Accessories - ND0402EN - 2018/10

MANUAL

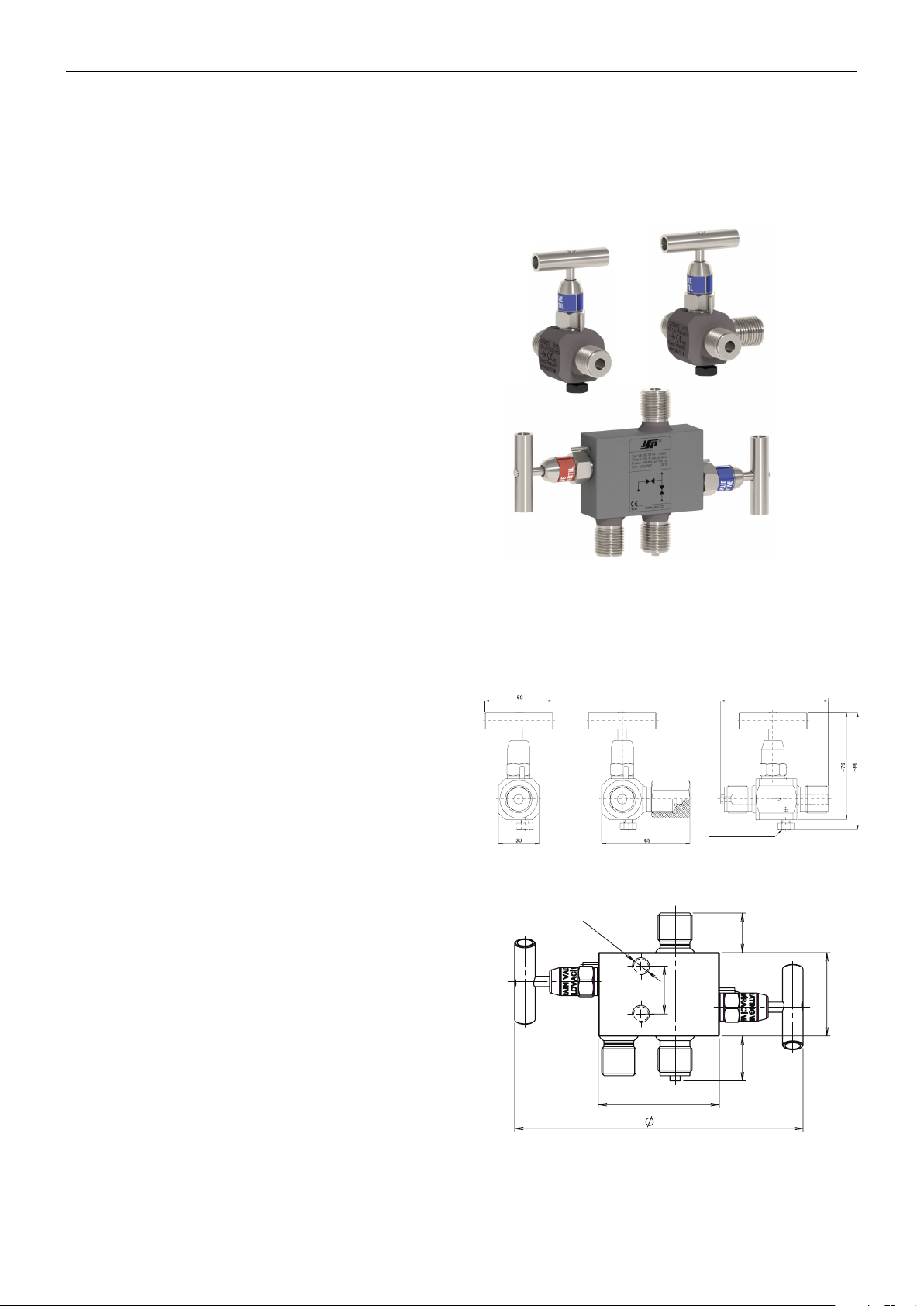

VS 100, VS 110, VS 120, VS 200

Isolating Vent Valve

Isolating Valve

Testing Vent Valve

Two Valve Manifolds

Operating pressure up to 42 MPa.

•

Operating temperature up to 500 °C.

•

Material stainless steel 1.4541.

•

Sealing component selection from different

•

material: Graphite, PTFE, PEEK, Viton, EPDM.

JSP, s. r. o.

Industrial Controls

CZ Raisova 547, 506 01 Jičín

+420 493 760 811 • jsp@jsp.cz

Gland packing adjuster.

•

Seat diameter 4 mm.

•

EU Type Examination Certificate

•

according to Directive PED 2014/68/EU.

SK Karloveská 63, 841 04 Braslava

+421 2 6030 1080 • predaj@jsp.sk

www.jsp.cz

Valves VS 100, VS 110, VS 120 and Two Valve Manifolds VS 200

Contents

1. General instructions and information ..........................................................................................................3

1.1 Symbols used ..............................................................................................................................................3

1.2 Scope of delivery .........................................................................................................................................3

1.3 Description of the delivery and packing .......................................................................................................3

1.4 Storage ........................................................................................................................................................3

1.5 Installation and commissioning ....................................................................................................................3

1.6 Spare parts ..................................................................................................................................................3

1.7 Repairs ........................................................................................................................................................3

1.8 Warranty ......................................................................................................................................................3

2. End of service and disposal .........................................................................................................................3

2.1 End of service ..............................................................................................................................................3

2.2 Disposal .......................................................................................................................................................3

3. Product description ....................................................................................................................................... 4

3.1 Application ...................................................................................................................................................4

3.2 Description ...................................................................................................................................................4

3.3 Dimensional drawings..................................................................................................................................4

4. Installation, operation and maintenanceu ...................................................................................................5

4.1 Installation and commissioning ....................................................................................................................5

4.2 Interconnection diagram ..............................................................................................................................5

4.3 Examples of mounting of the manifolds in operation ...................................................................................5

4.4 Examples of mounting with brackets ...........................................................................................................6

4.5 Connection of impulse piping by means of cutting rings .............................................................................6

4.6 Operation and maintenance ........................................................................................................................7

5. Product specifications...................................................................................................................................7

5.1 Technical specifications ...............................................................................................................................7

5.2 Supplementary parameters .........................................................................................................................7

5.3 Operation conditions ....................................................................................................................................9

6. Tests, certificates and standards ................................................................................................................10

6.1 Tests and certificates .................................................................................................................................10

6.2 Marking and type tag information ..............................................................................................................10

7. Optional accessories ...................................................................................................................................10

7.1 Optional accessories to connection of impulse piping ...............................................................................10

8. Ordering information ...................................................................................................................................11

8.1 Ordering table ............................................................................................................................................11

Contacts ...........................................................................................................................................................15

- 2 -

Valves VS 100, VS 110, VS 120 and Two Valve Manifolds VS 200

1. General instructions and information

1.1 Symbols used

Symbol of warning; for safe use it is necessary to

proceed according to the instructions

Symbol CE certifies compliance of the product with

EU directives and the respective government

directives

The product does not belong to public waste and it is

subjected to separate collection

1.2 Scope of delivery

With the product is delivered:

- manual for installation, operation and maintenance

Upon request can be provided:

- protocol on executed tests

- copy of the Inspection certificate 3.1 acc. to EN 10204 for

material of the main body

- copy of the EU Type Examination Certificate acc. to Directive

PED 2014/68/EU

1.3 Description of the delivery and packing

The product is packaged in a protective cover and provided

with an identification label with a mark of the output control.

The product must not be exposed to direct rain, vibrations and

shocks during transport.

presented. The claiming party shall give identification of the

product, number of the delivery note and description of the

fault or defect.

The manufacturer is not responsible for any defects caused

by improper storage, incorrect connection, damages caused

by external effects, in particular by effects of factors with

excessive values, unqualified installation, improper operation

or common wearing.

2. End of service and disposal

2.1 End of service

In case that the manifold with a pressure or pressure

difference sensor is under pressure, the sensor and

manifold shall not be dismounted. During the end

of operation or manifold replacement, before manifolds

dismounting is necessary to switch over the possible regulation

loop to manual operation or accept another suitable measure to

prevent any possible damages connected with end of service

of the pressure sensor. Then the supply of pressure medium

is closed, pressure medium from the sensor and manifold is

discharged and the manifold is dismounted.

2.2 Disposal

The products do not contain any environmentally

hazardous parts. When disposing packages, destroyed

or irreparably damaged products, proceed according to

local regulations.

1.4 Storage

The products shall be stored at temperatures from -20 to +50

°C and maximum relative humidity 80 % in the rooms with

elimination of condensation of water vapours on the products.

The stored products shall not be exposed to any shocks,

vibrations and effects of harmful vapours and gases.

1.5 Installation and commissioning

During installation, commissioning, operation and maintenance

follow the instructions in chapter 4.

1.6 Spare parts

Any of the compact parts of the product can be also ordered

as a spare part if there is not required special procedures

or technological operations for the exchange.

1.7 Repairs

Products are repaired by the manufacturer. The products for

repair should be sent in a packing that guarantees damping

of shocks and vibrations and protects against damage during

transport.

1.8 Warranty

Products are covered by a warranty for a period of 24 months

from the delivery date on the delivery note. The manufacturer

guarantees technical and operational parameters of the

products within scope of the applicable documentation.

Warranty period is specified with individual items and begins

from the day of takeover of the goods by the purchaser or

delivery to the carrier. Any claims concerning to defects of the

goods together can be filed in writing with the manufacturer

within the warranty period and the claimed product shall be

- 3 -

Valves VS 100, VS 110, VS 120 and Two Valve Manifolds VS 200

3. Product description

VS 100, VS 110, VS 120, VS 200

Isolating Vent Valve

Isolating Valve

Testing Vent Valve

Two Valve Manifold

Operating pressure up to 42 MPa.

•

Operating temperature up to 500 °C.

•

Material stainless steel 1.4541.

•

Sealing component selection from different

•

material: Graphite, PTFE, PEEK, Viton, EPDM.

Gland packing adjuster.

•

Seat diameter 4 mm.

•

EU Type Examination Certificate

•

according to Directive PED 2014/68/EU.

3.1 Application

Isolating valves are used to shut off the supply of pressured

medium to the pressure sensor. In addition, the valve type with

a small deaeration valve (VS 100, VS 120) allows discharge of

mud or deaeration of the impulse piping. VS 120 valve, thanks

to the side screwing, allows connection of other equipment to

pressure medium. Individual types of the valves are designed

for direct installation on a pressure sensor or for installation

between the impulse piping.

The two valve manifold VS 200 is used to shut off the supply

of pressured medium to the pressure sensor, allows discharge

of mud or deaeration of the impulse piping and possibly serves

to connect other equipment to pressure medium. The manifold

is designed for direct installation on a pressure sensor or for

installation between the impulse piping.

3.2 Description

All parts of the valve is made of stainless steel 1.4541 except

the sealing ball and spindle gland. As a sealing element of the

valve is used a ball, embedded into the valve spindle face and

closing the through seat with diameter 4 mm. Material of the

sealing ball is optional; it could be made of quenched stainless

steel 1.4125, ceramics Si3N4 or plastic PTFE 325. The valve

spindle of the standard version is sealed using a FPM (Viton)

or EPDM O-ring; in both cases with two Teflon supporting rings.

In case of valves with gland packing adjuster it is possible to

choose the sealing material PTFE, Graphite or PEEK. The

wide range of dimensions of the input and output screwing

allows installation of the valve into a welded on piece, on a

sleeve with a transition connection, into a sensor screwing or

connection of the impulse piping using a welding on nipple,

welding on plow or single cutting ring for piping diameters 8, 10

mm, or double cutting ring for piping diameters 12 or 14 mm.

3.3 Dimensional drawings

VS 100, VS 110

VS 200

2x M10

28

71

169

VS 100, VS 110, VS 120 VS 120

66 ÷ 82 (acc. to connection threads)

Vent screw

only for VS 100, VS 120

26 23

49

- 4 -

Valves VS 100, VS 110, VS 120 and Two Valve Manifolds VS 200

4. Installation, operation and maintenanceu

4.1 Installation and commissioning

4.1.1 General

The shut off valve is fixed using a connecting screwing,

between the impulse piping or directly on the pressure

sensor. The impulse piping with diameter 12 or 14 mm

is connected by welding to the plow or nipple, see Fig. 2. To

ensure correct position of the nipple or plow, after installation it

shall be welded together with the shut off valve.

Before installation, the impulse piping shall be cleaned from all

dirt. After welding it shall be disconnected from the manifold

and purged to remove any possible dirt from welding.

Piping with outer diameter 8, 10, 12 or 14 mm can be also

connected by using a cutting ring. The minimum length of the

impulse piping to the first bend shall be 33 mm from the pipe

face. The pipe face shall be cut off perpendicularly and the inner

and outer edges shall be deburred. To prevent penetration of

any possible dirt between the contact surfaces, all part shall be

properly cleaned before installation.

Before connection of the sensor it is recommended to test correctness of connection (welding) of the shut off valve by pressurization of the impulse piping.

When both connections of threaded parts are made of

stainless steel, there is danger of galling (formation of

cold weld). This can also occur during ordinary screwing by hand without using tightening key. If the cold weld is

made, the thread is then damaged and parts are unusable. Before first screwing, it is therefore necessary to check whether

threads are free of impurities (and clean if needed) and then

treat the threads against galling (formation of cold weld) by

appropriate lubricant. For example use paste G-Rapid plus or

Lukosan M11 (in case of connection for oxygen). For tapered

threads is usually used Teflon tape. Threads with silver covered

surface do not have to be lubricated against galling.

4.1.2 Commissioning

After connection or welding of the impulse piping the shut

offvalve is ready for operation.

After installation of a shut off valve into piping it is necessary to

carry out deaeration of the piping. Deaeration for shut off valve

VS 100 and VS 120 can be done by deaeration screw M6. In

another case the deaeration is done by releasing of air bubbles

by knocking on the piping. The whole system can be flooded

by condensate when the thermal circuit is shut down and the

valve is closed.

In case of a leakage of the spindle gland with valve having

gland packing adjuster, the leakage can be eliminated by

tightening the adjuster screw and the lock nut.

4.1.3 Cleaning the manifold

Clogged manifold may be cleaned only if pressure

medium in the impulse piping is completely disconnected.

Before cleaning of a clogged fitting, screw out the small

valve(s) from the basic body. First remove the valve lock

pin, then screw out the valve and clean the interconnection

channels eventually the valve seat. When cleaning the fitting,

pay attention to the seating (sealing) edge of the valve to

prevent its damage.

Before installation of the valve into the fitting body it is

necessary to screw in the valve spindle up to the stop into the

valve body. To improve tightening and sealing of the valve in the

fitting it is recommended to apply a Teflon tape or a liquid Teflon

compound on the seating surface behind the valve threads.

Tighten the valve to 55 Nm and then press in the locking pin.

In case of cleaning of a manifold designed for use with

oxygen, avoid staining of individual parts of the manifold

with grease. The threads and sealing joints may be

lubricated only by a paste approved for use with oxygen.

4.2 Interconnection diagram

VS 100 VS 110 VS 120 VS 200

4.3 Examples of mounting of the manifolds in operation

Bracket for wall mounting Bracket for pipe mounting Shim for mounting of VS 200

- 5 -

Valves VS 100, VS 110, VS 120 and Two Valve Manifolds VS 200

4.4 Examples of mounting with brackets

4.5 Connection of impulse piping by means of cutting rings

21 4

3

Max. deviation 0.5°

Max. odchylka 0,5°. Odhrotovat hrany trubky.

Deburr edges of the pipe.

5 6

Clean threads and contact surfaces.

Očistit závity a styčné plochy.

87 109

Nasadit matici a kroužek

Install a nut and ring on the pipe.

na trubku.

Correct

správně

Slide in the pipe down to

Trubku zasunout na dno

Wrong

špatně

* Tighten by 1 1/2 turn for single cutting ring (codes 04, 13) and by 1 1/4 turn for double cutting ring (codes 22, 24).

* O 1 1/2 otáčky pro jednoduchý zářezný kroužek (kódy 04, 13) a o 1 1/4 otáčky pro dvojitý zářezný kroužek (kódy 22, 24)

the bottom and tighten it

a matici dotáhnout rukou. Označit polohu matice.

by hand.

Mark position of the nut.

Tighten the nut using a wrench*

Dotáhnout matici

klíčem

- 6 -

.*

Valves VS 100, VS 110, VS 120 and Two Valve Manifolds VS 200

4.6 Operation and maintenance

The device is attendance- and maintenance-free.

Only in case of a leakage of the spindle gland (version with

gland packing adjuster), the leakage can be eliminated by

tightening the adjuster screw (position 4). Before tightening

the screw loosen the lock nut (position 5). Tightening torque of

gland packing adjuster is 15 Nm. After tightening the adjuster

retighten the lock nut.

2

4

9

5

1

6

8

7

8

3

1 - Valve body

2 - Spindle

3 - Seat packing

4 - Vent screw

5 - Nut

6 - Pressure ring

7 - Carrier ring

8 - Gland packing

9 - Tag

5. Product specifications

5.1 Technical specifications

Operation pressure:

up to 42 MPa

Operation temperature:

up to 500 °C

5.2 Supplementary parameters

Materials:

manifold body stainless steel 1.4541

sealing ball of valve stainless steel 1.4125

(X105CrMo17)

ceramics Si3N4,

plastic PTFE 325

vent screw stainless steel 1.4034

O-ring EPDM, Viton

carrier rings teflon

dust cap silicone rubber

gland packing adjuster PTFE, Graphite, PEEK

welding nipple carbon steel 1.0570

steel 1.7715

stainless steel 1.4541

welding cone carbon steel 1.0570

steel 1.7715

stainless steel 1.4541

cutting ring stainless steel 1.4571

Weight without accessories:

VS 100 0.35 kg

VS 110 0.32 kg

VS 120 0.45 kg

VS 200 1.1 kg

- 7 -

Valves VS 100, VS 110, VS 120 and Two Valve Manifolds VS 200

Table 1.

Chemical resistance of sealing materials

Medium Viton EPDM PTFE Grafit PEEK

Acetone - - + + +

Acetylene + + + + +

Gas + - + + +

Water solution - + + + +

Ammoniac

Ethylene + + + +

Hydraulic liquids Fireproof * - + + +

Hydroxides * + + + +

Boracic acid + + + +

Lemon acid + + + +

Nitric acid - - + + +

Fluoric acid

Phosphoric acid

Hydrochloric acid

Chromic acid + * +

Malic acid + + +

Carbolic acid - - +

Hydrocyanic acid + * +

Butyric acid * +

Lactic acid + + + +

Formic acid 10 % - * + + +

Acetous acid

Salicylic acid + + +

Sulphuric acid

Oxalic acid 10 % + + + +

Carbonic acid + + + +

Tartaric acid + + + + +

Oxygen + + + + +

Methane + - + + +

Oils + - + + +

Steam

Perchlorethylen + - + + +

Burning oil + - + + +

Gas fuels + - + + +

Propane + butane + - + + +

Radioactive radiation * * - * +

Compressed air + + + +

Toluene * - + +

Heating gases + - + + +

Hydrocarbons + - + +

Water

Hydrogen

Air

Natural gas + + + + +

+ Perfect resistance * Good resistance - No resistance

Liquid - + + +

Fluid * - + +

< 65 % * * + + > 65 % * * + 10 % + + + + +

Concentrate + + + +

Boiling concentrate + + + *

10 %, 80 °C * + + +

36 %, 20 °C * + + +

10 % - * + + +

Concentrate - - +

25 % * + + + +

80 % - * + + -

< 200 °C * * + + +

> 200 °C - - - + -

< 80 °C + + + + +

> 80 °C + + + + +

Cold + + + + +

Warm + + + + +

< 200 °C + + + + +

- 8 -

Valves VS 100, VS 110, VS 120 and Two Valve Manifolds VS 200

E-F

ucpávka PTFE

Tlak

AE

A-CO-kroužek EPDM

E-F

E-G

E-H

E-J

ucpávka PTFE

PEEK

GRAFIT+sedlo 1.4125

ucpávka

ucpávka

ucpávka GRAFIT+sedloSiN

34

BF

Teplota [°C]

-100

0

-55

420

220

250

150

-25

50

0

100

200

300

400

200 300 400 500

Tlak

Tlak

[bar]

CG

DH

J

260

100

5.3 Operation conditions

The manifolds are designed and manufactured for operation

in environment defined by conditions IE36 according to the

standard EN 60721-3-3 and technical regulation PT 500026.

Pressure and temperature characteristics

The operating characteristics of a manifold are given by

pressure and temperature, see Fig. 1. These characteristics

determine conditions for use of the manifold. The operating

variables pressure and temperature are in particular given

by the material used for the basic body, by valve and by

material of sealing elements of the valve seat and spindle.

When selecting material of sealing elements, it is needed to

take into account also condition of the operating fluid and its

corrosiveness with regard to the sealing materials and material

of the manifold. For steam is mostly used sealing of seat by

a steel ball (1.4125) with a graphite gland. A ceramic ball of

Si3N4 is used for corrosive chemicals and a soft ball of PTFE

325 is used for gases. Chemical resistances of gland sealing

materials see Table 1.

Figure 1.

The scope of application of the valve set depending on temperature and pressure

Pressure Pressure

[bar]

400

A - C O-ring EPDM

B - D O-ring VITON

B-D O-kroužek VITON

A - D Seat PTFE 325

A-D sedlo PTFE 325

[bar]

400

420

E - F Gland PTFE

E - G Gland PEEK

E-G

ucpávka

E - H Gland GRAPHITE + seat 1.4125

E-H

ucpávka

E - H Gland GRAPHITE + seat Si3N

E-J

ucpávka GRAFIT+sedloSiN

PEEK

GRAFIT+sedlo 1.4125

4

34

300

200

100

150

0

-100

-55

0

130

200

100

Teplota[°C]

Temperature [°C]

50

-15

300

200

100

250

220

150

0

-100

-55

-25

50

0

100

260

200 300 400 500

Temperature [°C]

J

Teplota [°C]

Table 2:

Maximal values of temperature and pressure depending on material of the sealing seat (ball) and material of the valve

spindle gland

Material of the

sealing seat

Steel 1.4125

(X105CrMo17)

Ceramics

Fluoroplastic

PTFE 325

(ball)

Pressure Temperature Pressure Temperature Pressure Temperature Pressure Temperature Pressure Temperature

40 MPa 100 °C 40 MPa 100 °C 42 MPa 100°C 42 MPa 100 °C 30 MPa 100 °C

20 MPa 130 °C 20 MPa 200 °C 25 MPa 200°C 15 MPa 260 °C 22 MPa 400 °C

40 MPa 100 °C 40 MPa 100 °C 42 MPa 100°C 42 MPa 100 °C 30 MPa 100 °C

Si3N

4

20 MPa 130 °C 20 MPa 200 °C 25 MPa 200°C 15 MPa 260 °C 20 MPa 500 °C

30 MPa 50 °C 30 MPa 50 °C 30 MPa 50°C 30 MPa 50 °C - 20 MPa 130 °C 15 MPa 200 °C 15 MPa 200°C 15 MPa 200 °C - -

EPDM Viton (FPM) PTFE PEEK Graphite

Material of the sealing valve spindle gland

- 9 -

Valves VS 100, VS 110, VS 120 and Two Valve Manifolds VS 200

6. Tests, certificates and standards

6.1 Tests and certificates

Valves and manifolds VS have the following certificates and

approvals according to PED 2014/68/EU:

EU Type Examination Certificate No. 10.598.661, TÜV CZ

s.r.o., Novodvorská 994, 142 21 Praha 4, Czech Republic, VAT:

CZ63987121, dated 18. 5. 2017.

6.2 Marking and type tag information

Coding on the valve body VS 100, VS 110, VS 120:

Example:

VS 120 0101 10 type number

40 MPa (100 °C) maximal operation pressure

up to temperature

200 °C (20 MPa) maximal operation temperature

up to pressure

CE1017 marking of conformity and number

of notified body, that makes

approval

99091234 serial number

2017 year of manufacture

Czech Republic country of origin

www.jsp.cz website address

Coding on the valve:

Code on the hexagon of the valve:

V O-ring Viton or

V- KY version for oxygen

E O-ring EPDM or

E-KY version for oxygen

T sealing PTFE or

T-KY version for oxygen

P sealing PEEK

G sealing Graphite

Aluminium tag on the manifold:

ISOLATING VALVE

UZAVÍRACÍ VENTIL marking of isolating valve

EQUALISING VALVE

PROPOJOVACÍ VENTIL marking of equalising valve

DRAIN VALVE

ODKALOVACÍ VENTIL marking of drain valve

Tag on valve with gland packing adjuster (PTFE, Graphite and

PEEK glands) is made of stainless steel.

7. Optional accessories

The direction of the flow is marked by arrow on the valve body.

Coding on the manifold body VS 200:

Example:

VS 200 0101 10 B01 type number

40 MPa (100 °C) maximal operation pressure

up to temperature

200 °C (20 MPa) maximal operation temperature

up to pressure

CE1017 marking of conformity and number

of notified body, that makes

approval

99091234 serial number

2017 year of manufacture

Czech Republic country of origin

logo of JSP, s.r.o.

www.jsp.cz website address

The direction of the flow is marked by arrow on the manifold body.

7.1 Optional accessories to connection of

impulse piping

- 10 -

Valves VS 100, VS 110, VS 120 and Two Valve Manifolds VS 200

Description

Male thread M20x1.5 manometric

02

04

05

06

∅∅∅∅

∅∅∅∅

Male thread M20x1.5 manometric

∅∅∅∅

∅∅∅∅

Code

B01

Male thread M20x1.5 manometric

∅∅∅∅

∅∅∅∅

•••

•

•

•

•

•

•

•

•

•

•

8. Ordering information

8.1 Ordering table

Type

VS 100

VS 110

VS 120

Code

•

Code

•

Code

•

Code

One-way vent valve

One-way valve

Testing one-way vent valve

Version of inlet thread

01

Male thread M20x1.5 with tapered seat

Male thread M16x1.5 with tapered seat (only for cutting ring, diameter of 8 mm)

Male thread M20x1.5L (left)

Male thread G1/2" manometric

Male thread 1/2"-14 NPT

07

Male thread 1/4"-18 NPT

08

Female thread 1/4"-18 NPT

11

Female thread 1/2"-14 NPT

12

Male thread M18x1.5 with tapered seat (only for cutting ring, diameter of 10 mm)

13

Double cutting ring for piping

22

Double cutting ring for piping

24

99

Other

Version of outlet thread

01

Male thread M20x1.5 with tapered seat

02

Male thread M16x1.5 with tapered seat (only for cutting ring, diameter of 8 mm)

04

Male thread M20x1.5L (left)

05

Male thread G1/2" manometric

06

Male thread 1/2"-14 NPT

07

Male thread 1/4"-18 NPT

08

Female thread 1/4"-18 NPT

11

Female thread 1/2"-14 NPT

12

Male thread M18x1.5 with tapered seat (only for cutting ring, diameter of 10 mm)

13

Double cutting ring for piping

22

Double cutting ring for piping

24

99

Other

Sealing valve spindle material / application

O-ring / EPDM - pmax 40 MPa, for ammoniac, for air up to 95 °C (not suitable for DEMI water!)

0

O-ring / Viton - pmax 40 MPa, for water and DEMI water up to 100 °C, for air up to 200 °C

1

Gland / PTFE - pmax 42 MPa, Tmax=200 °C

5

Gland / Graphite - pmax 30 MPa, Tmax=500 °C

6

7

Gland / PEEK - pmax 42 MPa, Tmax=260 °C

9 Other

Sealing ball material

Steel 1.4125 up to 400 °C

0

Ceramic Si3N4 up to 500 °C

3

Plastic PTFE 325 up to 200 °C/15 MPa, up 50 °C/30 MPa (not for sealing valve spindle Graphite and PEEK)

5

9

Other

OPTIONAL ACCESSORIES ONLY FOR VS 120

Version of side thread

12 mm, cap nut with silver-plated thread, material AISI 316

14 mm, cap nut with silver-plated thread, material AISI 316

12 mm, cap nut with silver-plated thread, material AISI 316

14 mm, cap nut with silver-plated thread, material AISI 316

Male thread M20x1.5 with tapered seat

B02

Male thread M16x1.5 with tapered seat (only for cutting ring, diameter of 8 mm)

B04

Male thread M20x1.5L (left)

B05

Male thread G1/2" manometric

B06

Male thread 1/2"-14 NPT

B07

Male thread 1/4"-18 NPT

B08

Male thread M20x1.5 cylindrical (without neck for centring seal)

B10

Female thread 1/4"-18 NPT

B11

Female thread 1/2"-14 NPT

B12

Male thread M18x1.5 with tapered seat (only for cutting ring, diameter of 10 mm)

B13

Double cutting ring for piping

B22

Double cutting ring for piping

B24

B99

Other

Code Reducing connection Material Only for thread codes

Code

M01 Nut M20x1.5 Stainless steel 1.4541 (B) 01; 10

M05 Nut M20x1.5L Stainless steel 1.4541 (B) 05

M06 Nut G1/2" Stainless steel 1.4541 (B) 06

M11 Plug 1/4"-18 NPT Stainless steel 1.4541 (B) 11

M99 Other

OPTIONAL ACCESSORIES

P1 M20x1.5L / M20x1.5 Carbon steel 1.0715 (B) 01; 05; 10

P2 M20x1.5L / M20x1.5 Stainless steel 1.4301 (B) 01; 05; 10

P3 M20x1.5L / G1/2" Carbon steel 1.0715 (B) 05; 06

P4 M20x1.5L / G1/2" Stainless steel 1.4021 (B) 05; 06

P9 Other

Blinding nut and plug

• ... Ex stock version ° ... Marked version can be dispatched up to 10 working days

12 mm, cap nut with silver-plated thread, material AISI 316

14 mm, cap nut with silver-plated thread, material AISI 316

Material Only for thread codes

- 11 -

Valves VS 100, VS 110, VS 120 and Two Valve Manifolds VS 200

∅∅∅∅

∅∅∅∅

∅∅∅∅

∅∅∅∅

∅∅∅∅

∅∅∅∅

∅∅∅∅

∅∅∅∅

∅∅∅∅

∅∅∅∅

∅∅∅∅

3

Stainless steel 1.4301

Stainless steel 1.4301

5 —Stainless steel 1.4571, silver-plated thread (not for Z10)

9

Other

—

Code

Sealing (not for cones and cutting rings)

Flat sealing,

∅∅∅∅

17/6.5 - 2 mm, material copper

Flat sealing,

∅∅∅∅

17/6.5 - 2 mm, material aluminium

Comb sealing,

∅

17/6.5 - 3.5 mm, material stainless steel 1.4541

Special version

•

Code Nipples, cones and cutting rings Only for thread codes

V12 ..

V14 ..

K12 ..

K14 ..

Z08 ..

Z10 ..

Code Nipple or cone material Cutting ring material

•

•

•

Code Material of nut for nipples or cones Material of nut for cutting ring

Code Supplements

•

•

•

Code

Example of order: VS 100 0101 10 V1210(2x) CU(2x)

Nipple for welding

Nipple for welding

Cone for welding

Cone for welding

Cutting ring for piping

Cutting ring for piping

1 Carbon steel 1.0570 —

2 Structural alloy steel 1.7715 —

4 Stainless steel 1.4541 —

5 — Stainless steel 1.4571

9 Other —

0 Galvanized carbon steel 1.0715 Galvanized carbon steel 1.0715

CU

AL

OC

GR G-Rapid plus paste (50 g) against thread seizure and for easy installation (not for oxygen)

LU Lukosan M11 paste (50 g) for lubricating of O-rings, threads and for oxygen application

TT Liquid teflon paste for high temperatures and for valves reassembling

KL Control valve handle for high temperatures

Q1 Material certificate of manifold body according to EN 10204, 3.1

TZ Pressure test

PL Adjustment of valve handle for sealing

KY Degrease version for oxygen (not for Graphite)

• ... Ex stock version ° ... Marked version can be dispatched up to 10 working days

12 (

14)/

14/

12/

14/

8 mm with cap nut M20x1.5

8 mm with cap nut M20x1.5

8 mm with cap nut M20x1.5

8 mm with cap nut M20x1.5

8 mm (±0.06 mm) with cap nut M16x1.5

10 mm (±0.07 mm) with cap nut M18x1.5

(B) 01

(B) 01

(B) 02

(B) 02

(B) 04

(B) 13

- 12 -

Valves VS 100, VS 110, VS 120 and Two Valve Manifolds VS 200

Male thread M20x1.5 manometric

Male thread G1/2" manometric

∅∅∅∅

24

∅∅∅∅

Code

01

Male thread M20x1.5 manometric

Male thread G1/2" manometric

∅∅∅∅

∅∅∅∅

Male thread M20x1.5 manometric

Male thread G1/2" manometric

B11

B12

B13

B22

∅∅∅∅

∅∅∅∅

Type

VS 200

Code

Code

Code

Code

Code

Code

M01 Nut M20x1.5 Stainless steel 1.4541 (B) 01; 10

M05 Nut M20x1.5L Stainless steel 1.4541 (B) 05

M06 Nut G1/2" Stainless steel 1.4541 (B) 06

M11 Plug 1/4"-18 NPT Stainless steel 1.4541 (B) 11

M99 Other

Description

Two-way manifold

Version of inlet thread

01

Male thread M20x1.5 with tapered seat

02

Male thread M16x1.5 with tapered seat (only for cutting ring, diameter of 8 mm)

04

Male thread M20x1.5L (left)

05

06

Male thread 1/2"-14 NPT

07

Male thread 1/4"-18 NPT

08

Female thread 1/4"-18 NPT

11

Female thread 1/2"-14 NPT

12

Male thread M18x1.5 with tapered seat (only for cutting ring, diameter of 10 mm)

13

Double cutting ring for piping

22

Double cutting ring for piping

99

Other

Version of outlet thread

Male thread M20x1.5 with tapered seat

02

Male thread M16x1.5 with tapered seat (only for cutting ring, diameter of 8 mm)

04

Male thread M20x1.5L (left)

05

06

Male thread 1/2"-14 NPT

07

Male thread 1/4"-18 NPT

08

Female thread 1/4"-18 NPT

11

Female thread 1/2"-14 NPT

12

Male thread M18x1.5 with tapered seat (only for cutting ring, diameter of 10 mm)

13

Double cutting ring for piping

22

Double cutting ring for piping

24

99

Other

Sealing valve spindle material / application

O-ring / EPDM - pmax 40 MPa, for ammoniac, for air up to 95 °C (not suitable for DEMI water!)

0

O-ring / Viton - pmax 40 MPa, for water and DEMI water up to 100 °C, for air up to 200 °C

1

Gland / PTFE - pmax 42 MPa, Tmax=200 °C

5

Gland / Graphite - pmax 30 MPa, Tmax=500 °C

6

7

Gland / PEEK - pmax 42 MPa, Tmax=260 °C

9 Other

Sealing ball material

Steel 1.4125 up to 400 °C

0

Ceramic Si3N4 up to 500 °C

3

Plastic PTFE 325 up to 200 °C/15 MPa, up 50 °C/30 MPa (not for sealing valve spindle Graphite and PEEK)

5

9

Other

Version of side thread

B01

Male thread M20x1.5 with tapered seat

B02

Male thread M16x1.5 with tapered seat (only for cutting ring, diameter of 8 mm)

B04

Male thread M20x1.5L (left)

B05

B06

Male thread 1/2"-14 NPT

B07

Male thread 1/4"-18 NPT

B08

Male thread M20x1.5 cylindrical (without neck for centring seal)

B10

Female thread 1/4"-18 NPT

Female thread 1/2"-14 NPT

Male thread M18x1.5 with tapered seat (only for cutting ring, diameter of 10 mm)

Double cutting ring for piping

Double cutting ring for piping

B24

B99

Other

OPTIONAL ACCESSORIES

Reducing connection Material Only for thread codes

P1 M20x1.5L / M20x1.5 Carbon steel 1.0715 (B) 01; 05; 10

P2 M20x1.5L / M20x1.5 Stainless steel 1.4301 (B) 01; 05; 10

P3 M20x1.5L / G1/2" Carbon steel 1.0715 (B) 05; 06

P4 M20x1.5L / G1/2" Stainless steel 1.4021 (B) 05; 06

P9 Other

Blinding nut and plug

• ... Ex stock version ° ... Marked version can be dispatched up to 10 working days

12 mm, cap nut with silver-plated thread, material AISI 316

14 mm, cap nut with silver-plated thread, material AISI 316

12 mm, cap nut with silver-plated thread, material AISI 316

14 mm, cap nut with silver-plated thread, material AISI 316

12 mm, cap nut with silver-plated thread, material AISI 316

14 mm, cap nut with silver-plated thread, material AISI 316

Material Only for thread codes

- 13 -

Valves VS 100, VS 110, VS 120 and Two Valve Manifolds VS 200

∅∅∅∅

∅∅∅∅

∅∅∅∅

∅∅∅∅

∅∅∅∅

∅∅∅∅

∅∅∅∅

∅∅∅∅

∅∅∅∅

∅∅∅∅

∅∅∅∅

0

Galvanized carbon steel 1.0715

Galvanized carbon steel 1.0715

3

Stainless steel 1.4301

Stainless steel 1.4301

5 —Stainless steel 1.4571, silver-plated thread (not for Z10)

9

Other

—

Flat sealing,

∅∅∅∅

17/6.5 - 2 mm, material copper

Flat sealing,

∅∅∅∅

17/6.5 - 2 mm, material aluminium

Comb sealing,

∅

17/6.5 - 3.5 mm, material stainless steel 1.4541

∅∅∅∅

Pressure test

•

•

•

•

•

•

•

•

•

•

Code Nipples, cones and cutting rings Only for thread codes

V12 ..

V14 ..

K12 ..

K14 ..

Z08 ..

Z10 ..

Code Nipple or cone material Cutting ring material

Code Material of nut for nipples or cones Material of nut for cutting ring

Code Sealing (not for cones and cutting rings)

•

Code Mounting brackets

DS21 Bracket for wall mounting of VS 200

•

DT21

•

Code Supplements

Code Special version

Example of order: VS 200 0101 13 B01 P2 Z1450 CU

Nipple for welding

Nipple for welding

Cone for welding

Cone for welding

Cutting ring for piping

Cutting ring for piping

1 Carbon steel 1.0570 —

2 Structural alloy steel 1.7715 —

4 Stainless steel 1.4541 —

5 — Stainless steel 1.4571

9 Other —

CU

AL

OC

Bracket for pipe mounting (max.

GR G-Rapid plus paste (50 g) against thread seizure and for easy installation (not for oxygen)

LU Lukosan M11 paste (50 g) for lubricating of O-rings, threads and for oxygen application

TT Liquid teflon paste for high temperatures and for valves reassembling

KL Control valve handle for high temperatures

Q1 Material certificate of manifold body according to EN 10204, 3.1

TZ

PL Adjustment of valve handle for sealing

KY Degrease version for oxygen (not for Graphite)

• ... Ex stock version ° ... Marked version can be dispatched up to 10 working days

12 (

14)/

14/

12/

14/

8 mm with cap nut M20x1.5

8 mm with cap nut M20x1.5

8 mm with cap nut M20x1.5

8 mm with cap nut M20x1.5

8 mm (±0.06 mm) with cap nut M16x1.5

10 mm (±0.07 mm) with cap nut M18x1.5

63 mm) with clip for VS 200

(B) 01

(B) 01

(B) 02

(B) 02

(B) 04

(B) 13

- 14 -

JSP, s.r.o. | Raisova 547, 506 01 Jičín, Czech Republic

+420 493 760 811 | export@jsp.cz | www.jsp.cz

Your Supplier:

Loading...

Loading...