................................................187

15.2 General information .......................................................................187

15.2.1 Calibration methods for ammonia sensors .................................... 187

15.2.2 Calibration default settings for ammonia sensors .......................... 187

15.3 Ammonia calibration routines ........................................................188

15.3.1 Zero-point calibration ..................................................................... 188

16 Calibrating CR conductivity sensors ..........................189

16.1 Notes .............................................................................................189

Page 8

Content

16.2 General information .......................................................................189

16.2.1 Calibration methods for CR conductivity sensors (conductive) ..... 189

16.2.2 Calibration default settings for CR conductivity sensors ................ 190

16.3 CR calibration routines ..................................................................192

16.3.1 Calibrating the relative cell constant .............................................. 192

16.3.2 Calibrating the temperature coefficient .......................................... 194

17 Calibrating Ci conductivity sensors ............................197

17.1 Important information ..................................................................... 197

17.2 General information .......................................................................197

17.2.1 Calibration methods for Ci conductivity sensors (inductive) .......... 197

17.2.2 Calibration default settings for Ci conductivity sensors ................. 198

17.3 Ci calibration routines ....................................................................201

17.3.1 Calibrating the relative cell constant .............................................. 201

17.3.2 Calibrating the temperature coefficient .......................................... 203

17.3.3 Calibrating the TC-Curve ...............................................................205

18 Calibrating universal inputs .........................................207

18.1 Important information ..................................................................... 207

18.2 General information .......................................................................207

18.2.1 Calibration methods for universal inputs ........................................ 207

18.2.2 Universal inputs calibration default settings ................................... 209

18.3 Universal input calibration routines ................................................ 211

18.3.1 Zero point/slope calibration (linear scaling) ................................... 212

18.3.2 Two-point calibration (linear scaling) ............................................. 213

18.3.3 Slope calibration (free chlorine, ph/Temp.-compensated) ............. 215

19 PC Setup Program .......................................................217

19.1 General Information ....................................................................... 217

19.2 Installing the JUMO PC setup program ......................................... 218

19.2.1 Procedure ......................................................................................218

19.3 Setup program login ......................................................................220

19.3.1 Rights in the setup program ........................................................... 221

19.4 QuickStart agent ............................................................................ 222

Page 9

Content

19.5 User interface ................................................................................224

19.5.1 Elements of the user interface ....................................................... 224

19.5.2 Display protection ..........................................................................226

19.5.3 Editing the setup file ...................................................................... 229

19.6 Menu bar ........................................................................................ 231

19.6.1 File menu ....................................................................................... 231

19.6.2 Data Transfer menu ....................................................................... 233

19.6.3 Extras .............................................................................................235

19.6.4 Windows ........................................................................................237

19.6.5 Info .................................................................................................238

19.7 Connection to device .....................................................................239

19.7.1 Device connections list .................................................................. 239

19.7.2 Configuring the connection with the assistant ............................... 241

19.7.3 Configuring the connection without the assistant .......................... 248

19.7.4 Searching for a device in the network ............................................ 250

19.8 Setting up the device with the JUMO PC setup program .............. 252

19.8.1 Configuring and parameterizing ..................................................... 252

19.8.2 User list .......................................................................................... 252

19.8.3 Country settings ............................................................................. 255

19.8.4 Device character set ...................................................................... 261

19.8.5 User level ....................................................................................... 263

19.8.6 Formula .......................................................................................... 264

19.8.7 Logic formula .................................................................................265

19.8.8 Customer-specific linearization ...................................................... 266

19.8.9 Buffer set tables ............................................................................. 269

19.8.10 Process screens ............................................................................ 270

19.8.11 Email ..............................................................................................284

19.8.12 SMS gateway ................................................................................285

19.8.13 Web server .................................................................................... 291

19.8.14 Calibration logbook ........................................................................293

19.9 Online parameters .........................................................................294

19.9.1 Date and time ................................................................................294

Page 10

Content

19.9.2 Screenshot ..................................................................................... 295

19.9.3 Ethernet ......................................................................................... 295

19.9.4 Enabling of extra codes ................................................................. 296

19.9.5 Deleting internal measurement data .............................................. 296

19.9.6 Adjusting / Testing .........................................................................297

20 Technical data ...............................................................303

20.1 Analog inputs base unit .................................................................303

20.1.1 Temperature measuring input (IN 4) .............................................. 303

20.1.2 Temperature measuring input (IN 5) .............................................. 304

20.1.3 Universal input (IN 6) .....................................................................304

20.1.4 Measuring circuit monitoring base unit .......................................... 304

20.2 Analog inputs optional boards ....................................................... 305

20.2.1 Universal input (IN 11, IN 12) ........................................................305

20.2.2 Analysis input: pH/Redox/NH

20.2.3 Analysis input: CR (resistive conductivity) ..................................... 306

20.2.4 Analysis input: Ci (conductivity, inductive) ..................................... 307

20.2.5 Temperature compensations .........................................................308

20.2.6 Measuring circuit monitoring, optional boards ............................... 309

20.3 Analog outputs of base unit and optional boards ........................... 310

20.4 Binary inputs base unit .................................................................310

20.5 Binary inputs optional boards .......................................................310

20.6 Binary outputs, power supply unit board ........................................ 310

20.7 Binary outputs, optional boards ..................................................... 311

20.8 Voltage supply outputs, optional board .......................................... 311

20.9 Interfaces .......................................................................................312

20.9.1 Serial interface RS485 (base unit ) ................................................ 312

....................................................... 305

3

20.9.2 Serial Interface RS422/485 (optional board) ................................. 312

20.9.3 PROFIBUS-DP (optional board) ....................................................312

20.9.4 Ethernet optional board (10/100Base-T) ......................................313

20.9.5 USB interfaces ............................................................................... 314

20.10 Electrical data ................................................................................315

20.11 Screen Touchscreen ...................................................................... 315

Page 11

Content

20.12 Case ..............................................................................................316

20.13 Functions .......................................................................................317

20.13.1 Controller channels ........................................................................317

20.13.2 Recording function ........................................................................ 318

20.13.3 Customer-specific linearization ...................................................... 318

20.14 Approvals/approval marks ............................................................. 318

Page 12

Content

Page 13

1.1 Warning symbols

DANGER!

This symbol indicates that the risk of personal injury from electrocution exists

if the appropriate precautionary measures are not taken.

WARNING!

In conjunction with the signal word "Warning", this symbol indicates that the

risk of personal injury or death exists if the appropriate precautionary measures

are not taken.

CAUTION!

In conjunction with the signal word "Caution", this symbol indicates that the risk

of equipment damage or data loss exists if the appropriate precautionary measures are not taken.

CAUTION!

This symbol indicates that components of the device can be destroyed as the

result of electrostatic discharge (ESD = ElectroStatic Discharge) if the appropriate precautionary measures are not taken. When returning modules, assemblies, or components from the device, use only the ESD packaging provided.

1 Safety information

READ THE DOCUMENTATION!

This symbol, which is attached to the device, indicates that the associated documentation for the device must be observed. This is necessary in order to recognize the nature of the potential danger and take the necessary measures to

avoid it.

1.2 Indicative symbols

NOTE!

This symbol refers to important information about the product, its handling,

or additional use.

REFERENCE!

This symbol refers to additional information in other sections, chapters or

other instructions.

DISPOSAL!

At the end of its service life, the device and any batteries present do not belong

in the trash! Please dispose of them as required by regulations and in an envi-

ronmentally sound manner.

13

Page 14

1 Safety information

1.3 Intended use

The JUMO AQUIS touch P is is designed for measurement, control, and automation tasks in industrial environments as specified in the technical data. Use

for any other purpose is considered contrary to the intended use.

v Chapter 20 "Technical data", Page 303

The device has been manufactured in compliance with applicable standards and

guidelines as well as applicable safety regulations. Improper use can result in

personal injury or property damage.

To avoid risks, the device may be used only as follows:

• For the intended use

• when in good order and condition

• when taking into account the technical documentation provided

Risks resulting from the application may arise, e.g. as the result of missing safe-

ty provisions or wrong settings, even when the device is used properly and as

intended.

1.4 Qualification of personnel

This document contains the information required to ensure use of the unit as intended. It is meant for technically qualified individuals who have been specially

trained and have the appropriate know-how in the field of automation technology

(measurement and control instrumentation).

Understanding and technically correct observance of the safety instructions and

warnings contained in the supplied documentation are prerequisites for safe

mounting, installation, and commissioning as well as safety during operation.

Only qualified individuals have the required technical knowledge to interpret and

put into practice the safety instructions and warnings used in this documentation

in any given situation.

14

Page 15

2 Acceptance of goods, storage, and transport

2.1 Checking the delivery

• ensure that the packaging and its contents are undamaged

• check the delivery for completeness against the delivery papers and the order details

• inform the supplier immediately if there is any damage

• retain damaged parts until the situation has been clarified with the supplier

2.2 Important information about storage and transport

• store the device in a dry, clean environment

• observe the permissible ambient conditions,

v Chapter 20 "Technical data", Page 303

• protect the device from shock during transport

• the original packaging offers optimal protection for storage and transport

2.3 Returning goods

• if repairs are needed, return the device in clean condition and in its entirety

• use the original packaging when sending the unit back

2.3.1 Accompanying letter for repair

Please include the completed accompanying letter for repair when returning

goods. Do not forget to state the following:

• Description of the application

• Description of the error that has occurred

The accompanying letter for repair is linked to www.jumo.de on the Internet under the heading Service & Support as follows:

Product Service

r Repair Service r Returning a unit

15

Page 16

2 Acceptance of goods, storage, and transport

2.3.2 Protection against electrostatic discharge (ESD)

CAUTION!

Electrostatic charges occur in non-ESD-protected environments.

Electrostatic discharge can damage assemblies or components.

For transport purposes, use only the ESD packaging provided.

To prevent damage from ESD, electronic assemblies, or components with a

high internal resistance must be handled, packaged, and stored in an environment that protects against ESD. Measures that protect against electrostatic discharge and electric fields are described in DIN EN 61340-5-1 and DIN EN

61340-5-2 "Protection of electronic devices from electrostatic phenomena".

When sending back electronic assemblies or components, please note the following:

• Pack sensitive components only in an environment providing protection

against ESD. Such workplaces conduct existing electrostatic charges to

ground in a controlled manner and prevent electrostatic charge buildup due

to friction.

• Use only packaging intended specifically for ESD-sensitive assemblies/components. These must be made from conductive plastics.

No liability is assumed for damage caused by electrostatic discharge (ESD).

2.4 Disposal

DISPOSAL!

At the end of its service life, the device and any replaced parts do not belong

in the trash. These items are made from materials that can be reclaimed

through "recycling".

Dispose of the device and the packaging material as required by regulations

and in an environmentally sound manner!

The country-specific laws and regulations for handling and disposing of waste

must be observed!

Disposing of the packaging material

All packaging material is recyclable.

16

Page 17

3.1 Brief description

Measuring

The JUMO AQUIS touch P provides a central platform for the display and processing of pH value, redox voltage, electrolytic conductivity, resistance of highpurity water, temperature, quantities of disinfecting agents such as free chlorine,

total chlorine, chlorine dioxide, ozone, hydrogen peroxide and peracetic acid or

even flow rates. Pulse frequency inputs (counters) are available for flow rate

measurement. Universal inputs can be used to measure analog measurands using standard signals [0(4) to 20 mA or 0 to 10 V] The unit can measure and manage up to 17 parameters simultaneously.

Controlling

Besides numerous simple alarm, limit value or time-controlled switching functions, up to 4 higher-order control loops can be defined in the JUMO AQUIS

touch P at the same time. Tried and tested JUMO control algorithms are used

for P, PI, PD, and PID control in these applications.

Display

A 3.5" TFT color screen with touch function serves to display all parameters as

well as operate and setup the device. The plain text operation philosophy virtually eliminates the need for a manual. German, English, and, on request, French

are included in the device at the factory as selectable user interface languages

(see order details). Using the PC setup program, the language library of the unit

can be expanded to as many as 15 languages. It's also possible to display languages that use Chinese and Cyrillic characters. As a result, the device is predestined for global use.

3 Device Description

Recording

A paperless recorder is integrated for data recording. Up to 8 analog quantities

and 6 binary signals are registered and displayed on the screen in a time-dependent curve. Storage is tamper-proof and enables official recording obligations to

be fulfilled. The data can be extracted using the JUMO PCC software or to a

USB flash drive for evaluation by the JUMO PCA 3000 PC evaluation software.

17

Page 18

3 Device Description

Application examples

The modular setup and open structure of the device permits a host of potential

applications:

• Municipal and industrial water treatment in wastewater treatment plants

• Process systems

• Drinking and bathing water monitoring

• Pharmaceutical water

• Food and beverage production (CIP/SIP plants)

• Gas scrubbers / air washers

• Cooling tower control

• Ion exchangers

• RO-units (reverse osmosis)

• Power stations and energy plants

• Fish breeding

• Desalination of seawater

NOTE!

The device is not suitable for use in a potentially

explosive atmosphere.

18

Page 19

3.2 Block diagram

Voltage supply

according - order details

AC 110 to 240 V, 48 to 63 Hz or

AC/DC 24 V +30/-25 %, 48 to 63 Hz

Optional board:

Ethernet

RS422/485 or PROFIBUS-DP

for web server, e-mail,

setup program, Modbus TCP/IP

and JUMO PCC/PCA3000

Power supply unit and base unit

with series connections

Expansion slots

for AddOn with

Optional boards

PWR IN

OUT 8/9

Analog/binary output

IN 11 analog input

IN 12 analog input

OUT 6/7

Analog/binary output

COM 2

COM 2

IN 11

IN 12

OUT 12/13

OUT 10/11

OUT 10/11

Analog/binary output

OUT 12/13

Analog/binary output

Optional boards for

Analog outputs:

Optional boards for

binary outputs:

only OUT 14/15

Optional board for

voltage supply

outputs

Standard signals 0 to 10 V/

0(4) to 20 mA

1-way relay changeover contact/

2-way relay normally open contact/

1-way solid state relay triac/

2-way solid state relay

PhotoMOS®/

1-way logic output 0/22 V/

2-way logic output 0/12 V

:

DC ±5 V for ISFET pH-sensors

DC 24 V for

transmitters, sensors etc.

Serial interface for Modbus

USB device interface

COM 1 RS485

Input for standard signal

(current signal) 0(4) to 20 mA

via USB flash drive firmware,

extract measurement-data memory,

save service data,

save/load configuration

Pt100, Pt1000,

RTD temperature probe with

customer-specific characteristic line,

IN 5 additionally: update resistance

transmitter and NTC

Switching signals

Pulse frequency signals

for e.g. manual

mode, timer start/stop etc.

IN 2 and IN 3 additionally:

for

Pulse generator, e.g. impeller

sensors for flow measurement

IN 1 binary input 1

IN 6 universal input

IN 2 binary input 2

IN 3 binary input 3

IN 4 temperature input 1

IN 5 temperature input 2

USB host interface

Standard signals

0 to 10 V or 0(4) to 20 mA

OUT 4 analog output

Relay switching outputs with

normally open contact

OUT 1 binary output

OUT 2 binary output

Optional board

Universal inputs:

0(4) to 20 mA, 0 to 10 V, Pt100,

Pt1000, RTD temperature probe

with customer-specific characteristic

line, Resistance transmitter

IN 13/14/15

Binary inputs

IN 16/17/18

Binary inputs

Optional board

3-way binary input:

for up - 3 switching signals

IN 7 Option analysis 1

IN 8 Option analysis 2

Optional boards for

analysis inputs

(in any combination):

pH-value/redox potential/NH

electrolytic conductivity

(conductive)

electrolytic conductivity

(inductive)

3

for pH sensors (conventional and

ISFET), redox-, or NH sensors/

for

Conductivity sensors

in 2-/4 conductor technology/

for inductive

conductivity sensors from JUMO

3

IN 7

IN 8

IN

13/14/15

IN

16/17/18

OUT 8/9

OUT 6/7

for setup program and

extract measurement data via

JUMO PCC/PCA3000

3 Device Description

19

Page 20

3 Device Description

(1)

(1)

(2)

(2)

(3)

(6) (7)

(4)(5)

3.3 Device setup

(1) Mounting brackets

(2) Metal case barrel

(3) Rear panel with connection terminals (base unit and optional boards)

(4) Housing front

(5) LED (voltage supply switched on)

(6) Touch screen TFT color screen

(7) USB interfaces

20

Page 21

4.1 Nameplate

(1)

(2)

(3)(4)

(6)

(7)

(5)

The nameplate on the device enclosure identifies the device version.

Example of a nameplate

4 Identifying the device version

(1) Datamatrix code

(2) Information symbol (Read documentation!

v Chapter 1.1 "Warning symbols", Page 13)

(3) Part number

(4) Serial number

(5) Approval mark

(6) Voltage supply

(7) Type key

It is helpful to become familiar with the technical features of the device prior to

commissioning. Compare the type code on the nameplate with the order details.

v „Order details“, Page 22

In the event of technical questions, please have the information from the nameplate available for the customer service representative.

21

Page 22

4 Identifying the device version

4.2 Order details

NOTE!

In addition to the standard languages of German, English and, French, 13 additional languages (e.g. Russian, Chinese, Italian etc.) are available. Please

use the contact information on the back of this manual to contact JUMO in this

regard.

(1) Basic type

202580 JUMO AQUIS touch P

(2) Version

8 Standard with factory settings

9 Customer-specific configuration (specification in plain text)

(3) Language

01 German

02 English

03 French

(4) Analysis input 1 IN 7

0 Not used

1 pH/redox/NH

2 CR resistive conductivity measurement (2 and 4-pole)

3 Ci inductive conductivity measurement

(5) Analysis input 2 IN 8

0 Not used

1 pH/redox/NH

2 CR resistive conductivity measurement (2 and 4-pole)

3 Ci inductive conductivity measurement

(6) Input/output 1 IN 11, OUT 6/7

00 Not used

10 Universal input

11 Relay (changeover contact)

12 2× relays (normally open contact)

13 Solid state relay triac 230 V, 1 A

14 Logic output 0/22 V

15 2× logic outputs 0/12 V

16 Analog output

17 2× solid state relay PhotoMOS®

3

3

Slot

22

Page 23

4 Identifying the device version

(7) Input/output 2 IN 12, OUT 8/9

00 Not used

10 Universal input

11 Relay (changeover contact)

12 2× relays (normally open contact)

13 Solid state relay triac 230 V, 1 A

14 Logic output 0/22 V

15 2× logic outputs 0/12 V

16 Analog output

17 2× solid state relay PhotoMOS®

19 Voltage supply output DC ±5 V, 24 V

(8) Input/output 3 IN 13/14/15,

OUT 10/11

00 Not used

11 Relay (changeover contact)

12 2× relays (normally open contact)

13 Solid state relay triac 230 V, 1 A

14 Logic output 0/22 V

15 2× logic outputs 0/12 V

16 Analog output

17 2× solid state relay PhotoMOS®

18 3× binary inputs

(9) Input/output 4 IN 16/17/18,

OUT 12/13

00 Not used

11 Relay (changeover contact)

12 2× relays (normally open contact)

13 Solid state relay triac 230 V, 1 A

14 Logic output 0/22 V

15 2× logic outputs 0/12 V

16 Analog output

17 2× solid state relay PhotoMOS®

18 3× binary inputs

(10) voltage supply

23 AC 110 to 240 V +10/-15 %; 48 to 63 Hz

39 AC/DC 24 V +30/-25 %; 48 to 63 Hz

(11) Interface Com2 COM 2

00

Not used

23

Page 24

4 Identifying the device version

08

54

64

Ethernet

RS422/485 Modbus RTU

PROFIBUS-DP

(12) Extra code

000

213

214

without extra code

Recording function

Math and logic module

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10) (11)

Order code: /---------/

Order example: 202580 / 8 - 01 - 1 - 2 - 10 - 10 - 13 - 13 - 23 - 64 -

(12)

a

, ...

213 , 214

a

List all desired extra codes separated by commas.

Scope of delivery

JUMO AQUIS touch P according to order details (including 4× mounting elements)

Panel seal

Mini-DVD with JUMO PC setup program as demo version, Adobe Acrobat Reader, operating man-

ual and data sheet in PDF format, GSD generator and JUMO PCC / PCA3000 as demo version

Installation instructions in 2 volumes B 202580.4

24

Page 25

4 Identifying the device version

Accessories

Order code Type Part no.

703571 (20258x)/10 Universal input 00581159

703571 (20258x)/213 Activation of the recording function 00581176

703571 (20258x)/214 Activate math and logic module 00581177

703571 (20258x)/11 Binary output relay (changeover contact) 00581160

703571 (20258x)/12 Binary outputs 2× relay (normally open contact) 00581162

703571 (20258x)/13 Solid state relay triac 230 V, 1 A 00581164

703571 (20258x)/14 Logic output 0/22 V 00581165

703571 (20258x)/15 2 Logic outputs 0/12 V 00581168

703571 (20258x)/16 Analog output 00581169

703571 (20258x)/17 Binary outputs 2× solid state relays PhotoMOS®

703571 (20258x)/54 Serial interface RS422/485 for Modbus RTU 00581172

703571 (20258x)/64 PROFIBUS-DP 00581173

703571 (20258x)/08 Ethernet 00581174

20258x/3 Analysis input Ci for inductive conductivity 00584265

20258x/2 Analysis input CR for resistive conductivity 00584263

20258x/1 Analysis input pH/redox/NH

3

20258x/18 Binary inputs 3× potential-free contact 00592962

20258x/19 Voltage supply output DC ±5 V, 24 V 00592963

USB flash drive 2.0 (1 GB)

b

USB cable, A-connector to Mini-B connector,

length 3 m

JUMO PC setup program AQUIS touch S/P,

(PG202599)

JUMO PCA3000/PCC software package

a

PhotoMOS® is a registered trademark of Panasonic.

b

The USB flash drive indicated has been tested and is designed for industrial applications. No

liability is assumed for flash drives from other manufacturers.

c

Communication and evaluation software for stored recording function measurement data

c

a

00581171

00584264

00505592

00506252

00594355

00431884

25

Page 26

4 Identifying the device version

26

Page 27

5.1 Notes

Mounting site

5 Mounting

DANGER!

Under no circumstances may the device be installed or removed while under

voltage! This poses the risk of electrocution.

Switch-off the entire system beforehand. This work must be performed only by

qualified personnel!

The device must never be installed in potentially-explosive areas! There is the

risk of an explosion.

When determining the mounting site, it is important to ensure that the device

specifications are respected. The relevant tables containing details of case

specifications can be found in the chapter entitled "Technical Data" . The device

must not be exposed to any severe shocks or permanent vibrations. Electromagnetic fields caused by equipment such as motors or transformers must be

avoided!

Climatic conditions

Installation position

Space requirement

The ambient temperature and the relative humidity at the mounting site must

correspond to the technical data.

v Chapter 20 "Technical data", Page 303

The device can be installed in any position. However, the viewing angle of the

TFT touchscreen should be taken into consideration.

v Chapter 20 "Technical data", Page 303

Ensure adequate access to the region around the cable entry points. The minimum bending radius of the cables must be taken into account!

v Chapter 5.2 "Dimensions", Page 28

27

Page 28

5 Mounting

92 mm

+0.8 mm

92 mm

+0.8 mm

130,9 mm

96 mm

123,1 mm

90,5 mm

97,1 mm

104,1 mm

96 mm

22,25 mm

22,25 mm

22,25 mm

22,25 mm

90,5 mm

97,1 mm

104,1 mm

5,5 mm

Panel thickness max. 5 mm

5.2 Dimensions

Spacings

For adequate ventilation, the following mounting distances from adjacent equipment must be respected:

• horizontal 35 mm

•vertical 80mm

When inserting the device, sufficient space for maneuvering the connecting cables must be left behind the case. A Ci-conductivity sensor is connected via a

M12 connector adapter. This increases the space requirement with respect to

mounting depth (see dimensional drawing below).

28

Page 29

Mounting depth with Ci-conductivity sensor

283,3 mm

2,3 mm

36 mm

25 mm

23,2 mm

5 Mounting

29

Page 30

5 Mounting

5.3 Panel insertion

The device is designed to be inserted in switch cabinets or machine/system

walls. The insertion operation is described below.

NOTE!

Insertion in a control panel provides protection class IP66. When the JUMO

AQUIS touch P is inserted in the wall of control cabinets with a protection class

higher than IP66, the protection class of the control cabinet lapses and corresponds to the protection class for control panel insertion (IP66).

CAUTION!

Ensure that the control panel provides adequate support for the device.

The weight values listed in the technical data must be taken into account to ensure adequate mechanical stability for control panel installation.

v Chapter 20.12 "Case", Page 316

30

Page 31

5 Mounting

(1)

(2)

(3)

(5)

(4)

Procedure

(1) Metal case barrel of the JUMO AQUIS touch P

(2) Mounting elements

(3) Seal from the scope of delivery for the device

(4) Case front

(5) Panel/control cabinet

Step Action

1 Push the panel seal provided (3) from the rear panel of the device

over the case barrel to the front panel.

2 Place the device in the cutout provided for this purpose in the con-

trol panel (5) as shown in the drawing.

3 Insert the mounting elements (2) into the holders on the case pro-

vided for this purpose, as shown on the drawing.

4 Screw the mounting element firmly against the panel so that the

case front (4) of the device is tight against the panel (5) and the device is firmly seated.

31

Page 32

5 Mounting

32

Page 33

6.1 Installation notes

DANGER!

Observe the following instructions!

Qualification of personnel

• The electrical connection must only be carried out by qualified personnel.

Electrical wiring

• When selecting the electrical wiring material as well as when installing and

connecting the device electrically, comply with the requirements of DIN VDE

0100 "Low-voltage electrical installations" and the applicable country-specific regulations (e. g. based on IEC 60364).

• The input, output, and power supply lines must be separated from one another spatially and not laid in parallel.

• Select suitable cables for sensors and interfaces (shielded and twisted or coaxial cable). These lines must not be installed near live electrical components or current-carrying wiring.

• Sensor lines must be uninterrupted (not connected via terminal blocks or the

like).

• Provide shielding in accordance with the connection diagram on the device.

• In a star wiring configuration, grounding wires must be connected to an equipotential grounding busbar and insulation must be intact. Keep lines as short

as possible. Ensure proper potential equalization/bonding.

6 Electrical connection

Electrical safety

• Disconnect all phases of the power supplied to the device (power grid, outside power supply sources for relays/solid state relays etc.) If current-carrying components could be touched while work is being performed.

• Fuses for power supply circuits should be rated at no more than 10 A (slowblow).

• To prevent destruction of device outputs in the event of an external short circuit, short-circuit currents in circuits with relay or semiconductor outputs

should be limited through use of appropriate fuses.

• The device is not suitable for installation in potentially explosive atmospheres.

• Besides incorrect installation, wrong settings on the device can adversely affect performance of the connected process. For this reason, independently

operating safety devices, e.g. pressure relief valves, temperature limiters/

monitors, liquid-metering limiters and overflow prevention devices should be

provided and adjustment of them restricted only to train technical personnel.

Appropriate safety regulations must be observed in this connection.

• Plug-in screw terminal strips should not be unplugged until after the power

has been disconnected.

References to other information

33

Page 34

6 Electrical connection

• The electromagnetic compatibility conforms to the standards and regulations

cited in the technical data.

• The USB interfaces and digital inputs are not electrically isolated.

The information regarding electrical isolation must be observed.

v Chapter 6.3 "Galvanic isolation", Page 39

34

Page 35

6 Electrical connection

ø5 mm

ø2 mm

ø1.5 mm

25 mm

Sensor

Inner conductor

Shield-Kon® connector

6.2 Connecting cables

6.2.1 Preparing coaxial cables for pH/redox electrodes

®

Coaxial cable with Shield-Kon

connector

Length Part number

1.5 m 00085154

5 m 00307298

10 m 00082649

Preparing your own coaxial cable

1

Remove outer sheathing from the cable

.

Remove black, semiconducting layer (see image) r Strip insulation off inside

conductor

r Attach Shield-Kon® connector

1.Shield-Kon is a registered trademark of THOMAS & BETTS INTERNATIONAL, Inc.,

Wilmington Del., US.

r Pull back the braided shield

1

for shield

35

Page 36

6 Electrical connection

Inner conductor

Shrink sleeve

60 mm

60 mm

Shield-Kon® connector

Use shrink tubing to insulate the braided shield

NOTE!

The black, semiconducting layer must not touch with the inside conductor! This

would short-circuit the signal from the pH electrode.

Preparing a shielded multiconductor cable

Strip the insulation off the connecting cable and pull back the shield

36

Attach wire ferrules to the ends of the conductors and a Shield-Kon® connector

for shielding

1.Shield-Kon is a registered trademark of THOMAS & BETTS INTERNATIONAL, Inc.,

Wilmington Del., US.

1

Page 37

6 Electrical connection

60 mm

Shield-Kon® connector

Use shrink tubing to insulate the shield and Shield-Kon® connector

6.2.2 Conductor cross-sections for base unit and power supply unit

The terminals on the base unit and power supply unit are plug-in screw terminals.

^

Ferrule Conductor cross sec-

tion

minimal maximal

without ferrule

Power supply unit voltage supply 0.2 mm

Power supply unit relay switching

0.2 mm

²

2.5mm² 7mm

²

2.5mm² 7mm

outputs

Base unit 0.14 mm

2

1.5 mm

Ferrule without lip

Power supply unit voltage supply 0.25 mm

Power supply unit relay switching

0.25 mm

2

2.5mm² 7mm

2

2.5mm² 7mm

outputs

2

Base unit 0.25 mm

1.5 mm

2

2

1

Length to

strip

7mm

7mm

with ferrule with lip

Power supply unit voltage supply 0.25 mm

Power supply unit relay switching

0.25 mm

2

2.5mm² 7mm

2

2.5mm² 7mm

outputs

Base unit 0.25 mm

2

0.5 mm

2

7mm

Rigid

Power supply unit voltage supply 0.2 mm

Power supply unit relay switching

0.2 mm

²

2.5mm² 7mm

²

2.5mm² 7mm

outputs

Base unit 0.14 mm

1.Shield-Kon is a registered trademark of THOMAS & BETTS INTERNATIONAL, Inc.,

Wilmington Del., US.

2

1.5 mm

2

7mm

37

Page 38

6 Electrical connection

6.2.3 Conductor cross-sections for optional boards

The terminals on optional boards are plug-in screw terminals.

Optional boards for Ferrule Conductor cross sec-

tion

minimal maximal

Universal inputs

Analog outputs

Binary inputs

Digital outputs PhotoMOS®

Logic outputs

without ferrule 0.14 mm

with ferrule with lip 0.25 mm

a

Ferrule without lip 0.25 mm

Rigid 0.14 mm

2

2

2

2

1.5 mm

0.5 mm

1.5 mm

1.5 mm

Voltage supply output

Analysis inputs pH/Redox/NH

Analysis inputs CR

Analysis inputs Ci

b

c

Digital outputs relay

Digital outputs triac

a

PhotoMOS® is a registered trademark of Panasonic.

b

CR analysis inputs = Analysis inputs for resistive conductivity

c

Analysis inputs Ci = Analysis inputs for inductive conductivity

without ferrule 0.2 mm

3

with ferrule with lip 0.25 mm

Ferrule without lip 0.25 mm

Rigid 0.2 mm

²

2.5mm² 7mm

2

1.5 mm

2

2.5mm² 7mm

²

2.5mm² 7mm

2

2

2

2

2

Length to

strip

7mm

7mm

7mm

7mm

7mm

38

Page 39

6.3 Galvanic isolation

Optional boards for binary outputs:

Relay for 2-way normally open contact,

1-way changeover contact

OUT 6 to OUT 13

Optional boards for binary outputs:

Solid state relay triac

OUT 6 to OUT 13

Optional boards for analog outputs:

0/4 to 20 mA or 0 to 10 V

OUT 6 to OUT 13

Optional boards for binary outputs:

Logic output 0/22 V

OUT 6 to OUT 13

Optional boards for binary outputs:

Solid state relay PhotoMOS

OUT 6 to OUT 19

®

Binary outputs

Relay, power supply unit board

OUT 1 to OUT 2

Analog input 0/4 to 20 mA, base unit

IN 6

Analog outputs, base unit

OUT 4

Binary inputs, base unit

IN1toIN3

Temperature input 1 on base unit

IN 4

Temperature input 2 on base unit

IN 5

USB host interface, base unit

USB device interface, base unit

RS485 base unit

COM 1

Optional board: Ethernet

COM 2

Optional boards for analysis inputs:

IN7toIN8

Optional boards for universal inputs:

IN 11 to IN 12

Optional board: RS485/RS422, PROFIBUS-DP

COM 2

Optional boards: 3-way binary inputs

IN 13 to IN 18

Optional boards

Base unit and

Power supply unit board

Optional boards for voltage supply

outputs DC 24 V and DC ±5 V:

OUT 8/9

Optional boards for binary outputs:

2-way logic output 0/12 V

OUT 6 to OUT 13

AC 30 V

DC 50 V

AC 30 V

DC 50 V

AC 30 V

DC 50 V

AC 30 V

DC 50 V

AC 30 V

DC 50 V

AC 30 V

DC 50 V

AC 30 V

DC 50 V

AC 30 V

DC 50 V

AC 30 V

DC 50 V

AC 30 V

DC 50 V

AC 30 V

DC 50 V

AC 30 V

DC 50 V

AC/DC 3.6 kV

Voltage supply

AC 110 to 240 V; 48 to 63 Hz or

AC/DC 24 V +30/-25 %; 48 to 63 Hz

AC 3.6 kV

AC 3.6 kV

AC 3.6 kV

6 Electrical connection

.

Note

If sensors that are not electrically isolated are connected to a digital input

and supplied by an external power source, potential differences between the internal and external ground can cause problems. Providing the supply voltage

from the voltage supply outputs of the JUMO AQUIS touch P is preferable in

such cases.

39

Page 40

6 Electrical connection

Base unit

Options

Supply unit

6.4 Connection diagram

6.4.1 Overview of connections

Module Connector terminal Type

Inputs Base

unit

Optional

boards

– IN 9 to IN 10 Not available

Optional

boards

IN 1 to IN 3 Binary inputs

IN 4 to IN 5 Temperature inputs

IN 6 Universal input

IN 7 to IN 8 analysis inputs

a

IN 11 to IN 12 Universal inputs

IN 13 to IN 18 Binary inputs

40

Page 41

6 Electrical connection

Outputs Power

OUT 1 to 2 Digital outputs (relay changeover contact)

supply

unit

Base

unit

–

Option-

OUT 3 Not available

OUT 4 Analog output

OUT 5 Not available

OUT 6 to OUT 13 Analog/digital outputs, OUT 8/9 also for

al

boards

Interfaces Base

unit

COM 1 RS485

USB device interface USB device interface

USB host interface USB host interface

Option-

COM 2 Ethernet, PROFIBUS-DP, or RS422/485

al

boards

a

Available only on the AQUIS touch S

a

a

voltage supply output DC ±5 V, 24 V

41

Page 42

6 Electrical connection

3

5

3

4

5

6

8

6

7

8

6

8

6

7

8

A

S

E

6

7

8

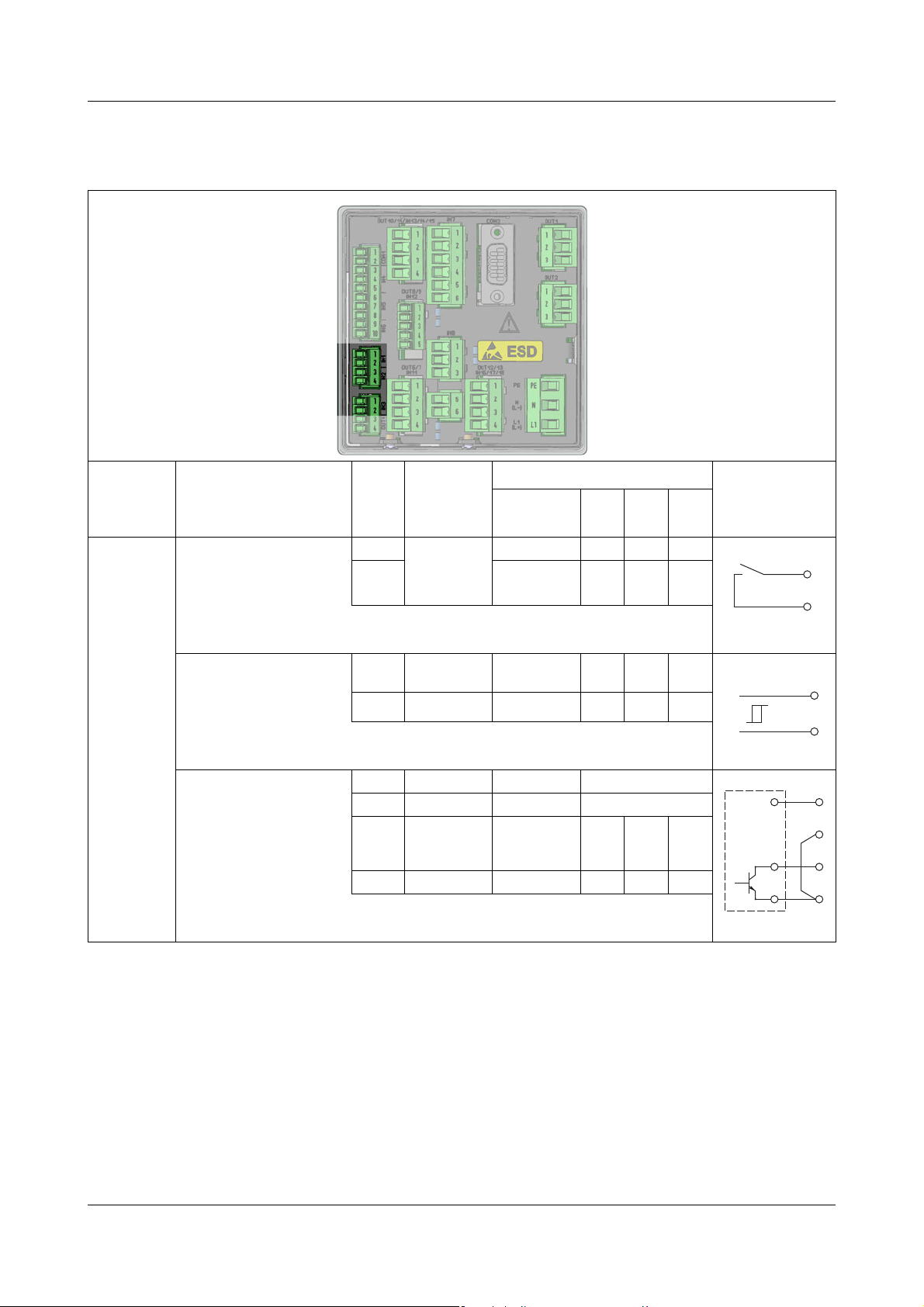

6.4.2 Analog inputs base unit

Connector/

Connection variant Symbol

terminal

IN 4 RTD temperature probe

2-wire circuit

Pt100, Pt1000 or

customer-specific characteristic line

RTD temperature probe

3-wire circuit

Pt100, Pt1000 or

customer-specific characteristic line

IN 5 RTD temperature probe

2-wire circuit

Pt100, Pt1000 or

customer-specific characteristic line

RTD temperature probe

3-wire circuit

Pt100, Pt1000 or

customer-specific characteristic line

NTC

2-wire circuit

NTC

3-wire circuit

Resistance potentiometer

A=Start

E=End

S = Slider

42

Page 43

6 Electrical connection

+

-

X

I

9

10

Connector/

Connection variant Symbol

terminal

IN 6 Standard signal

Current 0(4) to 20 mA

43

Page 44

6 Electrical connection

2

4

2

3

4

A

S

E

2

3

4

+

-

X

U

1

4

+

-

X

I

3

4

6.4.3 Analog inputs optional boards

Universal inputs

Slot Connection variant Symbol

IN 11

IN 12

RTD temperature probe

2-wire circuit

Pt100, Pt1000 or

customer-specific characteristic line

RTD temperature probe

3-wire circuit

Pt100, Pt1000 or

customer-specific characteristic line

Resistance potentiometer

A=Start

E=End

S = Slider

Standard signal

Voltage 0to10V

Standard signal

Current 0(4) to 20 mA

44

Page 45

analysis inputs

A

G

H

I

B

C

D

E

F

ϑ

G

H

I

6 Electrical connection

Slot Option/

connection variant

IN 7

IN 8

ISFET-pH

sensor

Wire

(color)

Potential Terminal Symbol

a

DC

±5 V

Tempera-

b

ture input

A (blue) DC +5 V 3

B (black)

GND

4

with jumper to F

C (green) DC -5 V 5

D (white/

black)

Ion-sensitive gate

E Bypass 3

F (yellow) Reference 6

G (white) Compensa-

H (red)

tion ther-

Connection

c

mometer in

I (red/

black)

3-wire circuit

Analysis

input

pH/redox

1

5

The RTD temperature probe is used to provide a temperature-compensated pH-value measurement, and can be connected

a

The conductor colors listed refer to JUMO ISFET-pH sensors. The orange-colored conductor is not connected.

b

The optional board "Voltage supply output DC ±5 V, 24 V“ (part no. 592963) is required for the voltage

supply to the JUMO ISFET-pH sensor.

c

The connection diagram for the analog input concerned must be observed when connecting the temperature probe.

to a temperature input or universal input.

d

45

Page 46

6 Electrical connection

A

B

1

3

5

6

d

When connecting the temperature probe of JUMO ISFET pH sensors to process connection 615 (NTC

8k55), no customer-specific linearization like that for the JUMO AQUIS 500 pH is needed. Temperature

input IN 5 supports connection of 8k55-NTC temperature probes.

Slot Option/connection variant Symbol

IN 7

IN 8

pH/Redox

Asymmetric connection of a combination electrode

Standard connection variant

For temperature compensation, a separate temperature sensor can be connected to an analog input.

A = Glass/metal electrode

B = Reference electrode

Terminal 2 is not connected!

46

Page 47

6 Electrical connection

?

A

B

E

F

D

C

1

3

5

6

Slot Option/connection variant Symbol

IN 7

IN 8

pH/Redox

Asymmetric connection of a combination electrode with

integrated RTD temperature probe and VarioPin terminal

head

The RTD temperature probe is used to provide a temperature-compensated pH-value measurement, and can be connected to a temperature input or universal input.

A = Glass/metal electrode (core)

B = Reference electrode (inner shield)

C = Shield (outer shield)

D = RTD temperature probe

E = RTD temperature probe

F = RTD temperature probe

Terminal 2 is not connected!

47

Page 48

6 Electrical connection

1

3

5

6

A

B

D

C

Slot Option/connection variant Symbol

IN 7

IN 8

pH/Redox

Symmetric connection of a combination electrode

Symmetric connection is used to reduce interference from

stray electromagnetic fields along the sensor cable.

A = Glass/metal electrode (core)

B = Reference electrode (inner shield)

C = Liquid potential (grounding pin, pipe, or container wall at

the measuring point)

D = Shield (outer shield)

Terminal 2 is not connected!

48

Page 49

6 Electrical connection

?

A

B

E

F

G

D

C

1

3

5

6

Slot Option/connection variant Symbol

IN 7

IN 8

pH/Redox

Symmetric connection of a combination electrode with

integrated resistance thermometer and VarioPin plug

head

Symmetric connection is used to reduce interference from

stray electromagnetic fields along the sensor cable.

The RTD temperature probe is used to provide a temperature-compensated pH-value measurement, and can be connected to a temperature input or universal input.

A = Glass/metal electrode (core)

B = Reference electrode (inner shield)

C = Liquid potential (grounding pin, pipe, or container wall at

the measuring point)

D = Shield (outer shield)

E = RTD temperature probe

F = RTD temperature probe

G = RTD temperature probe

Terminal 2 is not connected!

49

Page 50

6 Electrical connection

C

B

A

1

2

3

4

6

E

C

D

B

A

1

2

3

4

6

Slot Option/connection variant Symbol

IN 7

IN 8

Ci optional board (inductive conductivity measurement)

Connection via an M12 plug,

Attach connections for compensation

thermometer (2-wire cable for socket) to a

suitable analog input (2-wire circuit),

The factory-installed wiring must not be changed!

CR optional board (resistive conductivity measurement)

2-electrode system with 2-wire conductor

Terminal 1 must be connected to the

outer electrode on concentric conductivity sensors.

A = Outer electrode (core color for JUMO types with fixed cable: White)

B = Inner electrode (core color for JUMO types with fixed cable: Brown)

C= Shield

CR optional board (resistive conductivity measurement)

2-electrode system with 4-wire conductor

(Wiring to minimize the measuring error caused by lead-wire

resistance)

Terminal 1 must be connected to the

outer electrode on concentric conductivity sensors.

A/B = Outer electrode

C/D = Inner electrode

E=Shield

50

Page 51

6 Electrical connection

E

C

D

B

A

1

2

3

4

6

Slot Option/connection variant Symbol

IN 7

IN 8

CR optional board (resistive conductivity measurement)

4-electrode system

A = Outer electrode 1 (I hi) (core color of CR-4P cable for

JUMO types: Red)

B = Inner electrode 1 (U hi) (core color of CR-4P cable for

JUMO types: Gray)

C = Inner electrode 2 (U lo) (core color of CR-4P cable for

JUMO types: Pink)

D = Outer electrode 2 (I lo) (core color of CR-4P cable for

JUMO types: Blue)

E= Shield

51

Page 52

6 Electrical connection

+

-

U

I

X

X

3

4

+

-

U

I

X

X

1

2

6.4.4 Analog outputs

Base unit

Connector/

Connection variant Symbol

terminal

OUT 4 Analog output

DC 0to10V or

DC 0(4) to 20 mA

(configurable)

Optional boards

Slot Option/connection variant Symbol

OUT 6/7

OUT 8/9

OUT 10/11

OUT 12/13

Analog output

DC 0to10V or

DC 0(4) to 20 mA

(configurable)

52

Page 53

6.4.5 Binary inputs

A

B

+

-

A

B

+

-

A

B

C

D

Base unit

6 Electrical connection

Connec-

Connection variant Wire Potential Terminal Symbol

tor/

terminal

IN 1 to 3 Digital input

(potential-free

contact)

In the digital input configuration, the "Contact" option must be set to

"Potential-free contact".

Digital input

(external voltage

source)

In the digital input configuration, the "Contact" option must be set to

"Ext. voltage supply".

Digital input

(NPN transistor

switching output)

In the digital input configuration, the "Contact" option must be set to

"Potential-free contact".

DC 24 V

a

IN 1 IN 2 IN 3

OUT 8/9

A Potential-free

B242

ALogic signal

BLogic signal - 242

ASensor +1

b

BSensor -2

C Switching

DSensor - 242

contact

+

signal

(collector)

131

131

131

53

Page 54

6 Electrical connection

A

B

C

D

+

-

Connector/

terminal

IN 1 to 3 Digital input

Connection variant Wire Potential Terminal Symbol

DC 24 V

a

IN 1 IN 2 IN 3

OUT 8/9

ASensor +1

(NPN transistor

switching output)

b

BSensor -2

C Switching

signal

(collector)

DSensor - 242

131

In the digital input configuration, the "Contact" option must be set to

"Ext. voltage supply".

a

For the voltage supply to sensors with DC 24 V, the optional board for voltage supply (part no. 00592963)

must be integrated into the device.

b

The connection variants for transistor switching outputs (NPN / PNP) are especially important for the flow

measurement via impeller sensor (type 406020, part no. 00525530, 00525531) at inputs IN 2 and IN 3

(pulse frequency inputs). However, other sensors with transistor switching output can also be connected.

54

Page 55

Optional boards

1

2

3

4

NC

Com

NO

1

2

3

6 Electrical connection

Connector/

Connection variant Symbol

terminal

IN 13/14/15

3× binary input

IN 16/17/18

6.4.6 Binary outputs, power supply unit board

Connector/

terminal

OUT 1

OUT 2

Connection variant Symbol

Relay

Changeover contact

55

Page 56

6 Electrical connection

NC

Com

NO

1

2

3

NO

NO

1

2

3

4

1

2

1

2

3

4

+

-

1

2

+

-

+

-

1

2

3

4

6.4.7 Binary outputs, optional boards

Slot Option/connection variant Symbol

OUT 6/7

OUT 8/9

OUT 10/11

OUT 12/13

Relay

Changeover contact

2× relay

Normally open contact

Solid state relay triac

230 V/1 A

2× solid state relay PhotoMOS®

50 V/200 mA

Binary output

0/22 V

2× binary output

0/12 V

a

a

PhotoMOS® is a registered trademark of Panasonic.

56

Page 57

WARNING!

L1

N

PE

L1

PE

N

Combining a mains voltage circuit with a protective low-voltage

circuit on the option "dual normally open contacts" is not permissible.

6.4.8 Mains power connection

6 Electrical connection

Connector/

Connection variant Symbol

terminal

PWR IN Mains power input

57

Page 58

6 Electrical connection

+

-

-

-

U

=

3

4

5

+

-

U

=

1

2

6.4.9 Voltage supply outputs

Optional board

Slot Connection variant Symbol

OUT 8/9 Voltage supply DC ±5V

for ISFET sensors

Voltage supply DC 24 V

for external transmitters 24 V

58

Page 59

6.4.10 Interfaces

RxD/TxD+

RxD/TxD-

1

2

1

5

41

Base unit interfaces

6 Electrical connection

Connector/

Connection variant Symbol

terminal

COM 1 RS485

Connector/

Connection variant Symbol

terminal

USB device USB device

Type Mini-B (socket)

USB host USB host

Type A (socket)

59

Page 60

6 Electrical connection

1 2 3 4

1 2 3 4

RxD+

RxD-

TxD+

TxD-

1

3

4

2

RxD/TxD+

RxD/TxD-

3

4

5

4

3

2

9

8

7

6

1

Optional board interfaces

Slot Connection variant Terminating resistors Symbol

COM 2 RS422

terminating resistors with

DIP switches on

optional board configurable

with terminating resistors

without terminating resistors

RS485

terminating resistors with

DIP switches on

optional board configurable

PROFIBUS-DP

3 = RxD/TxD-P

5 = DGND

6 = VP

8 = RxD/TxD-N

LAN Ethernet

Type RJ 45 (socket)

—

—

60

Page 61

7 Startup

WARNING!

Prior to startup, ensure that the device has been installed and connected properly and

in compliance with the installation instructions. Observe the safety instructions

in this description.

v Chapter 1 "Safety information", Page 13

CAUTION!

A backup battery is built into the device. Its purpose is to maintain data when

the device is switched off or if the voltage supply is interrupted. If the battery

approaches the end of its operating life (approximately 7 years) then a battery

prealarm will indicate that status. When the battery is empty a battery alarm will

indicate that status. The battery must be exchanged before it is empty. The battery must be exchanged by the JUMO Service department! In this case, send

in the device!

CAUTION!

The touchscreen must not be operated with sharp or pointed objects, as these

could damage the protective film and the touchscreen.

7.1 Initial startup

Step Action

1 Switch on the voltage supply to the device and wait until it has boot-

2 Select the operating language.

3 Log in as user "Master" or "Service" in order to have access to the

4 Set the date and time.

5 Make the basic settings for the device.

6 Configure the analog and binary inputs you wish to use.

7 Check the hardware functions of the device.

8 Calibrate any analysis sensors connected to the device.

9 The device is now ready for use. You can configure the displays

ed up.

configuration in the device menu.

v Chapter 8.2.1 "Log-on/Log-out", Page 78

v Chapter 9.1 "Date and time", Page 109

v Chapter 10.2 "Basic settings", Page 116

v Chapter 10.5 "Analog inputs", Page 121

v Chapter 10.7 "Digital inputs of base unit and optional boards",

Page 133

v Chapter 7.2 "Function test", Page 62

vChapter 12 "Calibration in general", Page 169

and functions of the device according to your needs.

61

Page 62

7 Startup

Sample screen:

Hardware Information

for an optional board

"Universal input"

7.2 Function test

Important hardware information is displayed in the "Device Info" menu.