TEST 3

METER

EURORACK V/mA

TEST 3 BUILD INSTRUCTIONS

Test 3 is available as either a stand-alone circuit board for use on your workbench, or a module which can

be installed in your rack.

The Test 3 DIY Kit contains everything needed to build a functional module meter: a circuit board with

SMD parts pre-soldered, and just a few through-hole parts to hand-solder yourself.

If you want to mount Test 3 as a module, you’ll also need the Test 3 Front Panel Kit, which includes the

front panel and various pieces of mechanical hardware.

For instructions on how to use Test 3 after building it, the User Manual can be found at:

https://joranalogue.com/test3/manual

CONTENTS

Check if your kit includes all parts listed below. If anything is missing, please contact your dealer or

support@joranalogue.com.

DO-IT-YOURSELF KIT

Test 3 circuit board

Electrical parts bag

o 1 LED display

o 6 LEDs

o 2 tactile switches

o 2 16-pin shrouded headers

16-to-16-pin Eurorack power cable

FRONT PANEL KIT

Test 3 aluminium front panel

Mechanical parts bag

o 6 LED spacers

o 4 metal spacers

o 4 M3 nyloc nuts

o 4 M3 countersunk screws

o 2 mm hex key

2 switch caps (in separate bag)

Mounting hardware bag

o 2 black M3 screws

o 2 black nylon washers

o 2.5 mm hex key

1

TEST 3

METER

EURORACK V/mA

SOLDERING

Because Test 3 requires soldering just a handful of components, it’s a great starter kit if you’re just getting

into synth DIY. It will also help you to test and troubleshoot your future DIY projects.

Soldering is easy! Just keep the following things in mind:

If this is your first soldering project, ask a tech-savvy friend to assist you or visit a DIY soldering workshop

in your area. Also, many excellent soldering tutorials can be found online, such as this one by Dave

Jones from the EEVblog: https://youtu.be/fYz5nIHH0iY

Use a decent quality, temperature-controlled soldering station. These can be found very cheap.

Unregulated soldering irons which are plugged directly into the mains or gas soldering irons are not

suitable for electronics!

Use the biggest soldering iron tip you can. A bigger tip transfers the heat better, making soldering

quicker and easier. Chisel-shaped tips are preferred over conical tips.

1 mm tin/lead solder (Sn60Pb40) is recommended. Leaded solder is easier to use than lead-free solder,

and 1 mm is the ideal diameter for general through-hole soldering.

Clean your tip every few solder joints, using brass wool or a damp sponge. A dirty tip will not transfer

heat properly, making it hard to use.

When soldering a component, start by soldering one pin or two on opposite ends. Then check if the

part sits on the circuit board properly. If needed, you can still make adjustments by melting a solder

joint while applying pressure on the part, before soldering the rest of the pins.

The solder fumes do not contain lead, but are still not good for your health! Work in a well-ventilated

area. A solder fume extractor with filter is a good thing to have.

2

TEST 3

METER

!

EURORACK V/mA

BUILDING TEST 3

Before commencing construction, decide if you’ll use the Front Panel Kit, as there are some

differences and it is not easy to upgrade later.

Continue to page 6 if you are building Test 3 with the front panel.

WITHOUT FRONT PANEL

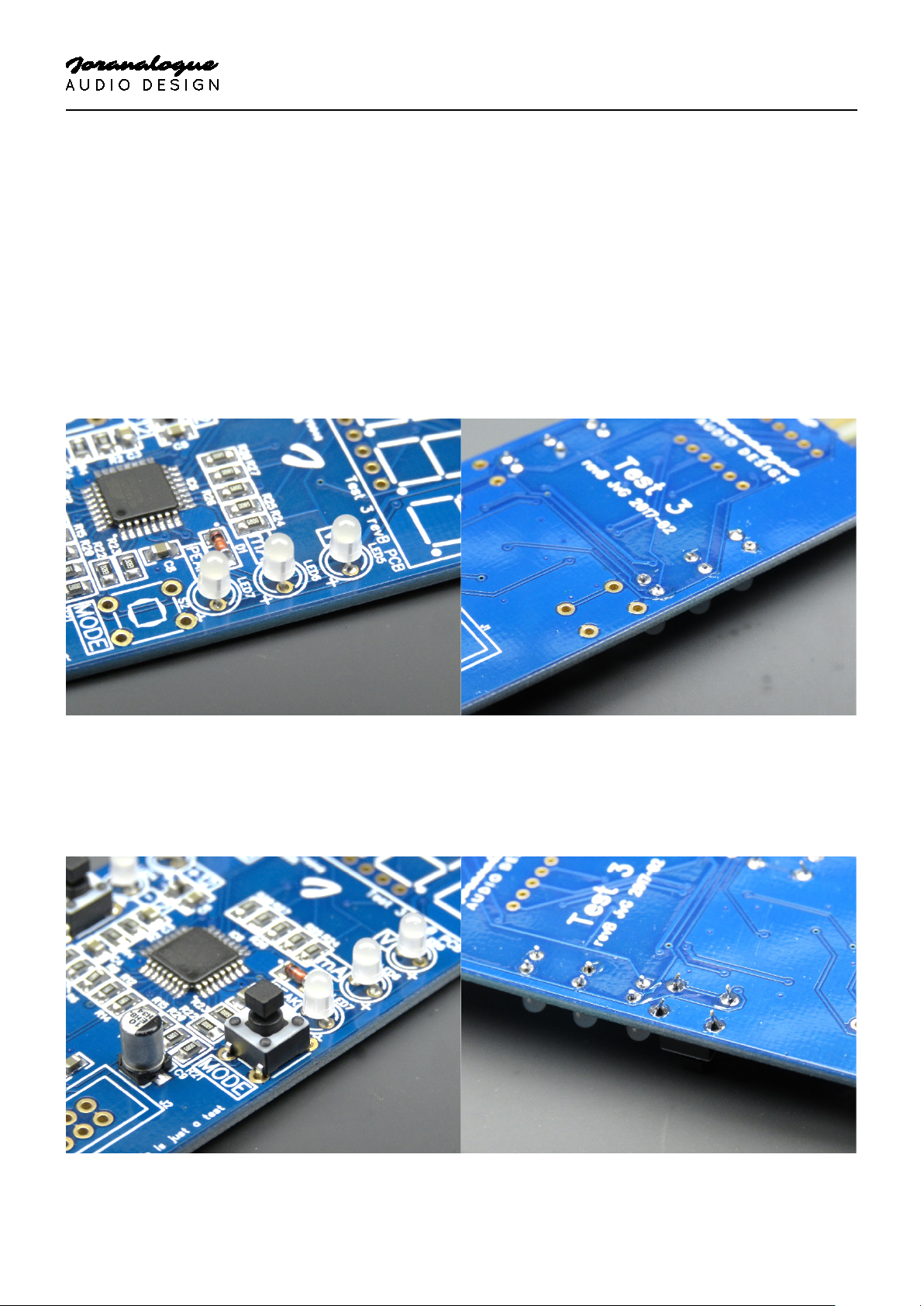

The Test 3 circuit board already has all SMD parts pre-soldered, so you only need to solder the eleven

included through-hole parts. Apart from your soldering gear and flush side cutters, no additional tools are

required.

You will want to start with the physically lowest parts, which in this case are the six white LEDs. Insert

them all the way, and take care to solder them nice and straight. Also watch out for the polarity: the

longer lead is the positive side (anode). This pin should be next to the little plus sign on the circuit board,

which is always on the right. After soldering, clip the leads just above the solder joints. These are the only

leads that need to be clipped.

Next to solder are the two tactile switches. These simply snap in place and don’t have a particular

orientation.

3

TEST 3

METER

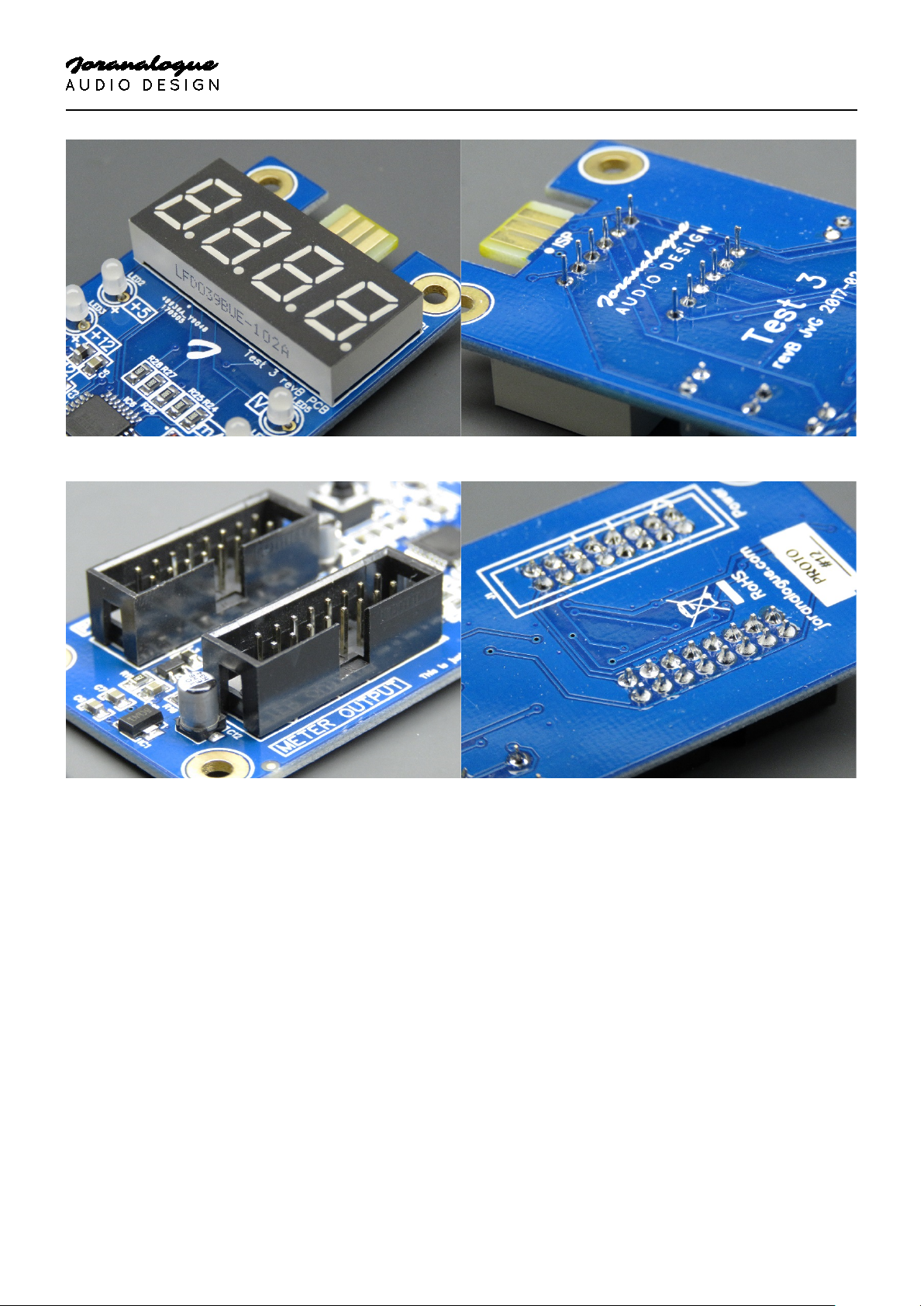

Insert and solder the LED display. Take note of the orientation again: the decimal points go on the bottom.

EURORACK V/mA

Finally, place and solder the two 16-pin shrouded headers. Both should be placed on the top side of the

circuit board. Again, check the orientation: the slot goes on the right. If you insert the included power

cable, the red stripe should go on the bottom. Be careful not to bump into the electrolytic capacitors

(silver cans) during placement.

4

TEST 3

METER

That’s it! Connect the left header (‘power supply’) to your Eurorack system with

the included cable and turn it on. The LEDs should light up, and you should be

able to measure the voltages of your system’s power supply.

This construction method leaves the mounting holes in the corners unused.

They each have a diameter of 3.2 mm, spaced 30 mm apart horizontally and 95

mm vertically. If needed, you can attach Test 3 to a non-conductive surface with

plastic PCB standoffs, M3 mounting hardware etc.

Enjoy!

EURORACK V/mA

5

TEST 3

METER

EURORACK V/mA

WITH FRONT PANEL

The build process is similar if you have the Front Panel Kit, with some minor differences. In addition to

your soldering gear, flush cutters and included hex keys, you’ll also need 5 and 5.5 mm nut drivers.

You will want to start with the physically lowest part, which in this case is the LED display. Insert it all the

way and solder all pins. Watch out for the polarity: the decimal points should be on the bottom. There’s

no need to clip the leads after soldering.

Next to solder are the two tactile switches. These simply snap in place and don’t have a particular

orientation.

6

TEST 3

METER

Place and solder the two 16-pin shrouded headers. The power supply header goes on the bottom, and

the module header on top. Again, check the orientation: in both cases, the slot goes on the right. If you

insert the included power cable, the red stripe should go on the bottom. Be careful not to bump into the

electrolytic capacitors (silver cans) during placement.

EURORACK V/mA

Now it’s time for the six white LEDs. Each of these has its own spacer, found in the Front Panel Kit. These

spacers bring the LEDs to the correct height for the front panel. They have two holes, one for each LED

lead, and a 1 mm deep cavity on top. Insert each LED into a spacer, taking care that each lead is in its own

hole and the LED sits in the cavity.

7

TEST 3

METER

Then insert the LED leads into the circuit board. Make sure the spacer sits nice and flat on the circuit

board, and the LED on the spacer. Also watch out for the polarity: the longer LED lead is the positive side

(anode). This pin should be next to the little plus sign on the circuit board. After soldering, clip the leads

just above the solder joints.

EURORACK V/mA

With the soldering done, only the mechanical assembly remains.

8

TEST 3

METER

Place the four metal spacers in the holes on the corners, and tighten the nyloc nuts on the back. Use the

5 mm nut driver for the spacers, and the 5.5 mm one for the nuts.

EURORACK V/mA

Place the switch caps on the tactile switches. Give them a good push to ensure they are inserted all the

way.

9

TEST 3

METER

The front panel can now be placed over the circuit board, and attached by way of the four countersunk

M3 screws. Screw these into the metal spacers using the small hex key (2 mm).

EURORACK V/mA

That’s it! Connect the rear header (‘power’) to your Eurorack system with the

included cable and turn it on. The LEDs should light up, and you should be able

to measure the voltages of your system’s power supply.

Now all that’s left is to install the Test 3 module in your case, using the included

mounting hardware.

Enjoy!

10

With compliments to the following fine people,

who helped to make Test 3 a reality!

Björn Jauss

Eric Lukac-Kuruc

Ģirts Ozoliņš

Jan D’Hooghe Jens Van Daele

Everyone at Wired Electronics

Boris Uytterhaegen

François Gaspard

Gregory Delabelle

Test 3 Build Instructions

version 2017-08-27

© 2017

info@joranalogue.com

https://joranalogue.com/

Designed & made in Belgium

Loading...

Loading...