Page 1

.......

..........

!^..........;.:.Z:/':.^..:i4f^^...

••

vt

y.M.«

TOKYO

FOREIGN

JOKI

INOOSTRIAL

TRADE

BUSINESS

CO.,

DIV.

LTO

Page 2

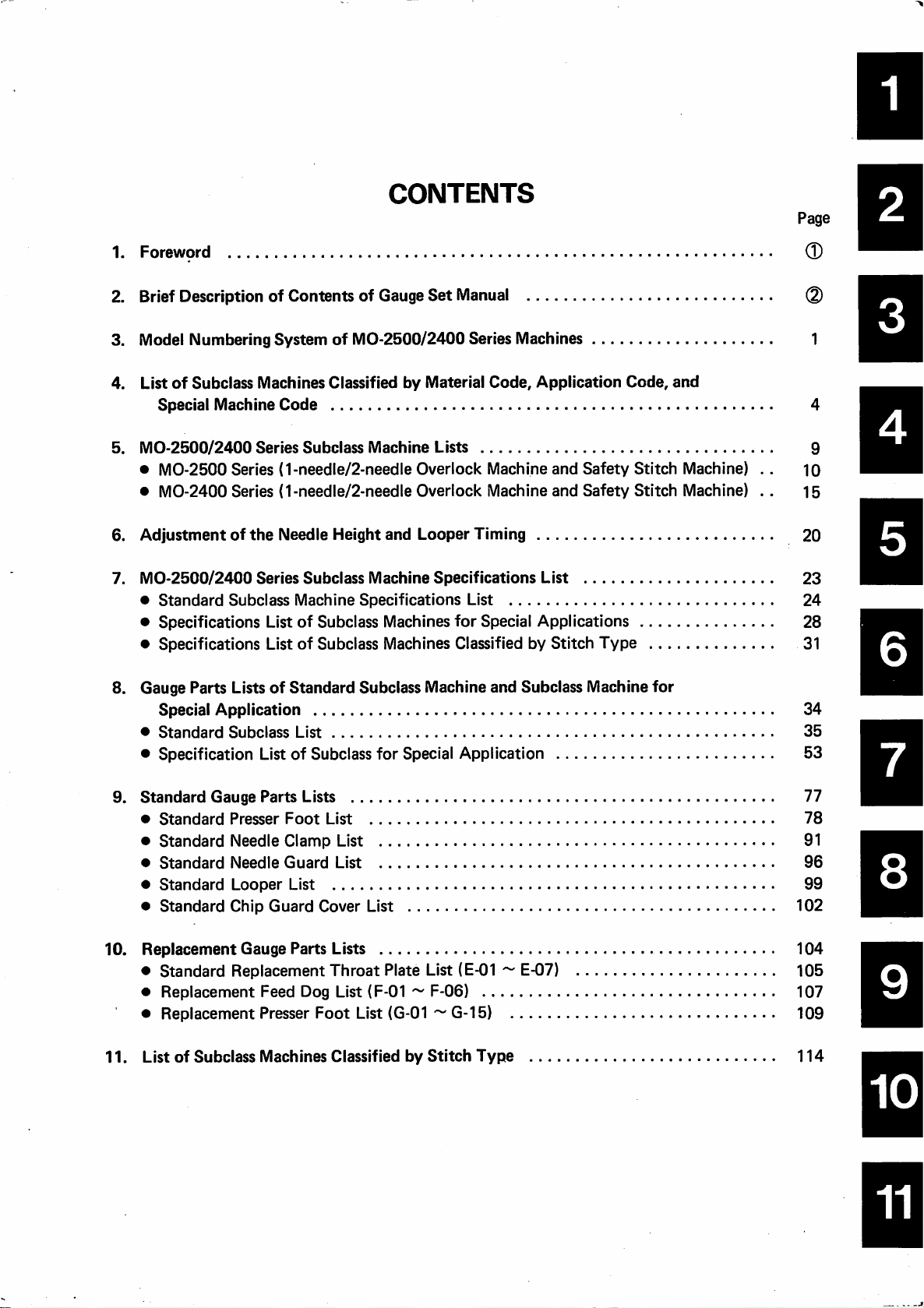

CONTENTS

Page

1. Foreword ®

2.

Brief

Description of Contents of

3. Model Numbering System of MO-2500/2400 Series Machines 1

Gauge

Set

Manual

(2)

4. ListofSubclass Machines Classified by Material

Special Machine

5.

MO-2500/2400

• MO-2500 Series (1-needle/2-needle Overlook Machine

• MO-2400 Series {1-needle/2-needle Overlook Machine and

6.

Adjustmentofthe

7.

MO-2500/2400

•

Standard

• Specifications ListofSubclass Machines

• Specifications List of Subclass Machines Classified by Stitch

8. Gauge Parts Lists

Special Application

•

Standard

Subclass

Subclass

Code

Series

Needle

Series

of

Subclass

Height

Subclass

Machine

Standard

List

Machine

and

Machine

Specifications

Subclass Machine

Lists

Looper

Specifications

Code,

Timing

List

for

Special Applications 28

Application Code,

and

List

and

Subclass Machine

Safety

Safety

Type

and

Stitch

Stitch Machine)

Machine)

for

• Specification List of Subclass for Special Application 53

9.

Standard

•

Standard

•

Standard

•

Standard

•

Standard

•

Standard

Gauge

Parts

Lists 77

Presser

Needle Clamp List 91

Needle

Looper

Chip

Foot

Guard

List

Guard

List

List

Cover List

4

9

..

10

..

15

20

23

24

31

B

34

35

78

96

99

102

10.

Replacement

Gauge Parts Lists

• Standard Replacement Throat Plate List (E-01 ~ E-07) 105

• Replacement Feed Dog List (F-01 ~ F-06) 107

• Replacement Presser

11.

ListofSubclass Machines Classified by

Foot

List (G-01 ~ G-15) 109

Stitch

Type

104

114

Page 3

1

Foreword

It is a

favored by

We

exactly

series machines. This manual shows

presser feet,

gauge

We will continue to provide

customer's

favor

hope

parts

from

great

pleasure

many

that

this gauge

meet

your

and

that

suittoyour

requirements, and we do

youtoour

that

our

customers

requirements

feed dogs used with typical models, so

since

set

particular

our

MO-2500/2400

MO-2500/2400

they

manual will help

from

customers with sewing machines

series

were placed on

you

the

vast variety of IVIO-2500/2400

the

dimensionsofthe

applications.

hope

that

series

machines.

the

find

we

machines

market.

out

that

may

receive

have

machines

throat

you

can select

that

further

been

that

plates,

satisfy

Page 4

2

Brief

of

This gauge set manual mainly

items. Brief

refertothe

1.

2. Model

3.

Gauge

Applicable

This

useofeach

This

MO-2500/2400

MO'2500/2400

These

of

standard

and

subclass

liststolocate

Description

Set

descriptionofeach

Individual

Models

gauge

set

model

Numbering

section

lists

contain

sections.

manualisIntendedtobe

of

MO-2500/2400

System

shows

subclass machines, subclass machines

machines

just

our

model

series

machines.

Series Subclass Machine Specifications Lists

the

specifications,

classified by

the

one

contains

item

that

Manual

information

is given here.

used

series

machines.

numbering

applications,

stitch

type.

meet

your

sewing

of

For

as a

guide

system

for

Carefully

requirements.

Contents

about

to

and

the

following

more

details, please

for

most

effective

specify

special applications,

individual

gauge sizes, etc.

look

into

these

4.

Subclass

These lists

subclass machines.

dimensions

your

When

given

The

Please

finger

clearness

5.

Replacement

These

presser

clusive

6.

Subclass

This

typical

Refertothe

Machine

particular

changingagauge

for

standard

note

guards

lists

feet

gauge

Machines ClassifiedbyStitch

section

modelsofpopular

show

are

each

that

of

the

Gauge

contain

exclusively

parts

contains

threading

Gauge

parts

given

applications.

model.

presser

the

but

views.

Parts

Nos.

For

throat

to

part,

foot

front

the

top

Parts

discrete

used

accordingtoyour

the

Illustrated

Lists

and

configurationsofthe

plates, feed dogs, etc.,

enable

Lists

specifications,

stitch

you

select

one

assembly

views

of

views

eliminate

replacement

for

particular

types.

when

to

is

the

specific

Type

using

select

from

the

provided

presser

these

throat

applications.

applications.

applications,

the

gauge

gauge

parts

replacement

withafinger

foot

assembly

finger

plates,

and

sewing

machine.

parts

used

their

required

that

gauge

show

guards

feed

dogs,

Use

these

adjustment

suit

parts

guard.

for

for

to

the

the

and

ex

of

Page 5

3.

Model

MO-2500/2400

Description is given

customer's

All of our MO-2500/2400 series machines are controlled by this model

numbering system. So, customers are requested

of

this

specific application

model numbering system.

Numbering

Series

to

the

codes used to specify a model best suited to

among

the

MO-2500/2400 series machines.

System

Machines

to

obtain full understanding

of

- 1 -

Page 6

Model

numbering

system

MO-2504

Series

code

Classification

M0.25M

Overlook

Safety

stitch

Super

high-speed

MO-24AA

Overlook

stitch

High-speed

of

safety

>

t

Model

No.

Code

Material

Classification

tobeused

code

basedonmaterials

(The

figures

grade of material thickness)

1

Extra-light

Light-weight

Light

weight

materials

Medium-

weight

materials

Medium-

weight

materials

I

Heavy

weight

materials

~

materials

show

For

training

wear,

etc.

Standard

(for

dress

skarts

sport

Knit

sweater,

etc.

Standard

knit,

to

wear)

The

material

"5"

representsamachine

those

suited

machine.

presser

rance.

In

other

used

for

Note

that

less

becauseofthe

code

"4"

material) exclusively

code

sewnby"3"

for

sewing

The

code

foot

for

words,

sewing

this

modelofmachine

denotes

"3"

denotes

standard

materials

"2"

producing

the

machine

knit

materials.

larger

the

"5"

used

suited

machine,

thinner

representsamachine

stitches

with

hookofthe

machine

for

the

for

material

has

sewing

standard

sewing

materials

while

than

those

with

better

code

presser

stitch

(for

sewing

heavy-weight

machine.

"1"

sewnby"3"

furnished

foot

tongue.

The

thicker

showsamachine

touch

and

"2"isexclusively

liftof6

Similary,

heavy-weight

knit

code

than

with

a

appea

mm

or

the

materials.

Page 7

Seam

code

Stitch

type

to

USA

Standard)

04-504

14-514

16-516

01-501

02-502

03-503

05-505

06-506

07-507

12-512

15-515

40-540

43—3-needle

45—2-needle

(double

chain

(conforms

stitch)

@

Basic

specification

code

Significant

in

specifications

main

unit

(§) —

General

Soft

chain

(E) —General

(F)—

With

threading

mechanism

(Only

MO-2500

series)

(§)

—Soft

chain

Special

spec.

(Sch lesser

specification)

T

difference

of

looper

spec,

order

®

Needle

gauge

Needle

gauge

0 —

1-needle

Z

-0.8

X-

1.2

A -

1.6

B

-2.0

C

-2.4

D-3.2

E

-4.0

F

-4.8

B.B-2.0X2.0

D.B-3.2x2:0

F.B-4.8

♦ ♦

CO

2

a «!.•<

(D

x2.0

C/>

(/>

cf, CO =• o

Q-

code

(mm)

f

—^

O

o

TT

Overedging

code

width

Overedging width

(from

right

needle

to

fabric

edge)

—

1.6

mm

—

2.0

mm

—

2.4

mm

—

3.2

mm

—

4.0

mm

—

4.8

mm

—

5.6

mm

—

6.4

mm

®

Feed

dog

code

Numberoffeed

dog

rows

5—1

-row

4 -

2-row

6 —

3-row

7 —

4-row

Attachment

&

Device

Code

-0D6-320/S098/T006

_

.1-—

Subclass Code by application

(D

Application

Classification

of

operation

0 —

Standard

1

—'For

hemming

2 —

(5057)

(5058)

3 —

4 —

5 —

6 —

7 —

A —

B —

C —

For

The special machine code denotes a requirement

than

the

0

Standard

and

1

Use

upper looper is required. In this case, the max. speed

willbelimited

2 Use

Use

Use

sewing

Use

in

one

is made by moving the stitch tongue of the presser foot.

code

basedontype

blind

(L001)

For

gathering

For

safety

stitch

For

overlook

stitch

For

piping (M075)

For

attaching

For

rolling in

For

rolling in

For

serging

For

wool

For

piping&gathering

doeskin

replacementofthe

machine

square

upper

this

code

whenamachine

becauseofweight

this

code

when

tape

tape

which

knife.

a flat

Special

Special

other

0 —

1 —

2 —

3 —

4 —

5 —

6 —

machine

specifications

than

Standard

Upper

adjustable

Flat

Corrugated

square

Looper

thread

Overedging

width

Provided

throat

differential

dog

7 —Large

looper

subclass gauge sets.

uses

the

fixed

upper

withanadjustable

limit.

upper

knife is desired.

this code whena square knife with corrugated blade isdesiredto sew

this

code

when

the

with wooly thread has the looperfor thicker thread.

this

code

fora

type,

the

overedging

standard

machine

looperisrequiredtobe

with

provision

widthisadjustedbymoving

1 I j I I

Labor-saving

saving,

automation

of

Z072

Z073

S084B—Pattern

7006

7016

materials.

thread.

the

machine

gauge

looper

knife

knife

for

adjustable

with

plate

lip

upper

travel

for

code

set

thick

and

feed

other

looper

overedging

Attachment

Modelofattachment

for

operation

Application

8097

8098

M076

M056

M077

Replacement

G01~Replacement

E01 ~

F01 ~

K066

N067

code

specified by

Code

Swing-type

device

for

Swing-type

device

for

Ready-made

tape

guide

Piping

folder

Piping

folder

gathering

parts

foot

Replacement

plate

Replacement

Rolling-in

Reinforcement

attaching

N077

Binder

and

bottom

I

replaced

width

the

bythe

adjustment.Inthis

pawlofthe

- 3 -

throat

required

gathering

safety

stitch

gathering

overlook

piping

for

presser

throat

feed dog

feller

tape

binder

(for

clean

top

finish)

heavy-weight

looper

for

plate,

thicker

case,

andinthe

Device

operation

L012—

7022

7023

8095

other

device

for

achieving

higher

productivity,

and

—

Chain-off

rolling-in

—

Chain-off

rolling-in device

(canbestopped

a fixed position)

Blind

attachment

automatic

of

stitch

sewing

—

One-touch

thread

device

—

Automatic

thread

device

—

Suction

cutter

—

Suction

cutter

—

Curl

attachment

Note

thatthe

comesintwo

type,

the

code

labor

greater

thread

device

thread

hemming

(with

preventer

deviation)

guide

cuff

lining

type

trimming

chain-off

trimming

type

type

removing

I

machine

types;

adjustment

ease

at

for

flat

side

for

Page 8

4.

List

of

Subclass

Classified

Application

Machine

Based

described.

Use

selectionofsewing

Also,

devices are given

on

the

material

this

listtofindamodel

several

examplesofsubclass

machines.

for

Code

code,

better

Machines

by

Material

Code,

typical

best

understandingofour

applications

suited

machines

to

your

combined

and

of

MO-2500

application

with

model

numbering

Code,

Special

series

outofthe

attachments

are

wide

or

system.

•

- 4 _

Page 9

List

of

subclass

machines classified

by

material

code.

Code

100

For

light-weight

materials

150

Roll-in seaming

light-weight

200

For

better

and

touch

210

Blind

materials

appearance

hemming

of

Application

Closing stitch of

stockings,

ing

etc.,

panty

and

hose toes,

crotch

seam

Safety stitching in side seaming

of

blouses,

men's

shirts,

etc.

Roll-in seaming of light-weight

materialsinhandkerchiefs,

scarfs,

etc.

For

runstitchingofknitwork,

etc.

Especially

requiring

and

touch

Blind hemmingofknit

For

better

touch

For

1-needle

ing

for

good

appearance

appearance

overlook

those

goods;

and

runstitch

Subclass

MO-2514E-ZA5-100

MO-2514E-XB5-100

MO-2514E.AB4-100

MO-2516E-DD4-100

MO-2516E-FF6-100

MO-2516E-RH6-100

MO-2504E-0A5-150

MO-2504E-0A4-150

MO-2504E-0D4-200

MO-2514E-BD4-200

MO-2505E-0D4-210

MO-2505E-0D4-210/L012

MO-2504E-0C4-300

MO-2504E-0D4-300

MO-2504E-0E4-300

MO-2504E-0F4-300

MO-2504E-0H4-300

MO-2504E-OD6-300

Model

Name

Remarks

1

Urethane

J

Feed

Rear presser

dog

feeddog

pitch

: 1.6

foot

Feed dog pitch : 1.6 mm

One

rowisof

urethane

feed dog

Presser

amount:

General

folded-edge

ming

—

ditto

Equipped

device

foot

—

blind

lifting

5.5

with

control

mm

hemming

automatic

mm

hem

300

Standard

For

2-needle

ing

Safety

overlook

stitching

3-needle safety stitching

runstitch

MO-2514E-AD4-300

MO-2514E-BB4-300

MO-2514E-BD4-300

MO-2514E-BE4-300

MO-2514E-BD6-300

MO-2514E-BE6-300

MO-2514E-CD4-300

MO-2514E-CD6-300

MO-2512E-CD4-300

MO-2512E-CD6-300

MO-2516E-AF4-300

MO-2516E-BD4-300

MO-2516E-BF4-300

MO-2516E-CD4-300

MO-2516E-CF4-300

MO-2516E-DD4-300

MO-2516E-DE4-300

MO-2516E-DF4-300

MO-2516E-DG4-300

MO-2516E-DH4-300

MO-2543E-BBD6-300

MO-2543E-DBD6-300

MO-2543E-FBD6-300

Usedasoverlock

by removing

one

machines

needle

- 5 -

Page 10

Code

Application

Subclass

Model

Name

Remarks

320

Gathering

330

Piping

For

For

For

For

For

1-needle

2-needle

safety

2-needle

safety

overlook

overlook

stitoh

overlook

stitoh

gathering

gathering

gathering

piping

piping

MO-2504E-0D6-320

MO-2504E-0D6-320/S098

MO-2514E-BD6-320

MO-2514E-BD6-320/S098

MO-2516E-BD4-320

MO-2516E-DD4-320

MO-2516E-DD6-320

MO-2516E-FF6-320

MO-2516E-RH6-320

M

0-2516E-B

MO-2516E-D

M

0-2516E-DD6-320/S097

MO-2516E-F

MO-2516E-R

MO-2514E-BD4-330

MO-2514E-BD4-330/M076

MO-2514E-BD4-330/M056

MO-2516E-DD4-330

MO-2516E-DD4-330/M076

MO-2516E-DD4-330/M056

D4-320/S097

D4-320/S097

F6-320/S097

H6-320/S097

Interlocked

Operated

1

nterlooked

Operated

Interlocked

Operated

For

general

For

ready-made

For

folding

For

general

For

ready-made

For

folding

with

presser

manually

with

presser

manually

with

presser

manually

tape

tape

foot

foot

foot

340

Tape

attaching

305

Overedging

adjustable

width

type

1-needle overlook

ing

2-needle

overlook

ing

2-needle overlook

&

tape

attaching

Safety

stitoh

tape

3-needle

attaching

1-needle

Overedging

throat

2-needle

Overedging

throat

Safety

Overedging

throat

safety

overlooking

width

plate

3.2~4.8

overlooking

width

plate

3.2

stitching

width

plate

3.2~4.8

tape

attach

tape

attach

gathering

attaching

stitoh

tape

adjustable

adjustable by

^ 4

adjustable

MO-2504E-0F6-340

MO-2504E-0H6-340

MO-2514E-BD6-340

MO-2514E-CD6-340

MO-2514E-BD6-320/G03

MO-2514E-BD6-320/S098/

G03

MO-2516E-DD4-340

MO-2516E-DF4-340

MO-2516E-DH4-340

MO-2543E-BBD6-340

MO-2543E-DBD6-340

MO-2543E-FBD6-340

MO-2504E-0D4-305/E05

by

MO-2514E-BD6-305/E06

MO-2514E-BD4-305/E08

MO-2516E-DD4-305/E07

by

Tape

width

With

tape

Tape

width

With

tape

This

model

into

code

been

code

tape attaching

Tape

With

Tape

With

320,

actually

340

becauseituses

width

tape

width

tape

: 4

mm

guide

: 4

mm

guide

shouldbeclassified

however,ithas

classified

foot

(G03).

into

the

: 5 ~ 10 mm

guide

: 4

mm

guide

1-needle

Overedging

by presser

Safety

stitching

Overedging

by presser

overlooking

width

foot

3.2~4.8

width

foot

3.2~4.8

adjustable

adjustable

MO-2504E-0D4-305/G14

MO-2516E-DD4-305/G15

- 6 -

Presser lifting

4

mm

Presser

lifting

4

mm

amount

amount

:

:

Page 11

•

360

For

4A0

For

square

tape

wool

knife)

Code

rolling-in

(Export:

Applicatlon

Safety

stitching

in

reinforcement

2-needle

For

double

rolling in

(clean finish

to

pocket

bags,

Overedging of

knit,

sweaters,

etc.

for

rolling

tape

chain

stitching

and

sewing

top

and

bottom)

etc.

medium-weight

bulky

material,

tape

Subclass

MO-2516E-DD4-360/N067

MO-2545E-DD4-360/N077

MO-2545E-ED4-360/N077

MO-2504E-0F6-4A0

MO-2514E-BD6-4AO

MO-2514E-BD7-4AO

Model

Name

Tape

width:10

Tape

width:20

Only

for

Provided

attaching

tape

guide.

Remarks

2400

with

presser

mm

mm

series.

tape

foot

and

4A3

For

wool (Square

with

knife

blade)

500

For

medium-

heavy-weight

3B0

corrugated

to

materials

Overedging of medium-weight

knit,

sweaters,

etc.

1-needle

Overedging of medium-

heavy-weight

bulky

material,

Imitation

medium-weight

be

donebyremoving

the

two

Safety

stitchingofmedium-

weight

materials,

bulky

overlocking

knit,

etc.

safety

stitching

materials

needles

material,

denim,

one

denim,

to

of

can

of

etc.

2-needle overlock piping &

gathering

MO-2504E-0F6-4A3

MO-2514E-BD6-4A3

MO-2514E-BD7-4A3

MO-2504E-0F6-500

MO-2504E-0H6-500

MO-2512E-CF6-500

MO-2512E-DD6-500

MO-2512E-DF6-500

MO-2516E-BD6-500

MO-2516E-CD6-500

MO-2516E-DD6-500

MO-2516E-DF6-500

MO-2516E-DH6-500

MO-2516E-FF6-500

MO-2516E-FG6-500

MO-2516E-FH6-500

MO-2514E-BD6-3B0

MO-2514E-BD6-3B0/S098

1

nterlocked

Operated

with

manually

presser

foot

Piping &

*3C0

For

*307

Larger

travel

*327

Larger

travel

Doeskin

upper

upper

gathering

looper

looper

Safety

stitch

piping

&

gathering

For

roll-in

industrial

stitching

towels,

of Doeskin

etc.

General-purpose 2-needle

overlock

medium-weight

2-needle

machine

overlock

for

knit

machine

light-

materials

gathering

for

MO-2516E-DD4-3B0

MO-2516E-DD4-3B0/S097

MO-2505E-0F5-3C0/K006

MO-2514E-BD4-307

to

MO-2514E-BD6-307

MO-2514E-BD6-327

MO-2514E-BD6-327/S098

Gathering

*337

Larger

travel

upper

2-needle

piping

looper

overlock

machine

for

MO-2514E-BD4-337

MO-2514E-BD6-337

Piping

Before ordering this machine, furnish us with your material samples for our confirmation.

- 7 -

Interlocked

Operated

1)

K006isexclusively

for

sary

with

manually

Doeskin,

when

factory.

2)

Only

MO-2500 series

Max. speed :

presser

and

shipped

6500

foot

used

unneces

from

s.p.m.

Page 12

Code

Application

Subclass

Model

Name

Remarks

*387

Larger

upper

travel

Piping & gathering

*347

Larger upper looper

travel. Tape attaching

306

For JE, With lips

Attachments

EXAMPLES

No.

1

OF

Blind hemming attachment + suction-type side

looper

COMBINATION

2-needle

overlook

machine

piping & gathering

2-needle

tape

overlook

attaching

machine

Feed dog with lip.

Throat

Sleeve

Rolling in

plate with lip

placket

Examplesofcombination

pattern

chain-off

thread

seamer

for

for

cutter

MO-2514E-BD6-3B7

MO-2514E-BD6-3B7/S098

MO-2514E-BD6-347

MO-2504B-0D4-306

MO-2504E-0D5-300/S084B

MO-2504B-0D4-300/Z072

With

tape

attaching

and

tape

guide

(Q056)

Soft

chain

Subclass

MO-2505E-0D4-210/L012/T023

model

name

foot

2

3

4

5

Piping One-touch

type

chain-off

Gathering (2-needle overlook)

Manual

chain-off

Manual

gathering

thread

cutter

galhering

(2-needle

(2-needle

Automatic

overlook)

overlook)

chain-off thread cutter + Tape attaching presser foot

6 Safety stitching (DD4)

7

8

9

10

11

Safety stitching (FF6) + Presserfoot for

Safety stitching (FF6) + Square knife with corrugated blade + Tractor

presser

foot

Soft chain + chain-off thread rolling-in attachment

Safety stitch machine with threader

cutter

Machine for wool + One-touch type chain-off thread cutter (for BD7)

-i-

Presserfoot for

MO-2500 series models are shown as examples.

thread

cutter

chain-off

attachment +

thread

One-touch

attachment+One-touch

sewing

sharp curves

sewing

sharp curves

(DD4)

Suction-type flat

cutter

type

type

M

0-2514E-B

M

0-2516E-D

MO-2514E-BD6-320/T016

MO-2514E-BD6-320/S098/T006

MO-2514E-BD6-320/S098/T006/

G02

MO-2516E-DD4-300/G12

MO-2516E-FF6-500/G13

MO-2516E-FF6-503/G09

MO-2504B-0D4-300/Z072

MO-2516F-DD4-300/T022

MO-2514E-BD7-4A0/T006

MO-2514E-BD7-4A3/T006

D4-330/T006

D4-330/T006

- 8 -

Page 13

5.

MO-2500/2400

Machine

The

gauge

sizes of 1-needle overlock machines, 2-needle overlook machines,

and safety stitch machines are grouped so

a

glance.

These lists may be conveniently used to locate a subclass machine by gauge

size.

Lists

Series

that

they may be Identified at

Subclass

E

- 9 -

Page 14

Subclass

MO-2500

SERIES

machine

1-Needle

list

Overlock

Machine

^Before ordering this machine, furnish us with

material samples

for

our

confirmation.

your

Description

Stitch

type

0A5

0D5

0F5

0A4

0C4

0D4

I

o

0E4

0F4

0H4

MO-2501

501

MO-2502

502

MO-2502E-0A4-150

MO-2502E-0D4-200

MO-2502E-0D4-300

MO-2503

503

MO-2503E-0D4-200

M0-2503E-OD4-300

MO-2503E-0F4-3G0

MO-2504

504

MO-2504E-0A5-150

MO-2504E-0D5-300/S084B

MO-2504E-0A4-150

MO-2504E-0C4-300

MO-2504E-0D4-200

MO-2504E-0D4-300

MO-2504S-0D4-3G0

MO-2504B-0D4-306

MO-2504E-0E4-300

MO-25G4E-GF4-3GG

MO-25G4E-GH4-3GG

'MO-2505E-0F5-3C0/K006

MO-2505E-0D4-210

MO-2505E-0D4-210/L012

MO-2505

505

0D6

0F6

0H6

MO-25G4E-GD6-3GG

MO-25G4E-GD6-32G

MO-25G4E-GD6-32G/SG98

MO-25G4E-GF6-5GG

MO-25G4E-GF6-4AG

MO-25G4E-GF6-4A3

MO-25G4E-GH6-5GG

Page 15

MO-2500

SERIES

2-Needle

Overlock

Machine

Description

\

Stitch

«

N

v>

0)

O)

3

CJ

ZA5

XB5

AB4

AC4

AD4

BB4

BD4

BE4

BD6

type

MO-2506

508

MO-2506E-BD4-200

MO-2506E-BD4-300

MO-2507

507

MO-2512

512

MO-2514

514

MO-2514E-ZA5-100

MO-2514E-XB5-100

MO-2514E-AB4-100

MO-2514E-AC4-300

MO-2514E-AD4-300

MO-2514E-BB4-300

MO-2514E-BD4-200

MO-2514E-BD4-300

MO-2514E-BD4-330

MO-2514E-BD4-307

MO-2514E-BD4-337

MO-2514E-BE4-300

MO-2514E-BD6-300

MO-2514E-BD6-320

MO-2514E-BD6-320/S098

MO-2514E-BD6-3BO

MO-2514E-BD6-3B0/S098

MO-2514E-BD6-307

MO-2514E-BD6-327

M

0-2514E-B

MO-2514E-BD6-337

MO-2514E-BD6-3B7

D6-327/S098

MO-2514E-BD6-3B7/S098

MO-2514E-BD6-340

MO-2514E-BD6-347

MO-2514E-BD6-4A0

MO-2514E-BD6-4A3

BE6

MO-2514E-BE6-300

Page 16

Description

Stitch

type

MO-2506

506

MO-2507

507

MO-2512

512

MO-2514

514

BD7

CD4

CD6

CF6

DD6

DF6

o

o>

s

CO

a

MO-2506E-CD4-300

MO-2507E-DF6-500

MO-2512E-C04-300

MO-2512E-CD6-300

MO-2512E-CF6-500

MO-2512E-DD6-500

MO-2512E-DF6-500

MO-2514E-BD7-4AO

MO-2514E-BD7-4A3

MO-2514E-CD4-300

MO-2514E-CD6-300

Page 17

MO-2500

Gauge

size

Description

Stitch

SERIES

type

Safety

MO-2515

Stitch

515

Machine

MO-2516

516

MO-2540

540

Special

3-needl8

safety

MO-2543

stitch

machine

Special

2-needle

double

MO-2545

chain

stitch

machine

AF4

BD4

BF4

BD6

CD4

CF4

CD6

DD4

MO-2515E-BD4-300

MO-2515E-DD4-300

MO-2516E-AF4-300

MO-2516E-BD4-300

MO-2516E-BD4-320

MO-2516E-BD4-320/S097

MO-2516E-BF6-300

MO-2516E-BD6-500

MO-2516E-CD4-300

MO-2516E-CF4-300

MO-2516E-CD6-500

MO-2516E-DD4-100

MO-2516E-DD4-300

MO-2516E-DD4-320

MO-2516E-DD4-320/S097

MO-2516E-DD4-330

MO-2516E-DD4-3B0

MO-2516E-DD4-3B0/S097

MO-2516E-DD4-360/N067

MO-2545E-DD4-360/N077

DE4

DF4

DG4

DH4

DD6

DF6

MO-2516E-DE4-300

MO-2516E-DF4-300

MO-2516E-DG4-300

MO-2516E-DH4-300

MO-2516E-DD6-320

MO-2516E-DD6-320/S097

MO-2516E-DD6-500

MO-2516E-DF6-500

Page 18

Description

Stitch

type

MO-2515

515

MO-2516

516

MO-2540

540

Special

3-needle

MO-2543

safety

stitch

machine

Special

2-needle

MO-2545

double

chain

stitch

machine

DH6

ED4

FF6

MO-2515E-FF6-500

MO-2516E-DH6-500

MO-2545E-ED4-360/N077

MO-2516E-FF6-100

MO-2516E-FF6-320

MO-2516E-FF6-320/S097

MO-2516E-FF6-500

FG6

FH6

RH6

MO-2516E-FG6-500

MO-2516E-FH6-500

MO-2516E-RH6-100

MO-2516E-RH6-320

MO-2516E-RH6-320/S097

«

BBD6

'Tn

e>

CD

3

cs

O

DBD6

MO-2543E-BBD6-300

MO-2543E-BBD6-340

MO-2543E-DBD6-300

MO-2543E-DBD6-340

FBD6

MO-2543E-FBD6-300

MO-2543E-FBD6-340

Page 19

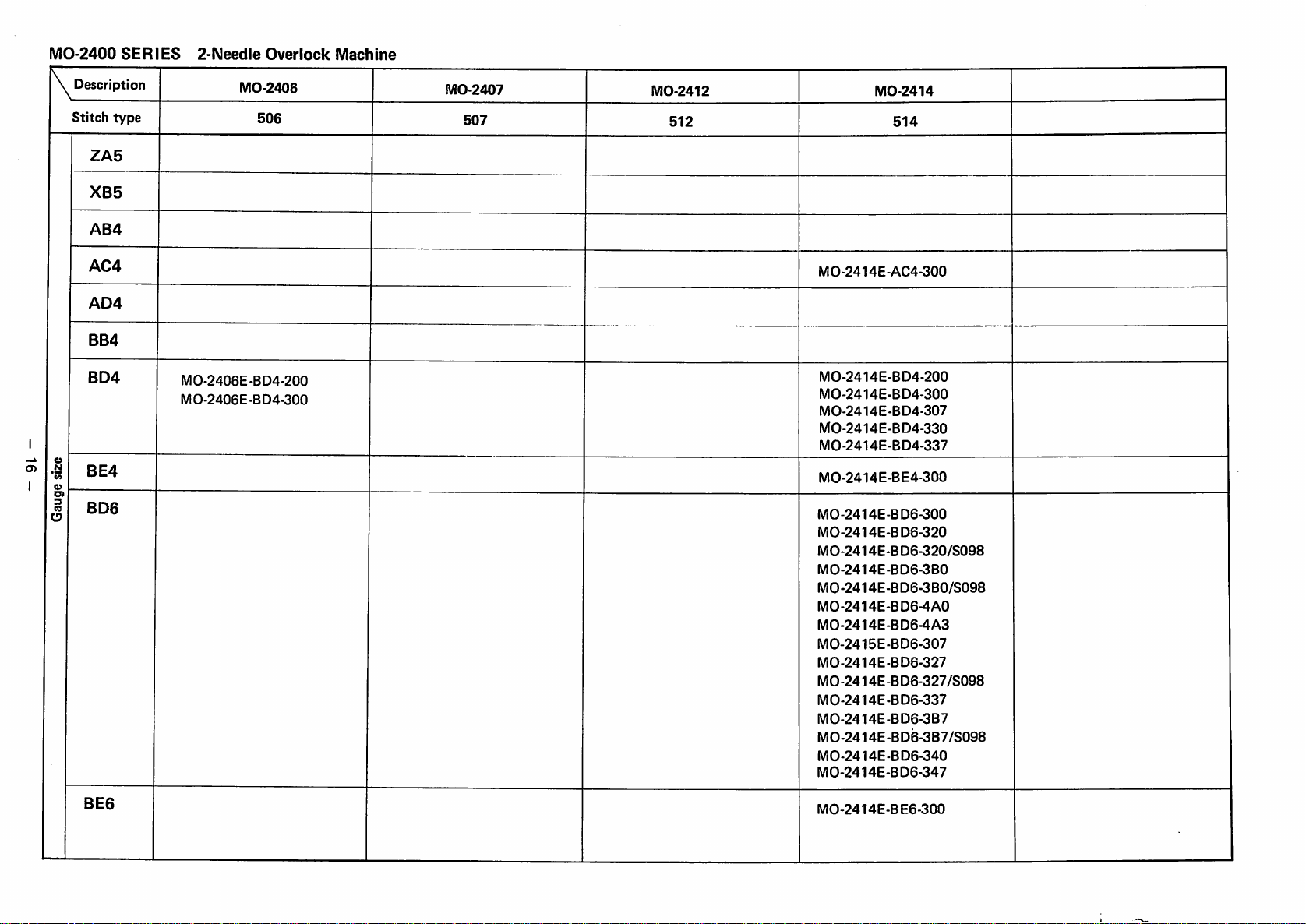

MO-2400

SE

RIES

1

-Needle

Overlook

Machine

Description

\

Stitch

type

OAS

CDS

MO-2401

501

MO-2402

502

MO-2403

503

MO-2404

504

MO-2404E-0A5-150

MO-2404E-0D5-300/S084B

MO-2405

505

0F5

0A4

0C4

0D4

I\/I0-2401

E-0D4-300

MO-2402-DD4-200

MO-2403E-0D4-2Q0

MO-2403E-004-300

MO-2404E-0C4-300

MO-2404E-0D4-200

IV1O-2404E-0D4-300

MO-2405E-0D4-210

MO-2405E-0D4-210/L012

MO-2404E-0D4-306

0E4

I

(71

0F4

Q>

N

v>

a>

0H4

o>

3

o

CDS

MO-2403E-0F4-300

MO-2404E-0E4-300

MO-2404E-0F4-300

MO-2404E-0D6-300

MO-2404E-0D6-320

MO-2404E-0D6-320/S098

0F6

0H6

-

MO-2404E-0F6-500

MO-2404E-0F6-4A0

MO-2404E-0F6-4A3

MO-2404E-0H6-500

Page 20

MO-2400

SERIES

2-Needle

Overlock

Machine

Description

\

Stitch

type

MO-2406

506

MO-2407

507

MO-2412

512

MO-2414

514

ZA5

XB5

AB4

AC4

MO-2414E-AC4-300

AD4

BB4

BD4

MO-2406E-BD4-200

MO-2406E-BD4-300

MO-2414E-BD4-200

MO-2414E-BD4-300

MO-2414E-BD4-307

l\/IO-2414E-BD4-330

Q>

a>

BE4

'«n

a>

O)

3

eg

BD6

CD

MO-2414E-BD4-337

MO-2414E-BE4-300

MO-2414E-BD6-3GO

MO-2414E-BD6-320

MO-2414E-BD6-320/S098

MO-2414E-BD6-3BO

MO-2414E-BD6-3B0/S098

MO-2414E-BD6-4AO

MO-2414E-BD6-4A3

MO-2415E-BD6-307

MO-2414E-BD6-327

MO-2414E-BD6-327/S098

MO-2414E-BD6-337

MO-2414E-BD6-3B7

MO-2414E-BD6-3B7/S098

MO-2414E-BD6-340

MO-2414E-BD6-347

BE6

MO-2414E-BE6-300

Page 21

Description

MO-2406

MO-2407

MO-2412

MO-2414

0)

OI

3

(S

O

Stitch

BD7

CD4

CD6

CF6

DD6

DF6

type

506

MO-2406E-CD4.300

506

MO-2407E-DF6-500

512

MO-2412E-CD4-300

MO-2412E-CD6-300

MO-2412E-DD6-500

MO-2412E-DF6-500

514

MO-2414E-BD7-4AO

M0-2414E-BD7-4A3

MO-2414E-CD4-300

MO-2414E-CD6-300

Page 22

MO-2400

Gauge

size

SERIES

Safety

Stitch

Machine

Description

\

Stitch

type

AF4

BD4

BF4

BD6

CD4

CF4

CD6

00

1

DD4

MO-2415E-BD4-300

MO-2415E-DD4-300

MO-2415

515

MO-2416

516

MO-2416E-BD4-300

MO-2416E-BD4-320

MO-2416E-BD4-320/S097

MO-2416E-BF4-300

MO-2516E-CD4-300

MO-2416E-DD4-100

MO-2416E-DD4-300

MO-2416E-DD4-320

MO-2416E-DD4-320/S097

MO-2416E-DD4-330

MO-2416E-DD4-3BO

MO-2416E-DD4-3B0/S097

MO-2416E-DD4-360/N067

MO-2440

540

MO-2440E-DD4-300

Special

3-needle

MO-2443

safety

stitch

machine

MO-2445

Special

2-needle

double

chain

MO-2445E-DD4-360/N077

stitch

machine

DE4

DF4

DG4

DH4

DD6

DF6

DH6

MO-2416E-DE4-300

MO-241

MO-2416E-DG4-300

MO-2416E-DH4-300

MO-2416E-DD6-320

MO-2416E-DD6-320/S097

MO-2416E-DD6-500

MO-2416E-DF6-500

MO-2416E-DH6-500

BE-DF4-300

Page 23

Description

Stitch

type

MO-2415

515

MO-2416

516

MO-2440

540

Special

3-needle

MO-2443

safety

stitch

machine

Special

2-neeclle

double

MO-2445

chain

stitch

machine

ED4

FF6

MO-2415E-FF6-500

MO-2416E-FF6-100

MO-2445E-ED4-360/N077

MO-2416E-FF6-320

MO-2416E-FF6-320/S097

MO-2416E-FF6-500

FG6

FH6

RH6

MO-2416E-FG6-500

MO-2416E-FH6-500

MO-2416E-RH6-100

MO-2416E-RH6-320

MO-2416E-RH6-320/S097

BBD6

(O

DBD6

o>

3

CO

CD

FBD6

MO-2443E-BBD6-300

MO-2443E-BBD6-340

MO-2443E-DBD6-300

MO-2443E.DBD6-340

MO-2443E-FB06-300

MO-2443E-FBD6-340

Page 24

6

Adjustment

the

Looper

Refer to

Note that these adjustment

somewhat

Perform

Needle

Timing

the

adjustment dimensions when changing gaugesizes.

accordingtosewing requirements.

adjustmentinaccordance

of

Height

values

are theoretical

with

actual

and

values,

conditions.

and may vary

E

-

20

-

Page 25

Adjustment of

1'needle overrode 2-rMedte 3-needleufefy

machine/ safely overtock machine stheh machine

stitch

machine

the

needle height and looper timing

2-needle

overlock

2'needle

nverlock

rrttchlne

machine

; 5

!

\V

e

1

u

S

•«

®

2A14E

2A14E

2A14E

_c

E

2A14E

je

2A14E

t

e

2A14E

2^12E

2A12E

2A12E

2A16E

c

2A16E

E

2A16E

1

2A43E

2A4SE

Sobclui

2A04E

2A04E

Z^4E

4A0

2A14E

007

4A0

Oescripljon

OAS~0F5

OAS-0F5

0D6

0F4~0H4

0F6~0H6

0F6

ZA5

XB5

AB4~A04

BB4~BD4

BD6

BE4

8E6

804-8E4

806-BE6

806

BD7

CD4

CDS

CD4

CD6

CF6

DD6~DF6

--AE4

--AE6

AF4~AH4

AF6~AH6

RH6

BBD6~FBD6

DD4.

ED4

Vnttdit

2-nMdlt

(lefti

® ®

ID

10

9.5

10

10

10

10

10

9.5

10.2

10.5

10.5

10.5

10

10

to

10

10

NMdIetitight

2-needlt

©

-

-

-

10

9,7

9

g

9

8.5

8.9

9.2

9.2

8.9

-

- 11

-

9

-

Uppar

(cantrsi

htlghl

®

11

11

10.2

n

10.7

10.7

10.5

10.3

10.2

10.5

10.3

10.8

10.8

11

11

10.2

-

Ippppr

«s)u»)

Proitction

upper

For

needle

For

needle

For

needfe

Upper

looper

componertts

righl

right

nght

Height

pu>

45.02

49».

47.3

45.02

46.60

46.89

47.3

47.3

47.3

47.3

46.6

46.6

46.6

45.02

46.9

46.9

47.3

of

®

-

of

iooper

©

4

4

4.5

4

4.8

4.8

4.3

4.3

4.5

4.3

the

4.3

the

3.6

the

4

4

4

4

4.5

-

Patliion

guide

of

support

asm.

©

6.5

5.5

7

7

6.5

6

5.5

6.5

5.5

6

6

7

6.5

5

6.5

-

Cen(cr-to-

eenier

looper

®

38

(118314011

-

-

38

(11831401)

-

-

-

-

-

-

-

-

-

38

(11831401)

-

38

(11B31401)

-

- -

erm

of

Center*to<

center

looper

®

-

39

(11831500)

39

(11831500)

-

39

(118315001

39

(11831500)

39

(11831500)

39

(11831500)

39

(11831500)

39

(11831500)

39

(11831500)

39

(118315001

39

(11831500)

-

39

(11831500)

-

39

(118315001

arm

Return

of

of

lower

looper

(ceniral

ealuel

lower

Radius

of

looper

®

4

4

3.5

4

4

4

32

3.5

3.5

3.2

3.5

2.6

2,6

4

4

3.5

4

-

66.4

66.4

66.9

66.4

66.4

66.4

66.4

66.4

66.9

66.4

66.4

66.4

66.4

66.4

66.4

66.4

66.4

-

'

11893609

-5-5

a

Standard.

for

wool

2Af2£.

2414E-BD7

heevy-we^hl

and

large

2a16^-RH6

over

edge

materials

width

For

Sundard.

ZAI6E-RH6

For

2-needle

heavy>weigh{

large

oweredge

11831500

39

overlock

materials,

width

-22-

machines.

and

(Note)

All

dimensions

i

Page 26

7

MO-2500/2400

Machine

•

Standard

This list covers

the

are of stitch types, 504, 514 (or 512), and 516 conforming to Stitch

Type Standard,

with

For subclass machines of other stitch types than the above three, refer

to "List of subclass machines classified by stitch type" on page31, and

"Special usage subclass machine specification list" on page 28.

Specifications List of Subclass Machinesfor Special Applications

This list shows

gauge

provide

Specifications List of Subclass Machines Classified by Stitch Type

This list describes

chines

for

standard

different

parts

special

other

special

Subclass

subclass

gauge sizes.

or

specifications.

than

applications.

Specifications

Machine

the

(IViO-2504,

the

specifications and applications of models in which

other

the

the

Specifications

specifications, applications, gauge sizes, etc.ofall

machine

parts

specifications

standard

models.

MO-2514 (or MO-2512), and

are

replaced

subclass

Series

List

The

standard

or

added

and

applicationsofsubclass ma

machines

to

and

subclass

make

subclass

Subclass

List

machines

IVIO-2516)

the

machines

models

B

-

23

-

Page 27

1.

MO-2500/2400

1-Needle

Overlock

Machine

Standard

subclass

machine

specifications

list

Sewing

qoppH Upper : Max. speed

No.

1

2

3

4

5

6

to

7

8

9

Model

MO-2A04E-0A5-150

MO-2A04E-0A4-150

MO-2A04E-0C4-300

MO-2A04E-0D4-200

MO-2A04E-0D4-3Q0

MO-2A04E-0E4-300

MO-2A04E-0F4-300

MO-2A04E-0H4-300

MO-2A04E-0D6-3G0

speea

(s.p.m.)

MO-2500

8500

8000

8500

8000

8500

8000

8500

8000

8500

8000

8500

8000

7500

7000

7500

7000

8500

8000

,,

. |^ormalspaed

MO-2400

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

No.

needles

No.

threads

1

x3

1 X 3

1 x 3

1 X 3

1 X 3

1 X 3

1

x3

1 X 3

1 X 3

of

of

x

Needle

(standard)

DCxi

#8

DCxi

#8

00x27

#11

00x27

#9

00x27

#11

00x27

#11

00x27

#11

00x27

#11

00x27

#11

Needle

X

Overedging

width

(mm)

Ox

1.6

Ox

1.6

0x2.4

0

x3.2

0x3.2

0x4.0

Ox

4.8

0 X

6.4

0x3.2

gauge

Presser

lifting

amount

(mm)

5

5

7

5.5

7

7

7

7

7

Applications

Closing

stitchonpanty

of

extremely

Roll-in

light-weight

seamingofsocks

crepedechine,

Overedgingofgeneral

Overedgingofgeneral

'Especially

touch.

Overedgingofgeneral

'Especially

touch.

for

for

Overedgingofgeneral

weight

materials

Overedgingofgeneral

weight

materials

Overedgingofgeneral

weight

materials

Overedgingofmedium-weight

knitwork,

bulky

silk,

those

those

with

with

with

materials

hose

materialsinscarfs,

toes,

rayon,

fabrics,

fabrics,

requiring

fabrics,

requiring

fabrics,

greater

fabrics,

greater

fabrics,

greater

toes,

and

handkerchiefs,

nylon,

etc.

knitwork,

knitwork,

good

knitwork,

good

knitwork,

overedging

knitwork,

overedging

knitwork,

overedging

general

roll-in

jersey,

jersey,

appearance

jersey,

appearance

mediumwidth.

mediumwidth.

mediumwidth.

fabrics,

seaming

etc.

longeries,

etc.

etc.

and

etc.

and

Feed

rubber

Feed

Remarks

dog

dog

with

urethane

(Standard

type)

10

11

MO-2A04E-0F6-500

MO-2A04E-0H6-500

7500

7000

7500

7000

6500

6000

6500

6000

1 X 3

1 X 3

00x27

#14

00x27

#14

Ox

0 X

4.8

6.4

7

7

Overedgingofmedium-weight

knitwork,

bulky

materials.

Overedgingofmedium-weight

knitwork,

bulky

materials.

general

general

fabrics,

fabrics,

Page 28

2-Needle

Overlook

Machines

No.

1

2

3

4

5

6

7

8

9

Model

MO-2A14E-ZA5-100

MO-2A14E-XB5-100

MO-2A14E-AB4-100

MO-2A14E-AD4-300

MO-2A14E-B

MO-2A14E-BD4-200

MO-2A14E-BD4-300

l\/IO-2A14E-BE4-300

MO-2A14E-CD4-300

84-300

Sewing

snppri Upper : Max. speed

y .

(s.p.m.) ^

MO-2500

B500

BOOO

B500

BOOO

BOOO

7500

BOOO

7500

BOOO

7500

BOOO

7500

BOOO

7500

BOOO

7500

7500

7000

..

Lower:Normal

MO-2400

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

speed

No.

needles

No.

threads

2x4

2x4

2x4

2x4

2x4

2x4

2x4

2x4

2x4

of

of

Needle

x

(standard)

#9

#9

#11

DCx27

#11

DCx27

#9

DCx27

#11

DCx27

#11

DCx27

#11

DCxC46

#9

DCxC47

DCx3

DCx3

Needle

gauge

XOveredging

width

(mm)

O.Bx

1.6

1.2x2.0

1.6X2.0

1.6X3.2

2.2X2.0

2.2X3.2

2.2X3.2

2.2X4.0

2.6X3.2

Presser

lifting

amount

(mm)

5

5

6.5

6.5

6.5

5.5

6.5

6.5

6.5

Applications

Seamingofpanty

Seamingofpanty

Overedgingofknitwork,

Overedgingofknitwork,

Overedgingofmedium-weight

materials.

Overedging of

jersey,

and

requiring

Overedgingofknitwork,

jersey,

good

and

Overedgingofknitwork,

jersey,

and

Overedgingofknitwork,

jersey,

and

knit

knit

knit

knit

knitwork,

hose

hose

materials.

appearance

materials

materials

materials

jersey,

jersey,

medium-weight

medium-weight

medium-weight

medium-weight

and

and

materials

'Especially

and

touch.

the

the

like

like

and

materials,

for

those

materials,

materials,

materials,

knit

One

With

One

With

Remarks

rowoffeed

urethane

rowoffeed

urethane

dog:

rubber

dog:

rubber

10

MO-2A14E-BD6-300

11

MO-2A14E-BE6-300

12

13

14

15

16

17

MO-2A14E-CD6-300

MO-2A12E-CD4-300

MO-2A12E-CD6-300

MO-2A12E-CF6-500

MO-2A12E-DD6-500

MO-2A12E-DF6-500

BOOO

7500

BOOO

7500

7500

7000

7500

7000

7500

7000

7500

7000

7500

7000

7500

7000

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

2x4

2x4

2x4

2x4

2x4

2x4

2x4

2x4

DCx27

#11

DCx27

#11

DCx27

#11

DCx27

#11

DCx27

#11

DCx27

#14

DCx27

#14

DCx27

#14

2.2X3.2

2.2X4.0

2.6X3.2

2.6X3.2

2.6X3.2

2.6X4.B

3.0X3.2

3.0X4.B

6.5

6.5

6.5

6.5

6.5

6.5

6.5

6.5

Overedgingofbulky

Overedgingofbulky

Overedgingofbulky

Overedgingofknitwork,

jersey,

and

knit

Overedgingofbulky

materials,

materials,

materials,

materials

materials,

medium-weight

Overedgingofmedium-weight

jersey,

and

knit

width

materials

with

Overedgingofmedium-weight

fabrics,

etc.

Overedgingofmedium-weight

fabrics,

etc.

with

greater

overedging

knitwork,

knitwork,

knitwork,

knitwork,

materials,

greater

materials,

materials,

width

jersey,

jersey,

jersey,

materials,

jersey,

knitwork,

overedging

general

general

etc.

etc.

etc.

etc.

Imitation

Imitation

Imitation

Imitation

Imitation

safety

safety

safety

safety

safety

stitch

stitch

stitch

stitch

stitch

Page 29

Safety

Stitch

Machines

No.

1

2

3

4

5

6

7

8

9

Model

MO-2A16E-AF4-300

MO-2A16E-BD4-300

MO-2A16E-BF4-300

MO-2A16E-CD4-300

MO-2A16E-CF4-300

MO-2A16E-DD4-100

Ma2Al6E-DD4-300

MO-2A16E-DE4-300

MO-2A16E-DF4-300

fP . Lower :

(s.p.m.)

MO-2500

7000

6500

7500

6500

7000

6500

7500

7000

7000

6500

7508

7000

7500

7000

7500

7000

7000

6500

Uppt;

Max.

speed

Normal

MO-2400

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

speed

No.

needles

No.

threads

2x5

2x5

2x5

2x5

2x5

2x5

2x5

2x5

2x5

of

of

Needle

x

(standard)

DCx27

#11

DCx27

#11

DCx27

#11

DCx27

#11

DCx27

#11

DCx27

#9

DCx27

#11

DCx27

#11

DCx27

#11

Needle

X

Overedging

width

(mm)

1.6X4.8

2.0X3.2

2.0X4.8

2.5X3.2

2.5X4.8

3.2X3.2

3.2X3.2

3.2X4.0

3.2X4.8

gauge

Presser

lifting

amount

(mm)

7

7

7

7

7

4.5

7

7

7

Applications

Safety

stitching of general fabrics (men's shirts,

jersey,

knit,

etc.)

Safety

stitching of general fabrics (men's shirts,

jersey,

knit,

etc.)

Safety

stitching of medium-weight materials

greater

overedging

Safety

stitchingofmen's

Safety

stitchingofmen's

Safety

stitch

weight

materials

Safety

stitching

and

knit

materials

Safety

stitching

and

knit

materials

Safety

stitching of fabrics such as in

and

knit

materials

width

shirts,

shirts,

overedging of general fabrics

suchasgeorgette

of fabrics

such

suchasjersey

of fabrics

such

suchasjersey

suchasjersey

jersey,

jersey,

as in

as in

etc.

etc.

men's

men's

men's

with

and

shirts,

shirts,

shirts,

light

Remarks

Rear-hinged

presser

foot

10

11

12

13

14

15

16

17

MO-2A16E-DG4-300

MO-2A16E-DH4-300

MO-2A16E-BD6-500

MO-2A16E-CD6-500

MO-2A16E-DD6-500

MO-2A16E-DF6-500

MO-2A16E-DH6-500

MO-2A16E-FF6-100

7000

6500

7000

6500

7500

7000

7500

7000

7500

7000

7000

6500

7000

6500

7000

6500

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

2x5

2x5

2x5

2x5

2x5

2x5

2x5

2x5

DCx27

#11

DCx27

#11

DCx27

#16

DCx27

#16

DCx27

#16

DCx27

#16

DCx27

#16

DCx27

#9

3.2X5.4

3.2X6.4

2.0X3.2

2.5X3.2

3.2X3.2

3.2X4.8

3.2X6.4

4.8X4.8

4.5

Safety

7

7

7

7

7

7

7

stitching

and

knit

Safety

stitching

and

knit

Smaller

weight

materials,

Smaller

weight

materials,

Smaller

weight

materials,

Safety

stitching

weight

materials.

Safety

stitching

weight

materials.

Light-weight material

fabrics

and

overedging

materials

of fabrics

such

suchasjersey

of fabrics such as in men's shirts,

materials

needle

needle

needle

gauge

jersey,

gauge

jersey,

gauge

jersey,

and

and

gerogette

width

suchasjersey

safety

stitchingofheavy

etc.

safety

stitching

etc.

safety

stitchingofheavy

etc.

powerful

powerful

safety

stitching of general

with

greater

feeding of heavy

feedingofheavy

as in

men's

of heavy

needle

shirts,

gauge

and

Feed

dog

Feed

dog

Rear-hinged

P=2,0

P=2,0

presser

mm

mm

foot

Page 30

Safety

Stitch

Machines

Sewing

sofifiH

No.

18

19

20

21

to

Model

MO-2A16E-FF6-500

MO-2A16E-FG6-500

MO-2A16E-FH6-500

MO-2A16E-RH6-100

speeu

(s.p.m.)

Upper : Max. speed

Lovj,er

MO-2500

7000

6500

7000

6500

7000

6500

6000

5500

: Normalspaed

MO-2400

6500

6000

6500

6000

6500

6000

6000

5500

No.

needles

No.

threads

2x5

2x5

2x5

2x5

of

Needle

x

(standard)

of

DCx27

#16

DCx27

#16

DCx27

#16

DCx27

#9

Needle

X

Overedging

width

(mm)

4.8X4.8

4.8X5.4

4.8X6.4

6.8X6.4

gauge

Presser

lifting

amount

(mm)

7

7

7

4.5

Safety

stitching

weight

materials

Safety

stitching

weight

materials

Safety

stitching

weight

materials

Light-weight

fabrics,

georgette,

and

overedging

and

and

and

material

etc.

width

Applications

powerful

powerful

powerful

safety

stitchingofgeneral

with

greater

feedingofheavy

feedingofheavy

feedingofheavy

needle

gauge

Remarks

Feed

dog

Feed

dog

Feed

dog

Rear-hinged

for

sharp

P=2,0

P=2,0

P=2,0

curve

mm

mm

mm

presser

stitch

foot

Page 31

2.

Special

usage

subclass

machine

specification list

No.

2

3

4

5

6

7

8

9

1

Model

MO-2AQ5E-0D4-210

MO-2A05E-0D4-210

MO-2A04E-0D6-320

MO-2A04E-0D6-320

MO-2A14E-BD6-320

MO-2A14E-BD6-3BO

MO-2A14E-BD6-320

MO-2A14E-BD6-3BO

MO-2A16E-BD4-320

/L012

/S098

/S098

/S098

^ . Lower :

(s.p.m.)

MO-2500

8500

8000

8500

8000

5500

5000

5500

5000

5500

5000

5500

5000

5500

5000

5500

5000

5500

5000

Upper:Max.

speed

Normal

MO-2400

6500

6000

6500

6000

5500

5000

5500

5000

5500

5000

5500

5000

5500

5000

5500

5000

5500

5000

speed

No.

needles

No.

threads

1 X 3

1 X 3

1 X 3

1 X 3

2x4

2x4

2x4

2x4

2x5

of

Needle

x

(standard)

of

DCx27

#9

DCx27

#9

DCx27

#11

DCx27

#11

DCx27

#11

DCx27

#11

DCx27

#11

DCx27

#11

DCx27

#11

Needle

X

Overedging

width

(mm)

0 X

3.2

0x3.2

Ox

3.2

Ox

3.2

2.2X3.2

2.2X3.2

2.2X3.2

2.2X3.2

2.0X3.2

gauge

Presser

lifting

amount

(mm)

5.5

5.5

7

7

6.5

6.5

6.5

6.5

7

Applications

Blind

hemmingofknitwork,

Blind

hemmingofknitwork,

Gatheringoflight-weight

Gatheringoflight-weight

Gatheringoflight-weight

Piping&gatheringoflight-weight

cloth,

etc.

Gatheringoflight-weight

Piping&gatheringoflight-weight

cloth,

etc.

Safety

stitch

georgette,

gatheringoflight-weight

etc.

jersey,

Jersey,

knitwork,

knitwork,

knitwork,

knitwork,

etc.

etc.

broad

broad

broad

knitwork,

broad

knitwork,

general

cloth,

cloth,

cloth,

broad

cloth,

broad

etc.

etc.

etc.

etc.

fabrics,

With

control

device)

Hand

Hand

Hand

Remarks

L0121

hemming

type

type

type

Folded-edge

10

11

12

13

14

15

16

17

MO-2A16E-BD4-320

MO-2A16E-DD4-320

MO-2A16E-DD4-3BO

MO-2A16E-DD4-320

MO-2A16E-DD4-3BO

MO-2A16E-DD6-320

MO-2A16E-DD6-320

MO-2A16E-FF6-320

/S097

/S097

/S097

/S097

5500

5000

5500

5000

5500

5000

5500

5000

5500

5000

5500

5000

5500

5000

5500

5000

5500

5000

5500

5000

5500

5000

5500

5000

5500

5000

5500

5000

550C

5000

5500

5000

2x5

2x5

2x5

2x5

2x5

2x5

2x5

2x5

DCx27

#11

DCx27

#11

DCx27

#11

DCx27

#11

DCx27

#11

DCx27

#11

DCx27

#11

DCx27

#11

2.0X3.2

3.2X3.2

3.2X3.2

3.2X3.2

3.2X3.2

3.2X3.2

3.2X3.2

4.8X4.8

Safety

stitch

7

7

7

7

7

7

7

7

georgette,

Safety

georgette,

Safety

general

Safety

fabrics,

Safety

general

Safety

fabrics,

Safety

fabrics,

Safety

fabrics,

gatheringoflight-weight

etc.

stitch

gathering

etc.

stitch

piping&gatheringoflight-weight

fabrics,

stitch

gatheringoflight-weight

georgette,

stitch

piping&gatheringoflight-weight

fabrics,

stitch

gatheringoflight-weight

georgette,

stitch

gatheringoflight-weight

georgette,

stitch

gatheringoflight-weight

georgette,

of light-weight general

georgette,

etc.

etc.

georgette,

etc.

etc.

etc.

etc.

*For

larger

general

general

general

general

general

overedging

fabrics,

fabrics,

width

Hand

Hand

Hand

Hand

type

type

type

type

Page 32

Sp6cial

usagesubclass machinespecification list

IMo.

18

19

20

21

Sewing ,,

Model

MO-2500

I\/I0-2A16E-FF6-320

MO-2A16E-RH6-320

MO-2A16E-RH6-320

MO-2A14E-BD4-330

22

23

24

25

26

27

28

29

30

31

32

33

MO-2A16E-DD4-330

M0-2A43E-BB06-300

MO-2A43E-BBD6-340

MO-2A43E-DBD6-300

MO-2A43E-DB06-340

MO-2A43E-FB06-300

MO-2A43E-FB06-340

MO-2A16E-OO4-360

MO-2A45E-OO4-360

MO-2A45E-E04-360

MO-2A04S-004-300

MO-2A04E-005-300

/S097

/S097

/N067

/N077

/N077

/S084B

5500

5000

5500

5000

5500

5000

6500

6000

6500

6000

7000

6500

7000

6500

7000

6500

7000

6500

7000

6500

7000

6500

6000

5500

6000

5500

6000

5500

8500

8000

2000

sr :

Max.

Normal

speed

9r :

-

MO-2400

5500

5000

5500

5000

5500

5000

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

6500

6000

6000

5500

6000

5500

6000

5500

6500

6000

2000

speed

No.

needles

No^

threads

2x5

2x5

2x5

2x4

2x5

3x6

3x6

3x6

3x6

3x6

3x6

2x5

2x4

2x4

1

x3

1 X 3

of

of

x

Needle

(standard)

DCx27

#11

DCx27

#11

DCx27

#11

DCx27

#11

DCx27

#11

DCx27

#11

DCx27

#11

DCx27

#11

DCx27

#11

DCx27

#11

DCx27

#11

DCx27

#11

DCx27

#14

DCx27

#14

DCx27

#11

DCx27

#11

Needle gauge

XOveredging

width

(mm)

4.8X4.8

6.8X6.4

6.8X6.4

2.2X3.2

3.2X3.2

2.0X2.2X3.2

2.0X2.2X3.2

3.2X2.2X3.2

3.2X2.2X3.2

4.8X2.2X3.2

4.8X2.2X3.2

3.2X3.2

3.2X3.2

3.8X3.2

Ox

3.2

0 X

3.2

Presser

lifting

amoum

(mm)

7

5

5

5

5

6

6

6

6

6

6

6.5

5

5

7

7

Applications

Safety stitch gathering of light-weight general

fabrics,

georgette,

etc.

Safety stitch gathering of light-weight general

fabrics,

georgette,

Safety stitch gathering of light-weight general

fabrics,

georgette,

Piping

stitchofknitwork,

Safety piping stitch of general fabrics, Jersey,

knit,

etc.

Safety stitch overedging of general fabrics,jersey,

knit,

etc.

Safety stitch overedgingof general fabrics, jersey,

knit,

etc.

Safety stitch overedgingof general fabrics, jersey,

knit

materials,

etc.

etc.

etc.

jersey,

and

the

like.

Safety stitch overedgingof general fabrics, jersey,

knit

materials,

Safety stitch overedging of general fabrics, jersey,

knit

materials,

etc.

etc.

Safety stitch overedging of general fabrics, jersey,

knit

materials,

Attaching double-faced reinforcing

bias

tapeof10mmwidthisused.)

Attaching double-faced reinforcing tape (for clean

finish top and bottom) (Cotton bias tape of 20mm

widthisused.)

Attaching double-faced reinforcing

finish top and bottom) (Cotton bias tape of 20mm

widthisused.)

For

soft

Pattern-seaming of cuffs and sleeve

chain

etc.

(for

Schiesser)

tape

tape

bottom

(Cotton

(for clean

plackets

Hand

Hand

For

For

For

Throat

Feed

tape

tape

tape

dog

Remarks

type

type

attaching

attaching

attaching

plate

"1

J"

With

,.

lips

34

MO-2505E-0F5-3C0

8500

8000

6500

6000

1

x3

DCx27

#14

0x4.8

6

Peripheral overedging of Doeskin

seaming)

cloths

(for roll-in

Page 33

3.

No.

List

MO-2A02E-0A4-150

1

of

subclass

Mode!

machines

speeo

(s.p.m.)

MO-2500

8000

7500

Upper;Max.

Lower:Normal

speed

MO-2400

6500

6000

classified

No.

needles

No.

threads

1 X 2

of

of

speed

X

by

Needle

(standard)

DCxI

#8

stitch

Needle

X

Overedging

width

0 X

(mm)

1.6

type

gauge

Presser

lifting

amount

(mm)

5

Applications

Overedging (roll-in seaming) of

and

topstitchingoftable

cloths,

handkerchiefs,

etc.

Remarks

etc.

MO-2A02E-0D4-200

2

MO-2A02E-0D4-300

3

MO-2A03E-0D4-200

4

MO-2A03E-0F4-300

5

I

CO

8000

7500

8000

7500

8000

7500

7500

7000

6500

6000

6500

6000

6500

6000

6500

6000

1 X 2

1 X 2

1 X 2

1 X 2

DCx27

#9

DCx27

#11

DCx27

#9

DCx27

#11

0 X

0 X

0 X

0x4.8

3.2

3.2

3.2

5.5

Topstitching

7

5.5

7

Topstitching

Blind

Blind

Only

hemming,

hemming,

0D4,

serging,

and

and

serging

serging

serging,

serging,

and

and

and

joining

joining

joining

L001

used

and

for

L012are

knitwork

Page 34

2-Needle

Overiock

machines

No.

1

2

3

4

Model

MO-2A06E-BD4-200

MO-2A06E-BD4-300

MO-2A06E-CD4-300

MO-2A07E-DF6-500

MO-2500

8000

7500

8000

7500

8000

7500

7500

7000

Upper:Max.

.

Lower:Normal

spaed

MO-2400

6500

6000

6500

6000

6500

6000

6500

6000

spaed

No.

needles

No.

threads

2x4

2x4

2x4

2x4

of

of

Needle

x

(standard)

DCx27

#9

DCx27

#11

DCx27

#11

DCx27

#14

Needle

X

Overedging

width

(mm)

2.2X3.2

2.2X3.2

2.6X3.2

3.0X4.8

gauge

Presser

lifting

amount

(mm)

5

6

6

6

Topstltching,

and

the

like.

Topstitching,

and

the

like.

Topstitching,

and

the

like.

Topstitching,

and

the

like.

Applications

and

overedgingofknitwork,

and

overedgingofknitwork,

and

overedgingofknitwork,

and

overedgingofknitwork,

Remarks

jersey,

jersey,

jersey,

jersey,

Page 35

Safety

No.

Stitch

Machines

Model

speea

(s.p.m.)

MO-2500

Upper:Max.

bovver:Normal

MO-2400

spaed

speed

No.

needles

No.

threads

of

Needle

X

(standard)

of

Needle

X

Overedging

width

(mm)

gauge

Presser

lifting

amount

(mm)

Applications

Remarks

MO-2A15E-BD4-300

1

MO-2A15E-DD4-300

2

MO-2A15E-FF6-500

3

CO

CO

7000

6500

7000

6500

7000

6500

6500

6000

6500

6000

6500

6000

2x4

2x4

2x4

DCx27

#11

DCx27

#11

DCx27

#16

2.0X3.2

3.2X3.2

4.8X4.8

Safety

7

7

7

stitchingoffabrics

and

knit

material

Safety

stitchingoffabrics

and

knit

material

Safety

stitchingofheavy-weight

suchasjersey.

suchasjersey.

such

such

as in

as in

material.

men's

men's

shirts,

shirts,

Page 36

8

Gauge

Subclass

Machine

These

lists

show

for

all

standard

tions

(blind hemming, gathering, piping, 1-needle wool spec., 2-needle wool

spec.,

etc.)

Use

proper

Note 1)

gauge

For

throat

page

2) Please

the

tension

In List

page

3) All

asm.

Parts

for

the

parts

subclass

partstoexpand

the

77.

same

114.

part

with

machines

configurations

plates

and

note

that

thread

spring

of

Subclass

Nos. of presser

finger

Lists

Machine

Special

Nos.

and

configurationsofthe

and

subclass

the

application

and

dimensionsofgauge parts

feed

dogs, see

the

column

tension

asm.,

guards.

spring

see

the

machines

foot

column