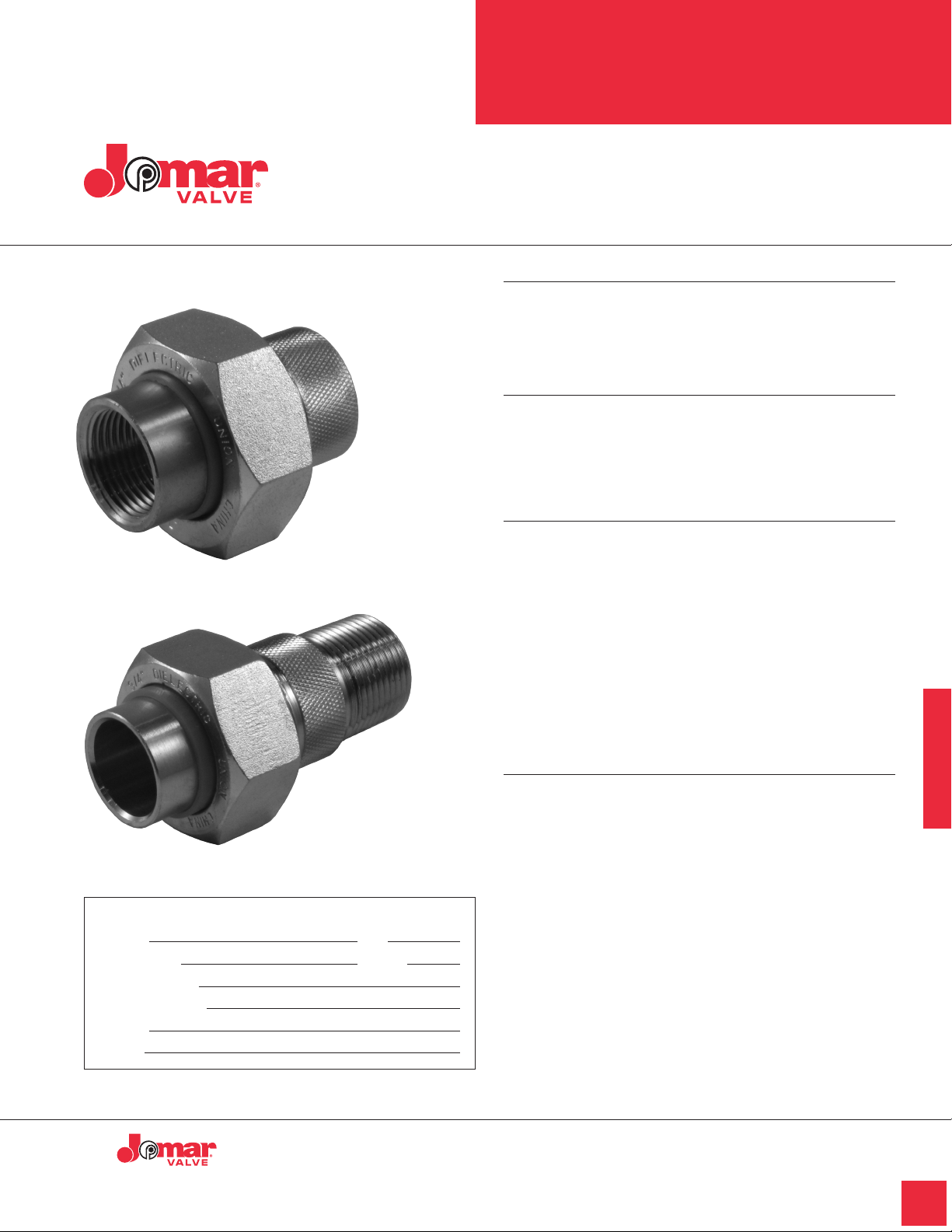

Dielectric Unions

Galvanized x Copper

Description

The most effective method for preventing piping system

deterioration from accelerated corrosion due to galvanic

and stray current is the use of dielectric unions.

Features

• Prevents accelerated corrosion

• Pressure rating: 250 PSI

• -20˚F to 180˚F - Buna Seats

• -20˚F to 220˚F - Teflon Seats

Male x Solder

FIP x Solder

Architect/Engineer approval

Job Name Date

Model Specified Quantity

Variations Specified

Customer/Wholesaler

Contractor

Architect

Approvals

• Meets ANSI B16.39.

• IPS ANSI B1.20.1

• Solder end ANSI B16.18

• Now available in Lead Free

Conforms with California code AB1953 - NSF 61 Annex

G - requires less than 0.25% lead

in plumbing products

used to convey drinking water in water utility distribution

pipes and in consumer plumbing fixtures.

Warranty

The Company, for a period of one year from the date of

shipment, warrants each product or system of its own

manufacture to the original purchaser to be free from

defects in material and workmanship under normal use,

service and maintenance.

Dielectric Unions

Note: Information subject to change without notice.

Jomar Valve

7243 Miller Drive

Warren, MI 48092

Phone: 800-325-5690

Fax: 800-628-4194

www.jomarvalve.com

© Copyright 2010 Printed in U.S.A.

Galvanized x Copper

0510

186

Dielectric Unions

Galvanized x Copper

Description

The most effective method for preventing piping system

deterioration from accelerated corrosion due to galvanic

and stray current is the use of dielectric unions.

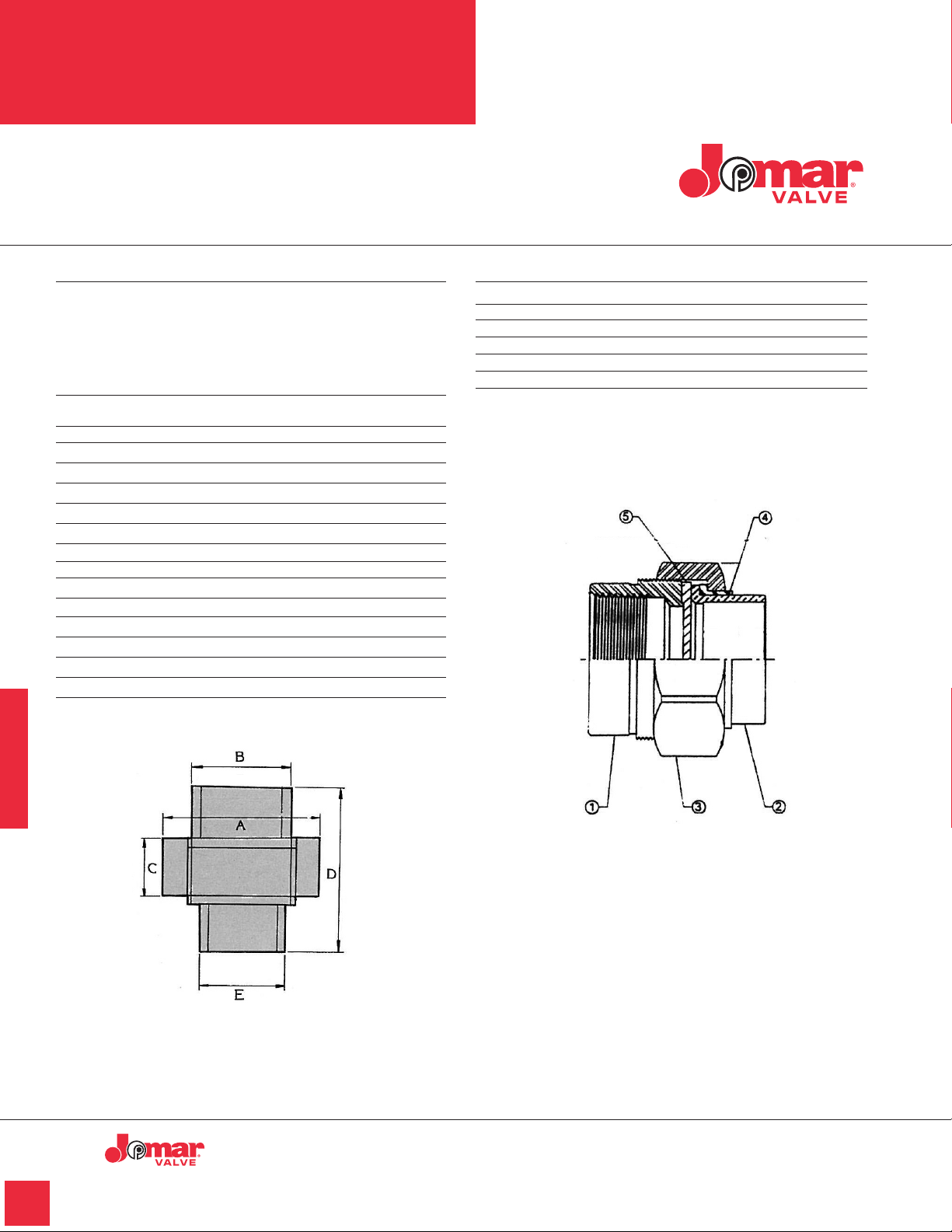

Dimensions in Inches

Computer

No. Size A B C D E

701-103 1/2” 1.63 1.04 0.72 1.85 .82

701-104 3/4” 1.85 1.26 0.72 2.03 1.07

701-105 1” 2.14 1.54 0.72 2.27 1.32

701-106 1-1/4” 2.56 1.86 0.85 2.52 1.57

701-107 1-1/2” 2.95 2.15 0.97 2.53 1.83

701-108 2” 3.76 2.74 1.06 2.85 2.38

REDUCING

701-204 3/4” x 1/2” 1.64 0.82 0.72 2.80 1.04

701-205 1” x 3/4” 1.85 1.07 0.72 2.89 1.23

MIP x Solder

701-303 1/2” 1.64 0.82 0.72 2.80 1.04

701-304 3/4” 1.85 1.07 0.72 2.89 1.23

701-305 3/4” x 1/2” 1.64 0.82 0.72 2.58 1.23

701-306 1” 1.89 1.30 0.86 3.18 1.30

Material Specification

No. Part Name Materials

1 Body Forged Steel

2 Tailpiece Forged Brass

3 Union Nut Forged Steel

4 Insulator Plastic (nylon w/ fiber filled)

5 Gasket BUNA-N (180˚)

* For higher temperature service, teflon seats are available (220˚)

Dielectric Unions

Note: Information subject to change without notice.

187

Jomar Valve

7243 Miller Drive

Warren, MI 48092

Phone: 800-325-5690

Fax: 800-628-4194

www.jomarvalve.com

© Copyright 2010 Printed in U.S.A.

0510

Loading...

Loading...