Page 1

•JUKI

Medium-sized

Computer-controlled

ENGINEER'S

Cycle

Machine

MANUAL

Page 2

PREFACE

This Engineer's Manual is written for the technical personnelwho are responsible for the service and maintenance

of

the

machines.

The Instruction Manual for these machines intended for the maintenance personnel and operators at an apparel

factory contains detailed operating instructions. And this manual describes "How to Adjust", "Results of Improper

Adjustments", and other information which are not covered by the Instruction Manual.

Itisadvis^letouse

carrying

This

"HowtoAdjust",

<xit

manual

the maintenanceofthese machines.

mainly

the

pertinent

consistofthree

andthe

third,

Instruction

sections;

"ResultsofImproper

Manual

the

first

and

Parts

List

section

Adjustment."

presents

together

"Standard

with

this

Adjustment",

Engineer's

the

Manual

second

when

section,

r

r

r

Page 3

CAUTION

X

1. When a pattern

winder

turned

automatically.

the

away from

in operation.

3.

switchorthe

ON,feeding frame O

feeding

During

operation,be careful not to

change

So,

frame.Besuretokeep

the

feeding frame while

feeding

never

is made, or

frame

comes

put

your

the

bobbin

switch

is

down

fingers

under

your

fingers

the

machine is

allow

your or any other person's head or hands to come close to the

Be

suretoturn

removing belt cover O

Do

cover

handwheel, V belt or motor. Also, do not place anything near any of

Doingsomay be

dangerous.

not

removed.

the

operate

these

power

switch

OFF

before

and

the

Y travel

machine

with

shaft

the

cover

belt

parts while is in operation.

4. Ifyour machine is equipped whit a belt cover, eye guard or any other protections, do not operate your

machine with any of them removed.

Page 4

CAUTIONS

BEFORE

OPERATION

1. Remove bed fixing bolt O before starting

operation.

When

transporting

fixing bolt

3.

Precautionsinhandling

Do

food

not

and

0>

place

drink.

the

your

floppy

AMS-215C,

floppy

disks

disk

nearanashtray

Install

bed

RIter

2.

Clean

the

filterofthe

Do

not

touch

or

the

fan

exposed

[13HI

once

every

partsofthe

week.

floppy

disk.

CjD

Do

not

material.

bring

the

floppy

disk

=3;

12

closetoa

magnetized

4.

Do

not

or

higher)ora

The

sewing

(In

the

the

pulley

the

reverse

place

the

floppy disk In a

place

machine

directionofthe

side.

Never

direction.

hot

exposedtodirect

should

run

counterclockwise

arrow)asobserved

allow

the

machinetorun

place (51*0

sunlight.

from

In

Page 5

5.Besureto

the bed, be sure movethe feeding frame to the

6.

Before

applyafew

surface

supply

starting

dropsofthe

0.

oil

the

until

the

machine

lubricating

oil

which

level

has

oil

reaches

been

tothe

red

marksQaic*

left.)

newiy

set uporhas not

crank

assembly

0

through

Be

sure

to load or unload floppy disk O whilethe

power is ON. if

turnedONor

the

data

storedinthe

®''

gauge.

been

used

foralong

holeO,one

the

power switch should be

OFF

with

droptoracing

the

floppy

disk

maybedestroyed.

(When

lubricating

periodoftime,

disk

mounted,

8. The

AMS-215Cisprovided

which

[When

detected

So,

sometimes

extends

inputting

with

beyond

accuracy.

pattern

data

the

using

data

with

sewing

the

the

main

area

main

(180mmx

unit

whichislarger

unit

input

input

thanthe

function

110

function,

sewing

as standard,

mm)

cannot

the

travel

areaspecified

besewnevenif

limit

however,asewing

inputting

ofthe

sewing

area

maybecreated.

pattern

it.

cannot

be

Page 6

9. To raise the sewing machine, attach grip O supplied withthe sewing machine and raise the sewing

machine

Be

in

the

suretouse

%

direction

stopper

of

the

arrow.

0 when working with

the

sewing machine raised.

10.

When

the

switched

the

thread

completed

disk

will

threader

ON,

tension

the

open.

sew

thread

and

the

desired

disk

trimming,

sewing

closed.

machine

sewing

Once

the

are

pattern

you

thread

with

have

tension

X

Closed

1 f//

oi

Opened

11. When polyethylene oiler O

oil,

removeitand

12.

Priortooperation,besuretoclose

box

cover

In order to prevent

into

the

control

may

leadtomalfunctionsorfailures.

box.

drain

the

Dust

becomes

oil.

dust

into

the

filled with

the

control

from getting

control

box

(Don't

Opem

Page 7

CONTENTS

1.

FEATURES

Z

SPECIFICATIONS

3.

OPERATION

3- 1. Names of the main components 6

3- 2.

Control

3-3.

Operation

3-4.Other

3- 5.

Checking

3- 6. Operation procedure 14

3- 7.

Precautions

4.

DESCRIPTION

4-1.

Sewing

4- 2. Control box 23

4-3.

Operation

4- 4. Motor 26

5.

ADJUSTMENTS

5-1.

Mechanical

5- 2.

Electrical

5-3.

Rotary

box

panel

switches

before

during

OF

machine

panel

parts

parts

DIP

switches

panel

EACH

operation

operation

MAIN

for

COMPONENT

setting

the

test

mode

1

3

6

8

10

12

13

20

21

21

25

27

27

1

121

6.

FUNCTION 127

6-1.

How

toset the

6-2.

Error

messages

6-3.

Changing

6-4.

Thread

6-5.

Temporary

6-6.

Functionofsetting

6-7.

Travel

limit

6-8.

Pattern

6-9.

Memory

6-10.

Max.

sewing

6-11.

Combining

7. MAINTENANCE AND INSPECTION 171

7-1.

Cleaning

7-2.

Changing

7-3.

Replacing

7-4.

Adjustment

7-5.

Replacing

7- 6.

Howtomeasure

7-7.

AC

input

8. TROUBLES AND CORRECTIVE MEASURES 182

8- 1.

Troubles

8- 2.

Troubles

8- 3.

Troubles

the

settingsonthe

breakage

stop

detecting

memory

detecting

function

the

second

function

switches

enlarging/reducing

back-up

function

speed

limit

control

patterns

the

filter

the

directionofrotationofthe

the

fuse

and

maintenanceofthe

the

printed

circuit

voltage

and

correaive

and

corrective

and

corrective

theline

voltage

tap

measures

measures

measures

panel

function

origin

function

knob

boards

displays

sewing

motors

(mechanical

(electrical

(Sewing

conditions)

parts)

parts)

machine

127

165

166

166

166

167

167

167

168

168

169

171

171

172

172

177

179

ISl

182

189

197

Page 8

9. VARIOUS INFORMATION ON THE SEWING MACHINE 206

9-1.

Changing

9-2.

Options

9-3.

BLOCK

9-4.

SOLENOID

9- 5.

VR-SW

9- 6.

SENSOR

9- 7. AIR

PEDALSWcircuit

9- 8.

9- 9.

POWER

9-10.

POWER

9-11.

MOTOR

the

diagram

circuit

circuit

VALVE

circuit

circuit

conneaion

sewing

circuit

diagram

diagram

circuit

diagram

diagram

specification

diagram

diagram

diagram

(A) 221

(B) 222

diagram

206

209

215

216

217

218

219

220

223

9-12. CLUTCH BRAKE connection diagram 223

9-13.

SYNCHRONIZER

circuit diagram

224

AMS-215CSB,

AMS-215CHB,

AMS-215CGB

(Computer-controlled cycle Machine with a Double-stepped Stroke Feeding frame) 225

1.

FEATURES

2.

SPECIFICATIONS

3.

OPERATION

OF

AND

THE

SPECIFIED

SEWING

VALUE

MACHINE

3- 1. Configuration 225

3- 2. How to operate the pedal switch 226

3- 3. Sewing without using the double-steppedstroke function 226

4.

ADJUSTMENTS

4-1.

Adjusting the mechanical components 227

5.

PARTS

DOUBLE-STEPPED

6.

MATERIALS

TO

BE

REPLACED

STROKE

WHEN

FEEDING

CHANGING

FRAME

THE

TYPE

STANDARD

MACHINE

TYPE

MACHINE

TO

THE

6- 1. Block diagram for the AMS-215CSB, -215CHB and -215CGB 244

6- 2. Air valve schematic diagram for the AMS-215CSB, -215CHB and -215CGB 245

6-3.Pedal

AMS-215CSL,

(Computer-controlled

1.

FEATURES

switch

schematic

AMS-215CHL,

Cycle

diagram

AMS-215CGL

Machine

with a

Double-stepped

Feeding

Frame) 247

225

225

225

227

243

244

246

247

2.

SPECIFICATIONS

3.

OPERATION

OF

AND

THE

SPECIFIED

SEWING

VALUE

MACHINE

3- 1. Configuration 247

3- 2. How to use the PK47 3-pedal unit 248

3- 3. How to operate the pedal switch 249

3- 4. Sewing with the monolithic feeding frame installed on the machine

3- 5. How to use a plastic blank 250

4.

ADJUSTMENTS

4-1,

Adjusting the mechanical components 251

5.

PARTS

DOUBLE-STEPPED

TO

BE

REPLACED

FEEDING

WHEN

FRAME

CHANGING

TYPE

THE

MACHINE

STANDARD

TYPE

MACHINE

TO

247

247

249

251

THE

267

Page 9

6. OPTIONS

7. dimensionsOFTHE

8.

MATERIALS

8-1.

Block

diagram

2.

8-

8- 3. Pedalswitch schematic diagram

FEEDING

for

the

AMS-215CSU-215CI^an

FRAME

•• "' V

269

. .

270

271

271

'

272

AMS-215CST,AMS-215CHT

1.

FEATURES

2.

SPECIFICATIONS

3.

OPERATION

3-1.

Configuration

3-2.Explanationofoperation

3-3.Howtouse

3-4.Sewing

3-5

Cautions

3-6.Controlling

3-7.When

3-8.Preparation

3. 9.

Precautions

4.

ADJUSTMENTS

4-1.

Adjusting

5.

PARTS

INVERTING

6.

OPTIONS

7.

WHEN

8.

MATERIALS

8-1.

8-2Air

8-3.

TO

MANUFACTURING

Block

valve

Pedal

AND

the

with

the

tobe

the

the

machineisusedasthe

and

tobe

the

BE

REPLACED

DEVICE

diagram

schematic

switch

(Computer-controlled

SPECIFIED

panel

PK47/3-pedal

inverting

taken

when

inverting

crank

precautionstobe

taken

during

mechanical

WHEN

TVPE

MACHINE

AN

for

the

AMS-215CST

diagram

schematic

diagram

VALUES

unit

intermediate

creatingapattern

presser

standard

taken

operation

components

before

CHANGING

INVERTING

•••• ' ' ]^

for

the

AMS-215CST

Cycle

Machine

with

removed

type

machine

operation

THE

STANDARD

INTERMEDIATE

. **

and

-215CHT

TYPE

PRESSER

.*

Inverting

Device)

y.'

'

y •

''

"

MACHINE

'

TO

274

274

275

275

276

276

277

279

280

^gQ

^go

281

281

THE

303

305

305

306

Page 10

1.

FEATURES

1.

Easy

pattern

The

work

The work holder is driven by a stepping motor. You can change a stitching pattern simply by specifying the

pattern No. affected

2.

Wide-range

The X and Y scale can be independently set 0.01 to 4 times the sizeofthe original pattern. This is further

supported by the machine's unique function whereby pattern enlargement/reduction is done by increasing or

decreasing the stitch length or the number of stitches. The combination of these functions permits highly

flexible pattern enlargement and reduaion.

3.

Permits

As for input through the main unit, the feed is operated by meansofa switch in the operation panel. In this

way, appropriate data are input so as to meet the requirementsof the sewing material which corresponds to

the sewing needle. Pattemscan also be easily input using the optional input device (PGM-5A).

change

holder

is

pattern

the

inputofvarious

scale

pattern

data

4. Micro

5.

6.

7.

8.

9.

floppy

A 2DD 3.5-inch micro floppy disk is used, accommodating 44 to 691 patterns.

Easy

operation

Key

switches

user's convenience and for better design.

Consistent

A

stepping

material.

selection in accordance with each sewing product.

The

incorporation of a 16-bit microprocessor allows

4,000

stitches

The

max.

16,000

stitches

stitches.

Safety

This

machineisdesignedtoindicateanerror

identify

incorporated

Easy

workpiece

In

additiontothe

which allows a workpiece to be set easily.

disktostore

and

are

used

for easier

sewing

quality

motorisusedtofeed

This

feed

timing

per

pattern.

numberofstitches

canbeinput.

and

the

testing

problem

intothe

facilities

at a

machine.

setting

second

sewing

better

design

canbechanged

fora

This

pattern

operation.

the

material,

sewing

enables

data

The

compact

allowing

using

patternisnormally

the

machinetoadapttothe

message

glance.Inaddition,afacility

This

facilityisuseful

origin

setting

function,

the

the

memory

for

liftofthe

operation

for

precise

the

4,000.

upon

the

for

testing

fast

troubleshooting.

switches,

detection

feeding

panelis

control

located

according

which

on the tablefor the

to the

permits

optimum

thickness

feed

of the

timing

machine to produce a maximum of

For

the

switches

combined

decorative

ofa

frame

pattern,asmany

stitching

malfunction,

andother

isas

highas25mm(standard),

with

many

enabling

functions

as

you

has been

to

10.

11.

12.

Assures

The

provide

speed.

Cylinder

The

The

The

stable stitch length regardless of sewing

AMS-215Cisdesignedtoadjust

the

optimum

bed

AMS-215C

maximum

stitch length can be increased to a maximumof12.7 mm.

feed

sewing

canbeused

stitch

timing

for

length

the

sewing

speed

for

the

sewing

speed.

cylinder

canbeincreased.

bed

sewingbyremoving

- 1 -

for

This

speed

each

changes.

stitch

ensures

the

before

consistent

throat

feeding

stitch

plate

the

material

lengths

auxiliary

for

cover.

soas to

any

sewing

Page 11

13.

Flexible

A

material. The needle can be changed with the face cover installed. Furthermore, the same needle bar can be

used regardless of the typeofneedle.

14.

Easy

Since the bobbin winder is located close to the operator, the operator is able to easily wind the bobbin thread.

15.

Multi

The

indicating function, which enhance the machine's sewing capability.

16.

Shorter

At the endofsewing, the feeding frame automatically returns to the sewing start position, allowing for a

quick sewing operation.

17.

Many

A micro floppy disk can accommodate nine different commands, and various pattern figures can be sew by

combining them.

18.

Capabilityofrespondingtopattern

response

DPxl7

needle is used to sew heavy-weight material, while a DPx5 needle is used to sew light-weight

windingofthe

sewing

machine comes with a needle thread breakage detecting function and a bobbin thread replacement

the

kindsofpattern

functions

time

to

material

bobbin

required

figure

for

changes

thread

sewing

changes

improved.

The machine is equipped with a feeding frame and feed plate which can be removed with the simple touch of

a key. This allows the machine to respond flexibly to any pattern change. (Option)

19.

Feeding

The pneumatic drivingsystemfor the

frame

mechanism

improved for

feeding

greater

stability

frameallowsthe material to be fed with greater stability.

Regardlessof the thickness of the material, consistent pressure is obtained.

20.

Consistent

sewing

speed

The 400W 4-pole sewing machine motor accommodates a standard pulley,allowing the machine to run at a

consistent sewing speed. (G type: 550W 2P motor)

21.

Capable

The sewing

22. A

A compressor unit is optionally available.

It can be attached to your AMS-215C with no additional machining.

23. A milling

A

of inputting

machine

compressor

unit

milling

unit is

and

modifying a

complicated

sewing

pattern.

is capableof inputting and modifying needle entry points in 0.1 mmsteps.

unit

canbeattachedtothe

canbeattachedtothe

optionally

available.

It canbe

machine

machine

attached

after

after

the

to your

the

set-up

set-up.

AMS-215C,

which

allows

you to

plasticfeeding frame or aluminum feedingframe as desired with ease.

24.

Patterns

AMS-215C.

used

for

the

AMS

series

modelofsewing

machine

can

alsobeused

for

The AMS-215C is capableof usingsewingpatternsthatare used for all the AMS series models of sewing

machines.

patterns

When

However,

for the

AMS-215C

usinga sewing

notethata sewing

cannot

be usedfor the otherAMSseries

pattern

used

for the otherAMS series

pattern

that

exceeds

thesewingarea of the

models

of sewing

models,

the

AMS-215C

AMS-215C.

machine.

willconvertthe

conventionalstitdi length of 0.16 mm to 0.1 mm. This means that the stitch length and shape of the sewing

pattern may change.)

machine

the

The sewing

(Note:

a

- 2 -

Page 12

2.

SPECIFICATIONS

The

specifications

follows:

ofthe

AMS-215C

(1-needle,

lockstitch

cylinder

bed

computer-controlled

cycle

machine)

areas

1. Sewing area:

2. Max. sewing speed

(adjustablein 3 mm or less):

3. Stitch length:

4. Feed motion

5.

Needle

6.

Needle:

bar

of

feeding frame:

stroke:

7. Lift of feeding frame:

8. Intermediate presser stroke:

9.

liftofintermediate presser:

10.

Shuttle:

11.

Bobbin

case:

12.

BcA)bin:

13. Lubricating oil:

14.

Thread

trimmer:

15. Wiper:

16. Intermediate presser lifter:

17. Memory storage:

18. Sewing operation:

19. Feeding frame:

20.

Start:

21. Temporary stop facility:

X (lateral) direction 180 mm

Y (longitudinal) direction 110 mm

2,000 s.p.m.

Max. 12.7 mm (adjustable in 0.1 mm steps)

Intermittent feed (2-shaft drive by stepping motor)

41.2

mm

DPxS,

DPxl7

25 mm (standard) Max. 30 mm

4 mm (standard) (0, 3 to 7 mm)

20

mm

Large-capacity, semi-rotary type (self-lubricated) (Semi-rotary

double-capacity hook for the sewing specification G)

Large-capacity, semi-rotaryshuttle type (Bobbin case for the

semi-rotary double-capacity hook for the sewing specification G)

Large-capacity shuttle type (Bobbin for the double-capacity hook

for the sewing specification G)

New Defrix Oil No. 2 (supplied by oiler)

Consistsofmoving knife and counter knife (actuated by grooved

cam)

Magnetically driven (with release switch)

Vertical motion driven by an air cylinder (with release switch)

3.5 inch

miao

floppy disk

Memory capacity: 691K

44 to 691 pattern can be stored in a cassette

Starts/ends at sewing start point or the 2nd origin

Descends when the feeding frame switch is pressed. Another press

on the switch causes the feeding frame to ascend.

The machine is started by turning the start switch ON with the

feeding frame down.

Used to stop machine operation during a stitching cycle. After a

temporary stop, the feeding frame can be moved along the stitching

line by operating the backward or forward switch. The interrupted

stitching cycle can be completed by pressing the start switch.

Alternatively, the return to origin switch may be pressed for quick

move to the sewing start point or the 2nd origin.

- 3 -

Page 13

22. Enlarging/Reducing

23.

Enlarging/Reducing

24. Max. sewing speed limitation:

25.

Pattern

selection:

26. Pattern checking facility:

27.

Error

indication:

28. Programming:

29.

Bobbin

30. Memory backup:

31. 2nd originsetting facility:

32. Needle-upstop facility:

33. Sewing machine motor:

34.

35. Gross weight:

36. Power consumption:

37. Operating temperature range:

38. Operating humidity

39.

thread

Dimensions

Line

voltage:

facility:

method:

counter:

(excluding

range:

thread

stand):

Allowsapatterntobe

axis,

independently

Scale:

0.001

to 4

Pattern

enlargement/reduction

eitherstitch

The

a

rangeof180to2,000

1to999

Nos.

A

pattern

machine ON/OFF switch to OFF.

17

typesoferror

Involves

jump

TeUs

works

In

case

length

maximum

patterns

configuration

point/linear/arc

data,

sewing

the

timetoreplace

asa 0 to

ofa

power

automaticallybestoredinmemorysothat

cycle

mayberesumed

the

jX)werisrestored.Nofloppy

held

for

100

hrs.

Using

jog

keys,a2nd

canbesetin

2nd origin is also storedin

When

be

broughtupto

the

the

needle

switchONor

400W,4Pelectronic-stop

specification G)

enlargedorreducedontheXaxis

when

sewingapattern.

times

(0.001

stepscanbe

canbedonebyincreasing/decreasing

or the

sewing

number

speed

s.p.m.,

or stitches.

canbeset

using

limitedtoany

the

canbeselectedbyspecifying

canbecheckedbysetting

indication

speed,

999

interruption,

ring

are

given.

numeral

the

data,

and

stitch

bobbin.Ifthis

counter

with

the

temporary

length.

resetting

pattern

simplybypressing

diskisnecessary.

origin

(needle

position

desired

does

the

OFF

position

not

upper

(provided

within

memory.

stop

inits

upper

positionbyturning

the

READY

motor

(550W,2P

external

the

the

the

lampisON.)

1,200mm(W)X977mm(L)x1,200mm(H)

250

kg

1

KVA

5'to40°C

20 to 80% (no

Rated

voltage

dew

condensation)

±10%

50/60Hz

selected)

value

control

the

desired

the

sewing

stop,

facilityisnot

function.

being

used

interrupted

set

ready

The

afterasewing

sewing

position,

for

the

area.

the

needle

the

sewing

and

within

knob.

pattern

thread

used,

wiU

sewing

switch

memory

cycle)

The

needle

threading

Y

trim,

it

after

is

set

can

- 4 -

Page 14

40. Air

41. Air consumption: 1.8 N{/min.

42.

pressure

Input

functions

used:

of

the

main

unit:

5 to5.5

Zigzag

Offset

Different

trimming,

etc.)

Point

kgf/cm"

sewing

sewing

adding,

(0.5to0.55

_|~

1_

types

of sewing

temporary stop,

point

moving,

MPa)

Spline

Curve,linear, point

machine

feeding

point

control

frame

erasing,

(pattern

up/down,

inverting etc.

erasing,

speed change

thread

- 5 -

Page 15

3.

OPERATION

3-1.

Namesofthe

main

components

O Power ON/OFF switch

O Sewingmachine head

0 Sewingmachine

O Control box

0

Operation

Feeding

©

O Start switch

0

Air

©

Temporary

0 Thread stand

frame

regulating

panel

device

stop

motor

switch

switch

0

Power

To turn ON/OFF the sewing machine motor, control box and operation panel.

0

Sewing

The work holder, which is driven by the stepping motor, moves a workpiece in synchronization with the

vertical motionofthe needle bar. This mechanism permits complicated pattern sewing.

0

Sewing

The use of an electronic stop motor allows sewing at the desired speed under the control of the clutch and

brake.

O

Control

Acts as the brain which controls the sewing machine. Elearonic components are incorporated, including

ON/OFF

machine

machine

box

switch

head

motor

printedcircuitboardsand transformers, andsends out variousinput and outputcommandsto other

components.

- 6 -

Page 16

0

Operation

Consists

outputs

The

the needle point.

The

0

Feeding

Turns

O

start

Actsasthe

panel

mainlyofswitches,

displaydata and switch information.

main

unit

input

operationisperformed

memory

switch is used for selectingoperations and changingset

frame

switch

ON/OFF

switch

the

sewing

feeding

command

digital

frame

switch,

solenoid

displays

and

starts

andabuzzer.Itreceives

whereby

at the

the

time

sewing

0 Air regulating device

Consists

theair

pressure during installation of the sewing machine.

0

Temporary

Pressthis switch to stop the feed and sewing

switchispressed

At this state, the

been performed by raising or lowering the needlethreadingswitch.

0

Thread

of the

source

stand

filter

regulator,

pressure,

stop

switch

during

returntoorigin,

pressure

indicating

a stitching

gauge,

it withan error

mechanism

cycle,

the

machine

forward

and

backward

air

cock,

code.

commands

patternisinput

specified

based

stops

to lift or

on the

pressure

The

device

of the sewing machineduringoperation. Whenthis

without

switches

values.

data

switch

is also

performing

become

while

lower

stored

andother

valid after

from

the

moving

the

in the

the

feeding

micro

parts.Itdetectsadrop

usedtoadjust

automatic

thread

control

feed

soastoadjust

frame.

floppy

the

operating

thread

trimming.

trimming

box,

disk.

and

in

air

has

- 7 -

Page 17

3-2.

Control

box

panel

r

Roppy disk

insertion

Eject button

o

Maximum

automaticaUy

counterclockwise.

slot

-m

speed

knob/Bobbin

S^Tset

adjusted

w

❖

E

Fig. 3-2

winder

the

maximum

accordingtothe

switch

sewing

speedofthe

stitch

length.Ifa

Microfloppy disk

Shutter

plate

Write protect hole

Fig. 3-3

machine.

slower

NormaUy,

speedisrequired,

Write protect tab

the

sewtag

rum

this

sj^

knob

is

m^Ae

state

come

that

pressing

that

0 Floppy

The

^ter

right

fiSore

too?

and

the

down,

then

thereisnothing

the

knob

the

bobbin

disk

operation

"ur^ng^ON

until

the

turning

you

feeding

the

under

(to

winder

driver

LED

shows

frame

sewing

turn

the?^^

eject

push-button

O^

toe

switchisoperative

(to

turn

ON

will

come

machine

the

needle.)

OFF

the

that

the

switch

pops

power

switch,

the

bobbin

winder

switch)

down.

Turn

ON

the

rotatesata

The

bobbin

driverisinaspecified

slowly

out.

press

constant

machine

winder

switch)orturamg

while

the

insert

the

toe

eject

- 8 -

canbestoppedbyre-tuming

feeding

floppy

pushbutton,

while

the

start

switchtoallow

speedtowmd

ON

frameisin

operating

disk

with

and

state.

side©(as

take

the

sewing

the

machineisin

the

ON

the

temporary

highest

showninFig.

out

toe

floppy

the

intermediate

the

stop

position.)

presser

start

switc^

switch.

3-3)

disk.

«op

to

(N

faang

Page 18

(3) Write-protect hole (Fig. 3-3)

When the write-protect tab is moved so as to open the write-protect hole, it is no longer possible to write

data on to the disk. Do this to store programming data. For writing data on to the disk, move the write-

protect tab until it is exposed.

[Caution]

Never

turn

ON/OFF

(4) Micro floppy disk (Fig. 3-3)

Precautions when handling and storing the floppy disk

1) Do not open the shutter and touch the magnetic surface.

2) Do not apply pressure on the shutter plate or the opening/closing spring (slider), or else the disk may

become damaged.

3) Do not allow the hub to become damaged and do not use the disk with dust on the hub, or else errors

may occur. Always keep the hub clean.

4) Do not use thinner, alcohol or Freon gas on the disk.

5) Do not use erasers on the disk.

6) Do not eat or drink near the disk.

7) Do not store the disk in a place where thereis a magneticfield.

8) Do not store the disk in a dusty place.

the

power

switch

with

the

fioppy

disk

loaded.

e Needle

(1) Whenthe needle threading switch is pressed side while the sewing machine is stopped, the intermediate

presser and the feeding frame will

pressed during needle threading, the sewing machine will not run.

(2)

When

forward

lowering the needle threading switch.

Ifthe

thenstoppedwith the needle up, by raising/lowering the needlethreadingswitch. Prior to the above

operation,

sewing LED is lit up.)

O Scale switch

Takingapattern

X-axis

patternis set eitherby increasing or decreasingthe stitch length or the numberof stitches. Pattern

enlargementorreduction

input,

0 Sewing

When

normal

Whenthisswitch is set to the position,only the feed

Whenever

position

threading

the

temporary

and

backward

needle

be sure that thereis

and/or

the

enlargementorreduction

machine

the

programtooperate

sewing

enlarging/reducingapatternorsewinganewly

to check the shapeof the

position to start sewing.

switch

stop

is notat its

(INC/DEC

written

Y-axis

independently

ON/OFF switch

operation

come

down to allow the needle to be threaded. If the start switch is

switchispressedONand

switches

highest

become

resting

nothing

valid

position

underthe

of Number of stitches)

on the

floppy

disk as

withinarangeof0.1%to400%.

dataisread

accordingtothe

the

for

computation

ofa

patternisalways

sewing

machineisstoredinthe

programbysetting

pattern

in the

after

thread

(error

needle.

100%,

program.

the

sewing

machineisstopped,

trimming

[3]),

the

(Theneedle

theoriginal

while

theSet

has

madiine

threading

pattern

The

Ready

been

performed,byraising

willbeautomatically

canbe

enlargementorreduction

indicator

donebyincreasingordecreasing

floppy

disk,

the

sewing

mechanism

programmed

After

completing

machine

will work.

pattern,

the

the

returntoorigin,

driven

switchis valid while the

enlargedorreduced

lampisON.

the

machine

switchtothe

set this

check,

switch

set theswitchto the

the

stitch

will

perform

^

to the 131

For

or

and

in the

of a

point

length.

position.

- 9 -

Page 19

3-3.

Operation

panel

READY

indicator lamp-

RE^

Pattern

X

Scale

Y

Scale

Counter

Error

I

Number

I Input

No.

Model

StitclitypeiSpeed

Displays

Funclion

Pijch

Misn

Forward

Backward

Return

Origin

Reset

(select)

Operation swKches Setting switches

to

Pattern

No.

X

Scale

(review)

Y

Scale

(end)

Counter

(set)

|

1

•JUICI

7

4

<

1 2

:1

0

(Cancel)

:|

AMS

8

•

5

(Enter)

T

Set

Set

9

6

•

3

Ready

(Test)

ready switch

Fig. 3-4

Setting switches

Theseswitchescan be set immediately after the powerswitchis turned ON or when the READYindicator

lampgoesout by

usingthe

The

numeric

designated

pressing

keys. The

number

theset

entered

must

consistofthree

ready

switch.

After

pressing

a setting

switch,

the

desired

valuewillbe shownon the corresponding digitaldisplay.

digits.Ifmore

thanthreedigitsare

entered,

valueis

onlythe last

digits entered will become the designated figures.

entered

three

Pattern

No.

Selects a pattern or patterns which have been stored in the floppy disk (001 to 999).

[Caution]

Ifa pattern No. not

X

number

Scale/Y

flashesonand

Scale

Takingapattern

stored

written

in the floppy disk is specified, error number "1" is given, and

offonthe

on the

display.

floppy

diskas

100%,

the

original

pattern

canbe

enlargedorreduced

the

specified

X-axisand/or Y-axis independently within a rangeof 0.1% to 400%. The origin or the scale reference point

determined

original pattern.

[Caution]

1. Whenever a pattern

check

2.

With

length

cannot

stitches

3. To enlarge/reduce

when the

that

the

enlarged

the

scale

switch

exceeds

be enlarged if

12.7 mm. With

by a jump input).

program

has

the

hasbeen input is used as the reference point for enlargingor reducing the

been enlarged, turn OFF

pattern

setto"INCorDEC of

the

stays

the

number of

Should

within

scale

stitches

this

switch

happen,

pattern in increments of 0.1%,

the

the

sewing

stitch

length,"apattern

setto"INC

exceeds

error

-

10

-

sewing machine ON/OFFswitch,

areaofthe

feeding

frame.

cannotbeenlargedifthe

andbesure

or DEC of number of stitches," a pattern

the

computable

number

set

"2" will be indicated.

the Item 1 of Memory switch No. 13 to "2."

range

(within 400 mm or 4,000

stitch

in the

to

Page 20

4.

Counter

Counts the number of garments sewn, and indicates when to replace the bobbin by means of an alarm. When

the quantity of the bobbin thread has been reduced to the preset level, the counter flashes on and off urging

you to replace the bobbin. Sewing is not possible while the counter is flashing on and off. Press the reset

switch after replacing the bobbin, and the counter will be reset to "000", allowing the machine to be restarted.

(The counter switch is turned OFF at the time of delivery.)

5. Set ready switch/READY (Sewing LED)

Sets off the following series of operation when pressed after setting the pattern No., X/Y scale, counter and

scale switch (INC/DEC of stitch length or INC/DEC of number of stitches):

1) The specified pattern or patterns are read from the floppy disk.

2) Operation is performed based on the entered scale data. While the compulation is being executed, the

sewing LED (READY) flashes on and off.

3) Upon completionofthe computation, the feeding frame comes down, automatically moves via the origin

to thesewingstart

[Caution]

Remember

performed

only

that

point

(the2nd

the

above-mentioned

when

the

origin

power

if the 2nd originhasbeenset), and then goes up.

seriesofoperationtoset

switchisturned

ON.

the

machine

ready

for

sewing

4) The READY lamp is continually lit instead of flashing on and off, showing that the machine is ready to

start sewing. Note that you are not allowed to make any setting changes while the READY lamp is ON.

To make a setting change in this case, press the set ready switch. This will cause the READY lamp to go

out, thus permitting a setting change.

[Caution]

Do

not

put

your

fingers

on

completionofcomputation,ifthe

been

used

until

the

this

time,

the

floppy

under

the

poweristurned

diskisnot

required.

feeding

frame

pattern

OFF

No.orX/Y

canbesewnbysimply

since

the

feeding

scaleisnot

frame

automaticaiiy

changed,

turningONthe

the

pattern

set

comes

ready

is

down

which

switch.

has

At

6.

Forward/Backward

When the forward switch is pressed with the feeding frame down, the material is fed forward by one stitch.

When the backward switch is pressed with the feeding frame down, the material is fed backward by one

stitch. If these switches are kept pressed, the material is fed slowly for the first stitch, after which it is

automatically fed quickly.

7. Return to origin

When this switch is pressed during a temporary stop, the feeding frame will automatically move to the

sewing start point or the 2nd origin, and the feeding frame will go up and stop.

8. Jog keys (Numeric key 2, 4, 6, 8: A mark)

These keys function as numeric keys while the READY lamp is OFF, and work as jog keys while the

READY lamp is ON. If any of these keys is pressed with the feeding frame down at the sewing start, the

needle will move in the direction shown by the arrow on the pressed key. At this time, the movementofthe

needle is automatically stored in memory. Set the 2nd origin at the desired position within the material

feeding range.

9.

Reset

Resets the counter value when pressed after a temporary stop following a press of the set ready switch or

completionof pattern sewing. If the reset switch is pressed while the counter is flashing on and off, the total

value

indicatedonthe

counter

willbereset.

-

11

-

Page 21

10. Error No. display

ifVnyofthe

foliowing

errors

occurs,i.willbeindicrrtedbyan

"Error

Number,"

andnofurrher

operarion

wiU

Error

code

Pattern No. error and read error.

1

Enlargemoit

2

Needleuperror

3

Sewing

4

Temporarystop fedication

5

Memorycapacity indication

6

Machine lock or needle position error

7

Solenoid

8

Thread breakage indication

9

Micro floppy disk format error

0

Air

A

E

11,

Electronic

The

electronic

3-4.

Other

switches

1, Feeding frame switch

pressure

Sewing

bu22er

buzzer

error

area

error

connector

drop

machine

beeps

Description

error

(less

than4kgf/cm^

reverse

rotation

each

timeaswitchispressed.

error

error

2.

3.

Start

switdi

Temporary

Wiper switch

stop switch

When

the

feeding

frame

will

the feeding frame to go up.

When

the

start

down,

the

This

switchisusedtostop

during

operation.

stitching

cycle,

Subsequently,

and

off

and will then remain lit up.

This

switchisusedtoselect

actuated after thread trimming.

come

down.

switch

machine

error

the

frame

switch

Another

(left)ispressed

starts

sewing.

When

this

number

error

indicationonthe

(right)ispressed,

pressonthe

with

the

feed

and

sewing

switchispressed

"5"

willbeindicated.

display

whether

the

wiper

the

switch

the

feeding

mechanisms

during

will

is tobe

feeding

causes

frame

a

flash

on

-

12

-

Page 22

3-5.

Checking

1.

Be

2. Be sure that the needle stays within the feeding frame.

before

sure that the line voltage is suitable for the machine table.

operation

3. Be sure that the needle entry point is set at the center of the intermediate presser.

4. Be sure that no micro floppy is in the disk driver.

[Caution]

If

the

power

be

erased.Sobe

the

disk

switchisturned

sure

except

when

writing

ON/OFF with a micro floppy

to load or

unload

dataonthe

the

disk.

disk

while

the

disk

power

loaded,

the

is ON. Also, be

data

storedinthe

sure

5. Check the direction of rotation of the sewing machine as follows:

Whenthe bobbin winder switch is turned

"ON"

uponcompletion of sewing preparation, the feeding frame

will come down. The sewing machinewill then run when the start switch is pressed. At this time, check

that the

direction, correa it by

reconnecting it.

[Caution]

Be

be

6.

Check

pulley

turns

counterclockwiseasobserved

reversing

sure

to turn OFF the power switch before connecting or disconnecting

suretosecurely

the

oil

connect

level

the motorpowerplug

the

plug.

from

connection,

the

pulley

side. If the pulley turns in the

i.e.,

turn

the plug 180 degreesbefore

the

motor power plug. Also,

Lubricate the machine (there are two lubrication holes) until the oil level readies the red mark on the oil

gauge. Before starting the sewing machine which has just been installed or which has not been used for a

long periodof time,apply a few drops of lubricating oil to the crank

hole, and

one

drop to the shuttle race surface.

assembly

throughthe crank lubricating

disk

may

to write-protect

opposite

7.

Remove

the bed

fixing

boltbeforestarting

operation.

Installthebed

jBxing

boltat the time of

8. When the polyethylene oiler is completely filled with oil, remove the oiler so that it can drain.

9. Compatibility of floppy disks

For the

them.

The

AMS-A

floppy

disk

type

(2DD)

floppy

for the

disk (ID) and

AMS-215C

AMS-B

type

cannotbeused

floppy

with the

disk

(2DD),

AMS-A

data can only be read

type,

AMS-B

type,

-212C and -22QCmodels of sewing machines.

transportation.

from

AMS-210C,

-

13

-

Page 23

3-6.

Operation

procedure

Follow the operation procedureflow chart given below:

Preparation

for sewing

c

Set

the

on

the

turnuNthe

power switch

Set

the

the panel?

Pattern

Y-scale

Counter

Load

Start

witches

s

ntrol

cc

switches

X-scale

the

No

YES

disk

box

3

Sewing machine ON/OFF switch — OFF

INC/DECof

stitches-•select

Bobbin

Needle threading switch-•OFF

Sewing machine motor

winder

the

stitch length or

eitherofthem.

switch-•OFF

starts

to run.

the

number of

Operation petnelindicator lamps light up.

YES

Turn OFF the power switch

Troubleshooting

Press

the

set

readv

switch

Data back-up?

N 0

Reads

the

data

Computes

the X

and

Y-scales

The feedingframe

comes

down

Immediately

the power switch

is turned

after^

ON?--*^

Tves

Feeds along the travel

limitsofthe

X/Y

axis.

YES

N 0

READY

lamp flashes on and offduring the

computation.

Error indication *A' {air pressure drop error)

Error indication No. "3* (needle up error)

(See P. 165 for the error indication)

Performedonce after the power switch is turned ON

-

14

-

Page 24

Origin retrieve

Check

for

the

directionofrotation

correct

Move to the sewing

start point

I

Feeding frame goes up

1

READYlamplights up

I

1 switch to

bbin

Srttte

bo

DN

The feeding fiame

comes

down

Start

switch

ON/OFF

Intermediate presser

comes

down

Sewing machine

starts running

Start

switch

ONADFF

winder

Move to

the

2nd

Make

sure

any

there

needle

indication

Remove

Directionofrotation

Refertoerror

origin, if it

is nothing

thread.

correct?

"E". (P.

has

under

been

165)

the

set

needle.

Trial operations

Sewingmachine

Intermediatepresser

goes

Set

switchtoOFF

up

bobbin

stop

winder

Feedingframe goes up

&t

sewing machine

ON/OFF

switchtoOFF

Set feeding frame

switchtoON

Feeding frame

comes

down

Machine

stop

with

the

needle

up.

-

15

-

Page 25

Sewing operation

Turn ON start switch

Fceti

control

YES

Feedingframe

goes

up

Set sewing machine

ON/OFFswitchto ON

Sec a woriqiiece

Set feeding frame

switch to ON

Feedingframe

comes

down

ongin

YES

Feed

control

TurnONthe

start

switch

Intermediate pcesser

comes

down

Sewing machine

starts running

Positioning

Material held

securely?

-

16

-

Page 26

Sewing

Thread

tension

balanced?

NO

.Needle thread broken?'

NO

Temporary

Thread

actuated

Sewing

Wper

Returns

sewing start point

Feeding

End?

YES

trimmer

machine

is actuated

to the

frame

stop?

NO

stops

goesup

YES

TurnON the

stopswitch

is

temporary

Returns to the 2nd origin, if it

been

set.

has

Onecycle

completed

' Displaysetting-

Set theset ready

switchtoON

YES

NO

<3^

-

17

Reset

the

Counter.

-

Page 27

Operation

stopped

n^le

thread

duetoL ^

breakage.

Feed contro] stop

Thread

is

Sewing machine

stops

Wiper is actuated.

Intermediate presser

goes

Return to

actuated

up

trimmer

YES

Threading ttie machine

YES

ongin

NO

Feed

YES

control

lumUNthe

to origin switch

Movetothe

sewing stait

Feedii^ frame

goes

up

return

pdnt

Move to

been

the

2nd

set

origin, if it

has

-

18

-

Page 28

Teoipotaiy stop opeiation

Stop feed control

N O

During sewing?

Sewing machines

stops

Intermediate prcsscr

goes

up

Re-start?

Thread trimming?

"TurnONthe

threading switch

Intermediate presser

comes

down

Turn

I '

OFF

threading

t

switch

Sewingmachineruns.

NO

YES

i:?

YES

YES

needle

the

needle

Eliminate

the

causeofthe

temporary

stop.

The

thread

is

trimmer

actuated

Sewing machine

stops

tViper is actuated

Intermediate presser

goes

up

-

19

-

Page 29

.

3-7.

1.

Precautions

Before

sewinganew

flae

sewing

speed

during

operation

patternora

with

respectto.be

accordingtothe

newly

enlarged

feeding

ffante.

typ

^

tt<>mbesuretocarry

pattern,besure

sewina

speed

out

trial

(s.p.m.)

sewingtocheck

th

Whenanerror

5.

Be

suretoturn

indicationisgiven,besure

riTTc

Ks.fnrp

the

power

OFF

, •

ooenins

before

openmg

-.rvhv1

to

testerorelse

r^nt^:Srr;ri,bedan,ag«..

completionofthe

9.

Avoid

point

1

computanon.

pulling

the

workpiece

shouldbedislocated,

press

f

the

the

Set

Reaay

identify

the

control

needle

before

the

cause

the

depressing

box

tester

and

take

prevent

cover.

voltage

^

corrective

dust

^

maybeappli

the

start

action.

from

getting

into

the

(^\fexv

pe

appliedtosen.iconduc.or

control

weCiC*

.,0nbobbin.

swiiui

the

corr^t

„XorY

sewing

needle

start

point,

entry

-

20

-

Page 30

4.

DESCRIPTION

4-1.

Sewing

machine

OF

EACH

MAIN

COMPONENT

Fig. 4-1

O Synchronizer O

X-axis stepping motor O

Y-axis stepping motor 0

O X-axis

0

0

sensor

Y-axis

sensor 0

Work

damp

foot

cylinder

-

Intermediate

Thread

Wiper

Thread

Temporary

Wiper

0

21

-

presser

trimmer

solenoid

breakage

stop

switch

liftingcylinder

solenoid

detector

switch

Page 31

O

Synchronizer

Mainly consists of a generator stator and position detecting solenoid incorporated into the sewing machine

pulley. It detects whether the needle is in its upper or lower position, and also detects the sewing speed, after

which it sends input signals to the control box based on the detection results.

X-axis

Feeds material in the directionofthe X-axis according to the pattern data given by the control box.

O Y-axis

Feeds material in the direction of the Y-axis according to the pattern data given by the control box.

O

X-axis

0

Y-axis

0

O

0

Thread

Actuates the clutch mechanism for the thread trimmer according to the command from the synchronizer. It

stepping

stepping

sensor

Mainly

consists of an

the

origin

in the

inputsignals to the control box based on the detection results.

sensor

Mainly

consists

origin

in the

signalsto the controlbox basedon the detection results.

Work

clamp

By

turning

comes down to securely hold the material.

Intermediate

During

sewing,

intermediatepresser causing it to go up and come down.

trimmer

thenactuates

X-axis

of a

Y-axis

foot

ON/OFF

presser

theair

solenoid

causing

motor

motor

X-axis

within

Y-axis

within

cylinder

the

feeding

cylinder

the

slit disk,an

slit disk,a

the

lifting

thread

the

sewing

sewing

frame

cylinder

controls

trimmer

X-axis

areaand the

Y-axis

area

and

switch,

the

vertical

cam

originsensorand an

boundary

origin

sensoranda

the

boundary

the

and

feeding

thread

stroke

frame

path

trimmer

of the

Y-axis

of the

activated

of the

mechanism

X-axis

limited

travel

limited

sewing

by theair

intermediate

travellimitsensor. It

sewing

area.Itsends

limit

sensor.Itdetects

area.Itsends

cylinder

presser,

and

to join together.

detects

the

the

the

input

goesupand

actuates

the

0 Wiper

<0 Thread

0

0

solenoid

Actuates the wiper after the threadhas been

breakage

Detects the connection between the thread take-up spring and the thread breakage detector disk each time a

stitch is formed, and sends the result in terms of an input signal to the control box. If needle thread breakage

is detected, the sewing machine will slow down, trim the thread, and stop.

Temporary

Thisswitchis

turned

ON, the

Wiper

switch

Usedto specify

stop

used

machine

whether

detector

switch

to stop the

feed

and

will stop without performing thread trimming.

the wiper is to be

trimmed.

operation

actuated

of the

after

sewing

thread

machine

trimming.

during

sewing.

If this

switch

is

-

22

-

Page 32

4-2.

Control

box

"\

Fig. 4-2

O CPU circuit board

l/F

circuit

board

O PMDC circuit board

o Power circuit board

O Switching regulator

0 Transformer

O Fuse box

O

0

-

23

-

Cooling

Floppy

fan

disk

driver

Page 33

receiving

.

including ICs.

•

Floppy

•

•

.

I/F

The

•

.

.

.

)

PMDC

Activates

circuit

^ •

.

the

reset

T^c

Microprocessor

Input

circuits

Switch

circuit

following

Magnet

Display

Solenoid

Sewing

circuit

board.Itincludes;

Current

Stepping

signal

disk

drive

for

signal

output

board

circuits

actuating

actuating

valve

machine

board

the

stepping

limiter

motor

conirol

control

the

circuit

actuating

actuating

circuit

driving

from

arcuit

circuit

switches

circuit

are

mounted.

circuit

motor

circuit

the

I/F

circuit.

U

arcuit

arcuit

receiving

after

receivmg

lender

the

sewing

the

control

solenoid

machineoroperation

valve

signal

from

after

the

CPU

panel

circuit

board

through

board.

0

:

C^4v'S^^"circuit

.

+5V,

+12V,

®

0

Transformer

o

^Str-daTlitle'toprotLtthetmoUngfan.

Cooling

Usedtocool

the

CPU

the

-12V

»"ut

outputs

wiring

from

received

for

the

circuits

the

secondary

from

PMDC

50V

lag

fusetoprotea

fan „ ^ j

the

drcuit

elements,

board

takingmfresh

the

solenoids,

the

secondary

circuit

board

transformer

AC

for

the

a

^ron,

outside

air

transformer

and

outputs

stepping

lOA

motor

fusetoprotect

the

machine.

to

provide

.5V.

.12V

actuator,

the

the

power

supply,

and

-HV.

lOOV

AC

for

the

stepping

motor

and

switching

and

coo

g

-

24

-

Page 34

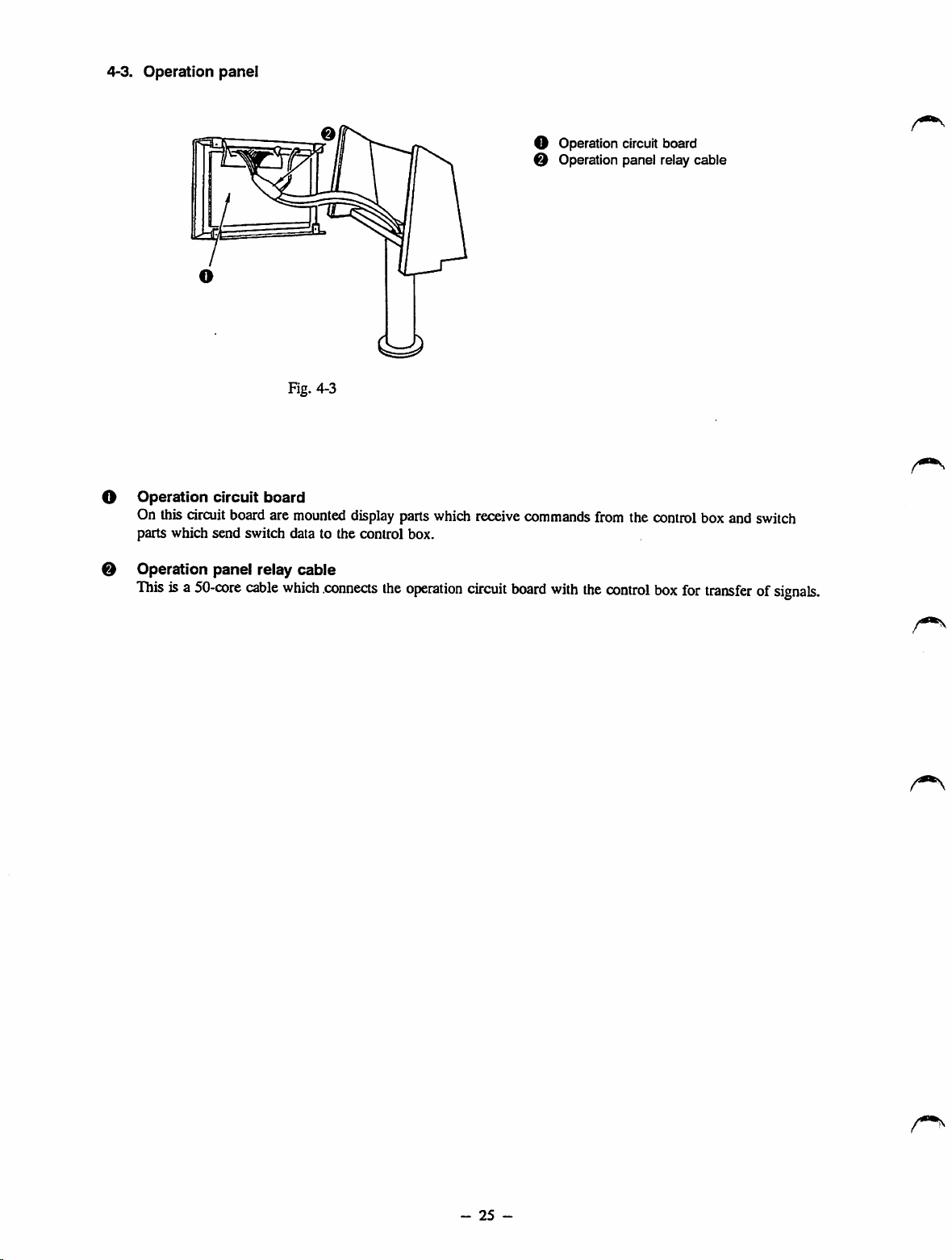

4-3.

Operation

panel

Fig. 4-3

O

Operation

On this circuitboard are

parts which send switch data to the control box.

0 Operation panel relay cable

This

isa

circuit

50-core

board

cable

mounted

which

.connects

O Operation

O Operation panel relay cable

displayparts which receive commands from the controlbox and switch

the

operation

circuit

board

with

the

circuit

control

board

box

for

transferofsignals.

-

25

-

Page 35

4-4.

Motor

A 400W, 4-pole electronic-slop motor is used for the sewing machine motor. The clutch brake disk components are

compatible with a general lockstitch sewing machine motor.

1. Structure of the motor and how the motor speed is changed

The following diagram shows the structure of the electronic-stop motor. As long as the power of the machine

stays ON, the motor (rotor, flywheel, and clutch disk) runs constantly. The clutch ring is connected to the output

shaft through the splines, so it rotates together with the output shaft, and can slide crosswise.

When the clutch coil is energized, lines of magnetic force are produced as shown by the solid line arrow, and the

clutch ring is pressed against the clutch disk, thereby transmitting the motor rotation to the output shaft. When

the brake coil is energized, lines of magnetic force are produced as shown by the broken line arrow, and the

brake ring is pressed against the brake disk (constructed integral with the pulley side bracket, and does not turn),

thus stopping the rotation of the output shaft.

At medium speed, the clutch coil and the brake coil are energized for a short period of time alternately for

rotation.

,—

^ ^

Brake

yoke

Pulley

side

bracket

End

cover

Clutch

Stator

\

„

Rotor

Intemal

Housing

bracket

yoke

X ^

Capacitor

machine)

Centrifugal fan

Fig. 4-4 Structure of Electronic-stop Motor

Clutch

/WWW/,

Clutch

disk

Brake

Clutch

Pulley cover

disk

shaft

-

26

-

Page 36

5.

ADJUSTMENTS

5-1.

Mechanical

parts

STANDARD

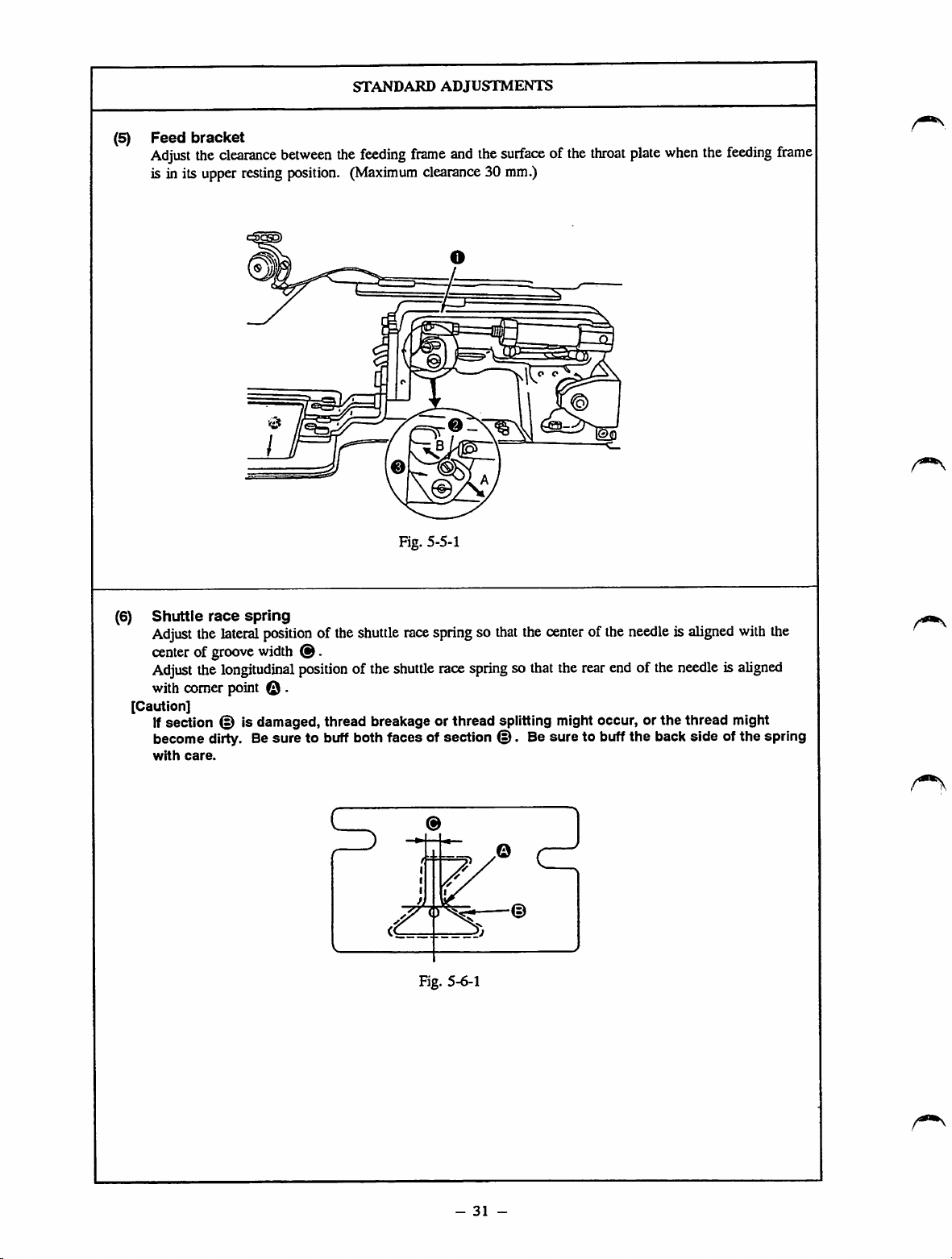

(1)

Checking

the

directionofrotationofthe

After confirming that the READY indicator

lamp has lit up, set the bobbin winder switch to

"ON", and press the start switch. At this time,

the handwheel should turn counterclockwise (in

the directionofthe arrow) as observed from the

pulley side.

reverse

and the

[Caution]

Be

suretocheck

the

handwheel

installedorthe

machine

Do

not

rotation

confirmed

If

direction,

madiine

has

been

start

sewing

of

the

as

correct.

the handwheel turns in the

error

willbeindicated,

wiU stop.

the

after

the

powers

completed.

unless

handwheel

direction

machine

supply

the

has

of

wiringofthe

direction

been

rotation

has

of

been

of

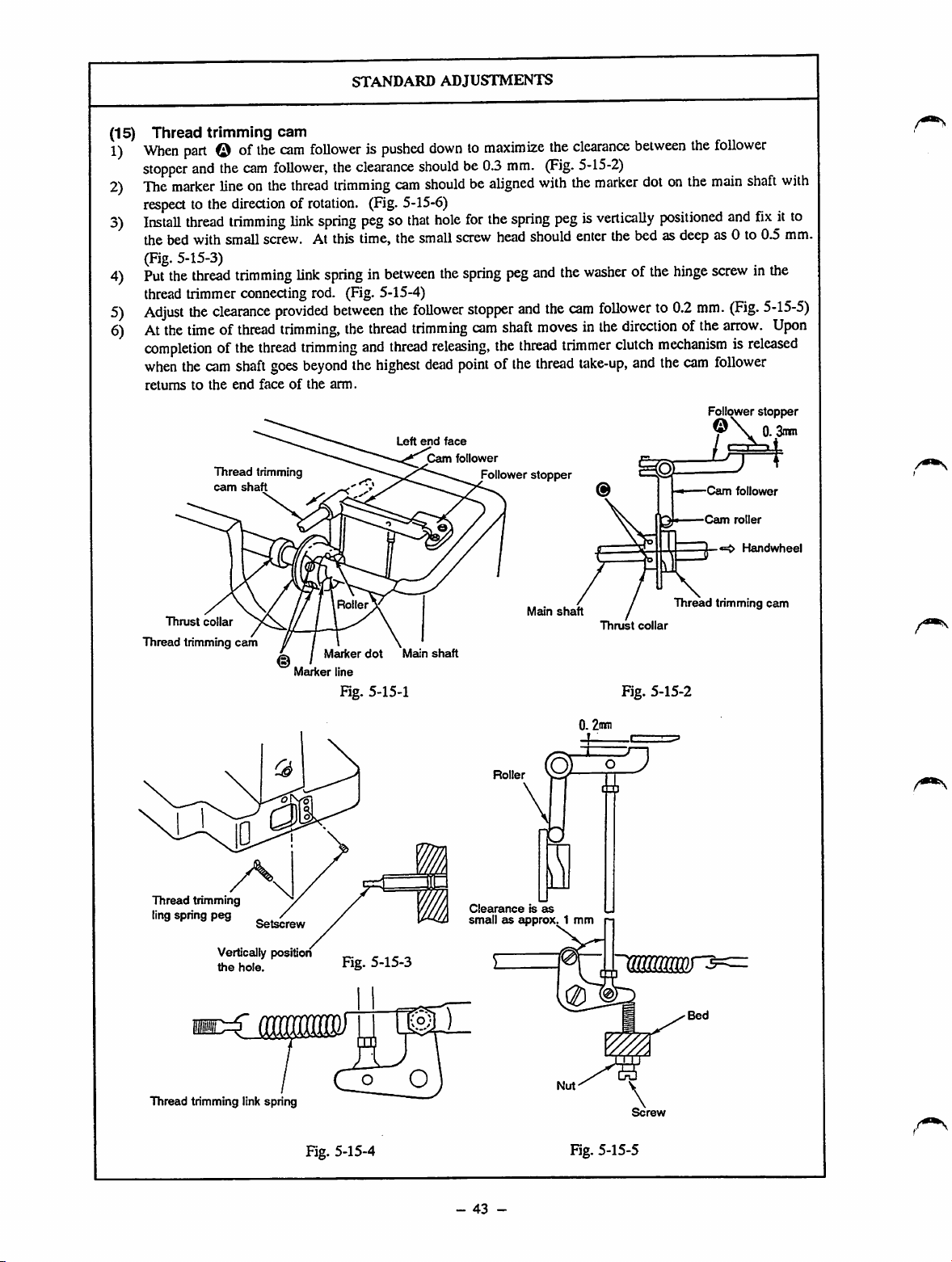

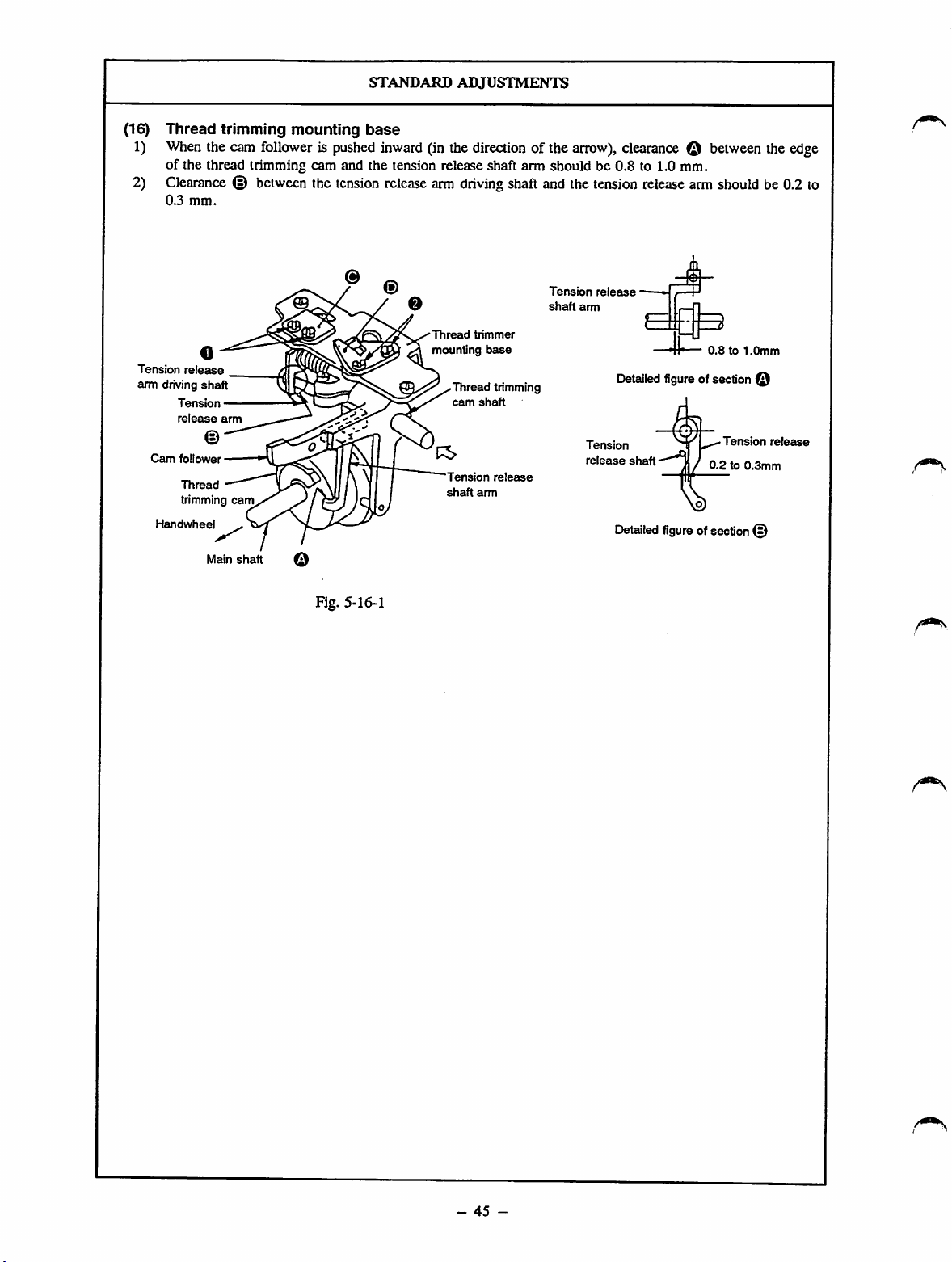

ADJUSTMENTS

handwheel

Fig. 5-1-1

ft&ADY

1 i

PdRernNa

XScato

YScato

Coiirter

Number

lln^

SMo»tm*iseM0

j 1

1

(2)

Heightofthe

needle

bar

Bringthe needlebar to the lowest dead point in its stroke. Adjust so that the

bar lower bushing is aligned with the upper marker line (for a DPx5 or

Marker

lines

the

DPx5

needle-

Marker

D

the

lines

DPx17

Fig. 5-2-1

for

needle

for

bottom

DPxl7

Fig. 5-2-2

end of the needle

needle).

Needle

lower

Upper marker line

V

Marker

the

(with

^of

bar

bushing

lines

for

DPx17

needle

needle

count

#22orhigher)

[Caution]

The

marker

lines

for

machineofwhich

DPx17 (#22orhigher

specification

code

G.

count)

are

only

engravedonthe

-

27

-

needle

barofthe

sewing

Page 37

oIfthe

motor

now

handwheel

power

turnsinthe

plug,

and

n

TO

ADJUST

reverse

direction,

reconnectitreversed.

0

Fig. 5-1-2

disconnect

the

RESULTS

o If

the

handwheel

direction,

the

error

switch

switchcan be operated.

OF IMPROPER

adjustment

the

machine

E.

In

canbeturned

turnsinthe

will

this

case,

OFF,

opposite

stop

showing

the

power

butnoother

1)

TurnONthe

up),

and

reaches

2^

Remove

3^

Loosen

^S

4)

After

5)

Turn

returntoits

6)

Attach

needle

threading

turn

the

handwheelbyhand

its

lowest

dead

rubber

plug0from

needle

bar

connection

o?

the

needlebyraisingorlowering

making

OFF

the

the

upper

rubber

adjustment,

needle

threading

resting

plug0to

switch

point.

the

setscrew0,and

securely

position.)

the

face

(the

until

face

p^te.

switch.

(The

plate.

the

needle

the

needle

needle

bar

adjust

me

bar

bar

O•

will

ill

o

Stitch

skippingorthread

occur.

breakage

may

-

28

-

Page 38

STANDARD

(3)

Stop

positionofthe

When the main shaft stops, marker dot O on the

machine arm should be midway between marker dot

No. 1 O and marker dot No. 2 on the handwheel.

For the sewing

G,

adjustsothat

machine

machine

arm rests between upper blue marker dot 0

main

shaft

of whichspecification code is

marker

dot O

engraved

and lower markerdot 0 engraved on the handwheel

when the sewing machinestops.

[Caution]

1. Be

suretodo

readytostart

2. This

adjustmentisunnecessary

operation.Ifthe

been adjusted, be

stop

position of

setonthe

this

sewing.

machine.

adjustment

stop

positionofthe

sure

the

main shaft with the workpiece

while

the

for normal

main

to check the newly adjusted

ADJUSTMENTS

on the

machine

shaft

is

has

Fig. 5-3-1

Direction

of

rotation

O

(4) Height of

1)

Make

and

up before setting the workpieceon the machine.

the

sure that the

the

sewing

Intermediate

sewing

pattern

indication

LED

presser

data has been

(READY

lamp)

2) Makesure that theneedleentry point is in the center

of intermediate presser

O-

3) Set Needle threading switch 0 in the control box to

the

4^

side.

The

feeding

presser

will

then

come

4) Turn the handwheel by hand until the needle bar

reaches

that

a 0.5

the

lowest

mm

dead

(standard

frame

down.

point

of its

adjustment

and

intermediate

stroke.

value)

Adjust

clearance

obtained between the top end of the intermediate

presser and the workpiece.

5)

After

making

the

adjustment,

set

Needle

threading

switch 0 to the side. The machinewill then

run

untilitreaches

maximum

the

intermediate

thicknessofthe

the

presser

needle-up

material

is 5

mm.)

stop

tobe

position.

sewn

read

has

(The

using

so

lit

is

Workpiece

Throat

Fig. 5-4-1

plate

-

29

-

Page 39

HOW

TO

ADJUST

RESULTS

ADJUSTMENT

OF

IMPROPER

Loosen

If the

solenoid

main

shaft

mounting

stops

prematurely

base

setscrew

before

O.

marker

dotNo.l O

or 0 on the handwheel reaches marker dot O on the machine

arm, move setscrew O in the direction of arrow (D and then

tighten the setscrew in that position. On the other hand, if the

main

shaftstops after

marker dotO,move setscrew O in the direction of arrow

and then tighten the setscrew in that position.

Repeat

3)

4)

step 1), 2)

located between marker dot No. 1 0 or 0 and marker dot No.

20

or 0 on the handwheel when the main shaft stops.

Securely

tighten

Directionofrotation

marker

until

solenoid

dot No. 2 0 or 0

marker

dot O on

mounting

the

machine

base

setsaew

Directionofrotation

passes

arm

O.

beyond

0,

is

If the main shaft stops before marker dot

O reaches marker dot No. 1 0 or 0

on

the

handwheel:

Thread trimming operation cannot be

completed (the main shaft stops before

the moving knife meets the counter

knife), leading to thread trimming

failure.

If the main shaft stops after marker dot

No. 2 0 or 0 passes

dot O on the machine arm:

A clearanceof1 mm or greater

beyond

marker

shown

in the figure cannot be obtained, and the

wiper and intermediate presser will come

in contact with the needle, which may

cause

the

needletobendorbreak.

The markerdot O on the

machine arm

marker

the

hcuidwheel.

dot

stopsatthe

No.2side

setscrew0,and

adjust

on

the

height

o

Loosen

The

msu'ker

machine

metrker

dot

the

handwheel.

intermediate

dot O on the

arm

stopsatthe

No.1side

on

presser

of the intermediate presser following the procedurestated on the

left. Uponcompletion of the adjustment,

tighten

the setsaew.

Be sure to adjust the height of the intermediate presser

according to the thickness of the material or the type

of thread to be used so that the material does not flap

during

sewing.

so that there is no clearance (0 mm),

o Afteradjusting the

check

the

position

ADJUSTMENTS (9).")

When

sewing

height

of the

of thewiper

floppy

material,

intermediate

adjust

presser,

be sure to

(Referto"STANDARD

1mmor

more

i

1mmormore

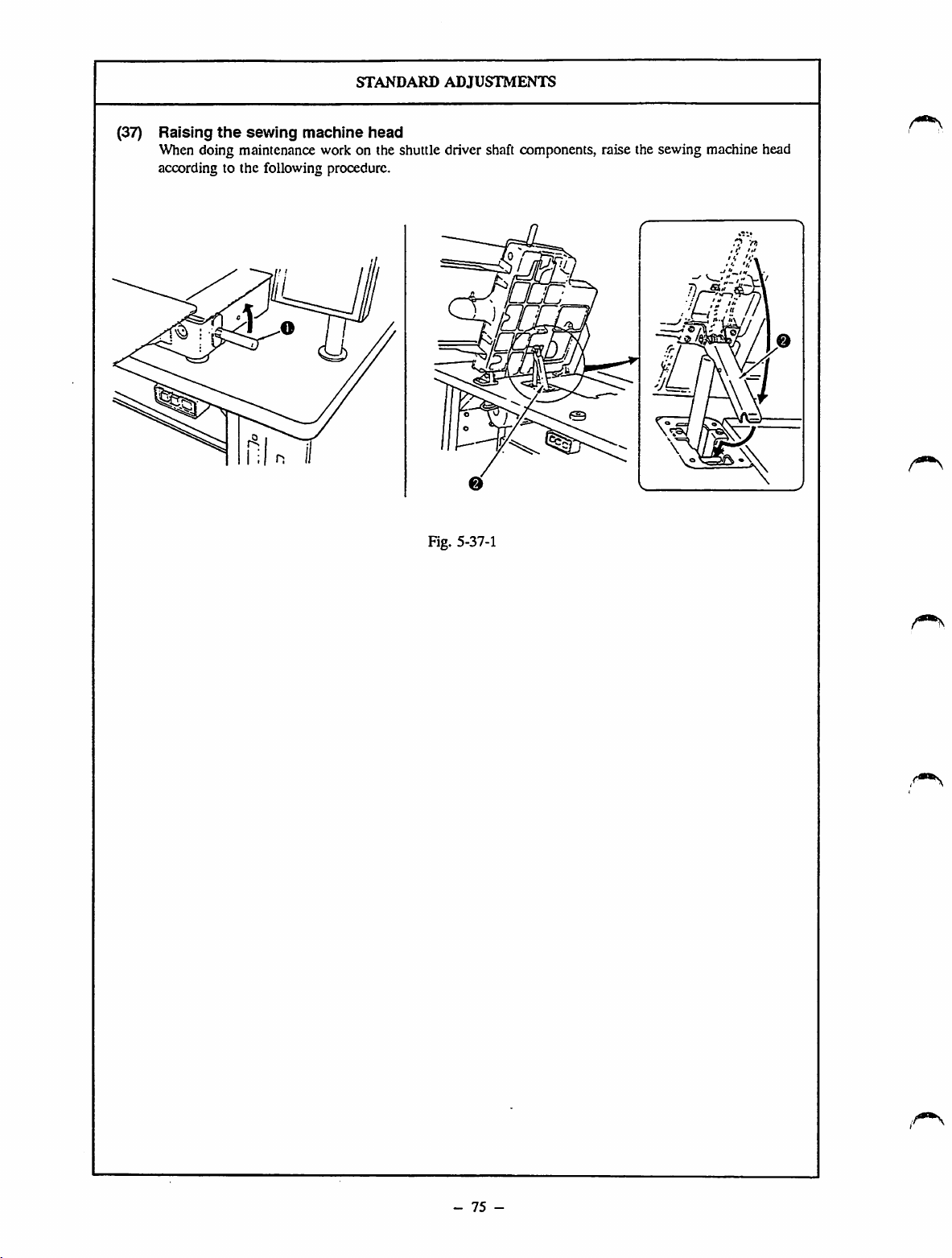

oIfthe clearance is too great: