Page 1

babv

latk

MODEL

INSTRUCTION

EF-405

BOOKLET

Page 2

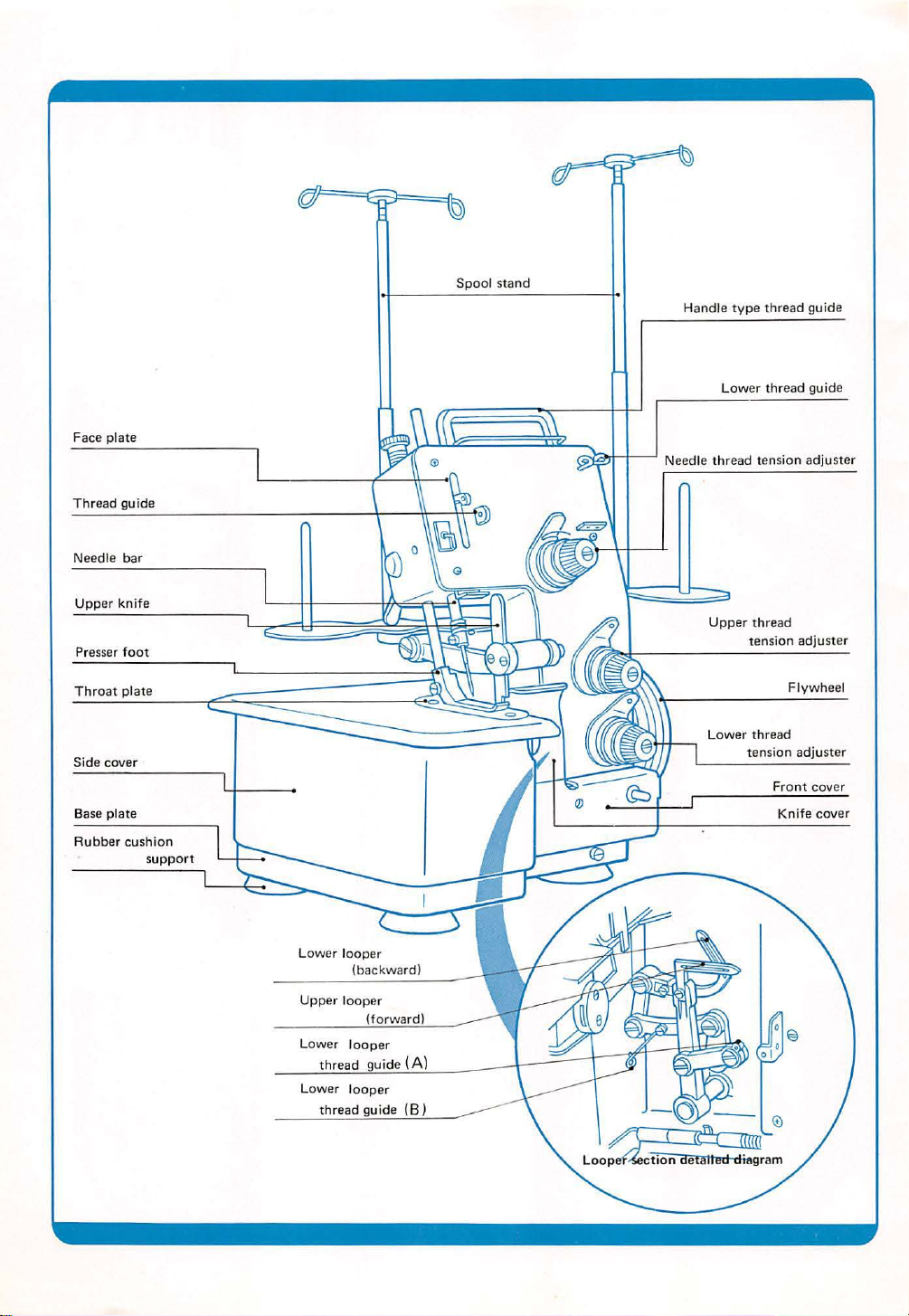

Spool

stand

Handle

typ

e thread guide

Face

plate

Thread guide

bar

Needle

Upper knife

Presser

foot

Throat plate

Si

de

cover

ate

Base pl

Rubber

cushion

thread gui

Lower

Needle thread t

ppo

rt

su

ension adjuster

Upper

thread

tension

Lower thread

tension a

Front

de

adjuster

Fl

ywhe

el

djuste

cover

Knife cover

r

Page 3

PREFACE

Than k you for your

Pl

ease refer

se

rvice in

1.

2. How

3.

4.

5. H

6. Adjusting sti

7.

8. L

9.

10

. Chec ki ng

11

. Changing the

12.

13

. Specifications ...

. Table showi ng relati o nship betw

14

to th

the future.

Setting

Correct installation of th e

1-1

1-

2 H

ow

ow

1-3 H

Con

1-4

to

2-1 H

ow

2-2 Sewing . . . . . . . .

Thread tension

Presser foot ad ju

ow

to

Replacing the c

ubr

ication

Set

ting

Supp

leme

purchase

is

booklet for

up the machine

to assemble

to set up the spool s

necti

ng

the con

thread correc tly

to thread correct ly ............

adjustment ......

stme

insta

ll

the needle

cth

length

utting

.....

......

up

the

sewing machine l

and

adjustment . . . .

carbon

nt

......

...

of

Baby L

ock

Model EF-

opt

imum use of this mach ine a

.................

motor ...

the spool stand .

tand

troller

to

...

. . ....

.......

nt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

..........

knives ...

brush es

.. ..

. .

. . . .

..............

......

amp

.... .......

of the

. .... . .

...................

...... . .

.......

the moto r

................

.......................

...

...........

. .

.........

.......

...

.....

. .

........

motor

.....

een thread

405

.

nd

.

.....

..

....

. ........

.

..........

.................

.

.................

. . . .

. ....

.....

.....

..

................ 14

and cloth

...... .

..........

. . .

.......

..............

. . . .

....

...... ..

...

.........

......

..

..........

.

......

. .

..

........

.

...

.....

......

. .

..

. .

for

. . . . 1

...

. . . 1

. . 2

...

.4

.4

...

. 9

1 0

..

11

11

..

12

13

...

15

16

long

1

3

6

7

8

Page 4

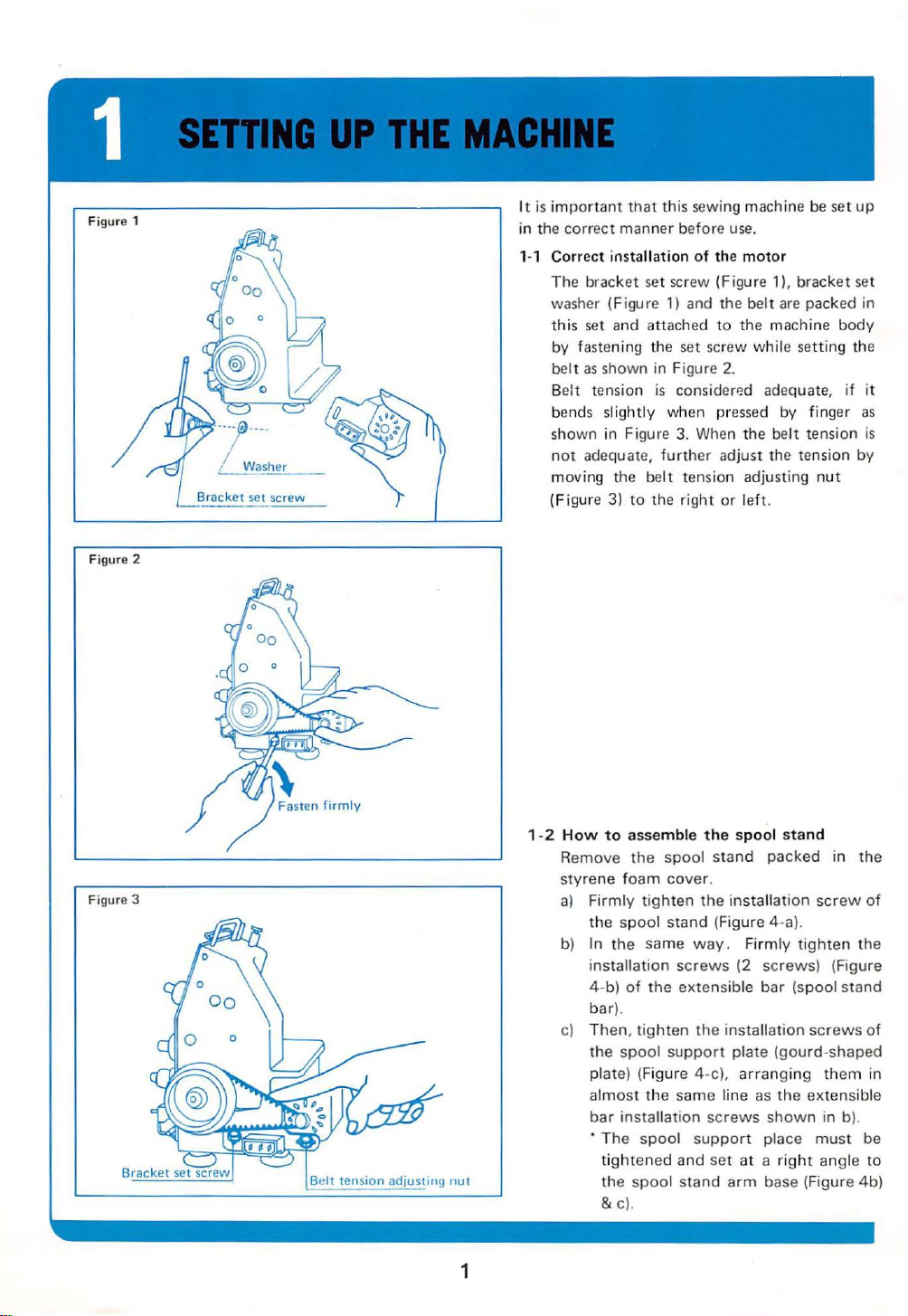

Figure 1

Figure 2

Bracket

set

screw

It is

impor

tant that this

in t

he

correc t manner before

1-1 Corre

ct

installation

T

he

bracket set screw (Figure 1

washer (Figure 1) and the

th

is

set and attached

by fastening t he set screw

belt

as

shown in Figure

Be

lt tension

be

nds slightly

sh

own

not

adequat

moving the

(Fi

gure 3) to th e

is

in Figure

e,

be

when pr

further

lt

sew

ing machine be set

use.

of

the

motor

),

brac

belt

are

packed in

to

the machi

wh

2.

considerP.d adequate,

essed

3.

When t

he

adjust the tension by

tension adjusting

right

or left.

ne

ile setti

by finger

belt tension

nut

up

ket

set

body

ng the

if it

as

is

1-2

How

to

assemble the

Figure 3

Remove

styre

a) Firmly

b)

c) Then.

the

ne foam

tighten the in

the

spool stand (Figure 4-a).

In

the

same

installation

4-b)

of

the extensible

bar) .

tighten

the

spool

plate) (Figure 4-c), arran

al

most

the same line

bar

insta

llation

· The

spool

ti

ghte

ned and

the

spoo

&

c)

.

1

spool

cover

way.

screws

the

support

screws

suppo

l stand

spool

stand

stand

.

set

packed in

stallation screw

Fir

mly

tighten

(2

screws)

bar

(spool stand

installation scr

plate (gourd-shaped

ging

them in

as

th e extensib le

shown

rt place

at a r

arm

base (Figure

ight

in b

must

angle to

the

of

the

(Figure

ews

of

).

be

4b)

Page 5

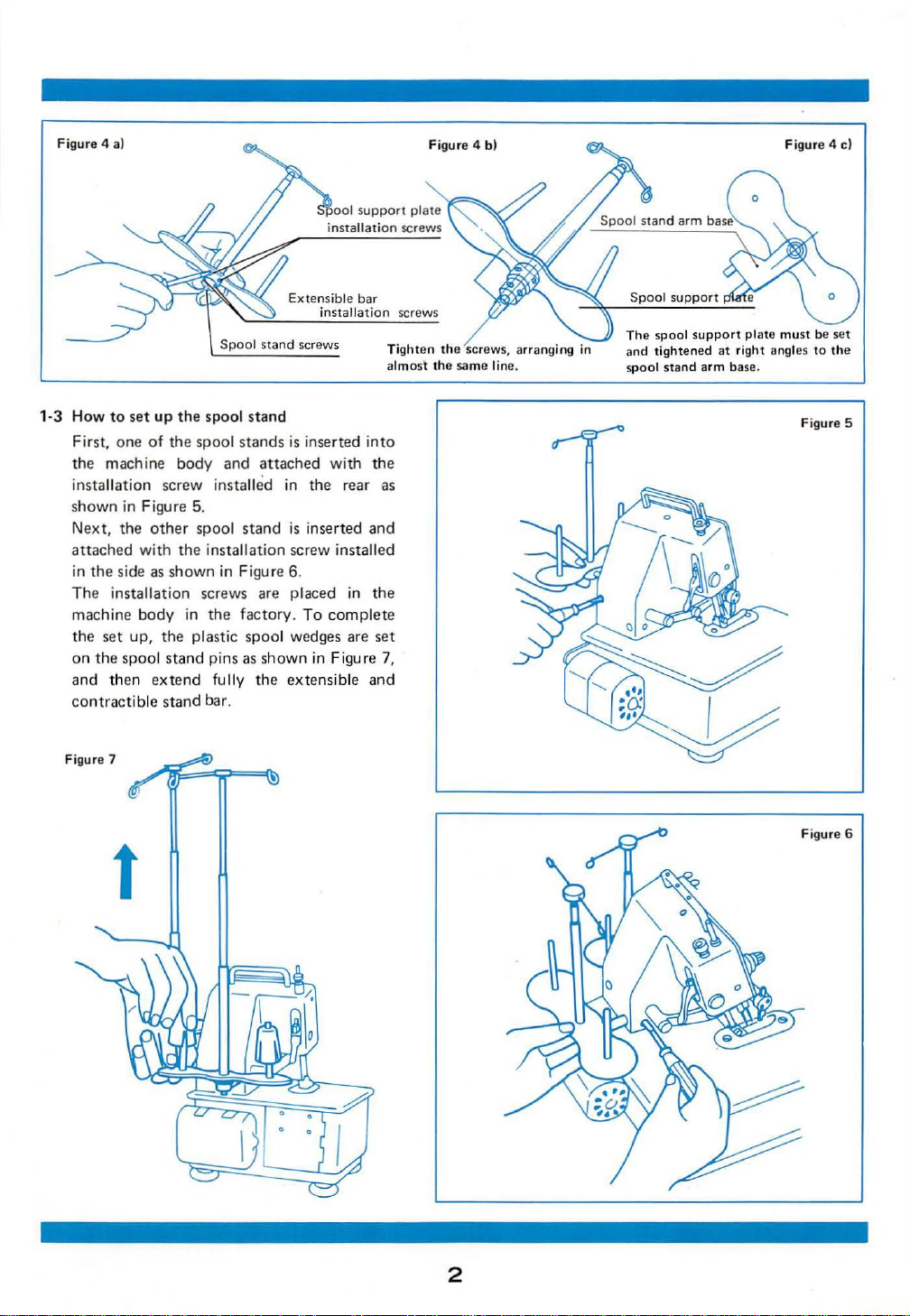

Figur

e 4 a)

Figur

e 4 b)

Figur

e 4 c)

1·3

How

to

set

up

First,

one

of

the

mach ine

installation screw inst

shown in Figure 5.

Next,

the

other spool

attached

in

Th

machine

the

on

and

the

side as

e install

set

up,

the

spoo

then

with

ation

body

l st a

extend

contractible

Figur

e 7

E

xtens

the

spool s

tand

the spool s

body

the

show

tands

is

and

attached

all

ed

in

stand

is inserted

installation screw installed

n in Figure 6.

screws are placed in the

in

the

the

nd

stand

plastic

pins as

fully

bar.

factory.

spool

To

wedges are set

sho

wn

the extensible

ible

bar

installation

inserted

with

into

the

the rear as

and

complete

in Figure 7,

and

screws

Tight

en the screw

alm

ost

the same line.

s,

arranging

in

Spool support

The

spool support

nd

tightened

a

spool

stand

plate must

at

right ang les

arm base.

be set

to

Figur

the

e 5

t

2

Page 6

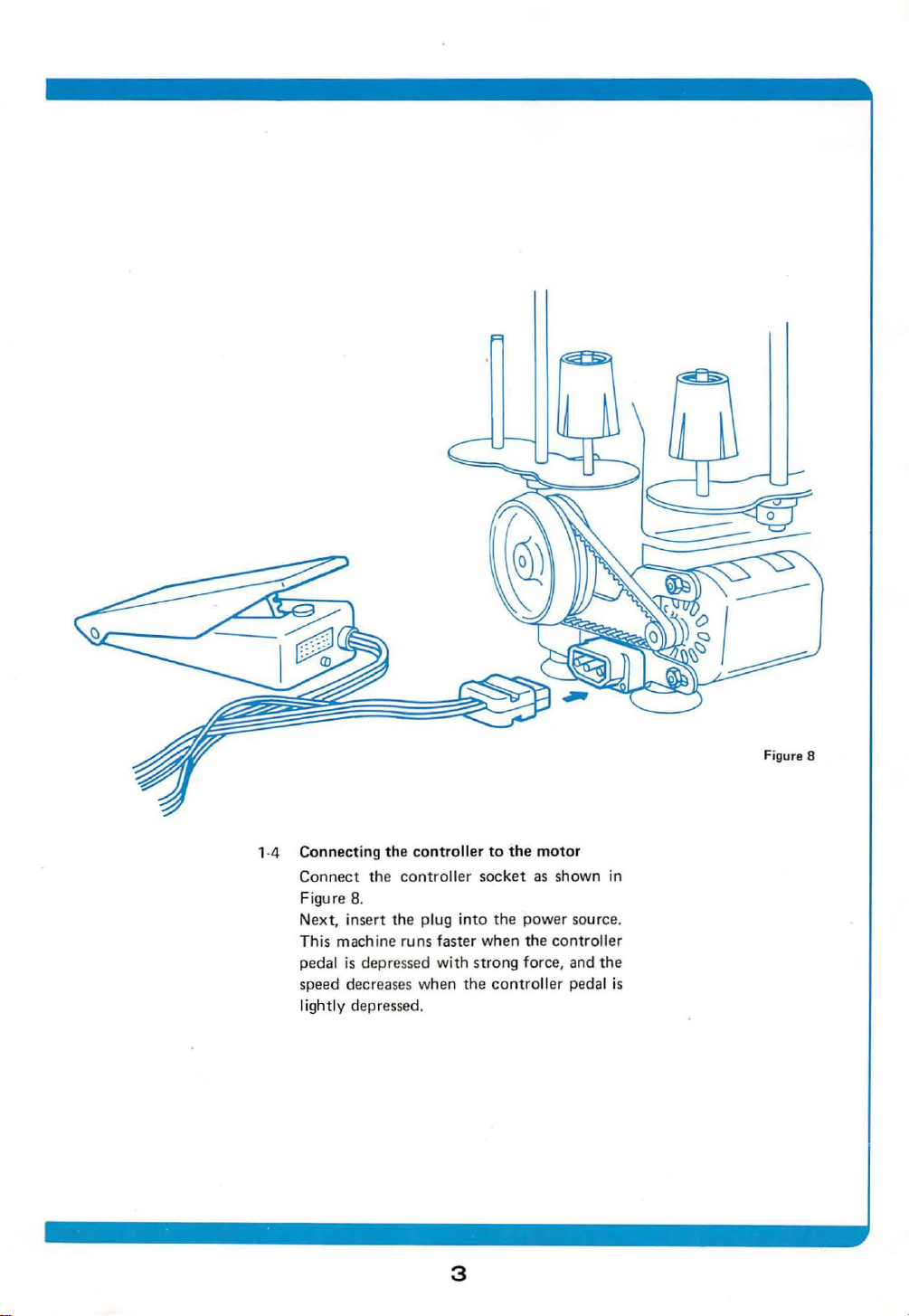

1-4 Connecting

Connect the

Figure 8.

Next, i

This machine run s faster

pedal is depressed wi

speed decreases when

lightly depressed.

nsert

the

controller

controller

the plug

to

the

motor

socket as shown in

into

the

power sour

when

the

controller

th stro

ng force, and

the

controller pedal is

ce.

the

3

Page 7

2-1 H

ow

( 1)

Spoo

Ch

ra

is

(Figure

r

such a way

is

(2) H

T

ord

After

front

while

thread

em

* T

need

to

thread

l se

tti

eese

spool thr

lly

used

possible

9) as

equ

ired

that

on

the

bottom

ow

to

thread nee

he

thread

er shown in F

inserting

to

faci ng

should

.

weezers are

le

eye.

correctly

ng

for

this

to use

we

the

that the

should

rear

through

the

machine,

be

ead

(F igure 9) is

machine, how

bobbin

ll. In

this

bobbin

.

igure

the

helpful for

spool be set in

winding stop

d le

thread

be inser

11

.

thr

ead

the

the end

pulled

out

spool

case,

correc

ted

from

needle

about

threading

gene

eve

r,

thread

it

groov

in the

the

eye

of

the

tly

10

Cheese

spool thread.

-

it

is

e

Boddin

spool thr

~

ead.

w;o

Figure 9

d;og><

op

~

Figure

10

Tension

discs

P

ass

thread be

Correct

twe

en t

wo

ten

threading at needle b

sion disc

ar

section.

4

s.

Fig

ure

12

Page 8

Figur

e 13

(3)

Upper

First,

re

Figu

Th

en, the

order

After

cover.

and

lower

open the

13.

threads shou

as s

hown

inserting

threads

front

ld be inser

in Figure

the

thread,

insertion

cover as sho

ted

15 and

close

Figure 16.

the

wn

in the

fro

nt

in

5

Page 9

2·2

Sewing

(1)

After

the

the

ends

fingers

of

tension

the

as shown

flywheel wi

clockwise direction.

(2)

threads

cloth, a

If

threads

that

that

Refer

ment".

are intertwining.

nd

the

tension

is

creases w

the

to

(Page 7)

completion

of

three

the left

hand

in

th

the

begin

to

sew.

balance

not

satisfactory,

ill

appear

seams will

the

"Thread

of

threading, hold

threads with

creat

ing a

Figure 18

right

and

hand

Confirm that

Then,

(Fiture

on

become

of

it

the

18)

the

is

cloth

irregular.

tension

the

minor

turn

in

the

three

set

the

three

possible

or

adjust

Figure 19

·

(3)

After

about

for

retaining

Figure

sewing is

2-3

em

and

20.

completed,

at

the

end

cut

the

blank stitch

of

the c

re

as s

hown

loth

in

Detail

ed

intertwining

thread.

diagram

showi

condition

ng

the

of the

Figu

re

20

6

Page 10

(A) When the t

Figure

22

(B) Wh

en

Fi

gure 23

(C)

When the tens

ension

the tensi

of the uppe

on

of the l

ion

of the

r thread is t

ower thr

need

le thread is

ead is

oo stro

too stron

loo

se.

ng.

g.

3-

1 H

Thread

cording

thread

the

adjust

21) Thr

turning

ow

to adju

need

st

tension

to

the

being used.

le,

upper

ers

while

ead tension

in a

clockwise

t he over

adjustment

type

of

Adjust

and

watching

may

edg

ing seams

clo

th,

the

lower

the

be

strenghtened

direction

will

diff

er

ac·

thickness,

and

tension using

thread ten

sion

seams. (Figure

by

.

Figure 24

(D

) Ideal stitching

ure 25

Fig

Needle

Upper

sea

m.

thr

thread

ead

Lower thread

1. Wh

2.

3.

4. When the

7

en

strong

tension

When

strong

tension

When

l

oose (Fi

tension

Fi

gure

the

tension

(Figure

adjuster.

the

tension

(Figure

adjust er.

the

te nsion

gure 24),

adjuster.

stict

h ing seams

25,

the tensions are

of

the

upper

22),

loosen

the

of the

lower

23), loosen

of

the

the

need

tighten the needle

appear

satisfactory.

Up

per thread

tension

Needle

tension

thread

upper

thread

lower

le th

as

adjuste

thread

adjuster

is

thread

is

th read

read

thread

shown

r

too

too

is

in

Page 11

The

preser

foot

is adj

usted

for

Adjust

very thi

Sew thin

thick

*

only

ck

cloth

cloth

clo

th with a stronger

Tighten

cloth. Loosen

W

ith

machine, "ORG

No. 11

(1 )

For

fly-w heel

far

Next,

(2 )

27).

need

first,

ely

clamp.

(3) Firmly

F

it

such a way

groove

machine

regard

can

needle

as

it

loosen

insert

le

and

deep into

or

the

is

requested

presser

be

will go.

drop

tighten

is

adjustment

standard

in

the

case

is

being

with a weaker pressure,

adjusting

the

to

the nee

AN" BLx1

used

for

installation,

so

as

to

the

the

hole

secondly

the

the

di r

ection

so

facing

as

shown

of

(medium)

when very thin

sewn

.

pressure

screw

screw

for

dles

(orDBx1)

overedging.

raise

the

need

le c l

amp

tip

of

the

(Figure

that

the

27)

insert

the

needle

hole

needle clamp

of

inserting

the

that

the

front

in

Figure

this

for

first

nee

needle

needle

when

machine

thickness

.

for

thick

thin

cloth.

this

No. 14

turn

dle

screw

on

the presser

needle

of

the need

screw.

the

be

thread

facing the

28.

.

or

and,

sew

bar

up

(Figure

into

complet-

need

set

guide

How to adju

st

the pressure.

Presser a

Ll"

18

.5

mm

Very

l.~

ing

and

Needle

Need

clamp

le

the

as

the

le

le,

in

-------

V

screw

clamp

screw

thick

t

~

ery thin

Weak

Strong

djusting

screw

cloth

cloth

Med i

um thi

Needle

ck

cloth

Figure 26

Figu

drop hole

re

27

Thr

ead guide

Needle eye

8

ndent

I

Figure

28

Page 12

- -

6 . . .

( 1)

Holding

hand, grasp the heart-shaped driver

the accessories box

and

screw. The feed regul

can

in a counterclockwide

pressing the

shaped driver.

(2)

Set the graduation on the feed regulator

knob

numbe r on the feed

larger the

(3)

After

tight

the flywheel

loosen the feed re

be

loosened by turning the

fixing

to

the indicator. The larger the

sea

ms

will

completing adjustments, firmly

en

the feed regulator

with

the right

with

the

left

gulator

ator

fixing

flywhe

direction

screw w

ith

the heart·

regulator knob, the

be.

fixing screw.

in

hand

fixing

screw

el

while

Figure

29

Heart-shaped

Figure

30

I

u

\

driv

er

Feed

regulator

fixing screw

9

Page 13

The

knife

should

the

electric

1) The upper

loosening the

knife may

k

nife ho

screw

power

upp

be

lder set screw and the l

as

shown in Figure 31.

ower

L

be

changed

source.

knife

er

knife

changed after loosening the

only

after

removing

may be changed after

set screw and the

ower

knife set

l Figure 31

-:6"'

Lower

knife

knife set screw

holder

Upp

set

er knife

set sc

screw

lower

lower

rew

2) Th e position

of

the lower

arranged in such a way

in the indentation

plate

as

shown in Figure

3)

Th

e normal position

knif

upper

upper

e can

knife

ing operation.

ting

edge

of

about 0.5"'1.0mm

tip

of

the

cutting

for

be

reaches its lowest

The

the

upper

against the surface

edge

(Figure 32)

Figure showing

highest

position

upp

.

er

knife

' .

Figure showing

position.

upp

er

knife

knife

must

be

so

that

it

can

be

set

the

knife

in the

throat

32

for

fixing

the

determined when the

point

dur-

front

tip

of

the cut-

knife

will

drop

of

the

on

the lower knife.

at

its

Thro

at

plate

-------

' I

----.._, I

at

i s lowest

Figure

32

10

Page 14

Figure

Five/ten

one

only

33

oiling

in

this

drops of

oil for

are necessay

portion

.

As special materials (oil

for

parts

of

used

lubrication

is

provided

provided no

to

those parts marked in r

from the outside

tho

se

parts shown

is suffici

ent

this m

is

negligible. However, since oil wi

for

the inner

more th

an once

of

the machi

in Figu

for

one oiling.

imp

regnated metal) are

achine

actual additional

sec

tions, oil sh

or

twice per m

ed

which can

ne,

in addition

re

33

1-2 drops

ould

ont

be

of

ck

be

h

seen

to

oil

Wh

en using a working lam

to u

se a co

position

mercially

as

shown in Figur e 34.

p,

it

is recommend

ava

ilable lamp set in the

Figu

re

ed

34

1 1

Page 15

This machine

no need

tely

ments.

Th

e following five

instances where difficulties are likely

through lack

Th

ese

when operating this machine.

A)

When

Is

the

plug

Is

the

Is

the

B)

When

Have

Is

the

Is

the

Is

Are there a

type

Has

C)

When

Is

plate or presser

Has

D)

When

Is the needle

Has

Is

E)

When

Is

wer

lo

Have

is

so designed

for

complex

examples

of

fundamental

points

there

the

the

the

the

should

the

machine does

electric

receptab

any

motor?

belt

loose?

the

thread

the

threads

thread

needle bent?

presser pressure

ny

of

thread

the

needle been inserted

the

needle breaks -

needle

the

needle been inserted

the

seams are

the

needle been inserted

presser pressure sufficient?

the

seams are

tension

and

needle

the

threads

be

carefully considered

cord

properly inserted into

le?

slipping in

breaks-

been inserted correctly?

tension

bent

too

adequate?

problems

being used?

touching

foot?

irregular-

or

the point

not

adjustment

threads

been correctly inserted?

that

there

professional adjust-

are the only possible

adjustments.

not

operate-

the

set

strong?

with

regard

correctly?

against

correctly?

worn?

correct

satisfactory-

of

satisfactory?

is

to

posit

the

ly?

the

absolu-

occur

the

ion

of

to

the

throat

upper,

12

Page 16

Two

carbon brushes (in

to

attached

be used

for

the

machine. The carbon brushes

to

the

according

worn

away

A) Pe

riod

The ca

they

have

following

after

I ong hours

for

changing carbon brushes

rbon brushes shou

worn

too

short

carbon brush figure).

B)

First

caps

remove the

(see

figure of

motor.

motor),

brushes.

Fig

ure

of

carbo

n brush

10mm

I

1--

L

-R

\.\\~

two

positions) are

motor

on

this sewing

should be changed

method,

of

ld

as

use.

be

changed when

for

contact (see

they

Remove the brush

and replac e the

Brush cap

are

(two)

•

The

carbon

brushes

should

th

e brush

sec

tion

mately 3 mm

Carbon brushes

sewing mac

shop.

Not

e: Specia l care should be taken

as shown

hin

e shop

has worn

may

regard to the aforemen

fa

ilure to

sparks

consequently

change the brush

emitting

from

further damage the

be

down

in

the

be

purchased fr

or

electr

tion

es

the

motor

figure.

Bracket set scr

changed

to

ical ap

ed

points

may

which

motor.

when

approx

om

plian

resu

any

ce

wit

lt in

will

ew

i·

h

as

13

Page 17

Detailed list

I.

Machine

2.

Motor

3.

Controller

of

content

4 Spool st and ( 2 sets)

5.

Vi

nyl cover

ts)

driv

(f

"ORGAN"

er

knife

be

booklet

er

ps

or

motor

driver

used for

using the machine

6. Instruction

7. Accessory box

(Conten

Sc

rew

Pl

us driver (Ph il li

Spanner

Needles

Upp

Tweezers

Cleaning brush

Oil

receptacle (capaci

Heart·shaped

(for adjusting sti tch length)

It

is

recommended

side cover

at

the

time of

Figu

re

36.

s

screw driver)

bracket)

BLx 1

(orDBx

No. 14 .

ty

: 30cc)

that the pocket on the

sec

uri ng the accessories

1)

No

.11 10

as

shown in

1

14

Page 18

ITEM

SPECIFICATION

Overedging width

Stitch length (feed)

Needle bar stroke

Knife

movement

Presser I ift

(upward volume)

Feed

dog height 0.8 m/m (standard)

Needle

Number

Method

Machine dimensions

Weight

of

threads 3

of

lubrication

of

machine 9.8 kg

4m

/m

1-6

m/m

27 m/ m

8m

/m

6m/m

"ORGAN"

Semi·automatic

Length

x Height

(with

Blx

1 (orDBx

oil

250 m/m x Breadth 250 m/m

280 m/m

motor)

1) No. 14, No.11

wick

lubrica

tion

15

Page 19

No. Type

of

cloth

U

se

Type

of

thread

Length of stitch

Ordinary

1

(cotton,

satin,

Thick

2

(tweed, overcoat

denim,

Knitted

(knitted

3

knitted

cloth

tricot

, linen, Overedgi

cloth

in general)

cloth

thick

cloth

suit cloth')

Overedging

cloth

goods, Overedging

cloth)

ng

Cotton

Silk #

50-

#60

- #1 00

#100

Cotton #40 -#60

Silk#40-

Tetron and

nylon

#6

threads

0

woo

Wooly nylon and

tetron

threads

3.0m/m-

3.0m/m-

lly

3.0m/m-5.0m/m

4.0m/m

5.0m/m

16

1972

P

rint

· 7 · I

ed

in Japan

Page 20

Loading...

Loading...