Page 1

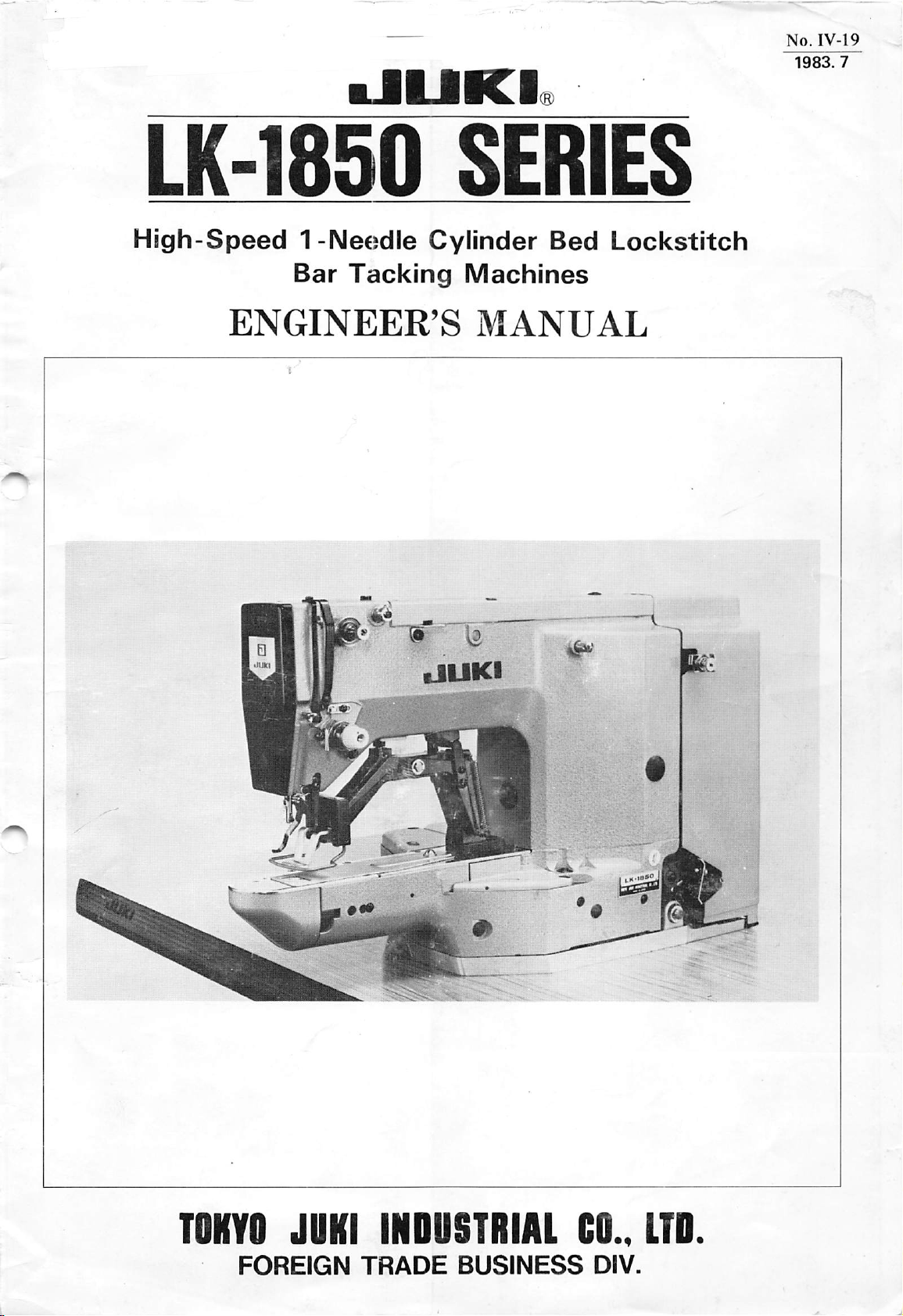

UUKI

LK-1850 SERIES

No.

1983.7

IV-19

High-Speed

ENGINEER'S

1-Needle

Bar

Tacking

Cylinder

Machines

MANUAL

Bed

Lockstitch

k

19

TOKYO

FOREIGN

JOKI

INOUSTRIAL

TRADE

BUSINESS

CO.,

DIV.

LTD

Page 2

PREFACE

This Engineer's Manual is written

maintenance

The

Instruction

a

garment

Adjustment",

is

not

coveredbythe

It is advisabletouse

Manual

when

of

the

machine.

Book

for

factory

contains

"HowtoAdjust",

Instruction

the

carrying

out

the

machine

detailed

relevant

the

maintenanceofthe

for

technical personnel

intended

operating

"EffectsofAdjustment",

Book.

Instruction

for

the

instructions.

Book

and

machine.

who

are responsible for

the

service and

maintenance personnel and operators at

This

and

various

Parts Book

manual

together

other

describes

information

with

this Engineer's

"Standard

which

Page 3

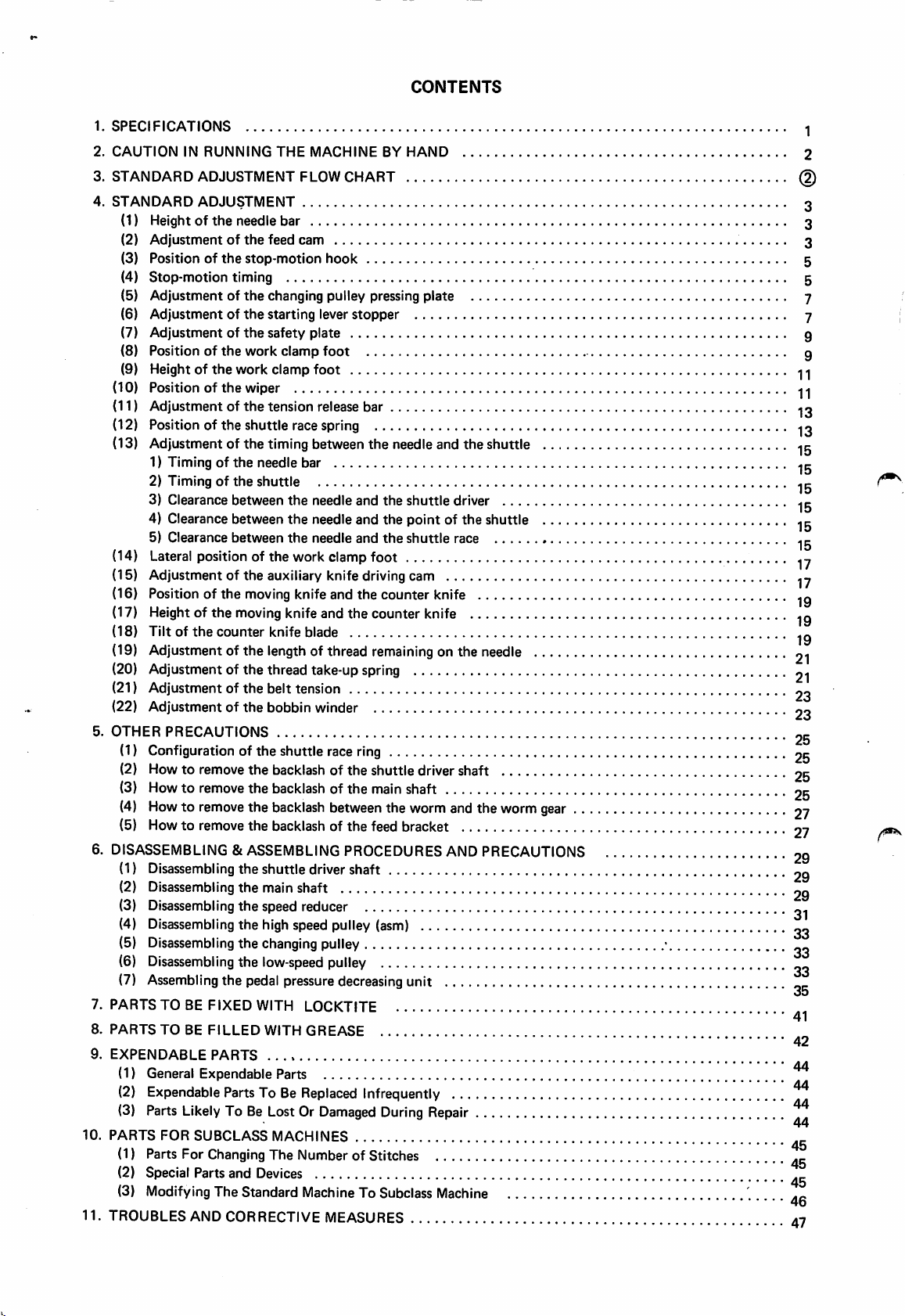

CONTENTS

1.

SPECIFICATIONS

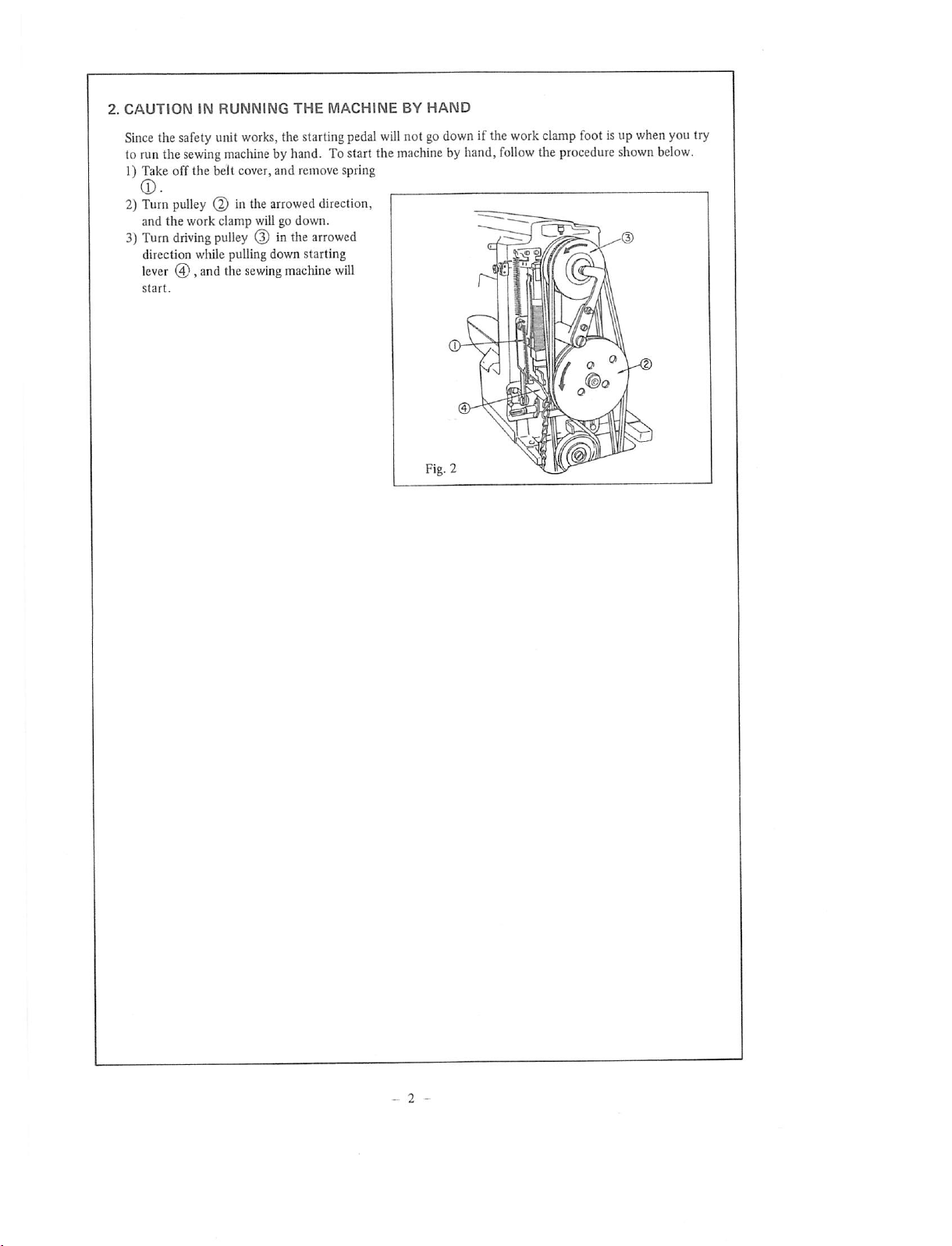

2. CAUTION IN RUNNING THE MACHINE BY HAND 2

3.

STANDARD ADJUSTMENT

4.

STANDARD

(1)

Height

(2) Adjustment of the feed cam 3

(3) Position of the stop-motion hook 5

(4) Stop-motion timing 5

(5) Adjustment of the changing pulley pressingplate 7

(6) Adjustment of the starting leverstopper 7

(7) Adjustment of the safety plate g

(8)

Position

(9)

Height

(10)

Position

(11)

Adjustment

(12)

Positionofthe

(13)

Adjustmentofthe

1)

2)

3)

4)

5)

(14)

Lateral

(15)

Adjustmentofthe

(16)

Positionofthe

(17)

Height of

(18)

Tiltofthe

(19)

Adjustmentofthe

(20)

Adjustmentofthe

(21)

Adjustmentofthe

(22)

Adjustmentofthe

5.

OTHER

(1)

Configurationofthe

(2)

Howtoremove

(3)

Howtoremove

(4)

Howtoremove

(5) How to remove

6. DISASSEMBLING & ASSEMBLING

(1)

Disassembling

(2)

Disassembling

(3)

Disassembling

(4)

Disassembling

(5)

Disassembling

(6)

Disassembling

(7)

Assembling

7. PARTS TO BE FIXED

8. PARTS TO BE FILLED

9.

EXPENDABLE

(1)

General

(2) Expendable PartsTo Be

(3) Parts

10. PARTS FOR

(1) Parts For

(2)

Special

(3) Modifying The Standard

11,

TROUBLES

ADJUSTMENT

of the

needle

ofthe work

ofthe

work

ofthe

ofthe

Timingofthe

Timingofthe

Clearance

Clearance

Clearance

between

between

between

positionofthe

the

moving knife and

counter

PRECAUTIONS

the

the

the

the

the

the

the

PARTS

ExpendableParts

Likely

To Be LostOr

SUBCLASS

Changing

Partsand

AND

CORRECTIVE

wiper

shuttle

moving

the

the

the

the

pedal pressure decreasing unit

FLOWCHART

bar 3

clamp

foot g

clamp

foot

tension

timing

needle

release

race

between

bar

spring

bar

the

needle

and

the

shuttle

shuttle

the

needle

and

the

shuttle

driver

the

needle

and

the

pointofthe

the

needle

and

the

shuttle

work

clamp

foot

auxiliary knife driving

knife

and

the

the

knife

blade

lengthofthread

thread

take-up

belt

tension

bobbin

winder

shuttle

race

ring

backlashofthe

backlashofthe

backlash

backlash of

shuttle

main shaft

speed reducer

high speed pulley (asm)

changing pulley •

low-speed pulley

WITH

WITH

MACHINES

The Numberof Stitches

Devices

between

the

PROCEDURES

driver

shaft

LOCKTITE

GREASE

Replaced

Damaged

Machine

To Subclass

cam

counter

counter

knife

knife

remainingonthe

spring

shuttle

feed bracket

Infrequently

main

the

During

driver

shaft

worm

Repair

Machine

shuttle

race

needle

shaft

and

the

AND

PRECAUTIONS

worm

gear

MEASURES

41

42

44

44

44

44

45

45

45

46

47

@

11

H

13

13

1g

1g

1g

1g

1g

15

iy

ig

19

2i

2i

23

23

25

25

25

25

27

27

29

2g

29

31

33

33

33

35

1

3

Page 4

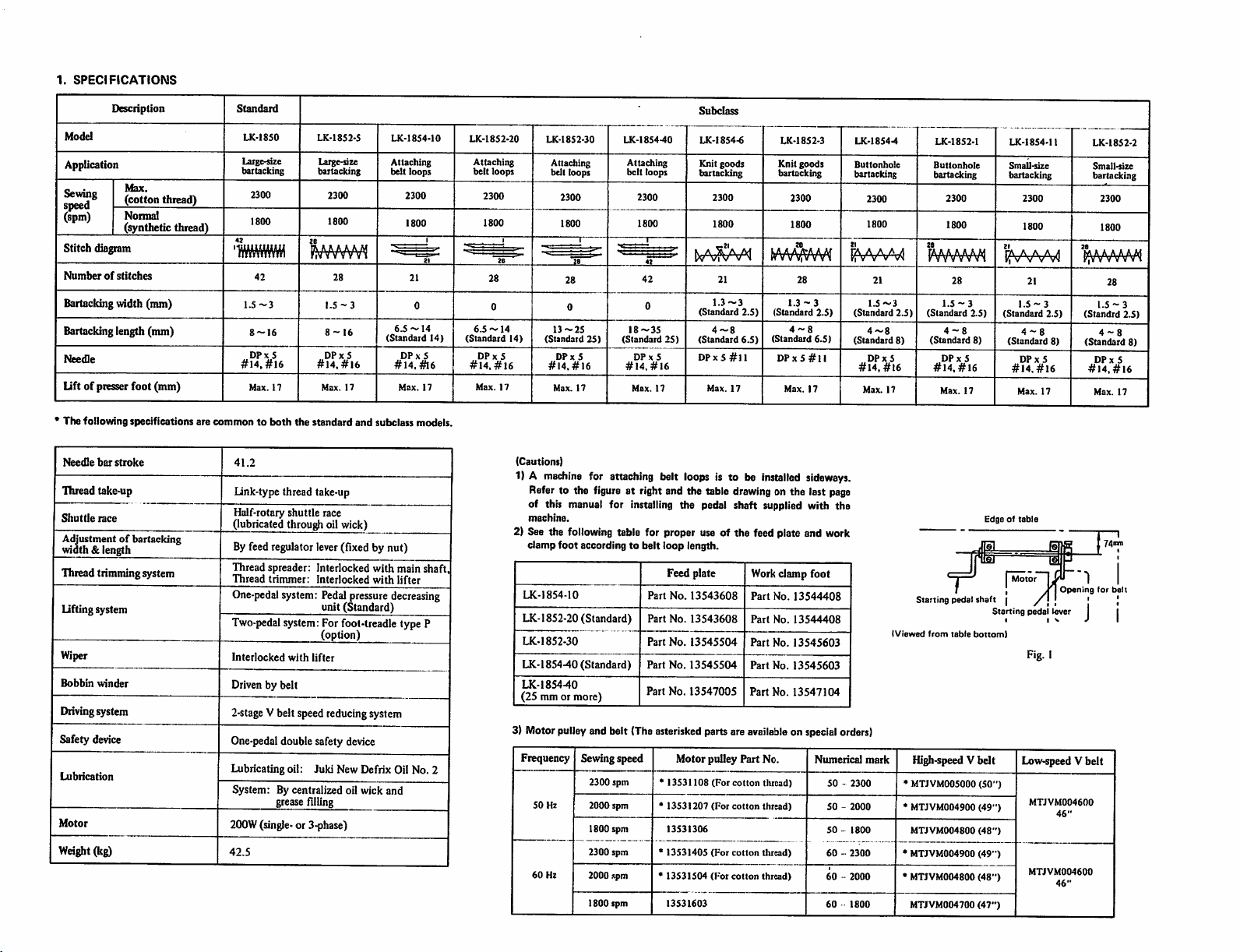

1.

SPECIFICATIONS

Description

Model

AppUcation

Sewing

speed

(spm)

Max.

(cotton thread)

Normal

(synthetic thread)

Stitch diagram

Numberofstitches

Bartacking

mdth

(mm)

Bartacking length (mm)

Needle

lift

of piesserfoot (mm)

* The following specifications are

NeetOe

bar

stroke

Thread take-up

Shuttle

race

Adjustmentof bartacking

width & length

Thread trimmingsystem

Liftingsystem

Wiper

Bobbin

winder

Drivingsystem

Safety device

Lubrication

Motor

Weight(kg)

Standard

LK-1850

Laig(>size

bartacking

2300

1800

LK-1852-5

Large-size

bartacking

2300

1800

LK-1854-10

Attaching

belt

'wmm

42

1.5

~3

8~I6

DPx5

#14.

#16

Max.

17

commontoboth

41.2

link-type thread take-up

Half-rotary shuttle race

(lubricatedthroughoilwick)

Byfeedregulator lever(fixed by nut)

Threadspreader: Interlocked with main shaft,

Thread

trimmer:

One-pedal

Two-pedal

system: Pedal

system:

Interlocked

Driven by belt

2-stage

Vbelt speed reducingsystem

One-pedaldouble safety device

Lubricating oil: Juki New Defrix Oil No. 2

System: By centralized oil wick and

greasefilling

2()0W

(single-or 3-phase)

42.5

28

1.5-3

8-16

DPx5

#14,#16

Max.

17

the

standard

Interlocked

pressure

unit (Standard)

Forfoot-treadle type P

(option)

with

lifter

and

6.5~14

(Standard

#14.

subclass

with

decreasing

2300

1800

DPx5

Max.

lifter

loops

21

0

#16

17

models.

14)

LK-1852-20

Attaching

belt

2300

1800

28

0

6.5

~ 14

(Standard

DPx5

#14,#16

Max.

Subclass

LK-185

loops

28

17

14)

Attaching

belt loops

2300

1800

28

0

13-25

(Standard

DPx5

#14.#16

Max.

2-30

17

25)

LK-1854-40

Attaching

belt

loops

2300

1800

1

42

42

0

18-35

(Standard

DPx5

#14.

Max.

#16

LK-1854-6

Knit

goods

bartacking

2300

1800

21

1.3-3

(Standard

2.5)

25)

17

4-8

(Standard

DP X5

Max.

6.5)

#11

17

(Cautions)

1) A

madiina

for attaching belt loops is to be installed

Refer to the figure at right and the table drawing on the last page

of this manual for installing the pedal shaft supplied with the

machine.

2) See the

3) Motorpulleyand belt (Theasterisked partsare

clamp

foot

LK-1854-10

following

table for proper use of the feed plate and work

according to belt loop length.

LK-1852-20 (Standard)

LK-1852-30

LK-l 854-40 (Standard)

LK-185440

(25 mm or more)

Frequency Sewingspeed

2300 spm *

50

Hz

2000 spm

1800 spm

2300 spm

60

Hz

2000 ispm

1800

spm

Part

Part

Part

Part

Part

*

*

*

Feed plate

No.

13543608

No.

13543608

No.

13545504

No.

13545504

No.

13547005

Motorpulley

13531108

13531207

13531306

13531405

13531504

13531603

(For

(For

(For

(For

Part

cotton

cotton

cotton

cotton

Work

Part

Part

Part

Part

Part

available

No.

thread)

thread)

thread)

thread)

LK-1852-3

Knit

goods

bartacking

2300

1800

28

1.3-3

(Standard

2.5)

4-8

(Standard

6.5)

DP X5

#11

Max.

17

sideways.

damp

foot

No.

13544408

No.

13544408

No.

13545603

No.

13545603

No.

13547104

on specialorders)

Numerical

m A A A 4

"i V V V vx

(Standard

(Standard

50-2300

50-2000

50-1800

60-2300

60-2000

60

1800

LK-1854-4

Buttonhole

bartacking

2300

1800

21

1.5-3

4-8

DPx5

#14.#16

Max.

mark

WWWV^

2.5)

(Standard

8)

17

Starting

(Viewed

from

High-speedV belt

• MTJVM005000

* MTJVM004900

MTJVM004800

•

MTJVM004900

•

MTJVM004800

MTJVM004700

LK-1852-1

Buttonhole

bartacking

2300

1800

28

1.5

4-8

(Standard

DPx

#14,

Max.

pedal

table

- 3

#16

5

17

2.5)

8)

Edge of

shaft

Starting

bottom)

(50")

(49")

(48")

(49")

(48")

(47")

LK-1854-11

Small-size

bartacking

2300

1800

21

TA

A A A S

kwwi

21

1.5-3

(Standard

4-8

(Standard

DPx

#14.#16

Max.

table

Motor

,

|

pedal

Fig. I

Low-speed V

MTJVM004600

MTJVM004600

2.5)

8)

5

17

in

Opening

/'

[ ' |

lever

46"

46"

LK-1852-2

Small-size

bartacking

2300

1800

bUUUUUVAl

riVVVVVV^

28

1.5-3

(Standrd

2.5)

4-8

(Standard

8)

DPx

5

#14.#16

Max.

17

forbelt

J |

belt

Page 5

Page 6

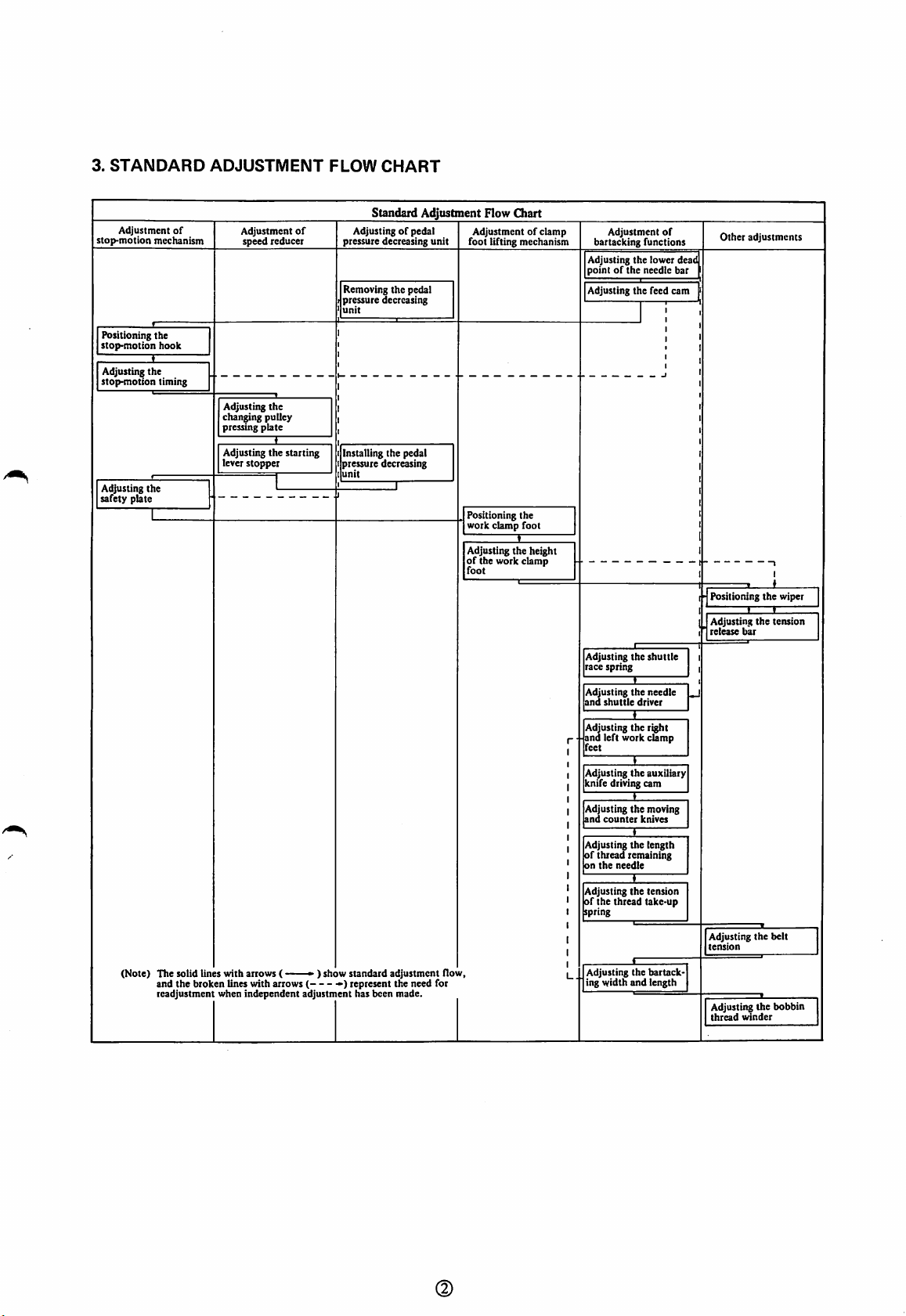

3.

STANDARD

Adjustment

stop-motion

Positioning the

stop-motion

Adjusting

stop-motion

Adjusting the

safety plate

(Note)

ADJUSTMENT

FLOW

CHART

Standard Adjustment Flow Chart

of

mechanism

hook

the

timing

The

solid

and the broken lines with arrows ( -•) represent the need for

readjustment

Adjusting

chan^ng pulley

pressing

Adjusting

lever stopper

lines

with

when

Adjustment

speed reducer

arrows

independent

of

the

plate

the

starting

( , ,

adjustment

Adjustingofpedal

pressure decreasing

Removing the pedal

pressure

unit

Installing the pedal

pressure decreasing

unit

) show

standard

has

decreasing

adjustment flow.

been

made.

Adjustmentofclamp

unit

foot lifting mechanism

Positioning the

work

Adjusting the height

of

the

foot

clamp

work

foot

clamp

Adjustment

bartacking functions

Adjusting the lower deat

pointofthe

Adjusting the feed cam

Adjusting the

race

spring

Adjusting

the

and

shuttle

driver

Adjusting the right

and left work clamp

feet

Adjusting

the

knife driving cam

Adjusting the moving

and

counter

Adjusting the

of thread remaining

on

the

needle

Adjusting

the

of the thread take-up

spring

Adjusting the

U.

ing width and length

needle

shuttle

needle

auxiliary

knives

length

tension

bartack

of

bar

Other

adjustments

t-

Positioning

Adjusting

release

Adjusting the belt

tension

Adjusting the bobbin

thread

bar

winder

the

the

wiper

teiuion

@

Page 7

4.

STANDARD

ADJUSTMENT

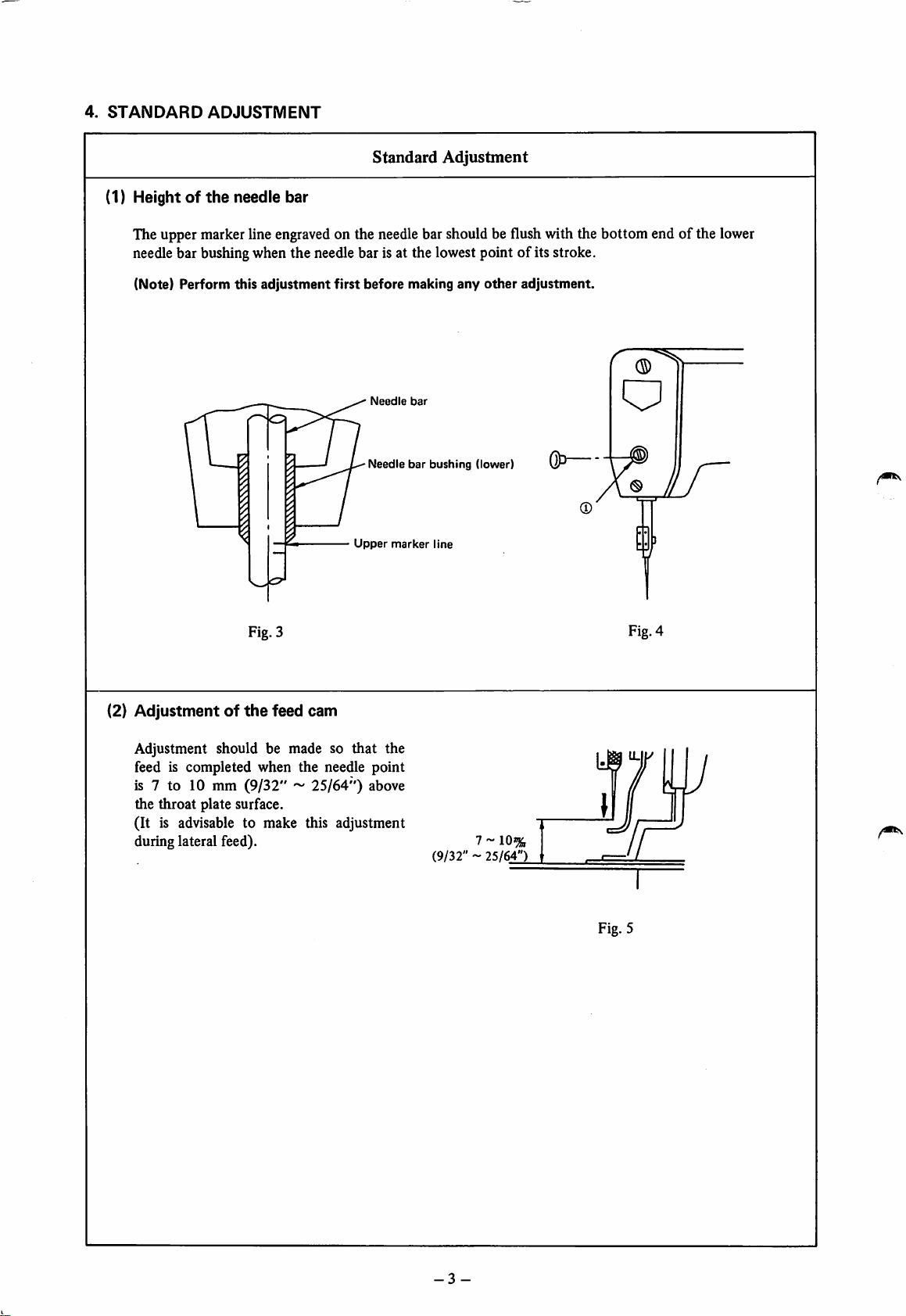

(1) Heightofthe

Standard

needle bar

Adjustment

The upper marker lineengraved on the needle bar should be flush with the bottom end of the lower

needle bar bushing when the needle bar is at the lowest point of its stroke.

(Note) Perform this

adjustment

first

before

Needle

Needle

Upper

making

bar

bar

marker

any

bushing

line

other

(lower)

adjustment.

&>—

E3

Fig. 3

(2)

Adjustmentofthe

Adjustment should be made so

feed cam

that

the

feed is completed when the needle point

is 7 to 10 mm

the

throat

(9/32"~25/64")

plate surface.

above

(It is advisable to make this adjustment

during lateral feed). ^ ~ 10%

(9/32"~25/64")

Fig. 4

Fig. 5

-3-

Page 8

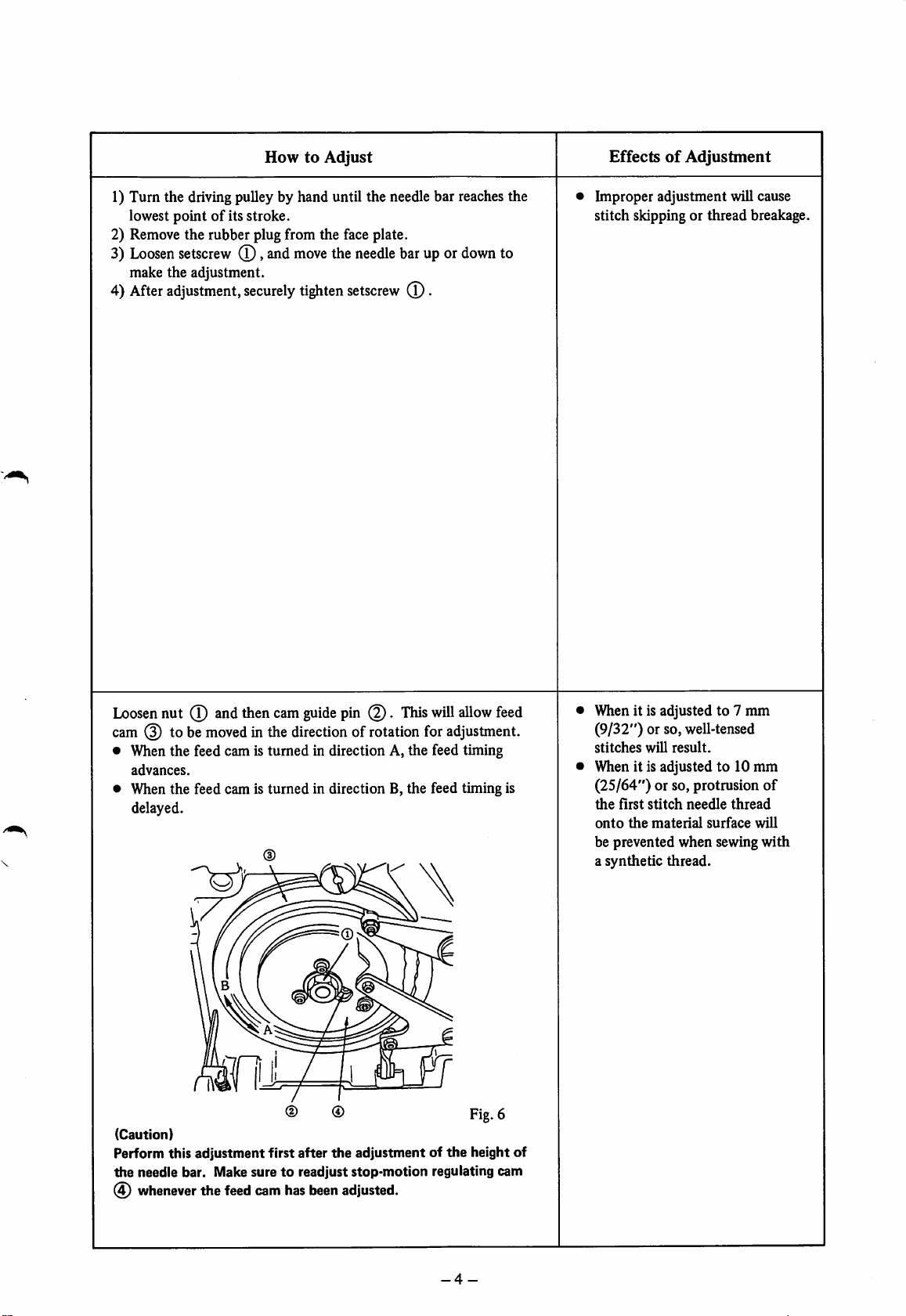

HowtoAdjust

EffectsofAdjustment

1) Turn the drivingpulley by hand until the needle bar reaches the

lowest point of its stroke.

2) Remove the rubber plug from the face plate.

3)

Loosen

make the adjustment.

4)

After

setscrew

adjustment,

(T),and

securely

move

tighten

the

needle

setscrew

barupor

(T)

.

down

to

• Improper adjustment willcause

stitch skipping or thread breakage.

Loosen

nut

(T)

andthen cam

guide

pin .

This

will

allow

feed

cam (3) to be movedin the direction of rotation for adjustment.

• When the feed cam is turned in direction A, the feed timing

advances.

• When the feed cam is

delayed.

turned

in direction B, the feed timing is

%

(Caution)

Perform this adjustment first after

the

needle bar. Make suretoreadjust

whenever

the

feed

cam

has

been

®

the

adjustment of

stop-motion

adjusted.

Fig.

6

the

height of

regulating cam

Whenit is adjusted to 7 mm

(9/32")

stitches

Whenit is adjusted to 10 mm

(25/64") or so, protrusion of

the

onto

be prevented when sewing

a synthetic thread.

or so, well-tensed

will

result.

first

stitch

needle

the

material

thread

surface

will

with

-4-

Page 9

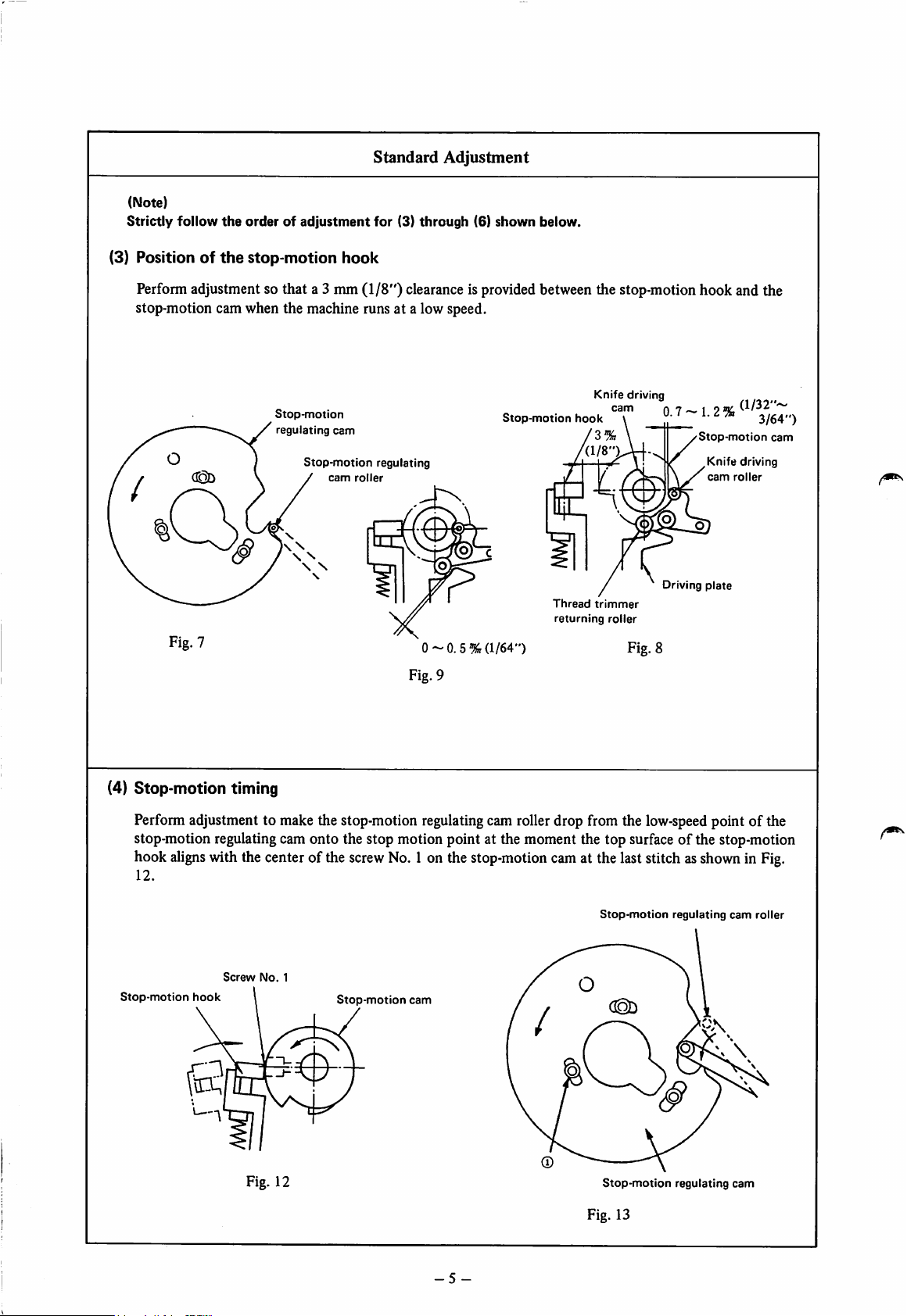

(Note)

Strictly follow

the

orderofadjustment

Standard

Adjustment

for (3) through (6) shown below.

(3) Positionofthe

stop-motion

hook

Perfonn adjustment so that a 3 mm (1/8") clearanceis provided between the stop-motion hook and the

stop-motion cam when the machine runs at a low speed.

Knife

driving

Stop-motion

regulating

Stop-motion

cam

cam

roller

regulating

Stop-motion

hook

'Wl

cam

'3

0.7

~ 1. 2 %

Stop-motion

,Knife driving

cam

%

Driving

plate

Thread

trimmer

Fig, 7

0-0.

Fig. 9

5%

returning

(1/64")

roller

Fig. 8

3/64")

cam

roller

(4) Stop-motion timing

Performadjustment to make the stop-motion regulating cam rollerdrop from the low-speed point of the

stop-motion regulatingcamonto the stop motion point at the moment the top surface of the stop-motion

hook

aligns

withthe centerofthe

12.

Screw

No.

1

Stop-motion hook Stop-motion cam

screw

No.

1on the

stop-motion

cam

at the laststitchas

Stop-motion

showninFig.

regulating

cam

£

Fig. 12

Stop-motion

Fig. 13

regulating

roller

cam

-5

-

Page 10

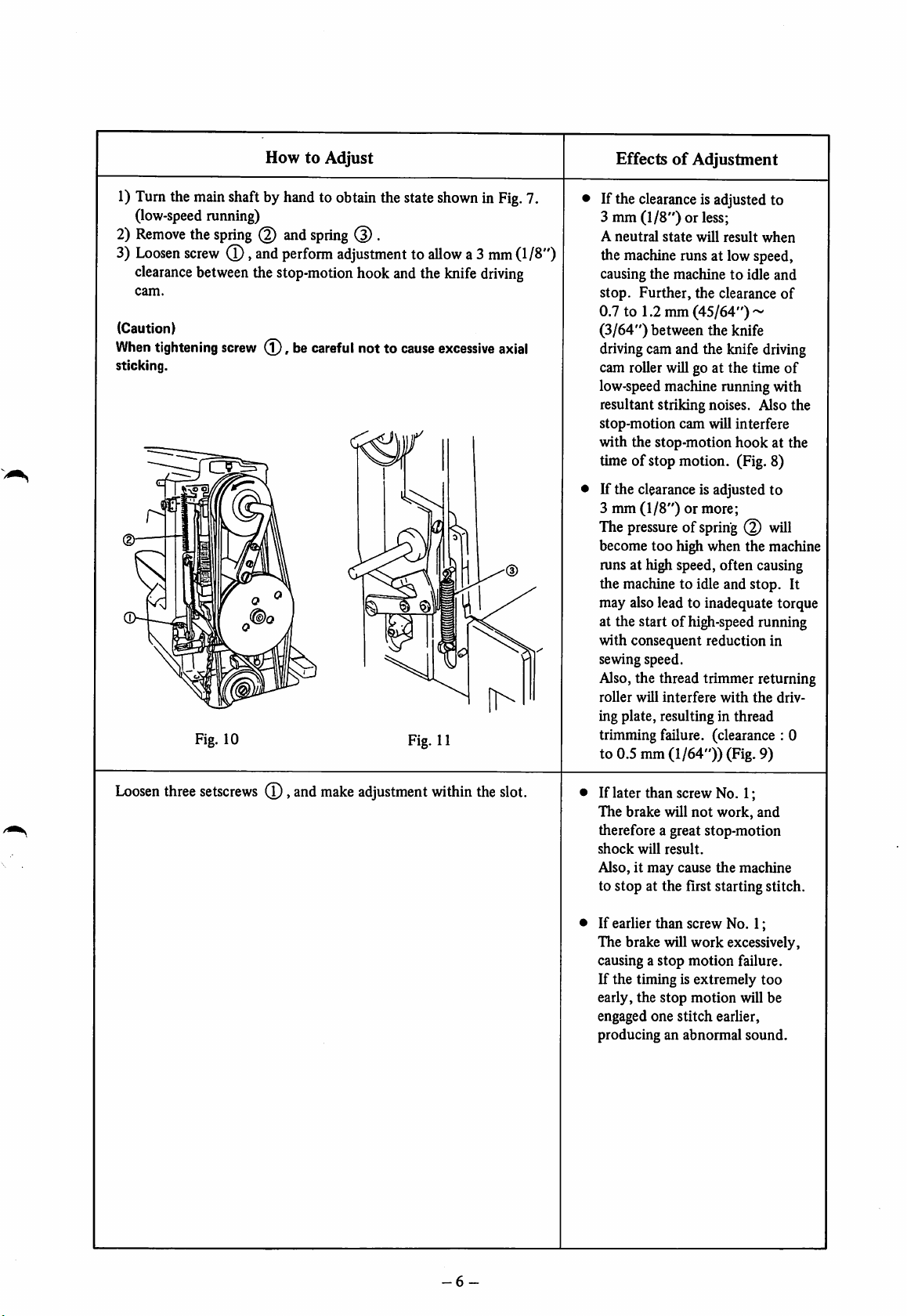

1)

Turn

the

main

(low-speed running)

2)

Remove

3)

Loosen

clearance

cam.

(Caution)

When

sticking.

the

screw

between

tightening

Fig. 10

HowtoAdjust

shaftbyhandto obtainthestate

spring

(2)

and

spring

(D .

(T),

and

perform

adjustmenttoallowa3mm

thestop-motion hook andthe

screw

(l),becareful

not to

showninFig.

cause

Fig. 11

knife

driving

excessive

(1/8")

axial

7.

EffectsofAdjustment

If the clearanceis adjusted to

3 mm (1/8") or less;

A

neutral

the machine runs at low speed,

causing the machine to idle and

stop.

state

Further,

will

result

when

the clearance

of

0.7 to 1.2 mm(45/64") ~

(3/64")

drivingcam and the knife driving

cam roller willgo at the time of

low-speedmachine running with

resultant striking noises. Also the

stop-motion

with the stop-motion

time of stop motion. (Fig. 8)

between the knife

cam

will interfere

hook

at the

If the clearanceis adjusted to

3 mm

(1/8")

or more;

The pressure of spring will

become too high when the machine

mns at high speed, often causing

the machine to idle and stop. It

may alsolead to inadequate torque

at the start of high-speedrunning

with consequent reduction in

sewing speed.

Also,the thread trimmer returning

roller

will

interfere

ing plate, resulting in thread

trimming failure, (clearance : 0

to 0.5 mm

(1/64"))

with

(Fig. 9)

the

driv

Loosen

three

setscrews

(D,

and

make

adjustment

within

the

slot.

• If later than screw No. 1;

The brake will

therefore a great stop-motion

shock

will

Also, it may cause

to stop at the first starting stitch.

• If earlier than screw No. 1;

The brake will work excessively,

causing a

If the timing is extremely

early, the stop motion will be

engaged one stitch earlier,

producing an abnormal sound.

result.

stop

not

work,

the

motion

machine

failure.

and

too

-6

Page 11

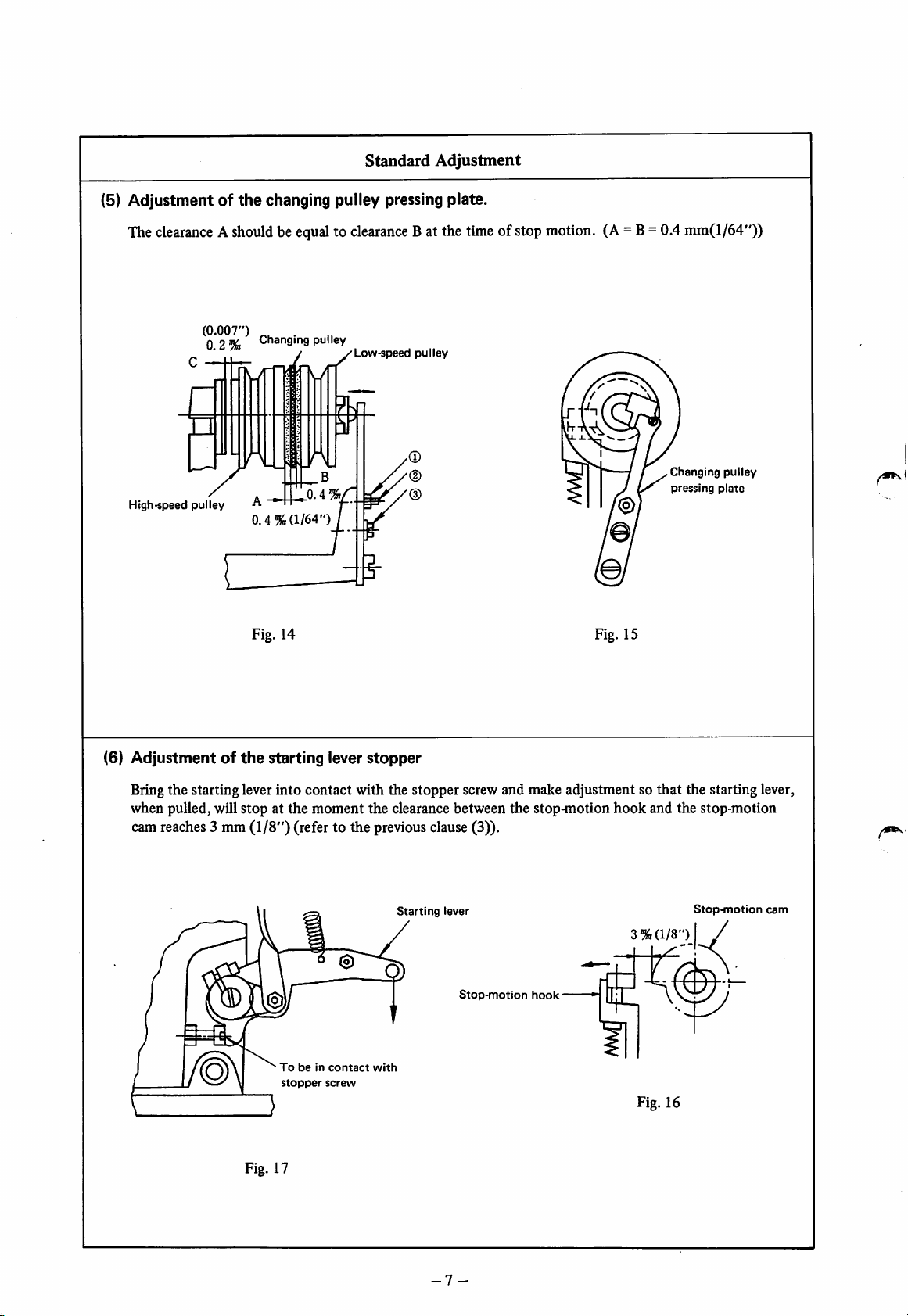

Standard

Adjustment

(5) Adjustment of

The

clearanceAshouldbeequaltoclearance

(0.007")

0 2%

High-speed

pulley

the

changing pulley pressing plate.

Changing

fKTT

.

j

pulley

Low-speed

Bat the

pulley

time

ofstop

motion.

r\

B

^

0.4%

Fig. 14 Fig. 15

0.4'

(1/64")

(A=B=0.4mm(l/64"))

Changing

pressing

pulley

plate

(6)

Adjustmentofthe

starting lever

stopper

Bring the starting lever into contact with the stopper screw and make adjustment so that the starting lever,

hook

when pulled, will stop at the moment the clearance between the stop-motion

and the stop-motion

cam reaches3 mm (1/8") (refer to the previous clause(3)).

(1/8")

Stop-inotion

I /

Tobein

stopper

contact

screw

with

Starting

lever

Stop-motion

hook-

3%

tn

Fig. 16

Fig. 17

cam

-7-

Page 12

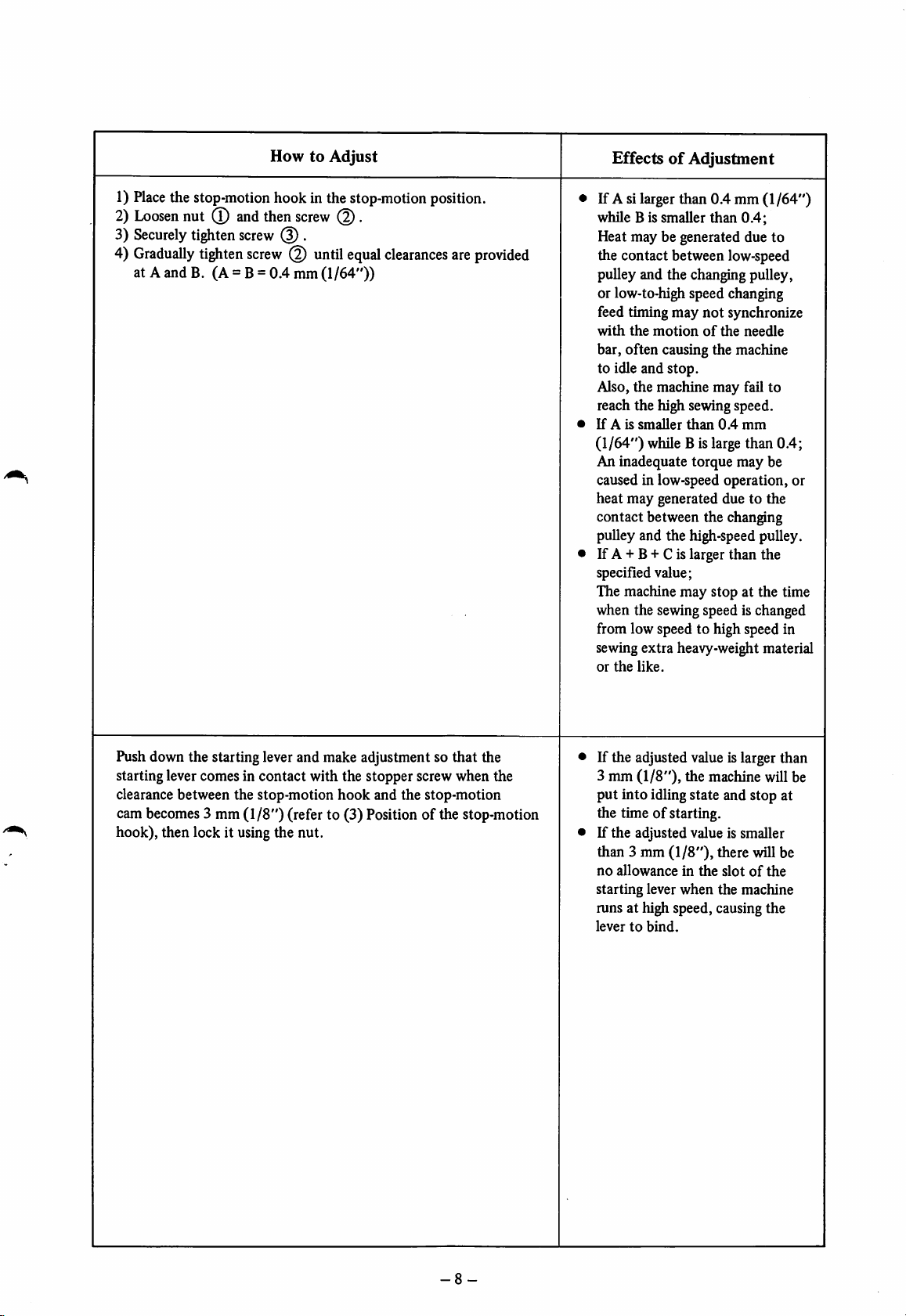

HowtoAdjust

1)

Place

the stop-motion hook in the stop-motion position.

2)

Loosen

3)

Securely

Gradually

4)

nut

tighten

tighten

(T)

and

screw

screw

then

screw

(3).

untilequal

at A and B. (A = B= 0.4 mm (1/64"))

Q).

clearances

are

provided

EffectsofAdjustment

If A si larger than 0.4 mm

while B is smaller

Heat may be generated due to

than

the contact between low-speed

(1/64")

0.4;

pulley and the changing pulley,

or low-to-highspeed changing

feed timing may

with

the

motionofthe

bar, often causing the machine

to idle and stop.

Also, the machine may fail to

not

synchronize

needle

reach the high sewingspeed.

If

A is

smaller

than

0.4

mm

(1/64") while B is large than 0.4;

An inadequate torque may be

caused in low-speed operation, or

heat may generated due to the

contact between the changing

pulley and the high-speed pulley.

If A + B + C is larger than the

specified value;

The machine may stop at the time

when the sewing speed is changed

from low speed to high speed in

sewing extra heavy-weight material

or

the

like.

Push down the starting lever and make adjustment so that the

starting lever comes in contact with the stopper screw when the

clearance between the stop-motion

hook

and the stop-motion

cambecomes3 mm (1/8")(refer to (3) Position of the stop-motion

hook), then lock it using the nut.

If the adjusted value is larger than

3 mm (1/8"), the machine will be

put into idling state and stop at

the timeofstarting.

If the adjusted value is smaller

than 3 mm (1/8"), there will be

no

allowanceinthe

starting lever when the machine

runs at high speed, causing the

levertobind.

slotofthe

-8-

Page 13

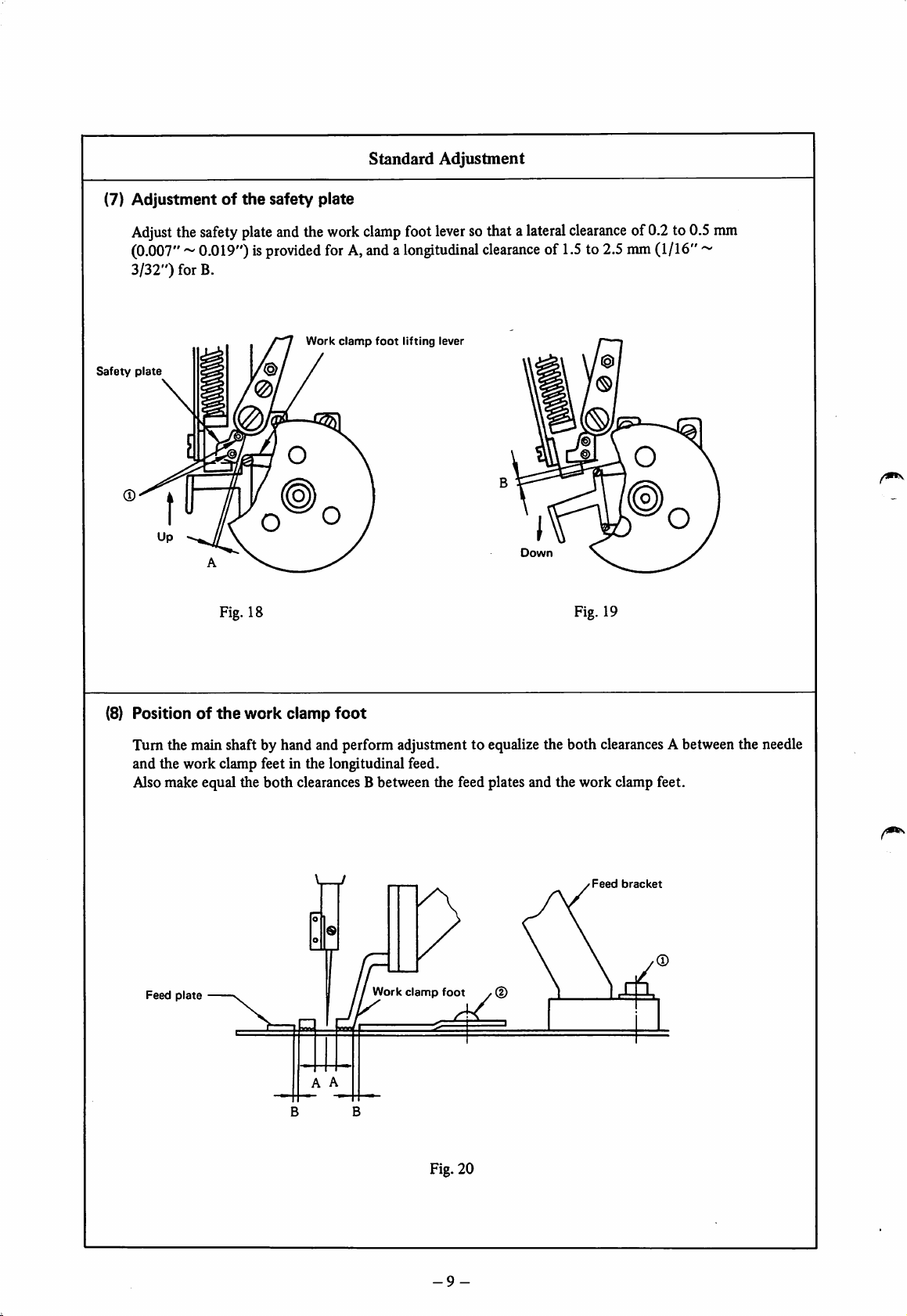

(7)

Adjustmentofthe

Adjust

the

(0.007"

3/32")

for B.

Safety

plate

safety

plate

~ 0.019")is

safety

andthe

provided

Work

Standard

plate

work

clamp

forA,anda

clamp

foot

Adjustment

foot

lever

longitudinal

lifting

lever

sothat a

lateral

clearanceof1.5

Down

clearance

to 2.5

@

!S!

of0.2 to 0.5

mm

(1/16"~

mm

Fig. 18

(8) Positionofthe

work

clamp

foot

Fig. 19

Tum the main shaft by hand and perform adjustment to equalize the both clearancesA between the needle

and the work clamp feet in the longitudinal feed.

Alsomake equal the both clearancesB between the feed plates and the work clamp feet.

Feed

bracket

Work

clamp

Feed

plate

foot

B B

Fig. 20

-9-

Page 14

HowtoAdjust

EffectsofAdjustment

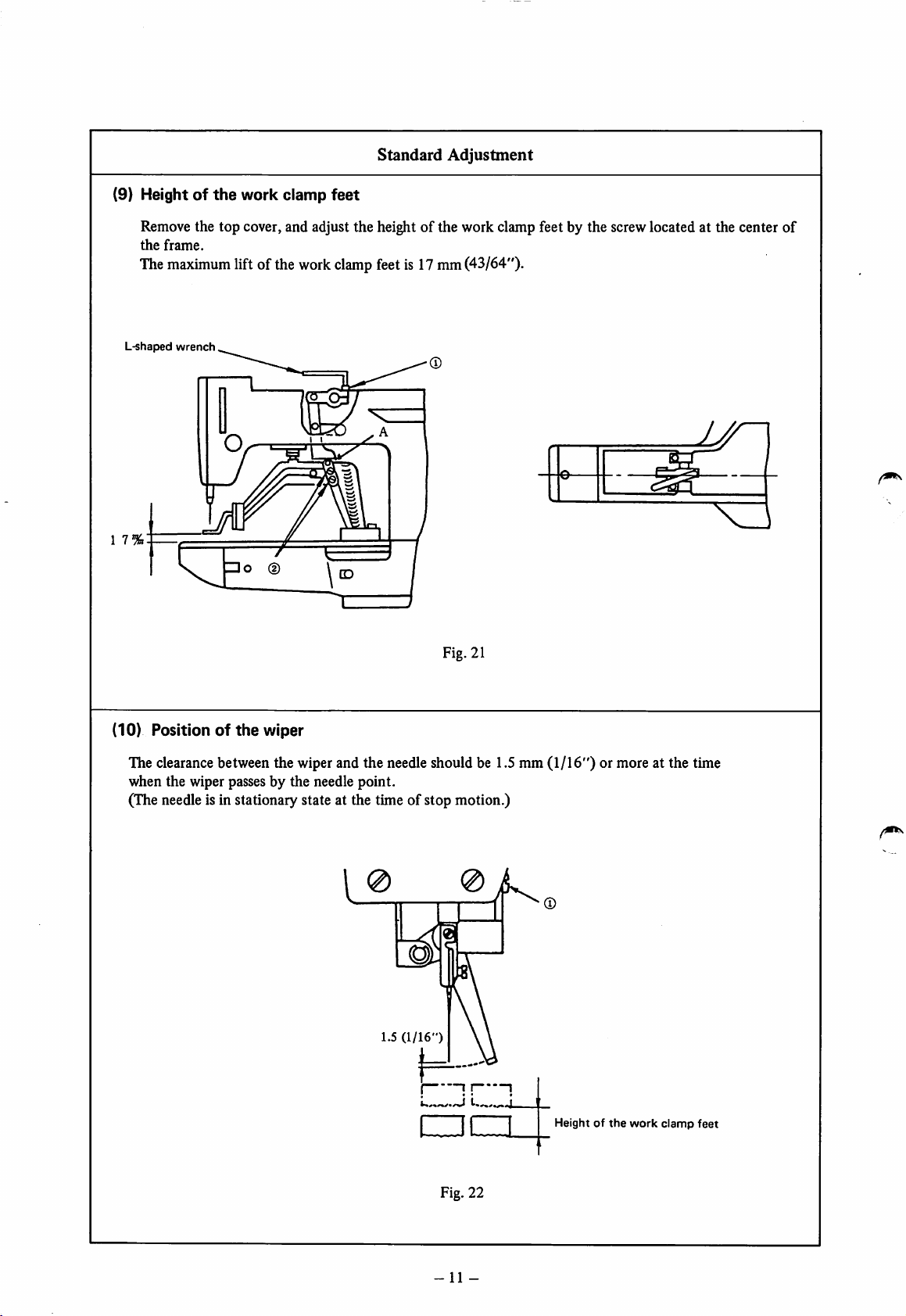

Loosen

setscrew

(T)tomake

adjustment.

After adjustment, securely tighten the setscrew.

If the clearance A is extremely

small, the work clamp foot will

notgoup.

If

the

clearance

B is

smaller

than

the specified value, the safety

plate and the work clamp foot

lifting lever will interfere with

each other, causing a stop motion

failure.

If

the

machine

clearance B is

can

zero,

notbestarted.

the

If the clearance Ais too large,

the wiper and the thread trimmer

willbe actuated before stop

motion, causing the wiper to

interfere

thread

threadtoremainonthe

with

the

needle,orthe

trimmertocut

the

needle

needle

too short with consequent slip

pageofthe thread from the needle

at stitching start.

1)

Loosen

foot

2)

Loosen

screw0and

within

the

screw0and

slotinthe

by the slot in the feed plate.

make

adjustmentofthe

feed

bracket.

adjust

the

position

ofthe

work

feed

clamp

plate

If

the

two

clearancesAare

not

equal, either work clamp foot

may

interfere

with

the

needle,

leading to needle breakage during

longitudinal feed.

-10-

Page 15

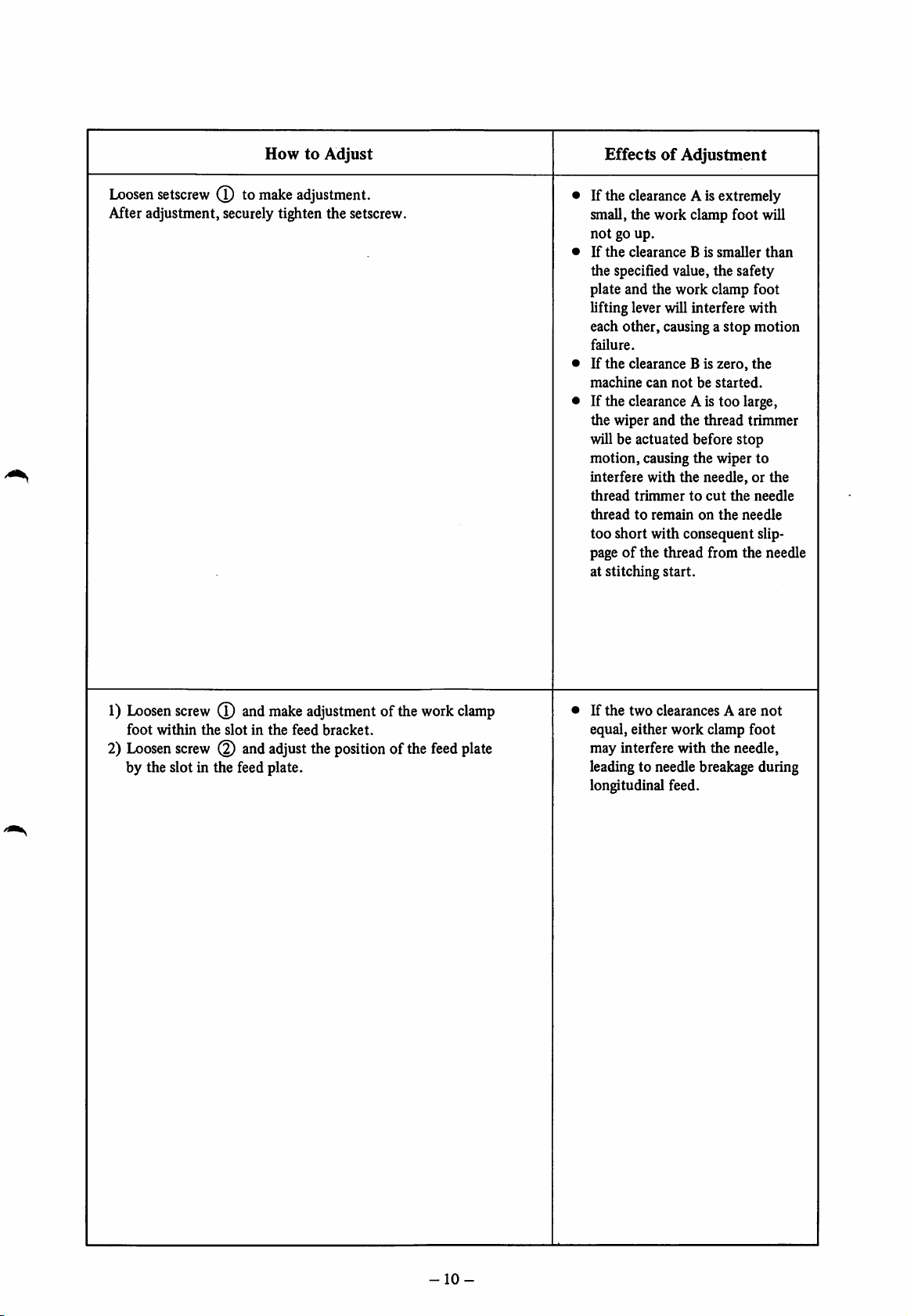

Standard

Adjustment

(9) Heightofthe

work

clamp

feet

Remove the top cover, and adjust the height of the work clamp feet by the screw located at the center of

the

frame.

The

L-shaped

maximum

wrench

lift ofthe work

clamp

feetis 17mm(43/64").

j/r^

r\

1 7

A

Fig. 21

(10) Positionofthe

wiper

The clearance between the wiper and the needle should be 1.5 mm (1/16") or more at the time

when the wiper passes by the needle point.

(The needleis in stationary state at the time of stop motion.)

o

1.5

(1/16")

j

;!

1

•czi

Fig. 22

-11

Height of

-

the

work

clamp

feet

Page 16

HowtoAdjust

EffectsofAdjustment

Stop the machine with the work clamp feet up, and loosen screw

(D to

make

adjustment.

If the right and left work clamp feet are

further

adjustment

using

screw

@ .

not

levelled, perform

If the work clamp feet are too

high, they will interfere with the

wiper when the wiper is actuated.

If

screws

feed

bracket

@ aretoo

will

low,

interfere

the

with

the loweringshaft. (Point A)

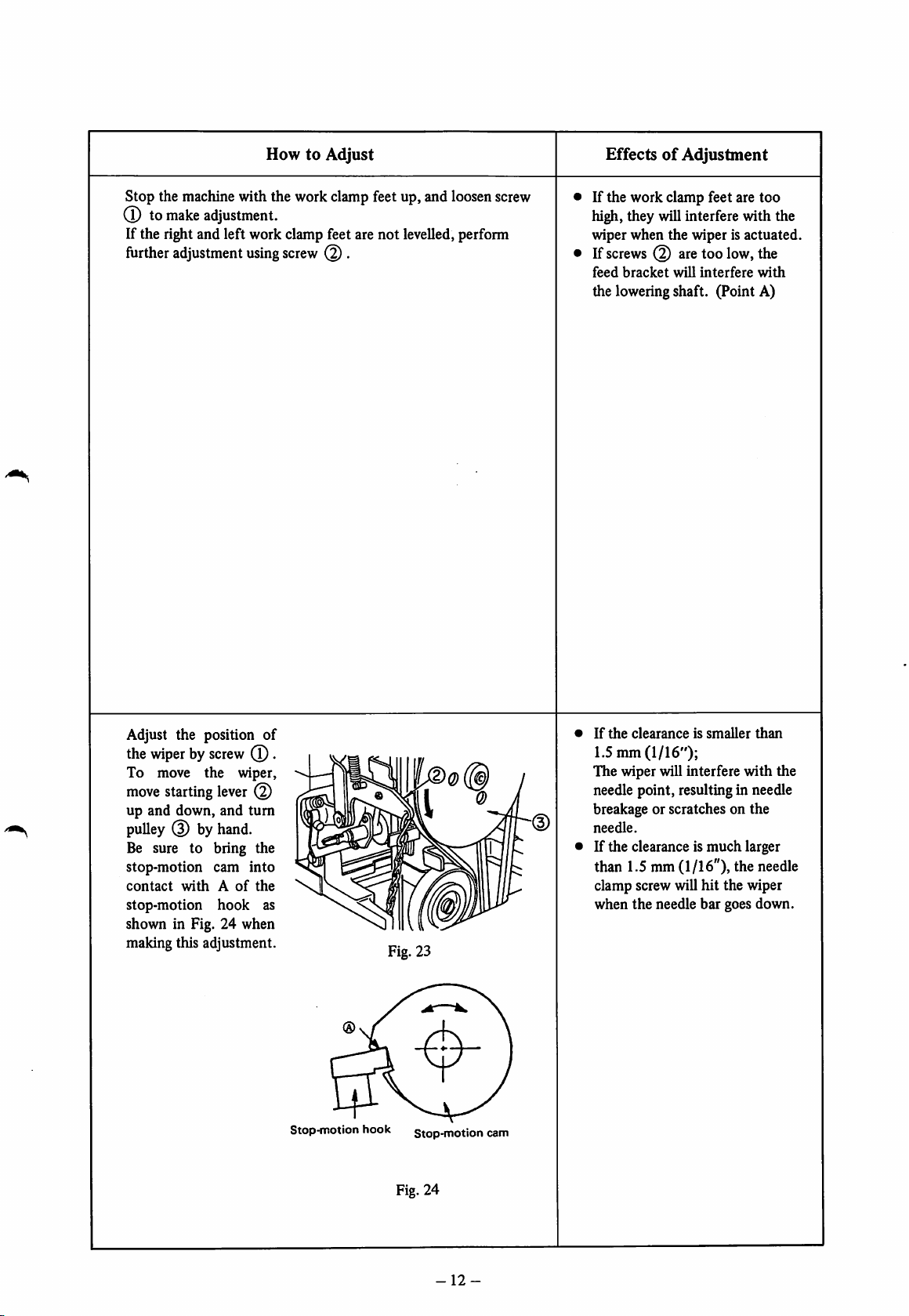

Adjust the position of

the

wiperbyscrew

To move the wiper,

move

starting

up and down, and

pulley

(3) by

Be sure to bring the

stop-motion cam

contact

stop-motion

shown in Fig. 24 when

making this adjustment.

withAof

lever

hand.

hook

(T)

(2)

turn

into

the

.

as

Stop-motion

Fig. 23

hook stop-motion

cam

If

the

clearanceissmaller

than

1.5nun (1/16");

The wiper will interfere

needle point, resulting in needle

breakage or scratches on the

needle.

If the clearance is

much

with

larger

the

than 1.5 mm(1/16"), the needle

clamp screw will hit the wiper

when

the

needle bar goes down.

Fig. 24

-12-

Page 17

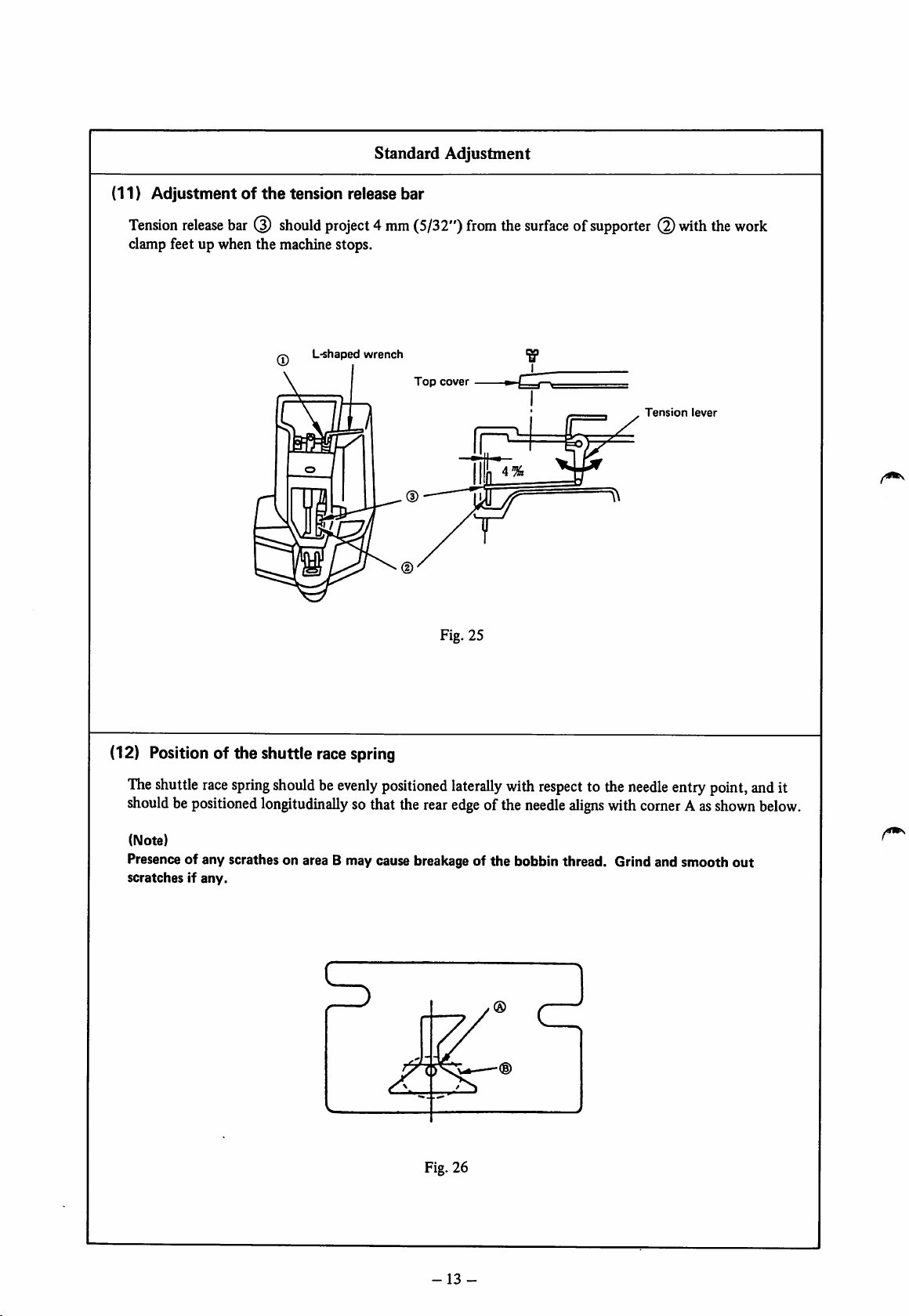

(11)

Adjustmentofthe

tension

Standard

release

Adjustment

bar

Tension

clamp feet up when the machine stops.

release

bar

(3)

should

L-shapedwrench

project4mm

(5/32")

Fig. 25

from

the

surfaceofsupporter

"g"

Tension

with

lever

the

work

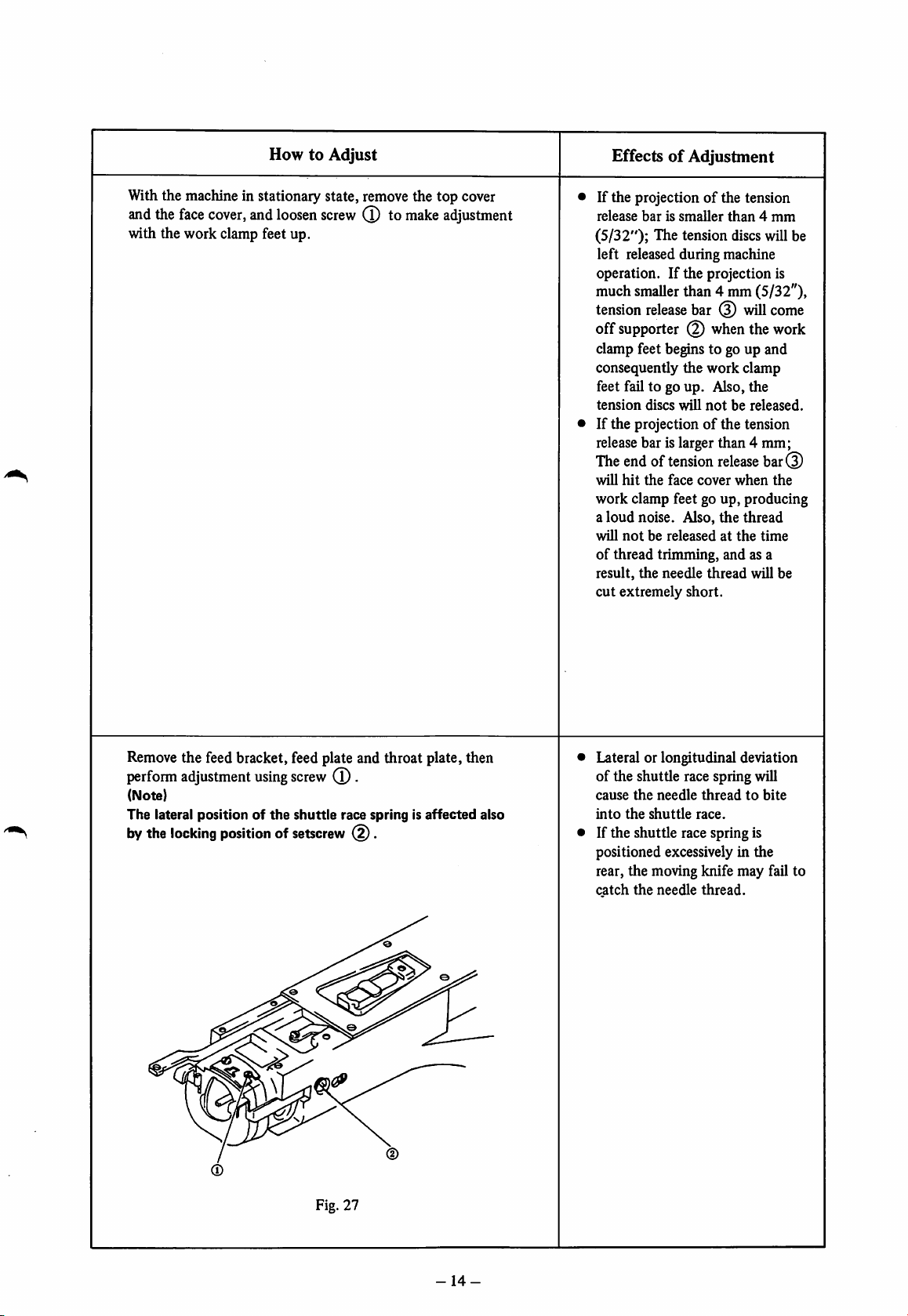

(12) Position of the shuttle race spring

The

shuttle

shouldbepositioned

(Note)

Presence of any scrathes on area B may cause breakage of the bobbin thread. Grind and smooth

scratchesIfany.

race

spring

shouldbeevenly

longitudinally

positioned

sothat the

laterally

rear

edge

Fig. 26

with

ofthe

respect

needle

to the

aUgns

with

needle

corner

entry

Aas

point,

shown

out

and

below.

it

-

13

-

Page 18

HowtoAdjust

EffectsofAdjustment

Withthe machine in stationary state, remove the top cover

and

the

face

cover,

and

loosen

screw

(T)tomake

adjustment

with the work clamp feet up.

If the projection of the tension

release

barissmaller

than4mm

(5/32"); The tension discswill be

left released during machine

operation. If the projection is

muchsmallerthan 4 mm (5/32"),

tension

off

release

bar (3) will come

supporter when the work

clamp feet begins to go up and

consequently the work clamp

feet fail to go up. Also, the

tension

discs

will

notbereleased.

If the projection of the tension

release bar is larger than 4 mm;

The end of tension

will

hit

the

face

cover

release

when

bar(3)

the

work clamp feet go up, producing

a

loud

noise. Also,

will

notbereleasedatthe

the

thread

time

of thread trimming, and as a

result,

the

needle

thread

will be

cut

extremely short.

Removethe feed bracket, feed plate and throat plate, then

perform

(Note)

The

bythe

adjustment

lateral

locking

using

positionofthe

positionofsetscrew

screw

shuttle

Fig. 27

(T)

.

race spring is

(^.

affected

also

Lateral or longitudinal deviation

of the shuttle race spring will

cause

the

needle

threadtobite

into

the

shuttle

race.

If the shuttle race spring is

positioned excessively in the

rear, the moving knife may fail to

catch

the

needle

thread.

-14-

Page 19

Standard

Adjustment

(13) Adjustment of

1) Timingofthe

Theneedle bargoesup from the lowestpoint of its stroke until the lowermarker line

the

needle

timing between

bar

the

needle and

the

shuttle

engraved

needlebar is flush with the bottom end of the needle bar bushing(lower). (Fig. 28)

2) Timing of

the

shuttle

Whenthe state is as described in the above 1), the center of the needle coincides with the point of the

shuttle at A. (Fig. 29)

3)

Clearance

between

the

needle

and

the

shuttle

driver

Whenthe state is as described in the above 2), there should be no clearance between the needle and the

shuttle driver. (Fig. 30)

4) Clearance between

the

needle and

the

pointofthe

shuttle

Whenthe state is asdescribed in 2), the clearance Bbetween the needle and the point of the shuttle

should

5)

Clearance

be0.05 to 0.1 mm(0.001" ~ 0.004")-

between

the

needle

arid

the

shuttle

(Fig-

race

31)

The clearance between the side face of the needle and the shuttle race should be 7.5 mm(19/64"). (Fig. 32)

1) Timing of

the

needle bar 2) Timing of

Shuttle

Needle

bar

Needle

bar

bushing

(lower)

the

shuttle

'0

Lower

marker

Fig. 28

line

on the

Fig. 29

3)

Clearance

the

Shuttle

Fig.

5)

shuttle

driver

30

Clearance

and

the

between

driver

between

shuttle

the

race

needle

the

7.5 %

needle

(19/64")

and

Shuttle

race

4)

Clearance

the

between

pointofthe

CD

©

shuttle

(D

the

needle

Fig. 31

0.3-0.5%

(0.011"-0.019")

and

0.0

5-0.1%

(0.001"-0.003")

Fig. 32

15-

Page 20

HowtoAdjust

1)

Referring

to Standard Adjustment (1)

Height

of the

needle

make the lower marker line engravedon the needle bar flush

with the bottom end of the bushing.

2)

and3)Loosen

setscrew

0 of

the

shuttle

driver,

and

adjust

the rotational and longitudinal directions of the shuttle driver.

(Caution)

Ensuretoturn

Fig.29when

the

shuttleinthe

adjusting

the

timingofthe

arrowed

directionasshown

shuttle.

4) Loosensetscrew (4) of the shuttle race, and turn eccentric

shaft

(D to

make

adjustment.

5)

Loosen

setscrew

0 to

perform

adjustment.

Enoughcare should be exercised whenperforming the

adjustmentdescribed in 4),

namely

the adjustmentof the

clearancebetween the needle and the point of the shuttle.

(Note)

The

clearanceinthe

and

the

shuttle

0.019") as shown in Fig. 29.

Strike

points

After

adjustment,

vertically

with

rotational

driver

shouldbe0.3

C or D

respecttothe

check

for

that

direction

mmto0.5

adjustment.

point

C is evenly spaced

shuttle.

between

mm

the

shuttle

(0.011

bar,

in

EffectsofAdjustment

1) and2)

Slightly

reduce

the height

of the needlebar (upper marker

line) for floppy material, and on

the contrary, slightly increase the

height for heavy-weight material

to adjust the timingofthe

shuttle.

(For prevention of stitch skipping)

3) If the clearance is more than 0

mm,

the

needle

will be

bent

the direction of the shuttle point,

causing scratches on

point

and

the

contrary,

contact

however, excessive

between

the shuttle driver may cause

the

shuttle

needle. On the

the

needle

stitch skipping.

4) If the clearanceis greater than

0.05 to 0.1 mm (0.001 ~ 0.003"),

stitch skipping will occur. If it is

smaller than the specifled values,

the needle strikes the shuttle point

and scratches occur, leading to

thread breakage or fine splits of

thread.

5) If the clearance is smaller than

7.5 mm(19/64") the needle

thread will

not

be fully spread,

often causing the needle thread

to

bite

into

the

shuttle.

in

and

Fig. 33

•Ifthe

shuttle

greater

clearance

drive

than

between

and

the

shuttle

0.3to0.5 mm

(0.011" ~ 0.019"), the shuttle

noise

willbelouder.

contrary,ifthe

enough, poorly tensed stitches

will result when sewing with a

thick

thread.

On

clearance is

the

is

the

not

-16-

Page 21

Standard

Adjustment

(14) Lateral positionofthe

The center of the work clamp foot should lie at the

the 18th stitch for 28-stitch large size bartacking.

Fig. 34

work

clamp

26th

stitch

(for

42-stitch

bartacking)

18th

stitch

(for 28-stitch large size

bartacking)

large size

foot

26th

stitch for 42-stitch large sizebartacking, and at

Fig. 35

(15) Adjustment of

The

clearance

(0.0H"~

between

0.019")

the

auxiliary knife driving cam

the

when

Changing

endofthe

roller©fits

pulley

auxiliary

inthe

knife

recess

driving

ofthe

<S)

cam

knife

Knife

and

roller(Dshouldbe0.3to0.5

driving

cam.

driving

cam

Auxiliary knife driving cam

Roller (2)

Roller

@

0.3-0.5%(0.0110.019")

(D

mm

Fig. 36

-17-

Page 22

HowtoAdjust

EffectsofAdjustment

Loosen

shaft in the arrowed directions for adjustment.

To conect slight deviation, loosen the lateral feed adjusting nut and

push the work clamp foot to the right or left to perform adjustment.

locknut

(T)

ofthe

feed

cam

roller

shaft,and

move

the

roller

• Improperly positioned center

the work clamp foot would cause

the needle to hit the work clamp

foot, leading to breakageofthe

needle.

of

1) Push down the starting lever, and manually turn the driving

pulley to lower the work clamp foot.

2) Further push down the starting lever,and turn the changing

pulley in the arrowed direction until roller fits in the recess

of

the knife driving cam.

3) Loosenthe setscrews,and make adjustment so that a clearance

of 0.3 to 0.5 mm (0.011"~ 0.019") is provided between the

end

ofthe

auxiliary

roller fits in the recess of the knife driving cam.

knife

driving

cam

and

roller

(3)

when

If

the

clearance is extremely

large, the thread trimming timing

will be delayed, resulting in

thread trimming failure.

Ifnoclearanceisallowed

the endofthe auxiliary knife

driving

trimming action will be inter

rupted at the timeofthread

spreading with resultant thread

cam

and

trimming failure.

roller

(3),

between

thread

-18-

Page 23

Standard

Adjustment

(16) Positionofthe

Positionofthe

Positionofthe moving knife

counter

moving knife

knife

The clearance between the counter knife and the needle hole guide

should be 0.5 mm (0.019")-

The needle hole in the needle hole guide should meet the hole in the

movingknife at the time of stop motion (before the work clamp foot

goesup).

Counter

Needle

guide

Moving

and

0.5%

(1/2")

hole

knife

the

knife

counter

knife

Moving

knife

link

(17) Height of

Moving

Counter

(18)

The

and bobbin thread).

knife : Engagement of the needlehole guidewith the

knife:Difference

Tiltofthe

counter

the

moving knife and the counter knife

between

the

needle

0.1 to 0.15 mm (0.003"~0.005")

Counter knife Moving knife

0.1-0.1

(0.003"-0.005'

5%

®

counter

knife

blade

knife

surface

blade

shouldbetilted

Counter

Fig. 37

hole

guide

f

r-w

ylT')Tv

Needle

hole Throatplate

guide

Fig. 38

by0.2mmto

knife

\ ® ©

moving

knifeblade 0.15 mm(0.005")

andthe counter

1

u.i

• m

(0.005")

evenly

cut thetwo

knife

bladeinheight

threads

(needle

thread

0.5% -T

(1/2")

t

Fig. 39

-19-

-r-0.2%

t (0.007")

Page 24

HowtoAdjust

1) Positioning the counter knife

Loosen

knife.

setscrew

(T),

and

adjust

2) Positioning the movingknife

Loosen

knife.

(Note)

The

knife passes by

by

normal

A.

setscrew

operationofthe

the

@ ,

Inside of

and

adjust

the

positionofthe

the

position

knives Is

the

needle hole guide as shown

such

that

ofthe

the

counter

moving

moving

EffectsofAdjustment

If

the

clearanceissmaller

than

0.5 mm (0.019"), the thread will

be trimmed by the blade point

of

the

counter

knife

when

the

moving knife pulls the threads

and

bobbin

too

therefore

short.

threads

the

needle

willbetrimmed

and

If the clearance is greater than

0.5 mm (0.019"), the thread

remaining on the fabric after

thread trimming will be longer.

If the moving knife is deflected

to

the

counter

trimmer

knife,

the

thread

willbeactuatedatthe

timeofstop motion, or the thread

spreader will fail to work properly,

resulting in thread trimming

failure.

If the moving knife is spaced too

much

from

the

counter

knife,

the

thread trimming mechanism will

stick, causing thread trimming

failure, or

the

needle will

strike

the moving knife, leading to

needle breakage.

1) Adjusting the heightof the

moving

knife

Adjust the height of the movingknife accordingto the thickness

of

washer

(3) of

Fig.

37. If properadjustment of the

moving

knife cannot be obtained, select and use one of the following

parts.

Part

B242328000A

B242328000B

B242328000C

B242328000D

No.

.

Description

Moving

Moving

Moving

Moving

knife

knife

knife

knife

washer

washer

washer

washer

Thickness

0.4

m/m

0.5

m/m

m/m

0.6

0.7

m/m

2) Adjusting the height of the counter knife

Wrench

portion

@

usingascrewdriver

orthe

liketomake

adjustment.

Shave

side

side

© ifthe

(Caution)

Make

degree

© ifthe

suretoform

when

threadonside

threadonside

either

shaving

sides

(g) isnot

© isnot

side Into an angle smaller

© or

©.

JZL-O,

trimmed,orshave

trimmed.

than

90

2

Acute

angle

Insufficient

differenceinlevel

(specifiedvalue: 0.25 to 0.3 mm)

(0.009"~

moving

0.011") between the

knife and the counter knife

will lead to thread trimming failure.

Excessive

differenceinlevel

(specifiedvalue: 0.1 to 0.15 mm)

(0.0030.005")

between the

needle hole guide and the counter

knife will cause the blade point

the

counter

knifetotrim

of

the

threads when the moving knife

pulls the threads, and as a result,

the

needle

and

willbetrimmed

If

the

tiltissmaller

(0.007"),

will

the

notbetrimmed.

bobbin

threadonside

too

short.

than

threads

0.2

mm

©

If the tilt is larger than 0.2 mm

(0.007")

will

the

threadonside

notbetrimmed.

©

-20-

Page 25

Standard

Adjustment

(19) Adjustment of

Thelengthofthe thread

1-37/64") from the needleeye.

In caseof a synthetic thread, the remainingneedlethread should be longerthan that of cotton thread.

the

remaining

length of

N

the

remaining needle thread

on the

needle

after thread

trimming

shouldbe35 to 40 mm (1-3/8'

Tension

controller

No.

1

(20) Adjustment of the thread take-up spring

Stroke:

Tension:Make

Should

the horizontal of the L-shaped thread guide.

(The

sewing operation.)

be adjusted so that the thread

adjustment

proper

while

checking

tensionissuch

thatthe

the stitch performance.

thread

take-up

Thread

a

spring

take-up

take-up

moves

spring

spring

Fig. 40

approx.8 mm(5/16") from

moves

for

the

full

strokeinactual

Fig. 41

-21

-

Page 26

HowtoAdjust

EffectsofAdjustment

Perform adjustment by the tension controller No. 1.

• As the tension controller No. 1 is turned in direction A, the

length of the remainingneedle thread willbe reduced.

• Asthe tension controller No. 1 is turned in direction B, the

length will be increased.

(Caution)

Take care

thread

too

RefertoStandard

trimming,

short.

nottomake

otherwise

Adjustment

the

thread release timing

the

needle

(11).

thread

too

will be

late for

trimmed

Insufficient lengthofthe remain

ing thread will cause the thread

to slip off the needleat

start.

sewing

If the remaining thread is too

long, the needle thread will

protrude

onto

the material, or

clumsy wrong sideofmaterial

will

result.

1) Adjustingthe stroke.

Loosening

controller

setscrew

No.

(T),

2 (2)to tum it for

insertascrewdriver

adjustment.

into

tension

2) Adjustingthe tension

First securely tighten the setscrew, then insert a screwdriver

into tension controller No. 2 to turn it for adjustment.

If the stroke is greater than 8 mm

(5/16"), the thread remaining on

the needle will be

the thread will slip

at sewing start.

too

off

short,

and

the needle

-22-

Page 27

(21)

Adjustmentofthe

belt

tension

Standard

Adjustment

Boththe

high-speed

belt and

low-speed

belt shouldslackabout 10mm(25/64") whenthe

middle

of the belts (the point shown by arrow) is pushed by a finger under an approx. 1 kg pressure.

i

Idler

puller

Motor

pulley

Fig.

42

Fig. 43

Driving pulley

(22)

Adjustmentofthe

bobbin

winder

The clearance between the bobbin windingwheeland the V belt shouldbe about 3 mm (1/8") when

the wheel is

not

winding a bobbin.

Brake

1

(D

Vbelt

3%

/

Winding

,

Bobbin

presser

0

boss

belt

support.

_rj

:±]

III—i

Fig. 44

(1/8")

Fig. 45

-23

-

Fig. 46

Page 28

HowtoAdjust

EffectsofAdjustment

1) Adjusting the high-speed belt tension

Adjust the tension of the high-speed belt first.

Loosen

themotor

belt tension has been obtained, tighten the screwand nut.

2) Adjusting the

Loosen

and

When

screws.

fixing

screw

(l)

and

nut ,

mounting

screws

move

the idlerpulleyto the rightandleft to makeadjustment.

basetomake

low-speed

Q) in

belt tension

the

holes

and

move

adjustment.

(three)ofthe

upor

When

driving

properbelt tensionhasbeen obtained, tighten the three

down

proper

pulley,

Excessive tension of the high

speed belt will prevent

mnofthe high-speedpulley with

consequent reduction in high

speed operation.

Inadequate tension will increase

idlingvibration, and prevent the

machine from reachinghighspeed,

causing the machine to idle and

stop.

smooth

1) Adjust the position of the V belt by

motor pulley.

2)

Perform

comesin light contact with the edge of the belt while a bobbin is

being wound.

3) Ifa

bobbin winder to the right or left.

adjustmentbyscrew@so

bobbiniswound

unevenly,

Bendtothe

loosen

left.

moving

that

Tobein

screw

the motor or the

the

winding

light

contact

0 and

bend

Bendtothe

belt

support

the

M

4) To adjust the amount of thread to be wound round a bobbin,

loosen

nut (2) and

to make adjustment.

move

backor forth the bobbin

presser

boss

right.

If

the

clearance

than 3 mm

touch the winding wheel and

wear

out.

If the belt support fails to come

in light contact with the belt, the

winding speed will be low.

allowedissmaller

(1/8"),

the belt will

-24-

Page 29

5.

OTHER

(1)

PRECAUTIONS

Configurationofthe

shuttle

race

Precautions

ring

If the shuttle point has been found worn

severely, remove the shuttle race ring and check

whether the hatched portion on the rear side

measures

(2)

Howtoremove

0.2 mm(0.007") x 8 mm (5/16").

the

backlashofthe

Shuttle

driver

out

shuttle

shaft

driver

shaft

0.2%

(0.007")

8%

* n r

Fig. 47

(5/16")

(3)

Howtoremove

Gear

connection

the

backlashofthe

Screwdriver

^ 1 ^

Fig. 48

main

shaft

-t

0 Thrust collar

Fig. 49

-25-

Page 30

Procedures

If the hatched portion does not measure0.2 mm (0.007") x

8 mm(5/16"), correct it usingan oilstone.

Removing the axial backlash

Loosen

while pushing the shuttle driver shaft in the directionofarrow.

Removing the rotational backlash

Replace

among the followings.

o 13508353 Shuttle drivershaft gearconnection (Y)

two

setscrews

the gearconnection by an appropriate one selected

(T)ofthe

thrust

collar,

and

tighten

them

(0.2 smallerindia.)

o 13509054 Shuttle drivershaft gearconnection (Z)

(0.1 smallerin dia.)

o 13509153 Shuttle driver shaft gear connection (A)

(Standard)

o 13509252 Shuttle driver shaft gearconnection (B)

(0.1 larger in dia.)

o 13509351 Shuttle driver shaft gear connection (C)

(0.2 larger in dia.)

Remarks

•

Tighten

in the direction of arrow using ascrewdriver or the like.

Setscrew

the fiat partofthe main shaft.

thrust

(T)isthe

setscrews

first

(T)

and

setscrew.

while

twisting

Tightenitso

thatit

the

crank

fits

to

•

An

axial

backlashonthe

shaft would adversely affect the

speed reducer and the feed timing.

• The properplayis0.01 to 0.04mm.(0.0003"~ 0.0015").

(Note)

Make suretocheck

motion

cam

after

the

timingofthe

removing

the

feed

backlash.

cam

and

-26-

the

stop-

main

Page 31

Precautions

(4)

Howtoremove

the

backlash

Cam

between

shaft

the

Worm

worm

and

worm

Worm

gear

(D Crank rod

gear.

Fig. 50

(5)

Howtoremove

the

backlashofthe

feed

bracket

Backlash of the feed cam roller(Fig. 74) or feed slideblock (Figs.73 and 74) would lead to lateral or

longitudinal backlash of the feed bracket.

-27-

Page 32

Procedure

Remarks

1) Remove the top cover.

2)

Loosen

four

screws

(T)

•

3) Holdingthe cam shaft, turn the worm in the direction of arrow

with care taken not to disturb the timing between the main

shaft

and

the

cam

shaft.

This

will

make

the

worm

advance

toward the rear bushing of the main shaft, removing the

backlash.

4)

After

(Note)

If

been

cam.

removing

the

timing

disturbed,

the

between

readjust

backlash,

the

main

the

securely

shaft

stop

motion

tighten

and

timing

the

four

cam

screws

shaft

and

the

(X).

has

feed

1) Replace the feed cam roller by one of the followings.

(69

B250228000A

B250228000B

B250228000C

Feed

Feed

Feed

cam

cam

cam

roller

roller

roller

5

09.5

09.5

+0.005

_o.So5

An

excessive

backlash

would

adversely affect the feed timing.

If no

backlash

worm will get

is allowed,

hot,

and the main

the

shaft torque will increase, causing

stop motion failure or idling stop.

2) Replace the feed slide block by one of the followings.

13516604

13516703

13516802

Feed

Feed

Feed

slide

slide

slide

block

block

block

12 °

-0.009

+0.009

+0.018

+0.009

0

-28-

Page 33

6.

DISASSEMBLING

&

ASSEMBLING

Disassembling & Assembling Procedures

PROCEDURES

AND

PRECAUTIONS

(1) Disassembling

the

shuttle

driver

shaft

1) Remove the pedal pressure

decreasing unit.

2)

Loosen

remove

3) Loosen the two setscrews of

the

4) Loosen and remove the set-

screw

regulating arm B, and take

out

ing arm B down from the

shaft. (See Fig. 72)

5) Draw

shafttothe

* Assemble them by reversingthe above disassembling procedure

(2) Disassembling

setscrew

the

shuttle

thrust

collar.

of

the stop-motion

the stop-motion regulat

out

the shuttle driver

rear.

driver.

the

(T),and

main

shaft

Shuttle

driver

Thrust

Fig. 51

collar

1) Remove the speed reducer.

2) Remove the needle.

3) Remove the stop-motion lever.

4)

Loosen

the counterweight and four

setscrews

5)

Loosen

the

the

6) Loosen and remove two set-

screws

collar.

7) Loosen and remove setscrew

0 of the

bushing.

8)

Remove

two

setscrews

of

the

two

setscrews

crank

rod,

and

crank

rod

cover.

@ of the thrust

main

the

thread

(Dof

worm.

(5) of

remove

shaft

take-up

rear

spring

( (3) in

Fig.

doesnot interfere with the rear end of the bushing.

9)

Applyasbrass

*

Assemble

barto pointA,tap it to

them by

reversing

draw

the abovedisassembling procedure.

11),

out the

and

main

position

shaft

the

knife

together

driving

with

rear

cam

arm

bushing

DO

sothat it

(2).

-29

Page 34

Precautions in disassembly

Precautions in Assembly

• When drawing out the shuttle driver shaft, never remove the

dowel pin from the shuttle drivershaft gear, or else the shuttle

drivershaft needle bearingwillbe damaged.

a

Dowel

pm

• Besure to use a soft metal such as a brass bar when tapping

point

A.

At this time, remember to tap it gradually.

• When reassembling the same

gears,

put

the mating faces

the gears to their original

position to prevent loud gear

noise.

To assemble the main shaft, place

a covering piece on the end

knife

driving

cam

©,

and

it gradually using a brass bar or

the

liketodriveinthe

bushing of the main shaft.

Securely fit the

© into

rear bushingofthe main shaft,

and

the

long

fit

it.

rear

endofsetscrew

groove

ofthe

of

of

tap

-30-

Page 35

Disassembling & Assembling Procedures

(3) Disassembling

1)

Remove

2)

Loosen

3)

Loosen

4)

5)

6)

7)

speed

* Assemble the unit by reversing the above disassembling procedure.

setscrews

setscrews

Remove

Loosen

setscrew

Remove

Loosen

setscrew

pulley

the

the

presser

(D to

(|)toremove

low-speed

A

changing

pulley

0 .

speed

reducer

plateof the

remove

pulley

®,

and

0

,

then

changing

ball

bracket

washers@and

adjusting

then

setscrew

and

low-speed

loosen

and

pulley.

(2)

shim

(5)

B 0

pulley

remove

(Fig.

15)

.

mounting

and

pulley

(tapered

spring

setscrew

(large)

disc

(s)

.

spacer

(8)

.

screw)toremove

© •

O

(tapered

low-speed

pulley

screw)toremove

shaft

high

(Q)

Fig. 53

-31

-

Page 36

Precautions

in Disassembly

Precautions in Assembly

Note that setscrew B is a tapered screws.

Low-speed

loosening the screw, however, it is advisable to remove

the screw for easier assembly.

pulley

shaft

O

canberemoved

only

by

1)

Attach

screw

O

d)

sothat

enters

tapered

tapered

hole

®.

2) Apply grease to the low-speed

pulley springs before attaching

them

to (© .

3)

Attach

screw

(g) in the mainshaft. At this

time,becareful

springs

the

changing pulley, and also

twist the pulley springs.

(Caution)

Take

otherwiseItwouldbedifficult

remove It later. (35 kg-cm)

(Q)

0

0 to

flatheaded

care

notto

sothat

enters

tapered

nottocause

interfere

screwsofthe

overtighten

Screw

tapered

hole

with

not

to

0

to

4) The clearances between low-speed

pulley®,changing

and

high-speed

be about 0.4 mm (0.015") each.

(Tieck

thatacontraction

1 mm is obtained when the

shown by an arrow in the figure

below is pushed forcibly (0.2 mm

-»•

(0.007")

adjustment by increasing or

decreasing the number

shims

thickness).

* As the number

shims is increased,

willgrow larger.

0 mm). Perform this

(2)

(0.1

0.2 %

(0.007")

pulley

pulley

0

of

of

adjusting

© ,

should

about

part

mm (0.003")in

of

the adjusting

the

clearances

uftfU

mmn

WA]

1

%C0.039")

mm

Push

here

JMLI

32-

Page 37

Disassembling & Assembling

Procedures

(4) Disassembling

1)Byremoving

pulley

(2)

(Ball

bearing0has

2)

Remove

3)

Loosen

cluth,

from

4) Stop-motion cam pawl and safety stopper

spring

stop-motion

(Stop-motion

* Assemble the high-speed pulley (asm) by

reversingthe above disassemblingprocedure.

three

and

stop-motion

O

the

high-speed pulley (asm)

bearing

canberemoved

preload

high-speed

snap

been

spring0and

screws

O

clutch

cam

ring(Dfirst,

together

force-fitted.)

and

@

0)

.

canberemovedbydrawing

cam

pin

(0)

.

cam

pin

0

is

force-fitted.)

with

pulley

spacer

© of

the

canberemoved

then

pulley

ball

bearing

0 .

high-speed

out

spacer

snap

<D

ring

and

adjusting

0,

washer0and

shim

(D,

high-speed

ball

bearing

0

(5) Disassembling

1)

Loosen

pulley.

2)

Changing

pulley

(6) Disassembling

1)

Remove

2)

Low-speed

force-fitted.

and

remove

pulley

(2).

ball

bearing

pulley@and

the

changing pulley

setscrew

shaft0comes

the

low-speed pulley

snap

0 of

ring0and

ball

the

changing

off

changing

then

washer

bearing@are

Fig. 55

0

Fig. 56

-33

Page 38

When

remove

ring in

Precautions in Disassembly

taking

ball

bearing®out

snap

ring

{4)

the

directionofarrow.

and

washer

from

(D,

high-speed

then

push

pulley

the

inner

(2),

Precautions in Assembly

1) Apply greaseto stop-motion cam

pin 16 before force-fitting it.

2) Apply a thin coat of greaseto

surface

cam.

® ofthe

stop-motion

3) Adjust the clearancebetween

high-speedclutch and high

speed

pulley

(2)byincreasing

decreasing the numberofadjusting

shim(D(0.1

thickness).

* As the number of the adjusting

shims is increased,

will grow smaller.

mm

(0.003")

the

clearance

in

or

•

Carefully

lock

tite.

remove

0.2

(0.007"

setscrews

±0.05-H

±0.002")

(T)

since

they

are

Adjusting

fixed

by

shim

4)Toinstall

a thin coatofgreasetothe inner

ring, and push the outer ring to

force-fit it into the pulley. At this

time, take care

scratchesonthe

the high-speed pulley.

5) Of the three setscrews for the high

speed

shorter

shorter

cam

Apply lock tite to three setscrews

ball

clutch,

than

screw

O •

bearing®,apply

not

to produce

end

one

the

for

surface

setscrew

rest.

(§)

of

O is

Use

this

stop-motion

©.

When force-fitting the ball bearing,

take care

scratches

the low-speed pulley.

-34-

not

on

to produce any

the

end

surface

of

Page 39

Disassembling & Assembling Procedures

(7) Assembling

1)

Attach

fixthem by nut (5) .

2)

Drive

3)

Fit

clutch

contact with the pinofthe clutch latch.

4)

Attaching

so that the groove of the inner sleeve fits to the pin of the pressure decreasingclutch latch.

5)

Apply

comesincontact

6)

Apply

to the input shaft.

7)

Attach

Attach

8)

through

the

reverse

lowering

spring

screw

Esso

TemprexN3to

Esso

TemprexN3to

input

shaft

outer

sleeve

(0

pedal pressure decreasing

rotation

shaft

and

preventing

collarB0)

(5)

onto

0 to

thrust

with

the

O to

guide

the

assembly

latch@and

into

pressure

outer

endofclutch

input

ball

ring

decreasing

collar®for

sleeve

shaft

bearing

(©toouter

comprising0through

input

sleeve,

Cj).and

spring

O ,

@ ,

sleeve

unit

spring

shaft

clutch

(j).

then

and

(D to

0)

.

latch0so

set

them

attach

itsothat

attach

needle

fixitby

(Q),then

0 .

mounting

onto

snap

install

that

the

inner

the

stopper

bearings

ring

© •

the

base0by

endofthe

sleeve0).

©

assembly

hinge

spring

Then

pinofthe

and

(Q),and

including

screw

comes

install

outer

collar

0,

in

them

sleeve

A O

O

O

-35

-

Page 40

Precuations

in Assembly

1) Pay attention to the attachingdirection when attaching the

reverserotation preventing latch, spring, and hinge screw.

Use

locktite to fixnut (?).

2)

When

driving

end

surfaces

collarB(01

flush

with

each

into

other.

input

Flush

shaft

(Q),make

their

Precautions

in Disassembly

3) Theclutch springshouldbe

screwed

onto the pressure

decreasingclutch latch so that the end of the spring comes

in contact with the stopper pin. However, be careful not to

screw the spring onto the latch excessively, otherwise the

spring will be deformed.

Apply Esso Temprex N3 to the circumferenceofthe screw.

Pay attention to the orientation of the spring.

4)

Fin

Grooveofthe

inner

sleeve

• To remove the clutch spring,

draw it out while wrenching

point

®

driverorthe

forcibly pull

usingasmall

like.

out

screw

Do

not

the spring, or

the spring would be deformed.

Endofthe

spring

5)

Bring the pin

the

outer

sleeveinthe

inner

sleeve.

contact

with

the

endofthe spring, and

directionofarrowtoattachitto

-36-

turn

the

into

Page 41

9)

Install

input

shaft@assemblytopressure

10)

Attach

idler

mounting

11)

Inserting

aligning the tapered holeofthe shaft

with the tapered hole

decreasing

12)

Tighten

pressure

clutch

setscrew

plate

decreasing

of

the pressure

latch

(Fig.

(J).

Disassembling & Assembling Procedures

(3)topressure

shaft

57,

from

©).

decreasing

decreasing

directionB(shownbyarrow),

unit

unit

frame,

frame

(from

(T)bysetscrew

the

directionofarrow

(3).

driveindowel

pin

A)

(^,

13)

14)

15)

Attach

Attach

by

hinge

Using

clamp

spring

upper

screw

setscrew

foot

lifting

suspension

and

lower

(3).

A ®

and

levers

to

work

clamp

work

clamp

foot

lifting

setscrewB(5),attach

(§),

respectively.

foot

(D

lifting

levers

lever

®

lever

(D to

latch

link

work

A ®

(T).

clamp

and

lever

foot

latch

lifting

B @ to

lever

link

work

®

Fig. 59

37-

Page 42

6)

When

frame,

installing

take

care

Precuations in Assembly

theinput

not to

shaft

pinch

to the

reverse

pressure

rotation

decreasing

preventing

unit

latch

Precuations in Disassembly

When

taking out the dowelpin,

be careful not to hit it reversely,

or

else

the

head

wouldbecrashed

and the dowel pin would not come

out.

7) The

8)

9)

dowel

reversely.

Use

lock

Apply

pinis tapered,and thereforedo not

tite to

grease

suspension0onto

fix

setscrews

to thepartsof

which

A 0

andB0.

hinge

screw

the

springishooked.

(3) and

drive

spring

it in

To draw out pressure decreasing

shaft (5), draw out the dowel

pin,

loosen

setscrew

tap the shaft from direction A.

® ,

and

-38-

Page 43

16)

Using

decreasing

17)

Fix

18)

Inserting

19)

Attach

20)

Tighten

hinge

screw

unit

eccentric

stopper

tension

sleeve

(3)

and

frame

0 .

pin0by

screw0into

spring

(8)tothe

thrust

collar

Disassembling & Assembling Procedures

eccentric

setscrew

screw

pin

0,

0.

pressure

work

clamp

((8) of

attach

work

decreasing

Fig.

foot

57).

unit

lifting

clamp

frame

lever.

© @

foot

0 ,

lifting

lever

fixitusing

(asm)

nut

(2)topressure

0 .

Fig. 60

-39-

Page 44

Precuations in Assembly

10)

Apply

greasetohinge

Make

11)

adjustmentbyeccentric

reverse rotation preventing latch comes in contact

with

the

pressure

by 1/4to 3/4

when

lever@touches

Fig. 57).

Outer

12)

When

the

clutch

and the adjustment has been considerablydisturbed,

replace

pressure

The

contact with the pressure decreasing clutch by 1/4 to

3/4 at the point shown below.

the clutchspringor cut the springendon the

decreasing

reverse

rotation preventinglatch should come in

screw

(3)

pin

decreasing

latchAof

the

sleeve preventing latch

spring

clutch

clutch

work

stopperofouter

Reverse

(^ of

latch

Fig.

(® of

and

eccentric

(J)sothat

latch

clamp

sleeve((Q)

rotation

57)

((6) of

foot

has

Fig.

pin

(§).

the

end

of

Fig.

57)

lifting

of

Pressure decreasing

clutch

In

contact

1/4to3/4

been

replaced

57).

Precuations in Disassembly

latch

by

Outer

sleeve

13)

The

clearance

andlatchAof

be 0.5 mm (0.019").

Adjust

14)

Fix the screwofthe pressure decreasing sleevecollar in a

position where it does not touch points A when the outer

sleeve

is turned with latch A of work clamp foot lifting

lever

sleeve.

between

work

clamp

the

clearancebystopper

0.5%

f

(0.019")

in

contact

with

outer

sleeve

foot

lifting

screw

I—

Stopper

the

circumferenceofthe

( O or

lever

©.

screw

Screw

Fig.

(g)

57)

should

outer

-40-

Page 45

7.

PARTS

TO

BE

FIXED

WITH

LOCKTIGHT

Sinceagreat

loosen

Accordingly,

have

number

been

fixed

whenever

ofstartsand

with

lock

stops

tite.

thesepartshavebeen

are

expectedinoperating

disassembled,

this

machine,

clean

themwith thinnerand dry

applying lock tite to them for reassembly.

If it is difficult to remove a screw fixed with lock

tite,

heat

it with a torch lamp or the like.

Theparts using lock tite that are usuallydisassembled are asshownbelow.

(1)

Stop-motion

•

Endofthe

Fig. 61

lever

shaft

lever

shaft

Screwonthe

lever

stop-motion

stud

(2) Stop-motion lever

•

Endofstop

link

^—Stop-motion

i-motion

rod

Setscrewsofchanging

spring

spring adjusting

adjusting

the

screws

(3) Changing pulley

Fig. 63

nut

(large)

nut

(small)

that

well

•

pulley

are

before

Setscrews

likely

to

(4)

Throat

•

Knife

Knife

(Caution)

Lock

else

plate

driving lever

driving

lever

Fig. 64

titeisused

the

functionsofthe

stud

for

stud

many

hinge screws. Be

parts

(5) Work

• Work clamp

Setscrew(B)

Setscrew®

Setscrew@

Fig. 65

very

may be damaged.

Fig. 62

clamp

Work

careful

foot

foot

Work

/

clamp

lifting lever

lifting lever latch

clamp

foot

lever

latch

foot

lifting

nottoallow

lifting

(A)

(6)

lock

titetosticktotheir

Shuttle

•

Gear

Fig. 66

driver

shaft

dowel pin

Dowel

shafts,

gear

pin

or

-41

-

Page 46

8.

PARTS

(1)

(2) Grease to be used

TO

Refill

grease

Lithium-based grease

BE

FILLED

once

every

WITH

other

GREASE

yearorwhen

the

parts

filled

with

grease

have

been

disassembled.

Maker

Esso

Shell

(3) Partsto be

If a

1) Main shaft components