Page 1

Version: 25/6/2016

User manual

Page 2

PoStep60 user manual

2

www.poscope.com

Please read the following notes

1. All information included in this document is current as of the date this document is issued. Such information, however,

is subject to change without any prior notice.

2. PoLabs does not assume any liability for infringement of patents, copyrights, or other intellectual property rights of

third parties by or arising from the use of PoLabs products or technical information described in this document. No

license, express, implied or otherwise, is granted hereby under any patents, copyrights or other intellectual property

rights of PoLabs or others. PoLabs claims the copyright of, and retains the rights to, all material (software, documents,

etc.) contained in this release. You may copy and distribute the entire release in its original state, but must not copy

individual items within the release other than for backup purposes.

3. Descriptions of circuits, software and other related information in this document are provided only to illustrate the

operation of the products and application examples. You are fully responsible for the incorporation of these circuits,

software, and information in the design of your equipment. PoLabs assumes no responsibility for any losses incurred by

you or third parties arising from the use of these circuits, software, or information.

4. PoLabs has used reasonable care in preparing the information included in this document, but PoLabs does not warrant

that such information is error free. PoLabs assumes no liability whatsoever for any damages incurred by you resulting

from errors in or omissions from the information included herein.

5. PoLabs devices may be used in equipment that does not impose a threat to human life in case of the malfunctioning,

such as: computer interfaces, office equipment, communications equipment, test and measurement equipment, audio

and visual equipment, home electronic appliances, machine tools, personal electronic equipment, and industrial robots.

6. Measures such as fail-safe function and redundant design should be taken to ensure reliability and safety when PoLabs

devices are used for or in connection with equipment that requires higher reliability, for example: traffic control

systems, anti-disaster systems, anticrime systems, safety equipment, medical equipment not specifically designed for

life support, and other similar applications.

7. PoLabs devices shall not be used for or in connection with equipment that requires an extremely high level of reliability

and safety, as for example: aircraft systems, aerospace equipment, nuclear reactor control systems, medical equipment

or systems for life support (e.g. artificial life support devices or systems), and any other applications or purposes that

pose a direct threat to human life.

8. You should use the PoLabs products described in this document within the range specified by PoLabs, especially with

respect to the maximum rating, operating supply voltage range and other product characteristics. PoLabs shall have no

liability for malfunctions or damages arising out of the use of PoLabs products beyond such specified ranges.

9. Although PoLabs endeavors to improve the quality and reliability of its products, semiconductor products have specific

characteristics such as the occurrence of failure at a certain rate and malfunctions under certain use conditions.

Further, PoLabs products are not subject to radiation resistance design. Please be sure to implement safety measures

to guard them against the possibility of physical injury, and injury or damage caused by fire in the event of the failure of

a PoLabs product, such as safety design for hardware and software including but not limited to redundancy, fire control

and malfunction prevention, appropriate treatment for aging degradation or any other appropriate measures.

10. Usage: the software in this release is for use only with PoLabs products or with data collected using PoLabs products.

11. Fitness for purpose: no two applications are the same, so PoLabs cannot guarantee that its equipment or software is

suitable for a given application. It is therefore the user's responsibility to ensure that the product is suitable for the

user's application.

12. Viruses: this software was continuously monitored for viruses during production, however the user is responsible for

virus checking the software once it is installed.

13. Upgrades: we provide upgrades, free of charge, from our web site at www.poscope.com. We reserve the right to charge

for updates or replacements sent out on physical media.

14. Please contact a PoLabs support for details as to environmental matters such as the environmental compatibility of

each PoLabs product. Please use PoLabs products in compliance with all applicable laws and regulations that regulate

the inclusion or use of controlled substances, including without limitation, the EU RoHS Directive. PoLabs assumes no

liability for damages or losses occurring as a result of your noncompliance with applicable laws and regulations.

15. Please contact a PoLabs support at support@poscope.com if you have any questions regarding the information

contained in this document or PoLabs products, or if you have any other inquiries.

16. The licensee agrees to allow access to this software only to persons who have been informed of and agree to abide by

these conditions.

17. Trademarks: Windows is a registered trademark of Microsoft Corporation. PoKeys, PoKeys55, PoKeys56U, PoKeys56E,

PoScope, PoLabs and others are internationally registered trademarks.

Page 3

PoStep60 user manual

3

www.poscope.com

Contents

1 Introduction ..................................................................................................................................... 6

1.1 General symbols for this instructions ...................................................................................... 6

2 Description ...................................................................................................................................... 6

3 PoStep60 features ........................................................................................................................... 6

4 Connection diagram ........................................................................................................................ 7

4.1 Board use requirements .......................................................................................................... 7

4.2 Connection and setting ........................................................................................................... 7

4.3 PoStep pinout .......................................................................................................................... 8

4.4 Stepper motor connection ...................................................................................................... 8

4.4.1 10 pin IDC connector pinout............................................................................................ 8

4.4.2 Stepper motor connections ............................................................................................. 9

4.5 DC motor connection ............................................................................................................ 11

4.5.1 6 pin PWM connector pinout ........................................................................................ 11

4.5.2 DC motor connection .................................................................................................... 11

4.6 PoStep LEDs ........................................................................................................................... 12

4.6.1 Status LED ...................................................................................................................... 12

4.7 Requirements ........................................................................................................................ 12

5 Installation ..................................................................................................................................... 13

6 Technical specifications ................................................................................................................. 13

6.1 Electrical specification – limiting values ................................................................................ 13

6.2 Electrical specification – static characteristic ........................................................................ 13

7 User application............................................................................................................................. 14

7.1 PoStep60 main application GUI ............................................................................................. 14

7.1.1 PoStep driver status ...................................................................................................... 15

7.2 Basic user control of the PoStep driver ................................................................................. 16

7.3 Advanced settings ................................................................................................................. 18

7.4 Step control ........................................................................................................................... 19

7.5 Auto control ........................................................................................................................... 19

7.5.1 Position control mode ................................................................................................... 19

7.5.2 BINx Up/down mode ..................................................................................................... 21

7.5.3 Speed / Auto run mode ................................................................................................. 21

7.6 DC motor control ................................................................................................................... 22

7.7 Log charts .............................................................................................................................. 23

7.8 Firmware update ................................................................................................................... 24

7.9 Major changes in application version 0.61 ............................................................................ 24

7.9.1 Major changes from 0.57 to 0.58: ................................................................................. 24

7.9.2 Major changes from 0.53 to 0.57: ................................................................................. 24

8 PoStep60 I2C protocol specification ............................................................................................. 25

Page 4

PoStep60 user manual

4

www.poscope.com

8.1 I2C address ............................................................................................................................ 25

8.2 PoStep60 I2C protocol ........................................................................................................... 25

8.2.1 Master write .................................................................................................................. 25

8.2.2 Master read ................................................................................................................... 26

8.3 PoStep60 I2C commands ....................................................................................................... 26

8.3.1 0x01 - Loopback read .................................................................................................... 26

8.3.2 0x03 – Set Run/Sleep mode .......................................................................................... 26

8.3.3 0x0A – Read HW/FW info .............................................................................................. 27

8.3.4 0x10 – Read voltage ...................................................................................................... 27

8.3.5 0x11 – Read temperature .............................................................................................. 27

8.3.6 0x12 – Read pin statuses ............................................................................................... 27

8.3.7 0x13 – Read driver status .............................................................................................. 27

8.3.8 0x14 – Read driver mode .............................................................................................. 28

8.3.9 0x20 – Read full scale current ....................................................................................... 28

8.3.10 0x21 – Read idle current ................................................................................................ 28

8.3.11 0x22 – Read overheat current ....................................................................................... 28

8.3.12 0x23 – Read step mode ................................................................................................. 28

8.3.13 0x24 – Read temperature limit ..................................................................................... 29

8.3.14 0x25 – Read faults ......................................................................................................... 29

8.3.15 0x30 – Set full scale current .......................................................................................... 29

8.3.16 0x31 – Set idle current ................................................................................................... 29

8.3.17 0x32 – Set overheat current .......................................................................................... 30

8.3.18 0x33 – Set step mode .................................................................................................... 30

8.3.19 0x34 – Set temperature limit ........................................................................................ 30

8.3.20 0x35 – Reset faults ........................................................................................................ 30

8.3.21 0x3F – Write settings to EEPROM ................................................................................. 30

8.3.22 0x40 – Read position ..................................................................................................... 30

8.3.23 0x41 – Read maximal speed .......................................................................................... 30

8.3.24 0x42 – Read acceleration .............................................................................................. 30

8.3.25 0x43 – Read deceleration .............................................................................................. 31

8.3.26 0x50 – Set position ........................................................................................................ 31

8.3.27 0x51 – Set maximal speed ............................................................................................. 31

8.3.28 0x52 – Set acceleration ................................................................................................. 31

8.3.29 0x53 – Set deceleration ................................................................................................. 31

8.3.30 0x5E – Set zero .............................................................................................................. 32

8.3.31 0x5F – Stop .................................................................................................................... 32

9 Errata information ......................................................................................................................... 33

10 User manual changes ................................................................................................................ 33

11 Grant of license ......................................................................................................................... 34

11.1.1 Access ............................................................................................................................ 34

11.1.2 Usage ............................................................................................................................. 34

11.1.3 Copyright ....................................................................................................................... 34

Page 5

PoStep60 user manual

5

www.poscope.com

11.1.4 Liability .......................................................................................................................... 34

11.1.5 Fitness for purpose ........................................................................................................ 34

11.1.6 Mission Critical applications .......................................................................................... 34

11.1.7 Viruses ........................................................................................................................... 34

11.1.8 Support .......................................................................................................................... 34

11.1.9 Upgrades ....................................................................................................................... 34

11.1.10 Trademarks ................................................................................................................ 34

Page 6

PoStep60 user manual

6

www.poscope.com

NOTE!

Tells you other important information.

CAUTION!

Tells you something that could be considered to reduce a risk of failure or

malfunction.

WARNING!

Tells you something that could cause damage to a property.

1 Introduction

This manual contains information required to configure over an USB and run the PoStep60 driver.

Please read the manual carefully to avoid damage to the driver. This section covers the instrument

general description, instrument specifications and characteristics.

1.1 General symbols for this instructions

A few symbols are used throughout this manual that you should be aware of in order to complete

certain tasks safely and completely. These symbols have different degrees of importance as

described below:

2 Description

The PoStep60 driver incorporate advanced stepper motor controller and external N-channel

MOSFETs to drive a bipolar stepper motor or two brushed DC motors. A micro-stepping indexer is

integrated, which is capable of step modes from full step to 1/256-step. An ultra-smooth motion

profile can be achieved using adaptive blanking time and various current decay modes, including an

auto-mixed decay mode. A simple step/direction or PWM interface allows easy interfacing to

controller circuits. An I2C serial interface can further be used to control all the driver functions

including position control on board. All running parameters (output current (torque), micro stepping,

step mode, decay mode...) can be set over USB and stored on board for standalone operation.

Internal shutdown functions are provided for over current protection, short circuit protection, under

voltage lockout and over temperature. Fault conditions are indicated via a FAULT LED, and each fault

condition can be read in configuration software.

3 PoStep60 features

up to 6,0 Amps Phase Current

advanced settings available through USB connection

compatible with 4, 6, and 8 wire stepper motors of any voltage

+10 VDC to +50 VDC Power Supply

up to 256 Micro-steps per Step

various modes of decay mode for smoother moving of motors

3,3V and 5V logic compatible inputs

250 kHz Max Step Rate

Advanced “Auto-run” modes

0 °C To 85 °C Operating Temperature

LED Power and Status Indicator

Small Size: 54 mm X 75 mm

Page 7

PoStep60 user manual

7

www.poscope.com

CAUTION!

Please make sure bipolar stepper motor is connected before applying power.

WARNING!

Please make sure power input polarity is correct. Double check before powering up

the driver. Reverse power input polarity results in permanent device failure.

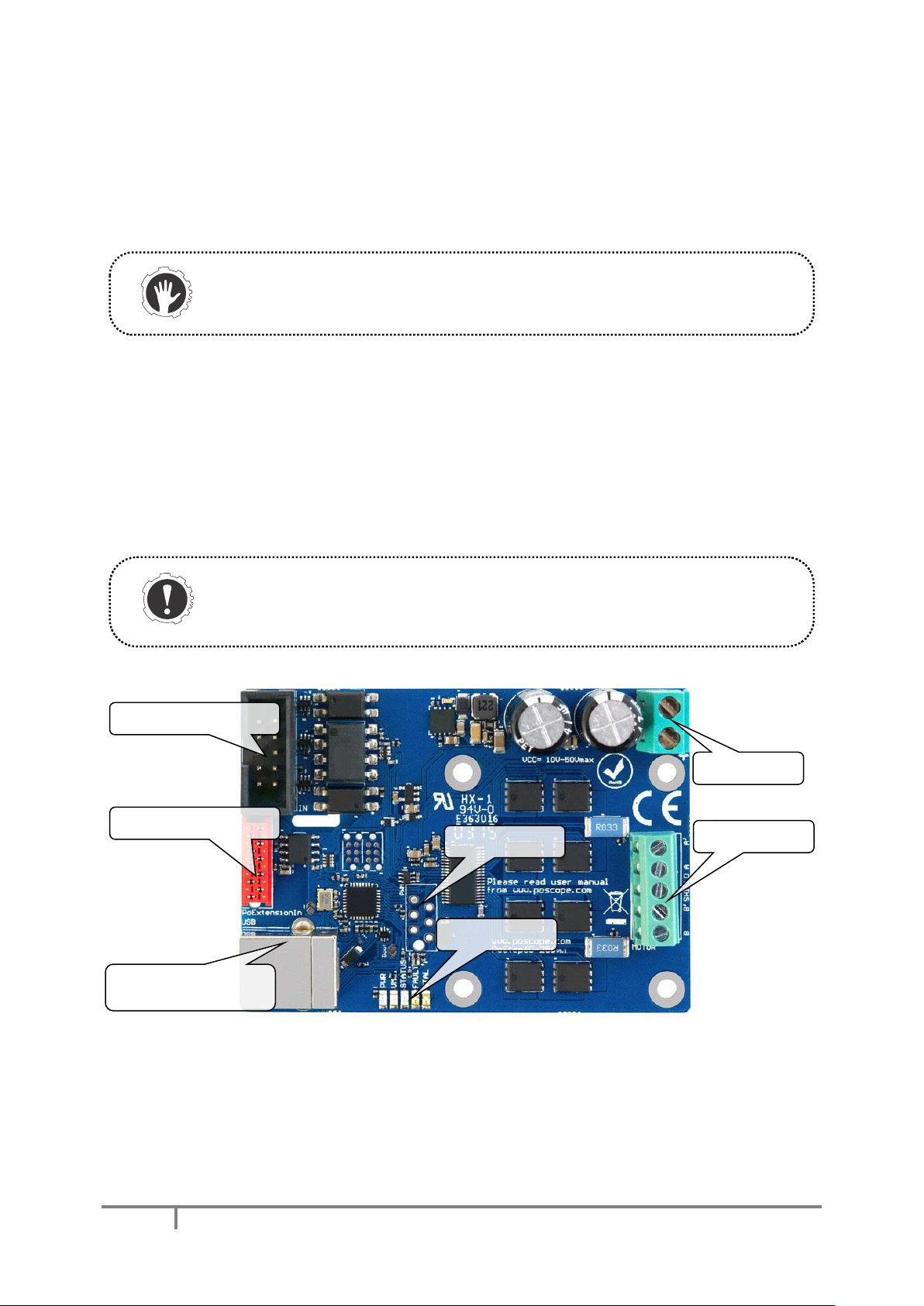

7: Status LEDs

1: USB connector

2. 10 pin IDC connector

3: PoExtension connector

4: Power input

6: PWM inputs

5: Motor outputs

4 Connection diagram

4.1 Board use requirements

To properly operate the PoStep60 driver using external controller following connections need to be

setup: step, direction and enable inputs; 10-50 VDC power supply, connected bipolar stepper motor

before applying power.

4.2 Connection and setting

1. Mount PoStep60 driver firmly to a stable surface. If PoStep60 is mounted to a conductive

(metal) surface, please make sure the driver is properly isolated.

2. Connect USB cable (1) to your PC and run PoStep user application

3. Please setup running parameters (output current (torque), micro stepping, step mode, decay

mode...) using PoStep user application.

4. Connect step, direction, enable and GND from PoStep60 (2) to controller or BOB

5. Connect steeper motor (5) using one of wiring options bellow(

6. Connect power supply (4)

Figure 1: PoStep connections

Page 8

PoStep60 user manual

8

www.poscope.com

Pin

Function

1

Enable (inverted, 0=enable, 1=disable)

3

Direction

5

Step

7

Fault feedback (OC, 1=driver OK, 0=fault

detected)*

9

+5V external supply voltage

2, 4, 6, 8, 10

GND

NOTE!

Please note some of the drivers are showing failed Under Voltage Lockout (UVLO)

fault status when disabled and supply voltage within required limits. The fault is

removed after driver is enabled and supply voltage within limits.

4.3 PoStep pinout

4.4 Stepper motor connection

4.4.1 10 pin IDC connector pinout

*Fault feedback signal is an open-colector signal. External pull-up resistor is needed to function

properly (please see Figure 2). For input and open-collector output limiting values please refer to

Section 6 - Technical specifications.

Figure 2: Fault feedback pin connection diagram

Page 9

PoStep60 user manual

9

www.poscope.com

CAUTION!

To avoid malfunctions please make sure the phase winds are connected correctly.

Resistance between leads of different phases is usually > 100kΩ. Resistance between

leads of the same phase is usually < 100Ω.

NOTE!

Simple method of finding correct pairs of each winding wires is as follows (before

proceeding none of the motor wires should be connected): take two random wires

and short circuit them. Try rotating the stepper axis. If the pair is matching the

resistance while trying to rotate the motor is much higher comparing to when none

of the wires is short circuited.

NOTE!

On the motor connector on the PoStep board there is a shield pin available (in the

middle). Please use proper shielding techniques for best performance.

type A

type B

type C

type D

type E

4.4.2 Stepper motor connections

The drive will work with 4-wire, 6-wire or 8-wire stepper motors.

Figure 3: Stepper motor wiring options

4.4.2.1 4-wire motors (type A)

are truly bipolar, and can only be run as such.

4.4.2.2 6-wire motors

can be wired two ways to work with the bipolar drive.

The first is half-winding (type B): In this method, one end wire, and the center-tap wire of the phase

is used. The other end is insulated and left unused. This method uses unipolar nameplate current

specifications, and will produce nameplate torque.

The second is series winding (type C): In this configuration, the center-tap is insulated, and unused.

This method uses all of the wiring per phase, but has double the number of wire turns as halfwinding

or unipolar mode. Because of this, the amperage requirement becomes half the nameplate rating.

Because the wire in the coil can handle more current than ‘half’, motor manufacturers will often

“boost” the torque rating by specifying currents up to 71% of unipolar rated current while running in

series mode. This is fine for FULL step motor drives, but not necessarily so good for microstepping

drives. Using this much can smear microstepping smoothness and accuracy. Any extra torque

achieved by this method will generally be lost to machine vibrations due to loss of microstepping

smoothness. The best performance will be somewhere between the 50% and 71% current rating.

Page 10

PoStep60 user manual

10

www.poscope.com

The advantage of using series winding is that lower power drives may be used. For example a

unipolar motor rated for 4.0A/phase running in series requires only 2.0A/phase to achieve the same

torque. The disadvantage of this method is that it raises motor inductance, which in turn, slows

motor coil charging time. Since proper torque is reached only when the coil has charged to the

required level, the longer it takes to charge, the longer until full torque is achieved. This leads to

slower full torque stepping rates. Conversely, a half-winding configuration requires full nameplate

rated current, but if the drive is capable of this, the advantage is that rated torque can be achieved

twice as fast as series winding (using the same voltage, when comparing half-winding and series).

4.4.2.3 8-wire motors

can be run in paralell (type E) or serial (type D) mode. Parallel mode needs higher current, has lower

inductance and better torque, Serial mode needs lower current and has lower torque. Please read

also 6-wire motors.

Page 11

PoStep60 user manual

11

www.poscope.com

Pin

Function

1

End Switch

2

PWM BIN2

3

PWM BIN1

4

PWM AIN2 (inverted)

5

PWM AIN1 (inverted)

6

GND

NOTE!

PWM AIN1 and PWM AIN2 inputs are inverted.

CAUTION!

Please make sure driver is configured to support DC motor drive. If not the DC motor

can randomly rotate in speed and direction due to active micro stepping indexer.

NOTE!

Full-scale current value still applys when in DC drive mode. Idle current is not

applicable and is not being used.

2 4 6

1 3 5

4.5 DC motor connection

4.5.1 6 pin PWM connector pinout

All PWM connector input pins has on board pull-up resistors. The pins can be either open-collector

toward GND or push-pull driven. For input limiting values please refer to Section 6 - Technical

specifications.

4.5.2 DC motor connection

The PoStep driver can be configured to enable direct control the state of the output drivers. This

allows for driving up to two brushed DC motors. First DC motor is connected to terminals A1 and A2

and second DC motor to terminals B1 and B2. Speed and direction of DC motor rotation is controlled

by PWM AINx and PWM BINx for first and second motor respectively. Driver allows connection of

only one DC motor on A or B terminals as well as two DC motors.

Figure 4: Connection of up to 2 DC motors

Page 12

PoStep60 user manual

12

www.poscope.com

LED

Status

PWR

LED is on when PoStep is connected to a PC over USB or power supply is connected

VM

LED is on when power supply is connected

STATUS

Indicates various driver states

FAULT

LED is on when driver fault occurred. To see the fault cause the PoStep has to be

connected to a PC and application running

STALL

LED is on when motor stall is detected in hardware.

Pattern

Status

……….

LED is fast blinking when driver is in firmware update mode.

-.. -..

One long two short blinks indicates default settings are being loaded. Please use PoStep

user application for proper configuration setup and store.

- -

Slow blinks indicate user configuration has been loaded

4.6 PoStep LEDs

There are five LEDs on the PoStep board showing status.

4.6.1 Status LED

Status LED is used to indicate various PoStep driver states.

4.7 Requirements

- One available USB 1.1, USB 2.0, or USB 3.0 port

- USB HID device driver enabled operating system (Windows 98 SE/ME/2000/XP/Vista/7,8,10)

- Included software requires Windows 2000/XP/Vista/7,8,…

- Microsoft Visual C++ 2010 Redistributable Package (x86 or x64) or Microsoft Visual Studio

2010 needs to be installed on the system prior running PoStep60 application.

Page 13

PoStep60 user manual

13

www.poscope.com

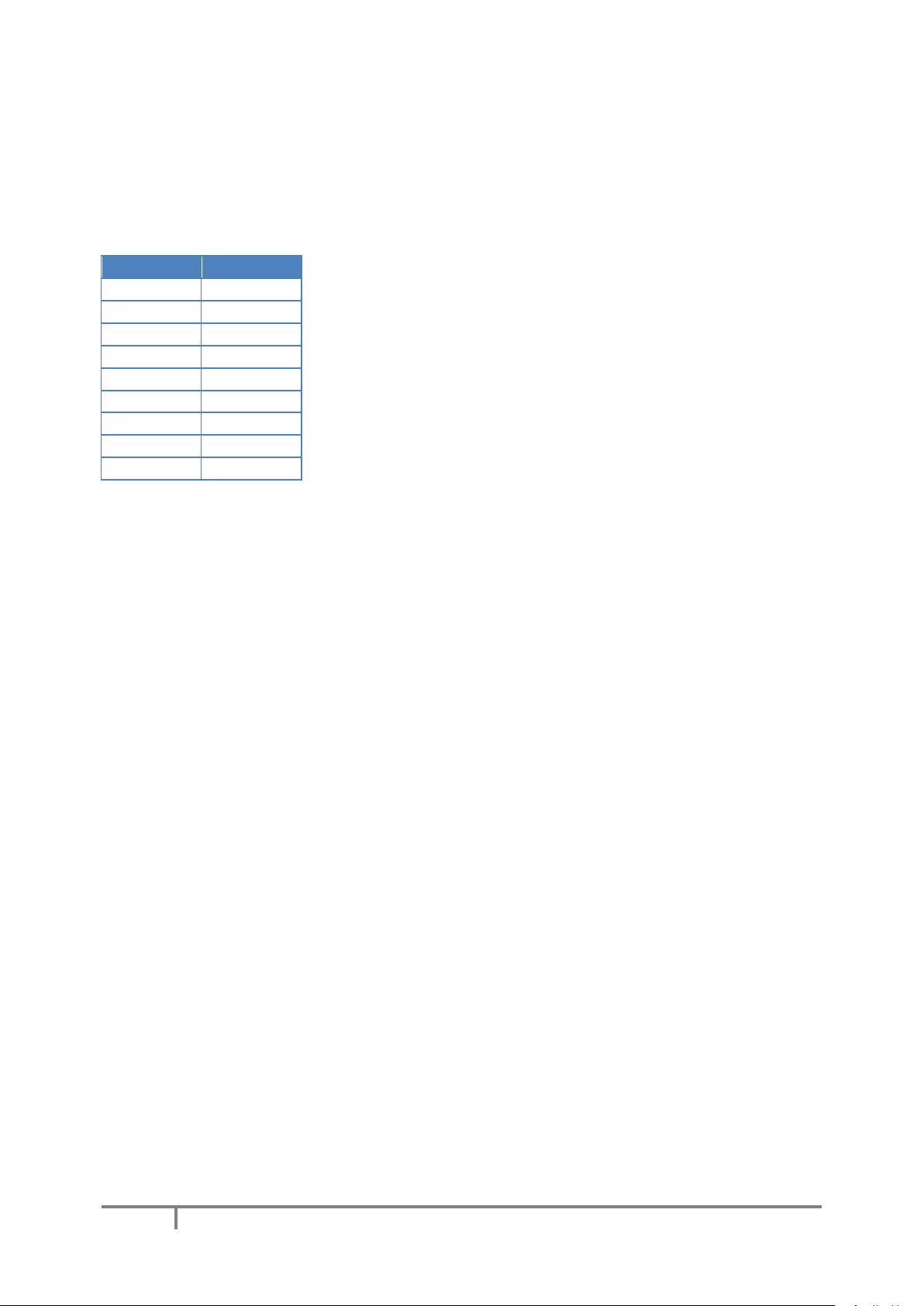

Symbol

Parameter

Min

Max

Unit

VM power supply

-0.3

50

V

VI input voltage on 10 pin IDC input pins

-0.3

5.8

V

V

ext

supply voltage on pull-up resistor for fault signal

-0.3

50

V

I

oc,max

Fault signal maximum collector current

50

mA

V

DI,MAX

maximum voltage applied to PWM input pins

5.5

V

V

iso

isolation voltage (AC for 1min, R.H. 40-60%)

3000

V

rms

V

esd

electrostatic discharge

-4000

4000

V

I

drv,max

maximum driver output full scale current

6.0

A

Symbol

Parameter

Conditions

Min

Typ

Max

Unit

V

I, HIGH

applied voltage for HIGH state on 10 pin IDC

input pins

3.0 5.8

V

V

I, LOW

applied voltage for LOW state on 10 pin IDC

input pins

-0.3 0.4

V

V

DI,HIGH

applied voltage for HIGH state on PWM pins

1.6 V V

DI,LOW

applied voltage for LOW state on PWM pins

-0.3 0.2

V

NOTE! - The program can’t start because MSVCR100.dll is missing from your computer.

If application fails to start showing above message most likely “Microsoft Visual C++

2010 Redistributable Package” has to be downloaded from MS pages and installed

prior running PoStep60 application.

NOTE! - The application was unable to start correctly (0xc000007b). Click OK to close the

application.

If application fails to start showing 0xc000007b error please install “Microsoft Visual

C++ 2010 Redistributable Package (x86)” no matter you have 64-bit MS Windows

operating system running.

5 Installation

PoStep60 is USB HID compliant device and as such require no additional drivers for operation.

To operate the device user software installation is necessary on a target system.

6 Technical specifications

6.1 Electrical specification – limiting values

6.2 Electrical specification – static characteristic

Page 14

PoStep60 user manual

14

www.poscope.com

NOTE!

Please note enable signal is shared between external “Enable” input. Disconnected

external signal when using application driver control features.

1: Tab selection for different

sub-applications

3: Device connection

status

2: Get device

information tab

6: Driver input statuses

7: Driver control mode

4: Driver status

5: Run/stop button

7 User application

User application enables various interactions with PoStep60 driver. The application enables setting of

all the vital driver parameters including driver current (active, idle, and overheated values), microstepping value, driver name for later recognition, and advanced control setting values. Moreover, the

application includes basic driving capabilities for stepper motors as well as two DC motors. For the

stepper motor there is simple step/direction mode and more advanced onboard speed profile

feature for out-of-the box drive of stepper motor. For DC motors drive there are two PWM channels

with adjustable PWM values and directions. The application also monitors input statuses and driver

status itself (temperature, mode, fault,…)

7.1 PoStep60 main application GUI

Figure 5: PoStep60 main application GUI

Figure 5 notes:

1. Tab selection for different sub-applications – please use tabs to navigate between sub-

applications

2. Click to get device information such as serial number, mode status, …

3. The application title bar displays connection status of PoStep device. If a device is connected a

serial number is displayed and if not “not connected” message is displayed. Please note only one

device at same time can be connected.

4. Driver status – The section displays real-time data of a driver connected if the driver is in

application mode.

5. Stop/Run button disables and enables PoStep driver. Useful feature when in various control

modes.

6. Driver input statuses displays current driver input statuses

Page 15

PoStep60 user manual

15

www.poscope.com

NOTE!

Driver real-time values are only available when driver is in application mode. In

bootloader mode all driver features are disabled.

CAUTION!

The displayed temperature value may differ from the actual driver temperature due

to indirect contact. Parts of the diver can have higher temperature than one

displayed and as such might cause you burns if touched.

2: Power supply voltage

1: PoStep application

version info

4: Driver temperature

3: Driver status

7. Driver control mode displays current driver control mode

7.1.1 PoStep driver status

Figure 6: PoStep driver status section

Figure 6 notes:

1. PoStep application version info – please check for latest update of PoStep application.

2. Power supply voltage – displays main power supply voltage.

3. Driver status – displays driver statuses

4. Driver temperature – displays main power supply voltage.

7.1.1.1 Driver statuses

Driver active – there was a signal change in step/direction inputs in the last 10 seconds. Full-

scale active current value is set

Idle – there was no change on step/direction inputs for more than 10 seconds. Idle current

value is set

Overheated – when driver exceeds limit temperature values drivers goes into overheated

mode. Reduced current value is set

Fault detected – displays that at least one of possible driver faults were detected. Please

check fault type in Advanced settings.

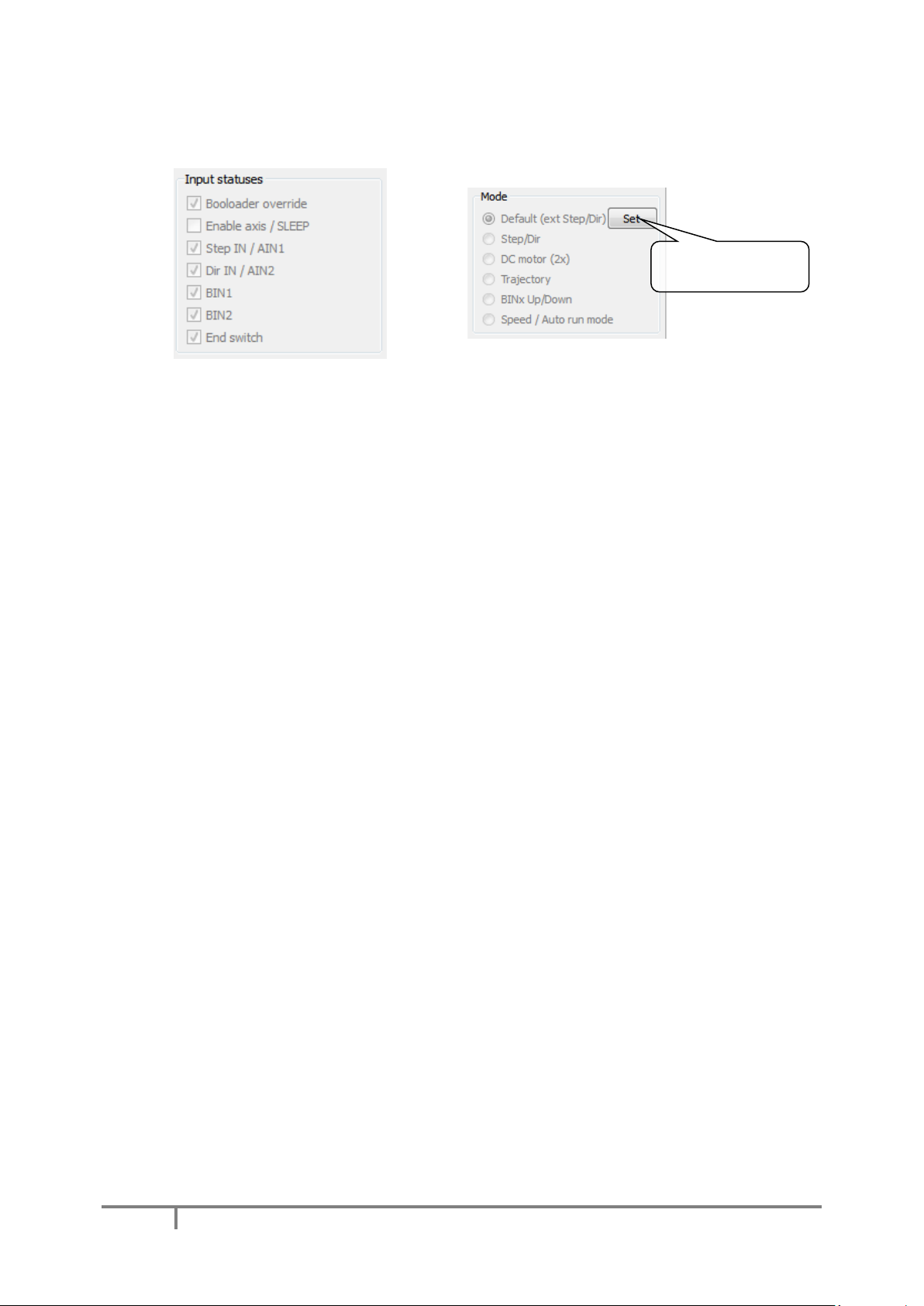

7.1.1.2 Input statuses

The application shows real-time data of all the driver IO pins - Figure 7 (tick represents high level):

Bootloader override – the pin should always be high

Enable axis / SLEEP – high level enables diver operation. Low level puts the driver to sleep

mode

Step IN / AIN1 – this is Step input signal in stepper motor operation or Motor 1 PWM control

AIN1 when in DC motor control mode

Dir IN / AIN2 – this is Direction input signal in stepper motor operation or Motor 1 PWM

control AIN2 when in DC motor control mode

BIN1 – Motor 2 PWM control BIN1 when in DC motor control mode

Page 16

PoStep60 user manual

16

www.poscope.com

Figure 7: Input statuses

Figure 8: Driver control modes

Set the driver to default

driver control mode

BIN2 – Motor 2 PWM control BIN2 when in DC motor control mode

End switch – end switch input status

7.1.1.3 Driver control modes

Driver control mode section displays current mode of the driver - Figure 8.

Default (ext Step/Dir) – this is the driver default state which enables Step/direction control

using external controller. Enable axis, Step IN, and Dir IN inputs shall all be connected for

proper operation.

Step/Dir – in this mode driver generates the driving signals. The mode is mainly used for

driver settings adjustments – fine tuning. Please see subsection 7.4 Step control.

DC motor – two DC motors can be controlled using direct PWM signals. Please see subsection

7.6 DC motor control.

Trajectory – in this mode the driver take over controller parts of motion planning. Required

position and speed profile parameters can be set. Please see subsection 7.5 Auto control.

BINx Up/Down – upgrade to “Trajectory” mode where movement is triggered by external

buttons. Please see subsection7.5.2 BINx Up/down mode.

Speed / Auto run mode – the mode enables automatic starting of driver at power up or

start/stop using external switch. Please see subsection 7.5.3 Speed / Auto run mode.

7.2 Basic user control of the PoStep driver

Basic user control section enables user selection of predefined driver configuration sets, setting

currents: full scale, idle, overheated reduction, and temperature limit. Moreover, the basic

manipulation with driver data is enabled: readout, change, and store. Furthermore, each of the

drivers can be set an unique name for easier identification.

Page 17

PoStep60 user manual

17

www.poscope.com

NOTE!

Please follow stepper motor datasheet when setting driver values. Setting higher

current value than nominal motor current may result in changed characteristics of

PoStep motor driver (overheating, motor ringing,…) due to motor running out of

specs.

NOTE!

Any change in configuration settings made in application is not valid to driver until

confirmed by “Write values to driver”.

6: Driver settings

manipulation

7: Load/save configuration

setting from/to file

5: Overheating temperature

limit and reduced current value

4: Step mode

2: Full scale

current value

1: Driver configuration

selection drop box

8: Device custom name

3: Idle current value

9: Enable/disable advanced

driver setup mode

11: Reset faults button

10: Detailed fault description

in case of fault detected

12: Enable/disable

DC motor mode

13: Enable/disable

BINx buttons mode

15: Set I2C

address

14: Enable/disable

BINx buttons mode

Figure 9: Basic user controls

Figure 9 notes:

1. Driver configuration selection drop box – select one of predefined configurations. Use default

configuration if you are not familiar with motor performance parameters.

2. Full scale current value – setup required motor current value.

3. Idle current value – setup idle current – idle current is a driver current when there is no activity

on “Step/Dir” inputs for more than 10s.

4. Step mode – select a step mode between full step and 1/256-step (256 micro steps) mode.

5. Overheating temperature limit and reduced current value – setup a temperature limit at which

driver reduces driver current to protect driver from possible overheating.

6. Driver settings manipulation – enables reading/writing configuration to/from PoStep60 driver

a. Read values from driver – reads driver configuration settings currently set on the driver.

b. Write values to driver – writes driver configuration settings and store them to a non-

volatile memory on the driver. The settings are read and loaded each time driver is

powered or reset.

Page 18

PoStep60 user manual

18

www.poscope.com

WARNING!

The advanced settings shall only be used by a person with a strong knowledge in

motor control. There is a chance of setting combination that may results in

permanent device failure.

NOTE!

When setting up the driver various compromises need to be considered such as:

Higher the input voltage longer the fixed off time has to be to control the

required current,

Higher the input voltage lower the step mode,

…

7. Setting files – enables loading/saving driver configuration settings from/to file

a. Load settings from file – load driver configuration settings previously saved.

b. Save settings to file – save currently set configuration to specified file.

8. Device custom name – displays or change driver custom name

a. Read custom name – reads driver name

b. Write custom name – writes and stores driver name

9. Enable/disable advanced driver setup mode – by checking advanced setup mode is enabled

allowing setting advanced parameters

10. Detailed fault description in case of fault detected – further describes detected fault and possible

cause of the fault

11. Reset faults – press the button to reset driver faults

12. DC motor mode – Enable or disable DC motor mode

13. BINx Up/Down – Enable or disable BINx buttons mode

14. Auto run – Enable or disable Auto run mode

15. I2C address – Sets an address of the PoStep60 driver when using I2C communication

7.3 Advanced settings

In stepping motors, current regulation is used to vary the current in the two windings in a sinusoidal

fashion to provide smooth motion. An ultra-smooth motion profile can be achieved using advanced

settings such as blanking and decay time, and various current decay modes, including an auto-mixed

decay mode.

The current through the motor windings is regulated by an adjustable fixed-off-time PWM current

regulation circuit. When an H-bridge is enabled, current rises through the winding at a rate

dependent on the DC voltage and inductance of the winding and the magnitude of the back EMF

present. Once the current hits the current chopping threshold, the bridge disables the current for a

fixed period of time, which is programmable between 500 nS and 128 us. After the off time expires,

the bridge is re-enabled, starting another PWM cycle.

Figure 10: Advanced driver setup settings

Page 19

PoStep60 user manual

19

www.poscope.com

NOTE!

If driver is used in combination with external controller or BOB please make sure to

stop the application step/dir control by pressing button “Stop”. This way external

controller takes over control of the step/dir pins again.

5: Manual speed set

1: Speed slider

2: Max speed dial

4: Auto update

3: Stop

6: Auto stop

7.4 Step control

The application enables simple internal control of step/dir pins. It allows a test of basic driving

capabilities of the PoStep60 driver.

Figure 11: Step control controls

1. Speed slider – use this slider to set step speed. Please note the maximum value is limited by

“Max speed” value.

2. Max speed dial – set maximum step speed to limit the step speed value set by “Speed” value.

3. Stop – stops internal step/dir generator and switch the pins control to external controller.

4. Auto update – if checked, any change in step speed value is sent to driver immediately.

5. Manual speed set – send new step speed value to driver if “Auto update” is disabled.

6. Auto stop – when checked step speed resets to zero when slider is released.

7.5 Auto control

7.5.1 Position control mode

Simple position control algorithm is implemented in the driver. The driver moves to required position

using standard “Trapezoidal motion profile” where acceleration, deceleration, and maximal speed is

defining the profile. Required position can be set using input box or slider. End switches (NC or NO;

please note – end switch reacts only on change of end switch state.) and position limits can be used

to define/limit a range of movement. The provided position control allows a test of basic driving

capabilities of the PoStep60 driver and is not intended to replace external controller.

Page 20

PoStep60 user manual

20

www.poscope.com

NOTE!

End switch reacts only on change of end switch state. Position change request after

end switch touched can be set in either direction.

NOTE!

If current position is out of new position limit values set then required position will

adjust accordingly and motor shall move if Auto update is enabled.

1: Trajectory chart

2: Motion profile

parameters

5: Clear chart

button

3: Required position

5: End switch enable and

wiring type

4: Actual speed

and position

6: Position slider

7: Upper limit

8: Lower limit

9: Navigation buttons

11: Increment

settings

10: Auto update

12: Stop button

13: Set zero

14: Set values

manually

15: BINx driver mode

settings tab

16: Auto run driver mode

settings tab

Figure 12: Position control controls

1. Trajectory chart – displays required and actual position and speed charts

2. Motion profile parameters – Trapezoidal motion profile parameters: acceleration, deceleration,

and maximum speed

3. Required position – set and displays (slider) required position

4. Actual speed and position – displays actual speed and position values

5. End switch – enable/disable end switch control and end switch wiring type settings

6. Position slider – required position can be set using slider

7. Upper limit – limits final position.

8. Lower limit – limits starting position

9. Navigation buttons – set required position by a step defined by increment settings (11)

10. Auto update – send new values to driver automatically if checked

11. Increment settings – defines Small and Large increments for navigation steps

Page 21

PoStep60 user manual

21

www.poscope.com

NOTE!

If driver is used in combination with external controller or BOB please make sure to

stop the application Position control control by pressing button “Stop”. This way

external controller takes over control of the step/dir pins again.

NOTE!

Make sure to confirm the change of driver mode and save mode settings by clicking

“Write values to driver”.

1: Enable BINx

buttons mode

4: Send values to

2: BIN1 step number

3: BIN2 step number

12. Stop button – stops position movement immediately (no deceleration profile applied)

13. Set zero – set both the required and actual position values to zero

14. Set values manually – send new values to driver manually

15. External – External navigation tab used to configure BINx driver mode settings

16. Speed mode – Speed mode navigation tab used to configure Auto run driver mode settings

7.5.2 BINx Up/down mode

In a BINx driver control mode the driver is set to be used alone (no external controller or BOB is

needed) just with two external buttons on pins BIN1 and BIN2 (please see subsection 4.5.1 - 6 pin

PWM connector pinout for proper wiring). Connect NO button between pin BIN1 and GND. Connect

NO button between pin BIN2 and GND. When BIN1 or BIN2 button is pressed motor moves number

of steps defined in BIN1 and BIN2 steps respectively. Same motion profile is valid as in position

control mode settings.

Figure 13: BINx Up/Down control settings

1. Enable BINx buttons – when checked driver is in BINx buttons control mode

2. BIN1 steps – Defines number of steps to move when BIN1 button pressed

3. BIN2 steps – Defines number of steps to move when BIN2 button pressed

4. Send data – send new values to driver (automatically if “Auto update” checked)

7.5.3 Speed / Auto run mode

In Auto run mode PoStep60 driver automatically starts motion of stepper motor after power up. No

external controller or BOB is needed. Optionally by enabling “Run/stop” a “Normally open - NO” or

“Normally closed – NC” switch can be used to control the motion on or off. For wiring please see

subsection 4.5.1 6 pin PWM connector pinout. Same motion profile settings apply as in Position

control mode above. At power up “Max speed” value applies and not “Requested speed” value.

Requested speed value applies only during active USB connection of PoStep60 driver.

Page 22

PoStep60 user manual

22

www.poscope.com

NOTE!

At power up “Max speed” value applies and not “Requested speed” value.

Requested speed value applies only during active USB connection of PoStep60

driver.

NOTE!

Make sure to confirm the change of driver mode and save mode settings by clicking

“Write values to driver”.

1: Enable DC motor

control

2: Channel A

3: Channel B

4: Set PWMs

5: Frequency dial

6: Frequency

input box

7: Auto update

8: Stop

1: Enable/disable mode

5: Max speed value

applies at power up

2: Invert direction of

3: Requested speed

slider

4: Requested speed

input and actual

speed value

Figure 14: Speed / Auto run control settings

1. Enable Auto run – when checked driver is in Auto run control mode

2. Invert direction – Inverts direction of stepper movement

3. Requested speed slider – Use the slider to set requested speed. Maximum speed value is limited

by “Max speed”

4. Requested speed – Requested and actual speed value. Due to hardware limitation actual speed

can differ from requested speed.

5. Max speed – Max speed value – this is the value of the speed at power up

7.6 DC motor control

PoStep60 driver can be configured to drive up to two dc motors bi-directionally. Enabling DC motor

control bypass driver internal indexer control used for stepper motor micro-stepping control. All the

driver parameters except idle current apply for DC motor control as well. This enable current limited

DC motor drive using PWM control. The PoStep60 application enables simple PWM control where

PWM and PWM frequency (period) can be set.

Figure 15: DC motor control controls

Page 23

PoStep60 user manual

23

www.poscope.com

NOTE!

Enabling or disabling DC motor control puts driver into stand-by to prevent sudden

movement of motor or accidental overheating of stepped motor winding.

NOTE!

If driver is used in combination with external controller or BOB please make sure to

zero PWM values by pressing button “Stop”. This way external controller takes over

control of the PWM inputs again.

1: Clear log data

1. Enable DC motor control – enables and disables DC motor control.

2. Channel A – Slider and input box for PWM value for DC motor connected to output terminals A

3. Channel B – Slider and input box for PWM value for DC motor connected to output terminals B

4. Set PWMs – send new values to driver manually

5. Frequency dial – set PWM frequency (period)

6. Frequency input box – set PWM frequency (period)

7. Auto update – send new values to driver automatically if checked

8. Stop – sets PWMs to zero and put open collector inputs to high state enabling external PWM

controller PWM control

7.7 Log charts

PoStep60 application enables simple log of major driver parameter through time. By the chart the

driver temperature can be monitored for possible overheating. This way driver setting can be

adjusted or heat dissipation elements checked for its performance.

Figure 16: PoStep60 driver parameters log chart

1. Clear log data – Clears log charts data.

Page 24

PoStep60 user manual

24

www.poscope.com

1: Restart driver manually

2: Trigger manual update

3: Update progress bar

7.8 Firmware update

Application automatically checks for PoStep60 driver firmware version and advises when update

needed. If by any chance automatic firmware update fails a manual update is possible. Please select

“Firmware” tab and manually reset PoStep60driver to enter boot mode ie. when “Full update”

button is enabled. Trigger update by pressing “Full update” and wait for finished update. After

update the driver automatically resets and enters normal mode.

Figure 17: Manual firmware update

1. Restart driver manually – trigger driver restart and enables the driver to enter boot mode.

2. Full update – trigger start of full firmware update

3. Update progress bar – shows status of update progress.

7.9 Major changes in application version 0.61

Added Auto run mode

Position control navigation tab changed to Auto control

Auto control tab restructuring

7.9.1 Major changes from 0.57 to 0.58:

Voltage Too Low when disabled bug fix

BINx mode - Button Up/Down control added

I2C communication added

7.9.2 Major changes from 0.53 to 0.57:

Predriver Fault bug fix

Position control added

DC motor mode setting added

DC motor control added

Improved Voltage and Temperature filtering

Added installation notes (MS VS 2010 redistributable package)

Page 25

PoStep60 user manual

25

www.poscope.com

Pin

Function

1

5V 2 GND

5

SCL – I2C clock pin

6

SDA – I2C data pin

3, 4, 7, 8, 9, 10

NC – not connected

STOP

I2C ADDRESS

R/W=0

A

COMMAND

A

BYTE0 A …

BYTEn

A

END

NOTE!

In a Master read operation always applies the last command send by the master in a

Master write operation. This way same parameter can be read continuously.

1: I2C address

2 1 4 3 6 5 8 7 10

9

8 PoStep60 I2C protocol specification

PoStep60 has implemented I2C communication connection which enables setup and read most of

the driver configuration parameters and statuses. I2C pins are located on PoExtension connector

(please see Figure 1).

8.1 I2C address

PoStep60 default I2C address is set to 1 (0x01), but can be configured within PoStep60 application to

any value between 1 and 127 (please see Figure 18). This way multiple PoStep60 drivers can be

connected to same I2C bus and be monitored and configured externally in real-time. To confirm the

I2C address “Write values to driver” has to be clicked.

Figure 18: PoStep60 I2C address setup

8.2 PoStep60 I2C protocol

I2C communication is driven by a single I2C master which communicates to multiple slaves (PoStep60

drivers). Every packet consist of I2C address, Read/Write command bit, command byte (in case of

write) and multiple data bytes. In write operation master specifies command for either write or read

operation. In a Master read operation, based on previously written command, data bytes are sent

back from PoStep60 driver (slave). Always applies the last command send by the master.

8.2.1 Master write

In Master write operation master always provide a command as a first data byte. Following bytes

represent data to be interpreted by PoStep driver.

From Master to PoStep driver

From PoStep driver to Master

Page 26

PoStep60 user manual

26

www.poscope.com

STOP

I2C ADDRESS

R/W=1

A

BYTE0

A

BYTE1 A …

BYTEn

A

END

Mode

BYTE0

Run

0xDA

Sleep

0x0F

BYTE

Mode

1

Default mode – external control

6

Auto run mode

NOTE!

Setting run over I2C overrides external enable signal. Similarly, external enable

overrides internal sleep signal.

CAUTION!

Please make sure to request Stop (8.3.38 0x5F – Stop) and Zero (8.3.37 0x5E – Set

zero) before changing driver mode to Auto run mode to prevent sudden motor

movement.

8.2.2 Master read

Before read operation we shall always perform a Master write operation providing command for

read operation. After command is provided the Master read can be performed. In the Master read

operation PoStep response with multiple bytes of data. The data has to be properly interpreted by

the master.

From Master to PoStep driver

From PoStep driver to Master

8.3 PoStep60 I2C commands

8.3.1 0x01 - Loopback read

In a Master write operation master sends 0x01 command followed by 4 bytes. In a Master read

operation the 4 bytes from previous write operation are send back from the PoStep driver. The main

purpose of the command is to test a response of PoStep60 driver.

8.3.2 0x03 – Set Run/Sleep mode

To enable or disable (Run/Sleep) the driver Master shall write 0x03 command followed by one byte

of data – BYTE0. BYTE0 relates to Run/Sleep mode as follows:

8.3.3 0x04 – Set I2C address

Master writes 0x04 command followed by two bytes of data. BYTE0 shall be equal to current I2C

address (basic check before applying new address) and BYTE1 shall represent new I2C address.

8.3.4 0x05 – Set driver mode

Master writes 0x05 command followed by one BYTE of data.

Page 27

PoStep60 user manual

27

www.poscope.com

BYTE

Info

0

0x41 – driver ID

1

HW version major release

2

HW version minor release

3

FW version major release

4

FW version minor release

Bit

Pin

0 (LSB)

Bootloader override

1

Sleep

2

Step / AIN1

3

Direction / AIN2

4

BIN1

5

BIN2

6

End switch

7 (MSB)

/

Status value

Status

1

Driver in sleep mode

2

Driver active

3

Driver in idle mode

4

Driver overheated

5

Driver in DC motor control mode

8.3.5 0x0A – Read HW/FW info

First Master writes 0x0A command (no data bytes are needed). In a next step Master reads 5 bytes of

data where meaning of byte is described in a table below.

8.3.6 0x10 – Read voltage

To read PoStep supply voltage first Master writes 0x10 command (no data bytes are needed). In a

next step Master reads two bytes of data. Calculated voltage is:

Voltage/V = (BYTE1 * 256 + BYTE0) * 0.072 = (BYTE1 << 8 | BYTE0) * 0.072

8.3.7 0x11 – Read temperature

To read PoStep temperature first Master writes 0x11 command (no data bytes are needed). In a next

step Master reads two bytes of data. Calculated temperature is:

Temperature/ºC = (BYTE1 * 256 + BYTE0) * 0.125 = (BYTE1 << 8 | BYTE0) * 0.125

8.3.8 0x12 – Read pin statuses

First Master writes 0x12 command (no data bytes are needed). In a next step Master reads one byte

of data. Each bit in the read byte represents one pin. 0 represents logic low level and 1 represents

logic high.

8.3.9 0x13 – Read driver status

First Master writes 0x13 command (no data bytes are needed). In a next step Master reads one byte

of data. Read value represents driver status:

Page 28

PoStep60 user manual

28

www.poscope.com

Mode value

Mode

1

Default mode – external control

2

Step control

3

DC motor control

4

Position control

5

BINx buttons

6

Auto run mode

Mode value

Mode

0

Full step

1

Half step

2

1/4 step

3

1/8 step

4

1/16 step

5

1/32 step

6

1/64 step

7

1/128 step

8

1/256 step

NOTE!

Driver mode is read only value for I2C communication and can only be set by using

USB connection and PoStep60 application!

8.3.10 0x14 – Read driver mode

First Master writes 0x14 command (no data bytes are needed). In a next step Master reads one byte

of data. Read value represents driver mode:

8.3.11 0x20 – Read full scale current

To read PoStep full scale current first Master writes 0x20 command (no data bytes are needed). In a

next step Master reads two bytes of data. Calculated current is:

current/A = 0.065*BYTE0 / (2

BYTE1

)

8.3.12 0x21 – Read idle current

First Master writes 0x21 command (no data bytes are needed). In a next step Master reads two bytes

of data. Same formula applies as in subsection 8.3.11 0x20 – Read full scale current to calculate idle

current value.

8.3.13 0x22 – Read overheat current

First Master writes 0x22 command (no data bytes are needed). In a next step Master reads two bytes

of data. Same formula applies as in subsection 8.3.11 0x20 – Read full scale current to calculate

overheat current.

8.3.14 0x23 – Read step mode

First Master writes 0x23 command (no data bytes are needed). In a next step Master reads one byte

of data. Read value represents step mode:

Mode value = BYTE0 & 0x0F

Page 29

PoStep60 user manual

29

www.poscope.com

Bit

Error

Description

0 (LSB)

OTS

Device has entered over temperature shutdown. OTS bit will clear once

temperature has fallen to safe levels

1

AOCP

Channel A overcurrent shutdown. Please check wiring or possible short circuit.

2

BOCP

Channel B overcurrent shutdown. Please check wiring or possible short circuit.

3

APDF

Channel A predriver fault. Please check driver settings.

4

BPDF

Channel B predriver fault. Please check driver settings."

5

UVLO

Power supply voltage too low Bit clears after voltage rises above lower limit.

6

STD

Stall detected.

7 (MSB)

STDLAT

Latched stall detect.

NOTE!

When there is no external power supply available the fault data shows 0xFF – all

errors active! Please ignore the value while the power supply is not available.

NOTE!

Limiting values from subsection 6.1 - Electrical specification – limiting values applies.

8.3.15 0x24 – Read temperature limit

To read temperature limit first Master writes 0x24 command (no data bytes are needed). In a next

step Master reads one byte of data. Calculated temperature is:

Temperature/ºC = BYTE0

8.3.16 0x25 – Read faults

First Master writes 0x25 command (no data bytes are needed). In a next step Master reads one byte

of data. Each bit in the read byte represents one fault. 0 represents no faults and 1 represents fault

occurred.

Fault 0 (OTS) cannot be cleared due to the nature of the fault. Faults 1 – 5 can be cleared and

operation resumed by writing 0 to the bit location. Please see subsection 8.3.22 0x35 – Reset faults.

Faults 6 and 7 are faults related to stall detection and are not real faults – they are not stopping

operation of the PoStep60 driver. The faults 6 and 7 can be ignored.

8.3.17 0x30 – Set full scale current

Master writes 0x30 command followed by two bytes of data. BYTE0 and BYTE1 are calculated as

follows:

int Tq = 123 * xxCurrent; //xxCurrent: current value in A

int Ai = 3;

while(Tq > 255){

Ai--;

Tq = Tq >> 1;

}

(uchar)BYTE0 = Tq;

(uchar)BYTE1 = Ai;

8.3.18 0x31 – Set idle current

Master writes 0x31 command followed by two bytes of data. BYTE0 and BYTE1 are calculated using

same algorithm as in subsection 8.3.17 0x30 – Set full scale current.

Page 30

PoStep60 user manual

30

www.poscope.com

Mode

BYTE0

Full step

0

Half step

1

1/4 step

2

1/8 step

3

1/16 step

4

1/32 step

5

1/64 step

6

1/128 step

7

1/256 step

8

8.3.19 0x32 – Set overheat current

Master writes 0x32 command followed by two bytes of data. BYTE0 and BYTE1 are calculated using

same algorithm as in subsection 8.3.17 0x30 – Set full scale current.

8.3.20 0x33 – Set step mode

Master writes 0x33 command followed by one byte of data – BYTE0. BYTE0 relates to step mode as

follows:

Other values are ignored.

8.3.21 0x34 – Set temperature limit

Master writes 0x34 command followed by one byte of data – BYTE0. BYTE0 is calculated as follows:

BYTE0 = Temperature/ºC

8.3.22 0x35 – Reset faults

To reset all faults Master shall write 0x35 command (no data bytes are needed).

8.3.23 0x3F – Write settings to EEPROM

To store changes made with any of the “Set” commands a Master shall write 0x3F command (no data

bytes are needed).

Following commands are related to internal position controller – please see subsection 7.5 Auto

control.

8.3.24 0x40 – Read position

To read PoStep position first Master writes 0x40 command (no data bytes are needed). In a next step

Master reads four bytes of data. Calculated position is:

position/steps = BYTE3 * 16777216 + BYTE2 * 65536 + BYTE1 * 256 + BYTE0 =

= BYTE3 << 24 | BYTE2 << 16 | BYTE1 << 8 | BYTE0

8.3.25 0x41 – Read maximal speed

To read PoStep maximal speed first Master writes 0x41 command (no data bytes are needed). In a

next step Master reads two bytes of data. Calculated maximal speed is:

Maximal speed/steps/s = BYTE1 * 256 + BYTE0 = BYTE1 << 8 | BYTE0

8.3.26 0x42 – Read acceleration

To read PoStep acceleration first Master writes 0x42 command (no data bytes are needed). In a next

step Master reads two bytes of data. Calculated acceleration is:

acceleration/steps/s2 = BYTE1 * 256 + BYTE0 = BYTE1 << 8 | BYTE0

Page 31

PoStep60 user manual

31

www.poscope.com

MSB

Required position (32 bit)

LSB

BYTE3

BYTE2

BYTE1

BYTE0

MSB

Maximal speed (16 bit)

LSB

BYTE1

BYTE0

MSB

Acceleration (16 bit)

LSB

BYTE1

BYTE0

MSB

Deceleration (16 bit)

LSB

BYTE1

BYTE0

NOTE!

Set position and internal position control profile settings are applicable only when

driver is in Position control or BINx buttons mode. To enable position control over

I2C after reset and (in standalone mode) please enable BINx buttons mode and write

values to driver.

8.3.27 0x43 – Read deceleration

To read PoStep deceleration first Master writes 0x43 command (no data bytes are needed). In a next

step Master reads two bytes of data. Calculated deceleration is:

deceleration/steps/s2 = BYTE1 * 256 + BYTE0 = BYTE1 << 8 | BYTE0

8.3.28 0x44 – Read current speed

To read PoStep current speed first Master writes 0x44 command (no data bytes are needed). In a

next step Master reads two bytes of data. Calculated deceleration is:

current speed/steps/s = BYTE1 * 256 + BYTE0 = BYTE1 << 8 | BYTE0

8.3.29 0x45 – Read requested speed

To read PoStep requested speed first Master writes 0x45 command (no data bytes are needed). In a

next step Master reads two bytes of data. Calculated requested speed is:

requested speed/steps/s = BYTE1 * 256 + BYTE0 = BYTE1 << 8 | BYTE0

8.3.30 0x46 – Read Auto run invert direction status

To read PoStep Auto run invert direction status first Master writes 0x46 command (no data bytes are

needed). In a next step Master read one byte of data. Calculated direction is:

Auto run invert direction = BYTE0 & 0x01

8.3.31 0x50 – Set position

To set required position of internal position controller Master writes 0x50 command followed by four

bytes of data where:

8.3.32 0x51 – Set maximal speed

To set required maximal speed of internal position controller Master writes 0x51 command followed

by two bytes of data where:

8.3.33 0x52 – Set acceleration

writes 0x52 command followed by two bytes of data where:

8.3.34 0x53 – Set deceleration

Master writes 0x53 command followed by two bytes of data where:

Page 32

PoStep60 user manual

32

www.poscope.com

MSB

Requested speed (16 bit)

LSB

BYTE1

BYTE0

MSB

Invert direction (8 bit)

LSB

BYTE0

BIT0

NOTE!

Set speed and invert direction settings are applicable only when driver is in Auto

run/Speed mode. To enable Speed mode control over I2C set driver mode to Auto

run mode (8.3.4 0x05 – Set driver mode0x05 – Set driver mode) or enable Speed

mode within PoStep application and write values to driver (standalone mode).

8.3.35 0x54 – Set requested speed

Master writes 0x54 command followed by two bytes of data where:

8.3.36 0x55 – Set invert direction

Master writes 0x55 command followed by one byte of data where only LSB bit defines direction:

8.3.37 0x5E – Set zero

Master shall write 0x5E command (no data bytes are needed).

8.3.38 0x5F – Stop

Master shall write 0x5F command (no data bytes are needed).

Page 33

PoStep60 user manual

33

www.poscope.com

9 Errata information

Auto run invert direction set cannot be applied over I2C. Driver update is needed to a

software version 0x0109 or above.

o Affected: All drivers with a software version above 0x0107 and bellow 0x0109.

I2C communication fails from time to time. Driver update is needed to a software version

0x0105 or above.

o Affected: All drivers with a software version bellow 0x0105.

Predriver Fault bug causing faulty driver failure status. Driver update is needed to a software

version 0x0103 or above.

o Affected: All drivers with a software version bellow 0x0103.

10 User manual changes¸

Changes in 6/25/2016 version:

Added Driver set mode over I2C

Fixed bug for Auto run invert direction set over I2C

Changes in 6/4/2016 version:

Added Auto run I2C commands

Added I2C address change I2C command

Changes in 5/2/2016 version:

Added Auto run control mode

Changes in 5/12/2015 version:

Fixed I2C communication breakage bug

Added new I2C commands

Changes in 10/9/2015 version:

Added BINx and I2C functionality related to application

Added I2C protocol specifications and commands

Added PoExtension pinout

Changes in 2/6/2015 version:

10 pin IDC connection diagram updated

PWM input pinout description and note updated

Technical specifications section updated

Page 34

PoStep60 user manual

34

www.poscope.com

11 Grant of license

The material contained in this release is licensed, not sold. PoLabs grants a license to the person who installs this software,

subject to the conditions listed below.

11.1.1 Access

The licensee agrees to allow access to this software only to persons who have been informed of and agree to abide by these

conditions.

11.1.2 Usage

The software in this release is for use only with PoLabs products or with data collected using PoLabs products.

11.1.3 Copyright

PoLabs claims the copyright of, and retains the rights to, all material (software, documents etc) contained in this release.

You may copy and distribute the entire release in its original state, but must not copy individual items within the release

other than for backup purposes.

11.1.4 Liability

PoLabs and its agents shall not be liable for any loss or damage, howsoever caused, related to the use of PoLabs equipment

or software, unless excluded by statute.

11.1.5 Fitness for purpose

No two applications are the same, so PoLabs cannot guarantee that its equipment or software is suitable for a given

application. It is therefore the user's responsibility to ensure that the product is suitable for the user's application.

11.1.6 Mission Critical applications

Because the software runs on a computer that may be running other software products, and may be subject to interference

from these other products, this license specifically excludes usage in 'mission critical' applications, for example life support

systems.

11.1.7 Viruses

This software was continuously monitored for viruses during production; however the user is responsible for virus checking

the software once it is installed.

11.1.8 Support

No software is ever error-free, but if you are unsatisfied with the performance of this software, please contact our technical

support staff, who will try to fix the problem within a reasonable time.

11.1.9 Upgrades

We provide upgrades, free of charge, from our web site at www.poscope.com. We reserve the right to charge for updates

or replacements sent out on physical media.

11.1.10 Trademarks

Windows is a registered trademark of Microsoft Corporation. PoStep, PoDDS, PoRef, PoScope, PoLabs and others are

internationally registered trademarks.

Support:

www.poscope.com

http://blog.poscope.com/stepper-motor-driver/

Loading...

Loading...