JUKI MOJ-2500N, MOK-2500N, MOJ 2500N series, MOK 2500N series, 2516 Instruction Manual

...

lYSi56'LWl

MATPARTS

No.

01

r

BEFORE OPERATION

1.

Do not hold the cloth plate cover when carrying the

machine.

2.

Resupply oil if the red color in the oil gauge is not seen

when the oil gauge

3.

Apply a few drops of oil to the needle bar guide

upper looper guide before operating your

starting your machine for

Also,

lubricate

presser bar. (Refer

4.

Never allow

directioi!.

.-

-

-

the

The

is

observed from the top or the side.

new

the

the

oil holi:

?o

"2,

sewing

hdndwhrei

first time

sf

link

(A)

and

LUBRiCATiUN".i

machine

to

shrjr;ld

sun

rcirr.

rnach~ne

~n

a

ioog time.

ttre

in

the

clockwise

top

and

or

feed

reverse

as

Thank you for buying the JUKI MOJ/MOK-2500N

series sewing machine. The MOJIMOK-2500N series

1

models have basically the &me mechanism

those of MOG-2500N series models except that the

top feed mechanism has been incorporated

I

MOJ/MOK-2500N series models. For this reason,

thl Instruction Manual mainly deals with

I

feed mechanism only.

quested to refer to separate instruction Manuals of

MOG-2500N series models for the common instruc-

tions omitted from

I

1

(Example) For

this

MOJ

MOK

he

manual.

-

25

16N

customers are re-

Top feed mechanism

I

CAUTIONS IN OPERATION

1.

Do not put your hand under or near the needle when

turning the power switch

ON

or while the machine

operating.

2.

Do not put your fingers into the face plate cover while the

machine

3.

Be sure to turn the power switch

V

4

Dor~ng operation, be careful not to allow your or any

belt.

is

operating.

OFF

when removing the

other person's head or hands to come, or place anything

V

close to the pulley,

may

"

F.

develop dangerous conditions.

if

vour machine

CJT

any other protectors, never operate your machine with

any

of these removed.

Do

not wlpe off the surface of the machine head using

racouer thinner.

-

--

belt or motor. Any of these actions

is

provided with a belt cover, finger guard

the

as

in

too

I

is

1

.

~..

~.

:

-

,-'

,..

.

I

\

:

~

..

i

,

i

<

'

j

1

I

("2)

12.

.

:

>r

.i,,:.~:-,,:i

i

.i

~~-~

1

!;[

{,<t:.,:

----

Y;:~I

,<,2i

-

1

~lr~.~~?~~,li::al

-

Lift

oi

*

i

Zleans the

adjusted

The top

top feed dug

LUBRICATION

~~-~

r:

.;j

~

~-

i:

-~

!.

:>-,.:

x?:c,kL,

.--

~-~

;?ri.\cr

-

1:

:

.

,'\,C

L,+

~

\:rok\>

~

f~o!

ratio

to

1

feed

.-

~-

~

<

.i:

'

:

~~

!<j?

:

;

,,

,!,

<)t

::;~j

ic,

,it

!hi:

:l

.I

-.

1

dog

has

is

nece.;sar)~.

--

--

,.

,!

.

~

J

..its

rndi!l

::.8

for

3

long

out the end

red

the

end

~ ~

...

-

3oi.r

blOJ-:(

for

betre:

.-.

..~

--.

...-.-.----.--.-".A

.;j,-:.:-

7,

.

.

h

;,

.

,.-

,

.>

i

/:

i

..-

.

I

:

.-

~.

-

Y

i;rr,

i!:~:giru.lii?:~l

136,

<titchine

ot

the

top

.,;:).:~:..;::*

.

~-

~~

l%.,

: :

.

t.

..:

i,

6

+,

,

.,

.

.

:::.

~

~

/

4

-,

a~id

i

:0.7

perforn:ance.

feed

i:~~:!?.

:,i.:,.;.

!.

fi<:1::

if:.

,

:.

,

:,

,

-

8-,;:~:,,

3

;I!;,;

.trok.r

-

dog

bl

\

....

.-

-:,.~

~.

-

,,!.t:':;

,!li,kL,

f,(;l;<j

.

:-

t,?

:

if;

~

the

1.8

j,i.

,(;,>kc,

of

,

:cr>

.

!op

for

the

-

----

8

mm

feed dog longitudinal stroke.

MOJ-2516N.

:9!!.3;

'(11

*..;

!

When the maximum longitudinal stroke

3

mm

by

a maximum.

~p~

-~

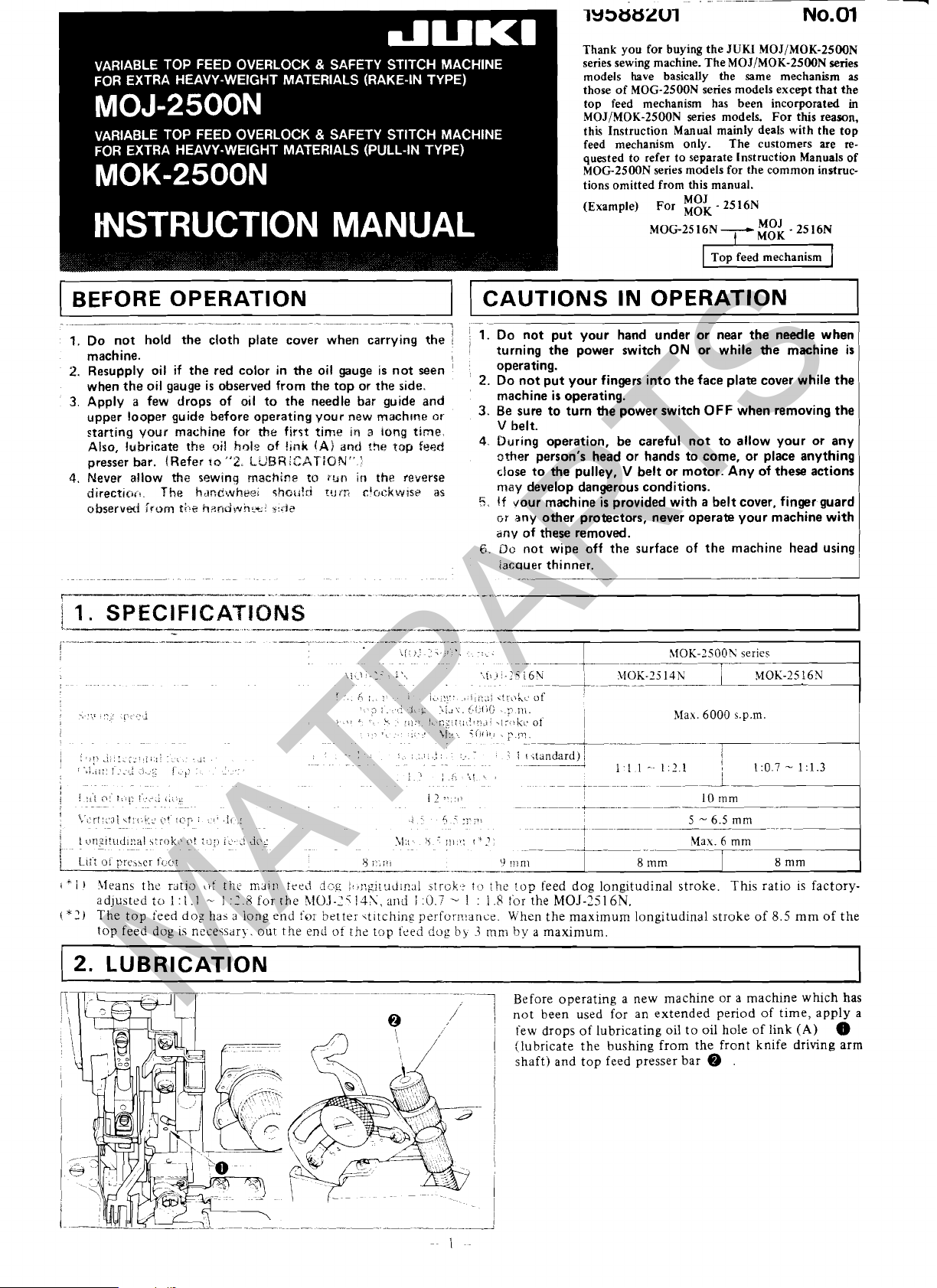

Before operating a new machine or a machine which has

not been used for an extended period of time, apply a

few drops of lubricating oil to oil hole of link

(lubricate the bushing from the front knife driving arm

shaft) and top feed presser bar

MOK-3500N

Max.

6000

5

-

6.5

Max.

6

This ratio

-

@

series

s.p.m.

mm

mm

.

of

- - --

8.5

-

-

is

factory-

mm of the

-

(A)

0

1

3.

MATPARTS

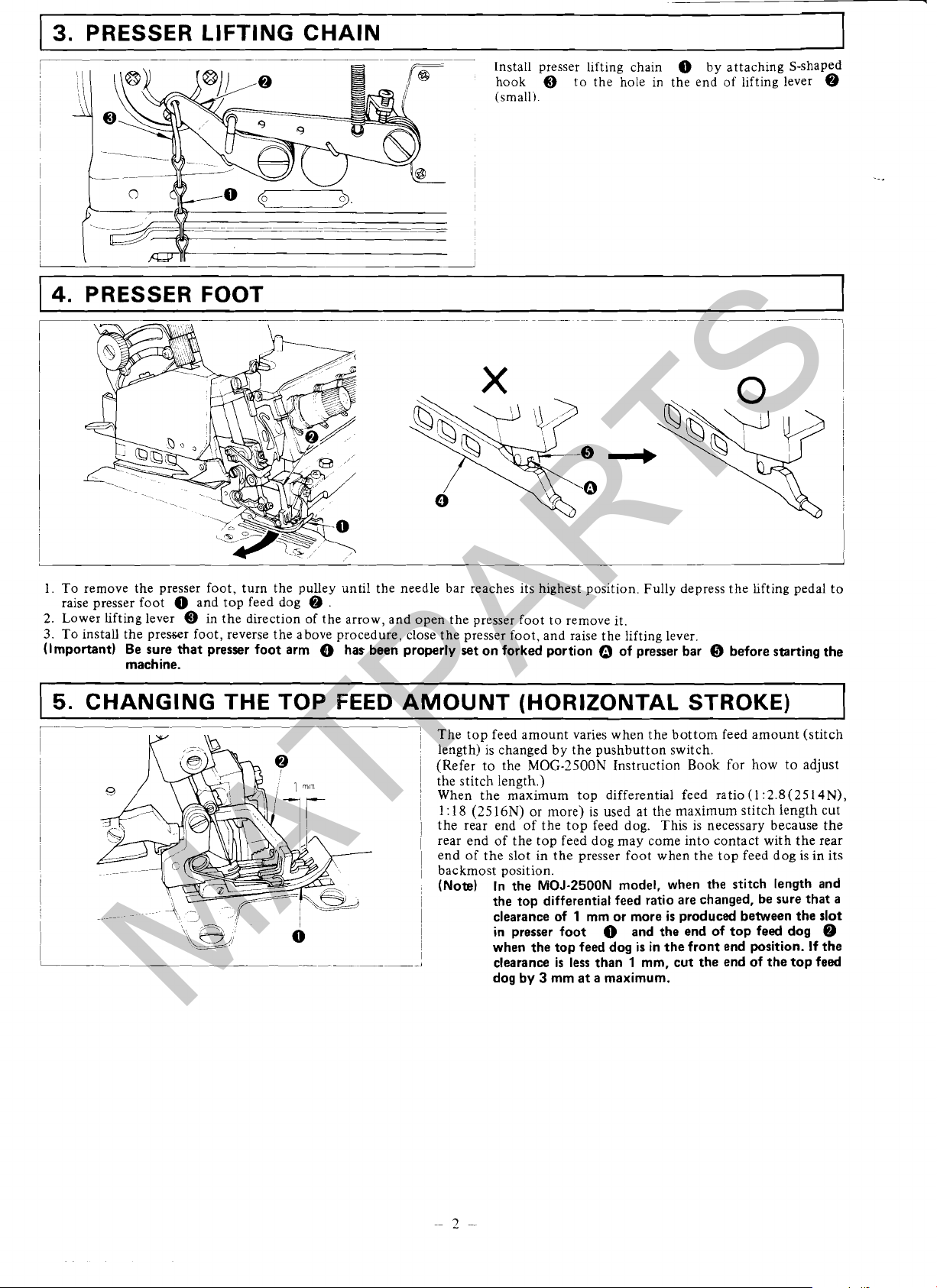

PRESSER LIFTING CHAIN

4.

PRESSER FOOT

Install presser lifting chain by attaching S-shaped

hook

(small).

@

to the hole in the end of lifting lever

@

.

1. To remove the presser foot, turn the pulley anti1 the needle bar reaches its highest position. Fully depress the lifting pedal to

raise presser foot

2. Lower lifting lever @ in the direction of the arrow, and open the presser foot to remove it.

3.

To install the presser foot, reverse the above procedure, close the presser foot, and raise the lifting lever.

(Important) Be sure that presser foot arm

machine.

5.

CHANGING THE TOP FEED AMOUNT (HORIZONTAL STROKE)

0

and top feed dog

@

.

@

has been properly set on forked portion 0 of presser bar Q before starting the

The top feed amount varies when the bottom feed amount (stitch

length) is changed by the pushbutton switch.

(Refer to the

the stitch length.)

When the maximum top differential feed

1:

18

(2516N)

the rear end of the top feed dog.

rear end of the top feed dog may come into contact with the rear

end of the slot in the presser foot when the top feed dog is in its

backmost position.

(Note) In the

MOG-2500N

or more) is used at the maximum stitch length cut

MOJ-2500N

the top differential feed ratio are changed, be sure that a

clearance of

in presser foot

when the top feed dog

clearance

dog by

is

3

mm at a maximum.

Instruction Book for how to adjust

ratio(l:2.8(2514N),

This is necessary because the

model, when the stitch length and

1

mm or more

less

than 1 mm, cut the end of the top feed

is

produced between the slot

and the end of top feed dog

is

in the front end position. If the

@

6.

MATPARTS

ADJUSTING THE VERTICAL STROKE OF THE TOP FEED

--

-

-

--

-

-

7

To change the vertical stroke of the top feed dog, move the side

cover back, loosen setscrew

to knife driving arm shaft

increase the vertical stroke or down to decrease it. Be sure to

securely tighten setscrews

Adjust the position of felt

link (A)

come into contact with other adjacent parts.

*

Adjust the vertical stroke of the top feed dog within the range

which red marker line @ engraved on knife driving arm shaft

stays between two red marker lines @ on top feed adjustor

When red marker line @ is set to lower red marker line

maximum vertical stroke of

When red marker Line

minimum vertical stroke of

(Caution) Never set red marker line

*

Adjust the vertical stroke of the top feed dog within the range

which red marker line 0 engraved on knife drivingarm shaft

stays between two white marker lines

adjustor

When red marker line

the maximum vertical stroke of

set to upper white marker line

of

@

.

At this time, be careful not to allow felt 0 to

For MOJ-2500N models

marker line engraved on the top feed adjust (Be sure

that the set vertical stroke does not exceed

For MOK-25001U models

@

.

5

mm is given.

@

0

@

.

@

6.5

@

0

mm is provided.

is set to upper red marker line

4.5

mm is given.

is set to lower white marker line

DOG

of top feed adjustor @ attached

.

and move adjustor

so that it is in slight contact with

0

beyond the lower red

engraved on top feed

@

6.5

mm is given, and when it is

@

,

the minimum vertical stroke

@

@

@

6.5

up to

in

0

@

,

the

,

the

mm).

in

0

@

I

.

,

1

7.

ADJUSTING THE TOP DIFFERENTIAL FEED RATIO

The top feed amount can be altered without changing the bottom

feed amount, by top-feed adjusting lever

@

0

ratios are necessary, adjust as follows:

@

0

1

Top feed dog

/e/

Presser

foot

1.

Turn lock nut

adjusting lever

nism.

2.

When the lever is set to

reduced. The top feed amount will increase as the adjusting

lever is set to a larger number on the scale.

3.

After adjustment, turn lock nut @ in the opposite direction

from the arrow to lock top-feed adjusting lever

*

For MOJ-2500N models

The Standard MOJ-2500N machine head is usuallv factorvadjusted to a 1 :2.8 (MOJ-25 14N),

feed dog: top feed dog) top differential feed ratio. If other top

differential

1.

Cut the front end of the top feed dog by 3 mm at a maximum

so a clearance of 1 mm or more is produced between the front

end of the top feed dog and the front end

presser foot when the top feed dog is in the most advanced

position.

2.

Then, loosen

to adjust clearance

feed

Clearance

Max. 1

.

in the direction of arrow. Move top-feed

to work the top differential feed mecha-

"S",

the top feed amount will be

0

.

1:

1.8

(MOJ-2516~) (main

of

the slot in the

of stopper 0 ,and move the stopper down

0

as tabulated below:

Max. top differential feed ratios

MOJ-2514N MOJ-25 16N

1

:2.1 1:1.3

1

:2.8

:4.8

1

:

1.8

I

3.

If

a

top differential feed ratio other than those listed above is

required, perform the following adjustment:

Remove the cover from the adjusting hole in the rear of the

machine frame, loosen locknut

pin

Q

,

is set at the lowest point, the maximum top differential feed

ratio of

tighten nut

and move the main feed arm pin down. When the pin

1

:6

will be provided. After adjustment, securely

0

.

@

to release main feed arm

8.

MATPARTS

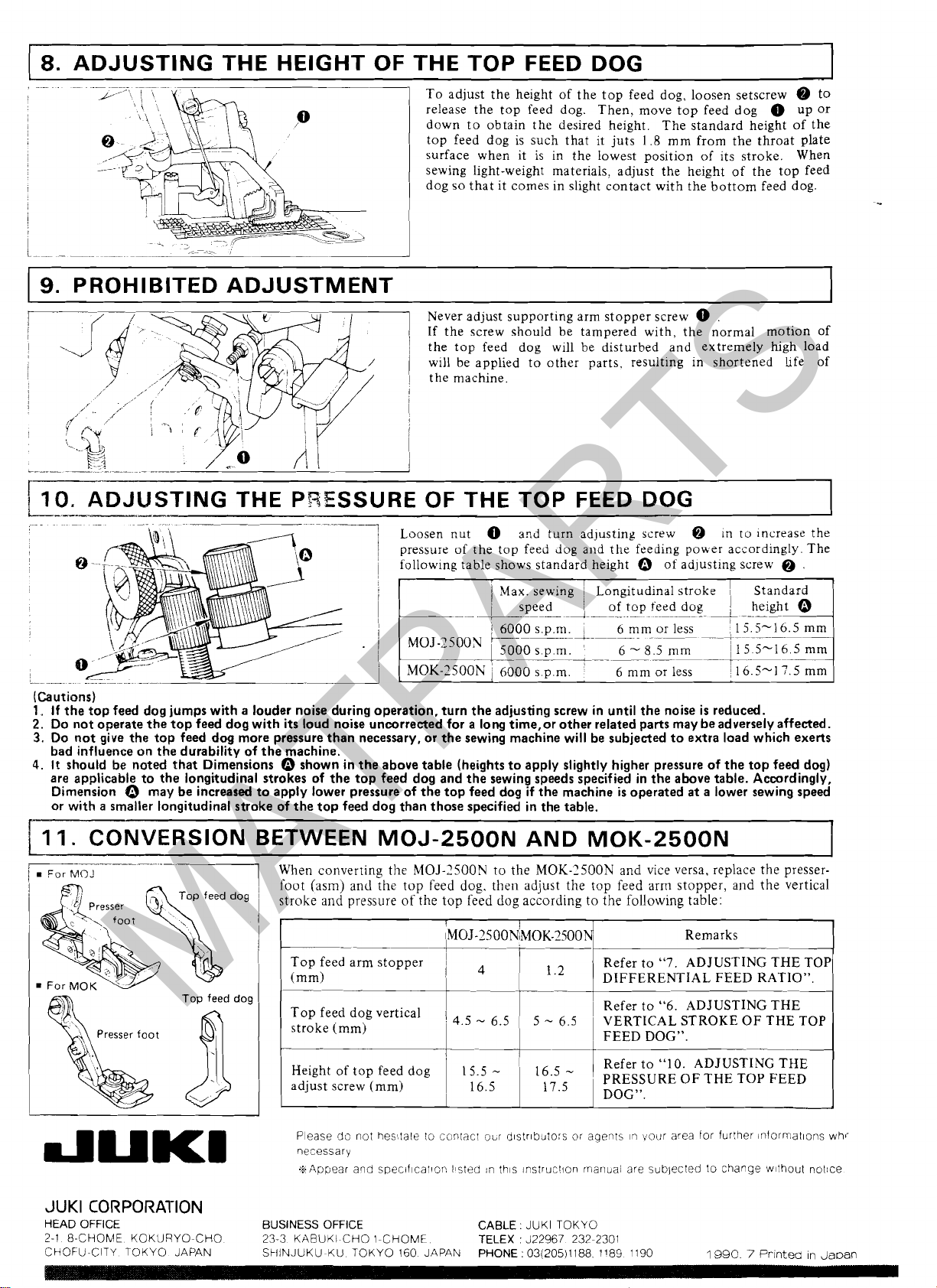

ADJUSTING THE HEIGHT OF THE TOP FEED DOG

To adjust the height of the top feed dog, loosen setscrew @ to

release the top feed dog. Then, move top feed dog

down to obtain the desired height. The standard height of the

top feed dog is such that it juts 1.8 mm from the throat plate

surface when it is in the lowest position of its stroke. When

sewing light-weight materials, adjust the height of the top feed

dog so that it comes in slight contact with the bottom feed dog.

9.

PROHIBITED ADJUSTMENT

0

up or

Never adjust supporting arm stopper screw

If the screw should be tampered with, the

the top feed dog will be disturbed and extremely

will be applied to other parts, resulting in shortened

1

1

10,

'---

(Cautions)

1.

2.

3.

4.

ADJUSTING THE PSESSURE OF THE TOP FEED DOG

.

.~

If the top feed dog jumps with a louder noise during operation, turn the adjusting screw in until the noise

Do not operate the top feed dog with

Do not give the top feed dog more pressure than necessary, or the sewing machine will be subjected to extra load which exerts

bad influence on the durability of the machine.

It

should be noted that Dimensions 0 shown in the above table (heights to apply slightly higher pressure of the top feed dog)

are applicable to the longitudinal strokes of the top feed dog and the sewing speeds specified in the above table. Accordingly,

Dimension

or with

~

--. ~ ...

~

0

a

may be increased to apply lower pressure of the top feed dog if the machine

smaller longitudinal stroke of the top feed dog than those specified in the table.

.~

-7

its

loud noise uncorrected for a long time,or other related parts may be adversely affected.

Loosen nut

pressure of rhe top feed dog and the feeding power accordingly. The

/

following table shows standard height

0

and

turn adjusting screiv

0

is

operated

0

.

normal motion of

@

In to Increase the

of adjusting screw

is

reduced.

at

a

lower sewing speed

hlgh load

life

@

of

1

I

.

1

I

1.

CONVERSION BETWEEN MOJ-2500N AND MOK-2500N

For

MO?

JUKl CORPORA1-ION

HEAD

OFFICE

2-1 8-CHOME

ChOFU

KOKURYO

CITY

TOKYO

JAPAN

Top

feed

CHO

dog

When converting the MOJ-?SOON to the MOK-?SOON and vice versa, replace the presser-

foot (asm) and the top feed dog. then adjust the top feed arm stopper, and the vertical

arid pressure of the top feed dog according to the following table:

stroke

I

I

Top feed arm stopper

feed

stroke (mm)

Height of top feed dog 15.5

adjust screw

Please

necessary

%Appear arld s~ecifcat~or> lsted in :hs instruc!ion rnariual

BUSINESS

23

SHINJUKU

3

KABUKI

OFFICE

(mm)

do

not hes!tale lo conracr

CHO 1 CHOME

KU

TOKYO

160

MOJ-?SOON/UOK-?~OON/ Remarks

~

1

4.5

I

1

I

JAPAN

-

6.5

1

5

-

-

16.5

16,5

obr

dlstr~bilto:~ or agents n vour area for further ~nforrnat~ons

CABLE

TELEX

PHONE

JUKl

TOKYO

322967

03(205)1188 1189 1190

Refer to

DIFFERENTIAL FEED RATIO".

1

Refer to "6. ADJUSTING THE

6.5

VERTICAL STROKE OF THE TOP

,

FEED DOG".

Refer to

-

1

PRESSURE OF THE TOY FEED

DOG".

232

2301

"7.

ADJUSTING THE TOP

"10.

are

subjected to change wthout

ADJUSTING THE

1990

7

Printed

I

whr

not~ce

In

JaDafl

I

MATPARTS

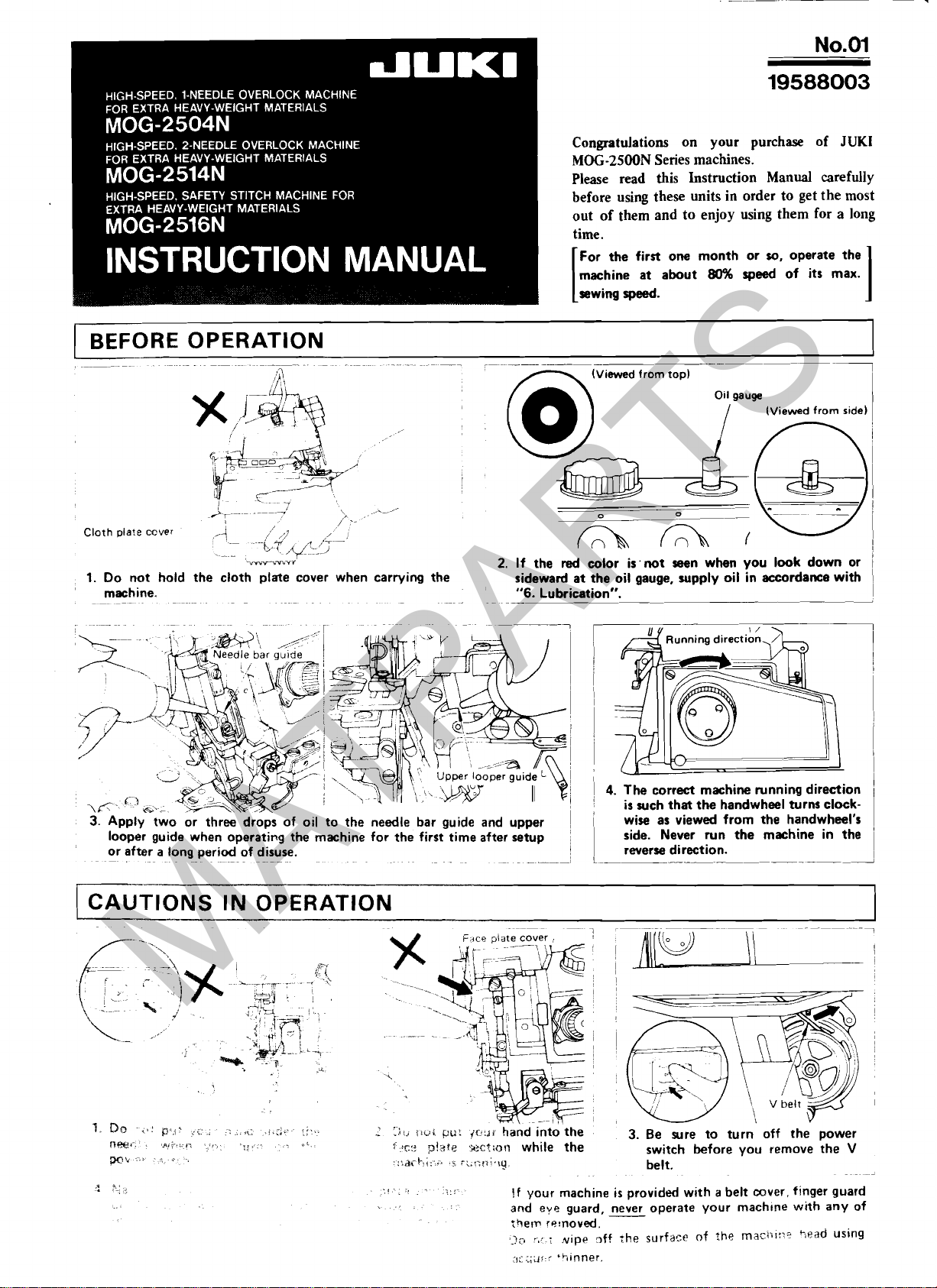

BEFORE OPERATION

Congratulations on your purchase of

MOG-2500N Series machines.

this

Please read

before using these units in order to get the most

out of them and to enjoy using them for

time.

For the first one month or

machine at about

sewing

speed.

-

--

--

(Vtewed

from top)

Instruction Manual carefully

so,

operate the

80%

speed

of

-

its

JUKI

a

long

max.

1

.~.--

.

--

.rw~Y-IWT

7

,,,;7

b-.ir

,.ti~i..i

-

T

,

i~

-.

cloth

plate

cever

1.

Do not hold the cloth plate cover when carrying the

machine.

-

--

3.

Apply two or three drops of oil to the needle bar guide and upper

looper guide when operating the machine for the first time after setup

or after

-

a

.

-i

.

.-

-

-

long period of disuse.

,

,,'..

.'

,

!

,

,,'T-

(Viewed

2.

If the

sideward at the oil gauge, supply oil in accordance with

"6.

-

red

Lubrication".

~

I

-

---

color is not seen when you look down or

--

4.

The correct machine running direction

is

such that the handwheel turns clockwise as viewed from the handwheel's

side. Never run the machine in the

reverse direction.

from

s~de)

i

1

I

CAUTIONS

IN

OPERATION

.

:-,

-

.I:,

j

~::aq!-.;:.::.

.,

*

.

Fdce

olate

cover

,

i:~i

pui

it.:i~

.-...,

SF,i

p!?te

,s

:,

3

.

.

.;::-

hand into the

cx~?;~~~i

r;,!;!?;.\q

while the switch before you remove the

1f

your machine

and

:hew

.lo

7..~r

.

eye

guard,

removed.

3.

Be sure to turn off the power

.

riff

belt.

is

provided with a belt wver, finger guard

never

operate your mach~ne

:he

of

?he

machi:??

with

%ad

V

-~-

any of

using

~-

1.

MATPARTS

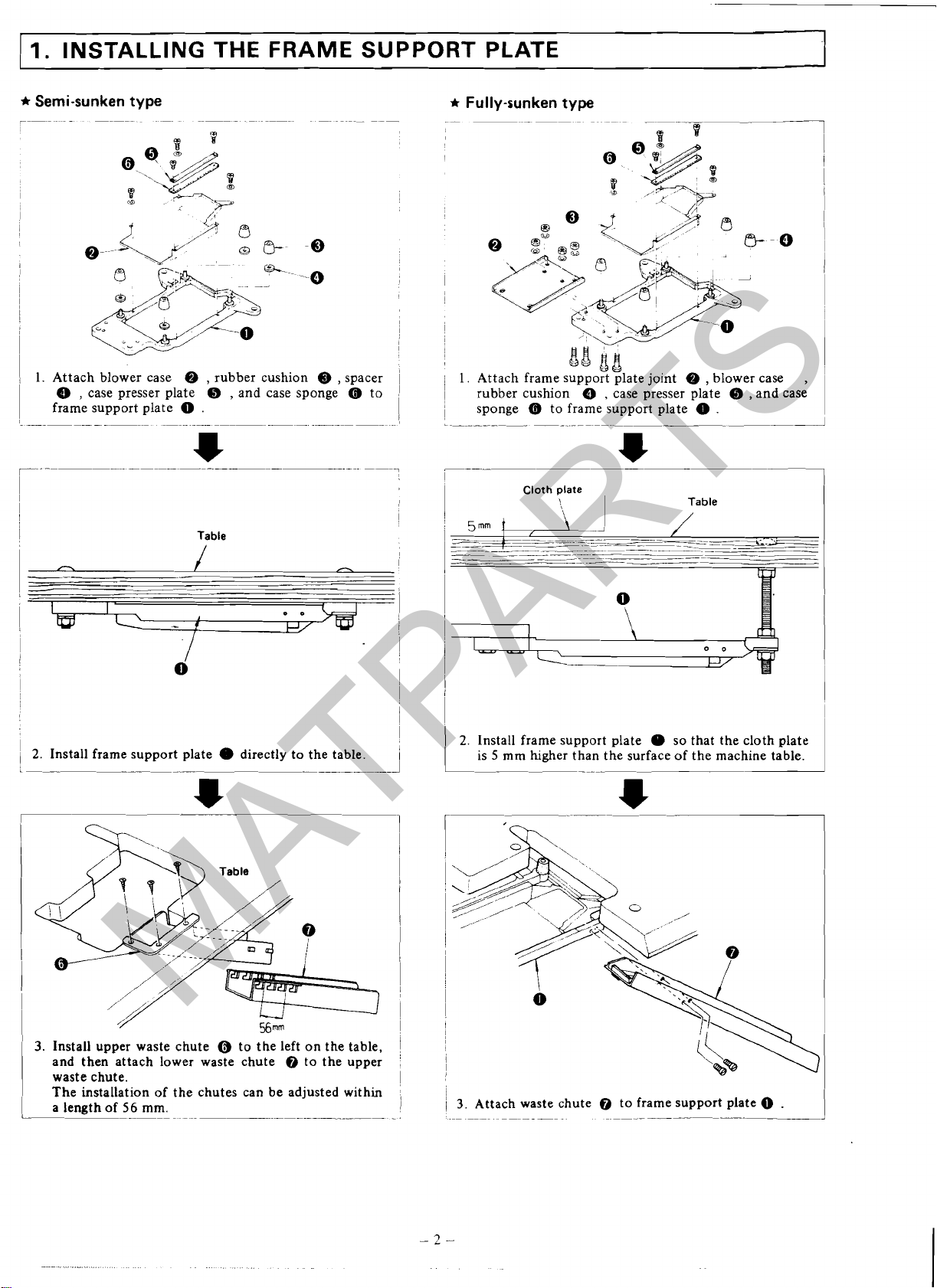

INSTALLING

*

Semi-sunken type

I

I Attach blower case

Q

,

case presser plate

frame support plate

'

THE

@

,

rubber cushion

@

0

,

.

FRAME SUPPORT PLATE

+

Fully-sunken type

@

,

spacer

and case sponge @ to

1. Attach frame supPo; ;late joint

rubber cushion

sponge

0

,

case presser plate

@

to frame support plate

Cloth

plate

\.

Q

,

blower case

0

.

Table

Q

,

and case

1

,

I

Table

1

2.

Install frame support plate 0 directly to the table.

2.

Install frame support plate so that the cloth plate

is

5

mm

higher than the surface of the machine table.

3.

Install upper waste chute @ to the left on the table,

and then attach lower waste chute

waste chute.

The installation of the chutes can be adjusted within

a length of

56

mrn.

-

-

--

@

to the upper

- - -

-

- - -

/

3.

-

Attach waste chute @ to frame support plate

-

-- - -

-

- . -

-

-

-

--

-

0

-

.

.-

2.

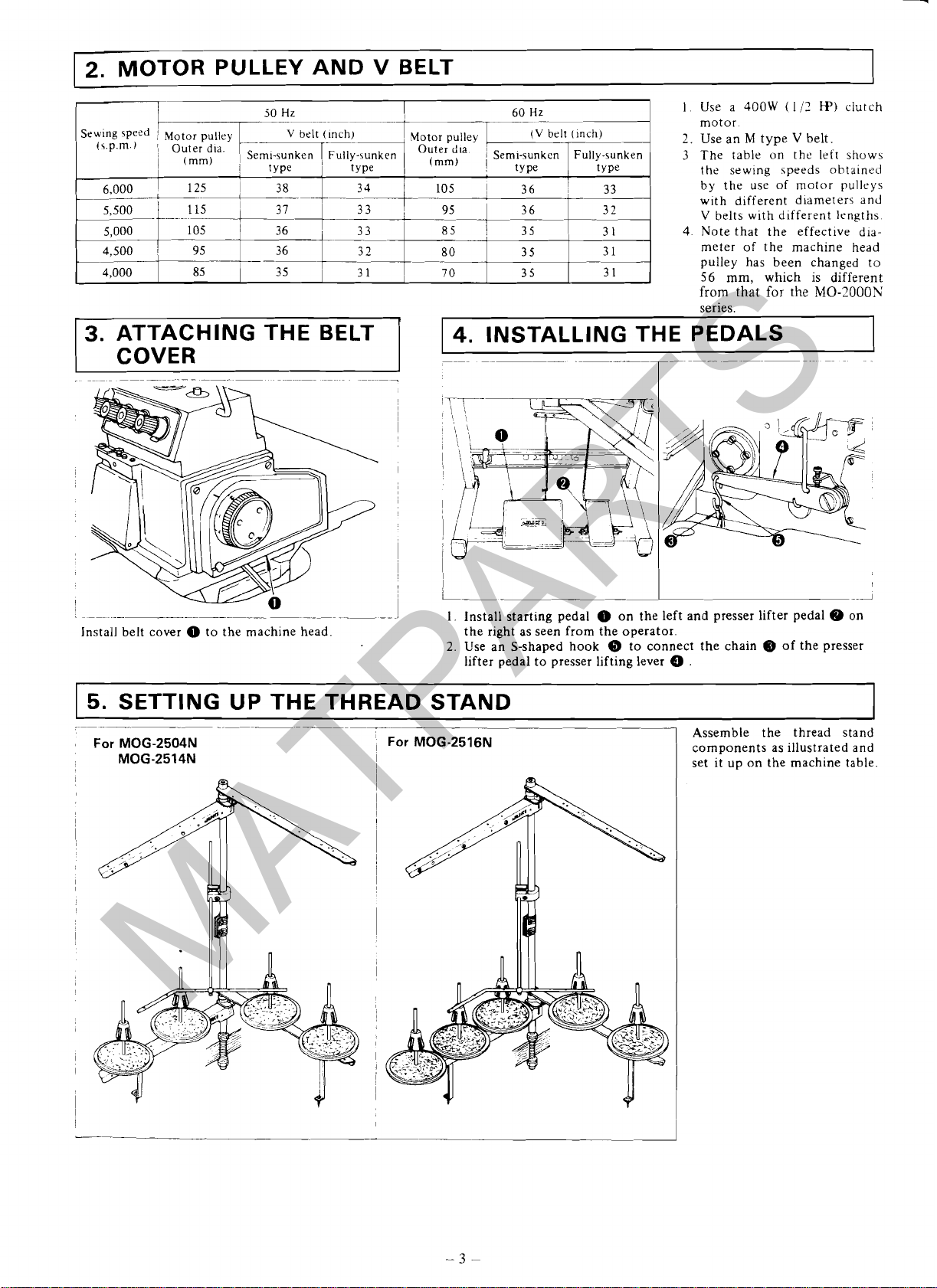

MATPARTS

MOTOR PULLEY AND V BELT

Sewing

5peed Motor pulley

"

'

"

'

Outer

*la

<--~Ty-\unken Outer

.

/

(mm)

6,000 125

3.

ATTACHING THE BELT

I

V

type

38

belt (~nch)

I

type

COVER

-

.

-

34

1

Motor pulley

(mm)

I

1105

-

I

I

I

I

1.

Use a

motor.

2.

*la

I

1

36

4.

INSTALLING THE PEDALS

3

3

Use an M type V belt.

3

The table

the sewing speeds

by the use of motor

with different diameters and

V

4.

Note that the effective

meter of the machine head

pulley has been changed to

56

from

series.

400W

(1

/2

W)

clutch

on

the

left

shows

obtaineci

pulleys

belts with different lengths

dia-

mm,

which is different

that

for

the

M0-2000W

i

1

I

.

.

Install belt cover

5.

SETTING UP THE THREAD STAND

For

MOG-2504N

MOG-2514N

0

to the machine head. the right as seen from the operator.

-~

--~,

I

1

For

MOG-2516N

1

I

Lppp-

I. Install starting pedal 0 on the left and presser lifter pedal 8 on

2.

Use an S-shaped hook @ to connect the chain @ of the presser

lifter pedal to presser lifting lever

0

.

Assemble the thread stand

components as illustrated and

set it up on the machine table.

--.l

I

1

MATPARTS

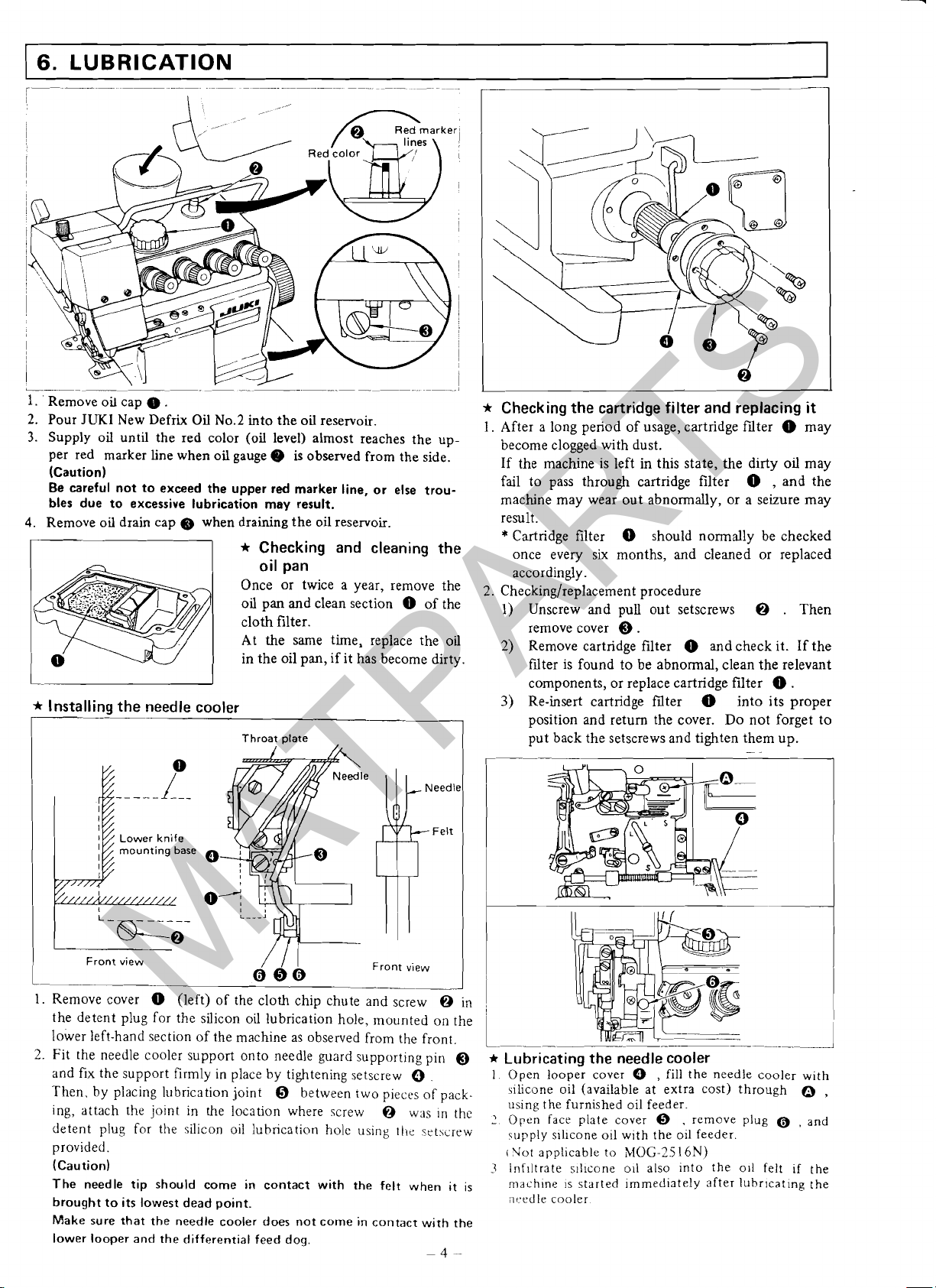

6.

LUBRICATION

1.

'

Remove oil cap

2. Pour JUKl New Defrix Oil No.2 into the oil reservoir.

3.

Supply oil until the red color (oil level) almost reaches the upper red marker line when oil gauge

(Caution)

Be careful not

bles due to excessive lubrication may result.

4.

Remove oil drain cap @ when draining the oil reservoir.

-1

1

0

*

Installing the needle cooler

1--

0

.

@

is

observed from the side.

to

exceed the upper red marker line, or else trou-

*

Checking and cleaning the

oil pan

Once or twice a year, remove the

oil pan and clean section

cloth filter.

At the same time, replace the oil

I

in the oil pan, if it has become dirty.

Throat plate

0

--

1

of the

*

Checking the cartridge filter and replacing

1.

After a long period of usage, cartridge filter 0 may

become clogged with dust.

If the machine is left in this state, the dirty oil may

fail to pass through cartridge filter

machine may wear out

result.

*

Cartridge filter

once every six months, and cleaned or replaced

accordingly.

2.

Checking/replacement procedure

1)

Unscrew and pull out setscrews

remove cover

2)

Remove cartridge filter

filter is found to be abnormal, clean the relevant

components, or replace cartridge filter

3)

Re-insert cartridge filter

position and return the cover.

put back the setscrews and tighten them up.

abnormally, or a seizure may

0

should normally be checked

Q

.

0

0

,

and the

@

.

and check it. If the

0

0

into its proper

Do not forget to

-

-

I

it

Then

.

Needle

mounting base

I

1

1.

2.

Front view

Remove cover 0 (left) of the cloth chip chute and screw @ in

the detent plug for the silicon oil lubrication hole, mounted on the

lower left-hand section of the machine as observed from the front.

Fit the needle cooler support onto needle guard supporting pin

and

fix

the support firmly in place by tightening setscrew

Then, by placing lubrication joint

ing, attach the joint in the location where screw

detent

provided.

(Caution)

The needle tip should

brought to its lowest dead point.

Make

plug

for the silicon oil lubrication hole using tile setscrew

come

sure that the needle cooler does not come in contact with the

lower looper and the differential feed dog.

/

I

I

000

Front

view

0

@

between two pieces of pack-

@

was ln the

in

contact with the felt when it is

Felt

I

Q

4-

*

Lubricating the needle cooler

Open looper cover

1

iilicone oil (available at extra cost) through

using the furnished oil feeder

2

Open fact? plate cover

upp ply

s~llcone oil wlth the

I

Vot applicable to

3

lnflltrate sllicone oil also Into the

rndchlne

nc.t.dle cooler

1s

~tdrted ~rnrned~ately after lubrlcat~ng the

0

,

fill

@

MOG-25

the needle cooler

.

remove plug

011

feeder

16N)

011

felt

@

~f

with

0

,

and

,

the

7.

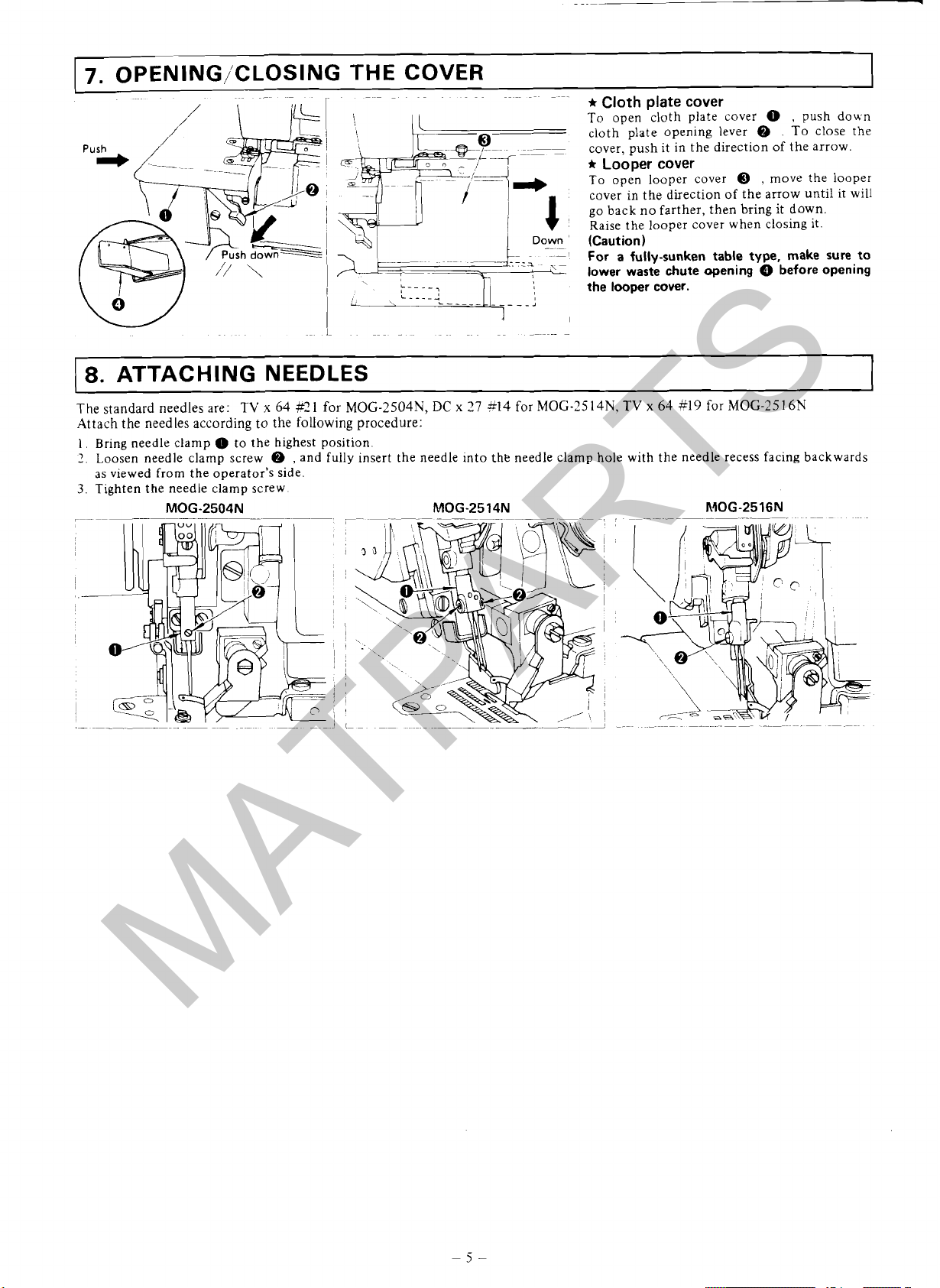

MATPARTS

OPENING/CLOSING THE COVER

~~

~-

~~~

-

I

\-

~-

~

--~

---~--~

(

~

--

~~

---.

Down

,\

*

Cloth plate cover

To open cloth plate cover

cloth plate opening lever

cover, push it in the direction of the arrow.

*

Looper cover

To open looper cover

cover in the direction of the arrow until

go back no farther, then bring it down.

Raise the looper cover when closing it.

'

(Caution)

For a fully-sunken table type, make sure

-

lower waste chute opening Q before opening

the

looper

cover.

0

.

@

.

To close the

@

,

move the looper

push down

it

will

to

1-

8.

ATTACHING NEEDLES

The standard needles are:

Attach

3.

the needles according to the following procedure:

1. Bring needle clamp 0 to the highest position.

2.

Loosen needle clamp screw

as viewed from the operator's side.

Tighten the needle clamp screw.

TV x 64

@

#2

1

for

MOG-2504N,

,

and fully insert the needle into

---

~

DC

-~ ~ --

x

27 *I4

for

the

needle clamp hole with the needle recess facing backwards

I

-

MOG-25 14N.

TV x 64

#19 for

MOG-25

16N

9.

MATPARTS

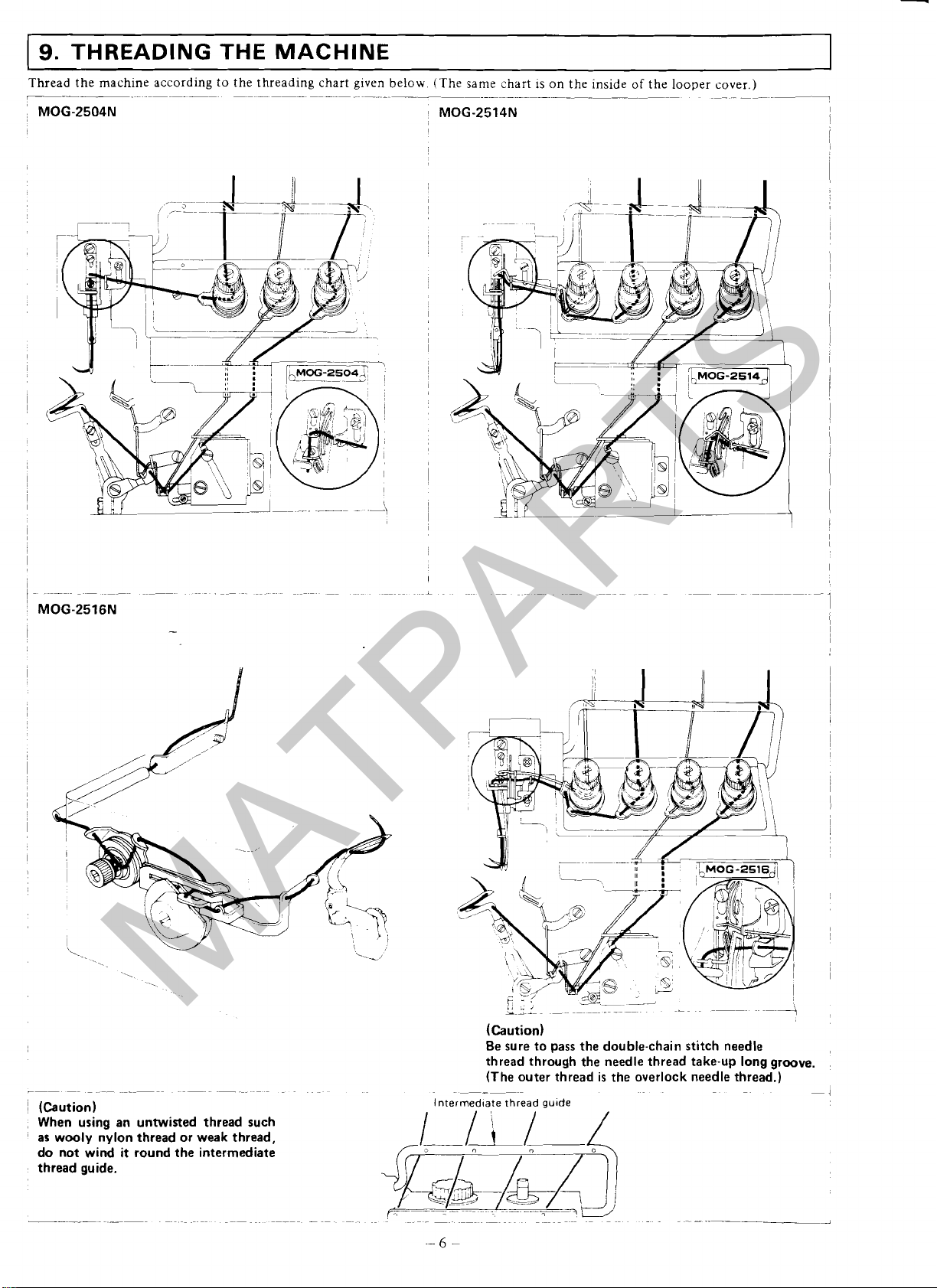

THREADING THE MACHINE

Thread the machine according to the threading chart given below. (The same chart is on the inside of the looper cover.)

.

-

:

MOG-2504N

. . .

.

-

-

.

--

-

-

-.

-

-

--

.

-

- . -

.

-.

I

-

-

-.

-

MOG-2514N

-

-

-

1

I

I

I

(Caution)

When using an untwisted thread such

'

as

wooly

do not

nylon thread or

wind

it

round the intermediate

weak

thread,

thread guide.

~~

-~

(Caution)

Be sure to pass the double-chain stitch needle

thread through the needle thread take-up long groove.

-~

~~

-~

~-

~ ~

lntermed~ate

-

(The outer thread is the

thread

guide

-~--

- ~ -

~- - ~-

overlock needle thread.)

-

- - - -

-

-

-

i

2

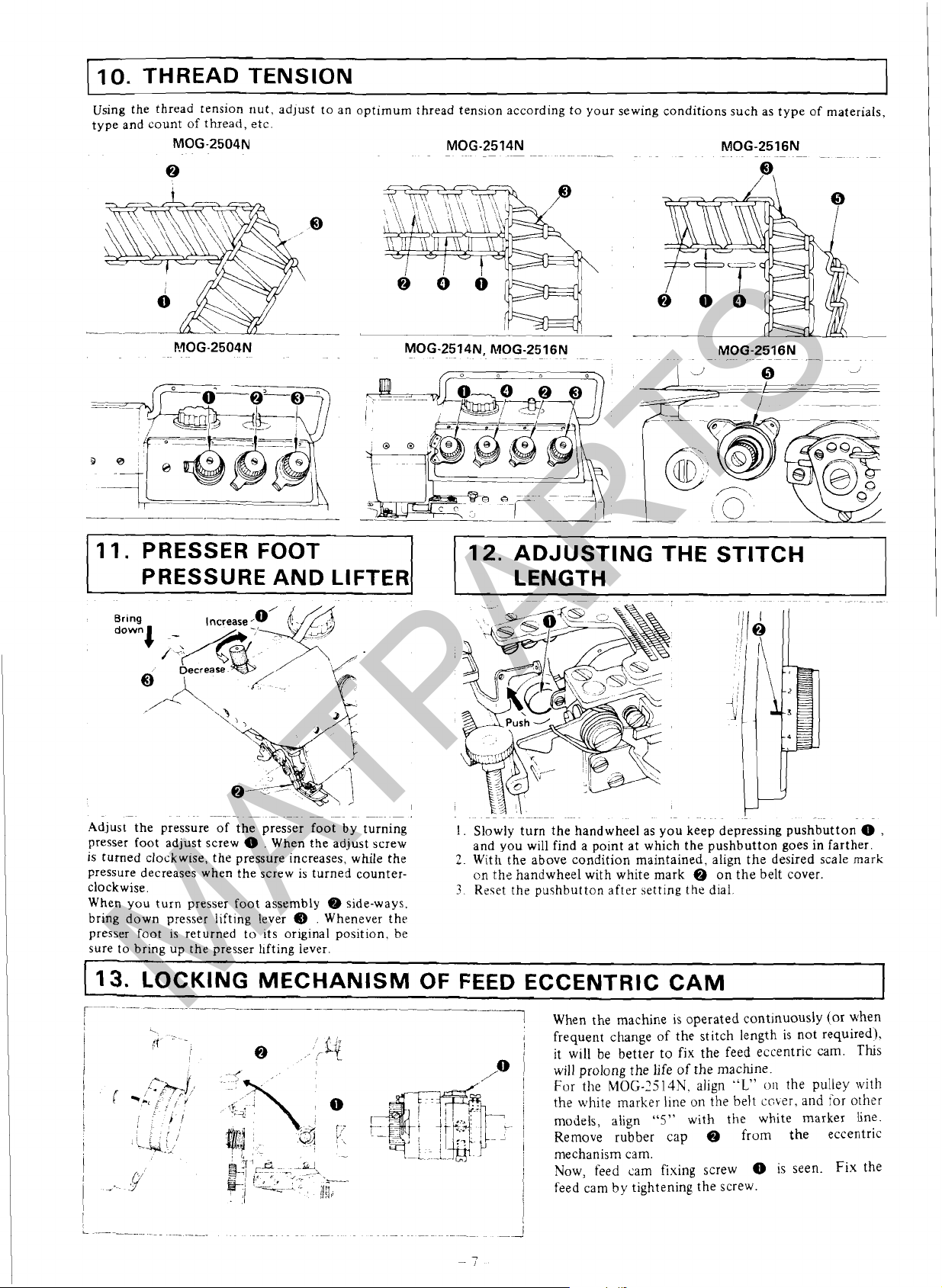

10.

MATPARTS

THREAD TENSION

Using the thread tension nut, adjust to an optimum thread tension according to your sewing conditions such as type of materials,

type and count of thread, etc.

11.

PRESSER

PRESSURE

-

-

Adjust the pressure of the presser foot by turning

presser foot adjust screw

is

turned clockwise, the pressure increases, while the

pressure decreases when the screw is turned counterclockwise.

When

you

bring down presser lifting lever

presser foot is returned to its original position, be

sure to bring up the presser

I

1

13.

--

!

I

I

I

i

>*-.

.

./

~

-

----

turn presser foot assembly

LOCKING MECHANISM OF

--

.~

<;

~,

fr'

'

-

;

.

.

.,

1

:,

,

/'

p/'

i

FOOT

AND LIFTER

-~

--

-~ - -

--

0

.

When the adjust screw

@

llfting lever.

&:

I

-,

~i

:/

@

;;-,-i

,--

-A

-~-

-_-

~s

-

.,,T7

..!

-W

'-

~

'

~

Qb

side-ways.

.

Whenever the

kj

I

>--

jgy

-

12.

ADJUSTING THE STITCH

LENGTH

,

. .

I.

and you will find a point at which the pushbutton goes in farther.

2.

With the above condition maintained, align the desired scale mark

on thz handwheel with white mark

3.

FEED

.

~--~~

Slowly turn the handwheel as you keep depressing pushbutton

Reset the pushbutton after setting the dial.

.-

~~~

@

on the belt cover.

-~

-

ECCENTRIC CAM

-

-

0

,

1

---!

When the machine is operated continuously (or when

1

frequent change of the stitch length is not required).

/

'

@

it will be better to fix the feed eccentric cam.

1

will prolong the life of the machine.

For

the

I

!

the white marker line on the belt

I

models, align

Remove rubber cap

1

mechanism cam.

1

Now, feed cam fixing screw

feed cam by tightening the screw.

1

1

MOG-25l4N.

align

"L"

ox

caber,

"5"

with the white marker 6ne.

Q

from the eccentric

0

is

the pulley with

and

seen. Fix

This

for other

the

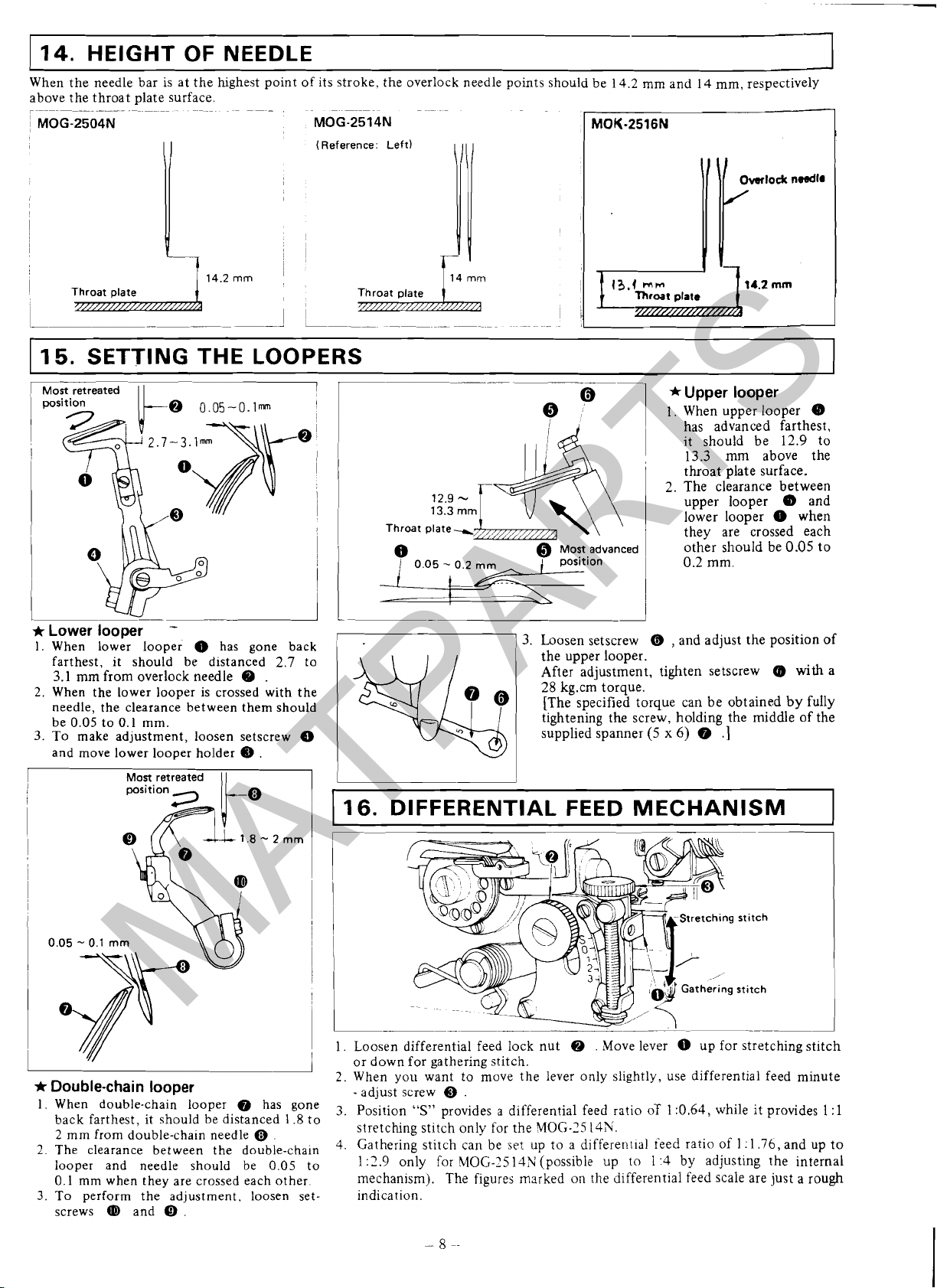

14.

MATPARTS

When the needle bar is at the hghert polnt of its stroke, the overlock needle po~nts should be 14 2 mm and

above the throat plate surface

- - -

MOG-2504N MOG-2514N

I

I

HEIGHT OF NEEDLE

-- - - - -

- - -

--

-

---

MOK-2516N

(Reference Left)

I

I

-

1

15.

1

SETTING THE LOOPERS

Most

retreated

I

I

--

I

*

1.

When upper looper

has advanced farthest,

it should be

throat plate surface.

2.

The clearance between

upper looper

lower looper 0 when

'

they are crossed each

other should be

1

O.2mm.

14

mm,

respectively

Upper looper

13.3

mm above the

(b

12.9

to

0

and

0.05 to

*

Lower looper

1.

When lower looper 0 has gone back

farthest, it should be

3.1

mm

2.

When the lower looper is crossed with the

needle, the clearance between them should

be 0.05 to 0.1 mm.

3.

To make adjustment, loosen setscrew

and move lower looper holder @ .

*

Double-chain looper

1. When double-chain looper has gone

back farthest, it should be distanced

2

2.

The clearance between the double-chain

looper and needle should be

0.1 mm when they are crossed each other.

3.

To perform the adjustment, loosen setscrews

from overlock needle Q .

mm from double-chain needle

@

Most

and

-

retreated

@

.

distanced

I

I

2.7

Q

1.8

@

0.05

to

I

to

to

3.

Loosen setscrew

the upper looper.

After adjustment, tighten setscrew

28

kg.cm torque.

[The specified torque can be obtained

tightening the screw, holding the middle of the

supplied spanner (5

1

16.

1.

2.

3.

4.

DIFFERENTIAL FEED MECHANISM

Loosen differential feed lock nut

or down for gathering stitch.

When you want to move the lever only slightly, use differential feed minute

-

adjust screw @ .

Position

stretching stitch only for the

Gathering stitch can be

1

:2.9

mechanism). The figures marked

indication.

"S"

provides a differential feed ratio

se:

only for

MOG-25

14N

Q . Move lever 0 up for stretching stitch

MOG-75

up to a differentla1 feed ratio of

(possible up

14N.

on

the differential feed scale are just a rough

to

6

,

and adjust the position of

B)

x

6) @ .]

oT

1

:0.64,

while it provides

1

:1.76,

1

:4

by adjusting the internal

by

and up to

with

fully

1

a

I

:1

17.

MATPARTS

PRESSER FOOT AND FEED DOG

~

-

*

Contact of the presser foot with the throat plate

top surface

*

Height of feed dog

1.

Feed dog 0 is usually set so that its teeth protrude about

1.3

rnm

its trajectory.

from the throat plate surface at the highest point in

Reduce the protrusion for light weight

materials.

2.

Use setscrew @ to adjust the protrusion of the feed dog

teeth.

,

3.

Using setscrew

feed dog

4.

Adjust the height of auxiliary feed dog

so that it is

Q

is level with the main feed dog.

0.5

-

make adjustment so that differential

by

rnm

lower than the main feed dog.

setscrew

Using adjust screw

the presser foot evenly comes in contact with the top surface

of the throat plate when presser foot

*Tilt

of feed dog

1.

Loosen screw

tion of the arrow to make the feed dog front up or turn it

in the reverse direction to set the feed dog front down.

2.

The feed dog should be levelled when the dot engraved on

the eccentric shaft faces exactly to the line.

@

,

line

'

(Q

Q

,

and turn eccentric shaft

18. CHAIN LOOPER THREAD CAM (MOG-2516N)

perform adjustment so that the sole c~f

0

comes down.

Front

up

p=YY1

0

in

the direc-

1

19.

THREAD GUIDE

AND

Loosen setscrew

so that, when the needle is in the highest position of

the flat part of chain looper thread cam

the top surface of thread guide

Parallel

looper thread cam releases the looper thread when the needle

point is about

i---

LOOPER THREAD

B

,

and adjust chain looper thread cam

its

0

is in parallel to

@

.

Be sure that the chain

2

mm below the throat plate bottom surface.

Approx.

2

mrn

TAKE-UP

0

stroke,

I

The table below shows the standard demensions of the individ-

ual thread

looper has gone back farthest.

r

--

F

+

-

(;

-

H

-

-I-

I

*--.- ~ +.-.

J

*-

~

-&

K

1-

gu~des and looper thread take-ups when the upper

-

7----

+

I

A

-

L~.~~.-~

--

~

63

26

4

4

26.5

-

1

~

~~.~--

22.5

.

--

Y

-~

--

~

1---

+

-~-~

~-

-+~-

.--

.*

~

-

I

..

-

-

.

.

~

19.5

-

63

41

26

41

18

--

17

1

:3

~

I--

-~

~.~--+

~~

-

r.-.~

~

!

~~+

-

+

+

-

+

.

6

3

41

26

44

9

17

~

22.5

9

~-

58.5

-

__I

.

~-

1

I

~.

.

-~

1

-

,

J

---

1

.

.

(!.init

:

mm)

20.

MATPARTS

KNIVES AND OVEREDGE WIDTH

*

He~ght

I

>e

'I>\,

*

Height of the upper knife

i..r\.;.

A:;:!.:

Ili3ptsr

*

Overedge width

iheirdgt. \+!dths of

<!!-lnglilg ri~c parts or

uidth

Pi)

1.

1

3

-

of the lower knife

,-TI

.iL',<

it.w and dtllust the helght

11,

zdg~

$\

tlush wlth thc throat plate \urtaie

n

iriccrews

@

.)\trlaps lower kn~te

kn~:-

i,

u~ii

he

<,h

ingc

L.ooscnlng setscrew

I1.x

1.~1nsen setscrew

tl~en i~u

Lllwcr the upper knife to its lowest point and Loosen setscrew

In contact with the upper knife.

slightly larger than the kn~fe cut width.)

the overedge wldth.

It.

it

@

.

,

@

and perform adjustment so that upper

0

dt

its lowert point

4.8

through

by

uslng hubclaha r~~vdels. (The overedge

@

,

push lower knife 0 to the left and

Q

and move upper knife Q as required.

Tighten setscrew @ when the lower knife comes

ot

lower kn~fe

hy

0

5

to

I

rnrn

10

rnrn dre provided by

0

SO

when the

1

21.

NEEDLE

GUARD

*

Resharpening the lower knife

When the lower knife has become dull, resharpen it as shown

in the figure left.

~-

~p

-

*

For

1-Needle

An

overlock machine is equipped with

and

@

I.

7

.

Position needle guard 0 so that it lightly comes in contact

w~th needle 0 when the blade point of lower looper

reached the center of needle

Position needle guard @ so that it

bottom surface of the throat plate

from needle Q when the needle is at its lowest point.

and

-

-

2-Needle

0

Overlock Machines

two

needle guards

is

1

mm lower than the

and

is distanced 0.1'mm

-

0

has

I

*

For

safety stitch machines

A

point

safety stitch machine has four needle guards

and

0

.

1

Position needle guards 0 and

overlock machne explained above.

2.

Position needle guard 0 so that it lightly comes in contact

with needle

distanced

1

lowest point.

I

I

@

,

and position needle guard 0 so that it is

0.1

mm from needleewhen the needle is at its

in the same manner as the

0

,

@ , @

1

MATPARTS

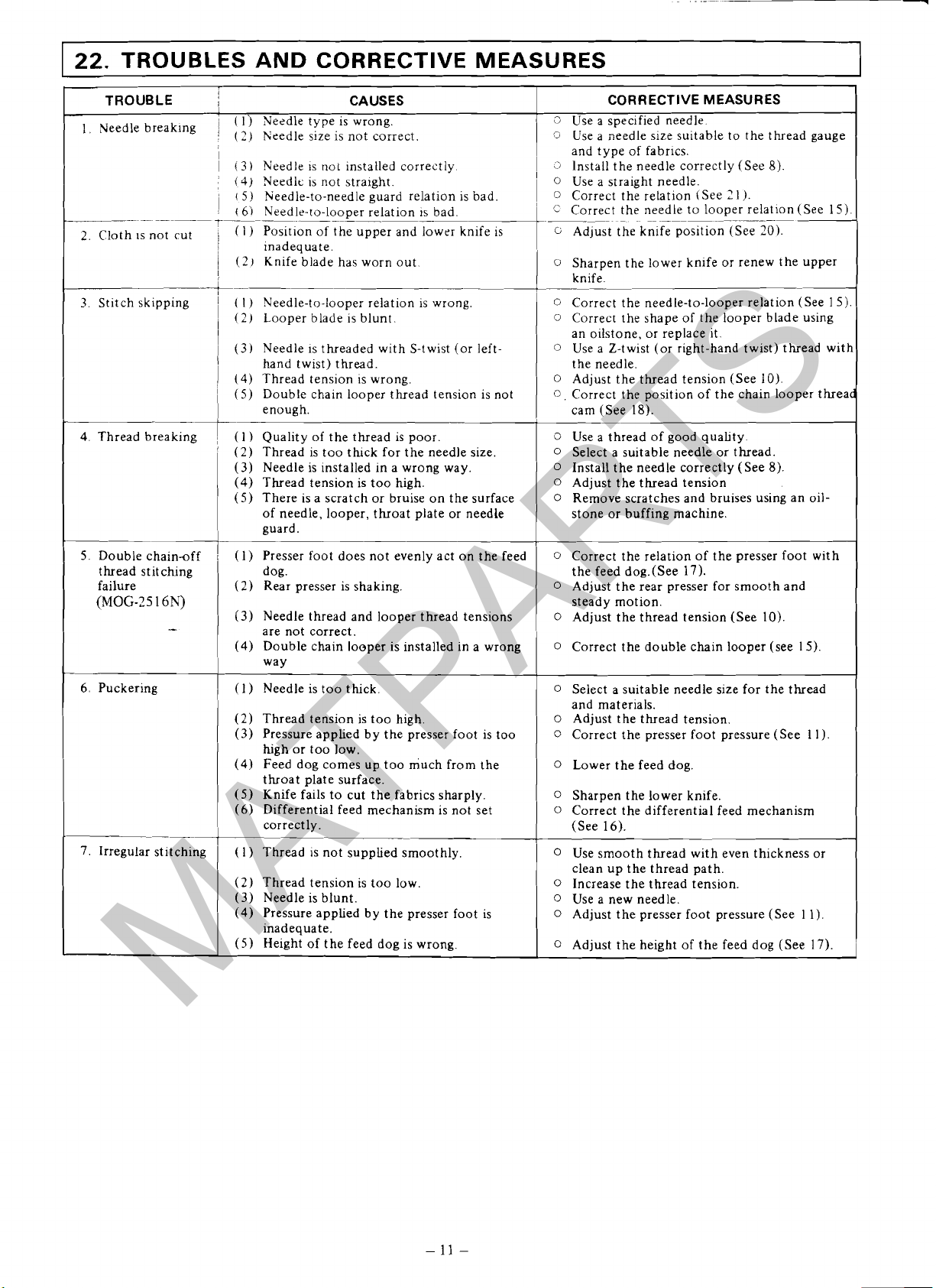

22.

TROUBLES AND CORRECTIVE MEASURES

Needle

-

2,

cloth

3.

Stitch skipping

4.

Thread breaking

breaking

Is

not cut

1

i

I

I) Needle type is wrong.

!

(2)

h'eedle size is not correct.

I

(3)

Needle

i4)

Needle is not straight.

(5)

1

T---..

I

/

Keedle-to-needle guard relation is bad

t

61 Needle-to-looper relation

(I)

Position of the upper and lower knife is

inadequate.

(21

Knife blade has worn out

(

I

)

Needle-to-looper relation is wrong.

(2)

Looper blade is blunt.

(3)

Needle is threaded with S-twist (or lefthand twist) thread.

(4) Thread tension is wrong.

(5)

Double chain looper thread tension is not

enough.

(

1

)

Quality of the thread is poor.

(2)

Thread is too thck for the needle size.

(3) Needle is installed in a wrong way.

(4)

Thread tension is too high.

(5) There is a scratch or bruise on the surface

of needle, looper, throat plate or needle

guard.

CAUSES

is

not installed correctly.

IS

bad.

1

,3

0

3

0

0

c

0

0

0

0

0

0.

0

0

0

0

0

CORRECTIVE MEASURES

Use a specified needle.

Use a needle size suitable to the thread gauge

and type of fabrics.

Install the needle correctly (See

Use a straight needle.

Correct the relation (See

Correct the needle to looper relation (See 15).

~

- . --

Adjust the knife position (See 20).

Sharpen the lower knife or renew the upper

knife.

Correct the needle-to-looper relation (See

Correct the shape of the looper blade using

an oilstone, or replace it.

Use a Z-twist (or right-hand twist) thread witb

the needle.

Adjust the thread tension (See 10).

Correct the position of the chain looper threa~

cam (See 18).

Use a thread of good quality.

Select a suitable needle or thread.

Install the needle correctly (See 8).

Adjust the thread tension

Remove scratches and bruises using an oilstone or buffing machine.

~

8).

2

1

).

~

I

-

15).

5.

Double chain-off

thread

stitcfung

failure

(MOG-25

6.

Puckering

7.

Irregular stitching

16N)

(I) Presser foot does not evenly act on the feed

dog.

(

2) Rear presser is shaking.

(3)

Needle thread and looper thread tensions

are not correct.

(4) Double chain looper is installed in a wrong

way

( 1 )

Needle is too thick

Thread tension is too high.

Pressure applied by the presser foot is too

high

or

Feed dog comes up too much from the

throat plate surface.

(5)

Knife fails to cut the fabrics sharply.

(6) Differential feed mechanism is not set

correctly.

(

1

)

Thread is not supplied smoothly.

(2)

Thread tension is too low.

(3) Needle is blunt.

(4) Pressure applied by the presser foot is

inadequate.

(5)

Height of the feed dog is wrong.

too low.

0

Correct the relation of the presser foot with

the feed

0

Adjust the rear presser for smooth and

steady motion.

0

Adjust the thread tension (See

0

Correct the double chain looper (see 15).

0

Select a suitable needle size for the thread

and materials.

0

Adjust the thread tension.

0

Correct the presser foot pressure (See

0

Lower the feed dog.

0

Sharpen the lower knife.

0

Correct the differential feed mechanism

(See 16).

0

Use smooth thread with even thickness or

1

clean up the thread path.

0

Increase the thread tension.

0

Use a new needle.

0

Adjust the presser foot pressure (See 11).

0

Adjust the height of the feed dog (See 17).

dog.(See 17).

10).

1

1

).

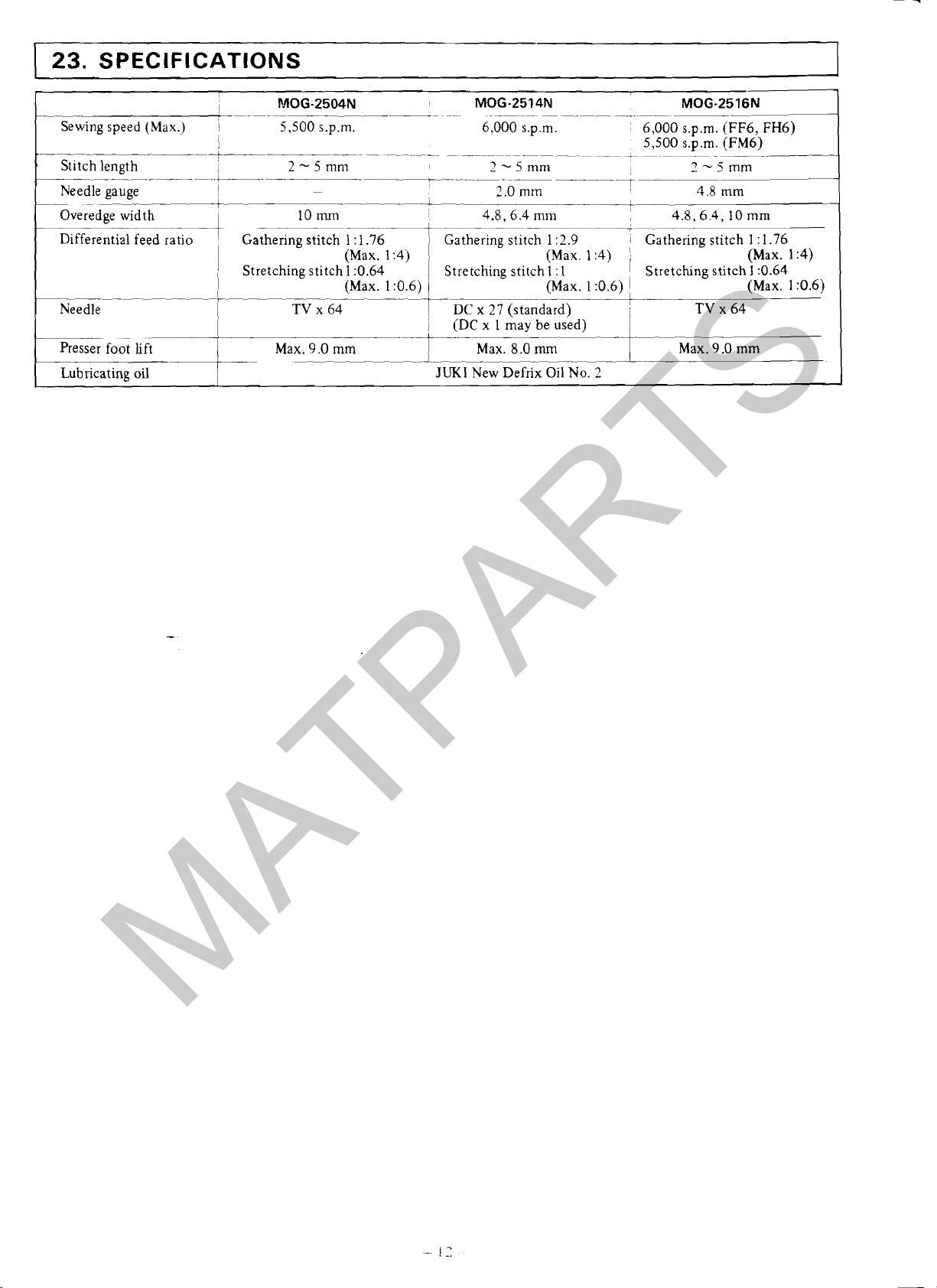

23.

MATPARTS

---

--

SPECIFICATIONS

Sewing speed (Max.)

Stitch length

Needle gauge

Overedge width 10

Differential feed ratio

Needle

Presser foot

Lubricating oil

-

-

-

-

lift

-.L-

-

.-

..

-*-.--

I

1

a--

I

I

Gathering stitch

i

Stretching stitch 1 :0.64 Stretching stitch

MOG-2504N MOG-2514N MOG-2516N

~

----

~

----

5,500 s.p.m. 6,000 s.p.m. 6,000 s.p.m. (FF6, FH6)

2

-

5 mm 2-Smm 2-5mm

rnm

TV x 64

Max. 9.0 mm

-

--

1

:

1.76

(Max. 1 :4) (Max. 1.4)

(Max. 110.6)

--

~ ~

-

-

1

1

DC

1

(DC x I may be used)

-f--

JUKI

-

-

-

_-

--_

_

2.0

rnm

---

4.8,6.4 mm 4.8.6.4,

5,500 s.p.m. (FM6)

_

.

-

4.8

i

Gathering stitch 1 :1.76

1

(Max. 1 :0.6)

x

27

(standary

Max. 8.0

New

-T

Defrix

Oil

No.

1

i

(

2

TV

Max.

9.0

_

__

mm

lOmm

(Max.

1

(Max. 1 :0.6)

x

64

mm

:0.64

1

14)

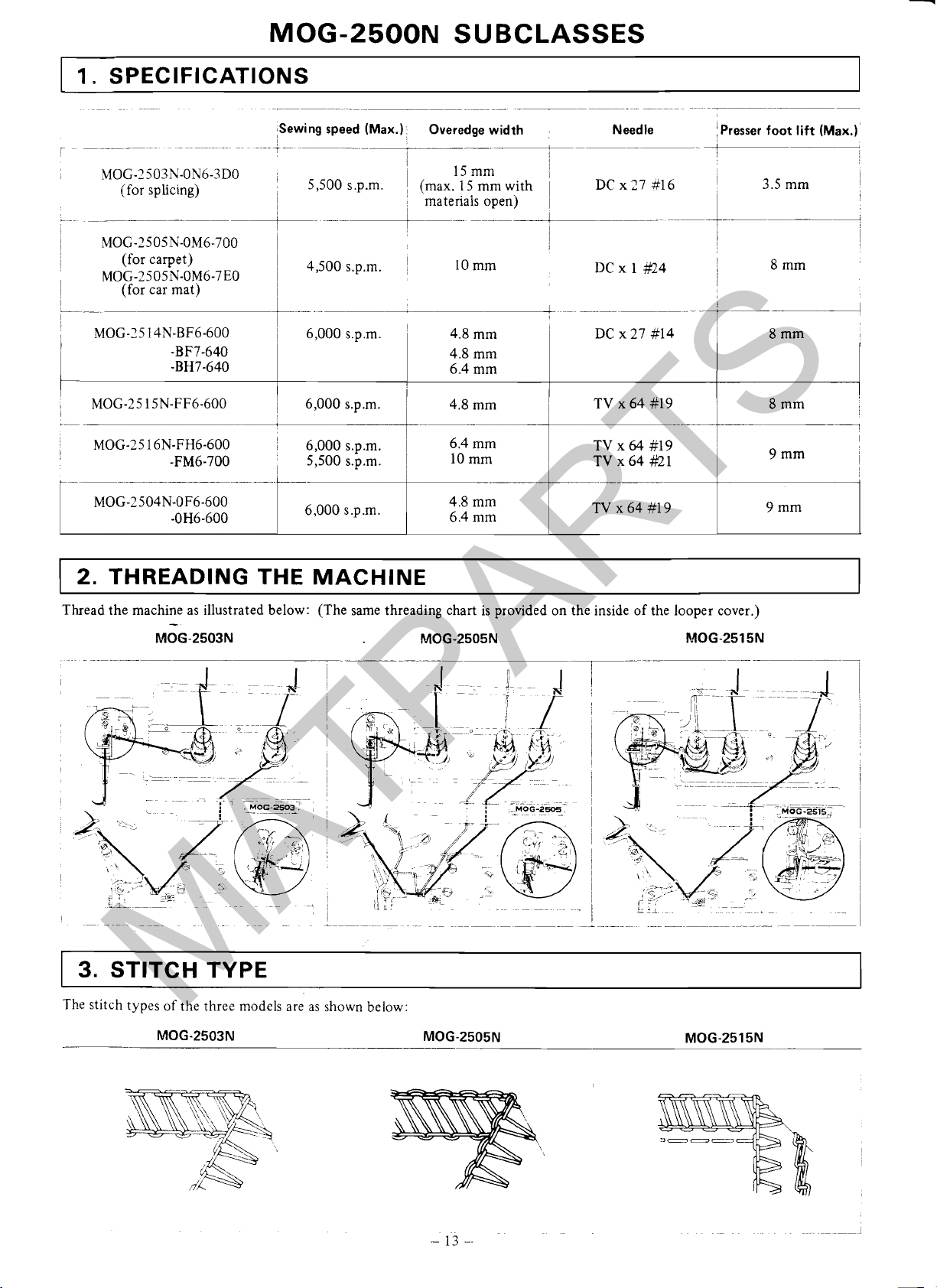

1.

MATPARTS

SPECIFICATIONS

MOG-2500N

SUBCLASSES

Sewing speed

MOG-2503N-ON6-3D0 15 mm

(for

splicing)

I

5,500 s.p.m. (max. 15 mrn with

(Max.)

I

~

,

I

~

(for carpet)

MOG-2505N-OM6-7E0

(for car mat)

I

4,500 s.p.m.

i

I

~

Overedge width Needle :Presser

materials open)

~

1

DC

x

27

#I6

foot lift

(Max.)

2.

THREADING THE MACHINE

Thread the machine as illustrated below: (The same threading chart is provided on the inside of the looper cover.)

3.

STITCH TYPE

The stitch types of the three models are as shown below:

-

MOG-2503N MOG-2505N MOG-2515N

MOG-2503N MOG-2505N

2

MATPARTS

-

E

/

'

/'

0

-

e,

3-r.

a

8

aa~

ZZ

g'~

2

-

G

.-

-

_____-i

-

C;

4

+

I

I

-

g.ci.9

GZ2

z

-

@

z9;

WwW

;

A

3

2

*

im

'y

a

*

2

o

0

2a.z

Uma

@

9

I:

2

*

N

8

32s

8%3

mB.2

wr

u+

A

--

'

1

G$

mw

-

?-

d

V

mm

-

-

-

30s

awaus@

b*LZ

w

r

,

g$+uw3,

%$

*

-

VVV

3

*X *X

3 * 3

4

WO

h

NN

-

I.?$

r-m

-

-

4

b

e,

h

0-

222

hhh

WNC(

o*

O*

I

9

&

g

42222

g&cZ-

gg2530

:

2

I

I

2

/

a

-

I

I

i

z

3

1

%

0

3

Q

0"OU

.E

g.;

I

I

1

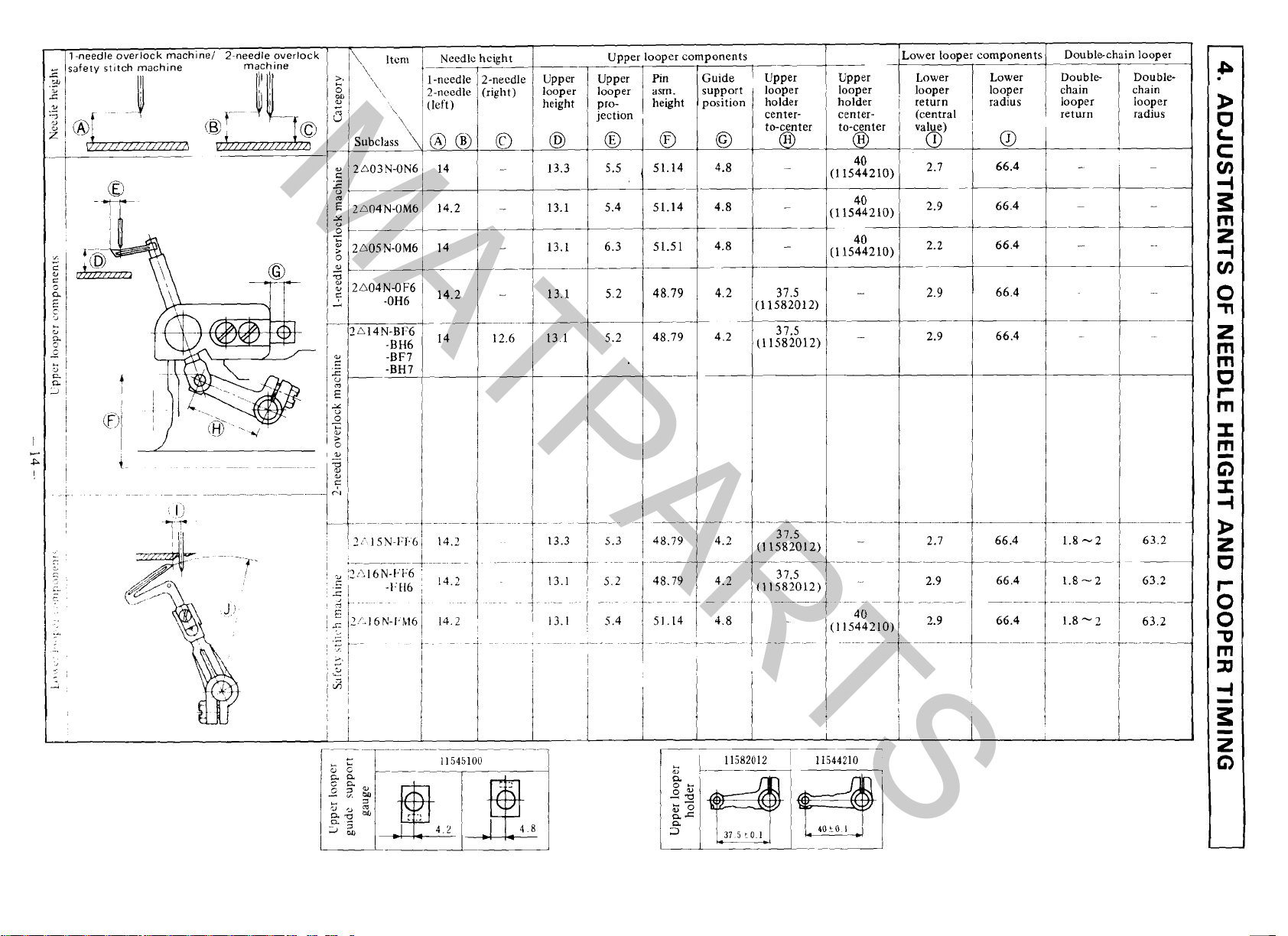

4.

ADJUSTMENTS

OF

NEEDLE

$

9

-

.-

-

VI

n

ZcEE

:-%Eos!~

s,

a.2

~5.22

gz

.

L

w

t

w

'+.

w

w

HEIGHT

-

___

ia!q-cul

q..1!1<

i~rjip

?----.-.

!

I

I

I

I

IPl

;u

I..

I

/,,

iC4

;;

a-

N

2

*

I

;--A7-

,m

d

,+

;&

..-.

~

:

-+

;"?

+---

i-

~

-

1

-

jLA

;"!'a

,LO

(

v,

1

a

--.I

I

/od

i.3

s!

lc,

-

~

+

I

t-+

I

I&

I*

1

111

I

1

.

--

-

I

;

-ru

LO,

e!

!

,

!

I

39,

1

I

!

i

G!

z;

I

1

a

;

I

I

i

ip?

id

,

Sj

i

iz

i

-

=.

I

~2

--...

i

I

I

-

___I-LA-.-~

AND

I

1

i

i

r!

rn

U)

n

c!

U)jU)l

i

in;i

1

N

1

i

LOOPER

l

TIMING

-

-

1

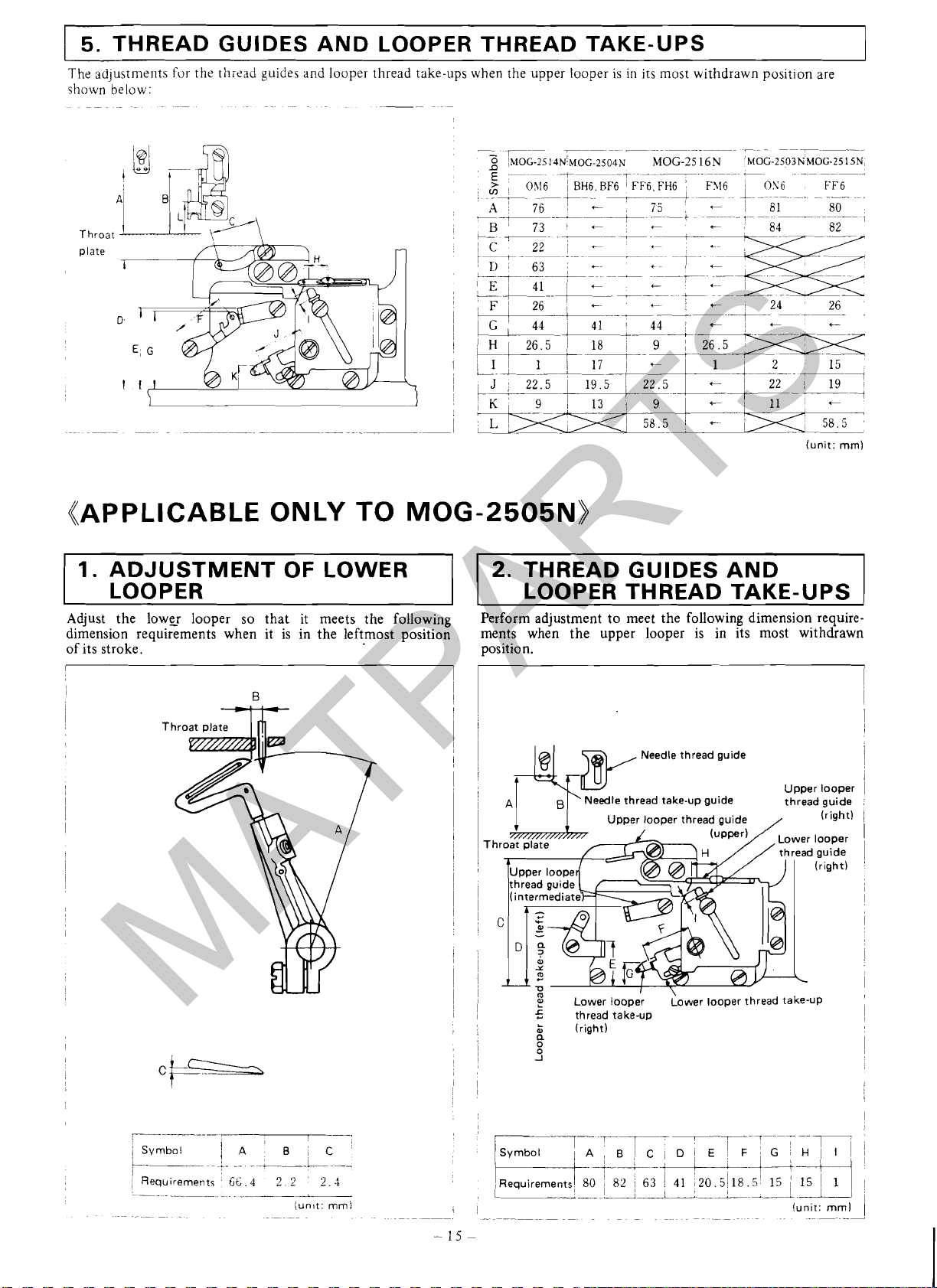

5.

MATPARTS

THREAD GUIDES AND LOOPER THREAD TAKE-UPS

The adjustments

shown

below:

-

Throat

plate

~- -

for

the thiead guides and looper thread take-ups when the upper looper is in

-

-- - -

~

--

- ~ -

I1

i

l

_-_i--

'

((APPLICABLE ONLY TO MOG-2505N)

its

most withdrawn position are

2

+

22

15

-1

i

19

(unit: rnm)

1.

ADJUSTMENT OF LOWER

LOOPER

Adjust the lower looper so that it meets the following

dimension requirements when it is in the

of its stroke.

leftmost position

2.

THREAD GUIDES AND

LOOPER THREAD TAKE-UPS

Perform adjustment to meet the following dimension requirements when the upper looper is in its most withdrawn

position.

Needle thread guide

I

I

I

A

1

I

I

I

l

m

5

d

9

Needle thread take-up guide thread guide

-

I

Upper looper thread guide

'

\

Lower looper

thread take-up

(right)

Lower looper thread

Upper looper

/

(right)

take-UP

i

1

1

/

l

3.

MATPARTS

ADJUSTMENT

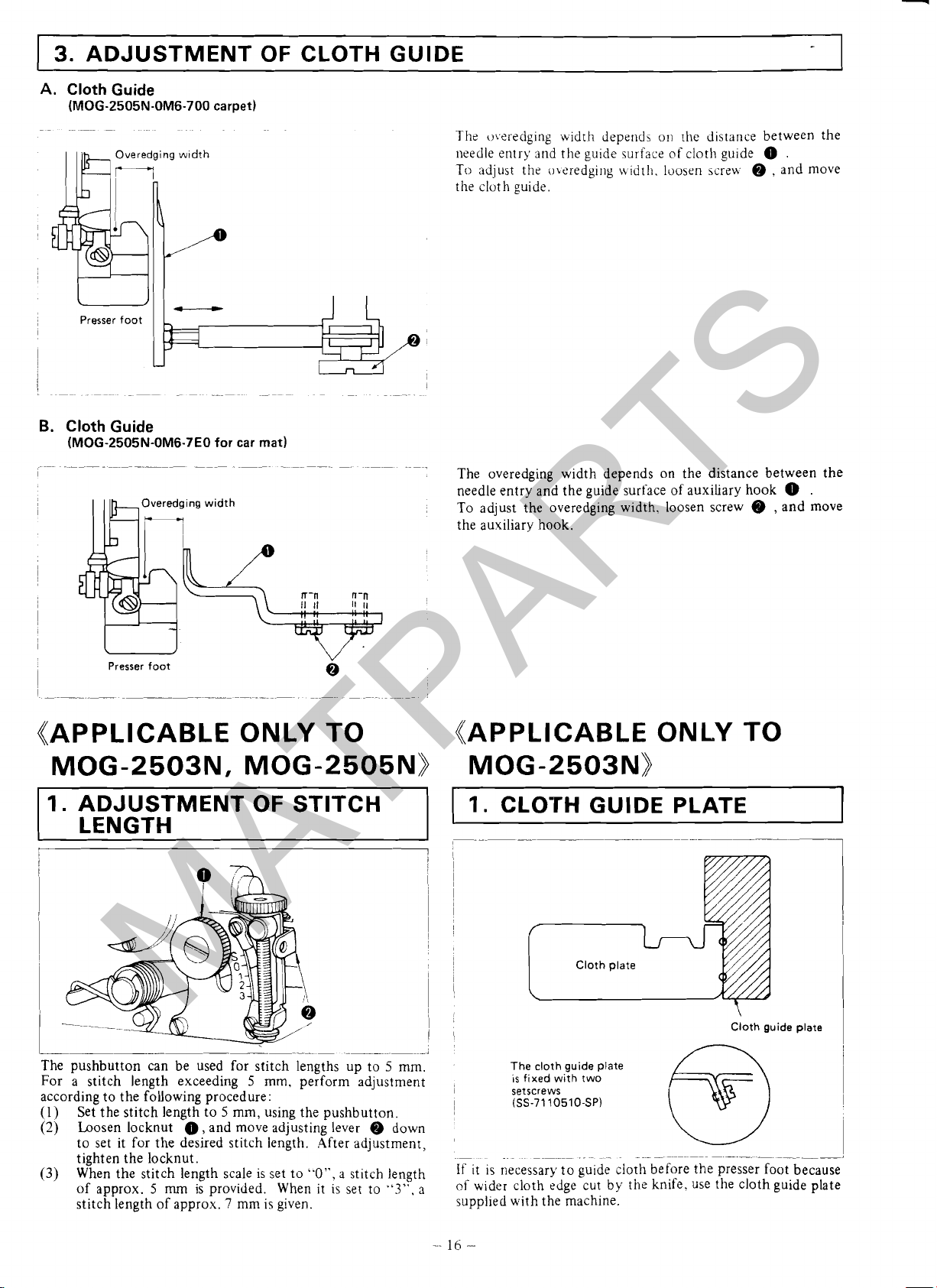

A.

Cloth

Guide

(MOG-2505N-OM6-700

Overedging width

Presser foot

I

I

B.

Cloth

Guide

(MOG-2505N-OM6-7E0

I

I

Ib,

carpet)

for car mat)

Overedging width

OF

CLOTH GUIDE

The overedging width depends on the distance between the

needle entry and the guide sur-face of cloth guide 0 .

To

adjust the overedgil~g widtll, loosen screw

the cloth guide.

The overedging width depends on the distance between the

needle entry and the guide surface of auxiliary hook

To adjust the overedging width. loosen screw

the auxiliary hook.

@

9

,

,

and move

0

.

and move

Presser foot

I

((APPLICABLE ONLY

v

0

TO

MOG-2503N, MOG-2505Nj)

1.

ADJUSTMENT OF STITCH

LENGTH

The pushbutton can be used for stitch lengths up to 5 mm.

For a stitch length exceeding

according to the following procedure:

Set the stitch length to 5 mm, using the pushbutton.

(1)

(2)

bosen locknut

to set it for the desired stitch length. After adjustment,

tighten the locknut.

When the stitch length scale is set to

(3)

of approx.

stitch length of approx. 7 mm is given.

0,

5

mrn

is provided. When it

5

mm, perform adjustment

and move adjusting lever @ down

"0".

a

stitch length

is

set to

"3",

((APPLICABLE ONLY TO

MOG-2503Nj)

1.

CLOTH GUIDE PLATE

!

The cloth guide

is

fixed with two

setscrews

(SS-7110510-SP)

~

-

..

~

If

it

is necessary to guide cioth before the presser foot because

of

a

wider cloth edge cut

supplied with the machine.

plate

.

.

-

-

~

-

by

the knife. use the cloth guide plate

Cloth guide

--

plate

.-

I

->

Loading...

Loading...