Portable O3 Ozone Tester/Detector

BX80

Operating instruction manual

Content

1. General……………………………………………………3

2. Technical performance and parameters………………3

3. Operating instruction……………………………………4

4. Adjusting and calibrating………………………………11

5. Daily use and maintenance …………………………14

6. Storage and quality assurance………………………14

7. Complete set……………………………………………15

Notice

Please read through this manual carefully before

operating the instrument!

1. General

BX80 O3 Ozone tester is a portable O3 gas detector/alarm that can be used to test

the ozone level in air or gas. The tester comprises circuit board, annunciator, LCD,

electrochemistry sensor. The sensor changes the ozone concentration into electricity

signal and displays on the LCD. If you set a threshold, the tester will make alarm signal to

remind you when the ozone concentration reach the threshold.

BX80 has a very clear and large LCD with audible and visible alarm, and can detect

accurate ozone level and send alarm to the operator in time for prevention even in very

inimical work environment.

2. Technical performance and parameters

Features

• Smart, portable and firm

• Audible and visible alarm

• Large screen digital and character display, instantaneous value, peak value

and mean value available

• Self-checking for displaying, battery, sensor, audible and visible alarm at

startup

• Regular light flashing and audible indication

• Distinct audible alarm

• Low maintenance cost

Main technical indexes

Gas for detect

Range

Precision

Least count

Response time

Ozone (O3)

0-5-20ppm

<±5% (F.S)

0.01/0.1ppm

≤ 60 sec

Detection mode: Gaseous diffusion

Battery: Lithium ion rechargeable battery, 3.7V

Battery working period: About 200 hours

Sensor work principle: Electrochemistry mode

Sensor service life: 2 years

Display: Large screen LCD

Alarm: Audible and visible alarm

Direct readings: instantaneous value, peak value, battery voltage, TWA, STEL

Ex-mark: Ex ibdIICT4

Protection degree: IP45

Work temperature: -10~50℃

Work humidity: 5~90% RH

Size: 126mm (L) x 66mm (W) x 32mm (H)

Weight: 220g (with charger)

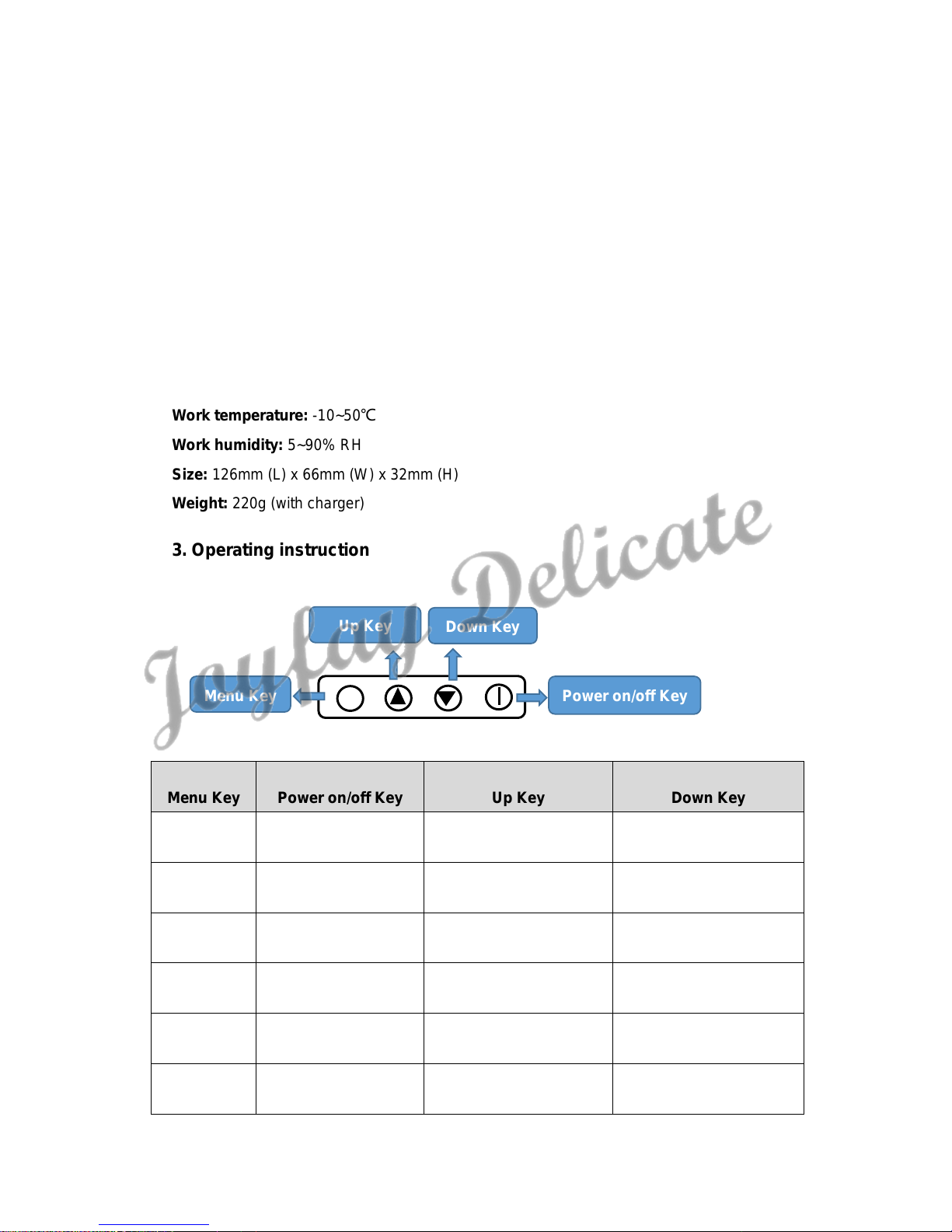

3. Operating instruction

Menu Key Power on/off Key Up Key Down Key

Enter Menu Switch-on Selecting menu Selecting menu

Exit Switch-off Value up Value down

Selfcheck Activate The Background

Activate the background

Zero Point Calibrating

Sensitivity Setting

Affirm Setting

Menu Key

Up Key

Down Key

Power on/off Key

Switching on

Press “ ” key and the detector will be switched on after two beeps.

Switching off

At measuring status, press and hold “ ” key down, the detector will be switched off

after 5 seconds’ countdown; if the holding time for pressing “ ” key is not long enough, the

detector will be brought back to the measuring status.

Low power

Audible and visible alarm for undervoltage will be activated if the battery voltage is

lower than the pre-set value. And the battery should be recharged at such situation. At

undervoltage alarm, the screen will also display a detection failure symbol besides the

audible and visible alarm, and meanwhile the symbol for detection pass will flicker

together with the symbol for battery undervoltage. When the power is exhausted, the

symbol for detection failure will flicker together with the symbol for battery

undervoltage, and the screen will display an indication of “battery off”, and then the

detector will be switched off automatically.

After an undervoltage alarm, the detector should be switched off and recharged for

4~6 hours around.

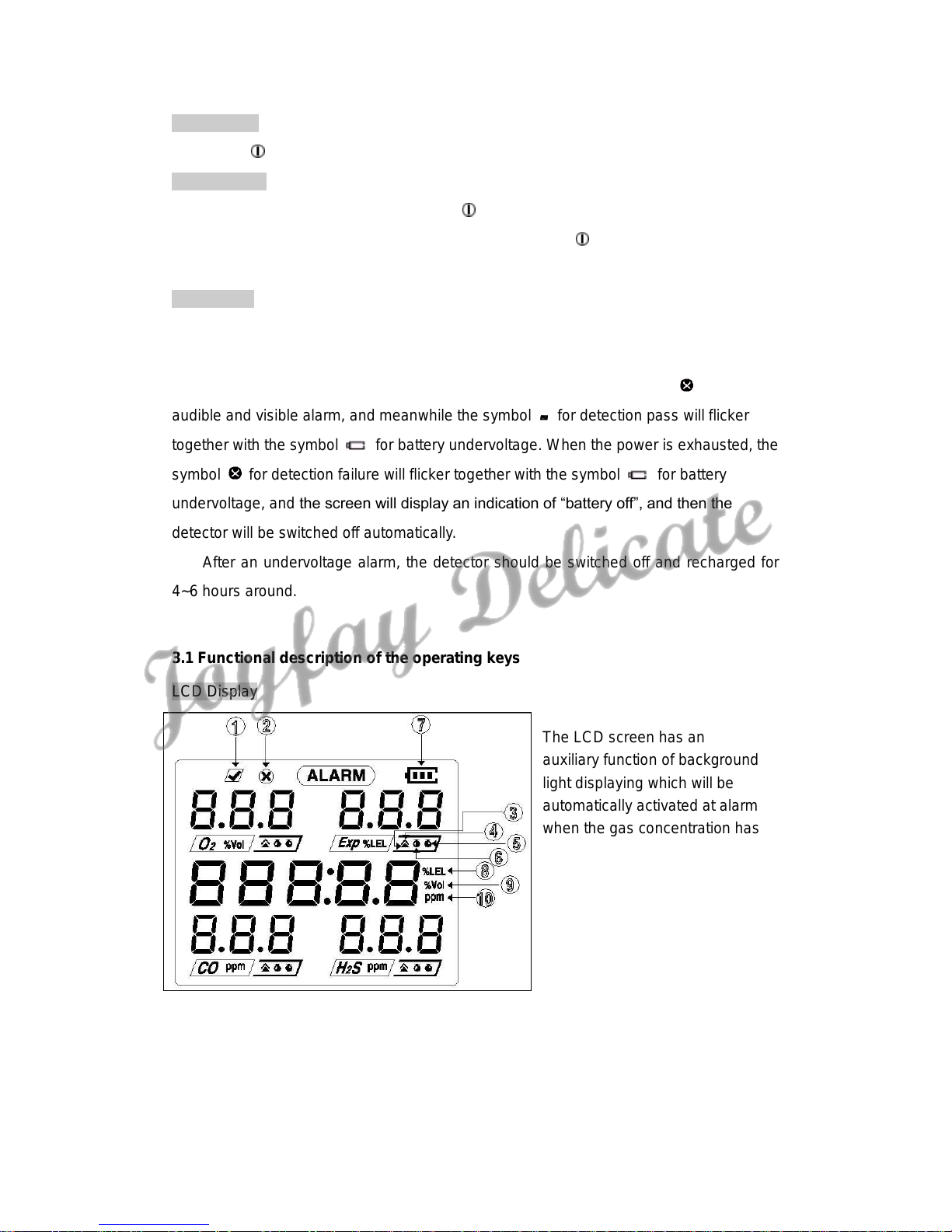

3.1 Functional description of the operating keys

LCD Display

The LCD screen has an

auxiliary function of background

light displaying which will be

automatically activated at alarm

when the gas concentration has

exceeded the alarm point; at

normal detecting in an

environment with weak light, it

can be activated by pressing UP

Key or DOWN Key once.

1. Detection pass 2. Detection failure 3. Grade I Alarm

4. Grade II Alarm 5. STEL Value 6 .TWA Alarm

7 Battery 8. %LEL (unit) 9. %Vol (unit)

10. PPM (unit)

3.2 Self-checking

Press “ ” key and with two beeps the screen will display the following information:

1. Displaying all the digital and character indications; checking audible and visible alarm;

Checking the battery, electric circuit and the sensor(s)

2. Displaying the version of software and detection range

3. Displaying Grade I alarm point (combustible gas, noxious gas, and high concentration

O2 alarm) and Grade II alarm point (combustible gas, noxious gas, and low concentration

O2 alarm); Displaying STEL and TWA alarm points (only for noxious gas)

Software Version

Detection Range

Grade I Alarm Point

Grade II Alarm Point

TWA Alarm Point

STEL Alarm Point

4. The result of self-checking will be displayed as follows:

In addition, the detector will check the battery, electric circuit and the sensor(s) regularly.

!Notice: at failure of self-checking, a re-selfcheck should be taken, if it fails again, please

contact us or the local agent for service

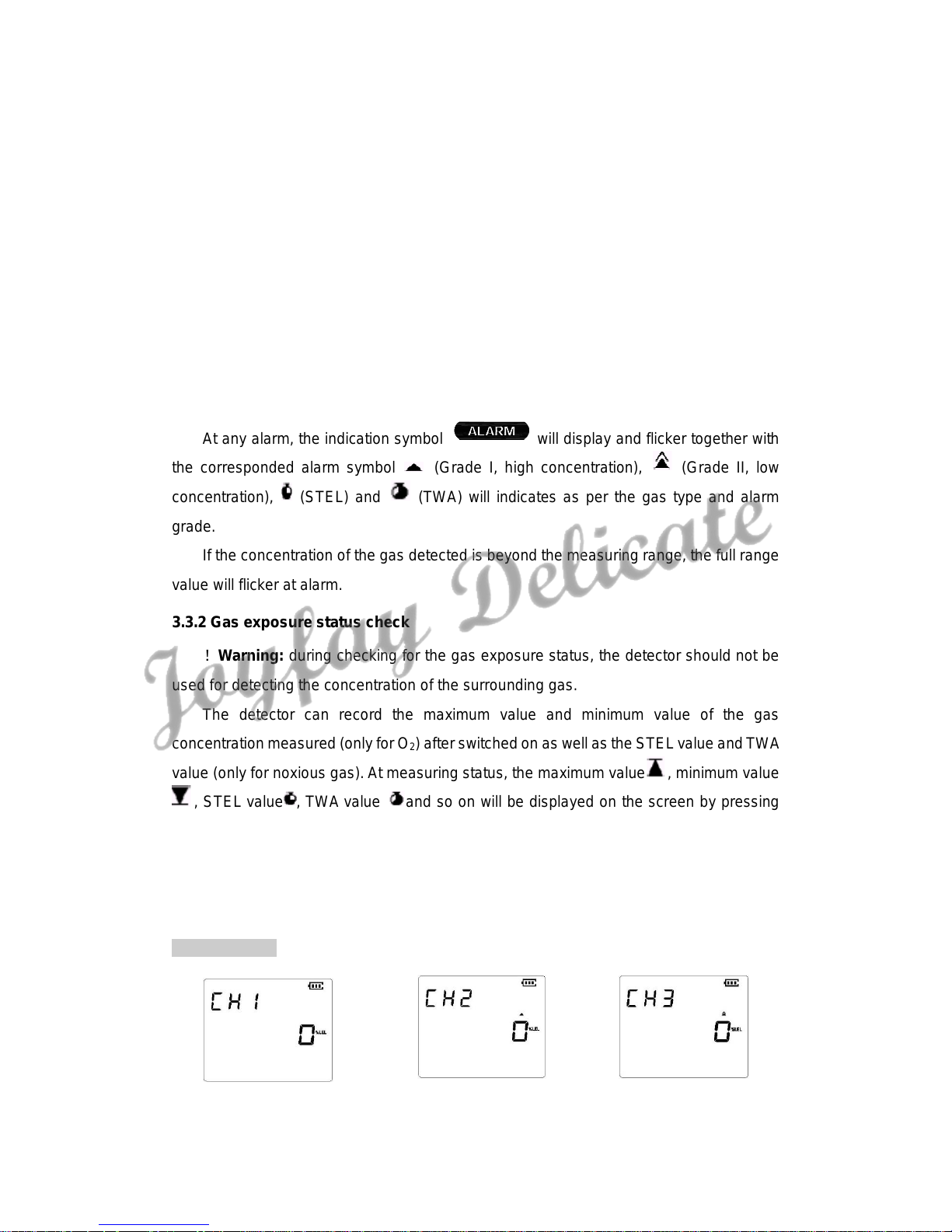

3.3 Measuring mode

A measuring mode of "Gas diffusion” or “Gas absorption" can be applied to the detector

which can be fixed to the waist belt or handled for use during normal operation. Once

switched on, the detector will start measuring continuously, and generally the surrounding

air can enter into the sensor through diffusion which will bring the target gas directly into

the sensor, and then the sensor will response to the concentration of the gas and output a

measuring result. The detection principle of diffusion mode applies the above way to

detecting the concentration of the surrounding gas with an advantage of swift response

time. If it is required to take a remote detection for the gas at the sample position, gas

absorption mode should be applied to measuring, and the detector should be equipped

with a calibrating case and an optional air pump, but at such situation, the direction for gas

sampling should be in accordance with the arrowhead. The gas kind and concentration will

be separately displayed on a same screen.

3.3.1 Gas alarm

The detector has two instantaneous gas alarm grades, in which Grade II alarm point

(high concentration alarm for combustible gas and noxious gas, low concentration alarm

for O2) should be more urgently treated than Grade I alarm point (low concentration alarm

Selfcheck Pass

Selfcheck Failure

Normal Display

for combustible gas and noxious gas, high concentration alarm for O2) in general, and it is

the same important for too high or too low concentration of O2. For noxious gases, it also

has a 15 minutes' STEL alarm point of mean exposure concentration and an 8 hours TWA

alarm point of mean exposure concentration. The user can carry out settings for Grade I

alarm point, Grade II alarm point, STEL alarm point and TWA alarm point.

Note: STEL stands for Short Time Exposure Limit and TWA for Time-Weighted

Average.

Notice: The setting value for Grade I alarm point should not exceed the setting value

for Grade II alarm point, or the detector will work only with Grade I alarm function if the two

setting values are the same.

At any alarm, the indication symbol will display and flicker together with

the corresponded alarm symbol (Grade I, high concentration), (Grade II, low

concentration), (STEL) and (TWA) will indicates as per the gas type and alarm

grade.

If the concentration of the gas detected is beyond the measuring range, the full range

value will flicker at alarm.

3.3.2 Gas exposure status check

!Warning: during checking for the gas exposure status, the detector should not be

used for detecting the concentration of the surrounding gas.

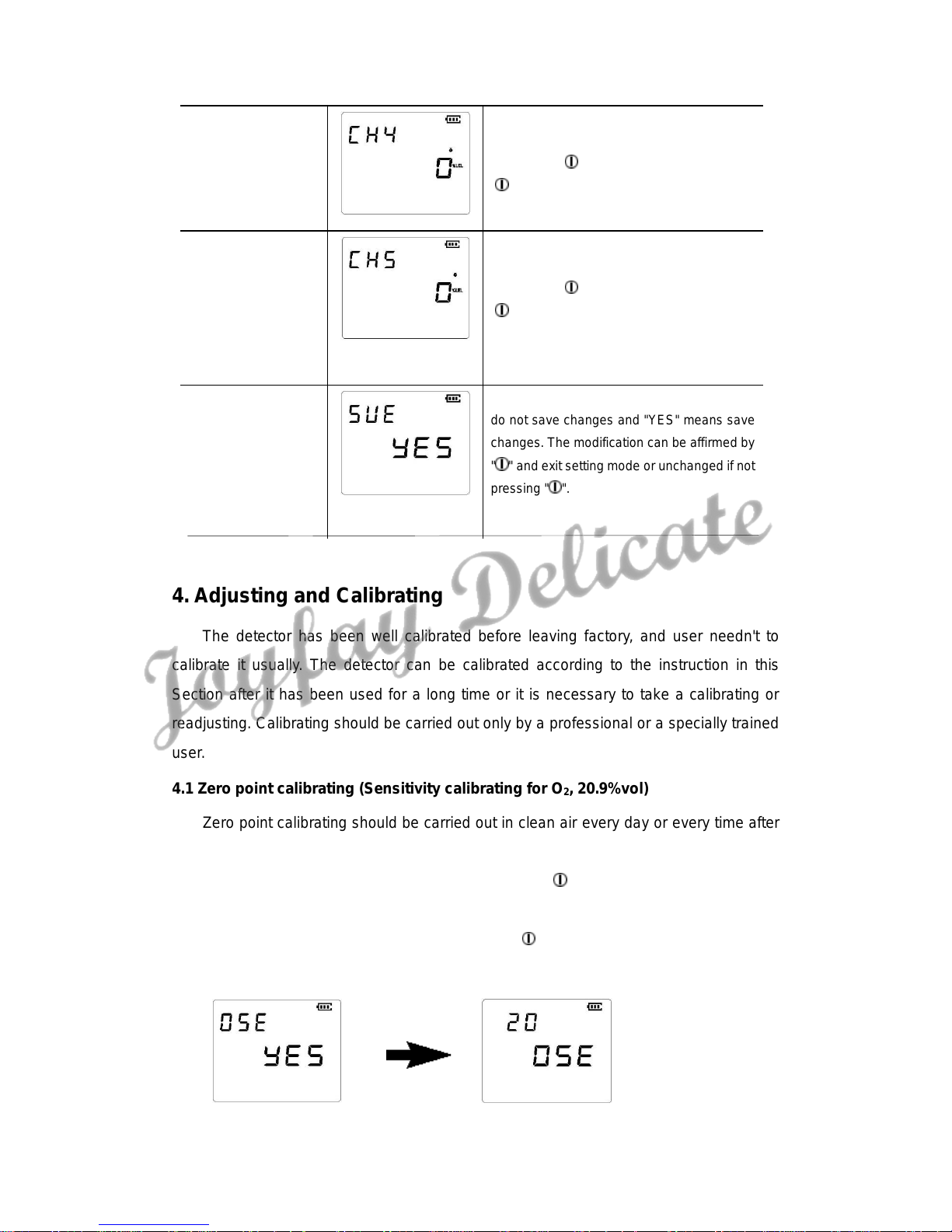

The detector can record the maximum value and minimum value of the gas

concentration measured (only for O2) after switched on as well as the STEL value and TWA

value (only for noxious gas). At measuring status, the maximum value , minimum value

, STEL value , TWA value and so on will be displayed on the screen by pressing

UP Key or DOWN Key. They will be displayed in sequence by pressing UP Key (in forward)

or DOWN Key (in reverse).

If no key is pressed down within 10 seconds, the detector will be brought back to the

normal measuring mode.

Screen display:

Current Value

Minimum Value

Maximum Value

3.3.3 Audible and visible indication

Audible and visible indication in every 5 minutes' intervals can be set to the detector

for indicating normal work status. The user can activate or close this function, or only use

visible signal or both indicating type for option (refer to Setting mode). The default setting

for audible and visible indication of the detector at leaving factory is both closed.

3.4 Setting mode

Notice: the detector cannot be used for measuring at setting mode.

At setting mode, the operator can carry out the following settings:

·Audible and visible indicating mode

·V ibration alarm indicating mode

·Mode conversion for alarm or non-alarm

·Setting value for Grade I alarm point

·Setting value for Grade II alarm point

·Setting value for STEL alarm point

·Setting value for TWA alarm point

3.4.1 Enter into setting mode

At normal measuring mode, press menu key for about 3 seconds, the detector

will be brought into the setting mode with audible indication.

3.4.2 Modify the detector settings

The menu structure at setting mode is shown as Table 1.

At setting mode, the setting time can be selected by pressing "▲" or "▼" and affirmed

by " ". And then the parameter of the selected item can be modified.

The parameter can be increased by pressing "▲" or decreased by "▼". And affirmed

by pressing " ".

Once a modification is finished, the new parameter will be saved in the detector.

TWA Value

STEL Value

Table 1

Setting type

Display (e.g.)

Instruction

Audible and

Visible Indication

Select by pressing "▲" or "▼"; "NO" means

the detector is in measuring function and will

not have Audible and Visible Indication at

exceeding; "YES" means the detector works

with measuring and Audible and Visible

Indication; the modification can be affirmed by

" " or unchanged if not pressing " ".

Vibration Alarm

Indication

Select by pressing "▲" or "▼"; "NO" means

the detector is in measuring function and will

not have Vibration Alarm Indication

at exceeding; "YES" means the detector

works with measuring and Vibration Alarm

Indication; the modification can be affirmed

by " " or unchanged if not pressing " ".

Alarm Mode

Select by pressing "▲" or "▼"; "NO" means

the detector is in measuring function and will

not alarm at exceeding; "On" means the

detector works with measuring and alarm

functions; the modification can be affirmed by

" " or unchanged if not pressing " ".

Grade I alarm

Increase the value by pressing "▲" or

decrease by "▼", the modification can be

affirmed by " " or unchanged if not pressing

" ".

Grade II alarm

Increase the value by pressing "▲" or

decrease by "▼", the modification can be

affirmed by " " or unchanged if not

pressing " ".

TWA alarm

Increase the value by pressing "▲" or

decrease by "▼", the modification can be

affirmed by "

" or unchanged if not pressing

" ".

STEL alarm

Increase the value by pressing "▲" or

decrease by "▼", the modification can be

affirmed by " " or unchanged if not pressing

" ".

Save Indication

Select by pressing "▲" or "▼"; "NO" means

do not save changes and "YES" means save

changes. The modification can be affirmed by

"

" and exit setting mode or unchanged if not

pressing " ".

4. Adjusting and Calibrating

The detector has been well calibrated before leaving factory, and user needn't to

calibrate it usually. The detector can be calibrated according to the instruction in this

Section after it has been used for a long time or it is necessary to take a calibrating or

readjusting. Calibrating should be carried out only by a professional or a specially trained

user.

4.1 Zero point calibrating (Sensitivity calibrating for O2, 20.9%vol)

Zero point calibrating should be carried out in clean air every day or every time after

an alarm.

At normal measuring status, press and hold down " " and "▼" for about 5 seconds,

the detector will be brought into zero point calibrating with an audible indication; pressing

"▲" or "▼" to select "YES" or "NO" and affirm by " ", the screen will display "CAL" and

flickering zero point calibrating symbol, and start a 20 seconds' countdown.

·After zero point calibrating for all the sensors are succeeded, the symbol for detection

pass will be displayed.

·If the zero point calibrating for one or more sensors is failed, the symbol for detection

pass will also be displayed but with an "Err" indication for a failed channel.

Notice: If there is any sensor failed, carry out the zero point calibrating again in clean air;

if it still fails, please contact us or the local agent for service.

4.2 Zero point calibrating (Sensitivity calibrating for O2, 0.0%vol)

For noxious gas sensors, the sensitivity calibrating should be carried out every 6

months. The user should apply a standard gas to sensor calibrating, and the detector will

identify automatically.

At sensitivity calibrating, the operator should apply the following calibrating tools:

·S tandard gas cylinder(s) with known concentration

Gas type

Standard gas concentration recommended

Combustible Gas

CH4 60%LEL

·Flow meter (300mL/min recommended) and pressure relief valve

·Connecting pipe between the pressure relief valve and the calibrating case

Zero Point Calibration

Dectection Failed

·Zero point calibrating and sensor channel On/Off setting should be finished before

sensitivity calibrating.

4.3 Standard gas setting

Information on standard gas setting will be displayed.

·At normal measuring status, press and hold down " " and "▲" for about 3 seconds, the

detector will be brought into sensitivity calibrating mode with audible indication.

·The user can adjust the gas type for calibrating by UP Key or DOWN Key, and affirm by "

". Then it will have a 20 seconds countdown

The Detector will automatically calculate the mean gas concentration value detected before within

20 seconds.

If gas is not detected, the tester will automatically show system error, press " " key to return

normal measuring status.

If the current value is to be modified, press " " to affirm. The value can be adjusted by UP

Key or DOWN Key and affirmed by " ".

If the sensitivity calibrating is succeeded, the symbol " " for detection pass will be

displayed.

5. Daily use and maintenance

5.1 This manual of instruction should be carefully read through before operating the

detector.

5.2 This detector should be used or maintained by a well-trained person or a

professional.

5.3 This detector should be used strictly as per the rules specified by our company.

5.4 Any maintenance or replace of any part should be carried out by a specially and

well trained person with original spare parts from our company.

5.5 Replace or recharge of battery should be carried out in a safe environment.

5.6 The detector should be well prevented against dropping down or excessive

vibration.

5.7 If the detector appears with any irregular display and some intermittent sound, it

means that the battery is under voltage and the detector can be recovered to

normal status after the battery is recharged.

5.8 The detector is forbidden to be used in a high concentration and corrosive gas

environment for a long period, or the sensor will lose sensitivity or be damaged at

serious conditions.

Calibration Succeeded

6. Storage and quality assurance

6.1 For BX80 O3 Ozone Detector/alarm, our company will take responsibility for a 12

months' guarantee for repair from the day when the user obtains the detector.

6.2 The user should obey the operating rules at all times, and any damage to the

detector upon any improper use or use under any improper environment will be

beyond the guarantee scope.

6.3 Our company will take no responsibility for the reliability of the detector if the user

has carried out any repair or replace of any part beyond the operating rules.

6.4 The detector should be protected in a damp-proof bag if it is transported or stored

on ship or in a very damp environment.

7. Complete set

7.1 BX80 O3 Ozone Detector/alarm 1 set

7.2 Device Charger 1 set

7.3 Operating instruction manual 1 book

7.4 Product certificate 1 sheet

7.5 Repair guarantee card 1 card

Loading...

Loading...