JUKI AMS-224E/IP-410 Instruction Manual

ENGLISH

AMS-224E / IP-410

INSTRUCTION MANUAL

* "CompactFlash(TM)" is the registered trademark of SanDisk Corporation, U.S.A.

i

CONTENTS

!

.

MECHANICAL SECTION (WITH REGARD TO THE SEWING MACHINE)

1. SPECIFICATIONS .................................................................................................................1

2. CONFIGURATION ................................................................................................................. 2

3. INSTALLATION ..................................................................................................................... 3

3-1. Installing the throat plate auxiliary cover .................................................................. 3

3-2. Table position adjustment: Only for 6030 .................................................................

3-3. Installing the panel ......................................................................................................

3-4. Installing the thread stand ..........................................................................................

3-5. Installing the air hose ..................................................................................................

3-6. Installing the eye protection cover ............................................................................

3-7. Changing the height of the table and stand ..............................................................

4. PREPARATION OF THE SEWING MACHINE ......................................................................

4-1. Lubrication ................................................................................................................... 9

4-2. Attaching the needle ...................................................................................................

4-3. Threading the machine head ....................................................................................

4-4. Installing and removing the bobbin case ................................................................

4-5. Installing the bobbin .................................................................................................

4-6. Adjusting the thread tension ....................................................................................

4-7. Intermediate presser height .....................................................................................

4-8. Adjusting the thread take-up spring ........................................................................

5. OPERATION OF THE SEWING MACHINE ........................................................................

5-1. Sewing ........................................................................................................................ 12

5-2. Needle thread clamp device .....................................................................................

5-3. How to use the plastic blank (supplied with the machine as an accessory) .......

... 1

4

6

7

7

7

8

9

9

10

10

10

11

11

12

12

13

14

@

.

OPERATION SECTION (WITH REGARD TO THE PANEL) ......................................15

1. PREFACE ............................................................................................................................ 15

2. WHEN USING IP-410 .......................................................................................................... 18

2-1. Name of each section of IP-410 ............................................................................... 18

2-2. Buttons to be used in common ................................................................................

2-3. Basic operation of IP-410 .........................................................................................

2-4. LCD display section at the time of sewing shape selection .................................

(1) Sewing shape data input screen ................................................................................................21

(2) Sewing screen ............................................................................................................................

2-5. Performing sewing shape selection ........................................................................ 25

2-6. Changing item data ...................................................................................................

2-7. Checking pattern shape ...........................................................................................

2-8.Performingmodicationofneedleentrypoint ......................................................

(1) Changing the thread tension value .............................................................................................30

(2) Changing the intermediate presser height value ........................................................................

2-9. How to use temporary stop ...................................................................................... 32

(1) To continue performing sewing from some point in sewing ........................................................ 32

(2) To perform re-sewing from the start ............................................................................................

2-10.Whensettingofsewingproductisdifcultbecauseofinterruptionofneedletip .. 34

2-11. Winding bobbin thread .............................................................................................

(1) When performing winding bobbin thread while performing sewing ............................................34

19

20

21

23

27

29

30

31

33

34

i

(2) When performing winding bobbin thread only ............................................................................

35

2-12. Using counter ............................................................................................................ 35

(1) Setting procedure of the counter ................................................................................................35

(2) Count-up releasing procedure ....................................................................................................

(3) How to change the counter value during sewing ........................................................................

37

38

2-13. Performing new register of users’ pattern .............................................................. 38

2-14. Naming users’ pattern ...............................................................................................

2-15. Performing new register of pattern button .............................................................

2-16. LCD display section at the time of pattern button selection .................................

(1) Pattern button data input screen ................................................................................................41

(2) Sewing screen ............................................................................................................................

39

40

41

43

2-17. Performing pattern button No. selection ................................................................. 45

(1) Selection from the data input screen .......................................................................................... 45

(2) Selection by means of the shortcut button .................................................................................

46

2-18. Changing contents of pattern button ...................................................................... 47

2-19. Copying pattern button .............................................................................................

2-20. Changing sewing mode ............................................................................................

2-21. LCD display section at the time of combination sewing .......................................

(1) Pattern input screen ...................................................................................................................50

(2) Sewing screen ............................................................................................................................

48

49

50

52

2-22. Performing combination sewing .............................................................................. 54

(1) Selection of combination data ....................................................................................................54

(2) How to edit combination data .....................................................................................................

(3) Deleting procedure of the combination data ...............................................................................

(4) Deleting procedure of the step of the combination data .............................................................

55

56

56

2-23. Changing memory switch data ................................................................................ 57

2-24. Using information ......................................................................................................

(1) Observing the maintenance and inspection information .............................................................58

(2) Releasing procedure of the warning ...........................................................................................

(3) Observing the production control information .............................................................................

(4) Performing setting of the production control information ............................................................

(5) Observing the working measurement information ......................................................................

58

59

60

61

63

2-25. Using communication function ................................................................................ 65

(1) Handling possible data ...............................................................................................................65

(2) Performing communication by using the media ..........................................................................

(3) Performing communication by using RS-232C ...........................................................................

(4) Take-in of the data ......................................................................................................................

(5) Taking in plural data together

......................................................................................................67

66

66

66

2-26. Performing formatting of the media ........................................................................ 69

2-27. Operation at the time of X/Y motor position slip ....................................................

(1) When the error is displayed during sewing .................................................................................70

(2) When the error is displayed after end of sewing ........................................................................

(3) When the rest switch is not displayed ........................................................................................

70

71

71

2-28. USING 2-STEP STROKE FUNCTION ....................................................................... 72

(1) Setting of 2-step stroke function ................................................................................................. 72

(2) Setting of 2-step stroke position .................................................................................................

(3) Motion of 2-step stroke function .................................................................................................

72

74

3. MEMORY SWITCH DATA LIST ........................................................................................... 76

3-1. Data list ....................................................................................................................... 76

3-2. Initial value list ...........................................................................................................

82

ii

4. ERROR CODE LIST ............................................................................................................ 84

5. MESSAGE LIST .................................................................................................................. 91

#

. MAINTENANCE OF SAWING MACHINE ...........................................

1. MAINTENANCE .................................................................................................................. 94

1-1. Adjusting the height of the needle bar (Changing the length of the needle) ...... 94

1-2. Adjusting the needle-to-shuttle relation ..................................................................

1-3. Adjusting the timing of main shaft and hook driving shaft ..................................

1-4. Adjusting the height of the feeding frame ..............................................................

1-5. Adjusting the vertical stroke of the intermediate presser .....................................

1-6. The moving knife and counter knife ........................................................................

1-7. Needle thread clamp device .....................................................................................

1-8. Thread breakage detector plate ..............................................................................

1-9. Draining waste oil ......................................................................................................

1-10. Amount of oil supplied to the hook .........................................................................

1-11. Replacing the fuse .....................................................................................................

1-12. Changing the voltage of 100

1-13. Replenishing the designated places with grease .................................................

(1)

Replenishing the face plate section (felt, intermediate presser link, hinge screw) with grease

(2)

Replenishing the face plate section (needle bar, intermediate presser bar, guide bar) with grease

1-14. Troubles and corrective measures (Sewing conditions) ..................................... 103

2. OPTIONAL ........................................................................................................................

2-1. Table of Needle hole guide ..................................................................................... 105

2-2. Silicon oil tank ........................................................................................................

200V ................................................................... 100

,/

94

94

96

97

97

98

98

98

99

99

99

101

...102

.. 102

105

105

iii

!

. MEcHaNIcaL SEctIoN (WItH rEGarD to tHE SEWING MacHINE)

1. SPEcIFIcatIoNS

1 Sewing area X (lateral) direction

AMS-224E-4530 : 450 mm ×

AMS-224E-6030 : 600 mm × 300 mm

2 Max. sew

3 Settable st

Feed motion of feeding frame

4

5 Needle bar stroke 41.2 mm

6 Needle DP x 17

ift of feeding frame Max. 30mm

7 L

Intermediate presser stroke

8

ift of intermediate

9 L

presser

10 Intermed

DOWN position

variable

11 Shuttle Double-capac

12 Lubr

13 Memory of pattern

data

emporary stop facility Used to stop machine operation during a stitching cycle.

14 T

15 Enlarg

facility

16 Enlarg

method

Max. sewing speed

17

limitation

18 Pattern select

facility

19 Bobb

20 Sew

21 Memory back-up In

22 2nd or

facility

23 Sew

24

Dimensions AMS-224E-4530 :

25 Mass (gross mass) AMS-224E-4530 : 401 kg

26 Power consumpt

Operating temperature

27

range

28

Operating humidity range

ine voltage Rated voltage ±10% 50 / 60 Hz

29 L

ir pressure used AMS-224E-4530 : 0.5 to 0.55 MPa (Max. 0.55 MPa)

30 A

31 A

ir consumption 1.8 dm3 / min (ANR)

32 Needle h

position stop facility

33 No

ing speed 2,500 sti/min (When sewing pitch is 3 mm or less)

itch length 0.1 to 12.7 mm (Min. resolution : 0.05 mm)

Intermittent feed (2-shaft drive by stepping motor)

4 mm (Standard) (0 to 10 mm)

20 mm

iate presser

icating oil New Defrix Oil No. 2 (Supplied by oiler)

ing / Reducing

ing / Reducing

ion

in thread counter UP/DOWN method (0 to 9,999)

ing counter UP/DOWN method (0 to 9,999)

igin setting

ing machine motor Servo-motor

ion 550 VA

ighest

ise '- Equivalent continuous emission sound pressure level (LpA) at the workstation :

Standard 0 to 3.5 mm (Max. 0 to 7.0 mm)

ity semi-rotary hook

• Ma

in body : Max. 200 patterns (Max. 20,000 stitches/pattern)

• External media : Max. 999 patterns (Max. 50,000 stitches/pattern)

Allows a pattern to be enlarged or reduced on the X axis and Y axis independently

when sewing a pattern. Scale : 1% to 400% times (0.1% steps)

P

attern enlargement / reduction can be done by increasing / decreasing either stitch

length or the number of stitches. (Increasing/decreasing stitch length only can be

performed when pattern button is selected.)

200 to 2,500 sti/min (Scale : 100 sti/min steps)

Pattern No. selection method

case of a power interruption, the pattern being used will automatically be stored in

memory.

Using jog keys, a 2nd origin (needle position after a sewing cycle) can be set in the

desired position within the sewing area. The set 2nd origin is also stored in memory.

1,703mm (W) x 1,370mm (L) x 1,200mm (H)

AMS-224E-6030 :

AMS-224E-6030 : 410 kg

5˚C to 35˚C

35 % to 85 % (No dew condensation)

AMS-224E-6030 : 0.5 to 0.55 MPa (Max. 0.55 MPa)

After the completion of sewing, the needle can be brought up to its highest position.

A-weighted value of 83.5 dB ; (Includes K

-ISO 11204 GR2 at 2500 sti/min.

'- Sound power level (L

A-weighted value of 92.5 dB ; (Includes K

-ISO 11204 GR2 at 2500 sti/min.

1,923mm (W) x 1,370mm (L) x 1,200mm (H)

) :

WA

Y (longitudinal) direction

300 mm

(Excluding thread stand)

(Excluding thread stand)

= 2.5 dB) ; according to ISO 10821- C.6.3

pA

= 2.5 dB) ; according to ISO 10821- C.6.3

pA

– 1 –

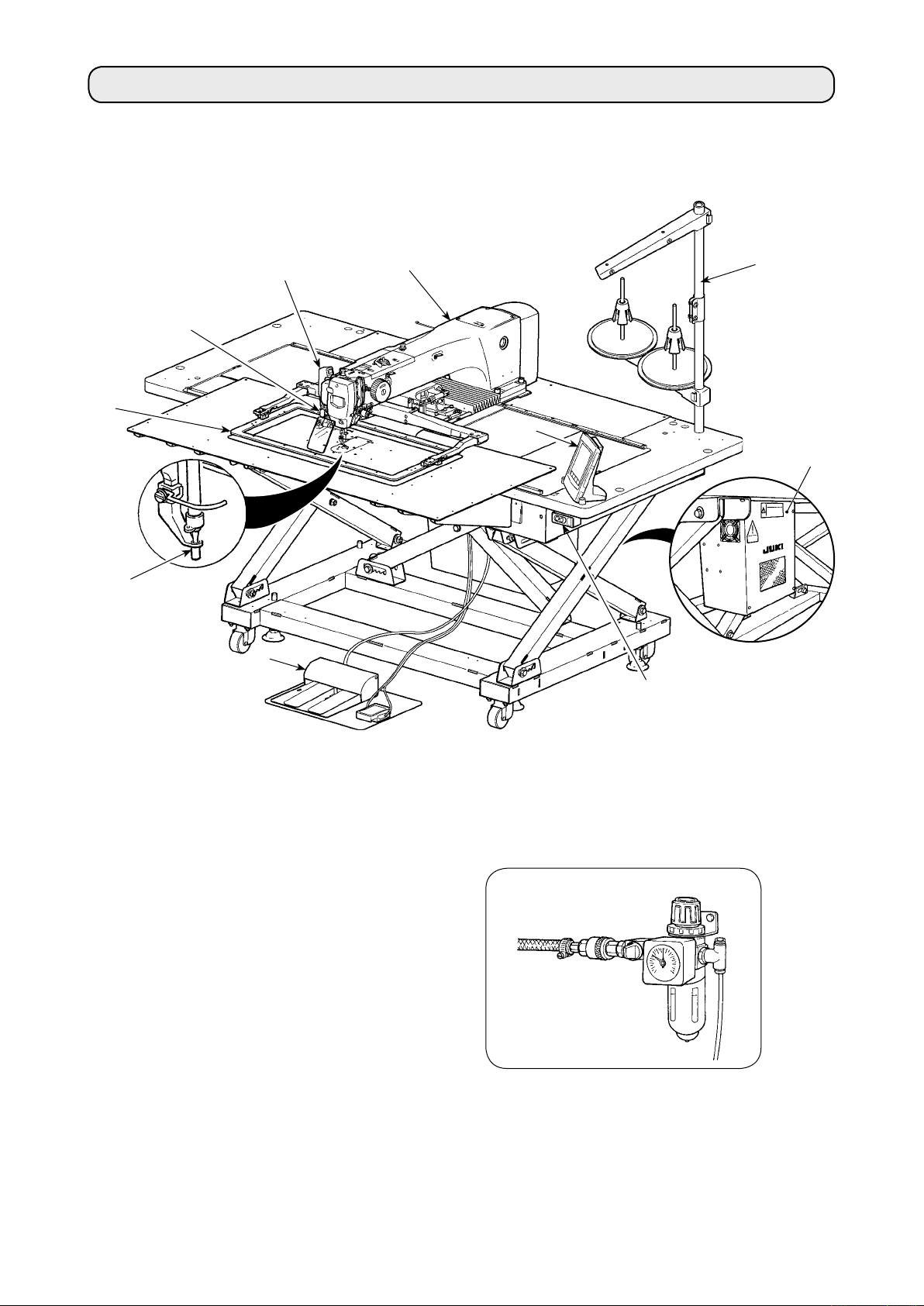

2. CONFIGURATION

4

5

3

!0

2

1

6

7

9

8

Machine head

1

Wiper switch

2

Temporary stop switch

3

Feeding frame

4

Intermediate presser

5

Thread stand

6

Operation panel (IP-410)

7

Power switch

8

Control box

9

Foot pedal

!0

Air regulator

– 2 –

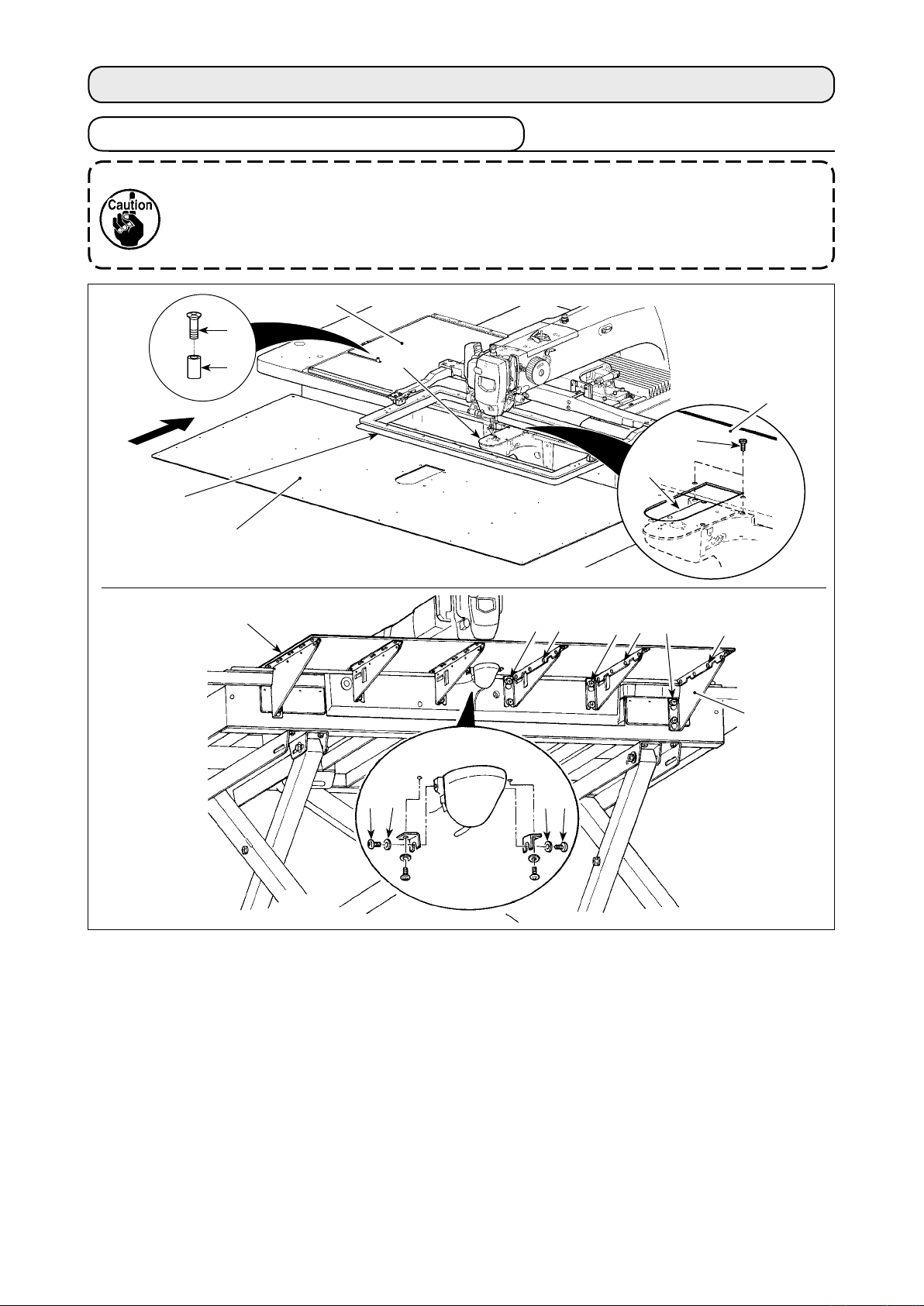

3. INSTALLATION

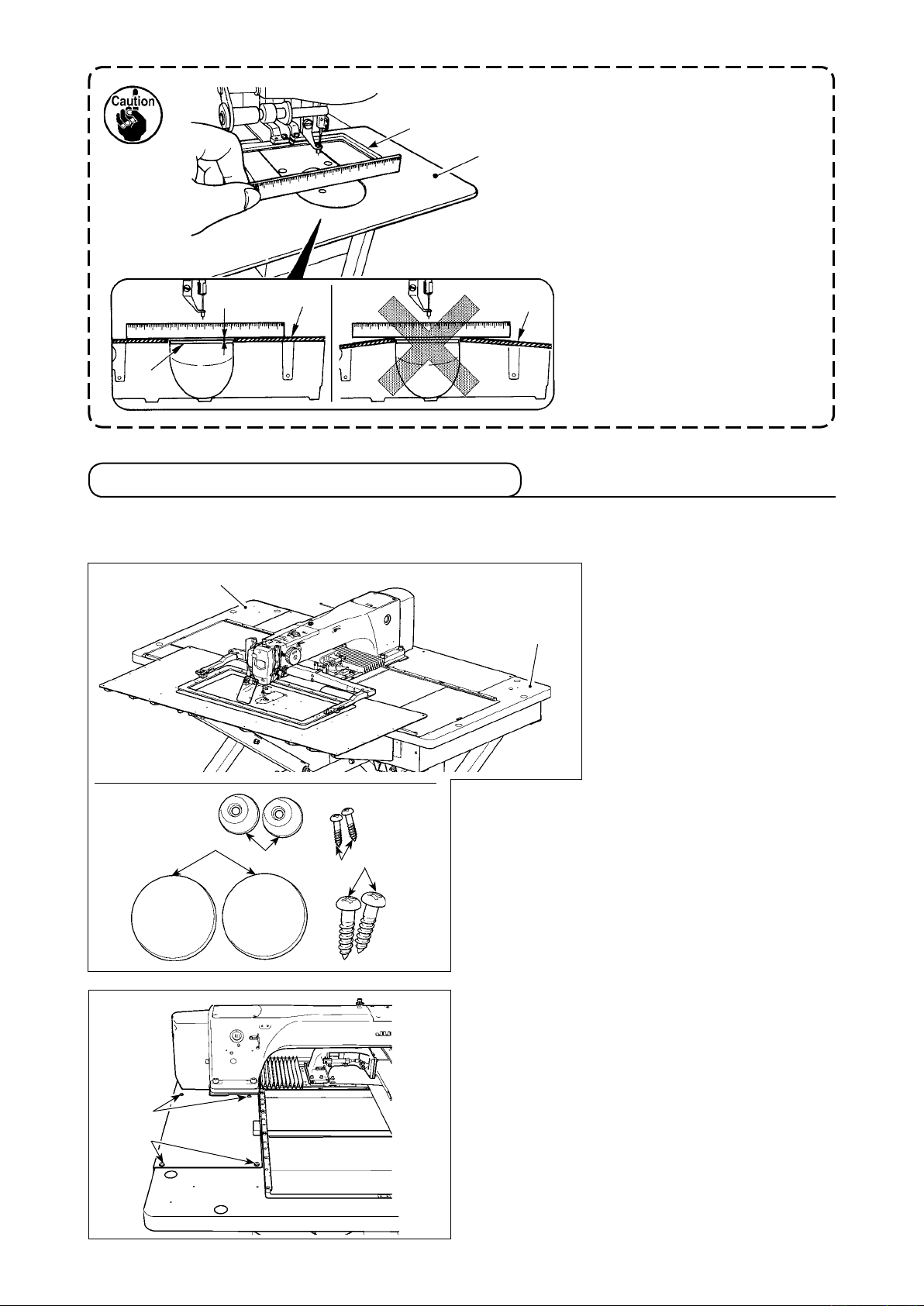

3-1. Installing the throat plate auxiliary cover

1. The throat plate auxiliary cover is very heavy and perform the installing work with two

persons or more.

2.Thestayandthelikearesettothethroatplateauxiliarycoverandthettingscrewsand

washers to the bed are packed together with the accessories at the time of delivery.

3. When using the cover sheet supplied as accessories, paste it to the throat plate auxiliary

cover before installing.

!0

!1

1

!2

3

3

2

3

8

2

7

9

45

4

5

7

9

7

9

6

1) Move the cloth feed base to the rear and place throat plate auxiliary cover (asm.) 3 from between

lower plate 1 and throat plate 2.

At this time, be careful not to bend lower plate

2) Temporarily x throat plate auxiliary cover (asm.)

.

1

with throat plate auxiliary cover support set

3

-

screws 5 and washers 4.

3) Temporarily x throat plate auxiliary cover support

4) Fix throat plate auxiliary cover (asm.)

5) Insert spacer

with setscrew

6) Securely tighten setscrews

Fix throat plate auxiliary cover setscrew 5.

7)

between cloth feed base cover

!2

.

!1

.

7

on the machine bed with two counter-sunk screws

3

to the machine bed with setscrews (M6)

6

and throat plate auxiliary cover (asm.)

!0

.

7

.

8

and x it

3

8) Referring to the caution below, perform positioning of the throat plate auxiliary cover. When the po-

sitioning is not performed enough, perform the positioning after loosening once throat plate auxiliary

cover setscrew

and throat plate auxiliary cover base setscrews

5

– 3 –

9

.

1. Fix the throat plate auxiliary

cover 3 so that is higher

2

Within 0.3 mm

3

1

3

2.Conrmbyputtingaruleror

3

than the throat plate 2 (within

0.3 mm). When it is lower

than the throat plate 2, needle breakage or the like due

to the defective feed will be

caused.

the like that the throat plate

auxiliary cover 3 is horizontally installed. If not, throat

plate auxiliary cover

lower plate

tact partially with each other,

and abnormal worn-out will

be caused.

come in con-

1

3

and

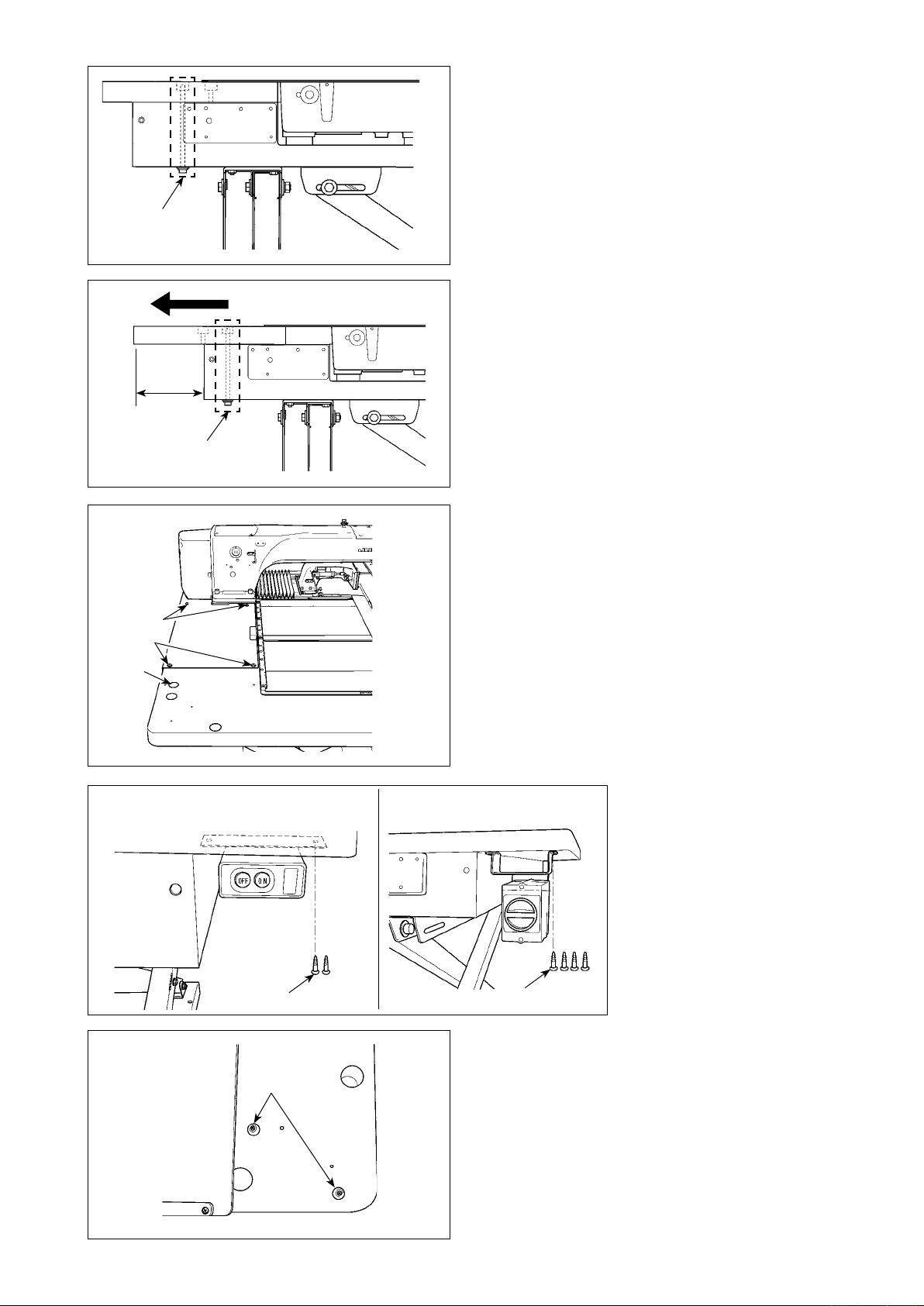

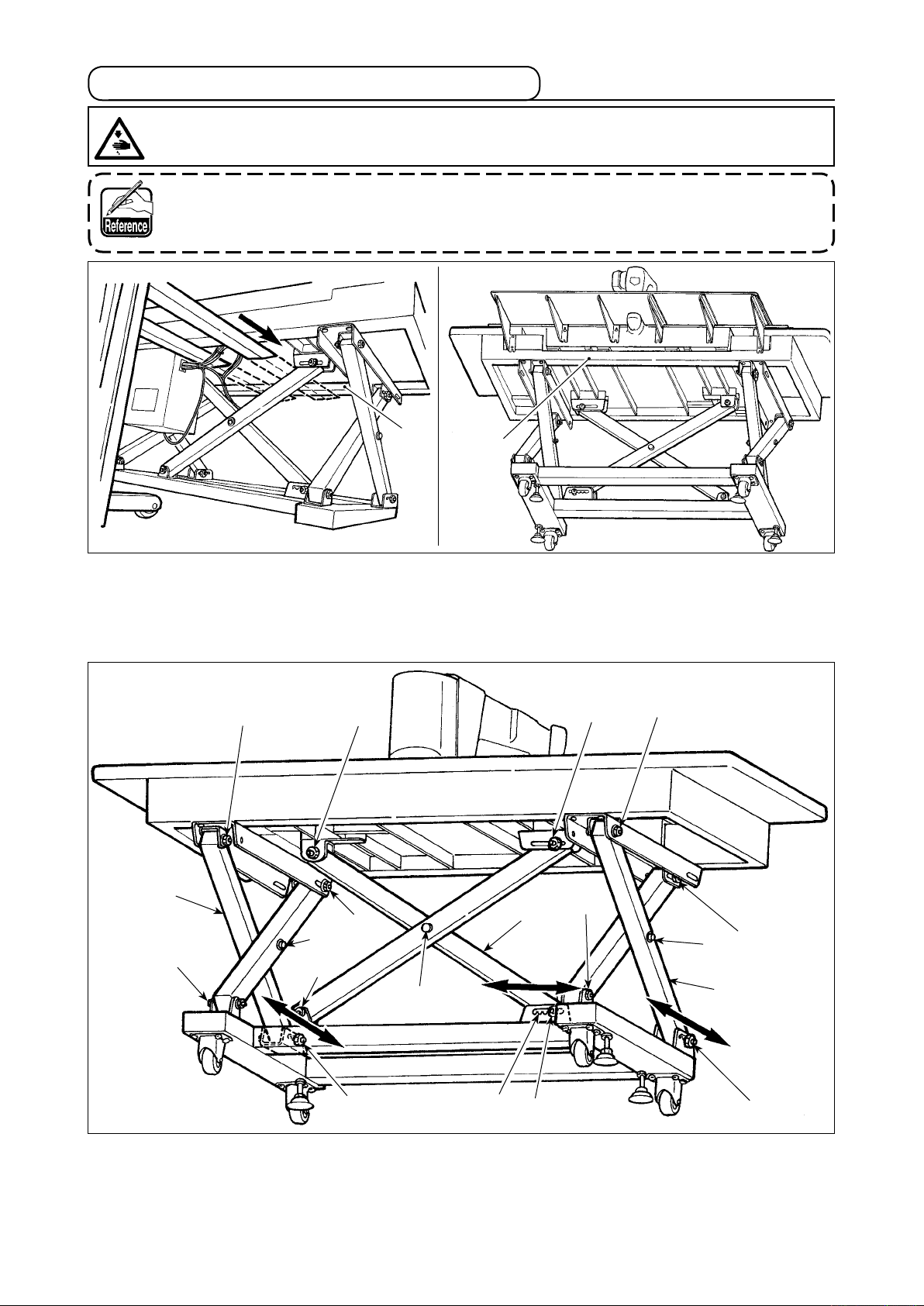

3-2. Table position adjustment: Only for 6030

For the 6030, the table has been retracted from the normal position in the factory in prior to shipment.

After unpacking, be sure to carry out the following steps 1) through 9).

L

Position adjustment for the

left table

is described as an

L

example. Adjust the position of

R

the right table R in the similar

manner.

[Accessories to be used]

: Table xing bolt cover

A

A

C

B

D

HX00326000B x 2

: Power switch setscrew

B

SK3512001SE x 2

(Four setscrews are used for the table of the

machine for JE.)

: Operation panel stopper

C

40072231 x 2

: Operation panel stopper setscrew

D

SK3271301SE x 2

2

1

1) Remove screws 1 and 2 to remove the cover.

* When removing screw 2, take care not to lose

the nut secured on the underside of the table.

– 4 –

3

175mm

1

2

A

3

2) Remove table xing bolts 3 which are mounted

at two locations of the table stand.

* The following steps 3) through 7) are the re-

assembly procedure of the table.

3) Shift the table to adjust so that it laterally pro-

trudes from the end of the table stand by 175

mm. For the longitudinal direction, also adjust so

that the table protrudes equally (approximately 3

mm on each side) from the end of table stand.

* If the table is not correctly positioned in the

longitudinal direction, the throat plate auxiliary

cover may not be removed.

4) Temporarily x table xing bolts 3 at two loca-

tions from the table stand side.

5) Tighten screws 1 and 2 to mount the cover.

* If the cover and tapped hole do not align, align them

by moving the table.

* Tighten screw 2 after mounting the nut from the

underside of the table.

6) Securely tighten the table xing bolts at two

locations from the table stand side. (For refer-

ence: Tightening torque: 6 N•m)

7) After mounting the cover, attach the table xing

bolt cover (accessory

) in position.

A

Power switch for the domestic market

and general export

B

C, D

Power switch for JE

B

9) Secure the operation panel stoppers (accessory

) in the punched locations at near side of the

C

right table using wood screws (accessory

8) Secure the power switch

in the punched location

at the lower right part

of the table using wood

screws (accessory B).

).

D

– 5 –

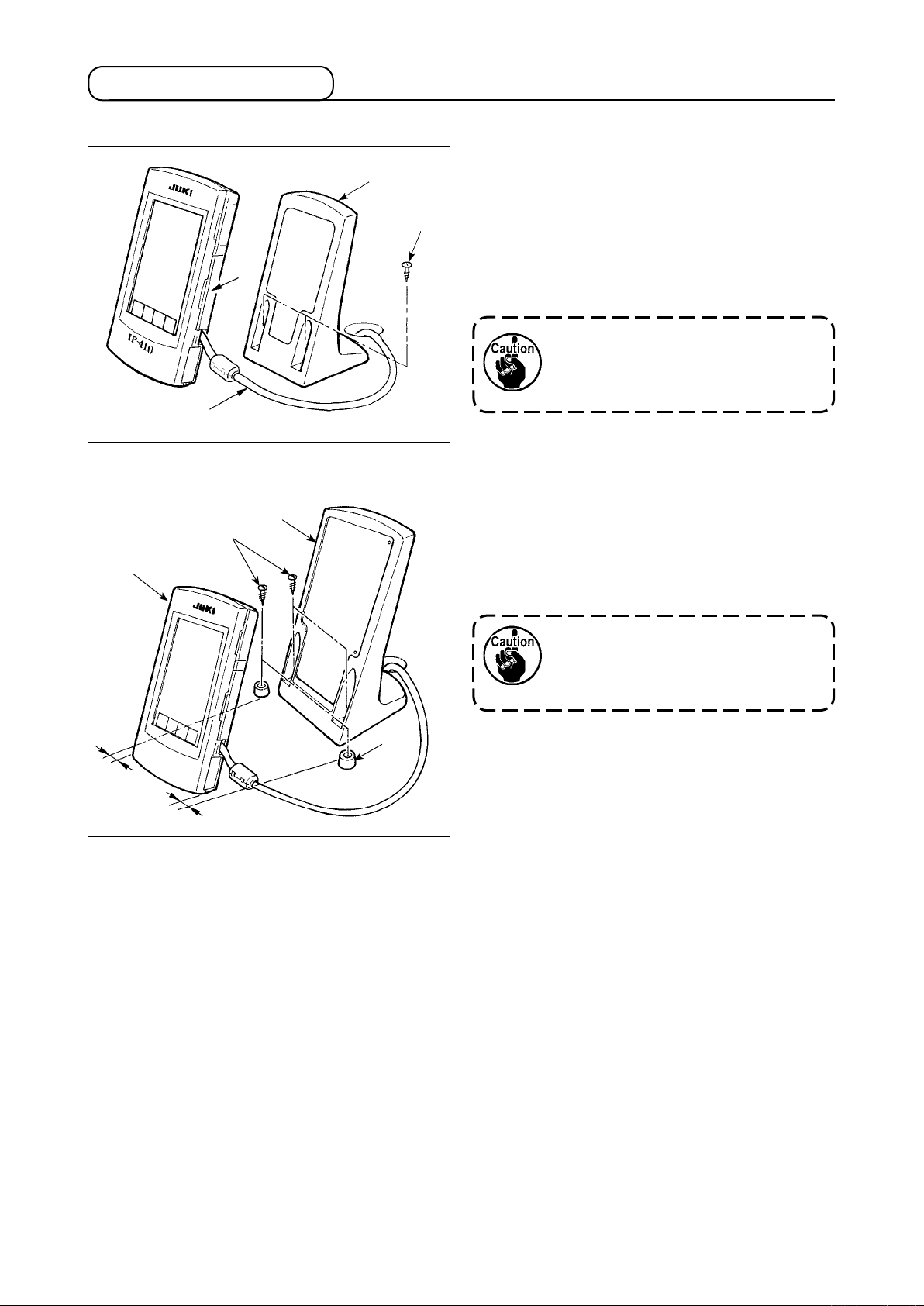

3-3. Installing the panel

1) Installing the IP-410

1

2

2) Installing the IP-410 guide

1

4

2

3

4

1) Open cover 1 and remove cable 2 once.

Then connect it again to the panel on the top

surface of the table after passing it through the

hole in the table.

2) Fix operation panel installing plate 3 to an op-

tional place on the table with two wood screws

.

4

Install the panel at the position where

X-move cover or head grip does not

interfere with it since breakage of the

panel will be caused.

1) Install IP-410 2 almost in the center of opera-

tion box installing plate 1.

2) Take a clearance of approximate 5 mm on both

ends of right and left sides of IP-410 2 and x

IP-410 guide 3 with two screws 4.

5 mm

Do not place the position of the guide

under the panel and install the guide at

the proper position since the breakage

of the panel will be caused.

3

5 mm

– 6 –

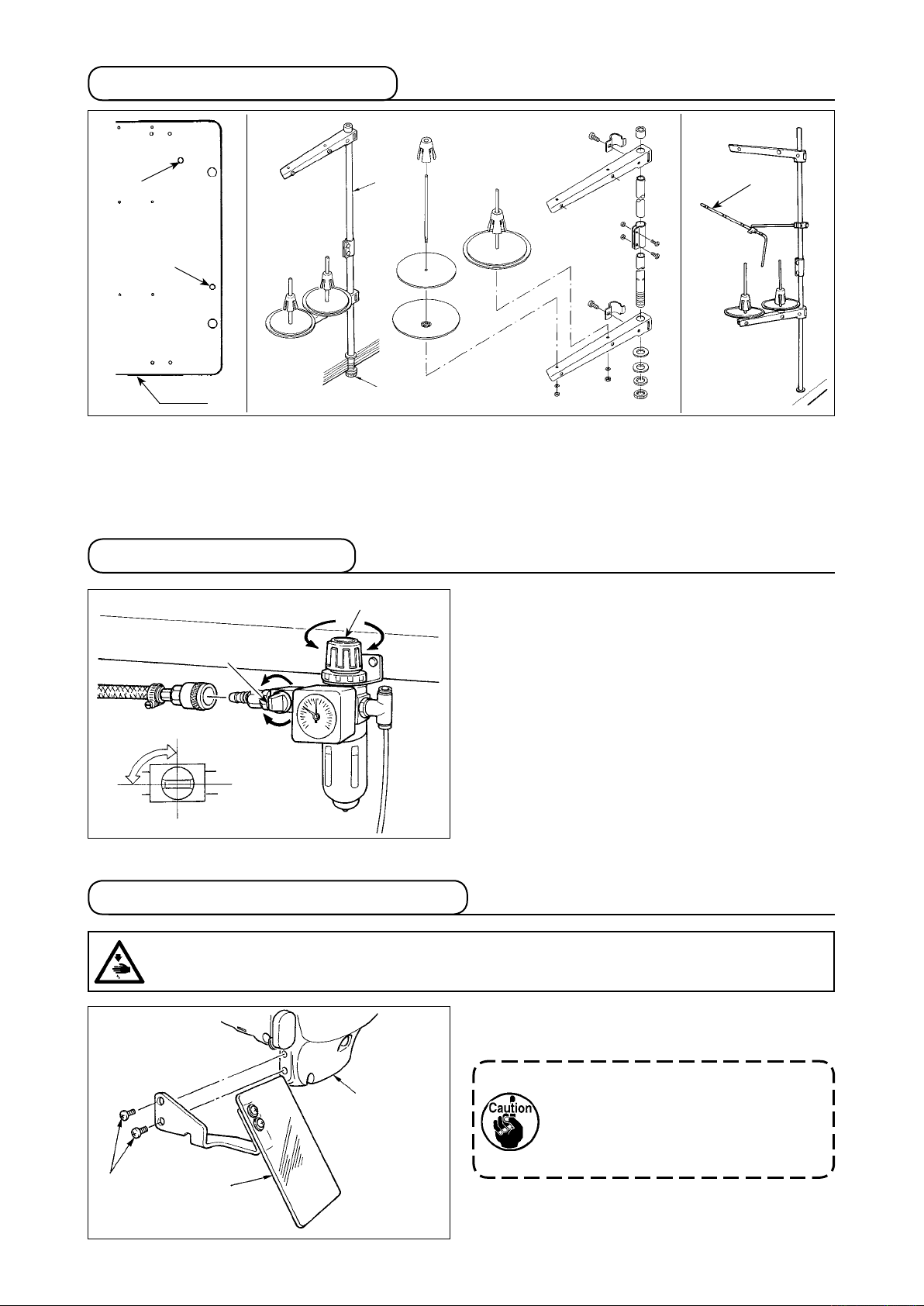

3-4. Installing the thread stand

A

B

Table

1) Assemble the thread stand. Then, put it in thread-stand mounting hole A or

2) Tighten locknut

3) When ceiling wiring is possible, pass the power cord through spool rest rod 2.

4) If thread sags, use thread stand guide arm (asm.) 3.

to x the thread stand.

1

2

1

B

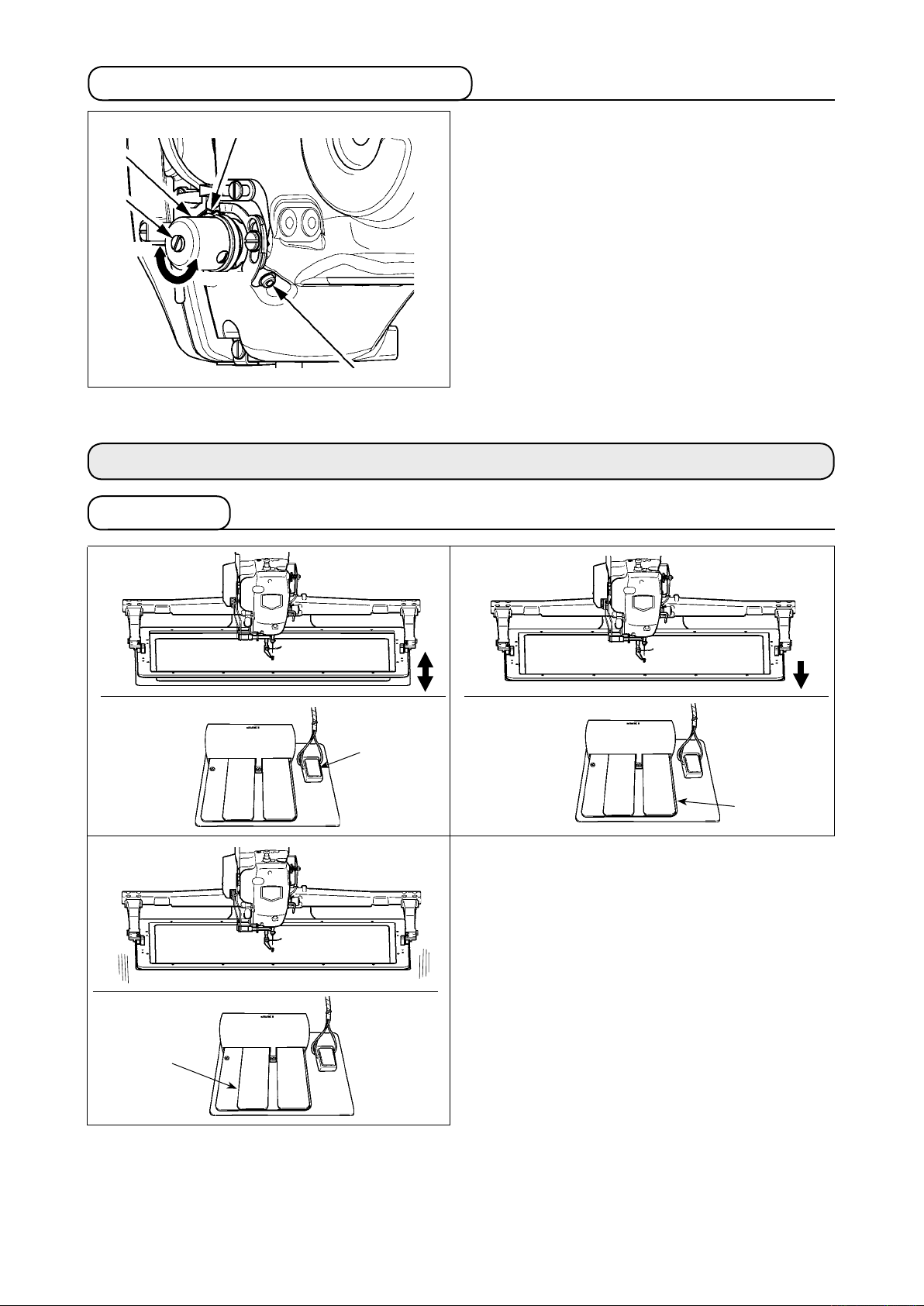

3-5. Installing the air hose

1

2

Close

Open

1) Connecting the air hose

Connect the air hose to the regulator .

2) Adjustment of air pressure

Open air cock 1, pull up and turn air adjust-

ment knob 2 and adjust so that air pressure

indicates 0.5 to 0.55 MPa (Max. 0.55 MPa).

Then lower the knob and x it.

* Close air cock 1 to expel air.

3

in the machine table.

3-6. Installing the eye protection cover

WARNING :

Be sure to attach this cover to protect the eyes from the disperse of needle breakage.

3

2

1

⇧

Use eye protection cover 1 after securely attach-

ing it on face plate cover

To prevent interference with the feed-

ing frame, be sure to install the thread

stand guide arm (asm.) with the eye

protection cover pressed in the direc-

tion of the arrow.

– 7 –

with screw

3

2

.

3-7. Changing the height of the table and stand

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

Theheightofthetable(measuredfromtheoortothetable)isadjustabletosixdifferentheights.

870mm 2 897mm 3 922mm 4 945mm 5 967mm 6 988mm

1

It has been factory-adjusted to 2 at the time of delivery.

A

1) Insert the claw of forklift up to the transverse beam

A

in front of the upper stand from the position as

A

shown in the gure in the rear of the sewing machine.

2) Lift the claw of the forklift up to the position where the claw of forklift comes in contact with the bot

tom surface of the upper stand and the upper stand does not fall.

* Take care not to allow the forklift claw to crush the cable.

!2

7

6

2

-

!8

!1

!5

!4

!0

8

!3

Regulating grooves

3) Loosen bolts of 1 through !5.

4) Lift the claw of forklift, release bolts of

and

in the directions of both arrow marks, and lower the claw of forklift at the positions where the

!8

3, 9

respective groove positions meet with one another.

At this time, make sure that bolts of

5) Securely tighten bolts of

through

1

and

3, 9

with tightening torque of 45 ± 2 N•m.

!5

!7

9

and

from the regulating grooves, move stands

!3

have been securely set in the grooves.

!3

– 8 –

4

5

!6

1

3

!6, !7

4. PREPARATION OF THE SEWING MACHINE

4-1. Lubrication

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

A

B

A

B

1

1) Check that the place between lower line B and upper l

ine A is

lled with oil. Fill there with oil using the oiler supplied with the

mach

ine as accessories when oil is short.

The oil tank to lubricate is for lubricating to the hook portion and the gear box portion.

For the hook portion, the oil amount can be decreased when the number of revolutions used is

low and the oil amount is large. (

1. Do not lubricate to the places other than the oil tank and the hook of Caution 2 below.

Trouble of components will be caused.

2. Whenusingthesewingmachineforthersttimeorafteranextendedperiodofdisuse,

use the machine after lubricating a small amount of oil to the hook portion. (For removing

#

-1-2. A

3.

the shuttle, see “

Do not put your foot or climb on the sewing machine table or table stand during lubrica-

tion.

Refer to “

djusting the needle-to-shuttle relation” p.94

#

-1-10. A

mount of oil supplied to the hook” p.99

2) Apply one drop of oil to the

hook race 1 part to spread

on

it.

.)

.)

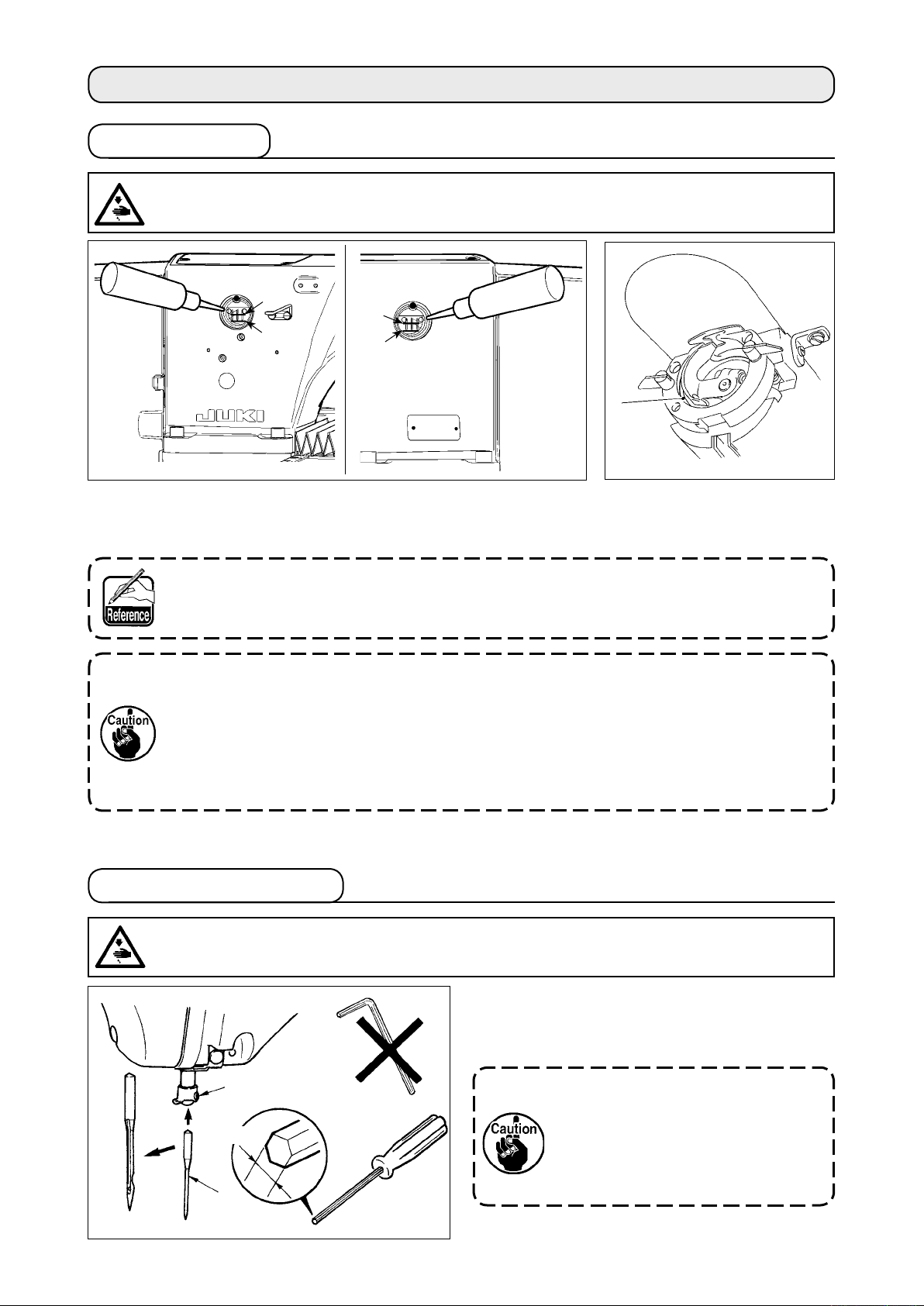

4-2. Attaching the needle

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

1

1.5 mm

2

Loosen setscrew 1 and hold needle 2

with the long

groove facing toward you. Then fully insert it into the

hole in the needle bar, and tighten setscrew 1.

When tightening setscrew 1, be sure

to use the screwdriver (Part No. :

40032763) supplied as accessories.

Do not use L-shaped hexagon wrench

key. There is a danger of breaking set-

screw 1.

– 9 –

4-3. Threading the machine head

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

※

Threading of L-type th read

※

guide in case of large return

of twist.

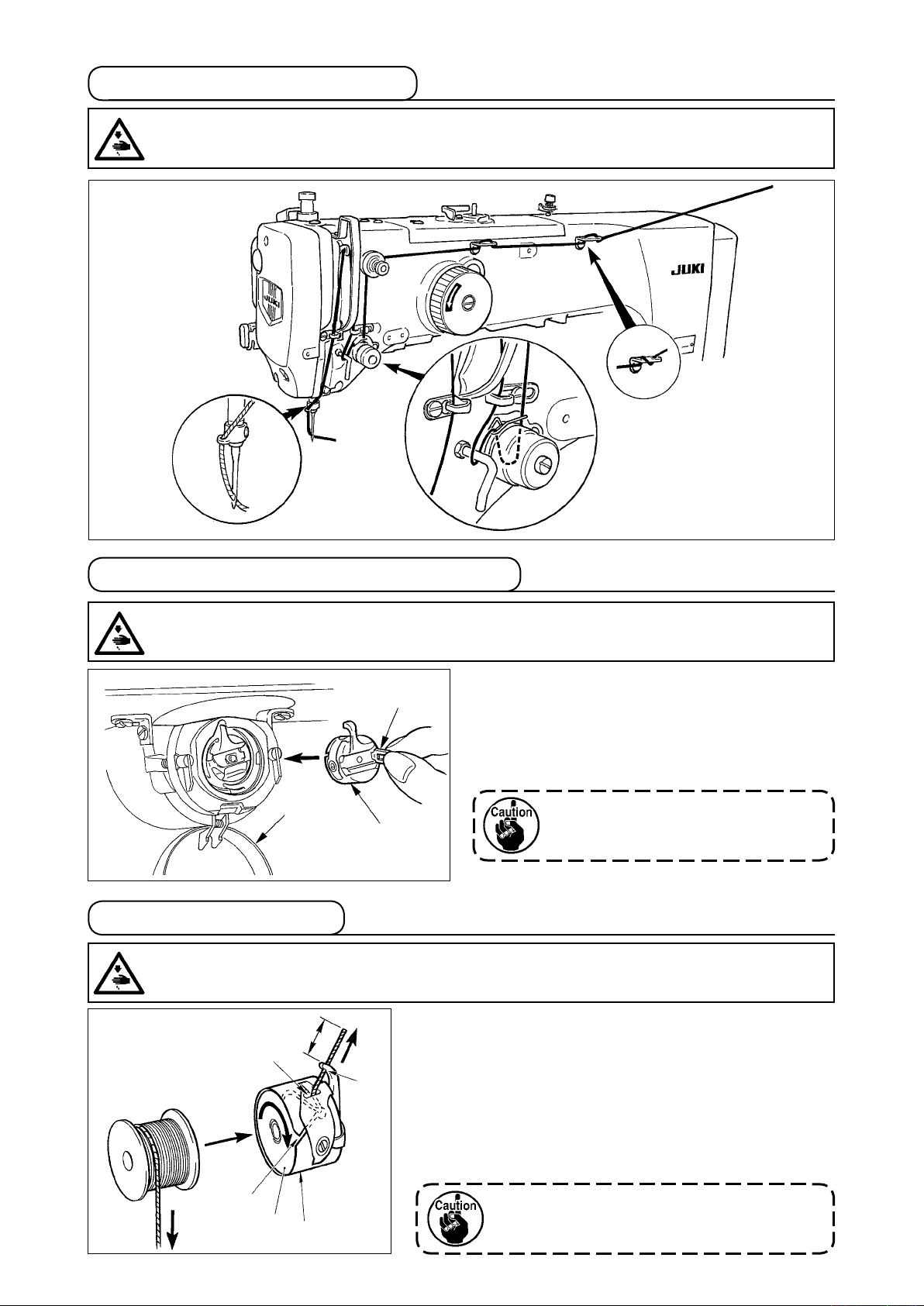

4-4. Installing and removing the bobbin case

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

1) Open hook cover 1.

3

2) Raise latch

3) When entering bobbin case, insert it with the

1

2

4-5. Installing the bobbin

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of

the sewing machine.

2.5 cm

4

5

1) Set the bobbin

shown in the gure.

2) Pass the thread through thread slit

and pull the thread as it is. By so doing, the thread will

pass under the tension spring and be pulled out from

thread hole 4.

3) Pass the thread through thread hole

and pull out the thread by 2.5 cm from the thread hole.

of bobbin case

3

the bobbin case.

latch tilted until "click" sounds.

If it is not fully inserted, bobbin case

may slip off during sewing.

2

into bobbin case 2 in the direction

1

3

5

, and remove

2

of bobbin case

2

of the horn section,

,

3

1

2

If the bobbin is installed in the bobbin case orienting the reverse direction, the bobbin thread

pulling out will result in an inconsistent state.

– 10 –

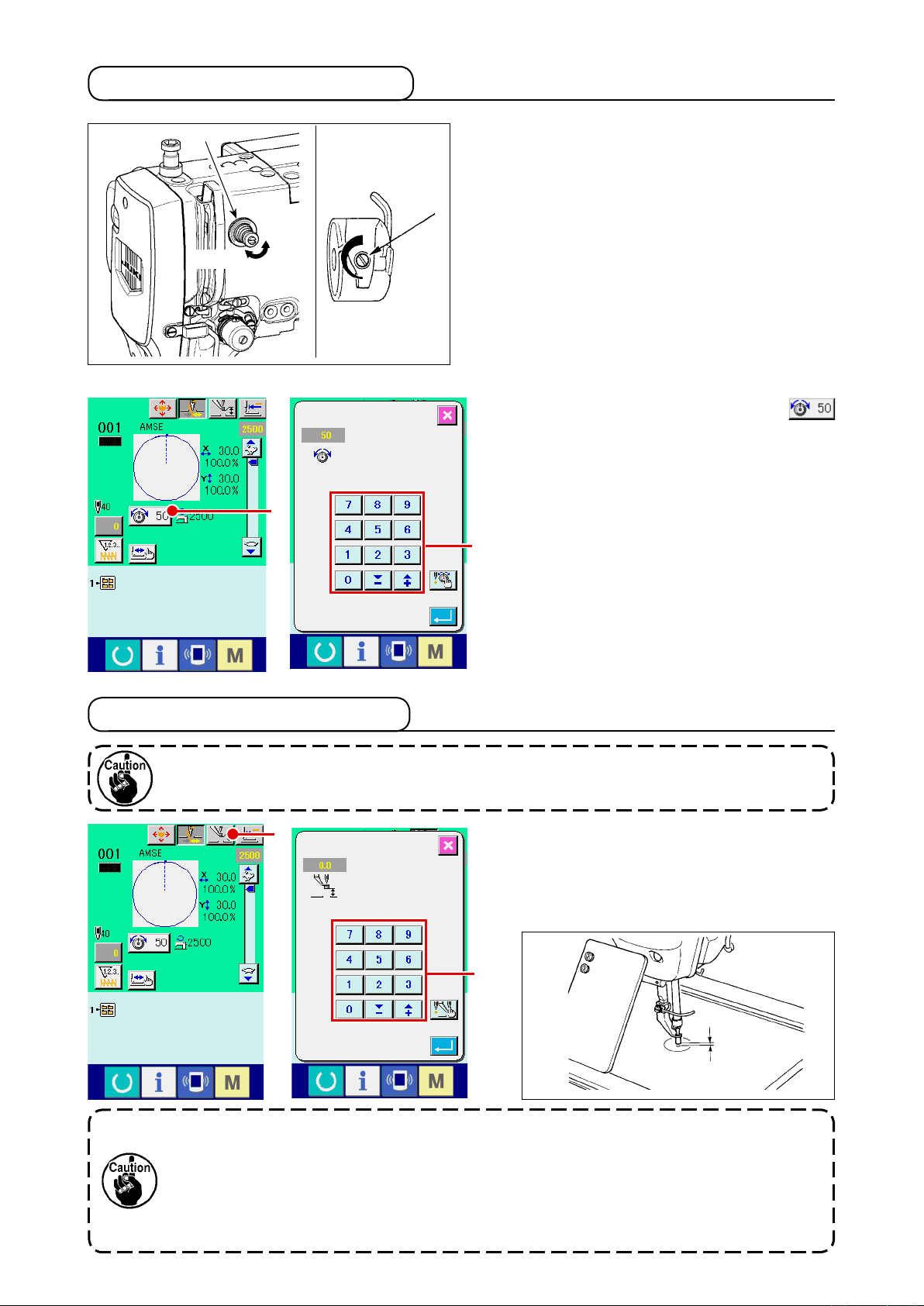

4-6. Adjusting the thread tension

1

Longer

Shorter

[Adjusting the needle thread tension]

A

If thread tension controller No. 1 1 is turned

clockwise, the length of remaining thread on the

needle after thread trimming will be shorter. If it is

turned counterclockwise, the length will be longer.

2

Shorten the length to an extent that the thread is

not slipped off.

Adjust needle thread tension from the operation

panel and bobbin thread tension with 2.

1) Select THREAD TENSION button

in the sewing screen.

A

2) Set needle thread tension with TEN

keys B. There is a setting range of 0 to

200. When the set value is increased,

B

the tension becomes higher.

* When the set value is 50 at the time of

standard delivery, the thread tension is

adjusted to 2.35N (spun thread #50).

(When thread tension No. 1 is released)

4-7. Intermediate presser height

When raising the intermediate presser height, turn the pulley by hand to lower the needle bar,

andconrmthattheneedlebardoesnotinterferewiththeintermediatepresser.

A

1. Setting range of the intermediate presser is up to the standard of 3.5 mm.

However, the setting range can be changed up to max. 7 mm with memory switch U112.

2. When increasing the height of intermediate presser or making the needle size thicker, con-

rmtheclearancebetweenthewiperandthecomponents.Wipercannotbeusedunless

the clearance is secured. Turn OFF the wiper switch. Besides, note that the wiper is set so

as to sweep at the position where the intermediate presser is in the lowest position in spite

of the setting of intermediate presser height at the time of delivery. (Memory switch U105)

Press INTERMEDIATE PRESSER SETTING button

so that the clearance between the bot-

B

and adjust with TEN keys

A

tom end of intermediate presser and the

cloth is 0.5 mm (thickness of thread used).

B

0.5 mm

– 11 –

4-8. Adjusting the thread take-up spring

1

3

Loosen setscrew 2, and turn thread tension asm. 3.

Turning it clockwise will increase the moving

amount and the thread drawing amount will

1) Adjusting the stroke

4

increase.

2) Adjusting the pressure

Increase

Decrease

To change the pressure of the thread take-

up spring

slot of thread tension post

tightened, and turn it. Turning it clockwise will

increase the pressure of the thread take-up

spring. Turning it counterclockwise will de

2

crease the pressure.

5. OPERATION OF THE SEWING MACHINE

5-1. Sewing

1) 2)

, insert a thin screwdriver into the

1

while screw 2 is

4

-

3)

C

[For the 2-step stroke pedal (PK47)]

* Refer to

@

"

-2-28. USING 2-STEP STROKE FUNCTION" p.72

A

B

[In case of the mechanical valve pedal]

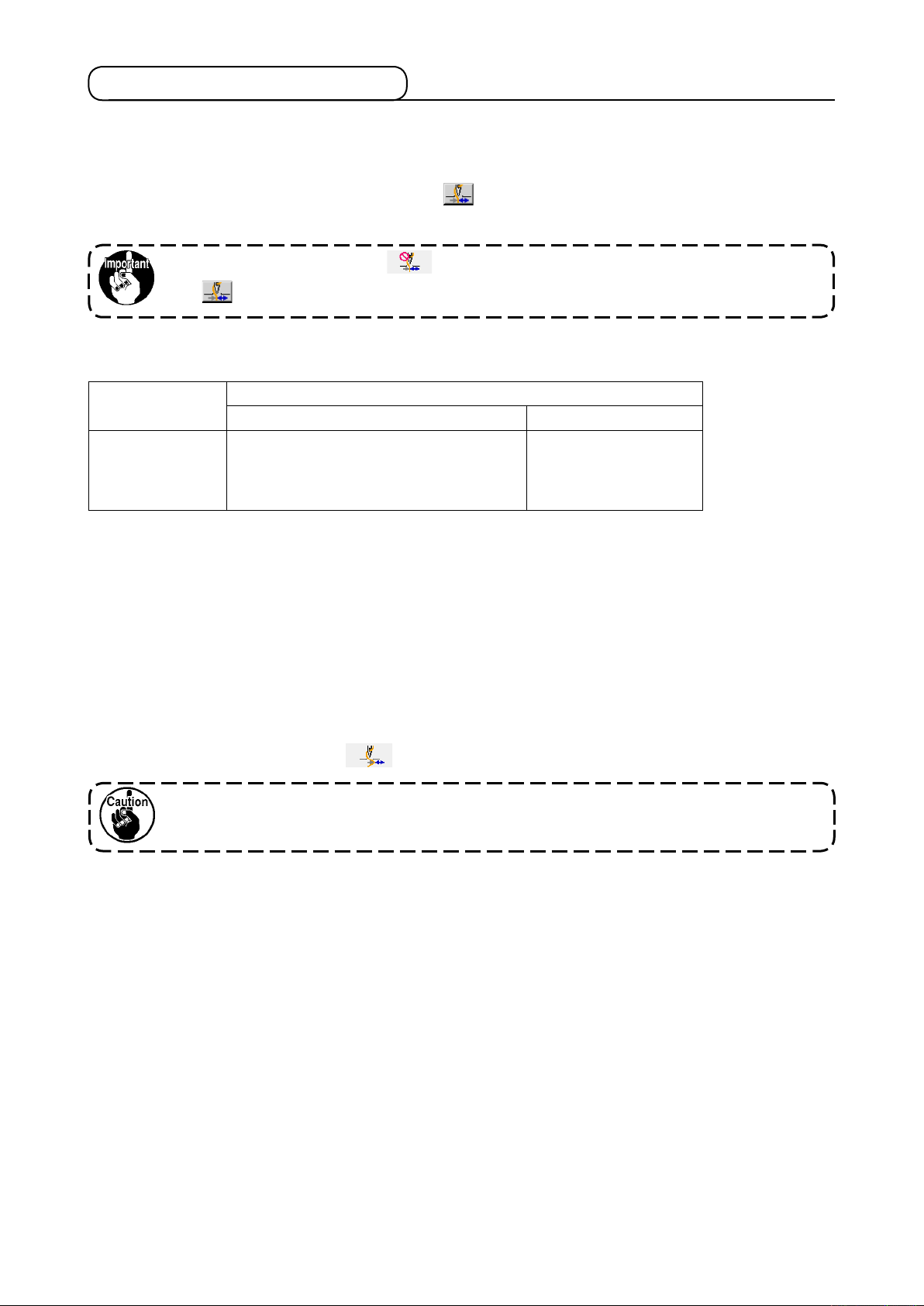

1) Set a workpiece under the feeding frame and

depress pedal

of the pedal switch. Then the

A

feeding frame comes down.

When the foot is detached, the feeding frame

returns to its home position.

The lowering speed of the feeding frame

changes according to the depressing amount.

This is used when positioning the parts.

2) When positioning the workpiece and depress

ing pedal

, the feeding frame comes down to

B

the bottom and holds the workpiece.

3) Depress pedal

when the feeding frame

C

comes down to the bottom and sewing starts.

.

-

– 12 –

5-2. Needle thread clamp device

By actuating the needle thread clamp device, trouble of sewing at the high-speed start (needle thread

slip-off, stitch skipping or needle thread stain) is prevented, and can reduce gathering (bird's nest) of

needle thread on the wrong side of cloth while keeping stable sewing. When mounting the IP-410,

changeover of motion ON/OFF is performed with

key.

When the needle thread clamp device is OFF, the machine automatically operates at slow-start.

When memory switch No. 35 is : prohibited, the thread clamp does not work. In addi-

tion, key is ineffective.

* Matters that demand special attention when using the needle thread clamp device

Refer to the list below for the contents of memory switches where the thread clamp unit can be set.

Sewing machine

type

AMS-224EHS 0 : Extra thin thread type

1 : Thin thread (standard) (#50 to #8)

2 : Intermediate (#20 to #5)

3 : Thick thread (#5 to #2)

U69 U70

Memory switch

Front (standard) or

Rear

[Regarding thread clamp unit]

Change the set value of memory switch U69 according to the thickness of needle thread. The value has

been set to 1 : Thin thread at the time of delivery.

Commendable value is Set value : 1 for thread count #50 to #8, Set value : 2 for thread count #20 to

#5, and Set value : 3 for thread count #5 to #2. (The value will change in accordance with the kind and

thickness of the actual thread and the kinds of materials to be sewn. Set the value by adjusting to the

state of needle thread on the wrong side of materials.) In addition, it is possible to select the thread

clamp position by means of memory switch U70. If the sewing material is tucked in or set in at the be

-

ginning of sewing in case of using thicker thread such as yarn count #5 to #2 or in any other occasion,

select rear position of thread clamp

Use the set value of the memory switch which is adjusted to the thread clamp unit type.

When the setting is wrong, the thread clamp fails to properly function. So, be careful.

by means of Memory switch U70.

– 13 –

(1) When with thread clamp (motion), use the sewing machine after adjusting the needle thread length

at the start of sewing to 40 to 50 mm. When the needle thread length is too long, the needle thread

end held with the needle thread clamp may be rolled in the seams.

1)

1) In case of with the needle thread clamp, the

standard of the length of needle thread is 40 to

50 mm.

40 to 50 mm

2) When needle thread is long after replac

ing thread or the like or sewing while holding

needle thread by hand, turn OFF the THREAD

CLAMP key .

3)

3) When needle thread held with the needle

thread clamp is rolled in the seams, when error

has occurred, or when needle thread is held

entangled with the needle thread clamp, do

not forcibly draw the cloth, but cut the con

nected needle thread with scissors or the like.

The seams cannot be broken because of the

needle thread at the start of sewing.

When needle thread is excessively long at the time of using the thick thread, the end of nee-

dle thread held with the needle thread clamp is rolled in the seams, and slip of position of

material may occur or needle breakage may be caused.

(2) When the thread clamp is used, and bobbin thread at the sewing start appears on the right side of

material, reduce thread tension at the sewing start (2 to 3 stitches) and bobbin thread becomes less

conspicuous.

[Example of setting]

Tension of 1 to 2 stitches at the sewing start is “20” when sewing tension setting is “35”.

* For setting of tension at the start of sewing, see of

1. Thread at the start of sewing may be rolled in case of some patterns. When thread is rolled

in even after performing adjustment of (1) or (2), use the sewing machine with thread

clamp OFF.

2. Thread clamp failure may occur in the state that thread waste is jammed in the thread

clamp device. Remove the thread waste referring to

"#-1-7. Needle thread clamp device" p.98.

@

"

-2-8.(1) Changing the thread tension value" p.30

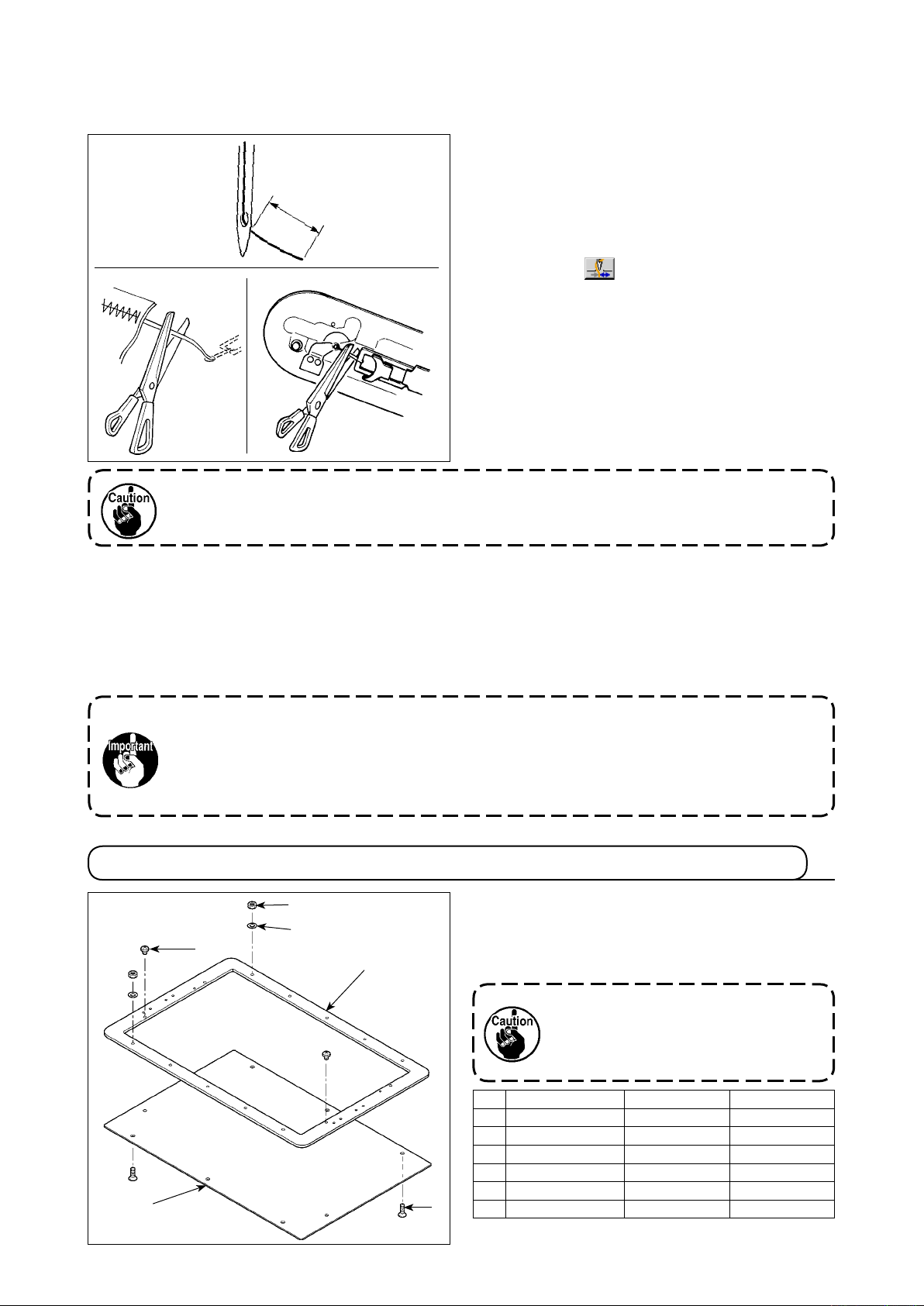

5-3. How to use the plastic blank (supplied with the machine as an accessory)

5

4

6

2

1) Machine the plastic blank supplied with the

machine according to the stitching shape.

2) Attach the plastic blank to the feeding frame as

illustrated in the gure.

Use a sponge sheet or rubber sheet

supplied with the machine in combina-

tion with the plastic blank, if neces-

sary.

.

1

3

– 14 –

4530 6030

Plastic blank 40072147 40074148

1

Feeding frame

2

Setscrew SM1041401SC SM1041401SC

3

Washer WP0430801SC WP0430801SC

4

Nut NM6040001SC NM6040001SC

5

Positioning screw

6

40072138 40072139

SM4040501SN SM4040501SN

@

.

OPERATION SECTION (WITH REGARD TO THE PANEL)

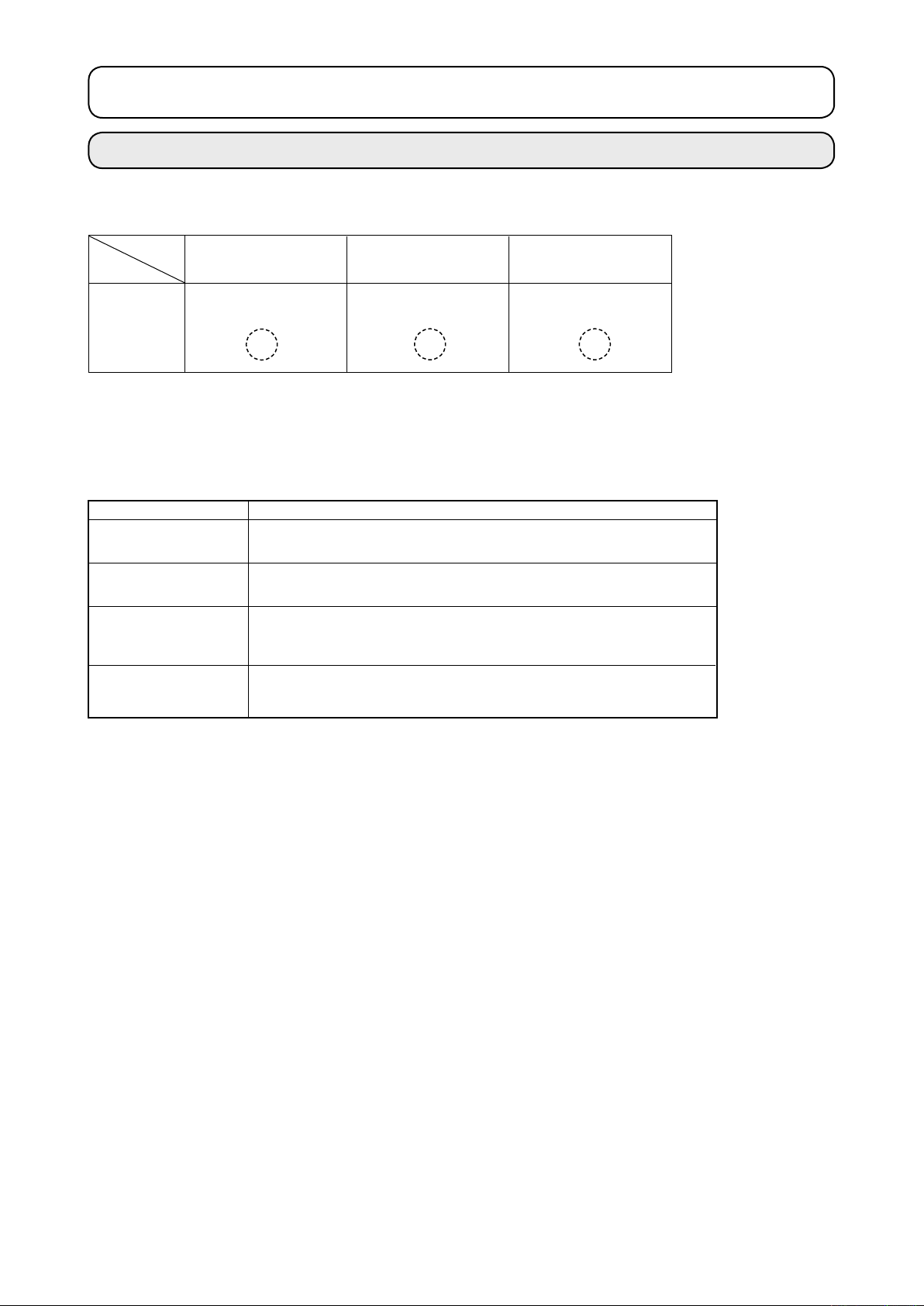

1. PREFACE

* Three kinds of service patterns are contained in the media of the accessories.

Area

Kind

4530

6030

H Type, G Type

(Vinyl leather)

ø 60 Pitch 3.6mm

Pattern No. 101

H Type, G Type

(Denim)

ø 60 Pitch 3 mm

Pattern No. 102

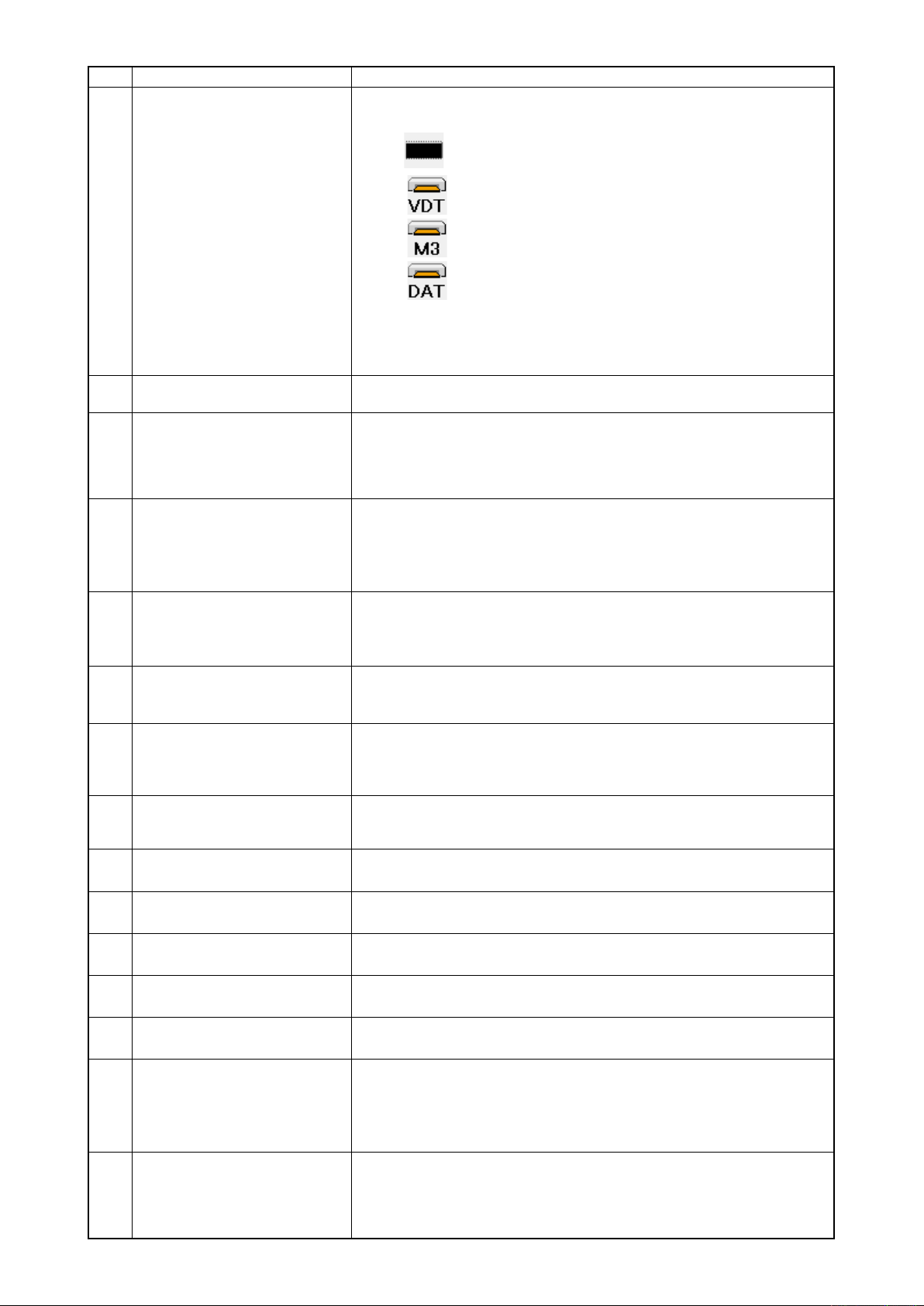

1) Kind of sewing data handled with IP-410

Sewing data that each panel handles are as shown below.

Pattern name

Users' pattern

Vector format data

M3 data

Sewing standard

format

Pattern that can be stored in the body.

Max. 200 patterns can be registered.

File that extension is ".VDT"

Read from media. Max. 999 patterns can be used.

Pattern data of AMS-D series

Used by copying from oppy disk of AMS-D series to media.

Max. 999 patterns can be used.

File that extension is ".DAT"

Read from media. Max. 999 patterns can be used.

Description

H Type, G Type

ø 60 Pitch 2.5 mm

Pattern No. 103

2) Using the data (M3 data) of AMS-D series with AMS-224E

There are two ways to use M3 data with AMS-224E.

Reading by using IP-410

1

Use PC (personal computer) and copy le (¥AMS¥AMS00xxx.M3) of M3 from oppy disk of AMS-D

to ¥AMS of media. Insert the media to IP-410, and select Pattern No.xxx from M3 data.

Changing to vector format data using PM-1

2

Change to the vector format data with PM-1. (For the details, refer to Help of PM-1.)

Copy the changed vector format data to ¥VDATA folder of the media.

Insert the media to IP-410 and select Pattern No.

– 15 –

– 16 –

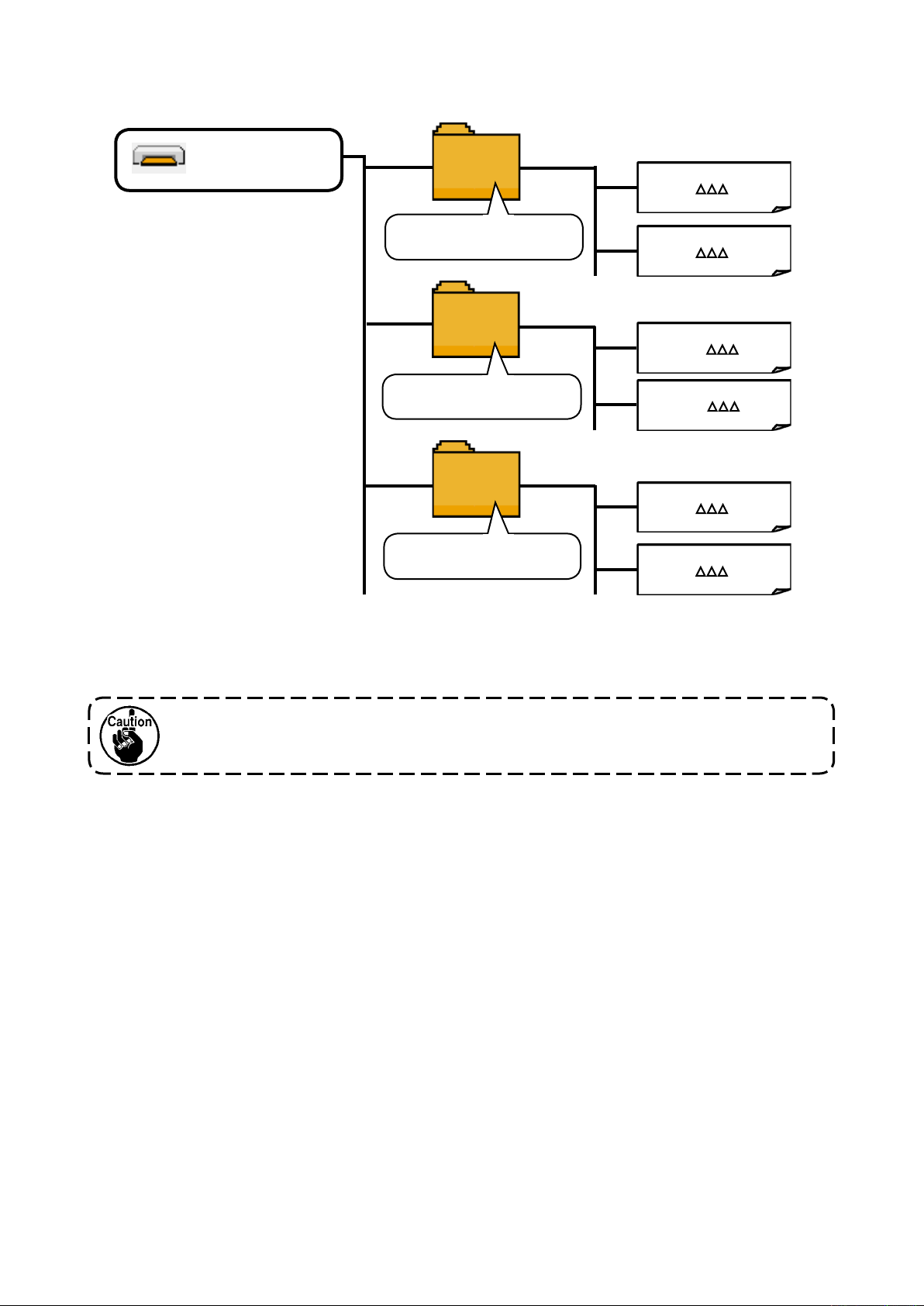

3) Folder structure of the media

Store each le in the folders below of the media.

Media drive

VDATA

Store vector format data.

AMS

Store M3 data.

SDATA

Store sewing standard data.

VD00 . VDT

VD00 . VDT

AMS00

AMS00

SD00 . DAT

SD00 . DAT

. M3

. M3

Vector format data : Store in ¥VDATA.

M3 data : Store in ¥AMS.

Sewing standard format : Store in ¥SDATA.

Data that are not stored in the folders above cannot be read. So, be careful.

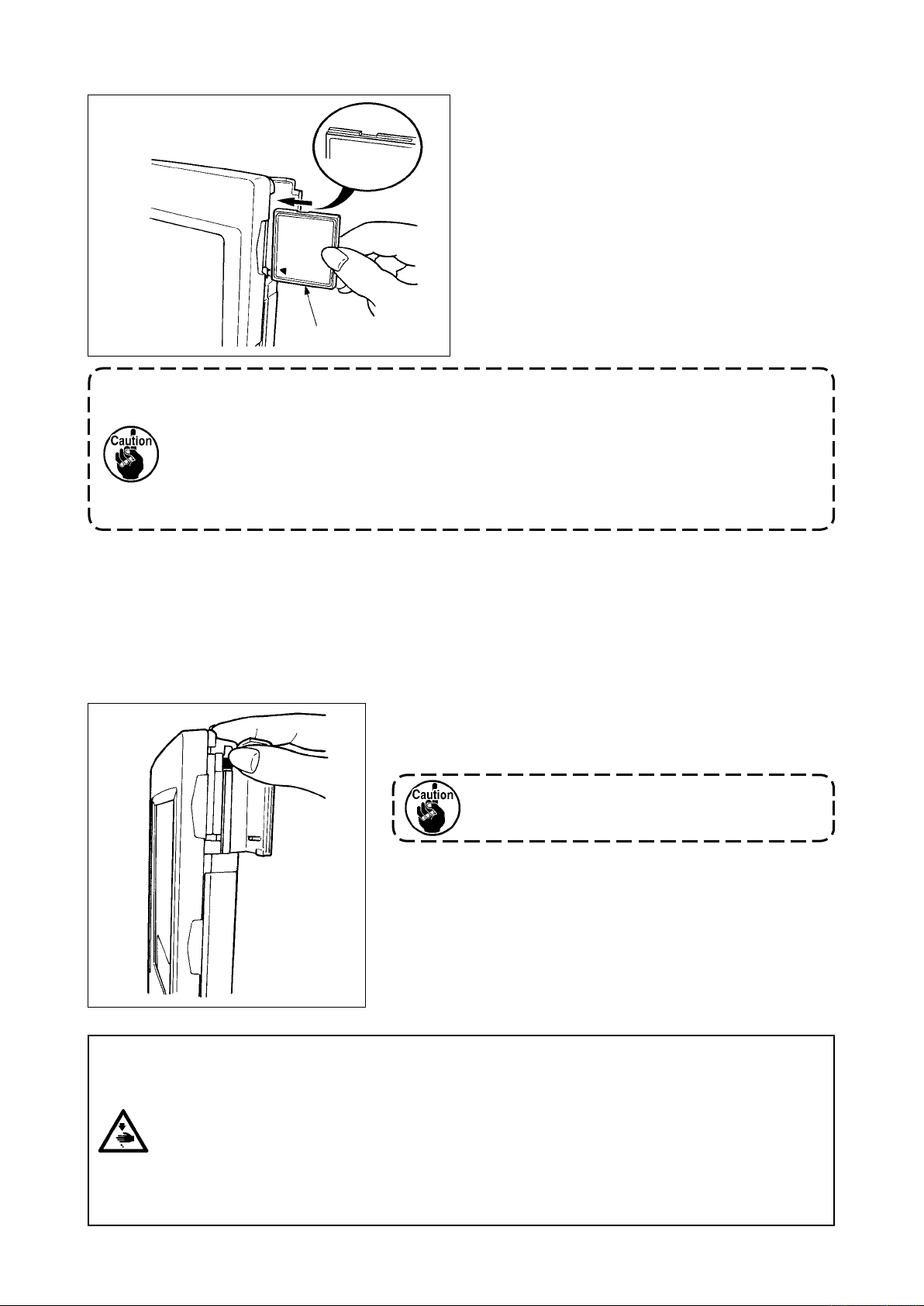

4) Inserting direction of the media

Turn the label side of the CompactFlash(TM)

1

to this side (place the notch of the edge to

the rear. ) and insert the part that has a small

hole into the panel.

Media

1. When the inserting direction is wrong, panel or media may be damaged.

2. Do not insert any item other than the CompactFlash(TM).

3. IP-410 corresponds to the CompactFlash(TM) of 2GB or less.

4. IP-410 corresponds to the format FAT16 of CompactFlash(TM). It does not correspond to

FAT32.

5. Be sure to use the CompactFlash(TM) which is formatted with IP-410. For the formatting

procedure of the CompactFlash(TM), see

"@-2-26. Performing formatting of the media", p.69.

After completion of setting of the media, close the cover. By closing the cover, it is possible to ac

2

cess. If the media and the cover come in contact with each other and the cover is not closed, check

the following matters.

• Check that the media is securely pressed until it goes no further.

• Check that the inserting direction of the media is proper.

5) Removing procedure of the media

Hold the panel by hand, open the cover, and press the

1

media removing lever. The media is eject.

When the lever is strongly pressed, the media may

be broken by protruding and falling.

When the media is drawn out as it is, removing is com

2

pleted.

-

-

Cautions when using the CompactFlash(TM)

• Do not wet or touch it with wet hands. Fire or electric shock will be caused.

• Do not bend, or apply strong force or shock to it.

• Never perform disassembling or remodeling of it.

• Do not put the metal to the contact part of it. Data may be disappeared.

• Avoid storing or using it in the places below.

Place of high temperature or humidity / Place of dew condensation /

Place with much dust / Place where static electricity or electrical noise is likely to occur

– 17 –

– 18 –

2. WHEN USING IP-410

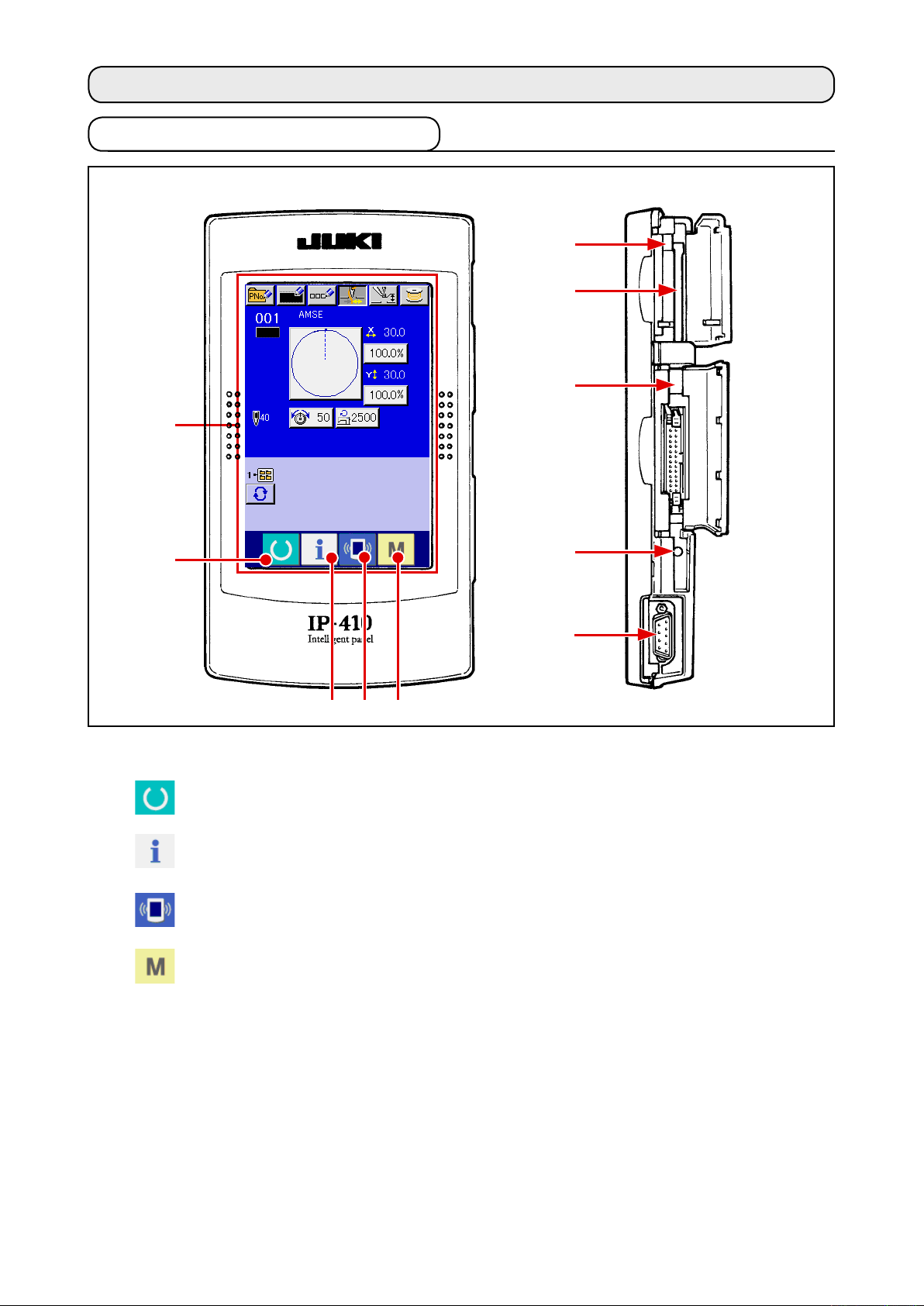

2-1. Name of each section of IP-410

1

2

(Front)

(Right side)

!0

6

9

8

7

4 5

3

Touch panel

1

2

READY key

LCD display section

・

Changeover of the data input screen and

→

the sewing screen can be performed.

INFORMATION key

3

Changeover of the data input screen and

→

the information screen can be performed.

COMMUNICATION key

4

Changeover of the data input screen and

→

the communication screen can be performed.

MODE key

5

Changeover of the data input screen and

→

the mode changeover screen which

performs various detail settings can be performed.

Media slot (Close the cover for use.)

6

Connector for RS-232C communication

7

Variable resistor for color LCD screen contrast adjustment

8

Connector for external input

9

Media removing lever

!0

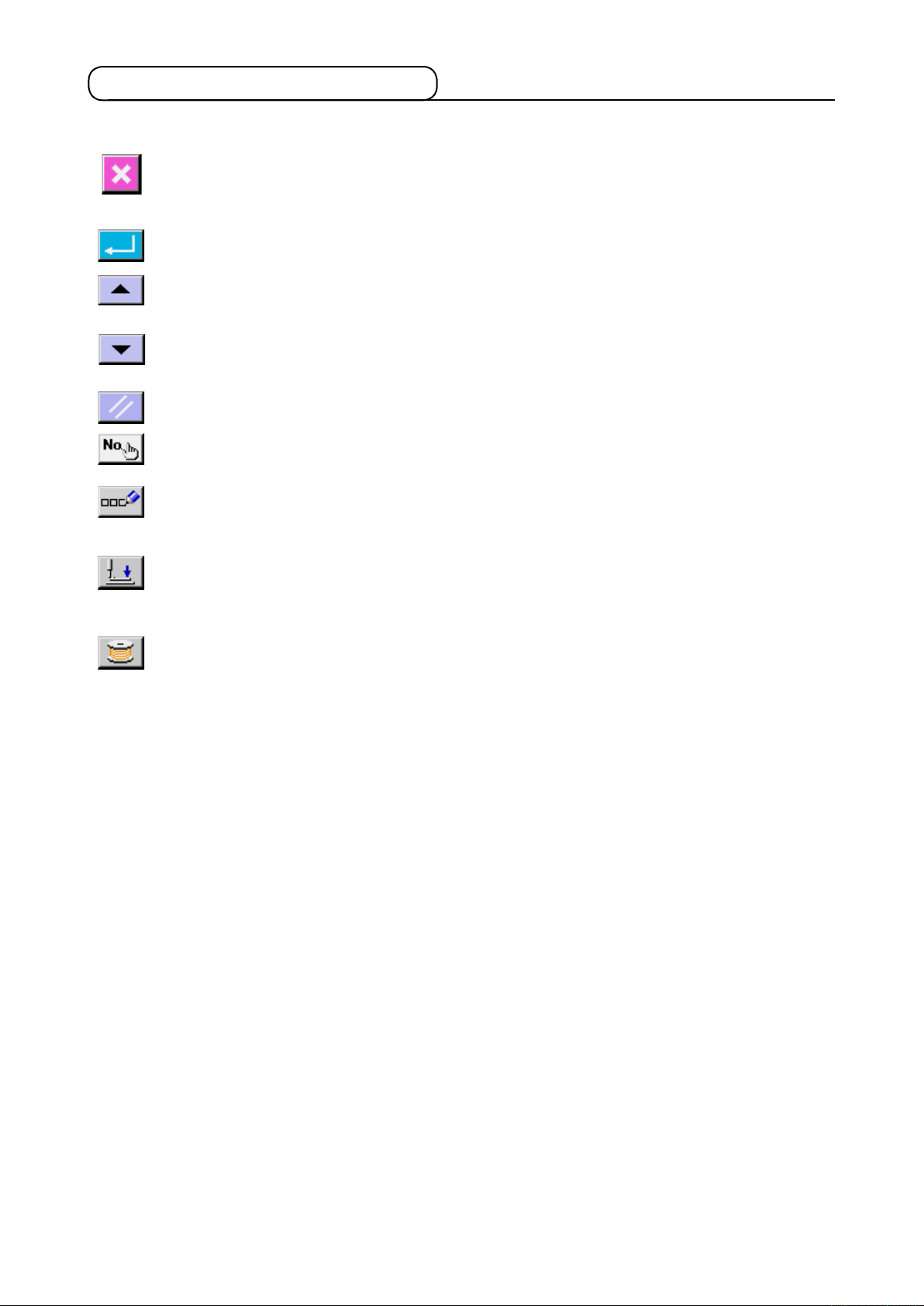

2-2. Buttons to be used in common

The buttons which perform common operations in each screen of IP-410 are as follows :

CANCEL button

In case of the data change screen, the data being

ENTER button

UP SCROLL button

DOWN SCROLL button

RESET button

NUMERAL INPUT button

CHARACTER INPUT button

→

RESSER LOWERING button

→

→

→

→

→

→

This button closes the pop-up screen.

→

changed can be cancelled.

This button determines the changed data.

This button scrolls the button or the display in the

upward direction.

This button scrolls the button or the display in the

downward direction.

This button performs the release of error.

This button displays ten keys and input of numerals

can be performed.

This button displays the character input screen.

Refer to

Presser is lowered, and the presser lowering screen

→

is displayed. To lift presser, press presser lift button

displayed in the presser lowering screen.

“@-2-14. Naming users' pattern” p.39

.

Bobbin winder button

Bobbin thread winding is performed.

→

Refer to

→

“@-2-11. Winding bobbin thread” p.34

.

– 19 –

– 20 –

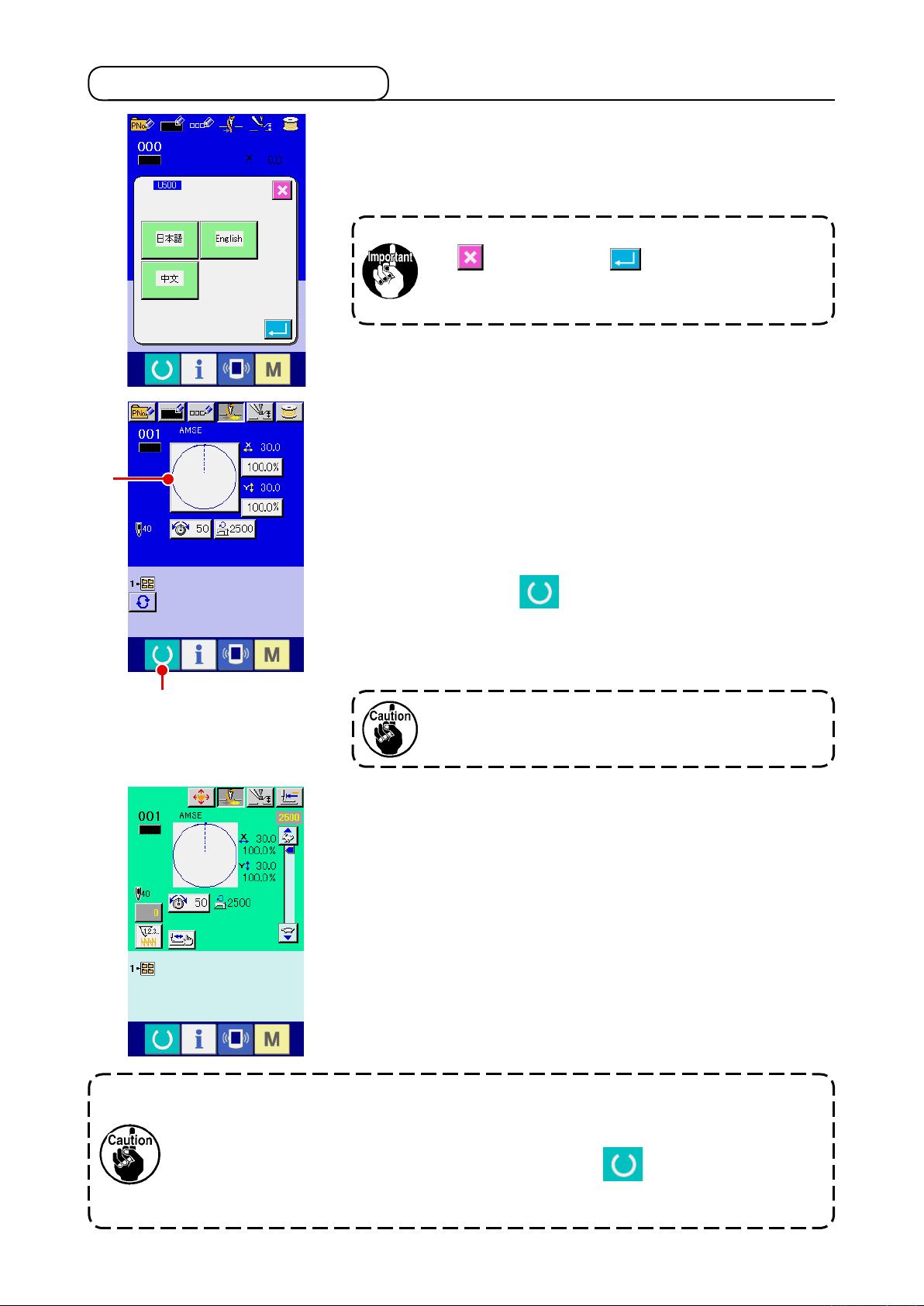

2-3. Basic operation of IP-410

1

When the power is turned ON rst, the language selection

2

When the power is turned ON, the data input screen is dis-

A

Turn ON the power switch

screen is displayed. Set the language you use. (It is possible

to change with Memory switch U500.)

When ending the selection screen with CANCEL but-

ton or ENTER button without performing the

language selection, the language selection screen is

displayed when the power is turned ON next.

Select the pattern No. you desire to sew.

played. Pattern No. button A which selected at present is

displayed in the center of the screen. Press the button to se-

lect the sewing shape. For selecting procedure of the sewing

shape, refer to "

.

p.25

@

-2-5. Performing sewing shape selection"

B

When READY key

is pressed, the back color of LCD

B

display is changed to green.

At this time, the presser performs the origin retrieval and

moves to the start of sewing.

When the presser is going up, be careful that your

ngersarecaughtwiththepressersincethepresser

moves after coming down.

Start sewing.

3

Start sewing referring to

* For the screen, refer to

"!-5-1. Sewing" p.12

@

"

-2-4. LCD display section at the

time of sewing shape selection" p.21

.

.

1.Whenusingtheexclusivepresser,conrmthepatternshapeforsafety'ssake.Shouldthe

pattern protrude from the feeding frame, needle interferes with the feeding frame during

sewing, and there is a danger of needle breakage or the like.

2. When turning OFF the power without pressing READY key

tern No.", "X enlargement/reduction ratio", "Y enlargement/reduction ratio", "Max. sewing

speed", "Thread tension" or "Intermediate presser height" is not stored in memory.

, the set value of "Pat-

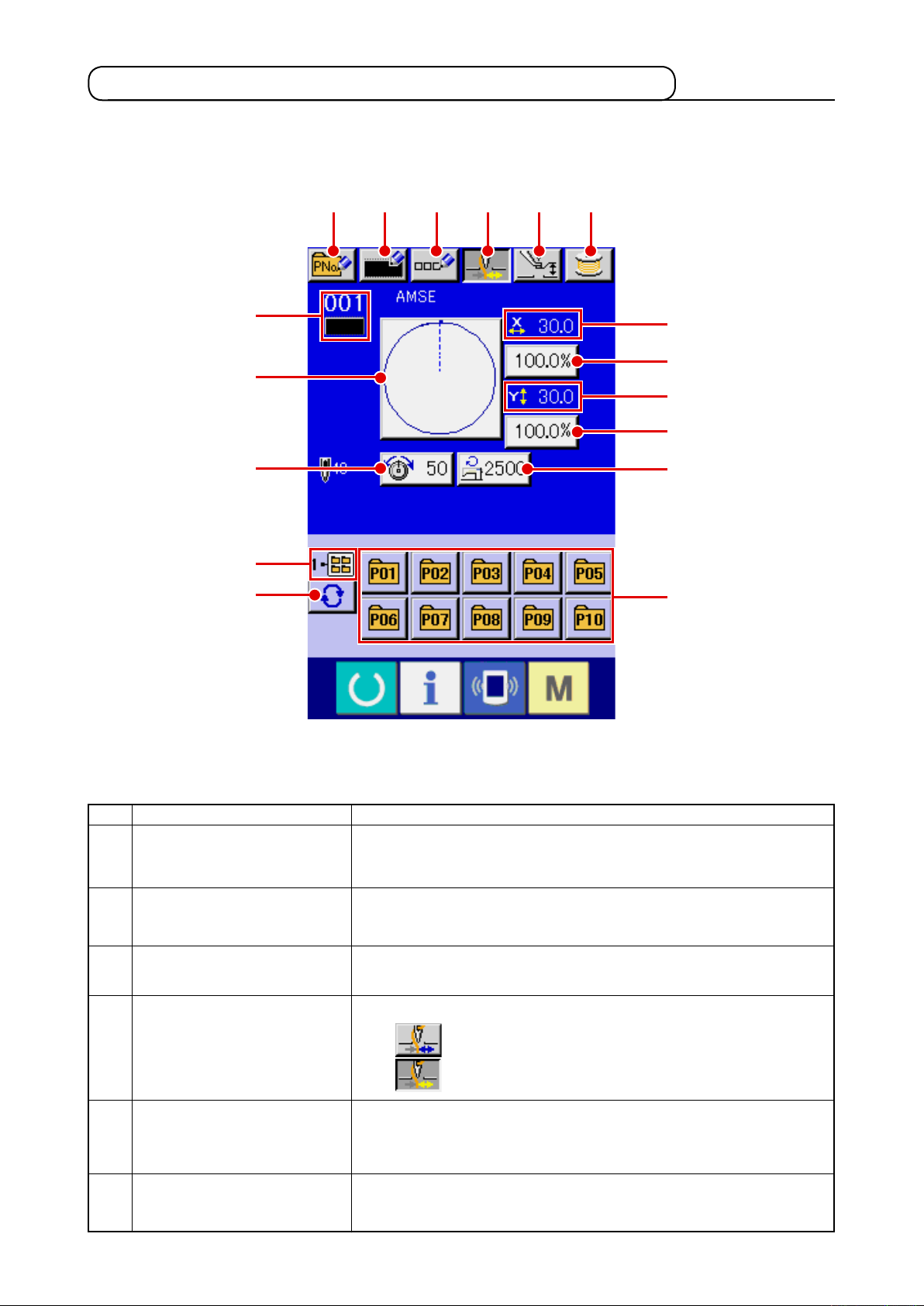

2-4. LCD display section at the time of sewing shape selection

(1) Sewing shape data input screen

G

H

I

O

P

A

B C D E F

J

K

L

M

N

Q

Button and display

A

PATTERN BUTTON

NEW REGISTER button

B

USERS’ PATTERN

NEW REGISTER button

C

PATTERN BUTTON

NAME SETTING button

D

THREAD CLAMP button

E

INTERMEDIATE PRESSER

SETTING button

F

BOBBIN WINDER button

Description

Pattern button new register screen is displayed.

Refer to

/

Users’ pattern new register screen is displayed.

Refer to

/

Pattern button name input screen is displayed.

Refer to

/

Effective/ineffective of thread clamp is selected.

: Thread clamp ineffective

: Thread clamp effective

Intermediate presser is lowered and the intermediate presser reference

value change screen is displayed.

Refer to

/

Bobbin thread can be wound.

Refer to

/

“@-2-15. Performing new register of pattern button” p.40

“@-2-13. Performing new register of users’ pattern” p.38

“@-2-14. Naming users’ pattern” p.39

@

“

-2-6. Changing item data

“@-2-11. Winding bobbin thread” p.34

” p.27

.

.

.

.

.

– 21 –

– 22 –

Button and display

SEWING SHAPE NO. display

G

Description

Kind and No. of the sewing shape being selected at present is displayed.

There are 4 kinds below of the kinds of sewing shape.

: Users' pattern

: Vector format data

: M3 data

: Sewing standard format

* Be sure to use the media that has been formatted with IP-410.

For the formatting procedure of the media, refer to

"@-2-26. Performing formatting of the media" p.69

.

SEWING SHAPE SELECTION

H

button

NEEDLE THREAD TENSION

I

SETTING button

X ACTUAL SIZE VALUE display

J

X SCALE RATE SETTING

K

button

Y ACTUAL SIZE VALUE display

L

M

Y SCALE RATE SETTING

button

Sewing shape being selected at present is displayed on this button and

when the button is pressed, the sewing shape selection screen is displayed.

Refer to

/

Needle thread tension value which is set to the pattern data being selected

at present is displayed on this button and when the button is pressed, the

item data change screen is displayed.

Refer to “

/

Actual size value in X direction of sewing shape being selected at present

is displayed.

When the actual size value input is selected by setting memory switch

Refer to “

/

Scale rate in X direction of sewing shape being selected at present is

displayed on this button.

When the scale input is set to non-selection by setting memory switch

Refer to “

/

Actual size value in Y direction of sewing shape being selected at present

is displayed.

When the actual size value input is selected by setting memory switch

Refer to “

/

Scale rate in Y direction of sewing shape being selected at present is

displayed on this button. When the scale input is set to non-selection by

setting memory switch

displayed.

“@-2-5. Performing sewing shape selection” p.25

@

-2-6. Changing item data”

, X actual size value setting button is displayed.

@

-2-6. Changing item data”

, the button goes out and the X scale is displayed.

@

-2-6. Changing item data”

, Y actual size value setting button is displayed.

@

-2-6. Changing item data”

, the button goes out and the Y scale is

Refer to “

/

@

-2-6. Changing item data” p.

p.27

p.27

p.27

p.27

.

.

.

.

27

.

.

N

MAX. SPEED LIMITATION

O

FOLDER NO. display

P

FOLDER SELECTION button

Q

PATTERN REGISTER button

Maximum speed limitation which is set at present is displayed on this button

and when the button is pressed, the item data change screen is displayed.

(However, maximum speed limitation which is displayed is different from

the maximum number of revolutions in the pattern.)

Refer to “

/

Pattern register button which is displayed indicates the folder No. which has

been stored.

Folders to display the patterns are displayed in order.

PATTERN REGISTER buttons stored in

displayed.

Refer to

/

* This button is not displayed unless the new register to the pattern button

is performed.

@

-2-6. Changing item data”

@

“

-2-15. Performing new register of pattern button”

.

p.27

FOLDE R NO display are

O

p.40

.

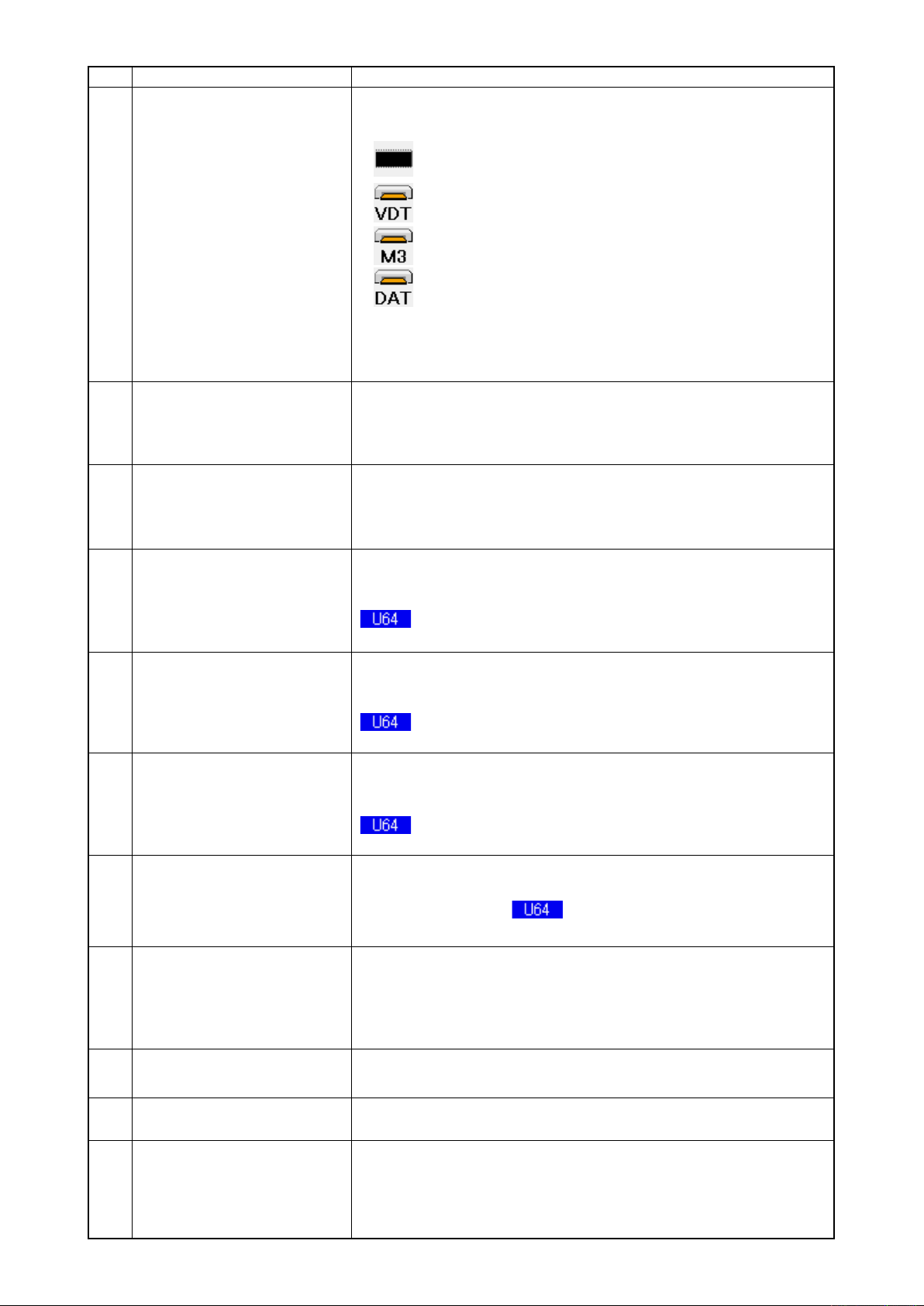

(2) Sewing screen

E

F

G

H

I

J

K

L

A B C D

O

N

P

M

Q

R

Button and display

A

PATTERN MOVE button

THREAD CLAMP button

B

Description

Pattern move screen is displayed.

Refer to

→

because of interruption of needle tip” p.34

Effective/ineffective of the thread clamp is selected.

: Thread clamp effective

@

“

-2-10.Whensettingofsewingproductisdifcult

.

: Thread clamp ineffective

S

C

INTE R MED I AT E PR ESSE R

SETTING button

D

RETURN TO ORIGIN button

Intermediate presser is lowered and the intermediate presser reference

value change screen is displayed.

Refer to

/

This button returns the presser to the start of sewing and raises the presser

when the present presser position is on the way of sewing.

“@-2-6. Changing item data” p.27

.

– 23 –

– 24 –

Button and display

E

SEWING SHAPE NO. display

Description

Kind and No. of the sewing shape being selected at present is displayed.

There are 4 kinds below of the kinds of sewing shape.

F

SEWING SHAPE display

G

NE ED LE T HR EA D TENSION

SETTING button

H

TOTAL NUMBER OF STITCHES

OF SEWING SHAPE display

* Be sure to use the media that has been formatted with IP-410.

For the formatting procedure of the media, refer to

“@-2-26. Performing formatting of the media” p.69.

Sewing shape being selected at present is displayed.

Needle thread tension value which is set to the pattern data being selected

at present is displayed on this button and when the button is pressed, the

item data change screen is displayed.

Refer to

/

Total number of stitches of the sewing shape being selected at present is

displayed.

* Displayed only when the sewing shape being selected is the standard

pattern.

: Users' pattern

: Vector format data

: M3 data

: Sewing standard format

“@-2-6. Changing item data” p.27

.

I

COUNTER VALUE CHANGE

button

J

COUNTER CHANGE OVER

button

K

STEP SEWING button

L

FOLDER NO. display

M

SPEED variable resistor

N

X SCALE RATE display

O

X ACTUAL SIZE VALUE display

P

Y ACTUAL SIZE VALUE display

Q

Y SCALE RATE display

Existing counter value is displayed on this button.

When the button is pressed, the counter value change screen is displayed.

Refer to

/

Display of sewing counter/No. of pcs. counter can be changed over.

Refer to

/

Step sewing screen is displayed. Checking of the pattern shape can be

performed.

Refer

/

Pattern register button which is displayed indicates the folder No. which has

been stored.

Number of rotations of the sewing machine can be changed.

Scale rate in X direction of sewing shape being selected is displayed.

Actual size value in X direction of sewing shape being selected is displayed.

Actual size value in Y direction of sewing shape being selected is displayed.

Scale rate in Y direction of sewing shape being selected is displayed.

“@-2-12. Using counter” p.35

“@-2-12. Using counter” p.35

“@-2-7. Checking pattern shape” p.29

.

.

.

R

MAX. SPEED LIMITATION

display

PATTERN REGISTER button

S

Maximum speed limitation which is set at present is displayed. However,

the display is different from the maximum number of revolutions in the

pattern. However, the display is different from the maximum number of

revolutions in the pattern.

Pattern register buttons stored in

Refer to

/

* This button is not displayed unless the new register to the pattern button

is performed.

“@-2-15. Performing new register of pattern button”

FOLDER NO. display are displayed.

L

p.40

.

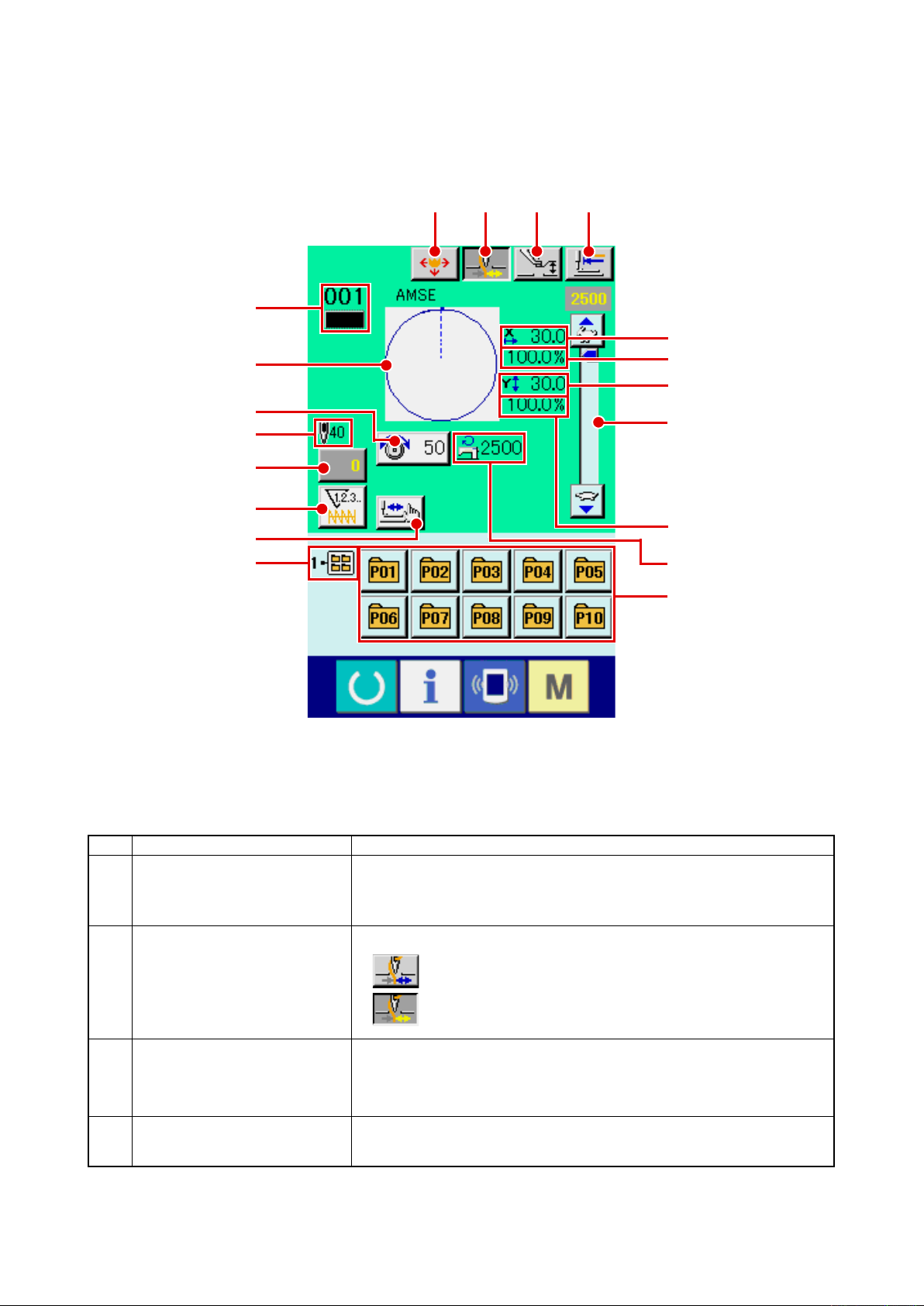

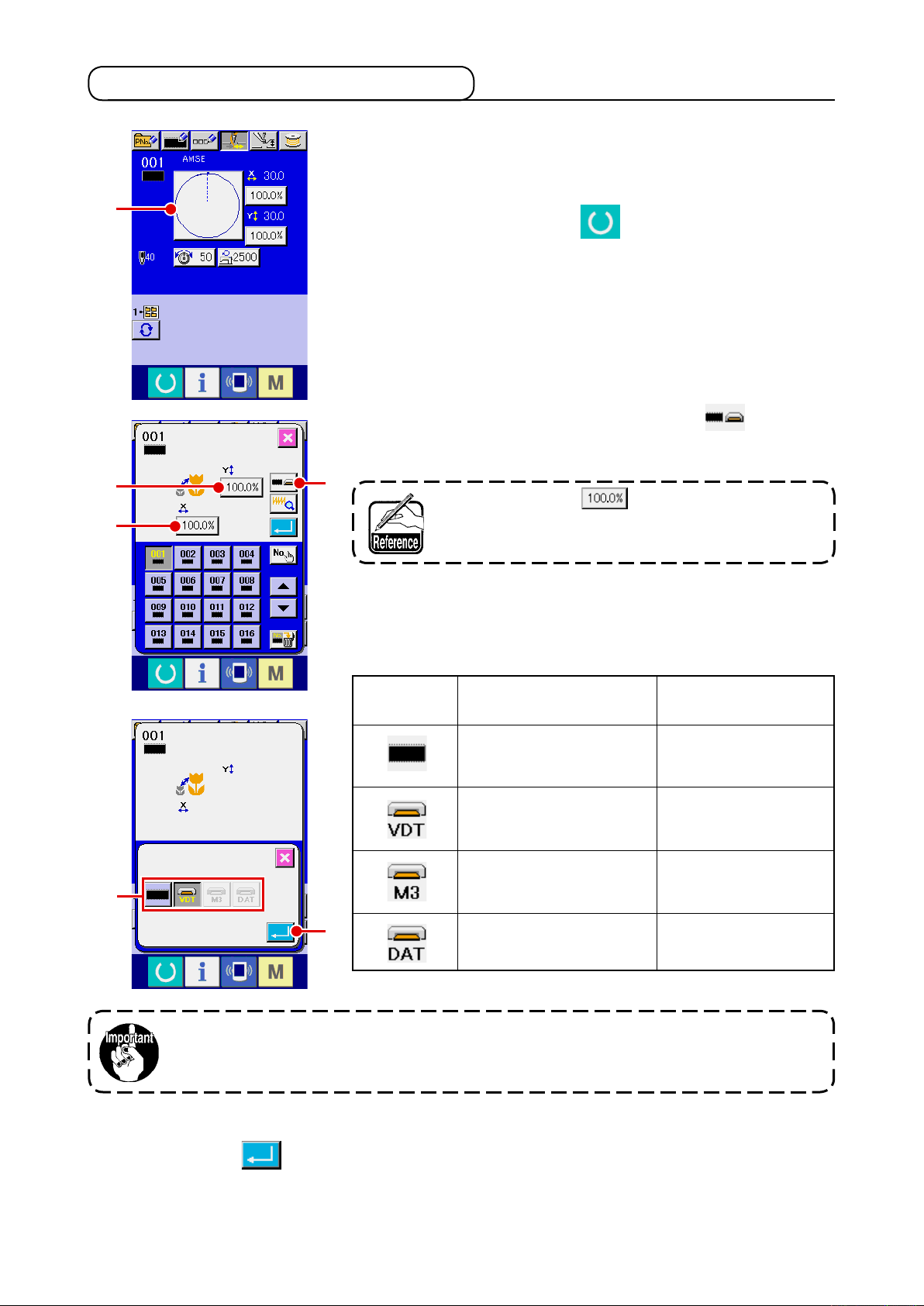

2-5. Performing sewing shape selection

Display the data input screen.

1

Only in case of the data input screen (blue), the selection of

sewing shape can be performed. In case of the sewing screen

A

(green), press READY key and display the data input

screen (blue).

Call the sewing shape selection screen.

2

Press SEWING SHAPE button A and the sewing shape

selection screen is displayed.

Select the sewing shape.

3

There are 4 kinds of the sewing shape.

C

D

Press SEWING SHAPE SELECTION button

B.

* This button is not displayed in the initial state.

B

When button C or D is pressed in this screen,

X or Y enlarging/reducing ratio can be changed. For the

details, refer to "

Determine the kind of sewing shape.

4

@

-2-6. Changing item data" p.27.

There are 4 kinds below of the sewing shape. Select the kind

you desire from among them.

Pictograph

Name

Users' pattern

Vector format data

Maximum number of

patterns

200

999

M3 data

999

E

F

Be sure to use the media that has been formatted with IP-410.

For the formatting procedure of the media, refer to

"@-2-26. Performing formatting of the media" p.69.

Sewing standard format

999

Select the sewing shape kind you desire from SEWING SHAPE KIND SELECTION buttons E and

press ENTER button F.

The sewing shape list screen corresponding to the kind of sewing shape you selected is displayed.

– 25 –

– 26 –

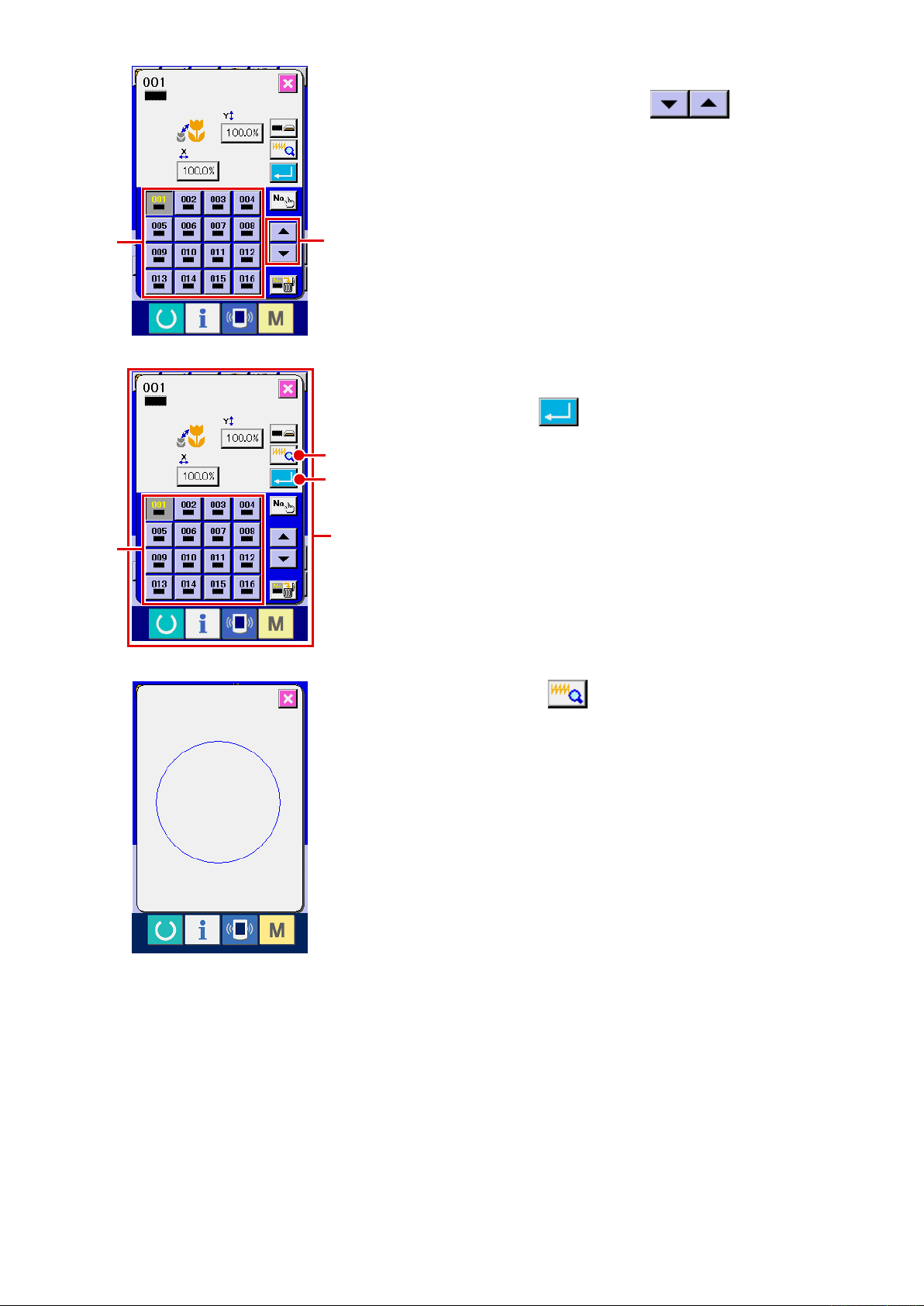

Select the sewing shape.

5

H

J

When UP or DOWN SCROLL button

G is pressed,

the SEWING SHAPE buttons H are changed over in order.

Here, press the SEWING SHAPE button you desire to select.

G

Determine the sewing shape.

6

is pressed, the sewing shape is

When ENTER button

K

I

determined and the data input screen is displayed.

When the sewing shape is users' pattern, the screen as A is

I

displayed.

A

PATTERN NO. SELECTION button J that is registered to us

ers' pattern is displayed. Press the button of PATTERN NO.

you desire to select.

-

When VIEWER button K is pressed, the shape of the

pattern No. selected is displayed and you can conrm it.

Loading...

Loading...