Instruction Manual

IM-0468

SM-1700 Series Rotary Actuator

General Information .............................................. 2-3

Introduction ....................................................... 2

Cautions ............................................................. 2

Receiving/Inspection .......................................... 2

Storage ............................................................... 2

Equipment Return .............................................. 2

Identification Label............................................. 3

Abbreviations Used in This Manual .................... 3

General Actuator Description ............................. 3

Basic Models ...................................................... 3

Specifications ........................................................ 4-5

Actuator ............................................................. 4

Options .............................................................. 5

Installation............................................................. 5-6

Typical Wiring Diagrams ........................................ 7-8

Start Up .............................................................. 9-11

Troubleshooting ................................................. 12-13

Parts Identification............................................. 14-16

Parts List ............................................................ 17-18

Maintenance ..................................................... 19-20

Major Dimensions ............................................. 21-22

Linkage Options ..................................................... 21

Actuator ................................................................. 22

Table of Contents

Due to wide variations in the terminal numbering

of actuator products, actual wiring of this device

should follow the print supplied with the unit.

1

GENERAL INFORMATION

INTRODUCTION

Jordan Controls, Inc., designs, manufactures, and tests

its products to meet national and international standards. For these products to operate within their

normal specifications, they must be properly installed

and maintained. The following instructions must be

followed and integrated with your safety program

when installing, using, and maintaining Jordan Controls

products:

Read and save all instructions prior to installing,

operating, and servicing this product.

If any of the instructions are not understood, contact

your Jordan Controls representative for clarification.

Follow all warnings, cautions, and instructions marked

on, and supplied with, the product.

Inform and educate personnel in the proper installation, operation, and maintenance of the product.

Install equipment as specified in Jordan Controls

installation instructions and per applicable local and

national codes. Connect all products to the proper

electrical sources.

To ensure proper performance, use qualified personnel

to install, operate, update, tune, and maintain the

product.

When replacement parts are required, ensure that the

qualified service technician uses replacement parts

specified by Jordan Controls. Substitutions may result

in fire, electrical shock, other hazards, or improper

equipment operation.

Keep all actuator protective covers in place (except

when installing, or when maintenance is being performed by qualified personnel), to prevent electrical

shock, personal injury, or damage to the actuator.

WARNING - ELECTROSTATIC DISCHARGE

This electronic control is static-sensitive. To

protect the internal components from damage

caused by static discharge, never touch the printed

circuit cards without being statically protected.

RECEIVING INSPECTION

Carefully inspect for shipping damage. Damage to the

shipping carton is usually a good indication that it has

received rough handling. Report all damage immediately to the freight carrier and Jordan Controls, Inc.

Verify that the items on the packing list or bill of lading

agree with your own.

STORAGE

If the actuator will not be installed immediately, it

should be stored indoors in a clean, dry area where

the ambient temperature is not less than -20° F. The

actuator should be stored in a non-corrosive environment. The actuator is not sealed to NEMA 4 until the

conduit entries are properly connected.

EQUIPMENT RETURN

A Returned Goods authorization (RG) number is

required to return any equipment for repair. This

must be obtained from Jordan Controls. (Telephone:

414/461-9200) The equipment must be shipped,

freight prepaid, to the following address after the RG

number is issued:

Jordan Controls, Inc.

5607 West Douglas Avenue

Milwaukee, Wisconsin 53218

Attn: Service Department

WARNING

Before installing the actuator, make sure that it is

suitable for the intended application. If you are unsure

of the suitability of this equipment for your installation,

consult Jordan Controls prior to proceeding.

WARNING - SHOCK HAZARD

Installation and servicing must be performed only

by qualified personnel.

To facilitate quick return and handling of your equipment, include:

RG Number on outside of box

Your Company Name, Contact Person, Phone/Fax #

Address

Repair Purchase Order Number

Brief description of the problem

2

GENERAL INFORMATION

IDENTIFICATION LABEL

An identification label is attached to each actuator

cover. The serial number is also stamped on the

aluminum housing, directly above the conduit entry.

When ordering parts, requesting information or service

assistance, please provide all of the label information.

EXAMPLE:

SM-1730

4585 C 99

120 / 50-60 / 1 / .9

95C 036051 - 1

SM-1730-0105

MODEL NUMBER: SM-1730 Series

SERIAL NUMBER: 4585 C 99

Year BuiltSequential Number

Month Built

GENERAL DESCRIPTION, ACTUATOR

The SM-1700 series actuators are electrically operated,

self-contained, bi-directional, low speed, high torque

devices. They are designed for up to 360° rotation with

bi-directional torque overload protection and have a

non-clutchable manual override handcrank. The drive

motor may be single or three phase ac or dc. Up to six

independently adjustable position limit switches, linear

potentiometer or characterized LVDT and 4 to 20 mA

feedback are available as options. Other options

include thermostatically controlled anti-condensation

heater, local control switches, integral or remote servo

amplifiers and linkage components.

The SM-1700 series includes 120/240 Vac single phase

models, 240/380/480 Vac three phase models and 24

Vdc models. These actuators are controlled by

switched power inputs or by a remotely installed

servo amplifier.

ABBREVIATIONS USED IN THIS MANUAL

A ............................................................................Ampere

AC......................................................... Alternating Current

° C .............................................................. Degrees Celsius

CW .....................................................................Clockwise

CCW ....................................................... Counterclockwise

DC ............................................................... Direct Current

° F ........................................................ Degrees Fahrenheit

G .................................................................. Earth Ground

Hz ............................................................................. Hertz

in. lbs. ............................................................. Inch Pounds

kg ......................................................................... Kilogram

L .......................................................... Line (power supply)

lbs. ................................................................ Pounds Force

LVDT ...................... Linear Variable Differential Transformer

mA ....................................................................... Milliamp

mfd ................................................................... Microfarad

mm ................................................................... Millimeters

N ................................................................ Newton (force)

NEMA ........... National Electrical Manufacturing Association

Nm .............................................................. Newton Meter

NPT .................................................. National Pipe Thread

PH ............................................................................ Phase

PL ...................................................... Position Limit Switch

RPM ............................................... Revolutions per Minute

SEC ......................................................................... Second

TL ........................................................ Torque Limit Switch

V .................................................................................Volts

VA ...................................................................... Volt Amps

Vac ......................................................................... Volts ac

Vdc ........................................................................ Volts dc

VR ......................................................... Variable Resistance

W................................................................................Watt

BASIC MODELS

SM-1720, SM-1730, SM-1750 and SM-1790 are all single

phase ac, three wire, plug reversible models. They are

compatible with Jordan Controls remotely located AD8230/EC-10836 servo amplifier, MT-6220 manual remote

control with position readout, or any bi-directional contact

type control.

These actuators may also be equipped with an integral

model AD-8130 servo amplifier that features loss of signal

detection for current command signal inputs and can be

calibrated to allow the actuator to lock-in-place or drive to a

preset position should the command signal drop below

3.8mA. Also included is a dynamic brake circuit to increase

positioning accuracy and a loop-powered, 4 to 20mA

position transmitter.

The SM-1700/AD-8130 series feature an integral servo

amplifier. These models require 120 or 240 Vac

(depending on model) unswitched, single phase line

voltage input and a dc analog command signal for a

complete, closed-loop positioning system in a compact

enclosure.

The SM-1715 is a three phase ac, reversible model compatible with Jordan Controls remotely located AD-8900 series

servo amplifier or any bi-directional contact type control.

The SM-1740 is a dc proportional control model and is

compatible with Jordan Controls remotely located model

AD-7530 servo amplifier or other compatible control

3

device.

SM-1700 Series Rotary Electric Actuator

GENERAL SPECIFICATIONS

Speed/Torque:

**Model

12/1200 (136), 24/1200 (136), 48/1200 (136)SM-1715

SM-1720

SM-1790

SM-1730

SM-1740

SM-1750

*Multiply these shift times by 1.2 for 50 Hz operation of AC

models. All travel times are for 90° movement of output shaft.

**NOTE: Models SM-1710 and SM-1770 are no longer being

offered. References to them are retained in this manual in order to

provide service to the field. They are replaced by SM-1730 and

SM-1750 respectively.

60/1800 (203), 31/1800 (203)

60/2400 (271)

12/1200 (136), 24/1200 (136), 48/1200 (136)

16/1000 (113), 31/1000 (113), 40/1000 (113)

12/1200 (136), 24/1200 (136), 48/1200 (136)

Rotation: Up to 90°

*Time/Torque

sec./i n. lbs. (Nm)

ELECTRICAL SPECIFICATIONS

Mode l

SM-1715*

SM-1720 120/1/50-60 0.9 1.2

SM-1730 120/1/50-60 0.9 1.2

SM-1740 24 Vdc 1.7 1.9

SM-1750

SM-1790

*Input power specified at time of order and not field-changeable.

Input Power

Volts/PH/Hz Run Stall

240/3/50-60 0.4 1.3

380/3/50 0.3 0.9

480/3/50-60 0.2 0.65

Current

Field Wiring: To barrier type terminal blocks.

MODELS WITH OPTIONAL AMPLIFIER

Positioning Accuracy: ± 0.25% of span

Repeatability: 0.1% of span

Hysteresis: 0.2% of span

(Amps)

0.50.45240/1/50-60

Duty Cycle: AC: 2,000 1% position changes/hour.

DC: 4,000 1% position changes/hour.

Temperature: -40°F to 150°F (-40°C to 65°C)

Environment Ratings: NEMA Type 4 (IP65), Dust

ignition proof, Class II, Division 1, Groups E, F & G

Weight: Approximately 40 lbs. (18.1 kg)

Enclosure Materials: Cast aluminum alloy

Non-Rotating When Motor Runs

Handcrank Gear Ratio: 1003:1

Lubrication Type: Permanently lubricated

Gearing: Spur gearing

Hold on Loss of Power: Motor drag brake

Mounting: Any position

Torque Limiting: Bi-Directional, disables motor when

torque rating is exceeded.

Linearity: ± .8% of span

Deadband: 0.25% of span

Integral Thermal Protection/Single Phase AC Motor:

130°C

End-of-Travel Position Limit Switches:

20 amp, 250 Vac

Output Shaft: One inch (25.4mm) diameter with 0.25

inch square (6.35 mm) keyway, or one inch (25.4mm)

diameter with 20 tooth spline.

4

OPTION SPECIFICATIONS

Servo Amplifier: Integral model AD-8130 for all single

phase AC powered actuators or remote model

AD-7530 for SM-1740 DC powered actuators or

remote model AD-8900 for SM-1715 three phase

actuators. Also model AD-8230/EC-10B36 for remote

mounted single phase AC powered actuators.

Input Impedance

Input Type

4 to 20mA

0 to 5 Vdc

0 to 10 Vdc

AD-8130

AD-8230

AD-8900

200 ohms

100,000 ohms 60,000 ohms

AD-7530

510 ohms

Anti-Condensation Heater: 120 or 240 Vac, 30 Watt

with thermostat set for 110°F (43.3°C).

Local Auto/Manual INC/OFF/DEC Toggle Switches

Output Shaft: 20 tooth splined shaft for use with

splined drive arm.

20 Tooth Splined Drive Arm: Reversible for ½ tooth

positioning.

Adapter/Clevis Kit: Includes two clevises, two adjustment rods with lock nuts, two pipe adapters, two pins

for clevises.

Auxiliary Position Limit Switches: (two or four): 20

amps, 250 Vac maximum.

Transmitter Position Feedback: 4 to 20mA, isolated

two wire loop-powered type.

AD-8130 and AD-8230 series amplifiers include a

field-adjustable command signal monitor that can be

set for lock-in-place, or drive to a pre-set position if the

current command signal is lost. They also have a

dynamic brake circuit which helps increase positioning

accuracy of the loop by minimizing motor coast.

These amplifiers are also equipped with a 4-20mA

isolated two wire, loop-powered transmitter.

Installation

MOUNTING

The outline and mounting dimensions for a standard unit

are shown on the last page of this manual. The rear cover

opposite the output shaft must have clearance so it can

be removed for adjustments and interconnect wiring.

When the actuator is directly coupled to a drive shaft, a

Jordan Controls type coupling is recommended. The

output shaft is also available with a splined output for

standard drive arms and linkage components to the

driven load.

The unit may be mounted on the standard foot mount,

the face mount around the output shaft, or on two sets of

side holes for a bracket mount. Mounting may be in any

position convenient to the driven load. When mounting

the unit, be sure that no excessive axial or side loading is

applied to the output shaft.

The limit switches and position feedback are gear connected to the actuator output shaft. Positively secure the

output shaft to the driven load shaft to prevent slippage,

which would cause misalignment or damage.

The manual handcrank is engaged for operation at all

times. When the manual override is required, the crank

Local Position Indicator: Reversible indicator.

Contactless LVDT Position Feedback: - Linear,

square, square root and field contourable cams supplied.

Potentiometer: 1000 ohm, 2 watts, 36 Vdc max.

should be turned in the appropriate direction for output

shaft movement. If during manual operation electric

power is applied to the actuator, this power cannot drive

back through the manual handcrank and harm the operator. Power must be removed or motor position overrides

manual position.

Torque of approximately seven inch pounds on the

handcrank will provide up to 2,400 inch pounds at the

output shaft. It takes approximately three full turns of the

handcrank to move the actuator output shaft one degree.

When the torque rating of the unit is reached, depending

upon the direction of cranking, the handcrank will move

in or out axially, an indication that full torque is being

delivered to the load.

The motor, limit switch, and feedback area of the actuator

depends upon the cover to maintain the NEMA Type 4

rating. This cover should be removed only when work is

being done internally, and should be reinstalled immediately upon completion.

This unit contains no internal mechanical stops. If it runs

outside of the initial factory alignment of the limit switches,

a realignment of switches and feedback may be required.

However, no internal damage will have occurred.

5

Installation

INSTALLATION WIRING

Typical wiring diagrams are shown on pages 7-8.

Actual wiring should follow the print supplied with

the actuator.

The wiring diagram shows the fundamental connections for the standard three-wire reversible singlephase motor, and the standard permanent magnet dc

motor. These units show an arrangement with torque

switches, four limit switches, two feedback potentiometers, and a heater. To meet special requirements,

certain items shown may not be supplied. In all

instances the wiring diagram appropriate to the

equipment will be supplied with each unit.

A barrier type terminal strip is located under the rear

cover opposite the output shaft. Two conduit entries

are located in the side of the unit to accommodate

standard 1 inch N.P.T. and inch N.P.T. fittings.

CAUTION: On standard single-phase wiring, the

position limit switches and the torque switches are

wired directly in the motor circuit and protect it at the

extremes of travel or at torque cutout. Three phase AC

or DC units must have these torque and position limit

switches wired into the controlling device to cause

end of travel or torque shutdown. Care must be taken

in wiring these to the controlling device so that the

appropriate direction of control is turned off when

that directions limit switch is actuated. If care is not

taken in phasing the equipment, damage may occur to

the actuator or driven load. Also, inductive devices,

such as lights and solenoids, must not be paralleled

across motor terminals 1 and 2 or 1 and 3 as this will

upset the motor capacitor phase shift and motor

torque will be lost.

All wiring should be done in accordance with pre-

vailing codes by qualified personnel.

Fusing must be installed in line power, and should be

of the slow blow type.

JORDAN CONTROLS SUPPLIED (OPTIONAL)

COUPLING (Field Installed)

Jordan Controls has designed a three piece wedgelock coupling which can be adjusted to align the

driven device to the actuator output shaft with no

concern as to keyway alignment of the shaft on the

drive device in relation to the spline on the actuator

output shaft.

ADJUSTMENT

1. Slide coupling (5) onto driven shaft.

2. Slide coupling cone (1) and cup (2) onto actuator

shaft.

3. Mount actuator with the two shafts in line and the

shaft ends about inch (3 mm) apart.

4. Turn the shaft of the driven device to the close

position.

5. Run the actuator to the close limit switch.

6. Lock coupling (5) to the driven shaft by pinning or

other suitable method.

7. Slide cone (1) to fit flat in recess of coupling (5).

8. Install three bolts and lockwasher (3) and (4) and

tighten. (20-30 ft. lbs.)

9. Operate the actuator in the open direction and

back to the close direction until the close limit

switch stops the actuator.

Wiring should be routed to the actuator through the

two conduit openings. Generally, one conduit will

contain input power and earth ground wires. The

other conduit would then contain low level input

and output signal wiring. It is required that all low

level signal wiring be a shielded type with the shield

grounded at source common.

After installation, it is required that all conduits be

sealed to prevent water damage and to maintain

NEMA 4 enclosure and applicable dust ignition

ratings.

10. If the driven shaft does not move to the exact close

position you want, loosen the three bolts and turn

the driven shaft. Tighten the bolts. (20-30 ft. lbs.)

NOTE: Keep the coupling parts clean while

assembling.

See page 21 of this manual for Jordan supplied linkage

components information.

6

Typical Wiring Diagrams

ACTUATOR WITHOUT A BUILT-IN AMPLIFIER

SM-1720 & SM-1730 (120 Vac)

SM-1740 (24 Vdc)

SM-1750 & SM-1790 (240 Vac)

Actuator

Action

Viewing Output Shaft CCW CW CW CCW

AC Power Applied to Terminals

1 & 2 1 & 3 1(+) & 2(-) 1(-) & 2(+)

DC Power Applied to Terminals

Notes: 1. The torque limit switches are factory set to trip if the rating of the actuator is exceeded.

2. Shielded wire is required for position feedback signal wiring.

SM-1715 SERIES ACTUATOR

Due to wide variations

in terminal numbering

of actuator products, actual

wiring should follow the print

supplied with the actuator.

Notes: 1. Optional remote three phase reversing starter shown.

2. Caution: Care must be taken in properly phasing position and torque limit

switches with respect to clockwise and counterclockwise positioning.

7

Typical Wiring Diagram

SM-1700 SERIES ACTUATORS WITH A BUILT-IN AD-8130 AMPLIFIER

(120/240 Vac, Single Phase, 50-60 Hz)

Due to wide variations

in terminal numbering

of actuator products, actual

wiring should follow the print

supplied with the actuator.

Notes:

1. All references to actuator output shaft rotation are as viewed facing the actuator output shaft.

2. An increasing command signal will result in CW rotation of the actuator output shaft.

3. The torque limit switches are factory set to trip if the torque exceeds the actuator rating.

Do not adjust these trip points.

4. Shielded wire is required for command and position feedback signal wiring.

5. Comand signal input:

4 to 20 mA into a 200 ohm impedance

0 to 5 or 0 to 10 Vdc into a 100,000 ohm impedance

6. The EC-10852 is for use with the AD-8130 servo amplifier with LVDT (voltage feedback).

The EC-10852 is used as the HI and LO trim for the AD-8130. The AD-8130 is factory set

for operation with the EC-10852. CAUTION: It is important not to adjust the HI and LO trim

on the AD-8130, which are torque sealed at the factory. For specific Setup information and

calibration, refer to the wiring diagram supplied with your unit. This option is not shown in

the above diagram.

Refer to IM-0607 for complete information on the AD-8130 servo AMPLIFIER.

8

Start Up

ACTUATORS WITHOUT SERVO AMPLIFIERS

A. POSITION LIMIT SWITCH ADJUSTMENT

(Ref. Fig. 1)

NOTE:

The actuator is shipped in its mid-travel position.

1. Referring to your wiring diagram, apply motor power and

drive the actuator in the CW output shaft direction

(looking at the shaft), until PL1 trips and stops the

actuator. This is the CW limit switch setting and starting

point for final switch adjustment.

2. Move the controlled equipment to the same starting

point and couple the actuator output shaft to the driven

shaft.

3. Apply motor power to rotate the output shaft CCW about

5 degrees, allowing PL1 switch to reset.

4. Apply motor power to rotate the output shaft CW until

PL1 trips, turning off the motor. If the driven device is not

at the desired position:

a. Remove motor power.

b. Using an 1/8 inch, long shaft allen wrench,

loosen Cam Screw #1 about 1/4 turn.

c. Rotate Cam #1 CCW to allow the actuator to run

further in the CW direction or rotate the cam CW

to turn the actuator off sooner. (Cam #1 will turn

off the motor for CW output shaft rotation, when

the switch roller lever moves to the high side of

the cam with the cam rotating CW.)

d. Position the Cam as desired and while holding in

place, tighten screw #1 with moderate force to

adequately clamp the cam in place.

DO NOT OVER TIGHTEN.

5. Apply motor power to drive the actuator to the desired

CCW position or until PL2 trips and stops the motor. If

the driven device is not at the desired position:

a. Remove motor power.

b. Loosen Cam Screw #2 about a turn.

c. Rotate Cam #2 CW to increase the actuators

total travel range or CCW to decrease the travel

range.

d. Hold the cam in place and tighten screw #2.

6. Electrically operate the actuator to its CW limit and back

to the CCW limit to check switch settings. Readjust Cam

#1 or #2 as needed.

7. Switches 3 through 6 (optional) are adjusted by loosening

their respective cam screws and rotating the cam. They

may be set anywhere within the range of PL1 or PL2.

8. If the unit is equipped with a feedback device and

switches PL1 or PL2 were readjusted, proceed with the

proper feedback alignment prior to any further adjustments or operation of the actuator.

B. 1000 OHM POTENTIOMETER ADJUSTMENT

1. Run the actuator to the center of travel. Loosen the three

panhead screws, securing the potentiometer body, and

rotate it to its center of travel (500 ohm) position. An

ohmmeter will be required for this adjustment. Tighten

the three screws.

2. Run the actuator to the zero or minimum travel limit.

With the actuator running, monitor the potentiometer

with an ohmmeter to ensure the potentiometer

deadband is not crossed.

3. If your system requires a low resistance starting point,

loosen the three screws and rotate the potentiometer

body for the required starting resistance. This is usually

20 to 50 ohms (measured from the potentiometer wiper

arm to the zero end of the potentiometer).

C. 4 to 20mA TRANSMITTER OPTION

ADJUSTMENT

The ST-4130 (1000 ohm-input, 4 to 20 mA output) two wire

transmitter modulates the current on a direct current supply

proportional to the input resistance. It is powered by a 12.0

to 36.0 Vdc regulated power supply line which is modulated

from 4 to 20 mA proportional to the resistance of the input.

9

For the unit to function optimally, the 4mA end of the

feedback potentiometer must be preset to 50 ohms.

1. Position the actuator to the desired 4mA setting.

2. With potentiometer resistance at 50 ohms, adjust

ELEVATION for 4.0mA output.

3. Position the actuator to the desired 20mA setting.

4. Adjust RANGE for 20mA output.

5. Repeat steps 1 through 4 until desired accuracy is

achieved.

6. To reverse the 4 and 20mA output, interchange the BLUE

and YELLOW wires and return to step 1.

D. ACTUATOR WITH INTEGRAL AD-8130

SERVO AMPLIFIERS

Switch and feedback potentiometer alignment is accomplished in the same manner as actuator without amplifiers,

except motor power is supplied from the amplifier. Varying

the command signal input to the amplifier will allow reversal

of the rotation of the actuator output shaft to run to the

minimum/maximum switch settings. If the actuator does not

run to the limit switch, but stops short, the amplifier has

nulled and adjustments of span, elevation, loss of signal, or

feedback potentiometer may be required. Refer to IM-0607

for information on the AD-8130 amplifier.

The EC-10852 is for use with the AD-8130 servo amplifier

with LVDT (voltage feedback). The EC-10852 is used as the

HI and LO trim for the AD-8130. The AD-8130 is factory set

for operation with the EC-10852. CAUTION: It is impor-

tant not to adjust the HI and LO trim on the AD-8130,

which are torque sealed at the factory. For specific Setup

information and calibration, refer to the wiring diagram

supplied with your unit.

The fourth cam is used for any value of x between 0.5 and 2

and must be cut by the user. For details on cutting this cam,

see To Shape Feedback Cam.

a. Run the actuator to the zero or minimum position limit.

While running, observe the direction of character cam

rotation.

b. Is the cam rotating in the direction of 100-0 for your

system requirement? If not, remove the thumb screw and

flip the cam over. Tighten the screw.

c. Have you selected the proper cam for the system require-

ment? If not, remove the thumb screw and change the

cam, installing the cam the same as in (b) above. (Green

or Black side up.)

d. Loosen three screws and remove the cam assembly.

e. Rotate the cam until the zero on the cam is in line with

the center line of the potentiometer or LVDT shaft.

f. Potentiometers need no further adjustment.

g. LVDT contactless feedback may require fine zeroing.

i. Apply power to the LVDT and monitor the output

with a volt meter.

ii. Loosen the two body clamp screws and slide the

body of the LVDT to obtain zero output.

iii. Tighten the body clamp screws.

E. CHARACTERIZED CAM ADJUSTMENT

(OPTION)

The characterized feedback assembly is an option which

directly replaces the standard linear feedback potentiometer.

Prior to adjusting the cam, the end of travel limit

switches must be set and the proper cam installed for

your particular system requirements on the characterized

cam shaft. Four different cams are supplied with each

characterized assembly. The cams are printed on both

sides and may be flipped over to reverse the characterization action in relation to the output shaft rotation.

The cams are each printed with a letter O, F, or B

which indicate the cam type. Three of the cams are shaped

to correspond to X=2, 1, and 0.5 respectively in the equation:

% amplifier input = (% shaft rotation)x

iv. If a finer adjustment is desired, loosen the nut on

the LVDT shaft and turn the shaft slightly one

way or the other and tighten the nut.

TO SHAPE FEEDBACK CAM

With characterized feedback, one of the four cams supplied

(cam B), is partially shaped. For installation, it must be cut to

its final shape by the user. This cam is used if none of the

other three cams produces the desired input-output relationship where:

% amplifier input = (% shaft position)X

Two typical conditions where the user might want to use the

fourth cam are:

1.In equation above, if the value of X is not equal to 0.5 or 2.

10

2.In equation, if the value of X is equal to 0.5 or 2, and if

upper shaft position is not equal to 100% (90°), and/or

lower shaft position is not equal to 5% (0°).

To lay out the cam shape for the desired input-output

relationship, it is necessary to determine outputs (rise in

cam), for various inputs (amount of cam rotation). The rise in

the cam corresponds to % of maximum output range and the

amount of cam rotation corresponds to % input signal to

amplifier.

1. Lay out on graph paper, axes and maximum and mini-

mum slopes as shown in figure 2. (Maximum slope is 25

units rise per 10% shaft rotation; minimum slope is 5 units

per 10% rotation.)

2. If either upper or lower shaft position is not at 0 or 100%

(0° or 90°) respectively, lay out additional x-axis scale as

shown in figure 3 on page 13. Use both sets of values

when plotting cam shape in step 3.

3. Calculate outputs (rise in cam) for 5% or 10% increments

in input for entire input scan (actual cam rotation). NOTE:

only output values that fall within maximum and minimum slope lines can be used.

4. Plot these values on cam. Scribe smooth line between

points and grind cam to this shape.

Refer to example for typical cam calculations and layout.

Figure 2

Figure 3

TYPICAL FEEDBACK CAM CALCULATIONS

EXAMPLE: Assume X in (input/output equation) = 0.5, and

that upper and lower shaft positions are at 100% and 20%

(90° and 18°), same as center illustration of Figure 3.

Figure 1

Input

% of actual

rotation

020%0

10 28 1*

20 36 4*

30 44 9*

40 52 16

50 60 25

60 68 36

70 76 49

80 84 64

90 92 81

100 100 100

Note: These values fall outside of minimum slope on graph.

location

on cam

Output

% rise

on cam

11

Troubleshooting Guide

TROUBLE PO SSI B L E CAUSE REMEDY

a. No power to actuator a. Chec k source, fuses, wiring

Mot or does not operate

Mot or hums but does not run

Mot or runs, output shaft does not

rotate

Mot or does not shut off at lim i t switc h

Ac tuator back dri ves when power is

removed

Handcrank does not m ove

out put sh aft

b. M ot or overheat ed and int ernal

thermal switc h t ripped (s i ngl e phas e

AC motors only)

c. Motor burned out

d. M ot or drag brake i m properly

adjus t ed

e. M ot or drag brake defective e. Replace drag brake

f. Bot h end of travel swit c hes open or

one open and one defective

g. A ctuator out put shaft st all ed

h. Defect i ve motor run capac i t or h. Replac e capacit or (A C model s)

i. Load ex c eeds act uat or t orque rati ng

j. Powe r ap plied to CW & CCW

rotation at same time

k. Ampli fier defect i ve k. Replace ampl ifier

l. A m pli fier is in Loss of S ignal

m. A m pli fier deadband is too wide m. Reduc e deadband s et t i ng

a. P ower applied t o CW & CCW

rotation at the same time

b. Damaged power gearing b. Repair gearing

c. Defec tive mot or run c apac i t or c . Replace capaci tor

d. M ot or drag brake d. A dj us t or replace as requi red

a. Defect i ve power gearing a. Repair gearing

a. S witch wired wrong or is defec t i ve a. Correct wiring or replace switc h

b. M ot or phas ed i ncorrectl y b. Correct wiri ng

a. M ot or drag brake i m properly

adjus t ed

b. M ot or drag brake defective b. Replace drag brake

a. P ower s t i ll on a. Remove power

b. Load is jammed and m ot or drag

brake s l ips

c. Drag brak e m i ssing or im properly

adjus t ed.

b. Let m ot or c ool and det ermi ne why

overheating occurred (suc h as,

excess ive duty cyc l e or ambi ent

tem perature)

c. Replace mot or and det ermi ne

cause of failure

d. A dj us t as detai l ed on page 20

f. Adjust switch settings or replace

defecti ve switch

g. Chec k dri ve load for mechanical

jam and c orrec t caus e

i. Reduce l oad or replac e actuator wit h

one with appropriate torque rating

j. Correct power input problem

l. Check command signal t o verify

si gnal great er t han 3. 8 m A i s present

a. Correct power input problem

a. A dj us t as detai l ed on page 20

b. Remove jammed load

c. Replace drag brake

12

Troubleshooting Guide

Motor runs , but only one way

Poor response to com m and signal

changes

a. P ower not appli ed for other

direction

b. P ower alway s appl ied to one

direction and elect ri c al l y st all s when

applied for opposit e di rec t i on

c. Open limit swit ch for ot her

direction

d. A ctuator i s t orqued out d. Determine obs t ruc tion and correc t

e. Motor has an open winding e. Replac e m ot or

f. Mot or and feedback pot ent i om et er

are out of phase

g. A m pli fier is defective g. Replac e am pli fier

a. A m pli fier deadband is too wide a. Reduce deadband set ting

b. A m pli fier is defective b. Replac e am pli fier

c. Excessive noise on command

signal

d. Defect i ve feedback potent iom et er d. Replac e pot ent i om et er

a. A m pli fier deadband is too narrow a. Inc reas e deadband s et t i ng

b. A m pli fier is defective b. Replac e am pli fier

a. Correct power problem

b. Correct power problem

c. Adjus t or replac e l i m i t switc h as

require d

f. Reverse pot ent i om et er end leads

c. Reduce noise. Also ensure that

com m and s i gnal wi ring i s shielded

with s hi el d grounded at source

common only.

Actuator os cillates at setpoint

Pot feedback signal not al way s

present during ac tuator rotat ion

Pot signal does not change as

act uator operates

Pot signal is revers ed for output shaft

rotation

Output s haft rot at es wrong direction

for CW and CCW i nput power

c. Reduce noise. Also ensure that

c. Excessive noise on command

signal

a. P ot not aligned with end of t ravel

ext rem es and i s bei ng driven through

dead region

b. P ot signal is errat i c or nonex i stent b. Replace pot

a. Defect i ve pot a. Replac e pot

b. Feedbac k gear not turning pot

shaft

a. P ot i s wi red wrong

a. Wiring to actuator incorrect a. Correct fiel d wiring

b. Wiring from motor to terminals or

switches is reversed

a. E xternal wiring error a. Refer to IM-0607

com m and s i gnal wi ring i s shielded

with s hi el d grounded at source

common only.

a. A l ign pot t o range of actuator

b. Chec k gearing engagem ent and

set screw in gear hub

a. Revers e wiri ng from ends of pot at

act uat or terminal bloc k

b. Correct internal ac tuator wiring

4-20 mA custom er feedback mis sing

or non-linear

b. P ower suppl y faul t b. Refer to IM-0607

c. Shunt resistanc e t oo l i ght c. Refer to IM-0607

13

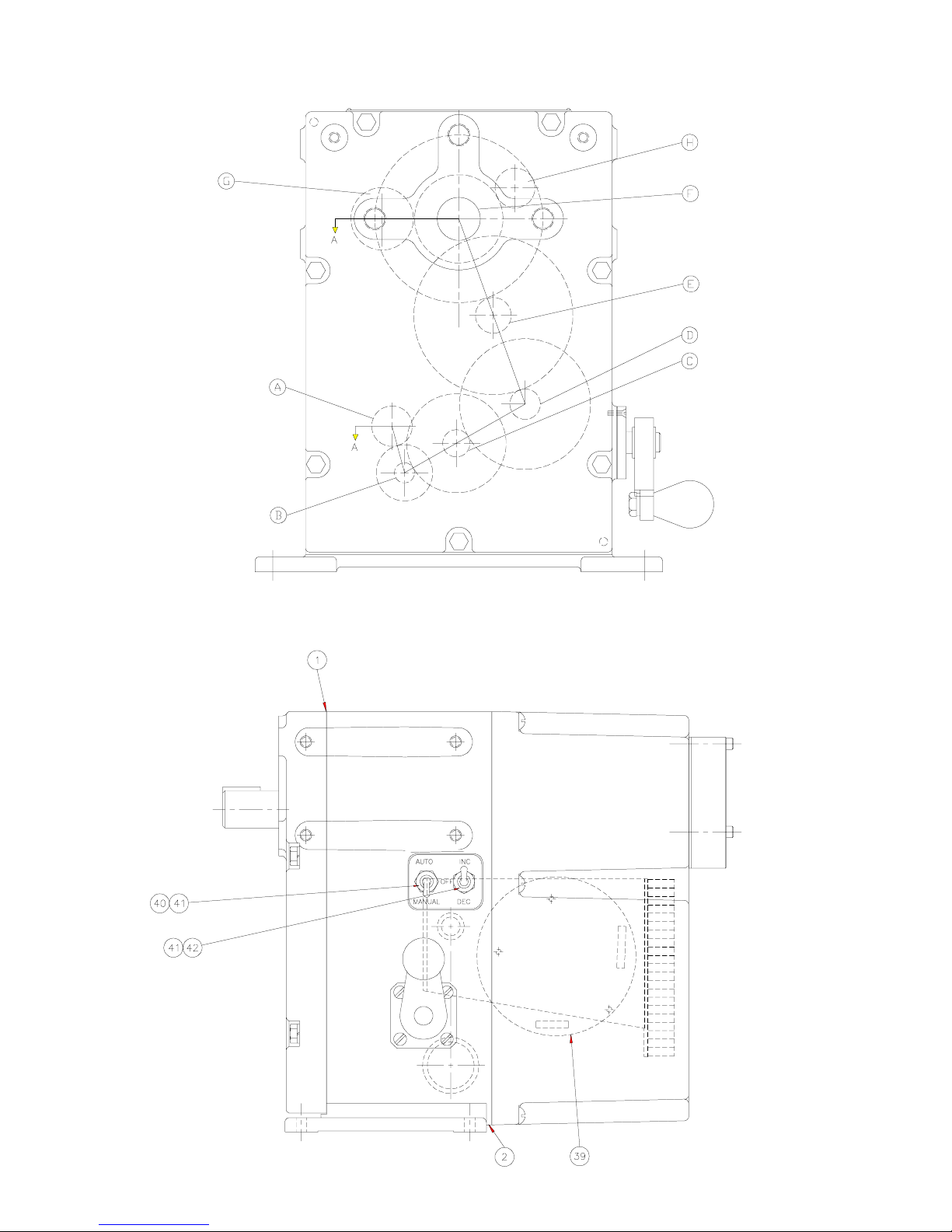

GEAR LOCATION

Front View

Letters in balloons

refer to gear

assembly drawing

on page 15.

Parts Identification

Side View

Numbers in balloons refer

to parts identification list

on pages 17-18.

14

Parts Identification

GEAR ASSEMBLY

Numbers in balloons refer to parts

identification list on pages 17-18.

15

Parts Identification

LIMIT SWITCH COMPARTMENT

Numbers in balloons refer to parts

identification list on pages 17-18.

16

Spare Parts List

Recommended Spare Parts Indicated in Bold

ID DESCRIPTION PART NUMBER QTY

1 Gasket, Gear Cover 13C-016024-001 1

2

3 Bushing (2nd Stage) 18B-SP1988-067 2

4 Bushing (3rd Stage) 18B-SP1988-007 2

5 Bushing (4th Stage) 18B-SP1988-068 1

6

7

8 Bearing (Output Shaft) 17B-003813-031 1

9 Bushing (Switch Shaft) 18B-SP1988-057 1

10

11 1

12

13

14 1

15 1

16

17

18

19

20

21

22 Woodruff Key #204 58B-016181-007 1

23

24 Handcrank 74A-016182-001 1

25 Lip Seal, Ha nd crank 19B -003815-017 1

26 Beari ng, Handcrank 17B-003813-011 1

Gasket, Rear Cover 13C-015754-001

Bearing (4th Stage) 17 B-003813-007 1

Bearing (4th Stage)* 17B-003813-077 1

Bearing (5th Stage) 17 B-003813-004 2

Bearing (5th Stage)* 17B-003813-083 2

Bushing (Output Shaft) 18B-003814-029 1

Bearing (Output Shaft)* 17B-003813-084 1

(See Motor Selection on p. 20)

Motor

Drag Brake Ass’y (ac)

(except 31/1800)

Drag Brake Ass’y (ac)

(31/1800 only)

Drag Brake Ass’y (dc) 68C-035339-00 2

Woodruff Key #202 58B-016181-001 1

Woodruff Key #404 58B-016181-009 1

Pi n i on Gear

Gea r Ass’ y

Gea r Ass’ y

Planetary Gear Ass’y

(4th Stage)

Planetary Gear Ass’y

4th Stage

Gea r Ass’ y

Gea r Ass’ y

Output Shaft Gear 16B-016030-001

O u tput Shaft Gear * 16B-036930-001

Woodruff Key #606 58B-016181-016 1

Key 0.25”square x 2’ long * 61B -010954-464 1

Output Shaft - Splined 62B-016028-001 1

Output Shaft - Keyed 62B-016029-001 1

Output S h aft - Splined * 62 B-036936-001 1

Output S h aft - Keyed * 62B-036935-001 1

Gear, Helical 16A-015674-001 1

Gear, Helical* 16A-015674-002 1

(See Gear Chart on page 20)

(2nd Stage) (See Gear Chart on page 20)

(3rd Stage)

(5th Stage)

(5th Stage)*

68C-035339-001

68C-038298-001

65A-016036-001

65C-016048-001

65B-036953-001

65A-016027-001

65A-016027-002

1

1

1

1

1

1

1

1

1

1

1

27 Worm Gear 16A-015673-001 1

28 Bushing 18B-SP1988-066 1

Capacitor 5 MFD (1710) 24B-029812-005 1

Capacitor 10 MFD (1720) 24B-029812-008 1

Capacitor 10 MFD (1730) 24B-029812-007 1

29

Capacitor 3 MFD (1750)(1790) 24B-029812-004 1

Capacitor 2 MFD (1770) 24B-029812-003 1

30

31 Thermal Switch 74A-02 35 65-001 1

32 “O” Ring 74B-012708-022 1

33 Gear, Feedback 16B-003804-100 1

34 Gear, Pot 16B-003803-096 1

35 Gear, Limit Switch 61A-025809-001 1

36 Woodruff Key #404 58B-016181-009 1

37

38

39

40 Selector Sw itch 46B-004053-319 1

41 Rubber Boot 46B-004053-320 2

42 Selector Sw itch 46B-004053-313 1

43

44 Resistor 10 ohm, 25W 33B-003852-205 1

45

46 Characterized Cam Set 68A-017793-005 2

47

48

Heater 120V, 30W 74A-016946-001 1

Heater 240V, 75W 74A-016946-002 1

Potentiometer, 1 K ohm 34B-033104-001

2 SPDT (AC units) 68D-0 21669-001 1

4 SPDT (AC units) 68D-0 21669-002 1

6 SPDT (AC units) 68D-0 21669-003 1

2 SPDT (DC units) 68D-021669-004 1

4 SPDT (DC units) 68D-021669-005 1

6 SPDT (DC units) 68D-021669-006 1

2 DPDT 68D-021669-007 1

4 DPDT 68D-021669-008 1

6 DPDT 68D-021669-009 1

AD-8130 Servo Amplifier 68C-035658-001

AD-8130/EC-10835

w/o 24 Vdc power supply**

AD-8130/EC-10835

with 24 Vdc pow er supply**

4-20 m A Transm itter 70A-019948-001

SPDT (AC unit) 46A-010017-001

SPDT (DC unit) 46A-010017-003

DPDT 46A-010017-002

Potentiometer 1K ohm Linear

(for cha racterized cam set)

LVDT

(for cha racterized cam set)

Torque Limit Switch

(not show n)

70C-035950-001 1

70C-035950-002 1

68C-015435-001 1

68C-019632-001 1

46B-004053-416 2

1

1

1

2

2

2

17

Motor, Motor Pinion Gear

& 2nd Stage Gear Assy. Selection

Model

SM-1710

SM-1715

SM-1720

SM-1790

SM-1730

SM-1740

Sh ift Time

(sec. )

12 61B-026406-004 16B -015633-001 65B-016034-001

24 61B-026406-004 16B -015633-003 65B-016034-003

48 61B-026407-001 16B -003806-015 65B-016034-005

12 23C-038332-001 16B-015633-001 65B-016034-001

24 23C-038332-001 16B-015633-003 65B-016034-003

48 23C-038333-001 16B-003806-015 65B-016034-005

31 61B-026406-003 16B -015633-004 65B-016034-008

60 61B-026407-002 16B -017896-001 65B-016034-007

12 61B-026406-003 16B -015633-001 65B-016034-001

24 61B-026406-003 16B -105633-003 65B-016034-003

48 61B-026407-002 16B -015633-015 65B-016034-005

16 61B-026404-001 16B -015633-003 65B-016034-003

31 61B-026405-001 16B -003806-015 65B-016034-005

40 61B-026405-001 16B -017896-001 65B-016034-006

Motor Part #

(Item 11)

Motor Pinion Ge ar

Part # (Ite m 14)

2nd Stage Gear Assy.

Part # (Ite m 15)

12 61B-026406-001 16B -015633-001 65B-016034-001

SM-1750

SM-1770

24 61B-026406-001 16B -015633-003 65B-016034-003

48 61B-026407-003 16B -003806-015 65B-016034-005

12 61B-026406-002 16B -015633-001 65B-016034-001

24 61B-026406-002 16B -015633-003 65B-016034-003

48 61B-026407-004 16B -003806-015 65B-016034-005

Note: Models with 12, 24 or 48 seconds shift time were previously rated 17, 34 and 67 seconds respectively.

18

LUBRICATION

Maintenance

Under normal service conditions the motor, gearing,

bearings, and parts are all pre-lubricated and should

not require periodic maintenance. If for any reason the

unit is disassembled in the field, all oilite bushings

should be resaturated with an SAE-10, non-detergent

oil and all gearing heavily coated with Amoco Rykon

Premium Grease #2 or equivalent grease. Care should

be taken to ensure that no foreign material is allowed

to become combined with the grease in the gear train,

which will cause premature failure. Keep gearbox

clean and dry.

DRAG BRAKE ADJUSTMENT

The drag brake serves two functions: a) to prevent

actuator from backdriving at maximum rated torque;

and b) to allow the motor shaft to slip when

handcranking and the output shaft load is in excess of

rated torque.

The drag brake was factory set and should not need

readjustment. If it does need adjustment:

1. Apply an overhung load, equal to the maximum

torque rating to the output shaft.

2. Loosen drag brake jam nut until the motor shaft

starts to backdrive.

TORQUE LIMIT SWITCH ALIGNMENT

The torque limit switches are factory set and field

adjustment is not advised unless proper test equipment is available. If adjustment must be done, use the

following procedure:

1. Load the output shaft with a known load which

matches the torque rating of the actuator in an

opposing direction for the switch being adjusted.

2. Apply power to the motor and run the actuator to

drive the opposing load.

3. Increase the load by 5% to 10% and adjust the set

screw (140C) to trip the torque switch.

4. Remove the 5% to 10% increase of load and the

switch should reset.

5. Load the actuator in the opposite direction and set

the other switch in the same manner.

NOTE: When looking at the torque limit switch

assembly as it is mounted in the actuator, the switch

on the top of the assembly controls the CW torque

and the switch on the bottom controls the CCW

torque. The torque should be set near equal for both

directions.

3. Tighten the drag brake jam nut just enough to

prevent backdriving.

4. While handcranking against the load, increase the

load until motor backdriving occurs.

When the actuator is driven into a torque condition

in the CW direction (looking at the output shaft), the

handcrank handle will move slightly outward. For

CCW direction the handle will pull slightly inward.

19

Maintenance

MOTOR REPLACEMENT

1. Disconnect all power to the actuator.

2. Remove screws, washers and rear cover.

3. Disconnect actuator output shaft from driven

device and remove actuator from mount.

4. Remove bolts, washers, and front gear case cover.

Note location of all gearing.

5. Remove motor pinion.

6. Remove brake assembly from top of motor.

7. Disconnect motor wires - note colors.

8. Remove motor.

9. Reverse the procedure to install new motor. (Clean

and regrease all gearing, check bushings and

bearings, lubricate bushings with SAE-10, nondetergent oil.)

10. Reinstall the actuator.

FEEDBACK POTENTIOMETER REPLACEMENT

A. One Turn Linear Potentiometer

1. Disconnect all power to the actuator.

2. Remove screws, washers, and rear cover.

3. Remove three screws holding potentiometer and

disc to housing.

4. Pull potentiometer and disc out of housing.

5. Measure location of gear from mounting disc to

farthest face of gear and note measurement.

6. Loosen set screws and remove gear.

7. Remove nut and washer holding potentiometer to

disc.

8. Cut shaft of new potentiometer to same length as

old.

9. Mount new potentiometer on disc, tighten potentiometer nut, install gear to measured dimension

from step 5.

POWER GEARING REPLACEMENT

1. Perform steps 1,3 & 4 of Motor Replacement.

2. Remove defective gear(s) and replace with new.

3. Ensure all gearing and oilite bushings are properly

lubricated as detailed above.

4. Install front cover and Reinstall actuator.

POSITION LIMIT SWITCH REPLACEMENT

1. Disconnect all power to the actuator.

2. Remove rear cover.

3. Remove two screws and washers from appropriate

switch on assembly.

4. Install new switch and transfer wires from old

switch one at a time.

5. No realignment should be necessary.

10. Install assembly in housing and tighten screws.

11. Using a 25 watt solder iron, remove wires from old

potentiometer one at a time and solder to corresponding terminals on new potentiometer.

12. Align potentiometer and install cover.

B. Characterized Potentiometer

1. Disconnect power and remove rear cover.

2. Remove three screws and pull potentiometer off of

pins.

3. Install new potentiometer and tighten screws.

4. Using a 25 watt solder iron, remove wires from old

potentiometer one at a time and solder to corresponding terminals on new potentiometer.

CAUTION - DO NOT USE EXCESSIVE HEAT

WHEN SOLDERING.

5. Align potentiometer and install cover.

C. LVDT Assembly Replacement

1. Same as Characterized Potentiometer replacement

above.

2. Align LVDT body for zero output (see alignment

procedure, characterized cam adjustment on page

12, step G).

20

Linkage Options

Damper Shaft

Actuator Shaft

NOTES:

1. Maximum total link length is specified to prevent

buckling under compressive load.

2. Adjustable drive arms are also available to allow

length to vary from 6 to 10 inches (152 to 254 mm).

In this case, the adapter-clevis has rod ball ends

with lubrication fittings.

3. Weight of all linkage components (including customer supplied schedule 40 pipe) must be taken

into consideration when calculating total actuator

torque requirements.

21

Fixed

Major Dimensions

Adjustable

NOTES:

1. The optional local toggle switches are located on this

surface.

2. The SM-1700 series actuators can be foot, face or side

mounted.

3. Overall depth is approximately 13 inches (330 mm) on the

SM-1715 three phase model.

4. The output shaft is available in a one inch (25.4 mm)

diameter with 1/4 inch (6.35 mm) square keyway, or with

the optional spline, as shown in upper right hand corner.

All connections

and adjustments

are inside

22

23

The dimensions in this manual are subject to change without notice and should not be used

for preparation of drawings or fabrication of installation mounting. Current installation

dimension drawings are available upon request.

JORDAN CONTROLS, INC.

5607 West Douglas Avenue

Milwaukee, Wisconsin 53218

Phone: (414) 461-9200

FAX: (414) 461-1024

E-Mail: jordan@jordancontrols.com

IM-0468 1/00

24

Loading...

Loading...