Page 1

223

Features––––––––––––––––––––––––

• Ultra-compact insulation displacement

connector

1.0mm (.039") pitch and only 3.0mm (.118") high (side entry

type). This connector is only about 61% as large as the

smallest conventional (JST) IDC designs.

• Header designed for vacuum pick and place

robotics

Although this shrouded header has locking features for its

mating receptacle, there are no holes in the header shroud

that would adversely effect vacuum grippig equipment. Since

there is enough flat surface for secure vacuum gripping, this

miniature surface mount connector is versatile for designers

and economic for manufacturing.

• Twin U-slot insulation displacement section

The insulation displacement section connected to each wire

consists of two tin-plated slots (twin U-slots), which ensures

reliable connection.

• 3-point grip construction

The 3-point insulation grip feature and the strain relief ensure a

firm grip on terminated wires and protection of the insulation

displacement connection from possible damage.

Specifications –––––––––––––––––––

• Current rating: 0.7A DC

• Voltage rating: 50V DC

• Temperature range: -25˚C to +85˚C(including temperature rise

in applying electrical current)

• Contact resistance: Initial value/20m Ω max.

After environmental testing/40m Ω max.

• Insulation resistance: 100M Ω min.

• Withstanding voltage: 500V AC/minute

• Applicable wire: AWG #30

Conductor/7 strands,

tin-coated annealed copper

Insulation O.D./0.56mm (.022")

* Contact JST for details.

Standards ––––––––––––––––––––––

0

Recognized E60389

1

Certified LR20812

SR CONNECTOR

Disconnectable Insulation displacement connectors

1.0mm

(.039") pitch

IDC

Emboss Tape

JST 9

Page 2

224

SR CONNECTOR

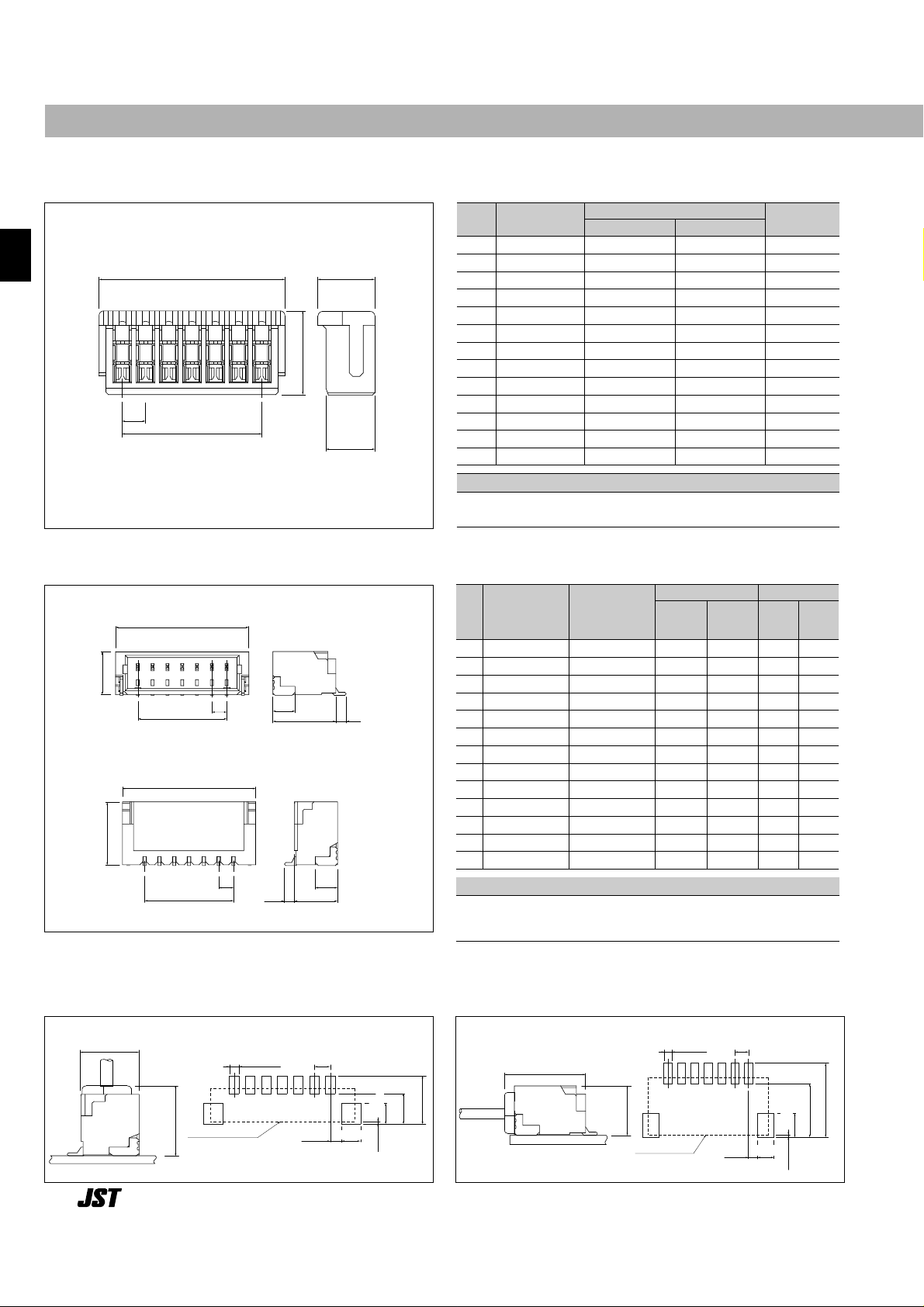

Receptacle–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

Cir-

Shrouded header –––––––––––––––––––––––––––––––––––––––––––––––––––––––––

2.9(.114)

B

4.25(.167)

1.5

(.059)

0.7(.028)

A

1.0

(.039)

A

4.25(.167)

0.7(.028) 2.9(.114)

1.5

(.059)

B

1.0

(.039)

Material and Finish

Cir-

cuits

Top entry

type

Dimensions mm(in.)Q'

ty / reel

Top

entry

type

Side

entry

type

B

2

3

4

5

6

7

8

9

10

11

12

13

14

BM02B-SRSS-TB

BM03B-SRSS-TB

BM04B-SRSS-TB

BM05B-SRSS-TB

BM06B-SRSS-TB

BM07B-SRSS-TB

BM08B-SRSS-TB

BM09B-SRSS-TB

BM10B-SRSS-TB

BM11B-SRSS-TB

BM12B-SRSS-TB

BM13B-SRSS-TB

BM14B-SRSS-TB

1.0(.039)

2.0(.079)

3.0(.118)

4.0(.157)

5.0(.197)

6.0(.236)

7.0(.276)

8.0(.315)

9.0(.354)

10.0(.394)

11.0(.433)

12.0(.472)

13.0(.512)

4.0(.157)

5.0(.197)

6.0(.236)

7.0(.276)

8.0(.315)

9.0(.354)

10.0(.394)

11.0(.433)

12.0(.472)

13.0(.512)

14.0(.551)

15.0(.591)

16.0(.630)

3,000

3,000

3,000

3,000

3,000

3,000

3,000

3,000

3,000

3,000

3,000

3,000

3,000

1,500

1,500

1,500

1,500

1,500

1,500

1,500

1,500

1,500

1,500

1,500

1,500

1,500

Contact: Copper alloy, copper-undercoated, tin/lead plated

Wafer: Polyamide, UL94V-0, natural (ivory)

Solder tab: Brass, copper-undercoated, tin/lead plated

A

Side entry

type

SM02B-SRSS-TB

SM03B-SRSS-TB

SM04B-SRSS-TB

SM05B-SRSS-TB

SM06B-SRSS-TB

SM07B-S RSS-TB

SM08B-SRSS-TB

SM09B-SRSS-TB

SM10B-SRSS-TB

SM11B-SRSS-TB

SM12B-SRSS-TB

SM13B-SRSS-TB

SM14B-SRSS-TB

Side entry type

Note: 1. The products listed above are supplied on embossed-tape.

2. Contact JST for the top entry type headers with suction cap.

PC board layout (viewed from component side) and Assembly layout––––––––––––––––––

2.95(.116)

4.85(.191)

Shrouded header

0.6 ± 0.05

(.024 ± .002)

0.7 ± 0.1

(.028 ± .004)

4.0 ± 0.1

(.157 ± .004)

0.2 ± 0.1

(.008 ± .004)

5.55 ± 0.1

(.219 ± .004)

1.0 ± 0.05

(.039 ± .002)

1.8 ± 0.1

(.071 ± .004)

1.2 ± 0.1

(.047 ± .004)

Note:

1. Tolerances are non-cumulative: ±0.05mm(±.002" ) for all centers.

2. Dimensions above should serve as a guideline. Contact JST for details.

Side entry type

4.9(.193)

2.9(.114)

Shrouded header

0.6 ± 0.05

(.024 ± .002)

0.7 ± 0.1

(.028 ± .004)

2.65 ± 0.1

(.104 ± .004)

0.2 ± 0.1

(.008 ± .004)

4.2 ± 0.1

(.165 ± .004)

1.0 ± 0.05

(.039 ± .002)

1.8 ± 0.1

(.071 ± .004)

1.2 ± 0.1

(.047 ± .004)

Top entry type

Top entry type

cuits

3.6(.142)

2.45(.097)

2.1(.083)

10

11

12

13

14

1.0

(.039)

B

A

Model No.

2

02SR-3S

3

03SR-3S

4

04SR-3S

5

05SR-3S

6

06SR-3S

7

07SR-3S

8

08SR-3S

9

09SR-3S

10SR-3S

11SR-3S

12SR-3S

13SR-3S

14SR-3S

Dimensions mm(in.)

A

1.0(.039)

2.0(.079)

3.0(.118)

4.0(.157)

5.0(.197)

6.0(.236)

7.0(.276)

8.0(.315)

9.0(.354)

10.0(.394)

11.0(.433)

12.0(.472)

13.0(.512)

B

3.0(.118)

4.0(.157)

5.0(.197)

6.0(.236)

7.0(.276)

8.0(.315)

9.0(.354)

10.0(.394)

11.0(.433)

12.0(.472)

13.0(.512)

14.0(.551)

15.0(.591)

Q

’

ty / box

3,000

3,000

3,000

2,000

2,000

2,000

2,000

2,000

2,000

2,000

2,000

2,000

2,000

Material and Finish

Contact: Phosphor bronze, tin-plated

Housing: Polyamide 66, UL94V-0, natural (ivory)

Page 3

225

Taping specifications ––––––––––––––––––––––––––––––––––––––––––––––––––––––

Side entry type

Cir-

cuits

Top

entry

type

Side

entry

type

2 to 3

4

5 to 7

8

9 to 14

Q'ty / reel

Top

entry

type

Side

entry

type

Top

entry

type

Side

entry

type

Top

entry

type

Side

entry

type

Top

entry

type

Side

entry

type

Taping dimensions mm(in.)

FSWW1

Reel dimensions mm(in.)

5.5(.217)

7.5(.295)

7.5(.295)

11.5(.453)

11.5(.453)

5.5(.217)

5.5(.217)

7.5(.295)

7.5(.295)

11.5(.453)

4.75(.187)

6.75(.266)

6.75(.266)

10.75(.423)

10.75(.423)

4.75(.187)

4.75(.187)

6.75(.266)

6.75(.266)

10.75(.423)

12(.472)

16(.630)

16(.630)

24(.945)

24(.945)

12(.472)

12(.472)

16(.630)

16(.630)

24(.945)

13.5(.531)

17.5(.689)

17.5(.689)

25.5(1.004)

25.5(1.004)

13.5(.531)

13.5(.531)

17.5(.689)

17.5(.689)

25.5(1.004)

1,500

1,500

1,500

1,500

1,500

3,000

3,000

3,000

3,000

3,000

Top entry type

SR CONNECTOR

Note:

1. Specifications conform to JIS C 0806. The tape width, connector recess hole dimensions, etc. are determined by the number of circuits and external shape of

the connector to be loaded.

2. Specifications are subject to change without prior notice.

Feeding direction

Feeding direction

Feeding direction

1.55±0.05

(.061±.002)dia.

4.0±0.1

(.157±.004)

13.0(.512)dia.

2.0±0.1

(.079±.004)

F±0.1

(W1

1.75±0.1

W1

(.069±.004)

(.004)

(S)

+2.5

-

1.0

+.098

-

.039

)

W±0.3(.012)

2.0 ± 0.5

(.079 ± .002)

Cover tape

± 2.0

380

[100(3.937)dia.]

(14.961 ± .079)dia

Carrier tape

Carrier tape

Tail tape

(Unloaded area)

40(1.575)

min.

Feeding direction

4.0 ± 0.1

1.55 ± 0.05

(.061 ± .002)dia.

(.157 ± .004)

Connector

loaded area

(.079 ± .004)

2.0 ± 0.1

1.75 ± 0.1

F ± 0.1

Cover tape leader area

Lead tape

(Unloaded area)

20 vacancies min.

400(15.748) min.

Cover tape

(.069 ± .004)

(.004)

W ± 0.3(.012)

(S)

Carrier tape

12±0.1

(.315±.004)

0.38±0.05

(.015±.002)

4.55

(.179)

8.0 ± 0.1

(.315 ± .004)

0.38 ± 0.05

(.015 ± .002)

3.25

(.128)

Page 4

WWW.ALLDATASHEET.COM

Copyright © Each Manufacturing Company.

All Datasheets cannot be modified without permission.

This datasheet has been download from :

www.AllDataSheet.com

100% Free DataSheet Search Site.

Free Download.

No Register.

Fast Search System.

www.AllDataSheet.com

Loading...

Loading...