Page 1

JUMO DELOS T

Electronic temperature switch

with display and analog output

B 90.2940.0

Operating Manual

2010-12-01/00536581

Page 2

Page 3

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1.1 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2 Device identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.1 Type specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 Type description for basic type 902940/10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2.1 Scope of delivery for basic type 902940/10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2.2 Accessories, process connection for basic type 902940/10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2.3 Accessories for basic type 902940/10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.3 Type description for basic type 902940/30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3.1 Scope of delivery for basic type 902940/30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.3.2 Accessories, process connection for basic type 902940/30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.3.3 Accessories for basic type 902940/30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.4 Type description for basic type 902940/50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.4.1 Scope of delivery for basic type 902940/50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.4.2 Accessories for basic type 902940/50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3.1 Installation notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.2 Device connection assignment for M 12x1 machine connector . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.3 Connection assignment for order code 470 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.4 Connection assignment for order code 471 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.5 Connection assignment for order code 475, 476 and 477 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.6 Connection assignment for RTD temperature probe for basic type 902940/50 . . . . . . . . . . . . . 25

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

4.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.1.1 Turning the LCD display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.1.2 Turning the display case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.2 Device dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.3 Process connection dimensions (PA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

5.1 Operating element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.2 LCD display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.2.1 Measuring mode (normal display) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.2.2 Setting mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.3 Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.4 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3

Page 4

Contents

5.4.1 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.4.2 Analog output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.4.3 Binary output 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.4.4 Binary output 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.4.5 Display and operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6 Commissioning/start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

6.1 Quick introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.2 Unlocking the device (enter the code). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.3 Operation cancellation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.4 Setting the unit of the measured value (Uni.T) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.4.1 Display and setting possibilities of the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.5 Setting the offset (zero point) (Off.T) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.5.1 Edited offset setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.6 Setting the filter time constant (damping) (DamP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.7 Setting the mains frequency (Freq) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.8 Setting the output signal (S.Type) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.8.1 Output performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.9 Setting the output signal scaling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.9.1 Setting the scaling start value (Sc.Lo) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.9.2 Setting the scaling end value (Sc.Hi) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.10 Setting the error signal of the analog output (S.Err) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.11 Behavior when the scaling range is exceeded . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.12 Setting the switching function (B.Fct) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.12.1 Hysteresis (switching difference) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.12.2 window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.13 Setting the switching point (B.Sp) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.14 Setting the release point (B.RSp) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.15 Setting the hysteresis (B.HyS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.16 Setting the switch-on delay time (B.Dly) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.17 Setting the display alignment (D.Dir) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6.18 Setting the display unit (D.Uni) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.19 Displaying the software version of the operating unit (SW.Di) . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.20 Displaying the software version of the signal unit (SW.Si) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

7 Setup program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

7.1 General information about the setup program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8 Overcoming errors and malfunctions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

8.1 Possible errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

9 Supplement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

9.1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4

Page 5

Contents

9.1.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

9.1.2 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

9.1.3 Measuring circuit monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

9.1.4 Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

9.1.5 Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

9.1.6 Auxiliary energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

9.1.7 Approval/approval marks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5

Page 6

Contents

6

Page 7

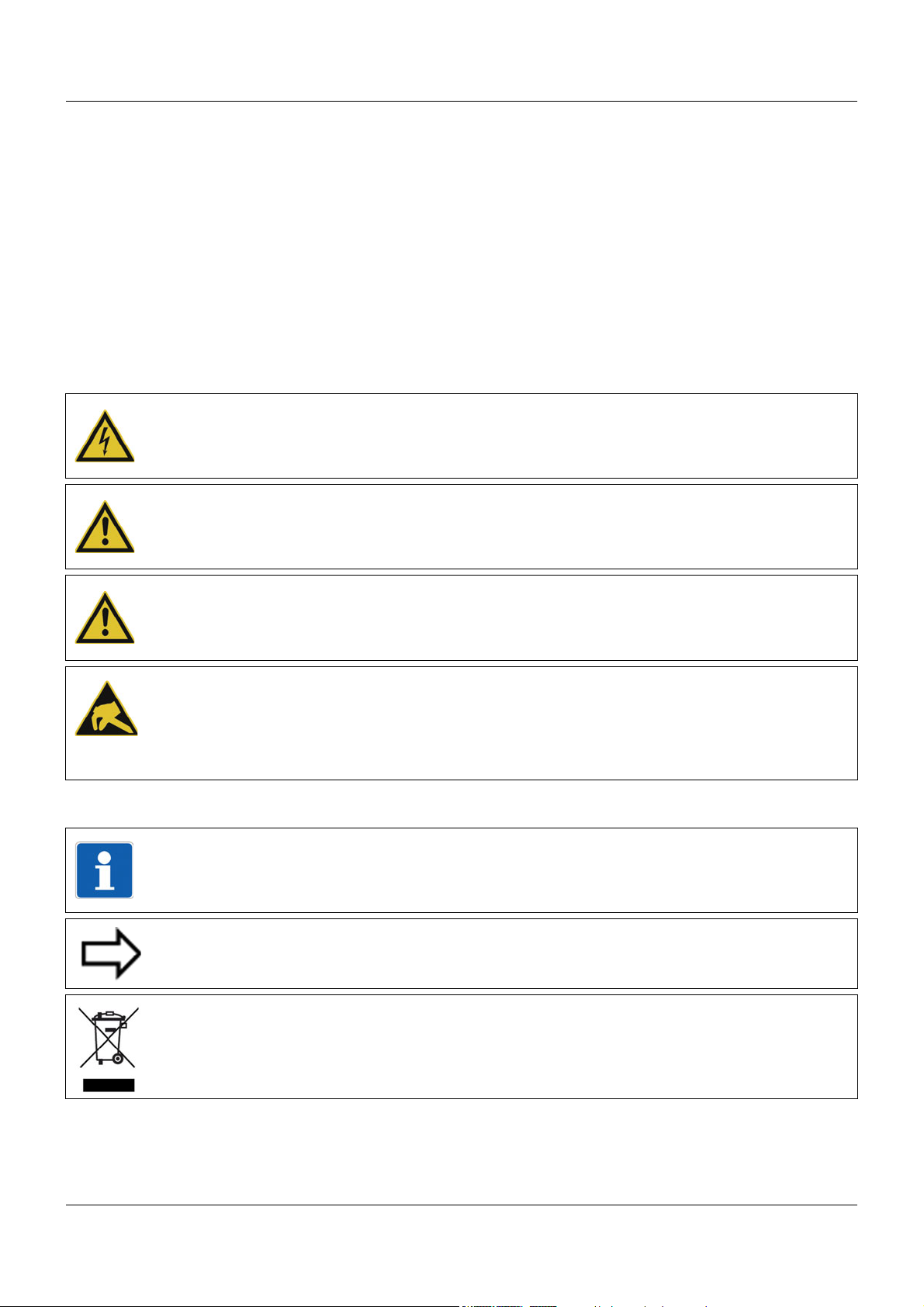

1.1 Safety information

General information

This manual contains information that must be observed in the interest of your own safety and

to avoid damage to assets. This information is supported by symbols which are used in this

manual as follows.

Please read this manual before commissioning the device. Keep the manual in a place accessible to all users at all times.

If difficulties occur during commissioning, please refrain from carrying out any manipulations

that could jeopardize your warranty rights.

Warning signs

DANGER!

This symbol indicates that injury to persons caused by electrical shock may occur, if the

respective protective measures are not carried out.

WARNING!

This symbol in connection with the signal word indicates that injury of persons may occur,

if the respective protective measures are not carried out.

1 Introduction

Note signs

CAUTION!

This symbol in combination with the signal word indicates that damage to assets or data

loss will occur if suitable precautions are not taken.

CAUTION!

This sign indicates that components could be destroyed by electrostatic discharge

(ESD = Electro Static Discharge), if the respective cautionary measures are not taken.

Only use the ESD packages intended for this purpose to return device inserts, assembly

groups or assembly components.

TIP!

This symbol refers to important information about the product or its handling or additional

use.

REFERENCE!

This symbol refers to further information in other sections, chapters or manuals.

DISPOSAL!

This device and, if installed, the batteries must not be disposed of in the garbage can after

use! Please ensure that they are disposed of properly and in an environmentally friendly

manner.

7

Page 8

1 Introduction

1.2 General information

(1) Locking screw for operation

• The device measures the temperature in liquids and gases.

• The temperature is displayed digital.

• Depending on the version, the following outputs are available:

- 1x PNP switching output

- 2x PNP switching outputs

- 1x PNP switching output and 1x analog output 0 to 20 mA, configurable

- 1x PNP switching output and 1x analog output 4 to 20 mA, configurable

- 1x PNP switching output and 1x analog output 0 to 10 V, configurable

• The device is also available in a version for use in increased medium temperatures.

• The device is additionally available in a version equipped with M 12x1 connection for RTD

temperature probes.

• The device can be set directly on site or configured via the setup program with a notebook/

PC.

CAUTION!

The protection class specified for the device is only achieved when the locking screw is inserted and tightened.

8

Page 9

1.3 Description

The highly precise, electronic temperature switch comprises a sheath with built-in temperature

probe, a process connection as well as an attached case with LCD display for the electronics.

Depending on the application, the following output variants are available: 1x PNP or 2x PNP

switching output (binary output) or 1x PNP switching output and 1x analog output.

The configuration of the output signal and the measuring range can be customized.

Depending on the version, the electronic temperature switch can be used in an operating tem-

perature range from -50 to +150 °C, -50 to +260 °C and -50 to +500 °C. The analog output signal 4 to 20 mA, 0 to 20 mA, 0 to 10 V or reversed 20 to 4 mA, 20 to 0 mA and 10 to 0 V is

available linearized (temperature linear).

The electronic temperature probe is designed for industrial applications and complies with the

European Standards to guarantee electromagnetic compatibility (EMC).

1 Introduction

9

Page 10

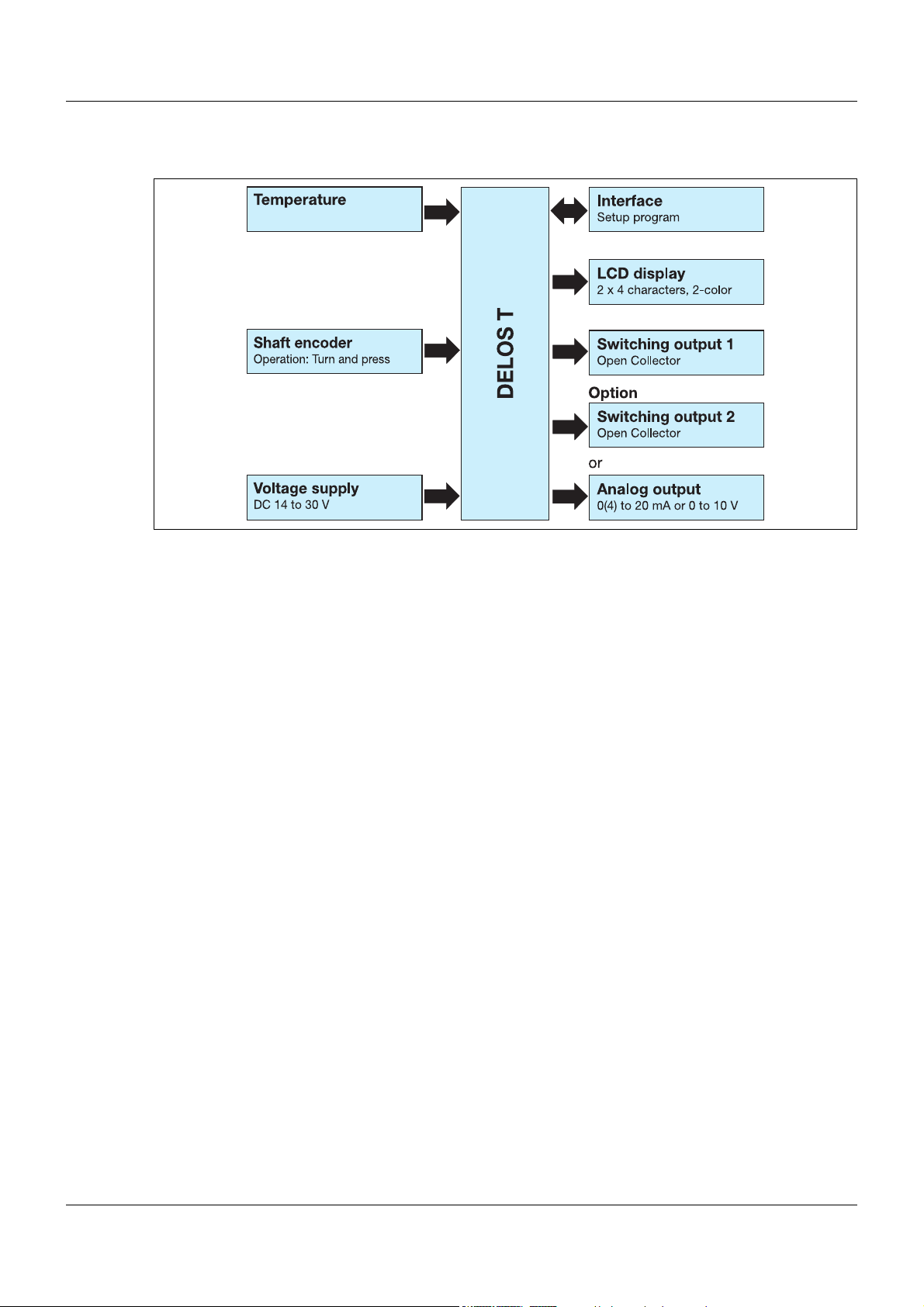

1 Introduction

1.4 Block diagram

10

Page 11

2.1 Type specifications

Position

A laser has been used to label the type specifications on the device display case.

Contents

The specifications contain important information. Amongst others:

Description Example

Basic type 902940/10

Voltage supply DC 14 to 30 V

Output signal 4to20mA

Measuring range (MB) -50 to +150 °C

Switching output 1x PNP 250 mA

Fabrication No. (F No.)

The serial number is used by the manufacturer to identify the device.

The F-No. is not located on the device but on the package.

The F-No. contains the production date (year and week) on position 12 to 15 (counted from the

left).

Example: F-No. = 0149678701010440

The device was produced in the 44th calendar week in 2010.

2 Device identification

11

Page 12

2 Device identification

2.2 Type description for basic type 902940/10

(1) Basic type

902940/10 DELOS T

Electronic temperature switch

with display and analog output

Ambient temperature on the display case: -20 to +75 °C

Parts coming into contact with the medium are electropolished,

roughness depth Ra ≤ 0.8 μm

(2) Version

x 8 Standard, with factory settings

x 9 Customer-specific configuration (specifications in plain text)

(3) Operating temperature in °C

x 370 -50 to +150 °C

(4) Measuring insert

x 1013 1x Pt1000 in 4-wire circuit

(5) Tolerance class as per DIN EN 60751

x 2 Class A (standard)

x 3 Class AA (1/3 DIN B)

(6) Output

x 470 1x PNP switching output

x 471 2x PNP switching output

x 475 1x PNP switching output and 1x analog output 4 to 20 mA, configurable

x 476 1x PNP switching output and 1x analog output 0 to 20 mA, configurable

x 477 1x PNP switching output and 1x analog output 0 to 10 V, configurable

(7) Sheath diameter D in mm

x6∅ 6mm

(8) Fitting length EL in mm (EL 50 to 1000 mm)

x5050mm

x 100 100 mm

x 150 150 mm

x ... Please specify in plain text (50 mm steps)

(9) Process connection PA

x 000 None (plain sheath made of stainless steel 316L)

x 102 Screw connection G 1/4 (stainless steel 316Ti)

x 103 Screw connection G 3/8 (stainless steel 316Ti)

x 104 Screw connection G 1/2 (stainless steel 316Ti)

x 118 Screw connection M 12x1.5 (stainless steel 316Ti)

x 126 Screw connection M 18x1.5 (stainless steel 316Ti)

x 128 Screw connection M 20x1.5 (stainless steel 316Ti)

x 144 Screw connection 1/2-14NPT (stainless steel 316Ti)

x 163 Union nut G 3/8 (stainless steel 316Ti)

x 380 Screw connection G 1/2 with CIP-conforming sealing cone and EHEDG certificate (stainless steel 316L)

x 601 Conical port with union nut DN 10 DIN 11851 (milk pipe union) (stainless steel 316L)

x 604 Conical port with union nut DN 25 DIN 11851 (milk pipe union) (stainless steel 316L)

12

Page 13

2 Device identification

x 605 Conical port with union nut DN 32 DIN 11851 (milk pipe union) (stainless steel 316L)

x 613 Clamp DN 25/40 (1“/1.5“) DIN 32676 (stainless steel 316L)

x 616 Clamp DN 50 (2“) DIN 32676 (stainless steel 316L)

x 617 Clamp 2.5“ similar to DIN 32676 (stainless steel 316L)

x 681 Spherical welding socket with clamp screw connection (stainless steel 316L)

x 682 Welding socket with CIP-conforming sealing cone (stainless steel 316L)

x 685 Varivent connection DN 32/25 with EHEDG certificate (stainless steel 316L)

x 686 Varivent connection DN 50/40 with EHEDG certificate (stainless steel 316L)

x 840 Spherical welding sleeve (stainless steel 316Ti)

x 997 JUMO PEKA with EHEDG certificate (stainless steel 316L)

(compatible process connection adapter, see data sheet 40.9711)

(10) Extra codes

x 000 None

x 310 Sheath ∅ 6 mm stepped down to ∅ 3.8 mm (fitting length EL max. 800 mm)

x 810 Welding socket (only for process connection 380)

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10)

Order code --------/ , ...

Order example 902940/10 - 8 - 370 - 1013 - 2 - 475 - 6 - 50 - 000 / 000

1

State extra codes one after another, separated by commas.

1

13

Page 14

2 Device identification

2.2.1 Scope of delivery for basic type 902940/10

Our scope of delivery includes:

• 1 device in the version ordered

• 1 combination tool

(required for operation on the device and to turn the display case through ± 160°)

• 1 operating instructions B 90.2940.0

In the event of questions, please contact your supplier.

2.2.2 Accessories, process connection for basic type 902940/10

The following articles must be ordered separately and with costs:

Article Part No.

Pipe screw connection G 1/4 (stainless steel 316Ti) for sheath screw connections 90/00080811

Pipe screw connection G 1/2 (stainless steel 316Ti) for sheath screw connections 90/00305445

2.2.3 Accessories for basic type 902940/10

The following articles must be ordered separately and with costs:

Article Part No.

Setup program on CD-ROM, multilingual 90/00550018

PC interface with USB/TTL converter and adapter (USB connection line)

(required for the configuration with the setup program)

Connection line (Y cable)

(required for the configuration with the setup program)

Combination tool

(required for operation on the device and after installation

to turn the display case through ± 160°to the LH or RH side)

Cable box, 4-pin (straight) M 12x1 with PVC connection line length 2000 mm

(can be used for individual assembling)

Cable box, 4-pin (angled) M 12x1 with PVC connection line length 2000 mm

(can be used for individual assembling)

70/00456352

40/00507861

40/00526614

40/00404585

40/00409334

14

Page 15

2 Device identification

2.3 Type description for basic type 902940/30

(1) Basic type

902940/30 DELOS T

Electronic temperature switch

with display and analog output

with neck pipe for higher medium temperatures

Ambient temperature on the display case: -20 to +75 °C

Parts coming into contact with the medium are electropolished,

roughness depth Ra ≤ 0.8 μm

(2) Version

x 8 Standard, with factory settings

x 9 Customer-specific configuration (specifications in plain text)

(3) Operating temperature in °C

x 386 -50 to +260 °C

(4) Measuring insert

x 1013 1x Pt1000 in 4-wire circuit

(5) Tolerance class as per DIN EN 60751

x 2 Class A (standard)

x 3 Class AA (1/3 DIN B)

(6) Output

x 470 1x PNP switching output

x 471 2x PNP switching output

x 475 1x PNP switching output and 1x analog output 4 to 20 mA, configurable

x 476 1x PNP switching output and 1x analog output 0 to 20 mA, configurable

x 477 1x PNP switching output and 1x analog output 0 to 10 V, configurable

(7) Sheath diameter D in mm

x6∅ 6mm

(8) Fitting length EL in mm (EL 50 to 1000 mm)

x5050mm

x 100 100 mm

x ... Please specify in plain text (50 mm steps)

(9) Process connection PA

x 000 None (plain sheath made of stainless steel 316L)

x 102 Screw connection G 1/4 (stainless steel 316Ti)

x 103 Screw connection G 3/8 (stainless steel 316Ti)

x 104 Screw connection G 1/2 (stainless steel 316Ti)

x 118 Screw connection M 12x1.5 (stainless steel 316Ti)

x 126 Screw connection M 18x1.5 (stainless steel 316Ti)

x 128 Screw connection M 20x1.5 (stainless steel 316Ti)

x 144 Screw connection 1/2-14NPT (stainless steel 316Ti)

x 163 Union nut G 3/8 (stainless steel 316Ti)

x 380 Screw connection G 1/2 with CIP-conforming sealing cone and EHEDG certificate (stainless steel 316L)

x 601 Conical port with union nut DN 10 DIN 11851 (milk pipe union) (stainless steel 316L)

x 604 Conical port with union nut DN 25 DIN 11851 (milk pipe union) (stainless steel 316L)

15

Page 16

2 Device identification

x 605 Conical port with union nut DN 32 DIN 11851 (milk pipe union) (stainless steel 316L)

x 611 Clamp DN 10/20 DIN 32676 (stainless steel 316L)

x 613 Clamp DN 25/40 (1“/1.5“) DIN 32676 (stainless steel 316L)

x 616 Clamp DN 50 (2“) DIN 32676 (stainless steel 316L)

x 617 Clamp 2.5“ similar to DIN 32676 (stainless steel 316L)

x 681 Spherical welding socket with clamp screw connection (stainless steel 316L)

x 682 Welding socket with CIP-conforming sealing cone (stainless steel 316L)

x 684 Varivent connection DN 15/10 with EHEDG certificate (stainless steel 316L)

x 685 Varivent connection DN 32/25 with EHEDG certificate (stainless steel 316L)

x 686 Varivent connection DN 50/40 with EHEDG certificate (stainless steel 316L)

x 840 Spherical welding sleeve (stainless steel 316Ti)

x 997 JUMO PEKA with EHEDG certificate (stainless steel 316L)

(compatible process connection adapter, see data sheet 40.9711)

(10) Extra codes

x 000 None

x 310 Sheath ∅ 6 mm stepped down to ∅ 3.8 mm (fitting length EL max. 700 mm)

x 810 Welding socket (only for process connection 380)

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10)

Order code --------/ , ...

Order example 902940/30 - 8 - 386 - 1013 - 2 - 475 - 6 - 50 - 102 / 000

1

State extra codes one after another, separated by commas.

1

16

Page 17

2 Device identification

2.3.1 Scope of delivery for basic type 902940/30

Our scope of delivery includes:

• 1 device in the version ordered

• 1 combination tool

(required for operation on the device and to turn the display case through ± 160°)

• 1 operating instructions B 90.2940.0

In the event of questions, please contact your supplier.

2.3.2 Accessories, process connection for basic type 902940/30

The following articles must be ordered separately and with costs:

Article Part No.

Pipe screw connection G 1/4 (stainless steel 316Ti) for sheath screw connections 90/00080811

Pipe screw connection G 1/2 (stainless steel 316Ti) for sheath screw connections 90/00305445

2.3.3 Accessories for basic type 902940/30

The following articles must be ordered separately and with costs:

Article Part No.

Setup program on CD-ROM, multilingual 90/00550018

PC interface with USB/TTL converter and adapter (USB connection line)

(required for the configuration with the setup program)

Connection line (Y cable)

(required for the configuration with the setup program)

Combination tool

(required for operation on the device and after installation

to turn the display case through ± 160° to the LH or RH side)

Cable box, 4-pin (straight) M 12x1 with PVC connection line length 2000 mm

(can be used for individual assembling)

Cable box, 4-pin (angled) M 12x1 with PVC connection line length 2000 mm

(can be used for individual assembling)

70/00456352

40/00507861

40/00526614

40/00404585

40/00409334

17

Page 18

2 Device identification

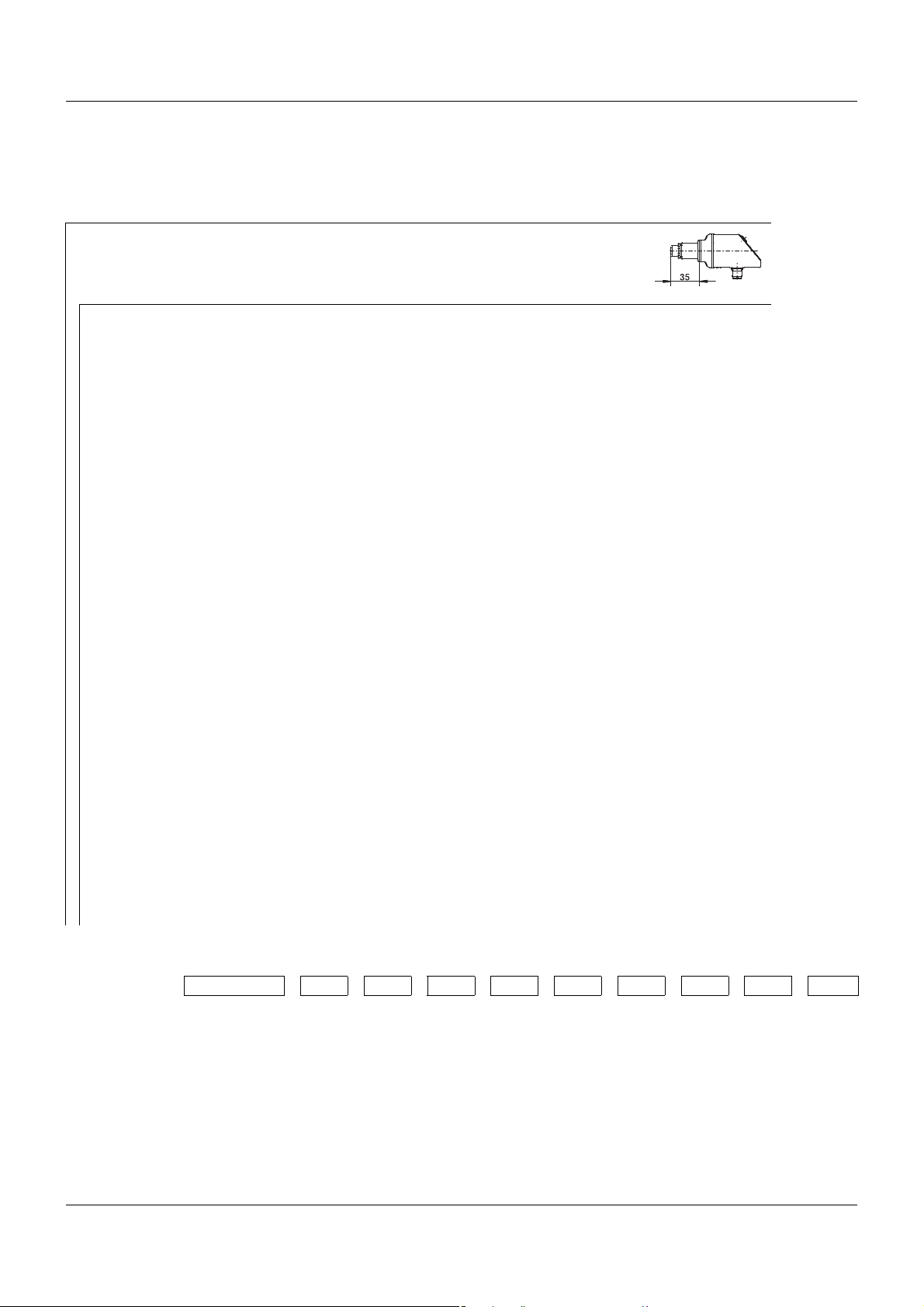

2.4 Type description for basic type 902940/50

(1) Basic type

902940/50 DELOS T

Electronic temperature switch

with display and analog output

and M 12x1 connection for RTD temperature probes

Ambient temperature on the display case: -20 to +75 °C

(2) Version

x 8 Standard, with factory settings

x 9 Customer-specific configuration (specifications in plain text)

(3) Operating temperature in °C

x 408 -50 to +500 °C

(4) Measuring input

x 1013 1x Pt1000 in 4-wire circuit

(5) Tolerance class as per DIN EN 60751

x 0 None (not relevant)

(6) Output

x 470 1x PNP switching output

x 471 2x PNP switching output

x 475 1x PNP switching output and 1x analog output 4 to 20 mA, configurable

x 476 1x PNP switching output and 1x analog output 0 to 20 mA, configurable

x 477 1x PNP switching output and 1x analog output 0 to 10 V, configurable

(7) Sheath diameter D in mm

x 0 None (not relevant)

(8) Fitting length EL in mm

x 000 None (not relevant)

(9) Process connection PA

x 000 None (not relevant)

(10) Extra codes

x 000 None

(1) (2) (3) (4) (5) (6) (7) (8) (9) (10)

Order code --------/

Order example 902940/50 - 8 - 408 - 1013 - 0 - 475 - 0 - 000 - 000 / 000

18

Page 19

2 Device identification

2.4.1 Scope of delivery for basic type 902940/50

Our scope of delivery includes:

• 1 device in the version ordered

• 1 combination tool

(required for operation on the device and to turn the display case through ± 160°)

• 1 operating instructions B 90.2940.0

In the event of questions, please contact your supplier.

2.4.2 Accessories for basic type 902940/50

The following articles must be ordered separately and with costs:

Article Part No.

Setup program on CD-ROM, multilingual 90/00550018

PC interface with USB/TTL converter and adapter (USB connection line)

(required for the configuration with the setup program)

Connection line (Y cable)

(required for the configuration with the setup program)

Combination tool

(required for operation on the device and after installation

to turn the display case through ± 160° to the LH or RH side)

Cable box, 4-pin (straight) M 12x1 with PVC connection line length 2000 mm

(can be used for individual assembling)

Cable box, 4-pin (angled) M 12x1 with PVC connection line length 2000 mm

(can be used for individual assembling)

Machine connector M 12x1, 4-pin as per IEC 60947-5-2 90/00404727

Wall holder for DELOS T with M 12x1 connector 90/00555129

Push-in RTD temperature probe with Pt1000 temperature probe

and machine connector M 12x1

902150/99-386-1006-2-6-100-56-2500/315

Sheath diameter 6 mm, fitting length 100 mm,

connection cable length 2500 mm

Push-in RTD temperature probe with Pt1000 temperature probe

and machine connector M 12x1

902150/99-386-1006-2-6-200-56-2500/315

Sheath diameter 6 mm, fitting length 200 mm,

connection cable length 2500 mm

70/00456352

40/00507861

40/00526614

40/00404585

40/00409334

90/00551310

90/00551311

19

Page 20

2 Device identification

20

Page 21

3 Electrical connection

3.1 Installation notes

CAUTION!

The electrical connection must only be carried out by qualified personnel!

• Ensure that the fuses of the load circuits are suitable for the maximum loads to avoid damage to the device.

• The electromagnetic compatibility meets standard EN 61326.

• Do not connect any additional consumers to the voltage supply of the device.

• The device is not suitable for use in areas with an explosion hazard (Ex areas).

• In addition to a faulty installation, also incorrectly set values on the device could impair the

orderly function of the following process or lead to damage. For this reason, always provide

safety devices/guards independent of the device, the setting of which is restricted to expert

personnel.

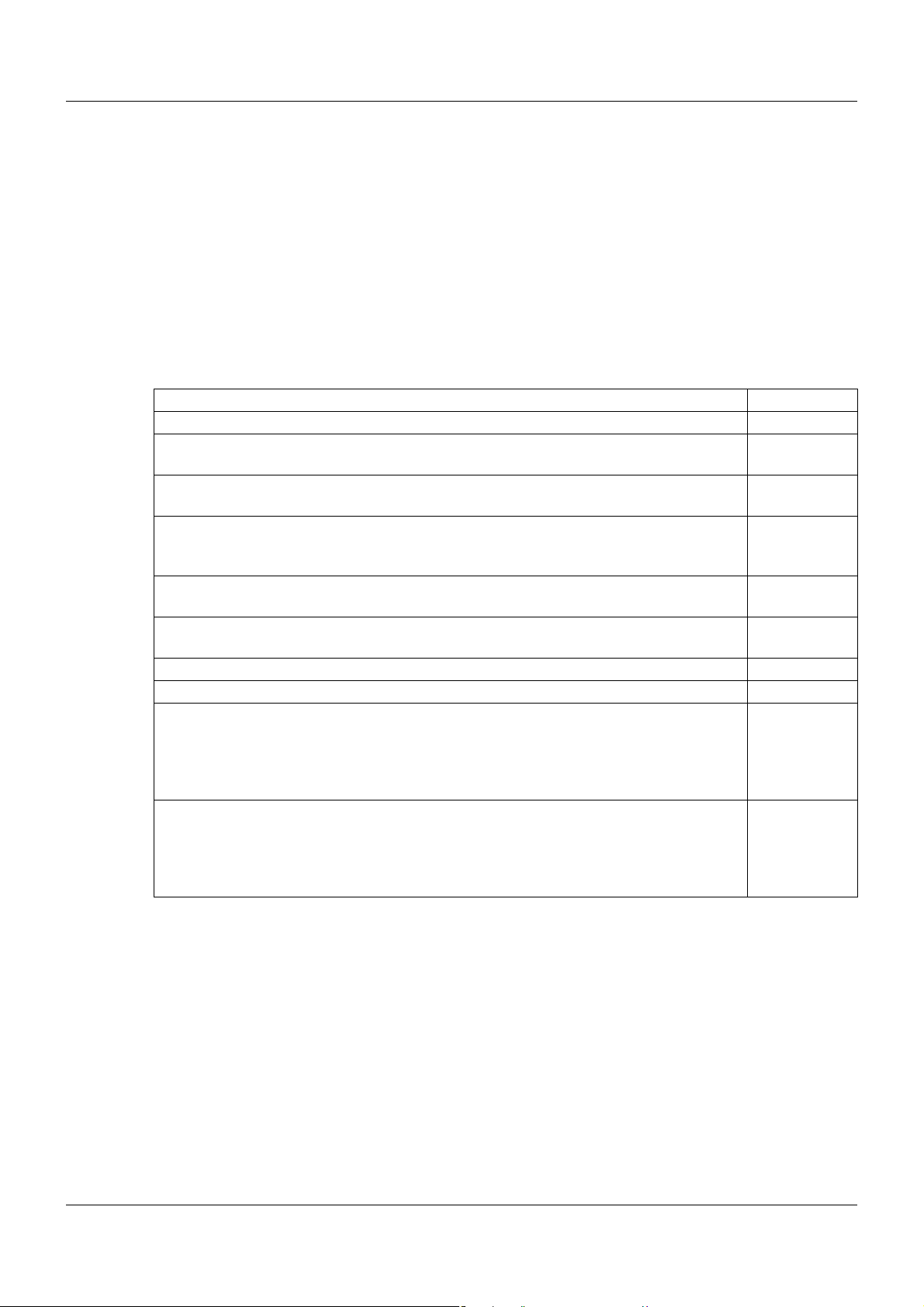

3.2 Device connection assignment for M 12x1 machine connector

The connection is located on the device rear!

TIP!

The assignment only applies to A-coded standard cables.

1 brown (bn) 2 white (wh)

3 blue (bu) 4 black (bk)

5 gray (gy)

21

Page 22

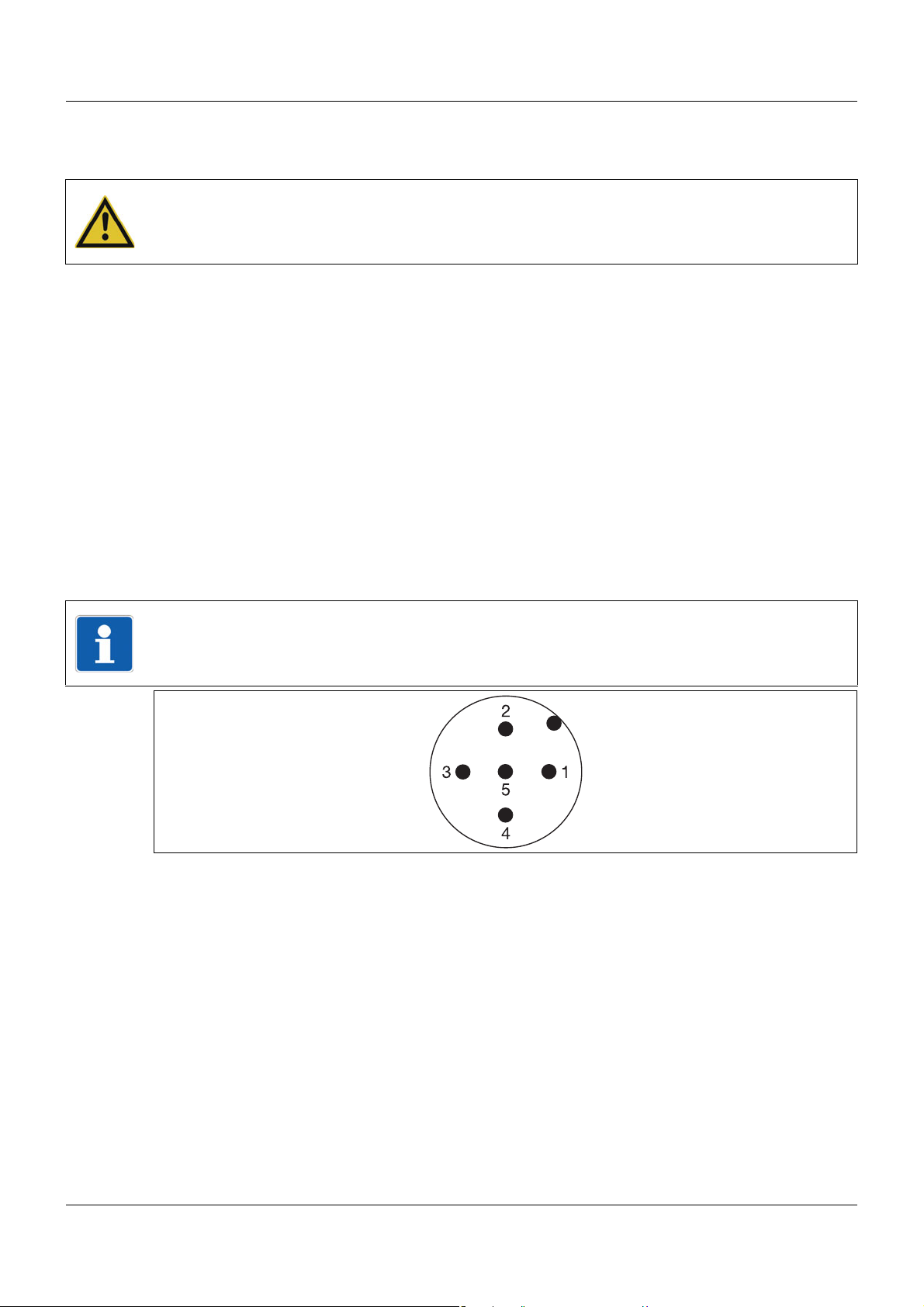

3 Electrical connection

1

2

3

4

5

L-

K1

L+

3.3 Connection assignment for order code 470

The connection is located on the device rear!

1x PNP switching output

Voltage supply

1 L+ DC 14 to 30 V

3 L- GND

Output

4 K1 Highside open collector

max. 0.25 A

2nc

5 Interface

22

Page 23

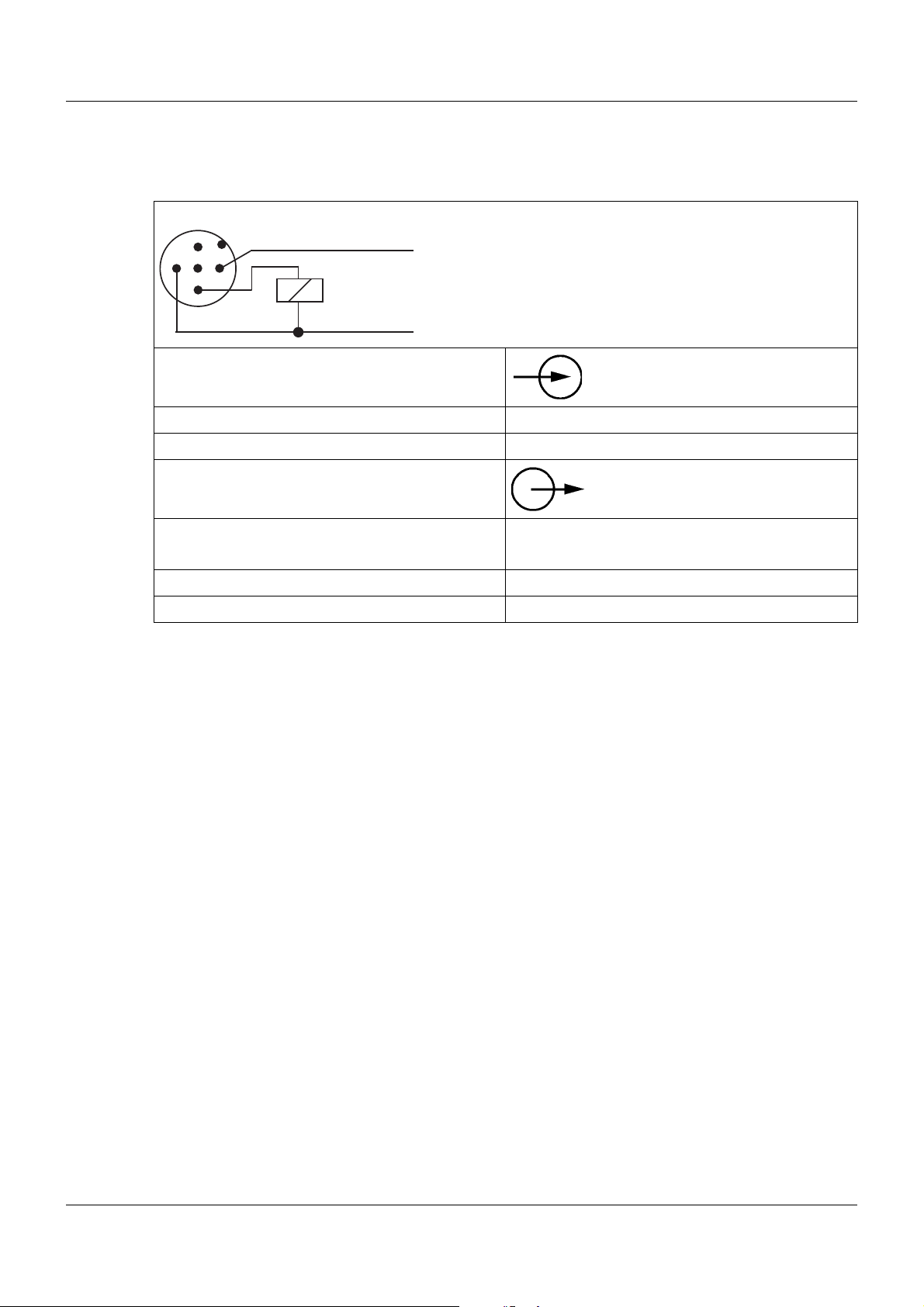

3 Electrical connection

1

2

3

4

5

L-

K1 K2

L+

3.4 Connection assignment for order code 471

The connection is located on the device rear!

2× PNP switching output

Voltage supply

1 L+ DC 14 to 30 V

3 L- GND

Output

4 K1 Highside open collector

2 K2

5 Interface

max. 0.25 A

23

Page 24

3 Electrical connection

1

2

3

4

5

L-

K1

L+

3.5 Connection assignment for order code 475, 476 and 477

The connection is located on the device rear!

1x PNP switching output and 1x analog output

Voltage supply

1 L+ DC 14 to 30 V

3 L- GND

Output

4 K1 Highside open collector

max. 0.25 A

2 analog 0(4)to20mA/0to10V

5 Interface

24

Page 25

3 Electrical connection

12 34

3.6 Connection assignment for RTD temperature probe for basic type 902940/50

TIP!

Please ensure that this connection is not mixed up with the connection on the device rear

(only for analog or switching output, voltage supply and interface)!

Machine connector M 12x1, 4-pole

as per IEC 60947-5-2

Top view to the machine connector on the corresponding RTD temperature probe!

Top view to the installed socket at the device bottom!

Connection assignment for RTD temperature

probe in 4-wire circuit (input)

25

Page 26

3 Electrical connection

26

Page 27

4.1 General information

CAUTION!

Check that the device is compatible with the medium to be measured.

Installation site

• Ensure that the device is easily accessible for the later operation.

• Ensure that the device is fastened safely and with low vibrations.

• Avoid direct sun radiation!

• Ensure an admissible ambient temperature at the installation site.

Installation position

The device can be installed in any position.

We recommend the "vertical" installation position.

4 Installation

27

Page 28

4 Installation

4.1.1 Turning the LCD display

The device LCD display can be turned through 180°. (Either via the setting on the device or the

optional setup program).

This will facilitate reading when, for example, the device is installed turned through 180°.

Chapter 6.17 "Setting the display alignment (D.Dir)", page 63

4.1.2 Turning the display case

The display case of the device can be turned to the LH or RH side through ±160° using the

supplied combination tool (1).

28

(1) Combination tool

Page 29

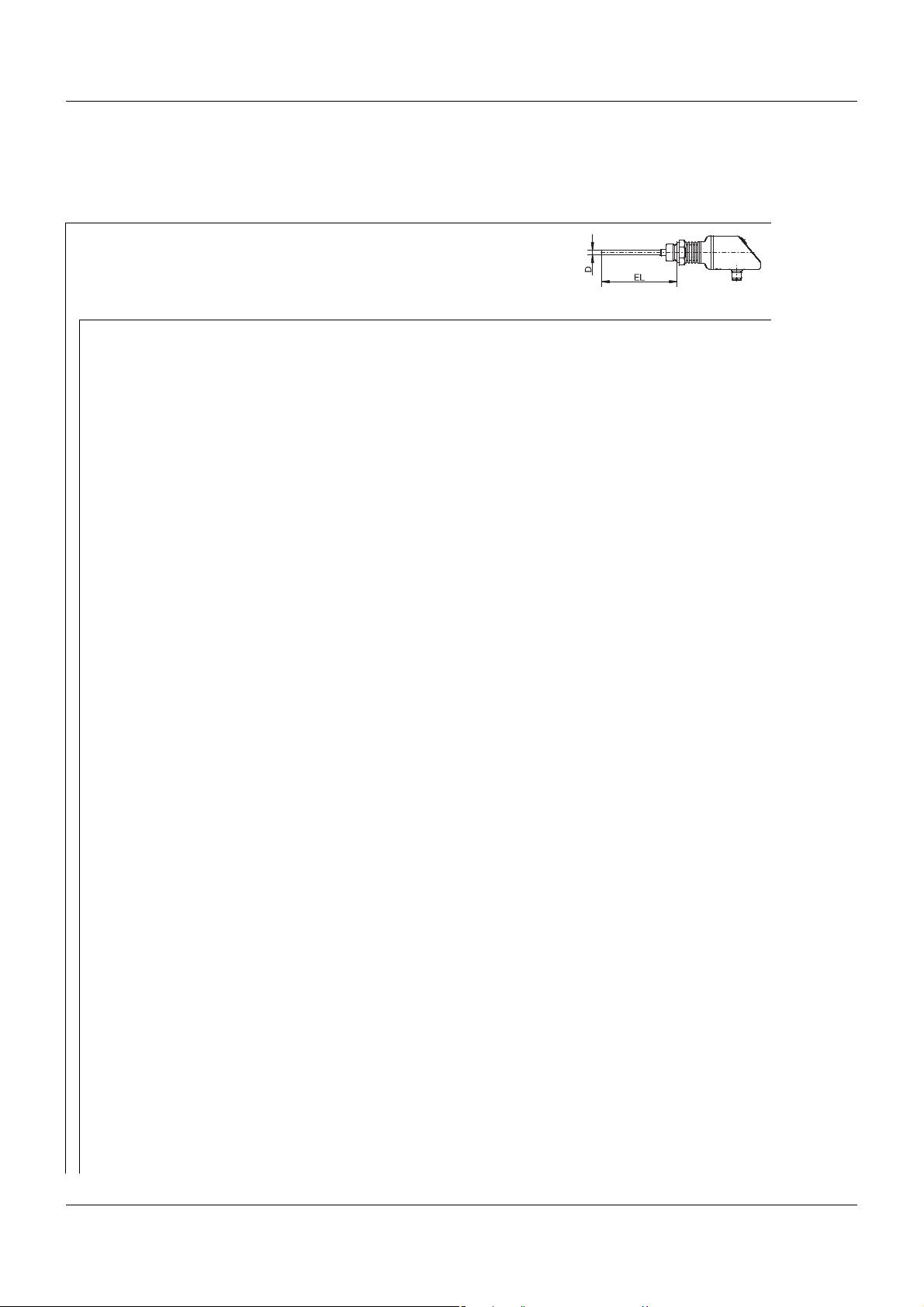

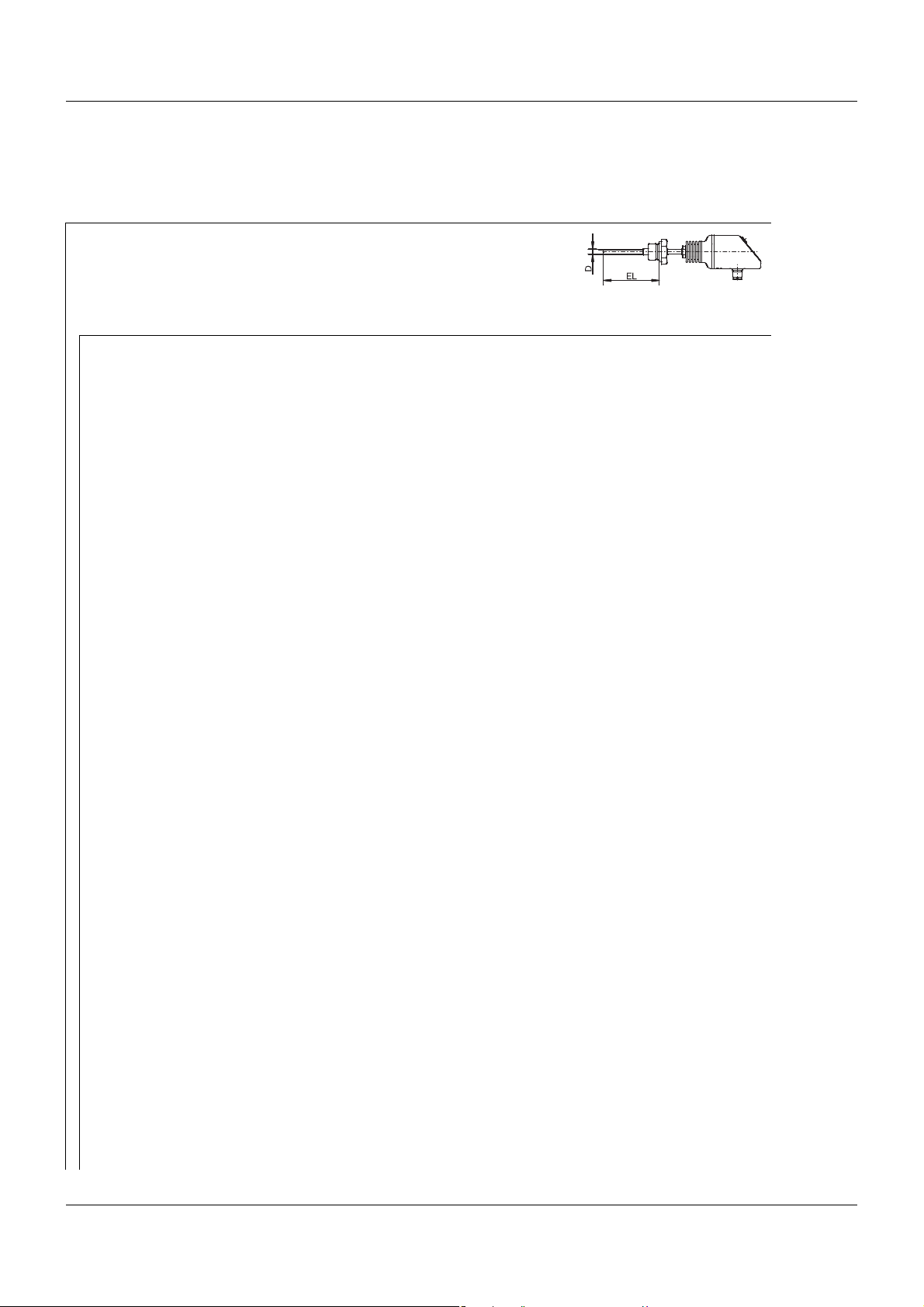

4.2 Device dimensions

4 Installation

Figure 1: Basic type 902940/10 with process connection (LH)

Basic type 902940/30 with neck pipe and process connection (center)

Basic type 902940/50 with M 12x1 connection for RTD temperature probe (RH)

29

Page 30

4 Installation

4.3 Process connection dimensions (PA)

Screw connection Screw connection

with CIP-conforming sealing cone

PA G PA

103 3/8 380

104 1/2

Clamp as per DIN 32676 Spherical welding socket

with clamping screws

PA DN D1 PA

--∅ 25 681

30

611 10/20 ∅ 34

613 25/1“ ∅ 50.5

613 40/1.5“ ∅ 50.5

616 50/2“ ∅ 64

617 2.5“ ∅ 77.5

Page 31

4 Installation

Clamp with union nut as per DIN 11851 (milk pipe union)

PA DN D1 D2 D3 D4 L1 L2

601 10 ∅ 22 ∅ 18 RD 28x1/8 ∅ 38 9 18

604 25 ∅ 44 ∅ 35 RD 52x1/6 ∅ 63 13 21

605 32 ∅ 50 ∅ 41 RD 58x1/6 ∅ 70 13 21

Welding socket

with CIP-conforming sealing cone

PA PA DN D1

682 684 15/10 ∅ 31

Varivent connection

685 32/25 ∅ 50

686 50/40 ∅ 68

31

Page 32

4 Installation

Spherical welding socket Process connection adapter 997 JUMO PEKA

PA Varivent Clamp Aseptic Welding

socket

681 DN 25/32 DN 25/32/40 DN 40 ∅ 55 mm

DN 40-125 DN 50 DN 50 -

- - NKS DN 40 -

TIP!

The 997 JUMO PEKA process connection adapter is EHEDG certified.

For detail information on this process connection adapter, refer to data and price sheet

40.9711.

32

Page 33

5.1 Operating element

5 Operation

(1) Locking screw (2) Operating element

How to proceed:

Step Activity

1 Remove the locking screw (1) using a suitable screwdriver.

2 Use the supplied combination tool

(or a 0.5 x 3 mm screwdriver or Allen key, width across flats 2)

to "Turn/press" the operating element (2).

33

Page 34

5 Operation

5.2 LCD display

5.2.1 Measuring mode (normal display)

Example:

The LCD display is lit yellow.

5.2.2 Setting mode

Operation

Example:

The LCD display is lit red.

Continue Press the combination tool for less than 1 second (< 1s)

Yes (take-over) Press the combination tool for less than 1 second (< 1s)

No (cancel) Press the combination tool for more than 3 seconds (> 3s)

Time out no action for more than 60 seconds (> 60 s)

TIP!

To change over from the setting mode to the measuring mode:

- "No" (Cancel) or

- Wait for "Timeout" = No actions for 60 seconds.

34

Page 35

5.3 Levels

5 Operation

35

Page 36

5 Operation

5.4 Parameters

5.4.1 Input

Parameters Display Setting range

Temperature unit °C

°F

Decimal place

temperature values

Offset

(zero point correction)

Damping

(filter time constant)

0

1

-100.0 to 0 to +100.0 °C

0.00 to 0.10 to 99.99 s

1

Mains frequency (Hz) 50 H

60 H

1

The standard setting is displayed bold.

36

Page 37

5.4.2 Analog output

5 Operation

Parameters Display Setting range

Type of signal

(only with analog output)

Scaling start

(only with analog output)

Scaling end

(only with analog output)

Error signal

(only with analog output)

4to20mA

0to20mA

0to10V

-50 °C

150 °C/260 °C/500 °C

Note:

Depending on the device ordered.

3.4 mA or 22 mA

with output signal 4 ... 20 mA

0mA or 22mA

with output signal 0 ... 20 mA

0 V or 10.7 V

with output signal 0 ... 10 V

Chapter 6.10 "Setting the error signal of the

analog output (S.Err)", page 53

Note:

Depending on the configured output signal.

1

The standard setting is displayed bold.

1

37

Page 38

5 Operation

5.4.3 Binary output 1

Parameters Display Setting range

Switching function = Hysteresis, N/O contact

1

= Hysteresis, N/C contact

= Window, N/O contact

= Window, N/C contact

Chapter 6.12 "Setting the switching function

(B.Fct)", page 55

Switching point 100 °C

Chapter 6.12 "Setting the switching function

(B.Fct)", page 55

Release point 90 °C

Chapter 6.12 "Setting the switching function

(B.Fct)", page 55

Hysteresis

(only with configured

switching point and

release point)

Switch-on delay 0.00 to 99.99 s

0to1 to 500 °C

Chapter 6.12 "Setting the switching function

(B.Fct)", page 55

Note:

Application exclusively with window switching

functions.

Chapter 6.12 "Setting the switching function

(B.Fct)", page 55

38

1

The standard setting is displayed bold.

Page 39

5.4.4 Binary output 2

5 Operation

Parameters Display Setting range

Switching function

(only with second switching output)

= Hysteresis, N/O contact

= Hysteresis, N/C contact

= Window, N/O contact

= Window, N/C contact

Chapter 6.12 "Setting the switching function

(B.Fct)", page 55

Switching point

(only with second switching output)

Release point

(only with second switching output)

Hysteresis

(only with second switching output and configured

switching point and

release point)

Switch-on delay

(only with second switching output)

100 °C

Chapter 6.12 "Setting the switching function

(B.Fct)", page 55

90 °C

Chapter 6.12 "Setting the switching function

(B.Fct)", page 55

0to1 to 500 °C

Chapter 6.12 "Setting the switching function

(B.Fct)", page 55

Note:

Application exclusively with window switching

functions.

0.00 to 99.99 s

Chapter 6.12 "Setting the switching function

(B.Fct)", page 55

1

1

The standard setting is displayed bold.

39

Page 40

5 Operation

5.4.5 Display and operation

Parameters Display Setting range

Display alignment Std = standard (for standard operation)

turn = turned through 180° (for operation turned

through 180°)

1

Chapter 6.17 "Setting the display alignment

(D.Dir)", page 63

Unit of the actual value

display

(only with analog output)

Software version of the

operating unit

(cannot be edited)

Software version of the

signal unit

(cannot be edited)

Uni.T = Temperature unit (Uni.T)

Proz = % from the scaled range (Sc.Lo and Sc.Hi)

Chapter 6.18 "Setting the display unit (D.Uni)",

page 64

Display of the software version of the operating

unit

Chapter 6.19 "Displaying the software version

of the operating unit (SW.Di)", page 65

Display of the software version of the signal unit

Chapter 6.20 "Displaying the software version

of the signal unit (SW.Si)", page 66

Code

(can only be programmed

via the setup program)

1

The standard setting is displayed bold.

0000 to 0072 to 9999

Chapter 6.2 "Unlocking the device (enter the

code).", page 42

40

Page 41

6.1 Quick introduction

TIP!

This is a proposal to be able to configure the device reliably within a short time. When checking the setting possibilities specified in this list prior to starting configuration, timeouts can be

avoided during configuration.

How to proceed:

Step Activity

1 Install the device.

Chapter 4 "Installation", page 27

2 Connect the device.

Chapter 3 "Electrical connection", page 21

3 Unlock the device.

Chapter 6.2 "Unlocking the device (enter the code).", page 42

6 Commissioning/start-up

4 Select the unit of the measured value.

Chapter 6.4 "Setting the unit of the measured value (Uni.T)", page 44

5 Set the output signal.

Chapter 6.8 "Setting the output signal (S.Type)", page 47

6 Set the output signal scaling.

Chapter 6.9 "Setting the output signal scaling", page 48

7 Set the switching function.

Chapter 6.12 "Setting the switching function (B.Fct)", page 55

8 Set the switching point.

Chapter 6.13 "Setting the switching point (B.Sp)", page 59

9 Set the release point.

Chapter 6.14 "Setting the release point (B.RSp)", page 60

41

Page 42

6 Commissioning/start-up

6.2 Unlocking the device (enter the code).

The device is protected against unauthorized operation by a code.

Code is set to 0072 (factory setting). Changes are only possible with the setup program. The

device will become unprotected when the setup program is used to set the code to 0000.

Unlocking

42

(1) Locking screw (2) Combination tool

Page 43

6 Commissioning/start-up

How to proceed:

Step Activity

1 Remove the locking screw (1) using a suitable screwdriver.

2 Briefly press the combination tool (2) until the third "0" (counted from the left) flashes.

Display previously changes to "red".

3 Turn the combination tool until "7" appears. Briefly press the combination tool.

4 Briefly press the combination tool until the fourth "0" (counted from the left) flashes.

5 Turn the combination tool until "2" appears. Briefly press the combination tool.

6 The device automatically changes over to the parameter level.

If an incorrect code was entered:

The display automatically changes over to the code entry after 3 seconds (or press the

combination tool). Repeat steps 2 to 5.

6.3 Operation cancellation

How to proceed:

Step Activity

1 Press the combination tool for more than 3 seconds or

2 wait for "Timeout" (no action for more than 60 seconds).

43

Page 44

6 Commissioning/start-up

6.4 Setting the unit of the measured value (Uni.T)

How to proceed:

Step Activity

1 Unlock the device.

Chapter 6.2 "Unlocking the device (enter the code).", page 42

2 "Turn" until "Uni.T" appears in the bottom line.

3"Press"

The measured temperature is displayed in °C.

4"Turn"

The measured temperature is displayed in °F.

Setting:

°C = Temperature unit °C (factory setting)

°F = Temperature unit °F

5 Confirm the setting: "Press" until the display stops flashing.

6.4.1 Display and setting possibilities of the device

Measuring range Temperature unit Display

Start End

-50to+150°C °C -50 +150

-50to+260°C °C -50 +260

-50to+500°C °C -50 +500

-58to+302°F °F -58 +302

-58to+500°F °F -58 +500

-58to+932°F °F -58 +932

44

Page 45

6 Commissioning/start-up

6.5 Setting the offset (zero point) (Off.T)

6.5.1 Edited offset setting

With this setting, the measured temperature can be increased by an adjustable value.

How to proceed:

Step Activity

1 Unlock the device.

Chapter 6.2 "Unlocking the device (enter the code).", page 42

2 "Turn" until "Off.T" appears in the bottom line.

3"Press"

TIP!

"-" means: the offset is negative - the measured temperature is reduced.

The value is entered "digit-by-digit".

45

Page 46

6 Commissioning/start-up

6.6 Setting the filter time constant (damping) (DamP)

The filter time constants (damping) can be used to "damp" the measured value.

Small filter time constant: the measured value is updated faster.

Large filter time constant: the measured value is updated slower.

The value is entered in seconds with two decimal places.

How to proceed:

Step Activity

1 Unlock the device.

Chapter 6.2 "Unlocking the device (enter the code).", page 42

2 "Turn" until "DamP" appears in the bottom line.

3"Press"

6.7 Setting the mains frequency (Freq)

This setting can be used to change the mains frequency from 50 Hz to 60 Hz.

How to proceed:

Step Activity

1 Unlock the device.

Chapter 6.2 "Unlocking the device (enter the code).", page 42

2 "Turn" until "Freq" appears in the bottom line.

3"Press"

Setting:

50H = Mains frequency 50 Hz (factory setting)

60H = Mains frequency 60 Hz

46

Page 47

6 Commissioning/start-up

6.8 Setting the output signal (S.Type)

How to proceed:

Step Activity

1 Unlock the device.

Chapter 6.2 "Unlocking the device (enter the code).", page 42

2 "Turn" until "S.Type" appears in the bottom line.

3"Press"

Setting:

4.20A = Output signal 4 to 20 mA

0.20A = Output signal 0 to 20 mA

0.10U = Output signal 0 to 10 V

6.8.1 Output performance

The output signal behavior in the event of an abrupt change of the input signal is specified in

the following table and the figure.

Output Dead time t1 Time constant t2

Current output < 200 ms at 50 Hz mains frequency

< 320 ms at 60 Hz mains frequency

Voltage output < 200 ms at 50 Hz mains frequency

< 320 ms at 60 Hz mains frequency

70 ms

80 ms

47

Page 48

6 Commissioning/start-up

6.9 Setting the output signal scaling

The output signal scaling describes how the measured temperature is "converted" to an output

signal.

Simple example:

Actual

The device has a measuring range (1) from -50 to +150 °C and the output signal 4 to 20 mA

(3).

Set point

The customer wants that the "Customer measuring range“ (2) -50 to +150 °C (100 % from the

measuring range (1)) complies with the 4 to 20 mA (100 %) output signal (3).

(1) Measuring range (2) Customer specific measuring range

(3) Output signal

48

Page 49

Customer specific scaling

It is frequently desired that a part of the measuring range is scaled to the output signal.

Example:

Actual

The device has a measuring range (1) from -50 to +150 °C and the output signal 4 to 20 mA

(3).

Set point

The customer wants that the "Customer scaling range“ (2) 0 to 50 °C (25 % from the measuring

range (1)) complies with the 4 to 20 mA (100 %) output signal.

Scaling is 1 : 4 (25 % : 100 %).

6 Commissioning/start-up

(1) Measuring range (2) Customer scaling range

(3) Output signal

49

Page 50

6 Commissioning/start-up

Inverting the output signal

The device offers the possibility to invert the output signal (3).

During this process the output signal

• 0 to 20 mA is inverted to the output signal 20 to 0 mA

• 4 to 20 mA is inverted to the output signal 20 to 4 mA

• 0 to 10 V is inverted to the output signal 10 to 0 V

Example:

20 to 4 mA

(1) Measuring range (2) Customer scaling range

(3) Output signal

50

Page 51

6 Commissioning/start-up

6.9.1 Setting the scaling start value (Sc.Lo)

TIP!

The output signal can only be scaled on devices with analog output.

Setting range: Measuring range

Factory-setting: Measuring range start

Example:

The device has a measuring range from -50 to +150 °C.

The device output signal is 0 to 20 mA.

Objective: The range from 0 to 100 °C (customer scaling) is to be displayed on the out-

put side by 0to20mA.

Setting: Scaling start value (Sc.Lo) = 0

Scaling end value (Sc.Hi) = 100

Result: At a temperature below 0 °C, the device indicates an error (measuring

range gone below) and provides the respective error signal (0 mA) on the

analog output.

At a temperature of 0 °C, the device provides 0 mA on the analog output.

At a temperature of 100 °C, the device provides 20 mA on the analog output.

At a temperature exceeding 100 °C, the device indicates an error (measuring range exceeded) and provides the respective error signal (22 mA) on

the analog output.

How to proceed:

Step Activity

1 Unlock the device.

Chapter 6.2 "Unlocking the device (enter the code).", page 42

2 "Turn" until "Sc.Lo" appears in the bottom line.

3"Press"

TIP!

The value is entered "digit-by-digit“!

51

Page 52

6 Commissioning/start-up

6.9.2 Setting the scaling end value (Sc.Hi)

TIP!

The output signal can only be scaled on devices with analog output.

Setting range: Measuring range

Factory-setting: Measuring range end

How to proceed:

Step Activity

1 Unlock the device.

Chapter 6.2 "Unlocking the device (enter the code).", page 42

2 "Turn" until "Sc.Hi" appears in the bottom line.

3"Press"

TIP!

The value is entered "digit-by-digit“!

52

Page 53

6 Commissioning/start-up

6.10 Setting the error signal of the analog output (S.Err)

TIP!

An error signal for overrange or underrange is only transmitted on devices with analog output.

In the event of errors (e.g. probe break or probe short-circuit), the analog output transmits the

signal configured here.

How to proceed:

Step Activity

1 Unlock the device.

Chapter 6.2 "Unlocking the device (enter the code).", page 42

2 "Turn" until "S.Err" appears in the bottom line.

3"Press"

Setting:

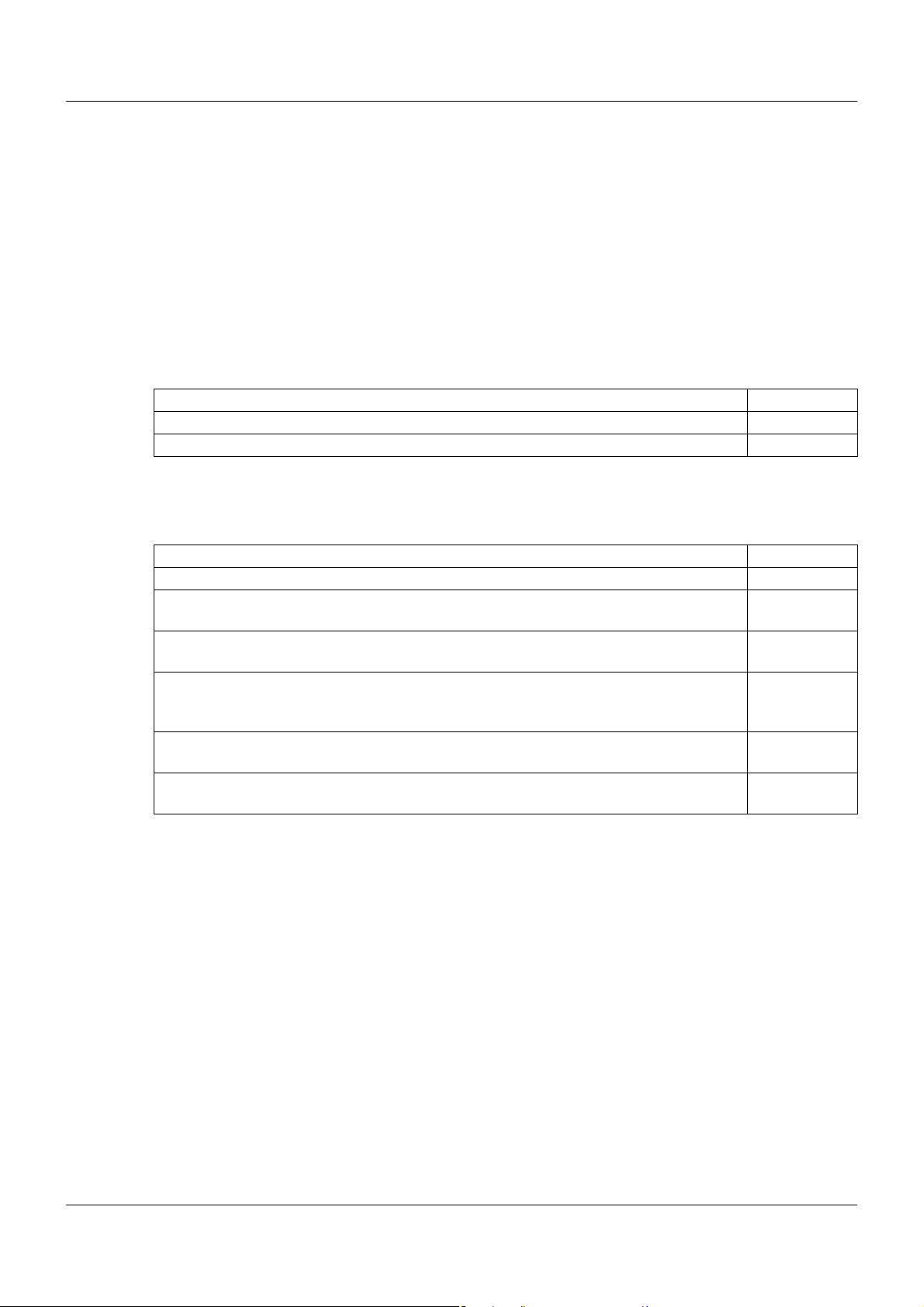

Type of signal Setting

4 to20 mA

0to20mA

0to10V

= 3.4 mA

= 22 mA

= 0 mA

= 22 mA

= 0 V

= 10.7 V

53

Page 54

6 Commissioning/start-up

6.11 Behavior when the scaling range is exceeded

The standard signal range of the analog output is limited as per recommendation of Namur NE

43.

Type of signal lower limit upper limit

4to20mA 3.8mA 20.5mA

0to20mA 0mA 20.5mA

0to10V 0V 10.2V

Example:

4to20mA (factory setting)

54

Page 55

6 Commissioning/start-up

6.12 Setting the switching function (B.Fct)

General information

The switching output behavior of the device can be set.

6.12.1 Hysteresis (switching difference)

Relay behavior

• Hysteresis, N/O contact

• Hysteresis, N/C contact

(1) Switching point (Sp) (2) Release point (RSp)

(3) Hysteresis (switching difference) (4) N/O contact

(5) N/C contact

55

Page 56

6 Commissioning/start-up

How to proceed:

Step Activity

1 Unlock the device.

Chapter 6.2 "Unlocking the device (enter the code).", page 42

2 "Turn" until "B.Fct" appears in the bottom line.

3"Press"

Hysteresis N/O contact = Max. contact (factory setting)

Hysteresis, N/C contact = Min. contact

56

Page 57

6.12.2 window

Relay behavior

• Window function, N/O contact

• Window function, N/C contact

6 Commissioning/start-up

(1) Switching point (Sp) (2) Release point (RSp)

(3) Hysteresis (switching difference) (4) N/O contact

(5) N/C contact

57

Page 58

6 Commissioning/start-up

How to proceed:

Step Activity

1 Unlock the device.

Chapter 6.2 "Unlocking the device (enter the code).", page 42

2 "Turn" until "B.Fct" appears in the bottom line.

3"Press"

Window function, N/O contact

Window function, N/C contact

58

Page 59

6 Commissioning/start-up

6.13 Setting the switching point (B.Sp)

Chapter 6.12 "Setting the switching function (B.Fct)", page 55

Setting range: Measuring range (> B.RSp)

Factory-setting: 100 °C

How to proceed:

Step Activity

1 Unlock the device.

Chapter 6.2 "Unlocking the device (enter the code).", page 42

2 "Turn" until "B.Sp" appears in the bottom line.

3"Press"

TIP!

The value is entered "digit-by-digit“!

59

Page 60

6 Commissioning/start-up

6.14 Setting the release point (B.RSp)

Chapter 6.12 "Setting the switching function (B.Fct)", page 55

Setting range: Measuring range (> B.Sp)

Factory-setting: 90 °C

How to proceed:

Step Activity

1 Unlock the device.

Chapter 6.2 "Unlocking the device (enter the code).", page 42

2 "Turn" until "B.RSp" appears in the bottom line.

3"Press"

TIP!

The value is entered "digit-by-digit“!

60

Page 61

6.15 Setting the hysteresis (B.HyS)

TIP!

Only with the window switching function.

Chapter 6.12 "Setting the switching function (B.Fct)", page 55

Setting range: 0 to 500 °C

Factory-setting: 1 °C

How to proceed:

Step Activity

1 Unlock the device.

Chapter 6.2 "Unlocking the device (enter the code).", page 42

2 "Turn" until "B.HyS" appears in the bottom line.

3"Press"

6 Commissioning/start-up

TIP!

The value is entered "digit-by-digit“!

61

Page 62

6 Commissioning/start-up

6.16 Setting the switch-on delay time (B.Dly)

Setting range: 0.00 to 99.99 s

Factory-setting: 0.00 s

How to proceed:

Step Activity

1 Unlock the device.

Chapter 6.2 "Unlocking the device (enter the code).", page 42

2 "Turn" until "B.Dly" appears in the bottom line.

3"Press"

TIP!

The value is entered "digit-by-digit“!

62

Page 63

6 Commissioning/start-up

6.17 Setting the display alignment (D.Dir)

Setting range: Std = Standard = Device vertical

turn = turned = Device turned through 180°

Factory-setting: Std

How to proceed:

Step Activity

1 Unlock the device.

Chapter 6.2 "Unlocking the device (enter the code).", page 42

2 "Turn" until "D.Dir" appears in the bottom line.

3"Press"

or

63

Page 64

6 Commissioning/start-up

6.18 Setting the display unit (D.Uni)

Setting range: Uni.t = Temperature unit set as for "Uni.T"

Chapter 6.4 "Setting the unit of the measured value (Uni.T)", page 44

Pro2 = Percent of the scaled measuring range = "Sc.Hi" minus "Sc.Lo"

Chapter 6.9.1 "Setting the scaling start value (Sc.Lo)", page 51

and

Chapter 6.9.2 "Setting the scaling end value (Sc.Hi)", page 52

Factory-setting: Uni.t

How to proceed:

Step Activity

1 Unlock the device.

Chapter 6.2 "Unlocking the device (enter the code).", page 42

2 "Turn" until "D.Uni" appears in the bottom line.

3"Press"

Uni.t = The measured value is displayed in the selected unit.

Chapter 6.4 "Setting the unit of the measured value (Uni.T)", page 44

or

Pro2 = The measured value is displayed in percent of the scaling range.

Chapter 6.9.1 "Setting the scaling start value (Sc.Lo)", page 51

and

Chapter 6.9.2 "Setting the scaling end value (Sc.Hi)", page 52

Example:

The device scaling range was set to 0 to 150 °C.

When the device measures a temperature of 75 °C, 50 % is displayed.

64

Page 65

6 Commissioning/start-up

6.19 Displaying the software version of the operating unit (SW.Di)

Setting range: Read only!

Factory-setting: -

How to proceed:

Step Activity

1 Unlock the device.

Chapter 6.2 "Unlocking the device (enter the code).", page 42

2 "Turn" until "SW.Di" appears in the bottom line.

3

65

Page 66

6 Commissioning/start-up

6.20 Displaying the software version of the signal unit (SW.Si)

Setting range: Read only!

Factory-setting: -

How to proceed:

Step Activity

1 Unlock the device.

Chapter 6.2 "Unlocking the device (enter the code).", page 42

2 "Turn" until "SW.Si" appears in the bottom line.

3

66

Page 67

7 Setup program

7.1 General information about the setup program

The setup program optionally available permits a comfortable and clearly structured setting of

the large number of device parameters. Settings made once can be saved on a data carrier as

a file and transmitted one to one to several devices.

Configurable parameters

Depending on the device, it is possible to set, for example:

• Measuring range and range limits

• Output behavior in the event of an overrange or underrange

• Functions of the K1 and K2 switching outputs

TIP!

For configuration, the device must be connected to the power supply.

Chapter 3 "Electrical connection", page 21

Connection

(1) Rated voltage supply DC 24 V (2) Device

(3) USB/TTL converter

included in VARTN 70/00456352

(a) Cable box 4-pin (straight) M 12x1

with PVC connection cable length 2000 mm

VARTN 40/00404585 or

Cable box 4-pin (angled) M 12x1

with PVC connection cable length 2000 mm

VARTN 40/00409334

(c) PC interface cable (gray)

Part of (3)

(4) Notebook/PC

(b) Connection cable (Y cable)

VARTN 70/00507861

67

Page 68

7 Setup program

How to proceed:

Step Activity

1 Install the setup program on the notebook/PC.

2 Screw-fit the connection cable (b) to the connector of the device (2).

3 Connect the USB/TTL converter (3) to the connection cable (b) and PC interface cable

(gray) (c).

4 Connect the PC interface cable (gray) (c) to the notebook/PC.

5 Connect the cable box to the rated voltage supply (1) and the connection cable (b) using

the PVC connection cable (a).

TIP!

During installation, the driver for the USB/TTL converter is also installed on the notebook/PC.

68

Page 69

8.1 Possible errors

Display Possible causes Measure

8 Overcoming errors and malfunctions

• Overrange

or underrange

• Probe break

Device error

• 1 = Internal

communication error

• 2 = Error, analog output

• 3 = Short circuit,

switching output 1

• 4 = Short circuit,

switching output 2

• 5 = VCC 8 V outside the

working range

• 6 ... 8 = Internal

communication error

• 9 = Invalid configuration

Display overrun:

Upper display: „- - - -“

Bottom display: Parameter name

Value is smaller than -9999

or exceeds +9999.

Check temperature and/or probe.

1, 6, 7, 8: Contact the service.

2: Check ambient temperature.

Check output for cable break. Output

load too high (for current output) or

too low (for voltage output).

3, 4: Check the switching output.

5: Check voltage supply.

9: Check the configuration.

Check switching output.

Check voltage supply.

69

Page 70

8 Overcoming errors and malfunctions

70

Page 71

9 Supplement

9.1 Technical data

Electrical connection Machine connector M 12x1, 4-pin as per IEC 60947-5-2

Process connections Screw connection G 1/4, G 3/8 and G 1/2

Sheath Stainless steel 316 L Material No. 1.4404/1.4435

Protection rating IP65 as per DIN EN 60529 with the machine connector inserted

Response time t

Measuring insert Pt1000 temperature probe, DIN EN 60751, class A or AA (1/3 DIN B), 4-wire circuit

Screw connection M 12x1.5; M 18x1.5 and M 20x1.5

Screw connection 1/2-14NPT

Union nut G 3/8

Pipe screw connection G 1/4 and G 1/2

Screw connection G 1/2 with CIP-conforming sealing cone and EHEDG certificate

Conical port with union nut (milk pipe union)

Clamp

Spherical welding socket with clamp screw connection

Welding socket with CIP-conforming sealing cone

Varivent connections with EHEDG certificate

JUMO PEKA with EHEDG certificate

Stainless steel 316 Ti Material No. 1.4571

: 3 s in water 0.4 m/s

0.5

t

: 8 s in water 0.4 m/s

0.9

9.1.1 General information

Reference conditions DIN 16086 and DIN EN 60770

Display positively lit LCD display

Alignment The display can be mirror-imaged by 180° using the setup program

after installation, the display case can be swivelled to the LH or RH side by ± 160°

(use the combination tool)

Size Display 16 x 26 mm / font size 7 mm / 2x 4-digit

Color Standard operation: amber

Error: red (text "Err", error code 1 to 9 flashes)

Setup interface occupied: red

Switching status display K1, K2

Temperature unit °C or °F

Operation

on the device with the rev transmitter beneath the locking screw with combination tool or screwdriver

with PC with the setup program with PC interface

0.5 x 3 mm or Allen key, width across flats 2

9.1.2 Input

Measuring input 1x Pt1000 temperature probe, 4-wire circuit

Measuring range Basic type 902940/10: -50 to +150 °C

Limit value deviation 0.15 + 0.002 x t, class A

Basic type 902940/30: -50 to +260 °C

Basic type 902940/50: -50 to +500 °C

0.10 + 0.017 x t, class AA (1/3 DIN B)

71

Page 72

9 Supplement

9.1.3 Measuring circuit monitoring

Probe short-circuit,

probe and cable break,

measuring range gone below,

measuring range exceeded

Analog output 0 to 20 mA, 0 mA or 22 mA configurable

Analog output 4 to 20 mA, 3.4 mA or 22 mA configurable

Analog output 0 to 10 V, 0 V or 10.7 V configurable

Switching outputs, low

Additional error message on the LCD display

9.1.4 Outputs

All analog outputs in 3-wire circuit/Open Collector, PNP switching output

Analog output

can be freely configured 4 to 20 mA and 1x PNP switching output

Switching output

Number 1x PNP switching output

Switching type N/C / N/O

Switching function Window / hysteresis

Switching capacity

- Voltage drop from UB PNP ≤ 2V

- Contact rating ON ≤ 250 mA/OFF ≤ 1mA

- Switching cycles > 10 million

Reaction time at 50 Hz: ≤ 200 ms

Short-circuit proof Yes

Load check, current

- Period duration 2 s; T

- Periodic protection circuitry

for overcurrent

Scaling range

Analog output Scaling can be freely selected within the measuring range

Behavior when the scaling range is gone

below

Behavior when the scaling range is

exceeded

Switching output

- Switching point Measuring range ( > Release point)

- Release point Measuring range ( < Switching point)

- Damping 0.00 to 99.99 s

- Switch-on delay 0.00 to 99.99 s

Apparent ohmic resistance

4to20mA R

0to20mA R

0to10V R ≥ 10 kΩ

0 to 20 mA and 1x PNP switching output

0 to 10 V and 1x PNP switching output

2x PNP switching output

at 60 Hz: ≤ 320 ms

40 ms

ON

f = 0.5 Hz

LCD display: Err3 switching output K1, Err4 switching output K2

Analog output 0 to 20 mA, linear drop to 0 mA

Analog output 4 to 20 mA, linear drop to 3.8 mA

Analog output 0 to 10 V, linear drop to 0 V

Analog output 0 to 20 mA, linear increase up to 20.5 mA

Analog output 4 to 20 mA, linear increase up to 20.5 mA

Analog output 0 to 10 V, linear increase up to 10.2 V

≥ (UB - 6.5 V)/0.022 A

I

≥ (UB - 6.5 V)/0.022 A

I

72

Page 73

9 Supplement

9.1.5 Ambient conditions

Admissible temperatures

Ambient temperature, display case -25 to +75 °C

Ambient temperature -50 °C; restricted function

Storage temperature -40 to +85 °C

Admissible air humidity

- during operation 100 % including condensation on the device outer case

- during storage 90 % without condensation

Admissible mechanical load refering to basic type 902940/10 and 902940/30 with fitting length 100 mm

- Vibration resistance 10 g, 10 to 2000 Hz as per IEC 60068-2-6

- Shock resistance 50 g for 11 ms / 100 g for 1 ms as per IEC 60068-2-27

Electromagnetic compatibility (only with 4-pin connection line and ground case)

- emitted interference Class A as per EN 61326

- interference resistance Performance characteristic A as per EN 61326

Protection rating IP65 as per DIN EN 60529

Ambient temperature error ≤ 0.05 %/Κ

only stationary use, risk of cable break, LCD display without function

9.1.6 Auxiliary energy

Voltage supply DC 14 to 30 V (nominal voltage supply DC 24 V)

- for output 0(4) to 20 mA DC 12 to 30 V

- for output 0 to 10 V DC 14 to 30 V

Reverse voltage protection Yes

Power consumption ≤ 45 mΑ without load, ≤ 545 mΑ with 2x PNP switching output

Electrical connection Machine connector M 12x1, 4-pin as per IEC 60947-5-2, A-coded

Circuit SELV

Influence of the voltage supply ≤ 0.02 %/V deviation from DC 24 V

Ripple: ensure that the voltage peaks do not exceed or go below the specified values

9.1.7 Approval/approval marks

Approval marks Inspection authority Certificate/ Inspection

number

EHEDG TUM MAK No. 03/2006 Document No. 8 Process connection 997

EHEDG TNO No. C03-5145 Document No. 8 380 Varivent process con-

Inspection basics valid for

JUMO PEKA

nection

73

Page 74

9 Supplement

74

Page 75

Page 76

JUMO GmbH & Co. KG

Street address:

Moritz-Juchheim-Straße 1

36039 Fulda, Germany

Delivery address:

Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

e-mail: mail@jumo.net

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Es

sex CM20 2DY, UK

P

hone: +44 1279 635533

Fax: +44 1279 635262

e-mail: sales@jumo.co.uk

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

8 Technology Boulevard

Canastota, NY 13032, USA

Phone: 315-697-JUMO

1-800-554-JUMO

Fax: 315-697-5867

e-mail: info@jumo.us

Internet: www.jumo.us

Loading...

Loading...