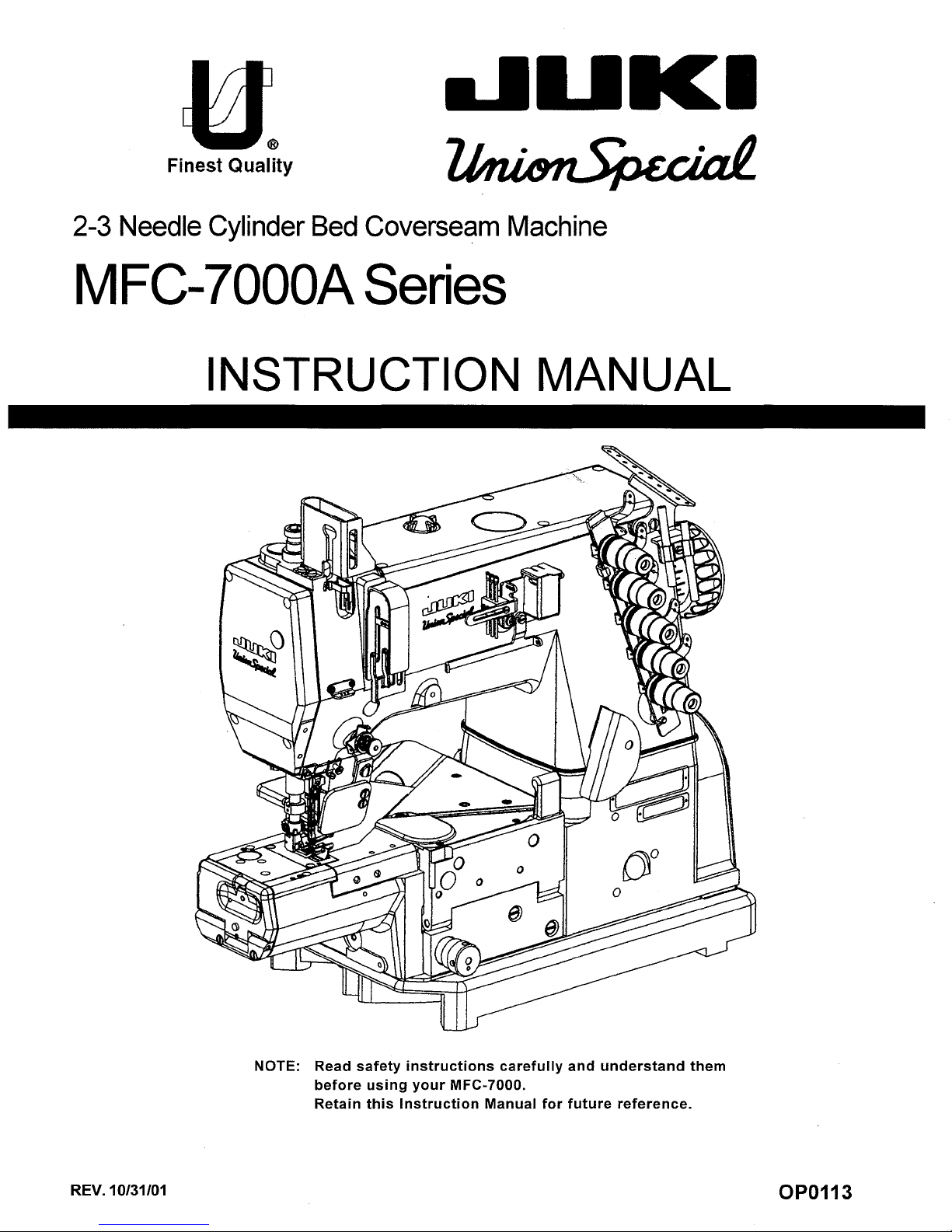

JUKI Union Special MFC-7406, Union Special MFC-7407, Union Special MFC-7602, Union Special MFC-7605 Instruction Manual

Page 1

2-3

Finest Quality

Needle

Cylinder

Bed

LIUKI

Coverseam

Machine

MFC-7000A

INSTRUCTION MANUAL

Series

NOTE: Read

before

Retain

REV.10/31/01

safety

using

this

instructions

your

MFC-7000.

Instruction

carefully

Manual

for

and

understand

future

them

reference.

OP0113

Page 2

PREFACE:

This

operator's

This

manual explains in detail

adjustments

manual has been prepared

and reference letters are used

the

proper

to

guide

settings

to

point

you

for

operation

out

while

operating

specific

of

the

items

the

MFC-7000 Series machines.

machine.

discussed.

Illustrations

are used

to

show

the

Careful attention

maintain

Adjustments

performed

This

incorporate a slight

On

machine.

the

manual has been

the

following

to

superior

and cautions are presented in

out

of

sequence may have an adverse

pages

CONTENTS

PREFACE:

SAFETY

................................................................................................................................................................. 2

RULES

.......................................................................................................................................................... 3

SPECIFICATIONS:

MOTOR

TABLING

CAUTION

OPERATOR'S

ROTATION:

OPERATING

OPERATING

OPERATING

LUBRICATION:

LUBRICATION

INSERTING

THREADING

THREADING

DIFFERENTIAL

ADJUSTING

PRESSER

ROLLER

PULLER

PULLER

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTING

ADJUSTMENT

MAINTENANCE:

PULLEY

AND V BELT:

INSTALLATION:

AREAS:

DAILY

.............................................................................................................................................................. 7

CAUTIONS:

CAUTIONS

THE

PEDALS:

......................................................................................................................................................... 9

(CONT.):

NEEDLES:

THE

MACHINE:

THE

MACHINE

FEED

THE

STITCH

FOOT

PRESSURE

PRESSURE

LIFTER

STIITCH

LEVER:

LENGTH:

OF

OF

OF

OF

OF

TAKE-UP

OF

....................................................................................................................................................

the

instructions

performance and reliability

comprised

modification

will

be

found

and

cautions

sequence

on

the

basis

of

configuration

illustrations

designed

effect

of

available

in

and

for

operating and

and

so

that

a logical

on

the

information.

illustrations

terminology

built

into

progression

function

or

cautions.

used

adjusting

every

of

the

other

Changes

in

describing

these

machines

Union

Special machine.

is

accomplished.

related parts.

in

design

operating

and/or

will

enable you

Some

adjustments

improvements

instructions

for

may

your

.................................................................................................................................................... 4

.................................................................................................................................. 4

................................... .-..................................................................................................... 5

................................................................................................................................................... 6

CHECK

UST:

.................................................................•........................................................... 7

......................................................................................................................................... 7

(CONT.): .......................................................................................................................... 8

......................................................................................................................................... 8

........................................................................................................................................

.............................................................................................................................................

.................................................................................................................................

(CONT.): ...................................................................................................................

MECHANISM:

LENGTH:

AND

ADJUSTING

........................................................................................................................

.........................................................................................................................

LIFTER:

KNOB:

.................................................................................................................

.................................................................................................................

............................................................................................................................................

.......................................................................................................................................

LOOPER

NEEDLE

LOOPER

NEEDLE

SPREADER:

GAUGE:

BAR

AND

GUARD:

......................................................................................................................

HEIGHT:

NEEDLE:

................................................................................................................

.............................................................................................................

.......................................................................................................................

................................................................................................................................

CAM: ..................................................................................................................................

THREAD

GUIDE:

........................................................................................................................

10

11

12

13

14

14

15

15

16

17

18

18

19

19

20

21

22

23

to

2

Page 3

l.

Before

of

each

putting

machine

the

machines

is

only

described

permitted

after

in this

taking

SAFETY

manual

notice

RU

into

of

LES

service,

the

instructions

carefully

and

read

by

the

instructions. The starting

qualified

operators.

IMPORTANT!

2.

Observe

3.

The sewing

been

ascertained

the

EC

Council

Each

machine

described

the

description,

4.

All safety

of

the

machine

5.

Wear

safety glasses.

6.

In

case

of

and

changes

7.

The

warning

Before putting the

and

inslruction from the motor supplier.

the

national

machines

in

paragraph

devices

machine

are

hints

safety rules

described

that

the

Directives (89/392/EEC,

is

only

allowed

is

not

as foreseen.

must

be

without

conversions

made

in

the

instructions

in this instruction

sewing units

to

"STYLES

the

at

OF

in

position

appertaining

and

your

own

valid

for

which

Annex

be

used

MACHINES"

when

changes

risk.

are

marked

machine

your

country.

these sewing

II

as

foreseen. The foreseen use

the

machine

safety

all

into service, also read the safety rules

manual

B).

of

devices

valid

with

are

prohibited

machines

this instruction

is

ready

is

prohibited.

safety

one

rules must

of

these

manual.

for

two

from

will

be

of

work

or

be

symbols:

being

put

built

into,

the

particular

Another

in

considered.

use,

operation.

into

service until

have

conformed

machine

going

beyond

Operation

Conversions

is

it

has

with

8.

When

doing

the

main

8.1

When

8.2 When

needle

8.3 When

8.4 When

8.5 When using

9.

Maintenance,

skilled personnel

l

0.

Any

work

special skilled personnel.

11.

Work

on

in

the

12.

Before

nected

compressed

the

switch or

threading

replacing

guard,

leaving

doing

repair

on

the

parts

and

applicable

doing

maintenance

from

the

air supply (i.e.

following

by

maintenance

clutch

under

electrical

equipment

sections

compressed

the

pulling

needle(s), looper,

any

folder,

the

workplace

motors

and

conversion

consideration

equipment

of

pneumatic

machine

out

the

parts such as needle(s), presser

fabric

work.

without

under

standard

and

repair

air supply.

has

main

guide

and

when

actuation

work

of

must

electrical

sheet

work

equipment

to

be

plug:

spreader

etc.

the

(see

the

instructions.

be

done

power

DIN

on

In

case

disconnected

etc.

workplace

lock,

wait

item

8) must

by

an

is

not

VDE

0105.

the

pneumatic

of

existing residual air pressure

with

air tank),

from

foot,

throat

is

unattended.

until

the

be

done

electrician

permitted.

equipment

the

pressure has

the

power

plate,

motor

is

only

by

trained

or

under

Permissible

the

supply

looper, spreader,

stopped

direction

machine

to

by

turning

totally.

technicians

and

exceptions

has

after

disconnecting

be

removed

off

feed

or

special

supervision

are

described

to

be

discon-

by

bleeding.

dog,

of

from

3

Page 4

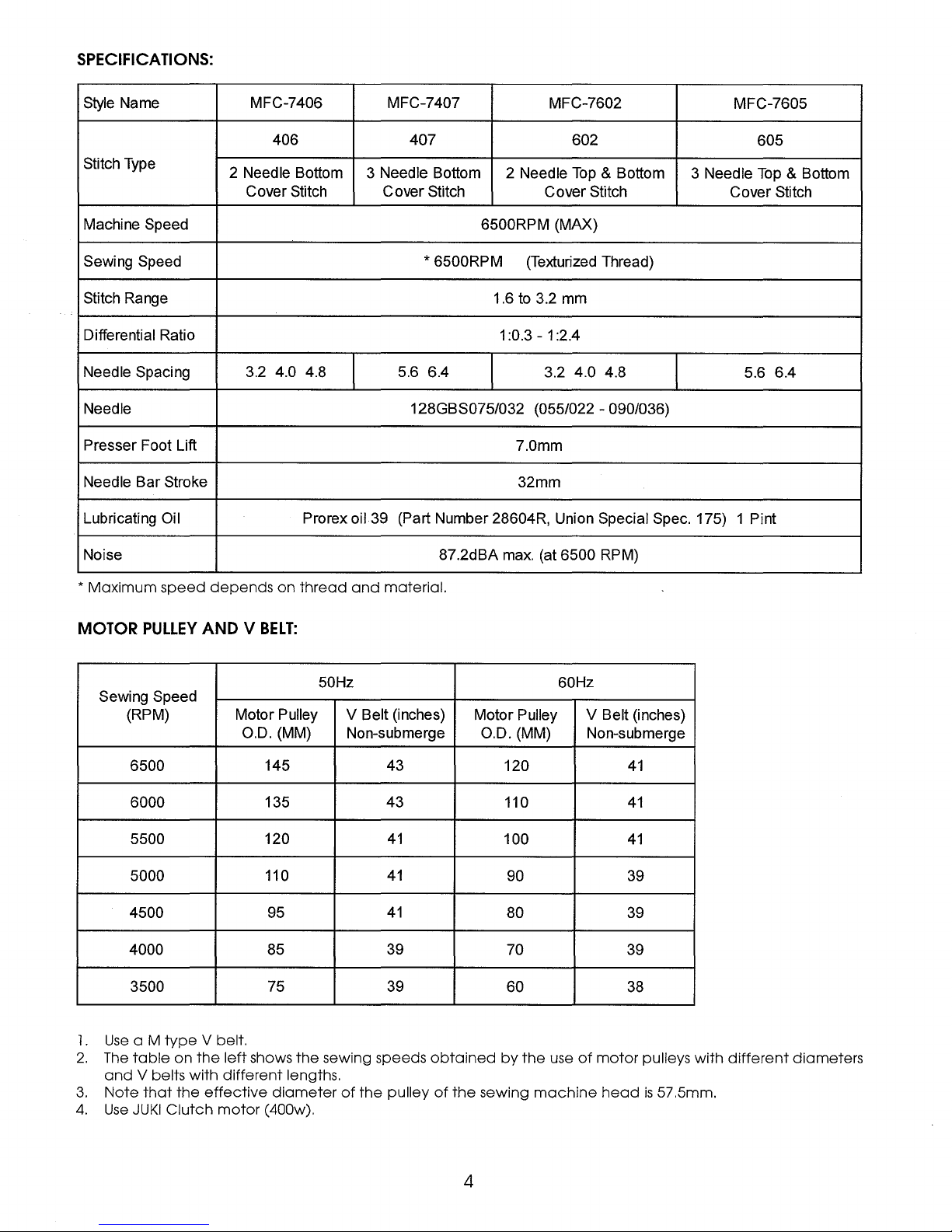

SPECIFICATIONS:

Style Name MFC-7406 MFC-7407 MFC-7602

406 407

Type

Stitch

Machine Speed 6500RPM (MAX)

Sewing Speed * 6500RPM

Stitch Range 1.6 to 3.2 mm

Differential Ratio

Needle Spacing 3.2 4.0 4.8 5.6 6.4 3.2 4.0 4.8

Needle 128GBS075/032 (055/022 - 090/036)

Presser Foot Lift

Needle Bar Stroke

Lubricating Oil Prorex oil 39 (Part Number 28604R, Union Special Spec. 175)

2 Needle Bottom 3 Needle Bottom

Cover Stitch Cover Stitch

2 Needle

1 :0.3 - 1 :2.4

7.0mm

32mm

602

Top

& Bottom

Cover Stitch

(Texturized Thread)

3 Needle

MFC-7605

605

Top

& Bottom

Cover Stitch

5.6 6.4

1 Pint

Noise 87.2dBA max. (at 6500 RPM)

* Maximum speed

MOTOR

PULLEY

Sewing Speed

(RPM) Motor Pulley V Belt (inches)

6500

6000 135

5500 120

5000

4500

depends

AND V

O.D. (MM)

on

thread

and

material.

BELT:

50Hz 60Hz

Non-submerge

145 43

43

41

110

95

41

41

Motor Pulley

O.D. (MM)

120

110

100

90 39

80 39

V Belt (inches)

Non-submerge

4000 85 39 70 39

3500

75

39

60 38

41

41

41

1 .

Use

a M

type

V belt.

2.

The

table

on

the

left

shows

the

3.

4.

and

V belts with different lengths.

Note

that

the

effective

Use

JUKI

Clutch

motor

(400w).

sewing speeds

diameter

of

the

pulley

obtained

of

the

sewing

by

the

use

of

machine

motor

head

4

pulleys with

is

57.5mm.

different

diameters

Page 5

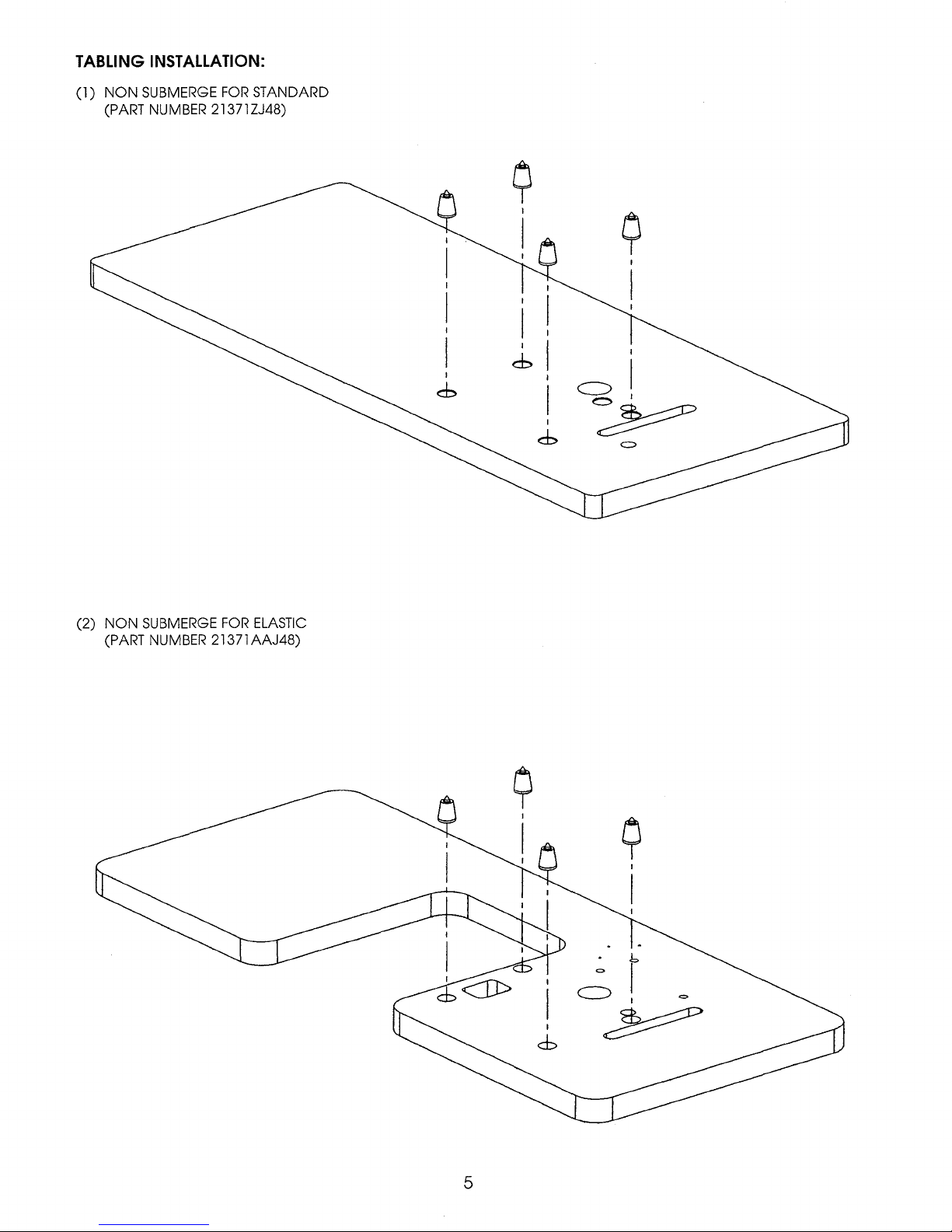

TABLING

(l)

INSTALLATION:

NON

SUBMERGE

(PART NUMBER 21371ZJ48)

FOR

STANDARD

9

I

I

I

(2)

NON

SUBMERGE

(PART NUMBER 21371AAJ48)

FOR

ELASTIC

C)

I

~

=

9

I

I

5

Page 6

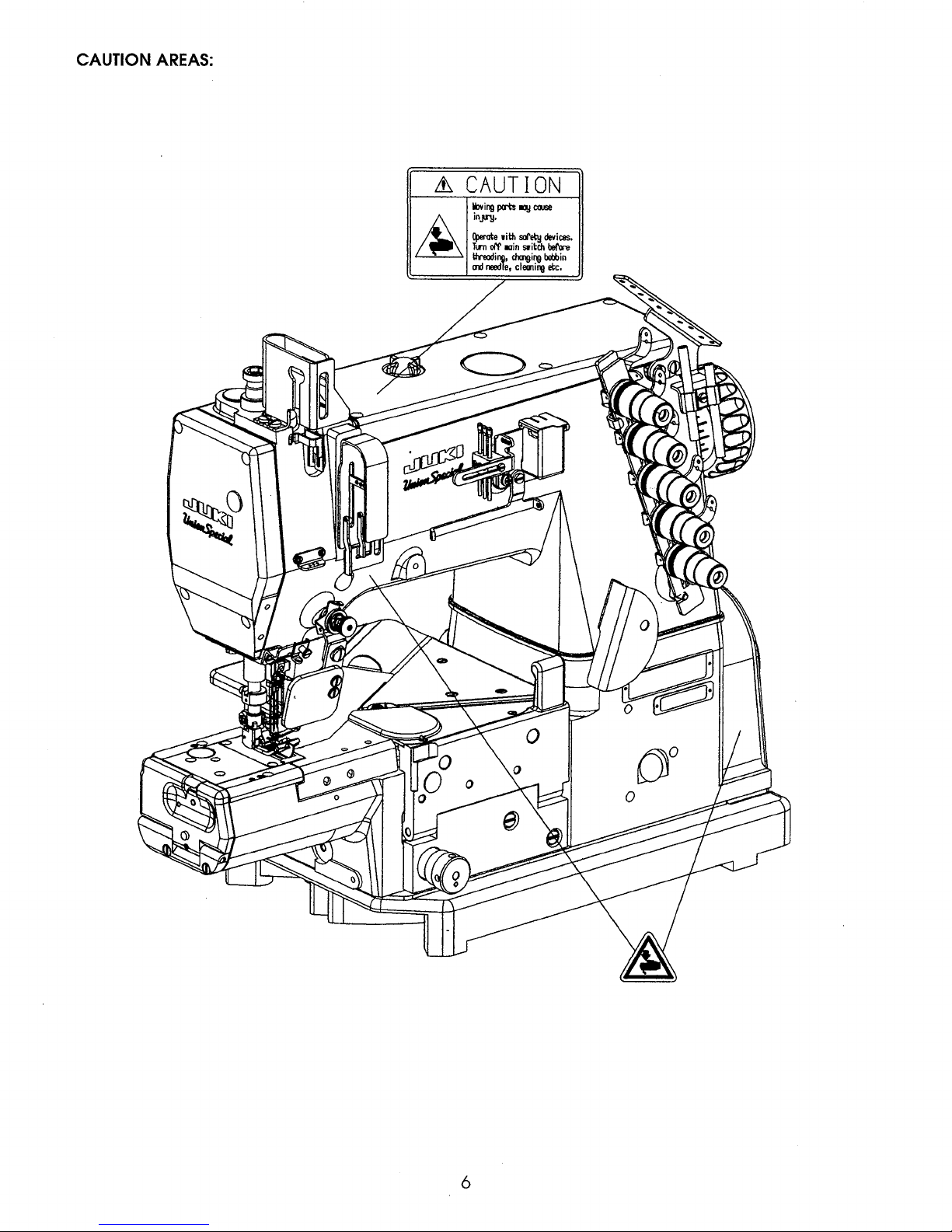

CAUTION

AREAS:

~

CAUTION

6

Page 7

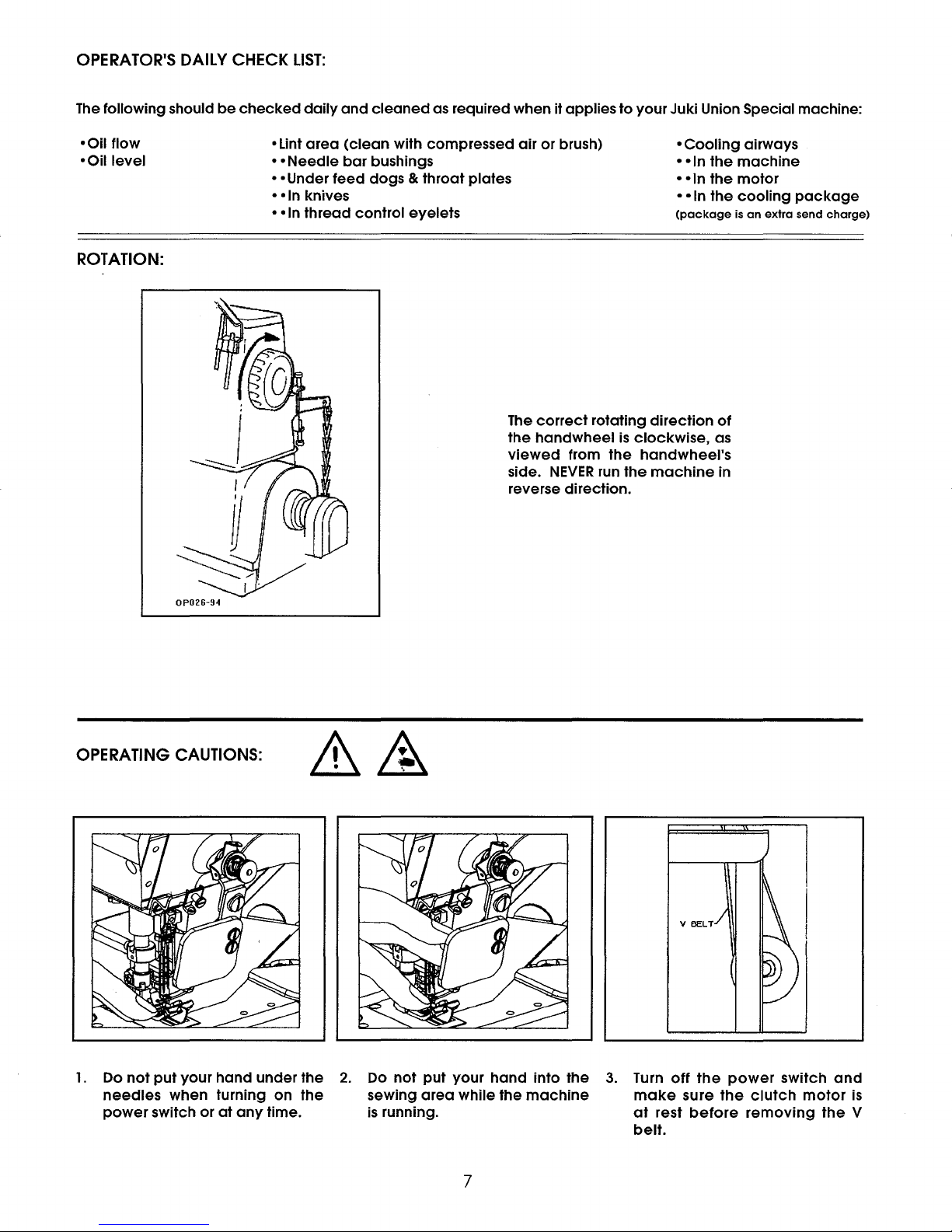

OPERATOR'S

The

following should

•Oil

flow

•Oil

level

ROTATION:

DAILY CHECK

be

checked

• Lint

• •

• • Under

• •In knives

••In

LIST:

daily

area

Needle

thread

and

cleaned

(clean

bar

bushings • • In

feed

dogs & throat

as required when it applies

with compressed

air

plates

or

to

brush)

control eyelets

The

correct

the

handwheel

viewed

side.

from

NEVER

rotating

is

the

run

reverse direction.

your Juki Union Special machine:

•

Cooling

• • In

• • In

(package

direction

clockwise,

the

the

the

is

of

as

airways

machine

motor

cooling

an

extra

package

send

charge)

handwheel's

the

machine

in

OPERATING

OP026-94

CAUTIONS:

V

BELT

1.

Do

not

put

your

hand

needles

power

switch or

under the

when turning on

at

any

time.

the

2.

Do

not

sewing

is

running.

put

area

your

while

hand

the

into the

machine

3.

Turn

make

at

belt.

7

off

rest

the

sure

before

power

the

clutch

removing

switch

motor

and

the

is

V

Page 8

OPERATING CAUTIONS

4.

During operation,

5.

Do not

been

6.

Before inspecting, adjusting,

Make

switch.

7.

Turn

8.

Do

operate

provided. Doing so

sure the flywheel on

DO

NOT

OFF

the

not

wipe

your

depress

power

the

machine

do

machine

switch

(CONT.):

not

allow

is

very

the

the

foot

when

surface with

head,

without

the

dangerous.

cleaning,

motor

has stopped, it will

pedal

you

leave

hands or

proper

threading

while

the

your

lacquer

any

instrument, tool

belt

guard, sewing guards or

the

head

or

replacing

be

kept

running

motor

is

running

machine

or

in

or

case

thinner.

etc.

near

needles, turn

by

it will

cause

of a power

handwheel, V belt

any

other protectors

OFF

the

inertia after turning

the

machine

to

failure.

and

motor.

that

have

power

OFF

the

switch.

power

rotate abruptly.

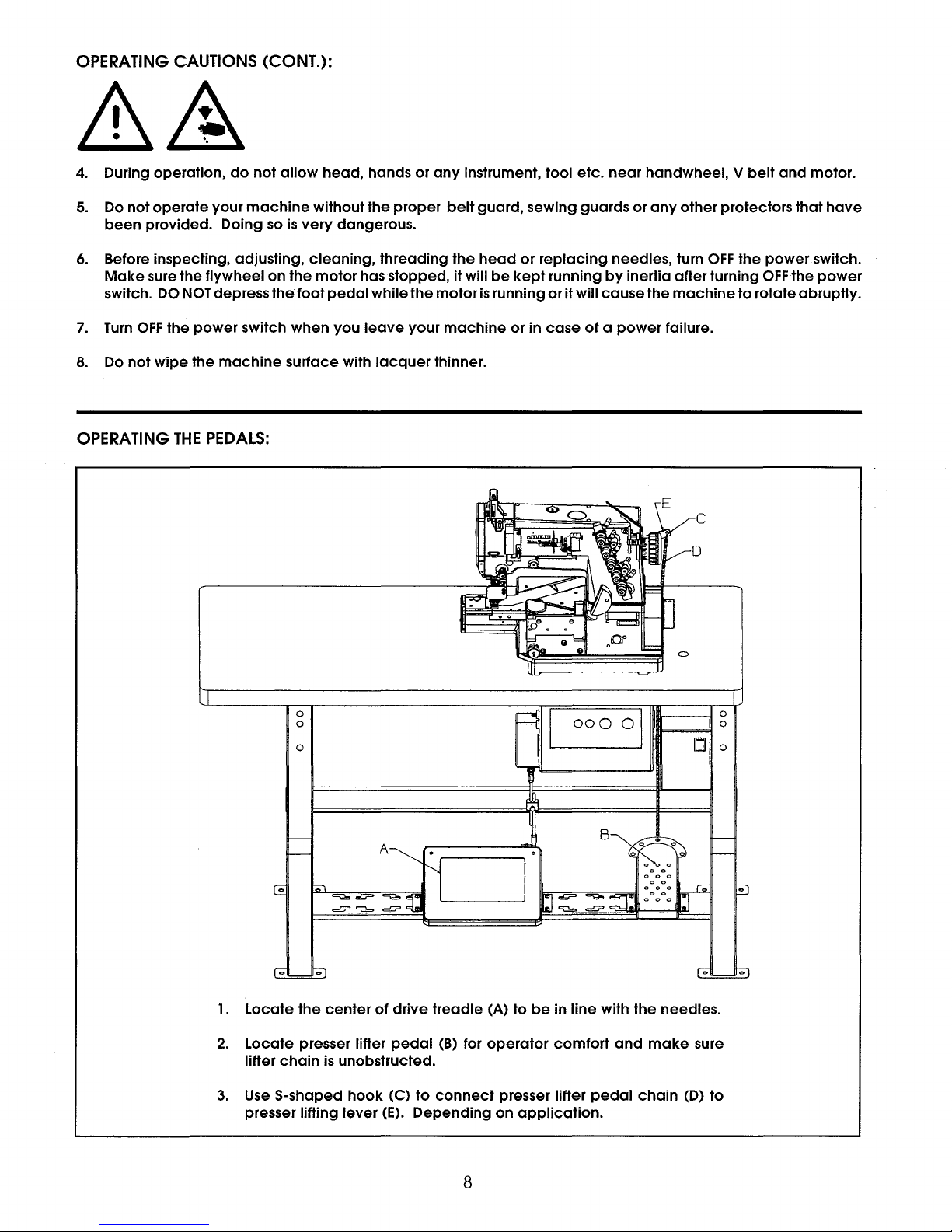

OPERATING

THE

PEDALS:

C

D

0

0

0

A

00

0 0 I

IUl!lr---

•--,1 :

1.

Locate

2.

Locate presser lifter

lifter

3.

Use

presser lifting lever

the

center

chain

is

S-shaped

of

drive

pedal

unobstructed.

hook

(C)

to

(E).

Depending

treadle

(B)

for

connect

(A)

to

be

in

operator

comfort

presser lifter

on

application.

line

with

and

pedal

the

chain

8

needles.

make

(D)

sure

to

Page 9

LUBRICATION:

The

oil should

1.

If oil

is

2.

Fill

between

&

3.

To

drain

4.

To

ensure oil flow through

be

between

required

lines

CAUTION:

oil reservoir,

the

two

remove

oil

cap

(B)

with Union Special

Do

not

exceed

leakage

remove

machine,

D

red lines in sight

(A).

Specification

the

upper

and

possible overheating.

oil

drain

cap

(C) on

check

oil flow

gauge

red

C

UPPER LEVEL

LINE

LOWER

LINE

175 oil (Union Special Part No. 28604R).

marker

the

underside

window

LEVEL

(B)

when

the

line. Excessive

of

(D).

machine

the

machine.

0

oil

in

is

at

the

rest.

0

machine

will result in oil

9

Page 10

LUBRICATION (CONT.):

A

Lubrication

*(Optional,

1.

Open

2.

The

back

3.

If

adjustment

4.

Saturate

of

extra

cloth

of

silicone

Needle

send

plate

the

needles

is

necessary

Tip

charge

and

oil

into

Dipper

item)

well

cover

should

loosen

felt

(C)

(A), fill

just

screw

if

the

well

touch

the

(D)

machine

(B)

approximately

front

and

move

is

started

of

felt

(C).

dipper

immediately

80%

as

required.

full

after

with

silicone

lubricating

oil.

needle

tip

dipper.

lO

Page 11

INSERTING

The

standard

Insert

needles

1.

Bring

needle

NEEDLES:

needle

according

is

head

A

128GBS,

to

the

(A)

to

the

needle

following

highest

range

sizes"

procedure:

position.

055/022 -090/036."

2.

3.

Loosen

the

Retighten

screws

operator's

(B),

side.

screws

insert

(B).

needles

into

holes.

The

needle

scarf

should

face

rearwards

as

viewed

from

11

Page 12

THREADING

Turn

the

.

&

Thread

NOTE:

the

machine

When

THE

MACHINE:

off

main

motor

has

according

threading

power

switch

completely

two

needle

before

stopped

to

the following

machines

threading! When using

.

threading

use needles "A" & "C".

illustrations.

clutch

motors

without

actuation

lock

wait

until

A Left

B

C Right

D

E Looper Thread

NOTE:

Needle

Middle

Spreader

Needle

Needle

When

Thread

Thread

Thread

Thread

threading

two

(D

Thread Lubricator

Needle

®

@

Needle

@ Thread Nipper,

@

Thread Take-Up

needle

machines

Area

Thread Eyelet

Bar

Area

use needles "A" & "C", DO

Area

Spreader

Area

Area

NOT

use

12

needle

"B".

Page 13

THREADING

THE

MACHINE (CONT.):

A

When

1.

Saturate

2.

Pass

When

1.

Remove

the

thread

the

needle

felt

needle

felt

thread

(A).

over

thread

(A).

lubricator

felt.

lubricator

is used:

is

not

used:

Twisted Thread

Non-Twist Thread

When using

as

wooly

thread,

immediate

do

CAUTION!

an

untwisted thread such

nylon

thread

not

wind

it

thread guide.

or

around the

weak

13

Page 14

ADJUSTING

1.

Locking

EN9424.

2.

To

change

and

rotate

THE

STITCH

Turn

length!

lock

feature

stitch

handwheel

off

main

When

wait

may

length

LENGTH:

power

using

until

the

be

engaged,

push

in

appropriate

switch

clutch

motor

down

before

motors

has

completely

refer

on

stitch

direction.

setting

without

to

Engineer's

regulator

the

stitch

actuation

stopped.

Manual

button

(A)

--

----------

oo©

-----

Clockwise

one

stitch.

Counterclockwise

3.

The

arrows

DIFFERENTIAL

1.

Turn

knob

Clockwise

of

one

stitch.

Counterclockwise

length

of

one

to

increase

on

the

FEED

MECHANISM:

(A)

to

change

to

decrease

stitch.

the

to

decrease

belt

cover

the

to

increase

stitches

the

travel

stitches

stitches

are

for

of

stitches

per

inch/shorten

per

operator's

the

differential

per

inch/increase

per

the

length

inch/increase

reference

feed

dog.

the

length

inch/decrease

the

only.

the

of

length

of

one

stitch.

14

Page 15

PRESSER

FOOT

PRESSURE

AND

LIFTER:

Adjust presser

1.

turning presser

pressure,

the

Retighten

2.

pressure

foot

adjust screw

foot

counterclockwise

(A).

nut

loosening

by

clockwise

(B)

decrease

to

nut

to

the

and

(A)

increase

pressure.

ROLLER

PRESSURE

ADJUSTING

KNOB:

1.

adjust

To

turn

sure,

the

adjusting

counterclockwise

pressure for

screw (A)

to

puller

the

clockwise

decrease

roller assembly

drive

Increase

to

pressure.

the

the

pres-

15

Page 16

PULLER

l .

To

engage

2.

To

LIFTER

disengage

LEVER:

puller

roller

puller

to

roller

material,

to

material,

push lifter

pull

lever

lifter

(A)

lever

away

(A)

from

the

towards

operator.

the

operator.

16

Page 17

PULLER

1.

Moving

• Set

•Set

2.

Loosen

STIITCH

lever

closer

farther

nut

LENGTH:

(A)

towards

to

operator

away

from

(B)

and

operator

move

or

for

lever

away

short

from

stitches.

for

longer

(A)

as

operator

stitches.

needed

to

to

set

obtain

stitch

proper

length

stitch

of

puller.

length.

A

17

Page 18

ADJUSTMENT

1.

Set

the

looper

OF

LOOPER

Turn

off

actuation

gauge

main

lock

to

GAUGE:

power

wait

be

switch

4.8mm

until

before

the

motor

+O. 1 mm.

setting

has

the

stitch

completely

length!

stopped.

A

When

using

clutch

motors

without

ADJUSTMENT

1.

When

2.

of

(Caution)

After

align

looper

past

the

Remove

looper

adjustment,

into

OF

left

face

is

aligned

the

Oo5

NEEDLE

moves

needle

cover

confirm

center

BAR

HEIGHT:

to

the

left

by

0.5 +O.Smm.

and

loosen

to

the

upper

that

of

the

holes

side,

screw

part

the

of

adjust

(B). Then

of

the

direction

the

throat

Move

I

ef't

~

the

eye

of

to

tip

adjust

needle

plate.

to

of

the

of

the

the

a I i

looper

needle

needle

head

gn

so

bar

on

is

correctly

that

to

the

it

the

left

set

comes

position

side.

and

to

the

where

the

respective

position

the

lower

located

part

needles

A I

1gn

m

Lef't

needle

Looper

18

Page 19

ADJUSTMENT

Turn

handwheel

base

back

and

OF

LOOPER

in

operating

forth so

that

AND

NEEDLE:

direction

the

clearance

Oto

0.05mm

until

tip

of

looper

between

Left

Tip

is

in

scarf

the

tip

of

looper

Needle

of

looper

Oto0.05mm~<:..:..._

of

left

Needle

needle.

and

the

~

Loosen screw (A)

scarve

of

left

A

Looper

and

needle

move

is O to

looper

0.05mm.

ADJUSTMENT

1)

Adjusting

• Loosen

height

the

2)

Adjusting

Loosen

is

needle

(Caution)

1.

2.

3)

Adjusting

• Loosen

part

provided

of 1 /2

right

O -

.05mm

Confirm

When

screw

of

looper

OF

NEEDLE

the

height

screw

screw

forward

(C)

of

side

of

front

to

(E)

between

that

tightening

the

height

(F)

blade.

in

parallel

GUARD:

of

and

the

end

right

back

and

slightly.

the

blade

screw

of

and

move

between

rear

needle

move

part

needle.

of

rear

Adjust

the

needle

The

of

(E),

front

needle

front

At

this

G

F

rear

of

rear

needle

the

rear

and

rear

looper

confirm

needle

time,

the

guard

needle

needle

guard

needle

the

guard

does

guard

also

angle

-·~·-._·._,

.

....

guard

guard

guard

looper

should

not

that

guard(G)

loosen

of

point.

touch

touch

there

screw

front

C

. : ·

........ _ :<·:

.·.:

..

-·-

,•·

- E

. "

H

up

and

(D)

so

when

but

the

is

no

up

and

(H)

needle

'.

:/

...

::

.

.

.

down

when

Use

the

not

scarves

.shake

down

and

guard

I.

75mm

so

that

the

blade

the

looper

rear

guard

deflect

of

all

left

and

so

that

adjust

so

and

all

j 4 I

~

FRONT

u GUARD

the

tip

point

reaches

to

push

the

left

needles.

right

.of

it

comes

that

clearance

needles.

rLOOPER

NEEDLE

of

needle

of

looper

the

the

needle.

rear

needle

1.75mm

right

right

comes

is

aligned

needle,

and

guard.

from

of

0.25mm

to

middle

the

the

with

there

lower

is

Contact

rear

needle

Align¢=,

~

0

--------

--------f

surface

of

guard

No

contact~

Pushing

0

to

112

--

~-

amount

0.1

mm

-

- .

NEEDLES

0.25mm

19

FRONT

GUARD

NEEDLE

Page 20

ADJUSTMENT

DescendJ

-+

Return

OF

SPREADER:

K

R

N

l)

Adjusting

•

Adjust

moving

(If

you

come

you move

2)

Adjusting

•

Adjust

after.loosening

up

and

• Adjust

extreme

(P)

back

from

0.5mm

needle.

• The

to

5.5

the

tip

moving

NOTE:

It

and

front

stroke

stroke

(M)

move

short,

it

the

the

down.

so

that

left,

and

the

left

is

provided

extreme

+/-0.

l

3mm

of

spreader

spreader

may

be

(R)

simultaneously

to

back

by

19mm

back

and

(M)

toward

and

the

stroke

backward.)

position

height

of

spreader

screw

when

loosen

forth.

to

screw (N)

And

the

right

between

left

position

from

by

left

and

necessary

and

left

by

loosening

forth.

you

will

of

spreader

(N).and

spreader

and

when

a

clearance

of

spreader

the

center

loosening

right.

to

loosen

to

obtain

to

right

the

stroke

become

to

be

l 0.5

move

spreader

is

located

move

spreader

spreader

of

left

screw

both

the

settings.

nut

(L)

and

will

be-

longer

-0.5mm

(P)

at

the

spreader

moves

of

0.3

to

and

left

is

adjusted

needle

(R)

to

and

screws (N)

proper

if

Align

of

fixing

r-------10.5-0.smm

Spreader

the

groove

of

the

spreader

Fixing spreader thread guide

left

thread

side

guide

0

-+Return

3)

Adjusting

•

Loosen

treme

thread

top

guide

the

part

• Then

top

right

guide

(T)

loosen

of

spreader

4) Adjusting

• Loosen

spreader

4.0mm

fixed

is

spreader

spreader

bar,

and

guide

over

spreader

fixed

screw

position.

where

of

the

meet.

screw

spreader

thread

needle

screw

thread

provided

thread

center

the

thread

spreader

(S)

groove

guide

head

(U)

guide

thread

when spreader

And

adjust

-the

tip

of

(5)

and

to

the

(T)

spreader

and

so

between

thread

guide

of

left

guide

guide

at

needle

side

(V).

of

guide

the

of

spreader

fixed

spreader

adjust

the

underside

to

be

0.4

thread

adjust

that

a

the

and

lowest

head

the

point

spreader

groove

is

in

the

fixed

spreader

and

thread

height

of

the

to

0.8mm.

guide

needle

clearance

upper

part

needle

of

needle

thread

of

ex-

the

from

fixed

head

of

of

head

fixed

4.0mm

Needle head

spreader

thread

guide

20

Page 21

ADJUSTING TAKE-UP

CAM:

1)

Looper

•

up

thread

needle,

back

4mm

parallel

2)

Adjustment

•

•

take-up

Center

take-up

plate.

cast-off

on

side

+/-0.8mm

to

Standard

Move

eyelet

Set

its

of

looper.

the

eyelet

setting

adjustments

cam

timing

of

occures

down

Set

above

plate.

eyelet

up

for

(W)

the

cam

when

stroke

the

the

is

tight

to

the

so

the

is 1

/2

retaining

take-up

all

the

looper

slots in

that

tip

way

finger

plate

way

thread.

the

the

of

the

down

(X)

down.

take-

looper

left

on

(Y)

to

and

Tight-

Loose

21

Page 22

ADJUSTMENT

Lowest

point

t

Fig 1

Lowest

Needle

strike

Flg2

threal-~

off

Lowest

Fig 3

point

/b

point

f[

-:E

~

OF

of

needle

~die

of

of

needle

needle

THREAD

bar

bar

eyelet

Needle

release

bar

Right

needle

.

thread

bar

eedle

bar

GUIDE:

B

thread

release

eyelet

l)

Adjusting

• Raise

•

•

.thread

thread

time.

When

Set

needle

Then

When

Set

needle

and

lower

very

For

be

raised

the

lower

needle

strike

loop

using

at

using

at

needle

does

stretchy

to

thread

off

when

the

cotton

the

lowest

needle

spun

thread

the

lowest

thread

not.touch.

spun

increase

strike

to

help

looper

thread

point,

thread

needle

thread

loop

off

increase

is

loosen

strike

point,

releasing

..

the

size.

the

needle

at

loop

taking

screw

off

(B).

loosen

thread.strike

screw

·so

strike

that

.off

(A).

(A)

the

off.

can

a No

_v'-:

r

~

Needle thread

slack

Thread

Fig.A

guide

strike

off

2) These

spreader

spreader

reaches

drawn

3)

Needle

NON KLIPP-IT KLIPP-IT

settings

from

thread

• Use

right

• Use

no

Fig A Fig B Fig A

are

thread

thread

its

left

the

needle

needle

control

becomes

end

cone.

nipper

thread.

for

all

types

of

eyelet

tight

when.

of

stroke

on

the

(Fig.

TEXTURIZED

STRETCH THREAD

and

nipper.

B)

SPUN COTTON

THREAD

thread.

(F)

so

that

the.spreader

no

thread

(Fig.

A)

Fig B

Set

the

the

is

22

Page 23

MAINTENANCE:

1)

Cleaning

the

To

and

machine

prevent

confirming

head

accidents

that

caused

the sewing

by

abrupt

machine

start

will

1)

of

the

not

run

Clear

cam

area

once

sewing

machine,

even

by

lint

from

and

or

twice a day.

material

turn

OFF

depressing

inside

the

needle

will

the

If not,

be

the

power

the

looper

bar

oil

soiled.

to

the

machine

start

pedal.

thread

components

may

leak

take-up

about

and

the

2)

H

Changing

oil

Proceed

1)

··

2)

(Caution)

Should

Change

When

recommended

case

For

1.

2.

as

Remove

Remove

take-up

be

oil

the

machine

of

excessive

changing

Drain

the

of

the

machine.

Unscrew

remove

follows:

Do

machine

so

done

every 6 months.

the

bottom

screw

cam

oil

(C)

cap

(A)

area.

not

wipe

will

damage

by

trained

is

to

change

contamination

the

oil

at

plug

six

screws

cover

and

and

the

head

with

the

technicians

operated

the

proceed

screw

(E)

(H)

clean

or

change

clean

coated

for

inside

surface

lacquer

coated

eight

oil

within 1 to 2 years

as follows:

(D) in

the

and

and

lint

the

bottom

gasket

thinner.

surface.

hours

filter

the

of

only!

daily

also

bottom

cover

(F).

(B).

looper

the

Doing

it

is

(in

earlier).

cover

and

I

I

$

Ej

.__

__________________

__.

3.

Remove

ber

one

4.

Clean

chambers

5.

Insert

filter

6.

Remount

the

for

screws

in.lbs.).

7.

Fill

the

in

the

(part

No. 999-254J).

the

plug

(G) in

bottom

surfaces

the

gasket

(E)

with

Union

filter

bottom

bottom

and

the

screw

the

right

cover

on

the

are

carefully

Special

(G)

cover

cover

gasket

(D)

machine

absolutely

to

23

from

in

oil

22.6 -

oil

the

and

with

for

the

sump

with

as

right

oil

replace

the

four

bottom

bottom

chamber.

gasket.

bed

and

clean!

23.1

Nm (200 - 205

described

sump

it

with a new

oil

sump

cover

cover,

Make

bottom

Torque

on

cham-

.

and

sure

cover

the

page

the

that

six

9.

Page 24

Union Special

EuropeanDistributionCenter

Raiffeisenstrasse 3

D-71696 Moglingen,

49•07141

Tel:

Fax:49•07141•247•100

GmbH

Germany

•247•0

Finest Quality

Union Special Corporation

Union

IL

Office

Special

60142

Plaza

Corporate

One

Huntley,

Phone:847•669•5101

Fax:847•669•4454

CORPORATION

JUKI

INTERNATIONAL

KOKURYO

1,

8-2-

CHOFU-SHI,

PHONE:

FAX:

03(3430)4001-5

03(3430)4909. 4914. 4984

SALES

- CHO,

TOKYO

DIVISION

JAPAN

182,

I

Loading...

Loading...