Page 1

8E240430tsoA

No.04

MODEL

MO.24O4

l.NEEDLE

OVEREDGER

MODEL

MO-241

4

2.NEEDLE

OVEREDGER

MODEL

MO

-241

6

SAFETY

STITCHER

InsrnucTtoN

Congratulations on'

your

purchase

of JUKI

MO-2400

Series machines.

Please read this Instruction Book

carefully

before

using these units in order

to

get

the most out of

them and to enjoy using them for a long

time.

[For

ttre

first

one

month or

so, operate the

I

lmachine

at about

80% speed of its

max.

I

[sewing

speed.

J

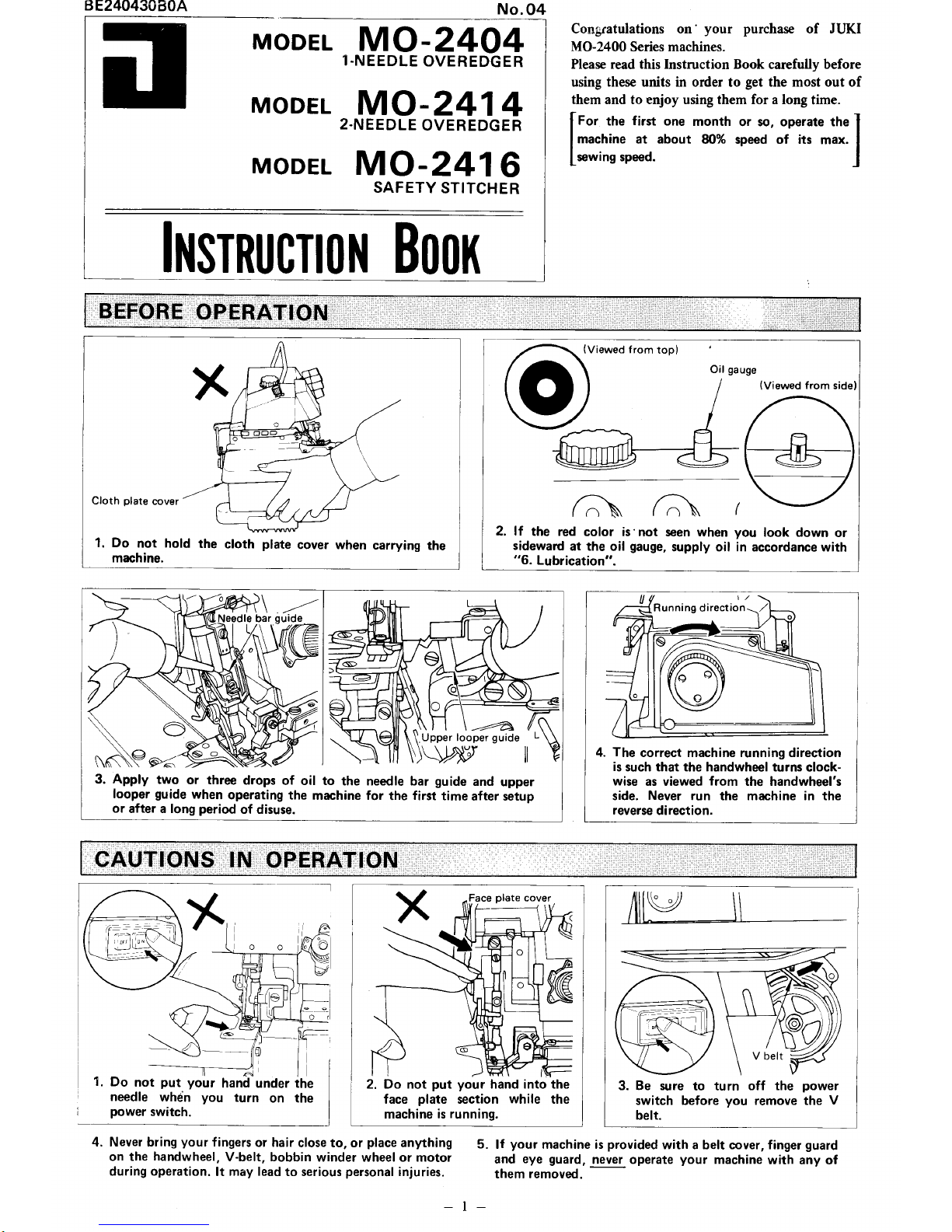

BEFORE

OPERATION

Cloth

plate

cover

1. Do

not hold

the

cloth

plate

cover when

carrying

the

machine.

3.

Apply

two

or three

drops

of oil to

the needle bar

guide

and

upper

looper

guide

when

operating

the

machine for

the

first

time

after setup

or

after a long

period

of disuse.

A"iewed

from

toP)

oir

sause

sz

f&

2. lf

the

red color is'not

seen when

you

look down

or

sideward

at the

oil

gauge,

supply oil in

accordance with

"6.

Lubrication".

Running direction

4.

The

correct machine running direction

is

such that the handwheel

turns clock-

wise

as viewed

from

the handwheel's

side.

Never

run the machine in the

reverse

direction.

CAUTIONS IN

OPERATION

1.

Do

not

put

your

hand under the

needle

whijn

you

turn

on the

power

switch.

4. Never bring

your

fingers

or hair

close to, or

place

anything

on the

handwheel,

V-belt, bobbin

winder wheel or motor

during operation.

lt

may lead

to serious

personal

injuries.

5.

lf

your

machine is

provided

with a belt cover, finger

guard

and

eye

guard,

never operate

your

machine

with

any of

them removed.

2. Do not

put your

hand into the

face

plate

section

while

the

machine is

running.

3. Be sure

to turn

off the

power

switch before

you

remove the

V

belt.

-l-

Page 2

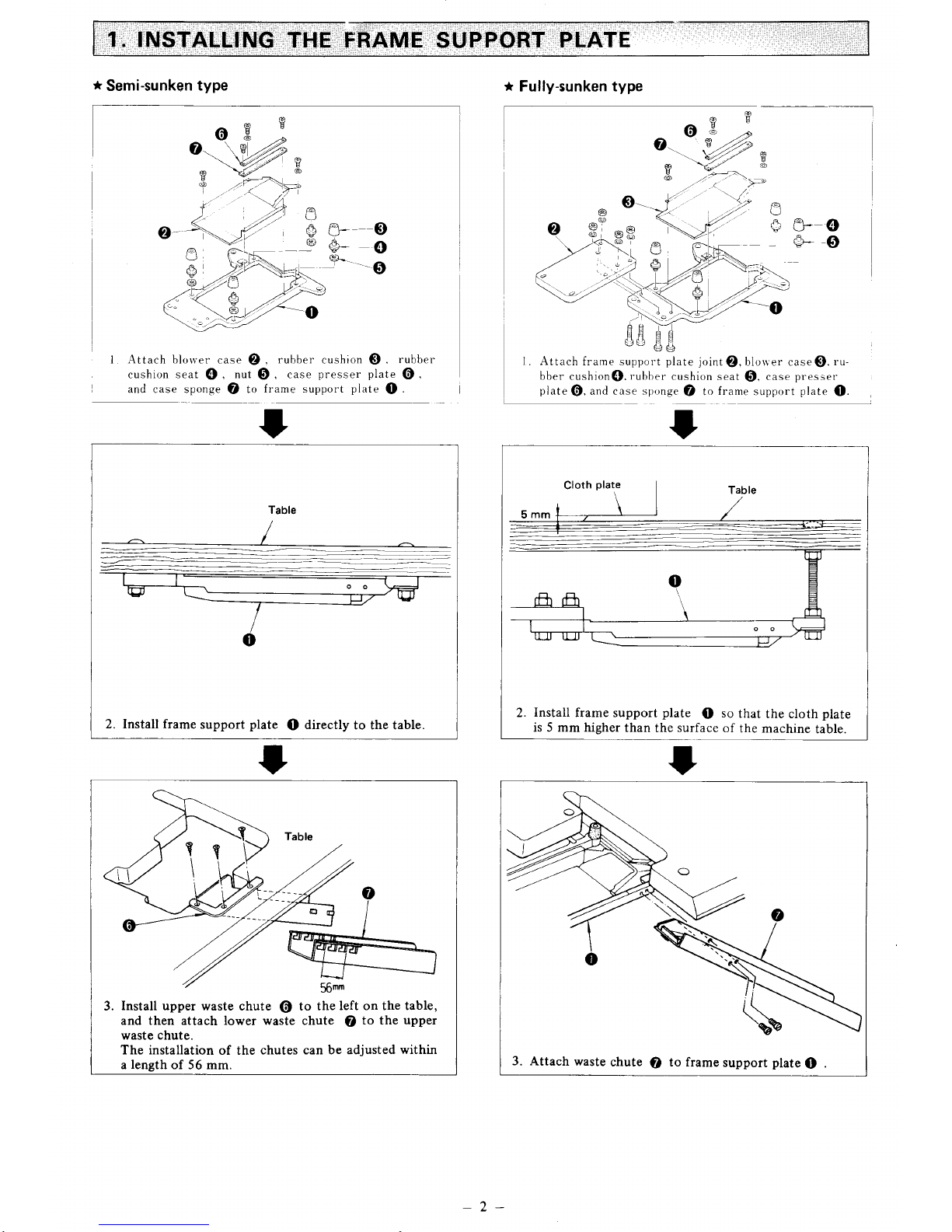

*

Semi-sunken

type

8-o

e-

o

_e-

_o

I

Attach

blo*'er case

@ ,

rubber

cushion

@

.

rubber

cushion

seat

@

,

nut

€)

,

case

presser plate

@.

and case sponge @ to frame

support

plate

Q

.

3.

Install upper

waste chute @ to the

left on the table,

and then attach lower waste chute

@

to the upper

waste

chute.

The installation

of the

chutes can be adiusted

within

a

length

of 56 mm.

1. Attach

frame support

plate

joint

€),

blu.rr'e. case€).

ru-

bber cushronO.

rubber

cushion

seat

O.

case

presser

plate

@,

and case sp,,nge

@

to

frame

support

plate

(D.

*

Fully-sunken type

8-O

g-o

-o

3.

Attach waste

chute @ to frame

support

plate

O

s

gg

os .,e

O

s

,tV)

V//

g

m

\.!./

9

gv

r.->:

-.4

e

c-l

(9

Table

I

2. Install frame

support

plate

O

directly

to the table

Install

frame support

plate

Q

so

that

the cloth

plate

is 5 mm higher

than

the

surface

of

the machine

table.

-2-

Page 3

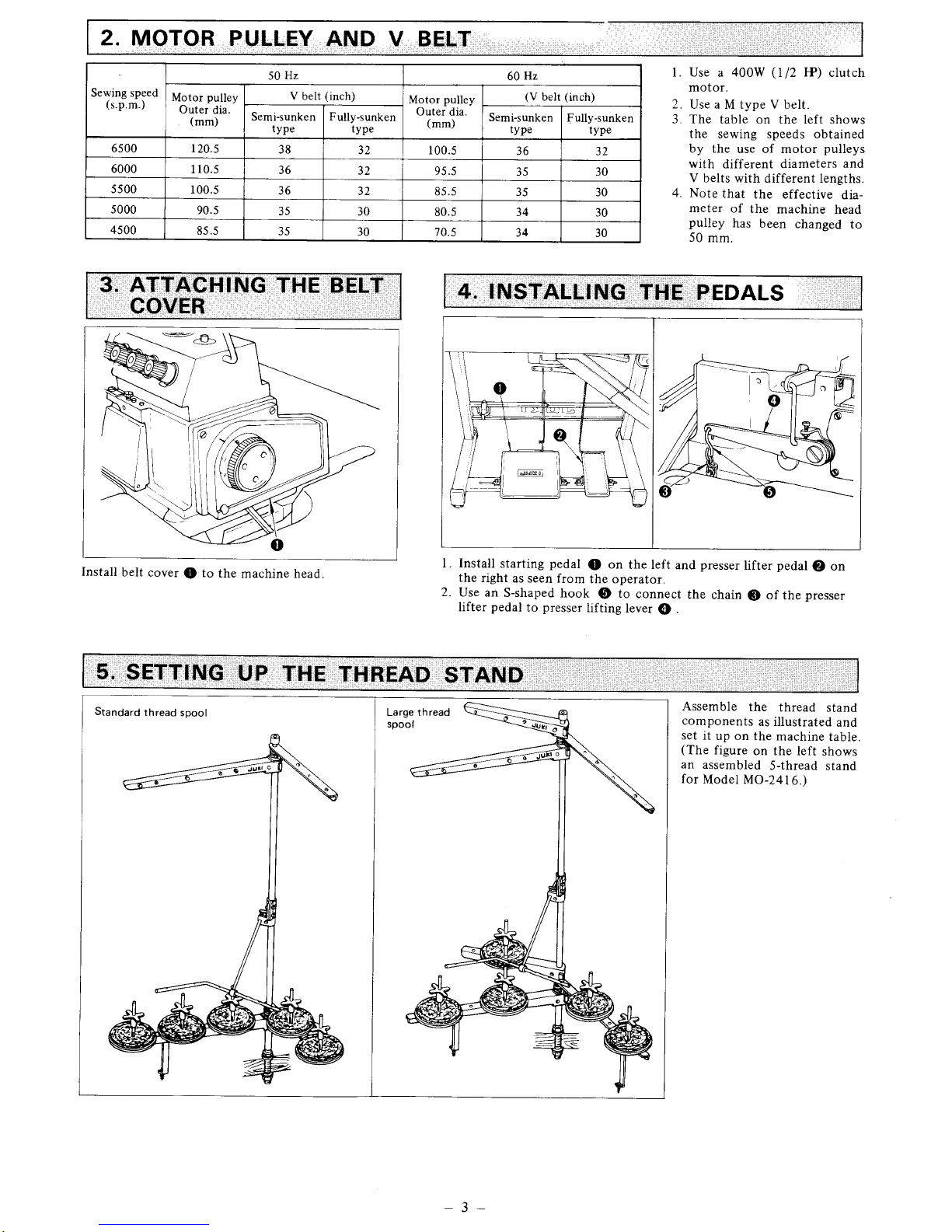

Sewing speed

(s.p.m.)

50

Hz

60

Hz

Motor

pulley

Outer

dia.

(mm)

V belt

(inch)

Motor

pulley

Outer

dia.

(mm)

(V

belt

(inch)

Semi-sunken

type

Fully-sunken

type

Semi-sunken

type

Fully-sunken

type

6500 r

20.5

38

32 t00.5

36

32

6000

110.s

36

32

95.5

35 30

5500

r

00.5

Jt)

)z

85.5

J5

30

s000

90.5

35

30

80.s

5.1

30

4500

85.s

35

30

70.5

34

30

Install

belt

cover

Q

to

the

machine head.

l Use a 400W

(1/2

tP)

clutch

motor.

2.

UseaMtypeVbelt.

3. The

table on

the

left shows

the

sewing speeds obtained

by the

use of motor

pulleys

with

different diameters

and

V belts

with different lengths.

4. Note

that

the effective

dia-

meter

of

the

machine

head

pulley

has

been

changed

to

50

mm.

4.

INSTALLING

THE

PEDALS

l. Install

starting

pedal

Q

on

the left

and

presser

lifter

pedal

O

on

the

right

as seen from

the operator.

2.

Use an

S-shaped

hook

O

to

connect

the chain

@

of

the

presser

lifter

pedal

to

presser

lifting

lever

@

.

t

651t3"'NG

rHE BELr

5.

SETTING

UP THE

THREAD

STAND

Standard

thread

soool

Assemble

the

thread

stand

components

as illustrated

and

set

it

up on

the

machine table

(The

figure

on the

left shows

an

assembled

5-thread

stand

for

Model MO-2416.)

-3-

Page 4

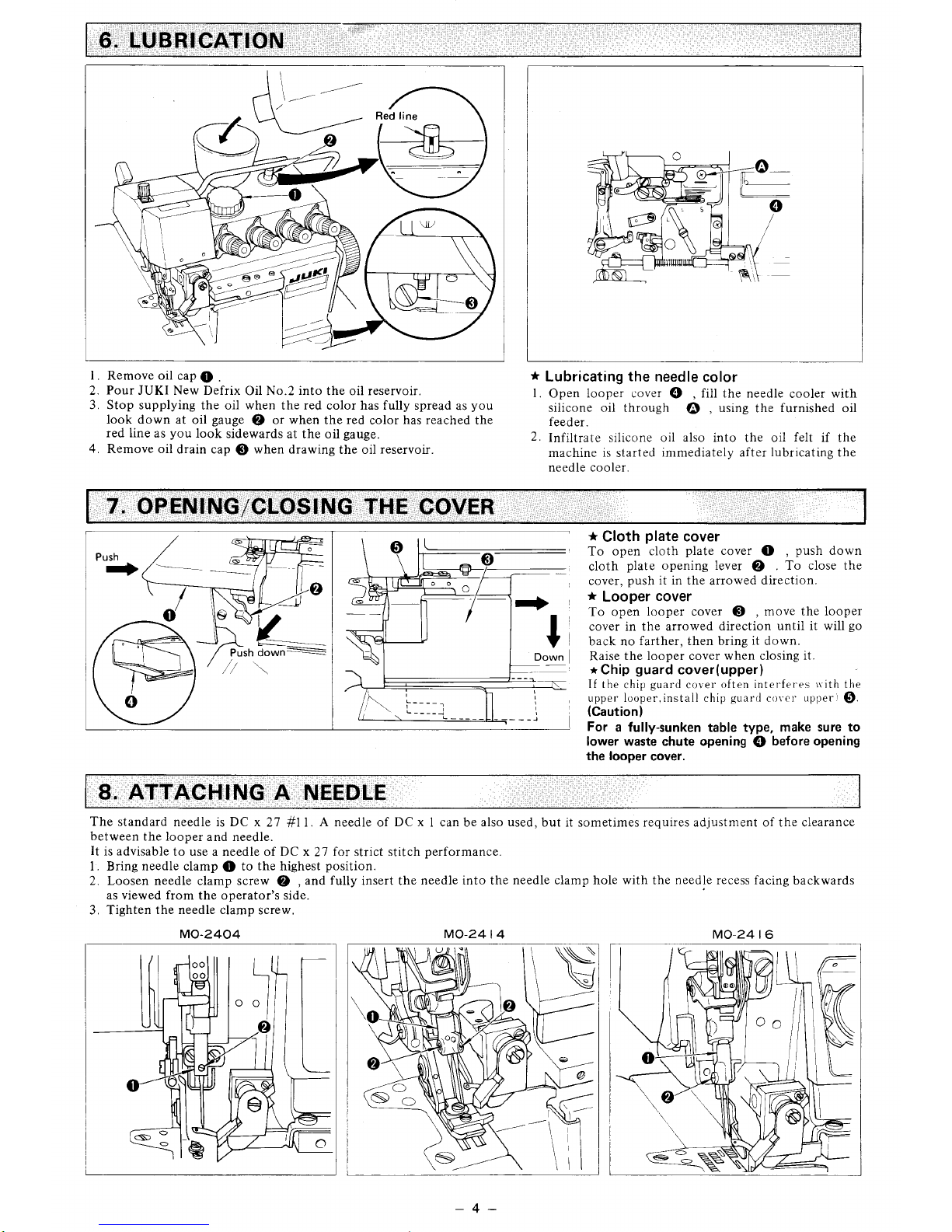

l.

2.

3.

Remove oil cap

()

.

Pour

JUKI New Defrix

Oil No.2

into

the oil reservoir.

Stop supplying

the oil

when

the red color has fully spread

as

you

look down at

oil

gauge

@

or when

the

red

color

has

reached the

red line

as

you

look

sidewards

at the oil

gauge.

Remove oil

drain cap @ when

drawing the oil

reservou.

*

Lubricating

the

needle

color

l.

Open looper cover

O

,

tltt the needle

cooler

with

silicone oil through

6

,

using

the

furnished

oil

feeder.

2.

Infiltrate silicone orl

also

into the oil

fett

if the

machine

is

started

immediately after

lubricating

the

needle cooler.

7 .

OP

EN

I NG

/CLOS

I NG THE

COVER

*

Cloth

plate

cover

To open

cloth

plate

cover

O

,

push

down

cloth

plate

opening lever

O

To close the

cover,

push

it in the

arrowed

direction.

*

Looper

cover

To open

looper cover

@

,

move

the looper

cover in the arrowed

direction until

it will

go

back no

farther, then bring

it

down.

Raise

the looper cover when closing

it.

*

Chip

guard

cover(upper)

If the

chip

guard

cover

often interferes

with

the

upper looper. install chip

guarrl

covet'

upper

)

@.

(Caution)

For

a fully-sunken

table type,

make

sure to

lower waste chute opening

@

before opening

the looper

cover.

8.

ATTACHING

A NEEDLE

The

standard needle is DC

x 27

#1

1. A needle of

DC x

I can be also

used,

but it sometimes requires adjustment of the clearance

between

the looper

and needle.

It

is advisable

to use a needle of DC x2'7 for strict stitch

performance.

1. Bring needle clamp O to

the

highest

position.

2. Loosen needle clamp screw

@

,

and

fully

insert the

needle into the

needle clamp hole with the needle recess facing

backwards

as viewed from

the operator's side.

3. Tighten

the needle clamp

screw.

MO-2404 MO-24t

4 MO-24 |

6

-4-

Page 5

9.

THREADING

THE MACHINE

Thread the

machine according to the threading chart

given

below.

(The

same chdrt

is on the inside

of the looper

cover.)

MO-2404

MO-24 |

6

MO-24t

4

Important

:

Lnri-z414:l

ffi:

(,trru+)

W/

Be

sure

to

pass

the double-chain stitch

needle

thread through the

needle

thread take-up.

(The

outer thread

is

the overlck

needle thread.)

(Gautionl

When using an untwisted thread

such

as wooly

nylon

thread or weak

thread,

do

not wind it round the intermediate

thread

guide.

-)-

I ntermediate

thread

guide

Page 6

MO-2404

MO-2414

Using

the thread tension

nut, adjust

to an optimum

thread

tension according to

your

sewing conditions such as type

of materials,

type

and size of thread,

etc.

11.

PRESSER

FOOT

PRESSURE

AND LIFTER

MO-2404

Adjust

the

pressure

of

the

presser

foot by turning

presser

foot adjust

screw O .

When

the adjust screw

is

turned clockwise, the

pressure

increases,

while the

pressure

decreases when

the

screw is turned

counterclockwise.

When

you

turn

presser

foot assembly

O

side-ways,

bring

down

presser

lifting lever

@

.

Whenever the

presser

foot is returned

to

its

original

position,

be

sure to

bring

up

the

presser

lifting

lever.

MO-24 t4.MO-24tb

MO-24 t6

1.

Slowly

turn the handwheel

as

you

keep depressing

pushbutton

O

,

and

you

will

find

a

point

at which

the

pushbutton

goes

in

farther.

2.

With

the above condition

maintained,

align a desired

dial on

the

handwheel with

white mark O on the

belt cover.

3.

Reset

the

pushbutton

after

setting the

dial.

t t.

fro*r3f,IrNG

rHE

silrcH

MO-24

t6

13. DIFFERENTIAL

FEED

MECHANISM

l. Loosen differential

feed lock

nut

O

.

Turn lever O

up

for

stretching stitch

or

down

for

gathering

stitch.

2. Position "S" is

for stretching

stitch

of a ratio of l:0.7

and

position

"0"

provides

a

differential

feed rrtio of 1:1.

3.

Gathering

stitch

can

be made

up to a

differential

feed

ratio of

1:2

(possible

up to l:4

by adjusting

the

internal mechanism).

The divisions bevond

"0"

mav be used

as a measure.

-6-

Page 7

When

the needle bar is

at the highest

point

of its stroke, the

pointed

end

of

the overedging

needle

should

be l0

mm above

the

throat olate surface.

MO-24

14

til|

]

(Stanoaro

teft

settins)

\/\/ I

MO-2404

10

mm

Throat

plate

Throat

plate

15.

SETTING

THE

LOOPERS

Go

back

farthest

*

Lower looper

l.

When lower

looper

Q

has

gone

back

farthest,

it

should

be distanced

3.7

to

4.3

mm from

overedging needle

O

.

2. When

the

lower looper

is

crossed with

the

needle,

the

clearance

between

them

should

be

0.05 to

0.1 mm.

3.

To

make

adjustment,

loosen

setscrew

O

and

move

lower

looper

holder

O

.

*

Upper looper

1. When

upper looper

@

has

advanced farthest,

it should be

distanced

10.4

to

11.0 mm

from

the

overedging

needle

for MO-2414,

and

10.7

to

1 1 .3

mm for

MO-2404

and

MO-2416.

2. The clearance

between

upper looper

O

and lower

looper O when

they are

crossed each

other should

be

0.05 to

0.2

mm.

3. To make

adjustment,

loosen

setscrew

@

and move

the

upper

looper.

*

Use a

proper

upper

looper

according

to the count

of

the

needle

used

in accordance

with

the table

shown

below. When

placing

orders,

specify

the bracketed

numbers[--l

.

Model

Numerals

engraved on

upper

looper

Count of Needle

1-Needle

Overedger

Safety

Stitcher

88@

#8 - #13

(#14)

88m

#14

-

#20

(#13)

I

888

2-Needle Overedger

I

888

#6

-

#8

(#9\

88 l8al

#9- #16

*

Avoid using needles

with

the bracketed

counts as

much as

possible.

Go back

farthest

*

1

Double-chain

looper

0.05 - 0.1 mm

When double-chain

looper O has

gone

back

farthest,

it should

be distance l 8 to

2 mm from

double-chain needle

@

.

The clearance between the

double-chain

looper and needle

should be

0.05 to

0.1 mm when they

are crossed each other.

To

perform

the adjustment,

loosen set-

screw

(E

and

move double-chain looper

holder

O

.

2.

o

-4

It-

tl

\1

1J.t

lio

t/

-]._1.8-2mm

3mm

0.05

-

0.1

mm

--\-,

rl

\\\r-u

"lm\

ry/'

--\+r\\

\\\----o

"-A

ry

L

MO-2404

MO_2416

_

ru./

MO-2414

-

10.4

-

11.3 mm

-

11.0

mm

0.05

-

0.2

mm

-'7

-

Page 8

0.8 mm

O.5 mm

I hroat

pl

ate

*

Height of

feed

dog

1. Feed dog

O

is usually

set so

that its teeth

protrude

about

0.8 mm

from

the throat

plate

surface at the highest

point

in

its trajectory. Increase the

protrusion

for

heavy-weight

materials

or reduce it for light-weight

materials.

2. Use setscrew O to adjust the

protrusion

of the feed dog

teeth.

3.

Using setscrew

O

,

make adjustment so

that

differential

feed dog @ is level

with

the

main

feed

dog.

4.

Adjust the height of auxiliary feed

dog

O

by

setscrew

@

so that it is 0.5 mm lower

than the main

feed

doe.

*

Contact

of

the

presser

foot with

the throat

plate

top surface

Usirrg

adjust screw

@ ,

perform

adjustment so that

the sole of

the

presser

foot evenly comes in contact

with the top surface

of the throat

plate

when

presser

foot O comes down.

|?).*=il)1

*

Inclination

of feed dog

1. Loosen

screw

O

,

and

turn eccentric

shaft O in the

arrowed

direction

to make the feed

dog

front up

or turn it

in

the reverse

direction to set the feed

dog front down.

2.

The feed

dog should be levelled

when the dot

engraved

on

the

eccentric

shaft

faces

exactlv

to the ieft.

i

o

Front

up

1 7.

CHAIN LOOPER THREAD

CAM(MO-2416)

Loosen setscrew

@

,

and adjust

chain looper thread cam O so

that

6

of the chain

looper thread

cam

meets

the bottom of

looper thread

cam

pawl

O

when the needle

is

at

its highest

position.

Make sure that the

chain

looper thread

cam releases

the

looper thread

at the moment

the

needle

point

starts to

go

below

the bottom

of the

throat

plate

under

this condition.

. | |

Overedge

'"'""Kf*

Throat

plate

18.

THREAD

GUIDE

AND

LOOPER THREAD TAKE.UP

The

table below shows the

standard demensions of the individ-

ual thread

guides

and

looper thread take-ups when the upper

looper

has

gone

back farthest.

3ode

MO-2404

MO-2416

(Standard)

MO-2414

(Standard)

MO-2405

(Hemming

bottom)-

MO-2404

(Soft

chain)

G w

G

w G w

G

w

74 79.5

B

74

79

C

22.5

D

63

.5

E 40.5

F

26

C

37

.5

45 45 37 .5 45 4l 7

H

t2

IJ

18.5 9.5 t2 l3 26.5

6.5

24.5 33. 5 2E.0

33.5

J

23 I

K

L 74

M

63

l

-8-

G

: General

thread W : Wooly thread

(Unit

:

mm)

Page 9

*

Height of the

lower

knife

Loosen

setscrew

€)

and

adjust the

height of lower

knife

O

so

that

its edge is

flush with the throat

plate

surface.

*

Height of the upper

knife

Loosen setscrews

O , O

and

perform

adjustment

so

that upper

knife

@

overlaps lower knife

O

by 0.5 to I mm

when the

upper

knife is at its lowert

point.

*

Overedge

width

Overedge

widths

of 1.6

thrqugh

6.4

mm are

provided

by

changing

the

parts

or

by using

subclass models.

(The

overedge

width will be

slightly larger than the knife cut

width.)

To change

the overedge widthl

l. Loosening

setscrew

@

,

push

lower

knife

O

to

the left

and

fix it.

2.

Loosen setscrew

@

and

move

upper knife @ as

required,

then

fix it.

3.

Lower the upper knife to its lowest

point

and

loosen set-

screw @ . Tighten

setscrew @ when the lower knife comes

in contact with the upper knife.

(Caution)

Be

sure

to

tighten

screw

G)

before operating

machine.

*

Resharpening

the lower knife

When

the

lower knife

has become dull,

resharpen

it as

shown

in the

figure left.

20. NEEDLE GUARD

*

For

1-Needle

and 2-Needle Overedgers

An overedger is equipped with two

needle guards O and O .

1 . Position needle

guard

O

so that

it lightly comes in contact

with needle O when the blade

point

of

lower looper

O

has

reached the

center

of needle O .

2. Position

needle

guard

O

so that

it is 1

mm

lower than

the

bottom surface of

the throat

piate

end is distanced 0.1

mm

from needle O when the needle is at

its lowest

point.

*

For safety

stitchers

A safety stitcher has four

needle

guards

O , O , @

and O .

1. Position needle

guards

tl) and O in the

same manner

as the

overedger explained

above.

2.

Position needle

guard

O

so

that

it

lightly comes

in

contact

with needle

O

,

and

position

needle

guard

@

so that

it is

distanced

0.1 mm

from

needle@ when

the needle

is at its

iowest

point.

i

-9

-

Page 10

STITCH

FAILURE CAUSES

CORRECTIVE

MEASURES

1. Needle

breaking

(l)

Needle type ls wrong.

(2)

Needle count is not

correct.

(3)

Needle is not installed correctly.

(4)

Needle is not straight.

(5)

Needle-to-needle

guard

is inadequate.

(6)

Needle-to-looper

relation is inadequate.

o

Use a

specified needle.

o

Use a needle size

suitable to the thread

gauge

and type of fabrics.

o

Install

the needle

in

the correct

way

(See

8).

o

Use a straight needle.

o

Correct

the relation

(See

20).

o

Correct

the needle

to looper relation(See 15).

2.

Cloth

is

not

cut

(

I

)

Position

of the upper and lower

knife is

inadequate.

(2)

Knife

blade

has worn

out.

o

Adjust

the knife

position

(

See

1

9).

o

Sharpen the lower

knife or

renew the

upper

knife.

3. Stitch skipping

(l)

(2)

(3)

(4)

(s)

Needle-to-looper

relation is

wrong.

Looper blade is blunt.

Needle is

threaded

with S-twist

(or

lefthand twist) thread.

Thread

tension

is wrong.

Double

chain looper thread

tension is not

enough.

o

Correct the needle-toJooper

relation

(See

1 5).

o

Correct the shape of

the looper blade using

an oilstone, or replace

it.

o

Use a Z-twist

(or

right-hand

twist)

thread with

the needle.

o

Adjust the t\read tension

(See

l0).

o

Correct the

position

of

the chain

looper threac

cam

(See

l7).

4.

Thread

breaking

(

1)

Quality

of the thread

is

poor.

(2)

Thread

is too thick

for the needle size.

(3)

Needle is installed in a wrong way.

(4)

Thread

tension is too high.

(5)

There

is a

scratch or bruise on the surface

of needle, looper, throat

plate

or needle

suard.

o

Use a thread

of

good

quality.

o

Select a suitable needle or

thread.

o

Install the needle correctly

(See

8).

o

Adjust

the thread

tension

(See

10).

o

Remove

scratches and

bruises

using an oil-

stone or buffing machine.

5. Double

chain-off

thread stitching

are not correct.

(MO-2416)

(

I

)

Presser foot

does

not

evenly

act on the feed

dog.

(2)

Rear

presser

is

shaking.

(3)

Needle

thread and looper thread

tensions

are not correct.

(4)

Double

chain

looper

is installed

in a wrong

wav

o

Correct the relation of the

presser

foot with

the

feed dog.(See I 6).

o

Adjust

the rear

presser.

for

smooth

and

steady motion.

o

Adjust

the thread

tension

(See

l0).

o

Correct the double chain

looper

(see

I 5).

6. Puckering

(

I ) Needle is

too

thick.

(2)

Tiread

tension

is too high.

(3)

Pressure

applied by the

presser

foot is too

high or too low.

(4)

Feed dog

comes

up too niuch

from

the

throat

plate

surface.

(5)

Knife fails to cut the

fabrics

sharply.

(6)

Differential feed mechanism is not set

correctly.

o

Select

a suitable

needle size for the thread

and materials.

Adjust

the thread

tension.

Correct

the

presser

foot

pressure

(See

I

1).

Lower

the

feed dog.

Sharpen the lower knife.

Correct

the

differential feed mechanism

(See

1 3).

o

o

o

o

o

Irregular

stitching

(

I ) Thread is not

supplied

smoothly

(2)

Thread

tension

is too low.

(3)

Needle is

blunt.

(4)

Pressure applied by the

presser

foot is

inadequate.

(

5) Height of

the

feed dog is wrong.

Use smooth thread

with even thickness or

clean up the thread

path.

Increase

the thread

tension.

Use a new

needle.

Adjust the

presser

foot

pressure

(See

I l).

Adjust

the

height of the feed dog

(See

I 6)

o

o

o

22.

SPECIFICATIONS

MO-2404

MO-2414 MO-2416

Sewing speed

(Max.)

6500

s.p.m.

6500

s.p.m.

6500

s.p.m.

Stitch

length

0.8 - 4

mm(1

164"

-

5132")

(special

model

: up

to 5 mm)

1.5-4mm(5mm)

Needle

gauge

1.6,2.0,2.4

mm

1 .6,

2.0,

2.4,

3.2,4.8, 6.8mn

Overedge width

r.6,

2.4, 3.2, 4.O,4.8,

6.4mm

2.0.3.2.4.0.4.8

mm

3.2,

4.0,

4.8, 5.6, 6.4

mm

Differential feed

ratio

Gathering stitch

l:2

(Max.

l:4)

Stretching stitch

l:0.7

(Max.

l:0.6)

Needle

DC x 27

(standard) (DC

x I

may

be used)

Presser

foot lift

Max.

7.0 mm\9

132")

(excluding

some subclass models)

Lubricating

oil

JUKI

New

Defrix Oil

No.

2

-10-

Page 11

(

iln:, l:,rl#'ii'fJT,ffi:i,:H $i:x't*ff

f:'

"

)

rl

I||llY||

JUlfi

Iil[U$In|l|.

80..[10.

I f

Head

Office &

Plant: 2-1,

8-chome,

Kokuryo-cho, Chofu-shi,

Tokyo, Japan

I I

Business Office: 23-3, Kabuki-cho

1-chome, Shiniuku-ku,

Tokyo 160, Japan

-

cabte: JUK| ToKYo

retex:22967:2g2-2301

Phone: 03(205)1 1 88,

1 189,

1 190

Appearance and specification listed

in

this catalog are

subjected to

change

without notice.

1981.'7

Printed

in Japan(11)

Loading...

Loading...