ENGLISH

INSTRUCTION MANUAL

CONTENTS

1. SPECIFICATIONS ............................................................................................................ 1

2. NAME OF EACH COMPONENT .....................................................................................3

3. INSTALLATION ................................................................................................................ 4

3-1. Caution at the time of set-up ................................................................................................................................ 4

3-2. Installation of the sewing machine ...................................................................................................................... 5

3-3. Adjusting the height of the knee lifter ................................................................................................................. 7

3-4. Installation of thread stand ................................................................................................................................... 7

4. PREPARATION OF THE SEWING MACHINE ................................................................ 8

4-1. Method of lubrication ............................................................................................................................................ 8

4-2. Lubrication to the oil tank ..................................................................................................................................... 9

4-3. Draining of oil from the oil tank ......................................................................................................................... 10

4-4. Adjusting the amount of oil in the hook ............................................................................................................ 10

4-5. Oil in the feed box ............................................................................................................................................... 12

4-6. Applying grease ................................................................................................................................................... 13

4-7. Installing the belt cover and the bobbin thread winder ................................................................................... 16

4-8. Attaching the needles .........................................................................................................................................16

4-9. How to take out the bobbin case ....................................................................................................................... 17

4-10. Insertlng a bobbin in a bobbin case ................................................................................................................17

4-11. Threading the machine head ............................................................................................................................ 18

4-12. Thread tension ................................................................................................................................................... 19

4-13. Thread take-up spring ....................................................................................................................................... 20

4-14. Adjusting the stitch length ...............................................................................................................................21

4-15. Needle-to-hook relation .................................................................................................................................... 21

4-16. Adjusting the needle stop position .................................................................................................................. 23

4-17. Pedal pressure and pedal stroke ..................................................................................................................... 24

4-18. Adjustment of the pedal .................................................................................................................................... 24

5. OPERATION OF THE SEWING MACHINE ..................................................................25

5-1. Pedal Operation ................................................................................................................................................... 25

5-2. Hand lifter ............................................................................................................................................................. 25

5-3. Adjusting the pressure of the presser foot ....................................................................................................... 26

5-4. Micro-lifter ............................................................................................................................................................ 26

5-5. Thread tension release changeover when using the knee lifter ..................................................................... 27

5-6. One-touch manual reverse feed (One-touch reverse feed type) ..................................................................... 27

6. MAINTENANCE ............................................................................................................. 28

6-1. Changing procedure to bottom feed and the adjustment (for LH-3528 only) ................................................ 28

6-2. Changing procedure to needle feed and the adjustment (for LH-3528 only) ................................................. 29

6-3. Adjusting the hook needle guard ....................................................................................................................... 30

6-4. Adjusting the inner hook guide .......................................................................................................................... 30

6-5. Adjusting the height and the inclination of the feed dog ................................................................................31

6-6. Replacing the gauge ........................................................................................................................................... 32

6-7. Adjusting the thread presser spring .................................................................................................................. 33

6-8. Adjusting the position of the moving knife ....................................................................................................... 34

6-9. Position of the wiper ...........................................................................................................................................35

6-10. Caution when installing the attachments ........................................................................................................ 35

6-11. Replacing the bobbin thread slack preventer sprlng (For LH-3568, 3568-7, 3588, 3588-7) ........................ 36

6-12. Stop of the needle bars and angle of corners for corners stitching (For LH-3568, 3568-7, 3588, 3588-7) 36

7. STITCH-TO-ANGLE TABLE BY GAUGE (PITCH AND mm CONVERSION TABLE) .. 37

8. GAUGE SETS ................................................................................................................ 38

9. TROUBLES AND CORRECTIVE MEASURES ............................................................. 45

10. MOTOR PULLEY AND BELT ...................................................................................... 46

1. SPECIFICATIONS

Model name LH-3528

Application

Hook Small hook Small hook

Thread trimmer Not provided Provided

Separately

driven needle bar

mechanism

Max. sewing speed

Needle DP x 5 #9 to #16 (For F,A and S types), DP x 5 #16 to #22 (G type)

Gauge size

Lift of presser foot 13 mm by knee lifter, 7 mm by hand lifter lever

Lubrication JUKI NEW DEFRIX OIL No. 1 or JUKI MACHINE OIL #7

Noise

S type : standard,F type : foundation, A type : light-weight materials, G type : jeans

Not provided Not provided

3/32" to 1-1/2" 1/8" to 1-1/4"

2.4 to 38.1 mm 3.2 to 31.8 mm

For light - and medium - weight materials

3,000 rpm

Workplace-related noise at sewing speed

n = 2,280 min–1 : Lpa ≦84 dB(A)

Noise measurement according to DIN 45635-48-A-1.

(with automatic thread trimmer)

LH-3528-7

Model name

Application

Hook Small hook Small hook

Thread trimmer Not provided Provided

Separately

driven needle bar

mechanism

Max. sewing speed

Needle DP x 5 #9 to #16 (S type), DP x 5 #16 to #22 (G type)

Gauge size

Lift of presser foot 13 mm by knee lifter, 7 mm by hand lifter lever

Lubrication JUKI NEW DEFRIX OIL No. 1 or JUKI MACHINE OIL #7

Noise

(with incorporating corner stitching)

LH-3568

For light- and medium-weight materials

S type : standard, G type : jeans

Provided Provided

3,000 rpm

1/8" to 3/4"

3.2 to 19.1 mm

Workplace-related noise at sewing speed

n = 2,140 min–1 : Lpa ≦84 dB(A)

Noise measurement according to DIN 45635-48-A-1.

(with automatic thread trimmer

incorporating corner stitching)

LH-3568-7

– 1 –

– 2 –

Model name LH-3578

(with automatic thread trimmer)

LH-3578-7

For medium - weight materials

Application

G type : jeans

Hook Large hook Large hook

Thread trimmer Not provided Provided

Separately

driven needle bar

Not provided Not provided

mechanism

Max. sewing speed

3,000 rpm

Needle DP x 5 #16 to #22 (G type)

3/16" to 1-1/12" 3/16" to 3/8"

Gauge size

4.8 to 38.1 mm 4.8 to 9.5 mm

Lift of presser foot 13 mm by knee lifter, 7 mm by hand lifter lever

Lubrication JUKI NEW DEFRIX OIL No. 1 or JUKI MACHINE OIL #7

Workplace-related noise at sewing speed

Noise

n = 1,800 min–1 : Lpa ≦84 dB(A)

Noise measurement according to DIN 45635-48-A-1.

LH-3588-7

Model name

LH-3588

(with incorporating corner stitching)

(with automatic thread trimmer

incorporating corner stitching)

For medium - weight materials

Application

G type : jeans

Hook Large hook Large hook

Thread trimmer Not provided Provided

Separately

driven needle bar

Provided Provided

mechanism

Max. sewing speed

3,000 rpm

Needle DP x 5 #16 to #22 (G type)

3/16" to 3/8"

Gauge size

4.8 to 9.5 mm

Lift of presser foot 13 mm by knee lifter, 7 mm by hand lifter lever

Lubrication JUKI NEW DEFRIX OIL No. 1 or JUKI MACHINE OIL #7

Workplace-related noise at sewing speed

Noise

n = 2,050 min–1 : Lpa ≦84 dB(A)

Noise measurement according to DIN 45635-48-A-1.

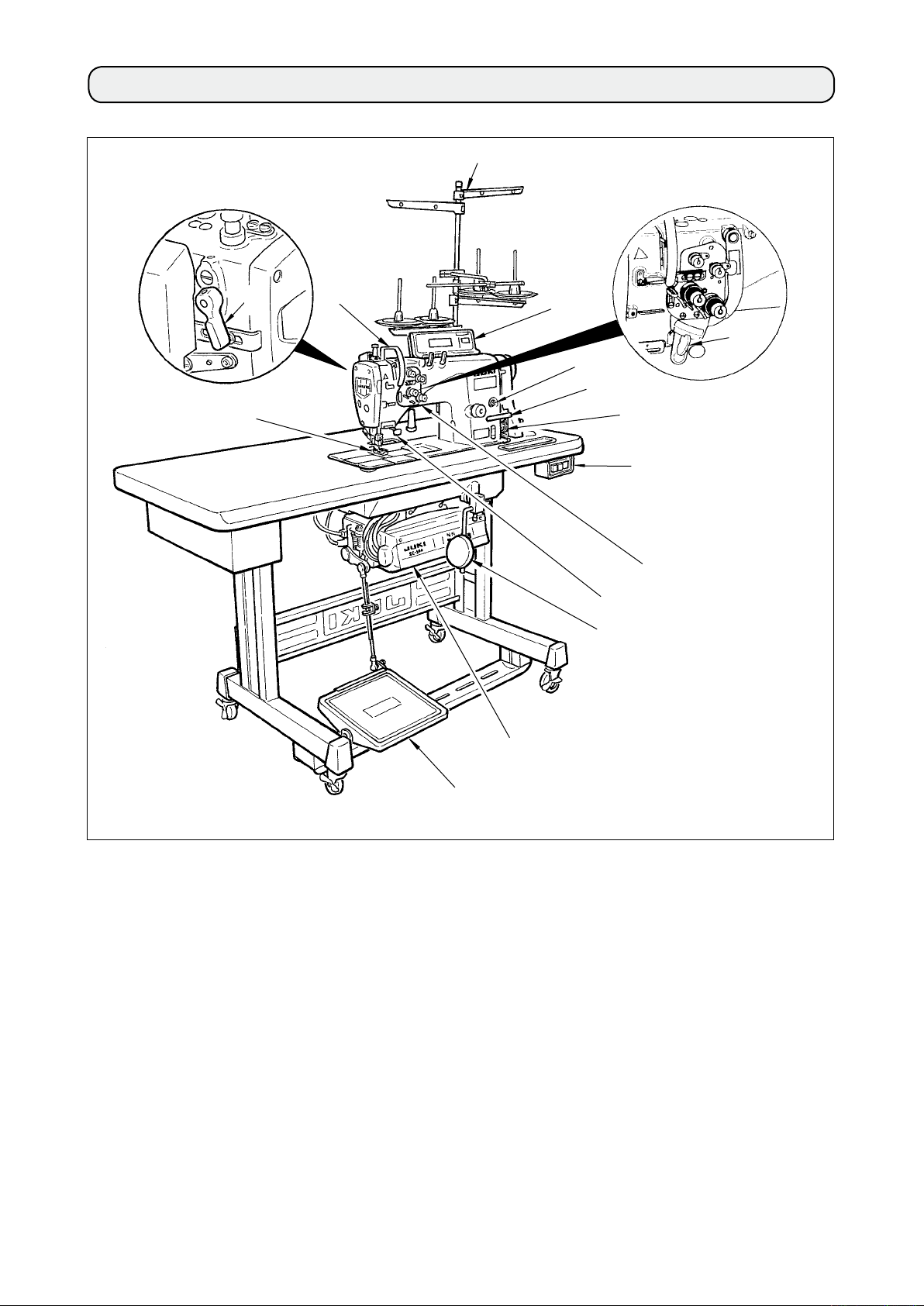

2. NAME OF EACH COMPONENT

!2

!5

3

2

!0

1

!3

!4

!1

8

4

9

7

5

Separately driven needle changeover lever

1

(LH-3568, 3568-7, 3588, 3588-7)

Thread take-up cover

2

Finger guard

3

Thread tension controller

4

Control box

5

Pedal

6

Knee padKnee pad

7

6

Power switch

8

Reverse feed switchReverse feed switch

9

Operation panel

!0

Bobbin winder

!1

Thread stand

!2

Oil supply opening

!3

Reverse feed control lever

!4

Hand lifter lever

!5

– 3 –

– 4 –

3. INSTALLATION

3-1. Caution at the time of set-up

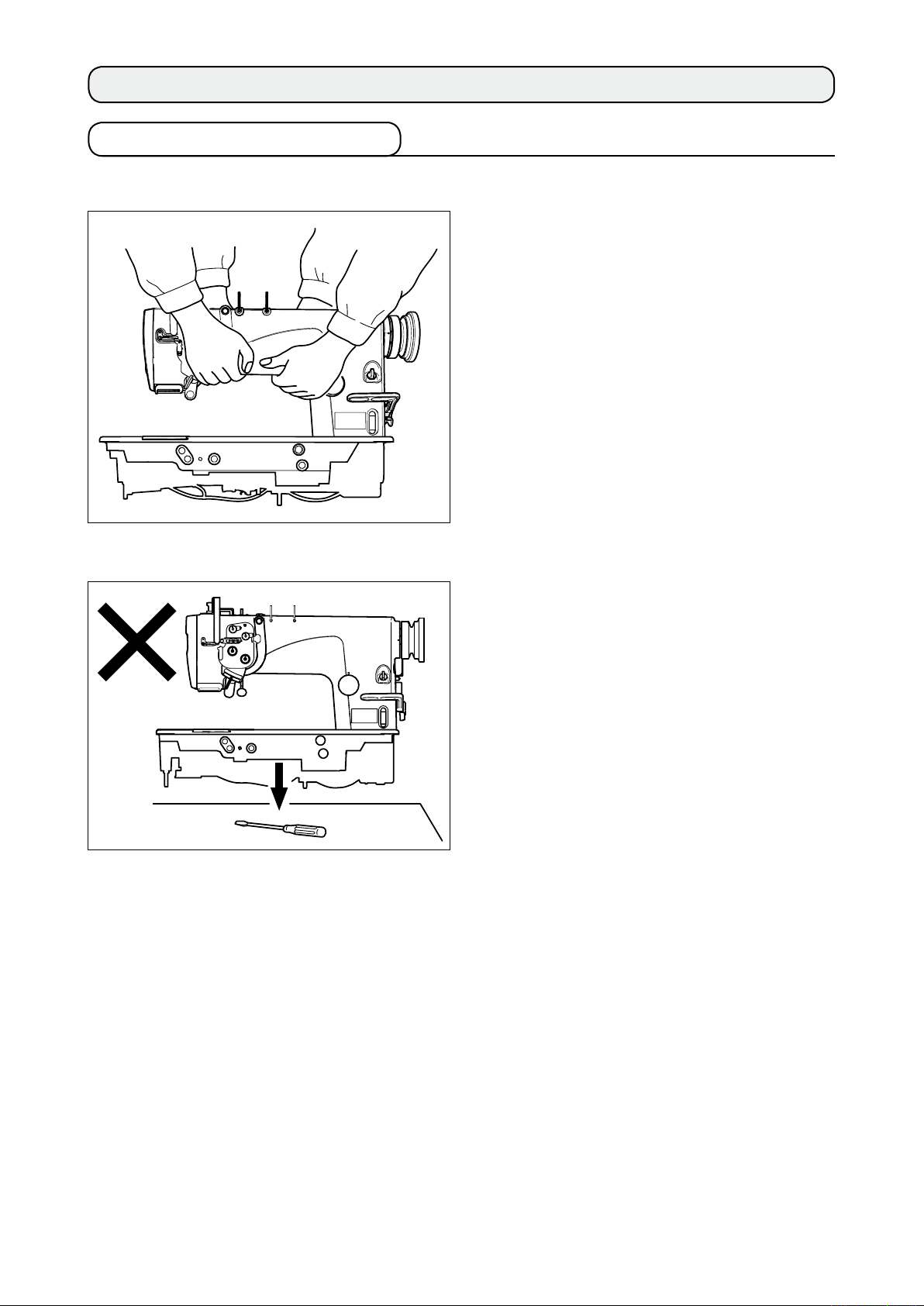

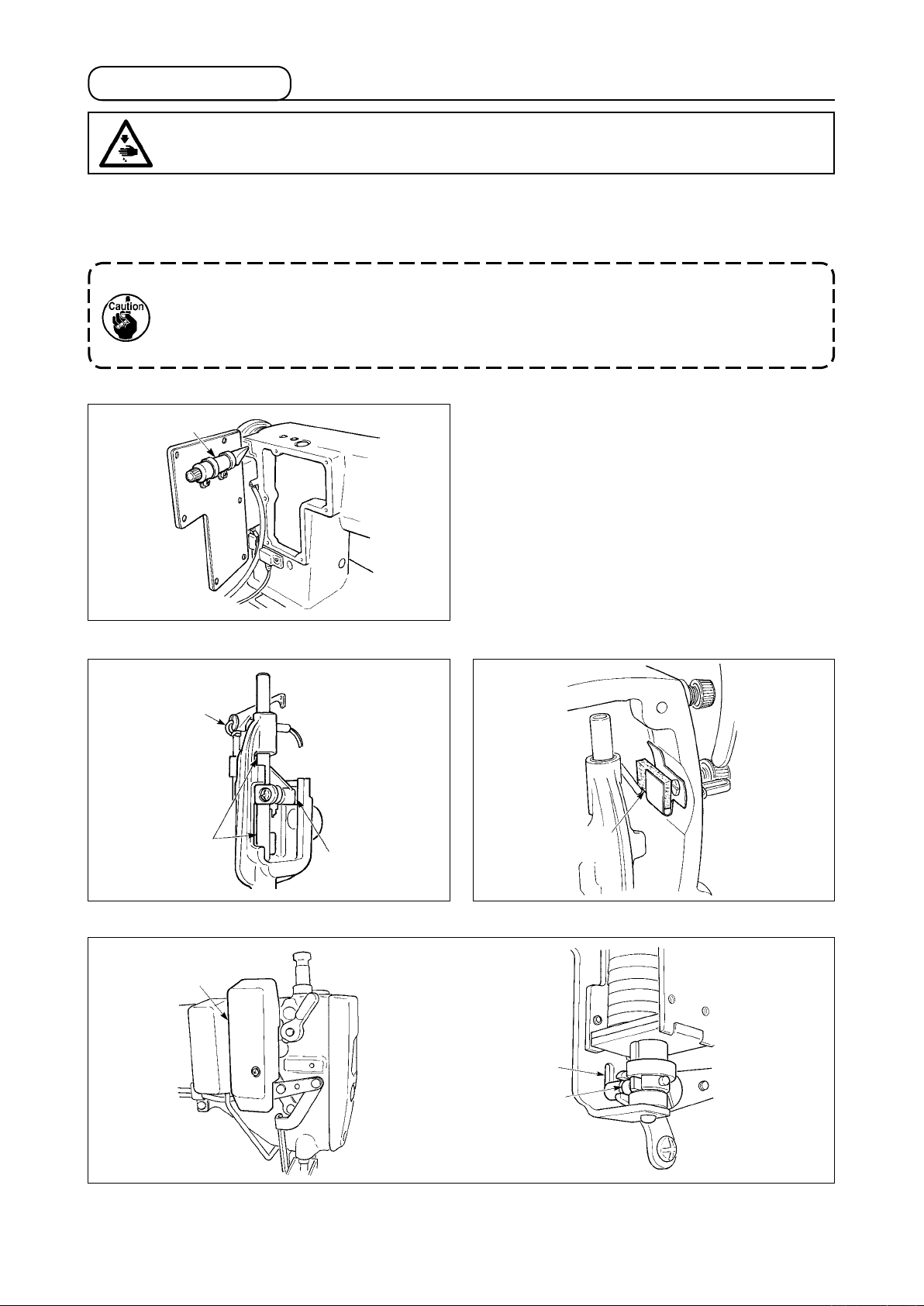

1) Transporting procedure of the sewing machine

Hold and transport the sewing machine with two

persons as shown in the illustration.

2) Caution when placing the sewing machine

Do not put protruding articles such as the

screwdriver and the like at the location where the

sewing machine is placed.

3-2. Installation of the sewing machine

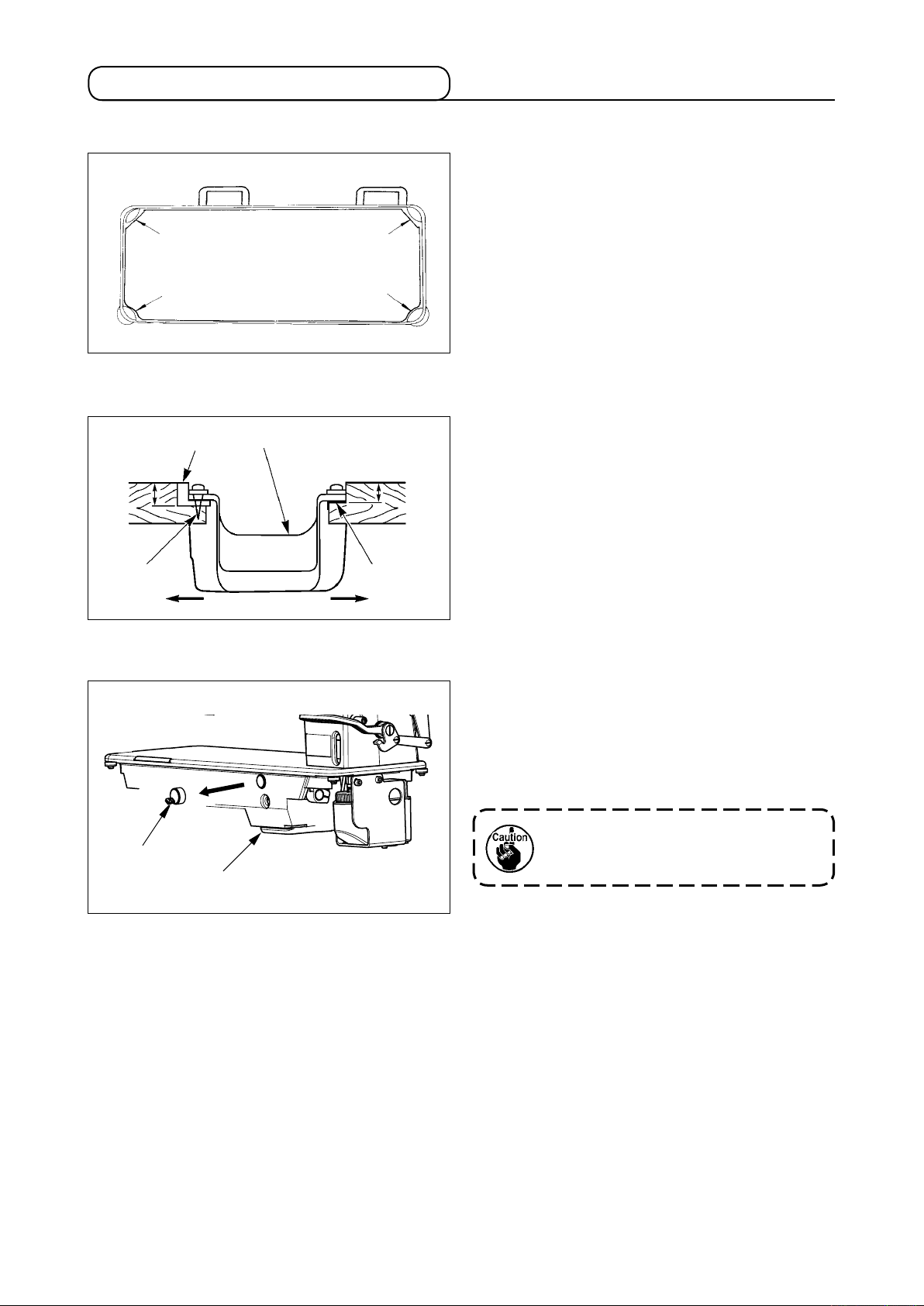

(1) Installing the under cover

1) The under cover should rest on the four

corners of the machine table groove.

22.5 mm

2

3

1

1

A

4

B

3

1

18.5 mm

3

2) Fix two rubber seats 1 on side A (operator’

s side) using nails 2 as illustrated above. Fix

two cushion seats 3 on side B (hinged side)

using a rubber-based adhesive. Then place

under cover 4 on the xed seats.

5

C

3) Remove air vent cap 5 attached to the

machine bed. (Be sure to attach cap 5 when

transporting the machine head in the state

that the machine head is removed from the

machine table.)

If the sewing machine is operated without

removing air vent cap 5, oil leakage from

gear box portion C may occur.

– 5 –

– 6 –

8

7

6

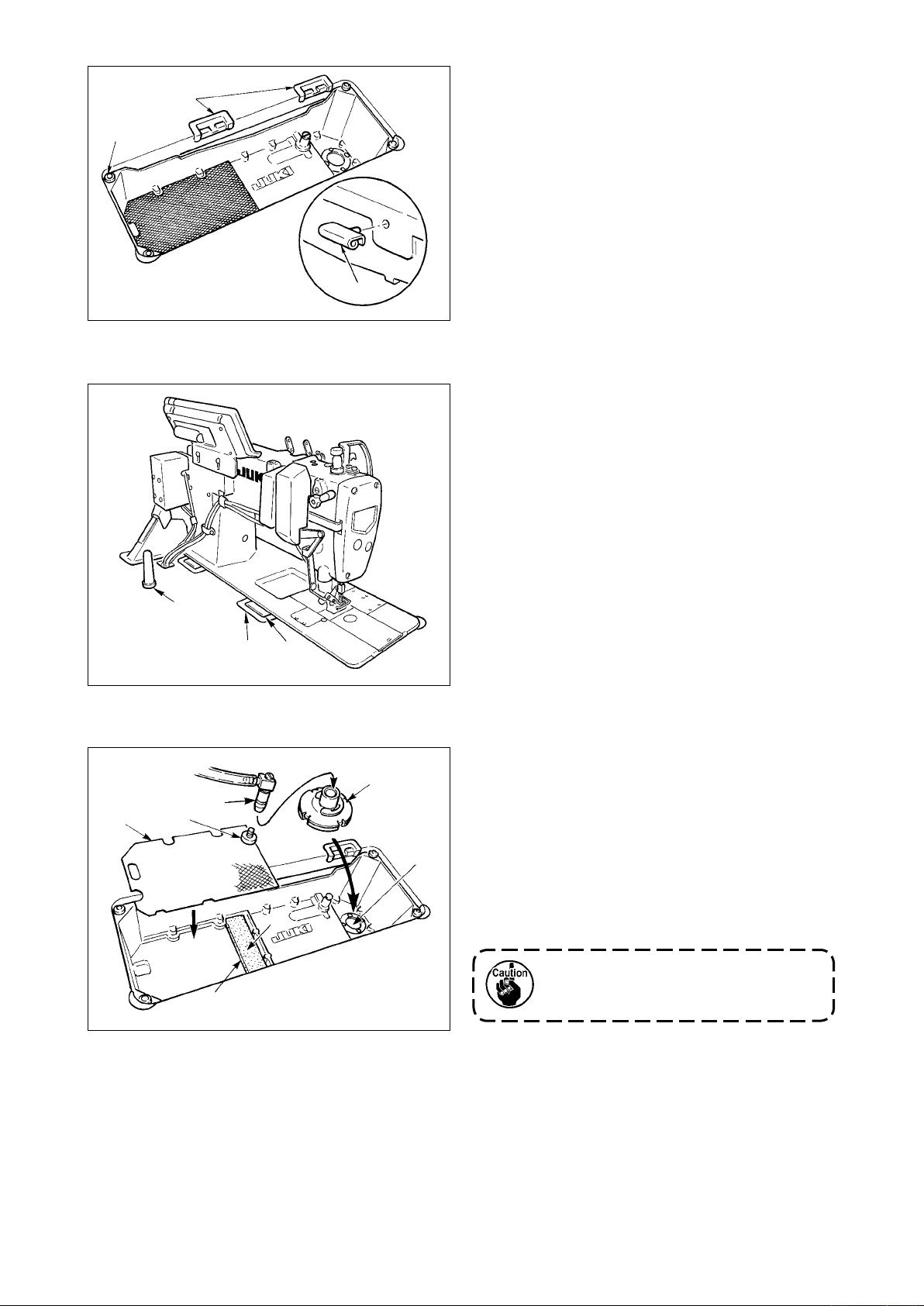

4) Insert hinge 6 into the machine main body.

Fit the machine head to table rubber hinges

and place it on head cushions 8 on the

7

four corners.

5) Attach head support rod 9 to the table.

!3

9

!4

!2

!0

7

E

6

!1

D

6) Remove inlet port !0 for circulation which

is xed to the oil tank installing plate, and

securely insert it into lter !1 until it goes

no further after removing cap !4 which is

attached to the end of the inlet port. Then set

the inlet port to D.

Place urethan lter !2 on E, and place lter

of thin plate type (small mesh plate) on it.

!3

Circulation trouble may occur unless inlet

port !0 for circulation is securely inserted

into ler !1 until it goes no further.

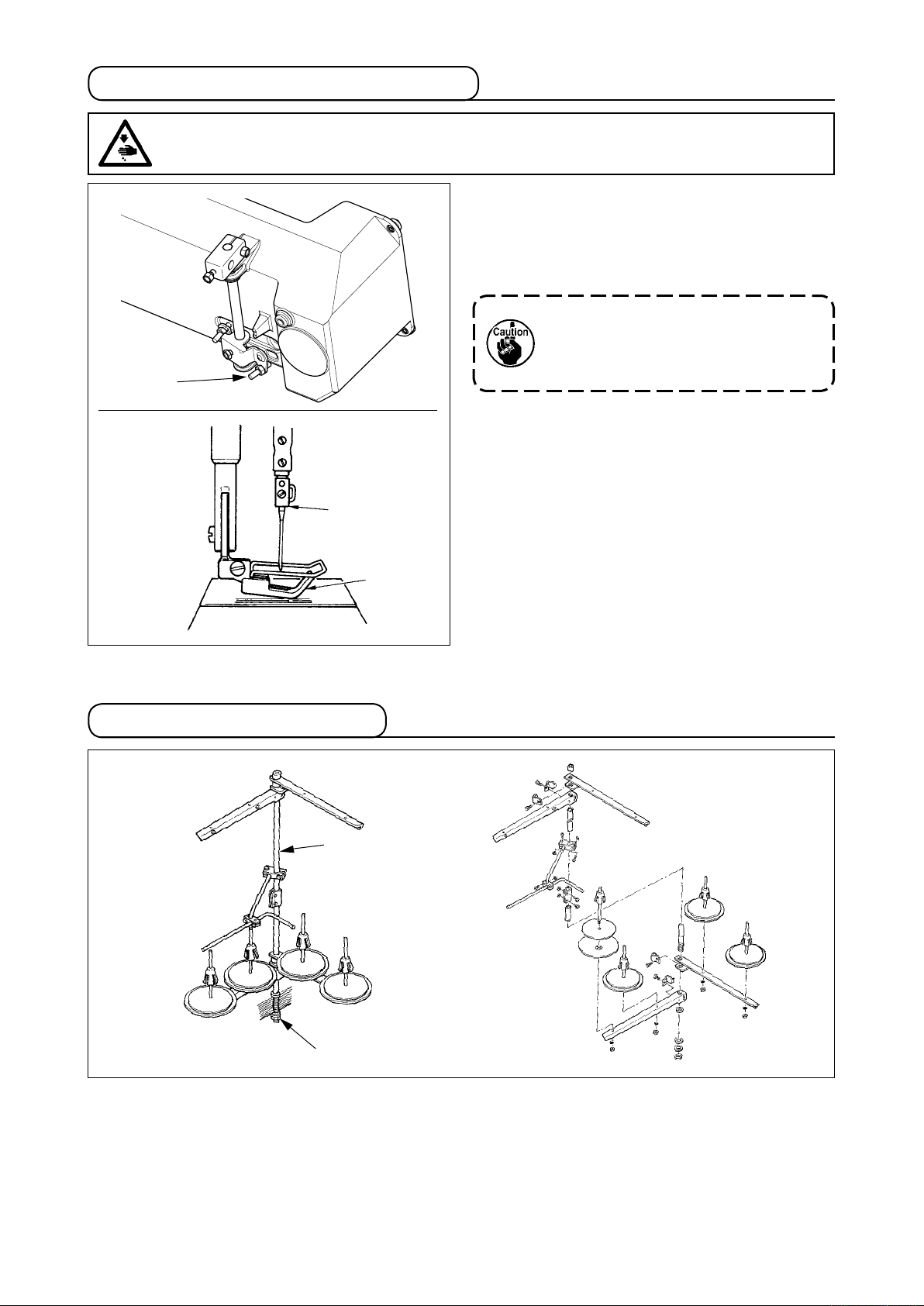

3-3. Adjusting the height of the knee lifter

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

1

2

1) The standard height of the presser foot lifted

using the knee lifter is 12 mm.

2) You can adjust the presser foot lift up to 13

mm using knee lifter adjust screw 1.

Do not operate the sewing machine in the

state that the presser foot 3 is lifted by

12 mm or more since the needle bar 2

comes in contact with the presser foot 3.

3-4. Installation of thread stand

2

3

1

Assemble the thread stand, set it up on the machine table using the installation hole in the table and

tighten nut 1 gently.

When you use power supplied by the overhead power line, pass the power supply cord through hollow

spool rest rod 2.

– 7 –

– 8 –

4. PREPARATION OF THE SEWING MACHINE

4-1. Method of lubrication

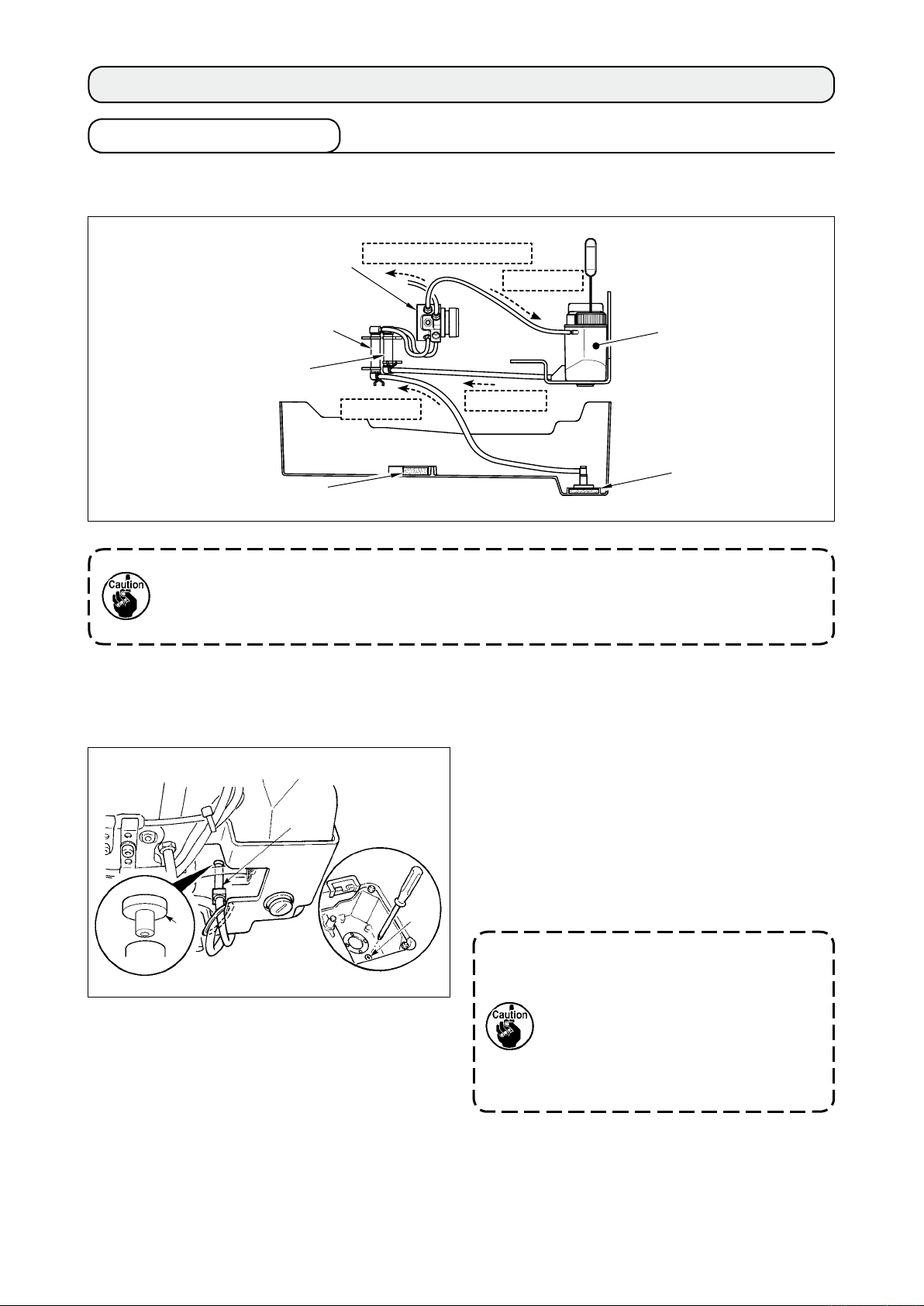

(1) Method of circulating lubrication (when the oil collected in the under cover is reused)

Plunger

Filter for plunger

Filter for plunger 2

Urethan lter

Periodically (approximately once in three months) clean the aforementioned lter sections (four

places) in order to use the machine for a long time. When the lter is clogged, lubrication trouble

will occur and break-down will be caused.

In addition, when the oil becomes dirty, replace the oil gathered in the oil tank and the under cover.

Lubrication to hook side

Circulation

Lubrication

Circulation

Oil tank

Filter for circulation

(2) Method of non-circulation type lubrication (when only the clean oil is always used)

Put cap 3 to inlet port for circulation 1 in the

same state as that at the time of delivery, and

securely x it to the position where it does not

1

come in contact with the moving section.

* Remove drain screw 2 and dump the oil

which has dropped to the under cover.

2

3

2

When inlet port for circulation 1 comes

in contact with the oil surface, oil is

absorbed without passing the lter. As a

result, break-down will be caused.

In addition, when cap 3 is not inserted,

oil leakage from inlet port for circulation

or unstableness of oil amount in the

1

hook may occur.

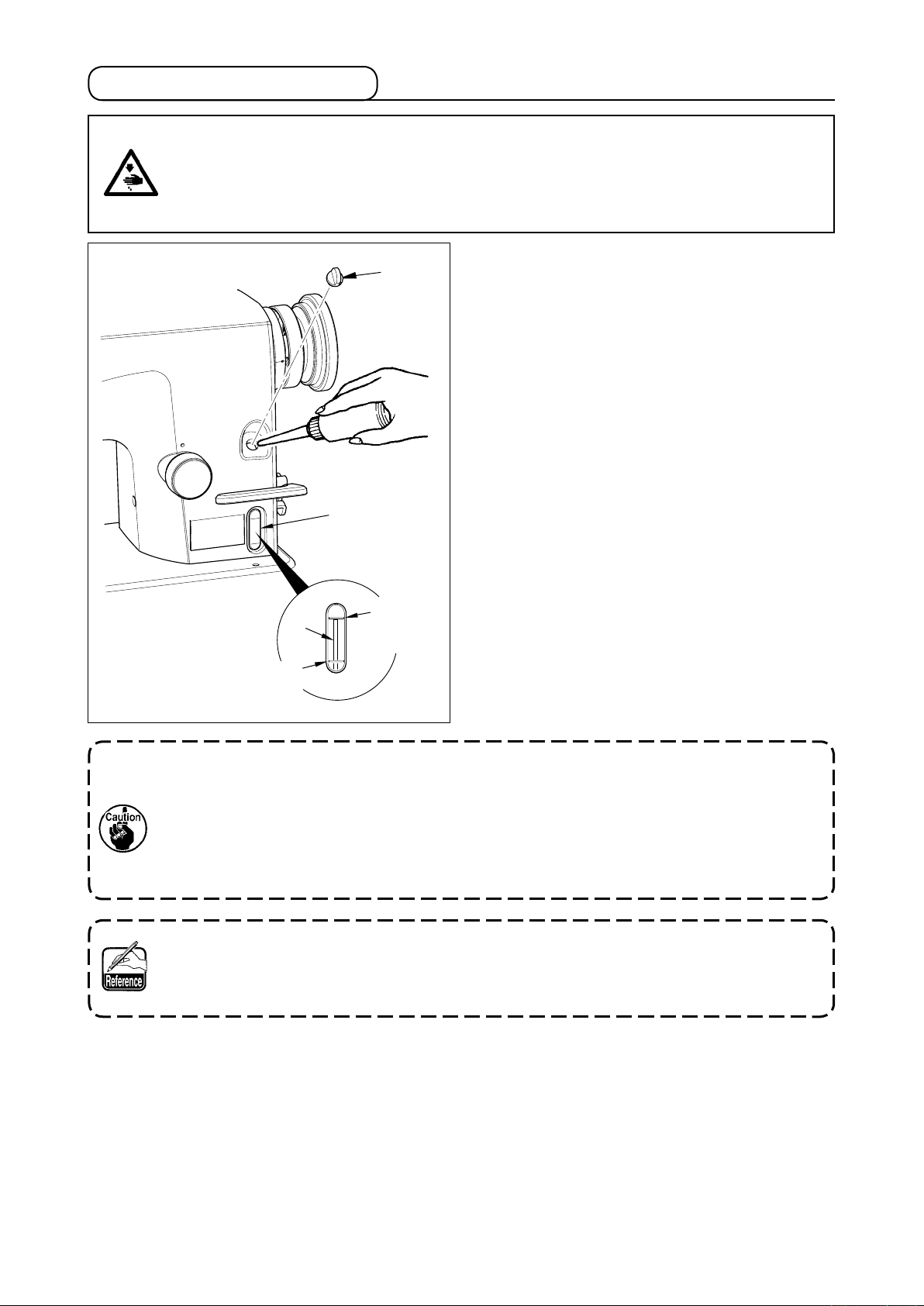

4-2. Lubrication to the oil tank

WARNING :

1. Do not connect the power plug until the lubrication has been completed so as to prevent

accidents due to abrupt start of the sewing machine,

2. To prevent the occurrence of an inammation or rash, immediately wash the related portions if

oil adheres to your eyes or other parts of your body.

3. If oil is mistakenly swallowed, diarrhea or vomitting may occur. Put oil in a place where children

cannot reach.

Lower

engraved

marker line

3

2

1

Upper

engraved

marker line

Fill the oil tank with oil for hook lubrication before

operating the sewing machine.

1) Remove oil hole cap 1 and ll the oil tank

with JUKI NEW DEFRIX OIL No.1 (Part No.

: MDFRX1600C0) or JUKI MACHINE OIL #7

(Part No. : MML007600CA) using the oiler

supplied with the machine.

2) Fill the oil tank with the oil until the top end of

oil amount indicating rod 3 comes between

the upper engraved marker line and the lower

engraved marker line of oil amount indicating

window 2.

If the oil is lled excessively, it will leak from

the air vent hole in the oil tank or proper

lubrication will be not performed. So, be

careful.

3) When you operate the sewing machine, rell

oil if the top end of oil amount indicating rod

comes down to the lower engraved marker

3

line of oil amount indicating window 2.

• When lling the oil tank with the oil initially, make sure that the oil amount indicating rod works.

When it does not work at this time, make it work by tilting the sewing machine once.

• When you use a new sewing machine or a sewing machine after an extended period of disuse, use

the sewing machine after performing break-in at 2,000 rpm or less.

• For the oil for hook lubrication, purchase JUKI NEW DEFRIX OIL No. 1 (Part No. : MDFRX1600C0)

or JUKI MACHINE OIL #7 (Part No. : MML007600CA).

• Be sure to lubricate clean oil.

In case of the circulation type lubrication method, when using the sewing machine for the rst time,

the oil amount in the oil tank decreases until the oil has collected in the ler for circulation. When

the top end of oil amount indicating rod is lower than the lower engraved marker line, add the oil to

the oil tank again so that the top end enters between the upper and lower engraved marker lines.

– 9 –

– 10 –

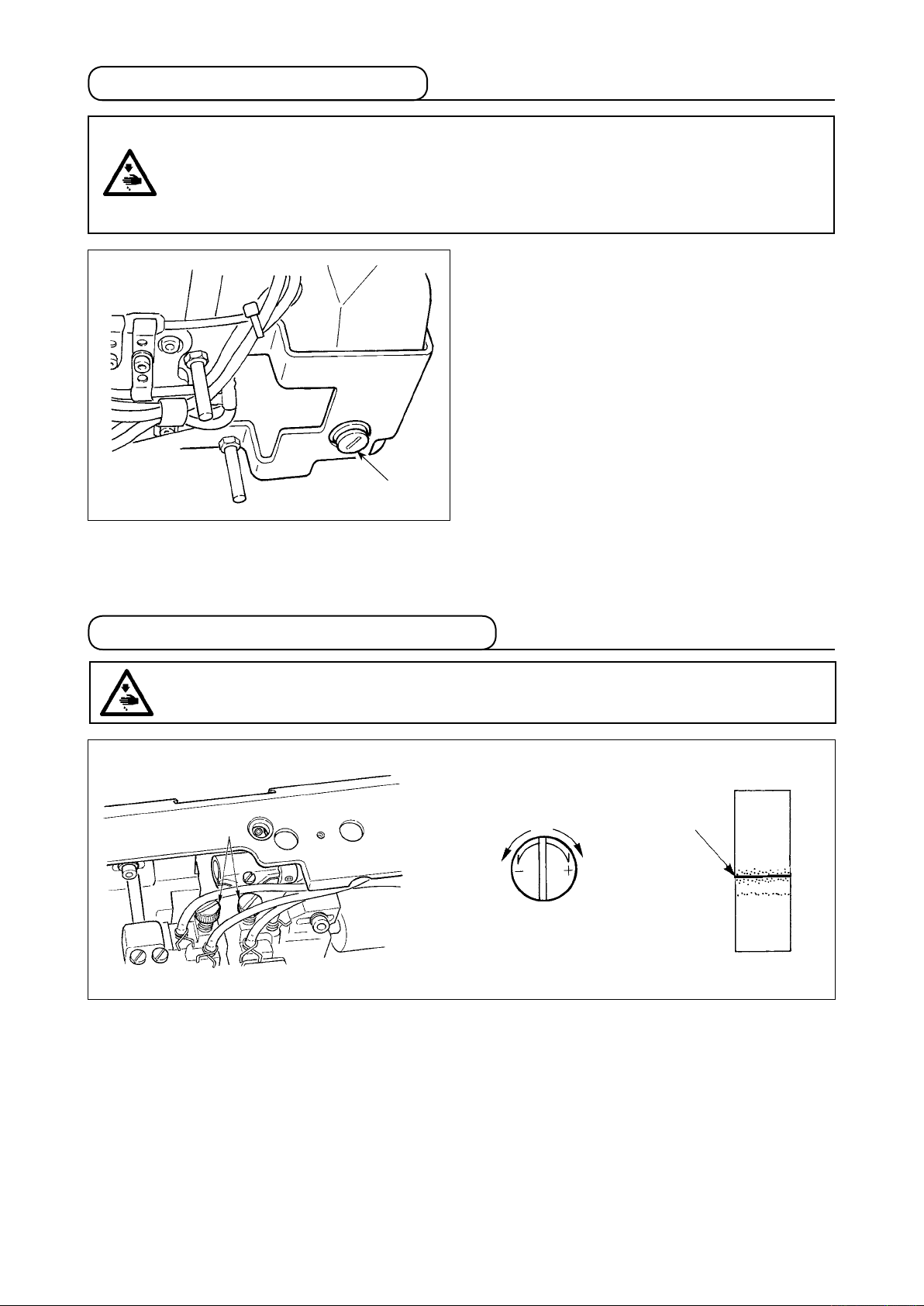

4-3. Draining of oil from the oil tank

WARNING :

1. To prevent accidents caused by abrupt start of the sewing machine, do not connect the power

plug until draining of oil has been completed.

2. To prevent the occurrence of an inammation or rash, immediately wash the related portions if

oil adheres to your eyes or other parts of your body.

3. If oil is mistakenly swallowed, diarrhea or vomitting may occur. Put oil in a place where children

cannot reach.

1

When draining oil from the oil tank, loosen drain

screw 1 with the L-shaped screwdriver (Part No.

: B9101490000) supplied as accessories and

remove it.

4-4. Adjusting the amount of oil in the hook

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

1

Oil amount

decreases

Adjust the amount oil using adjusting screw 1. Turn screw 1 clockwise to increase the amount of oil

in the hook or counterclockwise to decrease it. Measure the amount of oil in ve seconds. When the

amount of oil is excessively decreased, break-down will be caused. So, be careful.

Oil splashes

Oil amo unt

increases

To use in safety, replace the oil wick of hook section with a new one approximately once a year with

the procedure below.

1

3

4

2

1) Loosen setscrews

(small hook : 2 places,

2

large hook : 3 places) and remove hook gib 1.

2) Remove inner hook

3) Loosen oil plug

4

.

3

with the L-shaped

screwdriver (Part No. : B9101490000) and

remove it.

4) Draw out oil wick

inserted into oil plug 4,

5

and replace it with a new one.

[Part No. of oil wick 5]

Small hook 11015906

Large hook 11404704

When strongly pressing oil wick 5, it may

be broken. Lightly insert it to such an

extent that it is not drawn out.

5

After the replacement, assemble oil plug 4,

inner hook 3 and hook gib 1 to the hook by

reversing the above procedure.

Perform conrming of oil splash.

When loosening/assembling, do not allow

the slit section of oil plug 4 to be burred.

– 11 –

– 12 –

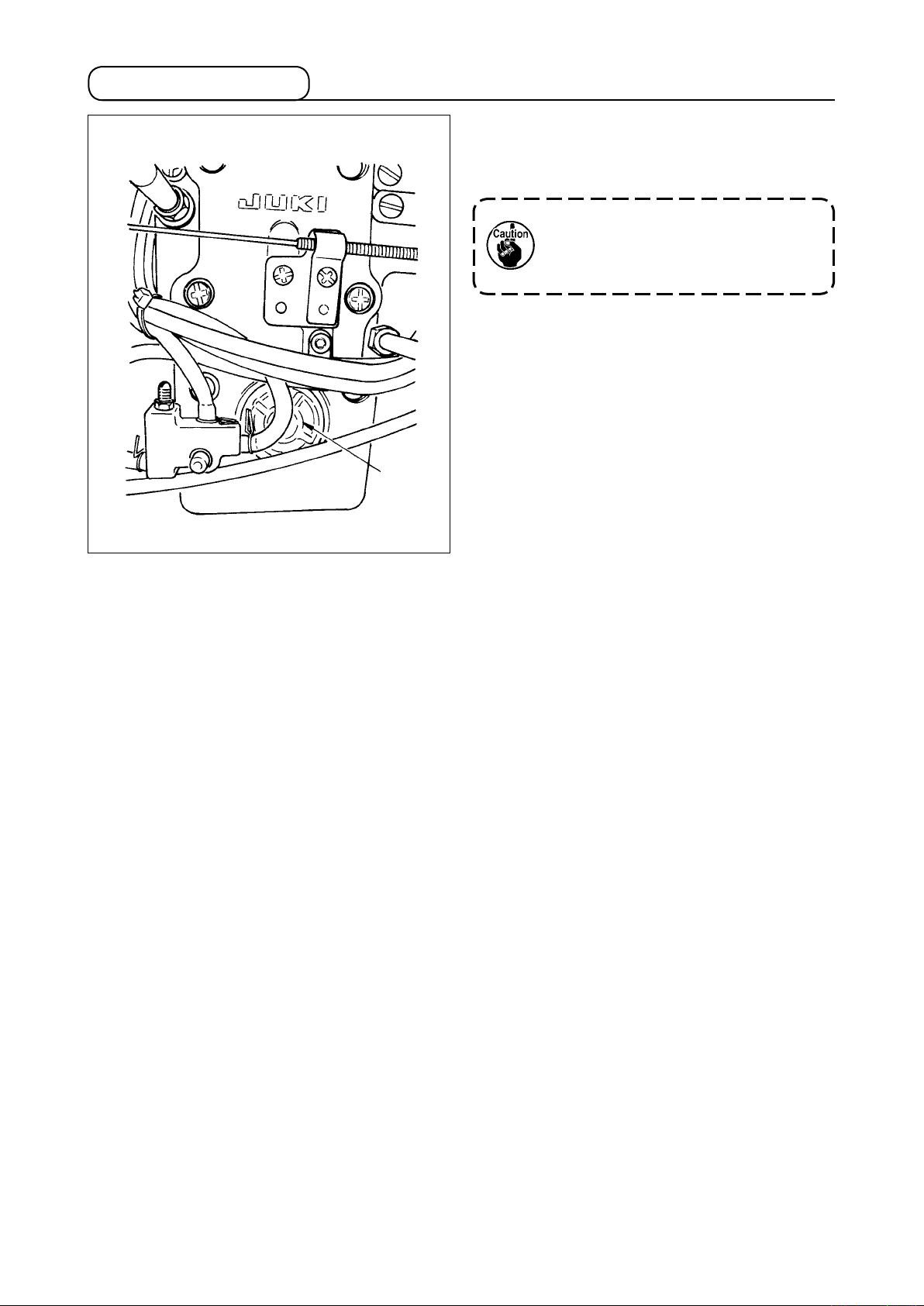

4-5. Oil in the feed box

1

When using the sewing machine, make sure that

the oil is put in the feed box from oil conrming

window

Do not add oil to the feed box since the

.

1

adequate amount of oil which is different

from the hook oil has been put in the feed

box.

4-6. Applying grease

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

To use the sewing machine in safety, periodically perform grease-up (standard is once in 2 to 3 years)

to the grease applying sections of the respective models with the cotton bar or the like. When using

SC-500, when the time of grease-up comes, the warning alarm sounds. When the alarm sounds,

perform grease-up.

• Never lubricate oil to the grease applying places.

• When grease is applied more than is necessary, there is a fear that grease leaks from the thread

take-up lever cover section or the needle bar. So, be careful.

• Be sure to use the grease contained in JUKI GREASE A TUBE (Part No. : 40006323) supplied with

the machine head as accessories.

[Grease keeping place]

The grease tube is installed on the inside of

A

window plate

A

.

[LH-3528, 3528-7, 3578, 3578-7]

Thread take-up

lever (oil wick)

Needle bar

Square block

[LH-3528-7, 3568-7, 3578-7, 3588-7]

1

Face plate

lubrication felt

2

3

Remove wiper cover 1, and apply grease to slot section 2 of wiper solenoid base and wiper link collar 3.

– 13 –

Loading...

Loading...