John Wood Water Heater Installation And Operating Instructions Manual

ATMOSPHERIC VENTED WATER HEATER

WARNING:

Improper installation, adjustment, alteration, service, or maintenance can cause

injury or property damage. Refer to this

manual. For assistance or additional information, consult a qualified installer, service agency, or the gas utility.

FOR YOUR SAFETY

• Do not store or use gasoline or other

flammable vapours and liquids in the

vicinity of this or any other appliance.

• Installation and service must be performed by a qualified installer, service

agency or the gas utility.

INSTALLATION AND

OPERATING INSTRUCTIONS

Read these instructions thoroughly before starting

WARNING:

If the information in these instructions is

not followed exactly, a fire or explosion

may result causing property damage, personal injury or death.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

PART NO. 324331-000 Rev. 01 (13-04)

TABLE OF CONTENTS

I) INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . .3

User Responsibilities 3

II) SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

For Installations in Canada 3

For Installations in the United States 3

Safety Warning (Flammable Vapours) 4

Safety Warning (Scalding) 4

Safety Warning (Carbon Monoxide) 4

Relief Valves (T&P) 4

Backflow Prevention 4

III) INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Unpacking the Water Heater 5

Location Requirements 5

In Earthquake Zones

Clearances and Accessibility 5

Gas Supply 6

Gas Pressure

Gas line purging

Gas Leak Testing

Air Requirements 8

Confined Space Air Requirements for Canadian

Installations 8

Confined Space Air Requirements for U.S.

Installations 9

Exhaust Venting 10

Vent Pipe System

Check for proper vent size

Drafthood Installation

Water Supply 10

Piping Installation

Union Connections

Mixing Valves 11

Closed System/Thermal Expansion

Temperature and Pressure (T&P) Relief Valve 12

The Temperature And Pressure Relief Valve:

The Discharge Line:

Electrical Supply 13

24 Volt Control precautions

Installations Check 14

IV) OPERATING INSTRUCTIONS. . . . . . . . . . . . . . . .14

Water Temperature Regulation 14

Temperature Adjustment

Lighting Instructions (White-Rodgers 37C) 16

Lighting Instructions (Honeywell 24 Volt) 17

V) OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Burner Flames 18

Emergency Shut Down 18

Checking the Draft 18

Operating Conditions 18

Condensation

Water Heater Sounds

Safety Shut-off

Anode/Water Odour

Water Heater Operation (24 Volt only) 19

System Error Codes for 24 Volt Controls

VI) MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Periodic Cleaning of the Wrap-around Filter 21

Draining and Flushing 21

Periodic Inspection 21

External Cleaning of the Flame-arrestor 21

Temperature and Pressure Relief Valve 22

Resetting and Replacing the Safety (TCO)

Switch (NG models) 22

Replacing the Thermocouple (TCO)

Assembly (LP models) 22

24 Volt Honeywell Control Service 23

Electronic Control Module Replacement

Valve Module Replacement

Temperature Sensor and Cable Replacement

VII) COMBO HEATING . . . . . . . . . . . . . . . . . . . . . . . . . 25

System Requirements 25

VIII) TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . .26

IX) REPAIR PARTS ILLUSTRATION . . . . . . . . . . . . .28

LIMITED WARRANTY . . . . . . . . . . . . . . . . . . . . . .31

RETAIN THESE INSTRUCTIONS IN A SAFE LOCATION FOR FUTURE REFERENCE

– 2 –

Your safety and the safety of others is very important.

We have provided many important safety messages in this manual and on your appliance.

Always read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word

“DANGER” or “WARNING”.

DANGER

You can be killed or seriously injured if you don’t immediately follow

instructions.

WARNING

You can be killed or seriously injured if you don’t follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the

chance of injury, and tell you what can happen if the instructions are not followed.

I) INTRODUCTION

We thank you for choosing a Flammable Vapour

Resistant Water Heater. Your satisfaction with this product

is very important to us. This gas-fired water heater has been

developed to produce domestic hot water and may also be

used in combination with space heating applications but

not space heating only. The Flame GuardTM safety system

is designed to reduce the risk of flammable vapour related

fires by trapping the burning vapours within the water heater

combustion chamber using the special flame arrestor. The

burning vapours literally “burn themselves out” without

escaping back into the room.

User Responsibilities

These instructions have been written for the proper installation, safe operation and maintenance of this water heater.

It is your responsibility to ensure that your water heater is

properly installed and cared for.

FAILURE TO FOLLOW THE INSTRUCTIONS IN THIS

MANUAL MAY RESULT IN SERIOUS BODILY INJURY

AND/OR PROPERTY DAMAGE. THOROUGHLY READ

ALL INSTRUCTIONS BEFORE YOU ATTEMPT TO

INSTALL, OPERATE OR MAINTAIN THIS HEATER.

Installation and service requires trade knowledge in the area

of plumbing, electricity, venting, air supply and gas supply. If

you lack these skills or do not understand these instructions,

enlist the help of a qualified professional.

The manufacturer of this water heater cannot be held liable

for those damages caused by improper installation, sizing or

failure to comply with these instructions.

Protect your warranty: Regularly maintain your water

heater and venting system as detailed in the “Maintenance”

section of this manual.

WARNING

Service to the Flame Guard

TM

safety system

should only be performed by a qualified service technician.

II) SAFETY

This water heater is design-certified by CSA International as

a Category I, non-direct vented water heater which takes its

combustion air either from the installation area or from air

ducted to the unit from the outside.

In addition to the installation instructions found in this manual, the heater shall be installed according to all local and

provincial or state codes and with the latest edition of the

following specifications.

For Installations in Canada

"Natural Gas and Propane Installation Code" CSAB149.1 and "Canadian Electrical Code (CAN/CSA C22.1),

Part I" available from:

Canadian Standards Association,

5060 Spectrum Way,

Mississauga, Ontario, Canada

L4W 5N6

For Installations in the United States

"National Fuel Gas Code" ANSI Z223.1 (NFPA 54) and

"National Electrical Code" (NFPA 70)" available from:

American National Standards Institute,

25 West 43rd Street,

New York, NY 10036

Massachusetts code requires this water heater to be

installed in accordance with Massachusetts Plumbing and

Fuel Gas Code 248 CMR Section 2.00 and 5.00.

Check your phone listings for the local authorities having

jurisdiction over your installation.

Important: All supply equipment, installation, approvals,

permits, inspections, etc. are the responsibility of the owner

of this water heater. Consult your local authorities for regulations specific to your area.

– 3 –

Safety Warning (Flammable Vapours)

WARNING

FLAMMABLES

FIRE AND EXPLOSION HAZARD

Can result in serious injury or death

Do not store or use gasoline or other flammable vapours and liquids

in the vicinity of this or any other appliance. Storage of or use of gasoline

or other flammable vapours or liquids in the vicinity of this or any other

appliance can result in serious injury or death.

There is a risk in using fuel-burning appliances such as

water heaters. Areas that may not be suitable for water

heater installation include those where flammable liquids,

gasoline, solvents, adhesives, etc., or engine-driven equipment or vehicles are stored, operated or repaired. Due to

the nature of air movement, flammable vapours can be carried some distance from the point of storage. The gas-fired

water heater igniter or main burner flame can ignite these

vapours causing a flashback, fire or explosion which may

result in serious personal injury or death, as well as severe

property damage.

Safety Warning (Scalding)

Flammable Vapours

DANGER

result in serious bodily harm or death from asphyxiation.

MAKE SURE THE FLOW OF COMBUSTION AND

VENTILATION AIR IS NOT RESTRICTED.

DANGER

Carbon Monoxide Warning

• Follow all vent system requirements by

the local authorities having jurisdiction

over your installation.

• Failure to do so can result in death, explosion or carbon monoxide poisoning.

Relief Valves (T&P)

All water heaters must be installed with a proper temperature and pressure relief valve. These valves must be

certified as meeting the requirements of the “Standard

for Temperature, Pressure, Temperature and Pressure

Relief and Vacuum Relief” CSA 4.4 in Canada. In the

United States “Relief Valves and Automatic Gas Shut-Off

Devices for Hot Water Supply Systems”, ANSI Z21.22 is

applicable.

If this water heater has been exposed to flooding, freezing,

fire or any unusual condition, do not put it into operation until

it has been inspected and approved by a qualified professional. THESE CONDITIONS CAN RESULT IN UNSEEN

INTERNAL DAMAGE which is not subject to warranty

coverage.

Backflow Prevention

Certain jurisdictions may require the installation of a backflow device (e.g., check valve) in the water supply line. Such

a device will require the use of a system expansion tank of

adequate size to control the thermal expansion generated

during the heating cycle. Consult your water supplier or local

plumbing authority.

Important: The supply water meter may have a built-in

check valve device. Contact your local water authority.

Hot water produced by this appliance can cause severe

burns due to scalding. The hazard is increased for young

children, the aged or the disabled where water temperatures

exceed 52°C (125°F). Use tempering valves (see Figure

11), in the hot water system to reduce the risk of scalding

at point-of-use such as lavatories, sinks and bathing facilities. Such precautions must be followed when this heater is

operated in combination with dishwashing or space heating

applications.

Safety Warning (Carbon Monoxide)

As with all fuel burning equipment, this heater requires an

adequate supply of air for combustion and ventilation. An

insufficient air supply can result in poor combustion or the

re-circulation of the exhaust flue gases. Such a condition

can cause soot build-up or present a fire hazard, and may

– 4 –

CAUTION

Hydrogen gas can be produced in a hot water system

served by this heater that has not been used for a

long period of time (generally two (2) weeks or more).

Hydrogen gas is extremely flammable and can ignite

when exposed to a spark or flame. To reduce the risk

of injury under these conditions, it is recommended that

the hot water faucet be opened for several minutes at the

kitchen sink before using any electrical appliance connected to the hot water system. Use caution in opening

faucets. If hydrogen is present, there will probably be an

unusual sound such as air escaping through the pipe as

the water begins to flow. There should be no smoking or

open flame near the faucet at the time it is open.

III) INSTALLATION

Unpacking the Water Heater

WARNING

Excessive Weight Hazard

• How and where to obtain combustion and ventilation air

• Routing and support of the vent piping.

• Position of water supply and placement of water piping

• Floor drain and service.

Use two or more people to move and install

water heater. Failure to do so can result in

back or other injury.

Important: Do not remove any permanent instructions,

labels or the rating plate from the outside of the water heater

or on the inside of panels.

1. Move the water heater to the location of installation

before removing the exterior packaging.

2. Remove exterior packaging and place installation components aside.

3. Inspect all parts for damage prior to installation and

start-up.

4. Completely read and understand all instructions before

attempting to assemble and install this product.

If you observe damage to the water heater or any of its components, DO NOT ASSEMBLE OR INSTALL IT OR MAKE

ANY ATTEMPT TO FIX THE DAMAGED PART(S). Contact

the place of purchase for further instructions.

5. After installation, dispose of packaging material in the

proper manner.

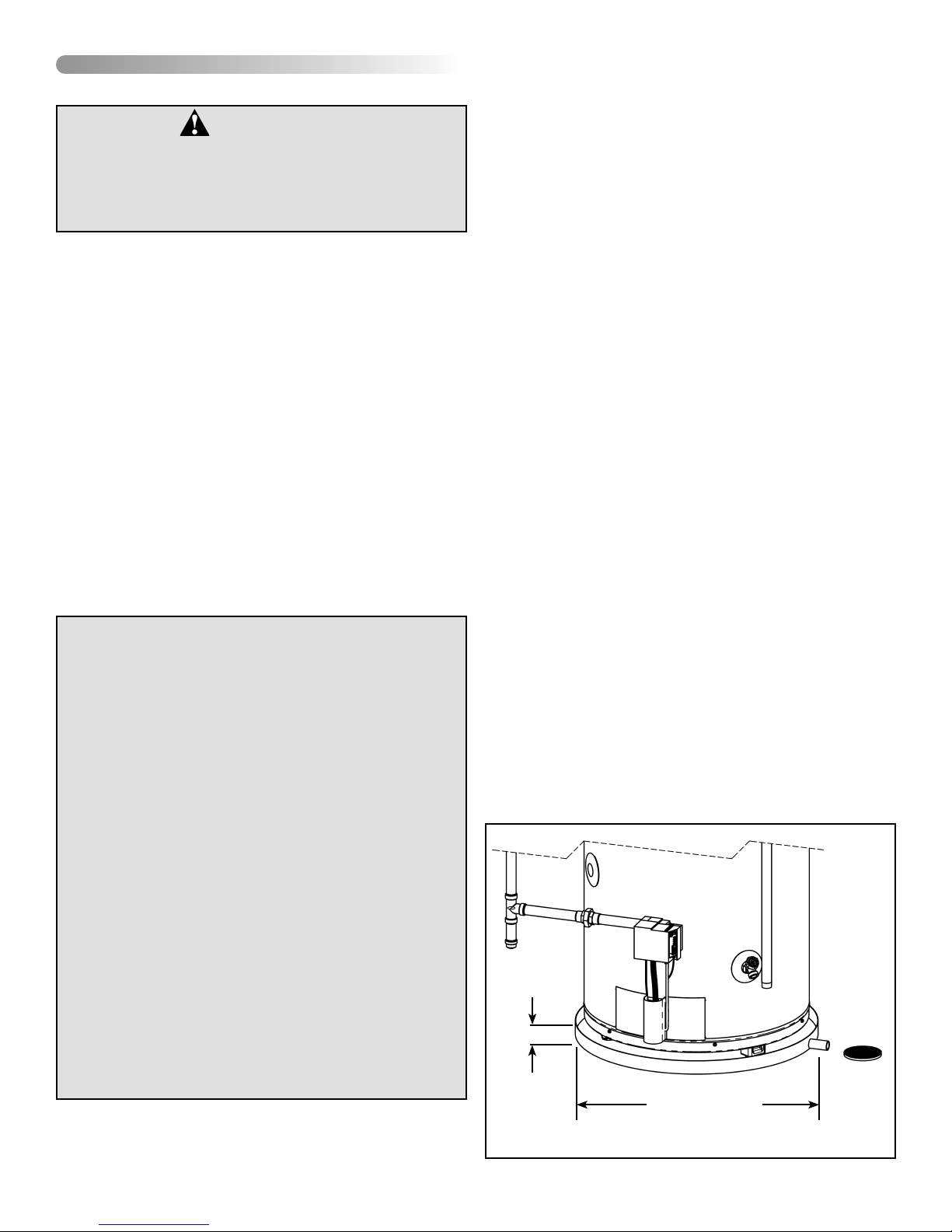

Location Requirements

IMPORTANT:

This water heater must be installed strictly in accordance

with the instructions enclosed, and local electrical, fuel

and building codes. It is possible that connections to the

water heater, or the water heater itself, may develop leaks.

IT IS THEREFORE IMPERATIVE that the water heater be

installed so that any leakage of the tank or related water

piping is directed to an adequate drain in such a manner

that it cannot damage the building, furniture, floor covering, adjacent areas, lower floors of the structure or other

property subject to water damage. This is particularly

important if the water heater is installed in a multi-story

building, on finished flooring or carpeted surfaces. THE

MANUFACTURER WILL NOT ASSUME ANY LIABILITY

for damage caused by water leaking from the water heater,

pressure relief valve, or related fittings. Select a location

as centralized within the piping system as possible. In any

location selected, it is recommended that a suitable drain

pan be installed under the water heater. This pan must

limit the water level to a MAXIMUM depth of 45mm (1 3/4

in.) and have a diameter that is a minimum of 50mm (2

in.) greater than the diameter of the water heater. Suitable

piping shall connect the drain pan to a properly operating

floor drain. When used with a fuel-fired heater, this drain

pan must not restrict combustion air flow.

Note: Before installing this water heater, consideration and

planning must be given to the following details:

In Earthquake Zones

Note: The water heater must be braced, anchored, or

strapped to avoid moving during an earthquake. Contact

local utilities for code requirements in your area.

Note: REVIEW SAFETY WARNINGS FOUND IN THE

FRONT OF THIS MANUAL BEFORE PROCEEDING

Clearances and Accessibility

Specific clearance locations are shown in Figure 3. A minimum of 600mm (24 in.) of front clearance shall be provided

for inspection and service. We recommend that 0.9m (36 in.)

above be maintained for serviceability.

Locate the water heater such that all controls are easily

accessible, and the rating plate is visible.

Clearance to combustibles varies by model. Refer to rating

plate to confirm clearances.

Heaters with a volume of 19 gallons through 50 gallons and

60 gallon (standard input) must have the following minimum

clearances to combustibles:

Front 102mm (4 in.)

Sides and Rear 25mm (1 in.)

Top 203mm (8 in.)

Flue 152mm (6 in.)

JW6058 and G6058 (high input) series heaters must have

the following minimum clearances to combustibles:

Front 127mm (5 in.)

Sides and Rear 25mm (1 in.)

Top 203mm (8 in.)

Flue 152mm (6 in.)

• Location and Clearances.

• Access for gas supply; See “Gas Supply”.

– 5 –

supply; See “Air Requirements”.

for hot and cold water; See “Water Supply”.

45mm

(1 3/4 in.)

MAX

AT LEAST 50mm (2 in.)

GREATER THAN THE

DIAMETER OF THE

WATER HEATER.

Figure 1 Typical Drain Pan Installation

PIPE TO

ADEQUATE

DRAIN

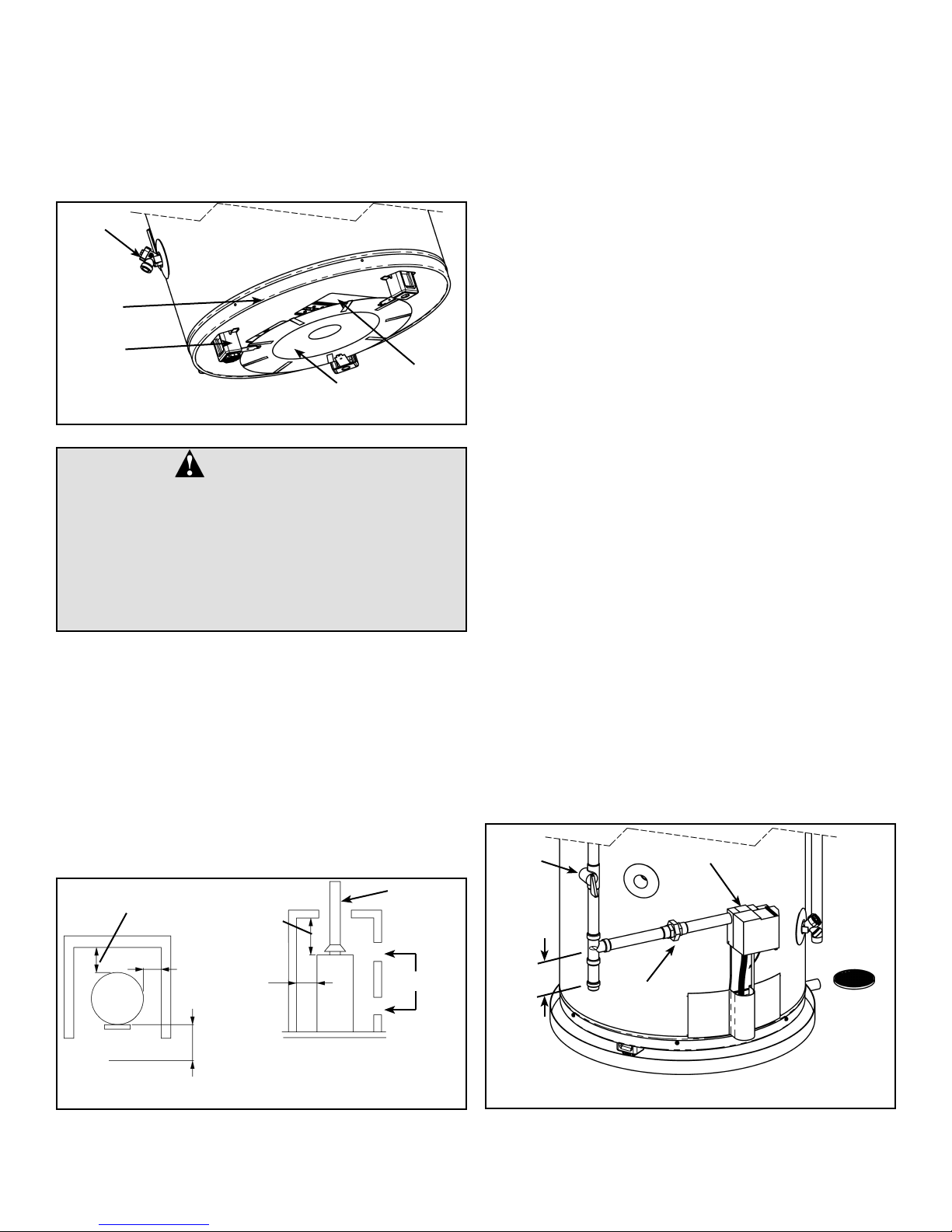

The 60 gallon heater is equipped with a Heat Reflector

Shield (see Figure 2). This Shield reflects heat from the

High-input heaters to prevent damage to combustible floors.

The Shield is held in place by three (3) tabs that rest on the

inside of the legs of the water heater. Ensure the Shield is

positioned horizontally (parallel to the bottom of the heater)

and in the designated position of 38mm (1.5 in.) below the

flame-arrestor.

DRAIN

VALV E

BOTTOM

PAN

LEG

FLAME

HEAT SHIELD

ARRESTOR

Figure 2 Heat Shield Installation (60 gallon only)

WARNING

Do not install directly on carpet. Instead, place the

water heater on a metal or wood panel extending a

minimum of 75mm (3 in.) from all sides. In alcoves

or closets, cover the carpet completely. Ensure this

panel is capable of supporting the weight of this

heater when filled with water.

FAILURE TO PROPERLY INSTALL THIS HEATER MAY

RESULT IN A FIRE HAZARD.

The water heater shall be located in an area not subject

to freezing temperatures. Water heaters located in unconditioned spaces (e.g., attics, basements, etc.) may require

insulation of the water and drain piping to protect against

freezing. Proper ventilation needs to be provided for water

heaters installed in unconditioned spaces (e.g., attics, basements, etc.) in order to avoid an event where air temperature exceeds 42°C (108°F). The drain and controls must be

easily accessible for operation and service. Maintain proper

clearances as specified on the data plate.

Ensure that the water heater is level. This heater may be

installed in a closet or alcove and is certified for operation

on a combustible floor.

VENT

BACK 25mm (1 in.)

TOP TO CEILING

200mm (8 in.)

affect the proper operation of the water heater. Special

attention must be given to conditions these devices may

create. Flow reversal of flue gases may cause an increase

of carbon monoxide inside of the dwelling, as shown in

Figure 7.

If the water heater is located in an area that is subject to

an excessive amount of lint, dirt or oil, it may be necessary

to clean the flame arrestor periodically (see “Maintenance”

section).

Important: It is always recommended that a suitable drain

pan be installed under the water heater to protect the area

from water damage resulting from normal condensation, a

leaking tank or piping connections. Refer to Figure 1. Under

no circumstances is the manufacturer to be held responsible

for any water damage in connection with this water heater.

Gas Supply

Install the gas piping as shown in Figure 4. Use only new

pipe and fittings with clean-cut threads. Sealing compounds

used on the pipe threads shall be approved for use with

natural and propane gas.

Use gas piping of adequate sizing to ensure gas input.

Gas piping material must be approved for use with natural gas and propane fuels. All piping must comply with all

local codes and with the latest edition of “Natural Gas

and Propane Installation Code” CSA-B149.1 in Canada,

“National Fuel Gas Code” ANSI Z223.1 (NFPA 54) in the

U.S.A. The final connection to the water heater is made

using 1/2” NPT.

Before connecting to the gas service, check that a properly

sized gas meter and regulator are available to service the

water heater. If other appliances are using the same meter

and regulator, ensure that the capacity of the meter and

regulator matches that of the combined input of all appliances connected to it.

DO NOT tamper with the gas control/thermostat, igniter,

thermocouple, or temperature and pressure relief valve.

Tampering voids all warranties. Only a qualified service

technician should service these components.

MANUAL

GAS

SHUT-OFF

GAS CONTROL/THERMOSTAT

SIDES

25mm

(1 in.)

SIDES

AND BACK

25mm (1 in.)

FRONT 600mm

(24 in.) MIN.

FOR SERVICE

Figure 3 Minimum Clearance Locations

Do not locate the water heater near an air-moving device.

The operation of air-moving devices such as exhaust fans,

ventilation systems, clothes dryers, fireplaces, etc., can

– 6 –

AIR INTAKE

75mm (3 in.)

GROUND-

JOINT UNION

Figure 4 Recommended Gas Piping

Gas Pressure

WARNING

Exposure to a higher gas supply pressure

may cause damage to the control, resulting

in explosion or fire. Consult your local gas

supplier and gas authorities. DO NOT PUT

INTO SERVICE IF OVER-PRESSURIZATION

HAS OCCURRED.

The Manufacturer recommends that the gas supply pressure, as measured on the inlet side of the water heater

control, be set at 7.0 in. w.c. (1.7 kPa) for natural gas and

11.0 in. w.c. (2.7 kPa) for propane gas. The above pressures

must be measured during water heater operation.

The gas control supplied with this water heater is designed

for a maximum inlet pressure of 0.5 psi (14 in. w.c.). Do

not exceed this limit. The Flame GuardTM safety system is

designed to operate within the pressure ranges shown in

Table 1. Rated manifold pressures are indicated on the rating plate of the water heater.

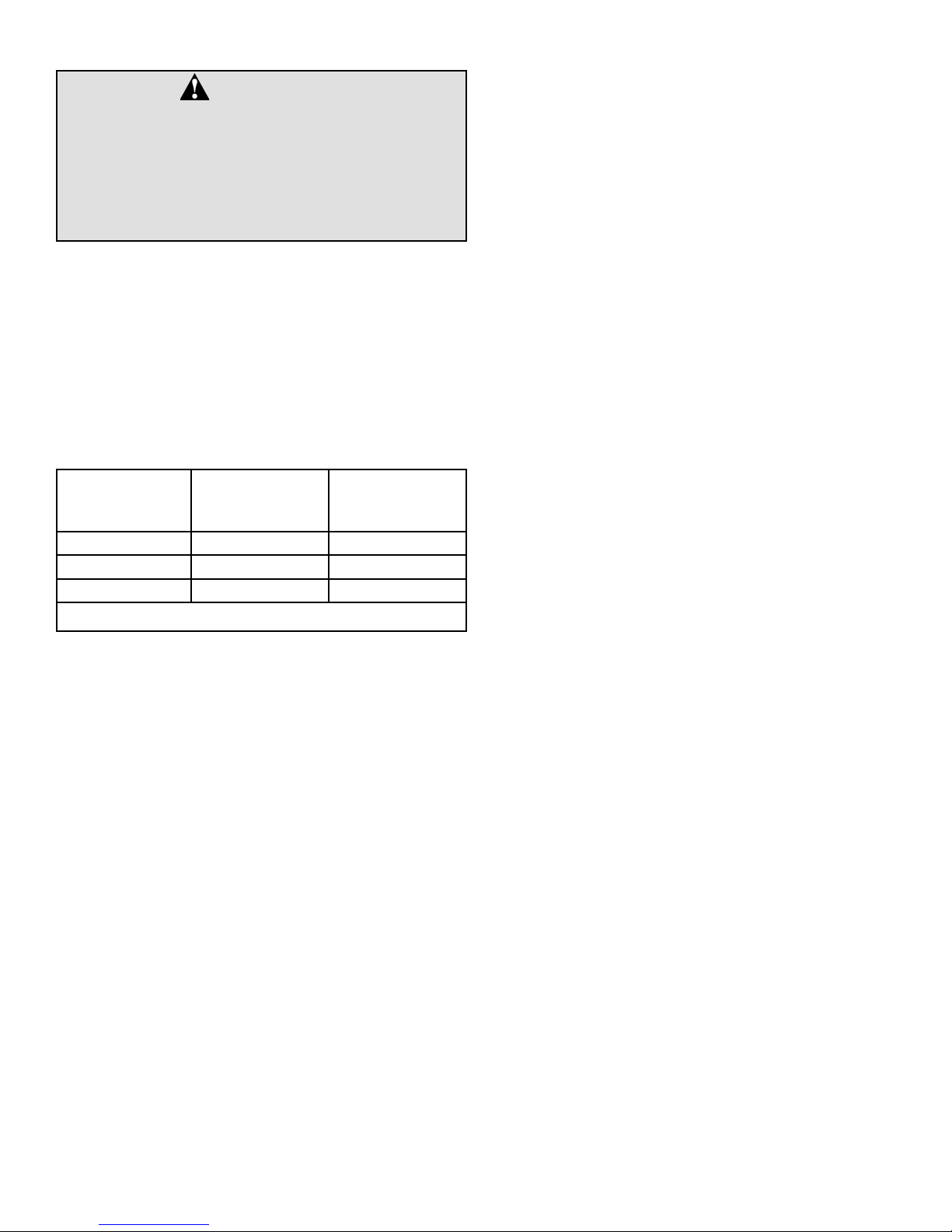

Rated Manifold

Pressure.

in. w.c. (kPa)

10 (2.48) 9.2 (2.28) 10.2 (2.53)

5 (1.24) 4.5 (1.11) 5.1 (1.26)

4 (0.99) 3.6 (0.89) 4.4 (1.09)

Min. Manifold

Pressure.

in. w.c. (kPa)

Max. Manifold

Pressure.

in. w.c. (kPa)

Gas line purging

Gas line purging is required to eliminate air from the piping

system. Purging should be performed by persons experienced in this type of gas service in compliance with the code

having jurisdiction. Do not purge in confined areas or space

where ignition may occur. To avoid risk of fire or explosion

ensure the area is well ventilated and all sources of ignition

are de-activated. Contact your local gas authority for local

requirements.

Gas Leak Testing

Important: This water heater and its gas connection must

be tested for leaks before placing the appliance in operation.

Perform a leak test at normal gas pressure. If the applicable

code(s) require the gas lines to be tested at a pressure of 14

in. w.c. (3.5 kPa) or greater, the water heater and its manual

shut-off valve must be disconnected from the gas supply

piping system and the line capped. Test all connections of

the gas system with a chloride-free soap and water solution

or equivalent leak test liquid. Bubbles will indicate leaks.

Never use a match or open flame to test for gas leaks. A fire

or explosion could result. If leaks exist repair as required

and retest.

DO NOT light the burner before the tank is filled with water

and you have confirmed that there are no leaks in the piping

and connections.

Table 1 Manifold Pressure

– 7 –

Air Requirements

Important: Air for combustion and ventilation must not

come from a corrosive atmosphere. Any failure due to corrosive elements in the atmosphere is excluded from warranty

coverage.

Installations in or for certain places including, but not limited

to, those listed below will require outdoor air for combustion

due to chemical exposure:

• Beauty shops

• Photo processing labs

• Buildings with indoor pools

• Water heaters installed in laundry, hobby or craft rooms

• Water heaters installed near chemical storage areas

(12 in.) equals 450mm (18 in.) as shown in Figure 5 (b).

All exterior vent openings are to be at least 300mm (12

in.) above the ground and clear of snow levels.

(a)

PERMANENT

OPENINGS

CONFINED

SPACE

UNCONFINED

SPACE

In such circumstances, outdoor combustion air may reduce,

but will not eliminate, the presence of corrosive chemicals in

the air. Combustion air must be free of acid-forming chemicals such as sulfur, fluorine and chlorine. These elements

are found in aerosol sprays, detergents, bleaches, cleaning

solvents, air fresheners, paint and varnish removers, refrigerants and many other commercial and household products.

When burned, vapours from these products form highly

corrosive acid compounds. These products should not be

stored or used near the water heater or air inlet.

The area in which the heater is located is classified as either

“an unconfined space” or “a confined space”.

An unconfined space is defined as a space having a vol-

ume not less than 50 cubic feet per 1000 BTU/hour (4.8

cubic metres per kilowatt) of combined input rating of all

appliances using the space. Adjacent open rooms may be

included as part of the unconfined space, provided there are

no closeable doors between these rooms. An example of

this is an open basement.

A confined space is one smaller than described above.

For buildings using tight construction (newer and renovated

structures), the air supply shall be introduced from the

outdoors, regardless of whether the space is confined or

unconfined.

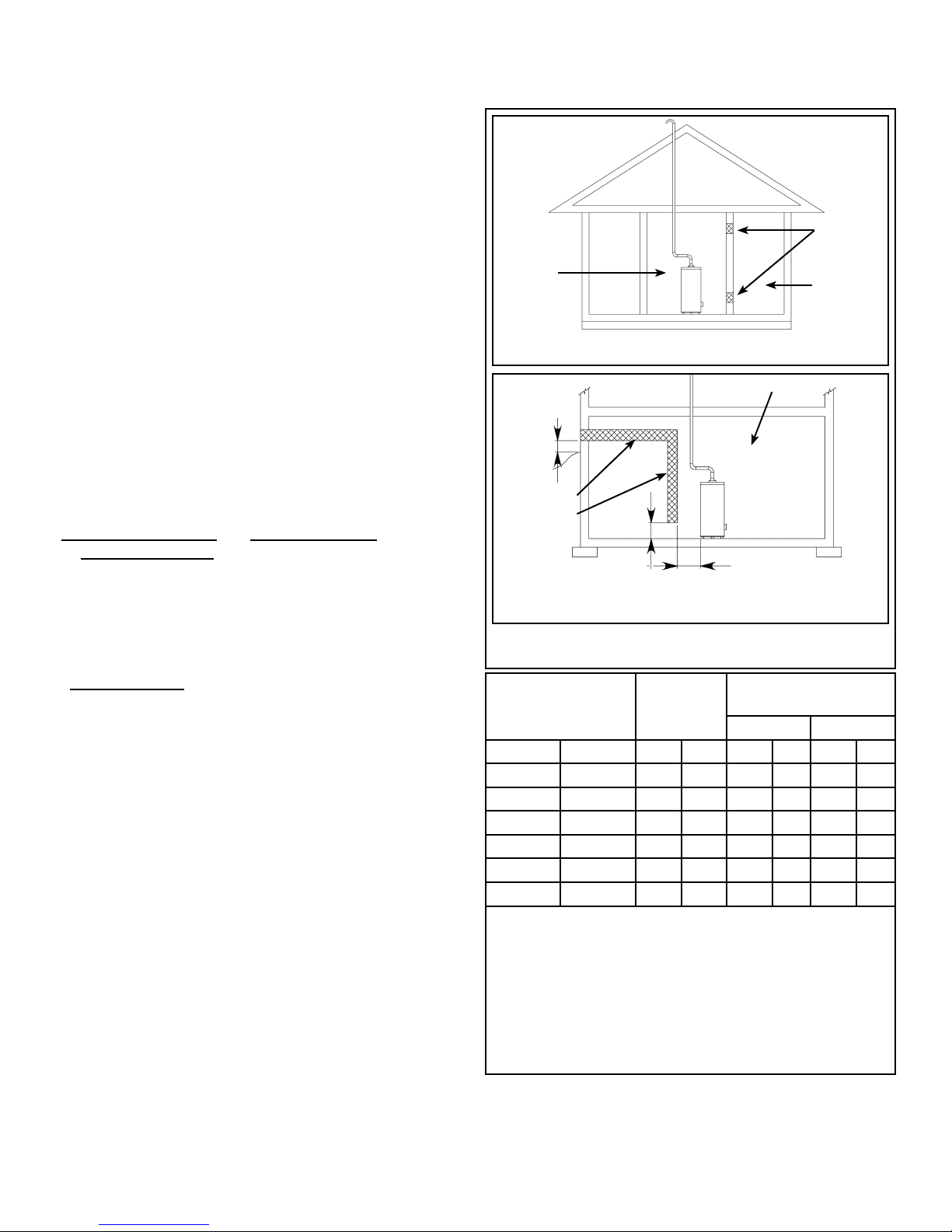

Confined Space Air Requirements for

Canadian Installations

Refer to Figure 5 (a), or (b), and Table 2 for proper sizing

and location of combustion air ducts and openings. CHECK

LOCAL CODES.

(a). Two permanent openings shall be provided connect-

ing the confined space (e.g., closet, small room) with

the unconfined space. Each opening shall have a free

area of one square inch per 1,000 BTU/hour input (22

cm²/kW) of all appliances in the confined space. The

top opening shall be located as close to the ceiling as

practical but never lower than the top of the heater (see

Figure 5 (a)). The bottom opening shall be located neither more than 450mm (18 in.), nor less than 150mm (6

in.), above floor level.

(b). When using a single air supply, the duct shall terminate

within 300mm (12 in.) above and within 600mm (24 in.)

horizontally of the burner level of the appliance having

the largest input. For example: if the water heaters’

burners are 150mm (6 in.) from the floor, plus 300mm

– 8 –

EQUIPMENT LOCATED IN CONFINED SPACES;

ALL AIR FROM INSIDE THE BUILDING.

300mm

(b)

(12 in.)

(MIN)

GRADE

COMBINATION

COMBUSTION/

VENTILATION

AIR DUCT

BASEMENT INSTALLATION, EQUIPMENT LOCATED

IN CONFINED SPACES; ALL AIR FROM OUTDOORS

450mm (18 in.)

CONFINED

SPACE

600mm (24 in.)

Figure 5 Combustion Air Supply Openings And Ducts

(Can.)

Combined Input of

All Appliances in

Confined Space*

Required

Free Area

Acceptable Round

Duct Size Diameter

A** B***

BTU/h (kW/hr) cm2in.2mm in. mm in.

25,000 8 45 7 76 3 100 4

50,000 15 45 7 76 3 100 4

75,000 23 70 11 100 4 125 5

100,000 30 90 14 100 4 125 5

125,000 37 120 18 125 5 150 6

150,000 45 140 22 125 5 150 6

* All appliances refers to, and includes, those appliances

using the same air source (e.g. water heater, furnace,

boiler, clothes dryer etc.).

** Maximum allowable length of ductwork listed in column

A is 6.1 equivalent metres (20 ft.).

*** Maximum allowable length of ductwork listed in column

B is 15.2 equivalent metres (50 ft.)

Table 2 Air Supply Sizing (Can.)

(a)

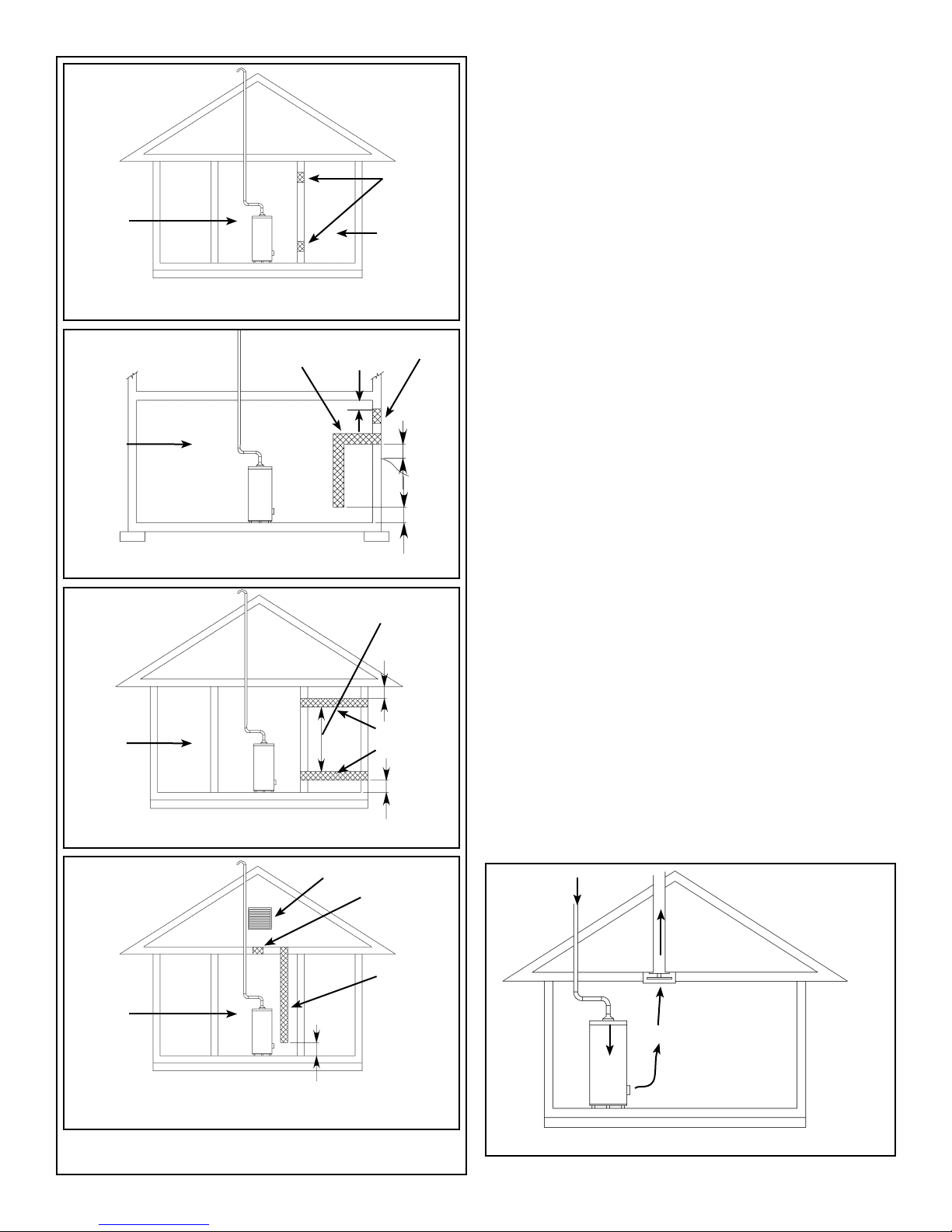

Confined Space Air Requirements for

U.S. Installations

Refer to Figure 6 (a), (b), (c) or (d) for proper sizing and

location of combustion air ducts and openings. CHECK

LOCAL CODES.

CONFINED

SPACE

(b)

CONFINED

SPACE

(c)

CONFINED

SPACE

UNCONFINED

EQUIPMENT LOCATED IN CONFINED SPACES;

ALL AIR FROM INSIDE THE BUILDING.

COMBUSTION

AIR DUCT

BASEMENT INSTALLATION, EQUIPMENT LOCATED

IN CONFINED SPACES; ALL AIR FROM OUTDOORS

EQUIPMENT LOCATED IN CONFINED

SPACES; ALL AIR FROM OUTDOORS.

300mm

(12 in.)

OUTDOORS

AIR DUCT

300mm (12 in.)

VENTILATION

COMBUSTION

300mm (12 in.)

PERMANENT

OPENINGS

SPACE

PERMANENT

VENTILATION

AIR.

300mm

(12 in.)

ABOVE

GRADE

OR

SNOW

LINE

GRADE

300mm

(12 in.)

(a) Equipment located in confined spaces; all air from

inside the building.

Two permanent openings shall be provided connect-

ing the confined space (e.g., closet, small room) with

the unconfined space. Each opening shall have a free

area of one square inch per 1,000 BTU/hour input (22

cm²/kW) of all appliances in the confined space, but not

less than 100 square inches (645 cm²). The top opening shall commence within 300mm (12 in.) of the top of

space and the bottom opening shall commence within

300mm (12 in.) of the bottom of the enclosure.

(b) Basement installation, equipment located in con-

fined spaces; all air from outdoors.

When supplying air directly from the outdoors, each

opening shall have a minimum free area of one square

inch per 4,000 BTU/hour input (5.5 cm²/kW) of total

input rating of all appliances in the confined space. The

inlets shall be a minimum of 300mm (12 in.) above the

grade (snow) line. The top opening shall commence

within 300mm (12 in.) of the top of the confined space.

(c) Equipment located in confined spaces; all air from

outdoors.

When supplying air directly from the outdoors using

horizontal ducting, each opening shall have a free

minimum area of one square inch per 2,000 BTU/hour

(11 cm²/kW) of total input rating of all appliances in the

confined space.

(d) Equipment located in confined spaces; all air from

outdoors through ventilated attic.

When supplying air directly through vertical ducting,

each opening shall have a free minimum area of one

square inch per 4,000 BTU/hour (5.5 cm²/kW) of total

input rating of all appliances in the confined space.

(d)

CONFINED

SPACE

EQUIPMENT LOCATED IN CONFINED SPACES; ALL AIR

FROM OUTDOORS THROUGH VENTILATED ATTIC.

ATTIC LOUVERS TO OUTDOORS

Figure 6 Combustion Air Supply Openings And Ducts

(U.S.A.)

– 9 –

OUTLET

AIR

INLET AIR

300mm (12 in.)

DUCT

EXHAUST

REVERSE

FLOW OF

GASES

Figure 7 Air Moving Devices

FAN

Exhaust Venting

Vent Pipe System

This water heater is a Category 1, non-direct vented appliance. The vent pipe must be sized and installed in accordance with all local and provincial or state codes and with

the latest edition of “Natural Gas and Propane Installation

Code” CSA-B149.1 in Canada, “National Fuel Gas Code”

ANSI Z223.1 (NFPA 54) in the U.S.A.

Check for proper vent size

It is possible that the existing venting system was sized, for

a previous installation, through a common vent. Such an

arrangement is appropriate for venting two appliances such

as the original water heater and a standard vent furnace.

If this is true and the second appliance has been removed

from the existing venting system (such as when the furnace

has been upgraded to a power vent type), the venting system is now supplying only one appliance. This condition is

commonly referred to as “orphaning” the water heater and

the venting system must be properly resized for a single

appliance. Improper sizing can cause a number of undesirable and potentially unsafe results including spillage of the

products of combustion into the room, poor combustion,

excessive condensation, pilot outage or delayed ignition.

The vent pipe must not be obstructed so as to prevent the

removal of exhaust gases to the outside atmosphere.

Note: The horizontal section of the vent must slope up

21mm per metre (1/4 in. per foot), (see Figure 8).

CSA/U.L. recognized fuel gas and carbon monoxide (CO)

detectors are recommended in all applications and should

be installed using the manufacturer’s instructions and local

codes, rules or regulations.

Important: If you lack the necessary skills required to properly install this venting system, you should not proceed, but

enlist the help of a qualified service technician.

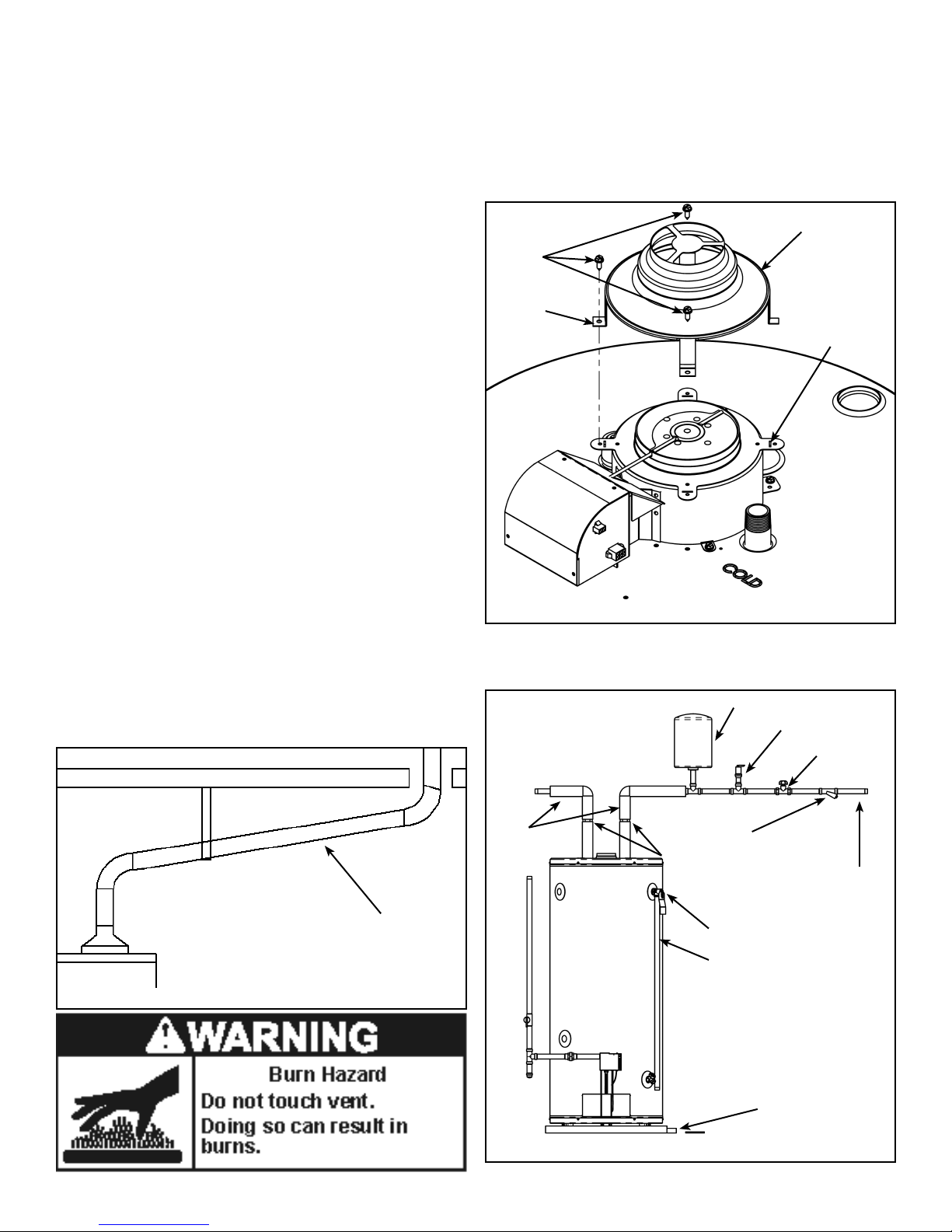

Drafthood Installation

Hook the tab leg of the drafthood into the slot in the heater’s

top or the flue damper if the heater is equipped with a flue

damper. Align the remaining legs with the hole/dimples and

secure the drafthood to the top with three screws as shown

in Figure 9. Do not alter the drafthood in any way. If you are

replacing an existing water heater be sure to use the new

drafthood supplied with the water heater.

DRAFTHOOD

SCREW

TAB LEG

SLOT

Figure 9 Drafthood Installation

Water Supply

Piping Installation

IN A CLOSED SYSTEM USE EITHER:

HOT WATER

OUTLET

1.THERMAL EXPANSION TANK

2.PRESSURE RELIEF VALVE

COLD WATER

INLET VALVE

SLOPE UP 21mm PER METRE

(1/4 in. PER ft) MIN.

Figure 8 Vent System

– 10 –

PIPE

INSULATION

UNION

PRESSURE REDUCING

VALVE WITH BYPASS

TEMPERATURE AND

PRESSURE RELIEF VALVE

DISCHARGE LINE 300mm

(12 in.) MAX (CANADA)

OR 150mm (6 in.) MAX

(U.S.A.) ABOVE DRAIN

MASSACHUSETTS:

INSTALL A VACUUM

RELIEF IN COLD WATER

LINE PER SECTION

19MGL 142

DRAIN LINE 19mm

(3/4 in.) ID MIN

Figure 10 Example Of Water Piping Installation

COLD WATER

INLET

Loading...

Loading...