Page 1

ENGLISH

LH-3500A Series

INSTRUCTION MANUAL

Page 2

CONTENTS

1. SPECIFICATIONS .......................................................................................................... 1

2. NAME OF EACH COMPONENT

3. INSTALLATION

3-1. Caution at the time of set-up ............................................................................................................................ 4

3-2. Installation of the sewing machine .................................................................................................................. 5

3-3. Adjusting the height of the knee lifter ............................................................................................................. 6

3-4. Installation of thread stand ............................................................................................................................... 6

.............................................................................................................. 4

...................................................................................3

4. PREPARATION OF THE SEWING MACHINE .............................................................. 7

4-1. Method of lubrication ........................................................................................................................................ 7

4-2. Lubrication to the oil tank ................................................................................................................................. 8

4-3. Draining of oil from the oil tank ....................................................................................................................... 9

4-4. Adjusting the amount of oil in the hook .......................................................................................................... 9

4-5. Oil in the feed box ........................................................................................................................................... 10

4-6. Applying grease............................................................................................................................................... 11

4-7. Setting up the SC-920 ..................................................................................................................................... 14

4-8. Installing the belt cover (For LH-3528A, 3568A, 3578A and 3588A) ........................................................... 18

4-9. Attaching the needles ..................................................................................................................................... 18

4-10. How to take out the bobbin case ................................................................................................................... 19

4-11. Inserting a bobbin in a bobbin case .............................................................................................................. 19

4-12. Threading the machine head .......................................................................................................................... 20

4-13. Thread tension ................................................................................................................................................. 23

4-14. Winding the bobbin thread ............................................................................................................................. 24

4-15. Thread take-up spring ..................................................................................................................................... 25

4-16. Adjusting the stitch length ............................................................................................................................. 27

4-17. Needle-to-hook relation .................................................................................................................................. 27

4-18. Pedal pressure and pedal stroke ................................................................................................................... 29

4-19. Adjustment of the pedal .................................................................................................................................. 29

5. OPERATION OF THE SEWING MACHINE ................................................................30

5-1. Pedal Operation ............................................................................................................................................... 30

5-2. Hand lifter ......................................................................................................................................................... 30

5-3. Adjusting the pressure of the presser foot ................................................................................................... 31

5-4. Micro-lifter ........................................................................................................................................................ 31

5-5. Thread tension release changeover when using the knee lifter ................................................................. 32

5-6. One-touch manual reverse feed (One-touch reverse feed type) ................................................................. 32

6. MAINTENANCE ...........................................................................................................33

6-1. Procedure of changing over between bottom feed and needle feed and the adjustment (for LH-3528A

only) .................................................................................................................................................................. 33

6-2. Changing the feed timing ............................................................................................................................... 35

6-3. Adjusting the thread trimming cam ............................................................................................................... 36

6-4. Adjusting the hook needle guard ................................................................................................................... 37

6-5. Adjusting the inner hook guide ...................................................................................................................... 37

6-6. Adjusting the height and the inclination of the feed dog ............................................................................ 38

6-7. Replacing the gauge ....................................................................................................................................... 39

6-8. Adjusting the thread presser spring.............................................................................................................. 39

6-9. Adjusting the position of the moving knife ................................................................................................... 40

6-10. Position of the wiper ....................................................................................................................................... 41

6-11. Caution when installing the attachments ...................................................................................................... 41

6-12. Replacing the bobbin thread slack preventer spring (For LH-3568A, 3568A-7, 3588A and 3588A-7) ..... 42

6-13. Stop of the needle bars and angle of corners for corners stitching (For LH-3568A, 3568A-7, 3588A and

3588A-7)............................................................................................................................................................ 42

7. STITCH-TO-ANGLE TABLE BY GAUGE (PITCH AND mm CONVERSION TABLE) 43

8. GAUGE SETS

..............................................................................................................44

9. TROUBLES AND CORRECTIVE MEASURES

10. MOTOR PULLEY AND BELT

...................................................................................... 55

i

........................................................... 53

Page 3

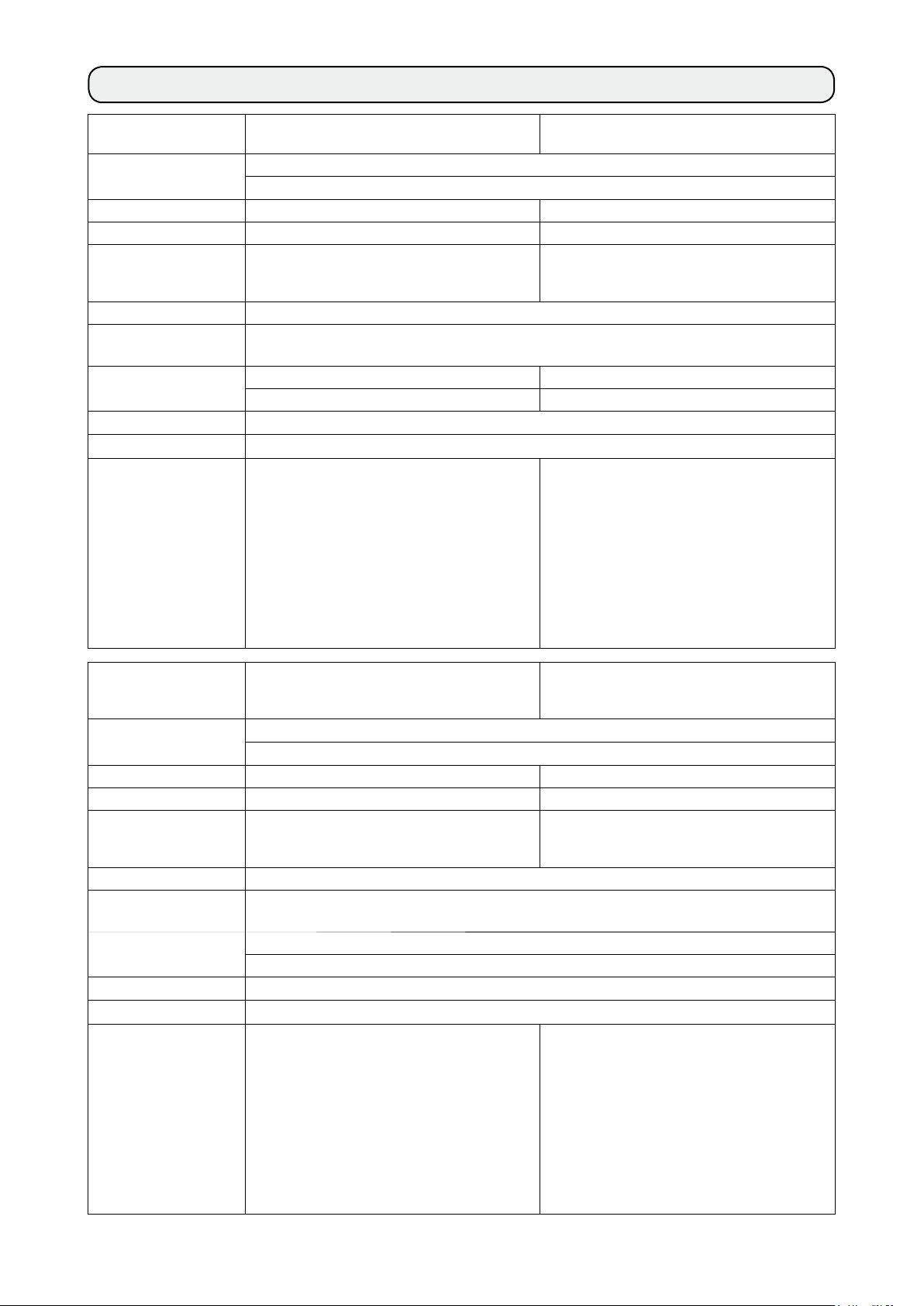

1. SPECIFICATIONS

Model name LH-3528A

Application

S type : standard, F type : foundation, A type : light-weight materials, G type : jeans

For light -, medium - and heavy - weight materials

(with automatic thread trimmer)

LH-3528A-7

Hook Standard hook Standard hook

Thread trimmer Not provided Provided

Separately

driven needle bar

Not provided Not provided

mechanism

Max. sewing speed

Needle

* 1

Gauge size

GROZ-BECKERT 134 Nm9 to Nm16 (For S, F and A types), 134 Nm16 to Nm23 (G type) (For S, F and A types), 134 Nm16 to Nm23 (G type)134 Nm16 to Nm23 (G type) (G type)

ORGAN needle DP x 5 #9 to #16 (For S, F and A types), DP x 5 #16 to #23 (G type)DP x 5 #9 to #16 (For S, F and A types), DP x 5 #16 to #23 (G type)

3/32" to 1-1/2" 1/8" to 1-1/4"

2.4 to 38.1 mm 3.2 to 31.8 mm

3,000 sti/min

Lift of presser foot 13 mm by knee lifter, 7 mm by hand lifter lever

Lubrication JUKI NEW DEFRIX OIL No. 1 or JUKI MACHINE OIL #7

Noise

Declaration

- Equ iva lent c ontinuou s emission so und

pressure level (L

) at the workstation :

pA

A-weighted value of 87.5 dB ; (Includes

K

= 2.5 dB) ; according to ISO 10821-

pA

C.6.2 -ISO 11204 GR2 at 3,000 sti/min.

- Sound power level (LWA) :

A-weighted value of 91.5 dB ; (Includes

KpA = 2.5 dB) ; according to ISO 10821C.6.2 -ISO 3744 GR2 at 3,000 sti/min.

Declaration

- Equ iva lent c ontinuou s emission so und

pressure level (L

) at the workstation :

pA

A-weighted value of 85.5 dB ; (Includes

K

= 2.5 dB) ; according to ISO 10821-

pA

C.6.2 -ISO 11204 GR2 at 3,000 sti/min.

- Sound power level (LWA) :

A-weighted value of 90.5 dB ; (Includes

K

= 2.5 dB) ; according to ISO 10821-

pA

C.6.2 -ISO 3744 GR2 at 3,000 sti/min.

LH-3568A-7

corner stitching)

Model name

Application

LH-3568A

(with incorporating corner stitching)

For light -, medium - and heavy - weight materials

S type : standard, G type : jeans

(with automatic thread trimmer incorporating

Hook Standard hook Standard hook

Thread trimmer Not provided Provided

Separately

driven needle bar

Provided Provided

mechanism

Max. sewing speed

Needle

* 1

Gauge size

GROZ-BECKERT 134 Nm9 to Nm16 (S type), 134 Nm16 to Nm23 (G type) (S type), 134 Nm16 to Nm23 (G type)134 Nm16 to Nm23 (G type) (G type)

ORGAN needle DP x 5 #9 to #16 (S type), DP x 5 #16 to #23 (G type)DP x 5 #9 to #16 (S type), DP x 5 #16 to #23 (G type)

3,000 sti/min

1/8" to 3/4"

3.2 to 19.1 mm

Lift of presser foot 13 mm by knee lifter, 7 mm by hand lifter lever

Lubrication JUKI NEW DEFRIX OIL No. 1 or JUKI MACHINE OIL #7

Declaration

- Equ iva lent c ontinuou s emission so und

pressure level (L

A-weighted value of 83.5 dB ; (Includes

K

= 2.5 dBA) ; according to ISO 10821-

Noise

PA

C.6.2 -ISO 11204 GR2 at 3,000 sti/min.

- Sound power level (LWA) :

A-weighted value of 87.5 dB ; (Includes

K

= 2.5 dBA) ; according to ISO 10821-

pA

C.6.2 -ISO 3744 GR2 at 3,000 sti/min.

* 1

: Needle used depends on the destination.

) at the workstation :

pA

Declaration

- Equ iva lent c ontinuou s emission so und

pressure level (L

) at the workstation :

pA

A-weighted value of 84 dBA ; (Includes

K

= 2.5 dB) ; according to ISO 10821-

PA

C.6.2 -ISO 11204 GR2 at 3,000 sti/min.

- Sound power level (LWA) :

A-weighted value of 88.5 dBA ; (Includes

K

= 2.5 dB) ; according to ISO 10821-

pA

C.6.2 -ISO 3744 GR2 at 3,000 sti/min.

– 1 –

Page 4

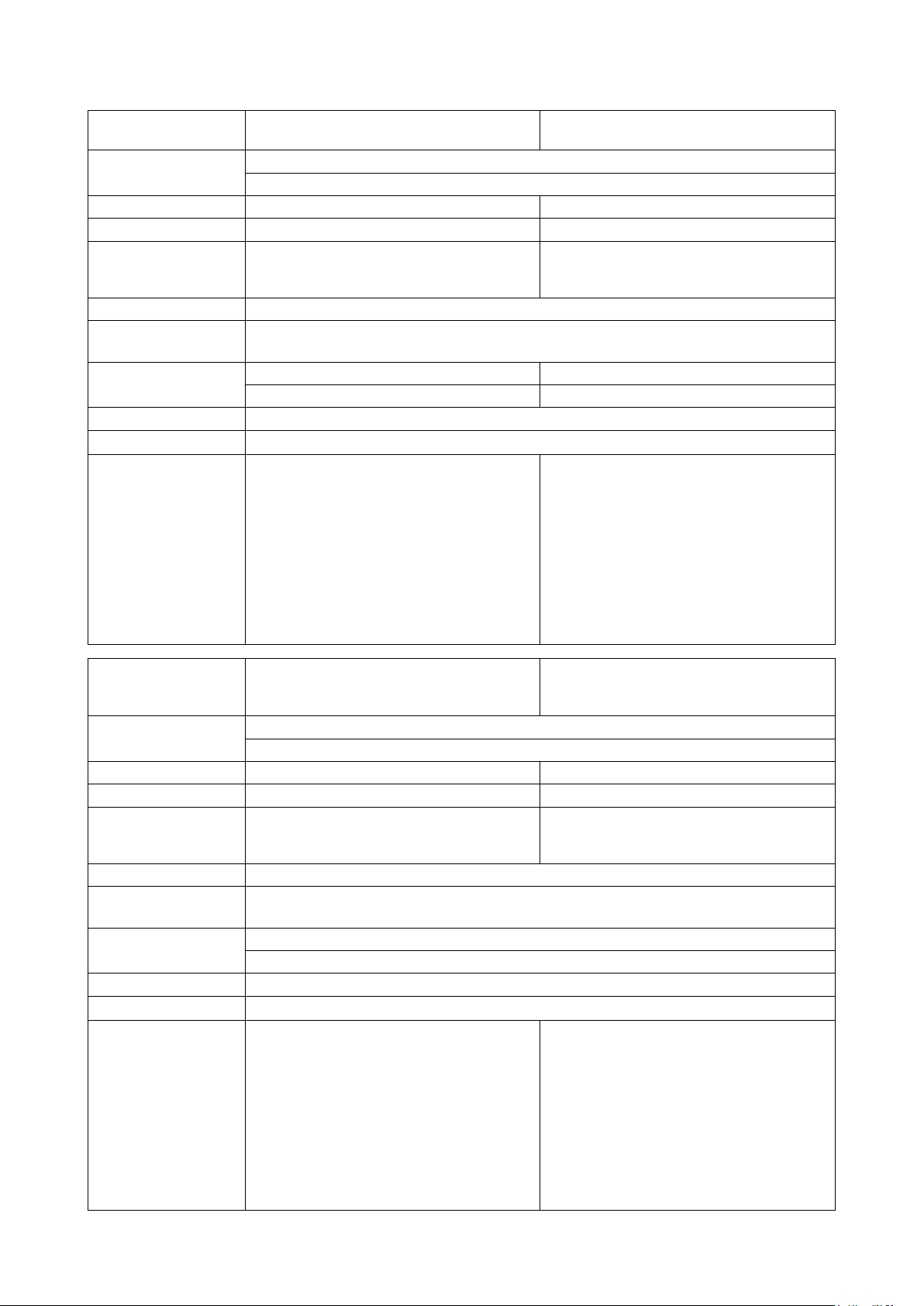

Model name LH-3578A

Application

For medium - and heavy - weight materials

(with automatic thread trimmer)

G type : jeans

LH-3578A-7

Hook Large hook Large hook

Thread trimmer Not provided Provided

Separately

driven needle bar

Not provided Not provided

mechanism

Max. sewing speed

Needle

* 1

Gauge size

Lift of presser foot

GROZ-BECKERT 134 Nm16 to Nm23 (G type) (G type)

ORGAN needle DP x 5 #16 to #23 (G type)DP x 5 #16 to #23 (G type)

3/16" to 1-1/12" 3/16" to 3/8"

4.8 to 38.1 mm 4.8 to 9.5 mm

13 mm by knee lifter, 7 mm by hand lifter lever

3,000 sti/min

Lubrication JUKI NEW DEFRIX OIL No. 1 or JUKI MACHINE OIL #7

Noise

Declaration

- Equ iva lent c ontinuou s emission so und

pressure level (L

) at the workstation :

pA

A-weighted value of 87.5 dB ; (Includes

K

= 2.5 dB) ; according to ISO 10821-

pA

C.6.2 -ISO 11204 GR2 at 3,000 sti/min.

- Sound power level (LWA) :

A-weighted value of 91.5 dB ; (Includes

KpA = 2.5 dB) ; according to ISO 10821C.6.2 -ISO 3744 GR2 at 3,000 sti/min.

Declaration

- Equ iva lent c ontinuou s emission so und

pressure level (L

) at the workstation :

pA

A-weighted value of 85.5 dB ; (Includes

K

= 2.5 dB) ; according to ISO 10821-

pA

C.6.2 -ISO 11204 GR2 at 3,000 sti/min.

- Sound power level (LWA) :

A-weighted value of 90.5 dB ; (Includes

K

= 2.5 dB) ; according to ISO 10821-

pA

C.6.2 -ISO 3744 GR2 at 3,000 sti/min.

LH-3588A-7

corner stitching)

Model name

Application

LH-3588A

(with incorporating corner stitching)

For medium - and heavy - weight materials

(with automatic thread trimmer incorporating

G type : jeans

Hook Large hook Large hook

Thread trimmer Not provided Provided

Separately

driven needle bar

Provided Provided

mechanism

Max. sewing speed

Needle

* 1

Gauge size

Lift of presser foot

GROZ-BECKERT 134 Nm16 to Nm23 (G type) (G type)

ORGAN needle DP x 5 #16 to #23 (G type)DP x 5 #16 to #23 (G type)

13 mm by knee lifter, 7 mm by hand lifter lever

3,000 sti/min

3/16" to 3/8"

4.8 to 9.5 mm

Lubrication JUKI NEW DEFRIX OIL No. 1 or JUKI MACHINE OIL #7

Declaration

- Equ iva lent c ontinuou s emission so und

pressure level (L

A-weighted value of 83.5 dB ; (Includes

K

= 2.5 dBA) ; according to ISO 10821-

Noise

PA

C.6.2 -ISO 11204 GR2 at 3,000 sti/min.

- Sound power level (LWA) :

A-weighted value of 87.5 dB ; (Includes

K

= 2.5 dBA) ; according to ISO 10821-

pA

C.6.2 -ISO 3744 GR2 at 3,000 sti/min.

* 1

: Needle used depends on the destination.

) at the workstation :

pA

Declaration

- Equ iva lent c ontinuou s emission so und

pressure level (L

) at the workstation :

pA

A-weighted value of 84 dBA ; (Includes

K

= 2.5 dB) ; according to ISO 10821-

PA

C.6.2 -ISO 11204 GR2 at 3,000 sti/min.

- Sound power level (LWA) :

A-weighted value of 88.5 dBA ; (Includes

K

= 2.5 dB) ; according to ISO 10821-

pA

C.6.2 -ISO 3744 GR2 at 3,000 sti/min.

– 2 –

Page 5

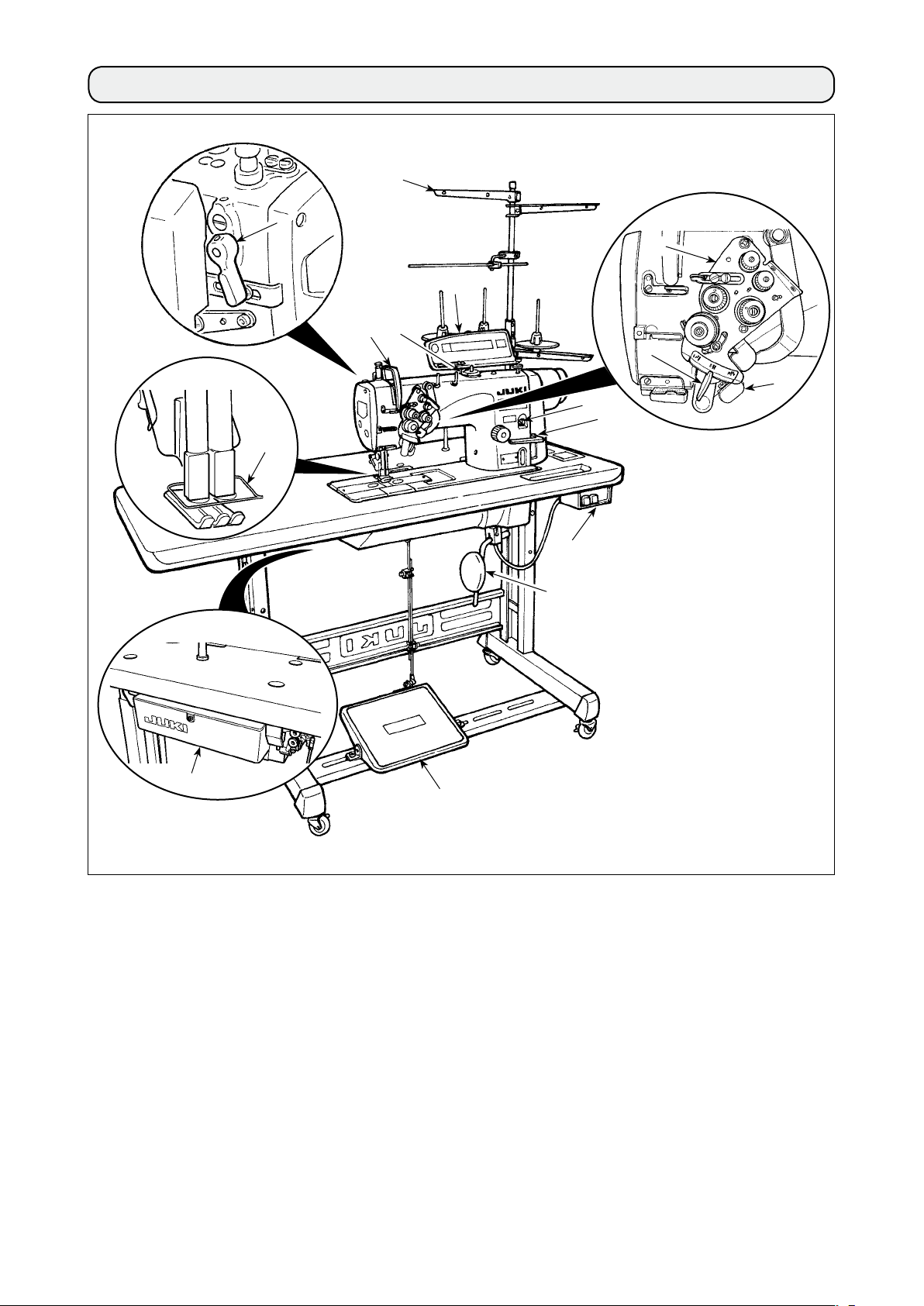

2. NAME OF EACH COMPONENT

!2

!5

!1

2

3

4

!0

1

9

!3

!4

5

Separately driven needle changeover lever

1

(LH-3568A, 3568A-7, 3588A, 3588A-7)

Thread take-up cover

2

Finger guard

3

Thread tension controller

4

Control box

5

Pedal

6

Knee pad

7

8

7

6

Power switch

8

Reverse feed switch

9

(LH-3528A-7, 3568A-7, 3528A (F type), 3578A-7

3588A-7)

Operation panel

!0

Bobbin winder

!1

Thread stand

!2

Oil supply opening

!3

Reverse feed control lever

!4

Hand lifter lever

!5

,

– 3 –

Page 6

3. INSTALLATION

3-1. Caution at the time of set-up

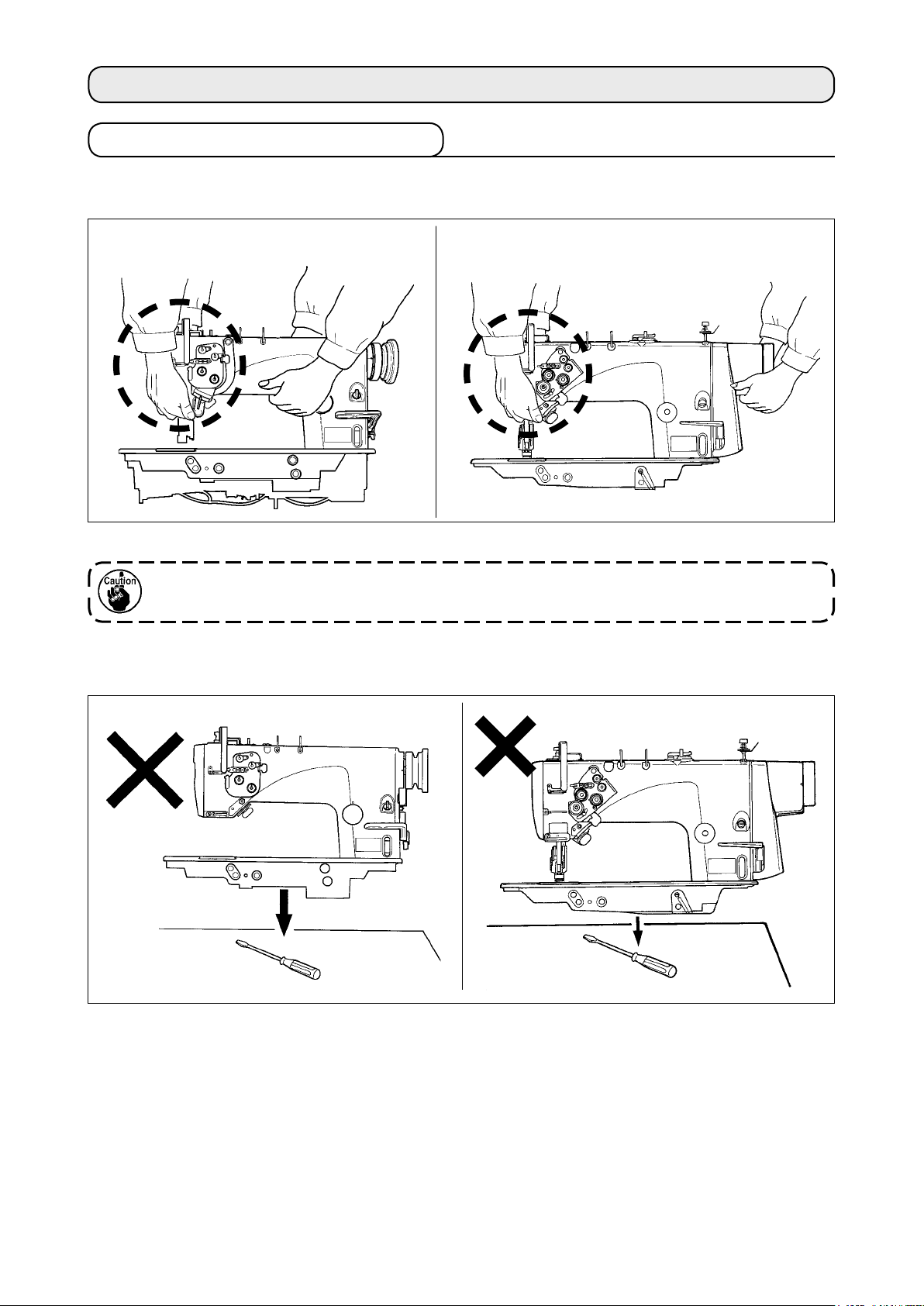

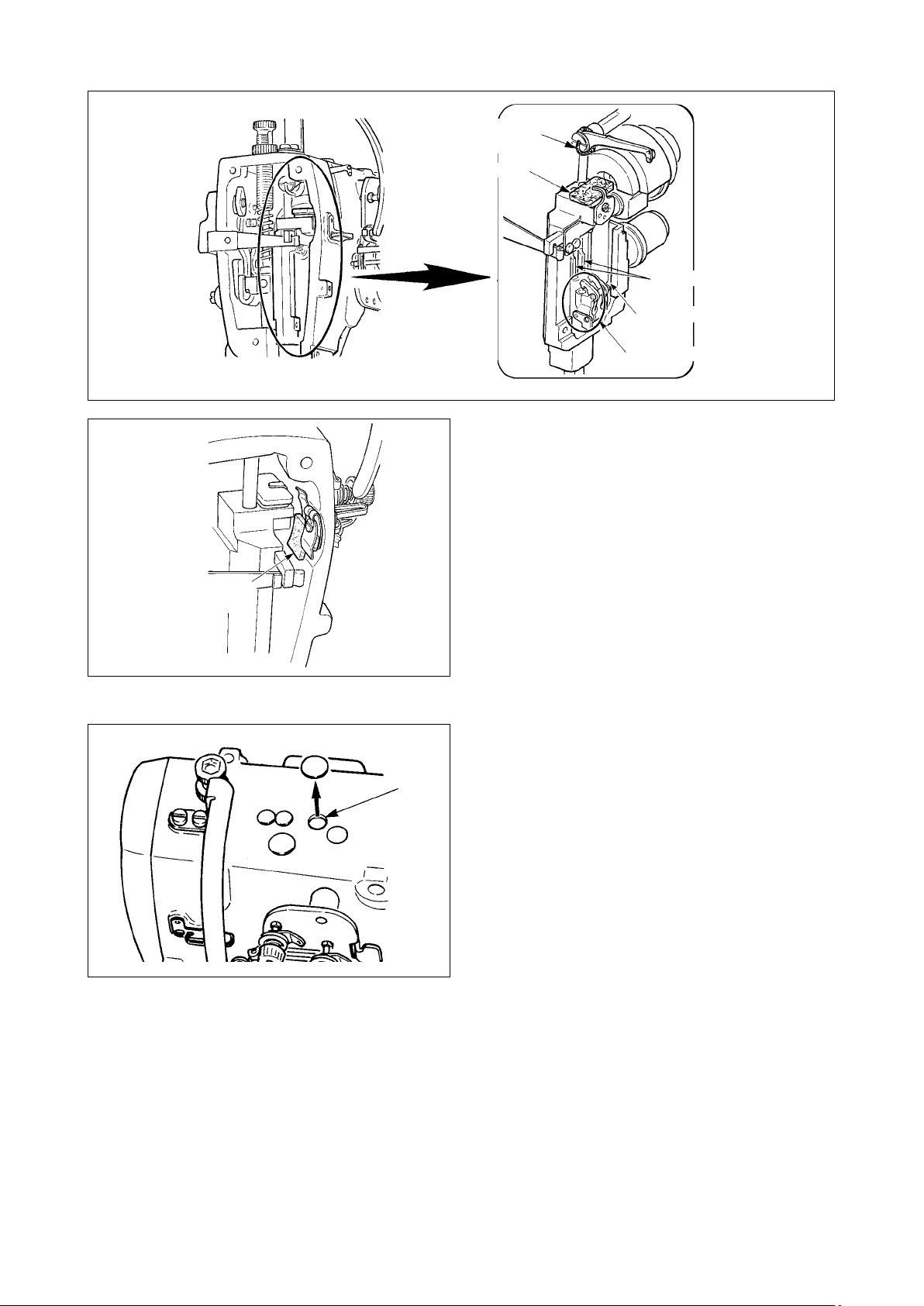

(1) Transporting procedure of the sewing machine

[LH-3528A, 3568A, 3578A, 3588A] [LH-3528A-7, 3568A-7, 3578A-7, 3588A-7]

Hold and transport the sewing machine with two persons as shown in the illustration.

When carrying the sewing machine, take extreme care not to hold the thread tension controllers

by hand. (If you hold the thread tension controllers by hand, they can break.)

(2) Caution when placing the sewing machine

Do not put protruding articles such as the screwdriver and the like at the location where the sewing machine

is placed.

– 4 –

Page 7

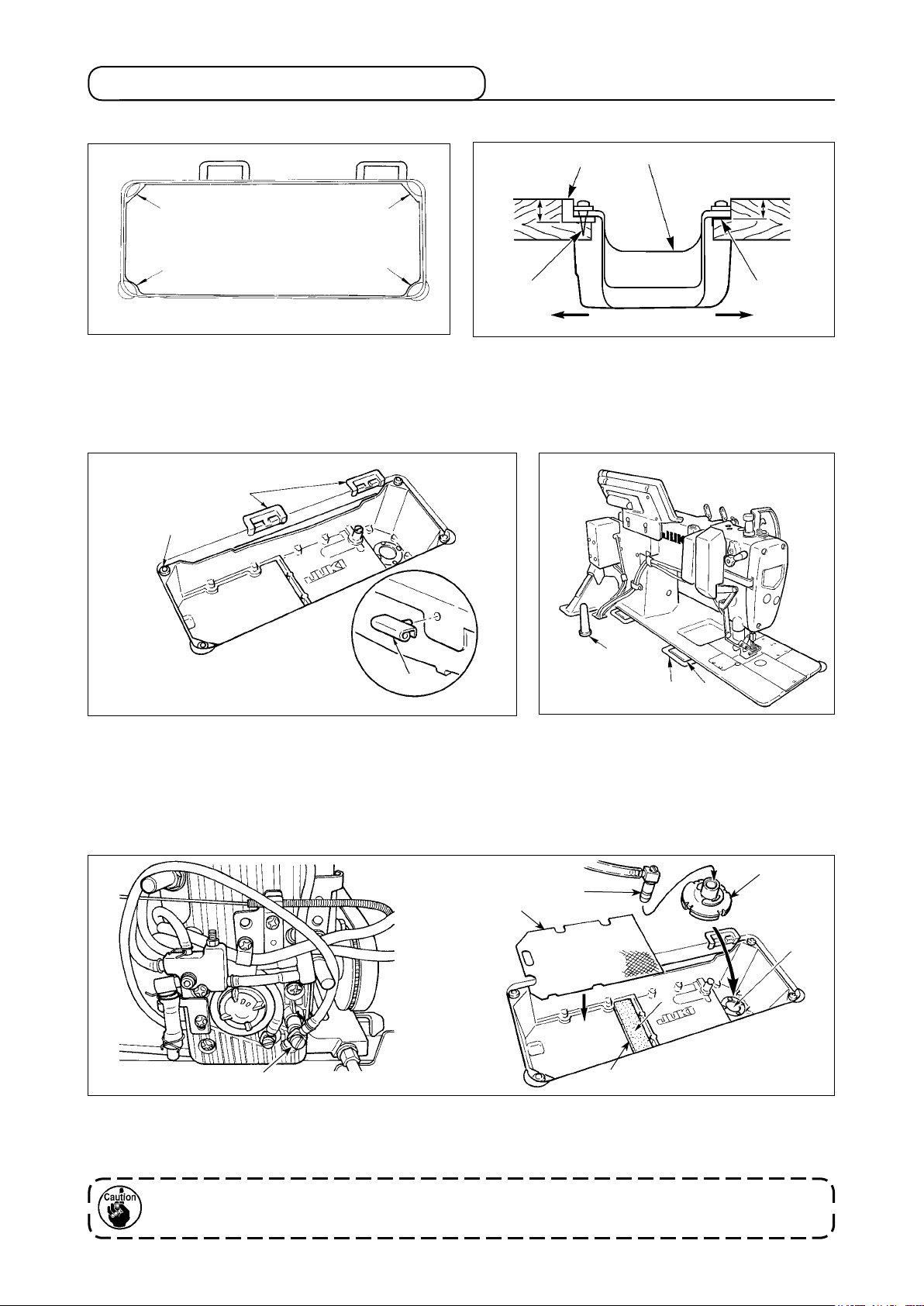

3-2. Installation of the sewing machine

(1) Installing the under cover

3

1

1) The under cover should rest on the four corners

of the machine table groove.

7

8

3

1

A

4

18.5mm

3

B

1

22.5mm

2

2) Fix two rubber seats 1 on side A (operator’s

side) using nails 2 as illustrated above. Fix two

cushion seats 3 on side B (hinged side) using a

rubber-based adhesive. Then place under cover

on the xed seats.

4

6

3) Mount rubber hinge seats 7 on the table and x the

table with nails.

Insert hinge 6 into the machine main body. Engage the hing-

es with rubber hinge seats 7 mounted on the table. Then,

put the machine head down on the machine head cushions

which are located at the four corners of the table.

8

!0

9

6

7

4) Attach head support rod 9 to the table.

!1

!0

!3

D

!2

C

5) Detach inlet port !0 for circulation which is xed on the feed box cover. Insert the inlet port into lter !1

until it will go no further without fail and place them in opening C.

Place urethan lter !2 on D, and place lter !3 of thin plate type (small mesh plate) on it.

Circulation trouble may occur unless inlet port !0 for circulation is securely inserted into ler !1

until it goes no further.

– 5 –

Page 8

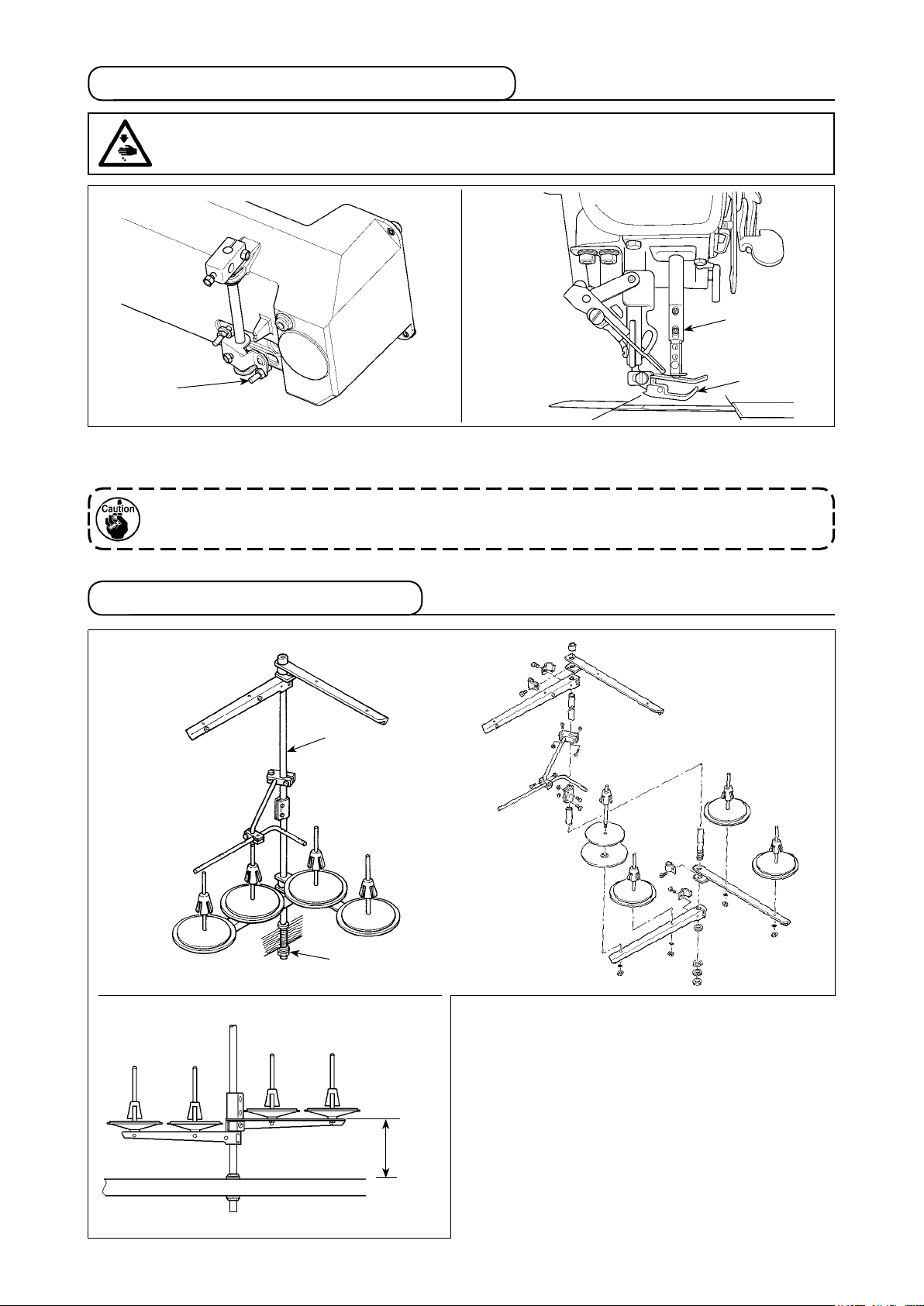

3-3. Adjusting the height of the knee lifter

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

2

1

1) The standard height of the presser foot lifted using the knee lifter is 12 mm.

2) You can adjust the presser foot lift up to 13 mm using knee lifter adjust screw 1.

Do not operate the sewing machine in the state that the presser foot 3 is lifted by 12 mm or

more since the needle bar 2 comes in contact with the presser foot 3.

3-4. Installation of thread stand

2

3

1

Assemble the thread stand, set it up on the machine

table using the installation hole in the table and

tighten nut 1 gently.

300 mm from the top

surface of table

When you use power supplied by the overhead

power line, pass the power supply cord through hol-

low spool rest rod 2.

– 6 –

Page 9

4. PREPARATION OF THE SEWING MACHINE

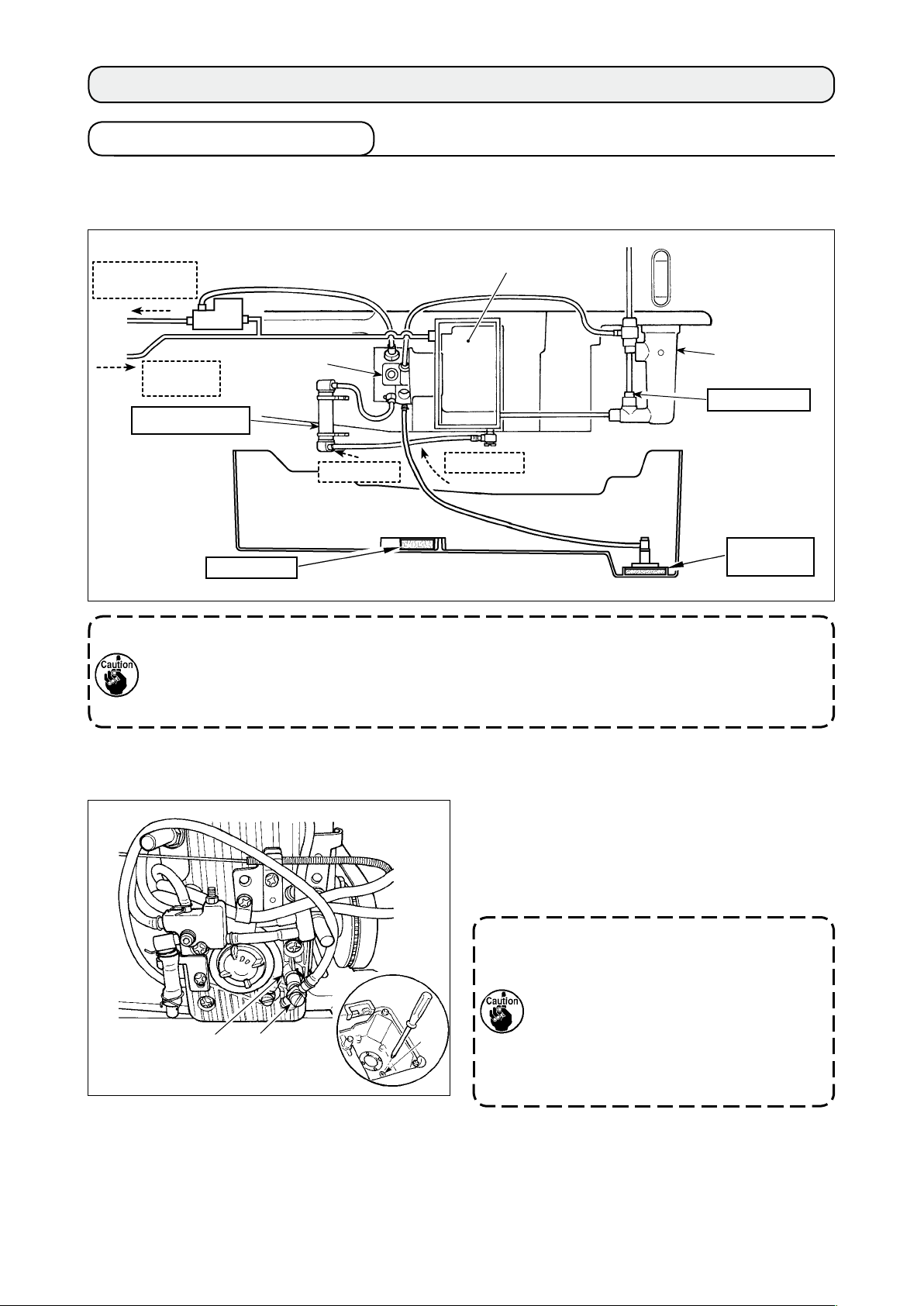

4-1. Method of lubrication

For this sewing machine, one of two different lubricating methods can be selected.

(1) Method of circulating lubrication (when the oil collected in the under cover is reused)

Lubrication to

hook side

Reux oil

from hook

Filter for plunger

To ensure the long service life of the sewing machine, be sure to clean up the aforementioned

lter sections (at four locations) periodically (approximately once three months). When the lter

is clogged, lubrication trouble will occur and break-down will be caused.

In addition, when the oil becomes dirty, replace the oil gathered in the oil tank and the under

cover.

Plunger

Urethan lter

Lubrication

Oil tank

Ball oat case

Oil inlet lter

Circulation

Filter for

circulation

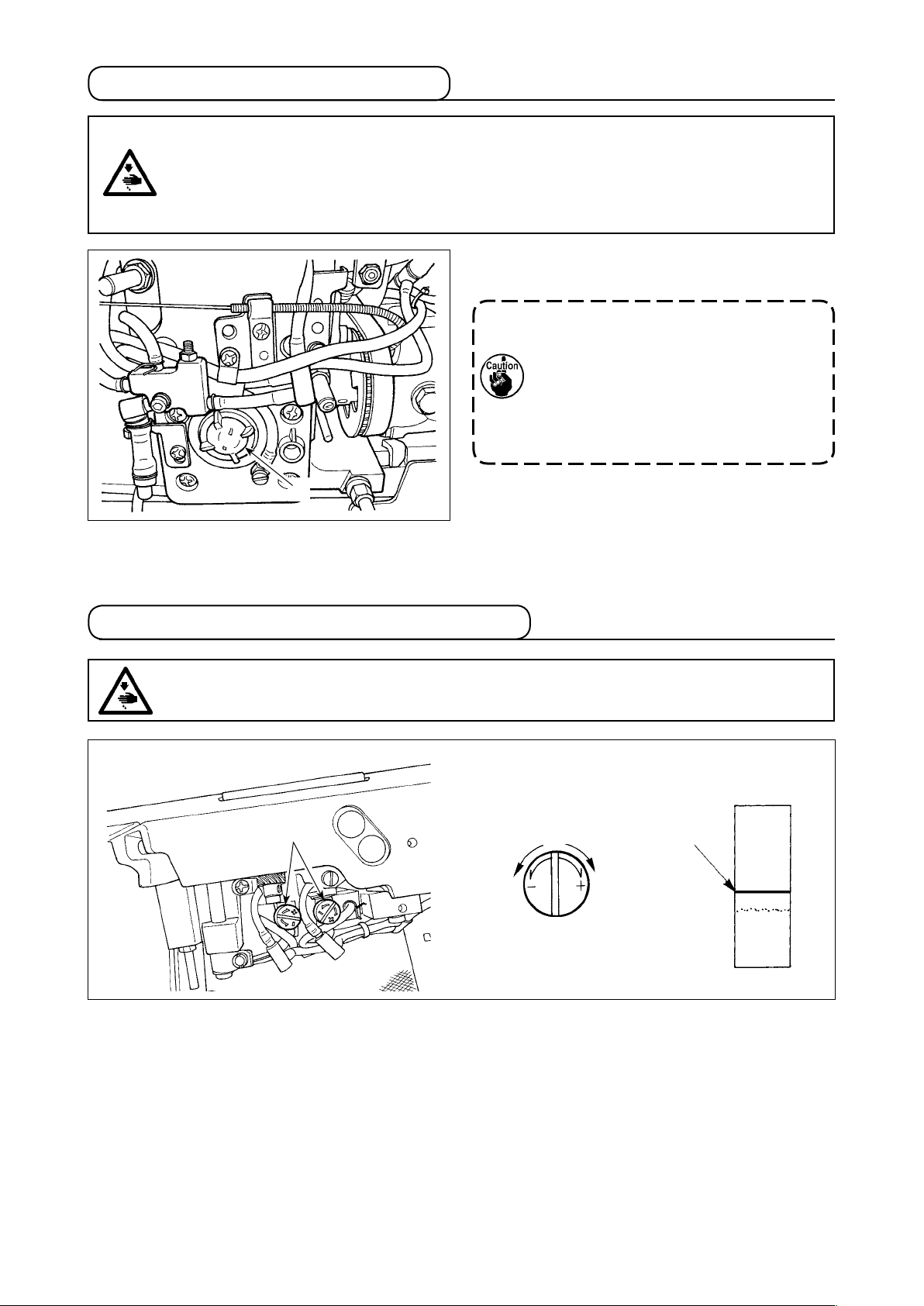

(2) Method of non-circulation type lubrication (when only the clean oil is always used)

Insert inlet port 1 for circulation into section 3 of

the feed box cover until it will go no further to put it

into the state as it has been delivered to your plant.

* Drain oil dropped into the under cover by remov-

ing drain screw 2.

When inlet port for circulation 1 comes

in contact with the oil surface, oil is

absorbed without passing the lter. As a

result, break-down will be caused.

If inlet port 1 for circulation is not insert-

3

1

2

ed into the feed box cover, oil may leak

from inlet port 1 for circulation or the

quantity of oil in the hook may uctuate.

– 7 –

Page 10

4-2. Lubrication to the oil tank

WARNING :

1. Do not connect the power plug until the lubrication has been completed so as to prevent

accidents due to abrupt start of the sewing machine,

2. To prevent the occurrence of an inammation or rash, immediately wash the related portions if

oil adheres to your eyes or other parts of your body.

3. If oil is mistakenly swallowed, diarrhea or vomitting may occur. Put oil in a place where children

cannot reach.

Lower

engraved

marker line

3

2

1

Upper

engraved

marker line

Fill the oil tank with oil for hook lubrication before

operating the sewing machine.

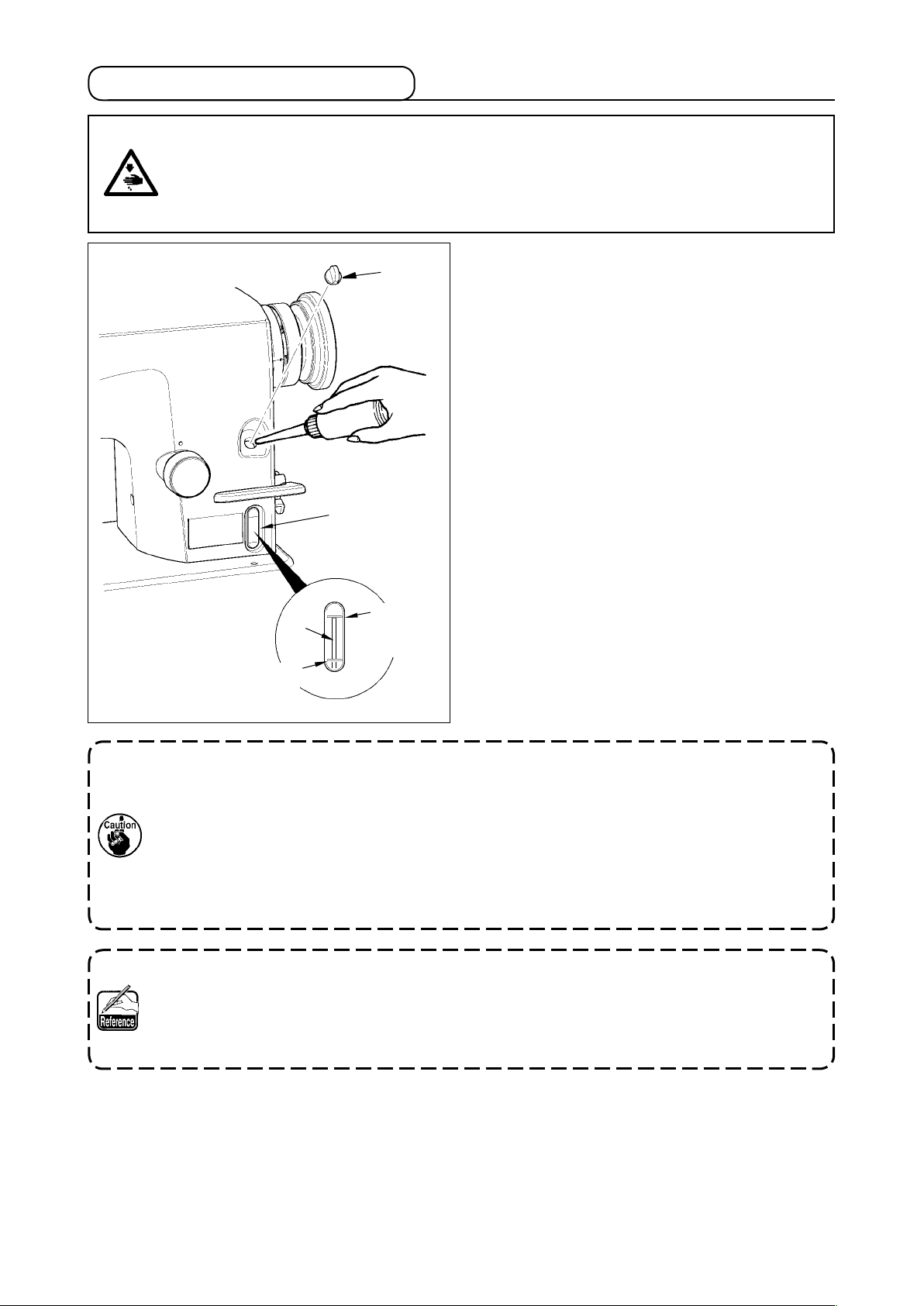

1) Remove oil hole cap 1 and ll the oil tank with

JUKI NEW DEFRIX OIL No.1 (Part No. : MD-

FRX1600C0) or JUKI MACHINE OIL #7 (Part

No. : MML007600CA) using the oiler supplied

with the machine.

2) Add oil until the top end of oil amount indicating

rod 3 does not go above the upper engraved

marker line.

If the oil tank is lled with an excessive amount

of oil, oil will leak from the air vent hole in the ball

oat case or proper lubrication will not be carried

out. So, be careful.

3) When you operate the sewing machine, rell oil if

the top end of oil amount indicating rod 3 comes

down to the lower engraved marker line of oil

amount indicating window 2.

• For the rst time you ll the oil tank with oil, add 280 cc of oil as a guide and check to be sure

that the oil amount indicating rod works. If the oil amount indicating rod does not work, bring it

to the workable state by tiling the sewing machine once.

• When you use a new sewing machine or a sewing machine after an extended period of disuse,

use the sewing machine after performing break-in at 2,000 sti/min or less.

• For the oil for hook lubrication, purchase JUKI NEW DEFRIX OIL No. 1 (Part No. : MD-

FRX1600C0) or JUKI MACHINE OIL #7 (Part No. : MML007600CA).

• Be sure to lubricate clean oil.

In case of the circulation type lubrication method, when using the sewing machine for the rst

time, the oil amount in the oil tank decreases until the oil has collected in the ler for circulation.

When the top end of oil amount indicating rod is lower than the lower engraved marker line, add

the oil to the oil tank again so that the top end enters between the upper and lower engraved

marker lines.

– 8 –

Page 11

4-3. Draining of oil from the oil tank

WARNING :

1. To prevent accidents caused by abrupt start of the sewing machine, do not connect the power

plug until draining of oil has been completed.

2. To prevent the occurrence of an inammation or rash, immediately wash the related portions if

oil adheres to your eyes or other parts of your body.

3. If oil is mistakenly swallowed, diarrhea or vomitting may occur. Put oil in a place where children

cannot reach.

1

When draining oil from the oil tank, loosen and re-

move oil conrming window 1.

Oil may burst out from the oil conrming

window at the time of draining.

It is recommended, in this case, only to

loosen the oil conrming window instead

of removing it. Then, drain oil while con-

trolling the oil amount bursting out from

the oil amount conrming window 1.

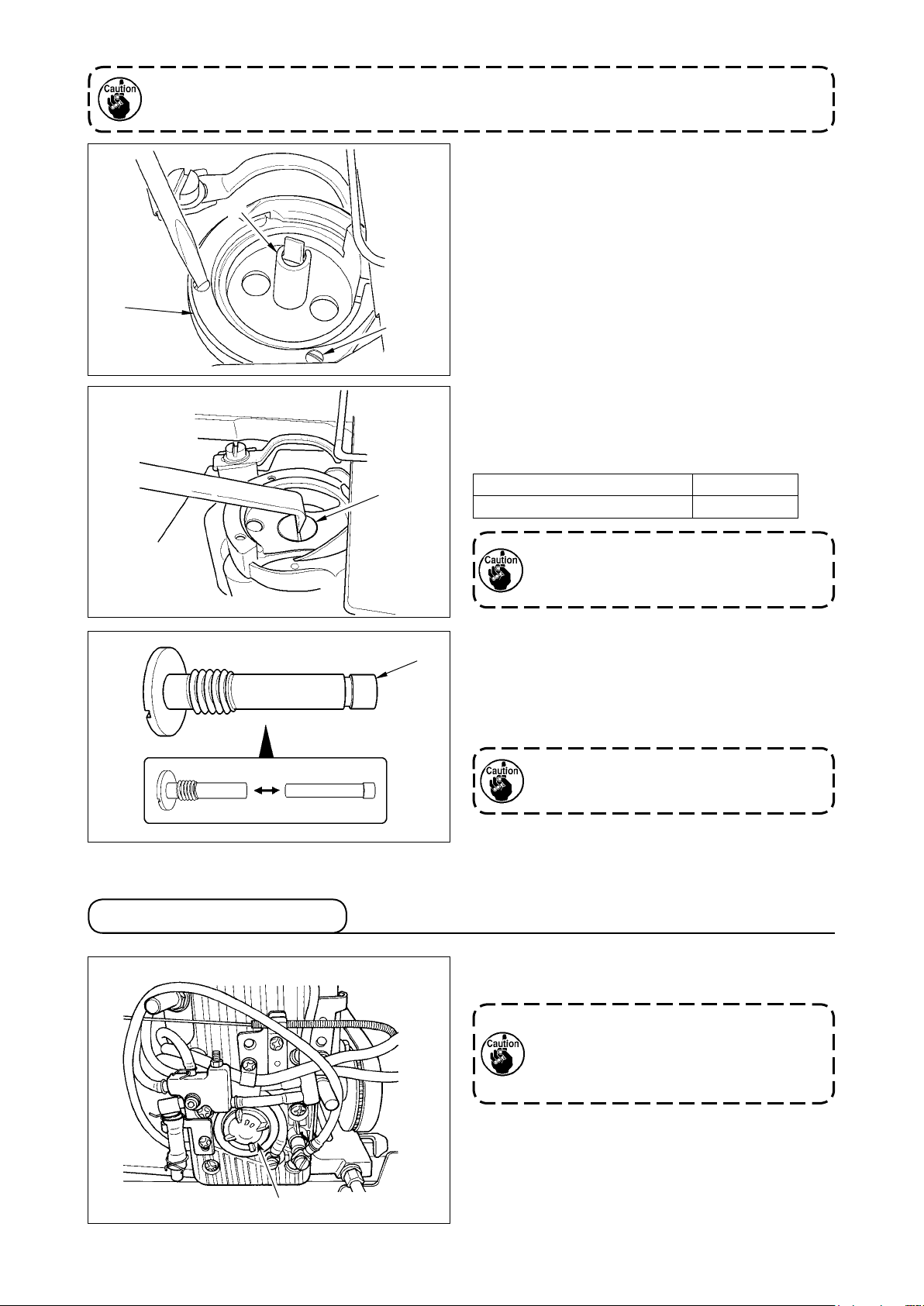

4-4. Adjusting the amount of oil in the hook

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

1

Oil amount

decreases

Adjust the amount oil using adjusting screw 1. Turn screw 1 clockwise to increase the amount of oil in the

hook or counterclockwise to decrease it. Measure the amount of oil in ve seconds. When the amount of oil

is excessively decreased, break-down will be caused. So, be careful.

Oil splashes

Oil a mount

increases

– 9 –

Page 12

To use in safety, replace the oil wick of hook section with a new one approximately once a year

with the procedure below.

1

3

4

2

1) Loosen setscrews

large hook : 3 places) and remove hook gib

2) Remove inner hook

(small hook : 2 places,

2

.

3

1

.

3) Loosen oil plug 4 with the L-shaped screwdriver

(Part No. : B9101490000) and remove it.

4) �raw out oil wick 5 inserted into oil plug 4, and

replace it with a new one.

[Part No. of oil wick 5]

Small hook / Large hook/ Large hookLarge hook 11015906

Oil Q’ty in the hook is largish 11404704

When strongly pressing oil wick 5, it may

be broken. Lightly insert it to such an

extent that it is not drawn out.

4-5. Oil in the feed box

5

After the replacement, assemble oil plug

inner hook 3 and hook gib

to the hook by

1

4

,

reversing the above procedure.

Perform conrming of oil splash.

When loosening/assembling, do not allow

the slit section of oil plug 4 to be burred.

When using the sewing machine, make sure that the

oil is put in the feed box from oil conrming window 1.

If you nd abnormal discoloring of oil

or dust in the oil through the oil amount

indicating window, loosen the window to

drain oil and ll the oil tank with new oil.

1

– 10 –

Page 13

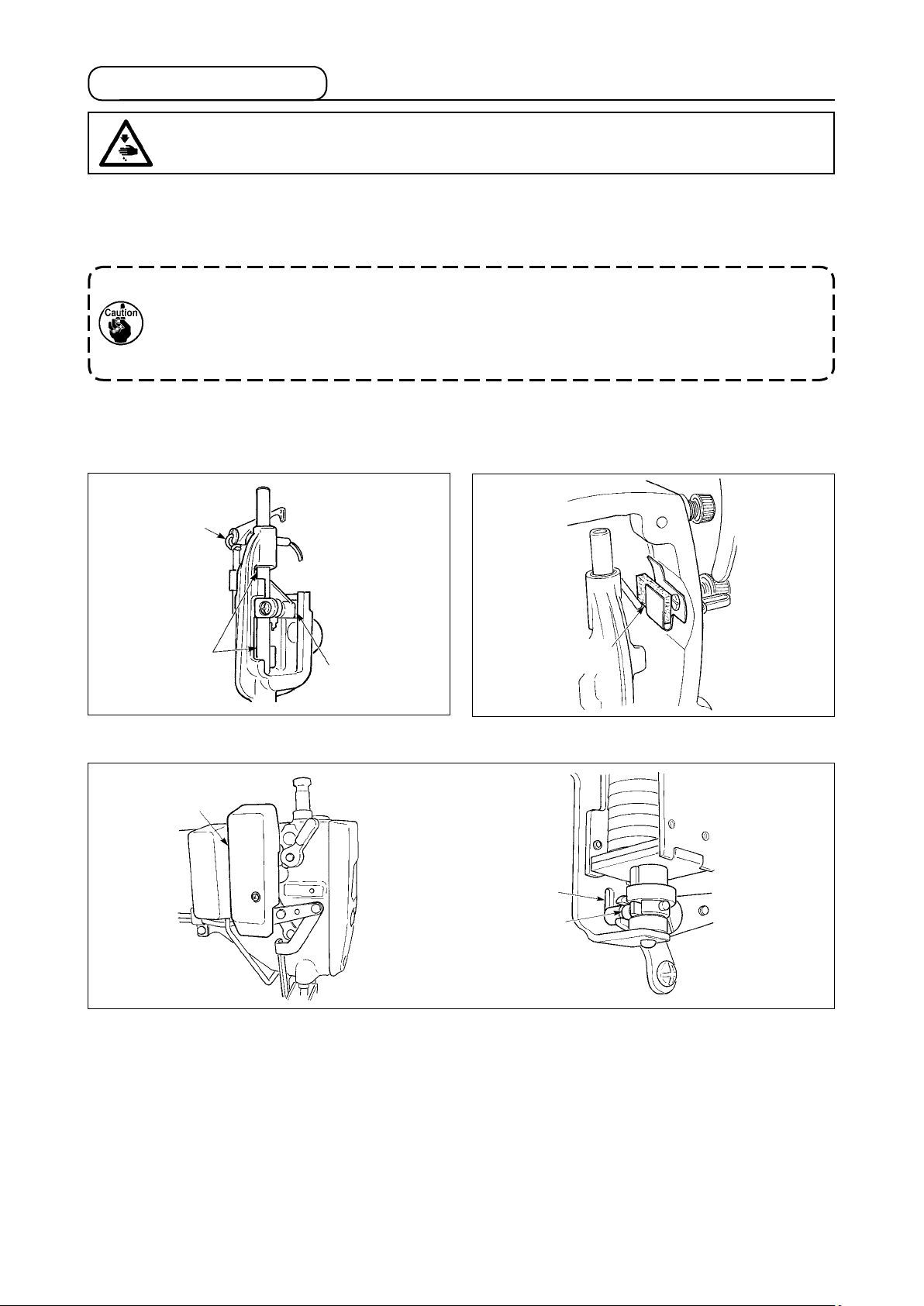

4-6. Applying grease

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

To use the sewing machine in safety, periodically perform grease-up (standard is once in 2 to 3 years) to the

grease applying sections of the respective models with the cotton bar or the like. When using SC-920, when

the time of grease-up comes, the warning alarm sounds. When the alarm sounds, perform grease-up.

• Never lubricate oil to the grease applying places.

• When grease is applied more than is necessary, there is a fear that grease leaks from the thread

take-up lever cover section or the needle bar. So, be careful.

• Be sure to use the grease contained in JUKI GREASE A TUBE (Part No. : 40006323) supplied

with the machine head as accessories.

(1) Sections to be applied with grease

[LH-3528A, 3528A-7, 3578A, 3578A-7]

Thread take-up

lever (oil wick)

Needle bar

Square block

Face plate

lubrication felt

[LH-3528A-7, 3568A-7, 3578A-7, 3588A-7]

1

2

3

Remove wiper cover 1, and apply grease to slot section 2 of wiper solenoid base and wiper link collar 3.

– 11 –

Page 14

[LH-3568A, 3568A-7, 3588A, 3588A-7]

Thread take-up

lever (oil wick)

Felt

Needle bar

Square block

Needle bar bracket

[Common]

Face plate

lubrication felt

A

Remove the rubber cap, take out the felt in A, pour

new grease in the hole, and put the felt to which

grease has been soaked after removing old grease

adhered to the inside of the hole and the felt.

Further, pour grease above the felt and cover it with

the rubber cap.

– 12 –

Page 15

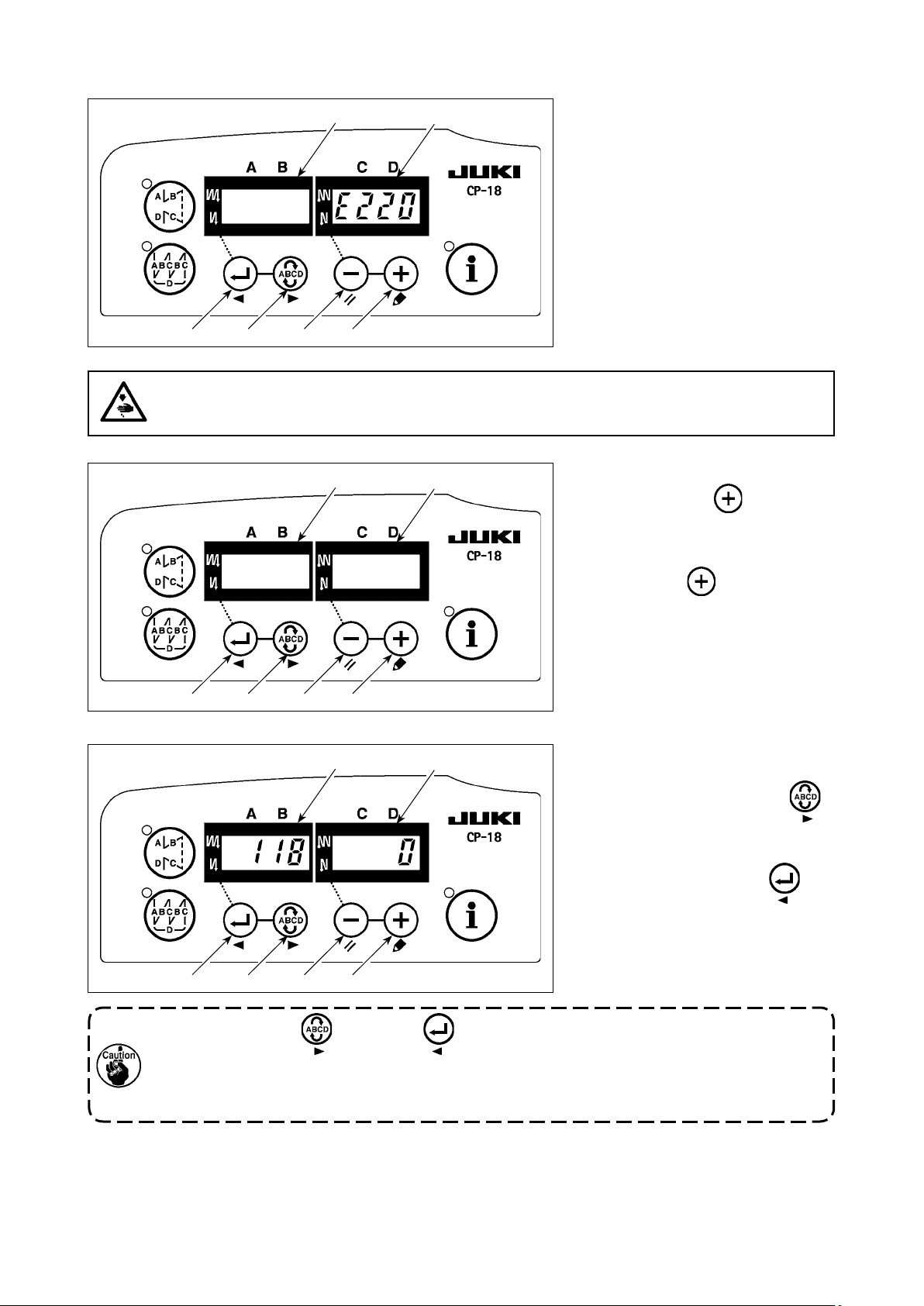

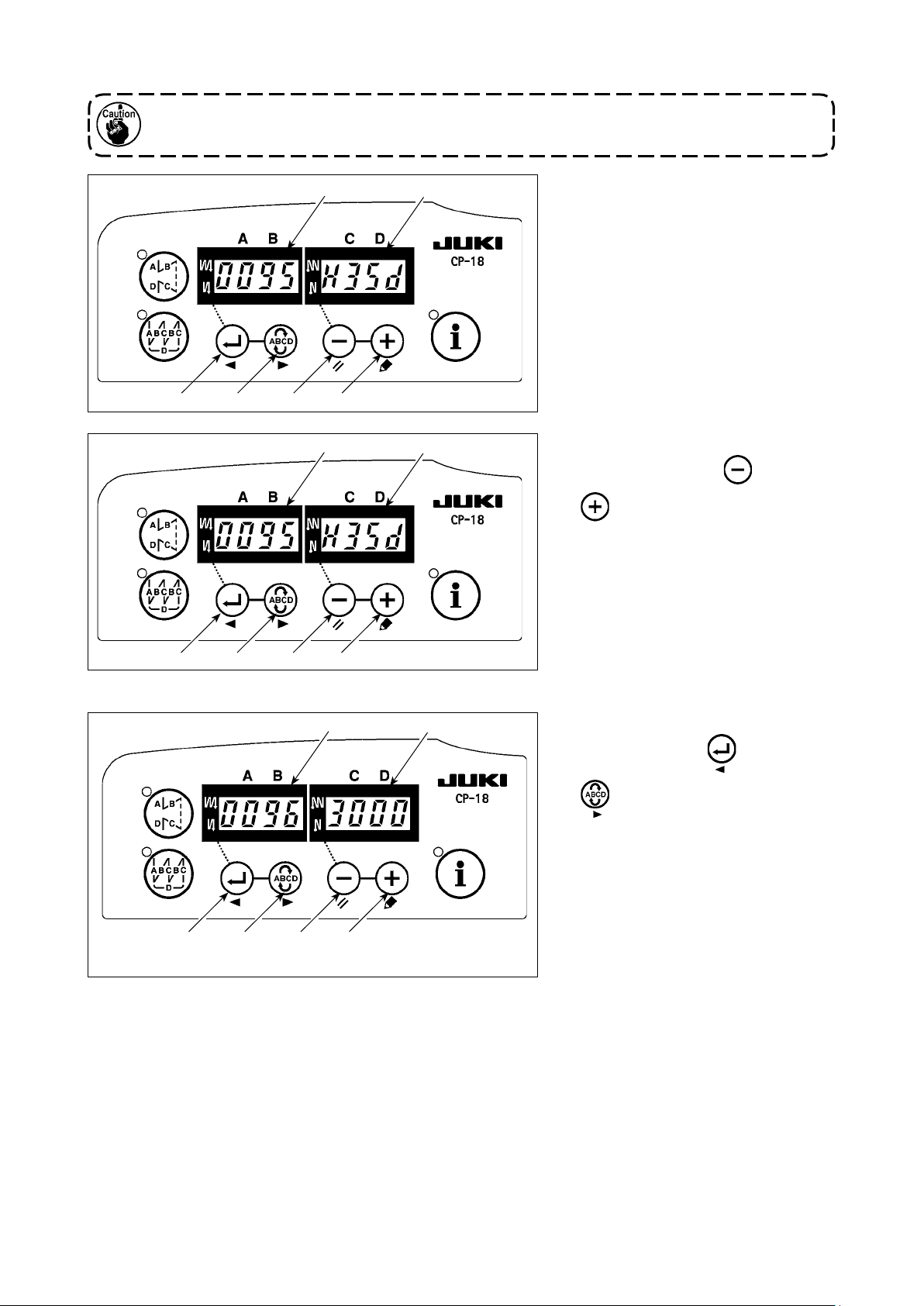

(2) Releasing procedure of the grease-up warning for SC-920

When the time of grease-up has

come, screen display of LED 5 on

the left-hand gure becomes "E220".

After performing grease-up, release

the warning following the procedure

below.

1

6

2 3 4

5

WARNING :

To avoid possible personal injuries caused by movement other than that you desired, do not operate

the switches in the procedure other than those required, as described below, to specify the functions.

6

5

1) Turn OFF the power to the unit.

2) Pressing switch

the power to the unit.

3) When the screen is displayed,

, turn ON

4

1

1

2 3 4

6

2 3 4

5

keep switch

for three seconds until the buzzer

sounds twice.

4) Set the setting No.6 to "118".

When you want to advance the

setting No.6, press switch

to advance the setting No.

2

When you want to return the set-

ting No.6, press switch

to return the setting No.

held pressed

4

6

6

1

Keep pressing switch 2 or switch 1, and the setting No. 6 will advance (return)

continuously. If the setting No. 6 is moved forward (or backward), the previous (or subsequent)

content of the setting is conrmed. Be careful when the content of a setting is changed (when

the up / down switch is touched).

– 13 –

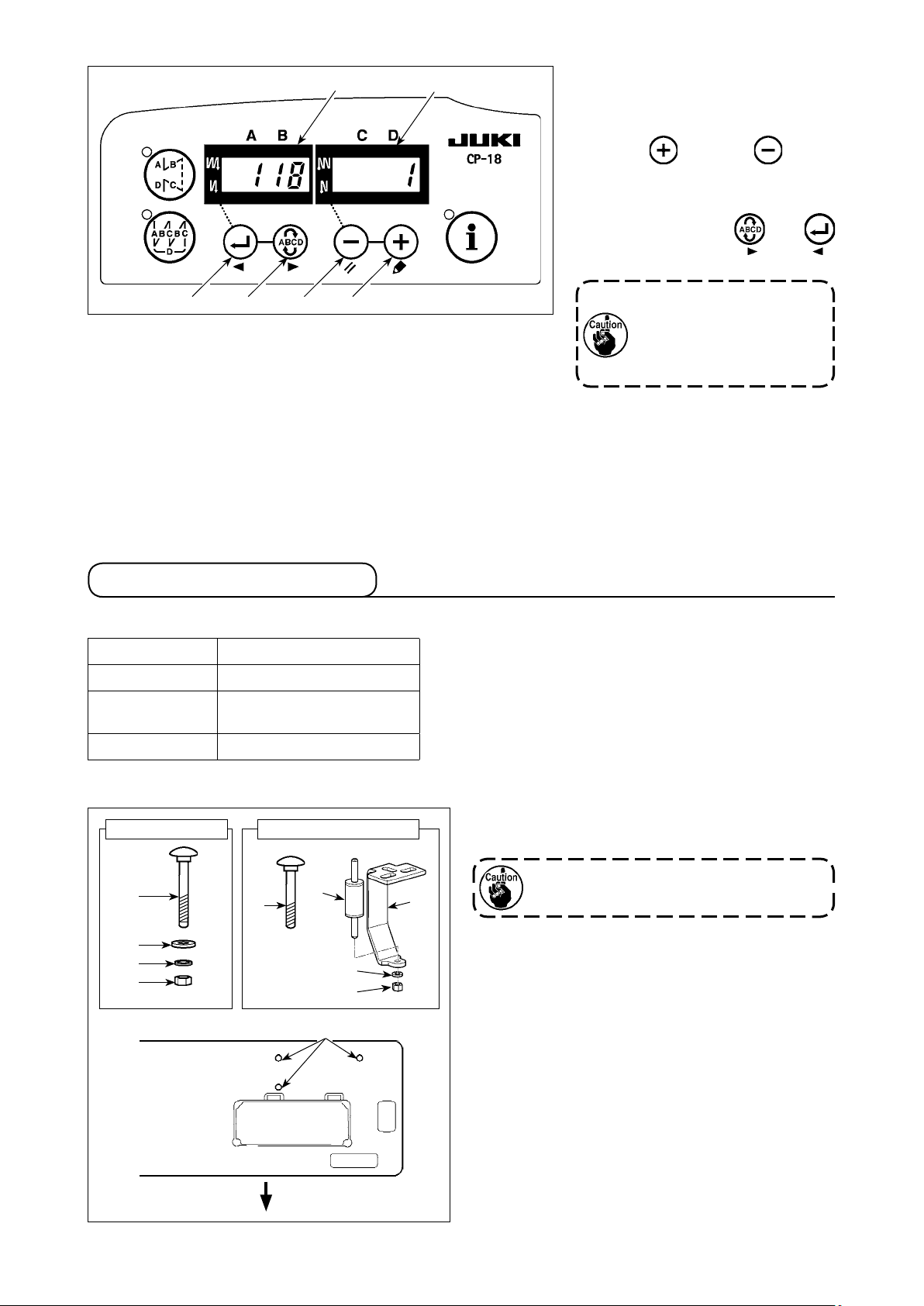

Page 16

6

5

5) When setting No. 6 is adjusted

to "118", the current set value is

displayed on LED 5. Then Press

switch 4 (switch 3) to

change to "1".

6) When the change has been com-

pleted, press switch 2 or

to specify the changed value.

1

1

2 3 4

After completion of the operation, turn the power OFF and re-turn it

ON to restore the normal operation.

When turning OFF the

power before performing

this work, the contents

which have been changed

are not updated.

(3) Releasing procedure of the grease-up “error” For SC-920

When using the machine for a certain period of time after the display of error No. 220 (continuing using the

machine without performing grease-up at the time of displaying No. 220), error No. 221 is displayed and the

machine stops running.

In this case, apply grease to the specied sections, then reset the error according to the description given in

"(2) Releasing procedure of the grease-up warning for SC-920" p. 13

.

After completion of the operation, turn the power OFF and re-turn it ON to restore the normal operation.

4-7. Setting up the SC-920

(1) Specications

Supply voltage 3-phase 200 to 240V

Frequency 50Hz/60Hz

Operating envi-

ronment

Input 320VA

Temperature : 0 to 40˚C

Humidity : 90% or less

(2) Installing on the table (LH-3528A-7, 3568A-7, 3578A-7 and 3588A-7)

Parts supplied with SC-920

×

8

9

!0

Table

Parts supplied with LH-3500A

6

1

7

4

1

Operator side

3

1) Hammer decoration boltHammer decoration bolt 1 supplied with the LH-

3500A into table.

The decoration bolt supplied with the

SC-920 is not used.

– 14 –

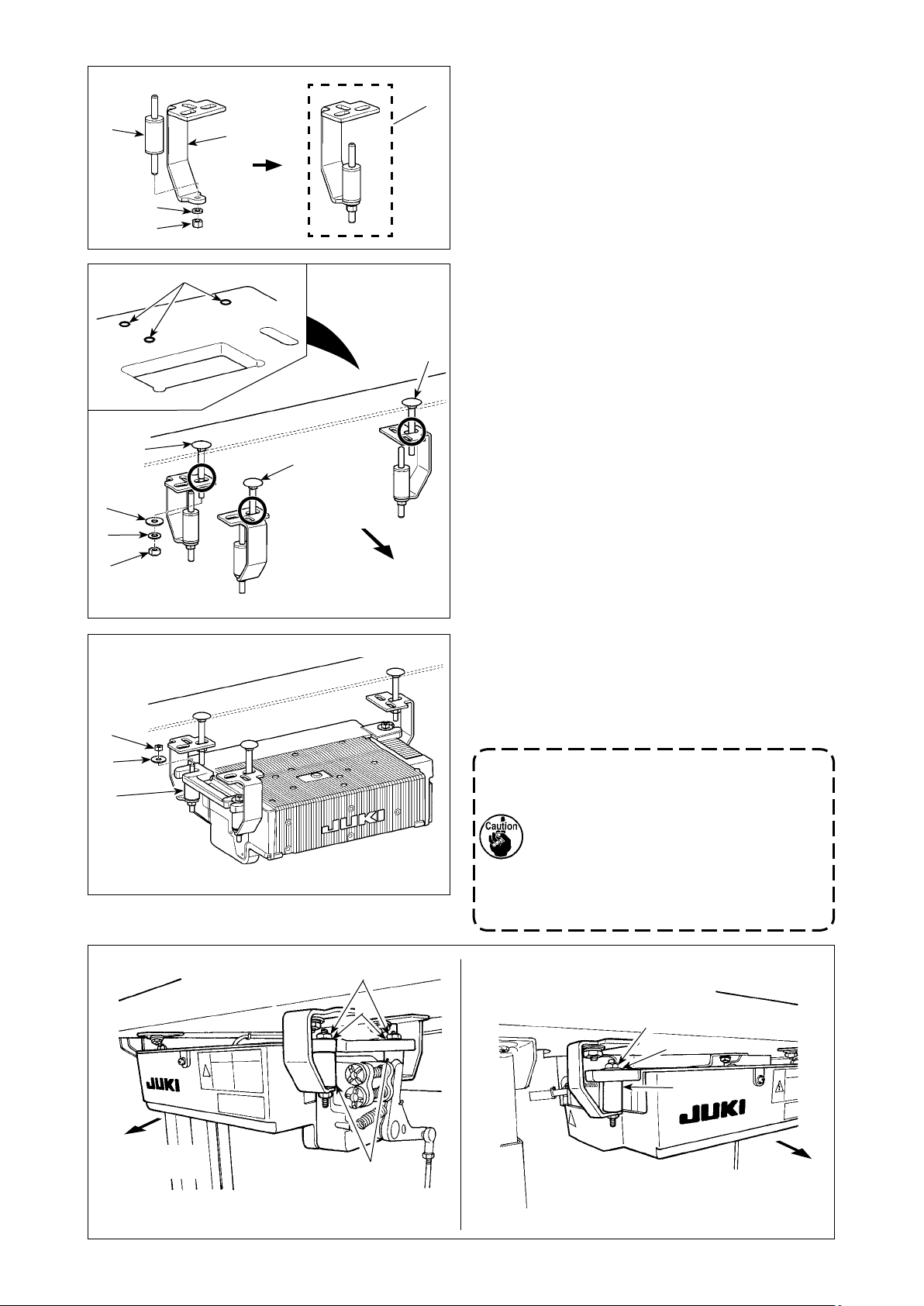

Page 17

6

7

4

3

2

2)

Fix rubber cushion 6 on control-box mounting plate

with nut 4 and spring washer 7. Three sets of

3

are required.

2

Table

8

9

!0

4

1B

1

1A

1B

Operator side

3) Fix control-box mounting plates 2 assembled

in step 2) on the table with decoration bolts 1,

washers 8, spring washers 9 and nuts !0.

Screw

at one location this side as observed

1A

from the operator should be securely tightened,

and two screws

at two locations far side

1B

from the operator should be temporarily tight-

ened.

* Install control-box mounting plate 3 as illustrat-

ed in the gure, carefully checking the installing

direction and the location of holes.

* The washers, spring washers and nuts supplied

with the SC-920 should be used.

4) Place the SC-920 on rubber cushions 6 and x

with nuts 4 and washers 5.

Install the control box while carefully changing the

position of the temporarily-xed control-box mounting

plate (right one as observed from the worker).

5

6

Away from the

operator side

4

5

6

1. If you use the decoration bolt supplied

with the SC-920, the control box cannot

be installed since the bolt interferes with

the control box.

2. If the control-box mounting plates are

xed on the table in a wrong installing

direction or with the hole located at a

wrong position, the control box cannot

be installed.

4

5

6

Away from the

operator side

– 15 –

Page 18

(3) Setting procedure of the machine head

For the operation panel other than CP-18, refer to the Instruction Manual for the operation panel

to be used for the setting procedure of the machine head.

1

1

6

2 3 4

6

2 3 4

5

5

1) Call function setting No. 95 refer-

ring to

SC-920"

"#-6. Setting functions of

in the Instruction Manual

for the SC-920.

2) The type of machine head can be

selected by pressing switch 3 (

switch 4).

* Refer to "CAUTIONS WHEN SET-

TING UP THE SEWING MACHINE"

or "Machine head list" on the sepa-

rate sheet for the types of machine

heads.

1

6

2 3 4

5

3) After selecting the type of machine

head, by pressing switch 1 (

switch 2), the step proceeds to

96 or 94, and the display automati-

cally changes to the contents of the

setting corresponding with the type

of machine head.

– 16 –

Page 19

(4) Adjusting the machine head (LH-3528A-7, 3568A-7, 3578A-7 and 3588A-7)

When the slip between the white marker dot on the handwheel and the concave of the cover is

excessive after thread trimming, adjust the angle of the machine head by the operation below.

1

6

2 3 4

6

5

5

1) Simultaneously pressing

switch 2 and switch 3, turn

ON the power switch.

2) is displayed (6) in the in-

dicator and the mode is changed

over to the adjustment mode.

3) Turn the pulley of the machine

head by hand until the main-shaft

reference signal is detected. At

this time, the degree of an angle

from the main-shaft reference

signal is displayed on the indica-

tor 5. (The value is the reference

value.)

1 2 3 4

8

6

5

4) In this state, align the white dot 7 of the hand-

7

wheel with the concave 8 of the pulley cover as

shown in the gure.

5) Press switch 4 to nish the

adjustment work. (The value is the

reference value.)

1

2 3 4

– 17 –

Page 20

4-8. Installing the belt cover (For LH-3528A, 3568A, 3578A and 3588A)

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

LH-3528A, 3568A

LH-3578A, 3588A

1

2

1) Drill guide holes A and B of wood screws in the table.

2) Temporarily x belt cover B 1 to the place of guide holes A and B.

3) Install belt cover A 2 to the arm installing section.

4) Adjust the position of belt cover B 1 and x it with wood screw.

4-9. Attaching the needles

67

A

47

B

(mm)

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

[LH-3568A, 3568A-7, 3588A and 3588A-7]

2

1

[LH-3528A(S type and G type), 3528A-7, 3578A and

3578A-7]

2

1

2

1

3

2

1

3

[LH-3528A(A type and F type)]

2

1

2

1

3

Switch "off" the motor.

Use DPx5(134) needles.

1) Turn the handwheel until the needle bar has

come up to the highest point of its stroke.

2) Loosen needle clamp screws 2 and pick up two

needles 1 in the way that their grooves 3 are

facing outwards.

3) Insert the needles into the needle clamp as far

as they will go.

4) Tighten needle clamp screws 2 rmly.

– 18 –

Page 21

4-10. How to take out the bobbin case

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

1

4-11. Inserting a bobbin in a bobbin case

1) Lift latch 1 and take out the bobbin case and the

bobbin together.

2) Hold the bobbin case by latch raised, put it into

the shaft in the hook correctly and release the

latch.

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

[LH-3568A, 3568A-7, 3588A and 3588A-7]

A

3

4

2

1

[LH-3528A, 3528A-7, 3578A and 3578A-7]

A

1

1) Set a bobbin to the bobbin case so that the bob-

bin turns in the direction of arrow mark A.

2) Pass the thread through thread slit 1 in the bob-

bin case and draw the thread and pull the thread

so that it passes under the tension spring.

3) Pass thread through another thread slit 2 then,

pass it through thread slit 3 on the bobbin case

from the inside.

4) Put the thread on bobbin threads slack preventer

spring 4.

1) Set a bobbin to the bobbin case so that the bob-

bin turns in the direction of arrow mark A.

2) Pass the thread through thread slit 1 in the hook

and draw the thread and pull it so that it passes

under the tension spring.

– 19 –

Page 22

4-12. Threading the machine head

[S type and G type] LH-3528A, 3528A-7, 3568A and 3568A-7

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

A

1

!0

Fig. 6 Fig. 7

Left-hand

needle thread

-

!0

-

!1

-

!2

-

!3

K

L

M

N

Right-hand

needle thread

!4

!5

K

2

O

P

B

Intermediate

thread guide

4

3

D

8

-

H

6

5

E

F

-

7

G

* Needle thread take-up eyelet is not

usually used.

8 mm

For lament

thread, thread the

machine head as

illustrated.

(The needle

thread take-up

eyelet should be

used for lament

thread.)

C

S type G type

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Thread the machine head following the order as illustrated in the gure.

Pass the left-hand needle thread, toward the machine head, in the order of 1 to !5. Pass the right-hand

needle thread in the order of A to P.

1. Carefully check how to thread the needle clamp thread guides (!4, O).

・ (S type) See Fig 1 for polyester spun thread, Fig. 2 for thick lament thread of yarn count #50

or lower and around #50, or Fig 3 for thin lament thread of yarn count #50 or higher.

・ (G type) See Fig. 4 for thick thread of yarn count #5 to #30.

2. When using lament thread for sewing, use the felt thread guides supplied with the sewing ma-

chine. If the needle thread loosens or breaks, take some preventive measure such as winding

the thread on the needle (S type).

3. To produce chain-off thread, the felt thread guide (in Fig. 2 or Fig. 3) should be used for the S

type, or the needle thread presser (in Fig. 5) should be used for the G type.

4. For the LH-3528A-7 or LH-3568A-7, thread the intermediate thread guide as follows:

・ For polyester spun thread, see Fig. 6. For lament thread, see Fig. 7.

– 20 –

Fig. 5

Page 23

[G type] LH-3578A, 3578A-7, 3588A and 3588A-7

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

A

1

!0

Fig. 1 Fig. 2

Left-hand

needle thread

-

!0

-

!1

-

!2

-

!3

K

L

M

N

Right-hand

needle thread

!4

!5

K

2

O

P

B

8

-

H

Intermediate

thread guide

14 mm

5

6

-

7

G

F

4

3

C

D

E

Thread the machine head following the order as illustrated in the gure.

Pass the left-hand needle thread, toward the machine head, in the order of 1 to !5. Pass the right-hand

needle thread in the order of A to P.

1. Thread guide (

tion. If the thread guide is inclined excessively, the needle thread can tangle on thread guide (!3,

). So, carefully adjust the inclination of the thread guide.

N

2. For the LH-3578A-7 or LH-3588A-7, thread the intermediate thread guide as follows:

For polyester spun thread, see Fig. 1. For lament thread, see Fig. 2.

・

, M) is able to prevent the needle thread from apping according to its inclina-

!2

– 21 –

Page 24

[A type and F type]

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

Left-hand

needle thread

-

!0

K

-

!1

L

-

!2

M

!0

Intermediate

K

thread guide

Right-hand

needle thread

Fig. 3

2

Fig. 4

A

1

B

-

!3

N

D

34

C

!4

!5

O

P

J

9

Fig. 1

Fig. 2

8

-

6

I

5

F

E

7 H G

Thread the machine head following the order as illustrated in the gure.

Pass the left-hand needle thread, toward the machine head, in the order of 1 to !5. Pass the right-hand

needle thread in the order of A to P.

1. Be careful of threading of needle clamp thread guides (!4, O).

・ See Fig. 1 for thin lament thread of yarn count #50 or higher, and Fig. 2 for thick lament

thread of yarn count #50 or lower, lament thread around yarn count #50 and polyester spun

thread.

2. Pass right-side needle thread through the upper side of thread guide pin H.

3. Pass the thread through the intermediate thread guide of LH-3528A-7 and 3568A-7 as follows.

・ Fig. 3 for polyester spun thread. Fig. 4 for lament thread.

– 22 –

Page 25

4-13. Thread tension

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

[S type and G type]

2

1

[A type and F type]

2

1

1) Needle thread tension

Turn thread tension nut No. 2 1 clockwise to increase or counterclockwise to reduce the needle thread

tension.

2) Bobbin thread tension

Turn tension adjusting screw 2 clockwise to increase or counterclockwise to reduce the bobbin thread

tension.

– 23 –

Page 26

4-14. Winding the bobbin thread

3

B

1

A

2

C

4

D

E

1) Insert the bobbin deep into the bobbin winder

spindle 1 until it will go no further.

2) Pass the bobbin thread pulled out from the spool

rested on the right side of the thread stand follow-

ing the order as shown in the gure on the left.

Then, wind clockwise the end of the bobbin thread

on the bobbin several times. (In case of the aluminum bobbin, after winding clockwise the end of the

bobbin thread, wind counterclockwise the thread

coming from the bobbin thread tension several

times to wind the bobbin thread with ease.)

3) Press the bobbin winder trip latch 2 in the direction of A and start the sewing machine. The

bobbin rotates in the direction of C and the bobbin

thread is wound up. The bobbin winder spindle 1

automatically as soon as the winding is nished.

4) Remove the bobbin and cut the bobbin thread

6

with the thread cut retainer 3.

5) When adjusting the winding amount of the bob-

7

bin thread, loosen setscrew 4 and move bobbin

winding lever 2 to the direction of A or B. Then

tighten setscrew 4.

6

5

To the direction of A : Decrease

To the direction of B : Increase

6) When the bobbin is not evenly wound with

thread, loosen nut 5 and adjust the height of

bobbin winder tension disk 6.

• It is the standard that the center of the bobbin is as

6

high as the center of thread tension disk 6.

• Adjust the position of thread tension disk 6 to

the direction of D when the winding amount of

the bobbin thread on the lower part of the bobbin is excessive

and to the direction E when the winding amount of the bobbin

thread on the upper part of the bobbin is excessive.

After the adjustment, tighten nut 5.

7) To adjust the tension of the bobbin winder, turn the thread tension nut 7.

1. When winding the bobbin thread, start the winding

F

2. When winding the bobbin thread in the state that sew-

3. There is the possibility that the thread pulled out from

4. Slackened part of the thread can get tangled on the

in the state that the thread between the bobbin and

thread tension disk 6 is tense.

ing is not performed, remove the needle thread from

the thread path of thread take-up and remove the bobbin from the hook.

the thread stand is loosened due to the inuence (direction) of the wind and may be entangled in the handwheel. Be careful of the direction of the wind.

pulley. It is recommended, in order to avoid the abovestated trouble, to wind the bobbin on the F side which

is located far from the motor.

– 24 –

Page 27

4-15. Thread take-up spring

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

[S type and G type]

(1) When you want to change the stroke of the thread take-up spring

3

1

5

7

4 2

1) For thread take-up spring 3 on the left side, loosen screw 2 and adjust the stroke of the spring by mov-

ing the screw along the slot for adjustment.

2) For thread take-up spring 1 on the right side, loosen screw 4 and adjust the stroke of the spring by

moving thread take-up spring adjusting plate 5 along thread take-up spring base 6.

In addition, for LH-3528A, 3528A-7, 3578A and 3578A-7, make sure that thread tension disks 8

and 9 securely rise when hand lifter lever 7 is turned in the direction of the arrow.

6

89

(2) When you want to change the tension of the thread take-up spring

1) To change the tension of thread take-up spring

on the left side, loosen nut 2 and turn spring

4

stud 3 clockwise to increase or counterclock-

wise to decrease the tension of the spring.

After the adjustment, x the stud by tightening

nut 2.

2) To change the tension of thread take-up spring

on the right side, loosen screw 5 and turn nut

1

clockwise to increase or counterclockwise to

6

decrease the tension of the spring.

After the adjustment, x nut by tightening screw

.

5

5

4

6

3

2

1

Decrease

Increase

– 25 –

Page 28

[A type and F type]

(1) When you want to change the stroke of the thread take-up spring

7

4

5

1

6

1) Stroke of thread take-up spring 1 on the right is adjustable by moving thread tension No. 2 asm. 3 to

the left or right after loosening thread tension No. 2 setscrew 2.

2) Stroke of thread take-up spring 4 on the left is adjustable by moving thread tension No. 2 asm. 6 to the

left or right after loosening thread tension No. 2 setscrew 5.

3) Move thread tension No. 2 asm. 3 and 6 to the right to increase or to the left to decrease the stroke of

the thread take-up spring.

When adjusting the stroke of thread take-up springs 1 and 4, thread release pins 7 and 8

should not come in contact with disk release plate 9.

In addition, for LH-3528A, 3528A-7 make sure that thread tension disks !1 and !2 securely rise

when hand lifter lever !0 is turned in the direction of the arrow.

2

3

9

8

!1

!0

To turn

!2

(2) When you want to change the tension of the thread take-up spring

1) Tension of thread take-up spring 1 on the right

is adjustable by turning spring stud 2 to the right

to increase or to the left to reduce.

2) Tension of thread take-up spring 3 on the left is

3

4

1

2

adjustable by turning spring stud 4 to the right

to increase or to the left to reduce.

– 26 –

Page 29

4-16. Adjusting the stitch length

3

1

4-17. Needle-to-hook relation

2

Turn stitch dial 1 counterclockwise (clockwise) to

set the value on the dial corresponding to a desired

stitch length to the marker dot 3 engraved on the

machine arm.

When it is hard to turn stitch dial 1, turn it while

slightly depressing reverse feed control lever 2.

• Reverse feed operation

1) Depress reverse feed control lever 2.

2) Reverse stitches are made as long as you keep

depressing the lever.

3) Release lever, and the machine will run forward.

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

[LH-3528A, 3528A-7, 3578A and 3578A-7]

3

1

• Adjust the needle and the hook as follows.

1) Set the stitch dial at 2 for the A or F type, 2.5 for the S type or 3 for the G type.

2) Turn the handwheel to bring the needle bar to the lowest position and loosen needle bar connecting stud

clamping screw 1.

3) Determine the height of needle bar. The upper two of engraved marker lines are for DPx5(134) needle,

and the lower two of them are for DP X 17(135x17) needle.

A

2

B

1.2mm

2.2mm

[Adjusting procedure for DPx5(134) needle]

Adjust top engraved marker line A of needle bar 2 to the bottom end of needle bar rocking base 3, and

tighten the needle bar connecting stud clamping screw 1. At this time, the needle bar goes up by 2.2 mm

from the lowest position (adjust the second engraved marker line B to the bottom end of needle bar rocking

base 3) and the blade point of hook aligns with the center of needle. Then the distance between the top end

of needle eyelet and the blade point of hook becomes 1.2 mm.

[Adjusting procedure for DP X 17(135x17) needle]

Use the lower two of the engraved marker lines, and perform the adjustment by the same procedure as that

of [Adjusting procedure for DPx5(134) needle].

– 27 –

Page 30

[LH-3568A, 3568A-7, 3588A and 3588A-7]

•

4

2

Adjust the needle and the hook as follows.

[Adjusting procedure for DPx5(134)

needle]

1) Set the stitch dial at 2.5 for the S type or

3

1.2mm

3 for the G type.

2) Turn the handwheel to align the blade

point of hook with the center of needle

when the needle bar goes up by 2.2 mm

from the lowest position (lower engraved

1

marker line of the needle bar aligns with

the bottom end of the needle bar rock-

2.2mm

ing base). At this time, it is the standard

that the distance between the top end of

needle eyelet and the blade point of hook

becomes 1.2 mm.

3) If the needle-to-hook relation is different from the afore-mentioned standard adjustment, remove needle

clamp screw 2 and turn needle clamp 1 by one revolution (the extent of adjustment : 0.6mm).

The needle-to-hook relation can also be adjusted by removing screw 4 from the spring shoe and turning

spring shoe 3 by a half revolu tion (the extent of adjustment : 0.3mm).

[Adjusting procedure for DP X 17(135x17) needle]

When replacing the needle with DP X 17(135x17), replace needle clamp 1. (Needle clamp for DP X

17(135x17) is an optional part.) Use the same engraved marker line of the needle bar for DPx5(134). Adjusting procedure is the same as that of DPx5(134).

[Common]

0.01 to 0.05mm

1

2

3

3

4

2

5

5

• Determine the position of the hook.

1) Loosen three setscrews 1 in the screw gear

(small), and turn the handwheel to lift the needle

bar from its lowest position by 2.2 mm.

2) In this state, loosen four setscrews 5 in hook

driving shaft saddle 4, and move hook driving

shaft saddle 4 to the right or left to adjust so

that a clearance of 0.01 to 0.05 mm is provided

between blade point 2 of the hook and needle 3.

Then tighten setscrews 5.

3) Next, in the state described in step 1), align the

blade point of hook with the center of needle and

tighten setscrews 1 in the screw gear (small).

5

5

– 28 –

Page 31

4-18. Pedal pressure and pedal stroke

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

2

1

4-19. Adjustment of the pedal

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

Upper

side

Lower

side

4

3

(1) Adjusting the pressure required to

depress the front part of the pedal

When the pedal pressure spring 1 is hooked to the

lower side, the pedal pressure will decrease, and

when hooked to the upper side, the pedal pressure

will increase.

(2) Adjusting the pressure required to

depress the back part of the pedal

The pressure increases as you turn reverse depress-

ing regulator screw 2 in, and decreases as you turn

the screw out.

(3) Adjusting the pedal stroke

The pedal stroke decreases when you insert con-

necting rod 3 into the left hole 4.

1

3

2

4

(1) Installing the connecting rod

1) Move pedal 3 to the right or left as illustrated

by the arrows so that motor control lever 1 and

connecting rod 2 are straightened.

(2) Adjusting the pedal angle

1) The pedal tilt can be freely adjusted by changing

the length of the connecting rod.

2) Loosen adjust screw 4, and adjust the length of

connecting rod 2.

– 29 –

Page 32

5. OPERATION OF THE SEWING MACHINE

5-1. Pedal Operation

[The pedal is operated in the following four

A

B

C

D

E

* When auto-lifter (AK135) is used, 1-step switch is increased between stop and thread trimming. The

presser foot goes up when the back part of the pedal is lightly depressed D, and the presser foot comes

down once when the back part of the pedal is further strongly depressed.

Then the thread trimmer is actuated and the presser foot goes up again.

steps: ]

1) The machine runs at low sewing speed when

you lightly depress the front part of the pedal.

2) The machine runs at high sewing speed when

you further depress the front part of the pedal. A

(If the automatic reverse feed stitehing has been

preset, the machine runs at high speed after it

completes reverse feed stitching.)

3) The machine stops (with its needle up or down)

when you reset the pedal toits original position.

C

4) The machine trims threads when you fully de-

press the back part of the pedal.

E

B

• If you reset the pedal to its neutral position during the automatic reverse feed stitching at seam start, the

machine stops after it cornpletes the reverse feed stitching.

• The machine will perform normal thread trimming even if you depress the back part of the pedal immedi-

ately following high or low speed sewing.

• The machine will completely perforrn thread trimming even if you reset the pedal to its neutral position

immediately after the machine started thread trimming action.

5-2. Hand lifter

1) When you want to keep the presser foot in the

lifted position, turn hand lifter 1 in the direction

of the arrow. By so doing, the presser foot rise 7

mm.

2) When you want to lower the presser foot, lower

the hand lifter. This will return the presser foot to

its predeterminded lower position.

1

To turn

3) Operate the knee lifter, and the presser will rise

by approximately 13 mm.

Never perform thread trimming operation

with the presser foot lifted since there is

a case where the wiper comes in contact

with the presser foot and the needle may

be broken when the sewing machine is

operated with the presser foot lifted.

– 30 –

Page 33

5-3. Adjusting the pressure of the presser foot

Loosen nut 2 by turning counterclockwise, and turn

presser spring regulator 1 to adjust the pressure.

Decrease

1

2

Increase

Turn the regulator clockwise to increase the pres-

sure and turn it counterclockwise to decrease the

pressure.

After the adjustment, tighten nut 2.

5-4. Micro-lifter

1

2

Loosen screw 1, turn micro-lifter pin 2, and the

height of the presser foot can be adjusted to 0 to 0.5

mm.

– 31 –

Page 34

5-5. Thread tension release changeover when using the knee lifter

For the LH-3568A, 3568A-7, 3588A and 3588A-7,

the thread tension release of the thread tension

controller has been factory-interlocked with the knee

lifter or AK device at the time of delivery.

1

• In the case the thread tension release is not

interlocked with the knee lifter or AK device

Remove the wiper solenoid in case of the machine

with wiper. Remove the cap at the back, loosen

screw 2, move screw 2 in the direction of arrow up

4

2

to the end of slot of lifting link 3, and x it.

The thread does not slacken unless

thread tension release plate 1 or hand

lifter lever 4 is actuated.

If you start sewing without releasing the

thread tension, a load will be applied to

the needle when the material is drawn out,

resulting in needle bending or breakage.

2

3

5-6. One-touch manual reverse feed (One-touch reverse feed type)

[LH-3528A, 3528A-7 and 3578A-7]

0B type

1

How to use

・

1) Press switch 1, and the sewing machine will immediately run in the reverse direction to perform the reverse feed stitching.

2) Reverse stitching is made as long as you keep pressing the switch.

3) Release the switch, and the sewing machine will run in the normal direction.

[LH-3568A-7 and 3588A-7]

1

– 32 –

Page 35

6. MAINTENANCE

6-1. Procedure of changing over between bottom feed and needle feed

and the adjustment (for LH-3528A only)

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

(1) Changing procedure to bottom feed and the adjustment

7

1

2

2

5

4

2) After replacing the feed dog and the throat plate

with the components for bottom feed, adjust the

position of needle rocking rod xing base 4 so

that the needle center aligns with needle holes

in throat plate 8, and x setscrews 5.

7

Then replace the presser foot with that for bot-

tom feed as well.

3

1) Set the stitch dial at the minimum value. Then, remove hinge screw 1. Move needle bar rocking rod 2

from needle bar rocking rod arm 3 to needle rocking rod xing base 4 and x the rod with hinge screw 1.

8

Needle

C

A

B

Fig. a

!0

!1

Fig. b

!0

!1

9

!3

!3

9

!2

!2

3) Loosen setscrews 9 and !3 (2 places) in

sprocket !2. Loosen the setscrews in the order

of !3 and 9. At this time, remove screw No. 1 9

which is put in screw hole A in sprocket !2, and

put it in screw hole C which is located on the op-

posite side at 180˚. (Fig. a)

Turn the pulley by 180˚ without turning the hook

driving shaft, align the at section of the hook

driving shaft with screw hole C in sprocket !2,

and x with setscrews 9. Screw No. 1 !1 in the

hook driving shaft rear bearing !0 aligns with the

at section of the hook driving shaft. Make the

state as the standard. (Fig. b)

Then x screw No. 2 !3 which is put in screw

hole B in sprocket !2 as well.

– 33 –

Page 36

(2) Changing procedure to needle feed and the adjustment

The procedure is the reverse of "(1) Changing procedure to bottom feed and the adjustment".

Loosen hinge screw 1, move needle bar rocking rod 2 from needle rocking rod xing base 3 to needle bar

rocking rod arm 4, and x it with hinge screw 1.

Replace the feed dog, the throat plate and, the presser with the components for needle feed.

Loosen setscrews 9 and

time, remove the setscrew 9 which is put in screw hole C, and put it in screw hole A which is located on

the opposite side at 180˚. (Fig. b)

Turn the pulley by 180˚ without turning the hook driving shaft, align the at section of the hook driving shaft

with screw hole A in sprocket !2, and x with setscrews 9. It is the standard that screw No. 1 !1 in hook

driving shaft rear bearing !0 aligns with the at section of the hook driving shaft. (Fig. a)

Then x screw No. 2

!3(2 places) in sprocket !2. Loosen the setscrews in the order of !3 and 9. At this

!3 which is put in screw hole B in sprocket !2 as well.

– 34 –

Page 37

6-2. Changing the feed timing

The feed timing has been factory-adjusted as illus-

trated in the sketch on the left.

The following describes how to change the feed tim-

ing to produce better-tensed seams from the state

given in the sketch on the right.

1) Turning pulley 1, remove

1

timing belt 2 from the pul-

ley.

2

Needle

Top surface of

throat plate

Align

3

4

Feed dog

2) Turn pulley 1 in the rotating direction of the sewing machine to lower the needle from its upper position

until it aligns with throat plate 3.

3) Turn hook driving shaft 4 to raise the feed dog from its lower position until it is ush with the top surface

of the throat plate.

4) Carefully keeping the needle and the feed dog in

the aforementioned state, put timing belt 2 on

the pulley.

5) Adjust the timing of the right and left hooks and

adjust the timing of the thread trimming cam,

referring to

and

p.27

cam."p.36.

"4-17. Needle-to-hook relation"

"6-3. Adjusting the thread trimming

2

The hook timing can change by removing/replacing the timing belt, resulting

in a stitching failure. To prevent this, be

sure to adjust the timing of the hook and

thread trimming cam.

– 35 –

Page 38

6-3. Adjusting the thread trimming cam

1

3

5

4

Surface B

2

6

7

!0

6

(1) Position of the thread trimming cam and

the thread trimming timing

1) Align engraved marker dot 1 on the arm with

engraved marker dot 2 (red) on the handwheel.

2) When thread trimmer driving arm stopper 3

comes in contact with knife driving arm 4, press

!1

8

cam roller 5 into the groove in thread trimming

cam 6.

3) Keeping the aforementioned state, turn thread

trimming cam 6 until the location as indicated

in the sketch on the left is reached. When the

thread trimming cam is brought to the location as

indicated in the sketch (the intermediate point of

the section where the shape of groove in thread

trimming cam 6 changes from linear shape to

diagonal shape), tighten two clamping screws of

thread trimming cam 6.

[Checking the timing of the thread trimming cam]

1) Press cam roller 5 into the groove in the cam

until it securely ts in there.

2) Turn handwheel 7 in the opposite direction of

the rotating direction of the sewing machine until

its smooth move is hindered. At this time, check

to be sure that engraved marker dot 1 on the

arm is aligned with engraved marker dot 2 (red)

on the handwheel.

(2) Clearance between the thread trimming

9

A

cam and thread tension release arm

1) Depress thread tension release arm 8.

2) At this time, adjust so that clearance A of 0.5 mm

is provided between surface B of the right end

face of thread trimming cam 6 and roller section

of thread tension release arm 8.

9

3) To adjust, loosen two setscrews !0, adjust the

position of thread tension release driving arm

stopper !1 so that it is spaced 0.5 mm from sur-

face B, and tighten two setscrews !0.

* In the case the clearance is larger than 0.5 mm:

The space pin mechanism does not rise enough,

resulting in a thread trimming failure.

* In the case the clearance is smaller than 0.5

mm:

Roller section 9 comes in contact with thread

trimming cam 6 to disable the thread trimmer

operation.

– 36 –

Page 39

6-4. Adjusting the hook needle guard

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

(Bend inward.)

(Bend outward.)

1

2

0 to 0.05mm

2

2

When replacing the hook, conrm the position of the needle guard.

The standard position of the hook needle guard is obtained when hook needle guard 2 comes in contact

with the side face of needle 1 and the engagement length between the needle and the hook needle guard is

0 to 0.05 mm. If not, adjust by bending the hook needle guard.

1) When bending the hook needle guard inward, perform by entering a screwdriver to the outside of the

hook needle guard.

2) When bending the hook needle guard outward, perform by entering a screwdriver to the inside of the

hook needle guard.

At this time, conrm that the clearance between the needle and the blade point of hook is 0.01 to 0.05 mm.

(

Refer to "4-17. Needle-to-hook relation [common]", p. 28.

)

6-5. Adjusting the inner hook guide

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

3

4

0.2 to 0.3mm

1

A

5

2

1) Turn the handwheel in the normal direction to

bring inner hook guide 1 to the extreme rear

position.

2) Turn bobbin case 2 in the direction of the arrow,

and make inner hook stopper 3 come in contact

with the groove of throat plate 4.

3) Loosen inner hook guide setscrew 5, set the

clearance between the inner hook guide and pro-

trusion A of the bobbin case to 0.2 to 0.3 mm,

and securely tighten inner hook guide setscrew

.

5

– 37 –

Page 40

6-6. Adjusting the height and the inclination of the feed dog

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

(1) Adjusting the height

1mm

2

3

3

1

4

1) Loosen feed driving link setscrew 1. Turn feed

driving link shaft 2 to adjust the height of the

feed dog. Standard height is 1 mm from the

throat plate in the highest position.

(2) Inclination

1) Remove cap 4 on the side of machine bed,

loosen feed bar shaft setscrew 3, and turn

knurled section 5 to adjust the inclination.

Standard inclination is the position where en-

graved marker dot A of feed bar arm aligns with

engraved marker dot B of feed bar shaft. (En-

graved marker dot C is not used.)

B

5

A

C

– 38 –

Page 41

6-7. Replacing the gauge

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

Drive arm pin

2

7

A

6

2

9

Drive arm pin

1

B

2

8

2

6

9

3

3

4

5

• Move of the hook shaft saddle when replacing the gauge

1) Loosen screws No. 2 4 of hook driving shaft gears 3.

2) Align the needle with the blade point of hook.

3) Slightly loosen screws No. 1 5 of hook driving shaft gears 3 so that the screws does not come off the

at section of the hook driving shaft.

•

Loosen

four

setscrews 6 of connecting link (asm.) 9.

(Sewing machine with thread trimmer)

4) Loosen two setscrews 2 of hook shaft saddle 1, and move the hook shaft saddle.

(At this time, the hook driving shaft gears move as well.)

5) Set the clearance between the needle and the blade point of hook to 0.01 to 0.05 mm.

6) Tighten two setscrews 2 of the hook shaft saddle.

7) Tighten from screws No. 1 5 at the position where the clearance between hook driving shaft gears 3

and hook shaft saddles 1 is 0.5 mm. Then tighten screws No. 2 4.

• Make driving arms 7 and 8 come in contact with the driving arm pin in the directions of A and B

respectively and tighten four setscrews 6 in connecting link (asm.) 9. (Sewing machine with thread trim-

mer)

6-8. Adjusting the thread presser spring

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

3

2

1

Insert a rod (thin rod, wrench, etc.) into adjusting

hole 2 in thread presser spring base 1, and loosen

A

setscrew 4 with a hexagonal wrench key of 1.5 mm.

Adjust the thread presser spring by moving rod 3 in

the direction of arrow mark A, and x it with setscrew

.

4

Clamp trouble occurs even when the

thread presser spring pressure is exces-

sive or insufcient. So, be careful.

4

– 39 –

Page 42

6-9. Adjusting the position of the moving knife

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

1) Align counter knife base 1 with plane A of

counter knife 2.

2

A

1

2) Loosen clamp screw 5 in the rear of machine

bed and adjust so that the distances B and C

between the top end of moving knife 3 and the

center of needle 4 at the time of waiting become

the dimensions as shown in the list below when

the feed pitch is minimum and needle 4 is in the

lower dead point.

LH-3528A-7

LH-3568A-7

LH-3578A-7

LH-3588A-7

2

3

E

C B

4

D

2

3

Operator's

side

Left knife Right knife

Reference value)

B(D

6.2 (3.5) 7.5 (2.7)

7.3 (4.1) 8.9 (3.1)

Reference value)

C(E

6

5

3

D

5

3) Set clearance D between moving knife 3 and

protrusion 6 of the inner hook to 0.3 ± 0.1 mm.

Loosen moving knife setscrews 7 and 8, and

adjust the clearance.

7

8

– 40 –

Page 43

6-10. Position of the wiper

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

1

3

Needle

5

4

1) Adjust engraved marker dot 1 on the machine arm to white marker dot 2 on the handwheel.

2) Move rod 3 in the direction of the arrow, and adjust with two clamping screws 5 so that the clearance

between the top end of needle and wiper 4 is approximately 2 mm.

2mm

2

6-11. Caution when installing the attachments

A

Be careful that screw A does not protrude in the

rear of the bed slide when xing the attachment to

the bed slide with the screw.

When it protrudes as shown in the gure,

the screw interferes with other compo-

nents and break-down will be caused.

– 41 –

Page 44

6-12. Replacing the bobbin thread slack preventer spring

(For LH-3568A,

1

3568A-7, 3588A and 3588A-7)

1) Loosen screw 1 and remove bobbin thread

slack preventer spring 2 from the groove on the

bobbin case.

2

Groove

2) Fit bobbin thread slack preventer spring 2 which

replaces the removed spring in the bobbin case

through the groove.

3) Fix bobbin thread slack preventer spring 2 in

the bobbin case by tighten screw 1. At this time,

carefully check the operating range and tension

or the spring.

6-13. Stop of the needle bars and angle of corners for corners stitching

(For LH-3568A, 3568A-7, 3588A and 3588A-7)

• Stop of the needle bar

When change lever 1 is moved to position L, the

left-hand needle bar stops, and when it is moved to

position R, the right-hand needle bar stops.

(3/16" gauge)

3 stitches

2

90˚

3 stitches

1

• When returning to 2-needle operation

Press change xing lever 2. Change lever 1 re-

turns to the position "0", and the machine returns to

2-needle sewing.

• Relation between the angle of corners and

stitch length

To perform corner stitching with accuracy, the stitch

length can be determined referring to the table of the

number of stitches by gauges.

However, check whether the stitch length determined

really matches the corner by actually sewing it.

(Example)

To sew a correr of 90˚ of angle using a 3/16" gauge

with the stitch length specied to 1.6mm, the number

of stiches can be obtained in the following way. Ob-

serve the "90˚" columns on the table of the number

of stitches by stitch length gauges to search for the

column in which "1.6" is indicated. Then, you can

nd "3" on the top of the "1.6" lines. This means the

number of stitches is 3.