John Wood Direct Vent Models No Longer in Production User Manual

GSW WATER HEATING

599 Hill Street West

Fergus, ON, Canada N1M 2X1

DIRECT VENT GAS FIRED WATER HEATER

INSTALLATION AND OPERATING INSTRUCTIONS

Read these instructions thoroughly before starting

TABLE OF CONTENTS

I) Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

II) Installation & Location . . . . . . . . . . . . . . . . . . .2-3

III) Vent Connections . . . . . . . . . . . . . . . . . . . . . .4-6

IV) Gas Connections . . . . . . . . . . . . . . . . . . . . . . . .6

V) Water Pipe Connections . . . . . . . . . . . . . . . . . . .6

VI) Temperature & Pressure . . . . . . . . . . . . . . . . . . .7

VII) Lighting & Operating Instructions . . . . . . . . . .8-10

VIII) Service And Maintenance . . . . . . . . . . . . . . .11-12

IX) Combo Heating . . . . . . . . . . . . . . . . . . . . . . . . .12

X) Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

PLEASE RETAIN THESE INSTRUCTIONS IN A

SAFE LOCATION FOR FUTURE REFERENCE

FOR YOUR SAFETY

• Do not store or use gasoline or other

flammable vapours and liquids in the

vicinity of this or any other appliance.

• Installation and service must be performed by a qualified installer, service agency or the gas supplier.

WARNING: Improper installation,

adjustment, alteration, service, or

maintenance can cause injury or

property damage. Refer to this manual. For assistance or additional

information, consult a qualified

installer, service agency, or the gas

supplier.

WARNING: If the information in

these instructions is not followed

exactly, a fire or explosion may

result causing property damage, personal injury or death.

WHAT TO DO IF YOU SMELL GAS?

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier from

a neighbor’s phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

GSW Water Heating is a division of GSW Water Products Inc.

PART NO. 71061 REV. A (04-09)

I) INTRODUCTION

Thank you for purchasing this water heater. Properly

installed and maintained, it will provide years of trouble

free service. This manual gives instructions for the proper installation, safe operation and maintenance of this

water heater. It is your responsibility to ensure that your

water heater is properly installed and cared for.

The warranty on this water heater is applicable only when

the water heater is installed and operated in accordance

with these instructions. The manufacturer of this water

heater will not be liable for any injury or property damage

resulting from failure to comply with these instructions.

Protect your warranty: Regularly maintain your water

heater as detailed in the service and maintenance section of this manual.

WARNING

This water heater must be installed strictly in

accordance with the detailed instructions

enclosed and local building codes. It must be

installed with a proper pressure relief valve

which may release water in operation. It is also

possible that connections to the water heater,

or the water heater itself, may develop leaks. It

is therefore IMPERATIVE that the water heater

be installed so that any water is directed to an

adequate drain in such a way that it cannot

damage the building, furniture, carpeting or

other property subject to water damage. GSW

CANNOT BE HELD RESPONSIBLE for damage caused by water from the water heater,

pressure relief valve, or related fittings where

adequate provision to drain such water has not

been made. Closets without drains and carpeted areas are examples of unsuitable locations

for any water heater.

will not result in damage to the area adjacent to the water

heater or to the lower floors of the structure. When such

locations cannot be provided, it is recommended that a

suitable drain pan be installed under the heater. Such

pans should be a maximum of 38mm (1-1/2 in.) deep and

have a minimum length and width of at least 50mm (2 in.)

greater than the diameter of the water heater and should

be piped to an adequate drain.

Under no circumstances is the manufacturer to be held

liable for any water damage in connection with this water

heater.

CAUTION: When this water heater is installed directly on

carpeting, carpeting must be protected by a metal or

wood panel beneath the appliance extending beyond the

full width and depth of the appliance by at least 76mm (3

in.) in any direction, or if the appliance is installed in an

alcove or closet, the entire floor must be covered by the

panel. The panel must be strong enough to carry the

weight of the heater when full of water. Failure to heed

this warning may result in a fire hazard.

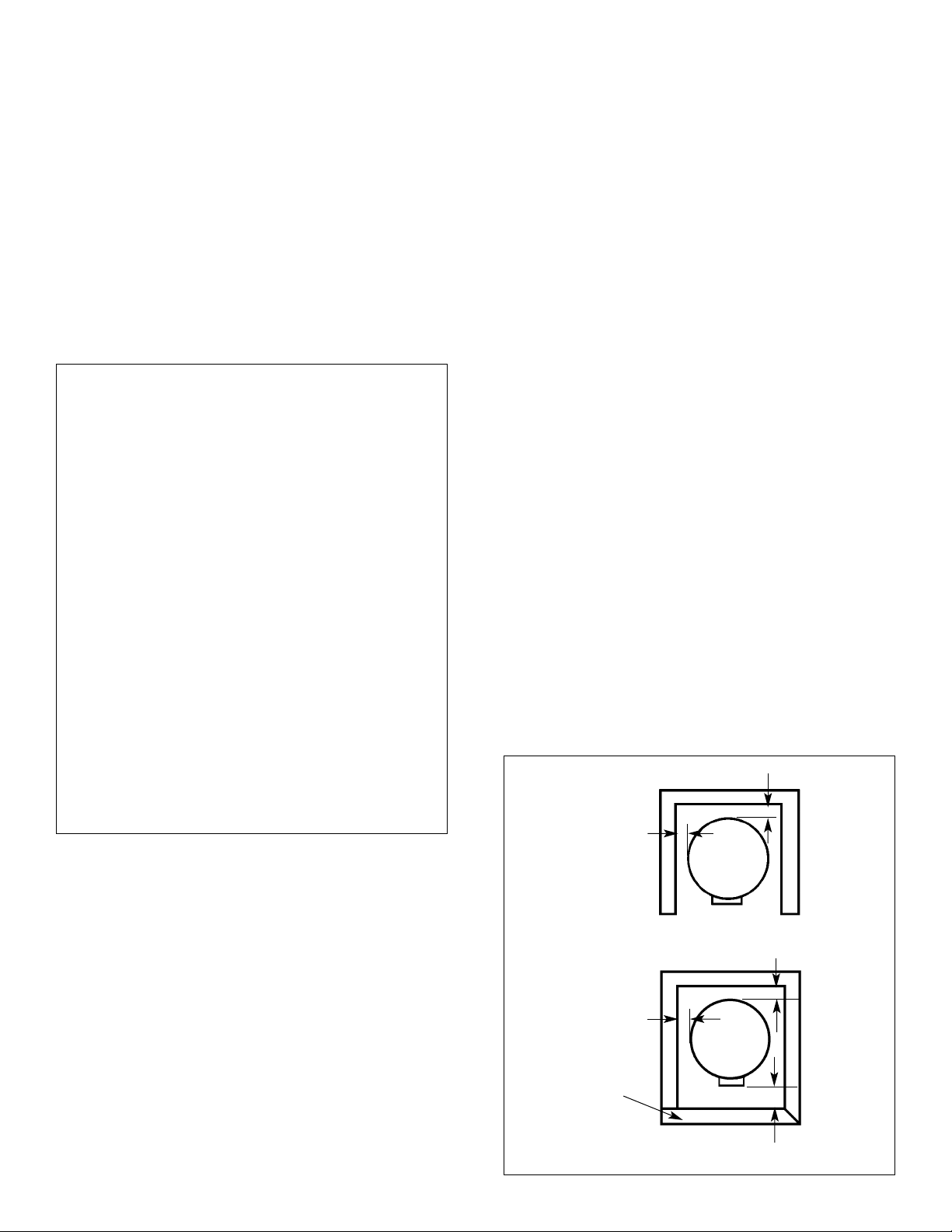

Minimum clearances between the heater and combustible/non combustible materials are 25mm (1 in.) at

the sides and rear; 508mm (20 in.) from the top of water

heater and 25mm (1 in.) around the vent pipe. A minimum

of 915mm (3 ft.) of clearance is required at the front (control) side of the heater for service.

For a closet installation, the door at burner side should be

openable and a minimum of 102mm (4 in.) clearance is

needed. Water heater is certified for installation on a

combustible floor (see Figure 1).

ALCOVE INSTALLATION

(TOP VIEW)

25mm (1 in.)

25mm (1 in.)

II) INSTALLATION

This heater must be installed by a qualified, licensed gas

fitter and according to CSA B149 Natural Gas and

Propane Installation Code or ANSI Z223.1 National Fuel

Gas Code and/or local codes. If in doubt, consult your

local utility.

LOCATION

Generally, the location selected should be as close to the

wall as practical and as centralized with the piping system as possible. Heater should be located in an area not

subject to freezing temperatures.

The water heater should be located so that the controls

and drain are easily accessible. The heater should be

located in an area where leakage of tank or connections

- 2 -

CLOSET INSTALLATION

(TOP VIEW)

25mm (1 in.)

CLOSET DOOR

25mm (1 in.)

102mm (4 in.)

Figure 1

SEAL TIGHTLY

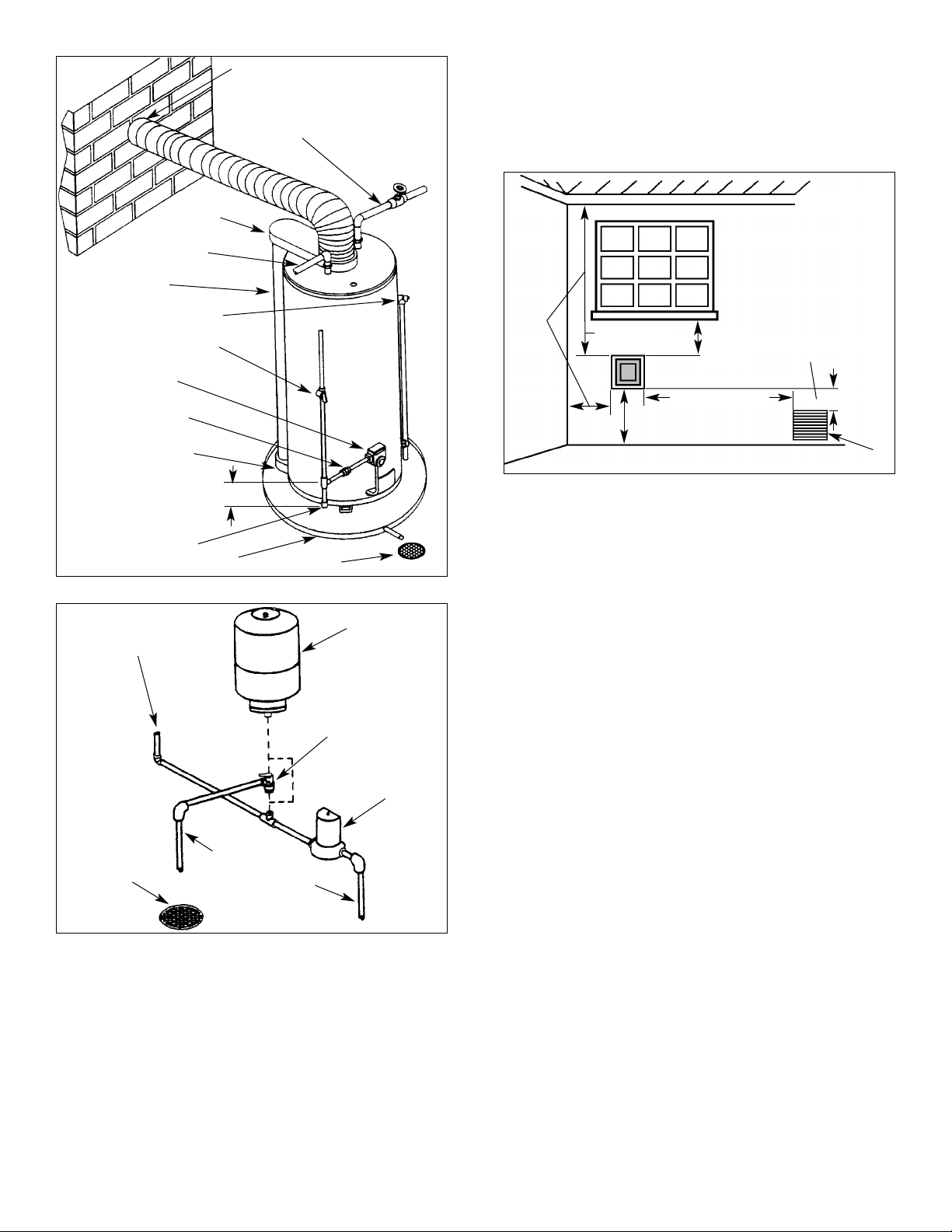

COLD WATER INLET

Specially For Direct Vent Water Heater:

Make certain to observe the vent location limitations

complying with the CSA B149 Natural Gas and Propane

Installation Code or ANSI Z223.1 National Fuel Gas

Code and/or local codes. There is some important information shown in Figure 3.

UPPER AIR

INLET BOX

HOT WATER OUTLET

REAR AIR TUBE

TEMPERATURE & PRESSURE

GAS CONTROL

UNION - GROUND

RELIEF VALVE

GAS SUPPLY MANUAL

SHUT-OFF VALVE

JOINT TYPE

LOWER AIR

INLET BOX

152mm

(6 in.)

SEDIMENT TRAP

DRAIN PAN

FLOOR DRAIN

Figure 2A - Installation Components.

WATER SUPPLY

TO HOME

EXPANSION TANK

OPTION 2

Vent Terminal must be located at

least 305mm (12 in.) from

Windows, Doors, or any other

Opening through which flue

gases could enter the building.

Vent terminal must

be located at least

915mm (36 in.)

above any Forced Air

457mm (18 in.)

Min.

305mm (12 in.) Min.

(18 in.) from any overhang or building corner

or other irregularity.

Vent Terminal must be located at least 457mm

above grade. Higher in

Areas of Heavy Snowfall

305mm

(12 in.)

Min.

Within 3m (10 ft.)

Inlet into the building

within 3m (10 ft.) of

the Vent Terminal

915mm

(36 in.)

Min.

Any Forced Air Inlet

into the building

Figure 3 - Vent Location Limitations

For a second or more direct vent unit, the distance

between vent terminals must have a minimum of 305mm

(12 in.).

INSPECT SHIPMENT –– There may be hidden damage

caused by transit. Check to be certain all parts of the

venting system, as shown in Figures 3A through 3M, are

present. Inspect the upper and lower air inlet boxes, rear

air tube and all parts of the venting system (see Figure

2A).

PRESSURE

RELIEF VALVE

OPTION 1

WATER METER

WITH BACKFLOW

PREVENTER

OVERFLOW

FLOOR DRAIN

WATER SUPPLY

TO METER

Figure 2B - Installation Options.

Figure 2B shows the location of a pressure relief and/or

expansion tank if a check valve or pressure reducing

valve is in the cold water supply to the house.

Use OPTION 1 or 2 whichever is more convenient. If

pressure relief valve is used, select one with a setting

172 kPa (25 psi) below the valve rating at tank.

CAUTION

If there are any damaged parts, DO NOT install this water

heater. Report any shortage to your distributor and damage to your carrier.

Note: The four fasteners that are required to secure the

vent terminal to the exterior wall are not provided. These

should be screw type (not nails) chosen for the type of

construction and obtained locally.

CAUTION

Cut edges of corrugated (flex) pipe are extremely sharp.

Wear gloves when handling.

- 3 -

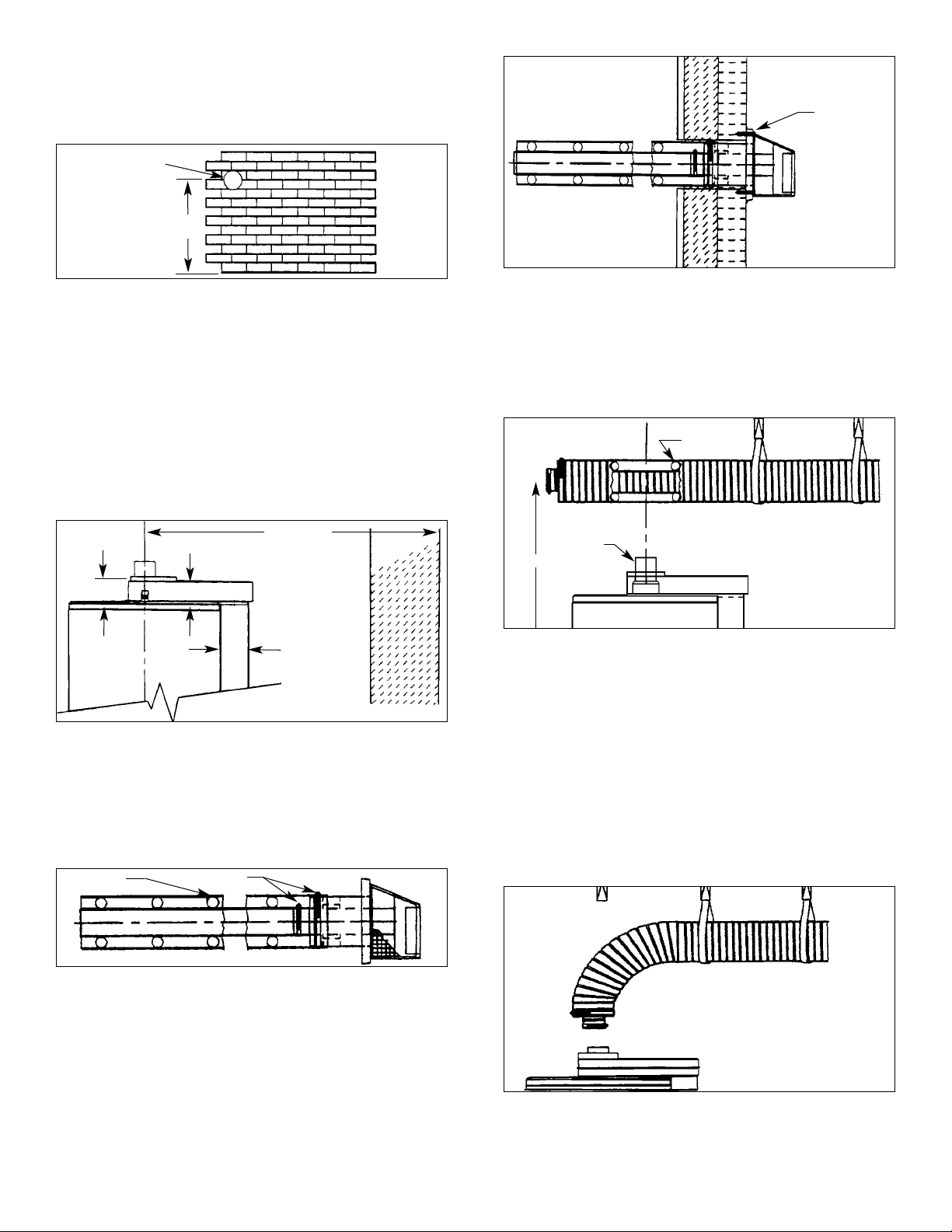

III) VENT CONNECTIONS

After the location for the vent terminal has been selected

as outlined in Figure 3, use the following illustrations for

installation:

178mm (7 in.)

DIAMETER

MINIMUM

(SEE TEXT)

BOTTOM OF HEATER

Figure 3A - Locating Clearance Hole For Vent.

Cut a clearance hole, approximately 178mm (7 in.) in

diameter, through the exterior wall for the vent assembly.

The minimum height should not be less than 1.72m (68 in.)

for Models 40BF and 50BF and not less than 1.93m (76

in.) for Model 50TBF, as measured from the hole center to

bottom of water heater. The maximum height recommended is 2.28m (90 in.) or in compliance with Figure 3M.

* Where the wall is combustible and the wall thickness is

over 356mm (14 in.), 25mm (1 in.) clearance to combustible materials around the terminal pipe is needed. The

first 356mm (14 in.) is zero clearance.

SEALANT

Figure 3D - Securing Vent Termination Assembly To

The Exterior Wall.

Introduce the 152mm (6 in.) pipe through the clearance

hole from exterior wall then secure the vent terminal to

the exterior wall with 4 screw anchors appropriate for the

type of wall construction. Caulk the junction of the vent

terminal base plate and the exterior wall with exterior type

silicone sealant.

SPRING

102mm

(4 in.)

76mm

(3 in.)

MAX. 2.28m

(90 in.)

102mm

(4 in.)

WALL

Figure 3B - Moving Water Heater To Its Final Installed

Location.

Move the water heater to its final installed location. Make

certain clearances from combustible material are

observed. The maximum distance from center of water

heater to outside wall must not be more than 2.28m (90

in.).

SPRING

CLAMP

REDUCER

H

Figure 3E - Pull The 80mm (3-1/8 in.) And 152mm (6

in.) Corrugated Pipe Towards The Water Heater

Individually.

1. Pull the 80mm (3-1/8 in.) corrugated pipe towards the

water heater and leave some length over the water

heater’s center for bending.

2. Pull the 152mm (6 in.) corrugated pipe toward the

water heater and leave it 25mm (1 in.) shorter than

80mm (3-1/8 in.) pipe.

3. Make sure there are two springs evenly spaced at the

bend in the pipe.

4. Use metal hangers to keep vent pipe level or with a

slope upward from the heater to terminal.

Figure 3C - Vent Assembly.

The vent pipe and terminal are assembled by the manufacturer as shown in Figure 3C. There are springs fastened inside the corrugated pipe. When the vent pipes

are pulled to a required length, the distances between the

springs will still be equally spaced.

Figure 3F

Bend the 80mm (3-1/8 in.) and 152mm (6 in.) corrugated

pipe all together toward the water heater’s flue connection.

- 4 -

Loading...

Loading...