JpS

IRIS-IMAC DRIVER

USER MANUAL

Version: V2.01

Software Rel.: V98.26

Panel Rel.: V9916

Safety Precautions and Warnings!

CAUTION! WARNING!

Pay attention to these

They indicate danger to human body or damage to the device. Before installing and putting the device into

operation, please read the safety precautions and warnings following this page.

1. Make sure that the warning signs are kept in a legible condition and replace missi ng or damaged signs.

2. Before starting, familiarize yourself with the operation of the inverter. It may be too late if you start working

with the inverter before read this instruction manual.

3. Never permit unqualified personnel to operate the inverter.

!

WARNING!

z This inverter produces dangerous electrical voltages and control s ro tating mechanical parts.

z Death, severe injury or substantial damage to property can occur if the instructions in this operating manual

are not completed with.

z Only personnel with appropriate qualifications should work with this inverter. These personnel must be

familiar with all the warning signs and precautions laid out in these operating instructions for the transpo rt,

installation and operation of this device.

z The successful and safe use of this inverter depends on the correct installation, commissioning, operation

and maintenance of the device.

z This device operates at high voltages.

!

CAUTION!

z The DC-link capacitors remain charged to dangerous voltages even the power is removed. For this reason it

is not permissible to open the inverter cover until five (5) minutes after the power has been turned off.

z When handling the open inverter it should be noted that live parts are exposed. Do not touch these live

parts.

z The terminals R, S, T, U, V, W, P, N, B, PR, and BR can carry dangerous voltages even if the motor is

inoperative.

z Only qualified personnel may connect, start the system up and repair faults. These personnel must be

thoroughly acquainted with all the warnings and operating procedures contained with this manual.

z Certain parameter settings may cause the device to start up automatically after power on or power recover.

!

CAUTION, WARNING, and

!

signals on the device or instruction documents.

DEFINITIONS

z Qualified Person

For the purposes of this manual and product labels, a qualified person is one who is familiar with the

installation, construction, operation and maintenance of this device and with hazards involved. In addition,

the person must be:

Trained and authorized to energize, de-energize, clear, ground and tag circuits and equipment in

accordance with established safety practices.

Trained in the proper care and use of protective equipment in accordance with established safety

practices.

Trained in rendering first aid.

z DANGER

For the purposes of this manual and product labels, DANGER indicates that loss of life, severe personal

injury or substantial property damage WILL result if proper precautions are not taken.

z WARNING

For the purposes of this manual and product labels, WARNING indicates that loss of life, severe personal

injury or substantial property damage CAN result if proper precautions are not taken.

z CAUTION

For the purpose of this manual and product labels, CAUTION indicates that min or personal injury or property

damage CAN result if proper precautions are not taken.

z NOTE

For the purpose of this manual and product labels, NOTES merely call attention to information that is

especially significant in understanding and operating the inverter.

1

!

DANGER and WARNING

z Make sure that the location selected for installation is safe, protected from moisture and spl ash and

drip-proof!

z Children and the general public must be prevented from accessing or approaching the equipment!

z The equipment may only be used for the purpose specified by the manufacturer. Unauthorized modifications

and the use of spare parts and accessories that are not sold or recommended b y the manufacturer of the

equipment can cause fires, electric shocks and injuries.

z Keep these operating instructions within easy reach and give them to all users!

!

WARNING

This is a Class A product. In a domestic environment this product may cause radio interference in which case the

user may be required to take adequate measures.

2

Contents

1. DESCRIPTION OF IRIS............................................................................................................................................... 5

1.1 CHECK ITEMS............................................................................................................................................................. 5

1.2 DESCRIPTION OF NAMEPLATE CONTENT.................................................................................................................... 5

1.3 THE SPECIFICATION OF IRIS SERIES........................................................................................................................... 6

2. CONDITION OF STORAGE ENVIRONMENT......................................................................................................... 7

3. ATTENTION OF INSTALLATION.............................................................................................................................. 7

4. OUTLINE DIMENSION................................................................................................................................................ 8

5. DESCRIPTION OF WI RING........................................................................................................................................ 9

5.1 POWER TERMINAL ..................................................................................................................................................... 9

5.2 THE CONTROL SIGNAL TERMINALS............................................................................................................................ 9

5.3 BRAKE RESISTOR TERMINALS.................................................................................................................................. 10

5.4 THE INPUT REACTOR ............................................................................................................................................... 10

5.5 THE PROPER SCREW DRIVE FOR POWER TERMINALS................................................................................................11

6. BASIC WIRING DIAGRAM FOR IRIS SERIES DRIVE ....................................................................................... 12

7. I/O INTERFACE........................................................................................................................................................... 13

7.1 THE MAP OF I/O TERMINAL POSITION ..................................................................................................................... 13

7.2 TM3 DESCRIPTION................................................................................................................................................... 14

7.3 CONNECTOR CON5 ................................................................................................................................................. 15

7.4 TERMINAL BLOCK TM1........................................................................................................................................... 15

7.5 CONNECTOR PG 1.................................................................................................................................................... 15

8. DIGITAL CONTROL PANEL DESCRIPTION ........................................................................................................ 16

8.1 DIGITAL CONTROL PANEL APPEARANCE INTRODUCTION .........................................................................................16

8.2 MONITOR'S GRAPHICAL DESCRIPTION ..................................................................................................................... 16

8.3 THE START UP MESSAGE OF PANEL.......................................................................................................................... 16

9. THE OPERATION GUIDE OF DIGITAL CONTROL PANEL..............................................................................17

9.1 LOCK AND UNLOCK.................................................................................................................................................. 17

9.2 CHANG E MOD E......................................................................................................................................................... 17

9.3 MONITOR MODE....................................................................................................................................................... 17

9.4 PARAMETER MODE (SELECT, READ, EDIT, WRITE) ..................................................................................................... 19

9.5 ALARM MODE .......................................................................................................................................................... 20

9.6 RESET .................................................................................................................................................................... 20

10. QUICK START......................................................................................................................................................... 21

10.1 RUN COMMAND SET FROM DIGITAL INPUT TERMINALS........................................................................................... 21

10.2 RUN COMMAND SET FROM CONTROL PANEL ..........................................................................................................21

10.3 CHANGE THE DEFINITION OF MOTOR’S DIRECTION ................................................................................................. 22

11. PARAMETER DESCRIPTION............................................................................................................................... 23

11.1 IRIS-IMAC PARAMETER LIST ................................................................................................................................. 23

11.2 MONITOR TYPE PARAMETERS’ ADDRESS ................................................................................................................. 26

11.3 PARAMETER’S TYPE................................................................................................................................................. 26

12. IRIS-IMAC PARAMETER DESCRIPTION......................................................................................................... 27

12.1 G00 DRIVER SPECIFICATION GROUP........................................................................................................................ 27

12.2 G01 DIGITAL INPUT GROUP ..................................................................................................................................... 28

12.3 G02 DIGITAL OUTPUT GROUP.................................................................................................................................. 29

12.4 G03 ANALOG INPUT GROUP..................................................................................................................................... 29

12.5 G05 ANALOG OUTPUT GROUP................................................................................................................................. 32

12.6 G07 MAGNETIC SENSOR GROUP.............................................................................................................................. 34

12.7 G10 IMAC MOTOR GROUP ..................................................................................................................................... 34

12.8 G15 IMAC CONTROL GROUP.................................................................................................................................. 35

12.9 G16 IMAC MULTI-SPEED SETTING GROUP .............................................................................................................39

12.10 G17 IMAC ACC/DEC/S-CURVE GROUP................................................................................................................ 39

12.11 G62 TIMER GROUP .............................................................................................................................................. 41

12.12 G64-MISC SPEED UP / DOWN COUNTER............................................................................................................. 41

12.13 G65 MISC. SPEED COMPARE GROUP................................................................................................................... 41

3

G66 MISC. ROTARY SWITCH GROUP................................................................................................................... 42

12.14

12.15 G82 H/W DC-BUS ADJUST GROUP..................................................................................................................... 42

12.16 G83 H/W THERMISTOR ADJUST GROUP............................................................................................................... 42

12.17 G84 H/W FAN ADJUST GROUP............................................................................................................................ 43

13. DIGITAL INPUT FUNCTION................................................................................................................................ 44

14. DIGITAL OUTPUT FUNCTION............................................................................................................................ 47

15. EMBEDDED MULTI-FUNCTION MO D ULE...................................................................................................... 49

15.1 TIMER ......................................................................................................................................................................49

15.2 SPEED UP / DOWN COUNTER.................................................................................................................................... 51

16. ALARM MESSAGE AND MAINTENANCE........................................................................................................54

16.1 ALARM MESSAGE ....................................................................................................................................................54

16.2 MAINTENANCE......................................................................................................................................................... 54

17. CE CERTIFICATE................................................................................................................................................... 57

17.1 EMC CERTIFICATE................................................................................................................................................... 57

17.2 LVD CERTIFICATE.................................................................................................................................................... 58

4

1. Description of IRIS

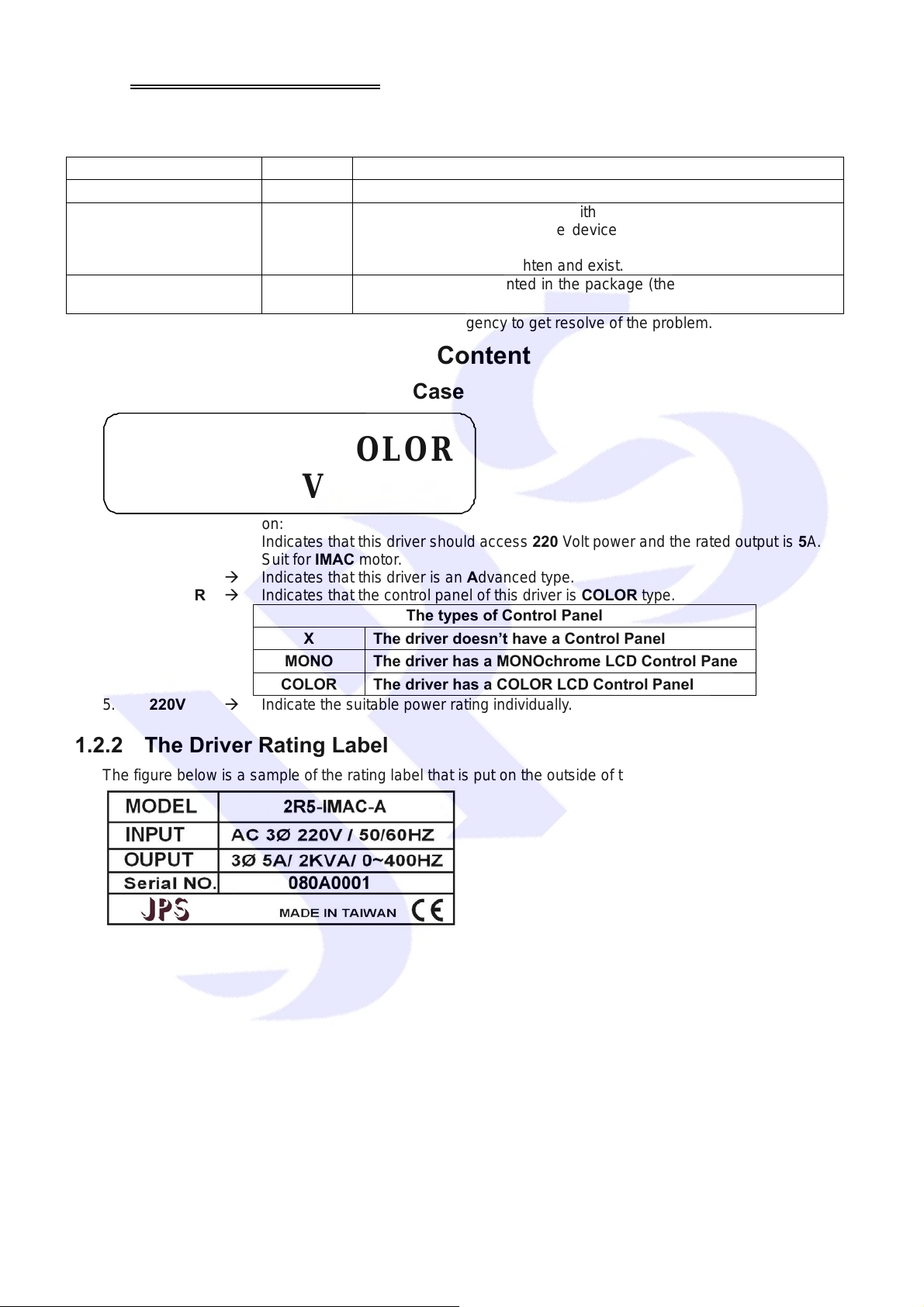

1.1 Check Items

To avoid the carelessness during packing and delivery, please check the list below carefully。

Items Amount Contents

IRIS IMAC Manual 1 book Please read carefully and keep with care for referring usage.

Check the spec. of the device with the case label is same or not.

IRIS IMAC Driver 1 set

Encoder Feedback cable 1 set

If any miss or defect happened, please contact with the agency to get resolve of the problem.

Check the out looking of the device to make sure that there is no

defect on it.

All screws should be tighten and exist.

Make sure it is contented in the package (the cable had been tested

before packing)。

1.2 Description of Nameplate Content

1.2.1 The Label on the Packing Case

2R5-IMAC-A-COLOR

220V

The contents of indication:

1. 2R5 Æ Indicates that this driver should access 220 Volt power and the rated output is 5A.

2. IMAC Æ Suit for IMAC motor.

3. A Æ Indicates that this driver is an Advanced type.

4. COLOR Æ Indicates that the control panel of this driver is COLOR type.

The types of Control Panel

X The driver doesn’t have a Control Panel

MONO The driver has a MONOchrome LCD Control Panel

COLOR The driver has a COLOR LCD Control Panel

5. 220V Æ Indicate the suitable power rating individually.

1.2.2 The Driver Rating Label

The figure below is a sample of the rating label that is put on the outside of the driver.

5

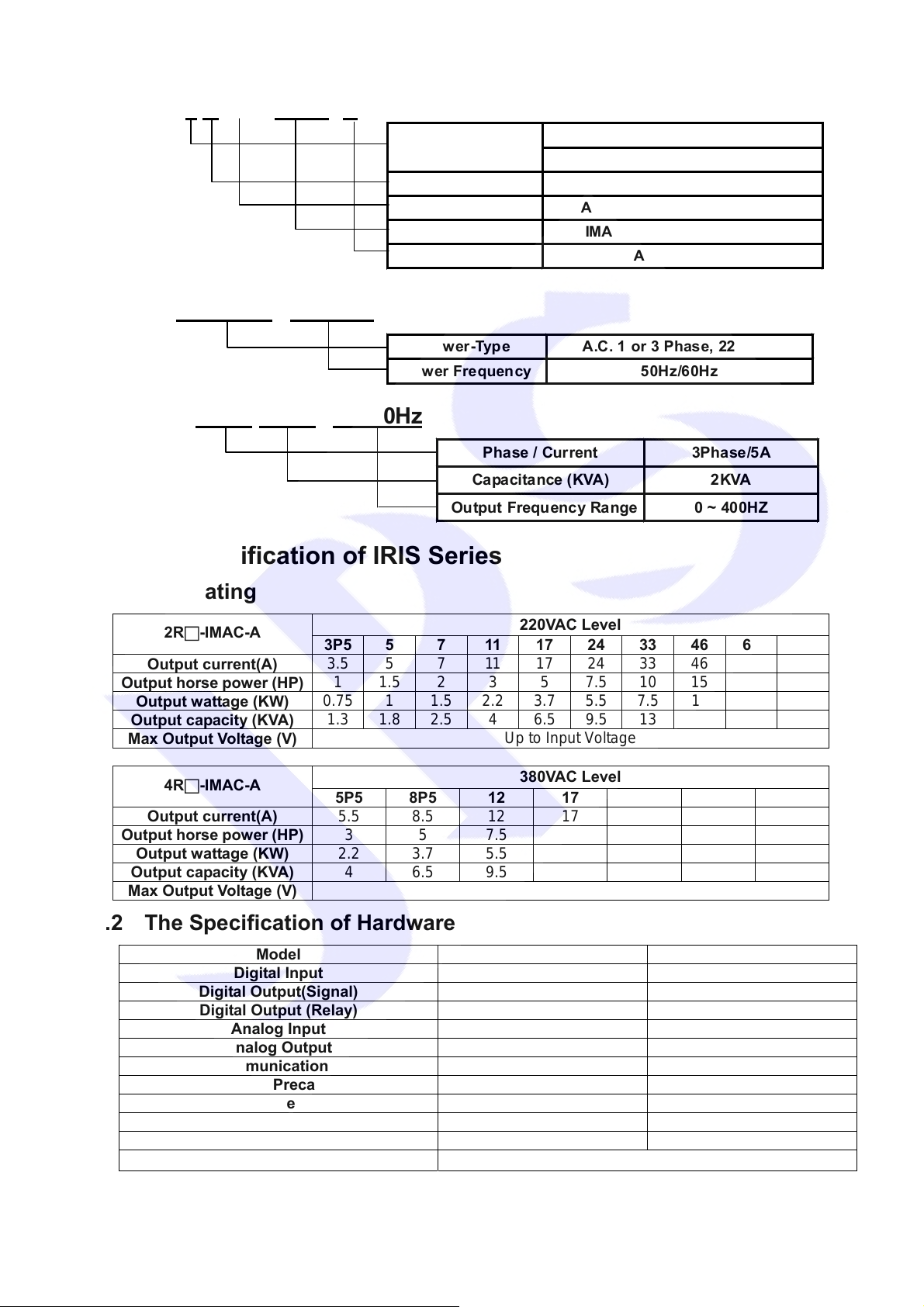

The contents of rating label are showed below:

MODEL:2 R □ - IMAC- A

INPUT :AC3Ø220 / 50/60HZ

OUTPUT : 3Ø5A 2KVA / 0~400Hz

Inp ut voltage

Model series R : IRIS Series

Output current According to Dr iver-Current

Suit mot or IMA C : Induct io n Moto r AC

Function A : Advanced

Pow er -Type A.C. 1 or 3 Phase, 220Volt.

Power Frequency 50Hz/60Hz

Pha se / Cur rent 3Pha se/5A

Capacita nce ( KVA) 2KVA

Output Frequency Range 0 ~ 400HZ

2 : 220VAC

4 : 380VAC

1.3 The Specification of IRIS Series

1.3.1 The Rating

2R□-IMAC-A

Output current(A)

Output horse power (HP)

Output wattage (KW)

Output capacity (KVA)

Max Output Voltage (V)

4R□-IMAC-A

Output current(A)

Output horse power (HP)

Output wattage (KW)

Output capacity (KVA)

Max Output Voltage (V)

1.3.2 The Specification of Hardware

Model 2R3P5~2R7 2R11~2R90 / 4R5P5~4R45

Digital Input

Digital Output(Signal)

Digital Output (Relay)

Analog Input

Analog Output

RS485 Communication Interface

Fan Malfunction & Precaution Function

Over Heat Protect Function

PG Feedback Interface

Brake Discharge MOS-FET

Digital Control Panel

3P5 5 7 11 17 24 33 46 61 90

3.5 5 7 11 17 24 33 46 61 90

1 1.5 2 3 5 7.5 10 15 20 30

0.75 1 1.5 2.2 3.7 5.5 7.5 11 15 22.5

1.3 1.8 2.5 4 6.5 9.5 13 19 25 34

5P5 8P5 12 17 23 31 45

5.5 8.5 12 17 23 31 45

3 5 7.5 11 15 20 30

2.2 3.7 5.5 7.5 11 15 22.5

4 6.5 9.5 13 19 25 34

1 Unit(12bit resolution) 2 Units(12bit resolution)

X:non-included ; M:Monochrome ; Color:Color

220VAC Level

Up to Input Voltage

380VAC Level

Up to Input Voltage

6 Unit 6 Unit

2 Unit 2 Unit

1 Unit 1 Unit

1 Unit 1 Unit

2 Unit 2 Unit

Included Included

Included Included

1Unit 1Unit

Included Included

6

2. Condition of Storage Environment

This driver should be contained in the packing case. If do not use this driver temporarily, in order to ensure this

driver in our warranty scope, please follow the items below:

z The ambient temperature must be in the scope of - 20℃ to +65℃, relative humidity 0% to 95%, and no dew

clings.

z Must be preserved in the environment that is dustless, stainless, and dry.

z Avoid to store under the environment that has caustic gas or liquid.

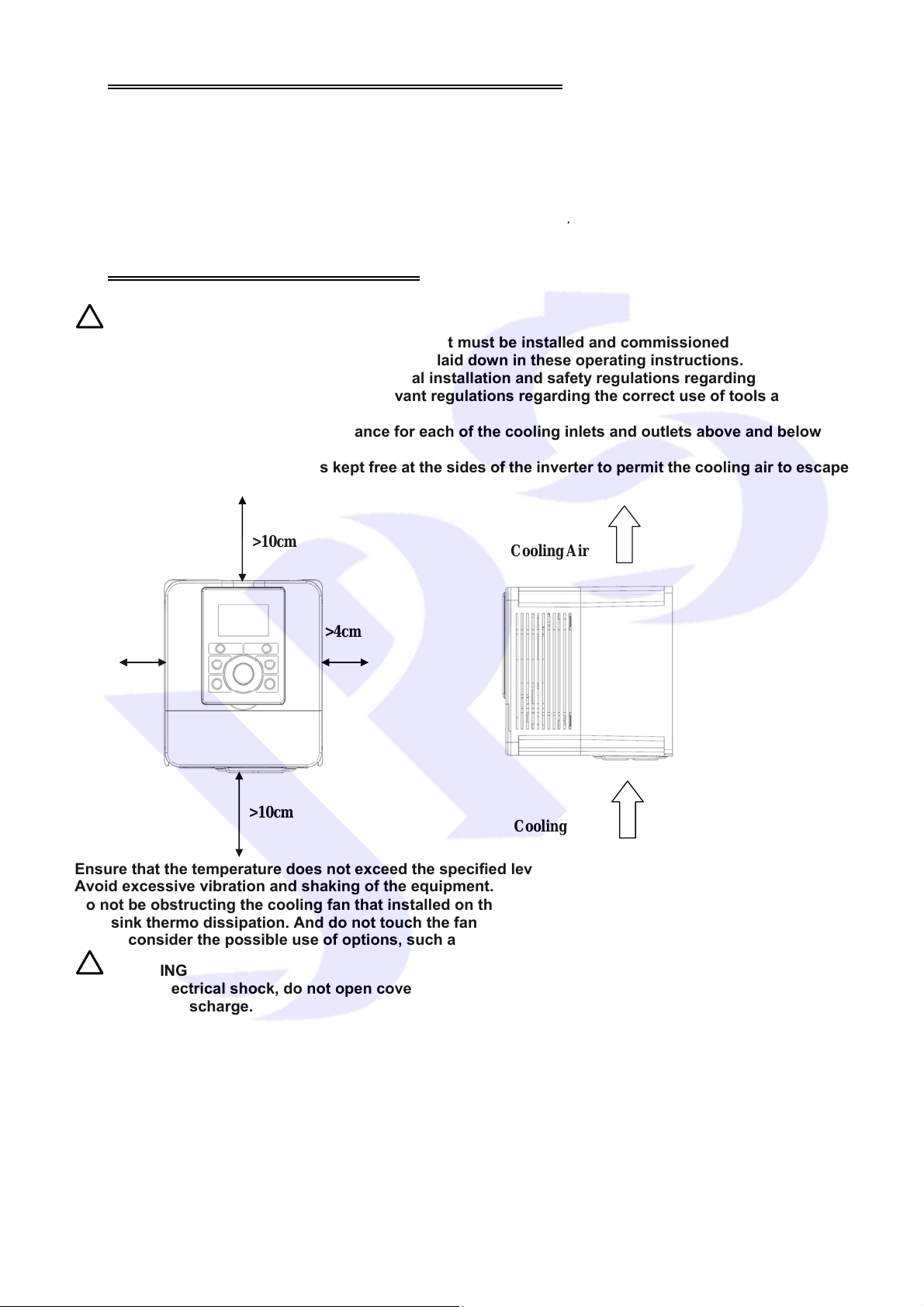

3. Attention of Installation

!

WARNING

To guarantee the safe operation of the equipment it must be installed and commissioned properly by

qualified personnel in compliance with warnings laid down in these operating instructions.

Take particular note of the general and regional installation and safety regulations regarding work on

high voltage regulations, as well as the relevant regulations regarding the correct use of tools and

personal protective gear.

Make sure that the unobstructed clearance for each of the cooling inlets and outlets above and below the

inverter is at least 100mm.

Make sure that a space of 40mm is kept free at the sides of the inverter to permit the cooling air to escape

from the side slits.

>10cm

>4cm

>10cm

Ensure that the temperature does not exceed the specified level when the inverter is installed in cubicle.

Avoid excessive vibration and shaking of the equipment.

Do not be obstructing the cooling fan that installed on the inverter, it is used to build proper airflow for

heat sink thermo dissipation. And do not touch the fan hole when it is running.

Please consider the possible use of options, such as RFI suppression filters at the planning stage.

!

WARNING

To prevent electrical shock, do not open cover for at least 5 minutes after removing AC power to allow

capacitors to discharge.

>4cm

Cooling Air

Cooling Air

7

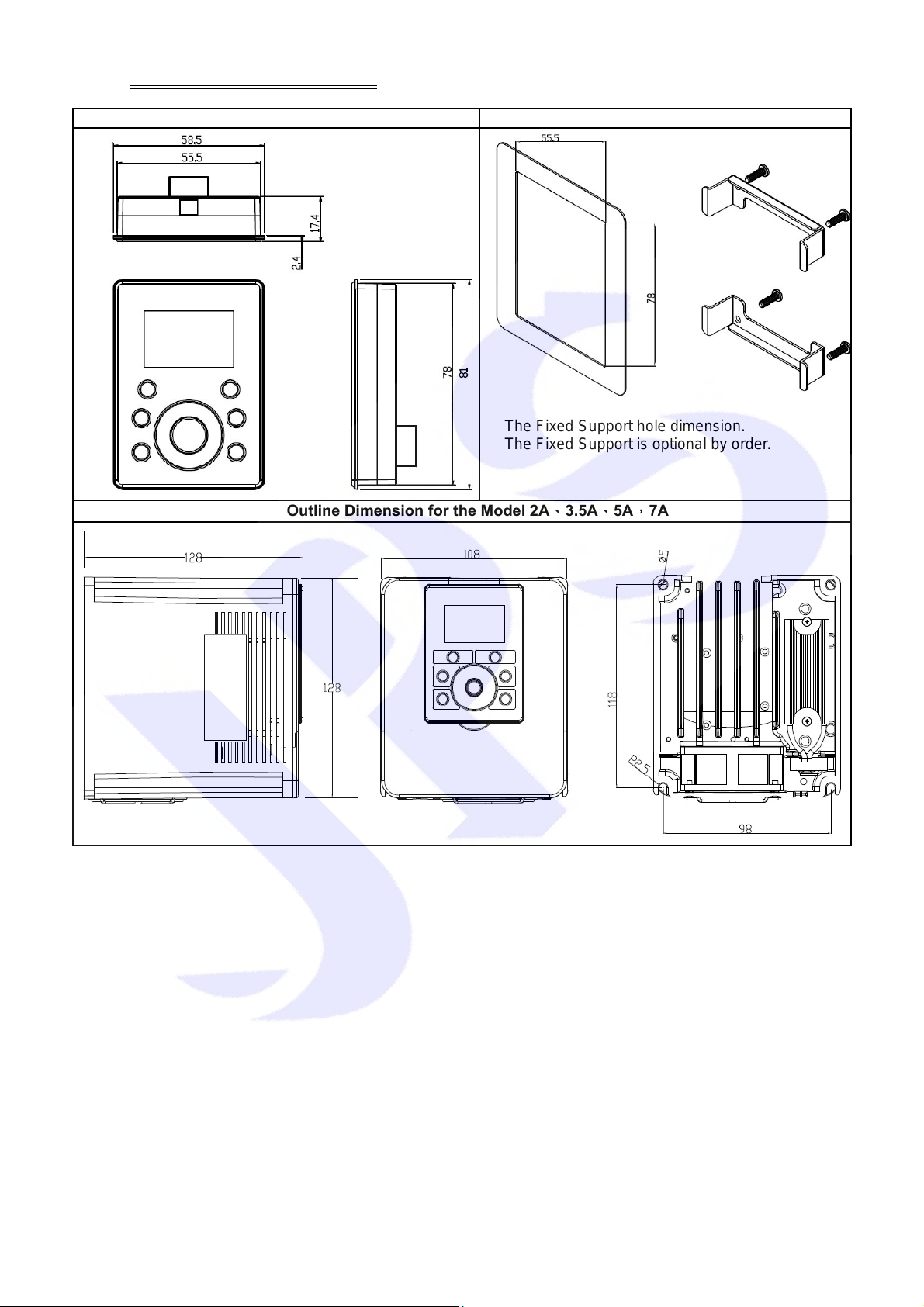

4. Outline Dimension

Control Panel The fixed Support of Control Panel

The Outline Dimension for the Model 2A、3.5A、5A,7A

The Fixed Support hole dimension.

The Fixed Support is optional by order.

8

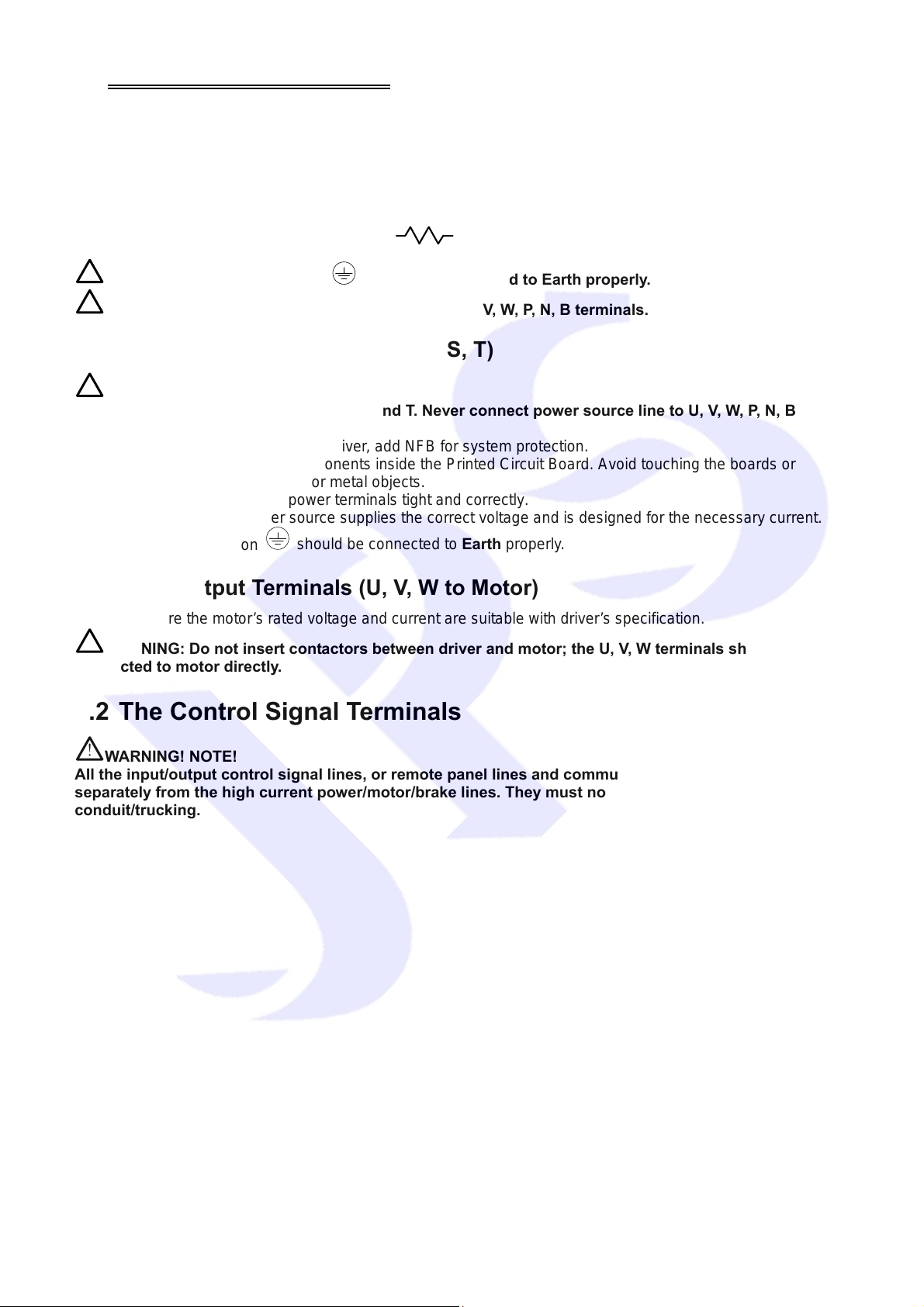

5. Description of Wiring

The upper cover must be removed in order to connect the electrical leads.

5.1 Power Terminal

The power terminals are divided into three portions:

1. The power input terminals (R, S, T) receives power fo r the operation of the inverter.

2. The output terminals (U, V, and W) deliver output power to motor.

3. Brake resistor should be connects to icon

!

NOTE: The terminal has icon should be connected to Earth properly.

!

WARNING: Never connect power source line to U, V, W, P, N, B terminals.

5.1.1 The Power Input Terminals (R, S, T)

!

WARNING! NOTE!

z The power input terminals are R, S, and T. Never connect power source line to U, V, W, P, N, B

terminals.

z Between the power source and driver, add NFB for system protection.

z There are static sensitive components inside the Printed Circuit Board. Avoid touching the boards or

components with your hands or metal objects.

z Make sure to connect the power terminals tight and correctly.

z Make sure that the power source supplies the correct voltage and is designed for the necessary current.

.

z The terminal has icon

should be connected to Earth properly.

5.1.2 The Output Terminals (U, V, W to Motor)

z Make sure the motor’s rated voltage and current are suitable with driver’s specification.

!

WARNING: Do not insert contactors between driver and motor; the U, V, W terminals should be

connected to motor directly.

5.2 The Control Signal Terminals

!

WARNING! NOTE!

All the input/output control signal lines, or remote panel lines and communication lines must be laid

separately from the high current power/motor/brake lines. They must not be fed through the same cable

conduit/trucking.

9

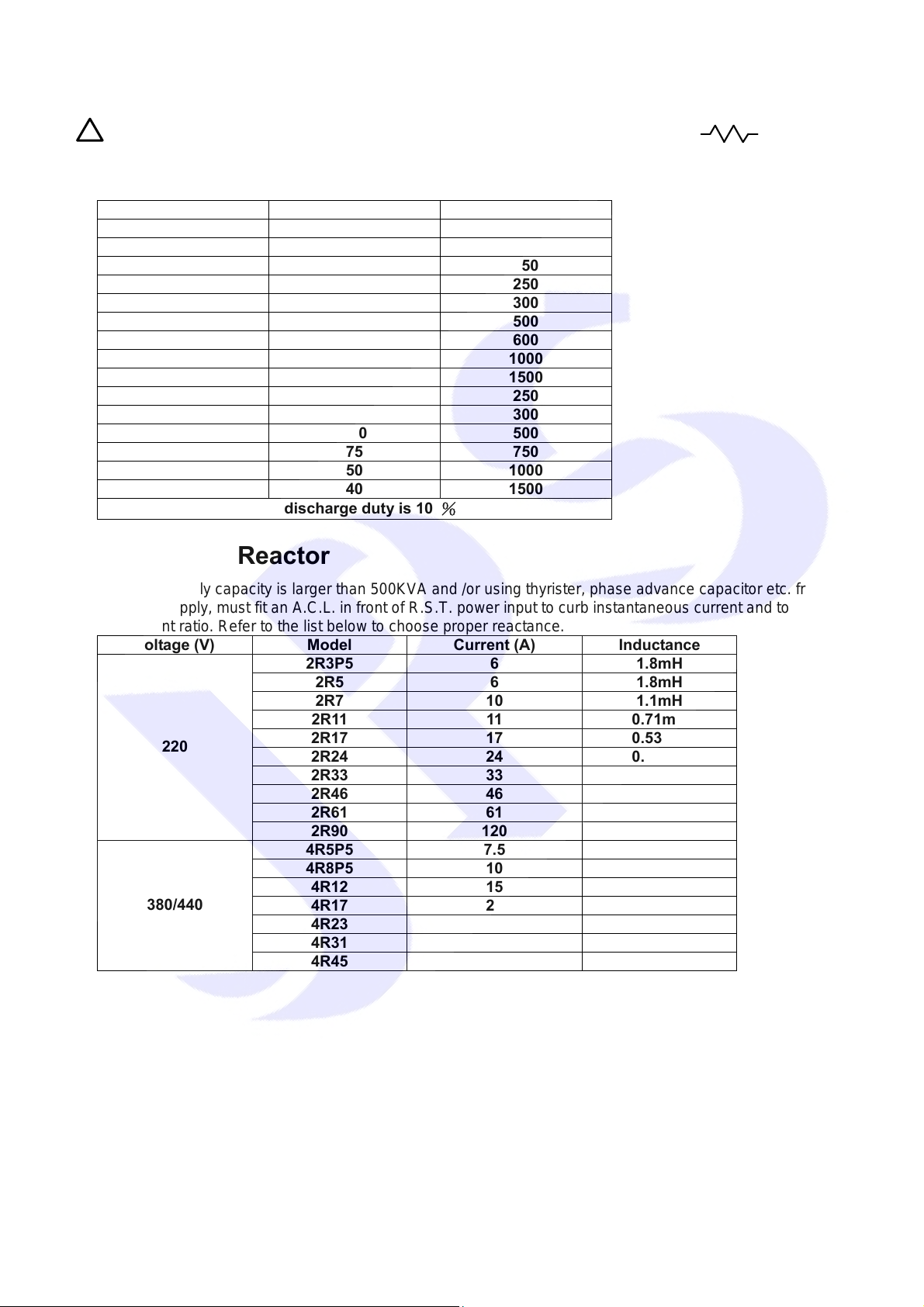

5.3 Brake Resistor Terminals

!

NOTE: This driver contains braking discharge circuits. The terminals have icon

connect external resistor to discharge the re-generating energy when in braking condition.

Refer to the list below when choosing resistor for braking discharge. The wattage of resistor can be

increased for heavier re-generating energy or higher discharge duty.

Model Resistance Wattage (W)

2R3P5 300 60

2R5 200 80

2R7 100 150

2R11 60 250

2R17 40 300

2R24 30 500

2R33 20 600

2R46 15 1000

2R61 10 1500

4R5P5 250 250

4R8P5 150 300

4R12 100 500

4R17 75 750

4R23 50 1000

4R31 40 1500

The discharge duty is 10 %

are used to

5.4 The Input Reactor

When power supply capacity is larger than 500KVA and /or using thyrister, phase advance capacitor etc. from

same power supply, must fit an A.C.L. in front of R.S.T. power input to curb instantaneous current and to improve

power efficient ratio. Refer to the list below to choose proper reactance.

Voltage (V) Model Current (A) Inductance

2R3P5 6 1.8mH

2R5 6 1.8mH

2R7 10 1.1mH

2R11 11 0.71mH

220

380/440

2R17 17 0.53mH

2R24 24 0.35mH

2R33 33 0.26mH

2R46 46 0.18mH

2R61 61 0.13mH

2R90 120 0.09mH

4R5P5 7.5 3.6mH

4R8P5 10 2.2mH

4R12 15 1.42mH

4R17 20 1.0mH

4R23 30 0.7mH

4R31 40 0.53mH

4R45 60 0.36mH

10

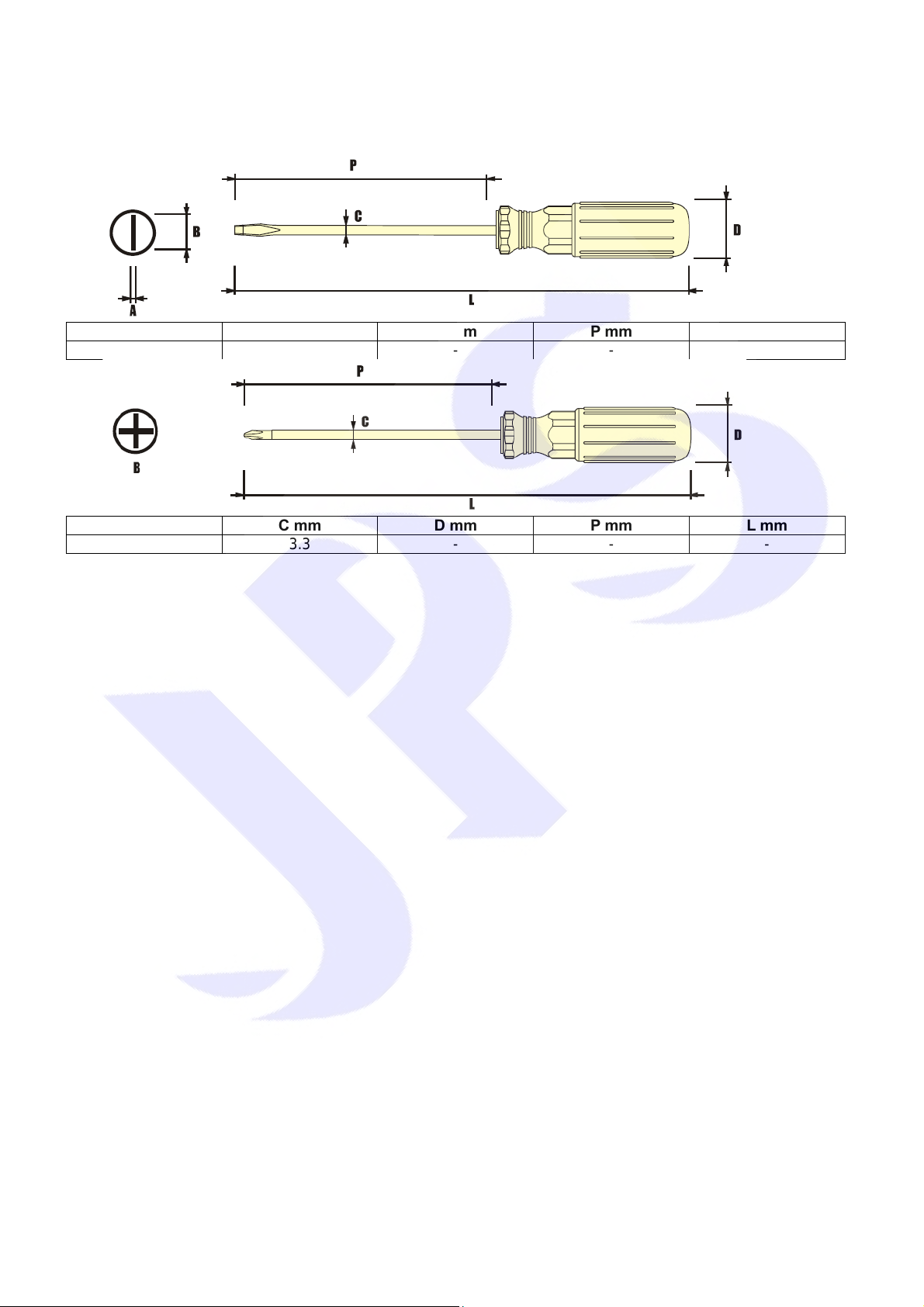

5.5 The Proper Screw Drive for Power Terminals

It is necessary to choose proper tool for wiring connection to avoid screw stripped or burst. Please refer to the list

below to choose a proper screw drive for driving power terminals.

A - B mm C mm D mm P mm L mm

0.6 - 3.3 3.3 - - -

B C mm D mm P mm L mm

#0 3.3 - - -

11

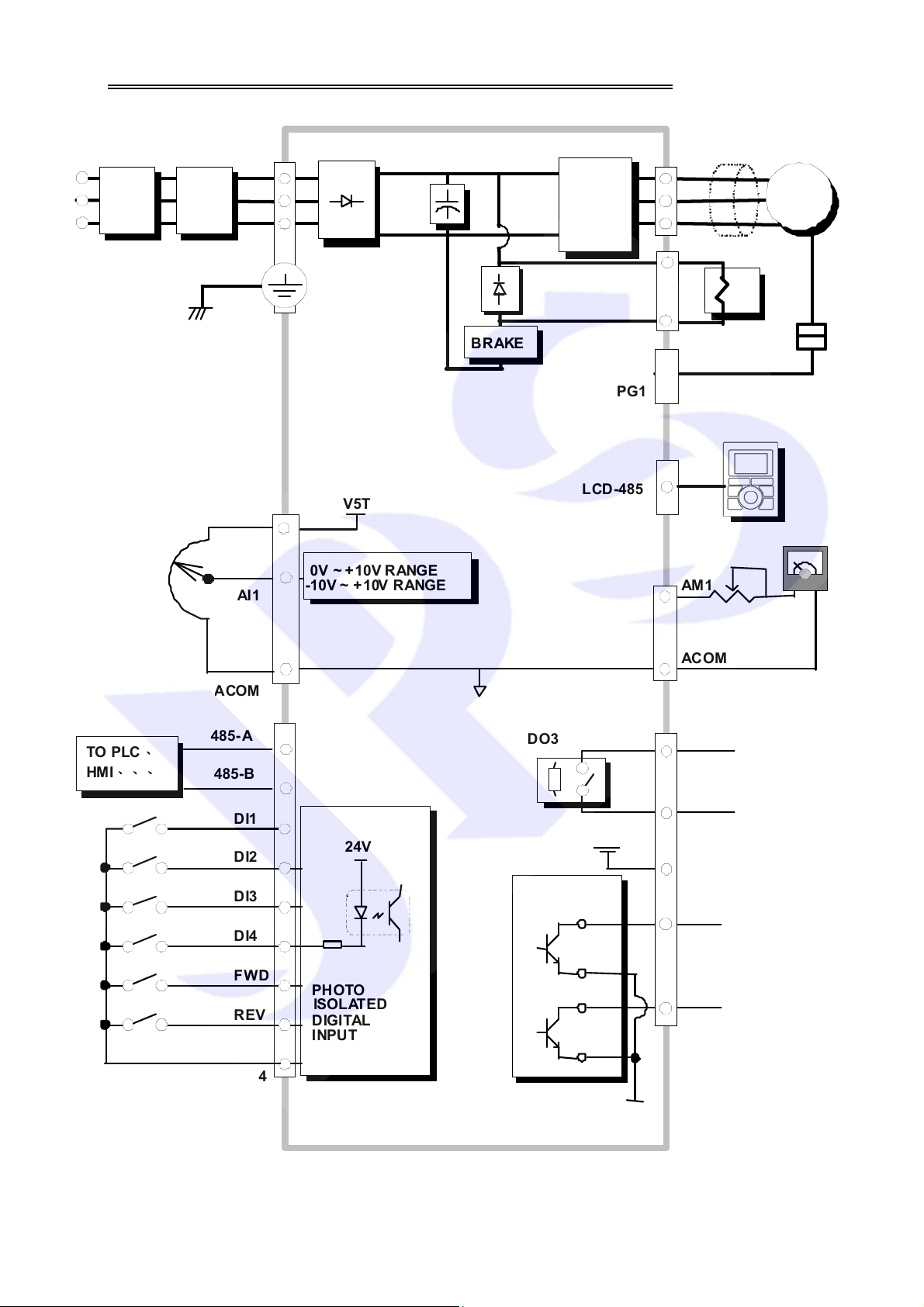

6. Basic Wiring Diagram for IRIS Series Drive

2

POWER

SOURCE

NFB

Filter

E

R

S

T

IGB T

BRAKE

PG1

U

V

W

EMI

MOTOR

POTENTIAL

METER

TO PLC、

HMI、、、

AI1

COM

485-A

485-B

DI1

DI2

DI3

DI4

V5T

0V ~ +10V RANGE

-10V ~ +10V RANGE

24V

LCD-485

DO3

24V

OPEN

COL LECTER

AM1

ACOM

RY3 A

MAX. RATING

00V, 3A

RY3 B

24V

DO1

FWD

REV

G24

PHOTO

ISOLATED

DIGI TAL

INPUT PORT

DO2

G24

12

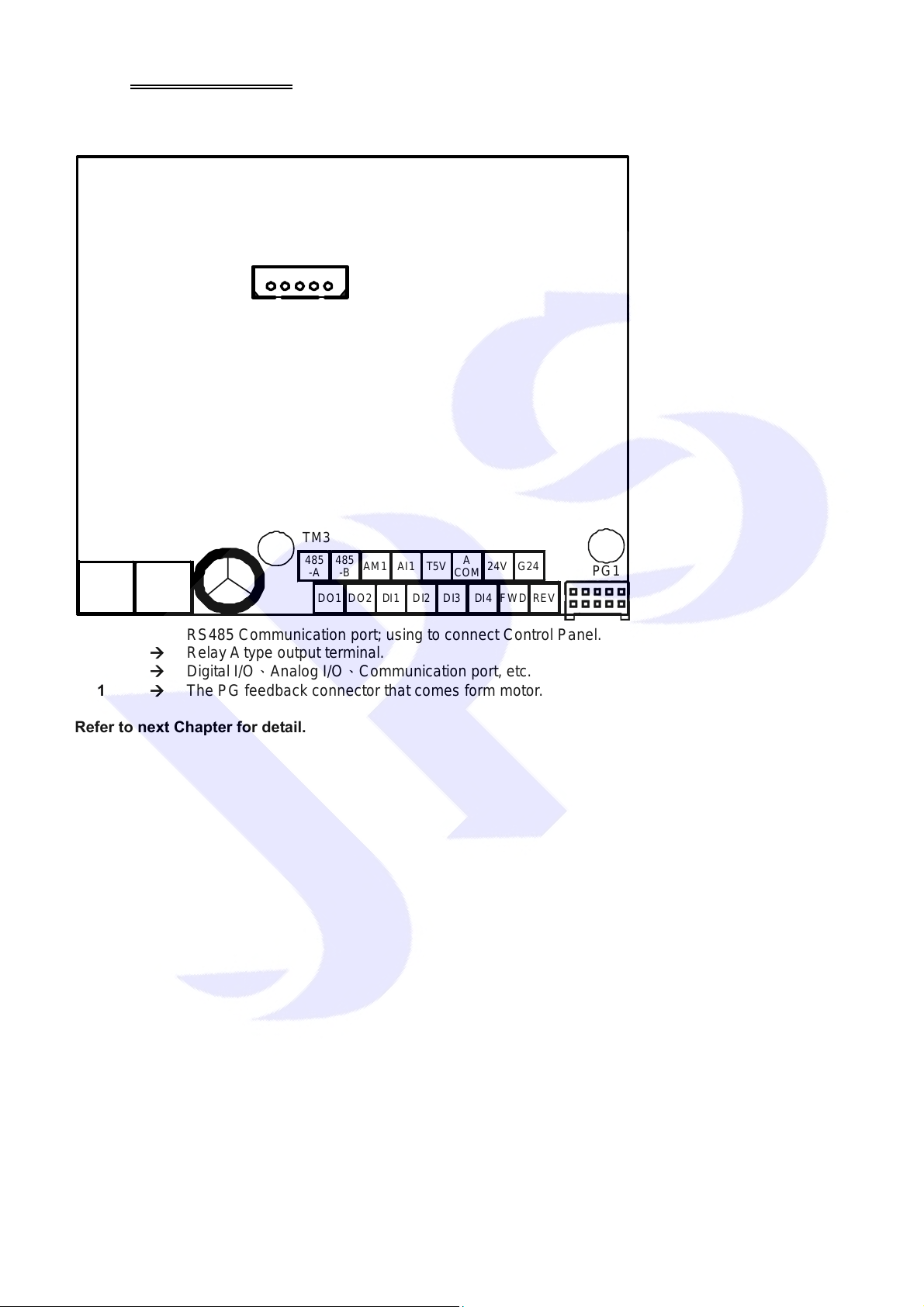

7. I/O Interface

7.1 The Map of I/O Terminal Position

Refer to the position map to locate the terminals or interface.

1

CON5

TM1

RY3A RY3B

TM3

485

485

-A

AM1 AI1 T5V

-B

DO1 DO2 DI1 DI2 DI3 DI4 FWD REV

A

COM

24V G24

PG1

CON5 Æ RS485 Communication port; using to connect Control Panel.

TM1 Æ Relay A type output terminal.

TM3 Æ Digital I/O、Analog I/O、Communication port, etc.

PG1 Æ The PG feedback connector that comes form motor.

Refer to next Chapter for detail.

13

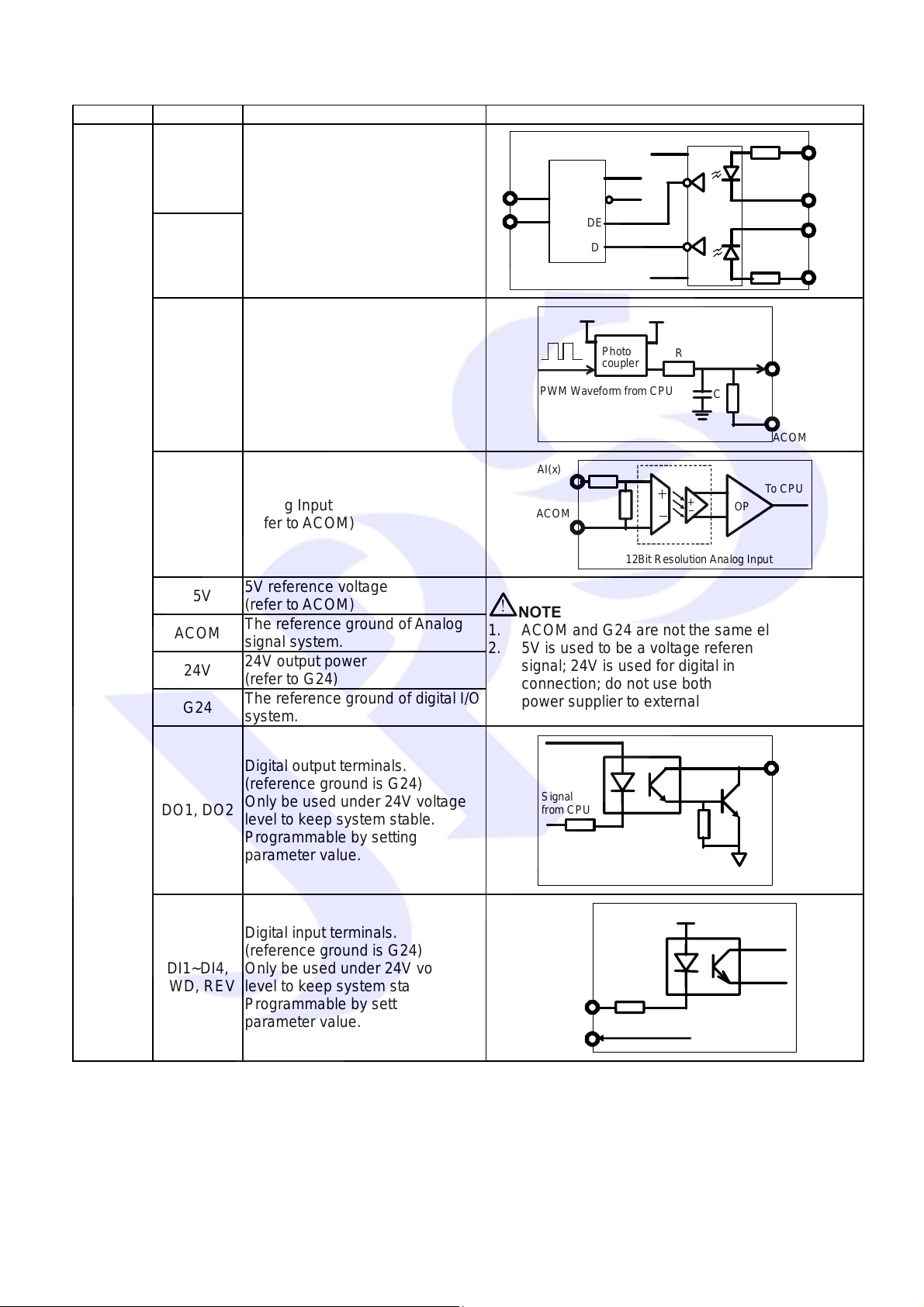

7.2 TM3 Description

C

A

G

A

A

A

AI(x)

)

V

-

(x)

Terminal Name Function Hardware construction

TM3

485-A

485-B

AM1

AI1

T5V

ACOM

24V

G24

RS485 communication port

(photo coupler isolated)

Analog output

(refer to ACOM )

Analog Input

(refer to ACOM )

5V reference voltage

(refer to ACOM )

The reference ground of Analog

signal system.

24V output power

(refer to G24)

The reference ground of digital I/O

system.

485-

485-B

B

PWM Waveform fr om CPU

COM

!

NOTE

CC

RX

R

ND

RE

DE

D

GND

Photo

coupler

12Bit Resolution Analog Input

R

C

To CPU

OP

M1

COM

VCC

TE

TX

VC

1. ACOM and G24 are not the same electric level.

2. 5V is used to be a voltage reference for analog

signal; 24V is used for digital input / output signal

connection; do not use both these two voltage as

power supplier to external circuits.

DO-(x

Digital output terminals.

DO1, DO2

(reference ground is G24)

Only be used under 24V voltage

level to keep system stable.

ignal

rom C PU

Programmable by setting

parameter value.

Open Collector

+24

4.7K

G24

G24

To CPU

GND

Digital Input

DI1~DI4,

FWD, REV

Digital input terminals.

(reference ground is G24)

Only be used under 24V voltage

level to keep system stable.

Programmable by setting

parameter value.

Digital Output

DI

G24

14

7.3 Connector CON5

Pin No. Function Description

Pin1 5V

Pin2 0V

Pin3 LCD-A

Pin4 LCD-B

Pin5 N.C.

Default designed to be the communication port of Control

Panel.

It is not suitable to apply to another communication usage.

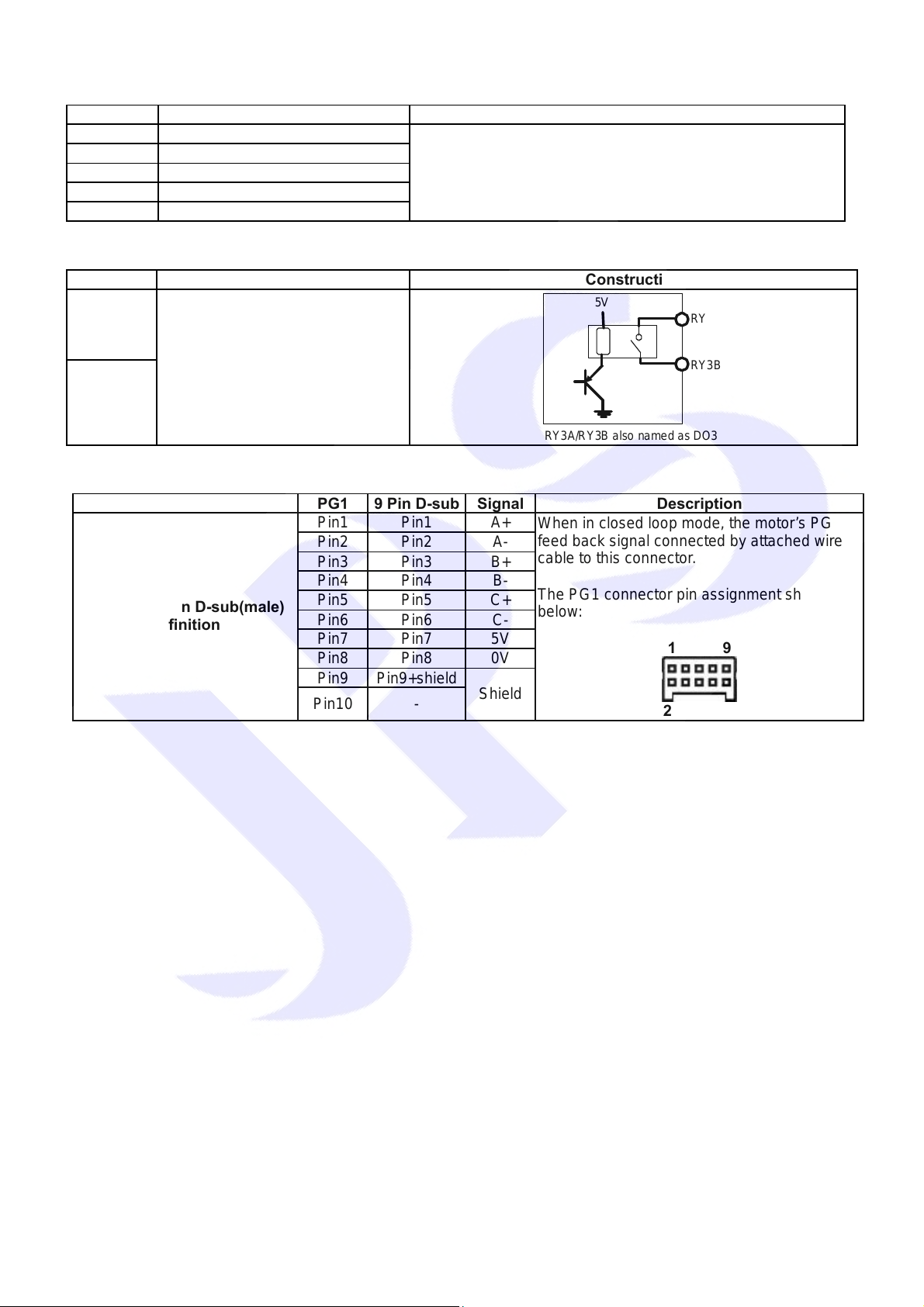

7.4 Terminal Block TM1

Terminal Function Construction

RY3A

RY3B

Relay A type output terminals.

Rating: 200V, 3A

Only be used under 24V voltage

level to keep system stable.

Programmable by setting

parameter value

RY3A/RY3B also name d as DO3

5V

7.5 Connector PG 1

Connector PG1 9 Pin D-sub Signal Description

PG1 and 9-pin D-sub(male)

definition

Pin1 Pin1 A+

Pin2 Pin2 A-

Pin3 Pin3 B+

Pin4 Pin4 B-

Pin5 Pin5 C+

Pin6 Pin6 C-

Pin7 Pin7 5V

Pin8 Pin8 0V

Pin9 Pin9+shield

Pin10 -

Shield

When in closed loop mode, the motor’s PG

feed back signal connected by attached wire

cable to this connector .

The PG1 connector pin assignment show as

below:

2 10

RY3A

RY3B

1 9

15

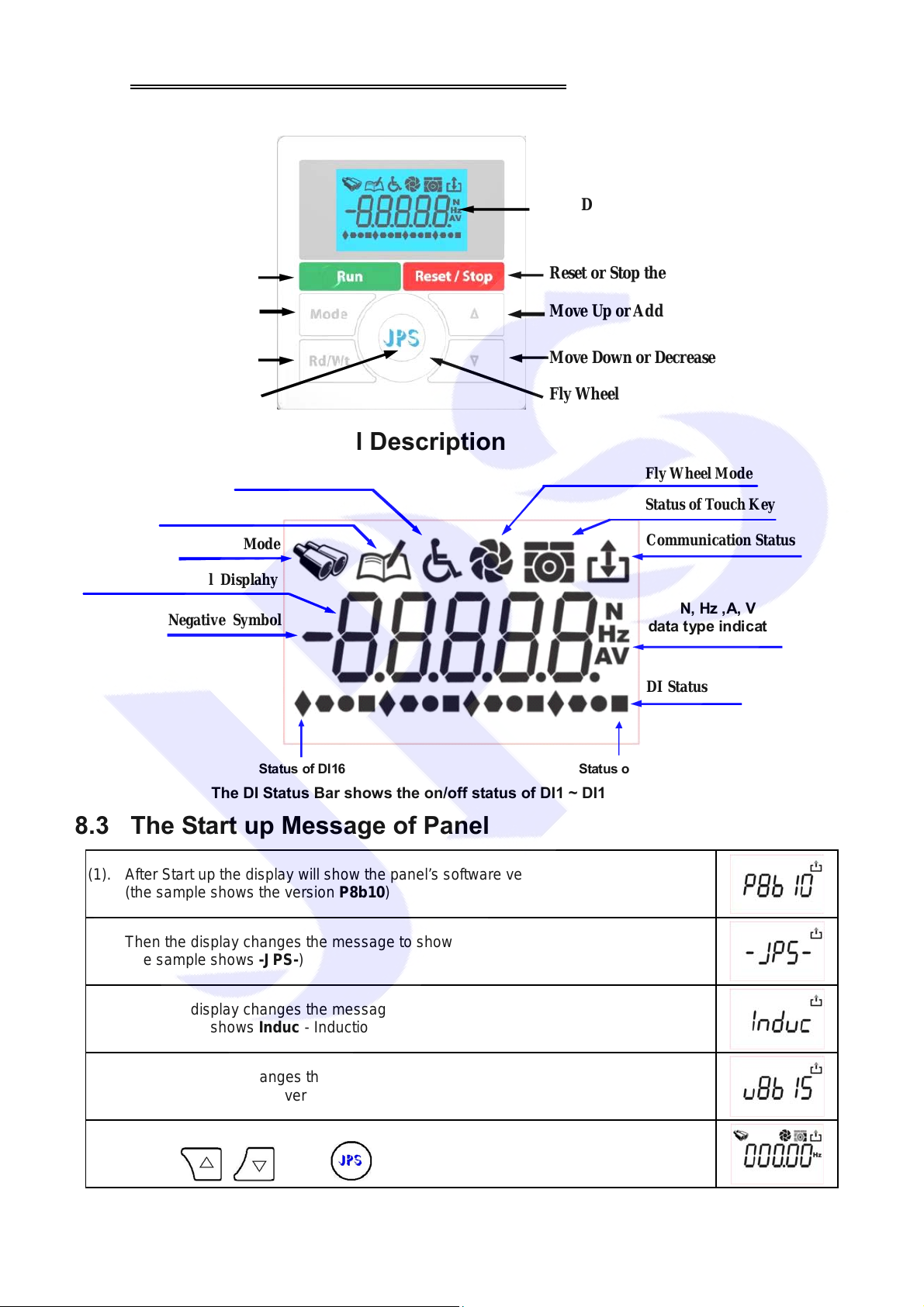

8. Digital Control Panel Description

k

r

8.1 Digital Control Panel Appearance Introduction

LCD Display

Run the Drive

Mode Switch

Read / Write

Lock / Unloc

8.2 Monitor's Graphical Description

Alarm Mode

Parameter Mode

Monitor Mode

5-digital Numerical Displahy

Negative Symbol

Reset or Stop the Driver

Move Up or Ad d

Move Down or Decrease

Fly Wheel

Fly Wheel Mode

Status of Touch Key

Communication Status

N, Hz ,A, V

data t ype indi cator

DI Status Bar

Status of DI1 Status of DI16

The DI Status Bar shows the on/off status of DI1 ~ DI16 for real time.

8.3 The Start up Message of Panel

(1). After Start up the display will show the panel’s sof tware version firstly.

(the sample shows the version P8b10)

(2). Then the display changes the message to show company’s logo.

(the sample shows -JPS-)

(3). Then the display changes the message to show the fitting motor type.

(the sample shows Induc - Induction type)

(4). Then the display changes the message to show the driver’s software version.

(the sample shows the version v8b15)

(5). At last, the display changes the status to show the monitor mode.

Only

, and keys can be operated at this status.

16

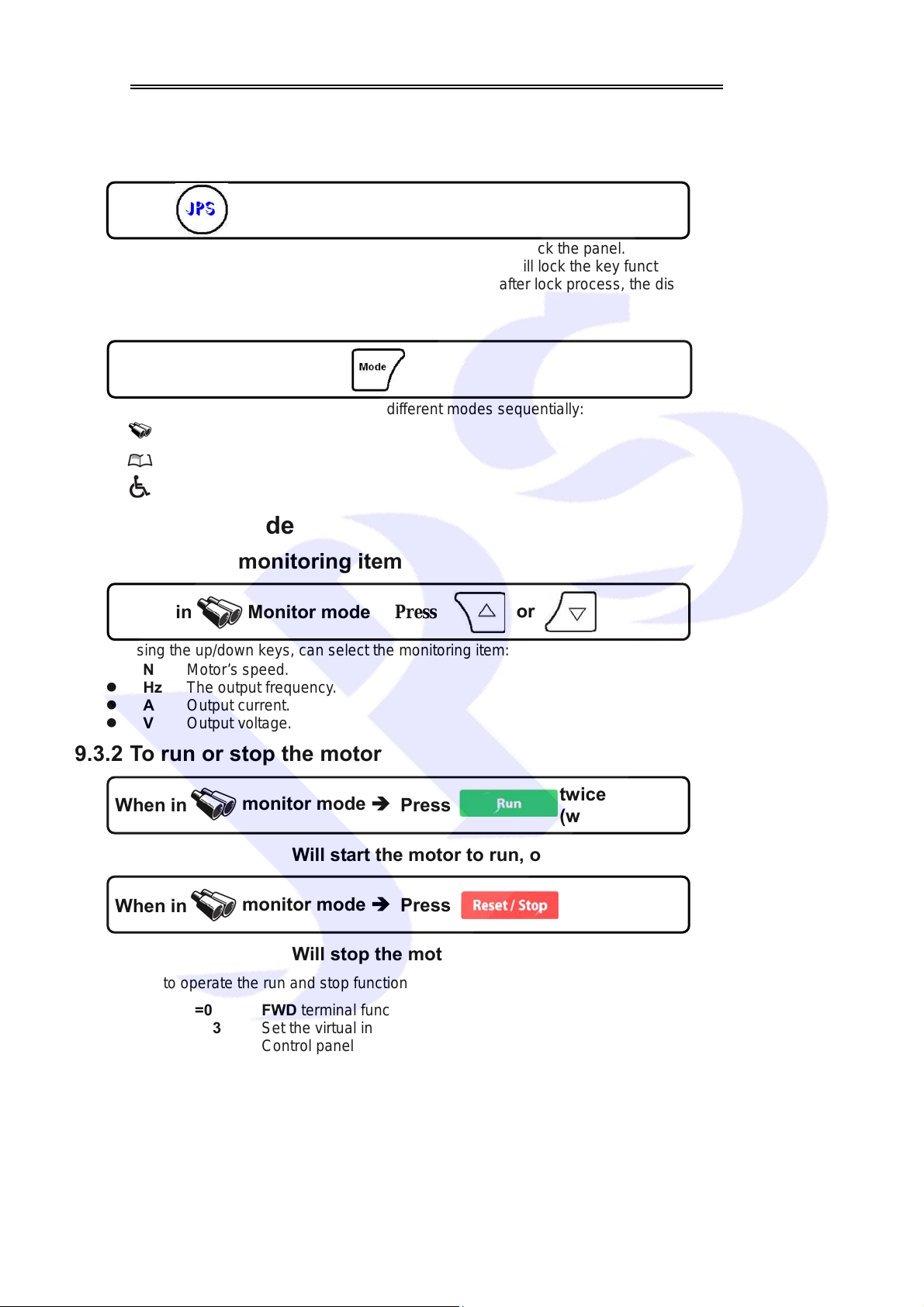

9. The Operation Guide of Digital Control Panel

When power-on start or reset the panel, the key will be locked and need user to unlock it. After user

left it after 10 minutes for not using, the panel will lock the keys automatically.

9.1 Lock and unlock

Press

at least 1 sec, till 4 beeps sound.

The panel will be unlocked.

z After unlock the panel, to do this proceedure again will lock the panel.

z Keep unprocees this panel for 10 minutes, the panel will lock the key function automatically.

z After unlock process, the display will show “unloc”; after lock process, the display will show “loc”.

9.2 Change mode

At any status Î

By pressing this bottom, can enter these different modes sequentially:

z

z

z

Monitor mode

Parameter mode

Alarm mode

Press

9.3 Monitor mode

9.3.1 Select the monitoring item

When in

Monitor mode

Press

By using the up/down keys, can select the monitoring item:

z N Motor’s speed.

z Hz The output frequency.

z A Output current.

z V Output voltage.

or

9.3.2 To run or stop the motor

When in

monitor mode Î

Press

Will start the motor to run, or

When in

monitor mode Î

Press

Will stop the motor.

In order to operate the run and stop function on the control panel, the condition list below should be sati sfied:

z G01-05=0 FWD terminal function: no function.

z G01-08=73 Set the virtual input function: FWD function.

z G01-17=1 Control panel RUN / STOP function switch: enable.

twice

(within 0.5sec)

twice

(within 0.5sec)

17

9.3.3 Use the fly wheel function in the monitor mode

In monitor mode, can enter the fly wheel mode by touching and draw on the wheel.

or

If enter the fly wheel mode successfully, the icon will be showed on the display; in the mean time,

the display will show the present speed, and the latest digital will flash to notice that the data is ready to

be edit.

9.3.4 Use fly wheel and the up/down keys to edit data

z Change the edit position

Touch the right or left

side of the wheel lightly

By using this way, can change the edit positon to save the operation time.

z Edit the value

1. Using the fly wheel to change the value

to change the edit

position.

or to increase or decrease the value.

2. Using up/down keys to change the value

press

Bothe of these two ways can be used to change the value.

z Write

Press

twice within 0.5sec, the value will be written into

memory.

or

to change the value.

18

9.4 Parameter mode (select, read, edit, write)

Press to enter parameter mode.

After enter parameter mode, LCD display will show 00-00; the left side of hyphen is group nu mber, and the

left side is parameter number in the group; that is to say, the presently showed parameter is G00-00.

In the parameter mode should follow the steps list below to read or change the parameter’s value.

1. Select parameter.

2. Read out the value of parameter.

3. Enter edit mode to change the value, if you wish.

4. Write down the value into the parameter and save in memory.

5. Exit from edit mode to select another parameter, or exit to the top level to change to another

operation mode.

9.4.1 Select the parameter

【NOTICE】All the operation described below can only work under the condition of the

(parameter mode) or

By using the operation described below, can select parameter, read value, edit value and write the value into

parameter .

1. Select parameter

z Enter select parameter mode

(edit mode).

Pres

or

to enter select parameter

or

Touch one of the left

or right side of

to enter select

parameter mode.

wheel lightly.

By these processes, the least digital of displayed data will be flashed to indicate that is ready to be

edit.

z Change the edit position

Touch the left

or right

to change the edit

position.

z Enter parameter number

Press

or

to increase or decrease value.

or

Draw on the fly wheel

to change the value.

circularly

19

2. Read the value of parameter

In

mode

3. Edit parameter value

4. Write down the parameter value

The proceedures of editing and writing the parameter value are same with the proceedure that are

introduced in paragraph 9.3.4Use fly wheel and the up/down keys to edit data.

5. Return

Press

to return to previous mode sequentially.

9.5 Alarm mode

Press

to select alarm mode.

Î

press

to read parameter value.

then

In mode Î

Press

By using Up or Down keys, can show A0 ~ A3 alarm messages sequentially:

z A0 Showing the present alarm message.

z A1 Showing the alarm message previous than A0.

z A2 Showing the alarm message previous than A1.

z A3 Showing the alarm message previous than A2.

** After power on or reset, all alarm record will be shift by the sequence A0ÆA1ÆA2ÆA3, and the

record A0 will be refresh by present status.

or

9.6 RESET

In

mode ÎPress

This procedure will reset the driver and panel itself, and the effect like power-on restart.

Twice within 0.5sec.

20

10. Quick Start

10.1 Run Command Set from Digital Input Terminals

Step I Setting Basic Parameters and Auto Tuning (Close Loop)

A. Setting the Parameter of Motor

Refer to the nameplate on motor to set the following parameters:

1. G10-00 Full Load Current (%)

This parameter defines the percentage of the motor’s rating and the driver’s rating.

Full Load Current (%) = (Rated Current of Motor / Rated Current of Driver) x 100%

2. G10-02 Motor Pole No.

3. G16-08 Max. RPM Limit

B. Execute R&L Auto Tuning

1. Setting G15-00 (Motor Operation Mode) to be 7 (select R&L Auto Tuning).

2. Reset the driver .

3. Connect FWD and G24 terminals, and wait till display shows .

After completing the R&L Auto Tuning, the driver will set the following parameters automatically:

1. G10-05 the phase resistance of motor.

2. G10-06 the phase inductance of motor.

C. Execute Current Gain Auto Tuning

1. Setting G15-00 (Motor Operation Mode) to be 6 (select Current Gain Auto Tuning).

2. Reset the driver .

3. Connect FWD and G24 terminals, and wait till display shows .

After completing the Current Gain Auto Tuning, the driver well set the following parameters

automatically.

1. G15-01 Current Loop P-gain

2. G15-02 Current Loop I-gain

D. Set Motor Operation Mode

1. Setting G15-00 (Motor Operation Mode) to be 2 (Close Loop Mode.

2. Reset the driver.

Step II Start to Run

1. Setting G16-00 (Speed Set 0) = 100. ÆSetting Speed Set 0 = 100 rpm.

2. Connect FWD and G24 terminals, the motor will start and run at 100 rpm speed.

10.2 RUN Command Set from Control Panel

After studying the paragraph 10.1, if want to control Run and Stop directly from Control Panel, follow the steps

below:

1. G16-00 (Speed Set 0) = 100 Î Setting Speed Set 0 = 100 rpm.

2. G01-05 (FWD function select) = 0 Î Disable FWD terminal function.

3. G01-08 (Virtual terminal function select) = 73 Î Setting virtual terminal function to be 73 (FWD function).

4. G01-17 (Panel’s Run / Stop Enable) = 1 Î Enable the Run / Stop function.

Now, the motor can be set to run or stop directly from Panel’s run / stop keys.

21

10.3 Change the Definition of Motor’s Direction

!

NOTE

In normally, the definition of running direction is defined by default setting, and the wiring of motor and

feed back encoder have been defined before packing. Somehow, there may happen some condition, for

example the G07-00 or the wiring of motor is changed, then the definition between the driver and motor

and encoder will not match and may cause serious vibration or laud noise. When in this situation, please

stop to operate the driver and contact with your agency to correct all the condition.

If in regular condition, the driver can drive motor normally and want to change the direction definition of motor.

Please following the steps listed below:

※ When driver is in Forward Run condition, and the motor rotating in CCW direction (face to the motor

axis):

1. Setting G01-05 (FWD terminal function select) to be 0 Î Disable FWD terminal functions.

2. Turn off AC input power

3. Connect the U, V, W wires to the terminals U, V, W of driver. Î Change the output power lines.

4. Turn on the AC input power.

5. Setting G07-00 (Magnetic sensor direction) to be 0. Î Phase A leads phase B.

6. Setting G01-05 = 73 Î Redefined the FWD terminal function.

※ When driver is in Forward Run condition, and the motor rotating in CW direction (face to the motor

axis):

1. Setting G01-05 (FWD terminal function select) to be 0 Î Disable FWD terminal functions.

2. Turn off AC input power

3. Connect the U, W, V wires to the terminals U, V, W of driver. Î Change the output power lines.

4. Turn on the AC input power.

5. Setting G07-00 (Magnetic sensor direction) to be 0. Î Phase A leads phase B.

6. Setting G01-05 = 73 Î Redefined the FWD terminal function.

22

11. Parameter Description

11.1 IRIS-IMAC Parameter List

G00-Driver Specification Group *There is different setting for different model.

No. Name Default Min. Max. Unit Type Pr.

Unit Address

00-00

00-01 Driver system software version -- 0 FFFF Version F 097

00-02 Motor type 1 0 4 -- F 348

00-03 Special Function *0 0 65535 -- F 337

00-04 AC power input voltage *220 10 1000 Vac(rms) FR/W 130

00-05 Rated output current *5.0 1.0 6000.0 Ampere FR/W 209

Carrier frequency

00-06

00-07 EAROM Lock 0 0 1 -- FR/W 368

00-08 Recover parameter to default 0 0 1 -- R/W 369

G01-Digital Input Group

No. Name Default Min. Max. Unit Type Pr.

01-00 Status of DI1~DI16 0000 0000 FFFF -- M 011

01-01 DI1 function select 0 0 255 -- R/W 061

01-02 DI2 function select 0 0 255 -- R/W 062

01-03 DI3 function select 0 0 255 -- R/W 063

01-04 DI4 function select 0 0 255 -- R/W 064

01-05 FWD (DI5) function select 73 0 255 -- R/W 065

01-06 REV (DI6) function select 74 0 255 -- R/W 066

01-07 FAN running status (fixed and cannot be changed) 30 30 30 -- F 0

01-08 The Run/Stop keys function select 0 0 255 -- R/W 068

01-09 ~ 01-14 are reserved -- --

01-15 DI15 function select (a virtual input, links to DO15) 0 0 255 -- R/W 475

01-16 DI16 function select (a virtual input, links to DO16) 0 0 255 -- R/W 476

01-17 The enable switch of panel’s Run/Stop keys 0 0 1 -- R/W 059

【NOTE】

The digital input function definition can’t be repeated. Check this point after finish setting this group.

G02-Digital Output Group

No. Name Default Min. Max. Unit Type Pr.

02-00 Status of DO1~DO16 0000 0000 FFFF -- M 012

02-01 DO1 function select 0 0 255 -- R/W 111

02-02 DO2 function select 0 0 255 -- R/W 112

02-03 DO3 function select 0 0 255 -- R/W 113

02-04 ~ 02-14 are reserved

02-15 DO15 function select (a virtual output, links to DI15) 0 0 255 -- R/W 165

02-16 DO16 function select (a virtual output, links to DI16) 0 0 255 -- R/W 166

G03-Analog Input Group

No. Name Default Min. Max. Unit Type Pr.

03-00 AI1 A/D output value 0 0 4095 -- M 229

03-01 AI1 max. input value 4095 0 4095 -- FR/W 230

03-02 AI1 0V input value 2048 0 4095 -- FR/W 231

03-03 AI1 min. input value 0 0 4095 -- FR/W 232

03-04 AI1 input type 0 0 1 -- R/W;R 233

03-05 AI1 % display of input value 0.00 0.00 100.00 % M 234

03-06 AI1 blind zone setting (used in ±10V input type) 0 0 1000 -- R/W 235

G05-Analog Output Group

No. Name Default Min. Max. Unit Type Pr.

05-00 AM1 Function Select 0 0 15 -- R/W;R 370

05-01 AM1 Full Scale Data Range 0 0 65535 -- FR/W 371

05-02 AM1 Output Volume Setting (0~100% full-scale) 0.0 0.0 100.0 % RAM 372

05-03 AM1 100% full scale adjustment 0.0 0.0 100.0 % FR/W 373

05-04 AM1 75% scale adjustment 0.0 0.0 100.0 % FR/W 374

05-05 AM1 50% scale adjustment 0.0 0.0 100.0 % FR/W 375

05-06 AM1 25% scale adjustment 0.0 0.0 100.0 % FR/W 376

05-07 AM1 12.5% scale adjustment 0.0 0.0 100.0 % FR/W 377

1 1 63 --

*10.0 2.0 16.0 Khz

FR/W;R

FR/W;R

071

239

23

G07-Magnetic Sensor Group

No. Name Default Min. Max. Unit Type Pr.

07-00 Magnetic sensor direction 0 0 1 -07-01 Magnetic sensor PPR 256 256 60000 --

Magnetic sensor angle alignment (do not change)

07-02

0.0 0.0 359.9 Deg

07-03 Magnetic sensor input buffer size 6 0 6

FR/W;R

FR/W;R

FR/W;R

FR/W;R

188

189

197

192

07-04 Magnetic sensor A/B/C stat us 0 0 7 -- M 190

07-05 Magnetic sensor Counter status 0 0 65535 -- M 191

07-06~07-07 Reserved

07-08 Magnetic sensor check time 0 0 30000 ms R/W 193

G10-IMAC Motor Group

No. Name Default Min. Max. Unit Type Pr.

10-00 Motor full load current ratio (%) 50 0 200 % FR/W 210

10-01 Motor exciting current ratio (%) 30 0 200 % FR/W 211

Motor pole no.

10-02

4 2 128

FR/W;R

116

10-03 Ke value 0 0 1000 V/krpm FR/W 198

10-04 Electronic thermo relay time 3 0 120 sec R/W 215

10-05 Phase resistance 1.000 0.000 60.000 Ohm FR/W 216

10-06 Phase inductance 1.00 0.00 60.00 mH FR/W 217

10-07 Reserved

10-08 Full Load Slip 60 0 1000 Rpm R/W 203

G15-IMAC Control Group

No. Name Default Min. Max. Unit Type Pr.

Operation mode

15-00

11 0 29

R/W;R

003

15-01 Current loop P-gain 1000 0 3000 R/W 004

15-02 Current loop I-gain 100 0 3000 R/W 005

15-03 Current loop filter level 0 0 7 R/W 008

15-04 Speed loop P/I gain select 1 1 2 R/W 018

15-05 1’st speed loop gain switch point 100 0 3000 rpm R/W 029

15-06 1’st speed loop P-gain 500 0 1000 R/W 031

15-07 1’st speed loop I-gain 50 0 1000 R/W 032

15-08 1’st speed loop filter level 0 0 7 R/W 033

15-09 2’nd speed loop gain switch point 100 0 3000 rpm R/W 160

15-10 2’nd speed loop P-gain 500 0 1000 R/W 161

15-11 2’nd speed loop I-gain 50 0 1000 R/W 162

15-12 2’nd speed loop filter level 0 0 7 R/W 163

15-13 Torque control mode 0 0 1 R/W 086

15-14 Torque limit-quadrant I setting 100.0 0.0 300.0 % R/W 087

15-15 Torque limit-quadrant II setting 100.0 0.0 300.0 % R/W 088

15-16 Torque limit-quadrant III setting 100.0 0.0 300.0 % R/W 089

15-17 Torque limit-quadrant IV setting 100.0 0.0 300.0 % R/W 090

15-18 Torque drooping range 10 0 100 % R/W 108

15-19 Direction limit 0 0 2 FR/W 110

15-20 Torque compare value 100 0 300 % R/W 95

G16-IMAC Multi-Speed Setting Group

No. Name Default Min. Max. Unit Type Pr.

16-00 Speed Set0 0 0 30000 rpm R/W 120

16-01 Speed Set1 0 0 30000 rpm R/W 121

16-02 Speed Set2 0 0 30000 rpm R/W 122

16-03 Speed Set3 0 0 30000 rpm R/W 123

16-04 Speed Set4 0 0 30000 rpm R/W 124

16-05 Speed Set5 0 0 30000 rpm R/W 125

16-06 Speed Set6 0 0 30000 rpm R/W 126

16-07 Speed Set7 0 0 30000 rpm R/W 127

16-08 Max. speed limit 3000 0 30000 rpm FR/W 128

Speed command select

16-09

Actual RPM setting Æ Actual Command RPM

16-10

Display

0 0 19 rpm

0

-3000

0

30000 rpm M 119

R/W;R

278

24

G17-IMAC Acc/Dec/S-curve Group

No. Name Default Min. Max. Unit Type Pr.

17-00 Acc. time (0~1000rpm) 5.00 0.00 650.00 Sec/Krpm R/W 053

17-01 Dec. time (1000~0rpm) 5.00 0.00 650.00 Sec/Krpm R/W 054

17-02 S-curve T1 time (start of Acc. period) 0.00 0.00 5.00 Sec R/W 055

17-03 S-curve T2 time(end of Acc. period) 0.00 0.00 5.00 Sec R/W 056

17-04 S-curve T3 time(start of Dec. period) 0.00 0.00 5.00 Sec R/W 057

17-05 S-curve T4 time(end of Dec. period) 0.00 0.00 5.00 Sec R/W 058

17-06 Brake Hold Time 1.00 0.00 60.00 Sec R/W 291

G62-Timer Group

No. Name Default Min. Max. Unit Type Pr.

62-00 Type of Timer A. 2 0 2 R/W 249

62-01 T1 time of Timer A. 1.00 0.01 300.00 sec R/W 250

62-02 T2 time of Timer A. 1.00 0.01 300.00 sec R/W 251

62-03 Type of Timer B. 2 0 2 R/W 252

62-04 T1 time of Timer B. 1.00 0.01 300.00 sec R/W 253

62-05 T2 time of Timer B. 1.00 0.01 300.00 sec R/W 254

G64-MISC Up/Down Group

No. Name Default Min. Max. Unit Type Pr.

64-00 Speed Up / Down Counter type select. 0 0 1 -- R/W 104

64-01 Speed Up / Down Counter start value. 0 0 3000 Rpm R/W 105

Speed Up / Down Counter change volume by

64-02

trigger.

Speed Up / Down Counter change volume by

64-03

time.

1.00 0.00 300.00 Rpm/Trigger R/W 106

100 0 30000 Rpm/Sec R/W 107

G65-MISC. Speed Compare Group

No. Name Default Min. Max. Unit Type Pr.

65-00 Speed compare value 30 0 30000 Rpm R/W 206

65-01 Speed arrive setting 1000 0 30000 R pm R/W 207

65-02 Speed arrive range 30 0 30000 Rpm R/W 208

G66-MISC. Rotary Switch Group

No. Name Default Min. Max. Unit Type Pr.

66-00 RSW TYPE 0 0 3 -- R/W;R 118

66-01 RSW Data 0 0 65535 -- M 137

66-02 RSW Backup Memory 0 0 65535 -- R/W 138

66-03 RSW Max Data Limit 1000 0 65535 -- R/W 152

G82-H/W DC-BUS adjust Group

No. Name Default Min. Max. Unit Type Pr.

82-00 DC bus measurement adjust 100 80 120 % FR/W 131

82-01 DC bus voltage 0 0 1000 Vdc M 132

82-02 Over-Discharge-Protect time 5.0 0.0 10.0 sec R/W 151

G83-H/W THERMISTOR adjust Group

No. Name Default Min. Max. Unit Type Pr.

83-00 Heat sink temperature (centigrade) 0 0 250 degC M 140

83-01 Over-Heat protect temperature (centigrade) 80 50 100 degree R/W 150

G84-H/W FAN adjust Group

No. Name Default Min. Max. Unit Type Pr.

84-00 FAN control type 0 0 1 -- R/W 146

84-01 FAN feed back signal (Factory set) 2 1 16 -- FR/W 147

84-02 Measured FAN speed 0 0 65535 rpm M 148

84-03 FAN low speed warning and trip level 2000 0 30000 rpm R/W 149

25

11.2 Monitor Type Parameters’ Address

The table showed below list the Monitor type parameters, and there address. User can rea d it by communication.

Name Unit Address (Pr.)

Driver’s output voltage

Motor’s actual speed

Driver’s output frequency

Alarm message

Driver’s output current

V 013

rpm 019

Hz 030

-- 035

rms(Amp) 213

11.3 Parameter’s Type

The table showed below describing the different type of all the parameter of this manual:

Type Description

R/W

FR/W

RAM

M

F

R

The parameter is Readable and Writable, and can be stored in EAROM.

All this type parameters can be initialized by the G00-08 function.

The parameter is Readable and Writable, and can be stored in EAROM.

This type of parameter is specially set by Factory and not for user normally usage.

This type of parameter only can be modified by authorized person.

The parameter is Readable and Writable, but it uses the RAM to temporally store the

change of parameter. After power on or reset it will be recover to be default value.

The parameter is Monitor type. Only readable and no effect for writing this parameter.

Factory set parameter, and should not be changed.

To indicate that any change of this type of parameter have to Reset the driver to enable the

change.

26

12. IRIS-IMAC Parameter Description

12.1 G00 Driver Specification Group

z G00-00 Î Unit Address (for communication)

This parameter can be set from 1 to 63. If there are above 2 driver connected to the

communication line, the unit address should be set for individual number.

【NOTICE】The communication port format should be 19200bps、8bits、1stop、no parity.

z G00-01 Î System software version

Indicate the CPU software version.

z G00-02 Î Motor Type

Setting this parameter to choice suitable motor type; it should select 1 (IMAC type) for this driver.

z G00-03 Î Special function select

Set this parameter to be 0 for standard model.

z G00-04 Î Input AC power voltage

This parameter defines the input AC power voltage level:

For 220V driver, it should set 220;

For 380V driver, it should set 380.

【NOTE】

This parameter has been defined well before leaving factory. User should not change it.

If necessary to adjust it, please measure the R, S, T voltage and get the average to write

into this parameter.

※ If the R, S, T input voltage is different form the designed level exceed 10%, please

contact with the agency or producer to confirm. Rashly change this parameter may

cause damage to this driver or public danger.

The driver will follow this parameter’s setting to calculate the followed voltage check level:

※ Over Potential trip level = 1.414 * G00-04 * 130 %。

※ OP recover level = 1.414 * G00-04 * 120%。

※ Under Potential trip level = 1.414 * G00-04 * 70%。

※ UP recover level = 1.414 * G00-04 * 80%。

※ CONTACTOR ON level = 1.414*G00-04*69%。

TOR OFF = 1.414* G00-04*65%。

※ CO

【NOTE】The Contactor is inside the driver to short the charging resistor.

※ Brake Discharge start level = 1.414*G00-04*117%。

NTAC

z G00-05 Î Rated Output Current

This parameter defines the rated output current of driver.

【NOTE】This parameter is set as the specification of driver, and there is no need to change it.

z G00-06 Î Carrier Frequency

This parameter defines the PWM carrier frequency. The range can be set from 2 KHz~16 KHz.

If setting higher carrier frequency, the output waveform will be less distortion for sinusoidal, and

the human ear will hear less noise, but the electronically interference to the environment will be

larger, and generate more switching loss on power module.

If setting lower carrier frequency, the output waveform there will be more distortion for sinusoidal,

and the human ear will hear more noise, but the electronically interference environment will be

less, and the switching loss on power module will be less too.

z G00-07 Î EAROM Lock

Value Description

0 The parameter value can be changed and stored into EAROM.

1 The change of parameter value will not be stored into EAROM

【NOTE】The value of G00-07 will not be changed after reset.

If G00-07=0, after reset the G00-07=0.

If G00-07=1, G00-07=1.

z G00-08 Î Recover Parameters to Default

If setting G00-08 to be 1, all the R/W type parameters in EAROM will be initialized to default val ue.

After changing the value of this parameter, must reset the driver.

27

12.2 G01 Digital Input Group

z G01-00 Î Status of DI1~DI16

This parameter shows the DI1 ~ DI16 status by hexadecimal numerical data. Converting thi s data

to be binary format, the status of DI1 ~ DI16 will be presented from LSB to MSB of the data.

For example:

if G01-00=0 Î Converting to binary is “0000 0000 0000 0000”. The DI1 ~ DI16 are OFF.

If G01-00=5 Î Converting to binary is “0000 0000 0000 0101”. The DI1 and DI3 are ON, and

others are OFF.

z G01-01 Î DI1 Function Select

z G01-02 Î DI2 Function Select

z G01-03 Î DI3 Function Select

z G01-04 Î DI4 Function Select

z G01-05 Î FWD (DI5) Function Select

FWD terminal has been set to be 73 Î Forward Run.

z G01-06 Î REV (DI6) Function Select

REV terminal has been set to be 74 Î Reverse Run.

z G01-07Î FAN running status (Factory set, cannot be changed)

This parameter is fixed set by factory and cannot be changed. The FAN runnin g status will

showed on the bit7 of G01-00.

z G01-08 Î The Run/Stop keys function select

Only in Monitor mode or Fly wheel mode can operate this way:

Press

change can be check from G01-00.

Press

change can be check from G01-00.

【NOTE】Usually the G01-08 is set to be 73 (FWD) or 74 (RWD).

z G01-09 ~ 01-14 Î Reserved

【NOTE】G01-09~G01-14 are reserved, and keep them all to be 0.

z G01-15 Î DI15 Function Select (virtual input, links to DO15)

z G01-16 Î DI16 Function Select (virtual input, links to DO16)

DI15 and DI16 are virtual inputs, and are directly links to DO15 and DO16 respectively.

【NOTE】 About the function of such inputs DI1~DI4/FWD/REV/DI15/DI16, please refer to

chapter 13 Digital Input Function.

The digita

this group.

z G01-17 Î The Enable Switch of Run/Stop

If G01-17 = 0, the Run/Stop keys have no function.

If G01-17 = 1, the Run/Stop keys have function.

【NOTE】The Run/Stop can be enable d or disabled from Dix(21) (refer to chapter 13 Digital

Input Func

l input function definition can’t be repeated. Check this point after finish setting

ti

on).

twice within 0.5 sec, the virtual input DI8 will be set to be ON, and this

twice within 0.5 sec, the virtual input DI8 will be set to be OFF, and this

28

12.3 G02 Digital Output Group

z G02-00 Î Status of DO1~DO16

This parameter shows the DO1 ~ DO16 status by hexadecimal numerical data. Converting this

data to be binary format, the status of DI1 ~ DI16 will be presented from LSB to MSB of the data.

For example:

if G02-00=0 Î Converting to binary is “0000 0000 0000 0000”. The DO1 ~ DO16 are OFF.

If G02-00=5 Î Converting to binary is “0000 0000 0000 0101”. The DO1 and DO3 are ON, and

others are OFF.

z G02-01 Î DO1 Function Select

z G02-02 Î DO2 Function Select

DO1~DO2 are reality output terminals. The function of these terminals can be selecte d by setting

these parameters.

z G02-03 Î DO3 Function Select

DO3 actual output terminals are the RY3A and RY3B of TM1. It is a A-type relay output. The

function of this terminal can be selected by setting this parameter.

z G02-04 ~ 02-14Î Reserved

z G02-15 Î DO15 Function Select (virtual output, links to DI15)

z G02-16 Î DO16 Function Select (virtual output, links to DI16)

DO15 and DO16 are virtual outputs, and are directly links to DI15 and DI16 re spectively.

【NOTE】About the function of such outputs DO1~DO3/DO15/DO16, please refer to chapter 14 Digital

Function.

t

Outpu

12.4 G03 Analog Input Group

z G03-00 Î AI1 A/D Output Value

This parameter displays the A/D value of AI1 input.

z G03-01 Î AI1 Max. Input Value

Applying the maximum input voltage to AI1 read the dat a from G03-00 and set into this p arameter

as the AI1 input maximum limit.

z G03-02 Î AI1 0V Input Value

Appling 0V to AI1 read the data from G03-00 and set into this parameter as the AI1 0V input

reference.

z G03-03 Î AI1 Min. Input Value

Appling the minimum input voltage to AI1 read the data from G03-00 and set into this parameter

as the AI1 input minimum limit.

z G03-04 ÎAI1 Input Type

Select the AI1 input type of volt age range.

Value Description

The input voltage range is 0 ~ +10V.

0

The input voltage range is -10V ~ +10V.

1

z G03-05 Î AI1 % Display of Input Value

The displayed data = (AI1 actually input voltage / AI1 input range) x 100 %.

The AI1 input range is adjusted by G03-01 ~ G03-03.

z G03-06 Î AI1 Blind Zone Setting

If G03-04 select type 0, the AI1 input in the rang e of G03-03 +/- G03-06 will be negated.

【NOTE】Only when G03-04 select type 1, the function of G03-06 is available.

29

Example 1: AI1 input range -10V ~ +10V

AI1 input range is -10V ~ +10V, and rated speed of motor is 3000rpm. Setting G03-04 = 1,

and G03-06 = 20. Please following the situation listed below to learn how to use the

parameters.

+rpm

-10V +10V

-30rpm

20 20

+30rpm

-rpm

4012 2014 18

※ Input +10V to AI1, and read G03-00 = 4012.

※ Set G03-0 1= 4012.

※ Input 0V to AI1, and read G03-00 = 2014.

※ Set G03-02 = 2014.

※ Input -10V, and read G03-00 = 18.

※ Set G03-03 = 18.

※ By the equation 3000÷(4012-2014)≈1.5 to know that one A/D count is about 1.5rpm.

※ By the equation 20x1.5=30 to know the range of Blind Zone is +/-30rpm.

If the input voltage of AI1 is in the range of 2014 +/-20, the motor will not run.

If the input voltage of AI1 exceeds f the range of 2014+/-20, the motor will run, and the min. start speed

of motor will be about 30rpm.

30

Example 2: Simply using a variable resistor to set the running speed

V

1. Wiring the variable resistor (VR) to control input terminals as the figure showed below.

2. Setting G03-04 = 0. Î Select AI1 input range (0 ~ 10V).

3. Turn the VR to the maximum input position and read G03-00.

4. Write the G03-00 value into G03-01 Î Setting AI1 maximum value.

5. Turn the VR to the min. input position and read G03-00.

6. Write the G03-00 value into G03-02. Î Setting AI1 0V value.

7. Write the G03-00 value into G03-03 Î Setting AI1 min. value.

8. Setting G16-09 (Speed Command Select)=1 Î Select AI1 input as speed command.

9. Reset the driver . Î Change G16-09, must reset driver.

485-A 485-B AM1 AI1 T5V Acom +24V G24

DO1 DO2 DI1 DI2 DI3 DI4 FWD REV

2

R

3

Example 3: Using external +10V ~ -10V signal as speed command.

1. Wiring the input signal lines to control terminals as the figure showed below.

2. Setting G03-04 = 1 Î Select AI1 input range (-10V ~ +10V).

3. Input maximum voltage to AI1, read G03-00.

4. Write G03-00 value into G03-01. Î Setting AI1 maximum value.

5. Input 0V to AI1, read G03-00.

6. Write G03-00 value into G03-02. Î Setting AI1 0V value.

7. Input min. voltage to AI1, read G03-00.

8. Write G03-00 value into G03-03. Î Setting AI1 min. value.

9. Setting G16-09 (Speed Command Select) =1 Î Select AI1 input as speed command.

10. Reset the driver. Î Change G16-09, must reset driver.

485-A 485-B AM1 AI1 T5V Acom +24V G24

DO1 DO2 DI1 DI2 DI3 DI4 FWD REV

0V

Vi = +10V ~ -10V

31

12.5 G05 Analog Output Group

【NOTE】 The output signal of AM1is used to drive the external analog meter . The rating of meter is 1V/1mA.

z G05-00 Î AM1 Function Select

Value Description

No output.

0

Output Frequency.

1

Output Current

2

Output Voltage

3

Motor’s Actual Speed

4

Reserved.

5~9

100% Test Output.

10

75% Test Output.

11

50% Test Output.

12

25% Test Output.

13

12.5% Test Output.

14

The output of AM1 is set by G05-02.

15

Description:

Select0. AM1 has no output.

Select1. The output of AM1 presents the driver’s output frequency. The accuracy is 0.01Hz.

Select2. The output of AM1 presents the driver’s output current. The accura cy is 0.1A.

Select3. The output of AM1 presents the driver’s output voltage. The accuracy is 1V.

Select4. The output of AM1 presents the motor’s actual speed. The accuracy is 1rpm.

Select5~9. All these are reserved. Should not select these function numbers for operation safety.

Select10. AM1 send out 100% volume for adjusting. The output is adjusted by G05-03.

Select11. AM1 send out 75% volume for adjusting. The output is adjusted by G05-04.

Select12. AM1 send out 50% volume for adjusting. The output is adjusted by G05-05.

Select13. AM1 send out 25% volume for adjusting. The output is adjusted by G05-06.

Select14. AM1 send out 12.5% volume for adjusting. The output is adjusted by G05-07.

Select15. The output of AM1 is set by G05-02.

【NOTE】After change this parameter, the driver should be reset to let the changes be effect.

【NOTE】

All these 5 functions are used to adjust the

linearity of AM1 output. Normally, the

linearity had been adjusted in factory

already; therefore, users don’t have to do it

again.

z G05-01 Î AM1 Full Scale Data Range

This parameter sets the maximum full scale of the external analog meter. Note the rules listed

below:

1. When execute the adjustment of AM1 signal, the output full scale is 100.0%; therefore, this

parameter should set to be 1000 for the need.

2. After finishing the adjustment of AM1 signal, the output full scale should refer to the actual

external analog meter .

3. AM1 output rating is 1V/1mA.

Example:

Frequency Meter (full scale 60.00Hz) Î the full scale should set to be 6000.

Current Meter (full scale 20.0A) Î the full scale should set to be 200.

Voltage Meter (full scale 500V) Î the full scale should set to be 500.

Speed Meter (full scale 1800rpm) Î the full scale should set to be 1800.

z G05-02 Î AM1 Output Volume Setting

IF G05-00 select function 15, the output of AM1 is set by this parameter. The range of this

parameter is 0.0% ~ 100.0%.

z G05-03 Î AM1 100% Full Scale Adjustment

Be used for AM1 100% output scale adjustment.

z G05-04 Î AM1 75% Scale Adjustment

Be used for AM1 75% output scale adjustment.

z G05-05 Î AM1 50% Scale Adjustment

Be used for AM1 50% output scale adjustment.

z G05-06 Î

Be used for AM1 25% output scale adjustment.

AM1 25% Scale Adjustment

z G05-07 Î AM1 12.5% Scale Adjustment

Be used for AM1 12.5% output scale adjustment.

32

EXAMPLE: Introduce how to use an external analog speed meter.

The meter’s full scale is 1800rpm.

Connect the meter to the AM1 and Acom terminals as showed in the following figure.

TERMINAL

485-A 485-B

AM1 AI1 T5V Acom +24V G24

DO1 DO2 DI1 DI2 DI3 DI4 DI5 DI6

Analog Meter

1V/1mA

【NOTE】AM1 output rati ng is 1 V /1mA .

Follow these steps to use the meter properly.

1. G05-00=4 Î Set AM1 function to output motor’s actual speed.

2. G05-01=1800rpm Î Set AM1 full scale dat a ra nge to be 1800rpm.

3. Execute RESET Î After reset the driver, the setting of AM1 is finished.

【NOTE】If there is need to adjust the output linearity of AM1, please follow below steps.

1. G05-00=10 Î Set AM1 function to send 100% scale output.

2. Execute RESET Î Reset the driver.

3. G05-01=1000 Î Set AM1 Full Scale Range to be 1000.

4. G05-03=100 Î Check if the meter point to 1800rpm.

【NOTE】If it is not in proper position, adjust by the VR knob of the meter.

5. G05-00=11 Î Set AM1 function to send 75% scale output.

6. Execute RESET Î Reset the driver.

7. G05-04=(check the meter to set %) Î Adjust the G05-04 to let the meter point to 1800x75%=1350.

8. G05-00=12 Î Set AM1 function to send 50% scale output.

9. Execute RESET Î Reset the driver.

10. G05-05=( check the meter to set %) Î Adjust the G05-05 to let the meter point to 1800x50%=900.

11. G05-00=13 Î Set AM1 function to send 25% scale output.

12. Execute RESET Î Reset the driver.

13. G05-06=( check the meter to set %) Î Adjust the G05-06 to let the meter point to 1800x25%=450.

14. G05-00=14 Î Set AM1 function to send 12.5% scale output.

15. Execute RESET Î Reset the driver.

16. G05-07=( check the meter to set %) Î Adjust the G05-07 to let the meter point to 800x12.5%=225.

17. G05-00=4 Î Set AM1 function to output motor’s actual speed.

18. G05-01=1800 Î Set AM1 full scale data range to be 1800.

19. Execute RESET Î After reset the driver, the setting of AM1 is finished.

33

12.6 G07 Magnetic Sensor Group

z G07-00 Î Magnetic Sensor Direction

If observe the signals A and B (of the Magnetic Sensor output):

z If motor is running in forward direction, the A signal leads the B signal, then G07-00 should

set 0.

z If the A signal lags the B signal, then G07-00 should set 1.

If observe G07-05 (Magnetic Sensor Counter Status) status:

z If motor is running in forward direction, the counter value is increased, and then G07-00

should set 0.

z If the counter value is decreased, then G07-00 should set 1.

z G07-01 Î Magnetic Sensor PPR

Input the Magnetic Sensor ppr value in this parameter.

z G07-02 Î Magnetic Sensor Angle Alignment (do not change)

Here records the magnetic sensor angle alignment data, and should not be changed.

【NOTE】This record is written by factory, and should not changed by user.

z G07-03 Î Magnetic Sensor Input Buffer Size

If using 256 pps sensor, G07-03 should set 6.

If Using 1024 pps sensor, G07-03 should set 2.

z G07-04 Î Magnetic Sensor A/B/C Status

This parameter displays the status of A/B/C of magnetic sensor.

【NOTE】About the detail of this status, please contact with agency or technical

department of factory.

z G07-05 Î Magnetic Sensor Counter Status

This parameter displays the magnetic sensor counter status. Th e counter will increase when

receive a forward direction pulse, and decrease when receive a reverse direction pulse. The

range of the counter is 0 ~ 65535.

z G07-08 Î Magnetic Sensor Check Time

This parameter is used to set the check time for driver to check the PG signal at every time the

speed command be send to check if the magnetic sensor is in good condition. Every time the

driver send a speed command to motor, and after the time which is set in this parameter the

driver will check the motor’s speed by checking the magnetic sensor feedback, if the speed is not

match the command the driver will show PG alarm message. This function can be disabled by

setting 0 into this parameter.

12.7 G10 IMAC Motor Group

z G10-00 Î Motor Full Load Current Ratio (%)

Set the ratio of the motor’s rating to the driver’s rating.

Motor Full Load Current ratio (%) = (motor's full load current / driver's rating current) x100%。

z G10-01 Î Motor Exciting Current Ratio (%)

Set the ratio of the motor’s exciting current to the motor’s full load current.

Motor Exciting Current Ratio (%) = (motor's exciting current / motor's full load current) x100%。

z G10-02 Î Motor Pole

According to the data of the motor’s manufacturer, set correct value.

z G10-03 Î Motor’s Ke Value

According to the data of the motor’s manufacturer, set correct value.

34

z G10-04 Î Electronic Thermo Relay Time

This Driver has built an electronic thermo function. If the driver volume is large then the motor

which is used, this function can prevent the motor overload. If this parameter sets to be 0, the

Electronic Thermo protect function is disabled.

(Irms / G10-00)

150%

110 %

G10-04

z G10-05 Î Phase Resistance

z G10-06 Î Phase Inductance

These two parameters should refer to the data of motor’s manufacturer, or can be auto tuned by

driver.

z G10-08 Î Full Load Slip

Refer to the data from motor’s manufacturer to set the correct value.

12.8 G15 IMAC Control Group

z G15-00 Î Operation Mode

Refer to the followed table to set the operation mode. Don’t select other value!

Value Description

IMAC open loop mode.

0

IMAC close loop mode.

2

This is standard operation mode for this driver. To operate in this mode, the motor

and feedback signal should be connect correctly.

Execute the Auto Current Gain Tuning.

6

Execute the Auto R&L Tuning.

7

【NOTE】After change this parameter, the driver should be reset then the change is effect.

If select wrong mode may cause damage to the driver and motor or the facility that use

this driver and motor.

z G15-01 Î Current Loop P-gain

Set the current loop P gain of the driver.

TIME

z G15-02 Î Current Loop I-gain

Set the current loop I gain of the driver.

【NOTE】This parameter is auto set by executing Auto Current Gain Tuning.

G15-01 should keep larger then G15-02.

z G15-03 Î Current Loop Filter Level

Define the current loop filter level.

z G15-04 Î Speed Loop P/I Gain Select

Value Description

1 Only use the 1’st Gain

2

z G15-05 Î 1’st Speed Loop Gain Switch Point

z G15-06 Î 1’st Speed Loop P-gain

z G15-07 Î 1’st Speed Loop I-gain

z G15-08 Î 1’st Speed Loop Filter Level

These are the 1’st PI tuning parameter for close loop control.

【NOTE】If G15-08 set too large, the response will be low, and the system will be unstable.

G15-06 should keep larger then G15-07.

According to the motor’s speed, the driver will use 1’st or 2’nd Gain for

different speed range.

35

z G15-09 Î 2’nd Speed Loop Gain Switch Point

p

z G15-10 Î 2’nd Speed Loop P-gain

z G15-11 Î 2’nd Speed Loop I-gain

z G15-12 Î 2’nd Speed Loop Filter Level

These are the 2’nd PI tuning parameter for close loop control.

【NOTE】If G15-12 set too large, the response will be low, and the system will be unstable.

G15-10 should keep larger then G15-11.

Example:

If set

z G15-05=300rpm

z G15-09=1500rpm

Gain

2’nd Ga in

1’st Gain

rpm

300

1. When speed start from 0rpm to 300rpm (under the 1’st gain switch point), the driver uses the

1’st PI tuning parameters for close loop control.

2. When speed is in the range of 300 ~ 1500rpm, the driver will change the PI tuning

parameters’ value from 1’st to 2’nd by linear manner.

3. When speed exceeds 1500rpm, the driver uses 2’nd PI tuning parameters for close loop

control.

z G15-13 Î Torque Control Mode

Define the torque control mode.

Value Description

0

Only use torque limit-quadrant I setting in any operation condition.

When operate in different quadrant, the driver use different torque limit respectively.

1

Refer to G15-14 ~ G15-17 for detail in this paragraph.

2

Use AI1 input as the torque limit with maximum speed limit and direction.

3

The torque limit and run direction are set by (AI1) x (G15-14 Torque Limit-quadrant I).

If G15-13 select 0:

The driver uses only Torque Limit-quadrant I setting as torque limit.

Q-Ⅱ

Reverse

Motor

+Torque

+G15-14

1500

Q-Ⅰ

Forward

Motor

Max rpm

-r

m

Reverse

Generator Generator

Q-Ⅲ Q-Ⅳ

-G15-14

-Torque

+rpm

+G16-0 8-G16-08

Forward

36

If G15-13 select 1:

p

p

V

V

p

V

V

When the motor runs in different guardant, the driver will use different torque limit setting

respectively.

Q-Ⅱ

Reverse

Motor

+Torque

G15-14

G15-15

Q-Ⅰ

Forward

Motor

-r

m

G15-16

G15-17

Reverse

Generator Generator

Q-Ⅲ Q-Ⅳ

-Torque

+rpm

+G16-0 8-G16-08

Forward

If G15-13 select 2:

Use AI1 input as the torque limit, and the motor will run in the direction of AI1 input with the limit of

max speed.

Q-Ⅱ

Reverse

Motor

-r

m

+Torque

aried by AI1

Q-Ⅰ

Forward

Motor

+rpm

+G16-0 8-G16-08

Reverse

Generator Generator

Q-Ⅲ Q-Ⅳ

aried by AI1

-Torque

Forward

If G15-13 select 3

The torque is set by AI1 x (G15-14 Torque Limit-quadrant I).

Q-Ⅱ

Reverse

Motor

-r

m

Reverse

Generator Generator

Q-Ⅲ Q-Ⅳ

+Torque

+G15-14

aried by AI1

aried by AI1

-G15-14

-Torque

Q-Ⅰ

Forward

Motor

+rpm

+G16-0 8-G16-08

Forward

37

z G15-14 Î Torque Limit-quadrant I Setting

Q

p

Set the torque limit value when motor is running in quadrant me.

In this guardant the motor is running in forward direction and output positive torque to load.

z G15-15 Î Torque Limit-quadrant II Setting

Set the torque limit value when motor is running in quadrant II.

In this guardant the motor is running in reverse direction and output positive torque to load.

z G15-16 Î Torque Limit-quadrant III Setting

Set the torque limit value when motor is running in quadrant III.

In this guardant the motor is running in reverse direction and there is negative torque comes from

load.

z G15-17 Î Torque Limit-quadrant IV Setting

Set the torque limit value when motor is running in quadrant IV.

In this guardant the motor is running in forward direction and there is negative torque comes from

load.

-Ⅱ

Reverse

Motor

m

-r

+Torque

Q-Ⅰ

Forward

Motor

+rpm

Reverse

Generator Generator

Q-Ⅲ Q-Ⅳ

z G15-18 Î Torque Drooping Range

Set the Torque Drooping Range (% ratio of max. speed) to prevent the motor vibrate at the

maximum speed.

T

Tcm

RPM-a RPM-b

RPM-a=(G16-08)

RPM-b=(G16-08) x(G15-18)

Example:

If motor’s maximum speed is 1000rpm, and set G16-08 = 1000, G15-18 = 10(%), the torque

limit will droop to zero by linear manner when the speed is in the range of 1000 ~ 1100rpm.

z G15-19 Î Direction Limit

Value Description

0 Permit forward and reverse direction run command.

1 Only forward direction run command is permitted.

The reverse direction run command will stop the motor.

2 Only reverse direction run command is permitted.

The forward direction run command will stop the motor.

-Torque

Forward

rpm

z G15-20 Î Torque Compare Value

Set the compared torque value for Over-torque-warning in this parameter.

【NOTE】About the detail, please refer to Chapter 14 Digital Output Function.

38

12.9 G16 IMAC Multi-Speed Setting Group

z G16-00 Î Speed Set0

z G16-01 Î Speed Set1

z G16-02 Î Speed Set2

z G16-03 Î Speed Set3

z G16-04 Î Speed Set4

z G16-05 Î Speed Set5

z G16-06 Î Speed Set6

z G16-07 Î Speed Set7