STORAGE BOOSTER TANKS

INSTALLATION AND

OPERATING INSTRUCTIONS

Read these instructions thoroughly before starting

PART NO. 71772 REV. D (09-07)

GSW Water Heating is a division of

A. O. Smith Enterprises Ltd.

WARNING:

If the information in these instructions is

not followed exactly, a fire or explosion

may result causing property damage, personal injury or death.

WARNING:

Improper installation, adjustment, alteration, service, or maintenance can cause

injury or property damage. Refer to this

manual. For assistance or additional information, consult a qualified installer, service agency, or the electric utility.

FOR YOUR SAFETY

• Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

• Installation and service must be performed by a qualified installer, service

agency or the electric utility.

TABLE OF CONTENTS

I)

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

II) Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

III) Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

IV) Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

V) Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

PLEASE RETAIN THESE INSTRUCTIONS IN A

SAFE LOCATION FOR FUTURE REFERENCE

- 2 -

I) INTRODUCTION

Thank you for purchasing this storage booster tank.

Properly installed and maintained, it will provide years of

trouble free service.

The warranty on this storage booster tank is in effect only

when the tank is installed and operated in accordance with

these instructions. The manufacturer of this tank will not be

liable for any injury or property damage resulting from failure to comply with these instructions.

IMPORTANT: Read and understand these instructions

before installing and operating your storage booster tank.

Description

The JOHN WOOD series of storage booster tanks, available in 40, 50 or 80 gallon sizes, have been designed to

supply hot water for domestic use when combined with a

tankless coil boiler or other water heating source. Each tank

is equipped with an adjustable thermostat, pre-wired and

ready for connection to a circulator pump (not supplied).

These tanks are not

constructed to ASME requirements and

should not be used for such applications.

II) SAFETY

Relief Valve Requirements

T&P Valve Check

Inspect the relief valve annually to ensure proper operation.

This involves opening the valve to check that it is flowing

freely and that there are no blockages and letting it snap

shut (see “MAINTENANCE” section).

III) INSTALLATION

Local Codes

The installation of this storage tank must be In accordance

with these Instructions and all applicable local codes.

Location

Locate the storage tank in a clean dry area close to the

water heating source and preferably central to the piping

system. Adequate clearance for accessibility to permit main-

WARNING

For protection against excessive temperatures and pressure, install temperature and pressure protective equipment required by local codes, but no less than a combination Temperature and Pressure (T&P) Relief Valve certified as meeting the requirements for Relief Valves and

Automatic Gas Shutoff Devices for Hot Water Supply

Systems, ANSI Z21.22, by a nationally recognized test-

ing laboratory that maintains periodic inspection of production of listed equipment or materials. The valve shall

be marked with a maximum set pressure not to exceed

the maximum working pressure of the storage tank. The

T&P valve shall be rated for the BTU INPUT of the entire

system.This T&P valve may be in addition to any T&P

valve that is required on the boiler, or other energy supply

system. Install the valve into the opening provided on the

storage tank, or other approved system location. Provide

tubing so that any discharge from the valve will exit within

152mm (6 in.) above, or any distance below the structural floor and cannot contact any live electrical part. The end

of the relief pipe opening should terminate near the floor

drain or other suitable location. Do not place a valve(s) or

any other blockage or restrictions between the tank and

the T&P valve.

Excessive Weight Hazard

Use two or more people to move and install

storage booster tank. Failure to do so can

result in back or other injury.

WARNING

CAUTION

Hydrogen gas can be produced in a hot water system

served by this storage tank that has not been used for a

long period of time (generally two (2) weeks or more).

Hydrogen gas is extremely flammable and can ignite

when exposed to a spark or flame. To reduce the risk of

injury under these conditions, it is recommended that the

hot water faucet be opened for several minutes at the

kitchen sink before using any electrical appliance connected to the hot water system. Use caution in opening

faucets. When hydrogen is present, there will probably be

an unusual sound such as air escaping through the pipe

as the water begins to flow. There should be no smoking

or open flame near the faucet at the time it is open.

IMPORTANT:

This storage booster tank must be installed strictly in

accordance with the instructions enclosed, and local electrical, fuel and building codes. It is possible that connections to the tank, or the tank itself, may develop leaks. IT

IS THEREFORE IMPERATIVE that the storage booster

tank be installed so that any leakage of the tank or related water piping is directed to an adequate drain in such a

manner that it cannot damage the building, furniture, floor

covering, adjacent areas, lower floors of the structure or

other property subject to water damage. This is particularly important if the tank is installed in a multi-story building,

on finished flooring or carpeted surfaces. GSW WILL NOT

ASSUME ANY LIABILITY for damage caused by water

leaking from the storage booster tank, pressure relief

valve, or related fittings. Select a location as centralized

within the piping system as possible. In any location

selected, it is recommended that a suitable drain pan be

installed under the storage booster tank. This pan must

limit the water level to a MAXIMUM depth of 45mm (1 3/4

in.) and have a diameter that is a minimum of 50mm (2 in.)

greater than the diameter of the storage booster tank.

Suitable piping shall connect the drain pan to a properly

operating floor drain.

- 3 -

tenance and service must be provided. Water lines and the

storage tank should be protected from freezing temperatures. Do not install the storage tank in outdoor unprotected

areas. It is desirable to have a floor drain nearby to permit

easy draining if necessary.

Circulator Pump

A circulator pump is not supplied. Use only a bronze body

model rated for 110/120 volts, 60Hz. Install in accordance

with the pump manufacturer’s instructions using standard

plumbing practices.

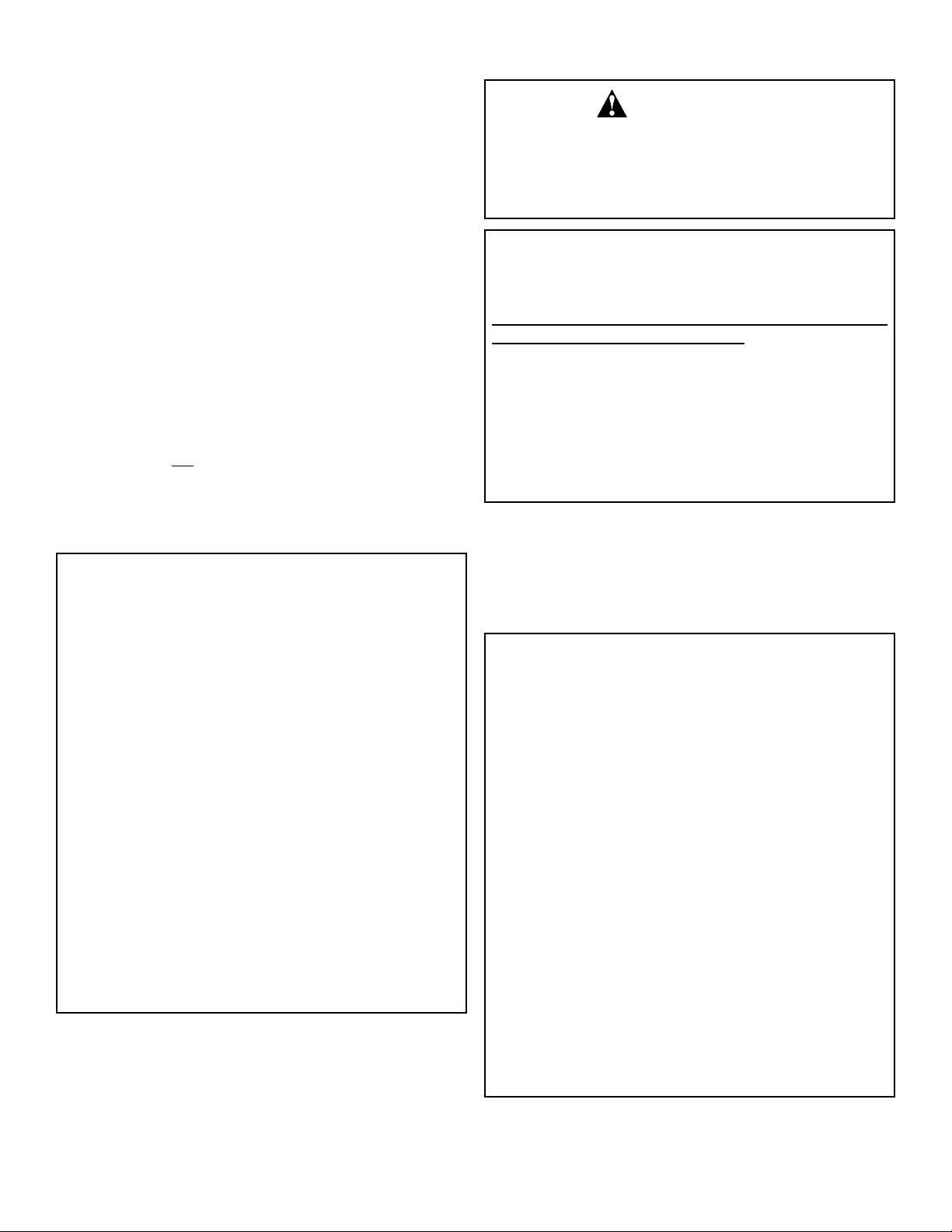

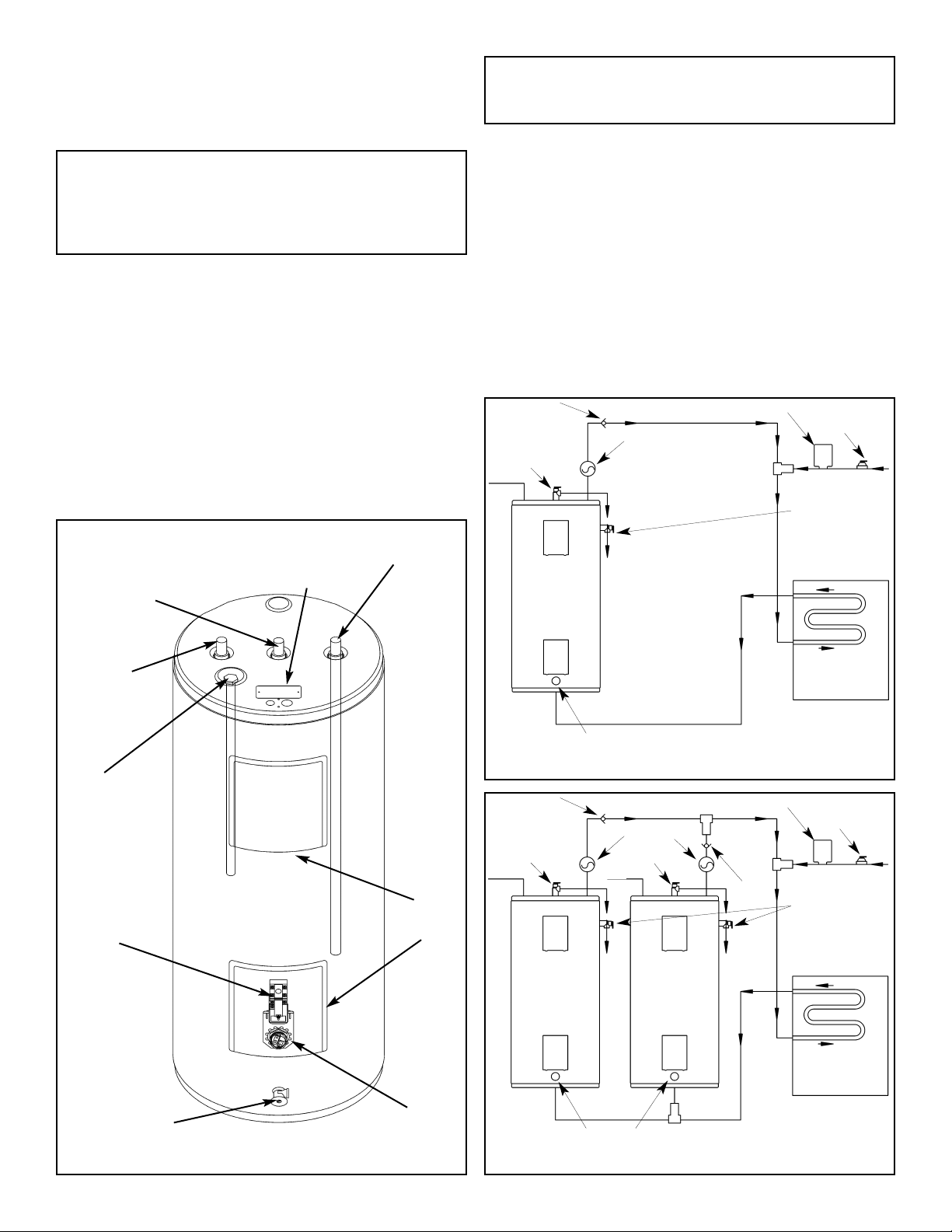

Plumbing Connections

The main parts and features of your storage booster tank

are identified in Figure 1. Install plumbing according to

Figure 2 for single storage tank and according to Figure 3

for multiple storage tank systems.

1. Ensure the storage tank is level before starting installation.

2. Install circulation loop as shown using 19mm (¾ in.)

copper pipe.

3. Install the cold water supply piping into a tee between

the circulator discharge and the boiler coil inlet.

4. Connect the boiler supply line to the combination return

and drain valve.

5. Connect hot water supply to top tank fitting.

6. Install 19mm (¾ in.), 150 psi Temperature and Pressure

Relief Valve into the tank as shown.

7. A check valve may be installed between the cold water

tee connection and the circulator. This will force the cold

water through the coil first.

NOTE: The check valve can often be noisy and cause

reduced supply pressures. For multiple storage tank sys-

ACCESS

DOORS

SUPPLY (TO BOILER

TANKLESS COIL)

T&P VALVE (SOME

MODELS WILL HAVE

A SIDE MOUNT FOR

THIS VALVE)

HOT

WATER

OUTLET

ANODE

THERMOSTAT

CONTROL

THERMOSTAT

RETAINER

COMBINATION

RETURN &

DRAIN VALVE

JUNCTION BOX

Figure 2: Single Storage Booster Plumbing Diagram

COMBINATION RETURN

& DRAIN VALVE

STORAGE

BOOSTER

TANK

TANKLESS

COIL BOILER

HOT

T& P VA LVE

(FOR SOME

MODELS)

HOT

T& P VA LVE

CIRCULATOR

PUMP

CHECK VALVE

EXPANSION TANK (OPTIONAL)

PRESSURE

REGULATOR

(OPTIONAL)

COLD

Figure 3: Multiple Storage Booster Plumbing Diagram

COMBINATION RETURN

& DRAIN VALVE

STORAGE

BOOSTER

TANK

STORAGE

BOOSTER

TANK

TANKLESS

COIL BOILER

HOT

T& P VA LVE

(FOR SOME

MODELS)

HOT

HOT

T& P VA LVE

CIRCULATOR

PUMP

CHECK VALVE

EXPANSION TANK (OPTIONAL)

PRESSURE

REGULATOR

(OPTIONAL)

COLD

CHECK

VALV E

T& P VA LVE

IMPORTANT

Do not apply heat directly to tank fittings when making

sweat connections. They contain non-metallic material.

Figure 1: Main Parts and Features

WARNING

The water heating source piping and components connected to the tank must be suitable for potable water use.

TOXIC chemicals such as used for boiler treatment must

not be introduced into the tank.

- 4 -

tem, check valves must be installed to prevent the circulator

from pumping hot water into another tank and overheating

it.

8. The use of a pressure regulator is optional, but recommended when the cold supply pressure is over 80 psi.

Reducing the inlet pressure to 45-60 psi will reduce

probability of relief valve discharge by thermal expansion.

9. The water utility supply meter may contain a check

valve, back-flow preventer or water pressure reducing

valve. This will create a closed water system. During the

heating cycle, the water expands creating a pressure

build-up in the water system. A Temperature and

Pressure (T&P) Relief Valve must be installed (150 psi

maximum pressure). See preceding section. If the T&P

valve discharges periodically, this may be due to thermal expansion in a closed system. To prevent this condition and to reduce the possible build up of lime on the

Temperature and Pressure Relief Valve seat, either one

of the following installations is required;

i) Install a 125 psi pressure relief valve in the cold water

supply line. Make sure that the discharge of this valve is

protected from freezing and directed to an open drain.

ii) Install an expansion tank on the cold water supply

line.

10. A vacuum relief valve may be installed to provide venting of a closed system. Check local code requirements.

Electrical Wiring

Electrical wiring must be in accordance with local codes; or

in the absence of local codes with the National Electrical

code ANSI/NFPA 70 or The Canadian Electrical Code, as

applicable.

1. Supply 110/120 volt, 60Hz power, to the junction box

located at the top of the tank.

2. Connect the circulator pump in series with the thermo-

stat as shown in Figure 4.

3. A ground wire must be supplied from the ground con-

nection at the service panel to the ground screw at the

junction box.

4. The thermostat is rated for a maximum inductive current

of 7 FLA at 120 VAC. Do not exceed this rating for the

circuit.

5. Do not install or connect electrical heating elements to

this tank.

Filling

NOTE: When filling, avoid water leakage. Do not allow the

insulation of the tank to get wet as water can cause electrical malfunction or reduce the effectiveness of the insulation.

1. To insure complete filling of the tank, allow air to exit by

opening a hot water faucet that is served by the tank

and is some distance away from the heater.

2. Ensure the storage tank drain valve is closed.

3. Open the cold water supply valve and fill the tank and

piping system with water. When an uninterrupted

stream of water, without apparent air bubbles, flows

from the open hot water faucet, the system is full.

4. Close the open hot water faucet. Check the system for

leaks, repair as necessary and retest.

5. Connect a hose to the drain valve and route to a suit-

able drain. Open the drain valve and let water run to

flush out any foreign matter that may have entered the

system. Once flushed, close the drain valve and disconnect hose.

Temperature Regulation

In order to reduce the risk of scald injury, the thermostat is

factory set to 49°C (120°F). The thermostat operates automatically and can be adjusted to provide higher or lower

water temperature as needed. A mixing valve in connection

with a higher temperature setting should be used to reduce

risk of scald injury.

Figure 4: Wiring Diagram

IF WIRE HAS TO BE REPLACED IN THE FIELD,

USE ONLY TYPE TEW 105°C WIRE.

BOOSTER TANK

MUST BE

GROUNDED TO

THE ELECTRICAL

SUPPLY SERVICE.

BLACK

BLACK

WIRE CONNECTORS

CIRCULATOR

PUMP

L1

120 VOLT SUPPLY

JUNCTION BOX

(AT CASING TOP)

THERMOSTAT

L2

DANGER

CAUTION

Increasing the thermostat setting above the pre-set temperature may cause severe burns and consume excessive energy. Hotter water increases the risk of scald injury.

IMPORTANT

RISK OF SCALDING. Hot water will cause third degree

burns in 6 seconds at 60°C (140°F), in 30 seconds at 54°

(130°F).

- 5 -

IV) OPERATION

1. Follow boiler or heat source installation and operating

instructions.

2. Fill the tank (see “FILLING” section).

3. The boiler or water heating source should be set to provide at least 11°C (20°F) higher water temperature than

the temperature setting of the storage tank

4. Turn power on, check for proper operation of boiler and

storage tank.

Temperature Adjustment

The setting of 49°C (120°F) has been proven to be satisfactory from the standpoint of operational costs and safety.

We recommend the thermostats remain set at 49°C

(120°F).

If water temperature adjustment is required:

1. Turn "OFF" the electrical supply to the tank.

2. Remove lower access door.

3. Turn back insulation.

4. Adjust thermostat to water temperature desired.

5. Replace insulation and access door.

6. Turn "ON" the electrical supply to the tank.

V) MAINTENANCE

T&P Valve Check

Do not attempt to operate this storage tank with the cold

water inlet valve closed. The Temperature and Pressure

Relief Valve must be manually operated at least once a

year. This involves opening the valve to check that it is flowing freely and that there are no blockages. WARNING!

WATER MAY BE HOT and water flow can be forceful.

Caution should be taken to ensure that:

1. No one is in front of or around the outlet of the T&P

valve discharge line.

2. The water manually discharged will not cause any bod-

ily injury or property damage. The water may be

extremely hot.

While standing clear of the outlet (discharge water may be

hot), lift the lever and let it snap shut. The water should stop

immediately. If it fails to reset completely and continues to

release water, the valve is not functioning properly and must

be replaced immediately. Close the cold water supply valve,

drain the tank as directed in the “Draining and Flushing”

section, and replace the T&P valve with a new one. Failure

to install and maintain an approved T&P valve will release

the manufacturer from any claim that might result from

excessive temperature or pressure. In systems where the

relief valve discharges periodically, this may be due to thermal expansion or to a thermostat that is operating at too

high a temperature. If you suspect a malfunctioning thermostat, contact a qualified service technician for repairs.

Draining and Flushing

Some service work to be performed on the tank requires the

tank to be drained. It is also recommended that the tank be

drained and flushed every 6 months to remove any sediment and lime which may build up in the bottom of the tank

during operation. Such buildup can result in noisy operation.

To drain the tank:

1. Turn "OFF" the electrical supply to the tank.

2. Close the cold water supply valve.

3. Open a nearby hot water faucet served by the system.

4. Connect a hose to the drain valve and route it to an adequate drain.

CAUTION! The water being drained can be extremely

hot! The drain hose should be rated for at least 93°C

(200°F). If the drain hose does not have this rating, open the

cold water supply valve and a nearby hot water faucet

served by the system until the water flow is no longer hot.

Close the cold water supply valve and resume.

5. Open the drain valve and allow all the water to drain

from the tank.

6. Open the cold water supply valve and flush the tank as

needed to remove sediment and any other foreign matter that may have entered the system. Close the cold

water supply valve when clean water flows.

7. Perform any other servicing as required.

8. Close the drain valve, disconnect hose and refill the

tank (see “FILLING” section).

9. Turn "ON" the electrical supply to the tank.

Cathodic Protection

Your storage booster tank has been equipped with one or

more anodes that protect the tank from corrosion. Over

time, as the anode works, it slowly dissolves and must be

replaced. If the anode(s) is less than 10mm (3/8 in.) in diameter, or has any of the inner steel core exposed, it must be

replaced. Depending on water conditions, an anode can last

from one to ten years. Many localities treat their water and

this can have a significant effect on the life of your heater.

Water conditioning, such as over-softening, can accelerate

the rate at which the anode(s) is consumed. Rapid depletion

can leave a heater unprotected causing a premature failure.

It is good practice to check the anode(s) annually to see if it

needs replacing. Operating a storage tank without an

actively working anode(s) will void the warranty. Failure to

maintain the anode may result in premature failure of the

storage tank due to corrosion and leaks.

CAUTION

The out-flowing water is hot. Avoid splashing the water on

yourself or on the surroundings where it may cause damage.

Figure 5: T&P Valve Test

Temperature and Pressure

Relief Valve

Manual Relief Valve

Discharge line to drain

- 6 -

Anode Maintenance

1. Turn "OFF" the electrical supply to the tank.

2. Close the cold water supply valve.

3. Open a nearby hot water faucet served by the system

to depressurize the system.

4. Connect a hose to the drain valve and drain 22 litres (6

gal.) as directed in the “Draining and Flushing” section.

NOTE: The anode(s) has been factory installed using a

power tool. It may be necessary for a second person to stabilize the tank. A few sharp blows on the handle of the socket wrench should loosen the anode nut. If an impact wrench

(power drive) is available, this is an easy way to remove an

anode.

6. Using a 1 1/16" socket, remove anode(s) and inspect it.

The surface may be rough, full of pits and crevices, but

this is normal. If it is less than approximately 10mm (3/8

in.) in diameter, or the inner steel core is exposed, the

anode(s) should be replaced.

7. Apply Teflon®tape or sealing compounds approved for

use with potable water, to the threads of the anode(s)

and install into the tank top.

8. Open the cold water supply valve and open a nearby

hot water faucet to purge air from the tank as directed

in the “Filling” section.

9. Check for leaks, repair as required, and re-test.

10. Turn "ON" the electrical supply to the tank.

- 7 -

LIMITED WARRANTY

RESIDENTIAL STORAGE TANK TYPE WATER HEATER FOR INSTALLATION IN A SINGLE FAMILY DWELLING

A. WHO IS COVERED.

GSW WATER HEATING AND ITS SUPPLIERS, (herein collectively referred to as “Manufacturer”) warrants only to the

original consumer purchaser (hereinafter “Owner”) of the water heater, within the boundaries of continental United States,

or Canada, or their territories, so long as he or she continuously occupies the single family dwelling in which this water

heater is initially installed for the period specified below. This warranty is not transferable. This warranty is reduced to one

year if the water heater is used in a commercial, or industrial application, or if the water heater is used to supply more than

one dwelling unit. Consumers must retain point-of-sale proof of purchase to validate warranty entitlement.

B. WHEN IT IS COVERED.

The water heater is warranted only when it is installed, operated and maintained in accordance with the printed instructions accompanying the water heater. The water heater shall/must be installed in such a manner that, if the tank or any

connection thereto should leak, the resulting flow of water will not cause damage to the area in which it is installed. The

water heater’s temperature and pressure relief valve must be piped to the nearest drain to avoid damage in the event the

valve is actuated. For detailed instructions read the manual accompanying the water heater and review drawings in the

manual.

C. WHAT THE MANUFACTURER WILL DO AND THE PERIOD OF COVERAGE.

1. The Inner T

ank.

If the inner tank leaks within the warranty period shown in the table at the top of this page after the

original installation, Manufacturer will furnish a new water heater of Manufacturer’s then prevailing comparable model.

If industry standards, regulatory changes, product improvements or product obsolescence prohibits Manufacturer from

furnishing an identical model replacement water heater under this warranty, the Owner will be furnished with a new

water heater of comparable capacity; however, the Owner will be charged for the additional value of the item(s) which

Manufacturer has incorporated in the replacement water heater. A prior authorization number must be obtained from

the Manufacturer before replacing the water heater. This warranty is limited to one replacement water heater at the

original installation site.

2. Component Part.

If any component part other than the inner tank proves to Manufacturer’s satisfaction to be defective in material or workmanship within one (1) year, the Manufacturer will furnish the Owner with a replacement for the

defective part(s). This warranty is limited to one replacement component part for each original part.

3. Return of Defective W

ater Heater and Component Parts. Manufacturer reserves the right to examine the alleged

defect in the water heater or component part(s), and it will be the Owner’s obligation (See paragraph D.5) to return the

water heater and/or component part(s) to the Manufacturer.

a. When returning a water heater it must include all component parts and the data plate label.

b. When returning component part(s), they must be individually tagged and identified with the water heater’s product

number, model number, serial number, date of purchase and date of installation.

c. THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF. THIS

EXPRESS WARRANTY IS, WHERE PERMITTED BY LAW, IN LIEU OF AND EXCLUDES AND REPLACES ALL

OTHER CONDITIONS, WARRANTIES, GUARANTEES, REPRESENTATIONS, OBLIGATIONS OR LIABILITIES

OF THE MANUFACTURER OF ANY NATURE OR KIND, EXPRESS OR IMPLIED, HOWEVER ARISING

(WHETHER BY CONTRACT, CONDUCT, STATEMENT, STATUTE, NEGLIGENCE, PRINCIPLES OF MANUFACTURER’S LIABILITY, OPERATION OF LAW OR OTHERWISE) WITH RESPECT TO THE UNIT OR ITS FITNESS

FOR A PARTICULAR PURPOSE, MERCHANTABILITY, INSTALLATION, OPERATION, REPAIR OR REPLACEMENT. THE MANUFACTURER EXPRESSLY DISCLAIMS ANY AND ALL IMPLIED WARRANTIES. IN NO EVENT

WILL THE MANUFACTURER’S LIABILITIES EXCEED THE COST OF THE DEFECTIVE PART(S) OR UNIT.

D. WHAT THIS WARRANTY DOES NOT COVER.

1. The Unit must not be installed where water damage can result from a leak, while provision(s) shall be made for directing any water escaping from the Unit, to a properly operating drainpipe. As all units of this type may eventually leak,

you must protect against any potential water damage. The Manufacturer accepts no responsibility for such damage,

nor any incidental or consequential loss, nor damage(s) related thereto, suffered by the Owner of the Unit nor by any

third party.

2. Manufacturer shall not be liable under this warranty and this warranty shall be void and have no effect if the following

events occur:

a. The water heater or any of its component parts have been subject to misuse, alteration, neglect or accident; or

b. The water heater has not been installed in accordance with the applicable local plumbing and/or building code(s)

and/or regulations or in their absence, with the latest edition of the Natural Gas and Propane Installation Code,

and/or the Canadian Electrical Code; or

c. The water heater is not installed, operated and maintained in accordance with the Manufacturer’s instructions; or

See Rating Label Serial Number prefix for

Warranty Code.

Warranty Code: P R S T U V W Y

Warranty Years: 3 5 6 7 8 9 10 12

- 8 -

d. The water heater or any of its component parts are damaged or fails from operation with an empty or partially

empty tank (such as, but not limited to elements burned out in a dry tank); or

e. The water heater or any part has been under water; or

f. The water heater is exposed to highly corrosive atmospheric conditions. No warranty extends, for example, and

without limitation of the foregoing, to Units exposed to: salts, chemicals, exhausts, pollutants or contaminants; or

g. The water heater is not continuously supplied with potable water; or

h. The water heater replacement is requested for reasons of noise, taste, odor, discoloration and/or rust; or

i. The water heater is operated at temperatures exceeding the maximum setting of the thermostat and/or high limit

control provided by the Manufacturer, or at water pressures exceeding the pressure reading stated on the Unit; or

j. The water heater is operated without an operating anode; or

k. The water heater is supplied or operated with deionized water; or

l. The water heater is removed from its original installation location; or

m. The water heater is installed outdoors (this water heater is intended only for indoor installation); or

n. The water heater is converted, or is attempted to be converted, from one voltage or wattage to another, if an elec-

tric water heater, or from one type gas to another, if a gas water heater; or

o. The water heater has not been fired at the factory rated input and fuel for which it was factory built; or

p. The water heater or any of its component parts fail due to sediment build-up; or

q. The water heater does not have installed a properly operating temperature and pressure relief valve, certified to

ANSI Z21.22/CSA “Requirements for Relief Valves for Hot Water Supply Systems”; or

r. The water heater or any of its component parts fail because of fire, floods, lightening, or any other act of God, or

any other contingency beyond the control of the Manufacturer; or

s. The water heater is installed in a closed system without adequate provision for thermal expansion.

3. Except when specifically prohibited by the applicable law, the Owner, and not the Manufacturer, shall be liable for and

shall pay for all charges for labour or other expenses incurred in the removal, repair or replacement of the water

heater or any component part(s) claimed to be defective or any expense incurred to remedy any defect in the product.

Such charges may include, but are not necessarily limited to:

a. All freight, shipping, handling and delivery costs of forwarding a new water heater or replacement part(s) to the

Owner.

b. All costs necessary or incidental in removing the defective water heater or component part(s) and installing a new

water heater or component part(s).

c. Any material required to complete, and/or permits required for, installation of a new water heater or replacement

part(s), and

d. All costs necessary or incidental in returning the defective water heater or component part(s) to a location desig-

nated by the Manufacturer.

4. The terms of this Limited Warranty cannot be modified by any person, whether or not he/she claims to represent or act

on behalf of the Manufacturer.

E. HOW THE ORIGINAL OWNER CAN MAKE A WARRANTY CLAIM.

1. The Owner should submit the warranty claim directly to Manufacturer’s Service Department, at the address or phone

number listed below, and Manufacturer will arrange for the handling of the claim.

2. Whenever any inquiry or request is made, be sure to include the water heater’s catalogue number, model number,

serial number, date of purchase, date of installation, and location of installation.

This warranty and the Manufacturer’s obligations shall be construed and determined in accordance with the laws of both the

Province of Ontario, and of Canada in force therein. This Warranty does not affect specific legal rights of a consumer under

applicable law, except to the extent that such rights may be waived or replaced, and the provisions hereof are deemed to be

amended to the extent necessary. The unenforceability of any provision, in whole or in part, of this Certificate shall not affect

the remaining provisions. Any and all repair and/or replacement of part(s) or Unit are the sole and exclusive remedy available

against the Manufacturer.

GSW Water Heating

599 Hill Street West

Fergus, ON Canada N1M 2X1

Should you have any questions please

Email us at techsupport@gsw-wh.com or

Visit our websites: www.gsw-wh.com or

www.johnwoodwaterheaters.com or

Call our Technical Support line at

1-888-GSW-TECH (479-8324)

GSW Water Heating is a division of A.O.Smith Enterprises Ltd.

Loading...

Loading...