Page 1

No.OO

BE5150SOBOA

Page 2

CONTENTS

I.

GENERAL DESCRIPTION

l.

Remarkable features

2.

Specifications

II. INSTALLATION AND

l.

Installation............................................................................................................... 3

2.

Motor pulley and belt

3.

Preparation for operation

III.

HOW

TO OPERATE THE MACHINE

I. Lubrication.............................................................................................................. 5

2.

Lubrication

3.

Attaching the needles

4.

Twist

of

5.

Passing the needle thread

6.

Passing the bobbin thread

7.

Adjusting the thread tension

8. Adjusting the stitch length

9.

Reverse feed (LH-515)

IV.

HOW

TO ADJUST THE MACHINE

l.

Timing

2.

Adjusting

3.

Movement

4.

Adjusting

the blade

5.

Detaching and attaching the sewing hook

6.

Adjusting the height of feed dog

7.

Adjusting the needle bar frame

8.

Adjusting the maximum stitch length (LH-515)

9.

Replacing the timing belt

10. Adjusting the position

V.

HOW

TO OBTAIN IDEAL SEWING CONDITIONS

Standard sewing conditions

Troubles and corrective measures

.........................................................................................................

OPERATION

.......................................................................................

.................................................................................

of

the sewing hook

.......................................................................................

thread

......................................................................................................

........................................................................................

of

the bobbin case opening motion

the

bobbin case opening mechanism

of

the needle and the sewing hook

the

clearance between the needle and

point

of

sewing hook

of

.....................................................................

.................................................................................

.................................................................................

...........................................................................

..............................................................................

.............................................

.......................................

..........................................

...............................................................

................................................

..................................................................

.....................................................................

.......................................

.................................................................................

the timing belt

....................................................................................

........................................................................

...................................................

2

3

4

6

6

6

7

8

8

10

I 0

11

11

12

13

14

14

15

16

16

17

18

19

Page 3

I.

GENERAL DESCRIPTION

JUKI Model LH-512

machine with a sewing speed

JUKI Model LH-515

machine equipped with reverse feed mechanism, which

high speed operations

at excellent durability.

1.

REMARKABLE FEATURES

is

a high speed, 2-needle, needle feed, lockstitch industrial sewing

of

4,200

s.p.m.

is

a high speed, 2-needle, needle feed, lockstitch industrial sewing

is

designed for withstanding

up

to

the

maximum sewing speed

of

3,500

s.p.m. and for aiming

o Link type thread take·up

This

type

of

industrial sewing machine has usually been designed

on

the

principle of a slide

sewing speed and durability. By overcomming such technical problems,

Model LH-515 has successfully been designed

take-up mechanism which has sufficient durability

type

thread take-up, although it was

to

employ

without

the

puckering

o Feed mechanism

This model employs a push

For

needle bearings.

high speed operation, a durable and seizure-free material is used

block

type

feed driving mechanism.

the

button

purpose

type

lead cam regulating system and also

of

preventing any abrasion

o Lubrication system

The lubricating oil y.rhich

pump

located on

driving shaft saddles, pushed

also

is

delivered

face plate

take-up lever shaft.

All

other

bearing metals are made

lubrication.

to

is

constantly

the

is

fed from

hook

driving shaft

up

the

thread take-up lever shaft.

lubricated through

the

to

the

oil sight window

of

special sintered alloy which does

oil reservoir by means

is

distributed

the

oil wicks connected

to

the

on

the

The

inside mechanism

o Bobbin case opening mechanism

The

bobbin

achieve one

the

conventional models

the

improvement extends

running noise.

case opening mechanism

motion

while

of

the

which

the

sewing

the

life-time

of

the

Model LH-515

hook

rotates twice, being different from

mechanism achieves

of

the

sewing

is

two

hook

o Hook shaft bearings

High speed feature and durability

precision needle bearings in

and right.

the

of

upper

this model

bushings

of

is

assured

hook

shafts

to

be operated

not

sufficient in

JUKI

link

type

thread

the

fabrics.

or

seizure during a

for

the

of

the

plunger

left and right

machine arm and

to

so designed as

motions. Thus,

and minimizes

by

employing

on

the

the

not

both

hook

of

thread

slide

the

need

to

the

left

-1-'-

Page 4

2.

SPECIFICATIONS

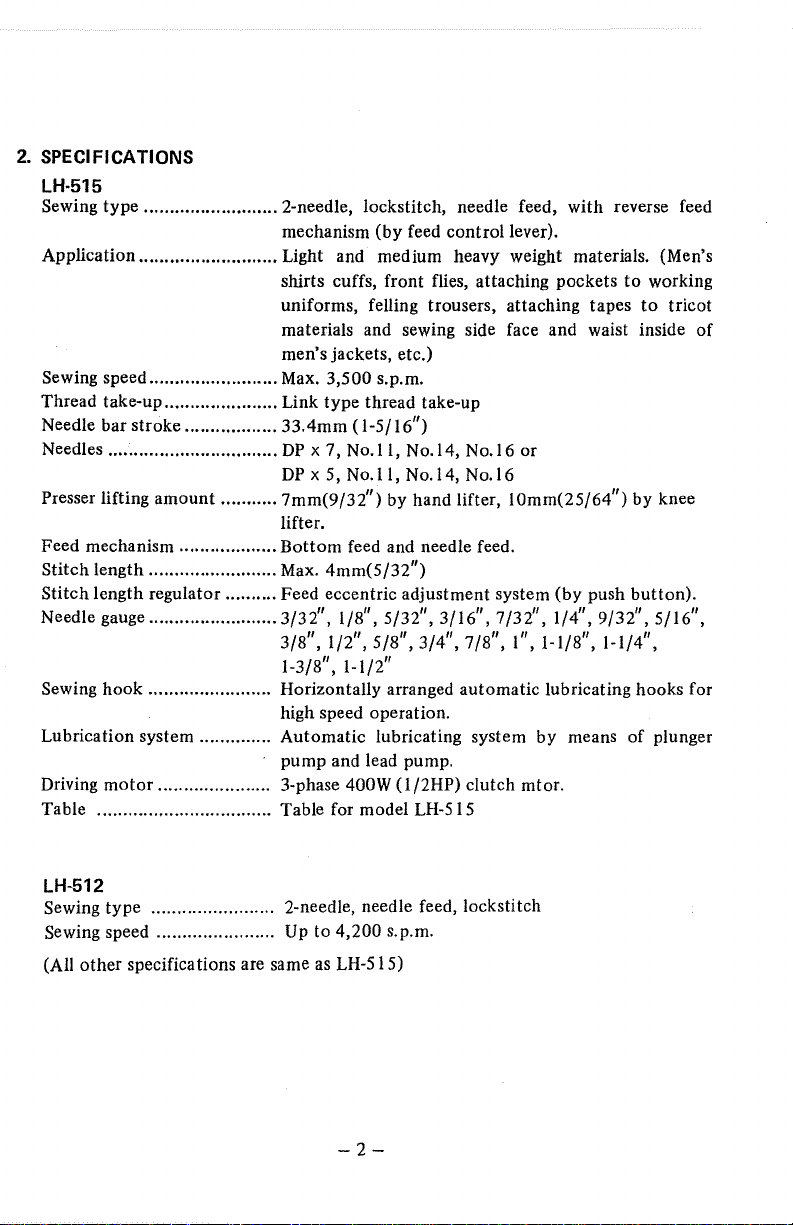

LH·515

Sewing

type

.......................... 2-needle, lockstitch, needle feed, with reverse feed

(by

mechanism

feed control lever).

Application ........................... Light and medium heavy weight materials. (Men's

shirts cuffs, front flies, attaching pockets

uniforms, felling trousers, attaching tapes

to

working

to

materials and sewing side face and waist inside

men's jackets, etc.)

Sewing speed ......................... Max.

Thread take-up ...................... Link

Needle bar stroke ..................

Needles .................................

Presser lifting amount ...........

3,500 s.p.m.

type

thread take-up

33.4mm

DP

DP

( 1-5/ 16")

x 7, No.I I,

x 5, No.I I,

7mm(9/32")

No.l4,

No.l4,

No.l6

No.l6

or

by hand lifter, 10mm(25/64")

by

lifter.

Feed mechanism ...................

Stitch length ......................... Max.

Stitch

length regulator .......... Feed eccentric adjustment system (by push

Needle gauge .........................

Bottom

4mm(5/32")

11

3/32

, 1/8

3/8",

l/2",

1-3/8",

feed and needle feed.

11

11

,5/32

,

3/16",

5/8",

3/4",

7/8",

1-l/2''

7/32",

I",

1/4",

1-l/8",

button).

9/32",

l-l/4",

Sewing hook ........................ Horizontally arranged automatic lubricating hooks for

high speed operation.

Lubrication system .............. Automatic lubricating system

by

means

of

pump and lead pump.

Driving

Table .................................. Table for model

motor

...................... 3-phase 400W

0/2HP)

LH-5

clutch mtor.

l 5

tricot

of

knee

5/16",

plunger

LH-512

Sewing type ........................ 2-needle, needle feed, lock stitch

Sewing speed .......................

other

(All

specifications are same

Up

to

4,200

as

LH-515)

s.p.m.

-2-

Page 5

II.

INSTALLATION AND OPERATION

1.

INSTALLATION

The

following procedure will simplify

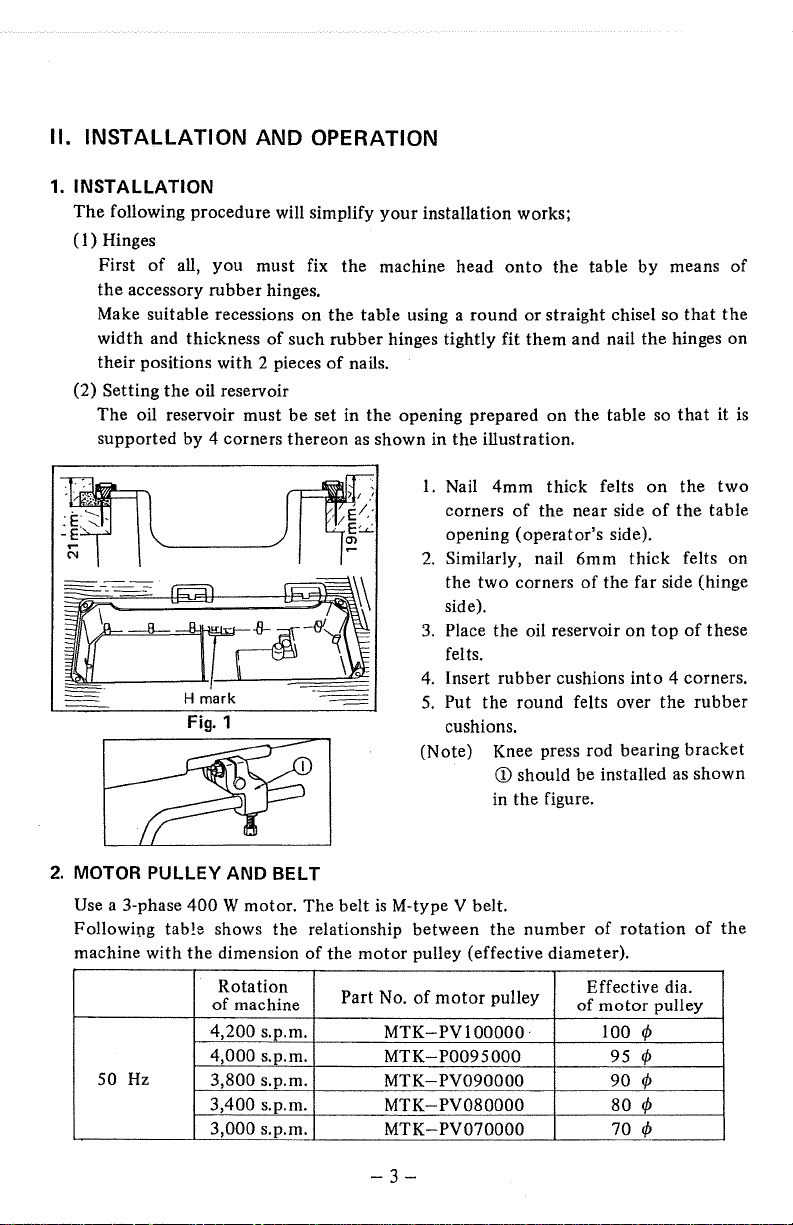

(1) Hinges

First

of

all,

you

must fix

the

accessory

Make suitable recessions on

width

their

positions

(2) Setting

The oil reservoir must

supported by 4 corners

---

rubber

and thickness

with

the

oil reservoir

hinges.

of

such

2 pieces

be

thereon

~

set

~~F~

~

Hmark

Fig.

-~

1

your

installation works;

the

machine head

the

table using a round

rubber

hinges tightly fit

of

nails.

in

the

opening prepared on

as

shown in

1.

2.

3.

4.

5.

(Note) Knee press rod bearing

the

Nail

corners

opening

Similarly, nail

the

side).

Place

felts.

Insert rubber cushions

Put

cushions.

onto

the

table

or

straight chisel so

them

and nail

the

illustration.

4mm

thick felts

of

the

near side

(operator's

6mm

two

corners

the

the

round felts over

CD

should be installed as

in

the

of

oil reservoir on

figure.

by

means

the

hinges on

table so

on

of

side).

thick

the

far side (hinge

top

into

4 corners.

the

that

the

that

it

the

two

the

table

felts on

of

these

rubber

bracket

shown

of

is

~I

2.

MOTOR PULLEY AND BELT

Use a 3-phase

Following tab!e shows the relationship between

machine

50

Hz

with

400

W motor. The belt

the

dimension

Rotation

of

machine

4,200 s.p.m.

4,000 s.p.m.

3,800 s.p.m.

3,400 s.p.m.

3,000

s.p.m.

of

is

M-type V belt.

the

motor

Part No.

MTKMTK-P0095000

MTK-PV090000

MTK-PV080000

MTK-PV070000

-3-

the

number

pulley (effective diameter).

of

motor

pulley

PV 1

00000

· 100

of

Effective dia.

of

motor

95

90

80

70

rotation

pulley

rp

rp

rp

rp

rp

of

the

Page 6

Rotation

of

machine

4,200

s.p.m.

4,

000

s.

p.m.

60Hz

(Note)

3.

PREPARATION

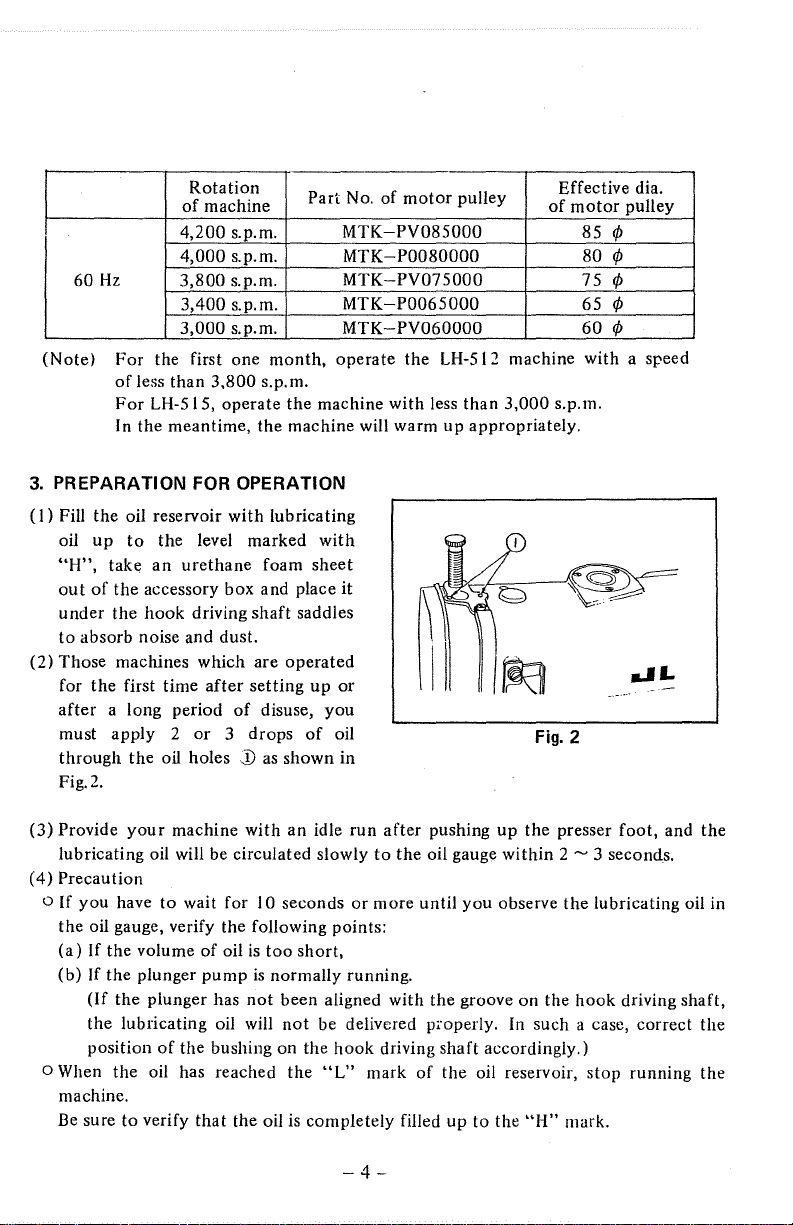

(I)

(2)

For

of

For

In the meantime, the machine will warm

Fill the oil reservoir with lubricating

oil

up

"H",

take

out

of

the accessory box and place

under

the

to

absorb noise and dust.

Those machines which are

for the first time

after

a long period

must apply 2

through

Fig.2.

3,800

s.p.m.

3,400 s.p.m.

3,000

s.p.m.

the first one

less than

LH-515, operate

to

hook

the oil holes

3,800

FOR

the level marked

an

urethane

driving

after

or 3 drops

month,

s.p.m.

OPERATION

foam sheet

shaft

setting

of

disuse,

j)

as shown in

Part

No. of

motor

MTK-PV085000

MTK-P0080000

MTK-PV075000

MTK-P0065000

MTK-

PV060000

operate

the

machine with less than

with

it

saddles

operated

up

or

you

of

oil

the

3,000

Fig.

Effective dia.

of

motor

pulley

85 ¢

80 ¢

¢

75

¢

65

¢

60

s.p.m.

2

pulley

LH-512 machine with a speed

up

appropriately.

(3)

Provide

lubricating oil will be circulated slowly

(4)

Precaution

o If

the oil gauge, verify the following points:

(a)

(b)

o When the oil has reached the

machine.

Be

your

machine with

you

have

to

If

the volume

If

the

plunger

(If

the plunger has

the

lubricating oil will

position

sure

to

of

verify

an

idle

wait for 10 seconds

of

oil

is

too

short,

pump

is

normally running.

not

been aligned with the groove on the

not

be delivered pl·operly. In such a case, correct the

the bushing on the

"L"

that

the oil is completely filled

run

after

pushing

to

the

oil gauge

or

more until

hook

driving shaft accordingly.)

mark

of

you

the

oil reservoir,

up

to

up

the

within

observe

the

"H"

presser

2 ~ 3 seconds.

foot,

the

lubricating oil in

hook

driving shaft,

stop

running the

mark.

and

the

-4-

Page 7

Ill.

HOW TO OPERATE THE MACHINE

1.

LUBRICATION

The

amount

plate mechanism has normally been ad-

justed at

necessary, you may adjust it

the

adjusting screw shown in

The stable

supplied

from

through

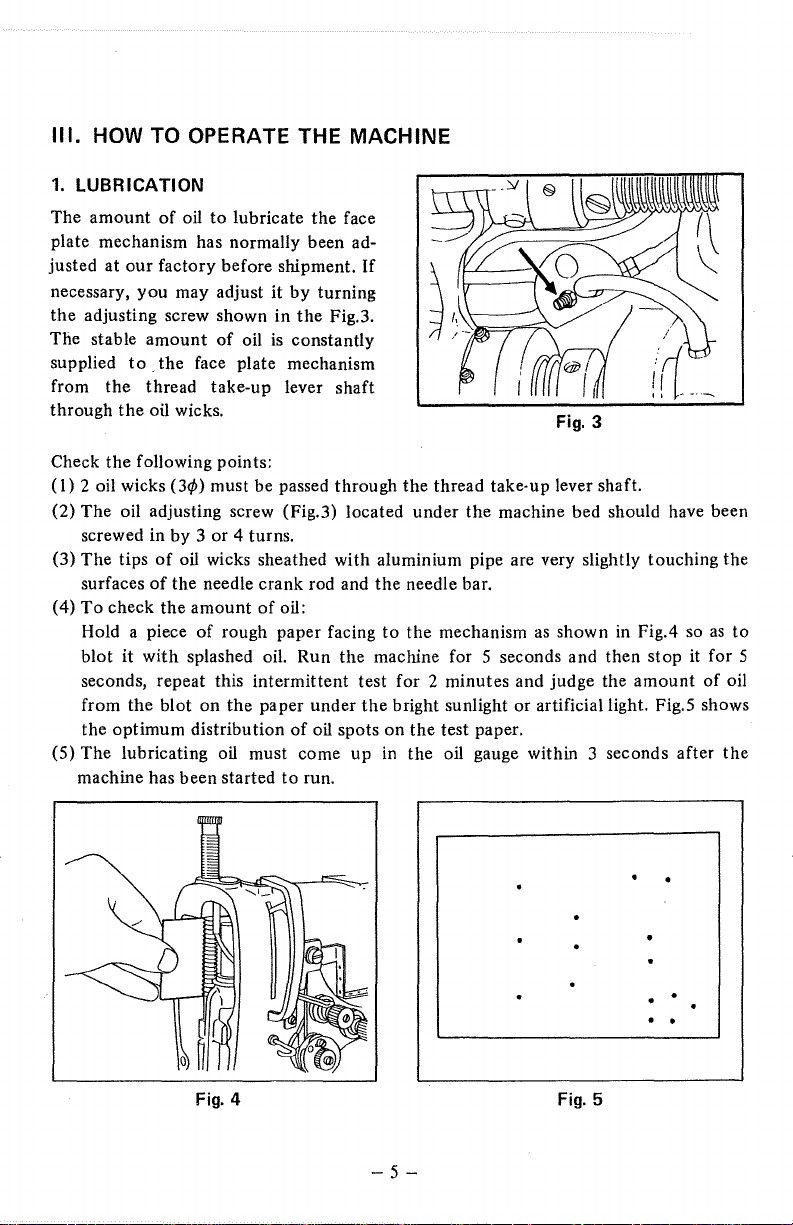

Check the following points:

(I)

2 oil wicks

The

(2)

screwed in

(3)

The

surfaces

(4)

To

Hold a piece of rough paper facing

blot

seconds, repeat this intermittent test for 2 minutes and judge the amount of oil

from the blot on

the optimum distribution

(5) The lubricating oil must come up in the oil gauge within 3 seconds after

machine has been started

of

oil

to

lubricate

our

factory before shipment.

amount

to

. the face plate mechanism

the

thread take-up lever shaft

the

oil wicks.

oil adjusting screw (Fig.3) located under the machine bed should have been

tips

of

of

check the amount

it

with

of

oil

(3c/>)

must be passed through

by

3 or 4 turns.

oil wicks sheathed with aluminium pipe are very slightly touching the

the needle crank rod and

splashed

the

the

face

If

by

turning

the

Fig.3.

is

constantly

Fig.

3

the

thread take-up lever shaft.

the

needle bar.

of

oil:

to

the mechanism

oiL

Run the machine for 5 seconds and then stop it for 5

paper under

of

to

the

bright sunlight or artificial light. Fig.5 shows

oil spots on the test paper.

run.

as

shown

in

Fig.4 so

as

to

the

• •

Fig.

4

Fig.

5

-5-

Page 8

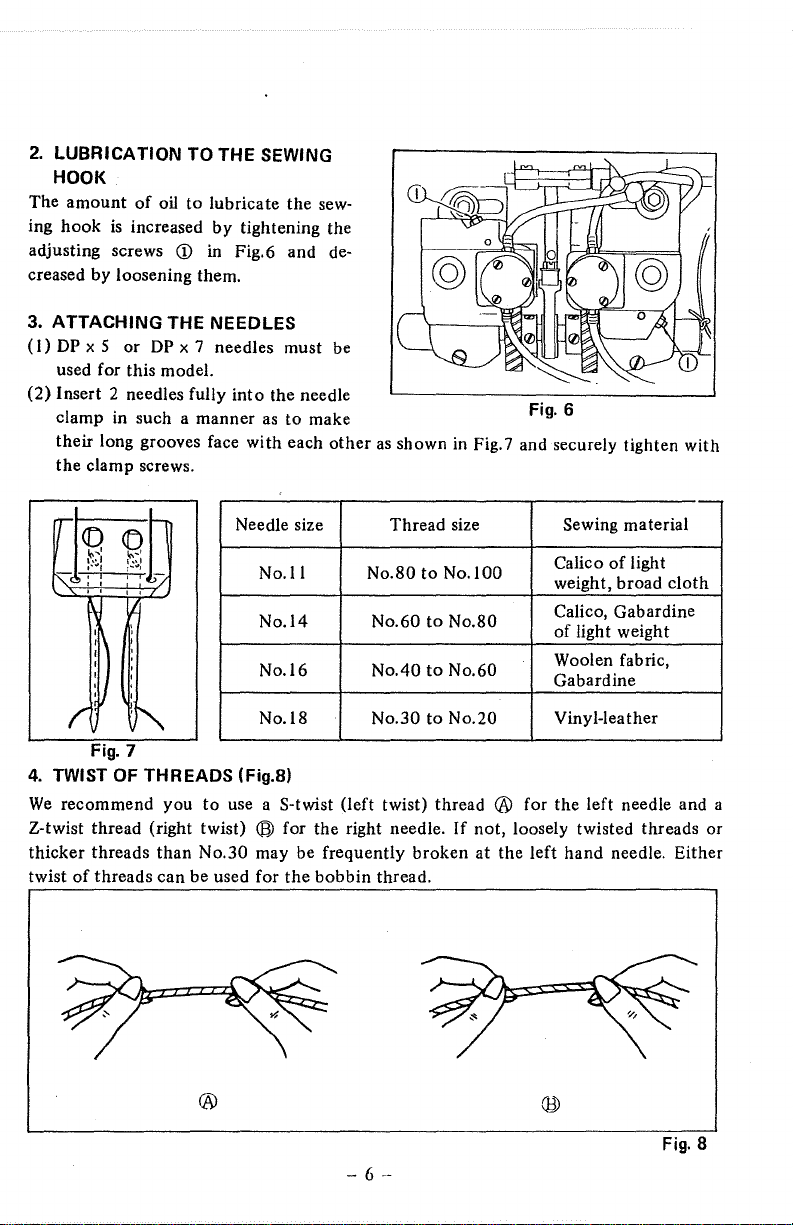

2.

LUBRICATION TO THE SEWING

HOOK

The

amount

ing

hook

adjusting screws

of

is

increased

oil

to

<D

lubricate

by

in

tightening the

Fig.6 and de-

creased by loosening them.

ATTACHING THE NEEDLES

3.

(I)

DP

x 5

or

DP

x 7 needles must be

used for this model.

(2) Insert 2 needles fully

clamp in such a manner

into

as

their long grooves face with each

the

clamp screws.

rT

<f)

<D

...

I

"''I

,,.J

i•"

,~

...

,

:

.....

,

)/

: I

'

'

!'C

Y.

: H

I I :

I '

I 1

I

I

I

Fig.

of

threads

·~

7

than

can

r

4.

TWIST OF THREADS (Fig.8)

We

recommend you

Z-twist thread (right twist)

thicker threads

twist

Needle size Thread size

No.I I

No.l4

No.16

No.l8

to

use a S-twist (left twist) thread ® for the left needle and a

® for the right needle. If not, loosely twisted threads or

No.30 may be frequently broken

be used for

the

sew-

the needle

to make

other

the

bobbin thread.

as

shown

No.80

No.60

No.40

No.30

in

Fig. 7 and securely tighten with

Sewing material

to

No.lOO

to

No.80

to

No.60

to

No.20

at

Calico

weight, broad

Calico, Gabardine

of

light weight

Woolen fabric,

Gabardine

Vinyl-leather

the left hand needle. Either

of

--

light

cloth

®

Fig.

8

- 6

--

Page 9

5.

PASSING THE NEEDLE THREADS

Pass the needle thread in the order shown in Fig.9.

The needle thread

operators' side) must be passed in the order

thread take-up lever upper hole

in the order

-+

hole

right needle).

to

of ® to

be passed through

-+left

the

of

needle). The right

® (Right thread tension disc

left hand needle (seeing from the

<D

to

® (Left thread tension disc

hand

needle

must

be passed

-+

thread take-up lever lower

-+

Fig. 9

-7-

Page 10

6.

PASSING THE BOBBIN THREAD

When

you

pull

out

the

bobbin

through the bobbin case holder, verify

that

the thread

notched

shown

7.

(1)

(2) Bobbin thread tension.

part

in

Fig.l

ADJUSTING THE THREAD

TENSION

Needle thread tension.

For

obtaining optimum needle thread

tension, turn the thread tension post

nut

<D

needle thread and

left

hand needle thread. The thread tension will be increased by clockwise turn and

decreased by counterclockwise turn.

For

adjusting the bobbin thread tension, turn the adjusting screws

the

left and right bobbin case holders. Clockwise

clockwise

is

passed through the

<D

of

thereof

0.

Fig.ll

turn

without

for the right hand

the

nut

decreased the bobbin thread tension.

thread

fail,

as

® for the

Fig.

10

<D

turn

increases and counter-

of

Fig.l2

on

Fig.

11

- 8 --

Fig.11

Page 11

(3) Tension

For

spring stud

by

tension post

ahout

of

thread take-up spring.

adjusting

the

tension

(['

of

Fig.l3. The tension

of

the thread take-up spring,

counterclockwise turn. After adjustment, lock

nut ® of

20

g.

and the stroke

Fig.l3.

is

Normally, the tension

7mm(9/32")

light fabric or a synthetic fiber material,

increase it's stroke.

To

change the stroke

and slide the stopper ®

Fig.

13

of

the thread take-up spring, loosen the screw

to

the right for increasing and

is

increased

to

you

turn

the thread take-up

by

clockwise

it

of

the thread take-up spring

10mm(i3/32

turn

and decreased

by

tightening

11

).

When you sew a very

the

thread

must lessen the spring tension and

<D

of

Fig.l4

to

the left for decreasing.

Fig.

14

is

-9-

Page 12

8.

ADJUSTING THE STITCH LENGTH (Fig.15)

As

you

keep on pressing

wheel

® manually. When

stitch length, which is indicated

pointer®

down

the

button

the

·button·is engaged with a groove, adjust a desirable

by

CD

the

graduations

Kl

on

the machine bed, rotate the hand

on

the handwheel,

!

to

the

Fig.15

9.

REVERSE FEED (LH-515)

To

produce

limited by the stopper. The reverse feed is

the

reverse stitches, press down the feed lever

kept

as long

Fig.

CD

as

you press it.

16

Fig.l6

fully until

it

is

-10-

Page 13

IV. HOW TO ADJUST THE MACHINE

1.

TIMING

When the

bottom

bar has gone

engraved marks located od the pivot

with each

OF

upper

surface

up

other

THE BOBBIN

line engraved

of

the needle bar frame ( ® of

by 0.2 ~ 0.3mm(l/l28" ~ 3/256")

as

shown in Fig.l8.

CASE

OPENING MECHANISM

on

the needle

of

the bobbin case opening lever link must aligned

bar

(CD

Fig.l7),

from

of

Fig.l7)

in other word, when the needle

it's

coincides with the

bottom

dead point,

two

Fig. 17

2.

ADJUSTING THE BOBBIN

Adjust the position

bobbin case holder allowing the thread

of

such thread

surface

of

throat

( ® of Fig.20),

careful

may make a high noise and shorten

not

to

of

the bobbin case opening lever

at

the moment when

plate

as

obtain

a correct position and finally tighten

allow it

Fig.

to

19

CASE

OPENING MECHANISM

the

shown in

open the bobbin case holder

Fig.l9.

it's

Fig.18

(CD

of

Fig.20) so

to

pass through depending

needle thread

To adjust the said lever, loosen

lifetime.

-

11-

is

pulled

the

too

much, or the sewing

Fig.

as

to

open the

upon

the thickness

up

along

the

bottom

the

screw

screw. You must be

hook

20

Page 14

3.

MOVEMENT

OF

THE NEEDLE AND THE SEWING HOOK

(1 I Timing

Set

o When the needle has gone

0 When

o The

of the needle

the

feed

amount

timing

of

the needle and

the

points

their needles,

0.05mm

of

2mm

as shown in Fig.21B.

hook

point must point

needle eye as shown in Fig.21A.

Fig.

and

the sewing hook (Fig.21A &

to

2mm(5/64"),

the

of

left and right sewing hooks coincide

the

clearance between each

21A

up

sewing

at

a higher level

(Note)

The upper engraved marking line on

surface

The lower engraved line

of

the

needle

bar

frame, when

thereon

will coincide with the

when the needle bar has gone up by

2mm(S/64

and remove

2mm(5/64

hook

the

needle

the

needle bar

the

11

) from it's

is

as shown

hook

by

0.05mm

bar

is

11

) from it's

21

B)

throat

plate.

bottom

in

Fig.

point and

1.2mm(3/64

Fig.

21

with

11

218

dead point,

A.

the

center

the

needle face

)

than

the

will coincide with the

at

the

bottom

bottom

bottom

dead point.

surface

of

dead point.

lines

top

bottom

the

the

of

is

edge

frame,

-12-

Page 15

(2) Matching

hook

Loosen

the

small gear which drives

driving shaft (small) and adjust

of

ing

In

order

ness,

the

said screw

push down

gear at

4.

ADJUST THE CLEARANCE BETWEEN THE NEEDLE

(Fig.23)

Adjust

way:

(a)

Remove

(b) Tilt

(c)

Loosen 3 screws which fix a

saddle; A', B' screws are for

(d)

Tap

(e)

Tighten

the

timing

of

the

set screw ( Q)

sewing hook.

to

eliminate any vertical loose-

after

adjustment,

with

the

the

same time.

the

clearance

the

the

machine head backwards.

the

hook

the

you

such a

hook

and

by

presser foot and the

driving shaft saddle gently

screws A(A') and B(B') and finally fix

the

sewing

of

Fig.22) on

the

the

must tighten

manner

to

pull

up

correcting

hook

the

hook

tim-

as

to

the

the

sewing

throat

driving shaft saddle (A, B screws

left saddle.)

plate.

to

correct

hook

AND

THE HOOK POINT

position according

it's

position.

the

saddle.

are

to

following

for

the

right

A

Fig. 23

-13-

Page 16

5.

DETACHING

THE SEWING HOOK

(1) Detaching the sewing hook.

(a)

Open the bed slide

(b) Bring up

remove

the

AND

ATTACHING

..

the

presser foot and

throat

plate.

(c) Loosen 2 hexagon socket head

screws

(CD

of

Fig.24), which fix

a sewing

by

hook

to

it's driving shaft,

using a hexagonal spanner

stored in the accessory box.

at

it's

(d) Bring up the needle

dead point

the

handwheel and take out

by

manually rotating

top

the

sewing hook upwards.

(2) Attaching the sewing hook

(a)

Reverse the procedures mentioned in

(b) Before attaching the

that

the protruding part thereof agrees with the groove on the

6.

ADJUSTING THE HEIGHT OF

THE FEED

DOG

The standard height

measuring from the

throat plate

in

Fig.25. Adjust it,

is

0.8mm(l/32"),

throat

of

the

top

surface

if

necessary, by

plate, manually rotate the bobbin case holder so

feed dog

of

the

as

shown

loosening 2 screws which set the feed

dog.

(1

Fig.

24

).

throat

plate.

Fig.

25

-

14-

Page 17

7.

ADJUSTING THE NEEDLE BAR

FRAME

The

correct clearance between

surfaces

ser

bottom

ing when

to

The correctly adjusted feed movement

constantly follows

center

For

( ®

needle bar so

dog and re-tighten the clamp screw.

If

clamp screw

screw

screw

the

holes on the feed dog as mentioned before.

of

the needle bar and the pres-

foot

is

14mm(35/64")

surface

Omm,

of

adjusting

of

Fig.27) on

the rock shaft driving

(CD

(CD

presser bar becomes

of

the

presser bar bush-

the

stitch length has been set

as

illustrated in Fig.26

up

the

the needle hole on the feed dog.

the

longitudinal position

the

needle bar rock shaft driving rod crank

that

the needles are pointed

(CD

of

Fig.28)

of

Fig.27), pull the driving rod crank fully towards you, re-tighten

of

Fig.28) at the point where

the

measuring

movement

rod

( ®

on

the

16.

5mm(21/32"),

outer

of

of

of

Fig.27) hits

rock shaft driving arm (rear) before tightening the

is

proved by the motion

the feed dog and

the

needle

bar

frame, loosen

at

the

center

of

the

the

surface

the

said clearance between

and finally align

the

Fig.

26

of

the

needle which

is

always pointing at

the

clamp screw

(CD

of

Fig.27), adjust the

needle hole

of

the arm, loosen the

needles with

on

the

needle bar and

the

the

the

clamp

needle

the

feed

Fig.

27

-IS-

Fig.

28

Page 18

8.

ADJUSTING THE MAXIMUM STITCH LENGTH(LH-515)

When

you can

position of the feed limiting plate (

machine bed.

If the maximum stitch length

backwards, loosen 2 screws (

plate upwards.

downwards and re-tighten the screws firmly. After adjustment you must measure the

maximum stitch length for the distance

stitches on a piece

The maximum stitch length

of

the feed limiting plate using the adjusting screw

(@

of

Fig.29) and turn the screw clockwise for increasing the stitch length or counter-

clockwise for decreasing.

9.

REPLACING THE TIMING BELT

Firstly, you must remove

feed control lever shaft. Tilt

head backwards and loosen 2 screws

which set the arm

shaft. And remove the end screw which

is

located on

feed lever and take

shaft as they are assembled together

the

from

right hand side.

(l)

Disengage the timing belt from

sprocket wheels.

(2) Take

with the built-in bearing.

Pull

(3)

opening made by

belt for replacement with care not

give

not

get the maximum stitch length, you can adjust it

of

®

of

If

the

stitch length is

of

paper.

of

the reverse feed can be adjusted by changing the height

the

the

machine

to

the

control lever

the

opposite side

out

the

lever and

machine head towards the

out

the

handwheel together

out

the timing belt from the

® and insert new

any sharp

bentto

the

new belt.

by

changing the

d)

of

Fig.29) located on the back side

the

normal feed

Fig.29) clamping the feed limiting plate and slip the

too

reverse

of

the

it's

the

to

is

not enough, tilt the machine head

long, on the contrary, slip the said plate

of

II

stitches by manually forming such

(@

of

Fig.29). Loosen the lock nut

Fig.

29

of

the

-

16-

Page 19

10.

ADJUSTING THE POSITION OF THE TIMING BELT

After

replacing

position

shaft with each other.

Rotate

same level as

hook

wheel (

belt

on

the

driving shaft

®

at this position.

or

of

it so as

main shaft in

the

of

Fig.31)

Fig.

disengaging

to

match

the

top

surface

in

the

normal direction

is

aligned

30

the

timing belt from

the

movements

normal direction

of

the

throat

plate as shown

until

with

the

timing mark ( ®

of

until

the

sprockets,

the main shaft and

the

needle has

in

Fig.30, then,

the

first screw

of

on

Fig.3l)

Fig.

you

must adjust

the

come

the

and

31

hook

down

lower

put

driving

to

rotate

sprocket

the

timing

the

the

the

-17-

Page 20

V.

HOW

TO OBTAIN THE IDEAL SEWING CONDITIONS

o STANDARD SEWING CONDITIONS

Thickness

of

thread

Sewing

material

Needle

Needle

thread

tension

Bobbin

thread 15 to

tension

Thread

take-up

tension

Thread

take-up

stroke

Sewing

speed.

(s.p.m.)

Tetoron

No.

Tetoron

broadcloth

2 sheets

DPx

No.I I

12mm 12mm

(15/32")

SO

7 DP X 7

20g

20g,

15g.

3,500

Nylon

No.60 No.

Tetoron

broadcloth gabardine gabardine

2 sheets 2 sheets 2 sheets 2 sheets

No.l4

25

to

30g. 45 to 50g. 50 to 60g. 80 to

15

to

20g. 25 to 30g.

15g. 25g.

(15/32")

3,500

Cotton Cotton

SO

Cotton Cotton

DPx

7

No.l4

lOmm lOmm 12mm

(25/64") (25/64") (15/32")

3,500 3,500 3,500

No.

SO

DPx

7

No.l4

25

to 30g. 30 to 40g.

25g.

Vinyl on

No.30

Vinylleather

DP

X 7

No.l8

lOOg.

30g.

-18-

Page 21

o TROUBLES

AND

CORRECTIVE MEASURES

Trouble

A.

Thread breakage.

1.

Thread

is

or worn

2.

out

Needle thread

snapped remaining a length

to

3cm (about

1") on the bot-

tom

surface

sewing material.

ravelling

is

of

2

of

Cause

{1)

There are scratches

surface

of

thread paths,

pointed end

hook point or on the rear groove the throat plate groove.

of

the throat plate

the bobbin case holder.

(2) Needle thread tension

high.

(3) Bobbin case opening mecha-

nism actuates too much. bobbin case opening mechanism

(4) Needle contacts with the o Tap the hook driving shaft

sewing hook.

(5) Lubricating oil fed

sewing hook

{1)

Needle thread tension

low.

(2) Thread take-up spring has

high tension and small stroke.

(3)

Needles are attached incor- o The cross-section view of 2

rectly.

(especially synthetic fiber thread top.

is

used.)

of

is

on

the o

on

the

the needle, on the for the hook

to

positioning

is

too

to

too short.

the

is

too

Corrective measures

Make

those surfaces smooth by

of

to

111-7.

of

~

~

@

point

of

thread take-up

111-7-(3)).

as

a fine sand-paper

or a buff for

to

the sewing

sewing hook.

of

oil fed to

is

affected

20g. and bobbin

is

15g. in the case

viewed from their

~

§

@

making use

o Refer

"Adjusting the thread tension".

o Loosen the set screw on the

and bring it closer

hook. (see IV-2).

saddle gently to adjust the clearance between the needle and the

blade point

(see IV-4)

o Adjust the amount

the sewing hook. (see III-2).

o Synthetic fiber thread

significantly. Suitable needle

thread tension is

thread tension

of Synthetic fiber thread.

(see III-7).

o Decrease the tension and increase

the stroke

spring. (see

needle eyes

a.

Not good for synthetic fiber

thread.

b.

Standard.

c.

In some cases good for synthe-

tic fiber thread.

-

19-

Page 22

Trouble

Cause

Corrective measures

B.

Skip-stitching.

(4) Motions

needle are

nized with each other. (see IV-3-(l)).

(5) Timing

motion

(l)

Clearance between the hook

point and needle

(2) Motions

the needle are not synchronized

correctly with each other.

(3)

Presser foot

(Pressing force

(4) Needles are positioned

incorrectly.

(5) Height of the needle bar

correct.

of

sewing hook and the o Adjust the timing between the

not

properly synchro- needle and the hook.

of

bobbin case opening o Adjust the timing

is

not

correct. opening motion. (see IV-1).

is

too much.

of

sewing hook and

is

not

functioning.

is

too small).

o Correct the clearance. (see IV-4)

o Correct their timing. (see IV-3-(1))

o Tighten the presser spring

regulatr.

is

not

~

o Correct their position.

(see above A-2-(3))

o Upper marking line on the needle

bar must coincide with the

bottom surface

frame when the bar

be:·,,~

of

bobbin

--~~

of

needle bar

is

at

the

1

C.

Irregular stitches.

(1) Bobbin thread

through the notched part of

tension spring on the bobbin

case.

Outer rim

(2)

smooth enough to rotate freely .

of

is

not

bobbin

....;_

20-

passed

is

not

~-l_\~E-..-,-ll...lt---

UJ

o

Pass

the bobbin thread through

the notched part. (see III-6).

o Replace the bobbin or polish it

with a fine sandpaper.

Page 23

Trouble Cause

Corrective measures

1.

Irregular stitches

are f orrned

sewing speed varies.

D.

Puckering

sewing material

occurs very

frequently

as

of

(1)

Tension

the spring

(2) Bobbin case opening mechanism does

(3) Bobbin thread tension

low. (see III-7-(2)).

( 4) Surface

smooth.

(5) Sewing hook

the

(1)

tensions are too high.

(2) Bobbin thread

tight in the bobbin. again more softly

(This

synthetic fiber thread.)

(3) Pressing force applied by the o Loosen the presser spring

presser foot

( 4) Bottom surface

foot is

(5)

of

the thread take-up

is

too low. (see

not

work timingly.

is

of

thread paths is

is

faulty.

Both needle and bobbin thread

is

wound too o Take out the bobbin and wind

is

usually happened in the

is

too

strong. regulator. (see the above B-(3)).

of

presser

not

smooth.

Level

of

feed dog is too low.

o Correct the tension.

Ill·

7·(3)).

o Adjust the timing. (see IV-1).

too o Tighten the tension spring.

not

o Polish such surface with a fine

sandpaper.

o Replace

o Correct such thread tension.

(see III-

7).

the thread tension regulator (A).

.

~

it

o Make

o Adjust

smooth by making use

a fine sandpaper.

it

level. But,

0.15mm on it's way back

about

measuring

of

throat plate.

it

with new sewing hook.

by

loosening

~

to

a little more high

it

must be lowered by

froll] the top surface

it

of

E.

Needle thread

hops up and

down during

sewing.

(1)

Bobbin case opening mecha- o Correct the timing

not

nism does

(2) Tension

spring is too low. (see III-7-(3)).

function timingly. case opening mechanism

the bobbin thread

pulled

out

of the bobbin.

(see IV-I and 2.)

of

thread take-up o Increase the tension.

of

bobbin

is

regularly

so

that

-21-

Page 24

To mder

()(

a.IUI<I

JUKI

CORPORATION

HEAD OFFICE

8·2·

i KOKURYO-CHO.

CHOFU-CITY,

BUSINESS OFFICE

1·23·3

SHINJUKU-KU,

PHONE: 03(3205)1188.

FAX:

TELEX:

TOKYO

182, JAPAN

KABUKI-CHO

TOKYO

160. JAPAN

03t3203)8260. (3205)9131

J22967.

1189,

232-2301

1190

Please

*The

*This

for further information, please contact :

do

not hesitate

to

description coVered in this instruction manual is subject

commodity without notioo.

instruction manual is edited and printed in accordance with the product specifications as of

September,

contact our distributors

1991.

or

agents in your area

lor

further informations when necessary.

to

change for improvement

of

the

Loading...

Loading...