JUKI AMS-251/IP-420 Instruction Manual

AMS-251 / IP-420

INSTRUCTION MANUAL

* "CompactFlash(TM)" is the registered trademark of SanDisk Corporation, U.S.A.

CONTENTS

I. MECHANICAL SECTION (WITH REGARD TO THE SEWING MACHINE) 1

1. SPECIFICATIONS ....................................................................................................... 1

2. CONFIGURATION ....................................................................................................... 2

3. INSTALLATION ........................................................................................................... 3

3-1. Removing the machine head xing plate ....................................................................................3

3-2. Setting up the machine..................................................................................................................4

3-3. Preparations of switches...............................................................................................................6

3-4. Connecting the power switch ....................................................................................................... 7

3-5. Installing the panel.........................................................................................................................8

3-6. Installing the thread stand ............................................................................................................8

3-7. How to install the thread stand for bobbin winding ...................................................................9

3-8. Connecting the cord .................................................................................................................... 10

3-9. Installing the air hose .................................................................................................................. 13

3-10. Cautions for the compressed air supply (source of supply air) facility ...............................14

4. PREPARATION OF THE SEWING MACHINE .......................................................... 15

4-1. Lubrication....................................................................................................................................15

4-2. Adjusting the oil quantity in the hook ........................................................................................ 16

(1) Checking the oil quantity in the hook .......................................................................................... 16

(2) Adjusting the hook oil quantity (oil spots) ....................................................................................17

(3) Sample of proper quantity of hook oil (oil spots) .........................................................................17

4-3. Checking the emergency stop switch ........................................................................................ 18

4-4. Attaching the needle ....................................................................................................................18

4-5. Needle size and gauge.................................................................................................................19

(1) Adjustment .................................................................................................................................. 19

(2) Gauge ......................................................................................................................................... 19

4-6. Threading the machine head ......................................................................................................20

4-7. Installing and removing the bobbin case ..................................................................................21

4-8. Installing the bobbin .................................................................................................................... 21

4-9. Preparing the cassette clamp ..................................................................................................... 22

4-10. Adjusting the thread tension ....................................................................................................25

4-11. Intermediate presser height ......................................................................................................26

4-12. Adjusting the thread take-up spring ........................................................................................26

5. OPERATION OF THE SEWING MACHINE ............................................................... 27

5-1. Sewing...........................................................................................................................................27

II. OPERATION SECTION (WITH REGARD TO THE PANEL) .................... 28

1. PREFACE .................................................................................................................. 28

2. WHEN USING IP-420 ................................................................................................ 32

2-1. Name of each section of IP-420 .................................................................................................. 32

2-2. Buttons to be used in common ..................................................................................................33

2-3. Basic operation of IP-420 ............................................................................................................ 34

2-4. LCD display section at the time of sewing shape selection .................................................... 35

(1) Sewing shape data input screen .................................................................................................35

(2) Sewing screen ............................................................................................................................37

2-5. Performing sewing shape selection ........................................................................................... 39

2-6. Changing item data ...................................................................................................................... 41

i

2-7. Checking pattern shape ..............................................................................................................43

2-8. Performing modication of needle entry point ......................................................................... 44

(1) Editing the thread tension ........................................................................................................... 44

(2) Editing the intermediate presser height ......................................................................................45

2-9. How to use temporary stop ......................................................................................................... 46

(1) To continue performing sewing from some point in sewing ........................................................46

(2) To perform re-sewing from the start ............................................................................................ 47

2-10. When setting of sewing product is difcult because of interruption of needle tip .............48

2-11. Winding bobbin thread .............................................................................................................. 49

2-12. Using counter ............................................................................................................................. 51

(1) Setting procedure of the counter ................................................................................................51

(2) Count-up releasing procedure ....................................................................................................53

(3) How to change the counter value during sewing ........................................................................ 53

2-13. Performing new register of users’ pattern ...............................................................................54

2-14. Naming users’ pattern ...............................................................................................................55

2-15. Performing new register of pattern button .............................................................................. 56

2-16. LCD display section at the time of pattern button selection .................................................57

(1) Pattern button data input screen .................................................................................................57

(2) Sewing screen ............................................................................................................................59

2-17. Performing pattern button No. selection ................................................................................. 61

(1) Selection from the data input screen ..........................................................................................61

(2) Selection by means of the shortcut button ..................................................................................62

2-18. Changing contents of pattern button ....................................................................................... 63

2-19. Copying pattern button .............................................................................................................64

2-20. Changing sewing mode ............................................................................................................. 65

2-21. LCD display section at the time of combination sewing ........................................................ 66

(1) Pattern input screen ....................................................................................................................66

(2) Sewing screen ............................................................................................................................68

2-22. Performing combination sewing ..............................................................................................70

(1) Selection of combination data .....................................................................................................70

(2) Creating procedure of the combination data ...............................................................................71

(3) Deleting procedure of the combination data ............................................................................... 72

(4) Deleting procedure of the step of the combination data .............................................................72

(5) Setting of the skip of steps ..........................................................................................................73

2-23. Using the simple operation mode ............................................................................................73

2-24. LCD display when the simple operation is selected...............................................................74

(1) Data input screen (individual sewing) ......................................................................................... 74

(2) Sewing screen (individual sewing) ..............................................................................................77

(3) Data input screen (combination sewing) .....................................................................................80

(4) Sewing screen (combination sewing) .........................................................................................82

2-25. Changing memory switch data ................................................................................................. 84

2-26. Using information ......................................................................................................................85

(1) Observing the maintenance and inspection information ............................................................. 85

(2) Releasing procedure of the warning ........................................................................................... 86

2-27. Using communication function ................................................................................................87

(1) Handling possible data ...............................................................................................................87

(2) Performing communication by using the media .......................................................................... 87

(3) Performing communication by using USB ..................................................................................87

(4) Take-in of the data ......................................................................................................................88

(5) Taking in plural data together ...................................................................................................... 89

ii

2-28. Performing formatting of the media ......................................................................................... 91

2-29. Operation at the time of X/Y motor position slip .....................................................................92

(1) When the error is displayed during sewing ................................................................................. 92

(2) When the error is displayed after end of sewing .........................................................................93

(3) When the rest switch is not displayed .........................................................................................93

3. MEMORY SWITCH DATA LIST ................................................................................. 94

3-1. Data list ......................................................................................................................................... 94

3-2. Initial value list .............................................................................................................................99

4. ERROR CODE LIST ................................................................................................ 101

5. MESSAGE LIST ...................................................................................................... 112

III. MAINTENANCE OF SAWING MACHINE ...............................................115

1. MAINTENANCE ....................................................................................................... 115

1-1. Adjusting the height of the needle bar (Changing the length of the needle) ....................... 11 5

1-2. Adjusting the needle-to-shuttle relation .................................................................................. 116

1-3. Adjusting the vertical stroke of the intermediate presser ...................................................... 11 8

1-4. The moving knife and counter knife......................................................................................... 118

1-5. Thread breakage detector plate ............................................................................................... 119

1-6. Amount of oil supplied to the hook .......................................................................................... 119

1-7. Periodical cleaning of the oil shield ......................................................................................... 119

1-8. Replacing the fuse ..................................................................................................................... 120

1-9. Replenishing the designated places with grease ................................................................... 121

(1) Types of grease ........................................................................................................................ 122

(2) Points to be applied with JUKI Grease A ..................................................................................122

1-10. Troubles and corrective measures (Sewing conditions)...................................................... 124

2. OPTIONAL ............................................................................................................... 126

2-1. List of the needle hole guides and intermediate pressers ..................................................... 126

2-2. Bar code reader .......................................................................................................................... 127

iii

I. MECHANICAL SECTION (WITH REGARD TO THE SEWING MACHINE)

1. SPECIFICATIONS

1 Sewing area X (lateral) direction Y (longitudinal) direction

1,000 mm × 600 mm

2 Max. sewing speed 2,500 sti/min (When sewing pitch is 3 mm or less)

3 Stitch length 0.1 to 12.7 mm (Min. resolution : 0.05 mm)

4

Feed motion of feeding frame

5 Needle bar stroke 41.2 mm

6 Needle GROZ-BECKERT 135x17, ORGAN needle DPx17

7 Amount of lift of the ma-

chine head unit goes up

8 Intermediate presser stroke 4 mm (Standard) (0 to 10 mm)

9 Lift of intermediate presser 20 mm

10 Intermediate presser DOWN

position variable

11 Shuttle Full-rotary three-fold capacity hook

12 Lubricating oil New Defrix Oil No. 2 (Supplied by oiler)

13 Memory of pattern data Main body, Media

14 Temporary stop facility Used to stop machine operation during a stitching cycle.

15 Enlarging / Reducing facility Allows a pattern to be enlarged or reduced on the X axis and Y axis independently

16 Enlarging / Reducing

method

17

Max. sewing speed limitation

18 Pattern selection facility Pattern No. selection method

19 Bobbin thread counter UP/DOWN method (0 to 9,999)

20 Sewing counter UP/DOWN method (0 to 9,999)

21 Memory back-up In case of a power interruption, the pattern being used will automatically be stored

22 2nd origin setting facility Using jog keys, a 2nd origin (needle position after a sewing cycle) can be set in the

23 Sewing machine motor Servo-motor

24 Dimensions 2,400 mm (W) × 1,800 mm (L) × 1,600 mm (H)

25 Mass (gross mass) 947 kg

26 Power consumption 800 VA

27

Operating temperature range

28 Operating humidity range 35 % to 85 % (No dew condensation)

29 Line voltage Rated voltage ±10% 50 / 60 Hz

30 Air pressure used Standard 0.35 to 0.5 MPa (Max. 0.55 MPa)

31 Air consumption 1.8 dm3 / min (ANR)

32 Needle highest position stop

facility

33 Noise - Equivalent continuous emission sound pressure level (LpA) at the workstation :

1

*

"sti/min" is an abbreviation for "stitches per minute."

Intermittent feed (2-shaft drive by stepping motor)

50 mm

Standard 0 to 3.5 mm (Max. 0 to 7.0 mm)

• Main body : Max. 999 patterns (Max. 50,000 stitches/pattern)

• Media : Max. 999 patterns (Max. 50,000 stitches/pattern)

when sewing a pattern. Scale : 1% to 400% times (0.1% steps)

Pattern enlargement / reduction can be done by increasing / decreasing either stitch

length or the number of stitches. (Increasing/decreasing stitch length only can be

performed when pattern button is selected.)

200 to 2,500 sti/min (Scale : 100 sti/min steps)

(Main body : 1 to 999, Media : 1 to 999)

in memory.

desired position within the sewing area. The set 2nd origin is also stored in memory.

5˚C to 35˚C

After the completion of sewing, the needle can be brought up to its highest position.

A-weighted value of 78.2 dB; (Includes KpA = 2.5 dB); according to ISO 10821C.6.2 -ISO 11204 GR2 at 2,500 sti/min *1.

– 1 –

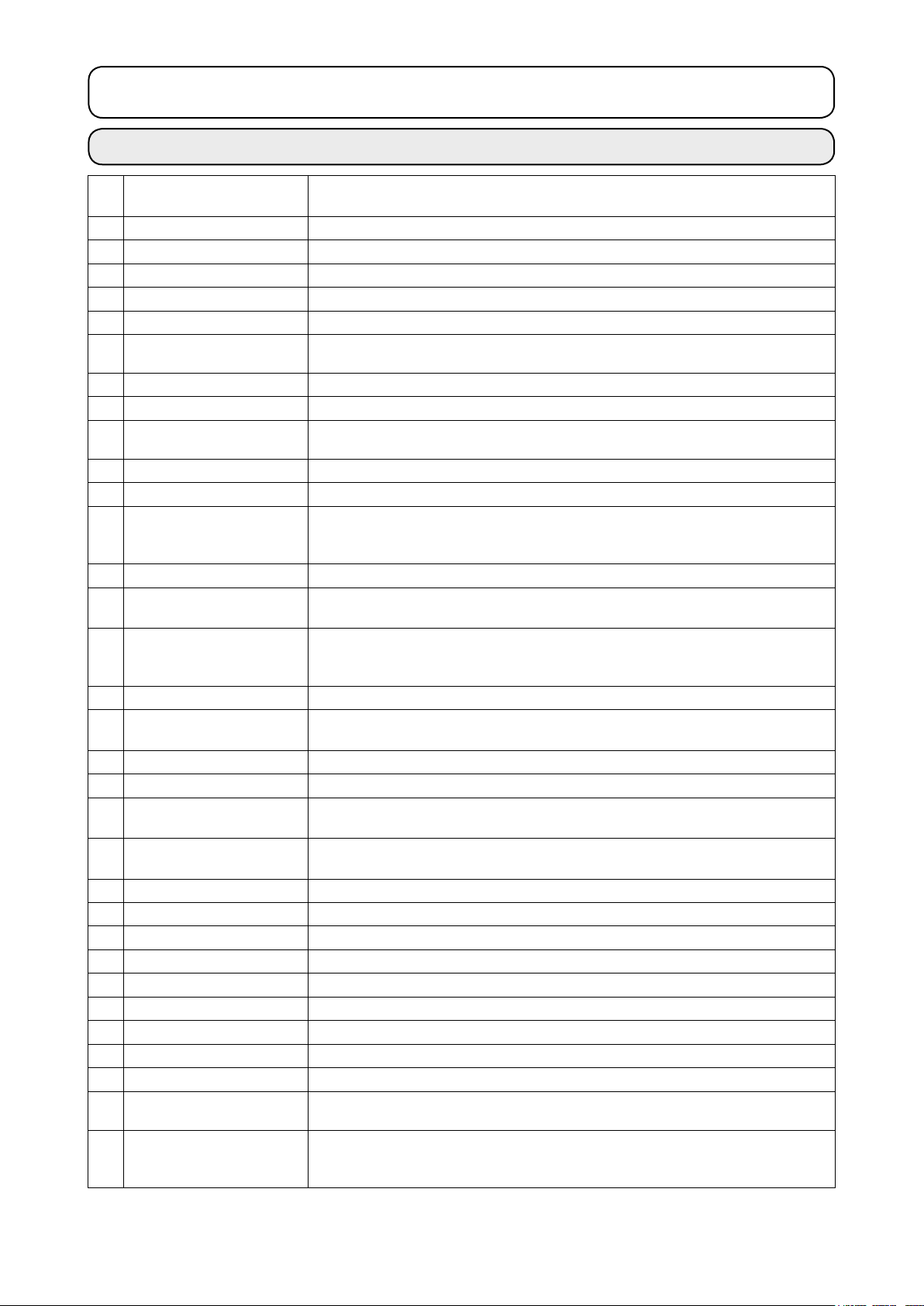

2. CONFIGURATION

❹

❸

❼

❾

❶

❺

❷

❽

❻

Air regulator

Machine head

❶

Cassette clamp

❷

Intermediate presser

❸

Thread stand

❹

Operation panel (IP-420)

❺

Power switch

❻

Emergency stop switch

❼

Start switch (green)

❽

Pause switch (white)

❾

Eject switch (blue)

Control box

Bobbin winder

– 2 –

3. INSTALLATION

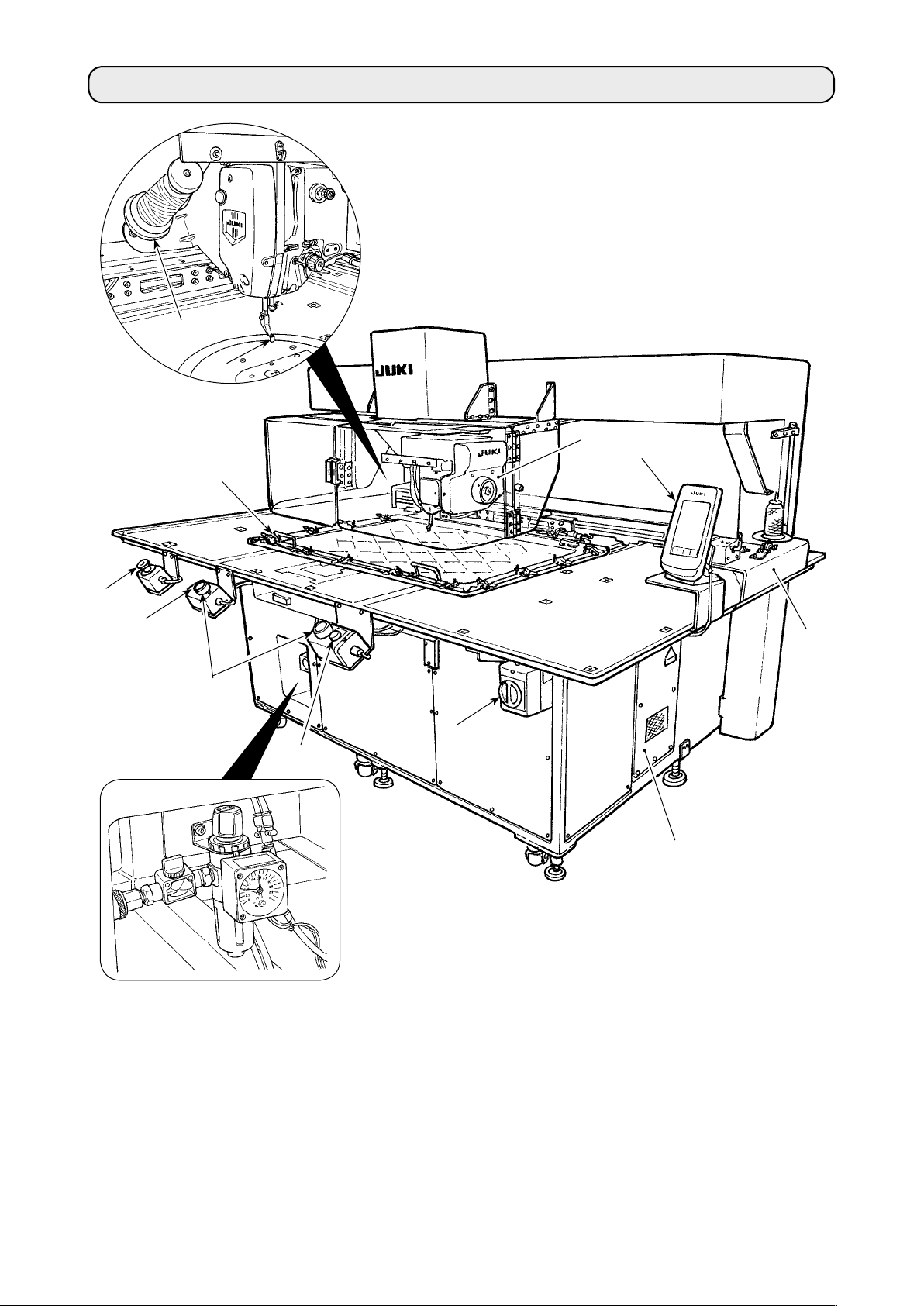

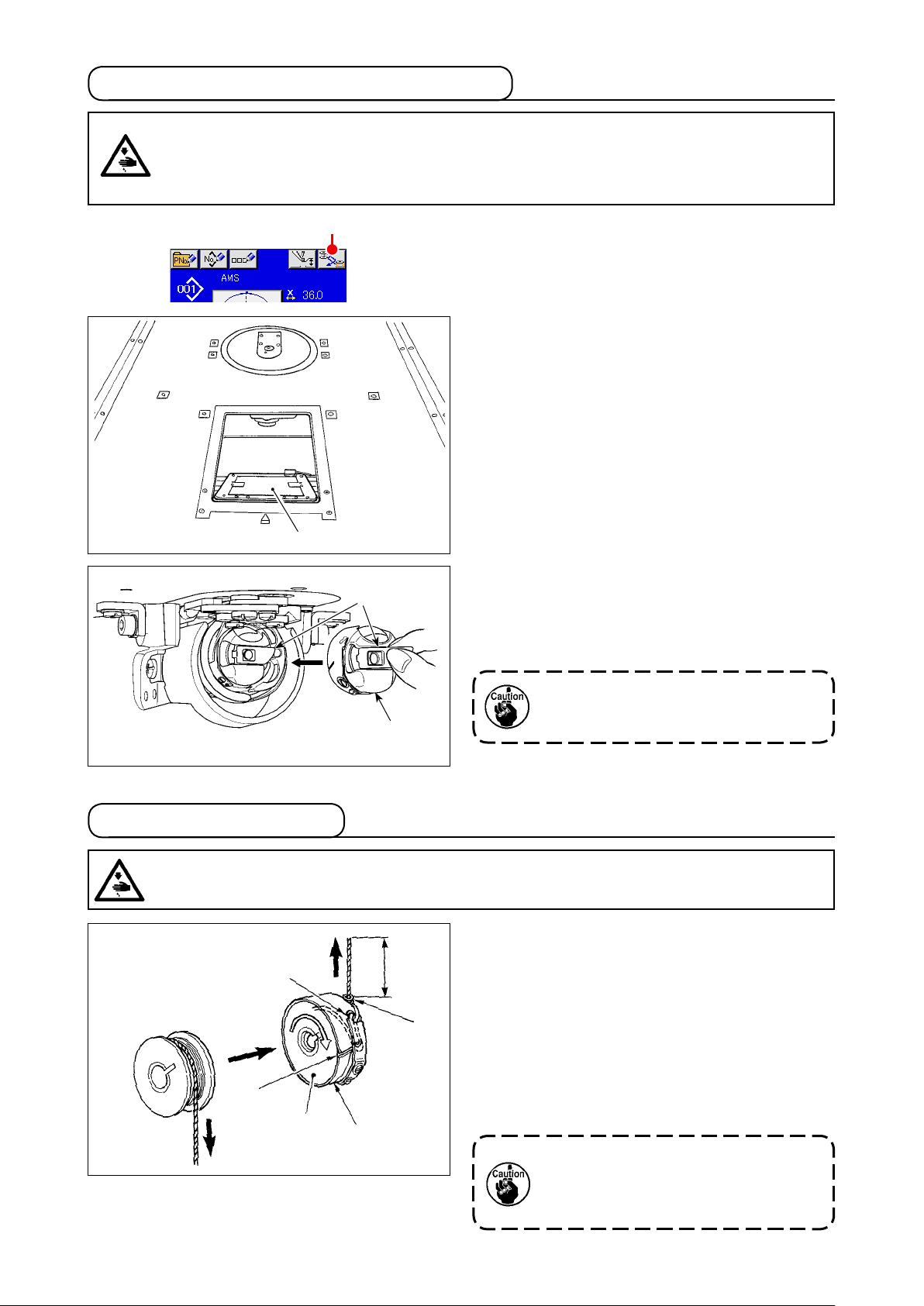

3-1. Removing the machine head xing plate

1) Open machine head safety cover ❶.

❶

2) Remove two setscrews ❷. Detach machine

3) Re-tighten two setscrews ❷ which you have

❷

Keep the machine head safety cover

closed while the sewing machine is

❶

in operation.

head xing plate ❸.

removed in step 2) back in their tapped holes.

❸

– 3 –

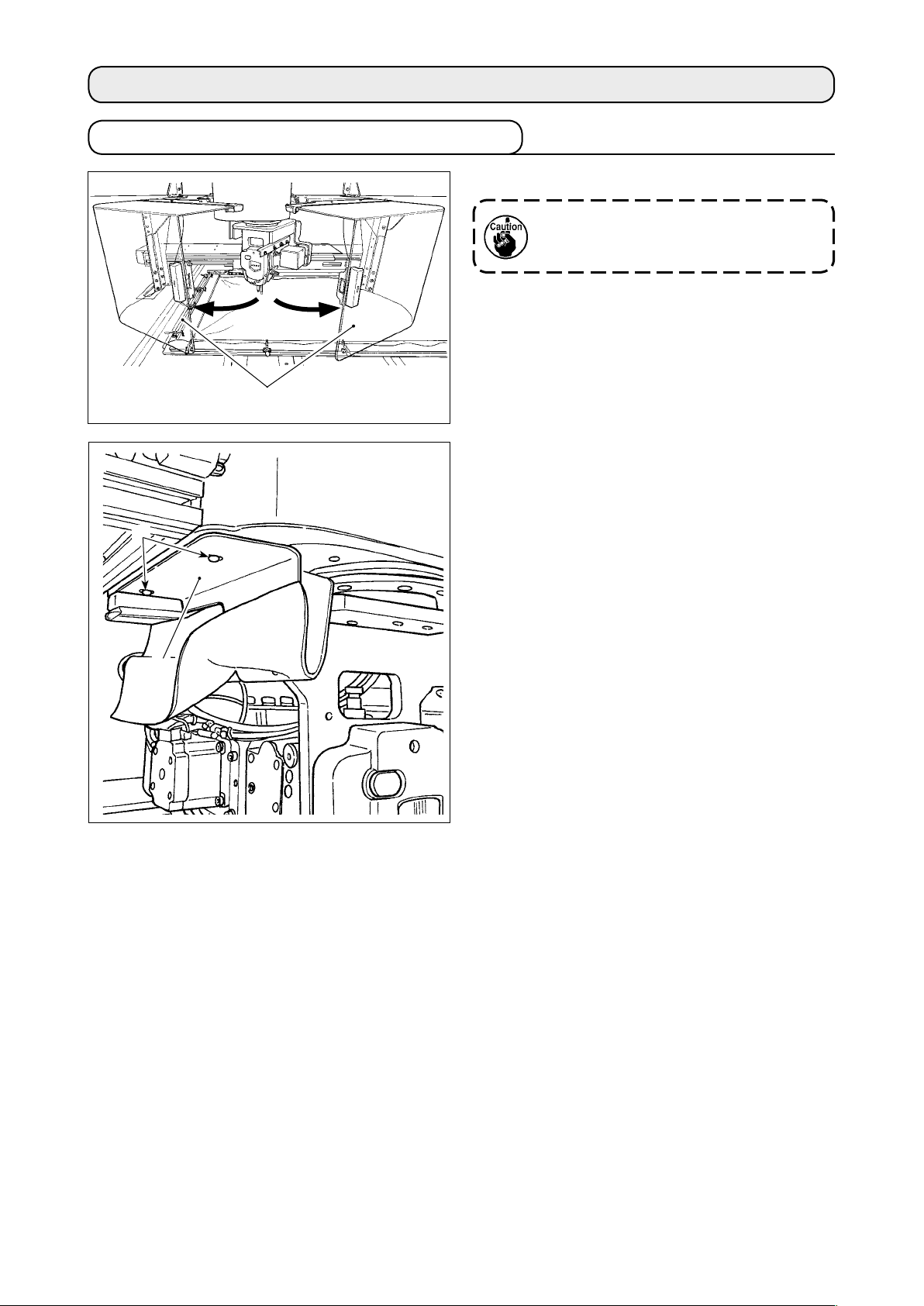

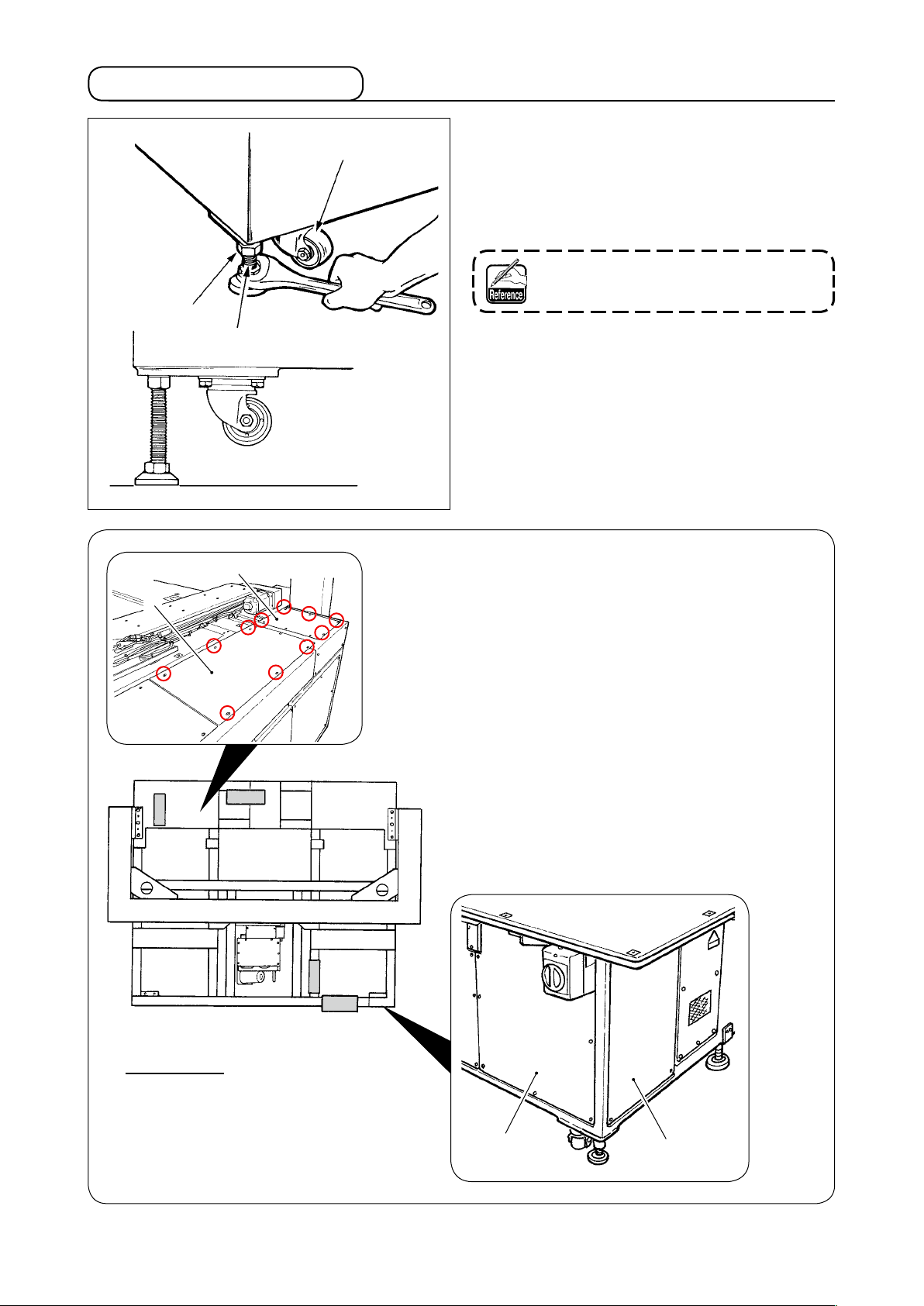

3-2. Setting up the machine

❶

❷

❸

1) Install the machine on a at place with leveled.

2) Loosen nut ❶ and turn level adjuster ❷ to lift

the machine until caster ❸ idles.

3) After the machine has been set up properly,

tighten nut ❶ and x level adjuster ❷.

Use 0.3-mm/m levels for leveling the

main body of device.

❺

A

❹

A

[Positions to check with levels]

1) Detach covers ❹, ❺, ❻ and ❼ of the main

body of device at four locations by removing

their screws.

2) Place a level respectively at positions A indicat-

ed in the gure. Adjust the adjusters mounted at

four corners so that the number of lines indicat-

ed on the level scale plate is within two.

After checking the levelness, adjust the adjuster

located at the center section of each strut until

it is stretched. Then, give it a 1/8 turn to further

stretch it. In this state, x each adjuster.

3) After the adjustment, re-place the covers back

in place.

A

Overhead view

Worker side

– 4 –

❼

❻

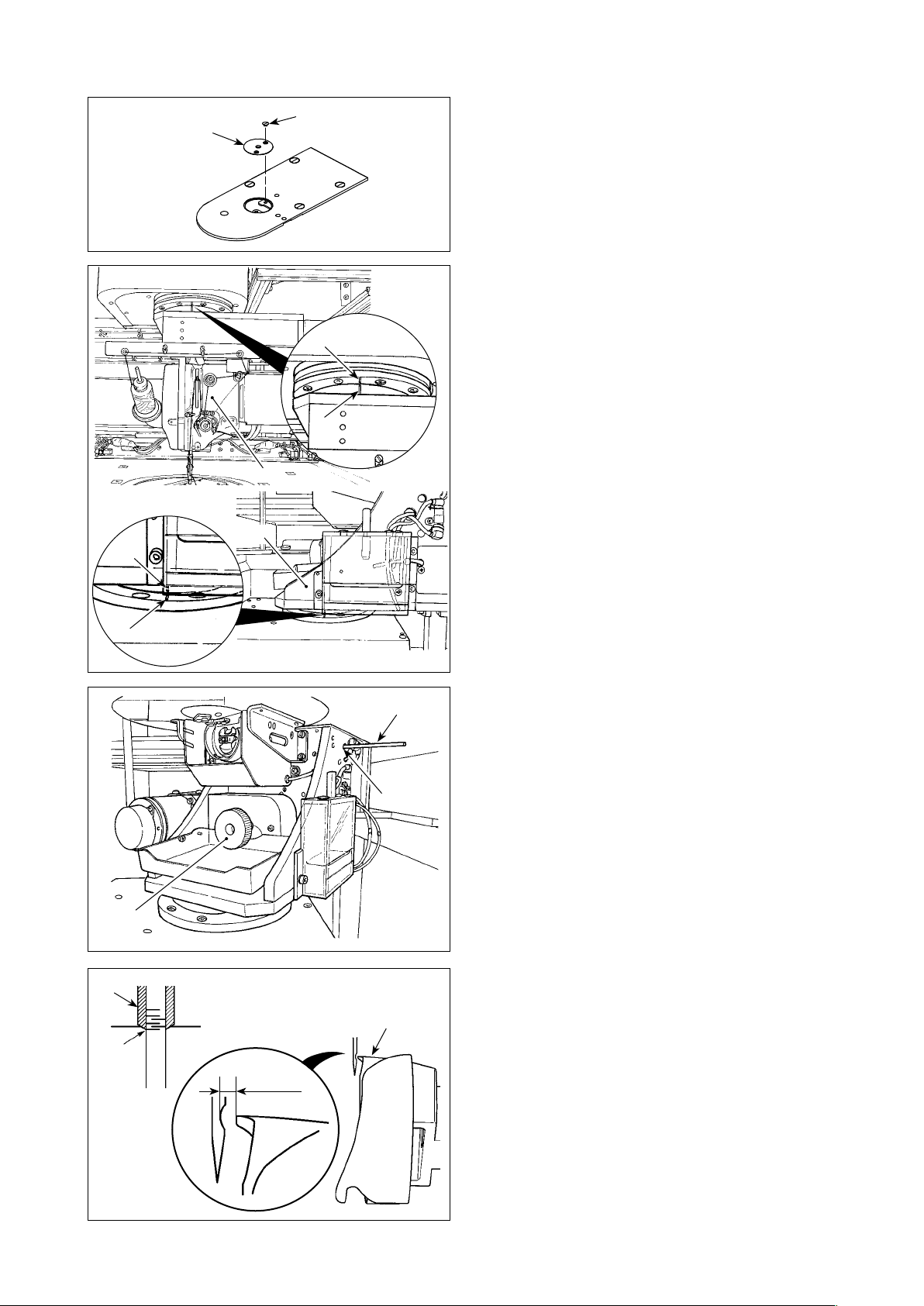

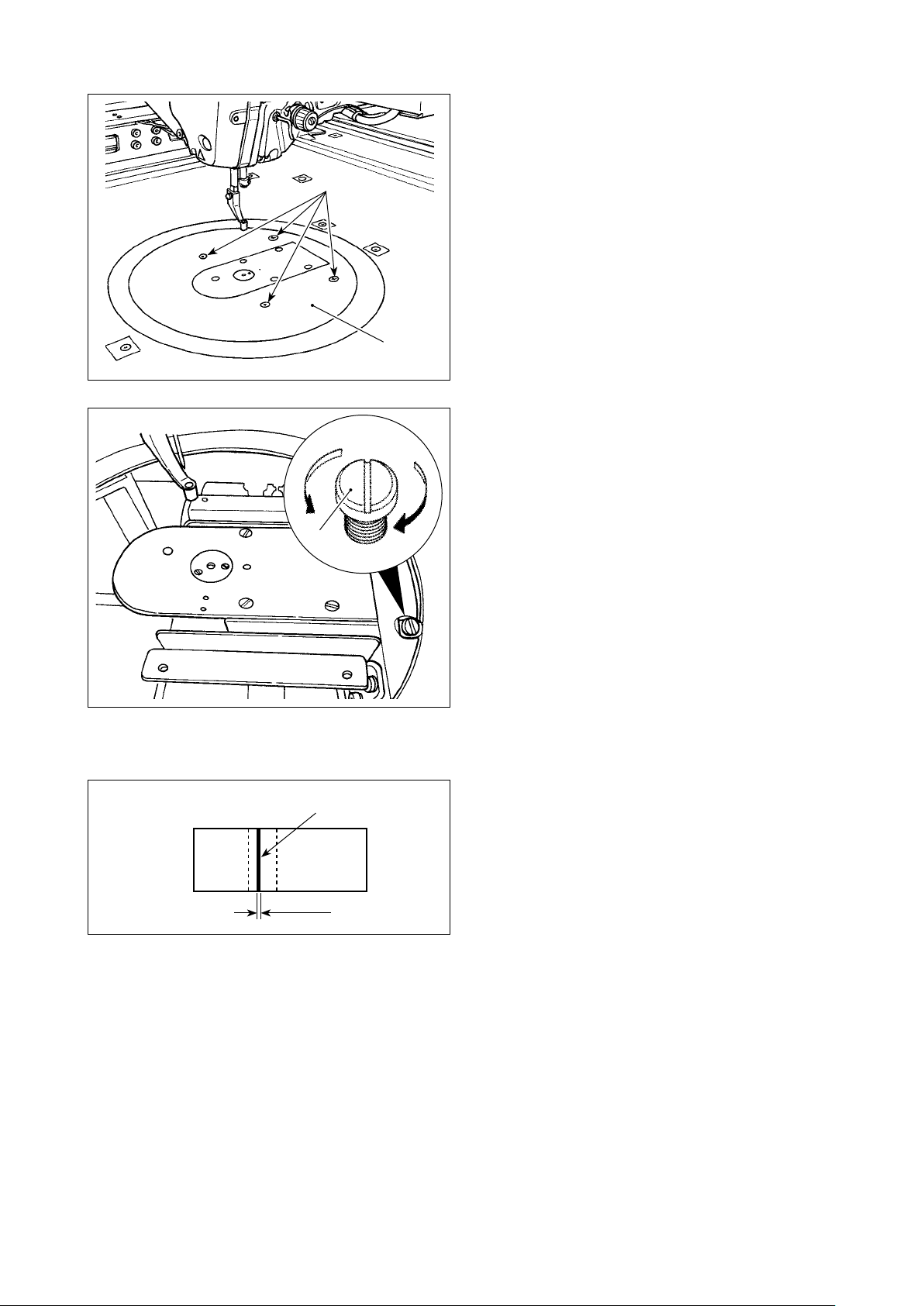

[Checking the needle entry]

B

❷

❹

❸

❶

A

B

1) Remove screw ❶. Detach needle hole guide

.

❷

2) Turn machine head ❸ and hook section ❹ so

that they face the front.

Align marker line A on the bearing with marker

line B on gear ring.

❾

❽

A

❼

0.03 to

0.1mm

❺

❻

3) Inserting hook shaft xing rod ❻ into hook

shaft xing rod insertion hole ❺, turn pulley

until hook shaft xing rod ❻ is fully inserted

❼

into the hole. (As a guide, turn the pulley until

the hook blade point is brought to the position

at which it faces upward.)

4) Turn the hand pulley of machine head until

needle-bar marker line ❽ is aligned with the

lower end of needle bar bushing ❾.

5) Check to make sure that a clearance of 0.03

to 0.1 mm is provided between the needle and

the hook blade point when the hook blade

point is aligned with the center of needle.

For each of four directions, check steps 2) to 4)

by turning the machine head and hook section

in steps of 90 degrees.

If the clearance of 0.03 to 0.1 mm is not pro-

vided between the needle and the hook blade

point, re-adjust the levelness of the main body

of device.

– 5 –

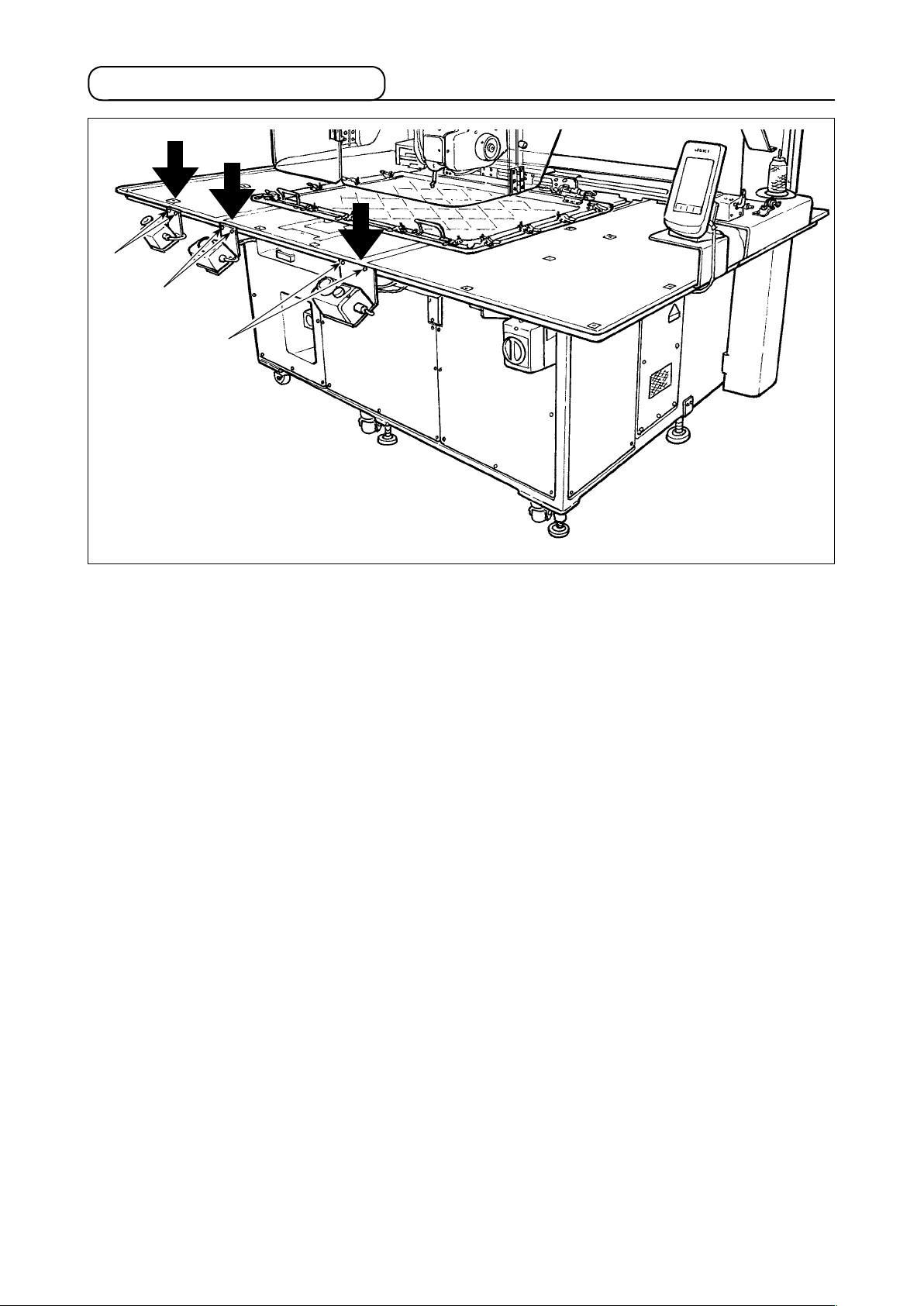

3-3. Preparations of switches

❶

❶

❶

Loosen respective screws ❶ of the power switch, start switch and emergency stop switch which are

placed upside down. Then, place the switches so that they face the worker side and re-tighten the

screws.

– 6 –

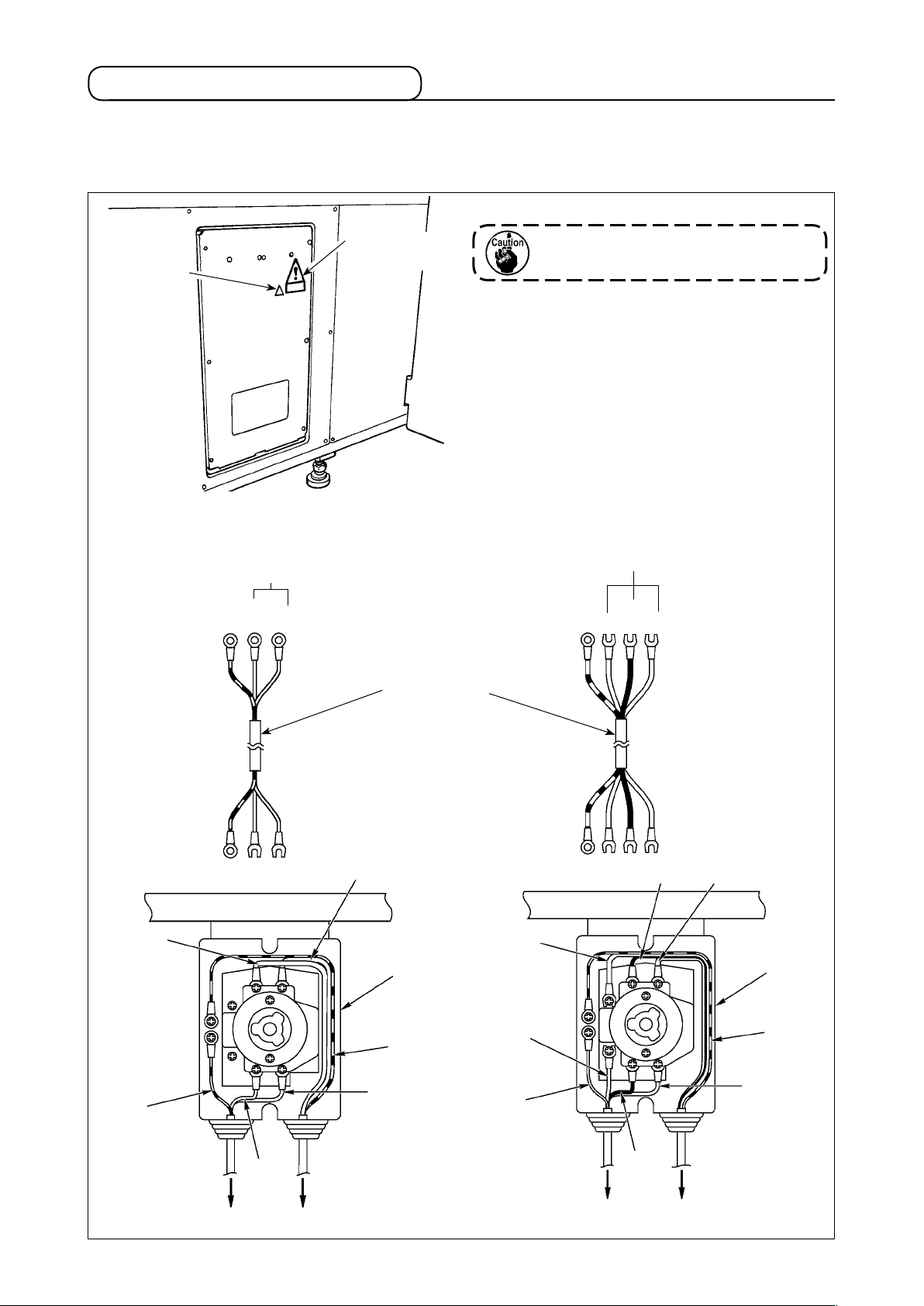

3-4. Connecting the power switch

Connecting the power source cord

The factory default voltage type is indicated on the voltage indication plate. Connect the cord in accor-

dance with the specications.

Voltage

caution seal

• Connecting single phase

200V, 220V, 230V and 240V

AC200 V, AC220 V

AC230 V, AC240 V

Brown OR

Green/Yellow

Black-No.1

– GND

Electric shock

warning label

Light blue OR

BLACK-No.2

Power source cord

Never use under the wrong voltage

and phase.

• Connecting three phase

200V, 220V and 240V

AC200 V, AC220 V, AC240 V

Green/Yellow

– GND

Black

Red White

Brown OR

Black-No.1

Green/

Yellow

Table

Brown

OR

Black-No.1

Control box

Plug

Light blue OR

BLACK-No.2

Power switch

Green/

Yellow

Light blue OR

BLACK-No.2

– 7 –

Red

Green

Red

Table

Black

Black

White

Power switch

Green/

Yellow

White

PlugControl box

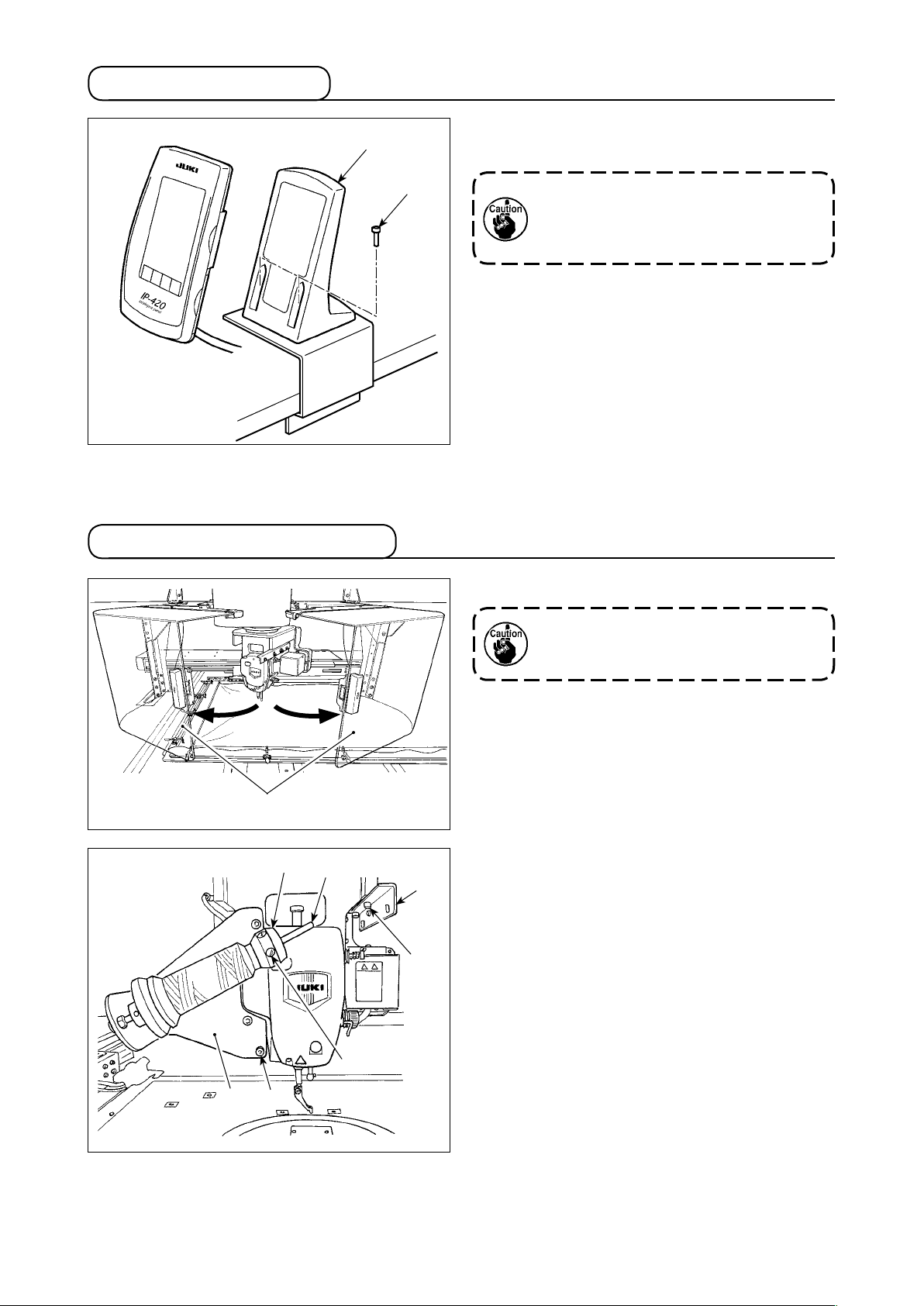

3-5. Installing the panel

❶

1) Fix operation box mounting plate ❶ with two

wood screws ❷.

3-6. Installing the thread stand

❷

Install the panel at the position where

X-move cover or head grip does not

interfere with it since breakage of the

panel will be caused.

1) Open machine head safety cover ❶.

Keep the machine head safety cover

closed while the sewing machine is

❶

in operation.

❹

❶

❺

❻

❽

❼

❸

❷

2) Fix thread guide plate ❷ with setscrews ❸ (two

small screws).

3) Fix thread stand mounting plate ❹ with set-

screws ❺ (three large screws).

4) Attach setscrew ❼ in thread winder support

block ❻.

5) Put the thread on bobbin winder support rod ❽,

Insert bobbin winder support block ❻ into bob-

bin winder support rod ❽ and x with setscrew

.

❼

– 8 –

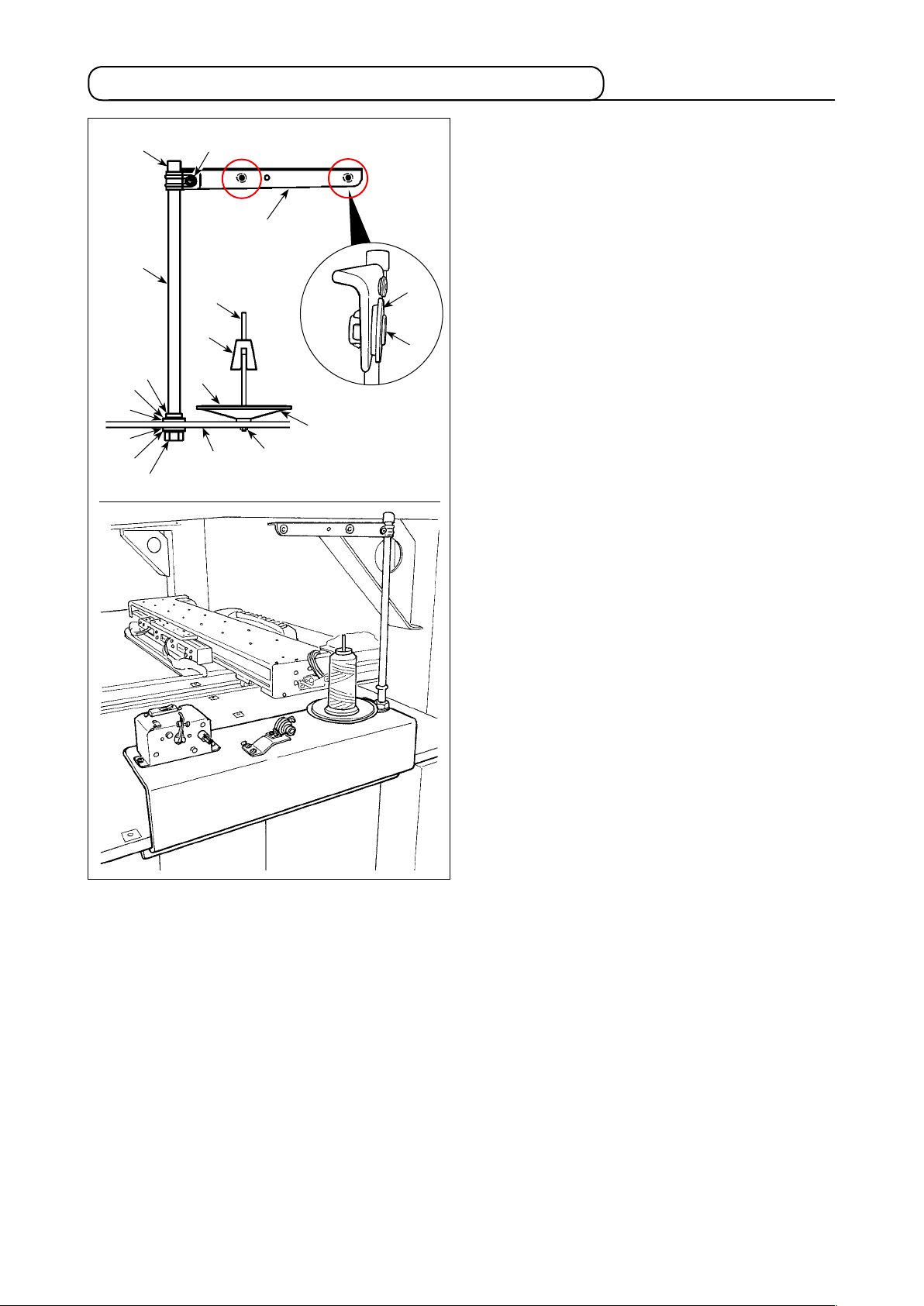

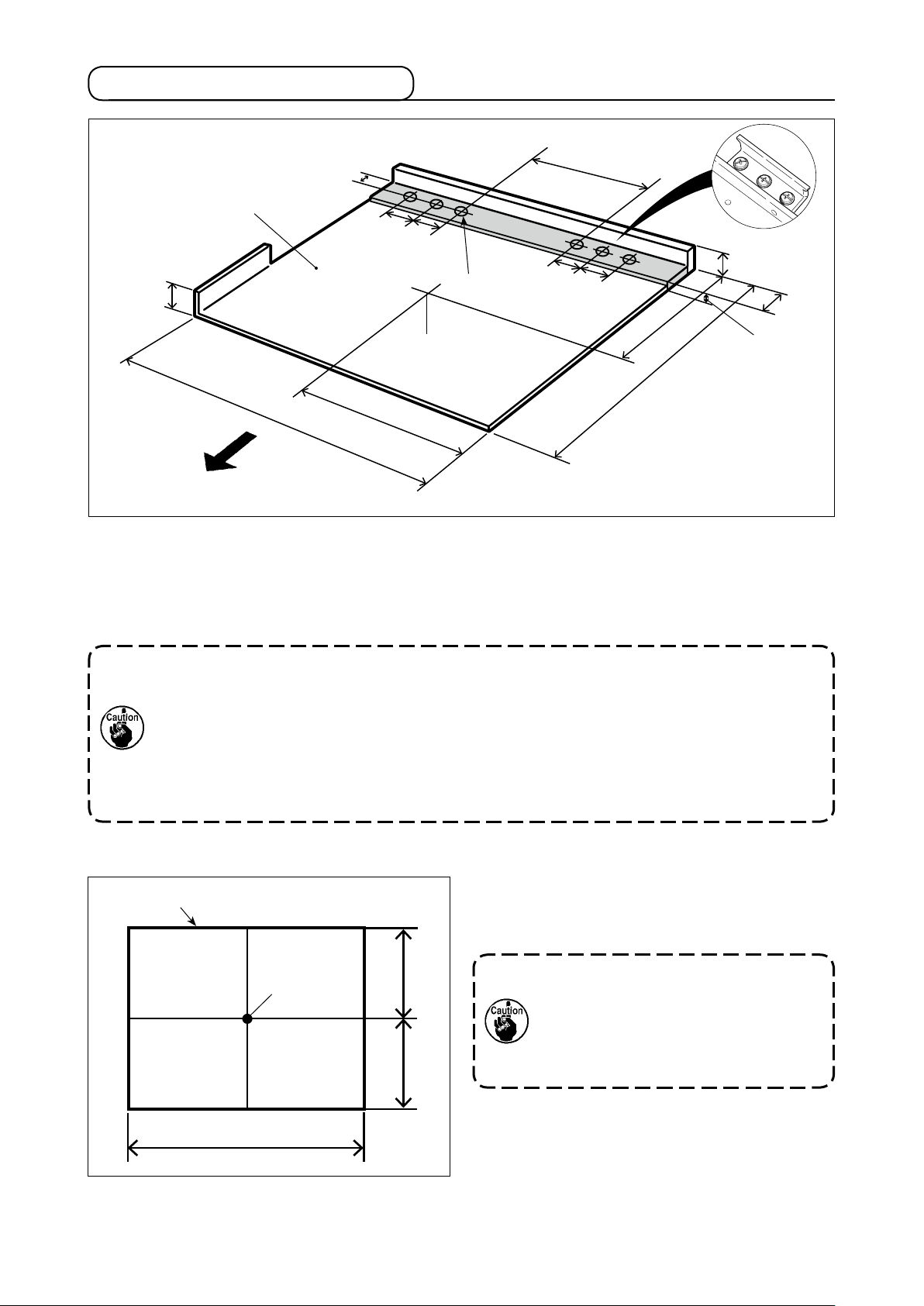

3-7. How to install the thread stand for bobbin winding

1) Pass thread stand arm ❷ over spool rest rod

❸❹

❷

❻

❼

and x with thread stand arm setscrew ❸

❶

and thread stand arm lock nut ❹.

Fit thread stand protection cap ❺ over the top

end of thread stand ❶.

2) Put thread path bush ❻ and thread path ❼ in

holes (two locations) in thread stand arm ❷ in

the written order.

3) Attach spool rest rod lock nut (small) ❽, rub-

ber washer ❾ and thread stand lock washer

to the lower end of spool rest rod ❶. Then, t

the spool rest rod in the hole in bobbin winder

base and x with thread spool rest rod lock

nut (large) .

4) Attach bobbin winder anti-vibrator , bobbin

winder tray cushion and bobbin winder tray

to bobbin winder support rod . Then, x

them on bobbin winder base with a screw.

5) Attach bobbin winder support rod lock plain

washer , bobbin winder support rod lock

spring washer and bobbin winder support

rod lock nut to the section of screw that pro-

trudes from the undersurface of bobbin winder

base and x them.

❾

❾

❺

❶

❽

– 9 –

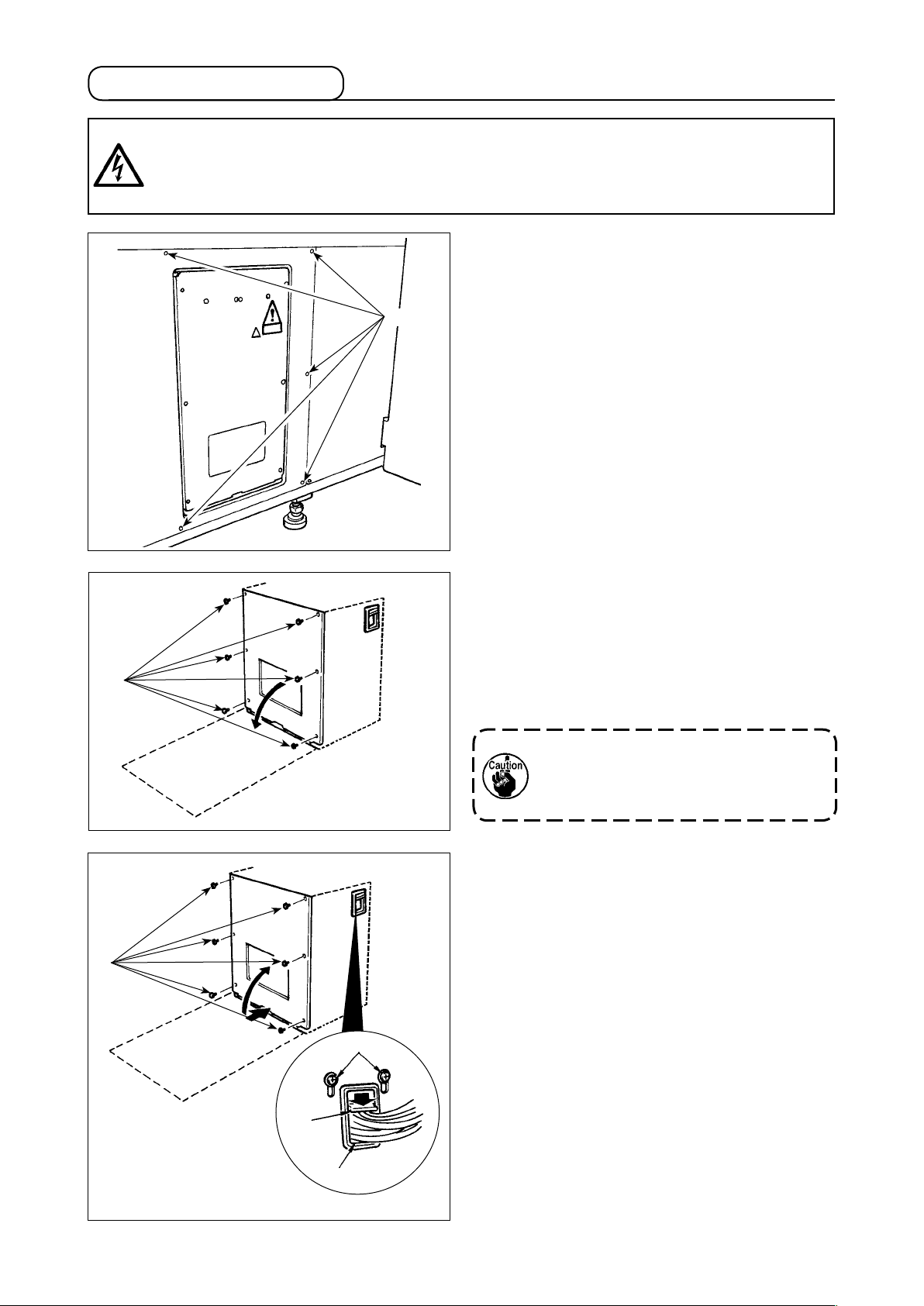

3-8. Connecting the cord

DANGER :

1. To prevent personal injuries caused by electric shock hazards or abrupt start of the sewing

machine, carry out the work after turning OFF the power switch and a lapse of 5 minutes or more.

2. To prevent accidents caused by unaccustomed work or electric shock, request the electric expert

or engineer of our dealers when adjusting the electrical components.

[How to detach the cover]

Remove eight setscrews ❶ of the side cover.

❶

❷

❷

Slowly

[How to open the control box]

Remove six screws ❷ which secure the front

cover of control box. When opening the front

cover, open it by holding it and turning carefully

by approximately 90°until it will go no further, as

shown in the gure.

Be sure to hold the cover with hands

in order to prevent it from dropping.

In this case, do not apply an extra load

to the front cover you have opened.

[How to close the control box]

1) Close the front cover by pushing its lower

side A and x with six screws ❷ while adding

special care not to allow cables to be caught

between the front cover and the control box.

2) Lower downward the cord located on the side

of the control box and cord presser plate C in

A

❸

the push hole B, press the cord and tighten

screws ❸.

C

B

– 10 –

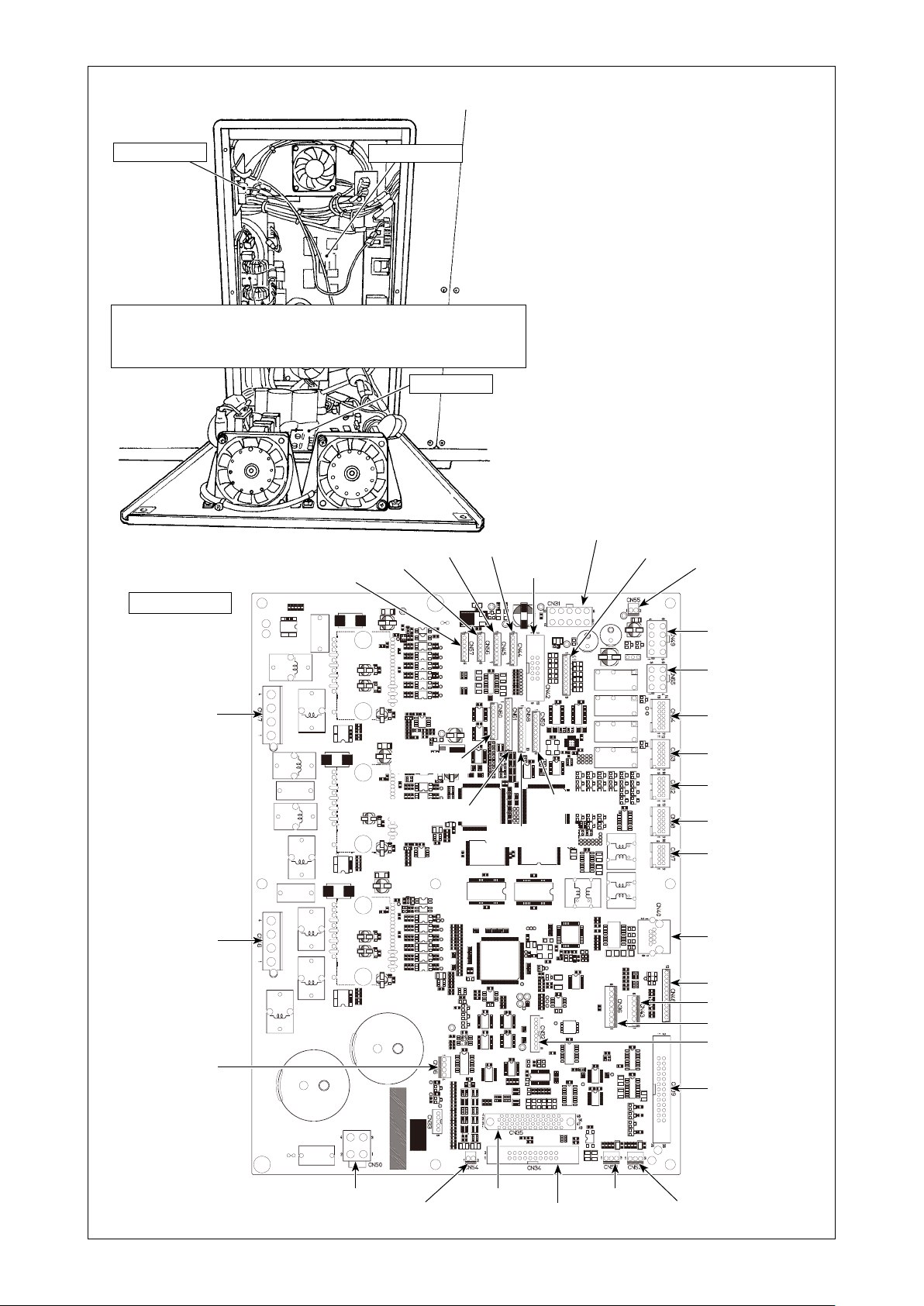

[Inside of the control box]

PWR PCB

MAIN PCB

FLT PCB

FLT-T PCB (single phase 100 to 200V、three phase 200 to 240V)

FLT-S PCB (single phase 200 to 240V)

SDC PCB

CN45 7P

CN56 6P

CN57 6P

CN44 7P

MAIN PCB

CN42 10P

CN31 10P

CN41 9P

CN55 2P

CN47 4P

CN46 4P

CN66 4P

CN60 8P

CN61 12P

CN58 10P

CN49 8P

CN65 6P

CN64 14P

CN63 12P

CN62 10P

CN59 9P

CN38 12P

CN37 10P

CN40 8P

CN48 12P

CN43 6P

CN36 8P

CN32 8P

CN39 26P

CN54 2P

CN35 50P

– 11 –

CN34 20P

CN53 3PCN50 4P

CN52 3P

PWR PCB

CN12 3P

CN13 8P

CN14 2P

CN11 3P

CN16 4P

CN18 10PCN20 2P CN19 10PCN21 2P

CN23 2P

CN22 2P

CN15 3P

CN17 6P

SDC PCB

CN81 2P

CN78 50P

CN77 10P

CN76 10P

CN74 10P

CN73 10P

CN84 5PCN82 12PCN80 8P

CN88 4P

CN87 4P

CN75 4P

CN72 6P

CN71 8P

CN86 4P

CN85 4P

CN70 10PCN79 2P

– 12 –

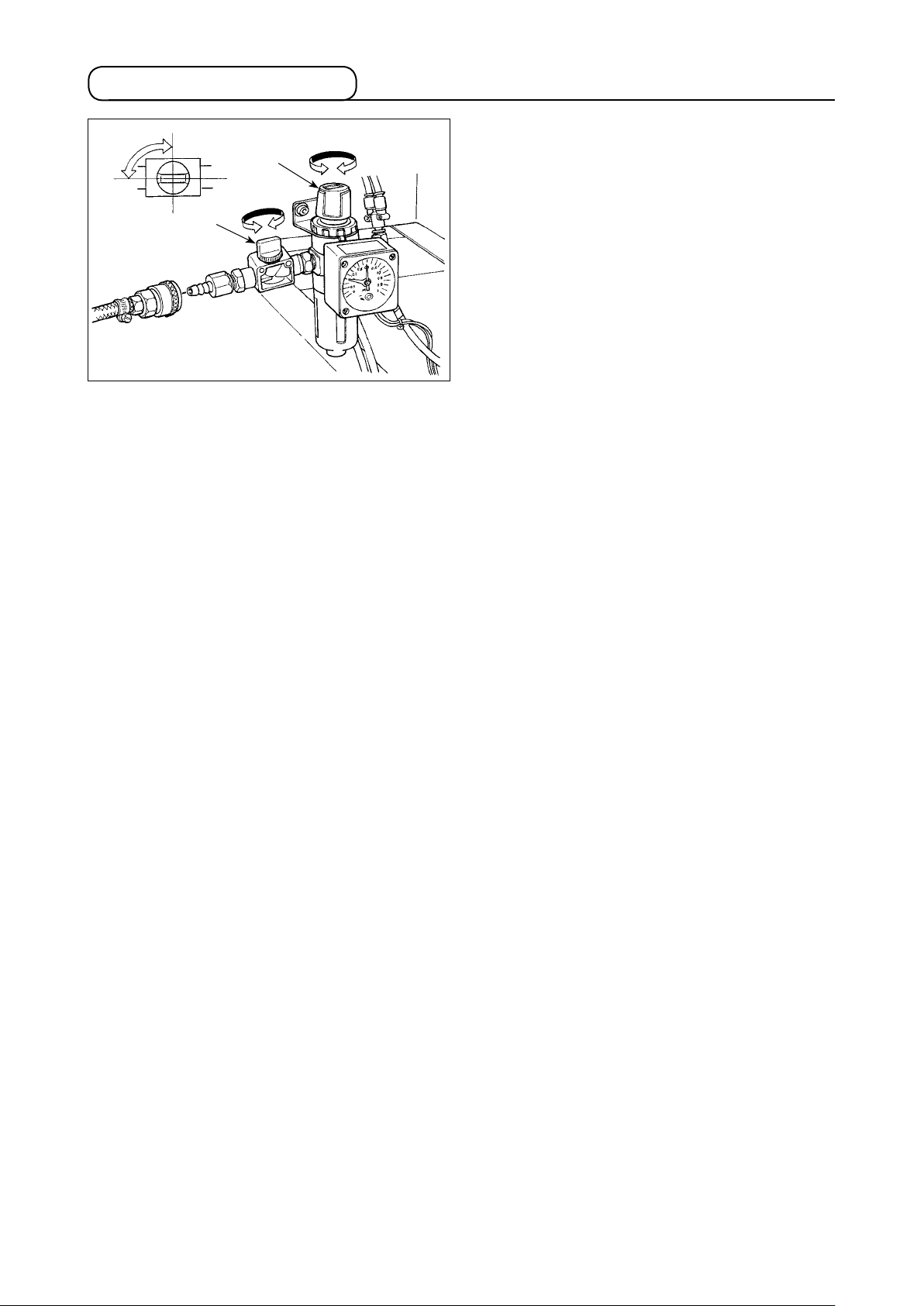

3-9. Installing the air hose

Open

Close

❶

❷

1) Connecting the air hose

Connect the air hose to the regulator.

2) Adjustment of air pressure

Open air cock ❶, pull up and turn air adjust-

ment knob ❷ and adjust so that air pressure

indicates 0.45 to 0.5 MPa (Max. 0.55 MPa).

Then lower the knob and x it.

* Close air cock ❶ to expel air.

– 13 –

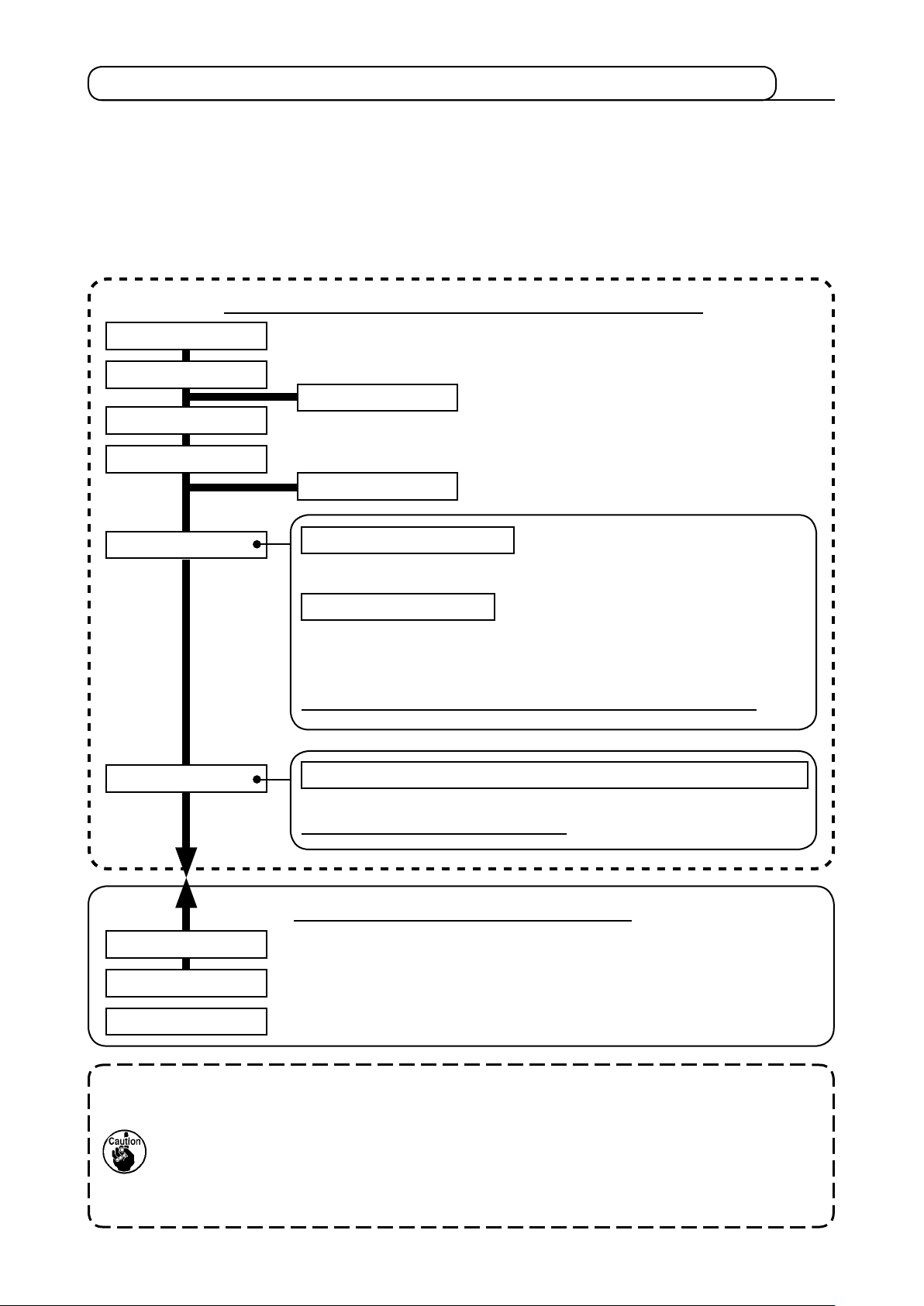

3-10. Cautions for the compressed air supply (source of supply air) facility

As large as 90 % of failures in pneumatic equipment (air cylinders, air solenoid valves) are caused by

"contaminated air."

Compressed air contains lots of impurities such as moisture, dust, deteriorated oil and carbon particles. If such "contaminated air" is used without taking any measures, it can a cause of troubles, inviting

reduction in productivity due to mechanical failures and reduced availability.

Be sure to install the standard air supply facility shown below whenever the machine provided with

pneumatic equipment is used.

Standard air supply facility to be prepared by the user

Air compressor

After cooler

Auto-drain

Air tank

Main line lter

Auto-drain

Air dryer

Mist separator

Filter regulator

Air solenoid valve

Quality of the air supply

When the supply air contains a considerable amount of moisture

Ambient environment

When our machine is installed at a place where the temperature

greatly changes in the morning and in the evening from that in the

daytime or freeze is like to occur

In the aforementioned cases, be sure to install an air dryer.

When the supply air contains a considerable amount of carbon

and dust

(Most troubles in the air solenoid valves are caused by carbon.)

Be sure to install a mist separator.

Standard equipment supplied by JUKI

Air cylinder

Cautions for main piping

• Be

sure to slope main piping by a falling gradient of 1 cm per 1 m in the direction of air ow.

• If the main piping is branched off, the outlet port of the compressed air should be provided at the top part of the piping using a tee in order to prevent drain settling inside

the piping from owing out.

• Auto drains should be provided at all lower points or dead ends in order to prevent the

drain from settling in those parts.

– 14 –

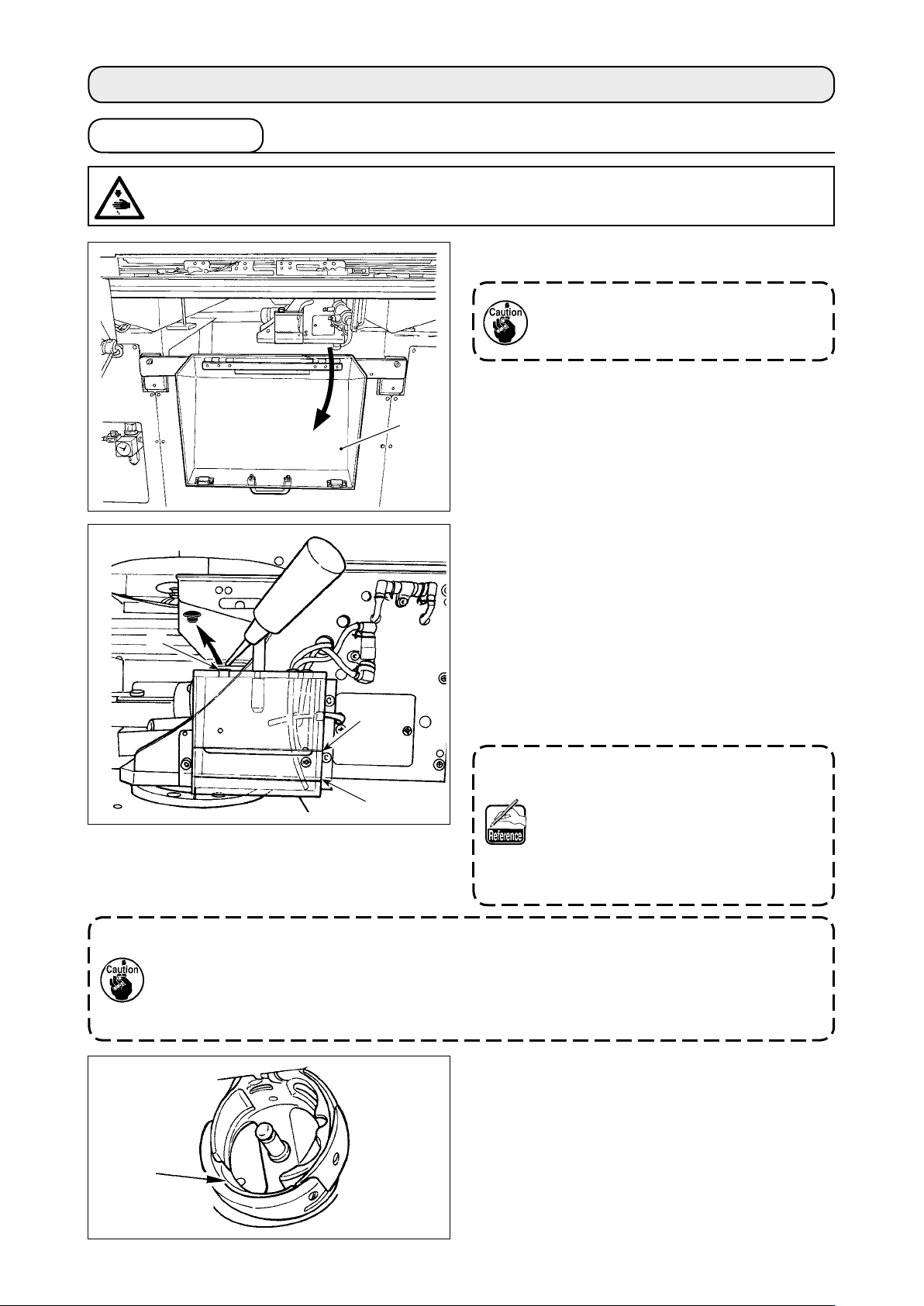

4. PREPARATION OF THE SEWING MACHINE

4-1. Lubrication

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start or

the sewing machine.

1) Open hook section safety cover ❶.

Keep hook section safety cover ❶

closed while the sewing machine is in

operation.

❶

2) Remove rubber cap ❷. Add JUKI New Defrix

Oil No. 2 supplied with the unit into the oil tank.

The oil surface in the oil tank must not exceed

upper line A.

3) Periodically check to make sure that the oil

❷

A

surface in the oil tank remains between lower

line B and upper line A while using the sewing

machine. Fill there with oil using the oiler supplied with the machine as accessories when oil

is short.

The oil tank which is lled with oil is

only for lubricating to the hook por-

B

1. Do not lubricate to the places other than the oil tank and the hook of Caution 2 below.

Trouble of components will be caused.

2. When using the sewing machine for the rst time or after an extended period of disuse,

use the machine after lubricating a small amount of oil to the hook portion. In addition,

use the sewing machine for sewing after having it run idle for approximately two minutes at 1,000 sti/min. (Refer to "III-1-2. Adjusting the needle-to-shuttle relation" p.116 .)

tion. It is possible to reduce the oil

amount when the number of rotation

used is low and the oil amount in the

hook portion is excessive. (Refer to

"III-1-6. Amount of oil supplied to the

hook" p.119 .)

When you use the sewing machine for the rst

time after the purchase, lubricate hook race surface ❸ until a drop of oil can be observed.

❸

– 15 –

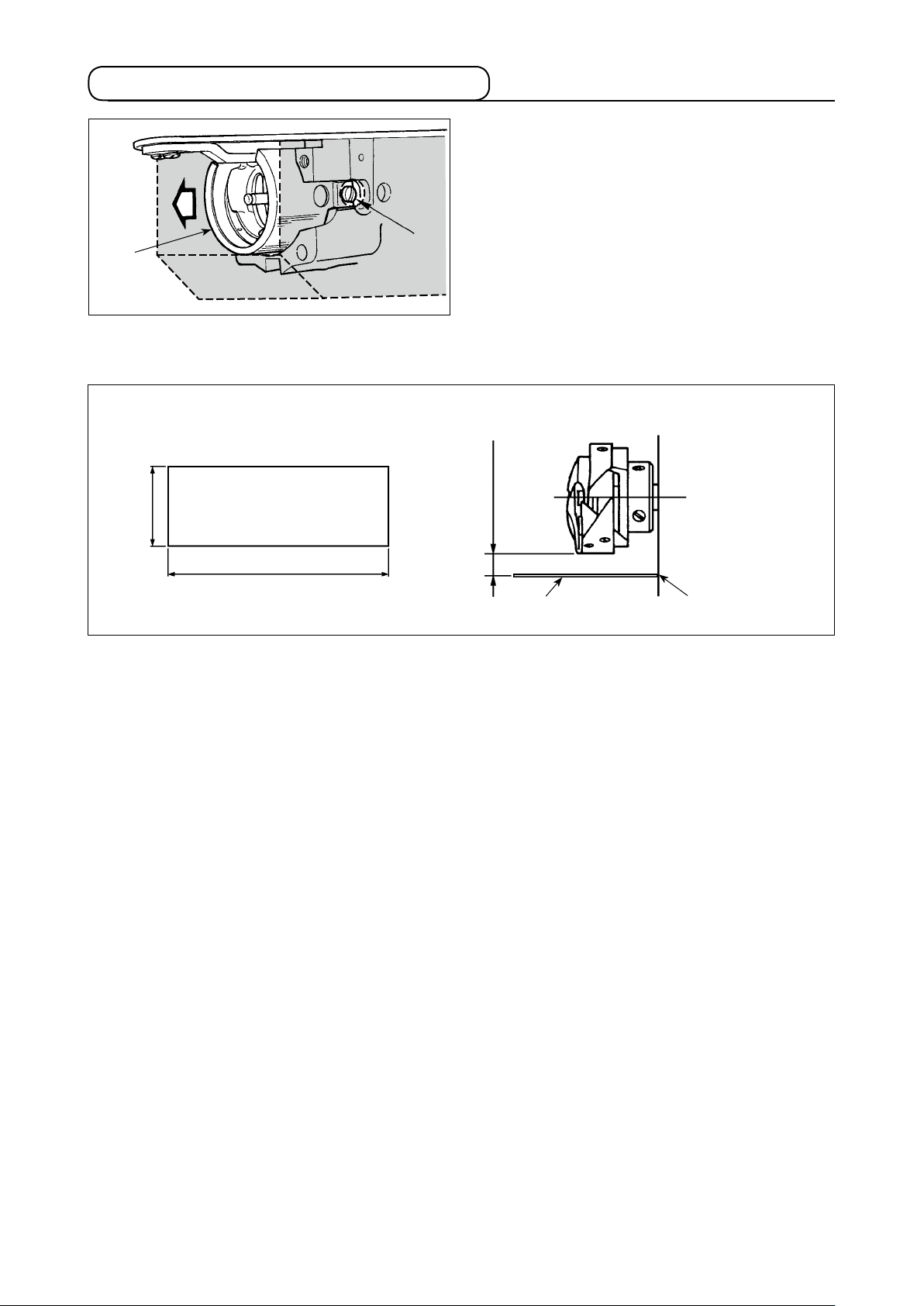

4-2. Adjusting the oil quantity in the hook

❶

❷

(1) Checking the oil quantity in the hook

1) Loosen setscrews ❶ (right and left). Detach oil

shield ❷.

At this time, do not attempt to forcibly remove

the oil shield. Before removing the oil shield,

turn the pulley until the needle stops at its up-

per end. Then, remove the oil shield.

2) Turn the hook section so that it faces the front.

Paper for checking the oil quantity (oil spots)

①

25 mm

70 mm

Position at which the oil quantity (oil spots) is

②

checked

3 to 10 mm

Oil-spots checking paper

Fit against the wall

* When carrying out the following work described in step 2), take added care not to allow your ngers

to come in contact with the hook.

1) In the case the machine head is cold, run it idle for approximately three minutes. (Low-speed opera-

tion)

2) Insert a sheet of paper for checking the oil quantity (oil spots) in the check position while the sewing

machine is in operation.

3) Check to make sure that the oil surface in the oil tank is at the level between the upper and lower

lines.

4) Check the oil quantity (oil spots) for ve seconds. (Measure with a watch.)

– 16 –

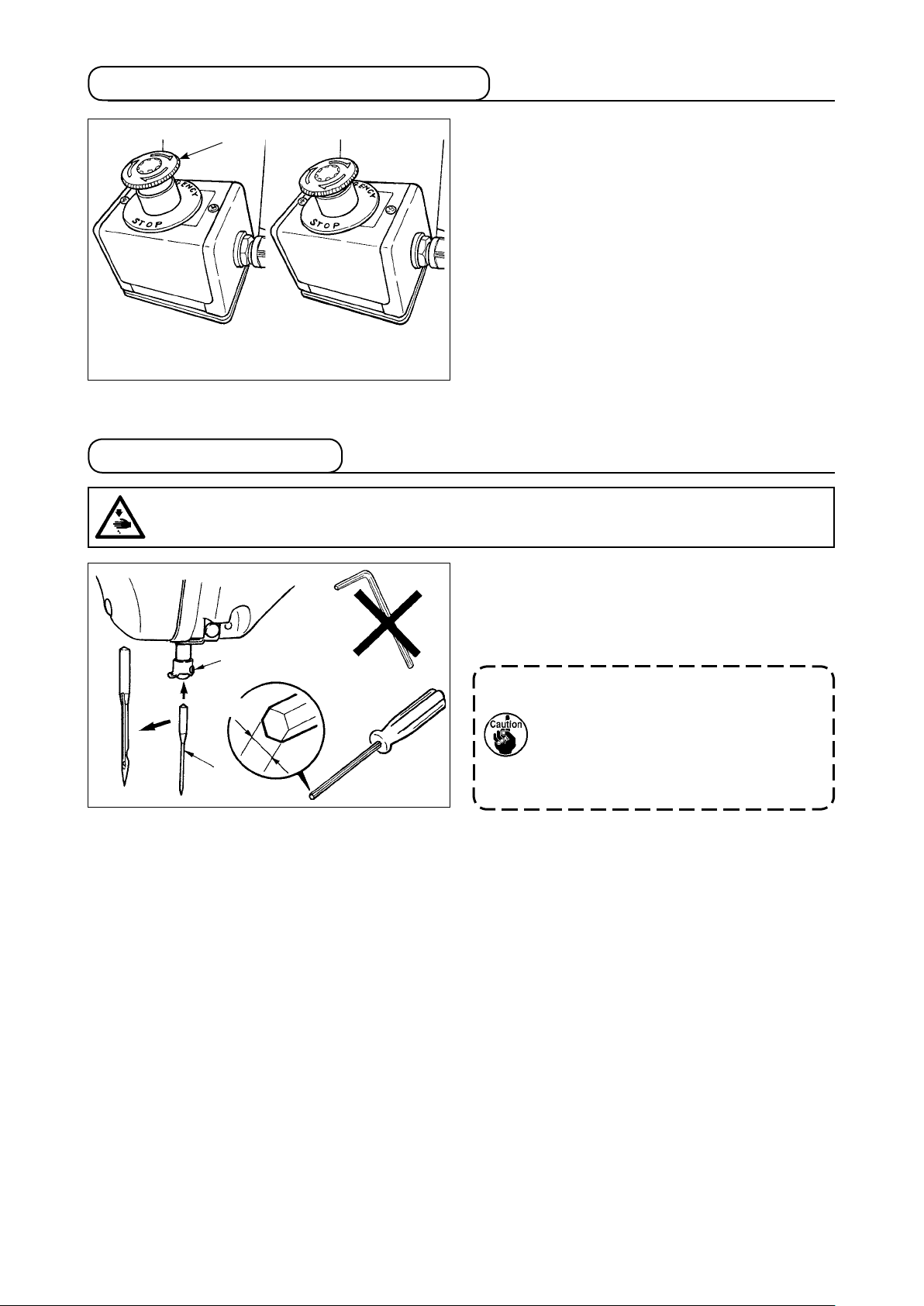

(2) Adjusting the hook oil quantity (oil spots)

❷

1) Remove four setscrews ❷ of round table ❶.

Detach round table ❶.

2) Turn oil quantity adjustment screw ❸ clockwise

until it is fully tightened.

A

3) Turn the screw counterclockwise B by half.

4) The oil quantity (oil spots) is increased by

turning oil quantity adjustment screw ❸ coun-

terclockwise B or is decreased by turning it

clockwise A.

❶

a. Decrease the hook oil quantity when the oil in

the oil tank at the bed side reduces quickly.

b. Decrease the hook oil quantity when the quan-

tity of oil splashing from the hook is large or

Carry out the adjustment in the following cases.

B

A

when oil leaks from the hook cover.

c. Increase the hook oil quantity when the hook

generates a large noise.

❸

d. Increase the hook oil quantity if the needle

thread is not adequately drawn up due to the

oil shortage.

5) After the adjustment of oil quantity, attach

round table ❶ in place and x with four set-

screws ❷.

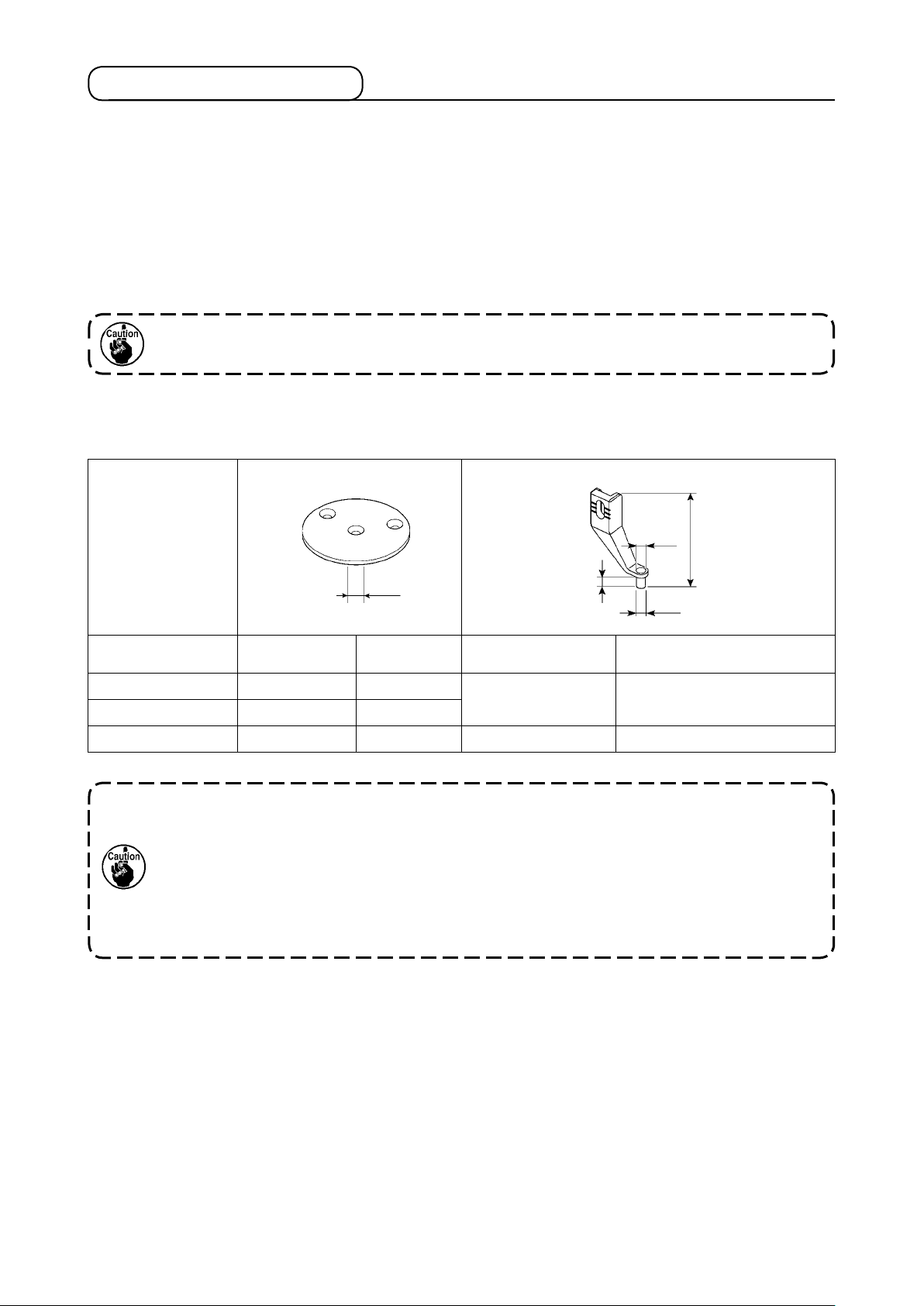

(3) Sample of proper quantity of hook oil (oil spots)

Proper quantity

Oil splashing from the hook

1 to 2 mm

1) The state shown in the gure represents the

proper quantity of oil (oil spots). Adjustment

may be required depending on the sewing pro-

cess. However, it is important not to excessive-

ly increase/decrease the oil quantity. (Smaller

quantity of oil = Hook seizure (hook becomes

hot); Larger quantity of oil = Oil stains on the

sewn products)

2) Check the oil quantity (oil spots) three times

(with three sheets of paper).

– 17 –

4-3. Checking the emergency stop switch

❶

Emergency stop switch

OFF state

Emergency stop switch

ON state

4-4. Attaching the needle

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start or

the sewing machine.

❶

1.5 mm

❷

When the red button of emergency stop switch ❶

is strongly pressed as far as it goes, the switch is

placed in its ON state. When the button is turned

clockwise, the switch is placed in its OFF state.

Check to be sure that emergency stop switch ❶ is

in its OFF state.

If emergency stop switch ❶ is in its ON state, the

operation panel screen will not light up even if the

power switch is turned ON.

Loosen setscrew ❶. Insert needle ❷ into the hole

in needle bar until it will go no further while facing

its long groove toward the frame. Then, tighten

setscrew ❶.

When tightening setscrew ❶, be sure

to use the screwdriver (Part No. :

40032763) supplied as accessories.

Do not use L-shaped hexagon wrench

key. There is a danger of breaking setscrew ❶.

– 18 –

4-5. Needle size and gauge

When changing the needle size, it is necessary to adjust the hook and to replace the gauge.

(1) Adjustment

In the standard delivery state, the hook has been factory-adjusted to DP × 17 #23 needle.

When changing the thickness of the needle, perform the adjustment of

dle-to-shuttle relation" p.116

.

When changing the length of the needle, perform the adjustment of

the needle bar (Changing the length of the needle)" p.115

.

When the adjustment of hook and driver is not t to the thickness of the needle, sewing troubles such as stitch skipping and the like or abrasion of the blade point of hook will be caused.

(2) Gauge

When changing the needle size, replace the gauge with the optional gauge of the correspondence table.

Needle Needle hole guide Intermediate presser

"III-1-2. Adjusting the nee-

"III-1-1. Adjusting the height of

øA

øA

Number (Thickness) Part No.

#18 to #21 14439509 ø2.3 B1601210D0BA ø2.7 × ø4.1 × 5.7 × 38.5

#20 to #23 14439608 ø3.0

#23 or thicker 14439707 ø4.0 B1601210D0CA ø3.5 × ø5.5 × 5.7 × 38.5

Needle hole

diameter (øA)

Part No.

H

L

øB

Dimension

(øA × øB × H × L)

1. The table above describes the typical optional gauges.

For the other special gauges, ask our sales distributors.

2. When using the gauge that is not t for the thickness of the needle, needle breakage,

abrasion of components such as inner hook and the like, sewing trouble such as stitch

skipping and the like will be caused.

Example : When sewing the sports shoes with a big size needle guide or inner hook

presser, needle thread loop becomes unstable and stitch skipping or thread

breakage may occur.

– 19 –

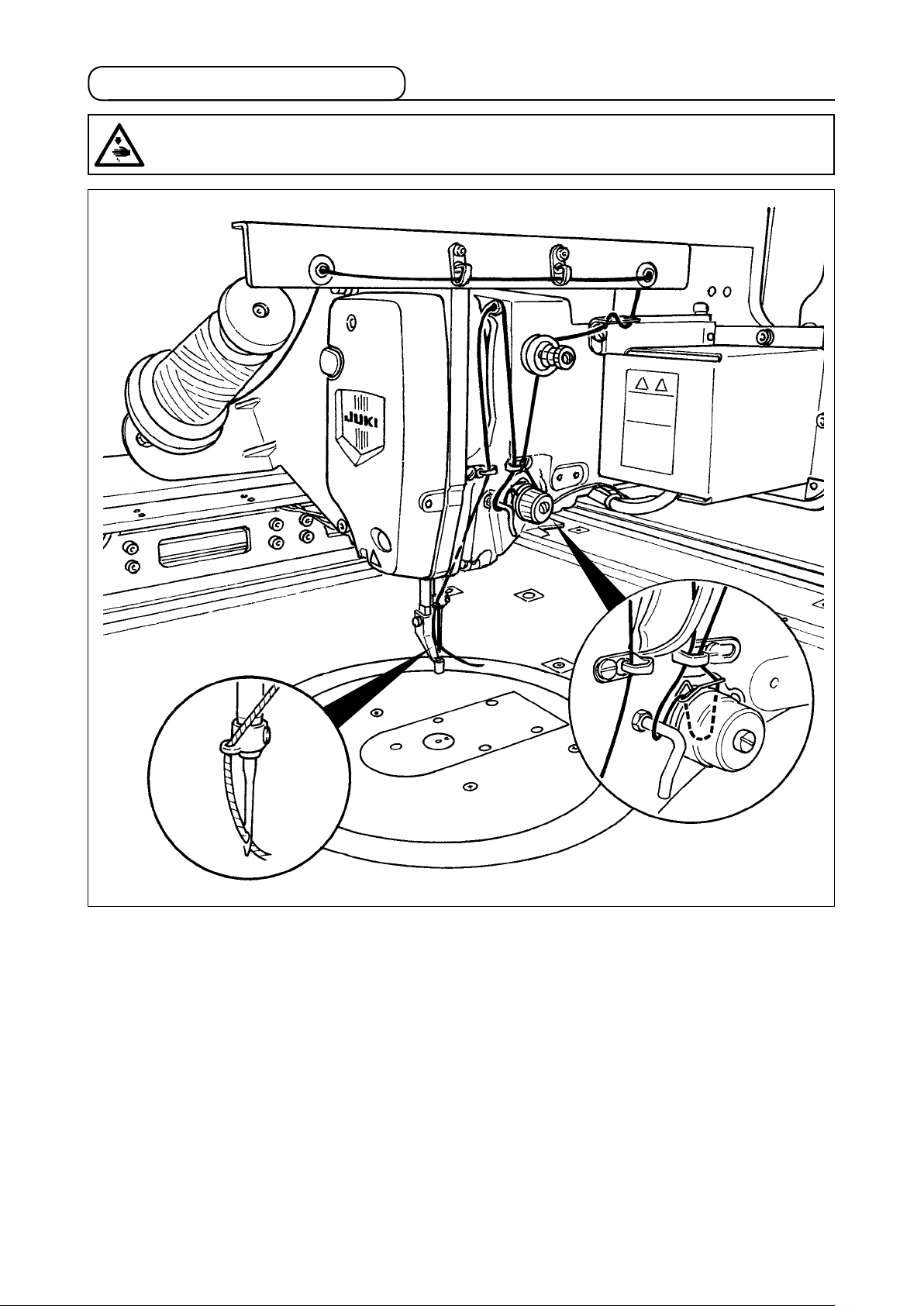

4-6. Threading the machine head

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start or

the sewing machine.

– 20 –

4-7. Installing and removing the bobbin case

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start or

the sewing machine.

In addition, be sure to close the bobbin replacement cover when re-starting operation in order to

prevent personal injury.

❶

A

❸

1) When button A is pressed, the turning section

rotates to allow the hook to face the front face

and bobbin replacement cover ❶ to open.

2) Raise latch ❸ of bobbin case ❷, and remove

the bobbin case.

3) When entering bobbin case, insert it with the

latch tilted until "click" sounds.

4-8. Installing the bobbin

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start or

the sewing machine.

❹

❸

❶

❷

❷

4 cm

❺

If bobbin case ❷ is not adequately tted in the hook, it can drop off the hook

or needle can break during sewing.

1) Set the bobbin ❶ into bobbin case ❷ in the

direction shown in the gure.

2) Pass the thread through thread slit ❸ of bobbin case ❷, and pull the thread as it is. By so

doing, the thread will pass under the tension

spring and be pulled out from thread hole ❹.

3) Pass the thread under bobbin thread guide ❺

and draw the thread by 4 cm out from the bobbin thread guide.

If the bobbin is installed in the bobbin

case orienting the reverse direction,

the bobbin thread pulling out will result in an inconsistent state.

– 21 –

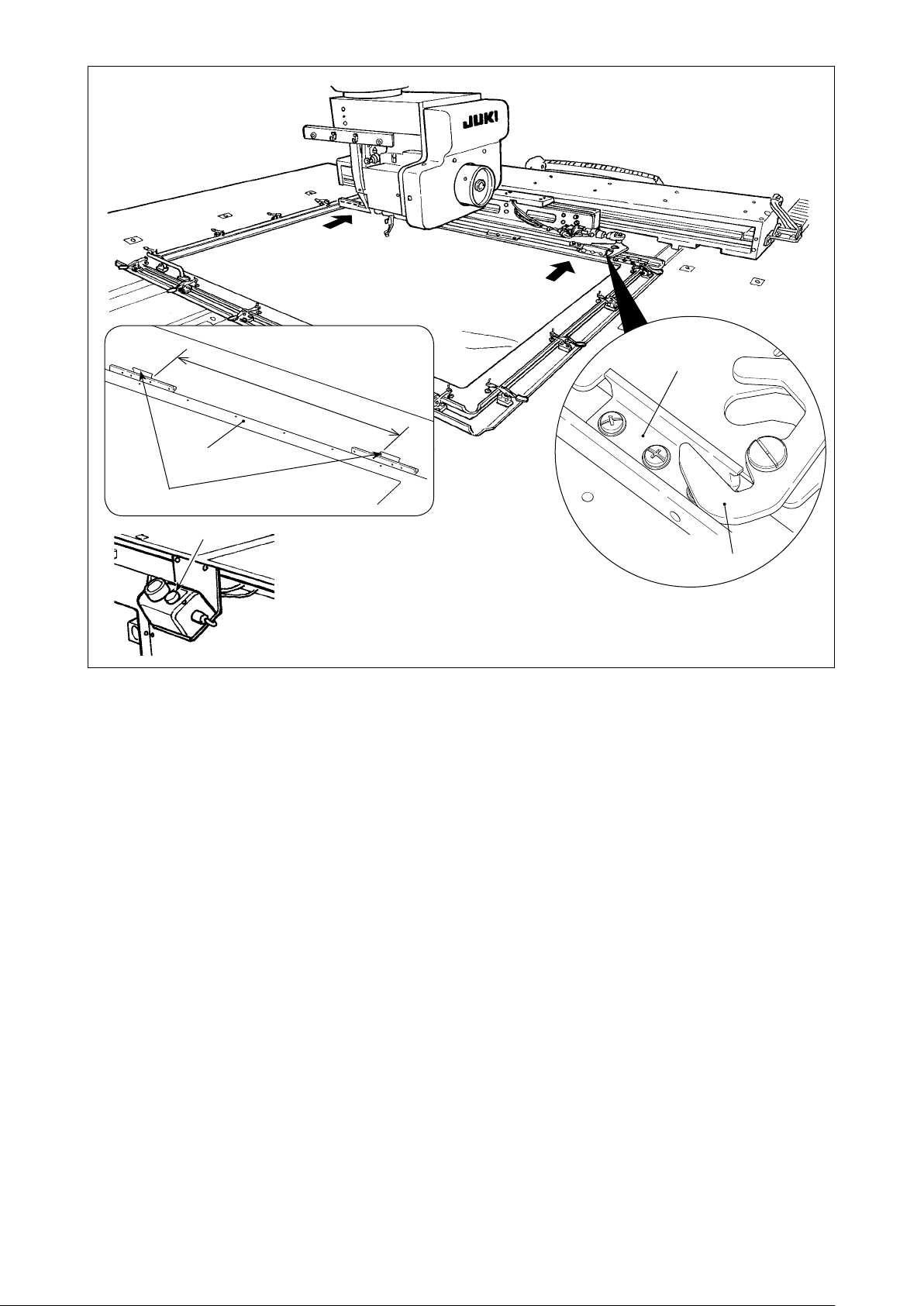

4-9. Preparing the cassette clamp

798 mm

22 mm

360.5 mm

Depth 750 mm (reference)

Weight 9.5 kg or less

8 mm or less

26 mm

Height 5.5 mm

(Chuck plate

mounting base,

height)

Height

12 mm

or less

Operator side

15 mm

(Outside dimension)

Cassette clamp

22 mm

22 mm

22 mm

6×M4

Origin

Width 1,170 mm (reference)

585 mm (reference)

1) The cassette clamp is separately available by a special order.

In the case the customer prepares a cassette clamp, the cassette clamp which is shown in the above

gure must be prepared.

2) Stick a piece of Teon sheet (option: 40123146) or the like on the undersurface of cassette clamp.

1. If a piece of Teon sheet or the like is not stuck on the undersurface of cassette clamp,

the top surface of throat plate can get dirty to cause stains on the sewing material.

The Teon sheet is a consumable part. It is necessary therefore periodically inspect it

and change it with a new one if it has worn out.

2. Clean the undersurface and material retaining surface of cassette clamp and the top

surface of throat plate auxiliary cover before use. After the cleaning, check to be sure

that the aforementioned sections are free from dirt. Then, start using the sewing machine.

[Sewing area]

The sewing area has been factory set to the area

Sewing area

(1,000 x 600) as shown in the gure at the time of

shipment.

In the case of using the sewing area

Origin

300mm300mm

that is 600 mm in longitudinal direction, the cassette clamp may protrude

the throat plate auxiliary cover when

the material is fed in Y direction. So,

be careful.

1,000mm

– 22 –

Chuck plate mounting pitch

782 mm

❶

❷

❹

❷

❸

3) Temporarily x chuck plates (40181516) ❷ at the 782-mm pitch positions of cassette clamp ❶ with

setscrews and washers. (Chuck plates, setscrews and washers are packed in the accessory box.)

4) While tting chuck plate ❷ against chuck ❸, attach the cassette clamp in place. Then, securely x

chuck plates ❷ with setscrews.

To detach the cassette clamp, press eject switch ❹ (blue).

5) Attach and detach the cassette clamp several time in repetition to check whether it can be complete-

ly attached in place.

After attaching the cassette clamp in place, move it back and forth to check whether there is a back-

lash.

– 23 –

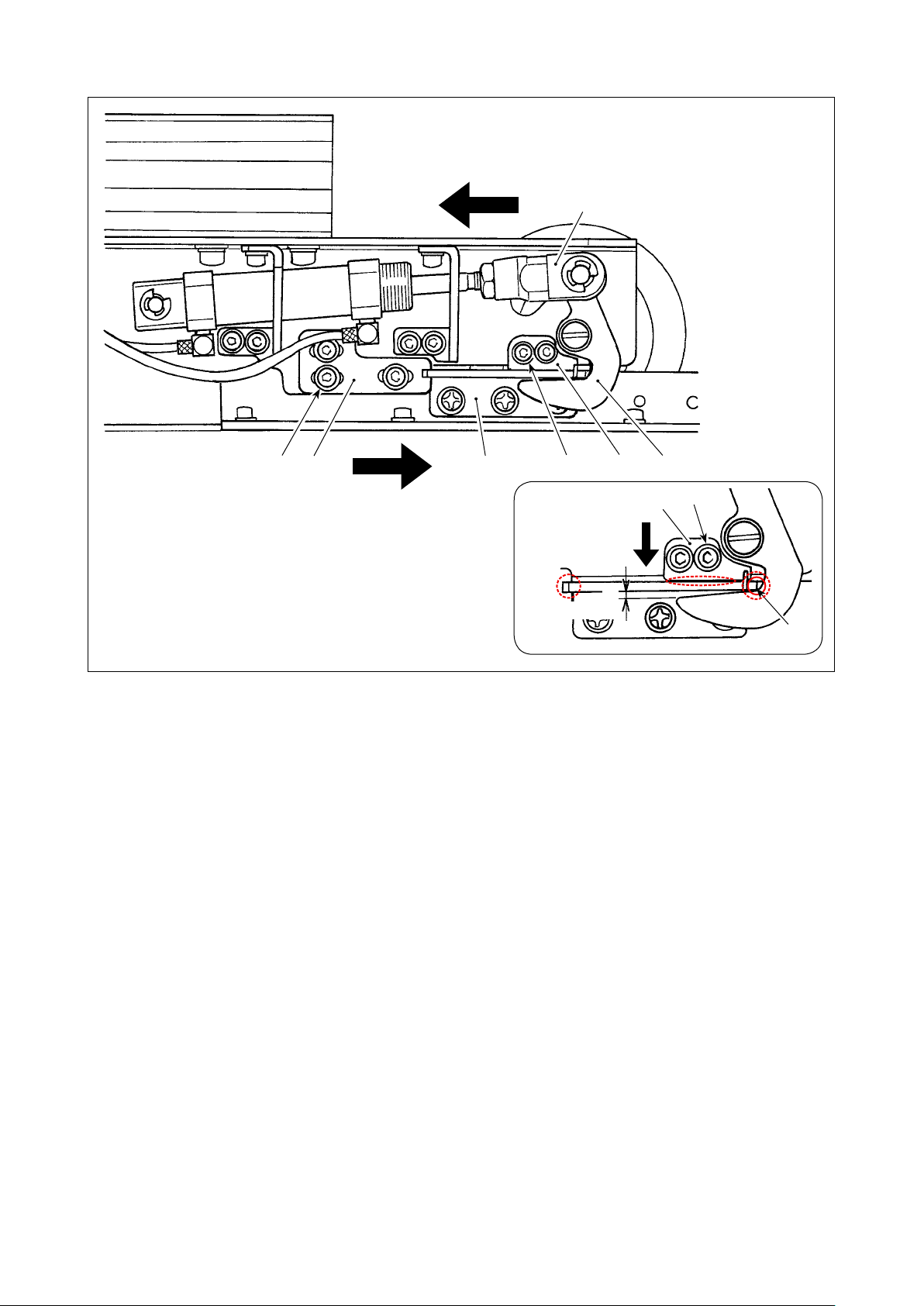

[In the case there is a backlash]

Releasing side

❼

❽❾ ❸❺❻ ❷

Fig. I

B

0.5 to 1 mm

❽

❾

A

1) Loosen screws ❻ (3 pieces). Press chuck plate bracket A ❺ against chuck plate ❷ of the cassette

clamp and x with screw ❻.

Adjust the position of chuck plate bracket A ❺ also on the opposite side in the same manner. At this

time, adjust so that right and left chuck plates ❷ and chuck plate brackets A ❺ are symmetrically

positioned.

2) Then, pressing cylinder knuckle ❼ toward the releasing side, loosen screws ❾ (2 pieces) of chuck

plate bracket B ❽. Adjust the positional relationship between chuck plate ❷ and chuck ❸ so that

they are positioned as illustrated in Fig. I.

Adjust, by pressing chuck plate bracket B ❽ in the direction of the arrow, so that a clearance of 0.5

to 1 mm is provided in section B when the chuck is aligned with the chuck plate at section A. Then,

x the chuck plate B with screws ❾.

* Apply JUKI Grease A to the contact section indicated in a dotted circle in Fig. I.

– 24 –

4-10. Adjusting the thread tension

❶

Longer

Shorter

[Adjusting the needle thread tension]

A

❷

If thread tension controller No. 1 ❶ is turned

clockwise, the length of remaining thread on the

needle after thread trimming will be shorter. If it is

turned counterclockwise, the length will be longer.

Shorten the length to an extent that the thread is

not slipped off.

Adjust needle thread tension from the operation

panel and bobbin thread tension with ❷.

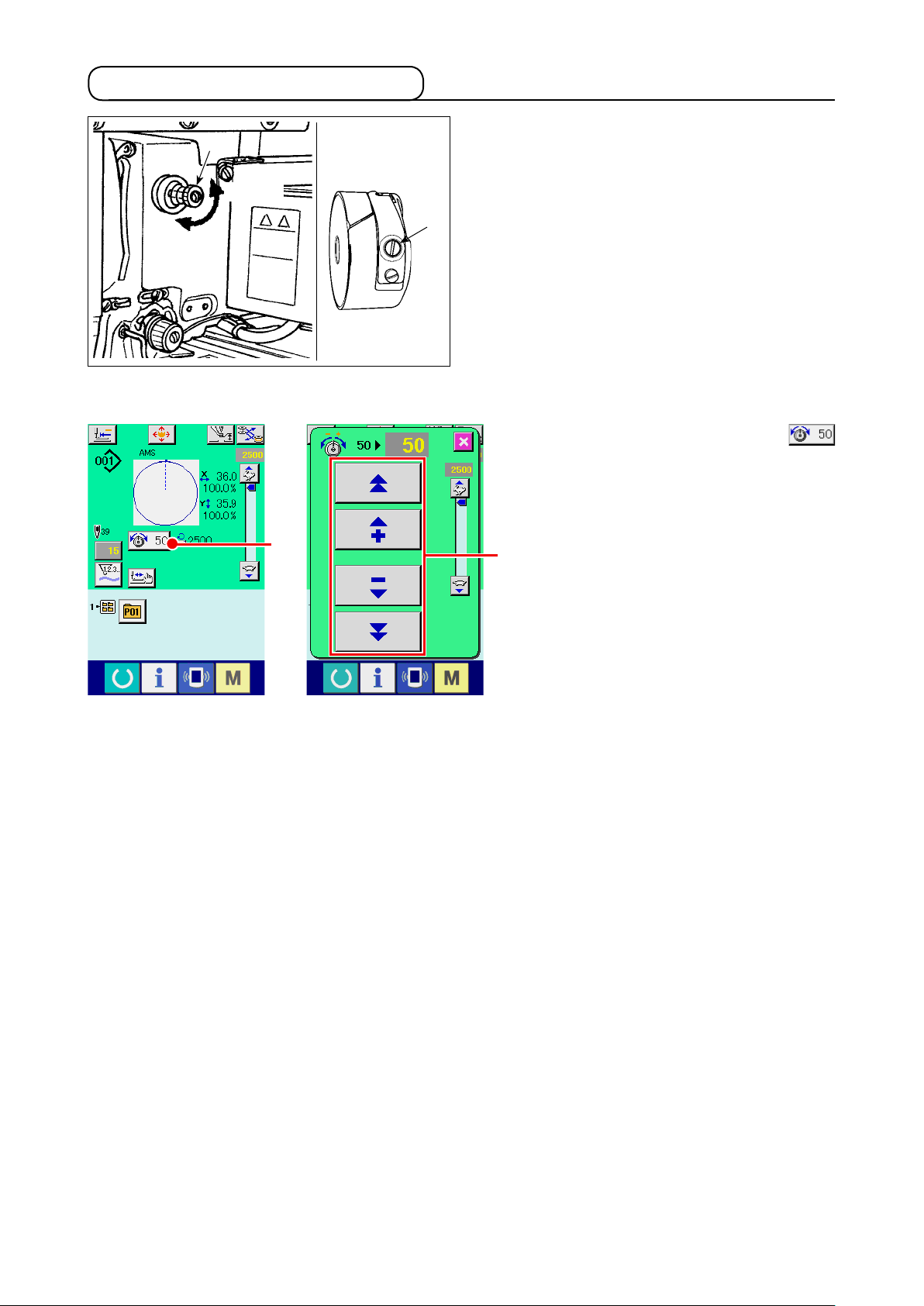

1) Select THREAD TENSION button

in the sewing screen.

A

2) Set needle thread tension with SCROLL

button B. There is a setting range of 0

to 200. When the set value is increased,

B

the tension becomes higher.

* When the set value is 50 at the time of

standard delivery, the thread tension is

adjusted to 2.35N (spun thread #50).

(When thread tension No. 1 is released)

– 25 –

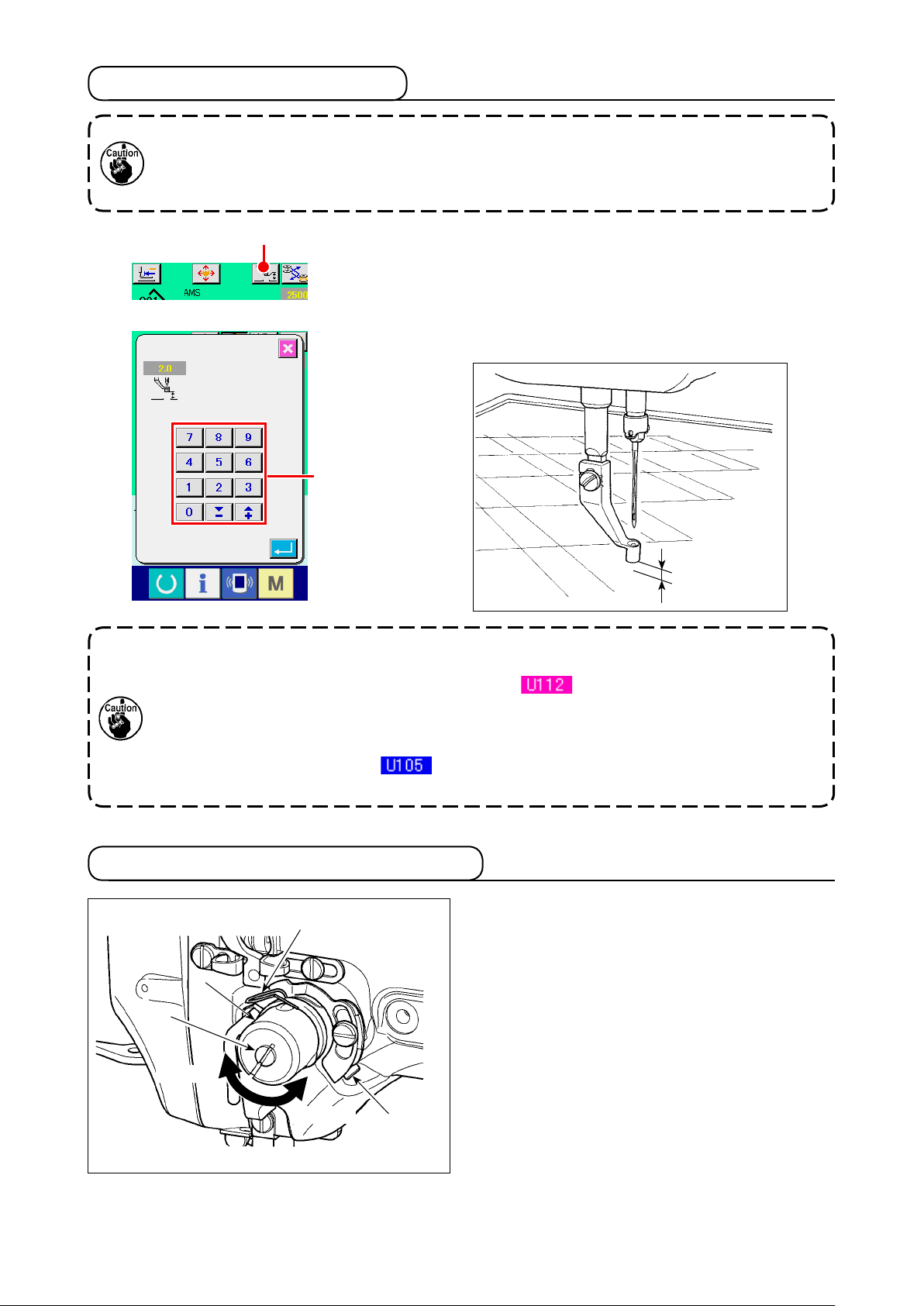

4-11. Intermediate presser height

1. When raising the intermediate presser height, turn the pulley by hand to lower the needle

bar, and conrm that the needle bar does not interfere with the intermediate presser.

2. Take care not to allow your hands and ngers to be caught in the cassette clamp or the

intermediate presser.

A

Press INTERMEDIATE PRESSER SETTING button A and adjust with TEN keys B so that the clearance between the bottom

end of intermediate presser and the cloth is 0.5 mm (thickness

of thread used).

B

0.5 mm

1. Setting range of the intermediate presser is up to the standard of 3.5 mm.

However, when using DP × 17 needle for H type or the like, the setting range can be

changed up to max. 7 mm with memory switch .

2. When increasing the height of intermediate presser or making the needle size thicker,

conrm the clearance between the wiper and the components. Wiper cannot be used

unless the clearance is secured. In this case, turn OFF the wiper switch, or change the

set value of memory switch .

(Wiper is optionally available.)

4-12. Adjusting the thread take-up spring

1) Adjusting the stroke

❸

❹

Increase

❶

Decrease

❷

Loosen setscrew ❷, and turn thread tension asm.

.

❸

Turning it clockwise will increase the moving

amount and the thread drawing amount will

increase.

2) Adjusting the pressure

To change the pressure of the thread take-

up spring ❶, insert a thin screwdriver into the

slot of thread tension post ❹ while screw ❷

tightened, and turn it. Turning it clockwise will

increase the pressure of the thread take-up

spring. Turning it counterclockwise will decrease the pressure.

is

– 26 –

Loading...

Loading...