JRC NJM3774D2, NJM3774FM3 Datasheet

NJM3774

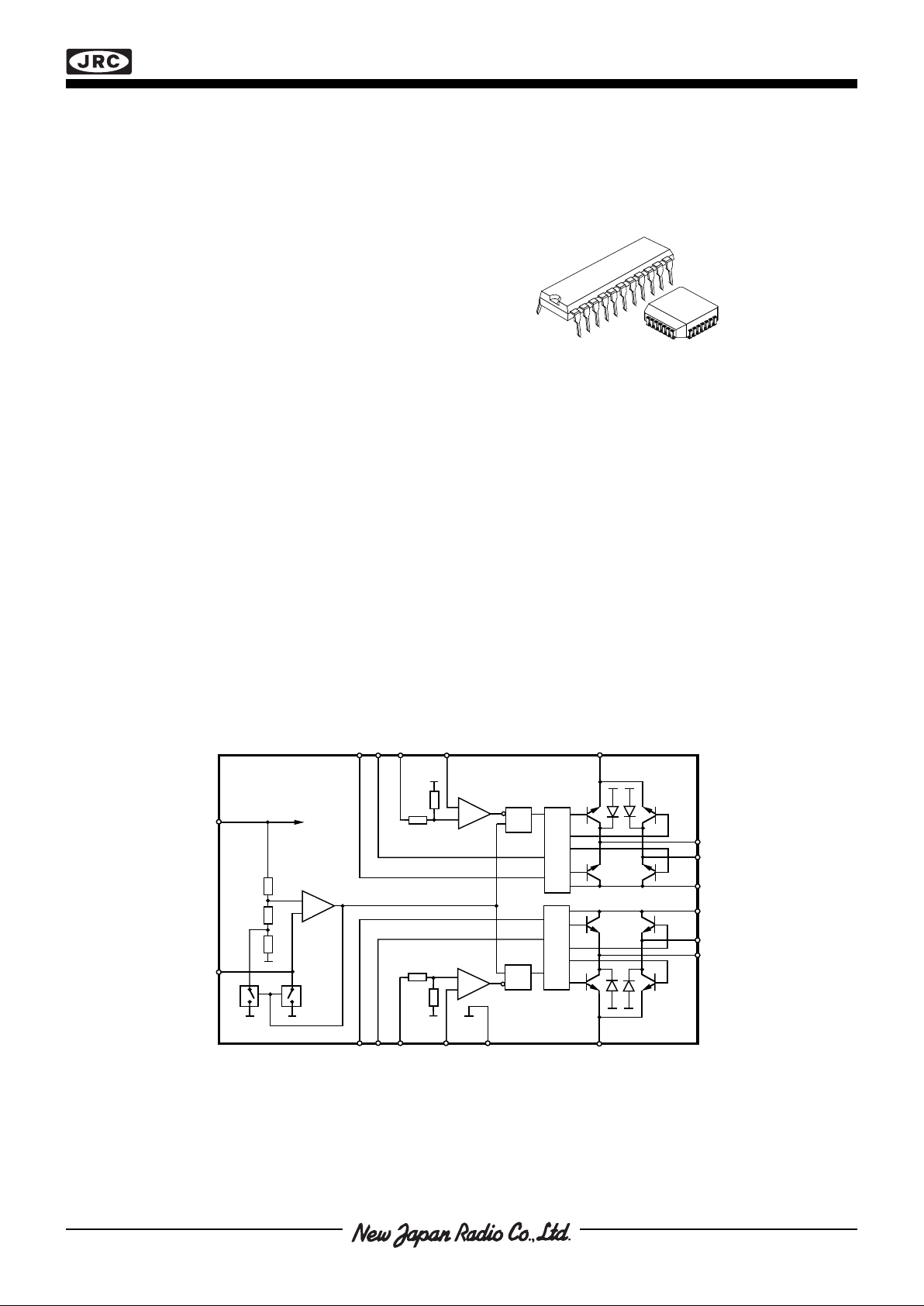

Figure 1. Block diagram

DUAL STEPPER MOTOR DRIVER

■ GENERAL DESCRIPTION ■ PACKAGE OUTLINE

RC

NJM3774

M

A1

M

B1

M

B2

M

A2

GNDC

2

V

R2

Phase

2

V

CC

C

1

V

R1

Phase

1

E

1

E

2

V

CC

SRQ

+

–

Logic

S

R

Q

+

–

Logic

+

–

V

MM2

V

MM1

Dis

1

Dis

2

NJM3774FM2

NJM3774D2

The NJM3774 is a switch-mode (chopper), constantcurrent driver with two channels: one for each winding of a

two-phase stepper motor. The NJM3774 is equipped with a

TTL level compatible Disable input to simplify half-stepping

operation. The circuit is well suited for microstepping

applications together with the matching dual DAC

NJU39610. In full/half stepping applications, the NJM3517

can be used as a phase generator (translator) to derive the

necessary signals for the NJM3774. The NJM3774 contains a clock oscillator, which is common for both driver

channels, a set of comparators and flip-flops implementing

the switching control, and two output H-bridges. Voltage

supply requirements are +5 V for logic and +10 to +45 V for

the motor. Maximum output current is 1000mA per channel.

■ FEATURES

• Dual chopper driver

• 1000 mA continuous output current per channel

• Specially matched to the Dual DAC NJU39610

• Packages DIP22 / PLCC28

■ BLOCK DIAGRAM

NJM3774

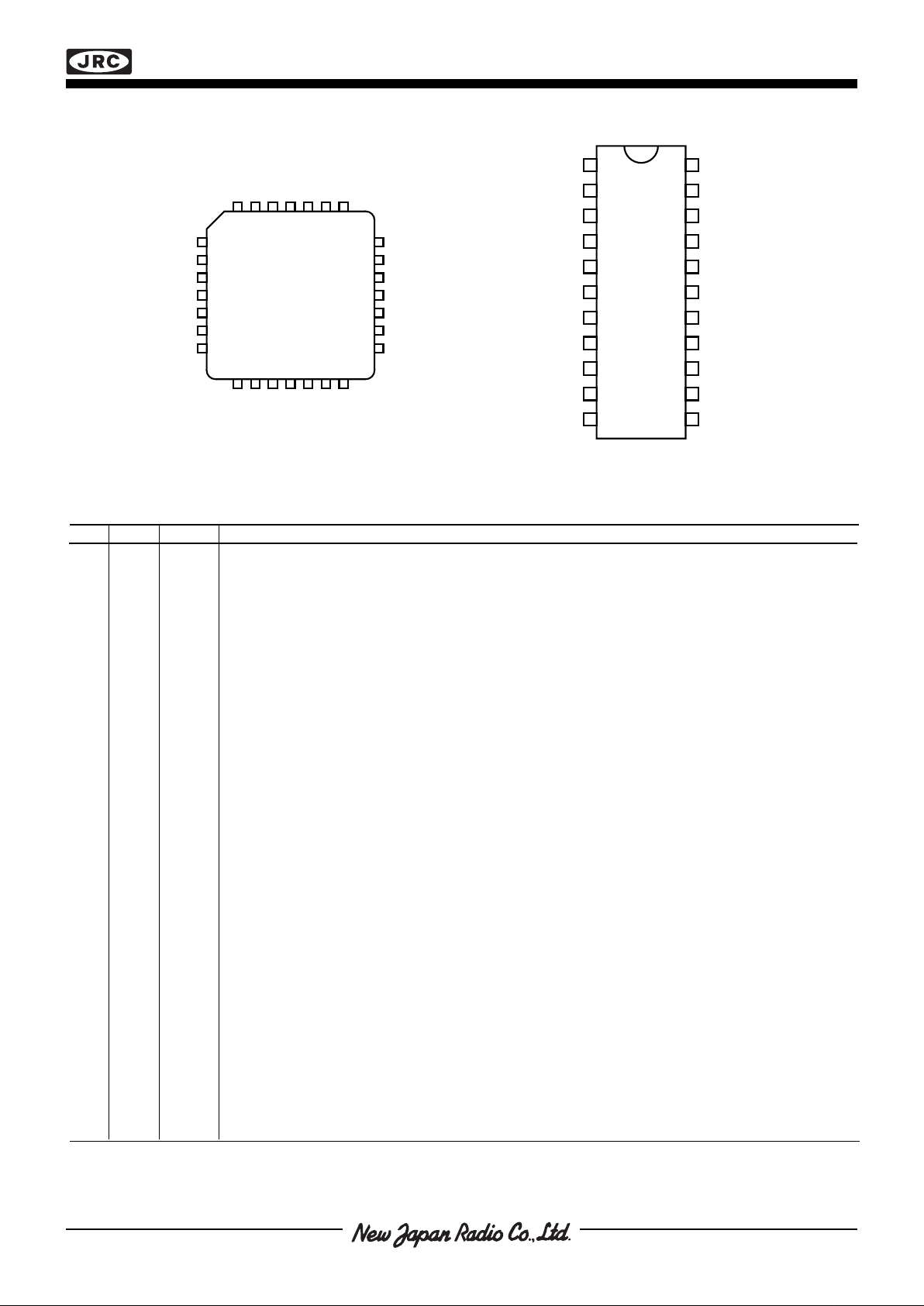

Figure 2. Pin configurations

C

E

B2

B1

GND

C

RC

V

M

GND

GND

GND

GND

A1

GND

GND

GND

GND

GND

5

6

7

8

9

10

11

25

24

23

22

21

20

19

4

3

2

1

282726

12131415161718

V

R2

V

R1

CC

Phase

2

A2

2

Dis

M

M

1

Dis

M

1

Phase

2

1

2

V

MM1

E

1

V

MM2

NJM3774FM2

1

2

3

4

5

6

7

8

9

10

11

22

21

20

19

18

17

16

15

14

13

12

C

R2

A1

GND

GND

1

R1

CC

M

V

M

GND

GND

Phase

Dis

RC

V

M

Phase

V

V

2

2

A2

MM2

B2

2

E

2

C

1

Dis

1

V

MM1

M

B1

E

1

NJM

3774D2

■ PIN CONFIGURATIONS

■ PIN DESCRIPTION

PLCC DIP Symbol Description

1-3, 9, 5, 6 GND Ground and negative supply. Note: these pins are used thermally for heat-sinking. Make sure that all

13-17 17, 18 ground pins are soldered onto a suitably large copper ground plane for efficient heat sinking.

28

48MA2Motor output A, channel 2. Motor current flows from MA2 to MB2 when Phase2 is HIGH.

59V

MM2

Motor supply voltage, channel 2, +10 to +40 V.V

MM1

and V

MM2

should be connected together.

610E2Common emitter, channel 2. This pin connects to a sensing resistor RS to ground.

711M

B2

Motor output B, channel 2. Motor current flows from MA2 to MB2 when Phase2 is HIGH.

812M

B1

Motor output B, channel 1. Motor current flows from MA1 to MB1 when Phase1 is HIGH.

10 13 E

1

Common emitter, channel 1. This pin connects to a sensing resistor RS to ground.

11 14 V

MM1

Motor supply voltage, channel 1, +10 to +40 V. V

MM1

and V

MM2

should be connected together.

12 15 M

A1

Motor output A, channel 1. Motor current flows from MA1 to MB1 when Phase1 is HIGH.

18 16 Dis

1

Disable input (TTL level compatible) for channel 1. When HIGH, all four output transistors are turned

off, which results in a rapidly decreasing output current to zero.

19 19 Phase

1

Controls the direction of motor current at outputs MA1 and MB1. Motor current flows from MA1 to M

B1

when Phase1 is HIGH.

20 20 V

R1

Ref. voltage, channel 1. Controls the threshold voltage for the comparator and hence the output

current.

21 21 C

1

Comparator input channel 1. This input senses the instantaneous voltage across the sensing resistor,

filtered by an RC network. The threshold voltage for the comparator is V

CH1

= 0.18 • VR1 [V], i.e. 450

mV at VR1 = 2.5 V.

22 22 V

CC

Logic voltage supply, nominally +5 V.

23 1 RC Clock oscillator RC pin. Connect a 15 kohm resistor to V

CC

and a 3300 pF capacitor to ground to obtain

the nominal switching frequency of 26.5 kHz.

24 2 C

2

Comparator input channel 2. This input senses the instantaneous voltage across the sensing resistor,

filtered by an RC network. The threshold voltage for the comparator is V

CH2

= 0.18 • VR2 [V], i.e. 450 mV

at VR2 = 2.5 V.

25 3 V

R2

Ref. voltage, channel 2. Controls the threshold voltage for the comparator and hence the output

current.

26 4 Phase

2

Controls the direction of motor current at outputs MA2 and MB2. Motor current flows from MA2 to M

B2

when Phase2 is HIGH.

27 7 Dis

2

Disable input (TTL level compatible) for channel 2. When HIGH, all four output transistors are turned

off, which results in a rapidly decreasing output current to zero.

NJM3774

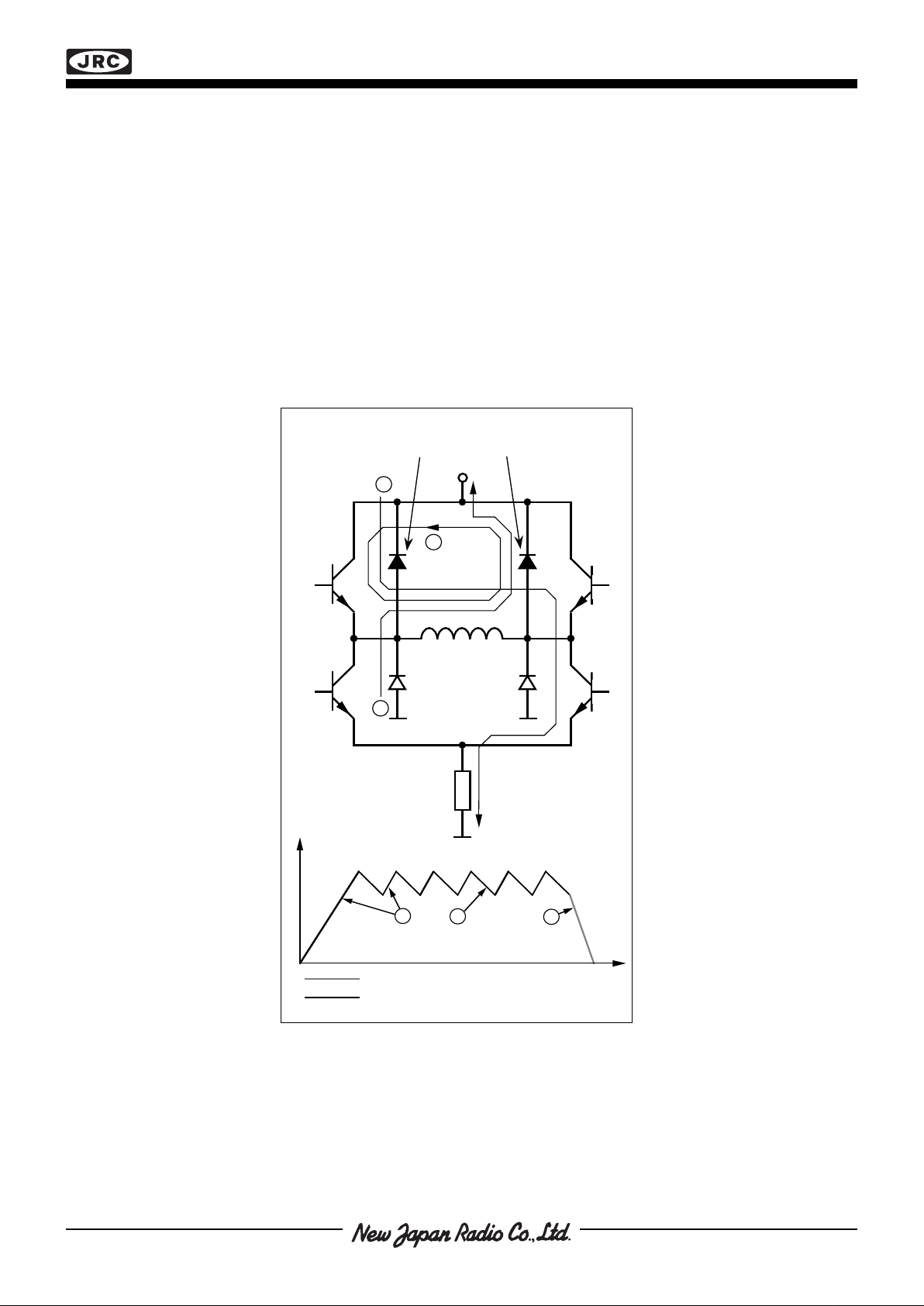

Figure 3. Output stage with current paths

during turn-on, turn-off and phase shift.

■ FUNCTIONAL DESCRIPTION

Each channel of the NJM3774 consists of the following sections: an output H-bridge with four transistors, capable

of driving up to 1000mA continuous current to the motor winding; a logic section that controls the output transistors;

an S-R flip-flop; and a comparator. The clock-oscillator is common to both channels.

Constant current control is achieved by switching the output current to the windings. This is done by sensing the

peak current through the winding via a resistor, RS, effectively connected in series with the motor winding during the

turn-on period. As the current increases, a voltage develops across the resistor, and is fed back to the comparator.

At the predetermined level defined by the voltage at the reference input VR, the comparator resets the flip-flop,

turning off the output transistors. The current decreases until the clock oscillator triggers the flip-flop, turning on the

output transistors, and the cycle is repeated.

The current paths during turn-on, turn-off and phase shift are shown in figure 3. Note that the upper recirculation

diodes are connected to the circuit externally.

Fast Current Decay

Slow Current Decay

Motor Current

Time

1 2

3

3

1

2

R

S

V

MM

External recirculation diodes

Loading...

Loading...