PART NO. 186714-000 REV. A (08-05)

WARNING:

If the information in these instructions is

not followed exactly, a fire or explosion

may result causing property damage, personal injury or death.

WARNING:

Improper installation, adjustment, alteration, service, or maintenance can cause

injury or property damage. Refer to this

manual. For assistance or additional information, consult a qualified installer, service agency, or the gas utility.

FOR YOUR SAFETY

• Do not store or use gasoline or other

flammable vapours and liquids in the

vicinity of this or any other appliance.

• Installation and service must be performed by a qualified installer, service

agency or the gas utility.

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

WHAT TO DO IF YOU SMELL GAS

GSW Water Heating is a division of

A. O. Smith Enterprises Ltd.

POWER VENTED GAS

FIRED WATER HEATER

INSTALLATION AND OPERATING INSTRUCTIONS

Read these instructions thoroughly before starting

– 2 –

This page intentionally left blank. May be used for notes or to record other installation information.

– 3 –

TABLE OF CONTENTS

Replacement Parts Listing/

Clearance to Combustibles . . . . . . . . . . . . . . . . . 4

I) INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

User Responsibilities 5

II) SAFETY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

For Installations in Canada: 6

For Installations in the United States: 6

Safety Warning (Flammable Vapours) 6

Safety Warning (Scalding) 6

Safety Warning (Carbon Monoxide) 6

Relief Valve Requirements (T&P) 7

III) INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Unpacking the Water Heater 7

Location Requirements 7

In Earthquake Zones

Clearances and Accessibility 8

Gas Supply 8

Gas Supply Pressure

Gas line purging

Gas Leak Testing

Gas Operating Pressures

Air Requirements 9

General

Combustion Air “Supply” Ducts 9

Louvers and Grilles 9

Air Requirements 10

Confined Space Air Requirements for Canadian

Installations 10

Confined Space Air Requirements for U.S.

Installations 11

Exhaust Venting 12

Important Notes and Warnings

Venting terminations and sizing

Venting instructions

Vent pipe connection to blower

Water Supply 16

Piping Installation

Filling the Water Heater

Closed System/Thermal Expansion

Temperature and Pressure (T&P) Relief Valve 17

The Temperature and Pressure Relief Valve:

The Discharge Line/Driptube:

Electrical Supply 18

Installation Checklist 19

IV) OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . 21

Temperature Regulation 21

Mixing Valves 21

Lighting Instructions

(Robertshaw) 22

Gas Control/Thermostat

Putting the Heater into Service

Temperature Adjustment

Heater Shutdown

Water Heater Operation

Lighting Instructions

(White-Rodgers Intelli-Vent

TM

)24

Gas Control/Thermostat

Putting the Heater into Service

Temperature Adjustment

Heater Shutdown

System Error Codes

Intelli-VentTMSystem Error Codes

V) OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Performance Checks 28

Burner Manifold Pressure

Checking Input

Checking burner flame

VI) SERVICE AND MAINTENANCE. . . . . . . . . . . . . . 28

Not Enough or No Hot Water

Energy Cut-off Control (ECO)

Water is Too Hot

Hot Water Odour

Discoloured Water

Water Heater Makes Noise

Extended Non Use Service

Condensation

Anode Maintenance

To inspect or change an anode:

Tank Flushing

Relief Valve Check

Vent Maintenance

Burner Maintenance

VII) COMBO HEATING . . . . . . . . . . . . . . . . . . . . . . . . 31

System Requirements 31

Installation 32

Fan Coil

Baseboard Radiator Heating

Maintenance 32

VIII) TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . 33

SUPERFLUE

TM

33

White-Rodgers Intelli-Vent

TM

35

INSTALLATION RECORD . . . . . . . . . . . . . . . . . . 36

LIMITED WARRANTY. . . . . . . . . . . . . . . . . . . . . . 37

RETAIN THESE INSTRUCTIONS IN A SAFE LOCATION FOR FUTURE REFERENCE

– 4 –

Replacement Parts Listing/Clearance to Combustibles

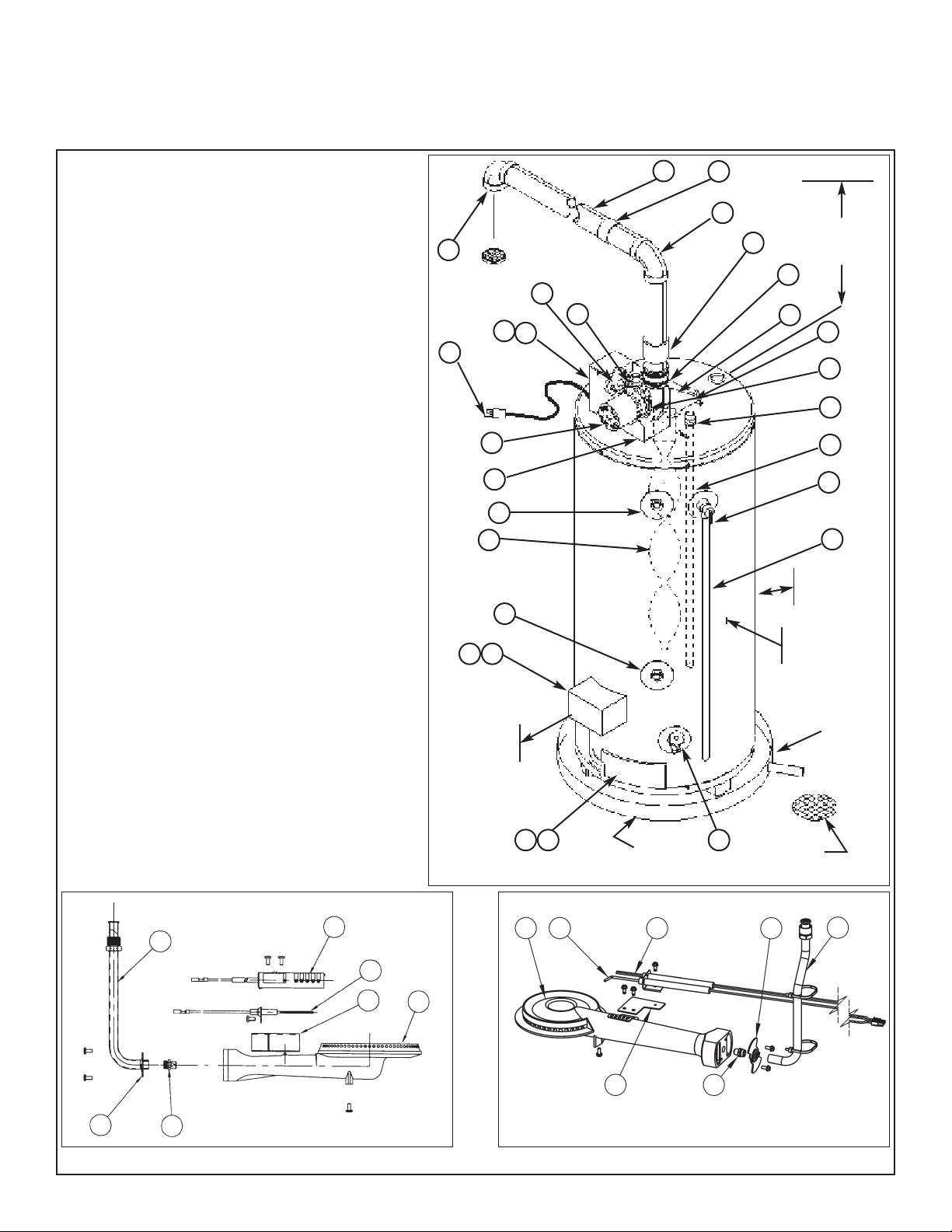

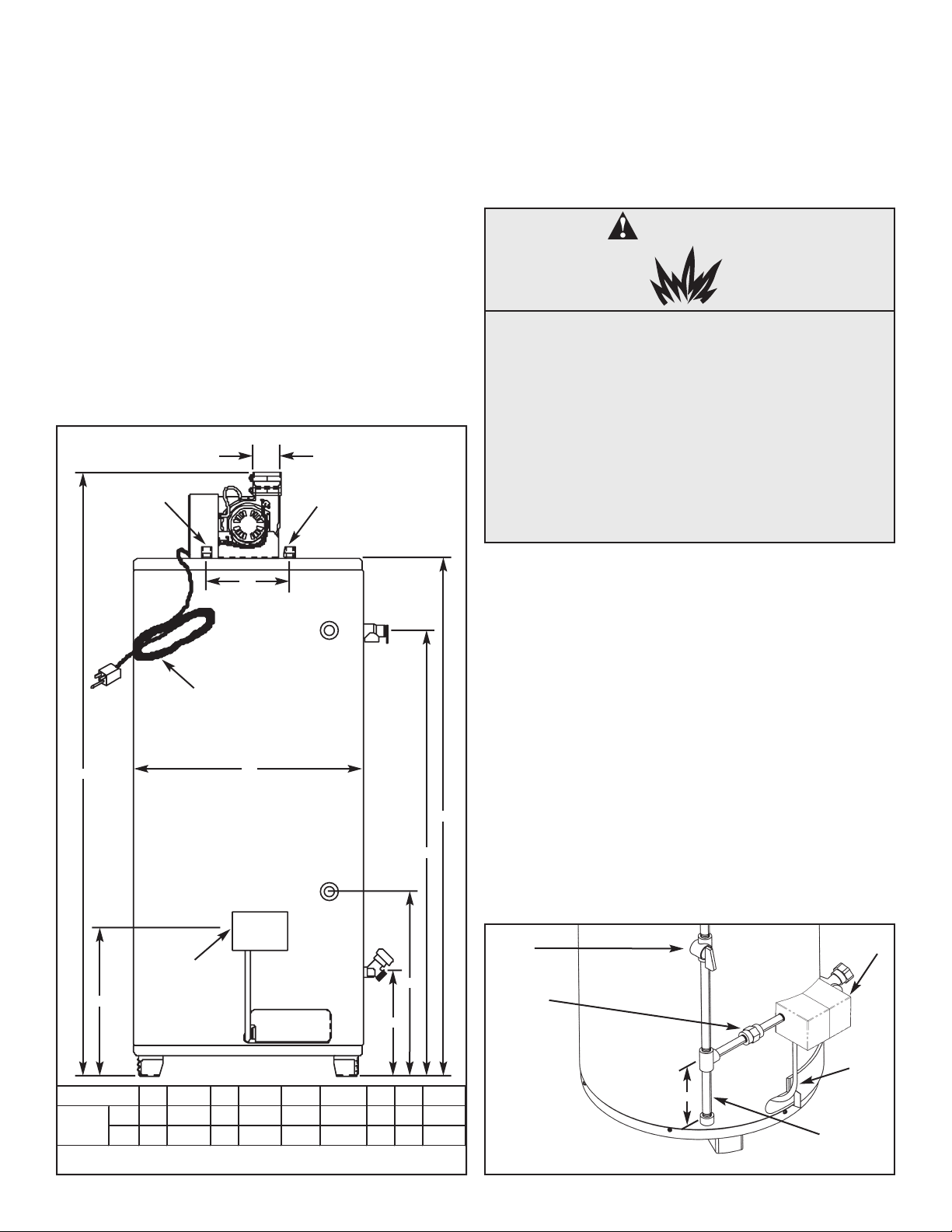

1. TERMINATION ELBOW WITH RODENT SCREEN

2. PIPE LENGTH *

3. PIPE COUPLING *

4. PIPE ELBOW *

5. RUBBER COUPLING

6. AIR TUBING

7. AIR SWITCH

8. JUNCTION BOX

9. JUNCTION BOX COVER

10. POWER CORD

11. BLOWER

12. BLOWER SUPPORT BRACKET

13. DRAFT DIVERTER

14. HIGH LIMIT SWITCH

15. ANODE (UNDER CAP)

16. INLET NIPPLE

17. DIPTUBE

18. T&P VALVE

19. DRIPTUBE *

20. BAFFLE ASSEMBLY

21. CONTROL VALVE (WHC)

22. CONTROL VALVE COVER (WHC)

23. INNER GAS DOOR

24. OUTER GAS DOOR

25. DRAIN VALVE

26. FLARE TUBE (GAS SUPPLY)

27. IGNITER ASSEMBLY

28. FLAME SENSOR

29. IGNITER BRACKET

30. ORIFICE

31. AIR SHUTTER

32. CAST IRON BURNER

33.

34. HEATING SYSTEM SUPPLY

35. HEATING SYSTEM RETURN

36. PVC ADAPTER

* OWNER SUPPLIED

Note: Manifold Tube Connections at Control Valve;

Right-Hand Threads for Natural Gas,

Left-Hand Threads for Propane

10

11

12

20

34

21 22

23 24

MINIMUM

CLEARANCE

50mm (2 in.)

DRAIN PAN IF REQUIRED

MIN. DIA. 660mm (26 in.)

MAX. PAN DEPTH

45mm (1 3/4 in.)

25

FLOOR DRAIN

MINIMUM

CLEARANCE

25mm (1 in.)

19

MINIMUM

CLEARANCE

25mm (1 in.)

18

17

16

14

15

MINIMUM

CLEARANCE

300mm (12 in.)

13

5

4

3

2

6

7

9

8

35

36

CAST IRON BURNER ASSEMBLY USED

WITH THE INTELLI-VENT

TM

GAS VALVE.

Figure 1 Water Heater and Burner Assemblies

1

30

28

32

27

29

31

26

26

27

28

29

32

30

31

CAST IRON BURNER ASSEMBLY USED

WITH THE 2000N WDER GAS VALVE.

– 5 –

Your safety and the safety of others is very important.

We have provided many important safety messages in this manual and on your appliance.

Always read and obey all safety messages.

All safety messages will tell you what the potential hazard is, tell you how to reduce the

chance of injury, and tell you what can happen if the instructions are not followed.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word

“DANGER” or “WARNING”.

DANGER

WARNING

You can be killed or seriously injured if you don’t immediately follow

instructions.

You can be killed or seriously injured if you don’t follow instructions.

I) INTRODUCTION

We thank you for choosing a GSW/John Wood Water

Heater. Your satisfaction with this product is very important

to us. This gas-fired water heater has been developed to

produce potable hot water and may also be used in combination with space heating applications. The “Superflue”™

series is designed to vent the products of combustion (flue

gases) horizontally through an exterior wall or vertically

through the roof using an integrated blower assembly and

plastic piping, without the need for a conventional chimney.

User Responsibilities

This manual has been prepared to acquaint you with the

installation, operation and maintenance of your gas fired

water heater and provide important safety information in

these areas. It is your responsibility to ensure that your

water heater is properly installed and cared for.

FAILURE TO FOLLOW THE INSTRUCTIONS IN THIS

MANUAL MAY RESULT IN SERIOUS BODILY INJURY

AND/OR PROPERTY DAMAGE. THOROUGHLY READ

AND UNDERSTAND ALL INSTRUCTIONS BEFORE YOU

ATTEMPT TO INSTALL, OPERATE OR MAINTAIN THIS

HEATER.

Installation and service requires trade knowledge in the

areas of plumbing, electricity, venting, air supply and gas

supply. If you lack these skills or have difficulty understanding these instructions, you should not proceed. Enlist the

help of a qualified service technician to install this water

heater.

Examples of qualified service technicians include those

trained in the plumbing and heating industry, local gas utility personnel or an authorized service person.

Service to the Power Vent System should only be performed by a qualified service technician.

The manufacturer and seller of this water heater will not

assume any liability for any property damage, personal

injury or death resulting from improper sizing, installation or

failure to comply with these instructions.

The warranty on this water heater is in effect only when the

water heater is installed and operated in accordance with

these instructions. A data plate identifying your water heater

can be found above the gas control/thermostat. When referring to your water heater, always have the information listed

on the data plate readily available.

Protect your warranty: Regularly service your water

heater as directed in the "Maintenance" section of this manual.

Retain your original receipt as proof of purchase.

Do not discard this manual. You or future users of this

water heater will need it for reference.

II) SAFETY

This water heater is design-certified by CSA International as

a Category III, non-direct vented water heater that takes its

combustion air either from the installation area or from air

ducted to the unit from the outside.

In addition to the installation instructions found in this manual, the water heater must be installed in accordance with

all local and provincial or state codes or, in the absence of

such, with the latest editions of the following specifications.

For Installations in Canada:

"Natural Gas and Propane Installation Code" CAN/CSAB149.1 and "Canadian Electrical Code” (CAN/CSA

C22.1), Part I available from:

Canadian Standards Association,

5060 Spectrum Way,

Mississauga, Ontario, Canada

L4W 5N6

For Installations in the United States:

"National Fuel Gas Code" ANSI Z223.1 (NFPA 54) and

"National Electrical Code" (NFPA 70) available from:

American National Standards Institute,

25 West 43rd Street,

New York, NY 10036

Massachusetts code requires this water heater to be

installed in accordance with Massachusetts Plumbing and

Fuel Gas Code 248 CMR Section 2.00 and 5.00.

Check your phone listings for the local authorities having

jurisdiction over your installation.

Safety Warning (Flammable Vapours)

There is a risk of property damage, personal injury or death

from the by-products of combustion (e.g., flue gases), in

using fuel-burning appliances such as water heaters. Areas

that may not be suitable for water heater installation include

those where flammable liquids, gasoline, solvents, adhesives etc. are stored, or where engine-driven equipment or

vehicles are stored, operated or repaired. These, and simi-

lar products, should not be stored or used near the water

heater or air intake. Due to the nature of air movement,

flammable vapours can be carried some distance from the

point of storage. The gas-fired water heater igniter or burner flame can ignite these vapours causing a flashback, fire

or explosion, which may result in severe property damage,

serious personal injury or death. If flammable liquids or

vapours have spilled or leaked in the area of the water

heater, leave the area immediately and call the fire department from a neighbor's home. Do not attempt to clean the

spill until all ignition sources have been extinguished.

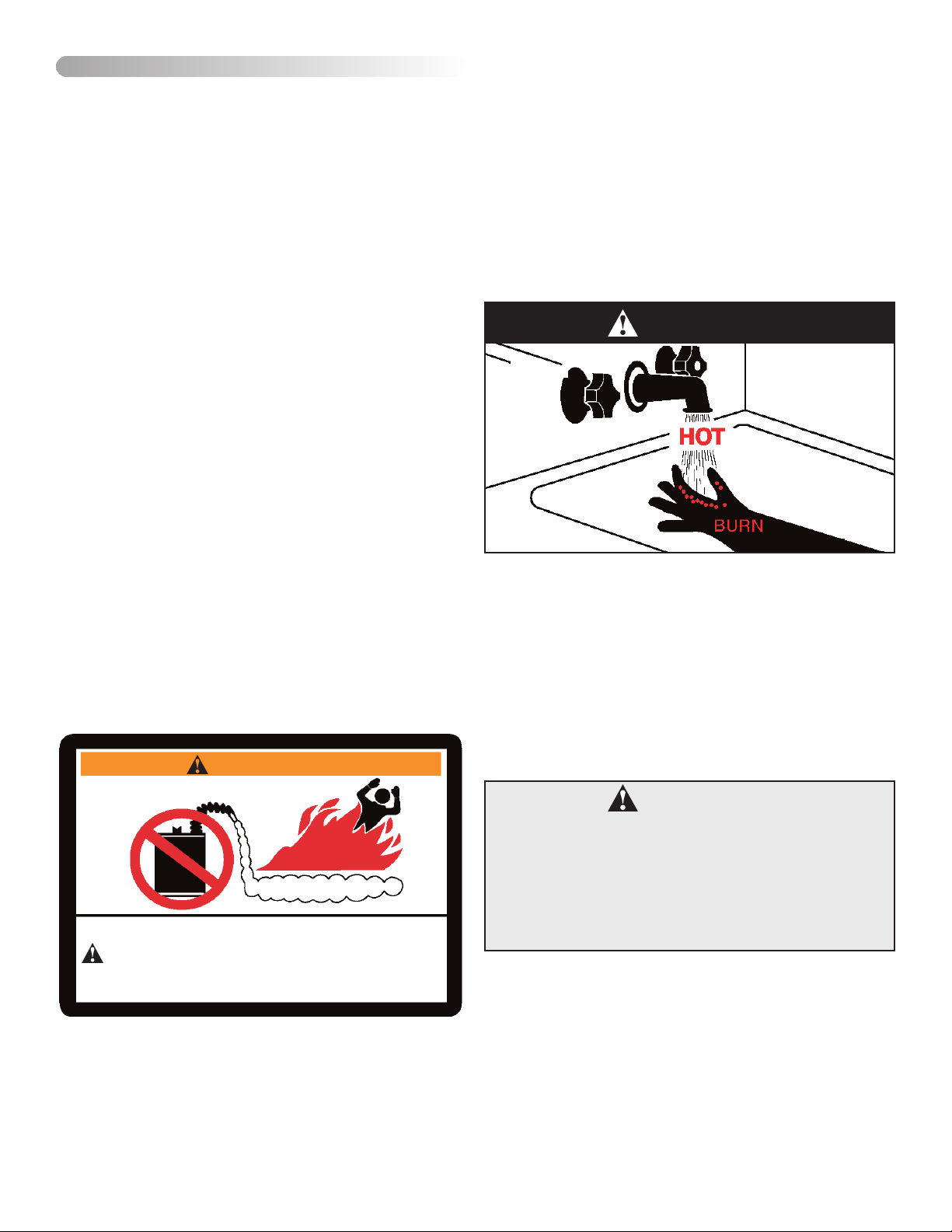

Safety Warning (Scalding)

Hot water produced by this appliance can cause severe

burns due to scalding. The hazard is increased for young

children, the aged or the disabled when water temperatures

exceed 52°C (125°F). Use tempering valves, also known as

mixing valves, in the hot-water system to reduce the risk of

scalding at point-of-use such as lavatories, sinks and

bathing facilities (see Figure 16). Such precautions must be

followed when this heater is operated in combination with

dishwashing or space heating applications.

Safety Warning (Carbon Monoxide)

As with all fuel burning equipment, this heater requires an

adequate supply of air for combustion and ventilation. An

insufficient air supply can result in poor combustion or the

re-circulation of the flue gases. Such a condition can cause

soot build-up and present a fire hazard. Flow reversal of flue

gases can cause an increase of carbon monoxide inside of

the dwelling that could result in serious bodily harm or death

from asphyxiation.

MAKE SURE THE FLOW OF COMBUSTION AND

VENTILATION AIR IS NOT RESTRICTED.

WARNING

Flammable Vapours

FLAMMABLES

FIRE AND EXPLOSION HAZARD

Can result in serious injury or death

Do not store or use gasoline or other flammable vapours and liquids

in the vicinity of this or any other appliance. Storage of or use of gasoline

or other flammable vapours or liquids in the vicinity of this or any other

appliance can result in serious injury or death.

DANGER

DANGER

Carbon Monoxide Warning

• Follow all vent system requirements by

the local authorities having jurisdiction

over your installation.

• Failure to do so can result in death, explosion or carbon monoxide poisoning.

– 6 –

Relief Valve Requirements (T&P)

All water heaters must be fitted with a proper temperature

and pressure relief valve. These valves must be certified as

meeting the requirements of the "Standard For Relief

Valves For Hot Water Supply Systems”, ANSI

Z21.22/CSA 4.4.

If this water heater has been exposed to flooding, freezing,

fire or any unusual condition, do not put it into operation until

it has been inspected and approved by a qualified service

technician. THESE CONDITIONS CAN RESULT IN

UNSEEN INTERNAL DAMAGE and are not subject to warranty coverage.

III) INSTALLATION

Unpacking the Water Heater

Important: Do not remove any permanent instructions,

labels, or the data label from outside of the water heater or

on the inside of panels.

•

Remove exterior packaging and place installation components aside.

•

Inspect all parts for damage prior to installation and

start-up.

•

Completely read all instructions before attempting to

assemble and install this product.

If you observe damage to the water heater or any of its components, DO NOT ASSEMBLE OR INSTALL IT OR MAKE

ANY ATTEMPT TO FIX THE DAMAGED PART(S). Contact

the place of purchase for further instructions.

•

After installation, dispose of packaging material in the

proper manner.

Location Requirements

The water heater must be installed indoors in an area not

subject to freezing temperatures and in a vertical position

on a level surface. Water heaters located in unconditioned

spaces (e.g., attics, basements etc.) may require insulation

of the water piping, drain piping and venting to protect

against condensation. The power vented series of water

heaters are designed to vent the products of combustion

horizontally through the wall or vertically through the roof.

The blower expels the products of combustion by means of

plastic piping to the outdoors without the need for a conventional chimney.

Select a location as centralized within the piping system as

possible. The heater should be located in an area where

leakage of the tank or connections will not result in damage

to the area adjacent to the water heater or to lower floors of

the structure (see "IMPORTANT" notice above). Before

installing this water heater, consideration and planning must

be given to the following details:

•

Proximity to walls and other objects (see "Clearance

and Accessibility").

•

Air supply (see “Air Requirements”).

•

Access to gas supply (see "Gas Supply").

•

Routing and support of the vent piping and termination

(see "Exhaust Venting").

•

Position of water supply and placement of water piping

and floor drain (see "Water Supply").

In Earthquake Zones

Note: The water heater must be braced, anchored, or

strapped to avoid moving during an earthquake. Contact

local utilities for code requirements in your area.

IMPORTANT:

This water heater must be installed strictly in accordance

with the instructions enclosed, and local electrical, fuel

and building codes. It is possible that connections to the

water heater, or the water heater itself, may develop

leaks. IT IS THEREFORE IMPERATIVE that the water

heater be installed so that any leakage of the tank or related water piping is directed to an adequate drain in such a

manner that it cannot damage the building, furniture, floor

covering, adjacent areas, lower floors of the structure or

other property subject to water damage. This is particularly important if the water heater is installed in a multi-story

building, on finished flooring or carpeted surfaces. GSW

WILL NOT ASSUME ANY LIABILITY for damage caused

by water leaking from the water heater, pressure relief

valve, or related fittings. Select a location as centralized

within the piping system as possible. In any location

selected, it is recommended that a suitable drain pan be

installed under the water heater. This pan must limit the

water level to a MAXIMUM depth of 45mm (1 3/4 in.) and

have a diameter that is a minimum of 50mm (2 in.) greater

than the diameter of the water heater. Suitable piping shall

connect the drain pan to a properly operating floor drain.

When used with a fuel-fired heater, this drain pan must not

restrict combustion air flow.

WARNING

Excessive Weight Hazard

Use two or more people to move and install

water heater. Failure to do so can result in

back or other injury.

CAUTION

Hydrogen gas can be produced in a hot water system

served by this heater that has not been used for a long

period of time (generally two (2) weeks or more).

Hydrogen gas is extremely flammable and can ignite

when exposed to a spark or flame. To reduce the risk of

injury under these conditions, it is recommended that the

hot water faucet be opened for several minutes at the

kitchen sink before using any electrical appliance connected to the hot water system. Use caution in opening

faucets. If hydrogen is present, there will probably be an

unusual sound such as air escaping through the pipe as

the water begins to flow. There should be no smoking or

open flame near the faucet at the time it is open.

– 7 –

Note: The water heater may be installed in a closet with a

door off a bedroom or bathroom providing the units are

installed and vented per the manufacturer's instructions.

Important: If installing over carpeting, the carpeting must

be protected by a metal or wood panel beneath the water

heater. The protective panel must extend beyond the full

width and depth of the water heater by at least 76mm (3 in.)

in each direction or if in an alcove or closet installation, the

entire floor must be covered by the panel.

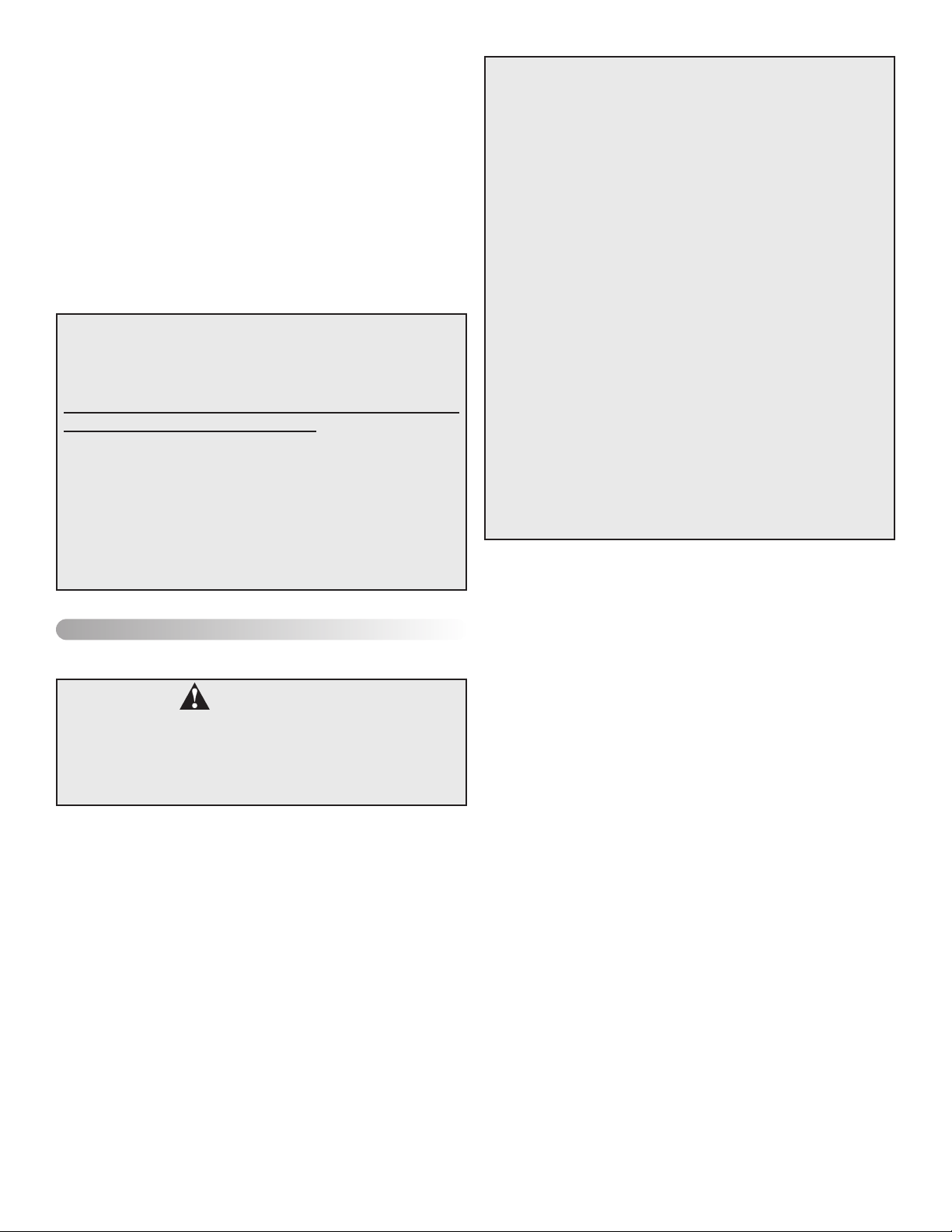

Clearances and Accessibility

•

The minimum clearances between the heater and com-

bustible materials are:

Top 300mm (12 in.)

Front 100mm (4 in.)

Rear and Sides 25mm (1 in.)

Note: These requirements are also listed on the data plate

located on the front of the water heater.

•

The water heater is certified for installation on a com-

bustible floor.

Figure 2 may be used as a reference guide to locate the

specific clearance locations. A minimum of 600mm (24 in.)

of front clearance and 100mm (4 in.) on each side should be

provided for inspection and service.

Gas Supply

Read the data plate to be sure the water heater is made

for the type of gas you will be using in your home. This

information will be found on the data plate located above the

gas control valve. If the information does not agree with the

type of gas available, do not install or attempt to start. Call

your dealer.

Note: An odourant is added by the gas supplier to the gas

used by this water heater. This odourant may fade over an

extended period of time. Do not depend upon this odourant

as an indication of leaking gas.

This gas piping must be installed in accordance with all local

and provincial or state codes or, in the absence of such, the

latest edition of "Natural Gas and Propane Installation

Code" CAN/CSA-B149.1 (Canada), or "National Fuel Gas

Code" ANSI Z223.1 (NFPA 54) (U.S.A.).

Use properly sized gas piping and to ensure full gas input

and a properly sized gas supply regulator to ensure ade-

DANGER

Explosion Hazard

• Use a new CSA approved gas supply line.

• Install a gas supply shut-off valve.

• Do not connect a natural gas water heater

to a L.P. gas supply.

• Do not connect a L.P. gas water heater to

a natural gas supply

• Failure to follow these instructions can

result in death, an explosion or carbon

monoxide poisoning.

GROUND-JOINT

UNION

MANUAL

GAS

SHUT-OFF

SEDIMENT

TRAP

GAS

VALV E

GAS

MANIFOLD

76mm (3 in.)

Figure 3 Gas Piping

– 8 –

Figure 2 Rough-in Dimensions

“G”

COLD INLET

3/4” NPT

HOT OUTLET

3/4” NPT

HEATING

OUTLET

HEATING

INLET

POWER CORD

(120) VAC/60Hz

GAS INLET

1/2” NPT

DRAIN

VALV E

T&P

VALV E

“A”

“I”

“B”

“E”

“D”

“F”

“C”

“H”

ABCD E FGH I

mm

610 302 432 1388 1575 1826 76 305 537

in. 24 11- 7/8 17 54-5/8 62 71-7/8 3 12 21-1/8

G/JW75

M ODEL NO.

quate gas supply pressure. The supply piping and regulator

must be large enough to satisfy the requirements of all

appliances connected to the gas service and when all appliances are operating simultaneously. Undersize piping and

insufficient pressure can restrict the gas flow causing the

water heater to perform poorly. Improperly sized piping may

pose a safety hazard.

Note: When installing gas piping, apply sealing compounds

approved for use with natural and propane gas.

1. Install a readily accessible manual shut-off valve in the

gas supply line as recommended by the local utility. The

owner/operator must be shown the location of this valve

and be given instructions on how to use it to shut off the

gas to the heater.

2. Install a drip leg (if not already incorporated as part of

the water heater) as shown. The drip leg must be no

less than 76mm (3 in.) long for the accumulation of dirt,

foreign material, and water droplets.

3. Install a ground joint union between the gas control

/thermostat and the manual shut-off valve. This is to

allow easy removal of the gas control/thermostat.

4. Turn the gas supply on and check for leaks. Use a chloride-free soap and water solution (bubbles forming indicate a leak) or other approved method.

Gas Supply Pressure

Important: The gas supply pressure must not exceed the

maximum supply pressure as stated on the water heater's

data plate.

Gas line purging

Air may be present in the gas lines and could prevent the

burner from lighting on initial start-up. The gas lines should

be purged of air by a qualified service technician after installation of the gas piping system.

Gas Leak Testing

Important: This water heater and its gas connection must

be leak tested before placing the appliance in operation.

•

If the code requires the gas lines to be tested at a pressure exceeding 14 in. w.c. (3.5 kPa), the water heater

and its manual shut-off valve must be disconnected

from the gas supply piping system and the line capped.

•

If the gas lines are to be tested at a pressure less than

14 in. w.c. (3.5 kPa), the water heater must be isolated

from the gas supply piping system by closing its manual shut-off valve.

Gas Operating Pressures

The gas supply pressure and burner manifold pressure is

listed on the data plate located on the front of the heater

above the gas control/thermostat. Ensure the gas supply

pressure to the water heater and the burner manifold pressure are properly adjusted while all appliances are in operation. Refer to Figure 20 for Gas Control/Thermostat

Details.

U.L. and CSA recognized fuel gas and Carbon Monoxide

(CO) detectors are recommended in all applications and

should be installed using the manufacturer's instructions

and local codes, rules or regulations.

Air Requirements

General

•

An adequate air supply shall be provided for combustion and ventilation of this water heater. An insufficient

supply can result in poor combustion and possible sooting of the burner, combustion chamber or flue passageway. This may present a potential fire hazard or could

create a serious health hazard by producing carbon

monoxide.

Where an exhaust fan or any other air consuming appliance

(e.g., clothes dryer, furnace, etc.) is installed in the same

space as the water heater, sufficient air openings must be

available to provide fresh air when all appliances are operating simultaneously.

For buildings that are not well-sealed (do not have tight fitting doors and windows) natural air infiltration may provide

sufficient air required for combustion and ventilation. For

buildings using tight construction (newer and renovated

structures), the air supply shall be introduced from the outdoors, regardless of whether the space is confined or

unconfined.

Combustion Air “Supply” Ducts

Air supply ducts shall be of galvanized steel or equivalent

corrosion resistant material. A single air duct may not be

substituted when required for upper and lower air openings.

Horizontal combustion air ducts shall not slope downward

toward the air inlet.

Louvers and Grilles

Openings for air supply ducts must provide free unobstructed air movement. Louver and grille openings must be sized

to ensure that the FREE OPEN AREA is never less than the

area of the air duct.

– 9 –

WARNING

Exposure to a higher gas supply pressure

may cause damage to the control, resulting

in explosion or fire. Consult your local gas

supplier and gas authorities. DO NOT PUT

INTO SERVICE IF OVER-PRESSURIZATION

HAS OCCURRED.

WARNING

Failure to properly install this heater may

result in a fire hazard.

Air Requirements

Important: Air for combustion and ventilation must not

come from a corrosive atmosphere. Any failure due to corrosive elements in the atmosphere is excluded from warranty coverage.

Installations in or for certain places including, but not limited

to, those listed below will require outdoor air for combustion

to reduce the risk of chemical exposure:

Beauty shops

Photo processing labs

Buildings with indoor pools

Water heaters installed in laundry, hobby or craft rooms

Water heaters installed near chemical storage areas

In such circumstances, outdoor combustion air may reduce,

but will not eliminate the presence of corrosive chemicals in

the air. Combustion air must be free of acid-forming chemicals such as sulfur, fluorine and chlorine. These elements

are found in aerosol sprays, detergents, bleaches, cleaning

solvents, air fresheners, paint and varnish removers, refrigerants and many other commercial and household products. When burned, vapours from these products form highly corrosive acid compounds. These products should not be

stored or used near the water heater or air inlet.

The area in which the heater is located is classified as either

"an unconfined sp

ace

" or "a confined sp

ace

."

An unconfined sp

ace is defined as a space having a volume not less than 50 cubic feet per 1000 BTU/hour (4.8

cubic metres per kilowatt) of combined input rating of all

appliances using the space. Adjacent open rooms may be

included as part of the unconfined space, provided there

are no closeable doors between these rooms. An example of this is an open basement.

A confined sp

ace is one smaller than described above.

For buildings using tight construction (newer and renovated

structures), the air supply shall be introduced from the outdoors, regardless of whether the space is confined or

unconfined.

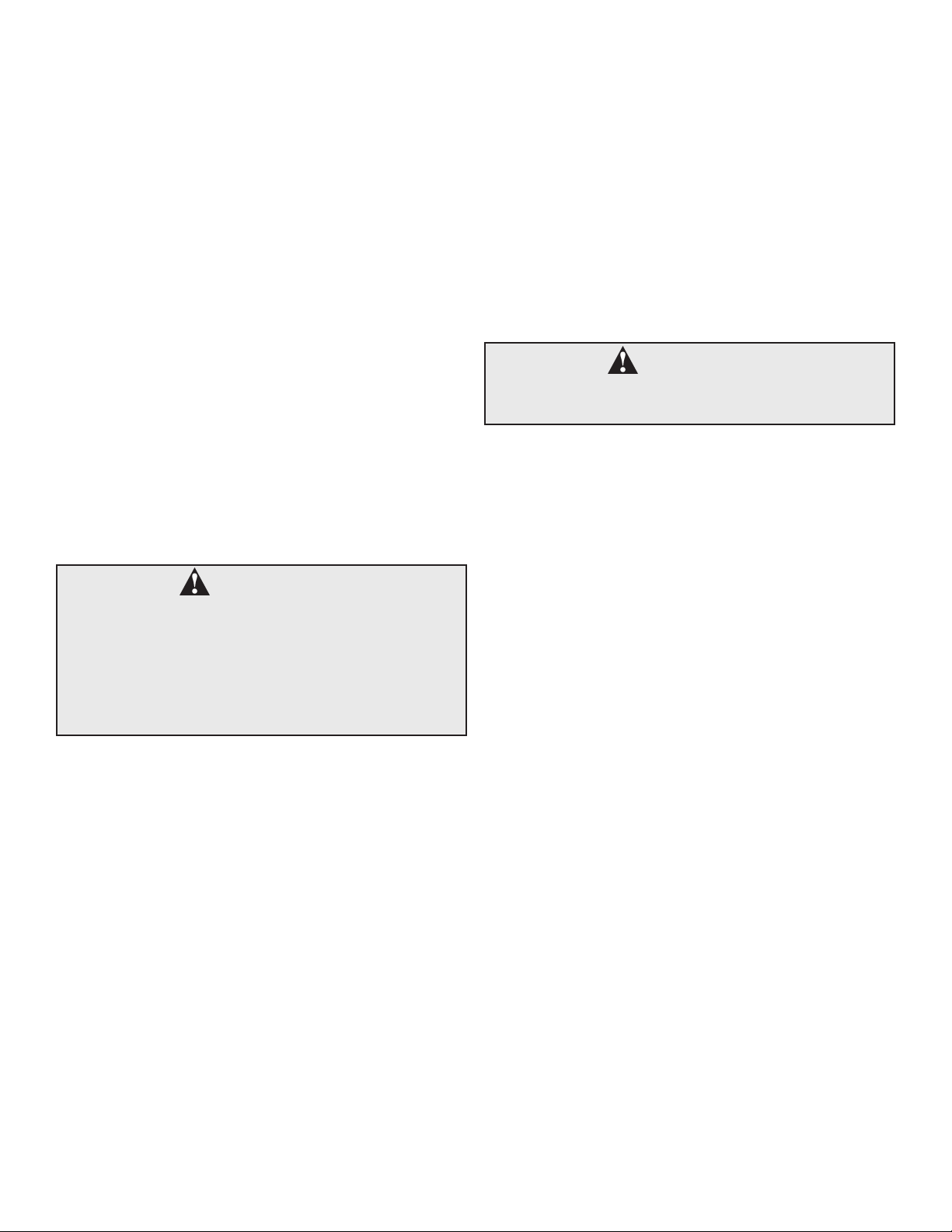

Confined Space Air Requirements for

Canadian Installations

Refer to Figure 4 (a), or (b), and Table 1 for proper sizing

and location of combustion air ducts and openings. CHECK

LOCAL CODES.

a). Two permanent openings shall be provided connecting

the confined space (e.g., closet, small room) with the

unconfined space. Each opening shall have a free area

of one square inch per 1,000 BTU/hour input (22

cm²/kW) of all appliances in the confined space. The top

opening shall be located as close to the ceiling as practical but never lower than the top of the heater. (see

Figure 4 (a)). The bottom opening shall be located neither more than 450mm (18 in.), nor less than 150mm (6

in.), above floor level.

Note: Ensure sufficient ventilation air to prevent elevated

temperatures in closets and confined spaces.

b). When using a single air supply, the duct shall terminate

within 300mm (12 in.) above and within 600mm (24 in.)

horizontally of the burner level

of the appliance having

the largest input. For example: GSW's water heaters'

burners are 150mm (6 in.) from the floor, plus 300mm

(12 in.) equals 450mm (18 in.) as shown in Figure 4 (b).

All exterior vent openings are to be at least 300mm (12

in.) above the ground and clear of snow levels.

– 10 –

CONFINED

SPACE

PERMANENT

OPENINGS

EQUIPMENT LOCATED IN CONFINED SPACES;

ALL AIR FROM INSIDE THE BUILDING.

(a)

UNCONFINED

SPACE

BASEMENT INSTALLATION, EQUIPMENT LOCATED

IN CONFINED SPACES; ALL AIR FROM OUTDOORS

(b)

CONFINED

SPACE

GRADE

COMBINATION

COMBUSTION/

VENTILATION

AIR DUCT

300mm

(12 in.)

(MIN)

450mm (18 in.)

600mm (24 in.)

Figure 4 Combustion Air Supply Openings And Ducts

(Canada)

BTU / h (kW / hr)

cm2in.2mm in. mm in.

75,000 23 70 11 100 4 125 5

100,000 30 90 14 100 4 125 5

125,000 37 120 18 125 5 150 6

150,000 45 140 22 125 5 150 6

Acceptable Round

Duct Size Diameter

Combined Input of

All Appliances in

Confined Space*

Required

Free Area

A**

B***

Table 1 Air Supply Sizing (Canada)

* All appliances refers to, and includes, those appliances

using the same air source (e.g. water heater, furnace,

boiler, clothes dryer etc.).

** Maximum allowable length of ductwork listed in column

A is 6.1 equivalent metres (20 ft.).

*** Maximum allowable length of ductwork listed in column

B is 15.2 equivalent metres (50 ft.).

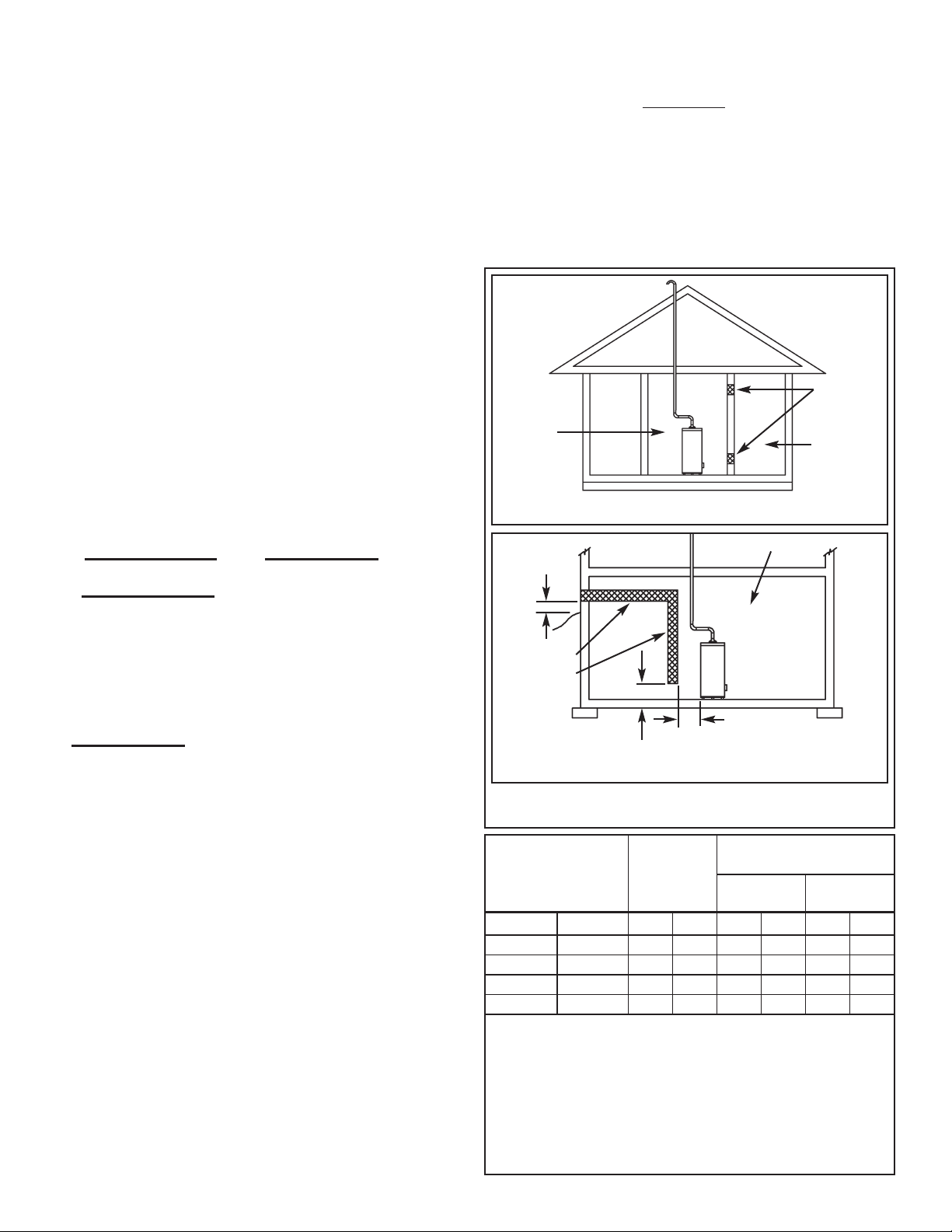

Confined Space Air Requirements for

U.S. Installations

Refer to Figure 5 (a), (b), (c) or (d) for proper sizing and

location of combustion air ducts and openings. CHECK

LOCAL CODES.

(a) Equipment located in confined spaces; all air from

inside the building.

Two permanent openings shall be provided connecting

the confined space (e.g., closet, small room) with the

unconfined space. Each opening shall have a free area

of one square inch per 1,000 BTU/hour input (22

cm²/kW) of all appliances in the confined space, but not

less than 100 square inches (645 cm²). The top opening shall commence within 300mm (12 in.) of the top of

space and the bottom opening shall commence within

300mm (12 in.) of the bottom of the enclosure.

(b) Basement installation, equipment located in con-

fined spaces; all air from outdoors.

When supplying air directly from the outdoors, each

opening shall have a minimum free area of one square

inch per 4,000 BTU/hour input (5.5 cm²/kW) of total

input rating of all appliances in the confined space. The

inlets shall be a minimum of 300mm (12 in.) above the

grade (snow) line. The top opening shall commence

within 300mm (12 in.) of the top of the confined space.

(c) Equipment located in confined spaces; all air from

outdoors.

When supplying air directly from the outdoors using horizontal ducting, each opening shall have a free minimum area of one square inch per 2,000 BTU/hour (11

cm²/kW) of total input rating of all appliances in the confined space.

(d) Equipment located in confined spaces; all air from

outdoors through ventilated attic.

When supplying air directly through vertical ducting,

each opening shall have a free minimum area of one

square inch per 4,000 BTU/hour (5.5 cm²/kW) of total

input rating of all appliances in the confined space.

Note: Ensure sufficient ventilation air to prevent elevated

temperatures in closets and confined spaces.

CONFINED

SPACE

PERMANENT

OPENINGS

EQUIPMENT LOCATED IN CONFINED SPACES;

ALL AIR FROM INSIDE THE BUILDING.

(a)

UNCONFINED

SPACE

CONFINED

SPACE

ATTIC LOUVERS TO OUTDOORS

EQUIPMENT LOCATED IN CONFINED SPACES; ALL AIR

FROM OUTDOORS THROUGH VENTILATED ATTIC.

(d)

INLET AIR

DUCT

OUTLET

AIR

BASEMENT INSTALLATION, EQUIPMENT LOCATED

IN CONFINED SPACES; ALL AIR FROM OUTDOORS

(b)

CONFINED

SPACE

GRADE

300mm

(12 in.)

300mm

(12 in.)

Figure 5 Combustion Air Supply Openings And Ducts

(U.S.A.)

COMBUSTION

AIR DUCT

PERMANENT

VENTILATION

AIR.

300mm

(12 in.)

ABOVE

GRADE

OR

SNOW

LINE

EQUIPMENT LOCATED IN CONFINED

SPACES; ALL AIR FROM OUTDOORS.

(c)

CONFINED

SPACE

COMBUSTION

300mm (12 in.)

300mm (12 in.)

300mm (12 in.)

OUTDOORS

AIR DUCT

VENTILATION

Burn Hazard

Do not touch vent.

Doing so can result in

burns.

– 11 –

Exhaust Venting

This heater is designed to exhaust the products of combustion (flue gases) to the outdoors using a sealed piping system. Table 2 lists the allowable vent materials and sizing

information. Figure 8 shows the general venting layout while

Figures 9-12 show various end termination details and

clearances. Connection of the venting piping to the blower

is shown in Figure 14.

Correct installation of the venting system is essential to the

safe and efficient operation of this water heater. Vent piping

must be installed in accordance with all applicable local and

provincial or state codes. In the absence of such codes, all

installation shall meet the requirements as stated in the latest edition of the "Natural Gas and Propane Installation

Codes" CAN/CSA-B149.1 (Canada) or "National Fuel

Gas Code" ANSI Z223.1 (NFPA 54) (U.S.A.).

Important Notes and Warnings

•

This heater is certified to be installed using Schedule 40

PVC or CPVC plastic vent material. In Canada some

jurisdictions require that this material be approved to

ULC S636. ULC S636 mandates that components from

different systems must not be mixed in the same vent

runs. Check local codes to determine which materials

are allowed in your area and only use approved material. All venting material and components must be joined

with the approved primer/cleaner and solvent cement.

•

Do not common vent this heater with any other appliance.

•

During operation the plastic piping will expand as it

heats up and contract as it cools down. This is normal

for this type of venting. Rigidly fastening the vent piping

can cause undue stress that may result in the cracking

or fracturing the vent piping material. A fracture of the

venting pipe poses a serious safety hazard. To prevent

stressing of the vent system, all hangers and supports

must allow the vent piping freedom to move.

•

All power vented water heaters generate a certain

amount of operational noise. In order to minimize noise

transmission to the support structure, use isolation pads

between the pipe hangers and the vent pipe.

•

Most power vent installations develop some condensation in the vent piping. When using long runs of venting

or when the venting passes through cold or unheated

areas, considerable amounts of condensate from the

flue gases can develop. Provision must be made for the

condensate to drain freely from the system or to be collected in a condensate trap(s) that can be drained.

Damage or fracture of the vent piping may occur if the

condensate is allowed to collect and freeze. Pooling of

condensate can restrict airflow and can cause nuisance

failures of the system.

•

Be aware of any concealed wiring or piping inside the

walls.

– 12 –

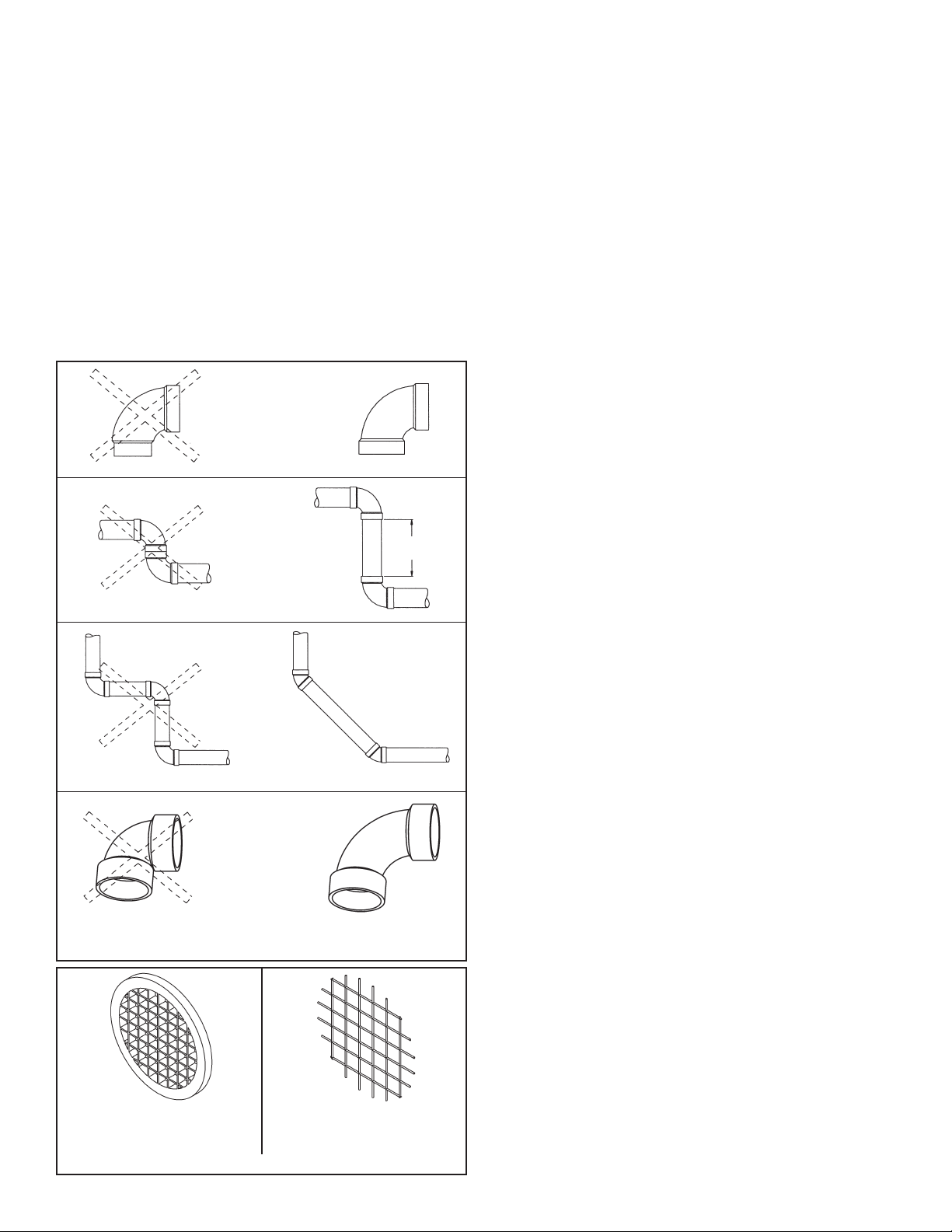

PREFERRED PRACTICE

150mm

(6 in.) min.

STREET ELBOW NORMAL ELBOW

BACK TO BACK ELBOWS

Figure 6 Correct Pipe Fittings

90° LONG SWEEP ELBOW

90° SHORT SWEEP ELBOW

VENT LENGTH LESS THAN OR

EQUAL TO 6.1 EQUIVALENT METRES

(20 FT.) USE PLASTIC SCREEN.

VENT LENGTH GREATER THAN 6.1

EQUIVALENT METRES (20 FT.) USE

STEEL MESH SCREEN.

Figure 7 Rodent Screens

Venting terminations and sizing

•

Refer to Figure 8 and Table 2 for vent pipe materials

and sizing and Figure 11 for vent termination clearances. Examples of the vent terminations are shown in

Figures 9 and 10. If the installation requires a vent riser,

suitable drainage must be provided to ensure condensation does not accumulate. Termination through a roof

is shown Figure 12.

•

G/JW75 gallon models are supplied with a 76mm (3 in.)

termination elbow that includes a steel mesh rodent

screen and a 76mm (3 in.) plastic screen.

•

The screen is required to keep foreign objects, rodents

and small birds from entering the venting system and

only one (1) screen is to be installed in the termination

elbow. These screens have been sized to ensure maximum energy efficiency of the venting system based on

the "equivalent length" of the vent piping. How to determine the equivalent length is shown in Figure 8. The

appropriate screen is to be installed into the end of the

termination elbow and secured with a small amount of

silicone sealant. This will allow for easy removal for

inspection and cleaning.

Venting instructions

1. Plan the venting layout starting at the vent termination

and work back toward the heater. Take into consideration the style and position of the vent termination, the

vent pipe routing, elbows and connectors required and

the necessary support hangers.

2. G/JW75 gallon heaters use 76mm (3 in.) schedule 40

venting material. Allowable venting length is determined

using the “Equivalent vent length” method described in

Table 2. See also section on “Vent pipe connection to

blower”.

3. Venting should be as direct as possible with the fewest

number of fittings. Use long radius 45-degree and long

radius 90-degree elbows wherever possible.

4. Do not use 90-degree elbows "back to back" and do not

use street elbows. Maintain a minimum 150mm (6 in.)

straight section between elbows. Closely coupled and

short radius elbows reduce the venting capacity. Figure

6 shows examples of vent pipe connections.

5. DO NOT USE AN ELBOW AS A SUPPORT POINT.

Elbows are not designed to carry the weight of the venting system.

– 13 –

Example for calculating equivalent feet.

Section “A” . . . . . . 0.15m . . (0.5 ft.)

90° elbow . . . . . . . 2.44m . . (8.0 ft.)

Section B . . . . . . . 0.31m . . (1.0 ft.)

45° elbow . . . . . . . 1.22m . . (4.0 ft.)

Section C . . . . . . . 0.46m . . (1.5 ft.)

45° elbow . . . . . . . 1.22m . . (4.0 ft.)

Section D

. . . . . . . 4.57m . (15.0 ft.)

Total Equivalent . 10.37m . (34.0 ft.)

Based on this example use the (fully open) rodent

screen for vent length greater than 6.1 equivalent

metres (20 equivalent ft.) (see Figure 7).

NOTE: VENT PIPE MUST BE SUPPORTED EVERY 1.2m (4 ft.). TO PREVENT VIBRATION, USE ISOLATION

PADS WHEN ATTACHING STRAPS TO FLOOR JOISTS, WALLS OR CEILINGS.

PVC ADAPTER

(SUPPLIED)

STRAP

150mm

(6 in.)

MIN.

45°

ELBOW

90°

ELBOW

RODENT SCREEN

(INSTALL INTO

ELBOW)

Figure 8 General Venting Layout

TERMINATION

ELBOW

GROUND LEVEL OR

MAXIMUM SNOW

LINE*

WATER

HEATER

MODEL

SUFFIX

VENT PIPE

SIZE

PRESSURE

SW ITCH

SETTING

* VENT

MATERIAL

(SCHEDULE 40)

MAXIMUM EQUIVALENT

VENT LENGTH

MINIMUM EQUIVALENT

VENT LENGTH

G/JW75

SNV,

SPV

76mm (3 in.)

- 0.50 in. w.c.

(-.124 kPa)

PVC**, CPVC

15.2m (50 ft.) +

termination elbow with

steel mesh screen

0.91m (3 ft.) + one 90°

elbow + termination elbow

with plastic screen

Notes:

1. Each 76mm (3 in.), 90° elbow is equivalent to 2.44m (8 ft.) of vent length.

2. Each 76mm (3 in.), 45° elbow is equivalent to 1.22m (4 ft.) of vent length.

3. Use long radius elbows. Minimum distance between elbows is 150mm (6 in.).

4. Do not mismatch venting materials. *Check local codes to determine which materials are allowed in your area.

5. **Pipe assembly adapter must be used with PVC venting material (see Figure 13).

Table 2 Allowable Vent Lengths and Materials (Vert. and Horiz.).

– 14 –

A

E

F

F

Figure 11 Horizontal Vent Terminal Installations

G

GAS METER AND

REGULATOR

MECHANICAL AIR

SUPPLY INLET

1.8m (6 ft.) (Canada),

3m (10 ft.) (U.S.A.)

D

C

L

C

F

F

F

B

1. ("A") Minimum 2.1m (7 ft.) above a paved sidewalk or

paved driveway that is located on public property.

2. ("B") Minimum 900mm (3 ft.) above any forced air or

mechanical air supply inlet located within 1.8m (6 ft.)

horizontally (Canada) or 3m (10 ft.) (U.S.A.).

3. ("C") Within 900mm (3 ft.) of any gas service regulator

vent outlet.

4. ("D") Minimum 900mm (3ft) horizontally of the vertical

centerline above the regulator vent outlet to a maximum

vertical distance of 4.5m (15ft).

5. ("E") Minimum 305mm (1 ft.) above grade level or anticipated snow level.

6. ("F") Within 305mm (1 ft.) of any window or door that

can be opened, of any non-mechanical air supply inlet

or of the combustion air inlet of any other appliance.

7. ("G") Minimum 305mm (1 ft.) distance between the top

of the vent termination and the underside of a veranda,

porch or deck.

8. The manufacturer recommends the vent termination

shall not be mounted directly above or within 900mm (3

ft.) horizontally from an oil tank or gas meter to avoid

potential freeze-up or fouling from condensation.

SEALANT

SEALANT

GROUND LEVEL

OR MAXIMUM

SNOW LINE*

Figure 9 Vent Termination Exterior Installation

RODENT SCREEN

(INSTALL INTO

ELBOW)

* WHERE SNOW COVER IS NORMAL DURING WINTER, ENSURE

SUFFICIENT VENT CLEARANCE TO PREVENT BLOCKAGE OR ICE BUILDUP.

300mm

(12 in.)

MIN.

ATTACH 90°

TERMINATION

ELBOW

150mm (6 in.)

VENT PIPING MAY BE

SLOPED IN ANY

DIRECTION, AS LONG

AS A WATER TRAP IS

NOT CREATED IN

THE VENTING SYSTEM. THE SLOPE

SHOULD BE KEPT TO

A MINIMUM SO AS

NOT TO EXERT ANY

UNDUE STRESS ON

THE PIPE.

BRACKET

VENT

RISER

SEALANT

SEALANT

ATTACH 90°

TERMINATION

ELBOW

GROUND LEVEL

OR MAXIMUM

SNOW LINE*

Figure 10 Installation Of Fabricated Vent Riser.

RODENT

SCREEN

(INSTALL

INTO

ELBOW)

VENT PIPING TO BE

SLOPED (DOWN)

TOWARD HEATER TO

PREVENT WATER

FROM COLLECTING.

EQUIVALENT

VENT LENGTH

MEASURED FROM

THIS POSITION

* WHERE SNOW COVER IS NORMAL DURING WINTER, ENSURE

SUFFICIENT VENT CLEARANCE TO PREVENT BLOCKAGE OR ICE BUILDUP.

300mm

(12 in.)

MIN.

6. Calculate "Equivalent Vent Length" before starting. Do

not exceed the values shown in Table 2. An example of

how this length is determined is shown in Figure 8. The

value from your calculations should also be used to

determine which rodent screen to install into the vent

termination elbow.

7. Measure the vent piping and cut to required lengths.

Pipes must be cut at right angles and deburred to

ensure a good smooth fit with sufficient overlap for the

glue joints. Correct any interference conditions.

8. Provide support hangers for horizontal vent piping every

1.2m (4 ft.) to prevent sagging and stress. Provide a

minimum of 3mm (1/8 in.) rise per 1.2m (4 ft.) of vent

piping to ensure adequate drainage. Horizontal vent

piping must not sag to form valleys where condensate

may collect. Vertical venting shall be supported every

1.5m (5 ft.). Use appropriate support straps and vibration isolators (foam pads) on straight sections only. Do

not use elbows as support points. Allow sufficient clearance for expansion and contraction of the venting system.

9. At the point where the vent pipe exits the building, cut a

90mm (3-1/2 in.) hole for 76mm (3 in.) venting.

10. Insert the vent piping through this hole and secure into

position. Connect the vent pipe to the end termination

elbow as shown in Figures 9-12.

11. Dry fit all vent pipes, elbows, connectors and fittings

before joining any parts with solvent cement. PARTS

MUST FIT WITHOUT STRESS OR BENDING OF ANY

SECTION and each connection must overlap a minimum of 13mm (1/2 in.). Do not force fit any of the connections. Use only the appropriate solvent cement.

12. Install the properly sized rodent screen into the outlet

elbow and secure with a small quantity of silicone

sealant.

13. Do not seal the vent piping to the wall until the venting

is properly connected to the blower assembly.

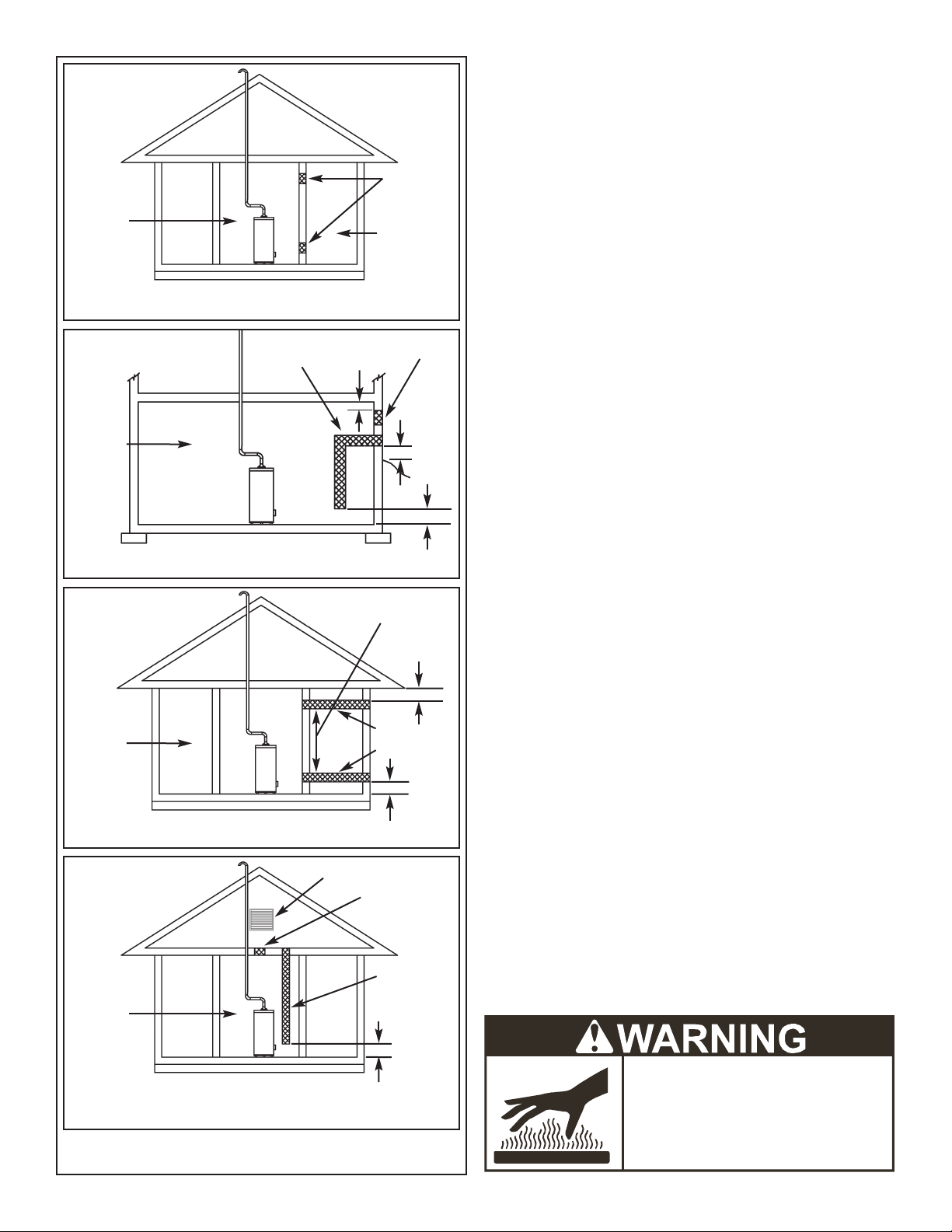

Vent pipe connection to blower

1. The plastic vent piping connects into the rubber coupling located on the top of the blower assembly. This

coupling includes gear clamps to connect the venting to

the blower. These connections must be properly seated

and tightened to prevent the leakage of flue gases into

the area. See Figures 13 & 14.

2. G/JW75 gallon heaters are supplied with a 76mm (3 in.)

adapter for installations using PVC vent piping. This

adapter must be used when using PVC piping. Securely

attach the PVC adapter to the first section of PVC vent

piping using the proper solvent cement before installation into the blower coupling.

3. G/JW75 gallon heaters using CPVC vent piping may be

connected directly into the rubber coupling.

4. Clean and lightly sand the end of the CPVC plastic vent

piping or PVC adapter that will connect into the rubber

coupling.

5. Loosen the upper clamp on the rubber coupling and

insert the sanded end of the CPVC vent piping or the

PVC adapter a full 32mm (1-1/4 in.). Do not use glue or

sealant in the rubber coupling. Check that there is no

stress on the connection or the vent piping that may be

caused by twisting or bending.

6. Tighten the upper clamp so that the vent piping is firmly secured in the coupling and is gas tight. Do not over

tighten or cause distortion of any of the parts. Ensure

that the bottom of the rubber coupling is firmly seated

on the blower outlet and that the lower gear clamp is

also secure. Check to ensure that there is no distortion

or movement of the clamped assembly once it is completed.

– 15 –

PVC PIPE

COUPLING

76mm (3 in.)

ADAPTER

FOR PVC

Figure 13 Pipe Assembly Adapters

PIPE

(CPVC)

UPPER GEAR

CLAMP

RUBBER

ADAPTER

LOWER

GEAR CLAMP

TERMINATION

MAY BE 90°

ELBOW OR A

“T” ELBOW

76mm (3 in.)

MIN. LENGTH

ROOF

LINE

Figure 12 Vertical Venting

A VENT USED IN A SPECIAL

VENTING SYSTEM WITH

POSITIVE VENT PRESSURE

AND PASSING THROUGH A

ROOF SHALL EXTEND AT

LEAST 450mm (18 in.)

ABOVE THE HIGHEST

POINT WHERE IT PASSES

THROUGH THE ROOF SURFACE AND ANY OTHER

OBSTRUCTION WITHIN A

HORIZONTAL DISTANCE OF

450mm (18 in.). A VERTICAL

VENTING SYSTEM MUST

BE SUPPORTED EVERY

2.4m (8 ft.).

RODENT

SCREEN

(INSTALL

INTO

ELBOW)

450mm

(18 in.)

CAUTION:

Use of Solvent Cement and Primer

• Use only in well-ventilated areas.

• Do not use near flame or open fire.

• Use only the Solvent Cement and Primer

appropriate for the venting material being

used.

• Solvent cements for plastic pipe are flammable liquids and must be kept away from

all sources of ignition.

7. Complete the venting installation by sealing around the

termination assembly where it passes through the outside wall, inside and out, with silicone or other suitable

sealant.

Water Supply

Piping Installation

Piping, fittings, and valves should be installed according to

the installation drawing (Figure 15). A pressure-reducing

valve and/or an expansion tank may be required for installations where the water pressure is high. The pressure-reducing valve should be located on the supply to the entire building in order to maintain equal hot and cold water pressure.

Important:

•

Do not apply heat to the water fittings on the heater as

they may contain nonmetallic parts. If solder connections are used, solder the pipe to an adapter before

attaching the adapter to the hot and cold water fittings.

•

Some models may contain energy saving heat traps to

prevent the circulation of hot water within the pipes. Do

not remove the inserts within the heat traps.

•

Always use a proper grade of joint compound and be

certain that all fittings are drawn up tight.

1. Install the water piping and fittings as shown in Figure

15. Connect the cold water supply to the fitting (3/4"

NPT) marked "COLD" (or "C"). Connect the hot water

supply to the fitting (3/4" NPT) marked "HOT" (or "H").

2. The installation of unions in both the hot and cold water

supply lines is recommended.

3. The manufacturer of this water heater recommends

installing a tempering valve in the domestic hot-water

line as shown in Figure 16. These valves reduce the

point-of-use water temperature by mixing cold and hot

water. Contact a licensed plumber or the local plumbing

authority.

4. If installing the water heater in a closed water system,

install an expansion tank in the cold water line as specified under "Closed System/Thermal Expansion".

5. Install a shut-off valve in the cold-water inlet line. It

should be located close to the water heater and be easily accessible. The owner/operator must be shown the

location of this valve and be given instructions on how

to use it to shut off the water to the heater.

Filling the Water Heater

Do not insert the power cord into the electrical receptacle

until all the following steps have been completed.

1. Make sure the drain valve is closed.

2. Open all hot-water faucets served by the system to

allow air to escape from the tank.

3. Open the cold-water inlet valve.

Note: When filling, avoid water leakage. Do not allow the

insulation of the water heater to get wet as water can reduce

the effectiveness of the insulation.

4. When an uninterrupted stream of water, without apparent air bubbles, flows from the open hot-water faucets,

the tank is full.

5. Close the hot-water faucets and check the system for

leaks. Repair as required and retest.

Please note the following:

DO NOT install this water heater with iron piping. The system should be installed only with piping that is suitable for

potable (drinkable) water such as copper, CPVC, PEX or

polybutylene. DO NOT use PVC water piping.

DO NOT use any pumps, valves, or fittings that are not compatible with potable water.

DO NOT use valves that may cause excessive restriction to

water flow. Use full flow ball or gate valves only.

– 16 –

COLD WATER

INLET

COLD WATER

INLET VALVE

PRESSURE

REDUCING

VALV E

WITH

BYPASS

TEMPERATURE AND

PRESSURE RELIEF VALVE

HOT

WATER

OUTLET

UNION

DRAIN PAN CONNECT TO

PROPERLY OPERATING

FLOOR DRAIN.

DISCHARGE LINE 300mm

(12 in.) max (CANADA) OR

150mm (6 in.) max (U.S.)

ABOVE DRAIN

IN A CLOSED SYSTEM USE EITHER: 1.THERMAL EXPANSION TANK

OR

2.PRESSURE RELIEF VALVE.

Figure 15 Water Piping Installation

MASSACHUSETTS: INSTALL A

VACUUM RELIEF IN COLD WATER

LINE PER SECTION 19MGL 142

NOTE: BLOWER

ASSEMBLY NOT

SHOWN FOR

CLARITY.

Figure 14 Blower, Fittings and Vent Pipe Options

BLOWER ASS’Y WITH RUBBER COUPLING FOR 76mm

(3 in.) NOMINAL PVC VENT

PIPE.

CPVC VENTING DOES NOT

REQUIRE ADAPTER.

150mm (6 in.)

MIN

VENT PIPE

76mm (3 in.)

ADAPTER

RUBBER

COUPLING

CAUTION:

• Do Not Overtighten The Top And Bottom

Gear Clamps Of The Rubber Coupling.

• Do Not Apply Solvent Cement Or Silicone

To The Rubber Coupling Connection.

DO NOT use any lead based solder in potable water lines.

Use appropriate tin-antimony or other equivalent material.

DO NOT tamper with the gas control/thermostat, igniter or

temperature and pressure relief valve. Tampering voids all

warranties. Only qualified service technicians should service these components.

DO NOT use with piping that has been treated with chromates, boiler seal, or other chemicals.

DO NOT add any chemicals to the system piping which will

contaminate the potable water supply.

Closed System/Thermal Expansion

Periodic discharge of the temperature and pressure relief

valve may be due to thermal expansion in a closed water

supply system. The water utility supply meter may contain a

check valve, backflow preventer or water pressure-reducing

valve. This will create a closed water system. During the

heating cycle of the water heater, the water expands causing pressure inside the water heater to increase. This may

cause the temperature and pressure relief valve to discharge small quantities of hot water. To prevent this, it is

recommended that a diaphragm-type expansion tank (suit-

able for potable water) be installed on the cold water supply

line. The expansion tank must have a minimum capacity of

5.6 litres (1.5 US gallons) for every 190 litres (50 US gallons) of stored water and be rated at the working pressure

of the water heater. Contact the local water supplier or

plumbing inspector for information on other methods to control this situation.

Important: Do not plug or remove the temperature and

pressure relief valve.

Temperature and Pressure (T&P) Relief

Valve

For protection against excessive pressures and temperatures, a temperature and pressure relief valve must be

installed in the opening marked "T&P RELIEF VALVE" (see

Figure 17). This valve must be design certified by a nationally recognized testing laboratory that maintains periodic

inspection of the production of listed equipment or materials

as meeting the requirements of the "Standard For Relief

Valves For Hot Water Supply Systems", ANSI

Z21.22/CSA 4.4. The function of the temperature and pres-

sure relief valve is to discharge water in large quantities in

the event of excessive temperature or pressure developing

in the water heater. The valve's relief pressure must not

exceed the working pressure of the water heater as stated

on the data plate.

Important: Only a new temperature and pressure relief

valve should be used with your water heater. Do not use an

old or existing valve, as it may be damaged or not adequate

for the working pressure of the new water heater. Do not

place any valve between the relief valve and the tank.

The Temperature and Pressure Relief Valve:

•

Must not be in contact with any electrical part.

•

Must be connected to an adequate discharge line.

•

Must not be rated higher than the working pressure

shown on the data plate of the water heater.

The Discharge Line/Driptube:

•

Must not be smaller than the pipe size of the relief valve

or have any reducing coupling installed in the discharge

line.

– 17 –

COLD

WATER

INLET

HOT

WATER

OUTLET

TEMPERING

VALVE (SET

TO 49°C

(120°F))

TEMPERED

WATER TO

FIXTURE

Figure 16 Tempering Valve Installation

FOLLOW THE

TEMPERING

VALVE MANU-

FACTURER'S

INSTRUCTIONS

T& P VALVE

AND DISCHARGE

LINE

COLD WATER

Figure 17 Temperature & Pressure Relief Valve

Installation

TEMPERATURE AND

PRESSURE RELIEF

VALV E

DISCHARGE LINE 19mm (3/4 in.)

MIN. DO NOT CAP OR PLUG.

DRAIN PAN. CONNECT TO

PROPERLY OPERATING

FLOOR DRAIN.

WARNING

Explosion Hazard

• If the temperature and pressure relief

valve is dripping or leaking, have a

licensed plumber repair it.

• Do not plug valve.

• Do not remove valve.

• Failure to follow these instructions can

result in death or an explosion.

•

Must not be capped, blocked, plugged or contain any

valve between the relief valve and the end of the discharge line.

•

Must terminate a maximum of 300mm (12 in.) (Canada)

or 150mm (6 in.) (U.S.A.) above the floor.

•

Must be capable of withstanding 121°C (250°F) without

distortion.

•

Must be installed to allow complete drainage of both the

valve and discharge line.

Electrical Supply

A three-wire cord and plug is provided with this water

heater. The plug shall be connected into an electrically

grounded, 120 VAC, 60 Hz, 15 Amps, fused receptacle.

Important: The electrical controls used inside the gas control/thermostat of this water heater are polarity sensitive.

Ensure the electrical supply is connected correctly in the

receptacle box. Failure to connect correctly will prevent the

unit from functioning properly. Before performing any elec-

trical service work, label all wires to avoid connection errors.

If wiring has to be replaced, use only TYPE TEW 105°C

wire, (except igniter wires). If there is a problem with igniter

wires, replace igniter assembly in its entirety. In locations

where a sump pump failure, flooding or exposure to water

may be present, a ground fault receptacle is recommended.

Important: Do not use an extension cord to connect the

water heater to an electrical outlet.

•

Ensure that the water heater and the outlet are properly grounded. Failure to properly ground the heater can

prevent the unit from operating.

•

Ensure that the water heater is installed in accordance

with prevailing provisions of local codes, or, in the

absence of such, the latest edition of "Canadian

Electrical Code” (CAN/CSA C22.1), Part I (Canada)

or "National Electrical Code" (NFPA 70) (U.S.A.).

Before applying power to the water heater, always make

sure:

•

The voltage and frequency correspond to that specified

on the water heater wiring diagram.

•

The electrical outlet has the proper overload fuse or

breaker protection.

– 18 –

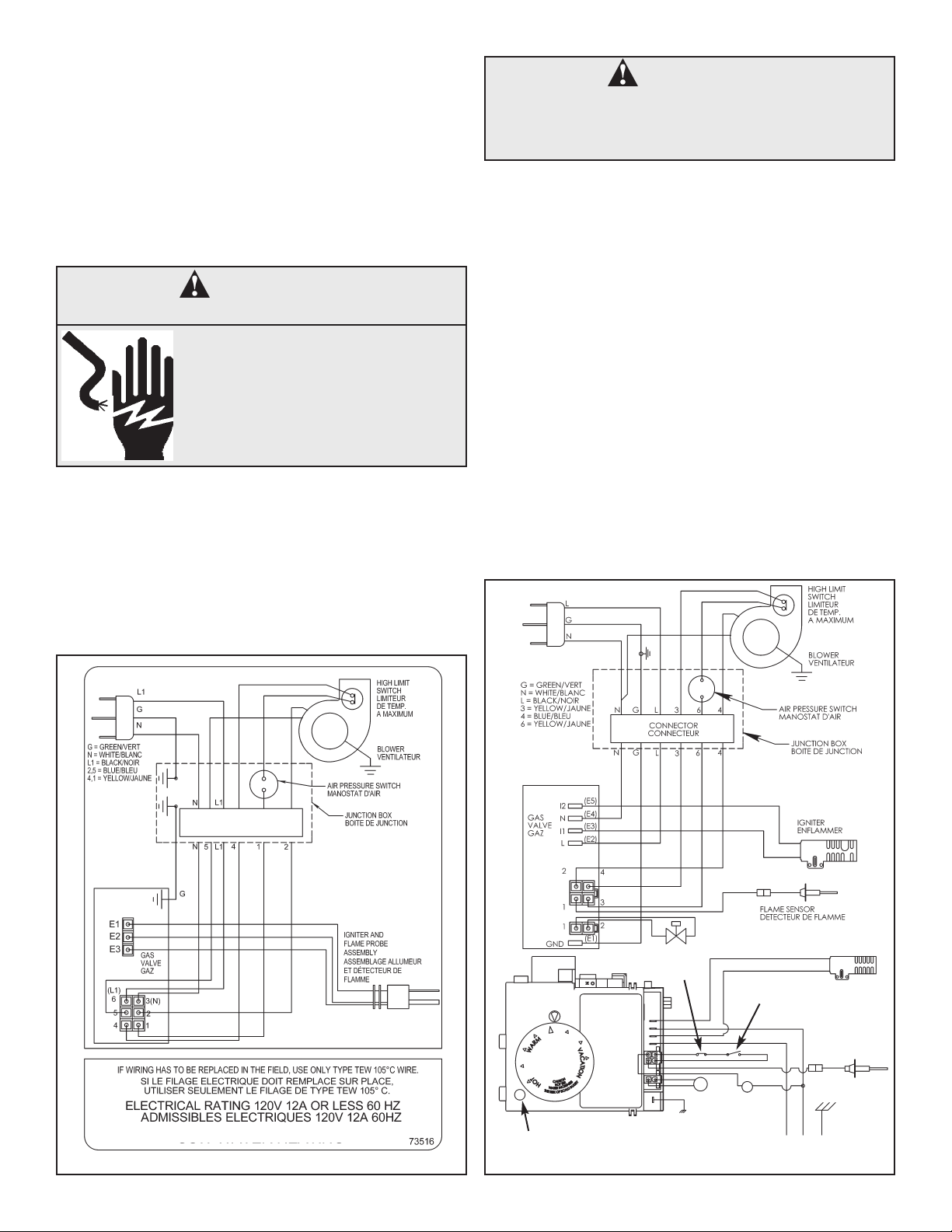

WARNING

When the unit is plugged in, 120VAC is present at the electric connections of the gas

control/thermostat.

WARNING

Electrical Shock Hazard

• Disconnect power before

servicing.

• Replace all parts and panels

before operating.

• Failure to do so can result in

death or electrical shock.

Figure 19 Wiring Diagram - (WDER 2000N)

E1

L1 N

GND

E2

E3

E4

E5

FLAME

SENSOR

GAS

VALV E

BLOWER

EXTERNAL MONITOR LIGHT

HIGH LIMIT

SWITCH

PRESSURE

SWITCH

IGNITER

BEIGE

HOUSING

Figure 18 Wiring Diagram - White-Rodgers Control

•

Fill the tank with water and check all connections for

leaks. Open the nearest hot-water faucet and let it run

for 3 minutes to purge the water lines of air and sediment and to ensure complete filling of the tank. The

electrical power may then be turned on. Verify proper

operation after servicing.

Note: Always reference the wiring diagram for the correct

electrical connections.

– 19 –

GAS CONTROL

SIDE VIEW

QUICK CONNECTS FOR

POWER SUPPLY AND IGNITER

LOCATED ON UNDERSIDE

OUTLET

PRESSURE

PORT

MANIFOLD PRESSURE

ADJUSTMENT (REMOVE

CAP FOR ACCESS)

3/4” NPT. WRAP

WITH TEFLON TAPE

(2 WRAPS MIN.)

GROUND

CONNECTION

GAS CONTROL

FRONT VIEW

GAS OUTLET

TO BURNER

GAS INLET

1/2” NPT

TEMPERATURE

ADJUSTMENT

BUTTONS

TEMPERATURE

INDICATORS

IGNITER AND FLAME

PROBE ASSEMBLY

COMBUSTION

BLOWER

AIR

PRESSURE

SWITCH

HIGH

LIMIT

SWITCH

TO POWER SUPPLY

DISCONNECT AND

OVERLOAD

PROTECTION

WHITE

BLACK

GREEN

INTELLI-VENT

TM

CONTROL

BOTTOM VIEW

Figure 21 Gas Control/Thermostat Details and Wiring Diagram (White-Rodgers)

CONNECTOR

GREEN

MAXIMUM SUPPLY INLET PRESSURE

14.0 in. w.c. (3.5kPa) ALL GASES

THIS GAS CONTROL IS EQUIPPED WITH AN ECO (ENERGY CUT-OFF)

THE ECO WILL SHUT THE GAS OFF SHOULD THE OUTLET WATER

TEMPERATURE EXCEED 93°(200°F)

SUPPLY INLET

PRESSURE PORT

SUPPLY GAS

INLET 1/2” NPT

MANIFOLD CONNECTION UNDER

CONTROL

MANIFOLD PRESSURE

PORT UNDER CONTROL

LED INDICATOR

BURNER MANIFOLD

PRESSURE ADJUSTMENT (REMOVE

DIAL FOR ACCESS

SAFETY

COVER

INCREASE

PRESSURE

DECREASE PRESSURE

GAS CONTROL VIEWED FROM GAS INLET

WITH TEMPERATURE DIAL REMOVED

Figure 20 Gas Valve/Temperature Control

BURNER MANIFOLD GAS PRESSURE

NATURAL GAS 3.5 in. w.c. (0.9kPa)

PROPANE GAS 10.0 in. w.c. (2.5kPa)

SUPPLY INLET GAS PRESSURE

NATURAL GAS 7.0 in. w.c. (1.7kPa)

PROPANE GAS 11.0 in. w.c. (2.7kPa)

GAS CONTROL SWITCH

GAS VALVE CONNECTOR

GAS VALVE

CONNECTOR

GND

QUICK CONNECTORS

MAIN AND IGNITER

PRESSURE SWITCH

AND INDUCER

GAS CONTROL/THERMOSTAT - VIEW OF ELECTRICAL

CONNECTIONS, WITH COVER REMOVED (WDER 2000N)

Installation Checklist

– 20 –

Check Here

1. Have the safety precautions described in this

manual been implemented?

2. Does the gas piping conform to the recommendations of your Gas Utility Company?

3. Has the gas piping been tested?

4. Is the supply pressure correct?

5. Is the water heater connected to the correct

gas supply as shown on the rating plate

(Natural Gas/Propane)

6. Is the clearance between the water heater and

combustible construction as per specifications?

7. Is the water piping correctly connected? Are

you certain that there are no leaks?

8. Is the water heater filled with water?

9. Is the cold water supply valve open?

10. Is the vent pipe installed properly and are the

vertical and horizontal runs properly supported?

11. Is the vent hood air intake opening unobstructed?

12. Is the T&P valve installed? Is the drain pipe

from the T&P valve unobstructed?

13. Is a drain pan installed (if required) with a proper overflow pipe, directed to a drain?

14. Have you taken steps to prevent water damage

in case of leaks?

15. Is the electric supply a 120V, electrically

grounded, 15A fused, correct polarity circuit?

16. Does the area around the water heater have

adequate ventilation?

If the answer to all of the questions

above is “Yes”, read the Operating

Instructions and proceed with lighting

the heater.

IV) OPERATING INSTRUCTIONS

Temperature Regulation

This water heater’s intended purpose is to heat water. Hot

water is needed for cleaning and sanitizing (bodies, dishes,

clothing etc.). Untempered hot water can present a scald

hazard. Depending on the time element and the people

involved (adults, children, elderly, infirm etc.) scalding may

occur at different temperatures.

It is recommended that lower temperatures be used to avoid

the risk of scalding. It is further recommended that the water

temperature be set for the lowest temperature that will satisfy your hot-water needs. This will also provide the most

energy efficient operation of the water heater.

Short, repeated heating cycles caused by small water uses

can cause temperatures at the point-of-use to exceed the

thermostat setting by up to 17°C (30°F). This condition is

referred to as “stacking”. If you experience this type of use

you should consider using lower temperature settings to

reduce scald hazards.

Valves for reducing the point-of-use temperature by mixing

cold and hot water are available.

Mixing Valves

Hot water can scald: Water heaters are intended to produce hot water. Water heated to a temperature that will satisfy space heating, clothes washing, dish washing, and

other sanitizing needs can scald and permanently injure you

upon contact. Some people are more likely to be permanently injured by hot water than others. These include the

elderly, children, the infirm, and physically/mentally handicapped.

If any one using the hot water fits into one of these groups

or if there is a provincial, state or local code requiring a certain temperature water at the hot water faucet, then you

must take special precautions. In addition to using the lowest possible temperature setting that will satisfy your hotwater needs, a means such as a mixing valve, should be

used at the hot-water faucets or at the water heater. Mixing

valves are available at plumbing supply or hardware stores.

Follow manufacturer’s instructions for installation of these

valves. Before changing the factory settings on the thermostat, read the “Temperature Regulation” section in this manual.

– 21 –

CAUTION:

Read before proceeding. If you do not

follow these instructions exactly, a fire or

explosion may result, causing property

damage, personal injury or loss of life.

This appliance is equipped with an ignition

device that automatically lights the burner.

Do not try to light manually with

a match or flame

.

WARNING

Never allow small children to use a hot-water

faucet, or to draw their own bath water.

Never leave a child or impaired person unattended in a bathtub or shower. Scald burns

can result.

DANGER

Water temperature over 52°C (125°F) can cause

severe burns instantly or death from scalds.

Children, disabled and elderly are at highest risk of

being scalded.

Feel water before bathing or showering.

Temperature limiting valves are available.

WARNING

Scald burns occur in under one second with

71°C (160°F) water, which the thermostat will

deliver if the temperature is set at “VERY

HOT”. Lower settings of the temperature will

reduce the risk of scald and will reduce your

fuel bill.

WARNING

Risk of scalding

Hot water can produce third degree burns

in 6 seconds at . . . . . . . .60°C (140°F)

in 30 seconds at . . . . . . .54°C (130°F)

in 5 minutes at . . . . . . . . .49°C (120°F)

Lighting Instructions (Robertshaw)

– 22 –

Gas Control/Thermostat

This heater may be equipped with a Robertshaw WDER

2000N gas control/thermostat and a hot-surface igniter. This

control is a combination gas valve, thermostat and ignition

controller for use on this power vented water heater. The

valve contains a micro-controller that supervises the ignition

sequence and monitors the temperature settings and operation of the heater.

This heater is equipped with a hot-surface ignition system that automatically ignites the burner. Do not

attempt to light this heater manually with a match or

flame-producing device.

Putting the Heater into Service

1. Turn the manual gas shut-off valve for the heater to the

“ON” position.

2. Turn the gas control switch to “ON”.

3. Follow the Lighting Instructions (Robertshaw) given on

the side of the water heater and also depicted in this

manual. See also “Gas Supply”, “Water Heater

Operation” and “Sequence of Operation”.

Temperature Adjustment

The temperature dial is adjusted to its lowest temperature position when shipped from factory.

•

The temperature of the water can be selected by adjusting the temperature dial located on the front of the control (see Figure 20).

•

The large arrow position of the thermostat is the preferred starting point.

•

Each division on the thermostat dial represents a 3°C

(5°F) water temperature change.

Note: To avoid scald injury, set the control to the lowest setting that will supply your hot-water needs.

There is a hot-water scald potential if the thermostat is set

too high. In households with children, disabled or the elderly, select a lower temperature setting. Tempering valves

(mixing valves) for reducing point-of-use water temperatures are available and may be required by your local

authority. Consult a licensed plumber or your local plumbing

authority.

Heater Shutdown

1. Turn the thermostat dial to the lowest setting.

2. If the heater is running let it shut down first.

3. Turn off all electrical power to the heater or unplug the

power cord from the receptacle.

4. a) For WDER 2000N controls, press the gas control

switch located on the top of the control. It will automatically turn to the “OFF” position.

5. Turn the manual gas supply valve to the water heater to

the “OFF” position.

Water Heater Operation

Figure 22 shows the water heater's sequence of operation

when a call for heat is initiated. The ignition control module

will attempt to light the burner three times. If the ignition control does not detect ignition it will enter lockout mode and

flash the error code.

– 23 –

CAUTION:

Read before proceeding. If you do not follow

these instructions exactly, a fire or explosion

may result, causing property damage, personal injury or loss of life.

WARNING

Risk of scalding

Hot water can produce third degree burns

in 6 seconds at . . . . . . . .60°C (140°F)

in 30 seconds at . . . . . . .54°C (130°F)

in 5 minutes at . . . . . . . . .49°C (120°F)

CONTROL CHECKS TO

ENSURE PRESSURE

SWITCH IS OPEN

BLOWER IS

ENERGIZED

CONTROL CHECKS TO

ENSURE PRESSURE

SWITCH CLOSES

INDICATING BLOWER

IS OPERATING AND

THERE ARE NO

VENTING BLOCKAGES

(INLET OR OUTLET)

IGNITER IS

ENERGIZED AND MAIN

VALVE IS OPENED

MAIN BURNER ON AND

THE FLAME IS

SENSED BY CONTROL

MAIN BURNER

CONTINUES TILL THE

WATER IN THE TANK

REACHES

THERMOSTAT

SETTING

MAIN BURNER SHUTS

OFF. BLOWER

CONTINUES FOR A

POST PURGE TIME

CALL FOR

HEAT

Figure 22 Sequence Of Operation

Lighting Instructions (White-Rodgers Intelli-VentTM)

– 24 –

Gas Control/Thermostat

Alternatively, this heater may be equipped with the WhiteRodgers Intelli-VentTMgas control/thermostat and a hot-surface igniter. This control is a combination gas valve, thermostat and ignition controller for use on this power vented

water heater. The valve contains a microcomputer that

supervises the ignition sequence and monitors the temperature settings and operation of the heater. The computer

also monitors the flammable vapour safety features of this

heater.

This heater is equipped with a White-Rodgers Silicon

Nitride Igniter system that automatically ignites the

burner. Do not attempt to light this heater manually with

a match or flame-producing device.

Putting the Heater into Service

1. Turn the manual gas shut-off valve for the heater to the

“ON” position.

2. Follow the Lighting Instructions (White-Rodgers) given

on the side of the water heater and also depicted in this

manual. See also “Gas Supply”, “Water Heater

Operation” and “Sequence of Operation”.

3. Upon start up all the indicator lights on the front of the

control will come on and then turn off. This indicates

that the control has completed a self-diagnostic test and

is ready for operation.

Note: If any of the indicator lights remain on, this indicates

a system fault that needs correcting. See the “System Error

Codes” and “Troubleshooting Guide (White-Rodgers)” for

corrective action.

Temperature Adjustment

The control is adjusted to its lowest temperature setting

(approximately 21°C (70°F)) when shipped from factory.

The temperature of the water can be selected by using the

temperature adjustment buttons on the front of the gas control (see Figure 18) as follows:

1. “Wake up” the temperature indicators by holding down

both the “COOLER” and “HOTTER” temperature adjustment buttons at the same time for one second. One or

two of the temperature indicators will light up. After 30

seconds, if no other buttons are pushed, the control will

go back to “Sleep” mode and both buttons will again

have to be pressed to see the water temperature setting.