DUAL STEPPER MOTOR DRIVER

■ GENERAL DESCRIPTION ■ PACKAGE OUTLINE

The NJM3775 is a switch-mode (chopper), constantcurrent driver with two channels: one for each winding

of a two-phase stepper motor. NJM3775 is equipped

with a Disable input to simplify half-stepping operation.

The NJM3775 contains a clock oscillator, which is

common for both driver channels, a set of comparators

and flip-flops implementing the switching control, and

two output H-bridges, including recirculation diodes.

Voltage supply requirements are + 5 V for logic and +

10 to + 45 V for the motor. Maximum output current is

750mA per channel.

■ FEATURES

• Dual chopper driver

NJM3775D2

NJM3775FM2

NJM3775E3

NJM3775

• 750 mA continuous output current per channel

• Digital filter on chip eliminates external filtering components

• Packages DIP22 / PLCC28 / EMP24(batwing)

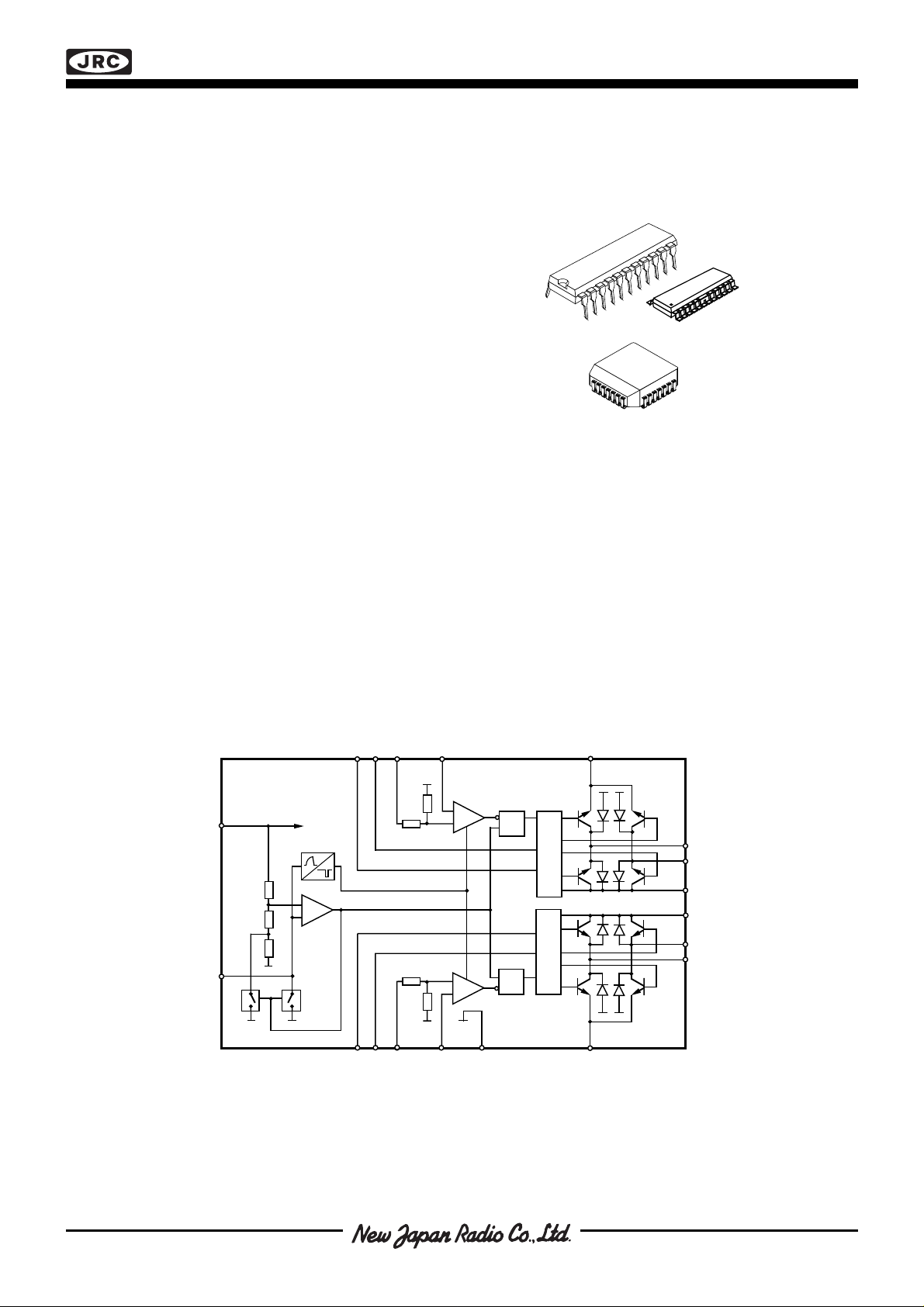

■ BLOCK DIAGRAM

C

Phase

1

NJM3775

V

CC

RC

V

CC

+

—

V

Dis

R1

1

1

—

+

+

—

R

S

SRQ

E

1

Q

M

A1

Logic

Logic

M

B1

V

MM1

V

MM2

M

B2

M

A2

Figure 1. Block diagram

Phase

Dis

V

2

2

R2

GNDC

2

E

2

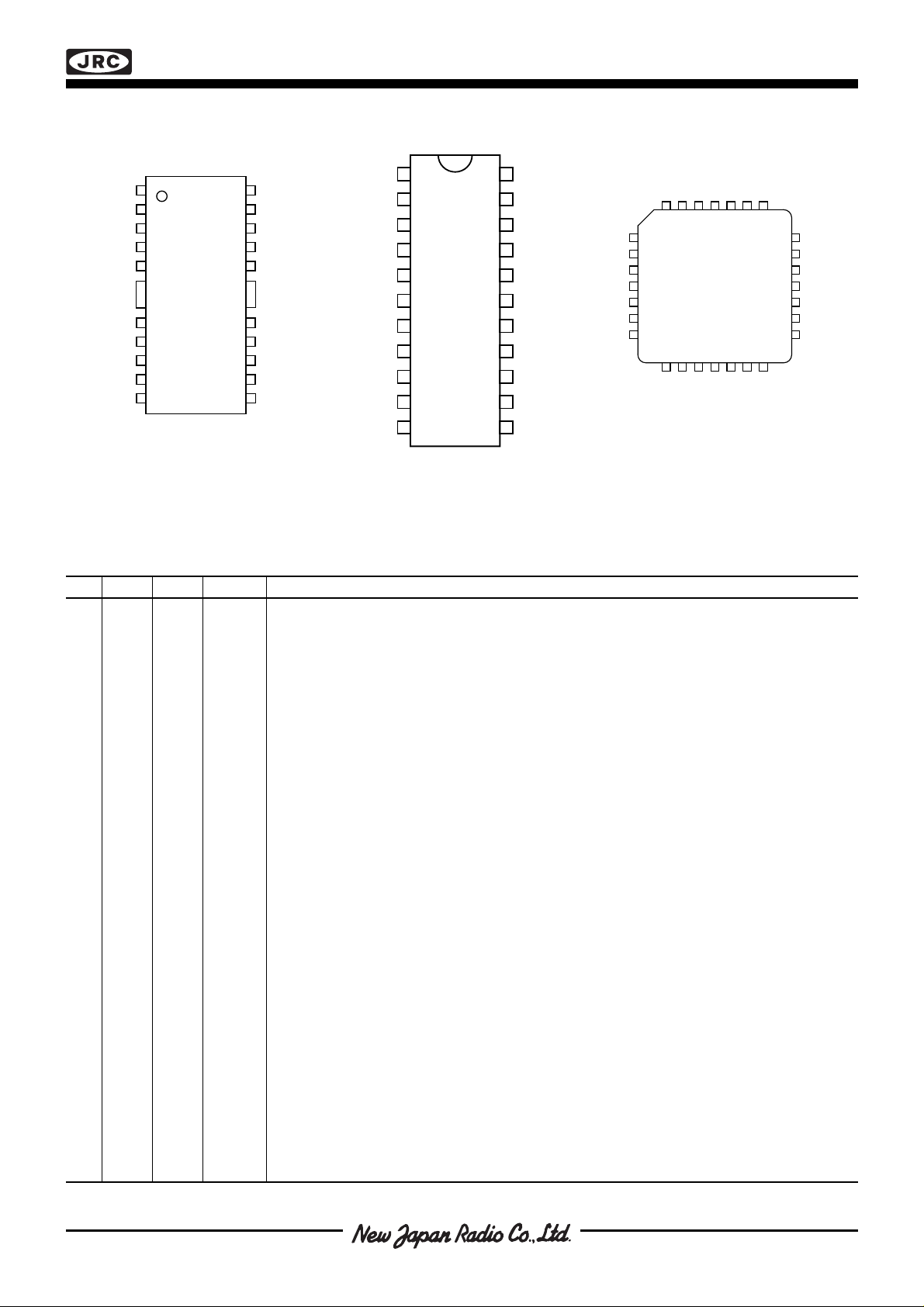

■ PIN CONFIGURATIONS

NC

1

2

MB

1

E

3

1

4

MA

1

5

VMM

GND

GND

VR

Phase

Dis

RC

1

1

C

1

1

1

6

7

8

9

10

11

NJM

3775E3

Figure 2. Pin configurations

24

23

22

21

20

19

18

17

16

15

14

1312

NC

MB

E

2

MA

VMM

GND

GND

VR

C

2

Phase

Dis

V

cc

NJM3775

M

1

B1

E

2

2

2

2

2

2

2

M

V

MM1

GND

GND

V

Phase

Dis

RC

1

A1

R1

C

1

1

1

3

4

5

6

3775D2

7

8

9

10

11

NJM

22

21

20

19

18

17

16

15

14

13

12

M

B2

E

2

M

A2

V

MM2

GND

GND

V

R2

C

2

Phase

Dis

2

V

CC

MM2

GND

GND

V

432

5

M

A2

E

6

2

7

M

B2

8

M

B1

NJM3775FM2

GND

9

E

10

1

11

M

A1

2

12131415161718

MM1

GND

GND

V

GND

1

GND

R2

V

GND

282726

GND

GND

C

25

Phase

2

24

Dis

2

23

V

CC

22

RC

21

Dis

1

20

Phase

1

19

C

1

R1

V

2

■ PIN DESCRIPTION

EMP DIP PLCC Symbol Description

2 1 [8] M

32[10]E

43[11]M

54[12]V

B1

1

A1

MM1

6,7 5, 6, [1-3, 9, GND Ground and negative supply. Note: these pins are used thermally for heat-sinking.

18,19 17, 18 13-17, Make sure that all ground pins are soldered onto a suitably large copper ground plane

28] for efficient heat sinking.

87[18]V

98[19]C

R1

1

10 9 [20] Phase

11 10 [21] Dis

12 11 [22] RC Clock oscillator RC pin. Connect a 12 kohm resistor to V

13 12 [23] V

CC

14 13 [24] Dis

15 14 [25] Phase

16 15 [26] C

17 16 [27] V

20 19 [4] V

21 20 [5] M

22 21 [6] E

23 22 [7] M

2

R2

MM2

A2

2

B2

Motor output B, channel 1. Motor current flows from MA1 to MB1 when Phase1 is HIGH.

Common emitter, channel 1. This pin connects to a sensing resistor RS to ground.

Motor output A, channel 1. Motor current flows from MA1 to MB1 when Phase1 is HIGH.

Motor supply voltage, channel 1, +10 to +40 V. V

MM1

and V

should be connected together.

MM2

Reference voltage, channel 1. Controls the comparator threshold voltage and hence the output

current.

Comparator input channel 1. This input senses the instantaneous voltage across the sensing

resistor, filtered by the internal digital filter or an optional external RC network.

Controls the direction of motor current at outputs MA1 and MB1. Motor current flows from MA1 to

1

M

when Phase1 is HIGH.

B1

Disable input for channel 1. When HIGH, all four output transistors are turned off, which results

1

in a rapidly decreasing output current to zero.

and a 4 700 pF capacitor to ground

CC

to obtain the nominal switching frequency of 23.0 kHz and a digital filter blanking time of 1.0µs.

Logic voltage supply, nominally +5 V.

Disable input for channel 2. When HIGH, all four output transistors are turned off, which results

2

in a rapidly decreasing output current to zero.

Controls the direction of motor current at outputs MA2 and MB2. Motor current flows from MA2 to

2

M

when Phase2 is HIGH.

B2

Comparator input channel 2. This input senses the instantaneous voltage across the sensing

resistor, filtered by the internal digital filter or an optional external RC network.

Reference voltage, channel 2. Controls the comparator threshold voltage and hence the output

current.

Motor supply voltage, channel 2, +10 to +40 V. V

MM1

and V

should be connected together.

MM2

Motor output A, channel 2. Motor current flows from MA2 to MB2 when Phase2 is HIGH.

Common emitter, channel 2. This pin connects to a sensing resistor RS to ground.

Motor output B, channel 2. Motor current flows from MA2 to MB2 when Phase2 is HIGH.

NJM3775

■ FUNCTIONAL DESCRIPTION

Each channel of the NJM3775 consists of the following sections: an output H-bridge with four transistors and four

recirculation diodes, capable of driving up to 750 mA continuous current to the motor winding,

a logic section that controls the output transistors, an S-R flip-flop, and a com- parator. The clock-oscillator is

common

to both channels.

Constant current control is achieved by switching the output current to the windings. This is done by sensing the

peak current through the winding via a current-sensing resistor RS, effectively connected in series with the motor

winding. As the current increases, a voltage develops across the sensing resistor, which is fed back to the comparator. At the predetermined level, defined by the voltage at the reference input VR, the comparator resets the flipflop, which turns off the upper output transistor. The turn-off of one channel is independent of the other channel.

The current decreases until the clock oscillator triggers the flip-flops of both channels simultaneously, which turns

on the output transistors again, and the cycle is repeated.

To prevent erroneous switching due to switching transients at turn-on, the

NJM3775 includes a digital filter. The clock oscillator provides a blanking pulse which is used for digital filtering of

the voltage transient across the current sensing resistor during turn-on.

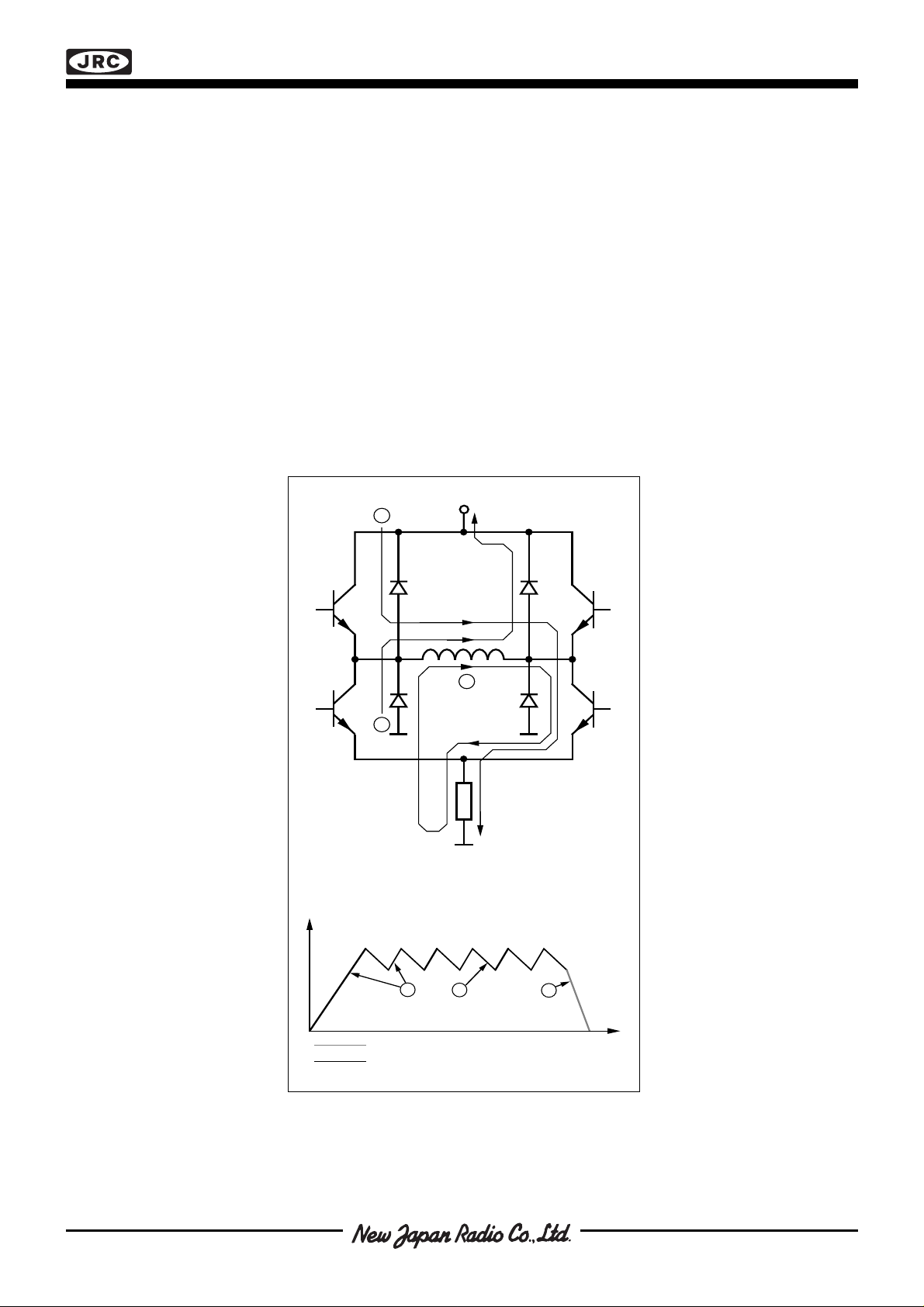

The current paths during turn-on, turn-off and phase shift are shown in figure 3.

V

1

MM

2

3

R

S

Motor Current

1 2

Fast Current Decay

Slow Current Decay

3

Figure 3. Output stage with current paths

during turn-on, turn-off and phase shift.

Time

NJM3775

V

R

t

d

t

50 %

t

on

t

off

| V – V |

MA MB

t

t

V

RC

t

b

V ( I )

E

M

f =

s

t

ontoff

+

1

D =

t

t

on

off

+

t

on

■ ABSOLUTE MAXIMUM RATINGS

Parameter Pin No. (DIP) Symbol Min Max Unit

Voltage

Logic supply 12 V

Motor supply 4, 19 V

Logic inputs 9, 10, 13, 14 V

Analog inputs 7, 8, 15, 16 V

Current

Motor output current 1, 3, 20, 22 I

Logic inputs 9, 10, 13, 14 I

Analog inputs 7, 8, 15, 16 I

Temperature

Operating junction temperature T

Storage temperature T

Power Dissipation (Package Data)

Power dissipation at T

Power dissipation at T

Power dissipation at T

= +25°C, DIP and PLCC package P

GND

= +125°C, DIP package P

GND

= +125°C, PLCC package P

GND

CC

MM

I

A

M

I

A

j

stg

D

D

D

07V

045V

-0.3 6 V

-0.3 V

CC

V

-850 +850 mA

-10 - mA

-10 - mA

-40 +150 °C

-55 +150 °C

-5W

- 2.2 W

- 2.6 W

■ RECOMMENDED OPERATING CONDITIONS

Parameter Symbol Min Typ Max Unit

Logic supply voltage V

Motor supply voltage V

Output emitter voltage V

Motor output current I

Operating junction temperature T

Rise and fall time logic inputs t

Oscillator timing resistor R

E

1

2

Q

Logic

Logic

3

1

4

19

22

20

21

E

2

V

E

R

S

Phase

1

NJM3775

V

I

CC

CC

12

12 kW

R

T

I

RC

RC

11

4 700 pF

V

CC

C

T

I I I

I IH IL

I

I

A

V

I

V

V

A

IH

V

V

R

IL

R

V

RC

9

V

CC

+

—

14

Phase

2

C1V

Dis

R1

1

87

10

—

R

+

S

SRQ

+

—

5, 6, 17, 18

15

16

13

Dis

2

GNDC2V

R2

I

C

I

A

V

CH

V

C

V

A

CC

MM

E

M

j

, t

r,

f

T

M

A1

M

B1

V

MM1

I

V

MM

MM2

M

B2

I I

M OL

M

A2

V

M

V

V

MA

MM

4.75 5 5.25 V

10 - 40 V

- - 1.0 V

-750 - +750 mA

-20 - +125 °C

--2ms

2 12 20 kohm

Figure 4. Definition of symbols

Figure 5. Definition of terms

NJM3775

■ ELECTRICAL CHARACTERISTICS

Electrical characteristics over recommended operating conditions, unless otherwise noted. - 20°C ≤ Tj ≤ + 125°C.

Parameter Symbol Conditions Min Typ Max Unit

General

Supply current I

Supply current I

Total power dissipation P

Total power dissipation P

Thermal shutdown junction temperature - 160 - °C

Turn-off delay t

Logic Inputs

Logic HIGH input voltage V

Logic LOW input voltage V

Logic HIGH input current I

Logic LOW input current I

Analog Inputs

Threshold voltage V

Input current I

|V

| mismatch V

C1—VC2

Motor Outputs

Lower transistor saturation voltage I

Lower transistor leakage current V

Lower diode forward voltage drop I

Upper transistor saturation voltage I

Upper transistor leakage current V

Upper diode forward voltage drop I

Chopper Oscillator

Chopping frequency f

Digital filter blanking time t

Note 4. - 55 70 mA

CC

Dis1= Dis2= HIGH. - 7 10 mA

CC

VMM= 24 V, IM1= IM2= 500 mA. - 2.0 2.3 W

D

Notes 2, 3, 4.

VMM= 24 V, IM1= 700 mA, IM2= 0 mA. - 1.7 2.0 W

D

Notes 2, 3, 4.

TA = +25°C, dVC/dt ≥ 50 mV/µs, - 1.1 2.0 µs

d

I

= 100 mA. Note 3.

M

IH

IL

VI = 2.4 V - - 20 µA

IH

VI = 0.4 V -0.2 -0.1 - mA

IL

CHVR

A

Cdiff

s

b

=5 V 480 500 520 mV

VR= 5 V - 500 - µA

= 500 mA - 0.4 0.8 V

M

=41 V,TA = +25°C. Dis1= Dis2= HIGH. - - 100 µA

MM

= 500 mA - 1.1 1.3 V

M

= 500 mA. - 1.1 1.4 V

M

=41 V,TA = +25°C. Dis1= Dis2= HIGH.

MM

= 500 mA. - 1.1 1.4 V

M

CT = 4 700 pF, RT = 12 kohm 21.5 23.0 24.5 kHz

CT = 4 700 pF. Note 3. - 1.0 - µs

2.0 - - V

- - 0.6 V

-1 -mV

- - 100 µA

.

■ THERMAL CHARACTERISTICS

Parameter Symbol Conditions Min Typ Max Unit

Thermal resistance Rth

Rth

Rth

Rth

Rth

Rth

Notes

1. All voltages are with respect to ground. Currents are positive into, negative out of specified terminal.

2. All ground pins soldered onto a 20 cm

2

PCB copper area with free air convection, TA = + 25° C.

3. Not covered by final test program.

4. Switching duty cycle D = 30 %, f

= 23.0 kHz.

s

DIP package. - 11 - °C/W

J-GND

DIP package. Note 2. - 40 - °C/W

J-A

PLCC package. - 9 - °C/W

J-GND

PLCC package. Note 2. - 35 - °C/W

J-A

EMP package - 13 - °C/W

J-GND

EMP package - 42 - °C/W

J-A

NJM3775

■ APPLICATIONS INFORMATION

Current control

The regulated output current level to the motor winding is determined by the voltage at the reference input and the

value of the sensing resistor, RS. The peak current through the sensing resistor (and the motor winding) can be

expressed as:

I

= 0.1•VR / RS[A]

M,peak

With a recommended value of 0.5 ohm for the sensing resistor RS, a 2.5 V reference voltage will produce an output

current of approximately 500 mA. RS should be selected for maximum motor current. Be sure not to exceed the

absolute maximum output current which is 850 mA. Chopping frequency, winding inductance and supply voltage

also affect the current, but to much less extent.

For accurate current regulation,

the sensing resistor should be a 0.5 -1.0 W precision resistor, i. e. less than 1% tolerance and low temperature coefficient.

+5 V

+5 V

10

14

13

16

12 kΩ

0.1µF

0.1 µF

12 4 19

V

9

Phase

Dis

7

V

Phase

Dis

V

CC

1

1

R1

2

2

R2

RC

11

5, 6,

VV

MM1 MM2

NJM3775

11

215 21

8

3

M

A1

M

1

B1

20

M

A2

22

M

B2

2

ECECGND

2

17, 18

V

MM

+

10 µF

STEPPER

MOTOR

4 700 pF

GND (V )

CC

R

0.47 Ω

S

R

S

0.47 Ω

Pin numbers refer

to DIP package.

GND (V

)

MM

Figure 6. Typical stepper motor driver application with NJM3775.

Direction

Step

Half/Full

Step

V (+5 V)

CC

+

4.7 µ F

6

DIR

7

STEP

10

HSM

11

INH

8

9

GND (V )

CC

4 x

10 kΩ

16

V

CC

4

P

A1

NJM

3517

2

P

fl

B

fl

A

B1

GND

3

9

10

7

14

13

16

12 kΩ

4 700 pF

11

Phase

Dis

V

R1

Phase

Dis

V

R2

RC

0.1 µF

1

2

1

2

5, 6,

17, 18

12 4 19

V

VV

CC

MM1 MM2

NJM3775

1122

215 21

8

R

S

1.0 Ω

1.0 Ω

0.1µ F

3

M

A1

M

1

B1

20

M

A2

22

M

B2

ECECGND

R

S

V

MM

+

10 µF

STEPPER

MOTOR

Pin numbers refer

to DIP package.

GND (V

)

MM

Figure 7. Half stepping system where NJM3517 is used as controller circuit in

order to generate the necessary sequence to the NJM3775.

NJM3775

Current sense filtering

At turn-on a current spike occurs, due to the recovery of the recirculation diodes and the capacitance of the motor

winding. To prevent this spike from reseting the flip-flops through the current sensing comparators, the clock

oscillator generates a blanking pulse at turn-on. The blanking pulse pulse disables the comparators for a short time.

Thereby any voltage transient across the sensing resistor will be ignored during the blanking time.

Choose the blanking pulse time to be longer than the duration of the switching transients by selecting a proper C

value. The time is calculated as:

tb = 210 • CT[s]

As the CT value may vary from approximately 2 200 pF to 33 000 pF, a blanking time ranging from 0.5 µs to 7 µs is

possible. Nominal value is 4 700 pF, which gives a blanking time of 1.0 µs.

As the filtering action introduces a small delay, the peak value across the sensing resistor, and hence the peak

motor current, will reach a slightly higher level than what is defined by the reference voltage. The filtering delay also

limits the minimum possible output current. As the output will be on for a short time each cycle, equal to the digital

filtering blanking time plus additional internal delays, an amount of current will flow through the winding. Typically this

current is 1-10 % of the maximum output current set by RS.

When optimizing low current performance, the filtering may be done by adding an external low pass filter in series

with the comparator C input. In this case the digital blanking time should be as short as possible. The recommended

filter component values are 1 kohm and 820 pF. Lowering the switching frequency also helps reducing the minimum

output current.

To create an absolute zero current, the Dis input should be HIGH.

Switching frequency

The frequency of the clock oscillator is set by the timing components RT and CT at the RC-pin. As CT sets the digital

filter blanking time, the clock oscillator frequency is adjusted by RT. The value of RT is limited to 2 - 20 kohm. The

frequency is approximately calculated as:

fs = 1 / ( 0.77 • RT • CT)

Nominal component values of 12 kohm and 4 700 pF results in a clock frequency of 23.0 kHz. A lower frequency will

result in higher current ripple, but may improve low level linearity. A higher clock frequency reduces current ripple,

but increases the switching losses in the IC and possibly the iron losses in the motor.

T

Phase inputs

A logic HIGH on a Phase input gives a current flowing from pin MA into pin MB.

A logic LOW gives a current flow in the opposite direction. A time delay prevents cross conduction in the H-bridge

when changing the Phase input.

Phase

1

Dis

1

Phase

2

Dis

Thermal resistance [°C/W]

80

70

60

50

40

30

20

5101520

PCB copper foil area [cm ]

PLCC package

DIP package

22-pin

DIP

24-pin

EMP

30 3525

2

28-pin

PLCC

V

140%

100%

V

140%

100%

I

140%

100%

–100%

–140%

I

140%

100%

–100%

–140%

2

R1

R2

MA1

MA2

Full step mode Half step mode Modified half step mode

Figure 8. Typical thermal resistance vs. PC Board

copper area and suggested layout.

Figure 9. Stepping modes

NJM3775

Dis (Disable) inputs

A logic HIGH on the Dis inputs will turn off all four transistors of the output H-bridge, which results in a rapidly

decreasing output current to zero.

VR (Reference) inputs

The Vref inputs of the NJM3775 have a voltage divider with a ratio of 1 to 10 to reduce the external reference

voltage to an adequate level. The divider consists of closely matched resistors. Nominal input reference voltage is 5

V.

Interference

Due to the switching operation of NJM3775, noise and transients are generated and might be coupled into adjacent

circuitry. To reduce potential interference there are a few basic rules to follow:

• Use separate ground leads for power ground (the ground connection of RS), the ground leads of NJM3775, and

the ground of external analog and digital circuitry. The grounds should be connected together close to the GND

pins of NJM3775.

• Decouple the supply voltages close to the NJM3775 circuit. Use a ceramic capacitor in parallel with an electrolytic

type for both VCC and VMM. Route the power supply lines close together.

• Do not place sensitive circuits close to the driver. Avoid physical current loops, and place the driver close to both

the motor and the power supply connector. The motor leads could preferably be twisted or shielded.

Motor selection

The NJM3775 is designed for two-phase bipolar stepper motors, i.e. motors that have only one winding per phase.

The chopping principle of the NJM3775 is based on a constant frequency and a varying duty cycle. This scheme

imposes certain restrictions on motor selection. Unstable chopping can occur if the chopping duty cycle exceeds

approximately 50 %. See figure 5 for definitions. To avoid this, it is necessary to choose a motor with a low winding

resistance and inductance, i.e. windings with a few turns.

It is not possible to use a motor that is rated for the same voltage as the actual supply voltage. Only rated current

needs to be considered. Typical motors to be used together with the NJM3775 have a voltage rating of 1 to 6 V,

while the supply voltage usually ranges from 12 to 40 V.

Low inductance, especially in combination with a high supply voltage, enables high stepping rates. However, to

give the same torque capability at low speed, the reduced number of turns in the winding in the low resistive, low

inductive motor must be compensated by a higher current. A compromise has to be made. Choose a motor with the

lowest possible winding resistance and inductance, that still gives the required torque, and use as high supply

voltage as possible, without exceeding the maximum recommended 40 V. Check that the chopping duty cycle does

not exceed 50 % at maximum current.

Heat sinking

NJM3775 is a power IC, packaged in a power DIP,EMP or PLCC package. The ground leads of the package (the

batwing) are thermally connected to the chip. External heatsinking is achieved by soldering the ground leads onto a

copper ground plane on the PCB.

Maximum continuous output current is heavily dependent on the heatsinking and ambient temperature. Consult

figures 8,10 and 11 to determine the necessary heatsink, or to find the maximum output current under varying

conditions.

A copper area of 20 cm2 (approx. 1.8” x 1.8”), copper foil thickness 35 µm on a 1.6 mm epoxy PCB, permits the

circuit to operate at 2 x 450 mA output current, at ambient temperatures up to 85° C.

Thermal shutdown

The circuit is equipped with a thermal shutdown function that turns the outputs off at a chip (junction) temperature

above 160° C. Normal operation is resumed when the temperature has decreased.

Programming

Figure 9 shows the different input and output sequences for full-step, half-step and modified halfstep operations.

NJM3775

Full-step mode.

Both windings are energized at all the time with the same current, IM1 = IM2. To make the motor take one step, the current

direction (and the magnetic field direction) in one phase is reversed. The next step is then taken when the other phase current

reverses. The current changes go through a sequence of four different states which equal four full steps until the initial state is

reached again.

Half-step mode.

In the half-step mode, the current in one winding is brought to zero before a complete current reversal is made.

The motor will then have taken two half steps equalling one full step in rotary movement. The cycle is repeated, but on the other

phase. A total of eight states are sequenced until the initial state is reached again.

Half-step mode can overcome potential resonance problems. Resonances appear as a sudden loss of torque at one or more

distinct stepping rates and must be avoided so as not to loose control of the motor´s shaft position.

One disadvantage with the half-step mode is the reduced torque in the half step positions, in which current flows through one

winding only. The torque in this position is approximately 70 % of the full step position torque.

Modified half-step mode.

The torque variations in half step mode will be elimi-nated if the current is increased about 1.4 times in the halfstep position. A

constant torque will further reduce resonances and mechanical noise, resulting in better performance, life expectancy and

reliability of the mechanical system.

Modifying the current levels must be done by bringing the reference voltage up (or down) from its nominal value correspondingly.

This can be done by using DACs or simple resistor divider networks. The NJM3775 is designed to handle about 1.4 times higher

current in one channel on mode, for example 2 x 500 mA in the full-step position, and 1 x 700 mA in the half-step position.

■ TYPICAL CHARACTERISTICS

PD (W)

Maximum allowable power dissipation [W]

6

V

CE Sat

NJM3775

(V)

3.0

2.0

1.0

Two channels on

One channel onOne channel onOne channel on

0

0 0.20 0.40 0.60 0.80

I

(A)

M

Figure 10. Power dissipation vs.

motor current.Ta = 25°C.

V

(V)

d, ld

1.2

1.0

0.8

0.6

5

4

3

2

1

0

Ambient temperature

0 25 50 75 125 150

-25

Temperature [°C]

PLCC package

DIP package

All ground pins soldered onto a

20 cm PCB copper area with

free air convection.

B

atw

ing

pin tem

perature

100

2

Figure 11. Maximum allowable power

dissipation.

V

(V)

CE Sat

1.2

1.0

0.8

0.6

1.2

1.0

0.8

0.6

0.4

0.2

0

0 0.20 0.40 0.60 0.80

I

(A)

M

Figure 12. Typical lower transistor

saturation voltage vs. output current.

(V)

V

d, ud

1.2

1.0

0.8

0.6

0.4

0.2

0

0 0.20 0.40 0.60 0.80

I

(A)

M

Figure 11. Typical lower diode voltage

drop vs. recirculating current.

0.4

0.2

0

0 0.20 0.40 0.60 0.80

I

(A)

M

Figure 12. Typical upper transistor

saturation voltage vs. output current.

0.4

0.2

0

0 0.20 0.40 0.60 0.80

I

(A)

M

Figure 13. Typical upper diode

voltage drop vs. recirculating current.

The specifications on this databook are only

given for information , without any guarantee

as regards either mistakes or omissions.

The application circuits in this databook are

described only to show representative

usages of the product and not intended for

the guarantee or permission of any right

including the industrial rights.

Loading...

Loading...