Page 1

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

Email: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

Email: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

Email: info.us@jumo.net

Internet: www.jumousa.com

JUMO AQUIS 500 CR

Transmitter/controller

2 analog inputs

Input 1:

Conductivity / resistivity

1 binary input

For floating contact

Functions:

- key inhibit

- alarm stop

- HOLD

Supply voltage

110—240 V AC

12—24 V DC

20—30 V AC/DC

Analog outputs (option)

Output 1 + 2:

0(4)—20 mA or 0—10 V

option

Setup interface

Switching outputs (option)

Outputs 3 + 4:

- relay, changeover (SPDT)

User-friendly configuration

Reloading of languages

Plant documentation

Configurable as analog process

value output and/or continuous

controller output (PID action)

Configurable as

- limit controller

- pulse width output

(PID action)

- pulse frequency output

(PID action)

- modulating controller

(PID action)

- USP contact

- "Purified water" contact

as per Ph.Eur.

- calibration timer run down

standard

Input 2:

Temperature

manual input or automatic

Pt100 / Pt1000 / 4 kΩ

Transmitter/Controller

for conductivity, TDS, resistivity

and temperature

Brief description

The instrument is used for the conductive measurement/control of electrolytic conductivity,

resistivity or the TDS value. In addition, the JUMO AQUIS 500 CR also offers the possibility of

showing the measured conductivity according to a customer-specific table.

Conductive two-electrode cells as well as four-electrode cells can be connected to the

instrument.

Temperature serves as the second input variable, measured by a Pt100/1000 probe. Depending

on the measured variable, it is therefore possible to implement specific, automatic temperature

compensation.

The instrument is operated using keys and a large LC graphics display on which the

measurements are clearly legible. The plain-text presentation of the parameters makes it easier

for the user to configure the instrument, and also helps in programming it correctly.

Thanks to its modular design, the instrument can be perfectly matched to the particular

application requirement. Up to four outputs are available (see the block diagram for the

functions).

Typical areas of application

Universally applicable in water and wastewater engineering, service/process water and

wastewater, drinking water and well/surface water, pure and high-purity water as well as for

pharmaceutical water (e.g. as per USP, Ph.Eur., WFI), water quality measurements, TDS

measurements (ppm or mg/l).

Block diagram

Approvals/approval marks (see Technical data)

V1.00/EN/00477047

Data Sheet 202565

h

t

i

w

t

n

a

>

i

l

5

4

p

6

m

<

o

P

C

S

U

Key features

• Direct changeover to

- conductivity (µS/cm or mS/cm)

- resistivity (kΩ x cm or MΩ x cm)

- TDS measurement (ppm or mg/l)

- customer-specific table

• Automatic temperature compensation:

off (e.g. USP), linear, ASTM, natural water

(EN 27888/ISO 7888)

• Large LC graphics display with

background lighting

• Choice of display: large numbers, bar

graph or trend display

• Calibration options according to

measured variable: cell constant and

temperature coefficient

• Calibration logbook

• Two-electrode cells (as standard) or

four-electrode cells can be connected

• Pollution detection can be activated

• Auto-range operation

• IP67 enclosure protection

(in surface mountable housing)

IP65 enclosure protection

(for panel mounting)

• Language changeover:

German, English, French;

further languages can be loaded through

the setup program

• Using the setup program: user-friendly

programming, plant documentation,

additional languages can be loaded

Page 1/12

Type 202565

Page 2

Page 2/12Data Sheet 202565

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

Email: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

Email: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

Email: info.us@jumo.net

Internet: www.jumousa.com

(1)

(2)

(4)

(5)

(6)

(7)

(8)

(9)

(3)

Functional description

The instrument is designed for use on site. A

rugged housing protects the electronics and

the electrical connections from corrosive

environmental conditions (IP67). As an

alternative, the instrument can also be

installed in a control panel, and is then

protected to IP65 on the front. The electrical

connection is made by easy-to-fit pluggable

screw terminals.

Transmitter

Two-electrode cells (standard) as well as fourelectrode cells can be used for measurement.

Two-electrode cells can be connected, in the

usual increments for cell constants (K=0.01;

0.1; 1.0; 3.0 and 10.0). Thanks to the widely

adjustable relative cell constant, it is also

possible to connect sensors with different cell

constants (e.g. K=0.2).

In the case of the 4-electrode cells, the values

K=0.5 and 1.0 have been predefined for the

cell constant. Here too, the instrument can be

matched to sensors with different cell

constants (e.g. K=0.4).

The instrument can perform automatic

temperature compensation, by acquiring the

temperature of the sample solution.

Displays and controls

(1) Switching output 1 or 2 is active

(2) Binary input 1 is actuated

(3) Keypad is inhibited

(4) Alarm has been activated

(5) Instrument is in manual mode

(6) Instrument status

(7) Temperature of medium

(8) Principal measurement

(9) Unit of principal measurement

The user can define what is to be shown in

positions (7) and (8) of the display:

•no display

• compensated or uncompensated

measurement

•temperature

• output level 1 or 2

•setpoint 1 or 2

V1.00/EN/00477047

Operation

For easy programming and operation, all

parameters are arranged in clearly structured

levels and shown in plain text. Operation is

protected by a code word. This facilitates

individual adaptation of the operation, since

parameters can be generally enabled or

specifically assigned to the protected area.

As an alternative to configuration from the

keys, the instrument can also be configured

through the convenient setup program for PC

(option).

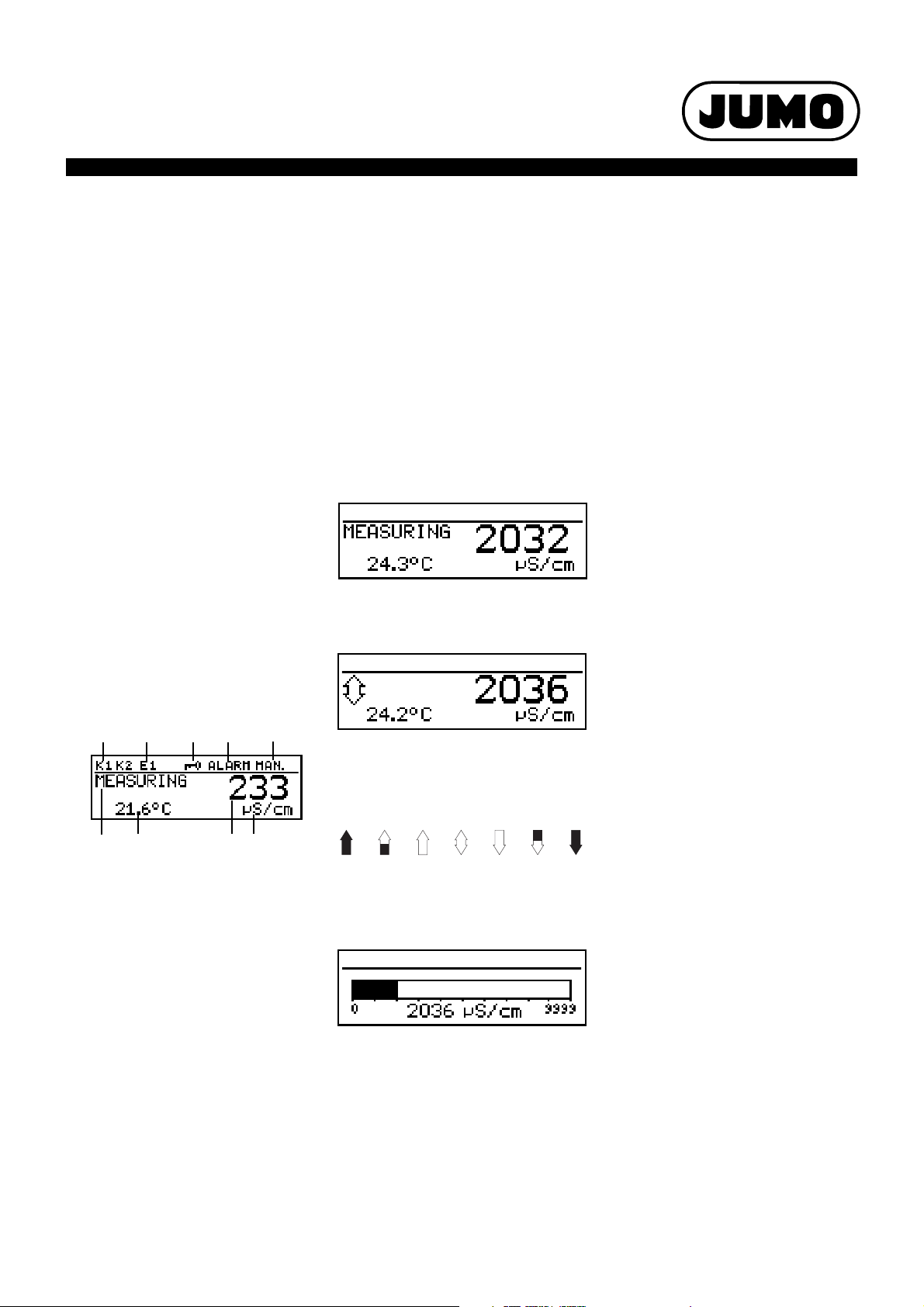

Display modes

Three display modes are available:

Large numbers

In this display mode, the measurements are

shown in digits, as usual.

Tre n d display

The numerical value is supplemented by a

symbol which indicates the change direction

and change speed of the measurement.

This can, for instance, be very useful during

controller optimization.

from left to right:

fast, medium and slow rise, stable,

slow, medium and fast fall.

Bar graph

This display mode allows the user to see at a

glance in which region the measurement is at

present.

The bar graph can be freely scaled.

Function modes

Electrolytic conductivity

Display/control, unit µS/cm or mS/cm.

Resistivity (high-purity water)

Display/control, unit kΩ x cm or MΩ x cm.

TDS

Display/ control with ppm for the unit.

In this mode, the specific TDS factor can be

entered in addition.

Customer-specific table

In this mode, the input value (conductivity or

resistivity) can be displayed in accordance

with a table (up to 20 value pairs). Thanks to

this function, it is possible to implement

simple concentration measurements, for

example. The values in the table can only be

entered through the optional setup program.

Calibration

Cell constant

Because of manufacturing tolerances, the cell

constant of a conductivity cell may deviate

slightly from its nominal value. In addition, the

cell constant may change during operation

(due to deposits or wear, for example). This

results in a change of the output signal from

the cell. The instrument provides the user with

the possibility of compensating any deviation

from the nominal value of the cell constant by

manual entry or automatic calibration of the

relative cell constant. A manual entry is used,

for instance, for calibration during high-purity

water measurement.

Temperature coefficient

The conductivity of almost all solutions

depends on the temperature. To ensure

correct measurement, it is therefore

necessary to know both the temperature and

the temperature coefficient [%/°C] of the

sample solution. The temperature can either

be measured automatically, with a Pt100 or

Pt1000 temperature probe, or it has to be set

manually by the user.

The temperature coefficient can be

automatically determined by the instrument,

or it can be entered manually.

Calibration logbook

The five most recent successful calibrations

can be called up in the calibration logbook.

This makes it possible to evaluate the ageing

of the sensor that is connected.

Calibration timer

The calibration timer indicates (if required)

when the next routine calibration is due. The

calibration timer is activated by entering a

number of days, after which recalibration has

to be carried out (plant or operator

requirement).

MIN / MAX value memory

This memory acquires the minimum or

maximum input variables that have occurred.

This information serves, for example, to

decide whether the sensor that is connected

is suited to the values that are actually

present.

Page 3

Page 3/12Data Sheet 202565

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

Email: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

Email: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

Email: info.us@jumo.net

Internet: www.jumousa.com

Hysteresis

Setpoint

pH

On

Off

Limit

Hysteresis

Limit

pH

On

Off

Setpoint

Hysteresis

Setpoint

pH

On

Off

Limit

Distance

Hysteresis

Setpoint

pH

On

Off

Limit

Distance

Time

On

Off

Pulse duration

Pulse

contact

Time

On

Off

Trigger

condition

Detection of deposits

Deposit detection can be activated for 4electrode cells.

During normal operation, it can happen that

deposits form on electrodes. This has the

result that a lower concentration is displayed

than actually present. With activated “deposit

detection” function, the instrument tells you

when the cell needs to be serviced.

Auto-range

For some processes, the availability of two

measuring ranges is advantageous, for

instance for rinsing or regeneration

processes.

What is usually required here, is the precise

acquisition of a low conductivity. Rinsing or

regeneration, however, involves a much

higher conductivity, which could lead to an

out-of-range condition (error). This situation is

not just unsatisfactory, but may even be

dangerous. Thanks to the auto-range

function, two measuring ranges can be

determined. The instrument then switches

between them in a defined manner.

Binary input

The following functions can be activated

through the binary input:

• Activate key inhibit

When this function has been activated,

operation from the keys is no longer

possible.

• Activate HOLD mode

After activating this function, the outputs

(analog and relay) adopt the states that

have previously been defined.

• Alarm suppression (controller alarm only)

This function temporarily deactivates the

alarm generation via the relay (has to be

configured accordingly).

Linking the corresponding terminals by

means of a floating contact (e. g. relay) will

activate the pre-defined function.

Control functions

The relays can have functions assigned that

are configured via parameters. The control

function is freely programmable as P, PI, PD or

PID action.

Relay outputs

Two relay changeover contacts are available

for the principle measurement variable and/or

temperature.

The following functions can be programmed:

• Switching direction

(min/max)

• Limit controller

(pull-in/drop-out delay, hysteresis)

• Pulse width output

(see control functions)

• Pulse frequency output

(see control functions)

• Modulating controller function

(see control functions)

• Limit comparators

(pull-in/drop-out delay, hysteresis)

• Pulse function

The output switches on briefly when

reaching the switching point and then off

again.

•Alarm

• Sensor or range error

• Response to alarm, over/underrange,

calibration and HOLD

Contact functions

MAX limit comparator

MIN limit comparator

Alarm window 1

Alarm window 2

Pulse contact

Trigger condition longer than pulse

duration

Analog Outputs

There are up to 2 analog outputs available.

The following functions can be selected:

Output Analog process value output Continuous controller

Main variable Temperature

1X-X

2-XX

With the analog process value output, the range start and end values are freely selectable.

The response of the outputs to over/underrange, alarm and calibration is freely programmable.

Simulation function: The analog process value outputs can be freely set in the manual ("Hand")

Application: "Dry run" start-up of the plant, troubleshooting, servicing.

V1.00/EN/00477047

mode.

main value

Page 4

Page 4/12Data Sheet 202565

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

Email: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

Email: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

Email: info.us@jumo.net

Internet: www.jumousa.com

Time

On

Off

Pulse duration

Pulse

contact

Time

On

Off

Trigger

condition

Process value X

Setpoint W

Proportional band X

P

100%

50%

0%

Output level y

Switching period

10%

90%

90%

10%

t

On

50%

50%

t

Off

10%

90%

X

P

X - W

0

1

100%

50%

0%

No pulses

50% of pulse frequency

Maximum pulse frequency

Setpoint W

Proportional band X

P

X

P

X - W

0

1

Output level y

Process value X

Pulse contact

Trigger condition shorter than pulse

Pulse width controller

(output is active with X > W and P action)

duration

If the process value X exceeds the setpoint W,

the P controller will control proportionally to

the control deviation. On going outside the

proportional band, the controller operates

with an output level of 100 % (100 % duty

cycle).

Measuring ranges / cell constants

This state-of-the art instrument offers a far wider dynamic range on the input side than can be

managed physically or chemically by the conductivity cells. For this reason, the range must be

matched to the operating range of the cell.

Examples of ranges for combination

with 2-electrode cells

Cell constant (K) Recommended/practical measuring span

0.01 1/cm 0.05 µS/cm to 20 µs/cm

0.1 1/cm 1 µS/cm to 1000 µs/cm

1.0 1/cm 0.01 mS/cm to 100 ms/cm

3.01/cm 0.1mS/cmto30ms/cm

10.0 1/cm 0.1 mS/cm to 200 ms/cm

(depending on the conductivity cell)

Pulse frequency controller

(output is active with X > W and P action)

If the process value X exceeds the setpoint W,

the P controller will control proportionally to

the control deviation. On going outside the

proportional band, the controller operates

with an output level of 100 % (maximum

switching frequency).

It is assumed that the measuring span of the

instrument is always larger than the

recommended or practically usable range of

the conductivity cell.

The smaller range (instrument or conductivity

cell) determines the maximum range that can

be used.

Example

Which span can the instrument cover with a

predefined cell constant?

The predefined cell constant is K=0.4

The span of the instrument is

0.1 µS/cm x 0.4 1/cm to

1250 mS/cm x 0.4 1/cm

➝ 0.04 µS/cm — 500 mS/cm

Example

A measurement is to be carried out in the 10 µS/cm to 500 µS/cm range. A conductivity cell with

the cell constant K = 0.1 1/cm is chosen.

The unit µS/cm without a decimal place is configured on the instrument.

Combination with 4-electrode cells and 2-electrode cells

having cell constants that deviate from the above graduation

This requires taking a closer look at the instrument technology and considering both the

uncompensated and the temperature-compensated measuring span.

The uncompensated measuring span of the instrument is calculated according to the formula:

Measuring span = 0.1 µs/cm x cell constant (K) to 2500 mS x cell constant (K).

After taking account of the temperature compensation range, the following compensated

measuring span (approx.) will remain:

Measuring span = 0.1 µs/cm x cell constant (K) to 1250 mS x cell constant (K).

Cell constant (K) Measuring span covered by instrument

0.01 0.001 µS/cm to 1.25 ms/cm

0.1 0.01 µS/cm to 12.5 ms/cm

1.0 0.1 µS/cm to 125 ms/cm

3.0 0.3 µS/cm to 375 ms/cm

10.0 0.1 mS/cm to 1250 ms/cm

V1.00/EN/00477047

(temperature-compensated)

Page 5

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

Email: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

Email: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

Email: info.us@jumo.net

Internet: www.jumousa.com

Technical data

Inputs

Principal input Indication range Accuracy Temperature error

µS/cm 0.000 v 9.999

00.00 to 99.99

000.0 to 999.9

0000 to 9999

mS/cm 0.000 to 9.999

00.00 to 99.99

000.0 to 999.9

0000 to 9999

kΩ x cm 0.000 to 9.999

00.00 to 99.99

000.0 to 999.9

0000 to 9999

MΩ x cm 0.000 to 9.999

00.00 to 99.99

000.0 to 999.9

0000 to 9999

≤ 0.6 % of range + 0.3 µS x cell

constant (K)

≤ 0.6 % of range + 0.3 µS x cell

constant (K)

≤ 0.6 % of range + 0.3 µS x cell

constant (K)

≤ 0.6 % of range + 0.3 µS x cell

constant (K)

0.2%/10°C

0.2%/10°C

0.2%/10°C

0.2%/10°C

Page 5/12Data Sheet 202565

Secondary input Measuring range Accuracy Temperature error

Temperature Pt100

(automatic detection)

Temperature Pt1000

(automatic detection)

Temperature

NTC/PTC

-50 to +250°C

max. 4 kOhm

Input via table

a

±0,5 K (up to 100 °C)

0.05 %/10 °C

±0,8 K (as of 100 °C)

±0,5 K (up to 100 °C)

±1,0 K (as of 100 °C)

b

≤ 0.3 %

0.05 %/10 °C

with 20 value pairs,

through setup program

a

Switchable to °F

b

Depending on interpolation points.

Temperature compensation

Type of compensation Range

Linear 0 to 8 %/°C -10 to 160 °C

ASTM D1125 - 95 (high-purity water) 0 to 100 °C

Natural water (ISO 7888) 0 to 36 °C

Reference temperature

adjustable from 15 to 30 °C; preset to 25 °C (standard)

a

Please note operating temperature range of sensor.

a

Measuring circuit monitoring

Inputs Over/underrange Short-circuit Cable break

Conductivity yes depending on range depending on range

Temperature yes yes yes

2-electrode systems

Cell constant

[1/cm]

0.01

0.1 0.02 to 0.5

1.0 0.2 to 5

3.0 0.6 to 15

10.0 2.0 to 50

V1.00/EN/00477047

Setting range of

relative cell constant

20 to 500 %

Resulting usable

range [1/cm]

0.002 to 0.05

Page 6

Page 6/12Data Sheet 202565

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

Email: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

Email: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

Email: info.us@jumo.net

Internet: www.jumousa.com

4-electrode systems

Cell constant

[1/cm]

0.5

1.0 0.2 to 1.5

Setting range of

relative cell constant

20 to 150 %

Resulting usable

range [1/cm]

0.1 to 0.75

Binary input

Activation through floating contact

Function key inhibit

HOLD

alarm suppression

Controller

Controller type limit comparators, limit controller, pulse width controller, pulse frequency controller, modulating controller,

Controller action P/PI/PD/PID

A/D converter dynamic resolution up to 14-bit

Sampling time 500 msec

continuous controller

Analog outputs (one or two)

Output mode Signal range Accuracy Temperature error Permissible

load resistance

Current signal 0/4 to 20 mA ≤ 0.25 % 0.08 %/10 °C ≤ 500 Ω

Voltage signal 0 to 10 V ≤ 0.25 % 0.08 %/10 °C ≥ 500 Ω

The analog outputs respond in accordance with the recommendation as per NAMUR NE43.

They are electrically isolated, AC 30 V/DC 50 V.

Switching outputs (two changeover (SPDT) max.)

Rated load 3 A/250 VAC (resistive load)

Contact life >2x10

5

operations at rated load

Setup interface

Interface for configuring the instrument through the optionally available setup program (for instrument configuration only).

Electrical data

Supply voltage AC 110 to 240 V; -15/+10 %; 48 to 63 Hz

AC/DC20to30V; 48to63Hz

DC 12 to 24 V; +/-15 % (permissible only for connection to SELV/PELV circuits)

Power consumption approx. 14 VA

Electrical safety EN 61 010, Part 1

overvoltage category III

a

, pollution degree 2

Data backup EEPROM

Electrical connection pluggable screw terminals

conductor cross-section up to 2.5 mm

conductor cross-section up to 1.5 mm

a

Not valid with protective extra-low voltage (PELV) of power supply variant DC 12 to 24 V.

2

(supply, relay outputs, sensor inputs)

2

(analog outputs)

Display

Graphics LC display 120 x 32 pixels

Background lighting programmable:

- off

- on for 60 seconds during operation

V1.00/EN/00477047

Page 7

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

Email: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

Email: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

Email: info.us@jumo.net

Internet: www.jumousa.com

Housing

Material ABS

Cable entry cable glands, 3xM16 and 2xM12 max.

Special feature venting device to prevent condensation

Ambient temperature range

-10 to +50°C

(the specified accuracy is adhered

to within this range)

Operating temperature range

-15 to +65°C

(instrument is operational)

Storage temperature range -30 to +70°C

Climatic conditions rel. humidity ≤ 90 % annual mean, no condensation

(following EN 60721 3-3 3K3)

Enclosure protection

as per EN 60529

in surface mountable housing: IP67

for panel mounting: IP65 front, IP20 rear

Vibration strength as per EN 60068-2-6

Weight surface mountable housing: approx. 900 g

for panel mounting: approx. 480 g

Dimensions see dimensioned drawings on page 10.

Standard accessories

Cable glands

Internal mounting material

Operating Instructions

Page 7/12Data Sheet 202565

Approvals/approval marks

Mark of confirmity Testing laboratory Certifikates/certification numbers Test basis valid for

c UL us Underwriters Laboratories E 201387 UL 61010-1 all versions

V1.00/EN/00477047

Page 8

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

Email: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

Email: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

Email: info.us@jumo.net

Internet: www.jumousa.com

Electrical connection

The electrical connection for the “surface mountable housing”

version can be made easily, after opening the unit.

Clamp (screen)

Row 1

Row 2

The connection cable between sensor and transmitter must

be a screened cable with a diameter of 8 mm max.

The instrument contains a guide plate for an optimized cable

routing.

The sensor cables (incorporating strain relief) are run to the

pluggable screw terminals where they are connected without

using any solder.

Page 8/12Data Sheet 202565

Connection Te rm i na l Ro w

Supply for transmitter/controller

Supply voltage (23): AC 110 to 240 V; -15/+10 %; 48 to 63 Hz

Supply voltage (25): AC/DC 20 to 30 V; 48 to 63 Hz

Supply voltage (30): DC 12 to 24 V; +/-15 %

1 N (L-)

2 L1 (L+)

NC 3

V1.00/EN/00477047

1

Page 9

Page 9/12Data Sheet 202565

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

Email: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

Email: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

Email: info.us@jumo.net

Internet: www.jumousa.com

2

1

3

4

2

1

3

4

2

1

3

4

ϑ

9

8

10

ϑ

9

8

10

11

12

6

4

5

10

8

9

Connection Te rm i na l Ro w

Inputs

Conductivity cell (2-electrode system)

Terminals 1+2 and 3+4 are linked in the instrument;

2-wire cable routed to the head of the conductivity cell.

For concentric cells, terminal 1 is connected to the outer electrode.

1

2

3

4

Conductivity cell (2-electrode system)

Wiring for the highest accuracy;

4-wire cable routed to the head of the conductivity cell.

For concentric cells, terminal 1 is connected to the outer electrode.

Conductivity cell (4-electrode system)

1 - outer electrode 1 (I hi)

2 - inner electrode 1 (U hi)

3 - inner electrode 2 (U lo)

4 - outer electrode 2 (I lo)

NC 5

RTD in 2-wire circuit 8

10

RTD in 3-wire circuit 8

10

Binary input 11

12

1

2

3

4

1

2

3

4

6

7

2

9

9

Outputs

Analog output 1

0to20mA or 20to0mA or 4to20mA or 20to4mA

or

0to10V or 10to0V

(electrically isolated)

Analog output 2

0to20mA or 20to0mA or 4to20mA or 20to4mA

or

0to10V or 10to0V

(electrically isolated)

Switching output K1

(floating)

Switching output K2

(floating)

V1.00/EN/00477047

4 common

5 break (SPST-NC)

6 make (SPST-NO)

8 common

9 break (SPST-NC)

10 make (SPST-NO)

+ 13

- 14

+ 15

- 16

2

1NC 7

Page 10

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

Email: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

Email: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

Email: info.us@jumo.net

Internet: www.jumousa.com

Dimensions

30

60

149

134

120

161

140

77

94

94

23

Note:

1. Fix template to panel

2. Drill holes ( 4.5 mm and 10 mm dia.)

3. Cut out the panel inside the

marked lines.

4. Debur

To ensure the protection rating

(see data sheet), the panel must

be sufficiently stable.

ø4.5

ø10

100.5

108.6

120.5

121.6

44.2

Note:

The drilling template is shown in its actual size

in the Operating Instructions B 202565.0.

Page 10/12Data Sheet 202565

Panel-mounting/drilling diagram

V1.00/EN/00477047

Page 11

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

Email: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

Email: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

Email: info.us@jumo.net

Internet: www.jumousa.com

Accessories

Page 11/12Data Sheet 202565

1

The suspended fitting consists of a fixing 20/00453191 (see accessories) and a cell with a suitable fitting (see data sheet 202922, for example).

V1.00/EN/00477047

Page 12

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

Email: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

Email: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

Email: info.us@jumo.net

Internet: www.jumousa.com

Order details: JUMO AQUIS 500 CR

(1) Basic type

202565 JUMO AQUIS 500 CR - Transmitter/controller for conductivity, TDS, resistivity and temperature

(2) Basic type extensions

10 for panel mounting

20 in surface mountable housing

(3) Output 1 (for principle measurement variable or continuous controller)

000 no output

888 analog output 0(4) to 20 mA or 0 to 10 V

(4) Output 2 (for principle measurement variable or continuous controller)

000 no output

888 analog output 0(4) to 20 mA or 0 to 10 V

(5) Output 3

000 no output

310 relay with changeover (SPDT) contact

(6) Output 4

000 no output

310 relay with changeover (SPDT) contact

(7) Supply voltage

23 AC 110 to 240 V; +10 %/-15 %, 48 to 63 Hz

25 AC/DC 20 to 30 V, 48 to 63 Hz

30 DC 12 to 24 V; ±15 %

(8) Extra codes

000 none

Page 12/12Data Sheet 202565

(1) (2) (3) (4) (5) (6) (7) (8)

Order code /-----/, ...

Order example 202565 / 20 - 888 - 000 - 310 - 000 - 23 / 000

Stock items (shipment: 3 working days after receipt of order)

Type Part no.

202565/20-888-888-310-310-23/000 00480055

202565/20-888-000-310-000-23/000 00480054

Accessories

Type Pert no.

Protective roof for JUMO AQUIS 500

Pipe installation set for JUMO AQUIS 500

DIN rail installation set for JUMO AQUIS 500

Support pillar with base clamp, arm and chain 00398163

Holder for suspension fitting 00453191

Back panel set 202560/65 00506351

PC setup software 00483602

PC interface cable including USB/TTL converter and two adapters (USB connecting cable) 00456352

a

The pole-mounting kit is needed for mounting the protection cover.

b

With the pipe installation set, the JUMO AQUIS 500 can be attached to a pipe (e. g. a support pillar or a railing).

c

With the DIN rail installation set, the JUMO AQUIS 500 can be attached to a 35 mm x 7.5 mm DIN rail as per EN 60715 A.1.

V1.00/EN/00477047

(shipment: 10 days after receipt of order)

a

b

c

00398161

00483664

00477842

Loading...

Loading...