Page 1

MODEL

MO-804

SUPER

SUPER

SPEED

SINGLE

INDUSTRIAL

SPEED

TWIN-NEEDLE

INDUSTRIAL

SUPER

INDUSTRIAL

NEEDLE

MODEL

MODEL

SPEED

OVEREDGING

SEWING

OVEREDGING

SEWING

SAFETY

SEWING

Instruction

MACHINE

MO-814

MACHINE

MO-816

STITCH

MACHINE

Book

CLASS

TOKYO

JUKI

INDUSTKIAL

CO..

LTD.

Page 2

FIRST

OF

ALL

We thank you for purchasingJUKI MOSOOSeries machines.

Before operating this machine, please read and digest the contentsofthe INSTRUCTION BOOK thoroughly and

understand the functions

SPECIFICATIONS

of

the machine and cherish it everlastingly.

Sewing speed

Stitch

length

Needle gauge

Overedging

Ratioofdifferential

Needle

Needle

Lubricating

bar

width

stroke

oil

feed

MO-804-DD4

Up to 7,500 s.p.m. Up to

Gather

Stretch

DCx27

(Standard)

DCxJ27

sewing:

sewing:

(In

caseoffine

New

MO-814-BD4

7,000

0.3 - 4

2.0mm(5/64")

3.2mm(l/8")

1:2

(Max.

1:0.7

synthetic

24.2

mm(61/64")

Defrix

s.p.m. Up to

mm(l/64"-5/32")

1:4)

(Max.

1:0.6)

thread)

Oil

No.

2

MO-816-DD4

3.2mm(l/8")

* Manyother subclassmachines are availableto meet all kinds of sewingrequirements.

CONTENTS

HOW

TO

INSTALL

How to install the

How to install

Motor

pulley

Howtoinstall

Starting pedal

HOW

TO

OPERATE

THE

MACHINE

thread

stand,

complete

the

frame

support

and

the

belt

the

head

and

presser foot lifting pedal 2

THE

plate

MACHINE

Cautionsonoperation

Lubrication and drainage 3

Howtoinstall

Threading

MO-804

MO-814

MO-816

The

thread

5.

Presser

6.

7.

Adjusting

Adjusting

8.

Adjusting

9.

III.

ADJUSTING

1.

Knife and overedging width 9

2.

Adjusting the needle guard 10

3.

Adjusting the height

4.

Matching

Matching the upper looper 11

5.

6.

Matching the double chain looper (In case of MO-816) 12

7.

Adjusting the chain looper thread cam (In caseofMO-816) 12

Adjusting the double chain looper avoiding motion (In case of MO-816) 12

8.

IV.

MAINTENANCE OF THE MACHINE 13

V.

CAUSES OF MALFUNCTIONS & CORRECTIVE MEASURES 13

the

needle

the

machine

tension

foot

and

feed dog 7

the

stitch

length

the

differential feed 8

the

the

THE

lower

differential

feed

ratio

MACHINE

of

the needle 11

looper

SPECIFICATIONS (Applicable to all models) 13

6,500

s.p.m.

1

1

1

2

2

3

3

3

3

4

5

6

7

8

9

9

11

Page 3

I. HOW TO INSTALL

THE

MACHINE

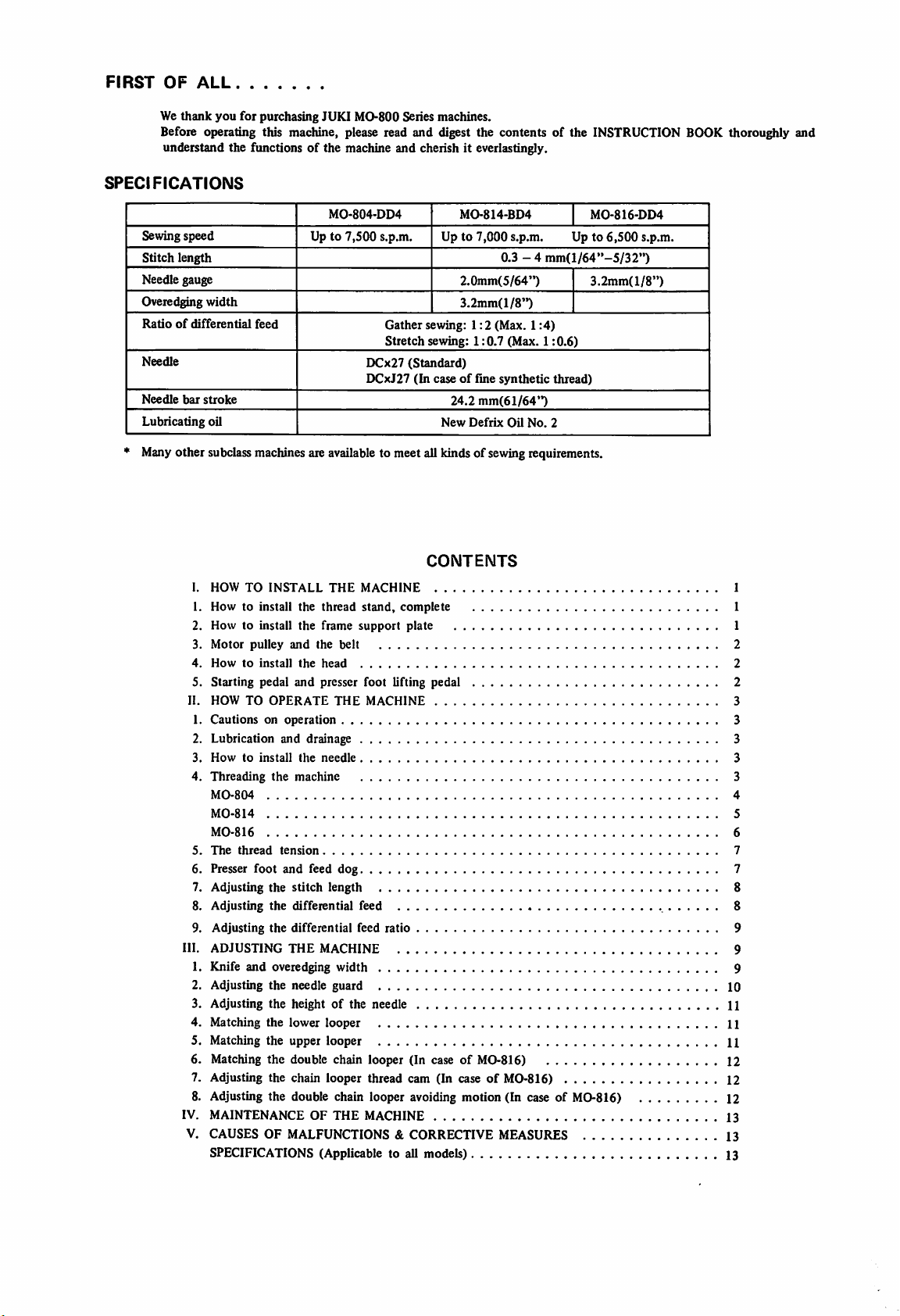

1. Howtoinstall

Install the thread stand, complete asshown in the flgure and set it to the table.

the

thread

stand, complete

—

2. Howtoinstall

1) First, install the oil reservoir support post and the-waste

cloth chute (upper) to the frame support plate as shown in

the figure.

Bushing

the

frame

support

Vibration absorbing rubber

Oil reservoir Cloth waste chute, upper

support

Frame

support

plate

plate

m

Table

i.

Bolt

-

"T"

Nut

Bolt tip surface

3) Heightofthe frame

A. In caseofsemi-sunken type table,

the

end

this

surface

case,

lowersurfaceofthe

In

bushingtothe

E

lower

insert

frame

Oil

support

of

end

reservoir

Frame

the

partofthe

the

support

a

X

plate

bolt

frame

plate.

•

support

plate

match

with

nut.

support

This can be

iJso.

the

Also,

is sticking

Cutitoff

applied

cut off the end of the bolt

out

from

2)

Attach

chute (upper) at an appropriate position. The installing length

canbeadjusted

esa

—

Bolt

^

Nut

M

the

J^Washer

Frame

'support

plate

to sunken type table B. In

which

the

nut.

- 1 -

Cloth

waste

within

Cloth

waste

chute,

lower

cloth

chute

(lower)tothe

the

areaof40

5mm(3/i6")

v^CLoth

plate

Bolt

caseoffully-sunken

upper

surface

(3/16")

higher

waste

chute,

upper

Set

screw

waste

cloth

mm(i-37/64").

Oil

cap

reservoir

Prame

I

support

plate

type, make the

of the cloth plate 5 mm

than the table

surface,

Page 4

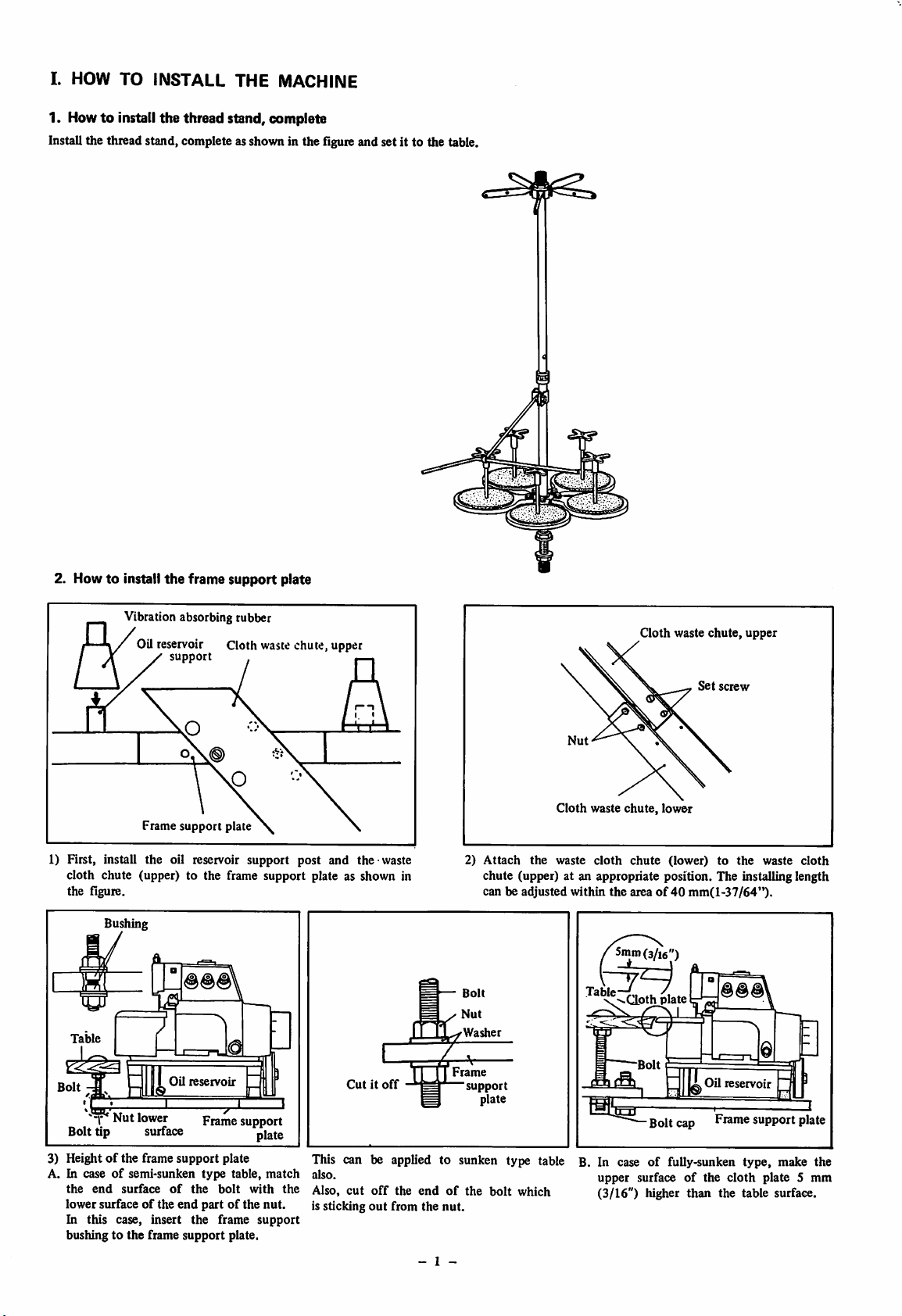

3. Motor pulley

When

connected

and

the

belt

directlytothe

power

source,

use an electric clutch motor of 3-phase 1/2 HP

(400 W). The dimensionsofthe

motor

pulley

and the belt (M type) are shown in the table

below.

Number

rotation

machine

(s.p.m.)

5,000

5,500

6,000

6,500

7,000

7,500

60

Desk

type

34

36

36

38

38

38

Hz

M-type

(inch)

All-

sunken

type

30

32

32

32

32

34

belt

50

Desk

type

36

38

38

38

40

40

Hz

M-type

(inch)

All-

sunken

type

32

32

34

34

34

36

belt

Motor

pulley

P.C.D.

(mm)

90

100

110

120

125

135

of

of

Motor

pulley

P.C.D.

(mm)

105

115

125

135

145

155

(Note)The dimension of the motor pulleyisshown in

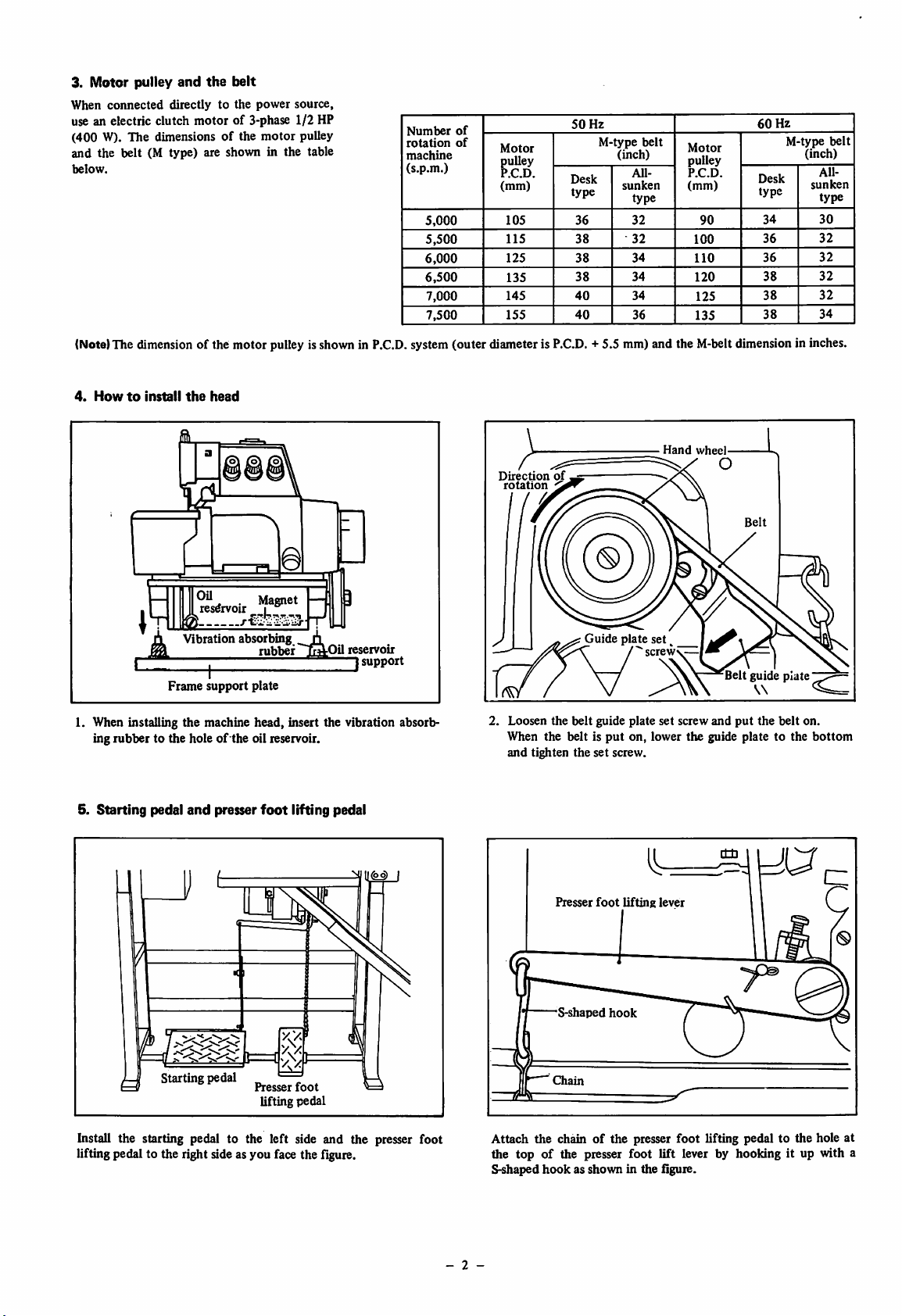

4.

HowtoInstall

I. When installing the machine

ing

rubber

the

head

Vibration

Frame

1

support

absorbmg

rubber

plate

head,

.11

jB:'

insert the vibration absorb

to the holeofthe oil reservoir.

Oil

reservoir

2

P.C.D.

support

system(outer diameteris

Direction

rotation

2.

Loosen

When

and

tighten

P.C.D.

of

/a

the

the

+ 5.5 mm) and the

Guideplateset

belt

guide plate

beltisput

the

set

on,

screw.

screw

lower

Hand

set

V—

screw

the

M-belt

dimensionin inches.

wheel

and

put

the

guide

platetothe

belt

on.

bottom

5.

Starting

pedal

Starting

and

presser

pedal

foot

Presser

lifting

foot

pedal

lifting pedal

Install the starting pedal to the left side and the presser foot

lifting pedal to the right sideas you face the flgure.

Presser

foot

lifting

lever

S-shaped

Cjiain

hook

Attach the chain of the presser foot lifting pedal to the hole at

the top of the presser foot lift lever by hooking it up with a

S-shaped

hookasshown

in the figure.

- 2 -

Page 5

n.

HOW

TO

OPERATE

1.

Cautionsonoperation

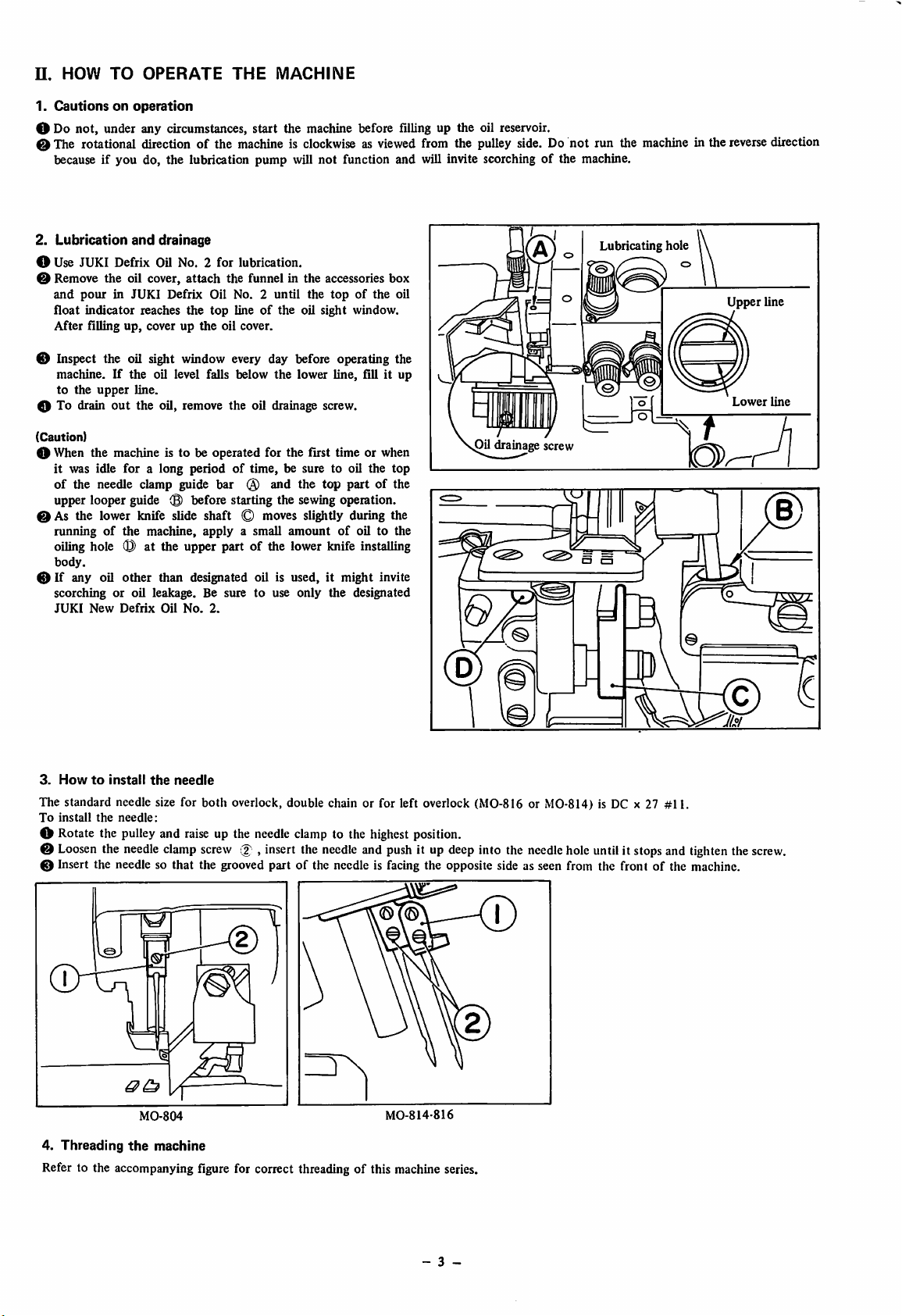

O Do not, under any circumstances, start the machine before filling up the oil reservoir.

e The rotational direction of the

because if you do, the lubrication pump will not function and will invite scorchingofthe machine.

2.

Lubrication

O Use JUKI Defrix Oil No. 2 for lubrication.

Remove

and

pourinJUKI

float

After

the

indicator

filling

and

drainage

oil cover,

reaches

up,

cover up

Defrix

attach

the

the

THE

MACHINE

machineisclockwiseasviewed

the funnel in

Oil No. 2

top

lineofthe

oil cover.

the

accessories

until

the

topofthe

oil sight window.

box

oil

from the

pulley

side. Do not run the

0 Inspect the oil sight window every day before operating the

machine.Ifthe oil level falls below the lower line, fill it up

to

the

upper

0 To drain

out

line.

the

oil, remove

the

oil drainage screw.

machine

Lubricating hole

in the

reverse

Upper line

Lower

direction

line

(Caution)

O When the machine is to be operated for the first time or when

it

was idle

of the needle clamp guide bar @ and the top part of the

upper looper guide 0 before starting the sewing operation.

foralong

periodoftime,

be sure to oil

the

top

Oil drainage screw

0 As the lower knife slide shaft © moves slightly during the

runningofthe machine, apply a small

amountofoil to the

oiling hole 0 at the upper part of the lower knife installing

body.

0 If any oil

scorching or oil leakage. Be sure to use only the designated

JUKI

New

other

than designated oil is used, it might invite

Defrix

Oil

No.

2.

0

3.

HowtoInstall

The standard needle size for both overlock, double chain or for left overlook (MO-816 or MO-814) is DC x 27 #11.

To

install

the

O Rotate the pulleyand

0

Loosen

0 Insert the needle so

the

needle:

needle

the

needle

raise

clamp

up the needleclamp to the

screw

that

the grooved partofthe needle is facing the opposite side as seen from the front of the machine.

,

insert

the

needle

highest

and

push

position.

it up

deep

into the

needle

hole

untilit

stops

and

tighten

the

c

screw.

©

MO-8I4-816

4.

Threading

MO-804

the

machine

Refer to the accompanying figure for correct threading of this machine series.

- 3 -

Page 6

MO-804

1. Ovcrlock needle iliread is No. 1 and is shown in red color.

2. Upper looper thread is No. 2 and is shown in blue color.

3. Lowerlooper thread is No. 3 and isshown in yellow color.

- 4 -

Page 7

MO-814

1.

Left

side

needle

threadisNo.1andisshowninred

2. Right side needle thread is No. 2 and is shown in

3.

Upper

4.

Lower

looper

looper

threadisNo.3andisshowninblue

thread

is No. 4

and

is si.

owninyellow

color.

green

color.

color.

color.

a

- 5 -

Page 8

MO-816

1.

Overlock

2.

Double

3.

Upper

4.

Lower

5.

Double

needle

chain

looper

looper

chain

threadisNo,Iandisshown

needle

thread

is No. 2

threadisNo,3andisshowninblue

thread

is No, 4

looper

threadisNo,5andisshowninblack

andisshown

andisshowninyellow

in

red

color.

in green

color.

color.

color.

color.

Q)

- 6 -

Page 9

5.

The

thread

tension

The thread tension varies according to the kinds of sewing material, thickness and kinds of sewing thread, overedging width, stitch

length

and

etc. and therefore the pressureofthe thread tension disc

must

be adjusted in each individual case.

MO-804

(1)

Overlock

(2) Upper looper thread should be adjusted by tension

(3)Lowerlooper thread should be adjusted by tensionknob @ .

(4)Double chain needle thread or left side overlockneedle thread should be adjusted by tension knob @ . (In case of

(5) Double chain looper thread should be adjusted by tension knob (5). (In case of MO-816)

needle

threadshouldbe

adjustedbytension

knob 0 .

knob®

MO-814

.

0 ® ©

MO-816

MO-816orMO-814)

6. Presser

(1)

*

When

to the original position, be sure to knock down the presser lifting lever toward front.

(2)The standard protrusion of the feed dog from the throat plate surfaceis 0.8 mm(l/32").

For heavy

The

height

lower

(3) Adjusting

Remove

hole ® of the eccentricshaft (D and rotated, the

Also,

from

The

foot

pressure

the

presser

weight

protrusion

ofthe

than

this height.

the

the rear side

in so

doing,

the

holeofthe

and

feed

dog

ofthe

presser

footis

adjustediby

foot is to be turned

materials, makethe protrusionamount

amount

main

slantingofthe

can be

feed

dog0and

feed dog

cover

of the

loosen

the

screw

feed

mechanism cover, comes directly overhead.

adjusted

thesub

machine.

® and

sideways,

by the feed

feed

Then,

move

rotating

the

presser

knock down the

bigger

dog

dog®becomes

remove

slanting

the thrust

foot

adjusting

presser

and for lightweightmaterials makeit

set

screws(Dand 0 .

equal.

the rubbercap and

of the feed dogcan be adjusted. Afteradjustment,

collar

sothat the

The

screw

lifting

auxiliary

loosen

screw

lever

0 .

The

standard

® to the rear.

When

making

feed

dog0shouldbeinstalled

8)

the set

screw

of the

feed

pressure

When

less.

this

CIQ

0 . Ifa roundbarisinserted into the

barshaftthrust

is4.5

kg.

(9.9

the

presser

foot isreturned

adjustment,besure

0.5

mm(l/64")

tighten

theset

collar

(Q)

lbs)

that the

screw

coming

(f).

out

- 7 -

Page 10

(4)

Unless

the

bottom

plate are

become curved and the chain-off thread stitching of double chain stitch can not be

performed

surface

when the

surface. (In case of MO-816)

(Note)

*

When

snuggly

well.

of the

presser

sewmg

irigordamagetothe

pitch

flaworcontracted

surface

of the

presscr

foot ® and the

upper

surface

of the

contacting each other when the feed dog is lowered, the stitches may

Loosen

presser

light

the

presser

foot

hinge

foot ® drops little to right

foot is lowered, the bottom

weight

materials,ifthe

sewing

cloth

stitches

might

pressing

may

result.Onthe

result.Besuretomake

screw © and adjust so that the bottom

when

the

presser

foot is

surface

snuggly

pressureistoo

contrary,ifthe

contacts the throat plate

strongorthe

protrusion

pressureistoo

correct

adjustment.

raised

throat

and

amountofthe

weakorthe

feed

dogistoo

protrusionofthe

great,

feed

shrink

dogistoo

stitch-

small,

7. Adjusting

The stitch length can be adjusted by changing the eccentric amount of the feed cam.

the

stitch length

\i

/

csT

(1)As you keep

rotate

a

"click"

(2) As you keep pressing the

is carved in the pulley with the indicating point of the frame.

8.

Adjusting

Tlie differential feed

of the-sub feed. If the differential feed lever ® is pushed up, gather

stitching

stitching

(1)Push

and

rotateittowards

stops.

(2) Loosen the differential feed lock

differential feed lever ® either up or down, adjust to the desired

differential feed

feed

lock

(3)

Next,

direction

(The

*

The

subclass machines, which can adjust

the knee during the running of the machine, are also available.

pushing

the

pulley

toward

sound and the push

the

differential

ratioisadjusted

can be

can be

the

cam

performed

performed.

sub

feed

nut

(3).

push

the

and

rotateittoward

whichisinside

amount.

sub

the push button

the desired direction.

button

button,

feed

andifit's

stopper

lever (2)

the

reverse

After

adjustment,

feed

stopper

the

will

rotate

(T)

with your

will

enter

match the stitch length which

by changing

moved

downwards,

toward

direction

nut

lever (2)

arrow

and

the frame direction,

of

(3) and by moving the

tighten

direction

sets

it).

the

differential feed by

finger,

You

will

deep inside.

the

moving range

the

arrow

the differential

toward

the

untilitstops.

hear

stretch

until

(3) The figures carved in the pulley indicate the stitch length.

If the figure

point of the frame, the stitch length becomes approximately

3

it

frame

mm.

Indicating

"3"

of the pulley is matched with the indicating

(D

Gather

stitcl^^^

Stretch

n

stitching

- 8 -

Page 11

9.

Adjusting

The

standard

the

differential feed

differential

feed

ratio

ratioofthis

machine

Gatherstitching 1:2 Stretchstitching 1:0.7

When

this

1) Remove the cover

standard

2) Loosen the main feed arm pin setting nut (2).

3) Ifthe

(1)

main

When

feed

differential

(l)

arm

feed

on the backofthe

pin

ratioistobe

(3)ismovedupand

machine.

the main feed arm pin israised to highest point, the differentialfeedratio becomes:

Stretchstitching 1:0.6 Gatherstitching 1:1.7

When

(2)

(3)

the main feed arm pinis loweredto lowestpoint, the differentialfeedratio becomes:

Gather stitching

When

the differential

match

the

center

1:4

feed

ratioisto be

ofthenut @

with

the

is :

changed

down,

changed

carved

dueto

the

differential

to the

line

ofthe

changeofsewing

feed

ratio

standard

main

differential

feed

conditions,

changesasfollows

feed

ratio(stretch

arm

(J).

adjustasfollows

:

stitching

if)

:

1:0.7,

gather

stitching

1:2),

Maximum

for stretch stitching

ni.

ADJUSTING

1. Knife

(1)Onthe

and

overedging

lower

Loosen the lower knife set screw (D and insert the lower knife

(3)

into

in the

the surface of the

screw 0

the grooveofthe lower knife slide shaft (2) as shown

figure.

THE

MACHINE

width

knife

Make

the tip of the lower knife the sameheight as

throat

plate and tighten the lower knife set

differential

feed

Throat

//////////////.

ratio

I

plate

Lower

knife

Maximum

for gather stitching

differential

0

/tlA

feed

tiAnft

ratio

A

- 9 -

m

Page 12

(2) On

the

upper

To install the upper knife, push the lower knife slide shaft (D to the

left

side and tighten the set screw

O

Loosen

knife

the upper knife set

screw

(2).

(3)

and insert the upper knife @ into

the upper knife support (D.

@

Make

the width of knife

knife) little less than the desired

(dimension

from

overedging

needle

position to the upper

width and lightly stop the

upper knife by the upper knife set screw from above the upper knife

presser (6) and the upper knife guide (7) .

®

Next,

rotate the

position, adjust so that the tip of the upper knife comes to 1.5

below

the

O

When

the

@ Loosenthe lowerknifeslideset screw

®

Rotate

the

throat

plateorthe

* When sewing heavy weight materials, be sure to re-tighten the lower knife

shaft

set

(3) Adjusting the lower knife spring pressure (Refer to sketch below)

Loosen the nut

When

the

In

caseofheavy

When the overedging

In noon ni-

In case

When the adjustment is completed, tighten

(4) Overedging

The standard

is slightly larger than the width of knife)

pulley

and

when

lower

knife.

adjustmentiscompleted,

pulleybyhand

waste

screw

(2).

(Z)

overedging

unuT

of

light weight matenals-'

width

overedging

and

cloth

and adjust by the screw (8),

widthiswide-j

weight

materials^

width

is narrow-, ,

»• 1.* * • 1

width is 3.2 mm(l/8") but

the upper

securely

verify

cover.

ti^ten the

(2)

.

that

the

•Tighten

r""Loosen

nut

knife

(7).

has

knives

screw

screw

risen

to the topmost

upper

are

not

overedging

mm(l/16")

knife

set

screw.

touching

width of 6.35 mm(l/4") is

the

available

as a subclass,

(The

overedging

width

2. Adjusting

2 needle guards (§) (g) axe attached to the Model MO-804 and

Model

1)

Loosen

and left, adjust as shown in the figure.

2) Then, when the needle has dropped to the lowest position,

MO-814.

screw

the

needle guard

(D and by

moving

the

needle

guard® to right

adjust the front and rear slanting of the needle guard ® so

that the needle barely touches the needle guard. Then tighten

screw (D .

3) Adjust the needle guard (g) by loosening the screw (2) and

adjust in the same manner as the needle guard ®

needle

guardis(F)).

4) For

MO-816,

the needle guard(gwith screw @ by matching, respectively,

with

5) The up and down height of the needle guard ® needle

the

and needle guard ©(MO-816) and the slanting angle of these

guards should be adjusted, respectively, by loosening the

and

screw

Needle

double

(?).

adjust the

chain

needles.

needle

guard © with screw ® and

Double

chain

needle

Overlook

(MC)-814

guard©

screw®

needl6

I.Dmm

2.5mm

-

10

-

Page 13

3.

Adjusting

When

the

the heightofthe overlook needle is 10 mm(25/64")

from

the

the

heightofthe

needle

clamp

surfaceofthe

is at the

throat

topmost

plate.

needle

position,

u

4b Matching

(1) Standard radius

Loosen the set screw (D and adjust so

standard

to the blade

of

(2-41/64").

(2)

Fore

Adjustsothat

lower looper comes to 2

lightly tighten screw

(3) Clearance between the looper and the needle

Standard

Fine

Loosen the set screw @ , move the lower

looper

adjustsothat

pointoflower

needle

(4) Returning

MO-804-0D4^

MO-814-BD4J4mm(5/32

MO-816-DD4 6 mm(15/64")

Next,

extreme

between the blade

centerofthe needle (returning

to the above distance by loosening the screw

the

lower

looper

....

66.5mm(2-5/8")

that

radius

(distance

pointoflooper)ofthe blade point

the lower looper ® comes to 67mm

and

aft

slant

the

fore

from

2

mm(5/64")

and

aft

mm(5/64")

the

shaft

slantofthe

center

(D.

thread

synthetic

thread

support

comestothe

arm (2) fore

the

looper

amountoflower looper

. . .

clearance

and

ibove

^

0.05-0.1

under

between

back

dimension.

mm

0.05

mm

and

aft

the

sideofthe

)

when

left

the lower

position,

looper

comes to the

adjustsothat

pointoflooper

amount)

the distance

and

comes

® and (D

the

and

and

blade

the

l0min(2S/64")(MO-804)

In caseofsingle

®—

(D-n

(4>i

Overlook

needle

J ® /

W 2

fjj^\

needle

—

10tnm(

j

4mm(5/32")

h-

(804-814)

6mm(15/64')

mm

25/64")

^

Q

(MO-814)

In

caseoftwin

10mm(25/64")<MO-8I6)

needles

Lower

looper

\ 0

• ~ ±

I

.05—0

—r

.limn

Matching

5.

(1) Heightofupper looper

the

upper

looper

....

llmm(7/16")

When the upper looper (D comes to the

extreme

left

position, loosen the

upper

looper

support arm set screw ® and adjust so that

the

distance

and

the

(7/16").

(2) Next, when the upper looper is rising, adjust

so

that

lower looper (2) comes to

throat

the

between

plate surface

clearance

the

with

looper

comes

the

about

back

blade

to 11mm

surface

0.1 mm

point

of

and lightly tighten screw @

(3) Protruding amount of upper looper...4mm(5/32")

When

the

upper

looper

left

position, adjust so

tween

the

blade

of

the

needle

ing

set

(4)Atthis

the

blade

throat

securely

screw @

(5)

Lastly, be absolutely sure

is

correctly

the

needleorlower

becomes4mm(5/32")

screw

(3)

time

re-verify

pointofthe

plate

surface is 11

tighten

matched

comestothe

the

that

that

upper

mm(7/16")

set

and

looper.

the

screw (3)

that

it is

pointoflooper

the distance be

distance

and

looper

the

the

upper

not

extreme

center

by loosen

between

and

the

and

then

and

set

looper

touching

4 mm Jto" )

f

/

0

11mm \

—

Needle

/ ^

(3)

\ \

1

Throat

plate

\ \

1

0

0 J

0

-

11

-

Page 14

6. Matching

the

double

chain

looper

(In case of MO-816)

O Loosen the double chain looper set screw (l)

and

A:

Adjustsothat

double

chain

(2-17/32")

the

standard

looper

(as high as possible as long as it

(2)

radiusofthe

becomes

64.5

doesn't touch the feed dog).

B:

Adjustsothatitslants

viewed from

screw ®

Next,

that:

A: When

from

blade

0.05—0.1

B: When

the

extreme

the blade

becomes

top

loosen

the

the

left

point

double

to right, the clearance between the

and

backsideofthe

mm.

the

double

left

position,

point

2.5mm(3/32")

and lightly tighten the

set screw (3)

and

1.5

mm(l/16")

and

chain

looper

needle becomes

chain

looper

the

the

centerofthe needle

by adjusting

has

distance

adjust

(2) moves

reached

between

the

double

chain looper support arm ® . Then, tighten

the

set

screw lightly.

When

allofthe

pleted,

verify

moves from

at the tip

the

centerofthe

double

chain

each

other

above

adjustments

that the

left

of

the double chain

looper

as viewed

double

to right and when the hole

needle

that

and

the

from

the

chain

looper

looper

the

holeofthe

needle

topofthe

are

com

comes to

eye

slant.

Then, securely tighten the set screws (D and (3).

mm

as

set

so

®

meet

Double

chain

0.05—0.1mm

looper

5mm(I/I6')

2.5mm

Double

chain

^Needle

looper

7.

Adjusting

(in

When

adjust so

the

chain

caseofMO-816)

the

needle

has

that

the right

looper

thread

cam

reached

its

highest

position,

comerofthe straight line

partofthe chain looper thread cam (2) matches

with the

upper

surfaceofthe chain looper thread

guide (D . Loosen the chain looper thread cam

screw (D and adjust the cam.

8.

Adjusting

the

double

chain

looper

avoiding motion (MO-816 Series)

Dependingonthe

the

double

changed

1.

2.

as follows:

Fore

and

For

heavy

(MO-816-DH6,

For

standard

(MO-816-DD4

Adjusting

O Remove the cover (D in the back of machine.

@ Loosen the screw® of the chain looper shaft slide arm.

0 Insert a bar of 2 0 into the hole oKBand rotate it.

size

looper

and

avoiding

chain

aft looper avoiding

weight

materials

FF6

Series)

weight materials

Series)

method

numberofneedle,

motion

can be

motion

Looper

avoiding

2.80-3.06

2.64-2.85

motion

mm

mm

Whenthe mark©is in front looper avoidingmotion is least

When the

opposite

mark©is

side

in the

looper

greatest

avoiding

motion

O After adjustment, securely tighten screw ®

Numberofneedle

#14-#21

#7-#16

is

-

12

-

Page 15

IV.

MAINTENANCE

OF

THE

MACHINE

O As the knife of the machine cuts the cloth, much waste cloth will be produced, so clean the machine at least once a day.

Dust and thread hards are liable to be collected especially in the clearancesofthe

throat

plate and clean it thoroughly at least once a week.

throat

plate, needle guard aMl feed dog, so remove the

0 Inspect the machinehead at leastonce a year and operate the machinein perfectlymaintainedcondition.

V.

CAUSES

No.

Malfunctions

1.

Needle

breaks

2.

Inadequate

cutting

knives

3.

Stitches

skip

4.

Thread

breaks

5.

Inadequate

chain-off

of

chain

(MO-816)

6.

Wrinkled

stitches

7.

Uneven

stitches

double

of

stitch

OF

MALFUNCTIONS

Reasons

(1) Wrong needle

(2)

Wrong size

(3)

Needle installed wrong

(4)

Needleiscurved

(5) Wrong

number

relation

needle used

with

needle

(6) Wrong relation with needle &

(1)

Inadequate

knives

(2)

Knives

(1) Relationofneedle

(2) Knife

(3) Needle

(4)

Inadequate

installationofupper

are

worn

out

with

pointoflooper is blunted

threadisright

adjustmentofthread

twist

(5) Inadequate adjustmentofchain looper

thread

cam

(MO-816)

(1)

Inferior

(2)

qualityofthread

Threadisthicker

than

(3) Inadequate installation of needle

(4)

Thread

(5)

Needle,

bruised

tension is

looper,

too

throat

strong

(1) Inadequate installation of presser

thread

(2)

Rattleofrear

(3) Inadequate timingoflooper thread cam

(4) Inadequate installation

looper

(1)

Needle is

(2)

Thread

(3)

Pressing pressure is

weak

(4)

Feed

(5)

Knife

(6)

Differential

(1)

Flawinthe

(2) Inadequate thread tightening

(3) Needle

(4)

Inadequate

presser

too

thick

tension

too

dog

protruded

does

not

cut

feedisnot

thread

pointisblunted

pressing pressure

foot

strong

either

too

well

tension

(5) Inadequate height of feed dog

AND

guard

looper

needle

plate,

needle

of

double chain

too

much

matched

CORRECTIVE

looper

and

lower

tension

guard

foot

stongortoo

MEASURES

(1)

Use

only

(2)

Use

needle

(3) Refer to

(4)

Exchange

(5)

Adjust

chapteron"How

the

(6) Refer to the

(1) Refer to the

Corrective

the

designated

which

fits

with

new

guard

chapter

needle

on "Matching the

needle

chapteron"Knife

measures

needle

thicknessofcloth

to install

and

the

overedging

and

needle"

looper"

(2) Sharpen the lower knife and exchange the upper knife

(1) Refer to

(2)

Sharpen

(3) Change it to left twist thread

(4) Refer to chapter on

the

chapter

with

on "Matching the

oil

whetstoneorexchangeitwith

"The

thread

looper"

tension"

(5) Refer to the chapter on "Adjusting the chain looper thread

cam"

(1) Use

good

quality

(2) Change to

(3) Refer to the chapter on "How to install the needle"

(4) Adjust by

(5) Sharpen by oU whetstone or

(1) Refer to

(2)

Adjusttoeliminate

(3) Refer to chapter on "Adjusting the looper thread

(4) Refer to chapter on "Matching the double chain

(1) Use needle

(2)

Adjustbythread

(3) Adjust the pressure by turning the adjusting screw either to

rightorleft

(4) Lower the feed dog and match the height of the main feed

dog with the heightofsub feed

(5) Resharpen

(6) Refer to chapter on "Adjusting the differential feed"

(1) Use uniform size

(2) Strengthen the thread tension

(3) Exchange the needle with a sharp pointed needle

(4) Refer to chapter on "Presser foot and feed dog"

(5) Refer to chapter on "Presser

thread

appropriate

thread

chapter

appropriatetocloth

the

needle or

tension

on "Presser

rattle

tension

knife

thread.

nut

buffer

foot

nut

Clean up

foot

thread

and

and

the

and

feed

thread

thread

feed

using

dog"

path

dog"

thread

width"

new

cam"

looper"

looper

SPECIFICATIONS(Applicabletoall models)

Stitch length:

Differential

ratio:

Lower

knife

pressure:

Overedge

width:

Presser lifting

amount:

Needles:

Needle

bar

Upper looper:

Double

chain

stitch

mechanism:

Presser

foot:

Lubrication:

feed

stroke:

0.3-4.0mm(l/64"-9/64")

Ratioofauxiliary feed to main feed: Gathering:

Spring pressure adjusting system

Standard

Byusing

adjust up to 6.35

Max.

DCx27

24.2

3.2

mm(l/8")

gauge

sets (throat plate, presserfoot, feed dog,needleclamp) whichconform to the

7.0

mm(9/32")

(Standard),

mm(61/64'*)

mm(l/4")

Slide type (Possible to change the up and down strokeoflooper depending on thickness of the sewingcloth)

Built-in inside the machine and geared with the lower looper (MO-816)

Fixed

presser

Two-stage presser

foot

foot...

Automatic lubrication system by meansofgear pump (equipped with oil cooling fan)

(Push-button system)(By special specification, up to 5mm(13/64") possibly

1:2

(Max.

1:4)

1:0.6)

DCxl

DCxJ27

(For

Stretching: 1:0.7 (Max.

fine

synthetic

thread)

MO-804, MO-814

MO-816

-13-

overedging

width, possibleto

Page 16

S»W*9

nun

Head Office & Plant, 2-1, 8-chome, Kokuryo-cho, Chofu-shi, Tokyo, Japan

Business

Cable

Address:

Office:

JUKI

23,

Kabuki-cho,

JUKI

TOKYO

INIUSIRIAl

Shinjuku-ku,

Telex:

22967

Tokyo,

JUKITK

GO..ITO.

Japan

Loading...

Loading...