CAM-LOK®SINGLE POLE CONECTORS

E-Z1016 & E-Z1018 SERIES

Installation and Maintenance Information

IM 1012

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

APPLICATION

Cooper Interconnect’s Cam-Lok connectors are

designed to meet NEC code requirements for

listed connectors that are of the locking type.

These single pole plugs and receptacles are

insulated in a specially formulated elastomeric

material for safety and watertightness. They

allow you to connect or disconnect electrical

equipment instantly without tools.

Cam-Lok connectors are the industry standard

for motors, generators, indoor and outdoor

lighting distrubution panels and numerous other

power applications.

Cam-Lok E-Z Series connectors are rated at

600Volts up to 400 Amperes continuous. Actual

operation must comply with the information

stipulated on the unit’s nameplate.

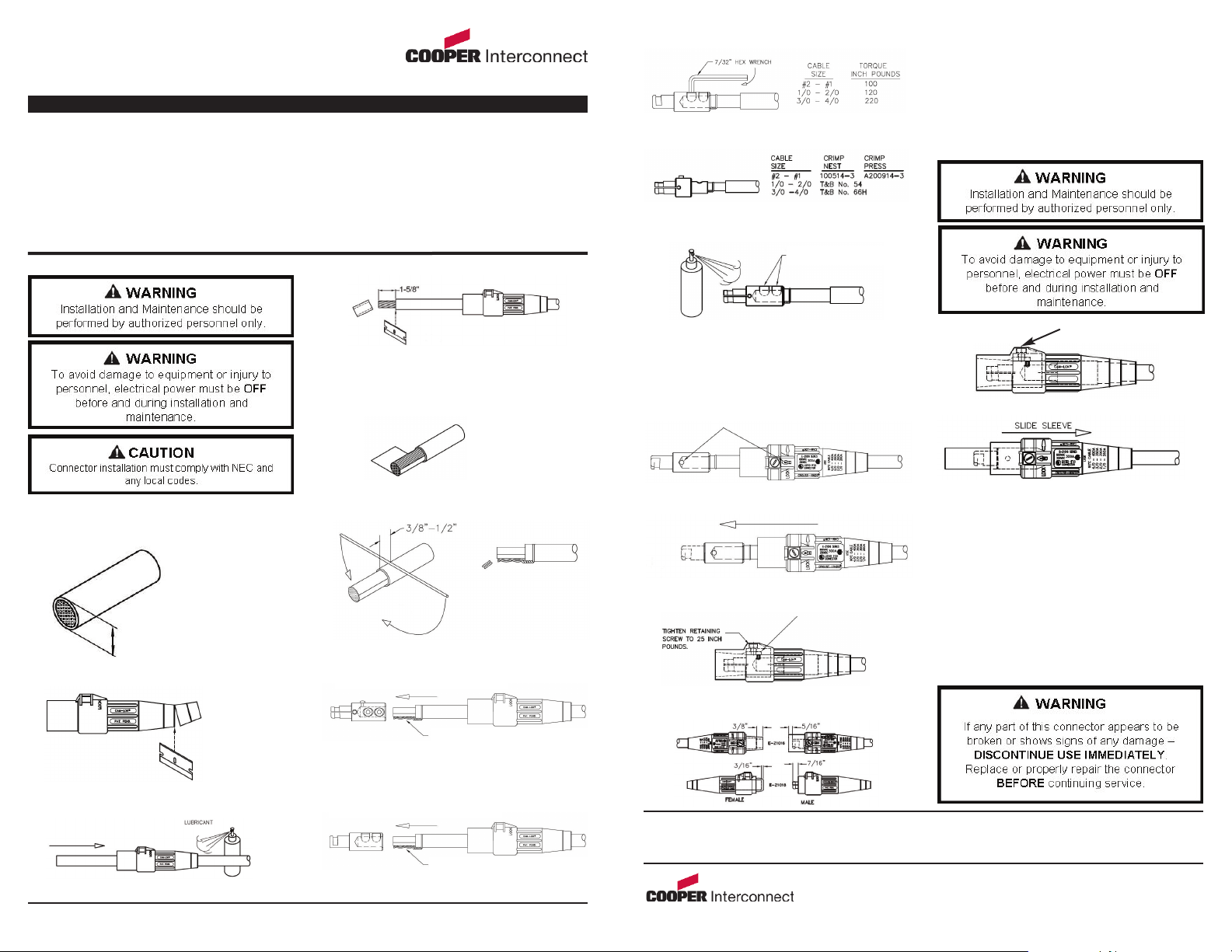

INSTALLATION

IM 1012 Copyright © 2009, Cooper Industries, Inc. Page 1

Note: Use Copper (CU) Conductors only.

1. Measure cable jacket diameter.

2. Cut sleeve to match cable jacket diameter.

4. Remove 1-5/8” of the cable jacket.

5. Wrap cable with copper shim.

NOTE: Use two shims for #2-1/0 cable and

one shim for 2/0-4/0 cable.

6. Wrap strain relief wire.

8b. Crimp Contact.

9. Lubricate contact.

INSULATOR SLEEVE REMOVAL

HOW TO OPERATE

MAINTENANCE

1. Loosen retaining screw 4-6 turns.

1. Fully engage male plug to female plug and

rotate 1/3 of a turn clockwise.

2. To remove, rotate male plug counter

clockwise 1/3 of a turn and pull straight out.

Perform visual, electrical and mechanical checks

of all components on a regular schedule. This

should be determined by the environment and

frequency of use, but it is recommended that it

should be at least once per year.

1. Make sure retaining screw is tight. (see Fig 6)

2. Clean contact thoroughly.

3. Clean all external parts of the connector

thoroughly.

All statements, technical information, and recommendations contained herein are based on information and tests we believe to be

reliable. The accuracy or completeness thereof are not guaranteed. In accordance with Cooper Interconnect’s “Terms and Conditions

of Sale,” and since conditions of use are outside our control, the purchaser should determine the suitability of the product for his

intended use and assumes all risk and liability whatsoever in connection therewith.

Cooper Industries, Inc.

Cooper Crouse-Hinds Division

4758 Washington Street, LaGrange, NC 28551 USA

Copyright© 2009, Cooper Industries

IM 1012

SBA018

3/20/2009

Figure 1

Figure 2

Figure 4

Figure 5

Figure 6

Figure 8b

Figure 9

Figure 3

7. Insert cable into contact.

Figure 7a

8a. Tighten set screw using 7/32” Hex Wrench.

Figure 8a

OR

NOTE: A lubricant is available from:

Chemtrend, Inc.

1445 West McPherson Park Drive

Howell, Michigan 4884-0860

Part #CT-39F

10. Line up button on contact with ‘Mate’ arrow

on sleeve.

11. Push sleeve over contact.

Figure 10

Figure 11

12. Ensure button stops at end of keyway and

tighten retaining screw.

Figure 12

13. Check final position.

2. Slide sleeve off contact.

Figure 14

Figure 15

Strain Releif Opposite Drive Pin

Set screws must not extend past the

outside of the contact.

3. Slide sleeve onto cable.

one wrap

then twist

1. Twist tightly 3-4 times

ensuring wire bites into

cable jacket then 2-3

loose turns.

2. Bend wire parallel to cable

3. Trim wire flush with cable

Figure 7b

Strain Releif Opposite Set Screws

7a. For 4/0 size cable:

OR

7b. For all other cable sizes:

Loading...

Loading...