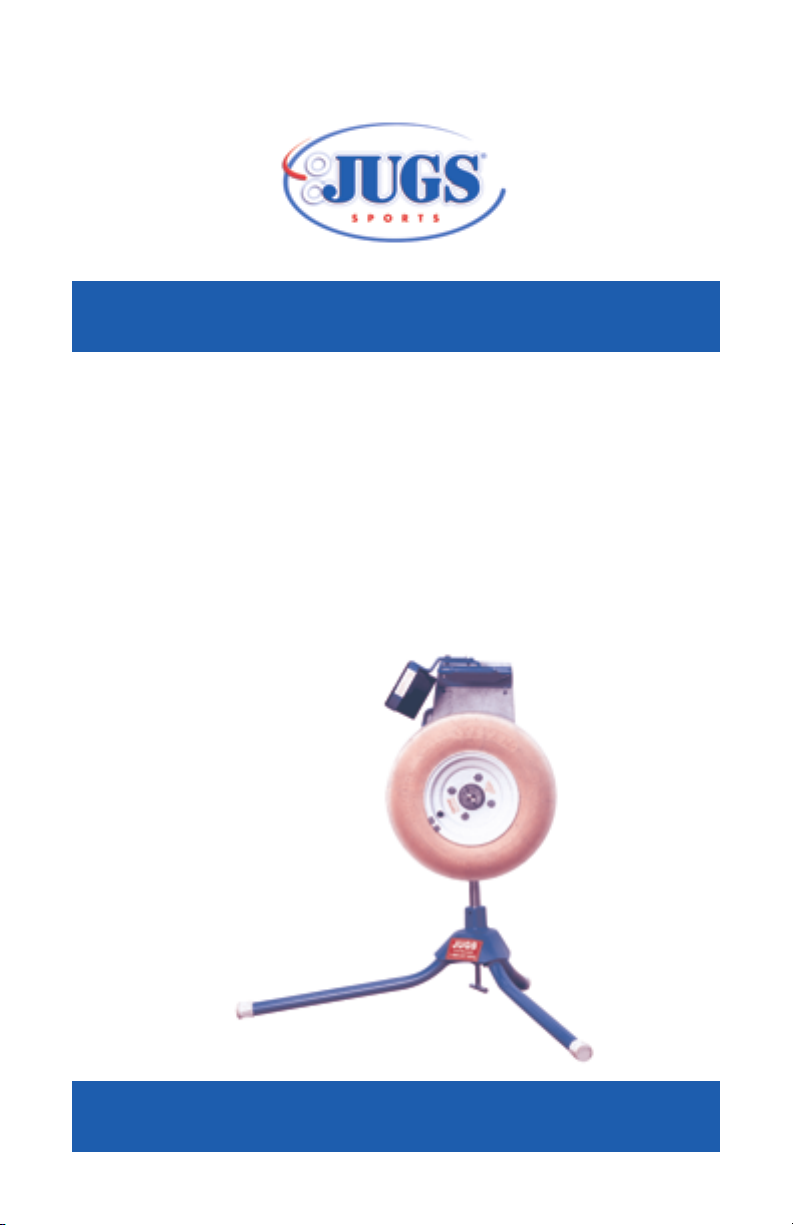

OWNER’S MANUAL

I

nstructions for the

JUGS Softball/Super Softball

Pitching Machine

Part No. Z7300

SAVE THIS MANUAL

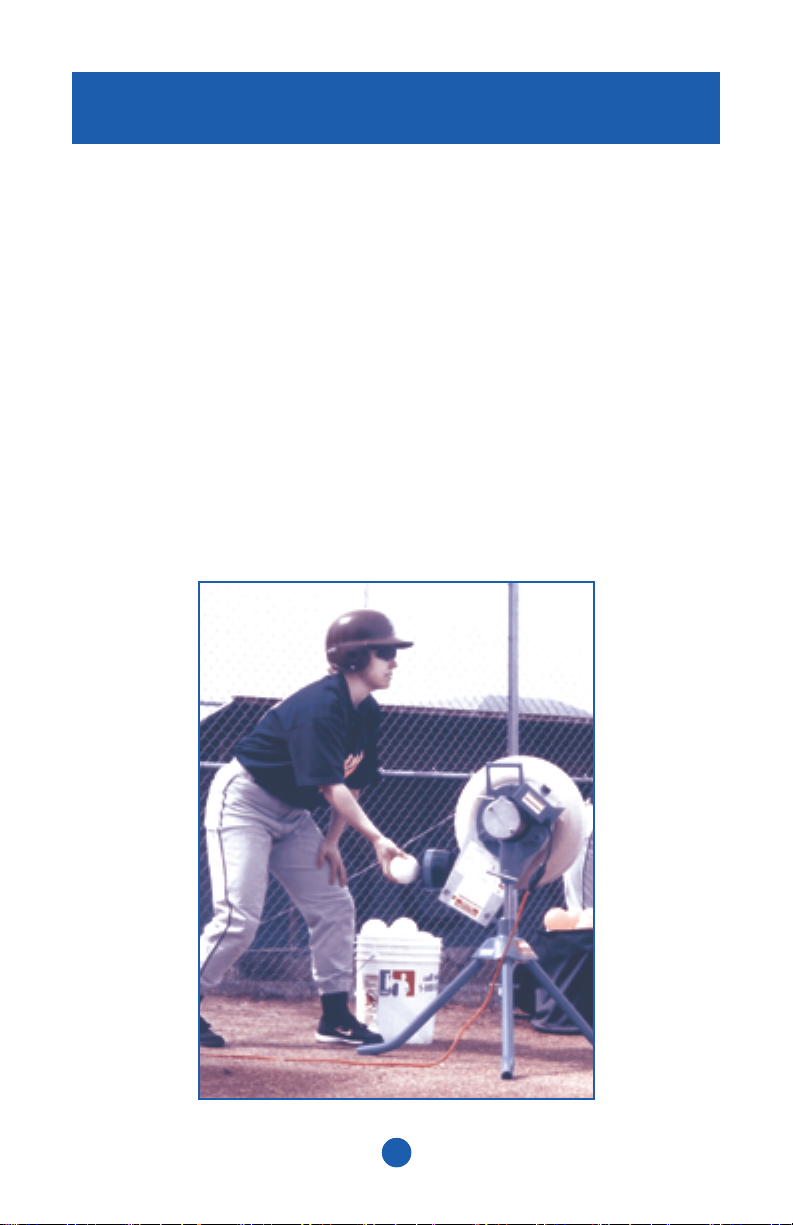

ATTENTION,

Coaches and Operators

of this Softball/Super Softball machine:

This manual must be kept with this pitching machine

AT ALL TIMES.

Each coach and/or operator

must read and understand the instructions in this manual

BEFORE USING

the JUGS Softball/Super Softball Pitching Machine.

Call 1-800-547-6843 or 503-692-1635

if you need additional copies.

Table of Contents

Introduction .................................................................................. 2

Product Safety Signs and Labels .............................................. 3

Rules for Safe Operation ............................................................ 5

Electrical....................................................................................... 8

Terminology ............................................................................... 10

Unpacking ................................................................................... 11

Assembly..................................................................................... 11

Operating Instructions .............................................................. 13

Transporting ............................................................................... 20

Maintenance ............................................................................... 21

Product Specifications ............................................................. 22

Operator Notes .......................................................................... 23

Warranty Information ................................................................ 27

1

Introduction

Your new JUGS pitching machine has been checked for quality and

craftsmanship. It’s innovative design is backed by three decades of

research, development and manufacturing experience. It has many

features designed to make your practices more efficient and enjoyable. Safety,

performance and dependability have been given top priority in the design

of all JUGS pitching machines, making them easy to operate and maintain.

With proper care, your JUGS pitching machine will give you many years of

enjoyable service.

At JUGS, we are committed to providing our customers with safe,

dependable products. Your comments are always welcome and they help us

to continue to be the #1 producer of ball throwing machines in the world. Call

or write to JUGS.

2

Product Safety Signs & Labels

Safety Alert Symbols

Safety Alert Symbols indicate DANGER, WARNING, or CAUTION. These

symbols may be used in conjunction with other symbols or pictographs.

Failure to obey a safety warning will result in serious injury to yourself or to

others. Always follow the safety precautions to reduce the risk of electric shock

and personal injury.

DANGER: Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury. This signal word

is to be limited to the most extreme situations.

WARNING: Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury. It may also

be used to alert against unsafe practices.

Product Safety Signs and Labels

The purpose of product safety signs and labels is to attract your attention to

possible dangers. The safety symbols, signal words and the explanations with

them, deserve your careful attention and understanding. The safety warnings

do not by themselves eliminate any danger. The instructions or warnings they

give are not substitutes for proper accident-prevention measures.

3

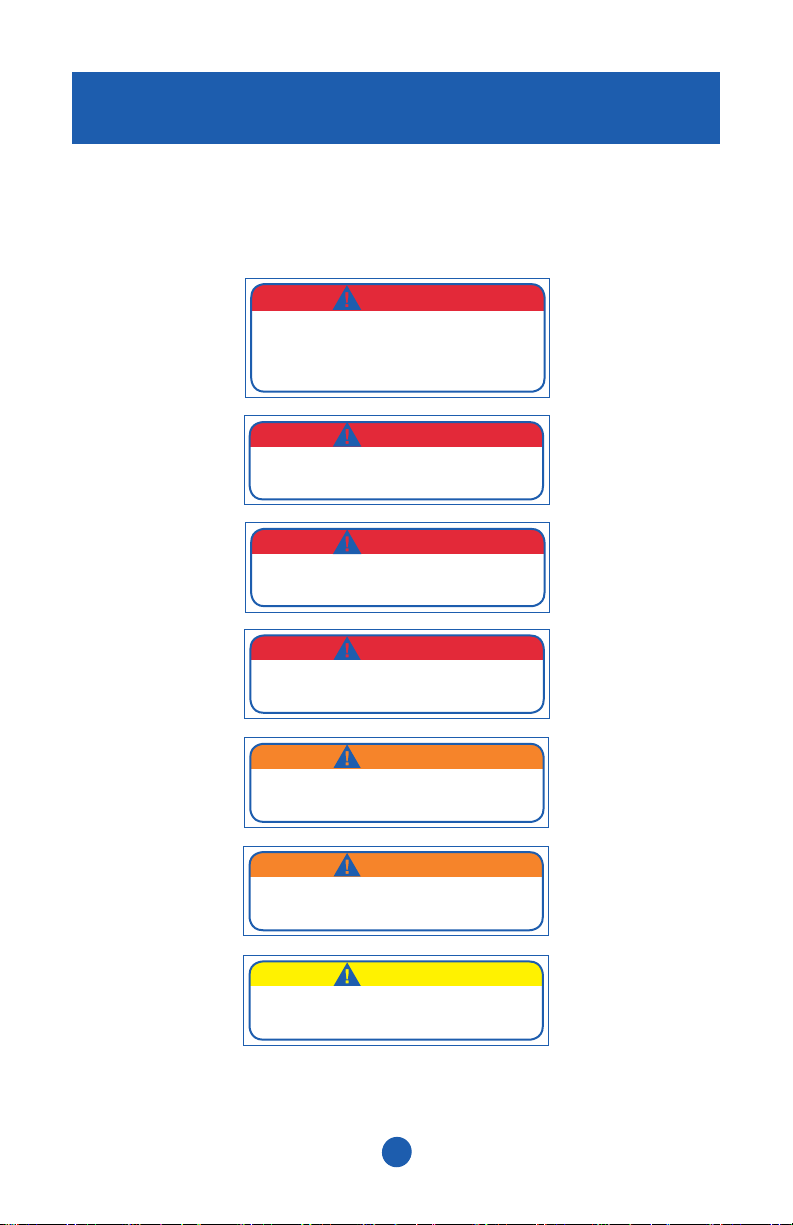

Safety Signs and Labels

Carefully read all safety sign decals affixed to machine before operating your

JUGS pitching machine. See some typical examples below.

DANGER

-MECHANICAL HAZARD- READ ALL

OPERATING AND SAFETY INSTRUCTIONS BEFORE

USING THIS MACHINE . ONLY INSTRUCTED

PERSONNEL SHALL OPERATE THIS MACHINE.

CJC-1

! DANGER

-IMPACT HAZARD-

CLEAR TO THE BATTER BEFORE FEEDING THE BALL.

CJC-4

-SHOCK HAZARD- ALWAYS UNPLUG MACHINE

CJC-5a

-SHOCK HAZARD- THIS MACHINE SHALL BE USED

AND STORED IN DRY LOCATIONS ONLY.

CJC-2

MAKE SURE PATH OF BALL IS

! DANGER

BEFORE CHANGING FUSES.

! DANGER

WARNING

-PINCH POINT HAZARD- DO NOT PLACE HANDS OR

OTHER BODY PARTS INTO AREA NEAR MOVING TIRE(S).

CJC-3

WARNING

-MECHANICAL HAZARD- ALL TIRE LUG BOLTS MUST

BE CHECKED FOR TIGHTNESS BEFORE EACH USE.

CJC-9

CAUTION

-STABILITY HAZARD- “T” HANDLE MUST BE IN PLACE

AND TIGHTENED BEFORE USING MACHINE.

CJC-7

Figure 1

4

Rules For Safe Operation

WARNING: JUGS pitching machines are intended for use by

operators who are at least 18 years of age and who have

been instructed in their use.

WARNING:

WARNING: Do not connect your pitching machine to a power source until

READ THIS MANUAL:

Know your pitching machine. Read the Owner’s Manual carefully.

•

Learn the machine’s capabilities, features and limitations as well as the

specific potential hazards related to this machine.

Guard against electrical shock by preventing body contact with

•

grounded surfaces. For example: radiators, pipes, fences, or other

enclosures.

Do not attempt to operate this machine until you have

read thoroughly and understand completely all instructions,

safety rules, machine labels, etc. contained in this manual.

Failure to comply can result in accidents involving electric

shock or serious personal injury. Save this Owners Manual

and review frequently for continuing safe operation, and for

instructing others who may use this machine.

you have assembled and adjusted the machine as described

in this manual and have read and understood all precautions

and operating instructions in the manual and printed on the

machine.

Keep the operator’s area free of clutter. Pick up all loose balls around

•

the machine and keep ball supply in a pail, bucket or other suitable

container. Cluttered operating areas invite accidents.

Do not allow children to operate the pitching machine. You must be

•

at least 18 years of age or older and instructed in the proper operation,

maintenance, care, and storage of this machine before operating it. Close

supervision is necessary when this machine is used near children.

5

Rules For Safe Operation

Use the right ball. Use only JUGS dimpled style, Lite-Flite, one-ounce

•

polyball softballs or high quality leather softballs in this machine.

Inspect extension cords periodically and replace if damaged.

•

Use the proper extension cord. Make sure your extension cord is in

•

good condition. When using an extension cord, be sure to use one heavy

enough to carry the current your machine will draw. An undersized cord

will cause a drop in line voltage resulting in loss of power and overheating.

A wire gauge size (AWG) of at least 16 is recommended for an extension

cord 25 feet or less in length. If in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord.

Do not abuse the cord. Never yank cord to disconnect it from receptacle.

•

Keep cord away from heat, oil, and sharp edges. Stay constantly aware of

cord location and keep it well away from the rotating tire.

Dress properly. Do not wear loose clothing, gloves, neckties, rings,

•

bracelets, or other jewelry. They can get caught and draw you into the

moving parts. Long hair should be tied up and tucked under hats and

helmets. Severe physical harm may result if loose clothing, jewelry or hair

is caught in rotating tires.

Always wear safety glasses and batting helmets while the wheels

•

are rotating. Debris on the tires can fly off and cause physical harm.

Everyday eyeglasses have only impact-resistant lenses; they are NOT

safety glasses.

Never touch rotating tire. Do not put hands or fingers into ball feed

•

chute. Hands and fingers should only go to the edge of the chute.

Inspect machine before every use. If damaged, have repaired by a

•

qualified JUGS service technician.

Inspect tire before every use. Be sure tire is free of grit and debris

•

before turning on machine.

6

Do not use machine if ON/OFF switch does not work. In the unlikely

•

event that the switch becomes defective, have it replaced by a qualified

JUGS service technician.

Keep machine clean, and free of grit and dirt. With the machine

•

unplugged, use only a clean damp cloth for cleaning. Never use brake

fluids, gasoline, petroleum-based products, or any solvents to clean

machine.

Tighten T-Clamp securely after adjusting trajectory.

•

To protect the operator, a pitcher’s screen must be placed in front of the

•

pitching machine.

Only operate and store this pitching machine in a clean, dry location.

•

Do not use outdoors if it is raining. If machine becomes wet, do not use.

A potential shock hazard exists if this machine is used while or after it has

been exposed to water. Hand dry surface water from machine with a clean

cloth and allow the machine to completely air dry before its next use.

Avoid awkward operations and hand positions where a sudden slip

•

could cause your hand to move into the rotating tire. ALWAYS make sure

you have good footing and balance.

Replacement parts. All repairs, whether electrical or mechanical, should

•

be made by a qualified JUGS service technician. When servicing, use

only JUGS replacement parts.

Do not operate this machine under the influence of drugs, alcohol,

•

or any medication.

Stay alert and exercise control. Watch what you are doing and use

•

common sense. Do not operate this machine when you are tired. Do not

rush.

Avoid accidental starting when reconnecting to a power supply.

•

Always turn off machine before disconnecting it from power source. Never

leave machine running unattended. Turn the power off. Do not leave

machine until tire comes to a complete stop.

7

Rules For Safe Operation

WARNING Do not allow your familiarity with the machine to cause

you to be careless. Remember that a careless fraction of a

second is enough time to inflict severe injury to yourself or

others.

SAVE THIS MANUAL. Refer to it often and use it to instruct other users. Do

not loan your pitching machine to anyone who has not been instructed in its

use. If you do loan your machine, be sure this manual goes with it.

Electrical

Grounding Instructions

This product must be grounded. If it should malfunction or break down,

grounding provides a path of least resistance for electric current to

reduce the risk of electric shock. This product is equipped with a cord having

an equipment-grounding conductor and grounding plug. The plug must

be connected to an appropriate GFCI outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

Do not modify the plug provided. If it will not fit the outlet, have the

proper outlet installed by a qualified electrician. Improper connection of the

equipment-grounding conductor can result in a risk of electric shock. The

conductor with insulation having an outer surface that is green with or without

yellow stripes is the equipment-grounding conductor. If repair or replacement

of the electric cord or plug is necessary, do not connect the equipmentgrounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the grounding

instructions are not completely understood, or if in doubt as to whether the

pitching machine is properly grounded.

8

Extension Cords

Use only 3-wire 16 AWG or larger grounding type extension cords that have 3prong grounding plugs and 3-pole receptacles that accept the machine’s plug.

When using the machine at a considerable distance from a power source, use

an extension cord heavy enough to carry the current that the machine will

draw. An undersized extension cord will cause a drop in line voltage, resulting

in a loss of power and causing the motor to overheat. Only round jacketed

cords listed by Underwriter’s laboratories (UL) should be used.

When working with the machine outdoors, use an extension cord designed for

outside use. This is indicated by the letters “WA” on the cord’s jacket. Before

using the extension cord, inspect it for loose or exposed wires and cut or worn

insulation.

WARNING: Keep the cord away from the rotating tire area. Repair or

replace a damaged or worn cord immediately.

Electrical Connection

Your JUGS pitching machine is powered by a 90 volt motor(s). Do not operate

this machine on direct current (DC). A substantial voltage drop will cause a

loss of power and the motor will overheat. If the machine does not operate

when plugged into an outlet, double check the power supply. Your pitching

machine will operate under a standard 110 voltage AC outlet. Do not use an

adapter with this product.

This machine is intended

for use on a circuit that

has an outlet like the one

shown in Figure 2. It also

has a grounding pin like

the one shown.

GROUNDING

PIN

Figure 2

9

GROUNDED GFCI

OUTLET BOX

High Profile Position

for drop pitch

Terminology

Figure 3

10

Unpacking

WARNING: To prevent accidental starting or electrical shock that could

cause possible serious injury, assemble all parts to your

machine before connecting it to the power supply. The

pitching machine should never be connected to a power

supply when you are assembling parts, making adjustments,

cleaning, servicing, or when not in use.

Carefully lift machine from carton and place on level surface.

•

Make sure you have all the parts (See Figures 3-4). If any parts are

•

missing, do not operate the machine until the missing parts are replaced.

Failure to do so could result in possible serious personal injury.

Do not discard the packing materials until you have carefully

•

inspected the machine, identified all the parts, and satisfactorily operated

the machine.

NOTE: If any parts are damaged or missing, do not attempt to plug in the

power cord and turn on switch until the damaged or missing parts are obtained

and are installed correctly.

Assembly

JUGS is shipped with the base secured tightly to the “top” of the machine.

1. Separate the top of the machine from the base.

• Loosen the horizontal T-Clamp.

• Grasp the lifting handle and pull the top of the machine off the base.

This can be done very simply with one person holding the “top” and

second person holding the base.

11

Assembly

2. Install the Legs:

A. Place the Leg Clamp Casting on the Base

Casting so that the leg slots line up.

B. Place the Base T-Clamp through the hole in

the Leg Clamp Casting and turn clockwise

until the T-Clamp engages the threads of

the Base (see Figure 4).

C. Slide the three legs into place. Be sure the

end of each leg is completely inserted and

in contact with the back of the assembly.

D. Hand tighten the Base T-Clamp and set the “bottom” of the machine

on its legs.

E. I f the legs appear wobbly:

• Make sure the legs are snug and properly

placed in the base.

Figure 4.

• Make sure the Base T-Clamp is turned as

tightly by hand as possible.

• Be sure the legs are equidistant from one

other (Figure 5).

12

Figure 5.

Operation

GENERAL OPERATING INSTRUCTIONS

1. Be sure the control switch is in the “OFF” position.

2. If you have the super softball model, position the dial pointer on the

control panel all the way to the left (min. speed). See Figure 12.

3. Both 11” and 12” softballs can be used with the JUGS Softball Pitching

Machine. When using the 11” softballs, you must use the proper 11”

softball feed chute in insure accuracy. The 11” feed chute is optional and

can be ordered from the factory. See decal on the pitching machine for

instructions on changing ball chutes.

4. Both 11” and 12” chutes can be mounted from the same hole settings in

the rotating plate.

5. Connect a 3-wire extension cord (3-prong) into a grounded (3-prong) 110

volt AC outlet.

6. Move control switch to “ON” position.

NOTE:

The JUGS Super Softball Pitching Machine is equipped with a digital speed

readout with an accuracy index of +/- 2 miles per hour. The Super Softball

model will throw balls up to 10 mph faster than the JUGS Softball Pitching

Machine.

IMPORTANT:

Always pitch balls at speeds suitable for the age and skill level of the batter.

Pitches thrown too fast will be counter-productive and dangerous.

13

Operation

Figure 6. Digital Readout Panel

WARNING: The digital speed readout on the JUGS Super Softball

Pitching Machine is calibrated ONLY for 12-inch softballs. If

you have purchased the optional 11-inch softball chute, the

JUGS Super Softball Pitching Machine will throw 11-inch

softballs approximately 3-miles-per-hour slower that what

the speed readout indicates.

12- and 11-inch softballs that are harder in composition than

the standard JUGS softballs will throw at speeds up to 10miles-per-hour faster than the speed readout indicates. To

maximize safe use of the machine, adjust the speed down

accordingly. NEVER mix different types of balls: use only

one style at a time.

14

Operation

PITCHING SOFTBALLS TO BATTERS

Follow all safety performance instructions in this manual. The following

feeding instructions should be used to insure accurate and efficient operation

of the JUGS pitching machine.

Important Pitching Machine Feeding Instructions:

1. When feeding the machine with leather balls, hold the ball the same way

every time. Across the seams is best.

2. Have all batters and observers stand well clear of the target as you throw

test balls to adjust trajectory and aiming point.

3.

VERY IMPORTANT: Before you place the ball in the feed chute,

you should look up at the batter and make absolutely sure the

batter is watching you and is ready to receive the pitch. It is

extremely important that you make sure that the immediate area in front

of the pitching machine and the flight path of the ball is clear before you

feed the balls into the pitching machine.

4. When the batter has taken his/her stance and indicates he or she is ready

to hit, hold the ball high in the air where the batter can see the ball. Then

bring the ball down to the chute simulating live action so that the batter

can time the ball correctly. Set the ball in the feed chute and release.

Do not drop the ball into the chute. Watch the ball into the wheels, then

look up at the batter. The whole feeding operation should be smooth and

without interruption.

5. Every batter, after taking his/her stance, as well as between pitches, goes

through a personal readiness routine. The ball feeder should adjust the

pitch spacing to each batters’ habits accordingly. This will assure that

the batter is ready to receive the pitch and will also help to simulate live

action. The batter can then regard each throw as a separate pitch and

avoid becoming an “automatic swinger”. Generally speaking, pitches can

be spaced between 6 and 10 seconds apart.

15

Operation

6. Out-of-round, soft, mushy, or wet balls will affect accuracy of pitches and

must not be used. Mixing different types of balls (leather, rubber, JUGS,

etc.) will affect consistency of pitches. Throw only one type of ball at a

time.

7. Use only JUGS dimpled style, Lite-Flite, Softie, poly softballs or high

quality leather softballs in this machine.

8. Do not permit more than one or two persons around the pitching machine

during its operation.

BATTING HELMETS MUST BE WORN AT ALL TIMES.

9. Operators of Jugs Pitching Machines must wear safety glasses and

batting helmets at all times.

WARNING: A pitching screen must be used to protect the operator and

the machine from batted balls.

NOTE: We suggest that each operator spend a couple of hours experimenting

with the JUGS Softball/Super Softball pitching machine. (You may

want to jot down the wheel position and speed dial settings in the

space provided on page 23 for future reference). Try many different

speed settings. Do not be afraid that any setting you make will harm

the pitching machine; however, you should use a wide backstop

when experimenting with faster speeds.

10. At the beginning of practice, or after any change in speed, or trajectory,

have the batter stand well clear while a sufficient number of test balls are

thrown to make certain the machine is properly aimed at the intended

target. If you move the machine for any reason, repeat this process.

11. Throw balls at speeds the batter can learn to hit. As the batter’s skills

increase you can throw faster pitches. Always pitch balls at a speed

suitable for the age and skill level of the batter. Pitches thrown too fast

will be counterproductive and dangerous.

16

Operation

12. Place ball into Feed Chute and watch the trajectory of the ball.

13. Increase the speed of the pitch by turning the dial clockwise on the Digital

Readout Panel (see Figure 6).

• When you increase speed of any pitch, you must lower the elevation

of aim; when you decrease the speed, you must increase the aim

elevation.

14. To regulate the height of the pitch:

• Hold the Feed Chute Handle and loosen the vertical T-Clamp.

• Move the feed chute TOWARDS home plate for a lower pitch.

Move the feed chute AWAY from home plate for a higher pitch.

• Hand tighten the vertical T-Clamp.

WARNING: NEVER loosen the vertical T-Clamp without holding the

Feed Chute Handle.

15. To regulate the direction of the pitch:

• Loosen the horizontal T-Clamp.

• Grasp the Feed Chute Handle and move the “top” of the JUGS

sideways until the chute is aimed at the desired target.

• Hand tighten horizontal T-Clamp.

NOTE: When throwing faster pitches (dial setting 75-100 mph), be sure to

line up horizontal T-Clamp over the red dot on the base and then

tighten the horizontal T-Clamp. To make small lateral adjustments

(for example, from “outside corner” pitches to “inside corner” pitches)

simply “shift” the legs of the pitching machine slightly by gently

tapping the legs with your foot. Be sure to throw test balls to ensure

pitch location before pitching to batter.

17

Operation

Proper Position of the Feed Chute for Various Throws:

Straight Balls and Risers:

•

Position the feed chute level to throw

straight balls and risers by adjusting the

vertical T-Clamp. To make the ball “rise”,

turn the control dial up to "75" or more.

Under "75", the ball will move straight.

Slow Pitch Tosses:

•

By adjusting the vertical T-Clamp, you can

position the feed chute slightly upward for

soft pitch tosses (or higher for flyballs, see

Fielding Practice). The dial setting should

be around "30" for slow pitch tosses.

Drop Balls (High Profile Leg Position):

•

The legs should be in the “High Profile” position. Position the two

legs so they point in the direction of second base, and one leg points

toward home plate. (This is the exact opposite of the position of the

legs when you are throwing straight balls. See Figure 5.) Position the

rotating plate so that the ball feed chute is near the bottom of the tire

or wheel and facing the operator.

One JUGS leg should be pointing at home plate when throwing drop balls.

When throwing risers, one JUGS leg should be pointing at second base.

FIELDING PRACTICE FOR SOFTBALL

Figure 7

18

Operation

1. VERY IMPORTANT: Before you place the ball in the feed chute,

you should look up at the fielder and make absolutely sure the

fielder is watching you and is ready to receive the ball. It is

extremely important that you make sure that the immediate area in front

of the pitching machine and the flight path of the ball is clear before you

feed the balls into the pitching machine.

2. When the fielder has taken his/her stance and indicates he or she is

ready, hold the ball high in the air where the fielder can see the ball. Then

bring the ball down to the chute simulating live action so that the fielder

can time the ball correctly. Set the ball in the feed chute and release.

Do not drop the ball into the chute. Watch the ball into the wheels, then

look up at the fielder. The whole feeding operation should be smooth and

without interruption.

3. Every fielder, after taking his/her stance, as well as between pitches,

goes through a personal readiness routine. The ball feeder should adjust

the throw spacing to each fielder’s habits accordingly. This will assure

that the fielder is ready to receive the ball and will also help to simulate

live action.

Proper Position of the Feed Chute to Simulate Various Batted Balls:

• Flyballs:

(Legs must be in “High Profile” or straight leg position

when throwing grounders) and the feed chute should

be pointed upward.

• Ground Balls:

High Profile: Position the feed chute so it is pointed

downward. The greater the downward angle, the

Low Profile: Position the feed chute so it is near the

bigger the hop will be on the ground ball.

bottom of the tire (or wheel) and facing the operator.

19

• Pop-up to Catcher:

By adjusting the vertical T-Clamp, position the feed

chute to point upward vertically for pop-ups to catchers.

The ball will go straight up.

Transporting

1. Using the vertical T-Clamp, lock the rotating plate in “Pop-up to Catcher”

position (vertically upward).

2. Make sure the horizontal T-Clamp engages the indentation of the base

shaft. This is done by lining up the horizontal T-Clamp with the red dot on

the base casting, and hand-tightening the T-Clamp.

3. Lower JUGS to a horizontal position, with the Feed Chute facing

upward.

4. Slightly loosen the Base T-Clamp that secures the legs.

5. Grasp two legs, and twist them towards your sides.

6. Tighten the Base T-Clamp.

7. Grasp and lift the two legs. Roll the JUGS as you would a wheelbarrow.

8. Do not roll tires on surfaces that might damage the tire. If the tire becomes

deformed, flat, or damaged, do not use it. Replace tire only with ones the

manufacturer recommends.

NOTE: When you want to instantly move the location of the throw for certain

ground ball and flyball drills, loosen the horizontal T-Clamp enough (6

or 7 turns) so that you can pivot the top of JUGS 360 degrees around

the base. However, when throwing to a specific target is desired, as

in pitching, ALWAYS make sure the horizontal T-Clamp is securely

tightened into the indentation on the shaft located directly above the

red dot on the base casting.

20

Maintenance

Review the following instructions carefully to maintain maximum

accuracy with your JUGS Pitching Machine.

Maintain tire pressure at 16 to 17 psi.

Cleaning

Keep the machine clean, and free of grit and dirt. Always use a clean

•

damp cloth when cleaning. Never use brake fluids, gasoline, petroleumbased products, or any solvents to clean machine.

Periodically, you must clean the wheel to help maintain its maximum

•

performance. A dirty wheel can easily be distinguished by either a dark

ring around the wheel surface or when the surface itself has turned yellow

and has a very glossy or shiny finish..

Using medium-grade sandpaper (sometimes an even coarser grade is

•

necessary depending on the amount of soil buildup) begin to scrub the

tire surface. This process can be very tedious and may take up to 10

minutes per tire. However, it is necessary to completely remove all foreign

substances from the tire to prepare it for better machine performance.

You should sand the tire whenever you notice the soil build-up forming.

Always sand the tire with the power switch OFF and the machine

unplugged.

Once you complete this operation the tire surface will, in most cases, take

•

on the white color it was originally. Maintaining the tire in this fashion will

not only maximize the performance and accuracy of your machine, but it

will extend the life of the tire.

Storage

• Always store the machine and extension cord in separate, clean, dry

secured areas. Cover the machine with a suitable dust cover that does

not retain moisture. Do not use plastic.

21

Product Specifications

JUGS Softball / Super Softball Pitching Machine

Product Specifications:

Motor Specifications:

Variable Speed

Maximum Developed Horse Power

Volts

Amps

Hertz

RPM (No Load) (Softball)

RPM (No Load) (Super Softball)

Overload Protection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90vDC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 amps

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50/60 Hz

Tire Specifications:

Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.00/4.80-8

Pressure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-17 psi

. . . . . . . . . . . . . . . . . . . . . . . . 1/4 hp

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1900 rpm

. . . . . . . . . . . . . . . . . . . . . . . . 2250 rpm

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . yes

Frame Specifications:

Legs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . steel tubing

Motor Mount and Leg Clamp Casting

Feed Chute

Overall Height

Overall Width

Overall Weight

Recommended Generator

Recommended Balls

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . cast aluminum

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 in.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 in.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 lbs.

. . . . . . . . . . . . . . . . . . . . . Yamaha® EF1000iS

. . . Jugs Softballs or high quality leather softballs

. . . . . . . . . . . . . . . . cast aluminum

IMPORTANT:

Servicing requires extreme care and knowledge of the machine and should

be performed only by JUGS. For service, we suggest you return the machine

to JUGS for repair. Always use original factory replacement parts when

servicing.

22

Operator Notes

23

Operator Notes Operator Notes

24

25

Operator Notes

26

Warranty

JUGS Sports guarantees that the JUGS® Pitching Machines are well made;

of good materials, and workmanship; and agrees that if, within five years

after shipment thereof, any part so guaranteed should fail because of

defective material or workmanship in its manufacture, the Company will repair

or replace such part, free of charge F.O.B. to its factory in Tualatin, Oregon;

provided, however, that upon request, the Buyer shall return the allegedly

defective part to the Company’s factory with transportation charges thereon

prepaid. Commercial use of any JUGS® product automatically limits this

warranty to 30 days after date of shipment.

This warranty shall not be effective if the equipment has been subject to

misuse, negligence or accident, nor if the equipment has been repaired or

altered outside of our Tualatin factory in any respect which, in our judgment,

affects its condition or operation.

RETURN P E R F O R ATED CARD B E L O W TO JUGS S P O R T S

Warranty Record

JUGS Serial No. Date Delivered:

Model:

Name:

Address:

Zip:

Phone: ( )

Purchased From:

Type of Activity (Youth League, High School, College, etc.):

Coach/Manager Name:

27

In the USA and Canada, call toll-free: 1-800-547-6843

Internationally, call collect: 0-503-692-1635

Fax us: 1-503-691-1100

Visit our website: www.jugssports.com

Model

Serial No.

Date Delivered

SAV E T H I S PORTION F O R Y O U R RECORDS

PLACE

STAMP

HERE

JUGS Sports

P.O. Box 365

Tualatin, Oregon 97062

If you need

more information about

this product

or any other

JUGS product or service,

please contact

the manufacturer:

In the USA and Canada,

call toll-free:

1-800-547-6843.

For International Orders,

call collect:

0-503-692-1635.

Our fax number is

1-503-691-1100.

Visit our website at

www.jugssports.com.

Se habla español.

© 2008 JUGS Sports

SB/SSBPMI-1008

Loading...

Loading...