Page 1

Instructions for use and

safety regulations

for

Induction heater

JH1500

T 152 1 130915236

Page 2

induction heating

PREFACE

Induction heater JH1500

JH1500 is a mobile induction heater, which

is used for heating metal parts on vehicles

without damaging nearby parts. All other use

of the equipment or use that does not comply

with the instructions in this instruction book,

can cause personal injury and/or damage to

the machine.

If the equipment is used incorrectly, JOSAM

AB cannot be held liable for damage to

the equipment, irrespective of whether the

damage has been caused intentionally or

unintentionally. Nor will JOSAM AB accept

liability for any subsequent nancial losses or

loss of income.

Warranty

JOSAM AB provides a one year warranty

from the machine's delivery date and a

three months warranty on consumable parts

(inductor). The warranty covers material faults

and presupposes normal care and normal

maintenance.

The warranty presupposes that:

• the equipment is installed correctly

and inspected in accordance with the

applicable regulations,

• the equipment has not been modied or

rebuilt without the consent of JOSAM AB,

• only original spare parts from JOSAM AB

have been used in the event of any repairs,

• handling and maintenance has been

performed according to the directions in

this instruction book.

In the event of any complaint, verication is

required that the fault has occurred during the

warranty period and that the equipment has

been used within the capacity limits stated

in the technical data. In the event of any

complaint, the product type and article number

must be stated. These details can be found on

the identication plate, see chapter "Marking".

Information

This instruction book provides advice

and directions for installation, handling,

maintenance and troubleshooting.

IMPORTANT! Read this instruction book

carefully so you can learn the correct way of

using the induction heater. Do not neglect to

do this, since incorrect handling can lead to

personal injury and damage to the equipment.

The illustrations in the instruction book are

only to help with comprehension and do not

necessarily represent the equipment's exact

appearance. The equipment is intended to

be used in accordance with current practice

and the applicable safety regulations. The

equipment, as shown in the instruction

book, may be changed in the future without

warning.

The content of this instruction book can also

be changed without warning.

This instruction book contains information

that is protected by the Copyright Act. No

part of this publication may be reproduced

or published without the written consent of

JOSAM AB.

Conformance with directives and

standards

The JH1500 series is designed and

manufactured by JOSAM AB, an

EN‑ISO9001/14001 certied development

and manufacturing company. The JH1500

series conforms with the requirements in the

CE standard.

2

Page 3

induction heating

CE CERTIFICATE

Induction heater JH1500

3

Page 4

induction heating

TABLE OF CONTENTS

Induction heater JH1500

Preface 2

Warranty .........................2

Information ........................2

Conformance with directives

and standards .....................2

CE certicate 3

Table of contents 4

Introduction 5

General Information .................5

Marking .......................6

Safety 7

General information .................7

General warnings ..................8

Safety sign .......................10

The placing of the safety sign ........11

Safety devices ....................11

Installation 12

Packaging check and delivery ........12

Filling the water tank ...............13

Connection to the electric supply ......14

Description 15

Cooler section ....................16

Electrical section ..................17

Main power switch ..............18

Residual current breaker .........18

Main fuse .....................18

Cooler fuse ...................18

USB connection ................18

Control panel .....................19

Alarm indicators ................20

Operation indicator .............20

Hose packet ......................21

Connection block ...............21

Handheld transformer with hose kit . 21

Trigger button ..................21

Inductor ......................22

Usage 23

General information about induction ...23

Information about heating ...........23

Heating .........................24

After completed work ...............25

Maintenance instructions 26

Maintenance interval ...............26

Maintenance description ............26

Check the cooling water .........26

Check the residual current breaker . 26

Check the hose couplings ........27

Check and clean the condenser ...27

Check cable glands on the

connection block ...............27

Fitting the inductor ..............27

Troubleshooting 28

Troubleshooting table ...............29

General information 31

Manufacturer .....................31

Machine designation ...............31

Intended usage areas

and environments .................31

Warranty ........................31

Recycling ........................31

Service .........................31

Technical data 32

4

Page 5

induction heating

INTRODUCTION

General information

JH1500 is a mobile induction heater, which is

used for heating up metal parts on vehicles

without damaging nearby parts. The induction

heater produces heat without physical contact

and without naked ames. Using the induction

heater makes it possible to leave nearby,

sensitive parts in place.

The are many application areas for the JH1500.

For example, the induction heater can be used

for:

• Heating nuts and bolts that have rusted in

place

• Heating hinge pins that have rusted in place

• Heat‑shrinking steel and aluminium panels

when making repairs

• Heating, for example, couplings to exhaust

systems that have rusted in place and

places that are difficult to reach

• Heating screws that have rusted in place

• Nuts on the suspension or the steering

• Simple removal of underbody protection and

PVC coating

• Frame straightening

Induction heater JH1500

The JH1500 is designed to heat metals, by

concentrating a powerful magnetic eld at the

inductor head. The induction heater also works

well on aluminium. The magnetic eld alternates

at a frequency of ca 14‑30kHz. The magnetic

eld induces eddy currents in the material, and

the electrical resistance produces heat in the

metal.

Since heat is created due to electrical losses

and radiation from the plates, JH1500 has an

internal cooling system, using water as the

coolant. The water circuit cools the high‑power

electronics, cables, induction handle and

inductor. When the machine starts, the water

pump begins to pump the cooling water in the

induction heater.

5

Page 6

induction heating

Marking

The identication plate is located on the back

of the JH1500.

Induction heater JH1500

#####

#####

400 V 200 V

6

Page 7

induction heating

SAFETY

General information

The JH1500 is designed and tested to conform

to the strictest safety requirements. Read the

following instructions carefully before you start

using the JH1500 and pay attention to the

applicable operating instructions, in order to

operate the induction heater safely.

The information provided in this manual

describes the work routines that we consider

work best, but may under no circumstances

be used as an excuse to ignore one's

own personal responsibility or applicable

regulations.

Great care has been taken during the design

and manufacture of the JH1500 to ensure

the system conforms with the applicable

safety regulations for this type of equipment.

During use and other work, everyone has a

personal responsibility for their own and other

individuals' safety.

Induction heater JH1500

Safe use of the induction heater is

guaranteed by using the equipment correctly,

in accordance with the descriptions and

instructions in this manual. By reading and

following the safety regulations, the JH1500

user can ensure a safe work environment for

himself/herself and his/her colleagues.

7

Page 8

induction heating

GENERAL WARNINGS

The following types of warnings and

information are used in this manual:

Induction heater JH1500

WARNING!

Warning is used in this manual

to draw attention to possible

dangers that can result in

personal injury. When an

instruction is given, it is normally

followed by a short explanation

and the possible results if the

instruction is not followed.

IMPORTANT!

Important is used to draw

attention to possible dangers

that can result in damage

to the equipment and/or the

environment.

NOTE!

Note is used to indicate

additional information that

should be followed to obtain

problem free or the best use of

the equipment.

WARNING!

Do not ll the water tank with

anything other than decalcied

water mixed with propylene

glycol. Incorrect handling can

cause personal injury and/or

damage to equipment.

WARNING! Do not touch

objects that have been close to

the inductor without checking

that they have cooled down.

WARNING! Do not touch the

inductor while it is activated

and the strong magnetic eld

and the heat are on. Danger of

personal injury.

WARNING! The work area

must be kept free of ammable

material when you are working

with the induction heater.

Apart from the safety signs shown in

the section "Safety Signs", the following

WARNING! Make sure that re

ghting equipment is available.

Danger of personal injury.

warnings and important information can

be found in the operating instructions:

WARNING! Loose cables

WARNING! Do not place the

induction heater on unlevel or

instable surfaces. The induction

heater can fall over and cause

personal injury or serious

damage to the induction heater.

WARNING! All electrical modi‑

cations must be performed by

a qualied electrician.

Danger of electrical shocks.

8

and hoses constitute a risk for

tripping. Danger of personal

injury.

WARNING! If you do not remove

paint and other chemicals from

the material before you heat it

up, you must use an extraction

fan to remove vapours that are

injurious to health. Danger of

personal injury.

Page 9

induction heating

GENERAL WARNINGS

Induction heater JH1500

WARNING! When you are

using the JH1500, performing

maintenance on it or working

near it, do not wear or use metal

objects such as watches, rings,

keys, etc. The objects can be

heated up by the magnetic eld

from the JH1500 and cause

burn injuries.

WARNING! Most of the

servicing must be performed

by service personnel or service

support from JOSAM AB.

Danger of electrical shocks.

WARNING! Never remove any

of the protective covers and

never perform any work on the

induction heater without rst

pulling the plug out of the wall

socket. Wait one minute. Danger

of electrical shocks.

WARNING! It is the owner's

responsibility to ensure that the

equipment has been installed in

accordance with the instructions

in this manual. It is also the

owner's responsibility to ensure

that the equipment is inspected

according to the applicable

regulations before it is used.

IMPORTANT! For

environmental reasons, it is

important that the equipment

is disassembled in an

environmentally friendly way.

IMPORTANT! Risk of con‑

densation in the JH1500. Fill the

water tank with room tempered,

not cold, water. If you move the

JH1500 from a cold location,

you should wait until the

water has warmed up to room

temperature before use.

WARNING! Remove the

induction heater's plug from the

wall socket before you begin

any form of service, cleaning

or maintenance. Danger of

electrical shocks.

WARNING! The inductor can

become very hot. Danger of

burn injuries.

WARNING! Read this manual

carefully so you can learn how

the equipment is to be used in

the right way. Do not neglect to

do this, since incorrect handling

can lead to personal injury and

damage to the equipment.

IMPORTANT!

During transport the water

tank must always be sealed.

Otherwise, there is a risk of

water leaks.

9

Page 10

induction heating

Safety sign

The safety sign must always be present and in

good condition, attached to the stated place.

If the sign is damaged or is missing, the owner

bears the responsibility for replacing it without

delay.

You can nd the following safety symbols on

the induction heater:

WARNING

Wear suitable safety equipment (protective

gloves and safety goggles) when you use the

equipment.

Induction heater JH1500

WARNING

Sparks from the induction heater can cause

res.

WARNING

Danger of tripping over loose hoses etc.

WARNING

Always read the user instructions before using

the product.

WARNING

Residual voltage. Wait one minute after

disconnecting before opening enclosure.

WARNING

When the JH1500 induction heater is activated,

there is a magnetic eld from the induction

head in its immediate vicinity.

10

WARNING

The JH1500 induction heater can interfere

with pulse generators. It is possible that a

pacemaker will not function correctly in the

vicinity.

Page 11

induction heating

The placing of the safety sign

The safety sign is placed on the back of the

JH1500, as in the picture.

Induction heater JH1500

Safety devices

When the induction heater is in use, the

inductor, cables, electronics and transformer

can frequently become very hot. To protect

the induction heater from overheating, it is

cooled continuously when in operation. The

induction heater is cooled all the time by

water that circulates through the inductor. The

water begins to circulate when the machine is

started. A sensor detects the water ow and

trips the induction heater if the ow is blocked.

The JH1500 must be connected to earth.

It has an inbuilt residual current breaker to

protect the user in case of a ground fault. It

also has an automatic fuse, which trips if the

current exceeds 32 A (for JH1500‑400V) or

63A(forJH1500‑200V).

In case the JH15000 would get overheated,

the overheating protection automatically

disables the heating function to protect the

machine and its electronic parts. However, the

cooling system continues to cool the machine

to make it ready for operation again.

The inductor handle is insulated to protect the

user from electric shocks.

11

Page 12

induction heating

INSTALLATION

The JH1500 is inspected and tested before it

leaves the factory to warrant uniform quality

and the greatest possible reliability. Below

follows a description of the installation and

general tips and instructions.

Induction heater JH1500

WARNING! Do not place the

induction heater on uneven or

unstable surfaces. The induction

heater can fall over and cause

personal injury or serious damage

to the induction heater.

WARNING! It is the owner's

responsibility to ensure that the

equipment has been installed in

accordance with the instructions

in this instruction book. It is

also the owner's responsibility

to ensure that the equipment is

inspected according to applicable

regulations before it is used.

Packaging check and delivery

Check the delivery against the packing

list, consignment note or other delivery

documentation to ensure that everything is

included in the correct quantities. Check the

JH1500 carefully, to assure yourself that no

damage has been incurred during transport.

If any part has been damaged or is missing,

the induction heater must not be used before

the part has been repaired or replaced. If

there is anything missing, contact the supplier.

Remove all of the packaging material from the

induction heater.

12

Page 13

induction heating

INSTALLATION

Filling the water tank

The JH1500 is delivered with a lled water

tank, but if the tank needs to be lled manually

at some point, follow the instructions below.

Fill the water tank with a mixture of decalcied

water and 30 % propylene glycol.

1. Open the front cover.

2. Open the tank cap.

3. Fill the water tank (it should be lled to

between 80‑90%).

Induction heater JH1500

WARNING! Do not ll the

water tank with anything other

than decalcied water mixed

with propylene glycol. Incorrect

handling can cause personal

harm and/or damage to

equipment.

IMPORTANT! Risk of

condensation in the JH1500.

Fill the water tank with room

tempered, not cold, water. If you

move the JH1500 from a cold

location, you should wait until

the water has warmed up to

room temperature before use.

NOTE! Do not ll the tank

completely, since the water

expands as it heats up. Fill the

tank with 35 litres of uid.

13

Page 14

induction heating

INSTALLATION

Connection to the electric supply

The induction heater is available in two

versions: 200 V or 400 V, 50–60Hz. The 400V

version is equipped with a plug so it can be

plugged into a wall socket. The source of

electrical current must be earthed and it must

also be protected by a fuse, according to the

following:

• The electric supply must be protected by

a 32A(400V) or 63A(200V) fuse when

using maximum power (step 5).

The JH1500 is connected to the electric mains

as follows:

Induction heater JH1500

• Plug the JH1500 into a wall socket.

NOTE! The JH1500‑200 V is

delivered without a plug.

A plug suited for local electrical

conditions must be acquired

separately and mounted by a

qualied electrician.

14

Page 15

3

induction heating

DESCRIPTION

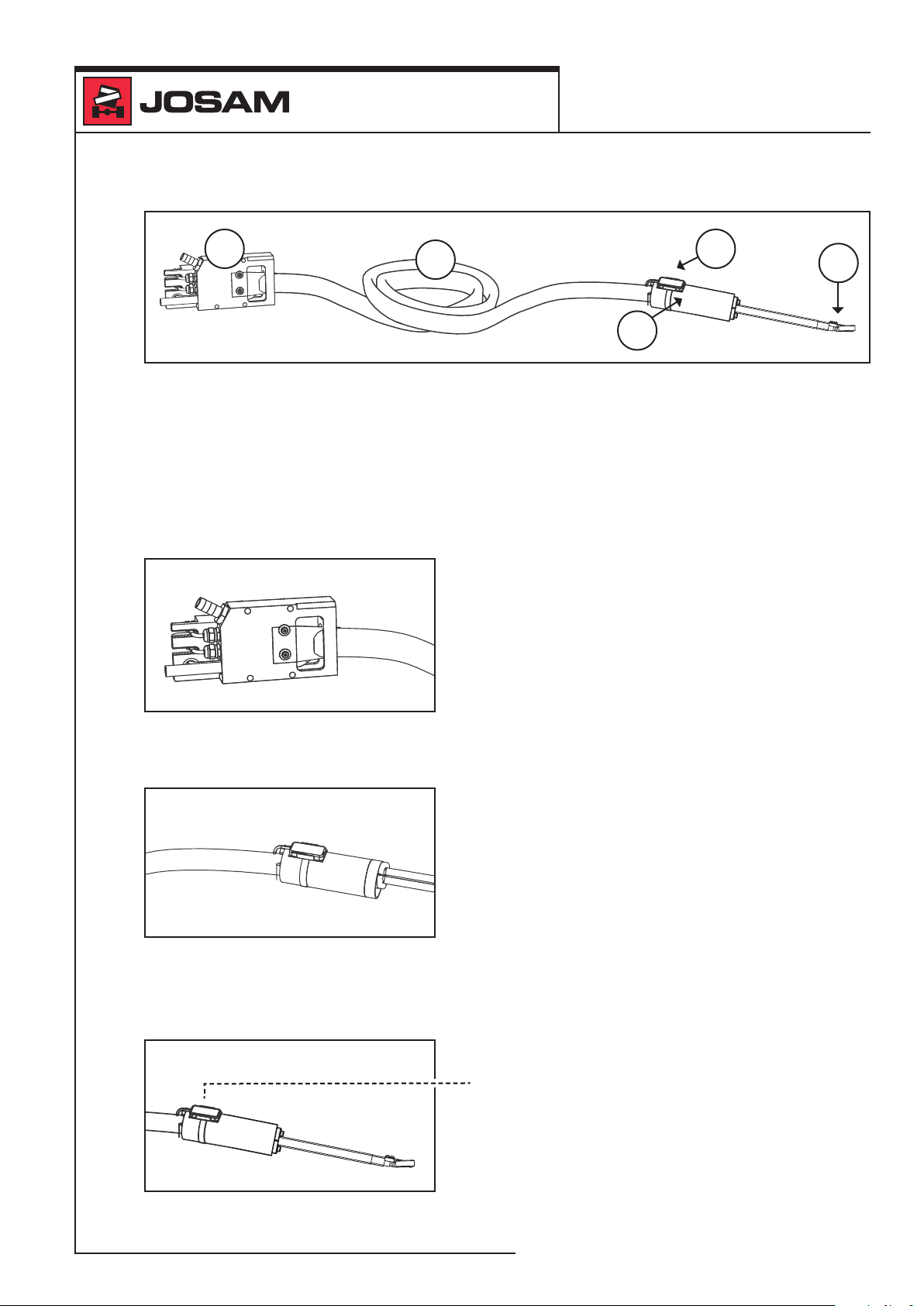

The machine comprises:

1. cooler section

2

1

2. electrical section

3. hose packet with inductor

During heating, a powerful magnetic eld is

concentrated in the inductor. The magnetic eld

alternates direction and induces eddy currents

in the material, which gives rise to heat. Since

intense heat is created in the work piece and

inductor, cooling water is used for cooling the

machine and its electronic parts. The control of

the cooling system is totally automatic.

The connection cable provides the machine's

electrical section with current, which in turn

power supplies the hose packet, inductor and

cooler section. The cooling section controls the

temperature of the components by circulating

cooling water in the hose packet, inductor and

a cooling block in the electrical section.

Induction heater JH1500

15

Page 16

induction heating

DESCRIPTION

1

Induction heater JH1500

5

5

4

3

2

Cooler section

The cooler section consists of a:

1. cooling water tank

2. water pump

3. connection box

4. condenser

5. condenser fan

16

Page 17

induction heating

DESCRIPTION

Induction heater JH1500

1

345

2

6

Electrical section

The electrical section has three main functions,

namely supplying current to: the hose packet,

electronic components and the cooling section.

The electrical section comprises:

1. control panel

2. main power switch

3. residual current breaker

4. main fuse (32 A/400 V or 63 A/200 V)

5. cooler fuse (10 A/400 V or 16 A/200 V)

6. USB connection

17

Page 18

induction heating

DESCRIPTION

Main power switch

When the main power switch is turned on, the

machine is connected to the electrical supply.

Residual current breaker

The machine is equipped with a residual

current breaker, which trips in the event of

an earth fault. There is a test button on the

residual current breaker. When the test button

is pressed, the residual current breaker should

trip.

Induction heater JH1500

Main fuse (32 A/400 V or 63 A/200 V)

The main fuse trips in the event of a fault in the

current supply to the hose packet.

Cooler fuse (10 A/400 V or 16 A/200 V)

The cooler fuse trips in the event of a fault in

the current supply to the water pump, fan or

compressor.

USB connection

For service work and updates.

18

Page 19

induction heating

DESCRIPTION

Control panel

Operation indicatorAlarm indicators

Induction heater JH1500

Increase power

On/Off

Reduce power

Power indicator

The following functions can be found on the

control panel.

On/Off

To use the induction heater, after it has been

connected to the electric mains, you must press

the On/Off button. When you have pressed the

button, one or more of the yellow LEDs lights up

on the power indicator.

Increase power

Increase power by one step (step 1‑5).

Reduce power

Decrease power by one step (step 1‑5).

Power indicator

Shows the chosen power (1‑5) and that the

unit is on.

Power 5

Power 4

Power 3

Power 2

Power 1

19

Page 20

induction heating

DESCRIPTION

Alarm indicators

The alarm indicators notify the user if a fault

occurs with the induction heater.

The alarm indicators are marked by a red LED.

Overheating

The red LED for overheating lights, if the

electronics become overheated. The induction

heater does not function if this indicator is

lit. The light goes out, when the temperature

drops below the warning limit.

Water ow

The red LED for the water ow lights, if the

cooling water is not owing as it should, that is,

if the water pressure is too low. The induction

heater does not function when this indicator is

lit.

Induction heater JH1500

General electronic alarm

If both LEDs are blinking at the same time,

the cause is often that one of the phases is

missing in the wall outlet. This alarm indication

will also be shown if the machine is consuming

current even though it is in idle, or if a current

sensor is faulty.

Operation indicator / Trigger activated

The operation indicator provides the user with

information when the induction heater is in use.

The green LED begins to blink when the

trigger is pressed in. It indicates that the cable

to the handheld transformer isn't damaged,

that the water ow is functioning and that

correct power is reached in the inductor head.

20

Page 21

induction heating

DESCRIPTION

Induction heater JH1500

1

2

3

4

2

Hose packet

The hose packet consists of:

1. connection block

2. handheld transformer with hose kit

3. operating button

4. inductor

Connection block

The connection block is mounted below the

electrical section, its upper section protrudes

into the electrical section. The cooling water's

pressure and return ow runs through the

connection block. The power cabling runs

from the electrical section, via two unions in

the connection block, and further, through the

hose up to the handheld transformer.

Handheld transformer with hose kit

During use, the handheld transformer functions

as a tool handle, the control button is mounted

permanently to the handheld transformer.

The inductor is attached to the handheld

transformer by four screws.

The hose kit comprises two hoses for the

cooling water's pressure and return ow. In

the hose for the pressure ow, there is also a

cable. Two earth cables and a control cable run

on the outside of the hoses.

Trigger button

Current switch to activate the heating. It sits in

a holder on the handheld transformer.

21

Page 22

induction heating

DESCRIPTION

Inductor

During use, the inductor is supplied with a

voltage and an alternating magnetic eld is

generated by the eld power amplier at the

inductor's tip. The cooling water circulates

through the inductor.

Induction heater JH1500

22

Page 23

induction heating

COLOUR TEMPERATURE SCALE

White

Light yellow

Yellow

Dark yellow

Induction heater JH1500

USAGE

General information about induction

Induction heaters work with low voltages and

high currents in order to create a magnetic

eld. The magnetic eld is concentrated to

the eld amplier. When the tip is placed

against iron or another magnetic material, the

magnetic eld is short‑circuited and heat is

formed.

Information about heating

It is important to control the temperature

of the heated work piece, if quality is to be

maintained.

The human eye is inuenced by the ambient

conditions. The illumination changes how the

eye experiences colour. Therefore, the heated

work piece should be examined in daylight.

The colour temperature scale, to the left,

simplies visual control and, at the same time,

the stepwise presentation of temperature

improves the accuracy during heating.

Orange

Light red

Light

cherry red

Cherry red

Dark

cherry red

Dark red

Brownish-red

23

Page 24

induction heating

USAGE

Heating

Induction heater JH1500

Warning! The user must

remove metal objects such as

watches, rings and suchlike

before use. Danger of serious

personal injury.

Warning! Take care that there is

good ventilation so as to avoid

breathing in the gases that are

formed during heating.

Warning! The work area must

be free from ammable objects.

Risk of re.

1. Place the inductor's tip at against the

object.

2. Press and hold the operating button.

Warning! Do not touch any

object that has been close to

the coil without checking the

temperature rst. Danger of

serious personal injury.

Important! Never keep the

inductor still for a longer time.

Risk for serious damage to

property.

24

3. Move the inductor's tip around the area to

be heated.

Page 25

induction heating

USAGE

4. Release the operating button.

5. Lift the inductor out of the way.

After completed work

1. Turn off at the main power switch.

2. Wrap the hose packet around the big

handle on the machine and place the

inductor in the holder.

3. Wrap the power cable around the small

handle on the machine.

Induction heater JH1500

Note! Never press the inductor

against the object, since this

would shorten the inductor's

service life more quickly than

necessary.

25

Page 26

induction heating

MAINTENANCE INSTRUCTIONS

Maintenance interval

Once a month:

• Check the cooling water

• Check the residual current breaker

• Check the hose couplings

• Check connection surface between heating

tip and handheld transformer

Once a year or when needed:

• Check and clean the condenser

• Check the cable connections

Maintenance description

Check the cooling water

Induction heater JH1500

Note! Do not mix different types

of glycol in the cooling water.

This would make the freezing

point impossible to control.

Check that the cooling water tank is lled to at

least 80% with cooling water. Note, for more

powerful heating (>15 min/occasion), the

cooling water level should be higher (80‑90%).

To rell the cooling water use decalcied

water and propylene glycol.

Check the residual current breaker

Check the residual current breaker once a

month, by pressing the test button (T). After the

test button is pressed in, the residual current

breaker must trigger. If this does not happen,

the residual current breaker must be replaced

before the machine is used again.

26

Page 27

induction heating

MAINTENANCE INSTRUCTIONS

Check the hose couplings

Check that the hose couplings in the induction

heater do not leak. Replace hoses when

necessary. To be checked once a month.

Induction heater JH1500

Note! If the machine is used

with a lot of cold water, a large

quantity of condensate is

formed, which can accumulate

in the hose packet and/or

the machine. This may be

misinterpreted as an indication

of leaking hoses.

Check and clean the condenser

Note! The condenser must

absolutely not be cleaned with a

high‑pressure wash.

The outside of the condenser should be

cleaned at least once a year, ahead of the

warm season, more often as required, so as

to obtain the best cooling effect. Rinse with

degreasing uid and tepid water.

Also check that the condenser fan is working

and that there is no unusual noise.

Check cable glands on the connection block

Check the cable glands on the connection

block, to ensure they are sealed. Tighten the

cable glands, if necessary. To be checked once

a year.

Fitting the inductor

Before use, the inductor must be attached

to the handheld transformer. The inductor

is screwed in place with four stainless steel

screws + washers.

27

Page 28

induction heating

TROUBLESHOOTING INSTRUCTIONS

The troubleshooting instructions in this

chapter will help you to quickly locate and

correct the majority of faults that can arise

when you use the JH1500.

WARNING! All electrical modi‑

cations must be performed

by a qualied electrician.

Danger of electrical shocks.

WARNING! Remove the

induction heater's plug from the

wall socket before you begin

any form of service, cleaning

or maintenance. Danger of

electrical shocks.

Induction heater JH1500

WARNING! Never remove

any protective covers and

never perform any work on the

induction heater without rst

removing the contact from the

wall socket. Wait one minute.

Danger of electrical shocks.

WARNING! When you are

using the JH1500, performing

maintenance on it or working

near it, do not wear or use metal

objects such as watches, rings,

keys, etc. The objects can be

heated up by the magnetic eld

from the JH1500 and cause

burn injuries.

28

Page 29

induction heating

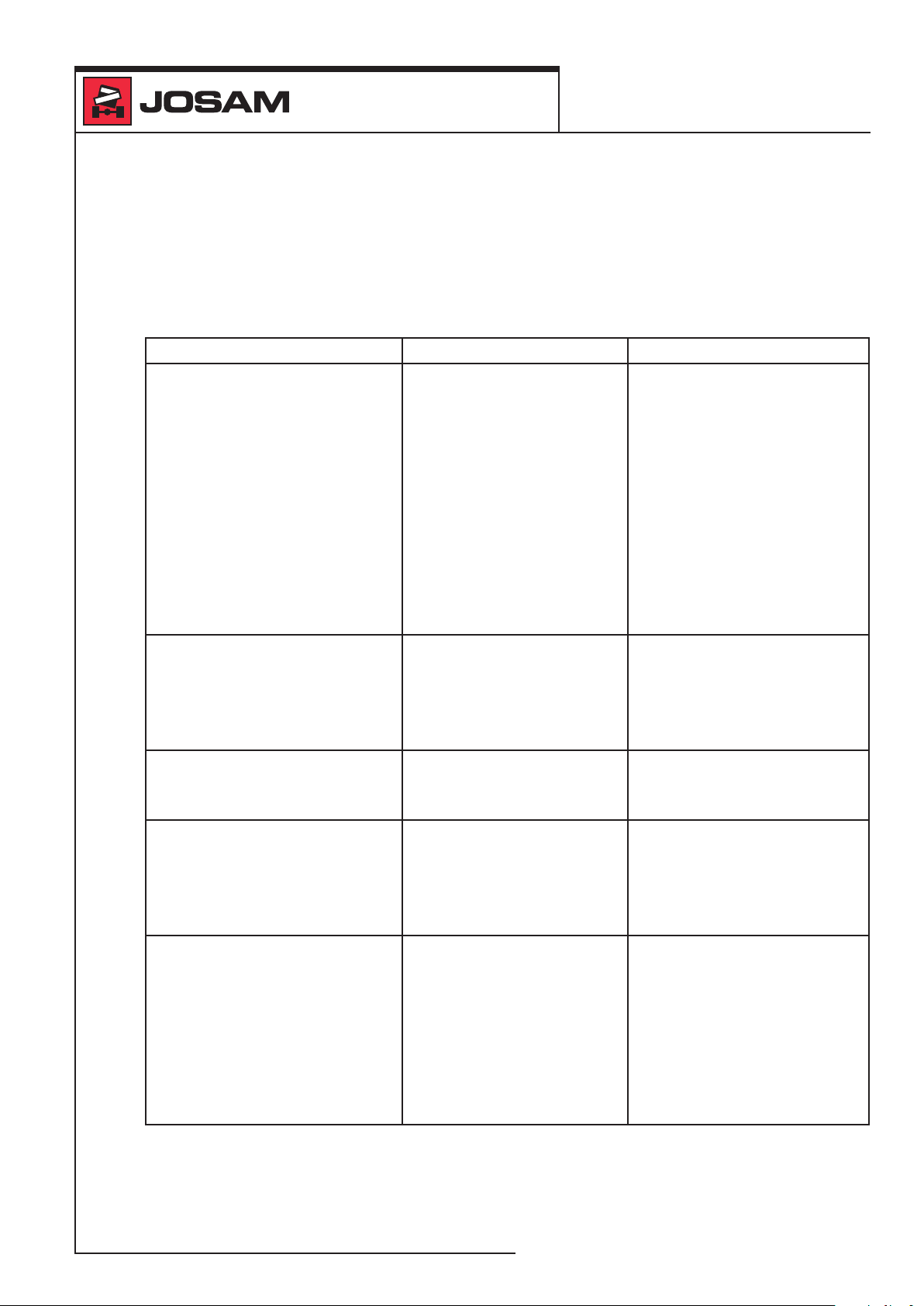

TROUBLESHOOTING INSTRUCTIONS

The following troubleshooting table is to help you locate faults on the induction heater.

However, the table only shows the most common faults and their possible causes.

There can be other faults and possible causes than those listed in the table.

Induction heater JH1500

Troubleshooting table

Fault Action

No current to the induction

heater.

The mains current is

sufficient, but the induction

heater doesn't work.

Water leak between the

inductor handle and the

inductor head.

The red LED for overheating

lights up and the induction

heater switches off.

The red LED for water ow

lights up and the induction

heater switches off.

The heater's plug is not in

the wall socket.

No current supply.

Loose connections.

The residual current

breaker has triggered.

The O‑rings are damaged

or the screws are loose.

The temperature in the

electronics or the cooling

water is too high.

There is a fault with the

cooling water ow.

Place the plug into the wall

socket.

Check that there is current

in the wall socket and

whether the main fuse or

the residual current breaker

have triggered.

Make sure that there are

no loose connections in the

plug or wall socket.

Identify the cause of

the error and take the

appropriate action. Then

reset the residual current

breaker.

Replace O‑rings or tighten

screws.

Let the induction heater

cool. The induction heater

can be used again when it

has cooled, and the LED is

no longer lit.

The water level is too low.

Top up with uid.

The pump lter is blocked.

Clean the lter.

One of the water hoses is

blocked. Try to clean with

compressed air.

29

Page 30

induction heating

TROUBLESHOOTING INSTRUCTIONS

Induction heater JH1500

The 2 red LEDs (water

ow and overheating) blink

simultaneously.

The LED for overheating is

blinking at start‑up.

The LED for water ow is

blinking at start‑up.

The operation LED is blinking

fast at start‑up.

The handle gets hot during

heating.

The RCB trips when turning

the machine on.

The cooler fuse trips when

turning the machine on.

The main fuse trips when

turning the machine on.

A phase fault or a current

sensor fault has occurred.

The electrical section is

overheated.

The temperature sensor

is giving the wrong value.

The water ow sensor is

giving the wrong value.

The heating button is

being pressed when

starting the machine.

Bad connection between

heating tip and handle.

A ground fault has

occured.

A problem with the cooler

section has occured.

A problem in the electrical

section of the machine

has occured.

One or more phases is

lacking. Check that all the

phases are available in the

socket, that no fuse has

been triggered and that the

cable is undamaged.

Check that the current

sensors are undamaged

and properly connected.

Wait until the electrical

section has cooled and the

LED is no longer lit.

Check for loose connectors

or replace temperature

sensor.

Check for stuck paddle

in water ow sensor or

replace water ow sensor.

Release button or replace

faulty heating button and

restart the machine.

Follow instructions on how

to clean surface between

heating tip and handle.

Check for damages on the

hose kit or change hose kit.

Check for faulty phase

switcher, water pump, fan

and compressor.

Check for faulty rectier,

power module or hose

packet.

30

Page 31

induction heating

GENERAL INFORMATION

Manufacturer

Josam AB

Box 418, Maskingatan 5

SE‑701 48 Örebro

Sweden

Machine designation

JH1500‑400 for 400V 50‑60 Hz

JH1500‑200 for 200V 50‑60 Hz

Intended usage areas and

environments

The machine is intended to be used indoors in

a workshop environment for repairing vehicular

damages.

Induction heater JH1500

Warranty

If the instructions in this manual are not

followed, the machine's warranty becomes null

and void.

Recycling

The machine must be recycled according to

the local provisions.

Service

Always contact an accredited:

• refrigeration technician for service of the

machine's cooling section.

• service technicians for service of the rest

of the machine.

Always request a written service report for the

work performed.

31

Page 32

induction heating

TECHNICAL DATA

Dimensions including handle

and wheels

(LxWxH): ..........973 × 663 × 1168 mm

Weight with full

cooling water tank: ...175 kg

Input power

requirement: ........15 kW

Degree of protection: . IP 21

Coolant: ...........Water + propylene glycol

Water tank volume ...40 litres

Installation/electric mains connection

Induction heater JH1500

Mains connection: ...3 × 380‑400 V+PE, 32 A

or 3 × 200 V+PE, 63 A

Frequency: .........50/60 Hz

Fuse: .............32 A at 400 V

63 A at 200 V

Requirements for ambient conditions

Recommended

working temperature: .........0 to +35 °C

Recommended air

humidity when in use: ........ < 90%

Recommended temperature

during transport or storage: ....‑10 to +50 °C

Recommended air humidity

during transport or storage: ....< 100%

32

Manufacturer:

JOSAM AB

Box 419 • SE-701 48 • ÖREBRO, Sweden

Phone: +46 19 30 40 00 • Fax: +46 19 32 03 16

E-mail: info@josam.se • Internet: www.josam.se

Printed on environmentally friendly paper

Loading...

Loading...