J. T. Eaton LCX9000 User Manual

LCX9000 Liquid-Cooled Drives

User Manual

January 2007

Supersedes September 2006

MN04005001E

For more information visit: www.EatonElectrical.com

LCX9000 Liquid-Cooled Drives User Manual

January 2007

Important Notice — Please Read

The product discussed in this literature is subject to terms and conditions outlined in Eaton

Electrical Inc. selling policies. The sole source governing the rights and remedies of any

purchaser of this equipment is the relevant Eaton Electrical Inc. selling policy.

NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF FITNESS FOR A

PARTICULAR PURPOSE OR MERCHANTABILITY, OR WARRANTIES ARISING FROM COURSE

OF DEALING OR USAGE OF TRADE, ARE MADE REGARDING THE INFORMATION,

RECOMMENDATIONS AND DESCRIPTIONS CONTAINED HEREIN. In no event will Eaton

Electrical Inc. be responsible to the purchaser or user in contract, in tort (including

negligence), strict liability or otherwise for any special, indirect, incidental or consequential

damage or loss whatsoever, including but not limited to damage or loss of use of equipment,

plant or power system, cost of capital, loss of power, additional expenses in the use of

existing power facilities, or claims against the purchaser or user by its customers resulting

from the use of the information, recommendations and descriptions contained herein.

The information contained in this manual is subject to change without notice.

®

Cover Photo: Cutler-Hammer

LCX9000 Liquid-Cooled Drive.

MN04005001E

For more information visit: www.EatonElectrical.com

i

LCX9000 Liquid-Cooled Drives User Manual

Table of Contents

LIST OF FIGURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

LIST OF TABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Definitions and Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Hazardous High Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Warnings, Cautions and Notices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

CHAPTER 1 — OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Receiving and Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Storage and Shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Technical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

CHAPTER 2 — INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Drive Derating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Input Chokes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

CHAPTER 3 — POWER WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Cable Installation Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Installation Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Grounding of Power Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Cable Installation and the UL Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Cable and Motor Insulation Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

CHAPTER 4 — CONTROL WIRING AND INTERNAL CONNECTIONS . . . . . . . . . . . . . . . 4-1

Control Board Power-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Control Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Control Terminal Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Control Unit Mounting Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Internal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

CHAPTER 5 — MENU INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Keypad Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Indicators on the Keypad Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Keypad Pushbuttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Menu Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Further Keypad Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

CHAPTER 6 — START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

APPENDIX A — FAULT CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Load Test with Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

DC Link Test (without Motor). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

APPENDIX B — TECHNICAL REFERENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Main Circuit and Control Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Fan Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

January 2007

ii

For more information visit: www.EatonElectrical.com

MN04005001E

January 2007

List of Figures

Figure 1-1: Liquid-Cooled Drive Principal Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Figure 2-1: Lifting Points for Drives Consisting of One Module (Left)

and Several Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

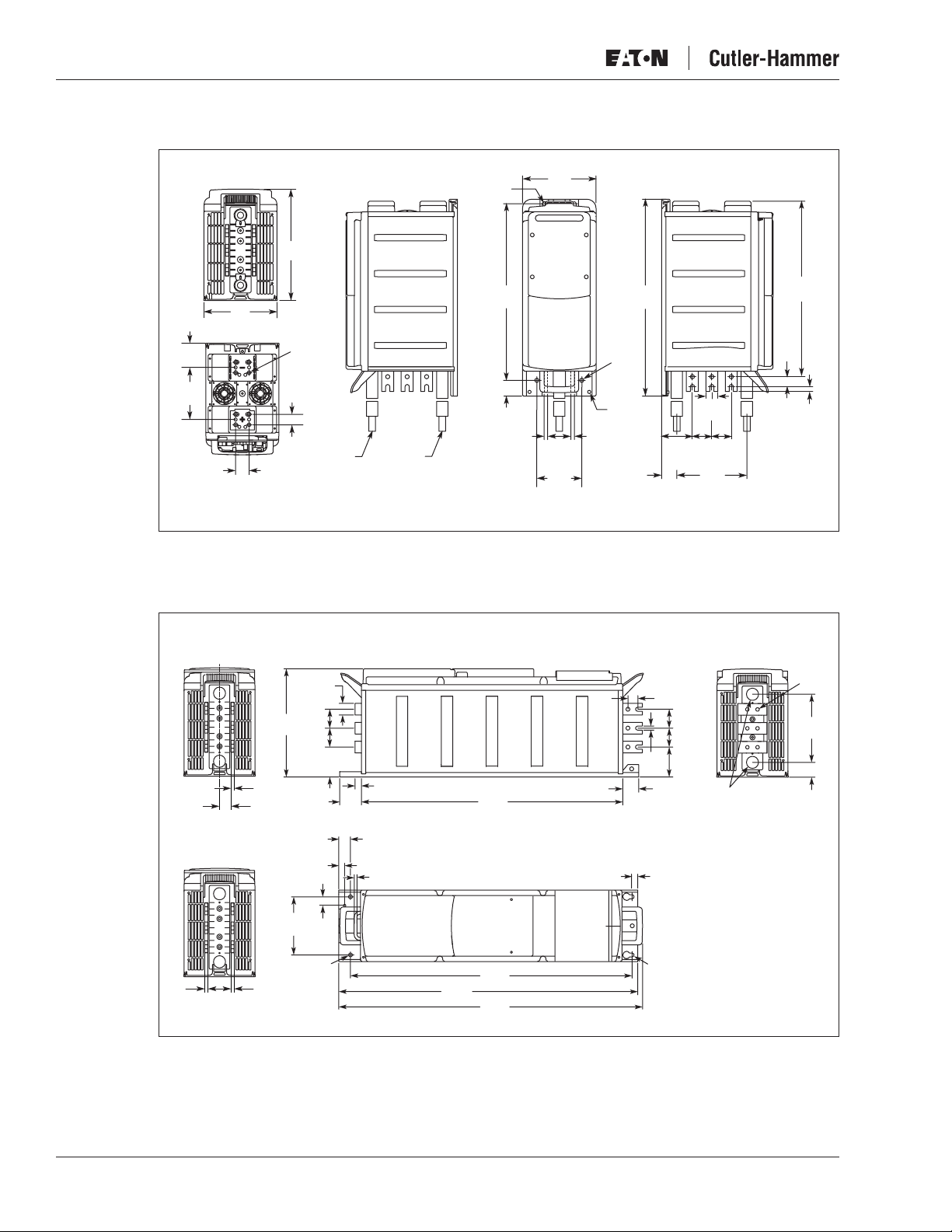

Figure 2-2: LCX9000 Liquid-Cooled Drive, CH3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Figure 2-3: LCX9000 Liquid-Cooled Drive, CH4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-4: LCX9000 Liquid-Cooled Drive, CH5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-5: LCX9000 Liquid-Cooled Drive, CH61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Figure 2-6: LCX9000 Liquid-Cooled Drive, CH72 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Figure 2-7: Drive Mounted Inside Mounting Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Figure 2-8: LCX9000 Liquid-Cooled Drive with Mounting Bracket, CH63 . . . . . . . . . . . . . 2-6

Figure 2-9: LCX9000 Liquid-Cooled Drive, CH74, IP00 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Figure 2-10: Example of Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Figure 2-11: Example PI-Diagram of Cooling System and Connections . . . . . . . . . . . . . 2-11

Figure 2-12: Safe Operating Conditions in Relation to Condensation . . . . . . . . . . . . . . . 2-13

Figure 2-13: Aluminum Hose Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Figure 2-14: External Thread of Hose Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Figure 2-15: Pressure Loss — CH6x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Figure 2-16: Pressure Loss — CH7x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Figure 2-17: Flow Switch: Hose Connection, Fast Connector (Electrical),

Fast Connector Lock Screw, Cable Seal and Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Figure 2-18: Direction of Coolant Circulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Figure 2-19: Example of Input Chokes for Liquid-Cooled Sizes Up to 62A . . . . . . . . . . . 2-21

Figure 2-20: Example of Input Chokes for Liquid-Cooled

Sizes 87 – 145A and 590A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Figure 2-21: Example of Input Chokes for Liquid-Cooled Sizes 261 – 1150A . . . . . . . . . . 2-23

Figure 3-1: Maximum Terminal Stresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Figure 3-2: Installation Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Figure 3-3: Grounding Terminal on Mounting Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Figure 4-1: Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Figure 4-2: Basic and Option Board Connections of the Control Board . . . . . . . . . . . . . . 4-2

Figure 4-3: Drives Connected in Parallel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Figure 4-4: Connection of Control Board Cable from the Power Board

WRONG: Terminal J1 (Upper) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Figure 4-5: Connection of Control Board Cable from the Power Board

CORRECT: Terminal J2 (Lower) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Figure 4-6: I/O Terminals of the Two Basic Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Figure 4-7: General Wiring Diagram of the Basic I/O Board (OPT-A9) . . . . . . . . . . . . . . . 4-5

Figure 4-8: General Wiring Diagram of the Basic Relay Board (OPT-A2) . . . . . . . . . . . . . 4-5

Figure 4-9: Galvanic Isolation Barriers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Figure 4-10: Positive/Negative Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Figure 4-11: Jumper Blocks on OPT-A9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Figure 4-12: Jumper Selection for OPT-A9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Figure 4-13: Control Unit Mounting Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Figure 4-14: Control Unit Installed into the Mounting Box;

Left: Front; Right: Back . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Figure 4-15: Terminals and Connections between ASIC and Driver Board

(CH61, CH62 and CH72) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Figure 4-16: Terminals and Connections between ASIC and

Driver Board (CH63) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Figure 4-17: Terminals and Connections between ASIC and Driver Boards

(CH64 and CH74) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

LCX9000 Liquid-Cooled Drives User Manual

MN04005001E

For more information visit: www.EatonElectrical.com

iii

LCX9000 Liquid-Cooled Drives User Manual

List of Figures (Continued)

Figure 4-18: Remove Cover to Access Power Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Figure 4-19: Optical Cable Adapter Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Figure 5-1: Control Keypad and Drive Status Indications . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Figure 5-2: Keypad Pushbuttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Figure 5-3: Keypad Display Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Figure 5-4: Keypad Navigation Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Figure 5-5: Monitoring Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Figure 5-6: Parameter Value Change Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Figure 5-7: Selection of Control Place . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Figure 5-8: Normal State, No Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Figure 5-9: Fault Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Figure 5-10: Fault History Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Figure 5-11: Selection of Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Figure 5-12: Change of Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

Figure 5-13: Storing and Loading of Parameter Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Figure 5-14: Parameter Copy to Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-19

Figure 5-15: Parameter Comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-20

Figure 5-16: Password Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Figure 5-17: Parameter Locking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Figure 5-18: Activation of Start-Up Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Figure 5-19: Disabling the Change of Multimonitoring Items . . . . . . . . . . . . . . . . . . . . . 5-23

Figure 5-20: Keypad Settings Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Figure 5-21: Default Page Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Figure 5-22: Timeout Time Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

Figure 5-23: HMI Acknowledge Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-25

Figure 5-24: Counter Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

Figure 5-25: Applications Info Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

Figure 5-26: Expander Board Information Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-29

Figure 5-27: Expander Board Information Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

Figure B-1: Main Circuit and Control Diagram, CH3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Figure B-2: Main Circuit and Control Diagram, CH4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Figure B-3: Main Circuit and Control Diagram, CH5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Figure B-4: Main Circuit and Control Diagram, CH61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Figure B-5: Main Circuit and Control Diagram, CH61, Control . . . . . . . . . . . . . . . . . . . . . B-3

Figure B-6: Main Circuit and Control Diagram, CH63, Module 1 . . . . . . . . . . . . . . . . . . . B-4

Figure B-7: Main Circuit and Control Diagram, CH63, Module 2 . . . . . . . . . . . . . . . . . . . B-4

Figure B-8: Main Circuit and Control Diagram, CH63, Control . . . . . . . . . . . . . . . . . . . . . B-5

Figure B-9: Main Circuit and Control Diagram, CH72 . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Figure B-10: Main Circuit and Control Diagram, CH72, Control . . . . . . . . . . . . . . . . . . . . B-6

Figure B-11: Main Circuit and Control Diagram, CH74, Phase U . . . . . . . . . . . . . . . . . . . B-6

Figure B-12: Main Circuit and Control Diagram, CH74, Control . . . . . . . . . . . . . . . . . . . . B-7

Figure B-13: Fan Mounting Pallet — Hot Dip Zinc Coated . . . . . . . . . . . . . . . . . . . . . . . . B-8

Figure B-14: Fan Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

January 2007

iv

For more information visit: www.EatonElectrical.com

MN04005001E

January 2007

List of Tables

Table 1-1: LCX9000 Liquid-Cooled Adjustable Frequency Drive

Table 1-2: Power Ratings and Dimensions of Liquid-Cooled Drive,

Table 1-3: Power Ratings and Dimensions of Liquid-Cooled Drive,

Table 1-4: Technical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Table 2-1: One-Module Drive Dimensions (Mounting Base Included). . . . . . . . . . . . . . . . 2-2

Table 2-2: Several Module Drive Dimensions (Mounting Bracket Included). . . . . . . . . . . 2-5

Table 2-3: Drinking Water Chemical Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Table 2-4: Drinking Water Quality Recommendations — Maximum Values . . . . . . . . . . . 2-8

Table 2-5: Drinking Water Quality Recommendations — Desired Values . . . . . . . . . . . . . 2-9

Table 2-6: Process Water Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Table 2-7: Information About Cooling Agent and Its Circulation . . . . . . . . . . . . . . . . . . . . 2-11

Table 2-8: Cooling Agent Flow Rates (GPM) in Relation to Power Loss

Table 2-9: Coolant Volumes and Temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Table 2-10: Liquid Connector Types (All Pressure Values at Nominal Flow). . . . . . . . . . . 2-14

Table 2-11: Pressure Losses — CH6x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Table 2-12: Pressure Losses — CH7x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Table 2-13: Flow Switch Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Table 2-14: Maximum Temperatures of Coolant at Switching

Table 2-15: Maximum Temperatures of Coolant at Switching

Table 2-16: Input Choke Dimensioning, 6-Pulse Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Table 2-17: Choke Dimensions Sizes 23 – 145A and 590A . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Table 2-18: Choke Dimensions Sizes 261 – 1150A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Table 3-1: Cable Types Required to Meet Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Table 3-2: Cable Sizes 400 – 500V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Table 3-3: Cable Sizes 525 – 690V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Table 3-4: Tightening Torques of Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Table 3-5: Fuse Sizes for LCX9000 Liquid-Cooled (500V) Drives . . . . . . . . . . . . . . . . . . . . 3-5

Table 3-6: Fuse Sizes for LCX9000 Liquid-Cooled (690V) Drives . . . . . . . . . . . . . . . . . . . . 3-6

Table 4-1: Control I/O Terminal Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Table 4-2: Installing the Control Unit Mounting Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Table 4-3: Terminals (CH61, CH62 and CH72) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Table 4-4: Terminals (CH63). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Table 4-5: Terminals between Driver Boards (CH64 and CH74) . . . . . . . . . . . . . . . . . . . . . 4-16

Table 4-6: Terminals on Adapter Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Table 5-1: Drive Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Table 5-2: Control Place Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Table 5-3: Status LEDs (Green – Green – Red) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Table 5-4: Text Lines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Table 5-5: Button Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Table 5-6: Monitored Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Table 5-7: Keypad Control Parameters, M3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Table 5-8: Fault Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Table 5-9: Fault Time Recorded Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

Table 5-10: Real Time Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

LCX9000 Liquid-Cooled Drives User Manual

Catalog Numbering System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Supply Voltage 380 – 500V AC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Supply Voltage 525 – 690V AC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

at Certain Glycol/Water Mixture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Frequency of 3.6 kHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Frequency of 1.5 kHz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

MN04005001E

For more information visit: www.EatonElectrical.com

v

LCX9000 Liquid-Cooled Drives User Manual

List of Tables (Continued)

Table 5-11: System Menu Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Table 5-12: Counter Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-26

Table 5-13: Resettable Counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

Table 5-14: Software Information Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-27

Table 5-15: Applications Information Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

Table 5-16: Hardware Information Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-28

Table 5-17: Expander Board Parameters (Board OPTA1). . . . . . . . . . . . . . . . . . . . . . . . . . 5-30

Table A-1: Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

January 2007

vi

For more information visit: www.EatonElectrical.com

MN04005001E

January 2007

Safety

Definitions and Symbols

This symbol indicates high voltage. It calls your attention to items

or operations that could be dangerous to you and other persons

operating this equipment. Read the message and follow the

instructions carefully.

This symbol is the “Safety Alert Symbol.” It occurs with either of

two signal words: CAUTION or WARNING, as described below.

LCX9000 Liquid-Cooled Drives User Manual

WARNING

WARNING

Indicates a potentially hazardous situation which, if not avoided,

can result in serious injury or death.

Indicates a potentially hazardous situation which, if not avoided,

can result in minor to moderate injury, or serious damage to the

product. The situation described in the CAUTION may, if not

avoided, lead to serious results. Important safety measures are

described in CAUTION (as well as WARNING).

Hazardous High Voltage

Motor control equipment and electronic controllers are connected

to hazardous line voltages. When servicing drives and electronic

controllers, there may be exposed components with housings or

protrusions at or above line potential. Extreme care should be taken

to protect against shock.

Stand on an insulating pad and make it a habit to use only one

hand when checking components. Always work with another

person in case an emergency occurs. Disconnect power before

checking controllers or performing maintenance. Be sure

equipment is properly grounded. Wear safety glasses whenever

working on electronic controllers or rotating machinery.

WARNING

CAUTION

WARNING

MN04005001E

For more information visit: www.EatonElectrical.com

vii

LCX9000 Liquid-Cooled Drives User Manual

Warnings, Cautions and Notices

January 2007

Warnings

Read this manual thoroughly and make sure you understand the procedures before you

attempt to install, set up, or operate this Cutler-Hammer

electrical business.

®

LCX9000 Drive from Eaton’s

WARNING

Only a competent electrician may carry out the electrical

installation.

WARNING

The LCX9000 Liquid-Cooled drive is meant for fixed installations only.

WARNING

Do not perform any measurements when the drive is connected to

the mains. Prior to measurements on the motor or the motor cable,

disconnect the motor cable from the drive.

WARNING

The drive has a capacitive leakage current.

WARNING

If the drive is used as a part of a machine, the machine

manufacturer is responsible for providing the machine with a main

switch (EN 60204-1).

WARNING

Only spare parts delivered by Eaton can be used.

WARNING

The motor starts at power-up if the start command is “ON”.

Furthermore, the I/O functionalities (including start inputs) may

change if parameters, applications or software are changed.

Disconnect, therefore, the motor if an unexpected start can cause

danger.

WARNING

The components of the power unit of the drive are live when it is

connected to mains potential. Coming into contact with this

voltage is extremely dangerous and may cause death or severe

injury. The control unit is isolated from the mains potential.

viii

For more information visit: www.EatonElectrical.com

MN04005001E

January 2007

LCX9000 Liquid-Cooled Drives User Manual

WARNING

The motor terminals U, V, W and the DC-link/brake resistor

terminals are live when the Liquid-Cooled drive is connected to

mains, even if the motor is not running .

WARNING

After disconnecting the drive from the mains, wait until the

indicators on the keypad go out (if no keypad is attached see the

indicators on the cover). Wait 5 more minutes before doing any

work on the Liquid-Cooled drive connections. Do not touch the

enclosure before this time has expired.

WARNING

The control I/O-terminals are isolated from the mains potential.

However, the relay outputs and other I/O-terminals may have a

dangerous control voltage present even when the Liquid-Cooled

drive is disconnected from mains.

Cautions

CAUTION

Always remove all cooling agent from the cooling element(s)

before shipping to avoid damage caused by freezing.

CAUTION

Do not perform any voltage withstand tests on any part of the

Liquid-Cooled drive. There is a certain procedure according to

which the tests shall be performed. Ignoring this procedure may

result in damaged product.

CAUTION

Do not touch the components on the circuit boards. Electrostatic

voltage discharge may damage the components.

CAUTION

Before connecting the Liquid-Cooled drive to mains, ensure the

functionality of the coolant circulation and check the circulation for

possible leaks.

CAUTION

Before connecting the drive to mains make sure that the enclosure

door is closed.

MN04005001E

For more information visit: www.EatonElectrical.com

ix

LCX9000 Liquid-Cooled Drives User Manual

Grounding and Ground Fault Protection

The LCX9000 drive must always be grounded with a ground conductor connected to the

ground terminal.

The ground fault protection inside the drive only protects the drive against ground faults in

the motor or the motor cable. It is not intended for personal safety.

Due to the high capacity currents present in the drive, fault current protective switches may

not function properly.

Motor and Equipment Safety

Before starting the motor, check that the motor is mounted properly

and ensure that the machine connected to the motor allows the

motor to be started.

CAUTION

January 2007

CAUTION

Set the maximum motor speed (frequency) according to the motor

and the machine connected to it.

CAUTION

Before reversing the motor, make sure that this can be done safely.

CAUTION

Make sure that no power correction capacitors are connected to the

motor cable.

CAUTION

Make sure that the motor terminals are not connected to mains

potential.

CAUTION

Before the Liquid-Cooled drive can be used to control the motor,

the proper functioning of the liquid-cooling system must be

ensured.

x

For more information visit: www.EatonElectrical.com

MN04005001E

January 2007

Chapter 1 — Overview

Receiving and Inspection

The standard delivery of Cutler-Hammer

business includes all or part of the following components:

●

power unit

control unit

●

●

water connection main line connecting hoses and conduits (1.5m) for CH61 – CH74;

Hoses in different lengths also available

●

Tema 1300 series fast connectors for CH3 – CH4

●

choke

control unit mounting kit

●

LCX9000 Liquid-Cooled Drives User Manual

®

Liquid-Cooled Drives from Eaton’s electrical

cooling fan for boards (CH4)

●

optic fiber & cable set (1.5m) for control unit; Optic sets in different lengths also

●

available

Cutler-Hammer Liquid-Cooled Drives have undergone scrupulous tests and quality checks at

the factory before they are delivered to the customer. However, after unpacking the product,

check that no signs of transport damages are to be found on the product and that the delivery

is complete (compare the type designation of the product to the code below, Table 1-1 ).

If the drive has been damaged during shipping, please contact the cargo insurance company

or the carrier.

If the delivery does not correspond to your order, contact the supplier immediately.

MN04005001E

For more information visit: www.EatonElectrical.com

1-1

LCX9000 Liquid-Cooled Drives User Manual

Table 1-1: LCX9000 Liquid-Cooled Adjustable Frequency Drive Catalog Numbering System

January 2007

Product Family

LCX = High Performance

Liquid Cooled Drive

Current Rating

016 = 16A

022 = 22A

031 = 31A

038 = 38A

045 = 45A

061 = 61A

072 = 72A

087 = 87A

105 = 105A

140 = 140A

168 = 168A

205 = 205A

261 = 261A

300 = 300A

385 = 385A

460 = 460A

170 = 170A

208 = 208A

261 = 261A

325 = 325A

385 = 385A

416 = 416A

460 = 460A

502 = 502A

590 = 590A

650 = 650A

750 = 750A

L C X 0 1 6 A 0 –4A 2 B 1

480V

520 = 520A

590 = 590A

650 = 650A

730 = 730A

820 = 820A

920 = 920A

H10 = 1030A

H13 = 1370A

H16 = 1640A

H20 = 2060A

H23 = 2300A

H24 = 2470A

H29 = 2950A

H37 = 3710A

H41 = 4140A

690V

820 = 820A

H10 = 1030A

H11 = 1180A

H13 = 1300A

H15 = 1500A

H18 = 1850A

H21 = 2120A

= 2340A

H23

H27 = 2700A

H31 = 3100A

Options

Options appear in alphabetical order.

Extended I/O Card Options

A3 = 2 RO, Therm

A4 = Encoder low volt +5V/15V24V

A5 = Encoder high volt +15V/24V

A7 =

A8 = 6 DI, 1 DO, 2 AI, 1AO

B1 = 6 DI, 1 ext +24V DC/EXT +24V DC

B2 = 1 RO (NC/NO), 1 RO (NO), 1 Therm

B4 = 1 AI (mA isolated), 2 AO (mA isolated),

1 ext +24V DC/EXT +24V DC

B5 = 3 RO (NO)

B8 = 1 ext +24V DC/EXT +24V DC, 3 Pt100

B9 = 1 RO (NO), 5 DI 42 – 240V AC Input

BB = SPI, Absolute Encoder

Communication Cards

CA = Johnson Controls N2

CI = Modbus TCP

C2 = Modbus

C3 = Profibus DP

C4 = LonWorks

C5 = Profibus DP (D9 Connector)

C6 = CANopen (Slave)

C7 = DeviceNet

C8 = Modbus (D9 Type Connector)

D1 = Adapter

D2 = Adapter

D3 = RS-232 with D9 Connection

Board Modifications

1 = Standard Boards

2 = Varnished Boards

Software Series

A = Standard

Enclosure Rating

0 = Open Chassis

4 = 380 – 500V

5 = 525 – 690V

Voltage Rating

Brake Chopper Options

N = No Brake Chopper Circuit

B = Internal Brake Chopper

Input Options

2 = 3-Phase, EMC N

Keypad

A = Alphanumeric

1-2

For more information visit: www.EatonElectrical.com

MN04005001E

January 2007

Storage and Shipping

If the drive is to be kept in storage before use, make sure that the ambient conditions are

acceptable:

Storing temperature -40 – 158°F (-40 – 70°C) (no cooling liquid inside cooling element

allowed below 0º)

Relative humidity <96%, no condensation

If the storage time exceeds 12 months, the electrolytic DC capacitors need to be charged with

caution. Therefore, such a long storage time is not recommended.

Maintenance

In normal conditions, Cutler-Hammer Liquid-Cooled drives are maintenance-free. However, if

the drive is used in conditions with temperatures below the freezing point and the liquid used

for cooling is likely to freeze, be sure to empty the cooling element if the drive must be

moved or if it is taken out of use for a longer time.

LCX9000 Liquid-Cooled Drives User Manual

CAUTION

Always remove all cooling agent from the cooling element(s)

before shipping to avoid damage caused by freezing.

It may also be necessary to clean up the coolant ducts in the cooling element. Contact the

factory for more information.

The instructions for the cooling system provided by its manufacturer must be followed.

Technical Data

Figure 1-1 presents the block diagram of the liquid-cooled drive. Mechanically, the product

consists of two units, the Power Unit and the Control Unit. The power unit can contain one to

six modules (cooling plates), depending on the drive size. Instead of air, liquid-cooled drives

use liquid for cooling. A charging circuit is embodied in the drives.

An external three-phase AC-choke (1) at the mains input together with the DC-link capacitor

(2) form an LC-filter. In drives, the LC-filter together with the diode bridge produce the

DC-voltage supply to the IGBT Inverter Bridge (3) block. The AC-choke also functions as a

filter against High Frequency disturbances from the mains as well as against those caused by

the drive to the mains. In addition, it enhances the waveform of the input current to the drive.

In chassis with multiple parallel line-rectifiers (CH74) AC-chokes are required to balance the

line current between the rectifiers.

The power drawn by the drive from the mains is mostly active power.

The IGBT Inverter Bridge produces a symmetrical, three-phase Pulse Width Modulated

AC-voltage to the motor.

MN04005001E

For more information visit: www.EatonElectrical.com 1-3

LCX9000 Liquid-Cooled Drives User Manual

The Motor and Application Control Block is based on microprocessor software. The

microprocessor controls the motor based on the information it receives through

measurements, parameter settings, control I/O and control keypad. The motor and

application control block controls the motor control ASIC which, in turn, calculates the IGBT

positions. Gate drivers amplify these signals for driving the IGBT inverter.

The control keypad constitutes a link between the user and the drive. The control keypad is

used for parameter setting, reading status data and giving control commands. It is

detachable and can be operated externally and connected via a cable to the drive. Instead of

the control keypad, a PC can also be used to control the drive if connected through a similar

cable (±12V).

You can have your drive equipped with a control I/O board which is either isolated (OPT-A8)

or not isolated (OPT-A9) from the frame. Optional I/O expander boards that increase the

number of inputs and outputs to be used are also available. For more information, contact

Eaton or your local distributor.

The basic control interface and the parameters (the Basic Application) are easy to use. If a

more versatile interface or parameters are required, a more suitable application can be

chosen from the application manual.

An internal brake chopper is available as standard for chassis CH3. For all other sizes the

brake chopper is available as an option and installed externally. The standard product does

not include a brake resistor. It should be ordered separately.

January 2007

1-4 For more information visit: www.EatonElectrical.com

MN04005001E

January 2007

LCX9000 Liquid-Cooled Drives User Manual

Brake Resistor *

Power Module

Mains

(1)

External

Choke

PE

(2)

(3)

IGBT

Inverter

=

Gate

Drivers

Motor

Control

ASIC

3~

Current

Sensors

Motor

U

V

W

Rectifier

(Frequency

Converters Only)

L1

L2

L3

Control Module

Control Keypad

3~

Charg. Res.

Power

Supply

RS-232

=

Brake *

Chopper

Measurements

Motor and

Application

Control

MN04005001E

Control

I/O

* Brake resistor is available as optional equipment for all sizes (CH3 to CH7).

An internal brake chopper is standard equipment in CH3 only, while in all other sizes it is optional

and installed externally.

Control

I/O

Control

I/O

Control

I/O

Control

I/O

Figure 1-1: Liquid-Cooled Drive Principal Block Diagram

For more information visit: www.EatonElectrical.com 1-5

LCX9000 Liquid-Cooled Drives User Manual

Power Ratings

The Cutler-Hammer Liquid-Cooled product range consists of (AC input, AC output) drives.

The following tables show the drive output values for both in Ith (current) and shaft power

(electrical) as well as the drive losses and mechanical sizes. The power achieved is given as

per the supply voltage.

Drives

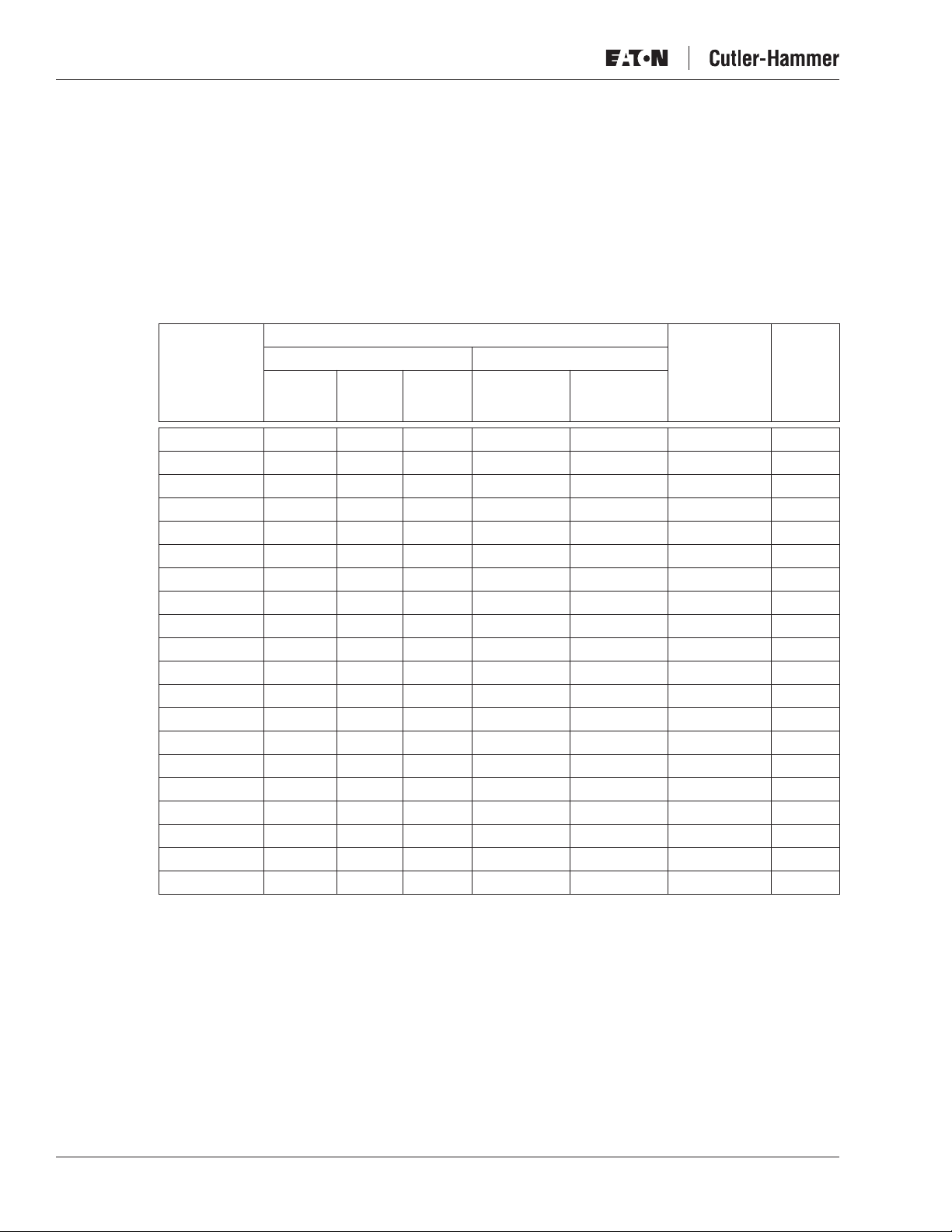

Table 1-2: Power Ratings and Dimensions of Liquid-Cooled Drive, Supply Voltage

380 – 500V AC

Drive Output

Current Electrical Output Power

Catalog

Number

LCX016A0-4 16 15 11 7.5 11 0.4/0.2/0.6 CH3

LCX022A0-4 22 20 15 11 15 0.5/0.2/0.7 CH3

LCX031A0-4 31 28 21 15 18.5 0.7/0.2/0.9 CH3

LCX038A0-4 38 35 25 18.5 22 0.8/0.2/1.0 CH3

LCX045A0-4 45 41 30 22 30 1.0/0.3/1.3 CH3

LCX061A0-4 61 55 41 30 37 1.3/0.3/1.5 CH3

LCX072A0-4 72 65 48 37 45 1.2/0.3/1.5 CH4

LCX087A0-4 87 79 58 45 55 1.5/0.3/1.8 CH4

LCX105A0-4 105 95 70 55 75 1.8/0.3/2.1 CH4

LCX140A0-4 140 127 93 75 90 2.3/0.3/2.6 CH4

LCX168A0-4 168 153 112 90 110 4.0/0.4/4.4 CH5

LCX205A0-4 205 186 137 110 132 5.0/0.5/5.5 CH5

LCX261A0-4 261 237 174 132 160 6.0/0.5/6.5 CH5

LCX300A0-4 300 273 200 160 200 7.0/0.6/7.6 CH61

LCX385A0-4 385 350 257 200 250 9.0/0.7/9.7 CH61

LCX460A0-4 460 418 307 250 315 6.5/0.5/7.0 CH72

LCX520A0-4 520 473 347 250 355 7.5/0.6/8.1 CH72

LCX590A0-4 590 536 393 315 400 9.0/0.7/9.7 CH72

LCX650A0-4 650 591 433 355 450 10.0/0.7/10.7 CH72

LCX730A0-4 730 664 487 400 500 12.0/0.8/12.8 CH72

Thermal

I

th

(A)

Rated

Cont. I

(A)

L

Rated

Cont. I

(A)

Optimum

Motor at I

H

400V (kW)

th

Optimum

Motor at I

500V (kW)

Power Loss

c/a/T

th

(kW) Chassis

January 2007

1-6 For more information visit: www.EatonElectrical.com

MN04005001E

January 2007

P3UnInϕcos×××=

LCX9000 Liquid-Cooled Drives User Manual

Table 1-2: Power Ratings and Dimensions of Liquid-Cooled Drive, Supply Voltage

380 – 500V AC (Continued)

Drive Output

Current Electrical Output Power

Catalog

Number

LCX820A0-4 820 745 547 450 560 12.5/0.8/13.3 CH63

LCX920A0-4 920 836 613 500 600 14.4/0.9/15.3 CH63

LCXH10A0-4 1030 936 687 560 700 16.5/1.0/17.5 CH63

LCXH11A0-4 1150 1045 766 600 750 18.5/1.2/19.7 CH63

LCXH13A0-4 1370 1245 913 700 900 19.0/1.2/20.2 CH74

LCXH16A0-4 1640 1491 1093 900 1100 24.0/1.4/25.4 CH74

LCXH20A0-4 2060 1873 1373 1100 1400 32.5/1.8/34.3 CH74

LCXH23A0-4 2300 2091 1533 1250 1500 36.3/2.0/38.3 CH74

LCXH24A0-4 2470 2245 1647 1300 1600 38.8/2.2/41.0 2xCH74

LCXH29A0-4 2950 2681 1967 1550 1950 46.3/2.6/48.9 2xCH74

LCXH37A0-4 3710 3372 2473 1950 2450 58.2/3.0/61.2 2xCH74

LCXH41A0-4 4140 3763 2760 2150 2700 65.0/3.6/68.6 2xCH74

Thermal

I

th

(A)

Rated

Cont. I

(A)

L

Rated

Cont. I

(A)

Optimum

Motor at I

H

400V (kW)

th

Optimum

Motor at I

500V (kW)

Power Loss

c/a/T

th

(kW) Chassis

Ith = Thermal maximum continuous RMS current. Dimensioning can be done according to

this current if the process does not require any overloadability or the process does not

include any torque ripple.

IL = Low overloadability current. Allows +10% torque ripple. 10% exceeding can be

continuous.

IH = High overloadability current. Allows +50% torque ripple. 50% exceeding can be

continuous.

All values with cosϕ = 0.83 and efficiency = 97%.

c/a/T: c = power loss into coolant; a = power loss into air; T = total power loss; power losses

of input chokes not included. All power losses obtained using max. supply voltage and

switching frequency of 3.6 kHz.

If some other mains voltage is used, apply the formula to calculate

the Liquid-Cooled drive output power.

The enclosure class for all Liquid-Cooled drives is IP00.

MN04005001E

For more information visit: www.EatonElectrical.com 1-7

LCX9000 Liquid-Cooled Drives User Manual

P3UnInϕcos×××=

Table 1-3: Power Ratings and Dimensions of Liquid-Cooled Drive, Supply Voltage

525 – 690V AC

Drive Output

Current Electrical Output Power

Catalog

Number

LCX170A0-5 170 155 113 110 160 7.5/0.4/7.9 CH61

LCX208A0-5 208 189 139 132 200 9.0/0.5/9.5 CH61

LCX261A0-5 261 237 174 160 250 6.5/0.3/6.8 CH61

LCX325A0-5 325 295 217 200 300 7.5/0.4/7.9 CH72

LCX385A0-5 385 350 257 250 355 9.0/0.5/9.5 CH72

LCX416A0-5 416 378 277 250 355 9.4/0.5/9.9 CH72

LCX460A0-5 460 418 307 300 400 10.0/0.5/10.5 CH72

LCX502A0-5 502 456 335 355 450 12.0/0.6/12.6 CH72

LCX590A0-5 590 536 393 400 560 13.0/0.7/13.7 CH63

LCX650A0-5 650 591 433 450 600 16.0/0.8/16.8 CH63

LCX750A0-5 750 682 500 500 700 18.0/0.9/18.9 CH63

LCX820A0-5 820 745 547 560 800 19.0/1.0/20.0 CH74

LCX920A0-5 920 836 613 650 850 21.3/1.2/22.5 CH74

LCXH10A0-5 1030 936 687 700 1000 22.0/1.1/23.1 CH74

LCXH11A0-5 1180 1073 787 800 1100 25.0/1.3/26.3 CH74

LCXH13A0-5 1300 1182 867 900 1200 31.0/1.6/32.6 CH74

LCXH15A0-5 1500 1364 1000 1000 1400 38.0/1.9/39.9 CH74

LCXH18A0-5 1850 1682 1233 1250 1650 39.6/2.0/41.6 2xCH74

LCXH21A0-5 2120 1927 1413 1450 1900 45.0/2.4/47.4 2xCH74

LCXH23A0-5 2340 2127 1560 1600 2100 55.8/2.9/58.7 2xCH74

LCXH27A0-5 2700 2455 1800 1850 2450 68.4/3.4/71.8 2xCH74

LCXH31A0-5 3100 2818 2066 2150 2800 — 2xCH74

Thermal

I

th

(A)

Rated

Cont. I

(A)

L

Rated

Cont. I

(A)

Optimum

Motor at I

H

525V (kW)

th

Optimum

Motor at I

690V (kW)

Power Loss

c/a/T

th

(kW) Chassis

January 2007

Ith = Thermal maximum continuous RMS current. Dimensioning can be done according to

this current if the process does not require any overloadability or the process does not

include any torque ripple.

IL = Low overloadability current. Allows +10% torque ripple. 10% exceeding can be

continuous.

IH = High overloadability current. Allows +50% torque ripple. 50% exceeding can be

continuous.

All values with cosϕ = 0.83 and efficiency = 97%.

c/a/T: c = power loss into coolant; a = power loss into air; T = total power loss; power losses

of input chokes not included. All power losses obtained using max. supply voltage and

switching frequency of 3.6 kHz.

If some other mains voltage is used, apply the formula to calculate

the Liquid-Cooled drive output power.

The enclosure class for all Liquid-Cooled drives is IP00.

1-8 For more information visit: www.EatonElectrical.com

MN04005001E

January 2007

Specifications

LCX9000 Liquid-Cooled Drives User Manual

Table 1-4: Technical Information

Description Specification

Mains Connection

Input voltage U

in

Input frequency 45 – 66 Hz

Connection to mains Once per minute or less

Motor Connection

Output voltage 0 – U

Continuous output current Rated current at nominal inflow cooling water temperature

Output frequency 0 – 320 Hz (standard); 7200 Hz (Special software)

Frequency resolution Application dependent

Control Characteristics

Control method Frequency control U/f

Switching frequency

(see parameter 2.6.9)

Frequency reference

Analog input

Panel reference

Field weakening point 8 – 320 Hz

Acceleration time .1 – 3000 sec

Deceleration time .1 – 3000 sec

Braking torque DC brake: 30% * T

Ambient Conditions

Ambient operating temperature 14°F (-10°C) (no frost) to +122°F (+50°C) (at I

Storage temperature -40 to +158°F (-40 to +70°C); No liquid in heatsink under 32°F (0ºC)

Relative humidity 5 to 96% RH, non-condensing, no dripping water

Air quality:

chemical vapors

mechanical particles

Altitude 100% load capacity (no derating) up to 1,000m; above 1,000m

Vibration

EN50178/EN60068-2-6

Shock

EN50178, EN60068-2-27

Enclosure class IP00/Open Frame standard in entire kW/hp range

400 – 500V AC; 525 – 690V AC; (-10% – 10%)

465 – 800V DC; 640 – 1100V DC; (-0% – 0%)

in

according to dimensioning charts

Open Loop Sensorless Vector Control

Closed Loop Vector Control

480V: Up to and including 61 Amp Size:

1 – 16 kHz; Factory default 10 kHz

From 72 Amp Size:

1 – 12 kHz; Factory default 3.6 kHz

575V: 1 – 6 kHz; Factory default 1.5 kHz

Note: Derating required if higher switching frequency than the

default is used!

Resolution 0.1% (10-bit), accuracy ±1%

Resolution 0.01 Hz

(without brake option)

N

)

122 – 158°F (50 to 70°C) derating required, see Pages 2-13 and 2-19

th

IEC 721-3-3, unit in operation, class 3C2

IEC 721-3-3, unit in operation, class 3S2 (no conductive dust allowed)

No corrosive gases

derating of 1% per each 100m required

5 – 150 Hz

Displacement amplitude .25 mm (peak) at 3 – 31 Hz

Max acceleration amplitude 1 G at 31 – 150 Hz

UPS Drop Test (for applicable UPS weights)

Storage and shipping: max 15G, 11 mS (in package)

MN04005001E

For more information visit: www.EatonElectrical.com 1-9

LCX9000 Liquid-Cooled Drives User Manual

Table 1-4: Technical Information (Continued)

Description Specification

EMC

Immunity Fulfils all EMC immunity requirements

Emissions EMC level N; EMC level T for IT networks

Safety

Approvals EN50178, EN60204-1, CE, UL, CUL, FI, GOST R,

Safe disable board The drive is equipped with OPTAF board for prevention of torque on

Control connections (apply to boards OPT-A1, OPT-A2 and OPT-A3)

Analog input voltage 0 to +10V, R

Analog input current 0(4) – 20 mA, R

Digital inputs (6) Positive or negative logic; 18 – 24V DC

Auxiliary voltage +24V, ±10%, max volt. ripple <100 mVrms; max. 250 mA

Output reference voltage +10V, +3%, max. load 10 mA

Analog output 0(4) – 20 mA; R

Digital outputs Open collector output, 50 mA/48V

Relay outputs 2 programmable change-over relay outputs

Protections

Overvoltage trip limit

Undervoltage trip limit

Ground fault protection In case of ground fault in motor or motor cable, only the drive is

Mains supervision Trips if any of the input phases is missing

Motor phase supervision Trips if any of the output phases is missing

Unit overtemperature protection Alarm limit: 149°F (65°C) (heatsink); 158°F (70°C) (circuit boards)

Overcurrent protection Yes

Motor overload protection Yes

Motor stall protection Yes

Motor underload protection Yes

Short-circuit protection of +24V

and +10V reference voltages

Liquid Cooling

Allowed cooling agents Drinking water (see specification on Page 2-7)

Volume See Page 2-11.

Temperature of cooling agent 32 – 86°F (0 – 30°C) (I

Cooling agent flow rates See Table 2-7.

System max. working pressure 87 psi

System max. peak pressure 580 psi

Pressure loss (at nominal flow) Varies according to size. See Table 2-10.

January 2007

(see unit nameplate for more detailed approvals)

motor shaft. Standards: EN954-1, cat. 3 (hardware disable); BGIA

(Safe Disable Function).

= 200kΩ, (-10V to +10V joystick control)

Resolution 0.1%, accuracy ±1%

i

= 250Ω differential

i

Dimensioning: max. 1000 mA/control box

1A external fuse required (no internal short-circuit protection on the

control board)

max. 500Ω; Resolution 10 bit; Accuracy ±2%

L

Switching capacity: 24V DC/8A, 250V AC/8A, 125V DC/.4A

Min. switching load: 5V/10 mA

480V: 911V; 575V: 1200V (all VDC)

480V: 333V; 575V: 461V (all VDC)

protected

Trip limit: 158°F (70°C) (heatsink); 185°F (85°C) (circuit boards)

Ye s

Water-glycol mixture

See derating specifications on Page 2-19

)(input); 86 – 149°F (30 – 65°C): derating

required, see Page 2-19.

th

Max. temperature rise during circulation max. 41°F (5°C)

No condensation allowed. See Pages 2-13.

1-10 For more information visit: www.EatonElectrical.com

MN04005001E

January 2007

Chapter 2 — Installation

Mounting

Liquid-cooled drive modules must be installed into an enclosure. The drives consisting of

one module will be mounted on the mounting plate. The drives that include two or three

modules are mounted inside a mounting bracket, which will then be installed in the

enclosure.

Note: If any other than vertical installation position is required, please contact your

distributor!

On Page 2-2 you will find the dimensions of liquid-cooled drives installed on mounting bases

(plates and brackets).

Lifting the Drive

Eaton recommends use of a jib crane or similar elevating device to lift the drive unit. See

Figure 2-1 for correct lifting points.

Use either the hole(s) in the middle of the mounting plate (Lifting point 1) or the hole in the

H-shaped part of the mounting plate (Lifting point 2) for lifting the drive. See Figure 2-1.

LCX9000 Liquid-Cooled Drives User Manual

Lifting Point 1

.51 (13.0) Dia.

Lifting Point 2

.35 (9.0) Dia.

Lifting Point 1

.51 (13.0) Dia.

MN04005001E

Figure 2-1: Lifting Points for Drives Consisting of One Module (Left) and Several Modules

Approximate Dimensions in Inches (mm)

For more information visit: www.EatonElectrical.com 2-1

LCX9000 Liquid-Cooled Drives User Manual

Liquid-Cooled Dimensions

Drives Consisting of One Module

Table 2-1: One-Module Drive Dimensions (Mounting Base Included)

Approximate Dimensions in Inches (mm)

Chassis

CH3 6.30 (160) 16.97 (431) 9.69 (246) 66 (30)

CH4 7.60 (193) 19.41 (493) 10.12 (257) 77 (35)

CH5 9.69 (246) 21.77 (553) 10.39 (264) 88 (40)

CH61/62 9.69 (246) 25.91 (658) 14.65 (372) 121 (55)

CH72 9.69 (246) 42.36 (1076) 14.65 (372) 198 (90)

Te rm inals

Weight

in Lbs. (kg)Width Height Depth

January 2007

9.69

(246)

Water In/Out

7.64

(194)

16.97

(431)

2.20

(56)

3.98

(101)

2.32

(59)

6.30

(160)

3.23

(82)

Dia. .35

(9)

.47

(12)

1.57

(40)

.51

(13)

1.18

(30)

Figure 2-2: LCX9000 Liquid-Cooled Drive, CH3

Approximate Dimensions in Inches (mm)

Dia. .39

(10)

.59

(15)

3.19

(81)

1.57

(40)

2.32

(59)

2-2 For more information visit: www.EatonElectrical.com

MN04005001E

January 2007

LCX9000 Liquid-Cooled Drives User Manual

7.60

(193)

1.18

(30)

Dia. .39

(10)

7.48

(190)

2.72

(69)

3.35

(85)

(12)

Bottom View

Water In/Out

.65

(16.5)

2.36

(60)

4.09

(104)

Bottom

.47

.98

(25)

19.41

(493)

Dia. .39

3.03

(10)

(77)

Top View

6.57

(167)

.43

(11)

1.77

(45)

5.24

(133)

M8

.63

(16)

1.02

(26)

Dia. .35

(9)

Figure 2-3: LCX9000 Liquid-Cooled Drive, CH4

Approximate Dimensions in Inches (mm)

M12

.16

(4)

.26

(6.5)

.39

(10)

.49

(12.5)

.98

(25)

Dia. .51

(13)

10.12

(257)

2.60

(66)

M8

Dia. .51

(122)

2.24

(57)

2.24

(57)

2.48

(63)

(13)

4.80

6.97

(177)

10.39

(264)

MN04005001E

Top

3.15

(80)

.16

(4)

9.69

(246)

3.94

(100)

19.88

(505)

21.77

(553)

7.87

(200)

1.30

(33)

Figure 2-4: LCX9000 Liquid-Cooled Drive, CH5

Approximate Dimensions in Inches (mm)

For more information visit: www.EatonElectrical.com 2-3

LCX9000 Liquid-Cooled Drives User Manual

January 2007

3.19

(81)

6.85

(174)

1.77

(45)

9.69

(246)

Bottom

14.69

(373)

1.38

(35)

.39

(10)

3.94

(100)

3.15

(80)

5.91

(150)

.39

(10)

M12

Coolant

Outlet

UVW

Coolant

Inlet

x = Grounding Bolt

M8x25

Dia. .51

(13)

23.23

(590)

2.09

(53)

Figure 2-5: LCX9000 Liquid-Cooled Drive, CH61

Approximate Dimensions in Inches (mm)

Dia. .55

(14)

x

2.01

(51)

25.91

(658)

4.06

(103)

1.57

(40)

L3 L2 L1

2.56

2.56

(65)

(65)

9.21

(234)

Left SideFrontRight SideTop

1.30

(33)

23.07

(586)

.63

(16)

Top V i ew

6-Pulse Supply

1.57

(40)

12-Pulse Supply

.39

(10)

3.15

(80)

.39

(10)

.39

(10)

14.65

(372)

7.87

(200)

1.57

(40)

2.56

(65)

2.56

(65)

4.06

(103)

.87

1.57

(40)

.39

(10)

(22)

41.73

(1060)

36.65

(931)

39.37

(1000)

42.40

(1077)

2.95

(75)

.79

(20)

1.18

(30)

Dia. .51

(13)

Figure 2-6: LCX9000 Liquid-Cooled Drive, CH72

Approximate Dimensions in Inches (mm)

.55

(14)

1.30

(33)

2.66

(67.5)

.79

(20)

R .28

(7)

2.56

(65)

2.56

(65)

4.06

(103)

Coolant In/Out

Bottom

Dia. .55

(14)

9.21

(234)

2.01

(51)

2-4 For more information visit: www.EatonElectrical.com

MN04005001E

January 2007

LCX9000 Liquid-Cooled Drives User Manual

Drives Consisting of Several Modules

Liquid-cooled drives consisting of several modules are mounted in a mounting bracket as

presented in Figure 2-7.

Figure 2-7: Drive Mounted Inside Mounting Bracket

Table 2-2: Several Module Drive Dimensions (Mounting Bracket Included)

Approximate Dimensions in Inches (mm)

Chassis

CH63 19.88 (505) 36.38 (924) 14.76 (375) 264 (120)

CH64 29.37 (746) 36.38 (924) 14.76 (375) 396 (180)

CH74 29.37 (746) 46.26 (1175) 15.16 (385) 617 (280)

Weight

in Lbs. (kg)Width Height Depth

MN04005001E

For more information visit: www.EatonElectrical.com 2-5

LCX9000 Liquid-Cooled Drives User Manual

.98

(25)

Dia. .43

(11)

2.36

(60)

Bottom Top

18.90

(480)

9.69

(246)

.39

(10)

1.18

(30)

9.21

(234)

1.77

(45)

January 2007

Dia. .55

(14)

.98

(25)

.87

(22)

Coolant

Outlet

1.97

(50)

6.85

(174)

4.53

(115)

.39

(10)

3.27

(83)

1.57

(40)

4.69

(119)

6.42

(163)

34.25

(870)

Dia. .43

Coolant

Inlet

Dia. .55

(14)

1.34

(34)

(11)

.24

(6)

3.94

(100)

4.06

(103)

2.95

(75)

19.88

(505)

3.94

(100)

3.94

(100)

2.09

(53)

(100)

13.98

(355)

3.94

3.94

(100)

3.94

(100)

.20

(5)

34.41

(874)

36.38

(924)

(224)

1.30

(33)

(16.5)8.82

1.20

(30.5)

.59

(15)

.65

.55

(14)

(105)

4.13

Dia. .98

(25)

2.56

(65)

14.76

(375)

Left SideRight Side Front

2.56

(65)

1.57

(40)

23.94

(608)

23.58

(599)

11.50

(292)

Figure 2-8: LCX9000 Liquid-Cooled Drive with Mounting Bracket, CH63

Approximate Dimensions in Inches (mm)

2-6 For more information visit: www.EatonElectrical.com

MN04005001E

January 2007

LCX9000 Liquid-Cooled Drives User Manual

28.39

(721)

.59

(15)

Bottom

5.79

(147)

1.38

(35)

1.18

(30)

Dia. .43

(11)

Dia. .55

(14)

15.16

(385)

.67

(17)

(105)

6.89

(175)

6.89

(175)

6.89

(175)

6.89

(175)

1.57

(40)

2.56

(65)

4.13

(10)

.47

(12)

.47

(12)

.39

(12)

.63

(16)

.47

.47

(12)

.55

(14)

(33)

2.87

(73)

1.3

2.99

(76)

43.31

(1100)

46.26

(1175)

29.29

(744)

3.46

(88)

3.15

(80)

.39

(10)

.98

(25)

Dia. .18

5.51

(140)

(4.6)

14.72

6.69

(170)

7.87

(200)

7.87

(200)

7.87

(200)

(374)

9.69

(246)

9.69

(246)

3.15

(80)

1.57

(40)

.39

(10)

.39

(10)

.39

(10)

Top

6-Pulse Supply

12-Pulse Supply

29.37

(746)

29.37

(746)

Figure 2-9: LCX9000 Liquid-Cooled Drive, CH74, IP00

Approximate Dimensions in Inches (mm)

MN04005001E

For more information visit: www.EatonElectrical.com 2-7

LCX9000 Liquid-Cooled Drives User Manual

Cooling

Instead of using air for cooling, Cutler-Hammer Liquid-Cooled drives are cooled with liquid.

The liquid circulation of the drive is usually connected to a heat-exchanger (liquid-liquid/

liquid-air) which cools down the liquid circulating in the cooling elements of the drive. The

cooling agents acceptable for use are drinking water, demineralized water or a mixture

(60/40) of water and glycol. In a closed circulation system, the values in Table 2-3 are

recommended reference values. To avoid electrochemical corrosion, Eaton recommends

adding an inhibitor (e.g. Ferrolix 332/Henkel or Cortec VpCI-649) in the cooling agent.

Note:

If no heat-exchanger is used, actions must be taken to avoid electrochemical corrosion.

Specifically no brass or copper elements may be used in the liquid circulation of the drive.

Drinking Water Specification

Table 2-3 provides general guidelines for water quality.

Note: 1 mg/L = 1 ppm.

Table 2-3: Drinking Water Chemical Specification

Quality Unit Value Quality Unit Value

Acrylamide µg/L 0.10 Mercury µg/L 1.0

Antimony µg/L 5.0 Nickel µg/L 20

Arsenic µg/L 10 Nitrate [NO

Benzene µg/L 1.0 Nitrate-Nitrogen [NO

Benzopyrene µg/L 0.010 Nitrite [NO

Boron mg/L 1.0 Nitrite-Nitrogen [NO

Bromate µg/L 10 Bactericides µg/L 0.10

Cadmium µg/L 5.0 Bactericides, total µg/L 0.50

Chromium µg/L 50 Polynuclear aromatic

Copper mg/L 2.0 Selenium µg/L 10

Cyanides µg/L 50 Tetrachloroethylene and

1,2-Dichloroethane µg/L 3.0 Trihalomethanes total µg/L 100

Epichlorohydrin µg/L 0.10 Vinyl chloride µg/L 0.50

Fluoride mg/L 1.5 Chlorophenols total µg/L 10

Lead µg/L 10

]mg/L50

3

]mg/L0.5

2

hydrocarbons

trichloroethylene total

January 2007

-N] mg/L 11.0

3

-N] mg/L 0.15

2

µg/L 0.10

µg/L 10

Table 2-4: Drinking Water Quality

Recommendations — Maximum Values

Quality Unit

Aluminum µg/L 200

Ammonium [NH

Ammonium [NH

Chloride

]mg/L0.50

2

-N] mg/L 0.40

2

mg/L <100

Manganese µg/L 50

Iron µg/L <0.5

Sulphate

mg/L 250

Sodium mg/L 200

Oxidizability [COD

No aggressive water allowed.

To avoid corrosion of piping, the sulphate content must not

exceed 150 mg/L.

]mg/L 5.0

Mn-O2

Max.

Val ue

2-8 For more information visit: www.EatonElectrical.com

MN04005001E