www.jokabsafety.com

6:6

www.jokabsafety.com

Safety relay

RT6

Approvals:

TÜV Nord

Safety relay for:

Emergency stops

Light curtains

Three position devices

Interlocked gates/hatches

Magnetic switches

Light beams

Safety mats

Contact strips

Foot operated switches

Would you like a single safety relay for all your

safety applications?

Then choose the RT6 universal relay to supervise both your

safety devices and the internal safety of your machinery. In

addition you can select the safety level required for each installation. All this is possible because the RT6 has the most

versatile input option arrangement available on the market.

Many other relays can therefore be replaced by the RT6.

The relay also comes with other options such as manual

or automatic reset. Manual supervised reset can be used

for gates and other safety devices that can be bypassed.

Automatic reset can be used for small hatches, if deemed

acceptable from risk assessment.

The RT6 also has information outputs that follow the inputs

and outputs of the relay. These outputs will for example

indicate if a gate is open or closed and if the safety relay

needs to be reset.

The RT6 is designed with a minimum amount of

components thus keeping both production costs and

component acquisitions to a minimum.

Choose the RT6 to simplify your safety circuits and reduce

your costs.

Features:

Five input options

Single or dual channel input

Manual supervised or automatic reset

Test input for supervision of

external contactors

Width 45 mm

LED indication of supply,

inputs, outputs, short-circuit

and low voltage level.

3 NO/1 NC relay outputs

Two voltage free transistor

information outputs

Supply 24 VDC, 24, 48, 115

or 230 VAC

Quick release connector

blocks

www.jokabsafety.com

6:7

Technical information - RT6

Inputs

The inputs from the safety devices must be connected according

to one of the following options in order to fulfill the expected safety

level and to avoid unsafe situations.

Single channel, 1 NO contact from +24 V DC, 1. category 1,

up to PL c

Dual channel, 2 NO contacts from +24 V DC, 2. category 3,

up to PL d

Dual channel 1 NO, 1 NC contact from +24 V DC, 3.

category 4, up to PL e

Dual channel, 1 NO contact from 0V and 1 NO contact 4.

from +24 V DC, category 4, up to PL e

Safety mats/contact strips 1 ‘contact’ from 0V and 1 5.

‘contact’ from +24 V DC, category 3, up to PL d

When the input /inputs are activated and the test /super vised reset

is complete, relays 1 and 2 are energized. Simultaneous activation

is not required where there are dual channels. The two relays are

de-energized when the input/inputs are de-activated in accordance with the input option chosen or in case of a power failure.

Relays 1 and 2 must both be de-energized before the outputs can

be activated again.

Transistor output status information

The RT6 has two voltage free transistor outputs that can be connected to a PLC, computer or other monitoring device. These

outputs give the input and output status of the relay.

Indication of low voltage

The ‘On’ LED will flash if the relay supply voltage falls below an

acceptable level. This indication will also be given if a monitored

safety mat/contact strip is actuated. See connection option 5.

Safety level

The RT6 has internal dual and supervised safety functions. A

short-circuit, internal faulty component or external interference

will not present a risk to options with the highest safety level. A

manual reset requires that the reset input is closed and opened

before the safety relay outputs are activated. A short-circuit or a

faulty reset button is consequently supervised.

When the RT6 is configured for dual channel input, both the

inputs are supervised for correct sequence operation before the

unit can be reset.

The input options 3 and 4 have the highest safety levels as all

short-circuits and power failures are supervised. This in combination with internal current limitation makes the relay ideal for

supervision of safety mats and contact strips.

Regulations and standards

The RT6 is designed and approved in accordance with appropriate directives and standards. See technical data.

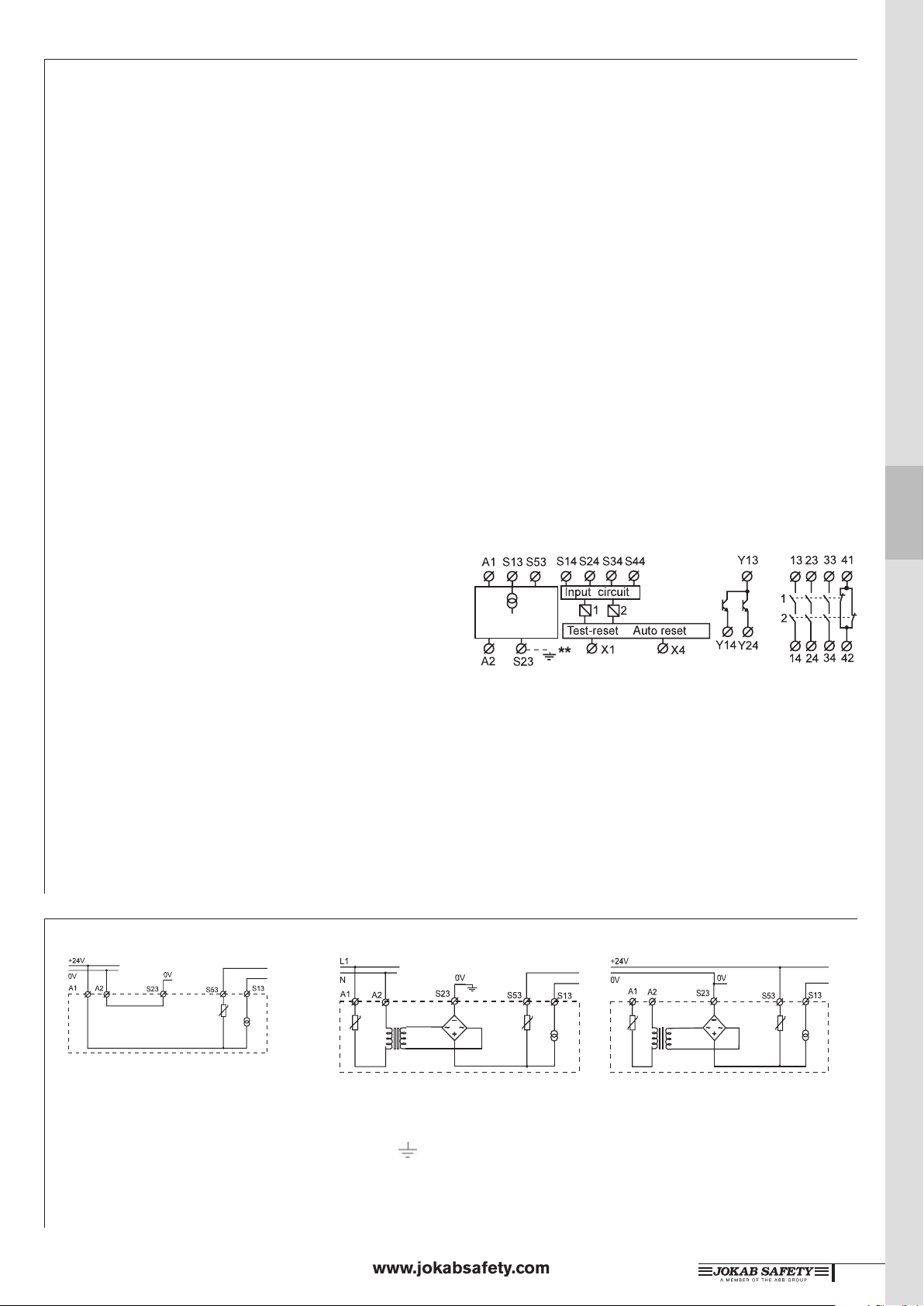

Connection examples

For examples of how our safety relays can solve various safety

problems, see the section “Connection examples”.

1

2

3

4

5

6

Reset and testing

The RT6 has two reset options� manual and automatic. The ma-has two reset options� manual and automatic. The ma- two reset options� manual and automatic. The manual supervised reset is used when the RT6 is monitoring safety

devices that can be bypassed, i.e. to ensure that the outputs of the

safety relay do not close just because a gate is closed. The automatic reset should only be used if deemed an acceptable risk.

In addition, the RT6 can also test (supervise) whether, for example, contactors and valves etc are de-energized/de-activated

before a restart is allowed.

Connection of supply - RT6

DC supply

AC supply

7

**Only for AC supply

8

9

10

DC-supply of AC-units

11

The RT6 DC option should be supplied

with +24 V on A1 and 0 V on A2.

The RT6 AC option should be supplied

with the appropriate supply voltage via

connections A1 and A2.

The S23/ must be connected to protective earth.

All AC-units can also be supplied by

+24 VDC to S53 (0VDC to S23).

NOTE!

With both DC and AC modules, if cable

shielding is used this must be connected

to an earth rail or an equivalent earth

point.

12

13

14

www.jokabsafety.com

6:8

www.jokabsafety.com

Connection of safety devices - RT6

1. SINGLE CHANNEL, 1 NO from +24V

3. DUAL CHANNEL, 1 NO, 1 NC from

+24V

5. Safety mat/Contact strip

The input (contact to S14) must be closed

before the outputs can be activated. When

the input contact is opened the relay safety

output contacts open.

2. DUAL CHANNEL, 2 NO from +24V

Both input contacts (S14 and S34) must

be closed before the relay outputs can be

activated. The safety relay contacts will

open if one or both of the input contacts

are opened. Both the input contacts must

be opened and reclosed before the relay

can be reset. A short-circuit between inputs

S14 and S34 can only be supervised if the

device connected to the inputs has short-

circuit supervised outputs, e.g. JOKAB

Focus light curtains.

Reset connections - RT6

One input contact must be closed (S14) and

one opened (S44) before the relay outputs

can be activated. The safety relay contacts

will open if one or both of the inputs

change state or in case of a short-circuit

between S14 and S44. Both inputs must

return to their initial positions before the

relay outputs can be reactivated.

4. DUAL CHANNEL, 1 NO from +24V,

1 NO to 0V

Relay functions as for option 2, but a shortcircuit, in this case between inputs S14

and S24, is supervised (safety outputs

are opened).

Both ‘contact’ inputs from a inactivated

safety mat/contact strip must be made in

order to allow the RT6 relay outputs to be

activated. When the safety mat/contact

strip is activated or a short-circuit is detected

across S14-S23, the relay will de-energize

(safety outputs open) and the ‘ON’ LED

will flash. As output S13 has an internal

current limit of 70 mA, the RT6 will not be

overloaded when the mat/contact strip is

activated or a short-circuit is detected.

Manual supervised reset Automatic reset

*

*connected to S13 for safety mat/

contact strip

The manual supervised reset contact con-

nected to input X1 must be closed and

opened in order to activate the relay out-

puts.

Automatic reset is selected when S53,

X1 and X4 are linked. The relay outputs

are then activated at the same time as

the inputs.

Output connections - RT6

Relay outputs

The RT6 has three (3 NO) safety outputs

and 1 NC information output.

In order to protect the output contacts

it is recommended that loads (inductive)

are suppressed by fitting correctly chosen

VDR’s, diodes etc.

Diodes are the best arc suppressors,

but will increase the switch off time of

the load.

Transistor outputs

The RT6 has two(2) voltage free transistor

outputs for information.

The transistor outputs are supplied with

voltage to Y13, either from S53 (+24V)

or an external 5-30 VDC supply. Y14 and

Y24 follow the relay inputs and outputs

as follows:

• Y14 becomes conductive when the relay

input conditions are fulfilled.

• Y24 becomes conductive when both the

output relays are activated.

Testing external contactor status

Contactors, relays and valves can be

supervised by connecting ‘test’ contacts

between S53 and X1. Both manual supervised and automatic reset can be used.

***NOTE

These outputs are only for information

purposes and must not be connected to

the safety circuits of the machinery.

www.jokabsafety.com

6:9

Technical data - RT6

Manufacturer ABB AB/Jokab Safety, Sweden

Article number/Ordering data

RT6 24DC 2TLJ010026R0000

RT6 24 AC 2TLJ010026R0200

RT6 115 AC 2TLJ010026R0400

RT6 230 AC 2TLJ010026R0500

Colour Black and beige

Weight 335 g (24 VDC)

485 g (24-230 VAC)

Supply

Voltage (A1-A2) 24 VDC +15/-20%,

24 /4 8/ 115 /2 30 VAC,

+15/-10%, 50-60 Hz

Power consumption

DC supply, nominal voltage 2,3 W

AC supply, nominal voltage 5,2 VA

Connection S13

Short-circuit protected voltage output, 70 mA ± 10% current

limitation. Is used for the inputs S14, S34 and S44.

Connection S53

Short-circuit protected voltage output, internal automatic fuse

270 mA. Is used for the reset and autoreset inputs X1 and X4

Connection S23

0V connection for input S24

Safety inputs

S14 (+) input 20 mA

S24 (0V) input 20 mA

S34 (+) input 20 mA

S44 (+) input 30 mA

Reset input X1

Supply for reset input + 24VDC

Reset current 300 mA current pulse at

contact, then 30 mA

Minimum contact closure time

for reset 100 ms

Maximum external

connection cable resistance

at nominal voltage for

S14, S24, S34 300 Ohm

S44, X1 150 Ohm

Response time

At Power on DC/AC <90ms/<220ms

When activating (input-output) <20 ms

When deactivating (input–

output) <20 ms

At Power Loss <150 ms

Relay outputs

NO 3

NC 1

Maximum switching capacity

Resistive load AC 6A/250 VAC/1500 VA

Inductive load AC AC15 240VAC 2A

Resistive load DC 6A/24 VDC /15 0 W

Inductive load DC DC13 24VDC 1A

Maximum total switching capacity

Resistive load 12A distributed on all contacts

Minimum load 10mA/10 V (if load on contact

has not exceeded 100 mA)

Contact material Ag+Au flash

Fuses Output (External) 5A gL/gG

Conditional short-circuit

current (1 kA) 6A gG

Mechanical life >1 07 operations

Transistor outputs Short-circuit proof

External supply to Y13 +5 to +30 VDC

Y14 Indicates that the input

conditions have been fulfilled

Y24 Indicates that the output relays

are activated

Maximum load of Y14, Y24 15 mA /output

Maximum voltage drop at

maximum load 2.4 V

LED indication

On

In1 In2

1 2

Mounting

Rail 35 mm DIN rail

Connection blocks

(detachable)

Maximum screw torque 1 Nm

Maximum connection area:

Solid conductors 1x4mm2/2x1,5mm2/12AW G

Conductor with socket contact 1x2 ,5mm2/2x1m m

Protection class

Enclosure IP 40 IEC 60529

Connection blocks IP 20 IEC 60529

Operating temperature range -10°C to + 55°C (with no icing

Operating humidity range 35% to 85%

Impulse Withstand Voltage 2.5kV

Pollution Degree 2

Performance (max.)

The relays must be cycled at

least once a year.

Conformity 2006/42/EC, 2006/95/EC,

Connector blocks are detachable

(without cables having to be disconnected)

Supply voltage OK, the LED

is on. Flashing light in case of

under-voltage or overload

Indicates that the input

conditions are fulfilled.

Indicates that the output relays

are activated.

2

or condensation)

Category 4/PL e

(EN ISO 13849-1:2008)

SIL 3 (EN 62061:2005)

PFHd 9.55E-09

2004/108/EC

EN 954-1:1996,

EN 62061:2005

EN ISO 13849-1:2008

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Loading...

Loading...