Combo V24T Centrifuge

Instruction Manual

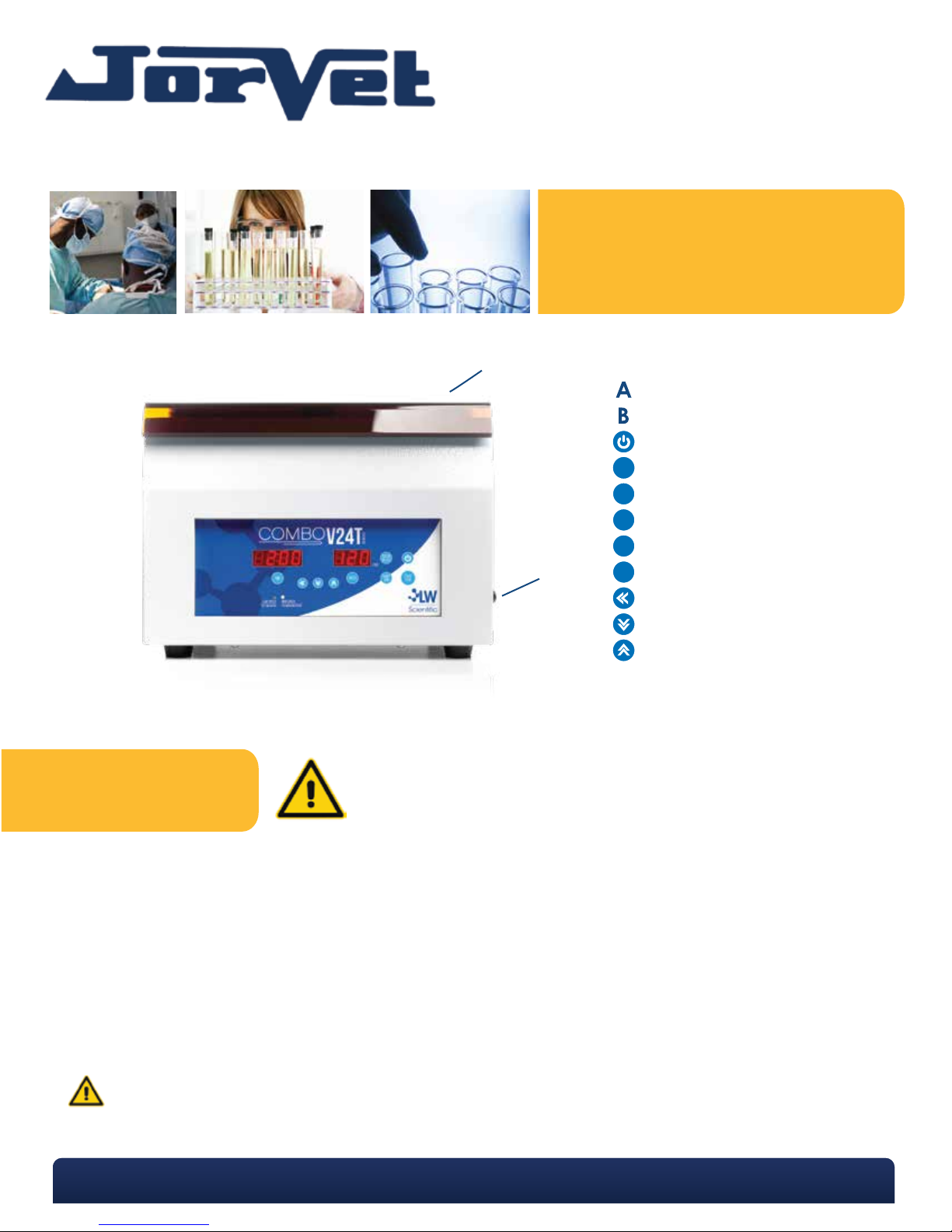

A

Lid

Main Power Switch

Display Power

Start

Stop

Start / Stop

Rotor

select

B

Rotor Select

speed

Speed

time

Time

Short

Spin

Short Spin

Select

Descrease Value

Increase Value

Before Operating

Jorgensen Laboratories instruments have a one (1) year limited warranty. This warranty is not valid on normal wear and tear,

1

cosmetic damages caused by chemicals, solvents, and/or cleaning solutions, as well as acts of God.

Please register your product online at: www.LWScientific.com/warranty_form.

Important: Warranty information must be completed within 30 days of purchase.

Remove the centrifuge from the shipping container and inspect for any possible shipping damage. If the centrifuge

2

appears to be damaged, please contact your distributor immediately.

Open the lid by pressing on the front center of the lid until it clicks (to close, press down again until it clicks).

The screw and washer in the motor shaft are for shipping only. Please remove and use the Thumbscrew for all normal operation.

Now, install rotor as seen on the next page.

WARNING: Ensure the rotor is securely fixed to the rotor shaft. Failure to properly secure rotor could lead to personal

injury or damage to the centrifuge.

P. 770.270.1394 F. 770.270.2389 865 Marathon Parkway Lawrenceville GA 30046

P. 800.525.5614 F. 970.663.5042 1450 Van Buren Ave Loveland Co 80538 USA

This symbol refers to hazards that may be encountered when using this product.

CAUTION means that damage to product or environment could occur

WARNING means that injury or contamination could occur

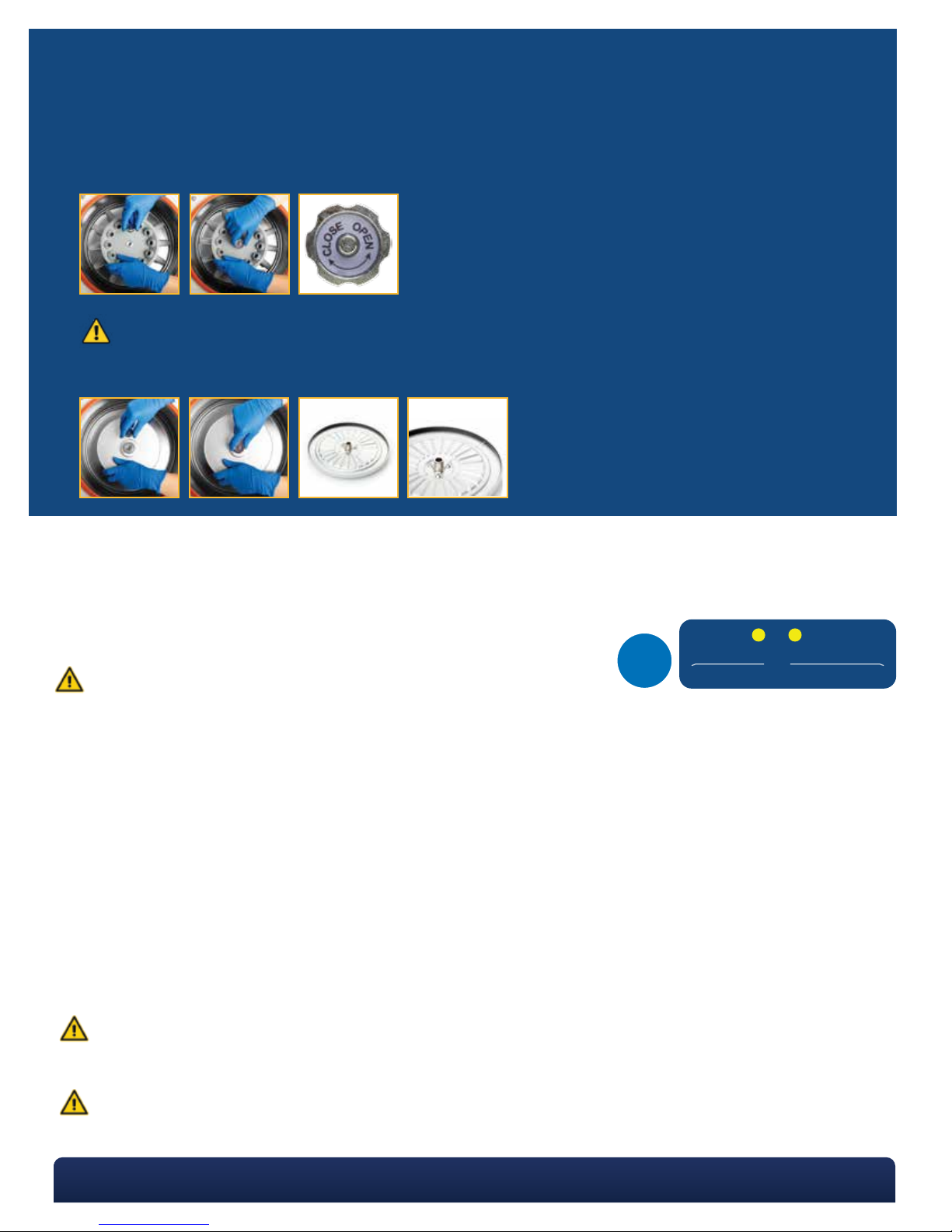

Selecting and Changing Rotors

Place the centrifuge on a sturdy, level surface. Verify that there are no loose objects or packing material in the tube

A

chamber. DO NOT PLUG UNIT IN.

Select a rotor and slide it down over the motor shaft, ensuring that the slot in the bottom of the rotor lines up with cross

B

pin on the motor shaft. The shaft should be lubricated with a fine layer of common grease every few months for easy

rotor changes.

Test Tube and Microtube Rotors: After seating the rotor properly on the motor shaft cross pin, tighten the chrome thumb-

C

screw down on the rotor. Do not over-tighten.

Microhematocrit Rotor: Place the cover plate onto the rotor by sliding it down over the center shaft.

D

WARNING: The rotor cover plate is not threaded and will not hold the rotor in place during operation.

Next, tighten the chrome thumbscrew down onto the rotor. Do not over-tighten.

NOTE: Please ensure that the black rubber rotor

gasket is positioned around the rim of the rotor such

that the capillary tubes are pushing into the rubber

while spinning. The rubber gasket is not affixed to the

rotor to allow for cleaning and re-positioning of the

gasket to prolong gasket life.

Verify that the main power switch is in the “OFF” position and plug the AC power cord into the appropriate approved and

3

properly grounded AC outlet. Next, turn the main power switch on, then press the front panel POWER button. The display

should illuminate.

4

DO NOT INSERT TUBES AT THIS TIME: Ensure that the Rotor Select is in the correct position: LOW SPEED for test tube rotors

(1,000-4,000 rpms) or HIGH SPEED for microhematocrit and microtube rotors (12,000 rpms).

To change speeds, press and hold the ROTOR SELECT button for three seconds.

WARNING: Spinning the 12 or 24-place test tube rotor at high speeds (above 4,000 rpm) can cause tube breakage and

centrifuge damage.

SPEED and TIME can only be adjusted when the lid is closed and locked.

5

To set the speed, press the SPEED button once, then use the UP/DOWN arrows to select 1,000 rpm, for an initial test run. Press

the SPEED button again to lock the speed.

To set the time, press the TIME button once to flash seconds, and use left arrow to flash minutes. Use the UP/DOWN arrows to

6

choose 1:00 minute for the initial test run. Press the TIME button again to lock the time.

Start the unit by pressing the START/STOP button. The unit should come up to speed with a smooth sound and little or no vibra-

7

tion. If there is excessive vibration or noise, shut off the unit immediately, check the troubleshooting tips, and contact

Jorgensen Laboratories if not resolved.

Spin only balanced loads. Make sure that tubes are placed opposite each other. Proper sample balancing will improve

8

sample separation and will extend the life of the centrifuge. Out of balance loads may damage the centrifuge.

Support your tubes: Tubes must always be supported from the bottom and never hanging by their caps. Use the large tube

9

sleeves for larger tubes and the small sleeve inserts for smaller tubes. Rubber tube cushions are also available from Jorgensen

Laboratories for supporting short tubes in the large tube sleeves.

Ready for operation: Load your tubes and set time and speed. When spinning the 24 -place microhematocrit rotor, keep the

10

speed set at 12,000rpm for rapid and complete separations in 3 minutes.

Rotor

select

Low Speed

Test Tube Rotors

High speed

Pcv/microtube rotors

WARNING: Ensure the rotor is securely fixed to the rotor shaft. Failure to properly secure rotor could lead to personal

injury or damage to the centrifuge.

WARNING: Be sure the thumbscrew is tightened before each centrifugation cycle.

P. 800.525.5614 F. 970.663.5042 1450 Van Buren Ave Loveland Co 80538 USA

Reading Microhematocrits

If you purchased a microhematocrit rotor, it includes a Reader Disc, which allows the tubes to be read directly from the rotor.

After the rotor has stopped, remove the cover plate by unscrewing the chrome thumbscrew and lifting the cover plate

1

straight up.

Place the reader disc over the hematocrit tubes, and adjust the disc until the 0% line is lined up with the bottom of the fluid

2

in the tube to be read.

While keeping the 0% line positioned at the bottom of the fluid, turn the disc until the 100% line aligns with the top of the

3

fluid.

Read the separation line in the middle for your microhematocrit results.

4

Care, Maintenance, Trouble-Shooting

Use only quality test tubes. Lower-quality plastic or glass tubes may fracture and release their contents into the tube cham-

1

ber.

Never force a tube into the tube shields. Some plastic conical test tubes are too large and should not be used.

2

Never hang a tube by its cap. Always make sure the tubes are supported by the bottom of the shield, or with a rubber cush-

3

ion.

Use only 75mm capillary tubes with the 24-place microhematocrit rotor.

4

Clean the inside of the centrifuge regularly. Always unplug electrical power before cleaning. Whenever there is a tube

5

breakage or a spill, it is recommended that the inside of the centrifuge be cleaned, and if possible, disinfected (do not

immerse the electrical components in any liquid).

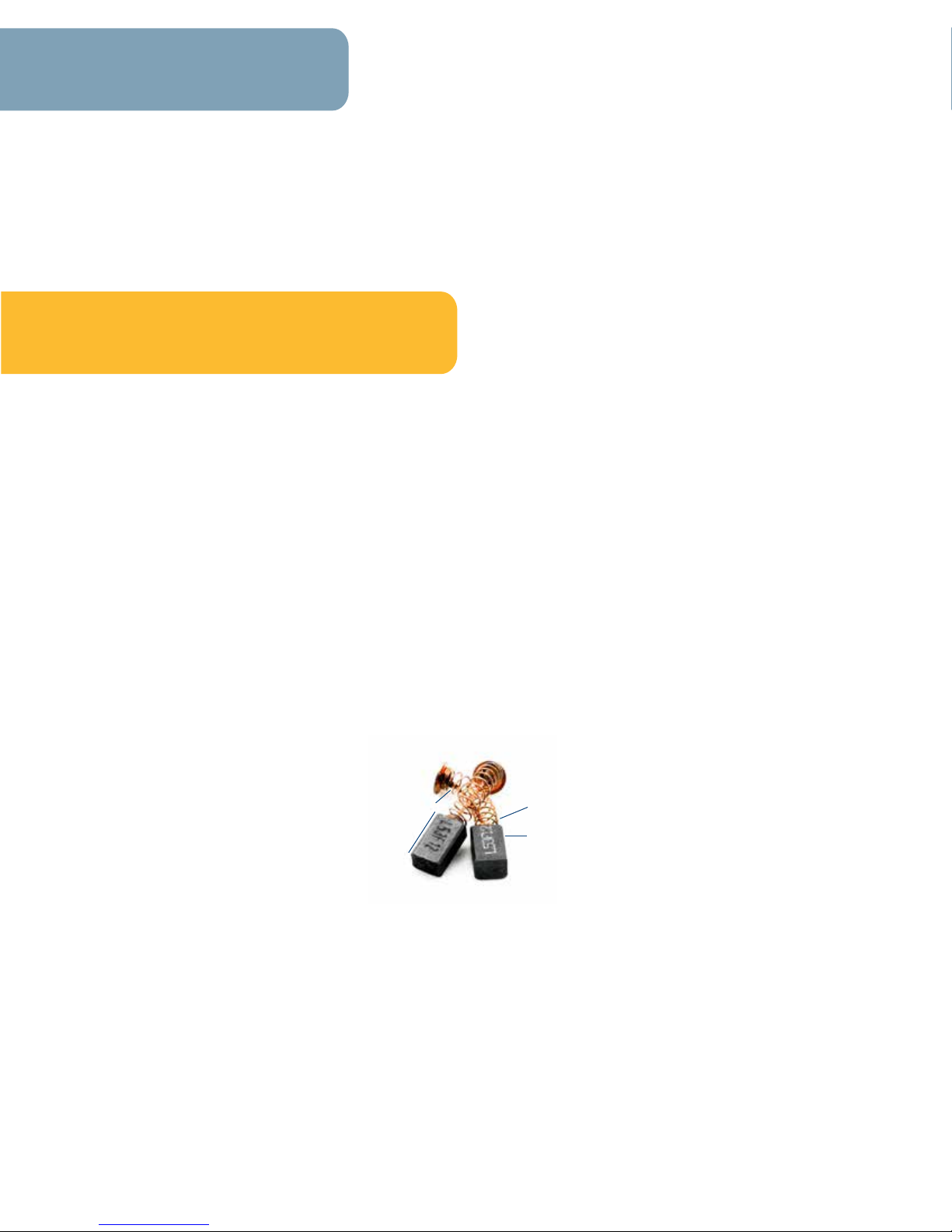

Motor and electrical maintenance: The Combo V24T utilizes a brushed motor, which includes bearings that are permanent-

6

ly lubricated. Likewise, the electrical components were designed for high reliability and should not need regular service,

other than brush replacement. However, if repairs or brushes should be needed, please contact Jorgensen Laboratories.

If the centrifuge will no longer maintain speed, inspect and/or replace the brushes. The life of the brushes depends upon

7

several factors (speed, load, duty cycle, etc.). To ensure optimum performance, we recommend you check the motor

brushes every 6 months. This will help you recognize your typical wear pattern and ensure the motor brushes are serviced

properly.

When new, the carbon bar of the motor brushes measures approximately 1/2” in length (see image below). The brushes

wear and should be replaced when the carbon bar reaches 1/4” in length. Operating your centrifuge with a carbon bar

that has worn beyond this point can damage the centrifuge motor.

When inspecting/replacing brushes, we recommend you blow out the motor/brush area with canned air. Excessive dust,

dirt, and hair can interrupt the brush contact and decrease performance.

8

If you have difficulty removing your rotor, you may have light oxidation on the motor shaft. To correct this we recommend

a clean—polish—clean procedure. Clean the motor shaft with alcohol. Polish it with 400-grit or finer sandpaper. Clean the

shaft again. Then, apply a small amount of household grease to the motor shaft. Do NOT use oil or spray lubricants such as

WD-40.

To prevent the reoccurrence of oxidation on the motor shaft, we recommend servicing it approximately once per week by

cleaning with alcohol and reapplying household grease. This should alleviate the issue.

Display comes on - Will not spin: Check to make certain the lid safety switch (near the back right hinge) is engaged. With

9

the power on and the timer set, depress the button with your finger. If the rotor spins, turn the safety switch button counter-clockwise to raise the height and allow it to contact the lid when it is closed.

No light - Not spinning: Confirm that your power source is working. Check the 6.3 amp fuse and replace if the filament is

broken. Speed slows down or stops...the brushes may need to be replaced on the motor after 1000 +/- hours of use if speeds

have decreased. Contact Jorgensen Laboratories to purchase new brushes (part #CMP-BRSH-PR77).

Because of the safety issues with high g-forces in a centrifuge, it is recommended that rotors be inspected every 6 months

for corrosion and fatigue. If there is any indication of wear, the rotor should be removed from service. Contact Jorgensen

Laboratories for return instructions, so the rotor can be evaluated by an Jorgensen Laboratories technician for repair or

replacement. It is also recommended that after 2 years of service rotors and tube shields* be returned to Jorgensen Laboratories for inspection. Following these procedures will ensure safety of lab personnel as well as extend the life of the centrifuge.

NOTE: Plastic tube shields should be replaced at least once a year. Tube shields should be inspected once a month for wear

or damage. Tubes that are being used in high volume applications should be replaced every three months or sooner.

Braided Wire

Length

Spring

Carbon Bar

WARNING: Failure to secure rotor or rotor lid could lead to personal injury or damage to the centrifuge.

CAUTION: If corrosion, scratches, or other abnormalities are found on rotor or tube shields, discontinue use and contact

our service center.

Speed Calibration

Your Combo V24T was pre-calibrated before it was shipped from Jorgensen Laboratories. If future calibration is needed, the

following procedure requires a hand-held tachometer and should only be performed by a qualified technician or the Jorgensen

Laboratories Service & Repair department. The bottom plate must be removed to access the calibration rheaostats.

With the Rotor Select on the front of the unit on high, the speed to 12,000 rpm, and a Microhematocrit rotor in place,

1

adjust the Vr-h rheostat on the circuit board up to 12000 RPMs.

With the Rotor Select on the front of the unit on low, the speed set to 4,000 rpm, and a tube rotor with tube shields in place,

2

adjust the VR-I rheostat on the circuit board up to 4,000 rpm.

Brush Replacement

Unplug the centrifuge, and turn it on its side.

1

Remove the feet and all Phillips head screws holding the metal base plate in place.

2

Using a flat head screwdriver, remove the two black caps on the bottom part of the motor.

3

Using your fingers, pull the brush out of the recessed hole that the black caps were removed from. The brushes consist of

4

springs with a graphite bar on them.

Place the new brushes in the recessed hole, and replace the black caps. Be careful not to overtighten. Black caps could

5

break. (See image).

Replace the metal plate and the feet.

6

Your Combo V24T is now ready to use.

7

Specifications

Max. Speed (HIGH):

Max. Speed (LOW):

Max. Volume:

Input Voltage:

Fuse:

Height:

Width:

Depth:

Weight:

P. 800.525.5614 F. 970.663.5042 1450 Van Buren Ave Loveland Co 80538 USA

12,000 RPM (+/- 600)

4,000 RPM (+/- 200)

24 3ml to 15ml test tubes

24 75mm capillary tubes

24 2ml microtubes

110v (220v available)

6.3 amp / 250 volt

8.7 inches

10.6 inches

12.5 inches

15.8 lbs.

Recommended Fluid Speeds & Times:

Blood (Serum) 4,000 rpms 7 to 10 minutes

Urine 1,700 rpms 5 to 10 minutes

Fecals 1,500 rpms 6 minutes

Microhematocrits 12,000 rpms 3 minutes

G-Force (RCF)

38

153

300

443

613

957

1,378

1,876

2,451

12,9000

14,500

Test Tube Rotor

Microtube Rotor

Microhematocrit Rotor

RPM

500

1,000

1,400

1,700

2,000

2,500

3,000

3,500

4,000

12,000

12,000

MKT-7.5.3-L-239.001 | Rev 0

Loading...

Loading...