Page 1

1/4

AE Series Electric Actuator Instruction Manual

For safe and proper operation, please carefully read this manual before using and save it for reference

Important note: The content of this manual is subject to change due to quality

improvements or any other reasons without notification.

After receiving actuator, please check the followings.

1) Individual test report, electrical wiring (inside of actuator) is provided.

2) Visual check : Painting, position indicator, etc

3) Specification : Make sure you have correct actuator.

1. Pre-Installation

1) Selection of valve and actuator : Review all specifications of actuator carefully before making selection,

include 30% torque safety factor.

2) Do not operate actuator before setting limit switches.

3) After electrical wiring, ensure cable entries are properly secured.

4) Ensure correct voltage is being supplied to actuator.

5) Storage : Keep actuator dry, clean and cool.

6) Trouble : Please refer to enclosed trouble shooting, do not dismantle the actuator without consulting with

factory.

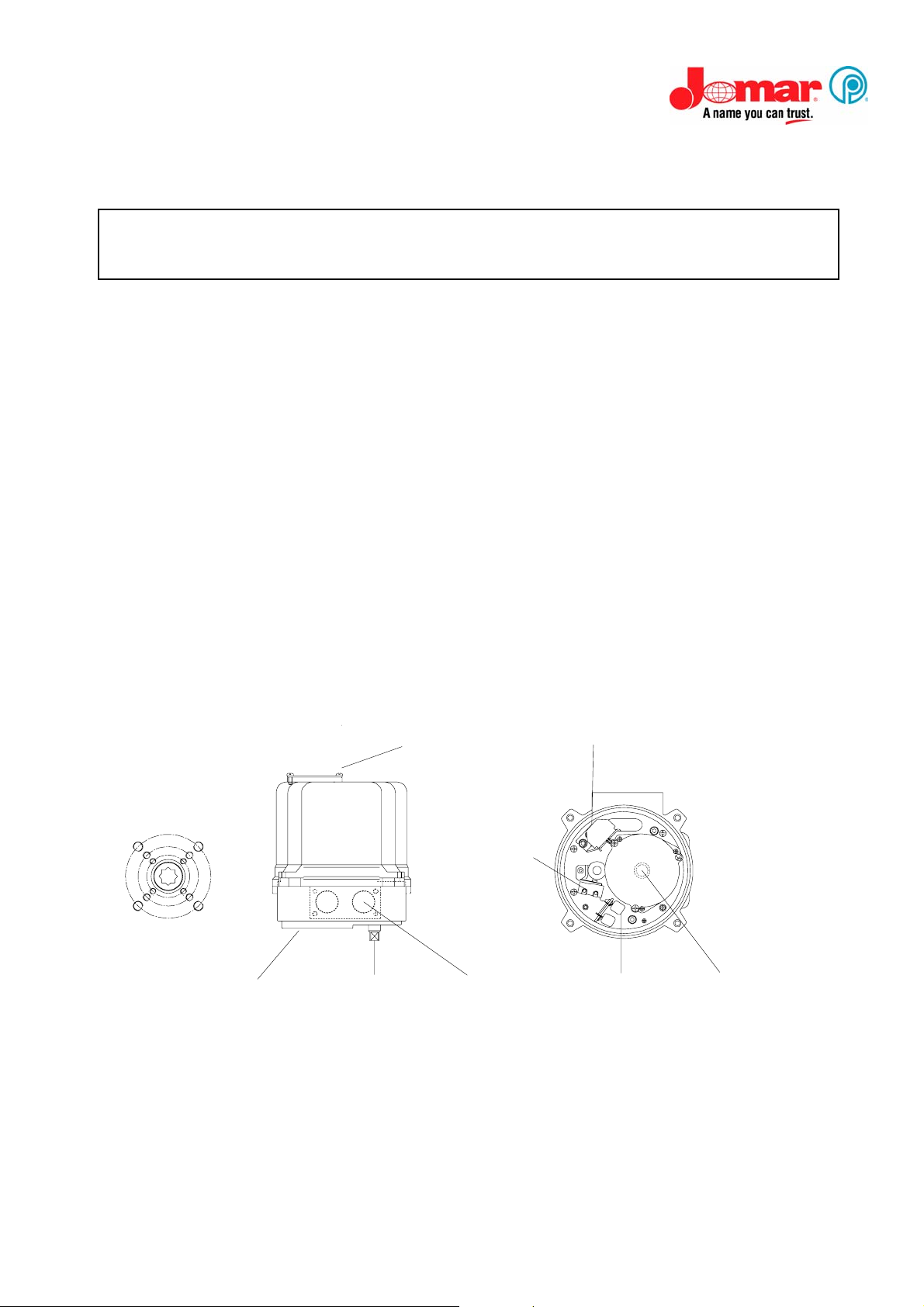

2. Identification

Indicator & cover

Terminal Block

Limit switch

Space heater

Mounting flange

according to ISO5211

F03, F05, F07

Manual Drive Cable entry Electric motor

AE Series Electric quarter turn actuator

Installation and maintenance manual

Page 2

h

2/4

3. Mounting

EA actuators are suitable for direct mount on ISO standard flanged valves and dampers.

There is no limitation in mounting actuator on valve. In a vertical pipeline, it is recommended that the conduit

entry is pointing downward in order to avoid water flow in through the cable entry.

When actuator is mounted on valve, the following procedure is recommended.

1> Watching the indicator, put actuator at fully closed position (Clockwise).

2> Valve stem must be properly machined to match with female drive shaft of actuator. An adapter may be

required.

3> Close the valve and mount actuator on valve.

4. Switch adjustment

1) Required tools for setting

Allen-Wrench 1 set(M2, Metric)

2) Manual operation

① Manual drive shaft is located at bottom of actuator. (AE 350)

② Clockwise direction is closed, Counterclockwise is open.

③ From fully closed position to fully open position requires approximately 9 turns.

④ Do not to manually operate the actuator past the setting of the limit switch.

3) Limit switch setting

1> Put actuator at fully closed position by watching indicator.

2> Turn the close cam until cam activates the lever of the limit switch and makes a “clicking” sound.

3> Tighten cam set screw(M2) to fix cam position.

4> Repeat for the open position

Limit Cam

Limit Switch

Open Cam

Open limit switch

Close Cam

Close limit switc

AE Series Electric quarter turn actuator

Installation and maintenance manual

Limit Switch Ass'y

Page 3

3/4

5. Electrical wiring

1) Before wiring

1> Cable entries are machined with PG13.5 tap and sealed with plug before delivery.

2> Leave the plug in place if both entries are not used.

3> Seal the entries by using rubber or metallic packing after wiring.

2) Electrical wiring

1> Verify actuator voltage matches supply power.

2> Wiring diagram is supplied together with actuator. (In vinyl pack or inside of top cover).

3> Complete the wiring as per the given wiring diagram.

4> Supply electric power to heater for keeping inside of actuator clean and dry of condensation.

4> Make sure that one relay operates one actuator only ( Cannot operate two or more actuators with one relay)

Electrical wiring should be performed by properly licensed personnel.

6. Simple trouble shooting

Trouble Cause Counter plan

Actuator doesn’t work at

all

Wiring is not correct and tight or loosen Do wiring again tightly

Setting of limit and torque switch is not correct Do setting switches again

Check if power is on Power on

Check if voltage is too low Check power

Motor and supplied power is different Check motor power and supplied power

Coil of motor is damaged Change the motor

Capacitor is damaged Change the capacitor

7. After sales service

1) Do not disassemble actuator, if actuator is disassembled in any way warranty is void.

2) Jomar warranties it actuators to be free of factory defects for a period of one year from date of purchase.

8. Mechanical Travel Stop Adjustment

The mechanical travel stops, located under the conduit entries, must be adjusted so that the cam cannot travel past

the Limit Switch in either the open or closed position.

(AE 880 and Larger)

AE Series Electric quarter turn actuator

Installation and maintenance manual

Page 4

4/4

9. Manual Override

The AE series Actuators are equipped with a manual override function.

To ENGAGE manual overr ide – Move lever to manual position. (AE 880 and Larger) Actuator must be

idle to engage manual override.

To DISENGAGE manual override – Actuator must be energized (run electrically) to disengage the manual

override. You cannot manually disengage the manual override.

10. Maintenance

1) Lubrication :

Lubrication is performed at the factory level, no further lubrication is required under normal operating

conditions

In very dry condition below 15% RH or temperatures higher th an 140°F, it is required to lubricate once every

two years.

2) Regular operation :

Electrical power always should be supplied to the actuator and should be cycled weekly.

Should you have any further questions, please contact us at your convenience.

AE Series Electric quarter turn actuator

Installation and maintenance manual

Loading...

Loading...