Juki AMS-210DHL-6350 AL6 User Manual

(

RfUIIfttlJOi±S

I®

I HOT-WIRE TYPE THREAD TRIMMER)

MS-210 HL-6350/

L6

INSTRUCTION MANUAL I PARTS LIST

;;t;;!lX!&maJll!f;J;,

ll!iilirf<=f§.JifllO)

)ilo\\ll!i!JiJ

;t;lt,

1flt;JJ

G)

1JO:il!fllif;j;,

(

tct!~

ill

1flt;JJ

t>

llli1<=1il!t.Jl~~

1<!:11llb"ld-~

Q)

:il!~IJD:il!<PI<=~<I>~l.ttr

~

?l<:t.J::>

tJ:d'3,

1i'ltJJtll9i~f;J;I~tl:lf<lifllif;j;

AMS21

AMS-21

;(!:i)\;JJ,

t>-Jlll:l<=:il!t'1i!:lfffl'-' n 13;90)<:', l'ilclili§

;k~:ii!<."ld-

lo

lml<:-t~C::iiio\1

<::~1a;9

ODHL6350SZAL61<::>~1Z"O)maJlj!c9

ODHL-6300

-t~~f¥10)J:c

b

3;90)c:k~1<!:fl.l:j<:~,

u ;1;9 o

<.

nr.:~i3,

0 :>;t;

t>,

"&11

AMS-21

C::!fffl

<.

ll::t!~

JlHt;l<:fl"l!ttJ:1il!1<!:~~t!tt

ttt!~

lo

:t<:~J:NPIJD:il!t.Jl<PI!Jitr

!fltJ.J

t>

f;J;ci!'t.J:~

OFF

l<:lll!'m

00

lo

1fltJJbftlliPJil<:f;J;'J'1<!:~MI<:>!i:il:t"ld-~

1;:

1:

f.,

Z"

® b

o

O)!li!!&maJlj!O)

!<::>~

IZ:i:tio\1<.

:Qfl'l1i!:lffilt!tl:Q~i31;J;,

n,

li~~7*

f<=tJ:

t>

a<9

3;9

o

f:£'<:~1<::>~

ttt!~lo

c1JD:il!tr

0

ll:"O)

I"C

'f0)1il!

nt.J:~

1

CAUTION:

This Instruction Manual

Read "Safety

AMS-2100 packed together

AMS-21

In

addition,

CD

Never allow your hands

very hot when they are heated.

C1)

Smoke occurs at the time of thread trimming. Be careful that you do not breathe in the smoke

when using thread which occurs

Gl

When the sewing machine is temporarily stopped during hot-wire heating, immediately heating

is interrupted for safety and heating is not performed

After all, thread trimming is not performed.

In

addition, thread breakage detector has been factory-set

Instructions"

ODHL6350/AL6.

be

careful

is

the Instruction Manual for AMS-210DHL6350/AL6.

described in

with

this

of

the following items since since hot wires are used for thread trimming.

to

come near the thread trimming place since the hot wires become

the

Instruction Manuals

machine and

harmful smoke for the human body.

fully

for

AMS-21 ODHL-6300 and

understand them before

until

the sewing has been completed.

to

OFF

at the time of delivery.

No.1301-00

29347804

using

your

13

~

1.~~

1.1\!f

2.1±

II

.

1 . ..t*tJJ!:)

2.

3 .

4.

5.

5-1.

5-2.

6. I

7.

m.

N.

m

1

<;:u-..,

Pl'"fiii•J:tE

l'*~!:):±llJ~O)~~

..t*~!:)

*tJJ!:)tJ-1'

*tJJ!:)

~~:r·-$'

~~7'-$'

7-11:

-t'O)it!J0)1'~i3'

:to

I

7-ij2ff~

.............................................................................................................

~

.............................................................................................................................

.............................................................................................................................

101il

:!!&

.......................................................................................................

i:ll~~~

:±I

lJ~O)~~

t--::0)~~

.~~j}JifiUlfi:P

'?l,

\ "(' ........................................................................................................ 1 5

'Y

?~

................................................................................................

.......................................................................................................

...............................................................................................

...............................................................................................

...................................................................................................

...........................................................................................................

A.t.J¥l11Ji

A.t.J'¥li!Ji

(00

(0

1

1,

o.

002)

020)

...................................................................

...................................................................

........................................................................................................

...........................................................................................

1

1

3

5

5

6

7

8

9

1 1

12

16

20

21

V .

H-

"Y

1J

:A

1--

............................................................................................

22

CONTENTS

I . OUTLINE ............................................................................................... 1

1. Features .............................................................................................................. 2

2.

Specifications ..................................................................................................... 4

II.

MAINTENANCE AND ADJUSTMENT .................................................. 5

1.

Adjusting

2.

Adjusting

3.

Adjusting

4.

Adjusting

5.

Thread

5-1. Sewing data

the needle thread

the

bobbin

the needle thread feeding amount .................................................. 7

the thread

trimming

input

thread feeding amount .................................................. 6

trimmer

drive control ........................................................................ 10

procedures (001, 002) ....................................................

trimmer

guide

position ................................................. 5

................................................................. 8

13

5-2. Sewing data

6.

Error ...................................................................................................................

7.

Other troubles ................................................................................................... 18

m.

BLOCK DIAGRAM ..............................................................................

input

procedures

(01

0,

020) .................................................... 14

N. AIR PIPING DIAGRAM .......................................................................

V.

PARTS LIST ........................................................................................

15

20

21

22

( I .

ll

II

I OUTLINE

)

215:~1<1:,

C:tJ-::>

This sewing machine is a sewing machine provided with the hot-wire type thread trimmer to the slide thread

take-up type

(1.~~

CD

<1l

® *1,j:jgb' G

@)

®

®

:A

5-1

t-0:7<:1'1If±.I!J\O)

C::l

'*9

0

AMS-210DHL-6300.

AMS-21

ODHL-6300

lc:W.WRI:::

)

AA~JRI:::

*W

<AA*iR0)1JDil:l\F7l'l~tld:,

ifrt'*?xfJ

(_t'*O)jgt¥Ji:EIL:ct:

~lW.>fbfJO)'*?xfJ

<?x*0)1&9LII111Il~bc:fl!l!c

§<?

(:l~!i"{±til\J?IJ

({f~~)!:/EJ?IJ

(ff~~£/Ei?UII

(ff~~)!:/EJ?Uill

-9-:l*!fJIL:ct:

fJ

WJrelJbl@lfl'*ti'fiL:f;G

C::tJlt¥Ji9

bi~''/;J..l

fJ,

:71-llllt:l:l::t:Jff~~)!:/EI

0

<:

C:

1:;$,J,

~l

fJifrt:il:b'S'*b'f;\(11ml

~!W.><:Ait*WfJ

0)'*

tJJ

fJ

!!BJJ.i

9

-1

.:::

::;

· "f,*tJl

I ·

..t'*~

·

.L*,WfJt±JG~..tTf5.1Wl'*tJlfJ)

·

T*WIJ~..t'*,WfJt±JG)

fJ~

fJ

::tfl1t'fci:JBJ!li11L:tJlt¥JiDJ~§c9

l5

C::

ffl'.l\U)!:/EDJ~§c9

c:

C::~®!J£cp

lc:ct:

fJ,

*la:-::Jf1(ljjlt7:1J~b'ill'

l~fj11JO),rfli,O)i;~W~''/;J..

1:;$.l,

lc:tt;rz3t±Jt l

o

*tel<!:,

<

C::).?iiif*9

~l

1~11JO)ifrt'*?xfJ

/2

9 o l

:;1'1,j::7J.Ilil

..t'*,W

t±l

G~

.1\t±l::t:J I L:

fJ

t±l

..t'*W

C::

G~

..t*W

fJ~

T*W

if

~~)1/EDJ

fJ)

: _t

fJ)

: T'*O)iif?!*liifii{lfo

:

ff~~)!:/EJ?IJ

:

T'*O)iiftJlt¥iio

-9-itO)*tJl

fJ~~1,j:~f.H_,tc=:

y::_;

o

~®!mHi~W

Sf1*9

o

S0)1JDAAb'DJ~§o)

o

b~~''/;J..

tXfc~''/;J..('/;J..-::>C::l

~§c

9 o

T?x*~~'tJl

I

<

C::)J"iiif*9

'*9

o)

o

lo

ct:IJ*WIJWira,b1ffillo

(J)

AA~JR:ti-1

(CJ::±t!J..til'il

@

1iJ':*O).)(:AJt'*tJl

<t~ii"ifrH&*l37iHJt~!i"':7

®

AA*iR~~::Ef*blf.(t*O)$<)

f:'IL:

ct

IJ

~®!~l::lt!J""-O)jgb'

C:Mn;'RC:

O)relJ!IIl\1,j:fii{lf

fJ~~biJlf!!fJDJ~§o

G~b'(ljjltc'C'*9

9 0

<:

C: I c:

ct

1J,

-1

J \

--it1,j:'t-0)**1%~)152'J#r!c~*9

l

/21L:Ijl~{t;cf'ltc:;$.l,

o

il1H£,

AA*iRb'CJ::±t!JI

c:mf1.@0)1,j:J!i¥11* 9 o)

o l

~®!{'F~IL:<l3110{'F~·Iibi[O]_t

G n

'*9

o

1

( 1. Features )

CD

By adopting the hot-wire heater, thick thread can be easily cut.

@ Thread trimming time can be optionally set in accordance with the thread count.

(Start of heating the hot-wire can be performed during sewing

external output setting.)

or

alter completion of sewing by optional

@ Thread

@ Bird's nest at the start of sewing can be reduced since the needle thread remaining

(Needle thread remaining at the start of sewing can be reduced since thread

needle eyelet because of the needle thread resulted in a ball by fusing.)

® The amount of thread remaining on the needle at the end of sewing

with our moving knife type thread trimmer.

(The alter-treatment process of remaining thread is not necessary.)

is

cut by fusing, and it

is

effective

to

prevent thread from fraying.

on

the needle is shorter.

is

hard to come out from the

is

reduced by less than 1/2 as compared

® Respective thread trimming drive timings can be optionally set by the external input/output.

(Standard setting example • Bobbin thread

: Amount of remaining needle/bobbin threads

(Optional

: Amount of remaining bobbin thread

(Optional setting example II • Needle thread

threads)

: Thread trimming time to cut thread

(Optional setting example

: Bobbin thread

(J)

The hot-wire guide can prevent sewing material from being fused.

(The direct contact of the hot-wire with the material can be avoided by securing the interval between upper

surface of material and the hot-wire.)

setting example I • Needle thread feeding - needle thread

only

is

III

• Bobbin thread

only is cut.

trimming-

is

small.

is

secured.

feeding-

shorter than that of the optional setting example

trimming-

needle thread

simultaneous thread trimming of needle/bobbin

needle thread feeding)

feeding-

trimming-

needle thread trimming)

bobbin thread trimming)

I.

® Both the conventional moving knife type thread trimmer and this one can be used.

(The standard throat

plate asm. and standard wiper set can be replaced.)

® Working property in sewing operation is improved since the whole hot-wire device is miniaturized

approximately 1/2 as compared with the conventional one.

by

2

(2.

CD

7tH:::·:-;

CfJ

1R

m

300

®

300

f±

~

· 71\C::::'/'T-

W

fJ

lfl

*

lfl

!fit

)

::Z

AMS21

_t T1Sllz:.WIIlrt ( fHl:

li::k

OPx 1 7

OOHL6300

#1

<2250

#261~211'

7'·=-JLtl-).P"JO)ft;m~*l

(#22 ~ 26.

0)7.

:5'

54

-1:::.

I-'7<:U/1Ji±1!JH~C:::I5l~o

/

:;:i'~~AE:rtl

Nm

140 ~ 230)

1.8 jg§\l'

® :;t-::Jy

®

~§

CD

/ill

®3Z~'Ji:E

®

~

::J/

0 m-1RID5Fr*fl

0

=-

1-'Jlt::/-5-

0

cp

3 5 ilit1\ti-{

0

1\"ifl]

3 x

4.4

0 *

1~211'

cp

4.5

0 /tiR!fiHMJR

(040

120

lONAH)

(B4720221

[--:'

(040020

(04021

(040020 1 ONOH)

(040

lONOK)

0 1

180 1 OPOPA)

¥

iRl;JJfJffi'WE\1•

[t~21f'lfiT~*JR

[/tiR!fiHMJR

~

iR?!IJ&~

~*JRl5BmlilliL:~~MR:O'.

~*JRl5BO)fflfl'!ll\'1ii~~JJ.itO)~,

~§

ilitiR:f.i.\111~.JJ.LtR:O',

T iRO)*Mill;::

1~211'

1.5 sec

(~IJEP

A)

(~IJEP

B)

..t=

1 mmJ:JT

T=

2 mmJ:JT

J®O)§l:l5JiiZ1a:Eia'9C:::90..tiR~IJ

if:''~

liftt~NO)?'\liR~

(ff~~~AE:)

fl!'lfliKJid:,

fl!'lfi!KJid:,

(iRl;JJIJ;t:J'--1

(~®'~MO)~~'f-l)l}!~IL:J:;IJ~IIIL*9ol

f*~tl!

i,liJ!Zff#~flillo

[+:t-C::::'::Z7''-1::Z7

f.ttJD~IKJFs~li::k

*:ttJD~IKJFs~li::k

\-11~

1a:

IDOimOJ

2.5

sec

3.0

sec

i-'O)iiJllmf~IL:J:;IJ~IIIL*9o)

o

(_tTY

~§

IJ

/:5''-""-0)S"3Z\:ffld:,

tl:lL~iiJllmrtY

C:::

L /ciiJllmrtT

OAO)

OPOP)

001 • 1Rl;JJIJ

J:JP"'~"fl

J;JP"J~"fl

iR~

[it!JI;::'Igm#~!J'If:''~o

[~IJEP

B)

9ilitilUJJO~rn19ill

IJ

/:5''-~flillo

IJ

tl:lL

~flill

0.25 ~ 0.28

o

IV~~\1)

MPa)

@)

I:P-)f:'l~~

3.6

N P-/min

* :;t-::Jy

[:::U

::1

-::1

v 'Y +:t-Id:,

/0)=-

f-:'J[;:/-5-fl!'lfiO)TJ;l€:ild:, J

750W

( 1

)j!jj:fJ)

J;)__tO)i:J0)1a:ii!lHll'lfiT~l

\J[;'J'~&flBi'i

65N P-/min

\o)

3

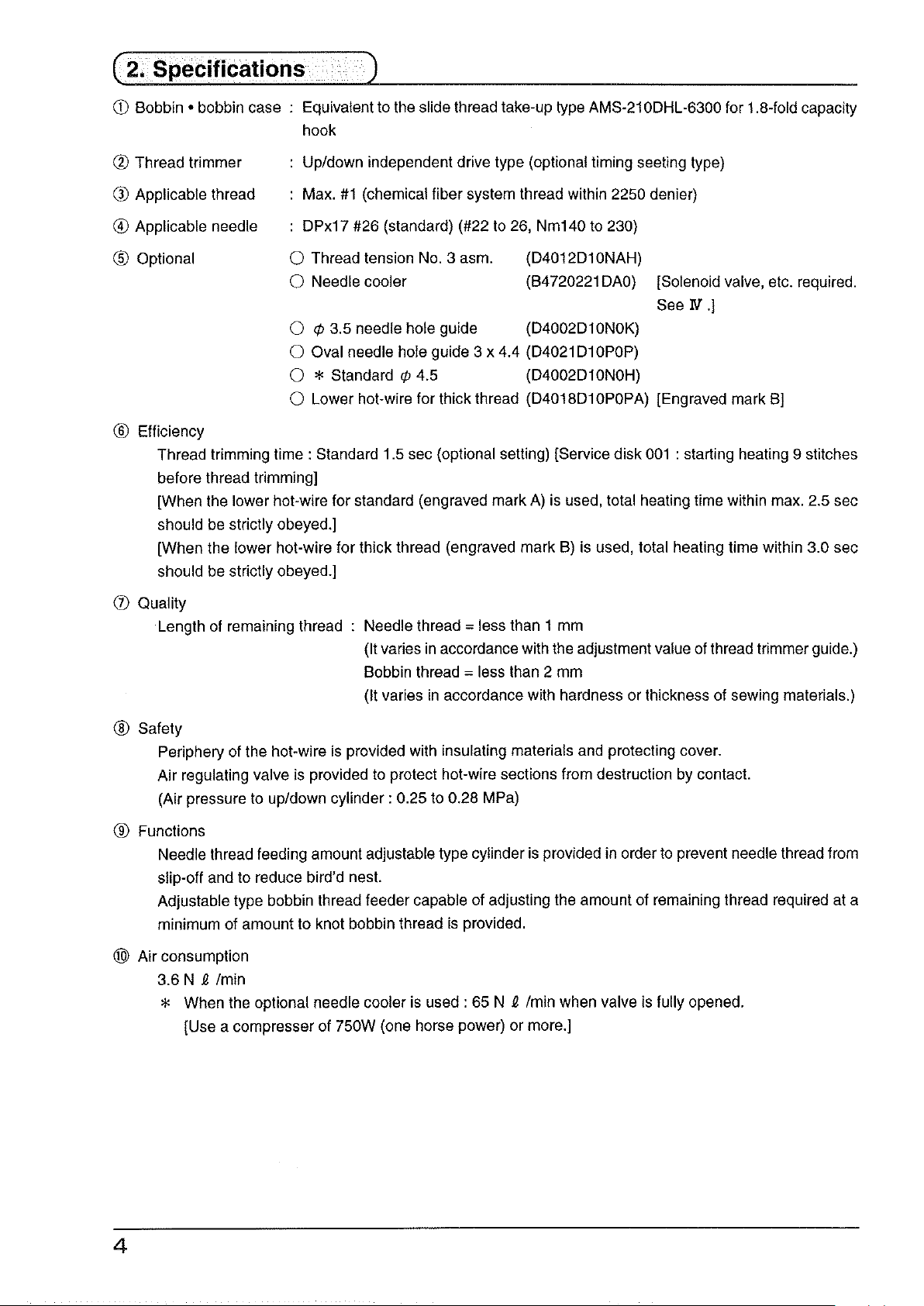

( 2. Specifications )

CD

Bobbin • bobbin case : Equivalent to the slide thread take-up type AMS-21

hook

CV

Thread trimmer

® Applicable thread

Up/down independent drive type (optional timing seeting type)

#1

Max.

(chemical fiber system thread within 2250 denier)

OOHL

-6300 for 1.8-fold capacity

@ Applicable needle

®Optional

0Px17

0 Thread tension No. 3 asm.

#26 (standard) (#22

0 Needle cooler

0

<P

3.5 needle hole guide (04002010NOK)

0 Oval needle hole guide 3 x 4.4 (04021 01

0 * Standard

<P

4.5 (0400201

0 Lower hot-wire for thick thread (04018010POPA) [Engraved mark B]

® Efficiency

Thread trimming time :

before thread trimming]

[When the lower hot-wire for standard (engraved mark

should be strictly obeyed.]

[When the lower hot-wire for thick thread (engraved mark

should be strictly obeyed.]

(])

Quality

Length of remaining thread Needle thread

Standard 1.5 sec (optional setting) [Service disk

(It varies

Bobbin thread

(It varies

in

accordance with the adjustment value of thread trimmer guide.)

in

accordance with hardness or thickness of sewing materials.)

to

26, Nm140 to 230)

(0401201

(B4720221

A)

is

used, total heating time within max. 2.5 sec

B)

= less than 1 mm

= less than 2 mm

ONAH)

OAO)

OPOP)

ONOH)

is used, total heating time within 3.0 sec

[Solenoid valve, etc. required.

SeeN.]

001

: starting heating 9 stitches

® Safety

Periphery of the hot-wire

Air regulating valve is provided

(Air pressure to up/down cylinder: 0.25 to 0.28 MPa)

is

provided with insulating materials and protecting cover.

to

protect hot-wire sections from destruction by contact.

® Functions

Needle thread feeding amount adjustable type cylinder

slip-off and to reduce bird'd nest.

Adjustable type bobbin thread feeder capable of adjusting the amount of remaining thread required at a

minimum of amount to knot bobbin thread

is

provided.

@ Air consumption

3.6 N

~/min

* When the optional needle cooler

[Use a compresser of 750W (one horse power) or more.]

is

used : 65 N ~ /min when valve

is

provided in order

to

prevent needle thread from

is

fully opened.

4

(

ll

• fii\Jili!f! I MAINTENANCE

( 1 .

..

b!fttJJ

t>

ftiili~~

I Adjusting the needle thread trimmer position )

AND

ADJUSTMENT

)

(~~~;t:.tO)~~{<:~

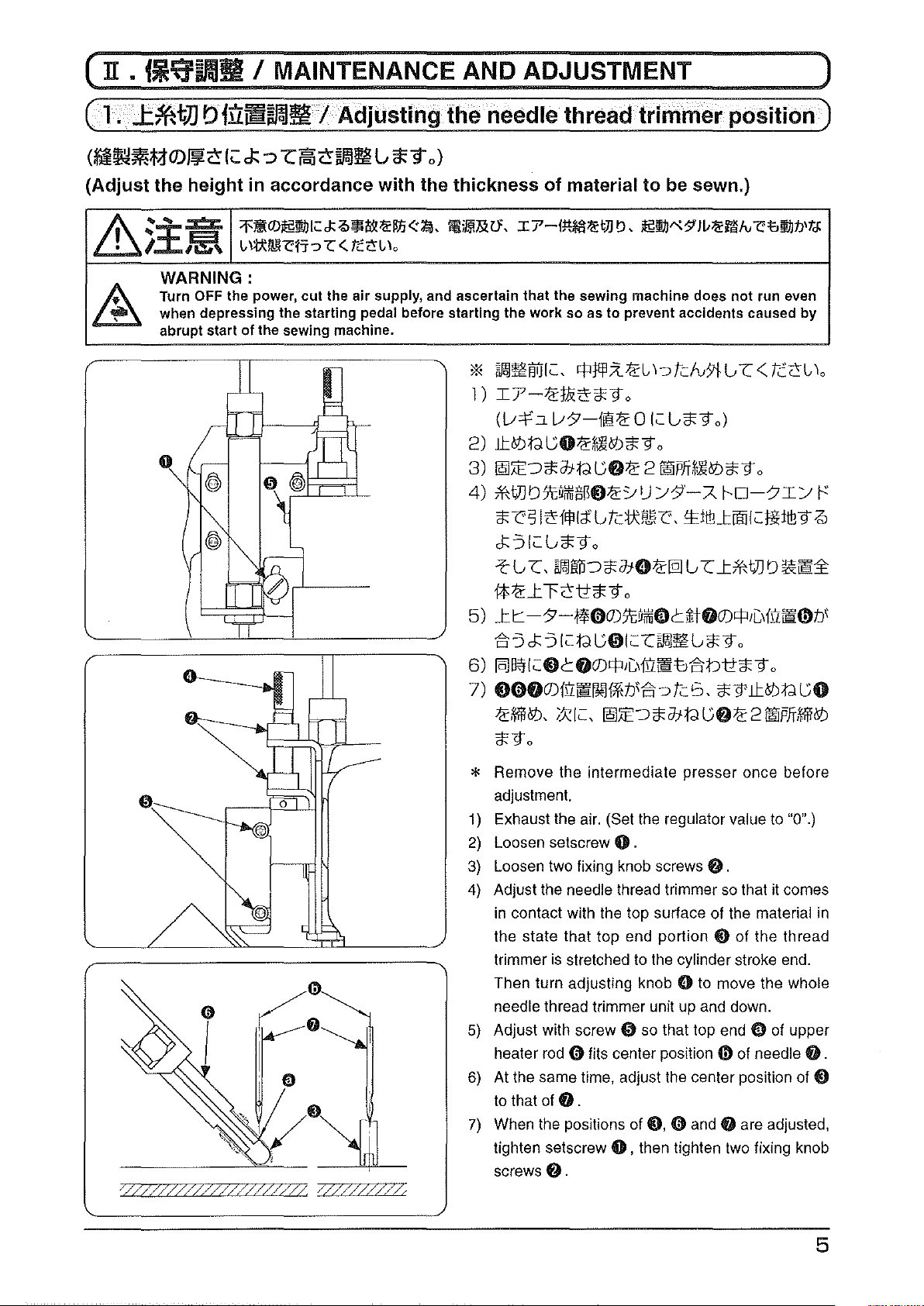

(Adjust

the

height

Lt~~~

iz,c,,

WARNING:

Turn

OFF

~

when depressing the starting pedal before starting the work so as to prevent accidents caused by

abrupt start

::>Z"Fcii~~mt.,~g

in

accordance

1'1i:\O)itil!l!JJ

~

lt\:1!\lC:l'J::>

the power,

of

the sewing machine.

I<:~

~ljl;ll(

c:

<.tee~

cut

the air supply, and ascertain that the sewing machine does

with

"<r!!.l:i

<."

lo

o)

the

thickness

~.

'llil!'!7iHJ,

of

material

I

7'

-fjijg"<!:t]J

*

&f.ll~MIC:.

l)

I:P-~t'i'i\'*9

(v:f

2)

ll::6b:!d

3)

~J'E-:J*O:i-:!d

4)

*trliJ)'Guffijg(lE)~ylj:;;~;;r-;;z

[tri!Jl;Z~l,l-::>tcfv:7l-G

.:J.

l..J:$7-j@~

LJO~~tl!.l*

LJO~ 2 ~PJT~J16b*9

*c51'il'i$1<f G

to

be sewn.)

I)

,

ilil!l!JJ"'

o

0

IC:

G*9o)

9 o

tct\:1'1\c\

$'

lv"<i:r.1A.

l:

not

run even

'b!l!JJIJ't.J:

<:<tccG\o

o

t--D-::/I/

l±:lttJJ=U'illc::t§<±ttJ9

!-'

~

ct'51C:G*9o

TGC::.&f.\JW-:J*O:I-O~§GC::J=*trliJ~~~

Jt:~_t

5)

_t

Tctt*9

1:::

-5'

-1$0(}))'GilffijQC::;litf)(})cj:Ji[,\{li~(!)bl

o

0

tJ-3 ct

Gl

15J~P-Jic:ee:e(})cp,e,\{1l~t:JtJbtt*9

7)

00f)(})jl1.~~1'*1JitJ-::>

~MU6b.

'SIC::!d

;xlc:.

LJ01C:C::&f.\J~G*9

tc

S,

~J'E-:J*O:I-:!d

o

o

*9"

Jl::6b:!d

LJO~ 2 ~P!Tmil6b

LJO

*9o

* Remove the intermediate presser once before

adjustment.

1)

Exhaust the air. (Set the regulator value to "0".)

2)

Loosen setscrew 0 .

3)

Loosen two fixing knob screws 6 .

4)

Adjust the needle thread trimmer

in

contact with the top surface of the material

the state that top end portion

is

trimmer

Then turn adjusting knob

needle thread trimmer unit up and down.

5)

Adjust with screw 0

heater

6)

At the same time, adjust the center position of

to that of

7)

When the positions of@), 0 and

tighten setscrew

screws

stretched to the cylinder stroke end.

so

that top end G

rod

0 fits center position(!)

f)

.

0 , then tighten two fixing knob

e.

so

that

it

comes

in

i)

of the thread

0 to move the whole

of

upper

of

needle

f)

are adjusted,

f).

i)

5

(

2.

""~'*~

b

ttl

GiiO)~~

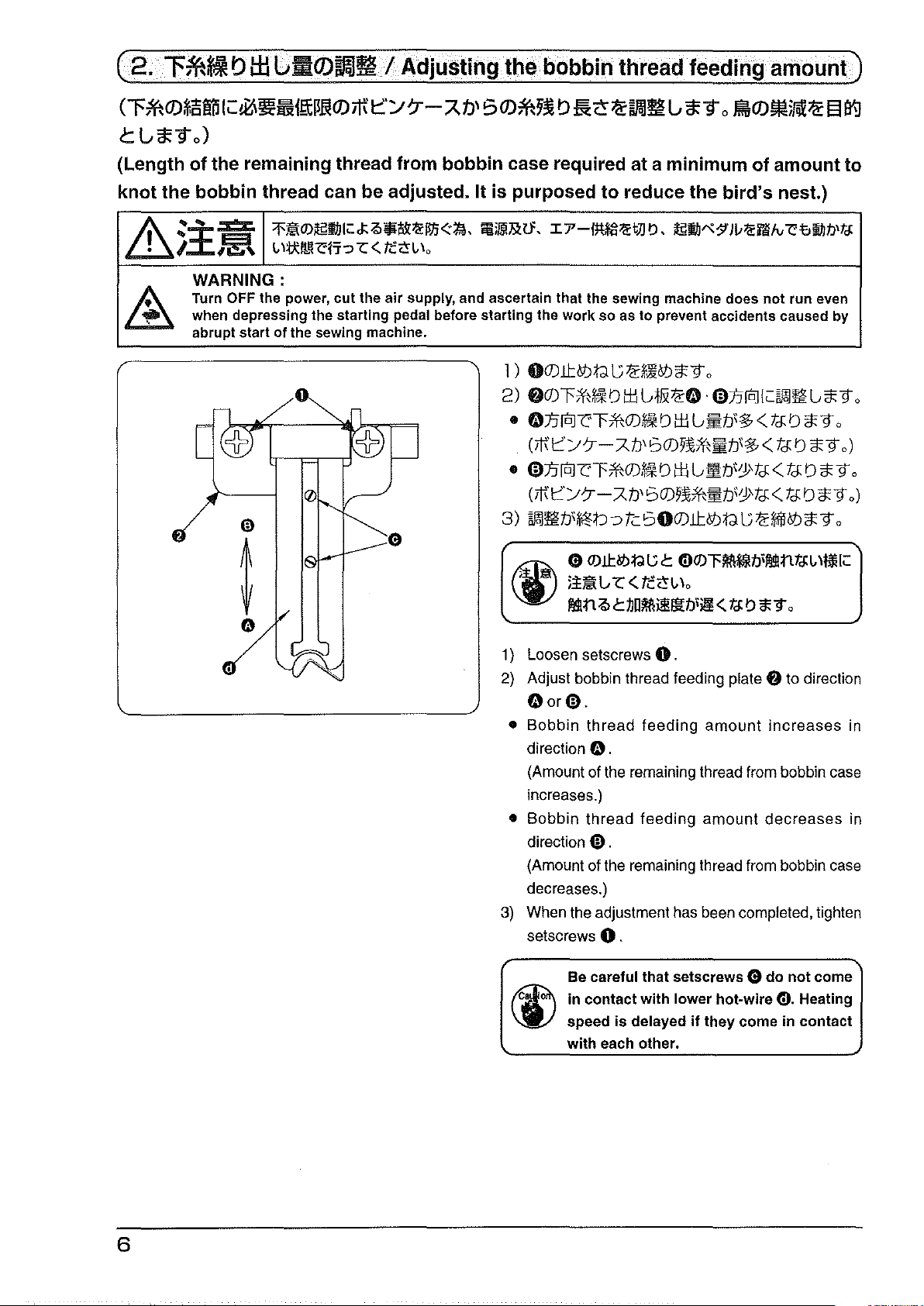

I Adjusting the bobbin thread feeding

amount)

(l'*O)*aWI<:~~iMit.t~NO)ffit::'/?"-"A1J'S0)*?3ifJ~~~~mlJ*9

C:

lJ*g

(Length

knot

&~'~

A

o)

of

the remaining thread from bobbin case required at a

the

bobbin

iz~.::.,

WARNING:

Turn

when depressing the starting pedal before starting the work so

abrupt start of the sewing machine.

thread can be adjusted. It is purposed

'l'~OJili:i!JI;:

L

lt\:ft~c!j:>

OFF

the power, cut the air supply, and ascertain that the sewing machine does not run even

J;

?>i!ili'&:ia:llJj

c:

< rc<!LI,

<:~.

i!!lil!lh"W',

l)

00)1.1::6btd

2)

f)O)Ti'Kl'*t:Jt±lLA&:It~

•

~7Jio.JC'Ti'KO)l'*

(Jt\~'/7-

•

07Jio:JC'Ti'KO)l'*

(Jt\~'/7-

3)M~~-b~kS00)1.1::6!Jtd.LJ:ItM6b~9o

to

I

J7-iJtf3:1a:tJJ

as

LJ1,N~6b~9

:::Zb'

:::Zb'

minimum

reduce

b,

ili:i!l-"$1

to prevent accidents caused

t:J

t±l

S0)9%i'k'Jibl:§-

t:J

t±l G 'Jibi:J,'ta: < ta:

S0)9%i'K'Jibi:J.,\1d:

o

~O)~i~~Elli'!l

of

the

amount

bird's

J!J:Ia:l!'JlA,

nest.)

c'Eii!JMJ:

to

by

o

·

07Jiollc::~~Lo~9,

Lo

'Jibl:§-

<

(

tJ.

1a:

(

t:J

t:J

1a:

~9

o

~9

t:J

~9

t:J

~9

o)

o

o)

1) Loosen setscrews 0 .

2)

Adjust bobbin thread feeding plate

~or€).

• Bobbin

direction~.

(Amount

increases.)

• Bobbin

direction

(Amount of the remaining thread from bobbin case

decreases.)

3)

When the adjustment has been completed, tighten

setscrews

thread

of

thread

feeding

the remaining thread from bobbin case

feeding

amount

amount

0 .

0 .

Be careful that setscrews 0

contact

in

speed

with

with

is

delayed

each other.

lower hot-wire

if

they

f)

increases

decreases

do

Q.

come in

to direction

not

Heating

contact

in

in

come

6

(

3.

J:~~b

1±1

l,:IIO)~~

I Adjusting the needle thread feeding amount)

(J::~O)*ai1JI;:~,!¥~f!i~NO)~t1i:t.J'

(Length

to

knot

6~~~

of

the remaining thread from needle eyelet required at a minimum

the

needle thread can be adjusted. It

1'

!\

0)

i!il!WJ

I;::

J;

i.:E,~,

~

lt\:li..~c!'i'::>

L"

SO)~~IJ

7.>

lfl;ll(

1d:

llJj

<'

~,

<tee~

lo

~(!1il:~m

is

purposed

ill!ii!!lhHf, I

7'

-{mg

L.,

a;-g

to

1d:

o~0)~~1il:EIB'ilt:

reduce the

t;JJ

!J

, ililliJ"'

$'I

WARNING:

Turn OFF the power, cut the air supply, and ascertain that the sewing machine does not run even

~

when depressing the

abrupt start of the sewing machine.

starling

pedal before starling the

work

so as to prevent accidents caused by

bird's

It

1d:

WJ!

L.,:J;9

of

amount

nest.)

A;c

1:J

iWJ

INJ:

o)

1)

_t;'fdi\~1)

2)

_t;<r-~1)

3)

iltfR@O)~I):±J

9o

4)

!tltBO)j]j,'~l<::litl

'5tJO:fl<::,

*9\

it£il<::00)ofdlJ},j:IQJ/EG2109o

5)

::'RI<::,

4

:$:1<::-c_t;<r-~l)

*

01,j:'.Fcl1Jl G l:"Ab-

'E-0)~1<::51

1)

Press down by hand stopper shaft 0 of the needle thread feeder cylinder.

2)

Check the feeding amount of needle thread 9 by needle thread feeder

(In

3)

To increase the remaining amount of needle thread, increase the distance of

it counterclockwise. To decrease

4)

Secure the distance from the top end of needle thread feeder

of the material in accordance with the thickness of the material.

Incidentally, the height from the top surface of throat plate H is set to

from the factory.

First, loosen two setscrews

Finally, tighten setscrews

optional needle cooler.

5)

Next, adjust the whole needle thread feeder unit with four setscrews 0 by moving it up or down since the feeding

amount of needle thread

:±J

l/1

IJ

Y5'-0Y::Z

:±J

G&I<::J::oiltfR€)0)~1)

Gl!;},j:~<

:!-'IJ:<9o~1§ll<t,

lJC::,

_t;<r-~1)

I~:±Jfof~l<t,

00)lt<lbofdl5

00)J.!!Z{1iO},j:_tT~mG/cL:C:::I<::J::

2

;$:1,j:*~<lb,

:±J

Vii\'ili[j:{:i;},j:_t

A"I<::.L

::>lifb' I)

case of 0=31 mm, the remaining amount of needle thread is approximately

b'®o~;§';l<t,

i'

~

J\-'li!JOJ,j:'.FcttJl G

:±J

Gl!;},j:!ii&'6G2109

9-QI<::I<:t,

~I<::@JG2109o

iltt&.LIT!ib'

DO)lfEiiJltl,j:~<

00)lfE1illtb'i:R210::>/cSOcOJ,j:ll'iJ/EG2109o

:±J

G@O)itr:,~~O))'c!llitj

SO)""~

00)J.!!Zf1iO},j:_tT~mG,

tJ<[),

01<t,

:t7Y

I),

T~mG2109

Tt!J9oL:C:::},j:!ii&'6GtJb'S.L

0C:::00)lt<lbofd

it,

turn the nut clockwise. When the distance 0 is determined, fix 0 with 0 .

0,

adjust installing base 0 by moving it up or down, and set the optional height

0.

In addition, 0 are screws used both for setting the installing base and for fixing the

r:l1iP!

o (0=31

G*9

o

mm

o

'tO)~,

00)7

cilti'R?'\11)

C:::!tltll.LITDOb'SO)lfEijl.},j:!iii¥

H = 1 2

iltfR@O)~I):±J

mm

=00)=-

},j:§'§'I<:::±Jfoj

ff~"'"e

H

r%?-5-ll'iJIEJ!:Rlofdl5c9 o

GlEb'?ltb I)

o

T~m},j:fJ'::>

c;

1<::-c~m<

f)

/eel

10

f)

.

D.

when it is in the lowest position to top surface 0

12

mm as standard at the time of delivery

9 changes by adjusting installing base 0 by moving it up or down.

lEI<t

18

mm

~

i--},j:*~<lb01,j:1J:"-@l

G2109

o

G

C::t,

12109

o

},j:~li:!EG2109o

21090)c,

l:

</eel

18

mm.)

At

this time, loosen nut 0 and turn

00)lt<lbofd

lo

ilil£il

G*

l5

H.

* Press 0 by hand and check that it smoothly moves up or down

when it does not move smoothly, adjust it with setscrews

0 and

to

perform the up/down adjustment. At this time,

0.

7

(

4.

*tJ.1

<*t.JJ

b

u

ll1:i

.lt

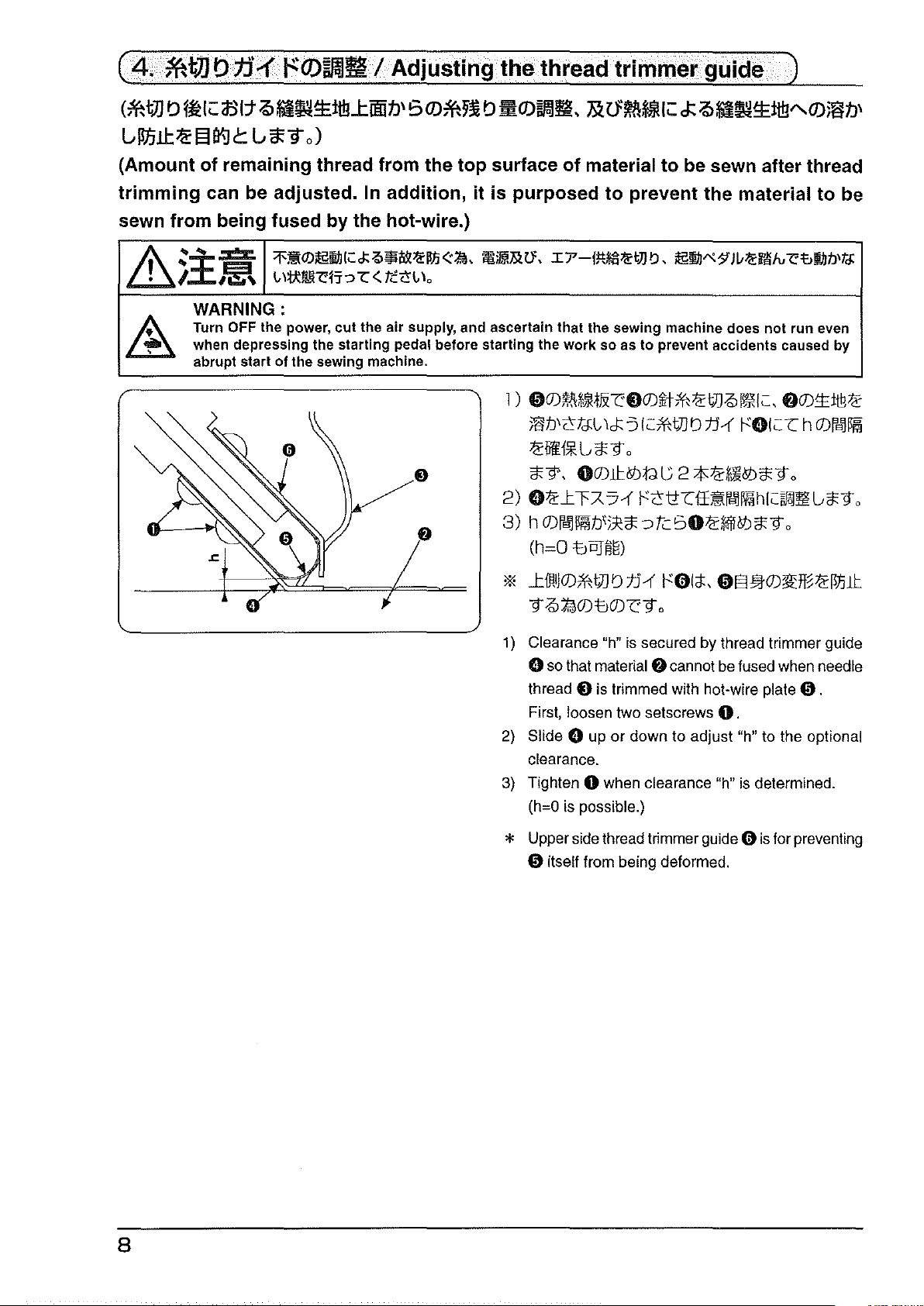

(Amount of remaining thread from the top surface of material to be sewn after thread

!iiC::

1,!:

El

b

jj

<BI:t

B'il

t:

~

t-::0)~~

7a>~~~:lt!t.t.im1J'

I Adjusting the thread trimmer guide )

S

OJ*?~

b

iiOJ~~-

"&lfim**IC::

u * 9 0)

J:

7a>~~~it!l"-OJ)g1J'

trimming can be adjusted.

sewn from being fused by the hot-wire.)

1'

!i;\

&

A

'~

:z%

ix,c.~

WARNING:

Turn OFF the power, cut the air supply, and ascertain that the sewing machine does not run

when depressing the starling pedal before starling the work so

abrupt start of the sewing machine.

(l)J!ili!J

l-\t\:Mc!J'?

In

addition, it is purposed to prevent the material to be

I<::

J;;

7.J

jJ!i\l(

".!:

llJ:i

<:

~,

c::

<

tC.t!\,

'·

i!iim!liH.f,

2)

3)

*

1)

2)

3)

I

7'

-I!±~".!:

1)

00)W,\~Jl!:t&l'80)ilit*:IJ'W.SJWR!c:,

i§1J'~)&\,

;~,r

lit

1!1(

G

*~'

O:IJ'...t

hO)F~IWJ1JI)~*-::>tcSO:IJ'~~*9,

(h=O

00)k~~~2*:1J'W~*go

T:A

t.>PJ~~)

...t1JlljO)*l;JJtJ

g.@~O)t.>O)l'g

Clearance "h"

0 so that material

thread

First, loosen two setscrews

Slide 0 up

clearance.

Tighten 0 when clearance "h"

(h=O

e is trimmed with hot-wire plate 0 .

is possible.)

t]J

b , ilili!J"'

as

to prevent accidents caused by

:$f

J v

".!:

il!l

A;<;

t>

i!J

IJ'tJ:

even

fJO)!:I:±tll:IJ'

IJ;

5/C:*l;JJb

anr

•

51'

f"'~t:'Tff!&:Fs1~h!L:ID<\J~

1J".1

is

secured by thread trimmer guide

fJ

or

down to adjust "h" to the optional

;lj-{

~0/C:l:"

h

O)Fs1~

G*9,

~0/cl:,

0

cannot be fused when needle

0§!f:;J-0)?3£%:1J'IlJJtt

0.

is

determined.

8

* Upper side thread trimmer guide 0

0 itself from being deformed.

is

for preventing

Loading...

Loading...