Page 1

Data Sheet 90.6021 Page 1/5

JUMO GmbH & Co. KG

Delivery address:Mackenrodtstraße 14,

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

e-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

e-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

8 Technology Boulevard

Canastota, NY 13032, USA

Phone: 315-697-JUMO

1-800-554-JUMO

Fax: 315-697-5867

e-mail: info@jumo.us

Internet: www.jumo.us

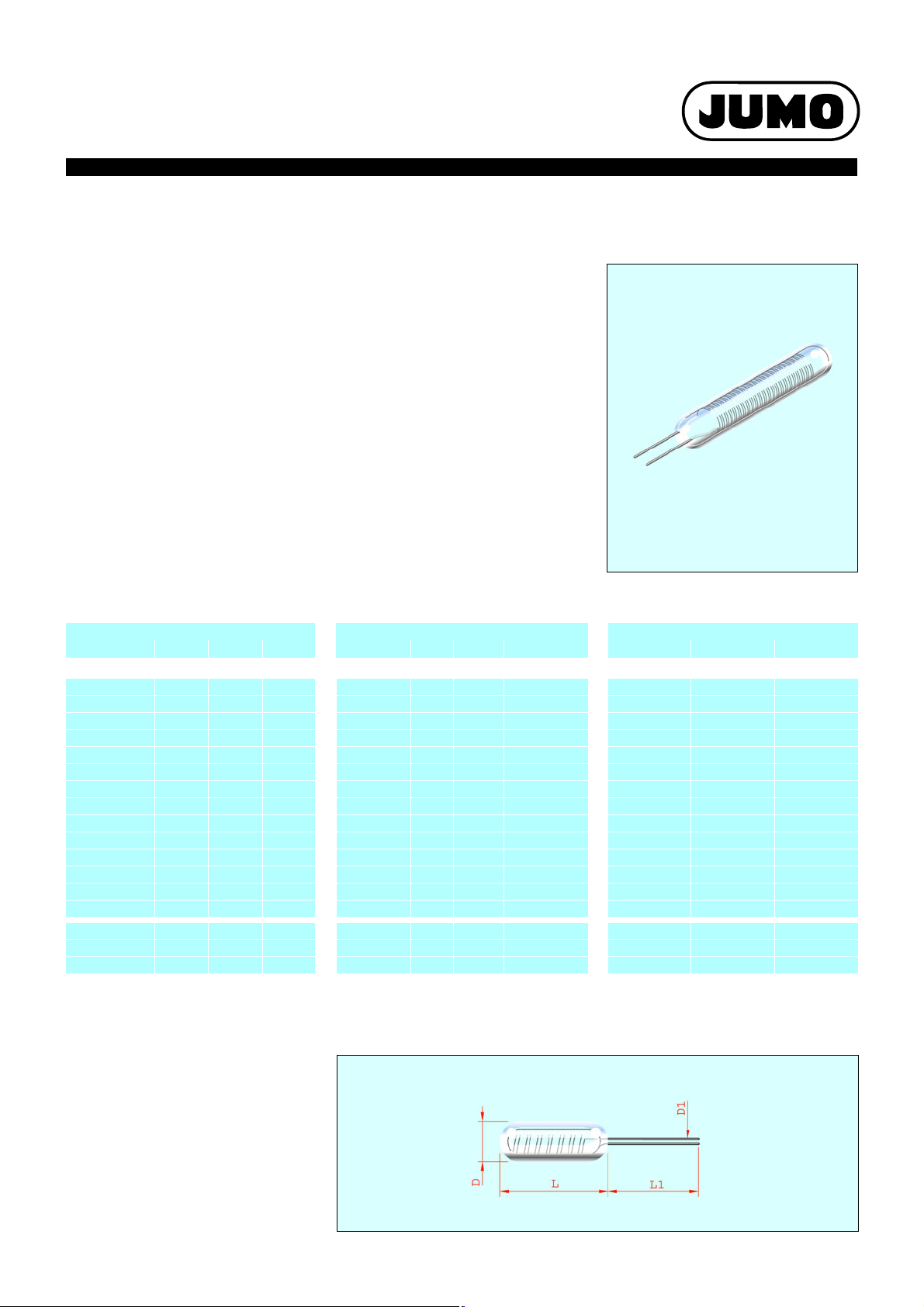

Platinum-glass temperature sensors

to EN 60 751

■ for temperatures from -200 to +400°C

■ standardized nominal values and tolerances

■ as single or twin temperature sensor

■ suitable for measurements under highly humid ambient conditions

■ can be used directly in many liquids

■ highly resistant to shock and vibration

Introduction

Platinum-glass temperature sensors belong to the category of wirewound constructions.

One or two measurement windings are wound on a glass rod, each in the form of a bifilar

winding. The winding is fused onto the glass and provided with connecting wires. The

nominal resistance is calibrated by altering the winding length. Afterwards, a sleeve is

pushed over the glass rod plus measurement winding and the components are then fused

together. The glass material used is matched to the expansion coefficient of the platinum

wire as far as possible. An additional artificial ageing process ensures that good long-term

stability is achieved. The operating temperature covers the range from -200 to +400°C.

JUMO platinum-glass temperature sensors are distinguished by a design that is extremely

resistant to shock and vibration. Furthermore, the connecting wires exhibit a very high

tensile strength. Another advantage of this style is that the temperature sensors can

readily be used for measurements in highly humid environments or directly in the liquid,

thanks to the hermetic sealing of the measurement winding and the excellent chemical

resistance of the glass. In addition, the familiar protection tube - a necessary component

with other styles - can now be dispensed with, allowing short response times.

A wide variety of platinum-glass temperature sensors with single or double windings and

standard nominal values to EN 60 751 are available from JUMO ex-stock.

Customized versions or laboratory resistance thermometers can be supplied on request

(see Data Sheet 90.6024).

PG + PGL styles

Technical publication

JUMO platinum temperature sensors

Construction and application of platinum temperature sensors Data Sheet 90.6000

Platinum-glass temperature sensors Data Sheet 90.6021

Platinum-ceramic temperature sensors Data Sheet 90.6022

Platinum-foil temperature sensors Data Sheet 90.6023

Platinum-glass temperature sensors with glass extension Data Sheet 90.6024

Platinum-chip temperature sensors with connecting wires Data Sheet 90.6121

Platinum-chip temperature sensors on epoxy card Data Sheet 90.6122

Platinum-chip temperature sensors with terminal clamps Data Sheet 90.6123

Platinum-chip temperature sensors in cylindrical style Data Sheet 90.6124

Platinum-chip temperature sensors in SMD style Data Sheet 90.6125

01.05/00311571

This revised edition takes account of altered

standards and recent developments. The

new chapter “Measurement uncertainty”

incorporates the basic concept of the

internationally recognized ISO guideline

“Guide to the expression of uncertainty in

measurement” (abbreviated: GUM).

In addition, the chapter on explosion

protection for thermometers has been

updated in view of the European Directive

94/9/EC, which has been in force since 1st

July 2003.

August 2002

Publication FAS 146

Sales No. 90/00085081

ISBN: 978-3-935742-07-8

Page 2

Data Sheet 90.6021 Page 2/5

JUMO GmbH & Co. KG

Delivery address:Mackenrodtstraße 14,

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

e-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

e-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

8 Technology Boulevard

Canastota, NY 13032, USA

Phone: 315-697-JUMO

1-800-554-JUMO

Fax: 315-697-5867

e-mail: info@jumo.us

Internet: www.jumo.us

Platinum-glass temperature sensors

PG style

to EN 60 751

Brief description

PG style platinum-glass temperature sensors are distinguished by their rugged

construction. The wire winding that has been fused into the glass ensures that JUMO

glass temperature sensors are generally extremely resistant to shock and vibration.

Furthermore, the connecting wires exhibit a very high tensile strength.

Platinum-glass temperature sensors also allow problem-free measurement in highly

humid environments, or even directly in various liquids.

Special miniaturized versions with small dimensions and fast response times round off the

product range to cover a variety of applications.

These temperature sensors are frequently used in analytical and laboratory technology as

well as in HVAC engineering, and for industrial humidity measurement.

Temperature sensors in blister belt packaging

Temperature sensor Connecting wire Sales No. for tolerance class

Type R0/Ω D L Material D1 L1 RL in mΩ/mm 1/3 DIN B A B

PG 1.0910.1 1x100 0.9 10 Pt-Ni 0.15 10 5 on request 90/00063058 90/00063057

PG 1.1308.1 1x100 1.3 8 Pt-Ni 0.15 10 5 on request 90/00063056 90/00063055

PG 1.1720.1 1x100 1.7 20 Pt-NiFe 0.20 10 12 90/00044808 90/00066020 90/00034067

PG 1.1810.1 1x100 1.8 10 Pt-NiFe 0.20 10 12 90/00062525 90/00088708 90/00043804

PG 1.2010.1 1x100 2.0 10 Pt-NiFe 0.20 10 12 on request 90/00064633 90/00064632

PG 1.2812.1 1x100 2.8 12 Pt-NiFe 0.20 10 12 90/00044809 90/00088709 90/00034065

PG 1.2830.1 1x100 2.8 30 Pt-NiFe 0.30 10 5 90/00046833 90/00087580 90/00031071

PG 1.3812.1 1x100 3.8 12 Pt-NiFe 0.30 10 5 90/00051231 90/00088710 90/00036206

PG 1.3830.1 1x100 3.8 30 Pt-NiFe 0.30 10 5 90/00062525 90/00088736 90/00080803

PG 1.4512.1 1x100 4.5 12 Pt-NiFe 0.30 10 5 90/00040492 90/00088711 90/00031072

PG 1.4825.1 1x100 4.8 25 Pt-NiFe 0.30 10 5 on request 90/00087490 90/00031073

PG 1.4850.1* 1x100 4.8 50 Pt-NiFe 0.30 10 5 on request 90/00088712 90/00054629

PG 1.3830.5 1x500 3.8 30 Pt-NiFe 0.30 10 5 90/00052496 90/00088737 90/00080802

PG 1.2828.10 1x1000 2.8 28 Pt-NiFe 0.30 10 5 90/00063456 90/00088738 90/00063259

PG 2.2525.1 2x100 2.5 25 Pt-NiFe 0.20 15 12 90/00056641 90/00087494 90/00038263

PG 2.4520.1 2x100 4.5 20 Pt-NiFe 0.30 15 5 90/00051227 90/00088713 90/00034544

PG 2.4850.1* 2x100 4.8 50 Pt-NiFe 0.30 10 5 on request 90/00088714 90/00054628

Dim. tolerances: ΔD = ±0.3 / ΔL = ±1.0 / ΔD1 = ±0.02 / ΔL1 = +1.0/-2.0; with 2 x Pt100 ±5.0 For a definition of the tolerance classes,

Dimensions in mm. see Data Sheet 90.6000

* Not in blister belt packaging, but packed in a cardboard box.

Dimensional drawing

01.05/00311571

Page 3

JUMO GmbH & Co. KG

Delivery address:Mackenrodtstraße 14,

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

e-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

e-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

8 Technology Boulevard

Canastota, NY 13032, USA

Phone: 315-697-JUMO

1-800-554-JUMO

Fax: 315-697-5867

e-mail: info@jumo.us

Internet: www.jumo.us

Technical data

Temperature coefficient α = 3.850 x 10

Temperature range -200 to +400°C

Measuring current Pt100 recommended: 1.0 mA

Operating conditions Suitable also for unprotected application in high-humidity environments and in liquid me-

Chemical resistance Water resistance class (ISO 719) HGB 3

Measurement point 2mm from the end of the wire; the nominal value given refers to the standard connecting

Long-term stability max. drift <0.05°C after 1000hrs at 200°C

Insulation resistance 100MΩ at room temperature

Vibration strength 30g within the frequency range 30 — 3000Hz

Data Sheet 90.6021 Page 3/5

Standard EN 60 751

-3°C-1

(between 0 and 100°C)

Tolerance Temperature validity range Class 1/3 DIN B: - 70 to +250°C

Temperature validity range Class A: -200 to +400°C

Temperature validity range Class B: -200 to +400°C

Pt500 recommended: 0.7mA

Pt1000 recommended: 0.1mA

Maximum current Pt100 10mA

Pt500 5mA

Pt1000 3mA

dia (e. g. caustic solutions). The medium to be measured must not form a chemical bond

with the temperature sensor (qualification by the user).

Acidity class (DIN 12 116) Class S1

Caustic solution class (ISO 695) Class A2

Connecting wires The connecting wires are of sheathed platinum wire, with varying diameters according to

the sensor geometry. Any unnecessary bending of the wires must be avoided, as this

may result in material fatigue and a wire break.

wire length L1, with the measurement being acquired 2mm from the end of the wire. Any

alteration to the wire length will lead to changes in resistance.

max. drift <0.10°C after 1000hrs at 400°C

2

Self-heating Δt = I

x R x E (see Data Sheet 90.6000 for definitions)

Packaging Blister belt

Exception: temperature sensors with an overall length >45mm, including the connecting

wires. These are packed in a cardboard box with foam padding.

Storage In normal surroundings, JUMO temperature sensors, PG style, can be stored indefinitely

in the (standard) belt packaging. It is not permissible to store the sensors in aggressive

atmospheres or corrosive media.

Self-heating coefficients and response times

Type Self-heating coefficient E in °C/mW Response times in seconds

in water

(v = 0.2m/sec)

PG 1.0910.1 0.02 0.2 0.1 0.3 2 7

PG 1.1308.1 0.02 0.2 0.1 0.4 4 13

PG 1.1720.1 0.015 0.1 0.2 0.7 8 28

PG 1.1810.1 0.02 0.2 0.2 0.8 9 30

PG 1.2010.1 0.02 0.2 0.2 1.0 9 35

PG 1.2812.1 0.015 0.2 0.3 1.4 13 44

PG 1.2830.1 0.01 0.1 0.3 1.5 13 47

PG 1.3812.1 0.02 0.2 0.8 3.2 10 33

PG 1.3830.1 0.01 0.1 0.7 3.2 8 28

PG 1.4512.1 0.02 0.1 0.8 3.5 13 39

PG 1.4825.1 0.01 0.1 0.8 4.5 13 40

PG 1.4850.1 0.01 0.05 0.9 4.3 15 50

PG 1.3830.5 0.005 0.05 0.7 3.0 8 28

PG 1.2828.10 0.005 0.05 0.3 1.5 13 47

PG 2.2525.1 0.02 0.2 0.3 1.2 8 23

PG 2.4520.1 0.02 0.2 0.7 3.4 15 41

PG 2.4850.1 0.02 0.2 0.9 4.8 15 50

01.05/00311571

in air

(v = 2m/sec)

in water

(v = 0.4m/sec)

t

0.5

t

0.9

in air

(v = 1m/sec)

t

0.5

t

0.9

Page 4

Data Sheet 90.6021 Page 4/5

JUMO GmbH & Co. KG

Delivery address:Mackenrodtstraße 14,

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

e-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

e-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

8 Technology Boulevard

Canastota, NY 13032, USA

Phone: 315-697-JUMO

1-800-554-JUMO

Fax: 315-697-5867

e-mail: info@jumo.us

Internet: www.jumo.us

Platinum-glass temperature sensors

PGL style

to EN 60 751

Brief description

PGL style platinum-glass temperature sensors are of a similar rugged construction to the

standard PG form. These temperature sensors, too, are distinguished by their excellent

resistance to shock and vibration, as a result of the wire winding being fused onto the

glass. In addition, the connecting wires exhibit a very high tensile strength.

Compared with the standard PG style, PGL style temperature sensors have an additional

glass neck, which, for example, allows for a better insulation of the connecting wires for

further processing. Furthermore, the glass neck enables glass extensions to be fitted at a

later stage and fabrication into laboratory resistance thermometers.

Temperature sensors in blister belt packaging

Temperature sensor Connecting wire Sales No. for tolerance class

Type R0/Ω D L L2 Material D1 L1 RL in mΩ/mm 1/3 DIN B A B

PGL 1.3530.1 1x100 3.5 30 10 Pt-NiFe 0.30 15 5 90/00033714 90/00088715 90/00038266

PGL 1.4825.1 1x100 4.8 25 10 Pt-NiFe 0.30 15 5 90/00046834 90/00088716 90/00031070

PGL 1.4845.1* 1x100 4.8 45 7 Pt-NiFe 0.30 15 5 90/00044811 90/00088717 90/00031068

PGL 2.3535.1 2x100 3.5 35 10 Pt-NiFe 0.20 15 12 90/00045836 90/00088719 90/00038270

PGL 2.4830.1 2x100 4.8 30 10 Pt-NiFe 0.30 15 5 90/00051229 90/00088720 90/00038271

PGL 2.4845.1* 2x100 4.8 45 7 Pt-NiFe 0.30 15 5 90/00044812 90/00088739 90/00027510

Dim. tolerances: ΔD = ±0.3 / ΔL = ±1.0 / ΔD1 = ±0.02 / ΔL1 = +1.0/-2.0; For a definition of the tolerance classes,

Dimensions in mm.

* Not in blister belt packaging, but packed in a cardboard box.

with 2 x Pt100 ±5.0 / L2 = approx. dimensions see Data Sheet 90.6000

Dimensional drawing

01.05/00311571

Page 5

JUMO GmbH & Co. KG

Delivery address:Mackenrodtstraße 14,

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

e-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

e-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

8 Technology Boulevard

Canastota, NY 13032, USA

Phone: 315-697-JUMO

1-800-554-JUMO

Fax: 315-697-5867

e-mail: info@jumo.us

Internet: www.jumo.us

Technical data

Temperature coefficient α = 3.850 x 10

Temperature range -200 + 400°C

Measuring current Pt100 recommended: 1.0 mA

Operating conditions Also suitable for unprotected application in high-humidity environments and in liquid me-

Chemical resistance Water resistance class (ISO 719) HGB 3

Measurement point 2mm from the end of the wire; the specified nominal value refers to the standard

Long-term stability 1000hrs at 200°C <0.05°C

Insulation resistance 100MΩ at room temperature

Vibration strength 30g within the frequency range 30 — 3000Hz

Data Sheet 90.6021 Page 5/5

Standard EN 60 751

-3°C-1

(between 0 and 100°C)

Tolerance Temperature validity range Class 1/3 DIN B: - 70 to +250°C

Temperature validity range Class A: -200 to +400°C

Temperature validity range Class B: -200 to +400°C

Pt500 recommended: 0.7 mA

Pt1000 recommended: 0.1mA

Maximum current Pt100 10mA

Pt500 5mA

Pt1000 3mA

dia (e.g. caustic solutions). The medium to be measured must not form a chemical bond

with the temperature sensor (qualification by the user).

Acidity class (DIN 12 116) Class S1

Caustic solution class (ISO 695) Class A2

Connecting wires The connecting wires are made from sheathed platinum wire, with varying diameters

according to the sensor geometry. Any unnecessary bending of the wires must be

avoided, as this will result in material fatigue and a wire break.

connecting wire length L1, with the measurement being acquired 2mm from the end of

the wire. Any alteration of the wire length will lead to changes in the resistance.

1000hrs at 400°C <0.10 °C

2

Self-heating Δt = I

x R x E (see Data Sheet 90.6000 for definitions)

Packaging Blister belt

Exception: temperature sensors with an overall length >45mm, including the connecting

wires. These are packed in a cardboard box with foam padding.

Storage In normal surroundings, JUMO temperature sensors, PGL style, can be stored indefinitely

in the original (standard) belt packaging. It is not permissible to store the sensors in aggressive atmospheres or corrosive media.

Self-heating coefficients and response times

Type Self-heating coefficient E in °C/mW Response times in seconds

in water

(v = 0.2m/sec)

PGL 1.3530.1 0.02 0.1 0.7 2.6 9 31

PGL 1.4825.1 0.015 0.1 0.8 4.0 12 40

PGL 1.4845.1 0.005 0.05 0.8 4.3 14 48

PGL 2.3535.1 0.02 0.2 0.6 2.6 7 27

PGL 2.4830.1 0.015 0.1 0.8 3.6 14 42

PGL 2.4845.1 0.01 0.1 0.8 3.8 15 49

01.05/00311571

in air

(v = 2m/sec)

in water

(v = 0.4m/sec)

t

0.5

t

0.9

in air

(v = 1m/sec)

t

0.5

t

0.9

Loading...

Loading...